Page 1

KAR-13

TECHNICAL EDUCATION

OUTDOOR AUTOMATIC

ICE MAKER

Model KUIO15NNLS

JOB AID 4317309

Page 2

FORWARD

This KitchenAid Job Aid, “Outdoor Automatic Ice Maker,” (Part No. 4317309), provides the

technician with information on the installation, operation, and service of the Outdoor Automatic Ice

Maker. It is to be used as a training Job Aid and Service Manual. For specific information on the

model being serviced, refer to the “Use and Care Guide,” or “Wiring Diagram” provided with the

ice maker.

The Wiring Diagram and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the KitchenAid Outdoor Automatic Ice Maker.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the ice maker to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2003, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Page 3

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

KitchenAid Model & Serial Number Designations.............................................................. 1-3

Model & Serial Number Label And Wiring Diagram Locations .......................................... 1-4

Specifications..................................................................................................................... 1-5

Outdoor Ice Maker Warranty ............................................................................................. 1-6

INSTALLATION INFORMATION ........................................................................................... 2-1

Electrical Supply Requirements ......................................................................................... 2-1

Water Supply And Drain Connections ............................................................................... 2-2

THEORY OF OPERATION ..................................................................................................... 3-1

The Controls ...................................................................................................................... 3-1

Water And Refrigerant Circuit ............................................................................................ 3-2

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Water Inlet Valve ....................................................................................... 4-2

Removing The Evaporator ................................................................................................. 4-3

Removing The Water Recirculation Pump......................................................................... 4-4

Removing The Evaporator Thermistor............................................................................... 4-8

Removing The Bin Thermostat ........................................................................................ 4-10

Removing The Hot Gas Valve And Solenoid ................................................................... 4-12

Removing The Master Switch, Recirculation Pump Motor Capacitor,

And Electronic Control Board ....................................................................................... 4-14

Removing The Condenser Fan Motor ............................................................................. 4-16

Removing The Condenser ............................................................................................... 4-18

Removing The Compressor ............................................................................................. 4-20

Removing The Door, Door Gasket, And Top Cover ........................................................ 4-22

COMPONENT TESTING ........................................................................................................ 5-1

Water Inlet Valve Solenoid ................................................................................................ 5-1

Water Recirculation Pump ................................................................................................. 5-1

Evaporator Thermistor ....................................................................................................... 5-2

Bin Thermostat .................................................................................................................. 5-2

Hot Gas Valve Solenoid..................................................................................................... 5-3

Master Switch .................................................................................................................... 5-3

Recirculation Pump Motor Capacitor ................................................................................. 5-4

Condenser Fan Motor ........................................................................................................ 5-4

Compressor, Overload, & Relay ........................................................................................ 5-5

- iii -

Page 4

Page

DIAGNOSIS & TROUBLESHOOTING ................................................................................... 6-1

Timing Chart ...................................................................................................................... 6-1

Troubleshooting Chart ....................................................................................................... 6-2

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... 7-1

Wiring Diagram .................................................................................................................. 7-1

Strip Circuits ...................................................................................................................... 7-2

TECH TIPS ............................................................................................................................. 8-1

Cleaning The Ice Maker..................................................................................................... 8-1

Routine Cleaning ......................................................................................................... 8-1

Cleaning The Spray Assembly .................................................................................... 8-2

- iv -

Page 5

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

ELECTRICAL POWER SUPPLY &

GROUNDING REQUIREMENTS

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1-1

Page 6

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere.

ESD may damage or weaken the electronic control assembly. The new control

assembly may appear to work well after

repair is finished, but failure may occur at

a later date due to ESD stress.

• Use an antistatic wrist strap. Connect the

wrist strap to the green ground connection point, or to an unpainted metal surface in the appliance.

- OR -

• Touch your finger repeatedly to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Before removing the part from its package, touch the antistatic bag to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Avoid touching electronic parts, or terminal contacts. Handle the electronic control assembly by the edges only.

• When repackaging the failed electronic

control assembly in an antistatic bag,

observe the previous instructions.

1-2

Page 7

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K UI O 15 NN L S 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

UI = UNDERCOUNTER ICE MAKER

MERCHANDISING SCHEME

O = OUTDOOR

CAPACITY / SIZE / SERIES / CONFIGURATION

15 = 15" WIDE

FEATURES

NN = NON-PUMP, NON-REVERSIBLE DOOR

YEAR OF INTRODUCTION

L = 2002

COLOR CODE

S = STAINLESS STEEL

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER EH P 04 54321

DIVISION RESPONSIBILITY

E = EVANSVILLE, IN / SOURCED

YEAR OF PRODUCTION

P = 2003, R = 2004

WEEK OF PRODUCTION

04 = 4th WEEK

PRODUCT SEQUENCE NUMBER

1-3

Page 8

MODEL & SERIAL NUMBER LABEL

AND WIRING DIAGRAM LOCATIONS

The Model/Serial Number label and Wiring Diagram locations are shown below.

Model & Serial Number Label Location

Wiring Diagram Location

(On Rear Of Front Panel)

1-4

Page 9

SPECIFICATIONS

(

)

(

)

(

)

(

)

AC Power Supply .........................................................................104 To 127 VAC, 60 Hz

Amperage....................................................... 3.4A (5 Minute Freeze @ 104°F/WT 80°F)

Minimum Circuit Capacity ................................................................................... 15 Amps

Maximum Fuse Size............................................................................................ 15 Amps

Ice Production Per 24 Hr. (Approximate) ...........................................................................

