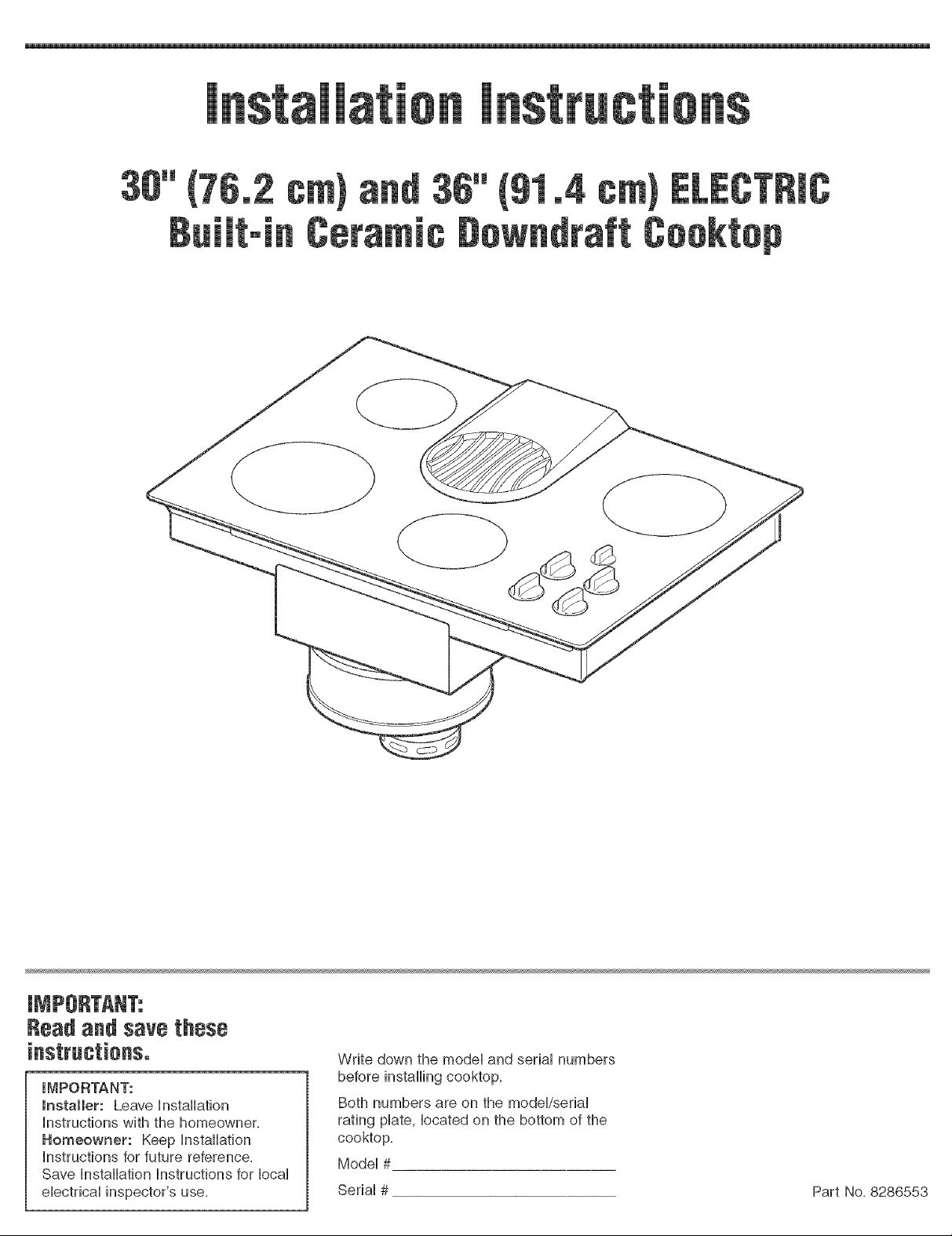

KitchenAid KECD806RSS03, KECD866RBL00, KECD866RBL03, KECD866RBL02, KECD866RSS00 Installation Guide

...Page 1

ui

C

Readandsavethese

IMPORTANT:

Installer: Leave HnstaHation

Hnstructions with the homeowner.

Homeowner: Keep hstaHation

Hnstructions for future reference.

Save hstaHation hstructions for HocaH

eHectricaHinspector's use.

Write down the modeHand seriaHnumbers

before installing cooktop.

Both numbers are on the modeH/seriaH

rating pilate, Hocatedon the bottom of the

cooktop.

ModeH#

Serial #

Part No. 8286553

Page 2

Before youstart...

Your safety and the safety of

others is very important.

