KitchenAid KECD865HWH3, KECD865HWH2, KECD865HBT2, KECD865HBT3, KECD865HBL05 Installation Guide

...Page 1

[] []

ui

C

Readandsavethese

IMPORTANT:

Installer: Leave installation

Instructions with the homeowner.

Homeowner: Keep Installation

Instructions for future reference.

Save Installation Instructions for local

ebctrical inspector's use.

KJtchen_kJd _

FORTHE WAY IT'S MADE _'

Write down the model and serial numbers

before installing cooktop.

Both numbers are on the modeVserial

rating plate, located on the bottom of the

cooktop.

Model #

Serial #

Questions regarding features,

operation, performance, parts or

service? Call 1-800o422-1230 or visit

our web site at www.kitchenaid.com

Part No. 8285364

Page 2

Before youstart,,,

Your safety and the safety of

others is very important.

We have provided many important

safety messages in this manual and

on your appliance. Ah_iays read and

obey all safety messages.

This is the safety alert

symbol.This symbol alerts

you to hazards that can kill

or hurt you and others. All safety

messages will be preceded by the

safety alert symbol and the word

"DANGER" or "WARNING". These

words mean:

You witi be killed or seriously

injured if you don't foltow

instructions.

You can be killed or seriously

injured if you don't foltow

instructions.

All safety messages will identify the

hazard, tell you how to reduce the

chance of injury, and tell you what

can happen if the instructions are

not followed.

Important: Observe all governing

codes and ordinances. Failure to meet

codes and ordinances could lead to

fire or electrical shock.

To eliminate the risk of burns by

reaching over heated surface units,

cabinet storage space located above

the surface units should be avoided, tf

cabinet storage is to be provided, the

risk can be reduced by instalJing a

range hood that projects horizontaJiy a

minimum of 5 inches (12.7 am) beyond

the bottom of the cabinets.

Proper installation is your responsibility.

oMake sure you have everything

necessary for correct installation.

oHave a qualified technician install

this cooktop.

• Comply with the electrical specifications

on the model/serial rating plate.

Model/serial rating plate is located on

the bottom of the cooktop. Write both

numbers down on the front cover now

before installing cooktop.

Downdraft cooktop location should be

away from strong draft areas, such as

windows, doors and strong heating vents

or fans. Locate cooktop for convenient

use in kitchen.

Grounded electrical system is required=

See "Electrical requirements," Page 6=

Venting system must terminate

outdoors.

AH openings in the wall or floor where

cooktop is to be installed must be

sealed.

tt is the customer's responsibility to

contact a qualified electrical installer,

to make sure that the electrical

installation is correct, and to make

sure the electrical installation follows

the National EJectrical Code,

ANSJ/NFPA 70 -- latest edition*, or

CSA Standards C22.1=94, Canadian

EJectrical Code, Part 1 and C22.2 No.

0-M91 =latest edition**, and aH local

codes and ordinances.

WARNING: To reduce the risk of fire,

electric shock, or injury to persons,

observe the following:

installation work and electrical wiring

must be done by qualified person(s) in

accordance with all applicable codes

and standards, including fire-rated

construction.

Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel

burning equipment to prevent back

drafting. Follow the heating equipment

manufacturer's guideline and safety

standards such as those published by

the American Society for Heating,

Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local

code authorities.

When cutting or drilling into wall or

ceiling, do not damage electrical wiring

and other hidden utilities.

Ducted fans must always be vented to

the outdoors.

WARNING: To reduce the risk of fire,

use only metal ductwork.

This downdraft eooktop is Not approved

for use in mobile homes.

Copies of the standards listed may be

obtained from:

* National Fire Protection Association

Batterymareh Park

Quincy, Massachusetts 02269

** Canadian Standard Association

178 Rexdale Boulevard

Etobicoke, (Toronto), Ontario Mgw 1R3

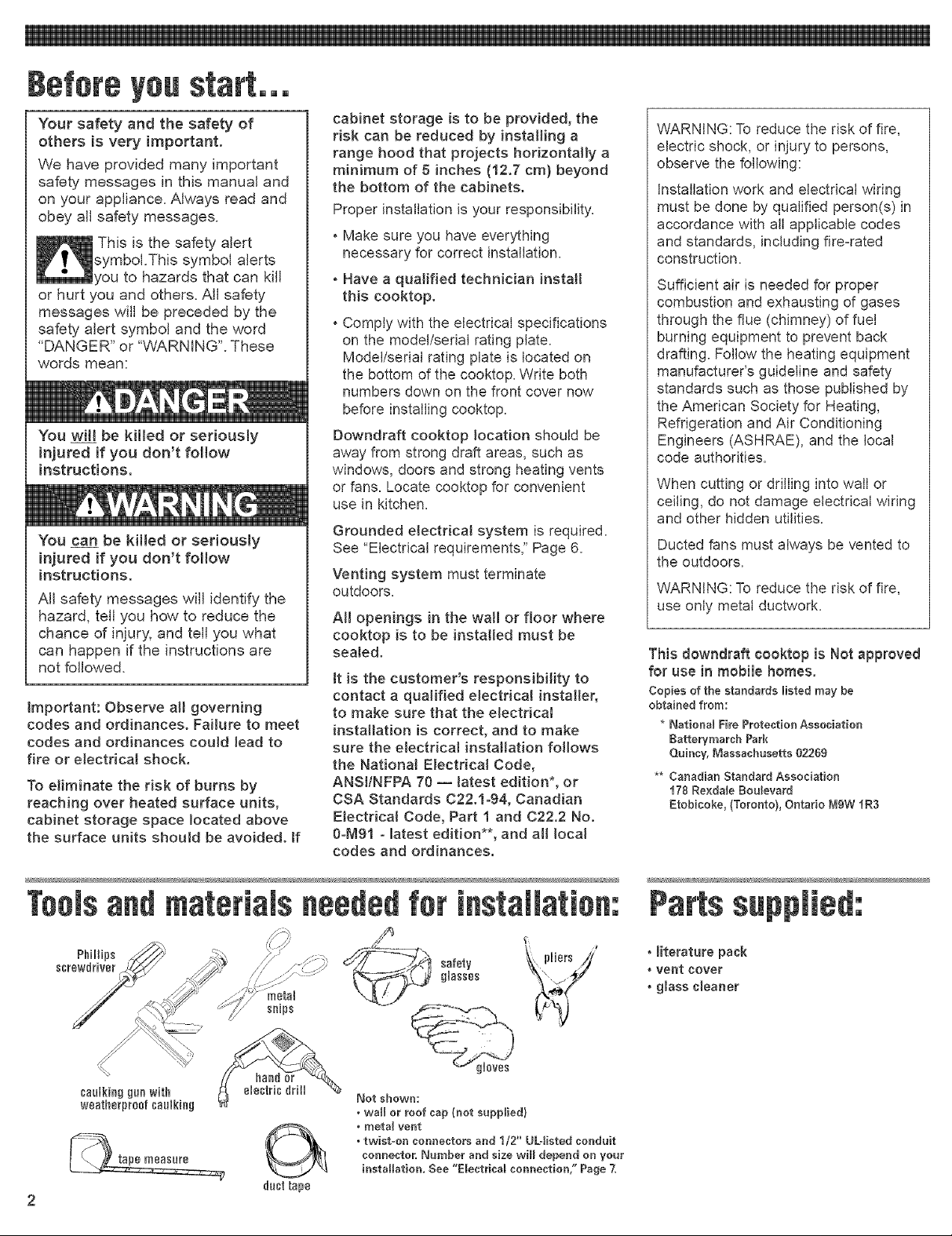

Toolsandmaterials neededfor installation:

PhHHps _, pliers ji

screwdriver // ._ :_:_ safety \_ ;_'Y.:j glasses

...._ snips , _'_

Not shown:

. wall or roof cap {not supplied)

. metal vent

. twist=on connectors and 1/2" UL=iisted conduit

connecter, Number and size will depend on your

installation. See "E_eetriea_ connection," Page 7.

Partssupplied:

* literature pack

* vent cover

* glass cleaner

Page 3

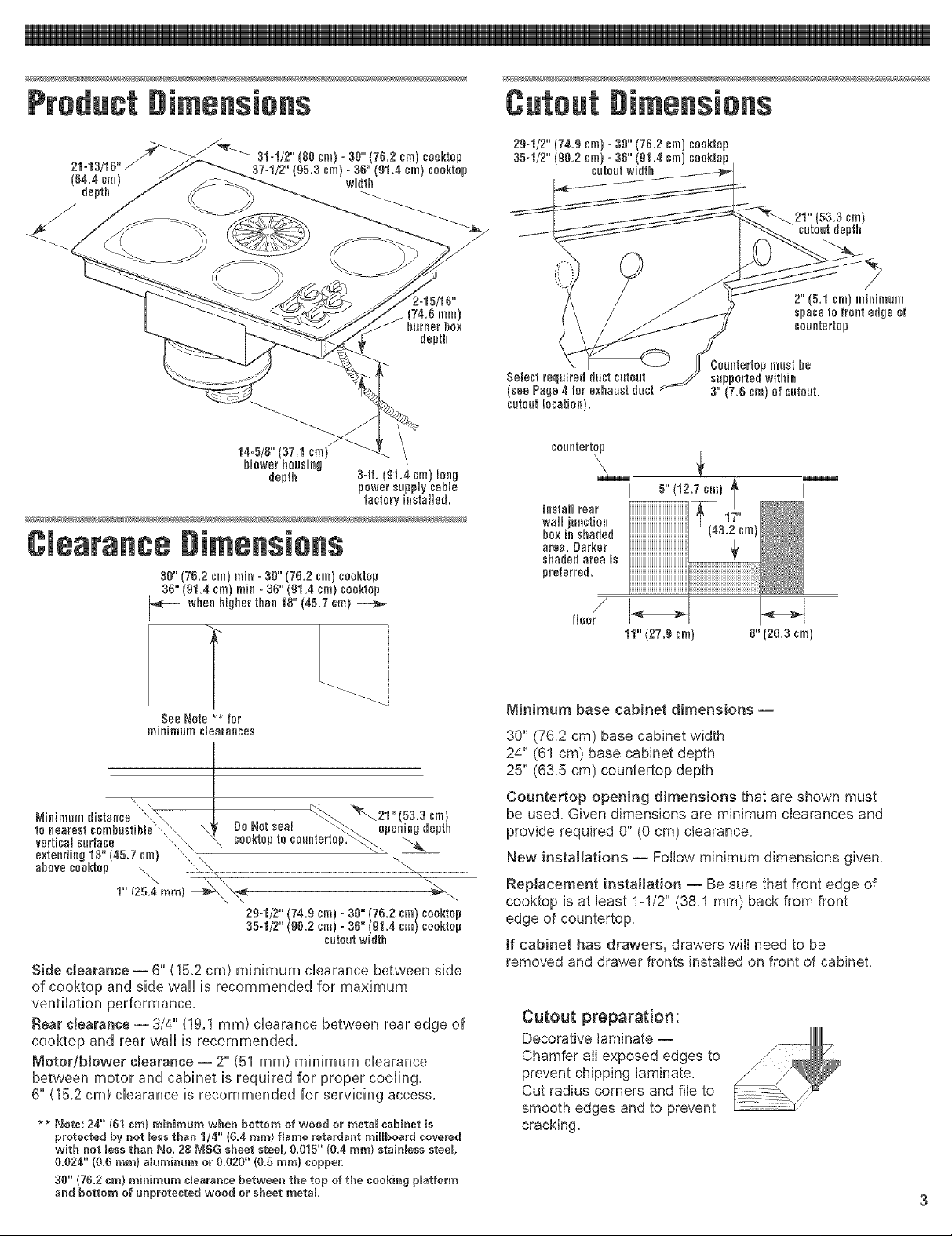

Product #[mens[ens

Cateat #imensiens

J_qr-_. 31-1/2" (88 cm) - 38" (76.2 cm) ceohtep

37-1/2" (95.3 cm) - 36" (91.4 cm) cooktop

14-5/8" (37.1 cm)

blower housing

depth

Clearancegimensiens

38" (76.2 cm) rain - 38" (76.2 cm) caoktop

36" (91.4 cm) rain - 36" (91.4 cm) cooktop

whee higher thee 18" (45.7 cm) _1

width

3-ft. gl.4 cm long

power snpp y cab e

factory installed.

B

29-112" (74.9 cm) - 38" (76.2 cm) ceoktop

35-1/2" (98.2 cm) - 36" (91.4 cm) ceoktep

J

J

Select required duct cotont

(see Page 4 for exhaust duct

cutoutlocation}.

install rear

wall junction

box in shaded

area. Darker

shaded area is

preferred.

cnteat width

cauntertap

fleer

2"(5,1 cm)minh_nm

spacetofrontedge of

cenetertep

Oouetertapmust he

supported within

3" (7.6 cm) of cutout.