Ambient

Temp (°F/°C)

70/21 51 lbs. (23 kg) 46 lbs. (21 kg) 43 lbs. (19 kg)

80/27 47 lbs. (22 kg) 40 lbs. (18 kg) 38 lbs. (17 kg)

90/32 46 lbs. (21 kg) 35 lbs. (16 kg) 32 lbs. (14 kg)

100/38 40 lbs. (18 kg) 34 lbs. (15 kg) 29 lbs. (13 kg)

Water Temperature (°F/°C)

50/10 70/21 90/32

Ice Shape ............................................................................................................. Top Hat

Ice Production Per Cycle........................................................ 24 pcs, 0.595 Ibs. (0.27 kg)

Storage Capacity (Approximate) ............................................................. 28 Ibs. (12.7 kg)

Bin Control Setting ...................................................................................22 Ibs. (10.0 kg)

Exterior Dimensions (W x D x H) ................... 14.9″ x 22.6″ x 33.5″ (378 x 575 x 850mm)

Exterior Finish ....................................... Stainless Steel, Plastic, Galvanized Steel (Rear)

Net Weight ..................................................................................................88 Ibs. (40 kg)

Cube Control System ....................................................... Thermistor & Electronic Control

Harvesting Control System ............................................................. Hot Gas & Thermistor

Ice Making Water Control...................................................................... Electronic Control

Bin Control System ......................................................................................... Thermostat

Refrigerant .............................................................................................................. R134a

Ambient Temperature .................................................................................... 45 To 100°F

Water Supply Pressure ............................................................................... 7 To113 PSIG

Electrical Consumption

Ambient

Temp (°F/°C)

70/21 222 Watts 228 Watts 235 Watts

80/27 227 Watts 237 Watts 242 Watts

90/32 228 Watts 244 Watts 250 Watts

100/38 237 Watts 246 Watts 255 Watts

Ambient

Temp (°F/°C)

70/21 3.1 min. 2.0 min. 2.0 min.

80/27 3.0 min. 2.0 min. 2.0 min.

90/32 3.0 min. 2.4 min. 2.0 min.

100/38 3.0 min. 2.0 min. 2.1 min.

Water Temperature

50/10 70/21 90/32

Water Temperature

50/10 70/21 90/32

°F/°C

°F/°C

Temp (°F/°C)

Temp (°F/°C)

Water Consumption (Per 24 Hrs.)

Ambient

70/21 44 Gal. 38 Gal. 33 Gal.

80/27 39 Gal. 31 Gal. 27 Gal.

90/32 38 Gal. 24 Gal. 20 Gal.

100/38 31 Gal. 23 Gal. 16 Gal.

Ambient

70/21 16 min. 19 min. 23 min.

80/27 18 min. 21 min. 26 min.

90/32 19 min. 24 min. 29 min.

100/38 25 min. 29 min. 33 min.

Water Temperature

50/10 70/21 90/32

Freeze Cycle TimeHarvest Cycle Time

Water Temperature

50/10 70/21 90/32

°F/°C

°F/°C

1-5

Page 10

OUTDOOR ICE MAKER WARRANTY

1-6

Page 11

INSTALLATION INFORMATION

ELECTRICAL SUPPLY REQUIREMENTS

WARNING

Electrical Shock Hazard

• A 115 Volt, 60 Hz, AC only 15 ampere electrical

supply, properly grounded in accordance

with the National Electrical Code and local

codes and ordinances, is required.

• It is recommended that a separate circuit,

serving only the ice maker, be provided. Use

a receptacle which cannot be turned off by a

switch or pull chain.

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

Before you move the ice maker into its final

location, it is important to make sure you have

the proper electrical connection:

Recommended Grounding Method

For personal safety, this appliance must be

grounded. This appliance is equipped with a

power supply cord having a 3-prong grounding

plug. To minimize possible shock hazard, the

cord must be plugged into a mating, 3- prong,

grounding-type wall receptacle, grounded in

accordance with the National Electrical Code

and local codes and ordinances. If a mating

wall receptacle is not available, it is the personal responsibility of the customer to have a

properly grounded, 3-prong wall receptacle

installed by a qualified electrician.

2-1

Page 12

WATER SUPPLY AND DRAIN CONNECTIONS

CAUTION: To prevent damage to the freezer

mechanism, do not operate this ice maker

when the water supply is OFF, or if the pressure is below 10 PSIG (0.7 bar), the recommended water pressure. Stop the ice maker

until proper water pressure is resumed.

• The water supply inlet is 1/2-14 NPT and

must only be connected to a potable water

supply.

• A water supply line shut-off valve and drain

valve must be installed.

• Water supply pressure should be a minimum

of 10 PSIG (0.7 bar), and a maximum of 113

PSIG (7.5 bar). If the pressure exceeds 113

PSIG (7.5 bar), use a pressure reducing

valve.

Ice Maker

• The drain outlet hose is 5/8″ (16mm) I.D. and

internally connected with a 2/3″ (17mm) O.D.

drain outlet.

• The drain must be 1/4″ fall-per-foot (2 cm

fall-per-meter) on horizontal runs for optimum flow.

• Keep a 2 vertical inch (5 vertical cm) air gap

or more between the drain pipe end and the

sink.

• The drain pipe must be used to prevent a

backflow into the storage bin.

• This ice maker should be installed in accordance with applicable national, state,

and local regulations.

Vent

1/4" Fall-Per-Foot

To Approved Floor Drain

Water Supply Inlet = 1/2-14 NPT

Shutoff Valve

Drain Valve (Air or CO2 For

Long Term Storage)

Bin Drain Outlet

Hose 5/8" I.D.

2-2

Page 13

THEORY OF OPERATION

THE CONTROLS

ICE MAKING CONTROL

The freeze and harvest cycles are controlled

by a thermistor and an electronic control.

The electronic controller uses a thermistor that

is attached to the top of the evaporator to

monitor the evaporator temperature. When the

thermistor signals 28°F (–2°C), the control

begins to count down 10 minutes. The electronic control then switches the contacts of

relays X1 and X2, which stops the pump and

fan motors, and engerizes the hot gas and

water valves. This completes the freeze cycle,

and starts the harvest cycle.

HARVEST CONTROL

The ice cubes formed inside the ice making

cells are released by hot gas warming the

evaporator. When a small portion of the ice

melts on the ice making cells interior, the ice

drops down the ice guide into the storage bin.

When the evaporator is warmed further (to

approximately 45°F / 7°C), the thermistor senses the temperature rise, and the electronic

controller begins to count down 50 seconds.

The controller then switches the contacts of the

relays, which starts the pump and fan motors,

and de-energizes the hot gas and water valves.

This completes the harvest cycle, and starts

the freeze cycle. The harvest and freeze cycles

will continue until the bin is full of ice and the bin

thermostat is satisfied.

At low temperature conditions where the harvest cycle exceeds 3 minutes, the water valve

will de-energize after 3 minutes.

At the initial start, or after a power failure, the

ice maker will begin in the harvest cycle, because the compressor is under a “no load”

condition (hot gas valve is energized). During

this time, any ice that is present on the evaporator will be removed.