We have provided many important

safety messages in this manual and

on your appliance, Always read and

obey all safety messages,

This is the safety alert

symbol,This symbol alerts

you to hazards that can kill

or hurt you and others, All safety

messages will be preceded by the

safety alert symbol and the word

"DANGER" or "WARNING", These

words mean:

You will be kilted or seriously

injured if you don't foIIow

instructions.

You can be kilted or seriously

injured if you don't follow

instructions.

All safety messages will identify the

hazard, tell you how to reduce the

chance of injury, and tell you what

can happen if the instructions are

not followed,

To eliminate the risk of burns by

reaching over heated surface units,

cabinet storage space located above

the surface units should be avoided, if

cabinet storage is to be provided, the

risk can be reduced by instalming a

range hood that projects horizontally a

minimum of 5 inches (12.7 cm) beyond

the bottom of the cabinets.

Important: Observe aH governing

codes and ordhances. Failure to meet

codes and ordinances could lead to

fire or electrical shock.

Proper installation is your responsibility.

, Make sure you have everything

necessary for correct installation.

° Have a qualified technician instatl

this cooktop.

,, Comply with the electrical specifications

on the model/serial rating plate.

Model/serial rating plate is located on

the bottom of the cookto F Write both

numbers down on the front cover now

before installing cooktoF

Downdraft cooktop location should be

away from strong draft areas, such as

windows, doors and strong heating vents

or fans. Locate cooktop for convenient

use in kitchen.

Grounded electrical system is required.

See "Electrical requirements," Page 6.

Venting system must terminate

outdoors.

A[[ openings [n the wail or floor where

cooktop is to be installed must be

seaJed.

It [s the customer's responsibility to

contact a qualified eJectrica[ hstaHer,

to make sure that the e_ectrical

hstaImation is correct, and to make

sure the electrical installation follows

the National Electrical Code,

ANSI/NFPA 70 i [atest edition*, or

CSA Standards 022.1-94, Canadian

Electrical Code, Part 1 and C22.2 No.

0-M91 - latest edition**, and am[ Iocam

codes and ordhancea.

WARNING: To reduce the risk of fire,

electric shock, or injury to persons,

observe the following:

Installation work and electrical wiring

must be done by qualified person(s) in

accordance with aii applicable codes

and standards, including fire-rated

construction.

Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel

burning equipment to prevent back

drafting. Follow the heating equipment

manufacturer's guideline and safety

standards such as those published by

the American Society for Heating,

Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local

code authorities.

When cutting or drilling into wail or

ceiling, do not damage electrical wiring

and other hidden utilities.

Ducted fans must always be vented to

the outdoors.

WARNING: To reduce the risk of fire,

use only metal ductwork.

This downdraft cooktop is Not approved

for use in mobib homes.

copies of the standards listed maybe

obtainedfrom:

* National FireProtectionAssociation

BatterymarchPark

Quincy, P4assachusetts 02269

** CSA [nterrnationaI

8501 East Pleasant Valley Road

Cleveland, Ohio 44131=5575

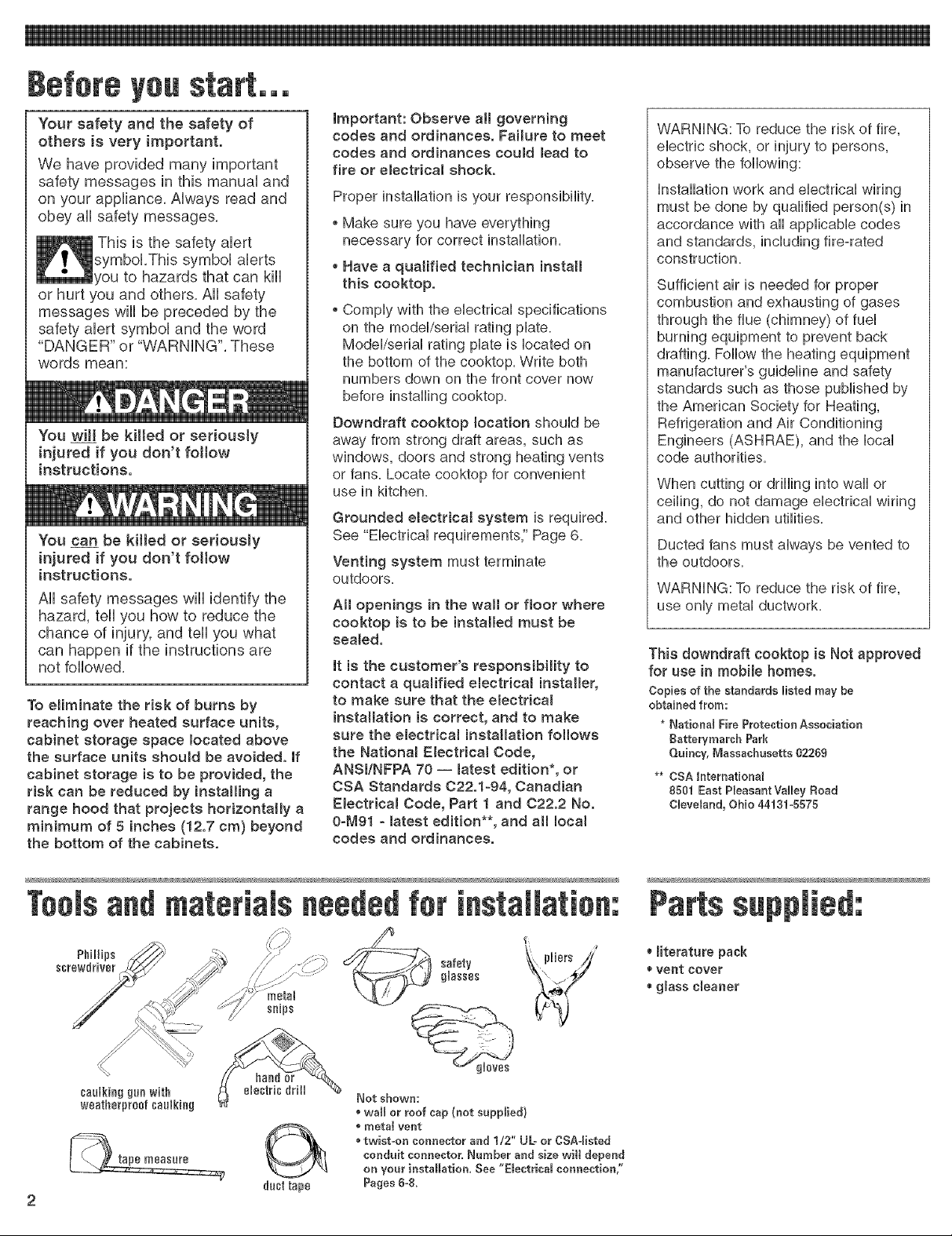

Toolsand materials neededfor installation:

Phillips _::_ __1 f\, pliers //

screwdriver Z" / j -y safety

Not shown:

* wall or roof cap (not supplied}

recta[ vent

twist-on connector and 1/2" UL- or CSA-Iisted

conduit connector, Number and size wi[[ depend

on your installation, See "E[ectdca[ connection,"

Pages 6-8.

Parts supplied:

* Biterature pack

_,vent cover

gBass cleaner

Page 3

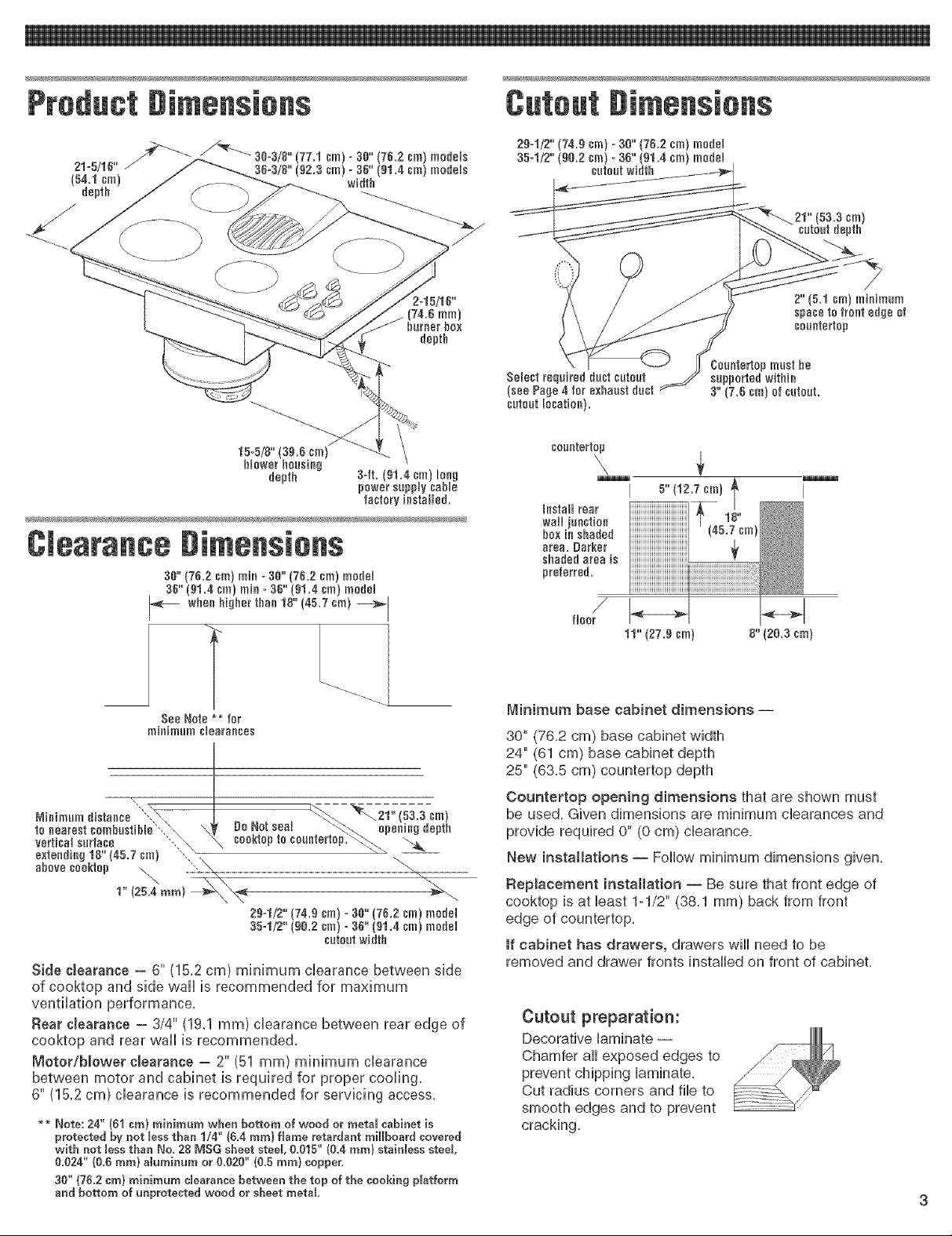

Product #[mens[ens

2-15/16"

j (74.6 mml

burner box

depth

Cateut#imensiens

cm)

_pth

15-5/8" (3&6 cm)

blower housing

depth

34t. 91.4 cm long

power suppy cab e

factory installed.

Clearancegimensiens

30" (762 cm) min =3g" (7&2 cm) model

36" (91.4 cm) min =36" (gl.4 cm) model

_- wbee higher thee 18" (45.7 cm) _1

See Note ** [or

minimum clearaeces

b

Nieiraumdistaece,i_ I. _ . , _ _\21"(5a.a cm)

to nearest oombostiNe"_\ \_, ue !.Jo_seal _.r_\ opening depth

vertical surface "..._ \ ceo,'neple ceoiHenep. -_......

extending 18" 4&7 cm) ',.,_ " " _--

above ceoktep _. ....:_.\_ ...............................................................................................................................................................................................

Side clearance - 6" (15.2 cm) minimum clearance between side

N I

29=1/2" (74.9 cm) ° 30" (7&2 cm) model

354/2" (96.2 cm) =36" (91.4 cm) model

cutout width

B

coontertop

5" (12.7 em)

_estall rear

wall junction

box ie shaded

area. #arker

shaded area is

preferred.

Minimum base cabinet dimensions i

30" (76,2 cm) base cabinet width

24" (61 cm) base cabinet depth

25" (63,5 cm) countertop depth

Countertop opening dimensions that are shown must

be used, Given dimensions are minimum clearances and

provide required 0" (0 cm) clearance,

New installations i Follow minimum dimensions given,

Replacement installation i Be sure that front edge of

cooktop is at least 1=1/2" (38,1 mm) back from front

edge of countertop,

If cabinet has drawers, drawers will need to be

removed and drawer fronts installed on front of cabinet,

of cooktop and side wall is recommended for maximum

ventilation performance.

Rear cJearance = 3/4" (19,1 mm) clearance between rear edge of

cooktop and rear wall is recommended.

Motor/blower clearance -- 2" (51 mm) minimum clearance

between motor and cabinet is required for proper cooling.

6" (15.2 cm) clearance is recommended for servicing access.

_ Note: 24" {01 era} rainiraura when bottom of wood or rectal cabinet is

protected by not less than 1/4" {0.4 rare} flarae retardant raillboard covered

with not Jessthan No. 28 MSG sheet steel, 0.015" (0.4 rare} stainless steel,

0.624" (0,0 rare} alurainura or &O20" (0,5 rare} copper,

30" {76,2 era) rainiraura cJearancebetween the top of the cooking platforra

and bottom of unprotected wood or sheet rectal,

Cutout preparation:

Decorative laminate --

Chamfer all exposed edges to

prevent chipping laminate,

Cut radius corners and file to

smooth edges and to prevent

cracking=

I

Page 4

Ventingsystemrequirements

Venting system must terminate to the

outside.

Do Not terminate the vent system in an

attic or other enclosed space.

Do Not use 4-inch (10 cm) laundry-type

wall caps.

Use metal vent only. Exception: See

"optional venting under a concrete

stab"", in "Venting methods" below.