5" (12.7 era)

11" (27.9 cm) 8" (28.3 cm)

cm)

_pth

I

See Note ** [or

minimum clearances

Minimum base cabinet dimensions --

30" (76.2 cm) base cabinet width

24" (61 cm) base cabinet depth

25" (63.5 cm) countertop depth

".. %.,

Nieimum distance "'..\ .... _. ---.21"_ (53.3 cm)

te nearestcombustibleS..\ \\_ uo !.Jptseal ,_,,_n_._ opeeing depth

vertical suflace "...._ _ ceo,'{mpto ceante_mp. "_._ _

extendieglS"(45,7cm) _,,', "" _-- --

ohovecoo,top _. ....--_\ \ _................................

29-1/2" (74.9 cm) - 38" (76.2 cm) cooktop

35-1/2" (98.2 cm) - 36" (91.4 cm) ceoktop

Side cJearance-- 6" (15.2 cm) minimum clearance between side

cuton_width

Countertop opening dimensions that are shown must

be used. Given dimensions are minimum clearances and

provide required 0" (0 cm) clearance.

New installations -- Follow minimum dimensions given.

Replacement installation -- Be sure that front edge of

cooktop is at least 1-1/2" (38.1 mm) back from front

edge of countertop.

ff cabinet has drawers, drawers will need to be

removed and drawer fronts installed on front of cabinet.

of cooktop and side wall is recommended for maximum

ventilation performance.

Rear cJearance- 3/4" (19.1 mm) clearance between rear edge of

cooktop and rear wall is recommended.

Motor/b_ower c_earance-- 2" (51 mm) minimum clearance

between motor and cabinet is required for proper cooling.

6" (15.2 cm) clearance is recommended for servicing access,

_ Note: 24" {61 era) rainiraura when bottom of wood or rectal cabinet is

protected by not _essthan 1/4" (&4 rare) florae retardant rag_board covered

with not Jessthan No. 28 MSG sheet steel 0.015" {0.4 ram) stainless steel

0,024" (0,6 rare) alurainura or 0,020" (0,5 rare) copper,

30" (7&2 era) rainiraura cJearanee between the top of the cooking p_atfotra

and bottom of unprotected wood or sheet metal

Cutout preparation:

Decorative laminate --

Chamfer all exposed edges to

prevent chipping laminate,

Cut radius corners and file to

smooth edges and to prevent

cracking.

Page 4

Ventin9systemreqeirements

Venting system must terminate to the

outside.

Do Not terminate the vent system in an

attic or other enclosed space.

Do Not use 4qnch (10 cm) laundry-type

wall caps.

Use metal vent only. Exception: See

"optional venting under a concrete

slab", in "Venting methods" below.

Rigid metat vent is recommended. Do

not use plastic or metal foil vent.

To reduce risk of fire and to properly

exhaust air, be sure to vent air outside.

Do Not vent exhaust air into spaces

within walls or ceilings or into attics,

crawl spaces or garages.

Before making cutouts, make sure there

is proper clearance within the wall or

floor for the exhaust vent.

Do Not cut a joist or stud unless

absolutely necessary. If a joist or stud

must be cut, then a supporting frame

must be constructed.

Vent materials needed for installation

are not supplied,

Determine which venting method to use.

See "Venting methods," below.

Next, determine the equivalent vent length

using chart on Page 5. The maximum

equivalent vent length is 60 feet (18.3 m).

The blower housing is set to vent

straight out the back from the cooktop. To

vent down, left or right, see "Installation,"

Step 2, Page 6.

This downdraft cooktop is rated at

60 feet (18.3 m) of straight vent or the

equivalent.

• if vent length is 10 feet (3 m) or less,

6" (15.2 cm) diameter round vent may

be used.

• tf vent length is more than 10 feet

(3 m), use 6" (15.2 cm) diameter round

or 3-1/4" x 10" (8.3 x 25.4 cm)

rectangular vent.

Thermal breaks: In areas of extreme

cold weather, it may be necessary to

provide a short length of nonmetallic duct

as close to the wall as possible to prevent

thermal conduction along the metal vent.

For attitudes above 4,500 ft (1372 m),

reduce recommended vent run by 20%.

For the most efficient and

quietest operation:

[_ Use 26=gauge minimum galvanized or

25=gauge minimum aluminum metal

vent. Poor=quality pipe fittings can

reduce air flow. (Note: Local codes may

require a heavier=gauge material.)