In the initial cycle at startup, or after shutdown

for bin control, water is supplied for 80 seconds. The water valve de-energizes approximately 30 seconds after the freeze cycle starts.

NO ADJUSTMENT

The thermistor and electronic control are factory adjusted to produce constant ice all year,

and are not affected by changes in the ambient

and water temperatures. No adjustment is required for any frequency 50/60Hz or ambient

temperature from 45 to 100°F.

No Adjustment.

Controls Are Sealed.

If Seals Are Broken,

Replace Control.

3-1

Page 14

WATER AND REFRIGERANT CIRCUIT

3-2

Page 15

COMPONENT ACCESS

This section instructs you on how to service each component inside the Outdoor Automatic Ice

Maker. The components and their locations are shown below.

COMPONENT LOCATIONS

TOP OF UNIT

Bin Thermostat

(On Rear Panel)

Evaporator Thermistor

Water Inlet Valve

Hot Gas Valve

(Behind Compressor)

Water Recirculation Pump

Evaporator

BOTTOM FRONT OF UNIT

Compressor

Condenser

Recirculation Pump

Motor Capacitor

Condenser Fan Motor

Master Switch

Electronic Control Board

4-1

Page 16

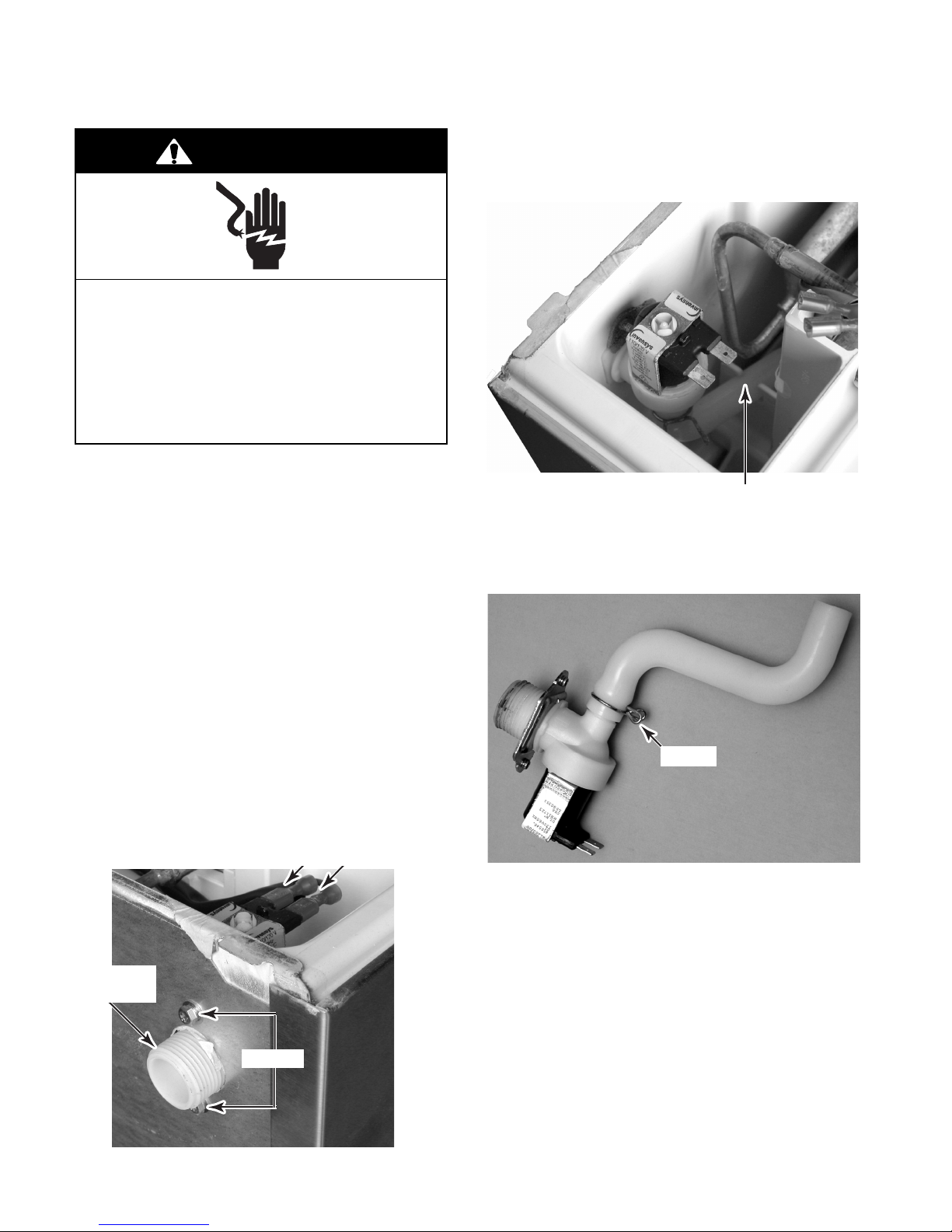

REMOVING THE WATER INLET VALVE

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Turn off the water supply to the ice maker.

10. Lift the water inlet valve, release the inlet

fill tube from the molded retainer, and

remove them from the ice maker.

Inlet Fill Tube In Retainer

3. Move the ice maker to gain access to the

rear of the unit.

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Remove the ice from the storage bin.

7. Remove the ice maker door and the top

cover (see page 4-22 for the procedures).

8. Remove the two screws from the water

inlet valve.

9. Disconnect the two wires from the water

inlet valve solenoid terminals.

Solenoid Wires

Water Inlet

Valve

Screws

11. Remove the clamp from the inlet fill tube

and remove the tube from the water inlet

valve.

Clamp

REASSEMBLY NOTES:

• When you reconnect the inlet fill tube to the

water inlet valve, be sure to position it, as

shown in the photo above.

• When you reinstall the water inlet valve and

inlet fill tube in the ice maker, be sure to fit

the tube inside the molded retainer, as shown

at the top of the page.

4-2

Page 17

REMOVING THE EVAPORATOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Turn off the water supply to the ice maker.

3. Move the ice maker to gain access to the

rear of the unit.

10. Remove the water inlet valve solenoid

wires from the terminals and move them

out of the way.