Rigid metat vent is recommended, Do

not use plastic or metat foil vent,

To reduce risk of fire and to properly

exhaust air, be sure to vent air outside,

Do Not vent exhaust air into spaces

within walls or ceilings or into attics,

crawl spaces or garages.

Before making cutouts, make sure there

is proper clearance within the wall or

floor for the exhaust vent.

Do Not cut a joist or stud unless

absolutely necessary, if a joist or stud

must be cut, then a supporting frame

must be constructed.

Vent materials needed for hstaHation

are not supplied,

Determine which venting method to use.

See "Venting methods," below.

Next, determine the equivalent vent length

using chart on Page 5. The maximum

equivalent vent length is 60 feet (18.3 m).

The blower housing is set to vent

straight out the back from the cooktop. To

vent down, left or right, see "installation,"

Step 2, Page 6.

This downdraft cooktop is rated at

50 feet (18.3 re) of straight vent or the

equivament,

o If vent mength is 10 feet (3 re) or less,

6" (15.2 cm) diameter round vent may

be used.

o if vent length is more than 10 feet

(3 m), use 6" (152 cm) diameter round

or 3ol/4" x 10" (8.3 x 25.4 cm)

rectangular vent.

Therma[ breaks: in areas of extreme

cold weather, it may be necessary to

provide a short length of nonmetallic duct

as close to the wall as possible to prevent

thermal conduction along the metal vent.

For attitudes above 4,500 ft (1372 m),

reduce recommended vent run by 20%.

For the most efficient and

quietest operation:

[] Use 26-gauge minimum galvanized or

25-gauge minimum aluminum metal

vent. Poor-quality pipe fittings can

reduce air flow. (Note: Local codes may

require a heavier-gauge materiaL)

Flexible metal vent is Not

recommended.

[] Do Not exhaust more than one

downdraft cooktop into a single vent

system.

[] The length of vent and number of

elbows should be kept to a minimum to

provide efficient performance.

[] The size of the vent should be uniform.

[] Use the fewest number of 90 ° elbows.

[] Do Not install two elbows together.

[] Make sure there is a minimum of 18"

(45.7 cm) of straight vent between the

elbows if more than one elbow is used.

(Elbows too close together cause

excess turbulence that reduces airflow.)

[] Do Not use a 5" (12.7 cm) elbow in a

6" (15.2 cm) or 3ol/4" x 10"

(8.3 x 25.4 cm) system.

[] Do Not reduce back to 5" (12.7 cm)

system after using 6" (15.2 cm) or

3ol/4" x 10" (8.3 x 25.4 cm) fittings.

[] Avoid forming handmade crimps.

Handmade crimps may restrict airflow.

[] Use the recommended vent caps for

proper performance, if an alternate wall

or roof cap is used, be certain cap size

is not reduced and that it has a

backdraft damper.

[] Use duct tape to seal all joints in the

vent system.

[] Use caulking to seal exterior wall or roof

opening around the cap.

Venting methods

9=5/8" (24,4 ¢m) =30" (70.2 sm) m0del

13=5/lt_" ,0 sm) =30" (01,4 sm) m0del

9=3/4" (24.8 sin)

h01ein rear or

side of cabinet

The cooktop may be vented through the wall or floor. Common venting methods and the

types of materials needed are shown.

Make sure there is proper clearance within the wall or floor for exhaust vent before

making cutouts.

3=1/4"x 10"

(0,3 x 25.4 em

transition

elbow

sabinet er island

ll outside wall _ peninsula

inside wall to roof directly between

or overhang outside floor joists

peninsula

a=1/4"x lO"

(0.3x 25.4sin}

cabinettoe space

to outside

Page 5

12".(30.5sra)

ram]raUra

6" (15.2 era) reund metal vent

Determine equivalent length of vent. Maximum

equivalent length of vent is 60 ft (18.3 m).

List the number of each piece and length of straight vent you will use.

Multiply the equivalent length by the number of pieces. Add the totals

to get the total equivalent length of your system.

6" (15.2 cra)

round PVC

coupling /

6" (15,2 era)

round 90° PVC

sewer pipe elbow

/

(76.2 cra) ;_ sewer pipe

max. \ 6" (15,2 era)

Tightly pack gravel or sand round 90°

completely around pipe. PVC sewer

6" (15,2 era)

round PVC

pipe elbow

optional vent arrangement under

concrete slab

12" (30.5 cra) 6" (15.2 era} round transition

minimum PVC sewer pipe /6" (15.2 cra)

wall 1 _ 6" (15,2 cra) round

cap PVC coupling

well

6" (106,7cra)

(15.2 era) i max.