Flexible metal vent is Not

recommended.

[_ Do Not exhaust more than one

downdraft cooktop into a single vent

system.

[_ The length of vent and number of

elbows should be kept to a minimum to

provide efficient performance.

_j The size of the vent should be uniform.

D Use the fewest number of 90° elbows.

[_ Do Not install two elbows together.

[_ Make sure there is a minimum of 18"

(45.7 cm) of straight vent between the

elbows if more than one elbow is used.

(Elbows too close together cause

excess turbulence that reduces airflow.)

[_ Do Not use a 5" (12.7 cm) elbow in a

6" (15.2 cm) or 3-1/4" x 10"

(8.3 x 25.4 cm) system.

[_ Do Not reduce back to 5" (12.7 cm)

system after using 6" (15.2 cm) or

3-1/4" x 10" (8.3 x 25.4 cm) fittings.

[_ Avoid forming handmade crimps.

Handmade crimps may restrict airflow.

[_ Use the recommended vent caps for

proper performance. If an alternate wall

or roof cap is used, be certain cap size

is not reduced and that it has a

backdraft damper.

[_ Use duct tape to seal all joints in the

vent system.

[_ Use caulking to seal exterior wall or roof

opening around the cap.

Venting methods

9=5/8''(24.4 ¢m} =30" (752 ¢m) ¢o0kt0p

13=5/16'' 8 eel} =35" (g1.4 ¢m) ¢00kt0p

g=3/4" (24.8 cm)

h01ein rear er

side ef cabinet

\

The cooktop may be vented through the wall or floor. Common venting methods and the

types of materials needed are shown.

Make sure there is proper clearance within the wall or floor for exhaust vent before

making cutouts.

peninsula

siti0n

@' 5_ elbow_

3ol/4" x 10"

(8.3 x 25,4 nm)

inside wall to roof directly between

or overhang outside floor joists

cabinet toe space

to outside

Page 5

8"(15.2era)roundmetalvent

8"(15.2era)transition

Determine equivalent Jength of vent. Maximum

equivalent length of vent is 60 ft (18.3 m).

List the number of each piece and Uength of straight vent you will use.

MuffipUythe equivalent Uengthby the number of pieces. Add the totals

to get the totaU equivalent Uength of your system.

5" (15.2 era) max. _ \ 5" (15.2 era)

round 90° PVC Tightly pack gravel or sand round 99°

sewer pipe elbow eornpleteJy around pipe. PVC sewer

pipe elbow

optional vent arrangement under

concrete slab

t2" (30.5 era) 5" (15.2 cm) round transition

90° PVC sewer

well

6" i (106.7era)

(15.2 era) max.

rain. 6" (15.2 era) round

PVC coupling

i l_ 42"

pipe elbow

Tightly pack gravel or sand

completely around pipe.

optional vent arrangement through

window welt under concrete slab

Vent

Piece

straight vent per lineal foot

3-I/4" x 19" (83 x25.4 cm)

6" (152 cm) round

6" (152 cm) flexible 2 ft.

elbow

6" (152 cm) round 450 elbow

6" (152 cm) round 99" elbow

_ ---_, 3-I/4" x 10" (8.3 x 25.4 crn)

_:9 flat elbow

3-1/4" x 19" (8.3 x 25.4 crn)

90° elbow

transition to round

_ _::_=__ 3-1/4" x 10" (8.3 x 25_4cm) to

_ -1/4" x 10" (8.3 x 25.4 crn) to

transition to flat

6"<15.2ore/99"elbo

-(-_¢_ air flow

6" (15.2 ern)

1ft. (30.5cm)

1ft, (30.5cm)

{6t cm)

2.5 ft.

(76,2 m)

5 ft.

(1,5 m}

12ft.

(3,7 m)

5 ft.

(1,5 m)

9 ft.

(2.7 m)

4.5 ft.

(1,4 m)

5 ft.

(1,5 m}

No. of

Pieces/

Length

Total

EquivaJent

Length

90° eUbows(3) = 15ft. (4.6 m)

12 feet (3.7 m) straight = 12ft. (3.7 m)

WaHcap = 0ft.(0m)

EquivaUentUengthof

= 27ft. (8.3 m)

6" (15.2 cm) round system

Note: Flexible metal vent is Not recommended.