11. Remove the evaporator thermistor screw

and remove the thermistor from the evaporator. NOTE: You will need to replace the

thermistor and rebond it to the new evaporator using the sealant provided with the

new thermistor.

12. Protect the area surrounding the two

evaporator joints.

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Open the ice maker door.

7. Remove the ice from the storage bin.

8. Remove the top cover (see page 4-22 for

the procedure).

9. Remove the four screws from the evaporator.

Evaporator Thermistor

Evaporator Joints

Water Inlet Valve

13. Access the sealed system and discharge

the refrigerant into an approved recovery

system.

14. Unbraze the two evaporator joints from

the sealed system and remove the evaporator.

Screw (1 of 4)

Evaporator

4-3

Page 18

REMOVING THE WATER RECIRCULATION PUMP

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

11. Squeeze the locking tabs on the tube clip

and remove the tube from the water reservoir.

12. Pull the other end of the tube off the water

recirculation pump.

2. Turn off the water supply to the ice maker.

3. Move the ice maker to gain access to the

rear of the unit.

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Open the ice maker door.

7. Remove the ice from the storage bin.

8. Remove the top cover (see page 4-22 for

the procedure).

9. Remove the ice scoop from its holder.

10. Remove the hex screws from the holder

and remove the holder from the unit.

Holder

Ice Scoop

90° Tube Clip

13. Push out on the left and right locking tabs

and pull the water reservoir out of the unit.

Reservoir

Push Locking Tab Out (On Each Side)

4-4

Page 19

14. Remove the screw from the right side of

the water recirculation pump cover. Grasp

the drain hose at the bottom of the cover,

then pull down and forward, and remove

the cover from the unit.

Water Recirculation

Pump Cover

Screw

16. Disconnect the recirculation pump 3-wire

connector.

17. Cut the indicated wire tie.

18. Remove the green ground wire screw.

Ground Screw

Cut Wire Tie

3-Wire Connector

Drain Hose

15. Remove the six screws from the rear channel cover and remove the cover from the

ice maker.

Rear

Channel

Cover

Screw (1 0f 6)

19. Remove the four evaporator screws and

the four ice making housing screws.

Ice Making Housing

Screw (1 of 4)

4-5

Evaporator Screw (1 of 4)

Continued on the next page.

Page 20

20. Lift the rear of the evaporator and the front

of the ice making component housing,

then slide the housing under the evaporator toward the front of the unit until the

housing clears the evaporator.

Evaporator

Ice Making Component Housing

21. Rotate the ice making component housing

so you can easily access the recirculation

pump mounting screws.

22. Use a 9/32″ socket or a phillips screw-

driver, and remove the recirculation pump

mounting screws.

23. Disconnect the end of the water inlet fill

tube from the recirculation pump and remove the pump.

Water Inlet Fill Tube

3 Pump Screws

Rotate Housing Over Evaporator

Water Recirculation Pump

4-6

Page 21

WARNING

Electrical Shock Hazard

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

Perform the following steps to reinstall the

water recirculation pump:

1. Connect the end of the water inlet fill tube

to the recirculation pump.

2. Mount the recirculation pump to the unit

with its three 9/32″ mounting screws.

REASSEMBLY NOTES:

• Be sure to route the water recirculation

pump wire cable toward the back of the unit

and behind the water inlet fill tube.

• Be sure to fit the water inlet fill tube inside the

molded retainer, as shown below.

Water Inlet Fill

Tube In Retainer

3. Reinstall the ice making component housing and evaporator in their proper locations and install the screws.

4. Connect the recirculation pump 3-wire

connector.

5. Install a wire tie around the 3-wire connector.

6. Reinstall the green ground wire with its

mounting screw.

4-7

Page 22

REMOVING THE EVAPORATOR THERMISTOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

9. Remove the screw from the evaporator

thermistor mounting bracket, and break

the bracket loose from the evaporator.

10. Remove the rubber grommet and remove

the evaporator thermistor wires from the

grommet.

Evaporator Thermistor Bracket & Screw

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Turn off the water supply to the ice maker.

3. Move the ice maker to gain access to the

rear of the unit.

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Open the ice maker door.

7. Remove the ice from the storage bin.

8. Remove the top cover (see page 4-22 for

the procedure).

IMPORTANT: You will need to install and

rebond a new evaporator thermistor if the old

thermistor is loose, or is removed from the

evaporator. Make sure that you have the new

thermistor available prior to removing the old

one. The correct sealant is provided with the

new thermistor. The ice maker will not operate

properly if the wrong sealant is used. Do not

use silicone sealant; it will insulate the thermistor, affecting its operation.

Rubber Grommet

11. Remove the six screws from the rear channel cover and remove the cover from the

ice maker.

12. Cut the wire ties from the evaporator thermistor wire down to the control board.

Rear

Channel

Cover

Wire Tie

Screw

(1 of 6)

4-8

Page 23

13. Disconnect the two evaporator thermistor

wire connectors from the electronic control board terminals TH1 and TH2, and

remove the evaporator thermistor. NOTE:

Refer to page 4-14 for the procedure for

accessing the electronic control board.

Evaporator Thermistor Wire Connectors

4-9

Page 24

REMOVING THE BIN THERMOSTAT

10. Remove the two screws from the bin ther-

WARNING

mostat bracket and remove the thermostat.

11. Cut the wire tie from around the plastic bag

and bin thermostat wires and remove the

bag.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Turn off the water supply to the ice maker.

3. Move the ice maker to gain access to the

rear of the unit.

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Open the ice maker door.

7. Remove the ice from the storage bin.

8. Remove the top cover (see page 4-22 for

the procedure).

9. Remove the six screws from the rear channel cover and remove the cover from the

ice maker.

Wire Tie

Bin Thermostat

Sensing Tube

12. Dsconnect the two wires from the bin

thermostat terminals.

13. Cut the black and white heater wires from

the harness. IMPORTANT: When reconnecting the wires to the harness, make

sure that you position the open end of the

wire connectors facing down to prevent

moisture from becoming trapped.

Cut Black & White

Heater Wires

Rear

Channel

Cover

Screw (1 0f 6)

Wire Connectors

Bin Thermostat

Screws

4-10

Page 25

NOTE: Before you remove the bin thermostat

sensing tube in the next step, note the way it is

routed.