rain. 6" (15,2 era) round

PVC coupling

round raetal vent

5" (15.2 cra)

round sewer pipe

5" (15.2 era) round

g0° £VC sewer

pipe elbow

Tightly pack gravel or sand

completely around pipe.

optional vent arrangement through

window well under concrete slab

Vent

Piece

straight vent per lineal foot

3-I/4" x 10" (8.3 x25.4 cm)

6" (152 crn) round

6" (15,2 crn) flexible

elbow

6" (152 crn) round 45° elbow

6" (15,2 crn) round 90° elbow

_--_ 3-1/4" x 10" (8.3 x 25,4 crn)

_:,5 3:_ flat elbow

3-1/4" x 10" (8.3 x 25,4 crn)

90° elbow

transition to round

_-:-_-_m 3-1/4" x 10" (8.3 x 25.4 crn) to

_i _ air flow

_ -1/4" x 10" (8.3 x 25,4 crn) to

6" (152 crn)

transition to flat

......._m 6" (15.2 crn) to 3q_4" x 10"

_iL(8.3x2&4crn) 90 elbow

.....L_2"_ air flow

_ ;_:/-; 6" (15,2 crn) to

?-¢_ _ i_;_3-1/4" x 10" 8.3 x 25,4 crn)

':_ air flow

wall cap*

x 10" (8.3 x 25,4 crn)

Equivalent

Length

1ft, (30.5era)

1ft. (30.5era)

2ft. (61era)

2.5 ft,

(76.2 era)

5 ft.

(1.5 ra)

12 ft.

(3.7 ra)

5 ft.

(1.5 ra)

9 ft.

(2.7 ra)

4.5 ft,

(1.4 ra)

5 ft.

(1.5 ra)

I ft.

(30.5era)

0 ft.

(0era)

No. of

Pieces/

Length

Total

Equivalent

Length

6" (15,2 era}

900 elbows

6" 15.2 cm

wa cap

\

6 ft, (1,8 m)

90° elbows (3) = 15ft. (4.6 m)

12 feet (3.7 m) straight = 12ft. (3.7 m)

Wall cap = 0ft.(0m}

Equivalent length of

= 27ff. (8.3 m)

6" (15.2cm) round system

Note: Flexible metal vent isNet recommended.

If it is used, calculate eachfoot (30 cm) of flexible vent

astwo feet (61 cm) of straight metal vent. Flexible

metal elbows count twice as much as standard elbows.

_ 6" (15,2crn) round

roof cap*

lO.x18,, x284

thermal break

0 ft.

(0era)

0 ft.

(0era)

2ft.

-/_ 6" (15,2crn) round

Total equivalent vent system length

(61era)

* Length for required wall/roof cap has already been incorporated

into rating for maximum vent system length. A suitable wall/reef

cap must be used.

Page 6

if codespermitandaseparateground

wireisused,itisrecommendedthata

qualifiedelectriciandeterminethatthe

groundpathis adequate.

Do Not ground to a gas pipe.

Check with a qualified electrbian if you

are not sure cooktop is properly

grounded.

Do Not have a fuse in the neutral or

grounding circuit.

The down@aft cooktop must be

connected to the proper electrical voltage

and frequency as specified on the

model/serial rating plate. The model/serial

rating plate is located on the bottom of the

cooktop.

[] A four-wire or three-wire, singb-phase,

240-volt, 60-Hz, AC-only electrical

supply is required on a separate

30-ampere circuit, fused on both sides

of the line.

[] A time-delay fuse or circuit breaker is

recommended. The fuse size must not

exceed the circuit rating of the

appliance as specified on the

model/serial rating plate.

[] CONNECT WITH COPPER WIRE

ONLY.

[] Connected directly to the fused

disconnect (or circuit breaker box)

through flexible, armored or non °

metallic sheathed, copper cable (with

ground wire).

[] Flexible armored cable should connect

cooktop directly to the junction box.

[] Fuse both sides of the fine.

[] Locate the junction box to allow as

much slack as possible between the

junction box and cooktop so that the

downdraft eooktop can be moved if

servicing is ever necessary.

[] A twist=on connector and 1/2"

(12.7 mm) U.L o or CSA=listed conduit

connector must be provided at the

junction box.

The recommended minimum copper

wire size is No.-lO gauge. However,

wire sizes and connections must conform

to the requirements of the National

Electrical Code, ANSI/NFPA 70 -- latest

edition*, or CSA Standards C22.1-94,

Canadian Electrical Code, Part 1 and

22.2

No. 0-M91 - latest edition** and all local

codes and ordinances. Wire sizes and

connections must conform with the rating

of the cooktop.

Copiesofthe standardlistedmaybeobtainedfrom:

* National FireProtection Association

BatterymarchPark

Quincy,Massachusetts02269

** CSA International

8501 East Pleasant Valley Road

CleveRand,Ohio 44131o5575

The wiring diagram is located on the

bottom of the cooktop.