If it is used, calculate eachfoot (30 cm) of flexible vent

astwo feet (61 cm) of straight metal vent. Flexible

metal elbows count twice as much as standard elbows.

i_;_'1 6" (15.2 cm) to

b-r:=_:'_ I' 3-1/4" x 19" 8.3 x 254 cm)

_'_ air flow

wall cap*

[_;_> 3-1/4" X 10" (8.3 X25.4 crn)

_'_j_ 6" (152 cm) round

roof cap*

19,,×19,,/954x254

thermaJ break

-_ 6" (152 cm) round

Total equivalent vent system length

1ft.

(30,5cm)

9 ft.

(9era)

9 ft.

(9era)

9 ft,

(9era)

2 ft.

(6t era)

* Length for required wall/roof cap has already been incorporated

into rating for maximum vent system length. A suitable wall/roof

cap must be used.

Page 6

if codespermitandaseparateground

wireisused,it is recommendedthata

qualifiedelectrician determine that the

ground path is adequate.

Do Not ground to a gas pipe.

Check with a qualified eJectNcian if you

are not sure cooktop is properly

grounded,

Do Not have a fuse in the neutral or

grounding circuit,

The downdraft cooktop must be

connected to the proper electrical voltage

and frequency as specified on the

model/serial rating plate. The model/serial

rating plate is located on the bottom of the

cooktop.

[_ A four-wire or three-wire, single-phase,

240-volt, 60-Hz, AC-only electrical

supply is required on a separate

30-ampere circuit, fused on both sides

of the line.

[_ A time-delay fuse or circuit breaker is

recommended. The fuse size must not

exceed the circuit rating of the

appliance as specified on the

model/serial rating plate.

[_ CONNECT WITH COPPER WIRE

ONLY.

Connected directly to the fused

disconnect (or circuit breaker box)

through flexible, armored or non-

metallic sheathed, copper cable (with

ground wire).

[_ Flexible armored cable should connect

cooktop directly to the junction box.

[_ Fuse both sides of the line.

[_ Locate the junction box to allow as

much slack as possible between the

junction box and cooktop so that the

downdraft cooktop can be moved if

servicing is ever necessary.

[_ A U.L.-listed 1/2" (12.7 mm) conduit

connector must be provided at the

junction box.

The recommended minimum copper

wire size is No.olO gauge. However,

wire sizes and connections must conform

to the requirements of the National

Electrical Code, ANSI/NFPA 70 -- latest

edition*, or CSA Standards C22.1-94,

Canadian Electrical Code, Part 1 and 22.2

No. 0-M91 - latest edition** and all local

codes and ordinances. Wire sizes and

connections must conform with the rating

of the cooktop.

Copies of the standard listed may be obtained from:

* National Fire Protection Association

Batteryrnarch Park

Quincy, Massachusetts 02209

** Canadian Standard Association

178 Rexdale Boulevard

Etobieoke, Ontario MgW 1R$

The wiring diagram is located on the

bottom of the cooktop.

Twist-on connectors and U.L.-Iisted 1/2"

(12.7 mm) conduit connector are not

provided.

m Remove shipping materials andtape

from cooktop.

2m The blower is set to vent straight out

the back of the cooktop.

To vent to the [eft side, right side or down

through the bottom of the cabinet, add an

elbow to the blower assembly exhaust vent.

it may be easier to connect appliance

cable to junction box before inserting

cooktop into cutout. See "Electrical

connections," Page 7.

Excessive Weight Hazard

Use two or more people to move

and install cooktop.

Failure to do so could result in

back or other injury.

Lift entire cooktop up from cutout

when positioning cooktop in

countertop opening.

S_ Insertdowndraflcooktopintocutout.

Checkthat:

[_ cooktopis centeredin cutout.

[_ front edge of downdraflcooktopis at least

1-1/2"(38.1 mm)from front edgeof

countertopand parallelto countertop.

[_ rearedge of cooktopis at least3/4"

(!9.! mm)from rearwall as recommended.

[_ side edgeof cooktopis atleast 6 inches

(!5.2 cm) from sidewall.

Connect vent system. See "Venting

requirements," Pages 4-5. Use duct tape to

seal all ioints. Vent must end with a wall or roof

cap outside the building.

Page 7

Wire connections chart

Electrical Shock Hazard

Turn power supply off before

connecting wires.

Use lO=gauge solid copper wire.

Electrically ground cooktop.

Failure to follow these

instructions can result in death,

fire, or electrical shock.