15. Pull the sensing tube and heater out of the

rear of the unit, and remove the bin thermostat.

14. From inside the ice maker, straighten the

end of the sensing tube, and pull it out of

the holder.

Sensing Tube Holder

Heater Sleeving

REASSEMBLY NOTE: When you reinstall the

sensing tube and heater from the new bin

thermostat, make sure that you keep the

sleeving at the same location inside the ice

maker as the old sensing tube and heater.

Straighten End Of Sensing Tube

4-11

Page 26

REMOVING THE HOT GAS VALVE AND SOLENOID

10. Remove the six screws from the unit com-

WARNING

partment cover, remove the cover, and

pull the power cord and strain relief out of

the u-channel.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Turn off the water supply to the ice maker.

3. Move the ice maker to gain access to the

rear of the unit.

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Open the ice maker door.

Power Cord & Strain Relief

Unit Compartment Cover

Screw (1 0f 6)

11. To remove the hot gas valve solenoid:

a) Disconnect the solenoid 2-wire con-

nector from the harness. Cut any wire

ties from around the solenoid wires.

7. Remove the ice from the storage bin.

8. Remove the top cover (see page 4-22 for

the procedure).

9. Remove the six screws from the rear channel cover and remove the cover from the

ice maker.

Rear

Channel

Cover

Screw (1 0f 6)

Hot Gas Valve

Solenoid Connector

4-12

Page 27

b) Remove the 7mm hex-head screw from

the solenoid and lift the solenoid off the

hot gas valve.

Screw

c) Access the sealed system and discharge

the refrigerant into an approved recovery

system.

d) Unbraze the hot gas valve from the

sealed system (see the photo in the left

column for the joints to braze).

Hot Gas

Valve

Solenoid

Tubing Joints

12. To remove the hot gas valve:

a) Remove the hot gas valve solenoid

(see step 11 for the procedure).

b) Shield the tubing insulation.

Hot Gas Valve

REASSEMBLY NOTE: When installing the new

hot gas valve, use a generous amount of

thermal heat trap paste between the valve and

tubing joints to protect the valve when brazing.

4-13

Page 28

REMOVING THE MASTER SWITCH, RECIRCULATION PUMP

MOTOR CAPACITOR, AND ELECTRONIC CONTROL BOARD

4. To remove the master switch:

WARNING

Electrical Shock Hazard

a) Remove the hex nut w/boot from the

master switch.

Electronic Control Board Cover

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Remove the screws from the lower front

panel and grille assembly and remove the

assembly.

Nut W/Boot

Cover Screw

b) Disconnect the five wires from the mas-

ter switch terminals and remove the

switch from the enclosure. NOTE: If

necessary, see the switch wiring on

page 5-3.

Master Switch

Front Panel &

Grille Assembly

3. Remove the screw from the electronic

control board cover and remove the cover

(see the photo at the top of the next

column).

4-14

Page 29

5. To remove the recirculation pump mo-

tor capacitor:

a) Disconnect the two wire connectors

from the capacitor terminals.

b) Remove the mounting screw from the

capacitor and remove the capacitor from

the enclosure.

Recirculation Pump

Motor Capacitor

Screw

6. To remove the electronic control board:

a) Disconnect the wire connectors from

the electronic control board terminals.

b) Squeeze the locking tab on each stand-

off while you pull the board off the

standoffs.

Board Standoff

(1 Of 4)

Pink (B1)

Black (C1)

Blue (A1)

Black (C2)

Violet (A2)

Electronic Control Board

TH1 TH2

Black White

4-15

Page 30

REMOVING THE CONDENSER FAN MOTOR

3. Remove the two 8mm hex head bolts from

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Remove the screws from the lower front

panel and grille assembly and remove the

assembly. Condenser Fan Motor

the condenser fan motor bracket.

Bracket Bolts (1 of 2)

Front Panel & Grille Assembly

4. Cut the wire tie, disconnect the 2-wire

condenser fan motor connector, and remove the fan motor.

Condenser Fan Motor

Wire Connector

Wire Tie

4-16

Page 31

5. Remove the three 1/4″ hex-head screws

from the condenser fan motor and remove

the motor from the bracket.

Condenser Fan Motor

Bracket Screw (1 Of 3)

6. Remove the 7/16″ nut and lockwasher

from the condenser fan motor shaft and

remove the fan blade from the motor.

7/16″ Fan Blade

Nut & Lockwasher

4-17

Page 32

REMOVING THE CONDENSER

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Turn off the water supply to the ice maker.

3. Move the ice maker to gain access to the

rear of the unit.

9. Remove the two screws from the condenser flanges.

10. Remove the two screws from the top condenser bracket.

Top Condenser Bracket Screws

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Open the ice maker door.

7. Remove the ice from the storage bin.

8. Remove the screws from the lower front

panel and grille assembly and remove the

assembly.

Condenser Flange Screws (1 of 2)

11. Remove the six screws from the unit compartment cover, remove the cover, and

pull the power cord and strain relief out of

the u-channel.

Power Cord & Strain Relief

Screw (1 0f 6)

Front Panel & Grille Assembly

Unit Compartment Cover

4-18

Page 33

12. Access the sealed system and discharge

the refrigerant into an approved recovery

system.

13. Unbraze the two condenser joints from the

sealed system and remove the condenser.

Joint Connections

Condenser

4-19

Page 34

REMOVING THE COMPRESSOR

WARNING

9. Remove the six screws from the unit compartment cover, remove the cover, and

pull the power cord and strain relief out of

the u-channel.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. Turn off the water supply to the ice maker.

3. Move the ice maker to gain access to the

rear of the unit.

4. Disconnect the drain outlet hose from the

ice maker.

5. Disconnect the water inlet line from the ice

maker.

6. Open the ice maker door.

Power Cord & Strain Relief

Unit Compartment Cover

10. Push in on the front sides of the terminal

cover clip and unhook it from the compressor slots, then remove the terminal cover.

Screw (1 0f 6)

Compressor

7. Remove the ice from the storage bin.

8. Remove the screws from the lower front

panel and grille assembly and remove the

assembly.

Front Panel & Grille Assembly

Terminal Cover Clip

4-20

Page 35

11. Remove the wire connectors from the

relay and the overload protector.

12. Pull the relay and the overload protector

from the compressor pins.