Twist-on connector and 1/2" (12.7 ram)

U.L o or CSA-listed conduit connector are

not provided.

E Remove shipping materials and tape

from cooktop.

The blower is set to vent straight out

the back of the cooktop.

To vent to the left side, right side or down

through the bottom of the cabinet, add an

elbow to the blower assembly exhaust vent.

It may be easier to connect appliance

cable to junction box before inserting

cooktop into cutout. See "Electrical

connections," Pages 6-8.

Excessive Weight Hazard

Use two or more peopte to move

and install cooktop.

Failure to do so can result in back

or other injury.

[] front edge of downdraft cooktop is at least

lq/2" (38.1 ram) from front edge of

countertop and parallel to countertop.

[] rear edge of cooktop is at least 3/4"

(19.1 ram) from rear wall as recommended.

[] side edge of cooktop is at least 6 inches

(152 cm) from side wall.

m Connectvent system.See"Venting

requirements,"Pages4=5.Useduct tapeto

sea!all joints.Ventmustend witha wallor

roofcap outsidethe building.

This cooktop must be connected to a

grounded, metallb permanent wiring

system or a ground connector shoumd be

connected to the ground terminam or wire

bad on the cooktop.

This cooktop is manufactured with a frame

connected, green or bare ground wire. Connect

the cooktop cable to the junction box through

the 1/2" (1£7 mm) U.L.=or CSA-listed conduit

connector. Complete electrical connection

according to local codes and ordinances.

Make the electrical connection:

Lift entire cooktop up from cutout

when positioning cooktop in

countertop opening.

3m insert downdraft cooktop into cutout.

Check that:

[] cooktop is centered in cutout.

Electrical Shock Hazard

Turn power supply off before

connecting wires.

Use !O-gauge solid copper wire.

Electrically ground cooktop.

Failure to follow these

instructions can result in death,

fire, or etectricaJ shock.

Page 7

I For all cooktop models with three-wire cable from the cooktop:

Where tocal codes Do Not permit connecting the frame-

ground conductor to the neutral (white) junction box

wire. (Used for Canadian installations):

4=wire cable from power supply

red wires _Junctiee box

Ungrounded

neutra_ j

Figure 1

1oDisconnect wires

power supp{yo 3-wire cable conduit connector

bare or green

white wire

twist-on

connector

U,L,- or CSA- listed

2oRemove the junction fromcooktop

box cover from the junction box inside the cabinet,

3oConnect the flexible, armored cable from the cooktop to the

junction box using a U=L=or CSAqisted conduit connector,

Tighten screws on conduit connector.

4, Connect the two black wires together; then connect the two red

wires together using twist-on connector. (See Figure 1.)

5, Connect the green or bare ground wire from the cooktop cable

to the grounded wire in the junction box or other grounded

connector using twist-on connector,

6oPut a twist-on connector on end of white wire. Do Not connect

bare ground wire to neutra8 (white) wire in junction box,

7. Replace the junction box cover,

Where Jocal codes permit connecting the frame-ground

conductor to the neutral (white) junction box wire. (Not

used for Canadian installations):

3=wire cable from power supply

Groundedneutra_Figure2 redwiL_ __nestor_--q_r'--,._/junctiontwist-onbox

bare or J -"

white _ _ Mack wires

green wire

1. Disconnect from cooktop _ conduit connector

power supply.

2. Remove the junction box cover from the junction box inside

the cabinet,

3. Connect the flexible, armored cable from the cooktop to the

junction box using a U,L- or CSAqisted conduit connector,

Tighten screws on conduit connector,

4. Connect the bare cooktop wire with the white wire; the two

red wires together; and the two black wires together using

twist-on connectors, (See Figure 2,)

5. Replace the junction box cover,

3-wire cable _J _ U.L- or CSA- listed

For aH cooktop models with four-wire cable from the cooktop. (These cooktops are manufactured with white

[neutron] power supply wire and a cabinet-connected bare ground wire factory-crimped together.):

Where tocaJ codes Do Not permit connecting the frame-

ground conductor to the neutraJ (white) junction box

wire: (Used for Canadian installations):

4-wire cable from power supply

red wires J junction box

_J

U ng re u n ded _ white wires

Where tocaJ codes permit connecting the frame-ground

conductor to the neutraJ (white) junction box wire. (Not

used for Canadian installations):

3-wire cable from

junction power supply

box

red

black

neutra_

Figure 4

Figure 3 _ \twist=on

green

wires

1o Disconnect 4-wire cable

power supplyo from cookto \ U,L,- or CSA- listed

2. Remove the junction

J '_Mack wires

conduit coneector

cormector

box cover from the junction box inside the cabinet,

3. Connect the flexible, armored cable from the cooktop to the

junction box using a U=L- or C=S=A=qistedconduit connector,

Tighten screws on conduit connector,

4. Connect the two black wires together; then connect the two red

wires together using twist-on connectors, (See Figure 3,)

5. Separate the factory-crimped bare and white cooktop cable wires,

6oConnect the two white wires together using twist-on connectors,

7. Connect the bare ground wire from the cooktop cable to the

grounded wire in the junction box or other grounded connector

using twist-on connector, (See Figure 3,)

Do Not connect bare ground wire to neutron (white) wire in

1. Disconnect 4-wire cable from cooktop connector

power supply.