Thiseooktopmust be connected to a

grounded, metallic permanent wiring

system or a ground connector should be

connectedto the ground terminal or wire

lead on the ¢ooktop.

This cooktopis manufacturedwitha frame

connected,green or bare groundwire.Connect

thecooktopcabletothe junction boxthrough

the 1/2"(12.7ram)UA.4isted conduit

connector.Completeelectricalconnection

accordingto localcodes and ordinances,

mMakethe electricalconnection:

1.Disconnect the power supply.

2.Removethe junction boxcoverfromjunction

boxinsidecabinet.

3.Connectcooktop powersupplycable to

junction box usinga U.L.-listedconduit

connector.Tightenscrewson conduit

connector.

4.Connectthe two blackwires togetherwith

twist-onconnectors.

5.Connectthe two red wirestogetherwith

twist-onconnectors.

6.Completethe electricalconnection

accordingto localcodes and ordinances.

(See"WiFeconnectionschart.")

cable from fused dissennect

jormfiae

box

red

wires

grace or_

bare

g_eued

wure

green ground

appHaoce cable

wure

Figure 1

or dr0oit breaker box

white

/ wire

black

wires

conduif

connector

power supply

sable frora saektop

if local codes DO NOT PERMIT

connecting cooktop-ground

conductor to neutral white wire

in junction box:

(four-wire system)

7. Connect the green ground power

supply cable wire to the ground wire

in junction box or other ground

connector with twist-on connector,

See Figure 1,

8. Put a twist=on connector on end of

white wire,

9. Replace junction box cover.

Check operation

Turnon electricalsupply.

Checkthat cooktopsurfaceelements

heatand indicatorlightsare operating

correctly.

8[] Checkthat downdraftvent operates.

if the cooktopdoes notoperate,disconnectthe

powersupply and checkthat wire connections

havebeenmadecorrectly.

cable from fused disseeeect

or circuit breaker box

junction

box

red

white

wire

green gl

appliance cable

wire

Figure 2

power supply cable

from cooktop

U.L=listed

"- coedoif

cocneofor

black

wires

IfIocaEcodes PERMIT

connecting cooktopoground

conductor to neutral

junction box wire:

(three-wire system)

7. Connect the green power supply

cable wire to the neutral (white) wire

in junction box with twist=on

connector. See Figure 2.

8. Replace junction box cover.

You have just finished installing your

new KitchenAid downdraft cooktop.

To get the most efficient use from

your new cooktop, read your Use &

Care Guide.

Keep hstallation Instructions and

Guide close to cooktop for easy

reference.

Page 8

Cooktopremoval

If removing the ¢ooktop is necessary

for cleaning or maintenance:

1. Disconnect electricat supply.

2. Disconnect vent duct system,

3. Lift cooktop out of countertop to

comptete cleaning or maintenance,

After cleaning and maintenance:

1. Reinstattcooktop in cutout.

2. Checkthat front edge of cooktop is

paratlet to front edge of countertop,

3. Connect vent duct system.

4. Connect electricat sup#y,

If cooktop does not

[_ Checkthat circuit breaker is not

tripped or the house fuse Mown.

[_ Checkthat wire connections are intact.

[_ See Use and Care Guide for

troubleshooting list.

if you need

assistance:

The KitchenAid Consumer Assistance

Center is open 24 hours a day, 7 days a

week. Call 1-(800) 422-1230.The call is

free within the continental United States.

In Canada, call 1o(800)461-5681 for

English and 1-(800)461-5703 for French.

Or visit our web site at

www.kitchenaid.com.

When you call, you will need the cooktop

model number and serial number. Both

numbers can be found on the

model/serial rating plate located on the

bottom of the cooktop.

If you need service:

Consult your Use & Care Guide.

In the event that your KitchenAid

appliance should need service, call the

dealer from whom you purchased the

appliance or a KitchenAid-designated

service company. A KitchenAid-

designated service company is listed in

theYellow Pages of your telephone

directory under "Appliances --

Household -- Major -- Service and

Repair:'

Part No. 8285364

© 2002 KitchenAid.

® Registered Trademark/Trademark of

KitchenAid U.S.A., KitchenAid

Canada licensee in Canada

KJtchenAid ®

HOME APPLIANCES

Prepared by KitchenAid, Benton Harbor, Michigan 49022

Printed in U.S.A.

Loading...

Loading...