Overload

Protector

Wire

Filter/Drier

Wire

Relay

13. Access the sealed system and discharge

the refrigerant into an approved recovery

system.

14. Cut the suction and discharge lines.

15. Cut the filter/drier (see the photo at the top

of the next column) from the system (do

not use a torch to remove the filter/drier).

Discharge Line

16. Remove the four compressor mounting

screws from the rubber isolators and remove the compressor from the unit.

Compressor Screws

(1 Of 4)

Suction Line

4-21

Page 36

REMOVING THE DOOR, DOOR GASKET, AND TOP COVER

3. To remove the door gasket, grasp the

WARNING

gasket, and pull it out of the door channel.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug ice maker or disconnect power.

2. To remove the ice maker door:

a) Remove the 3/8″ hex-head hinge pin

from the bottom hinge.

Door Gasket

4. To remove the top cover:

a) Remove the two screws from the front

of the cover.

b) Lift the front of the cover, unhook the

rear edge from the clip, and remove the

cover.

Hinge Pin

b) Pull the bottom of the door out and

remove the door from the cabinet.

Unhook

Screws

4-22

Page 37

COMPONENT TESTING

Before testing any of the components, perform

the following checks:

• Control failure can be the result of corrosion

on connectors. Therefore, disconnecting and

reconnecting wires will be necessary throughout test procedures.

• All tests/checks should be made with a VOM

or DVM having a sensitivity of 20,000 ohmsper-volt DC, or greater.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

• Check all connections before replacing components, looking for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

• Resistance checks must be made with power

cord unplugged from outlet, and with wiring

harness or connectors disconnected.

WARNING

WATER INLET VALVE SOLENOID

Refer to page 4-2 for the procedure for servicing the water inlet valve.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 100 scale.

3. Touch the ohmmeter test leads to the

water inlet valve solenoid terminals. The

meter should indicate between 900 and

1400 Ω.

WATER RECIRCULATION PUMP

Refer to page 4-4 for the procedure for servicing the water recirculation pump.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 100 scale.

3. Touch the ohmmeter test leads to the

indicated water recirculation pump wire

connector pins. The meter should indicate

as follows:

Black & Red Wires = 290 to 325 Ω.

Black & Blue Wires = 210 to 230 Ω.

5-1

Page 38

WARNING

(

)

(

)

(0)

(10)

(21)

(32)

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

EVAPORATOR THERMISTOR

Refer to page 4-8 for the procedure for servicing the evaporator thermistor.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the appropriate scale.

3. Disconnect the wire from electronic control board terminal TH1 or TH2.

BIN THERMOSTAT

Sensor

Refer to page 4-10 for the procedure for servicing the bin thermostat.

NOTE: The bin thermostat is fragile and should

be handled with care.

1. Unplug ice maker or disconnect power.

NOTE: If the evaporator thermistor fails, it will

normally fail completely open or shorted. Use

the chart below to check for the approximate

resistance at a given temperature.

4. Touch the ohmmeter test leads to the two

evaporator thermistor connectors. The

meter should indicate as shown in the

following chart.

Sensor Temperature

°F (°C)

0

–18

10

–12

32

50

70

90

Resistance

12,467 - 14,933

9,373 - 11,227

5,500 - 6,500

3,550 - 4,250

2,275 - 2,725

1,547 - 1,853

2. Set the ohmmeter to the R x 1K scale.

3. Disconnect the wires from the bin thermostat terminals.

4. Touch the ohmmeter test leads to the two

bin thermostat terminals. The meter should

indicate continuity (0 Ω) at room tempera-

ture.

Ω

5-2

Page 39

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

HOT GAS VALVE SOLENOID

Refer to page 4-12 for the procedure for servicing the hot gas valve solenoid.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Touch the ohmmeter test leads to the pins

of the hot gas valve solenoid 2-wire connector. The meter should indicate between

240 and 300 Ω.

MASTER SWITCH

1 OR

2 BR

3 OR

Refer to page 4-14 for the procedure for servicing the master switch.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Disconnect the wires from the terminals of

the master switch.

4. Touch the ohmmeter test leads to the

following master switch terminals (the terminal numbers are on the side of the

case). When the switch is in the indicated

position, as shown on the cover, the meter

should read:

Centered Position: All connections are an

open circuit (infinite):

4 BK

5 RD

6 N/C

Ice Position:

Pins 1 and 2 = closed circuit (0 Ω).

Pins 4 and 5 = closed circuit (0 Ω).

Wash Position:

Pins 2 and 3 = closed circuit (0 Ω).

5-3

Page 40

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

RECIRCULATION PUMP

MOTOR CAPACITOR

Refer to page 4-14 for the procedure for servicing the recirculation pump motor capacitor.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 10K scale.

3. Touch the ohmmeter test leads to the

capacitor terminals. The meter should

deflect momentarily, and then move to

infinity. To repeat the test, reverse the

ohmmeter test leads. The result should be

the same if the capacitor is good.

CONDENSER FAN MOTOR

Refer to page 4-16 for the procedure for servicing the condenser fan motor.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Touch the ohmmeter test leads to the pins

of the condenser fan motor 2-wire connector. The meter should indicate between 45

and 65 Ω.

5-4

Page 41

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

COMPRESSOR, OVERLOAD,

& RELAY

Overload

Relay

Refer to page 4-20 for the procedure for servicing the compressor, overload, and relay.

1. Unplug ice maker or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. To test the compressor windings:

a) Touch one of the ohmmeter test leads

to the Common (C) pin, and the other

lead to the Start (S) pin. The meter

should indicate between 8 and 11 Ω.

b) Touch one of the ohmmeter test leads

to the Common (C) pin, and the other

lead to the Run (M) pin. The meter

should indicate between 2 and 3 Ω.

4. To test the overload, touch the ohmme-

ter test leads to the terminals. The meter

should indicate a closed circuit (0 Ω).

Common (C)

Overload

Terminals

5. To test the relay, touch the ohmmeter

test leads to the following test points:

Run (M)Start (S)

Terminal 2 to pin M = 0 Ω.