2oRemove the junction

box cover from the junction box inside the cabinet,

3oConnect the flexible, armored cable from the cooktop to

the junction box using a U,L- or C,S,A,qisted conduit

connector, Tighten screws on conduit connector,

4, Connect the two black wires together; the two red

wires together; and the factory=crimped bare and

white cooktop cable wires to the white (neutral) wire

in the junction box using twist-on connectors, (See

Figure 4,)

5. Replace the junction box cover,

white

wire

white and

grounding oven cable

wires -- factory U,L,- or CSA-

crimped listed conduit

junction box.

8. Replace the junction box cover=

Page 8

For all cooktop models with four-

wire cable from the cooktop.

(:These cooktops are

manufactured with white

(neutra 0 power suppJy wire and

a cabinet-connected bare ground

wire factory-crimped together.):

Where tocal codes Do Not permit

connecting the frame-ground

conductor to the neutra! (white}

junction box wire:

1, Disconnect power supply.

2, Remove the junction box cover from

the junction box inside the cabinet.

3, Connect the flexible, armored cable

from the cooktop to the junction box

using a U.L =or C.S.A.qisted conduit

connector. Tighten screws on conduit

connector.

4, Connect the two black wires together

and the two red wires together.

5. Separate the factory-crimped bare and

white cooktop cable wires.

6, Connect the two white wires together

using twist-on connectors.

7, Connect the bare ground wire from the

cooktop cable to a grounded wire in

the junction box or other grounded

connector using twist-on connector.

(See Figure 3.)

Do Not connect bare ground wire to

neutral (white) wire in junction box,

8. Replace the junction box cover.

Check operation

Turnon electricalsupply.

71 Check that cooktop surface elements

heat and indicator lights are operating correctly.

8B Checkthat downdraftvent operates,if

thecooktop does not operate,disconnectthe

powersupplyand checkthat wire connections

havebeen madecorrectly.

You have just finished installing your

new downdraft cooktop. To get the

most efficient use from your new

cooktop, read your Use & Care Guide.

Keep Installation instructions and

Guide close to cooktop for easy

reference.

Ceektepremevam

tf removing the cooktop is necessary

for cJeaning or maintenance:

1. Disconnect electrical supply.

2. Disconnect ventsystem.

3. Lift cooktop out of countertop to

complete cleaning or maintenance.

After cJeaning and maintenance:

1. Reinstall cooktop in cutout.

2. Check that front edge of cooktop is

parallel to front edge of countertop.

3. Connect vent system.

4. Connect electrical supply.

If ceektep

net eperate:

[_ Check that the circuit breaker is not

tripped or the house fuse blown.

[_ Check that the power supply cord is

plugged into the outlet (120 V models).

[_See Use and Care Guide for

troubleshooting list.

Note: Refer to Use and Care Guide for

operating and cleaning instructions.

If youneed

if you have questions about

operating, cJeaning or maintaining

your cooktop:

[_ Refer to Use and Care Guide,

[_ Call the Customer Interaction Center.

Check your Use and Care Guide for

a toll-free number to call or call the

dealer from whom you purchased

this appliance. The dealer is listed in

the Yellow Pages of your phone

directory under "Appliances --

Household -- Major -- Service and

Repair."

Maintain the quality buitt into your

cooktop by calling an authorized

service company.

To obtain the name and number of the

authorized service company:

[_ Contact the dealer from whom you

purchased your cooktop; or

[_ Look in the Yellow Pages of your

telephone directory under

"Appliances -- Household --

Major -- Service and Repair;" or

[_ Call the Customer Interaction Center.

The toIFfree number is listed in your

Use and Care Guide.

When you call, you will need:

E_The cooktop model number.

E_The cooktop serial number.

Both numbers are listed on the

model/serial rating plate located on the

underside of cooktop burner box.

Part No. 8286553 Printed in U.S.A.

Q 2005 Whirlpool Corporation Benton Harbor, Michigan 49022 04/2005

Page 9

NOTES

Page 10

NOTES

10

Loading...

Loading...