Terminal 2 to pin S = 4.3 Ω

Pin S

Terminal 2

Pin M

Relay

5-5

Page 42

— NOTES —

5-6

Page 43

DIAGNOSIS & TROUBLESHOOTING

TIMING CHART

6-1

Page 44

TROUBLESHOOTING CHART

PROBLEM CHECK POSSIBLE CAUSE REMEDY

[1] The icemaker will not

start

[2] Compressor will not start a) Compressor 1. Wiring to Compressor 1. Check for loose

[3] Fan Motor or Pump

Motor will not run

[4] Harvest cycle time is

too long

[5] Hot Gas Valve will not

open

a) Power Cord 1. Loose connections 1. Tighten

2. Open circuit-damaged 2. Repair or replace

b) Master Switch 1. "OFF" position 1. Move to “ICE" position

2. Loose connections 2. Tighten

3. Open contacts 3. Check for continuity and

replace

c) Supply Voltage 1. Too low

2. Power supply shared with

other equipment

d) Bin Control Thermostat 1. Ambient temperature too

cool

2. Open contacts 2. Check for continuity and

e) Bin Thermostat Heater 1. Open circuit

Low ambient temperature

2. Coil winding opened 2. Check for continuity

b) Overload 1. Open contacts 1. Check for continuity and

c) Relay 1. Open contacts 1. Check for continuity and

a) Wiring 1. Loose connections or

broken wire

b) Fan Motor, Pump Motor 1. Coil winding opened 1. Replace

c) Fan Blade 1. Fan blade bound 1. Check and repair

d) Pump Motor Impeller 1. Defective or bound

impeller

e) Pump Motor Capacitor 1. Defective 1. Replace

f) Electronic Controller 1. Defective 1. Replace

a) Thermistor 1. Out of position or loose

attachment

2. Loose connections 2. Repair

b) Electronic Controller 1. Defective 1. Replace

a) Wiring 1. Loose connectors or

broken wire

b) Hot Gas Valve 1. Coil winding opened 1. Replace

1

. Contact a qualified

electrician to correct

problem

2.

Contact a qualified

electrician to correct

problem

1. Do not operate below

45°F / 7°C

replace (see page 5-2)

1. Check for continuity and

replace

connection or open, and

replace (see page 5-5)

between terminals and

replace (see page 5-5)

replace (see page 5-5)

replace (see page 5-5)

1. Repair or replace

1. Replace or clean

1. Refer to “Removing The

Evaporator Thermistor”

(see page 4-8)

1. Repair or replace

6-2

Page 45

PROBLEM CHECK POSSIBLE CAUSE REMEDY

[6] Will not fill with water a) Water Supply

b) Water Valve 1. Filter clogged

[7] Water continues to be

supplied in freeze cycle

[8] No water comes from

Water Tank

[9] All components run but

no ice is produced

[10] Large-hole cubes a) Ambient temperature 1. Low 1. No problem. Low ambient

a) Water Valve 1. Diaphragm does not close 1. Check for water filling

b) Electronic Controller 1. Defective 1. Replace

a) Wiring to Pump Motor 1. Loose connectors or

b) Pump Motor 1. Coil winding opened 1. Replace

c) Pump Motor Impeller 1. Defective or bound

d) Pump Motor Capacitor 1. Defective 1. Replace

e)

Water Recirculation

System

f) Water Supply Line 1. Water pressure too low

a)

Water Recirculation

System

b) Nozzle 1. Clogged

c) Refrigerant Circuit 1. Refrigerant leak or 1. Check with a leak

d) Compressor 1. Defective valve 1. Replace Compressor

e) Hot Gas Valve 1. Continues to open in

f) Water Valve 1. Stuck open 1. Replace

b) Electronic Controller 1. Built-in timer does not

1. Shut-off Valve or Water

Tap closed

2. Coil winding opened 2. Replace

broken wire

impeller

1. Water leaks 1.Check connections for

2. Clogged

and water level in Water

Tank too low

1. Water leaks 1. Check connections for

2. Clogged

2. Misaligned Nozzle and

Water

Tank

restriction

2. Undercharged 2. Check for leaks and

3. Air or moisture trapped 3. Replace drier, and

freeze cycle

count 10 min

. Open

1

1. Repair or replace water

valve

with icemaker off

1. Repair or replace

1. Replace or clean

water leaks and repair

2. Clean system (see page

8-1)

1. Check for recommended

pressure

water leaks and repair

2. Clean system (see page

8-1)

1. Clean system (see page

8-1)

2. Place in correct position

detector. Repair & recharge.

Replace refrigerant drier.

recharge

recharge

1. Check and replace

temperature results in ice

cubes with slightly larger

diameter holes.

1. Replace

6-3

Page 46

PROBLEM CHECK POSSIBLE CAUSE REMEDY

[11] Cloudy cubes a) Water Quality 1. High hardness or contains

impurities

b) Noz

zle 1. Clogged

2. Misaligned Nozzle and

Water Tank

c) 1. Scaled up 1. Clean or remove scale

Water Recirculation

System

[12] Freeze cycle time is too

long

[13] Icemaker will not stop

when Bin is filled with ice

[14] Abnormal Ice a) Nozzle 1. Clogged

[15] Some cells on the

evaporator form no ice

a) Ambient temperature 1. T oo high ( freeze cycle

b) Condenser inlet / outlet 1. Blocked. Bad air

c) Thermistor 1. Out of position or loose

d) Refrigerant Circuit 1. Refrigerant leak or

e) Fan Motor 1. See [3]

f) Condenser 1. Blocked 1. Clean

a) Bin Control Thermostat 1. Fused contacts 1. Replace

b) Pump Motor 1. Bearing worn 1. Replace

c) Pump Motor Impeller 1. Defective or bound

d) Compressor 1. Inefficient. 1. Replace

e) Refrigerant Circuit 1. Leak or restriction 1. Repair

a) Nozzle 1. Clogged

2. Water leaks 2.Check connections for

will be extremely long at

more than 40°C / 104°F)

circulation greatly reduces

ice production capacity

attachment

2. Leads short-circuit

restriction

2. Undercharged 2. Check for leaks and

2. Misaligned Nozzle and

Water Tank

impeller

2. Misaligned Nozzle and

Water Tank

1. Install a water filter or

scale treatment

1. Clean system (see page

8-1)

2. Place in correct position

water leaks and repair

1. Check for recommended

ambient temperature

1. Clean condenser

1. Refer to “Removing The

Evaporator Thermistor” (see

page 4-8)

2. Check continuity (see

page 5-2)

1. Check with a leak

detector. Repair & recharge.

Replace the refrigerant

drier.

recharge

1. Clean system (see page

8-1)

2. Place in correct position

1. Replace or clean

1. Clean system (see page

8-1)

2. Place in correct position

6-4

Page 47

WIRING DIAGRAM & STRIP CIRCUITS

WIRING DIAGRAM

BR

2

Master

Switch

5

RD

L1

BK

N

GR

WH

Evaporator Thermistor

2.5K Ω @ 70°F

Bin Control

OR

Thermostat

BK

U

C1

C2

1

3

4

6

6K Ω @ 32°F

TH1 TH2

Electronic

Control Board

Relay

X2

Relay

X1

B1 A1A2

PK

N.O.N.C.

Capacitor

1.0 UF

LBU

V

LBU

OR

Water Pump

RD

BU

A = 314 Ω

A

BK

M

M = 220 Ω

WH

WH

Condenser Fan Motor

PTC Relay

9.7 Ω @ 68°F

Compressor

2.4 Ω @ 68°F

BK

52 Ω

Hot Gas Solenoid

RD

270 Ω

Water Valve Solenoid

VT

1.2K Ω

BK

BU

WH

WH

WH

Bin Thermostat Heater

WHBK

4.1K Ω

WH

BK

Overload

WH

S

C

M

7-1

Page 48

ICE MAKING MODE

STRIP CIRCUITS

L1 N

BK

BR

L1

BK

BR

Master

Switch

2

Master

Switch

2

Bin Control

Thermostat

1

OR

1

OR

BK

Bin Control

Thermostat

Control

Switch

4

BK

5

PTC Relay

RD

X1 Relay

Compressor

S

M

LBU

BK

C

Capacitor

1.0 UF

LBU BU

Fan Motor

Overload

BK WH

Water Pump

OR RD

BK

BK

N

WH

WH

HARVEST MODE

L1

BK

BR

L1

BK

BR

Master

Switch

2

Master

Switch

2

1

1

Bin Control

Thermostat

X1 Relay

OR BK PK RD BU WH

Hot Gas Solenoid

Bin Control

Thermostat

X2 Relay

Water Valve Solenoid

WHVTOR BK

N

N

7-2

Page 49

TECH TIPS

CLEANING THE ICE MAKER

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

6. Push in on each of the ice guards and

unhook them from the hanger rod.

ICE GUARDS

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

NOTES:

• KitchenAid recommends cleaning the ice

maker at least once a year. More frequent

cleaning may be required in areas that contain heavy amounts of minerals in the water

supply.

• To prevent damage to the ice maker, do not

use ammonia or abrasive-type cleaners. Use

only LIME-A-WAY® Cleaner (see step 9 on

page 8-2).

• Always wear rubber gloves when handling

cleaning solutions.

ROUTINE CLEANING

1. Set the master switch to OFF and turn off

the water supply to the ice maker.

Hanger Rod

7. Squeeze the locking tabs on the suction

tube to release them and disconnect the

tube from the water tank. Drain the water

from the tank.

2. Unplug the ice maker or disconnect power.

3. Open the ice maker door.

4. Remove the ice from the storage bin.

5. Remove the ice scoop and its holder.

® Economics Laboratory, Inc.

Suction Tube

Locking Tabs

Tank

Continued on the next page.

8-1

Page 50

8. Pull out on the left and right locking tabs,

and pull the reservoir out of the unit. Empty

the reservoir, and then reinstall it.

9. Dilute approximately 5 oz. (148 ml) of

LIME-A-WAY® cleaner with 1 gallon

(3.8 lit.) of water.

10. Slowly pour the cleaning solution into the

reservoir.

CLEANING THE SPRAY ASSEMBLY

NOTE: If the ice maker spray assembly requires further cleaning, perform the following

steps.

1. Lift the ice chute off the front and rear

frame pipes and remove the chute from

the unit.

Rear Frame Pipe

Pull Out

Reservoir

11. Position the master switch to the WASH

position.

12. After circulating the cleaning solution for

30 minutes, position the master switch to

OFF.

13. Remove the reservoir and drain it, then

reinstall it in the unit.

14. Turn on the water to the ice maker.

15. Position the master switch to the WASH

position and allow the water to circulate for

5 minutes.

16. Position the master switch to OFF and

immediately back to WASH and allow the

system to rinse.

17. Repeat steps 15 and 16 three times to

completely rinse the system.

Ice Chute

Front Frame Pipe

2. Pull the end of the discharge tube off the

spray assembly nozzle.

Spray AssemblyDischarge Tube

3. Pull the spray assembly out of the unit.

Master Switch

Spray Assembly

8-2

Page 51

4. Remove the two end caps from the spray

assembly.

End Caps

Spray Assembly

5. Dilute approximately 5 oz. (148 ml) of

LIME-A-WAY® cleaner with 1 gallon

(3.8 lit.) of water.

6. Clean the caps and spray assembly. If the

spray nozzles are clogged, use a wire to

remove the clog, or use a suitable wire

brush.

7. Thoroughly rinse the spray assembly with

clean water.

8. Reinstall the two caps on the spray nozzle

assembly.

9. Reassemble the ice making components.

NOTE: During normal operation, if ice is sticking to the evaporator plate, check the “weep”

holes in the top of the plate. The holes must be

open to allow ice to drop.

Weep Hole (1 of 24)

(Top Of Evaporator)

8-3

Page 52

— NOTES —

8-4

Page 53

— NOTES —

8-5

Page 54

— NOTES —

8-6

Page 55

PRODUCT SPECIFICATIONS

AND

WARRANTY INFORMATION SOURCES

IN THE UNITED STATES:

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL:

FOR WHIRLPOOL PRODUCTS: 1-800-253-1301

FOR KITCHENAID PRODUCTS: 1-800-422-1230

FOR ROPER PRODUCTS: 1-800-447-6737

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-253-2870

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED SERVICER

FOR LITERATURE ORDERS:

PHONE: 1-800-851-4605

FOR TECHNICAL INFORMATION AND SERVICE POINTERS:

www.servicematters.com

IN CANADA:

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL:

1-800-461-5681

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-488-4791

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED SERVICER

Page 56

Loading...

Loading...