KitchenAid KAC-24, KBMC140H, KBMC147H, KBHC179J, KBHC109J Technical Education

TECHNICAL EDUCATION

BUILT-IN

MICROWAVE OVEN

KAC-24

JOB AID 4317283

FORWARD

This Job Aid, “KitchenAid Built-In Microwave Oven,” (Part No. 4317283), provides the technician

with information on the installation and service of the KitchenAid Built-In Microwave Oven. It is to

be used as a training Job Aid and Service Manual. For specific information on the model being

serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the microwave oven.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Built-In Microwave Oven.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the microwave oven to proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repair

made on our products by anyone other than Authorized Factory Service

Technicians.

Copyright 2000, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Table of Contents

Page

SPECIFICATIONS .................................................................................................................. 1-1

COMPONENT ACCESS ......................................................................................................... 2-1

Oven Cabinet Component Locations ................................................................................... 2-1

Microwave Oven Component Locations .............................................................................. 2-1

Removing The Microwave Oven Assembly ......................................................................... 2-2

Removing The Oven Control & Display Boards

And The Touch Panel Assembly ....................................................................................... 2-3

Removing The Low Voltage Transformer, The Light Power

Supply, & Suppressor Board ............................................................................................. 2-5

Removing The Blower Motor Assembly ............................................................................... 2-7

Removing The Microwave Oven From The Oven Cabinet .................................................. 2-8

Removing The Primary, Secondary, & Monitor Interlock Switches

And The Air Pressure Relief Valve.................................................................................. 2-10

Removing The Grill Thermal Fuse And The Grill Element Assembly ................................ 2-12

Removing The Convection Temperature Sensor, The Halogen Lamp,

And The Cavity Thermal Fuse ........................................................................................ 2-14

Removing The Convection Thermal Fuse, Convection Element,

And Convection Fan Motor ............................................................................................. 2-16

Removing The Cooling Fan Motor & Air Vent Solenoid ..................................................... 2-18

Removing The Magnetron Thermal Fuse And The Magnetron.......................................... 2-20

Removing The High Voltage Transformer.......................................................................... 2-22

Removing The Line Fuse & Fuseholder, The High Voltage Rectifier,

& High Voltage Capacitor ................................................................................................ 2-24

Removing The Turntable Motor ......................................................................................... 2-26

Removing The Oven Door Handle & Front Door Glass ..................................................... 2-27

Removing The Oven Door & The Inner Glass ................................................................... 2-28

COMPONENT TESTING ........................................................................................................ 3-1

The Turntable & Cooling Fan Motors ................................................................................... 3-1

The Low Voltage Transformer & Light Power Supply .......................................................... 3-2

The Blower & Convection Fan Motors ................................................................................. 3-3

The Convection Temperature Sensor .................................................................................. 3-4

The Cavity, Grill, Convection, & Magnetron Thermal Fuses ................................................ 3-5

The Convection Element & Grill Element Assembly ............................................................ 3-6

The Line Fuse, High Voltage Rectifier, & High Voltage Capacitor ....................................... 3-7

The Air Vent Solenoid & Interlock Switches ......................................................................... 3-8

The High Voltage Transformer & Magnetron ....................................................................... 3-9

Control Panel Resistor ....................................................................................................... 3-10

DIAGNOSIS & TROUBLESHOOTING.................................................................................... 4-1

Failure/Error Display Codes ................................................................................................. 4-1

Components That Can Be Tested At The Control Panel ..................................................... 4-1

Electronic Oven Control Pinouts .......................................................................................... 4-2

Microwave Oven Power Output Test ................................................................................... 4-3

Microwave Oven Relay Logic............................................................................................... 4-3

Troubleshooting Chart.......................................................................................................... 4-4

WIRING DIAGRAMS & STRIP CIRCUITS .............................................................................. 5-1

TECH TIPS ............................................................................................................................. 6-1

- iii -

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K B M C 1 4 7 H WH 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID BRAND

PRODUCT IDENTIFICATION

BH = BUILT-IN HIGH-SPEED OVEN

BM = BUILT-IN MICROWAVE

CM = COUNTERTOP MICROWAVE

HM = MICROWAVE HOOD

MERCHANDISING SCHEME

S = STANDARD

C = MICRO-CONVECTION

CAPACITY / SIZE / SERIES / CONFIGURATION

05 = 0.5 CU FT

08 = 0.8 CU FT

10 = 1.0 CU FT

13 = 1.3 CU FT

14 = 1.4 CU FT

FEATURES

2 = PLUS FEATURES

5 = DELUXE FEATURES

6 = MICRO-CONVECTION

7 = MICRO-CONVECTION WITH SENSOR

S = CARRY-IN WARRANTY (EFFECTIVE 02/96)

X = IN-HOME WARRANTY (EFFECTIVE 02/96)

YEAR OF INTRODUCTION

H = 1999, J = 2000, K = 2001

COLOR CODE

WH = WHITE, BL = BLACK, SS = STAINLESS STEEL

ENGINEERING CHANGE (0, 1, 2, ETC.)

SERIAL NUMBER

SERIAL NUMBER X K 1 6 01004

MANUFACTURING SITE

X = OXFORD

YEAR OF PRODUCTION

K = 2000, L = 2001, M = 2002

WEEK OF PRODUCTION

16TH WEEK

PRODUCT SEQUENCE NUMBER

- iv -

MODEL NUMBER

MODEL NUMBER K BH C 1 7 9 J WH 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID BRAND

PRODUCT IDENTIFICATION

BH = BUILT-IN HIGH-SPEED OVEN

BM = BUILT-IN MICROWAVE

CM = COUNTERTOP MICROWAVE

HM = MICROWAVE HOOD

MERCHANDISING SCHEME

S = STANDARD

C = MICRO-CONVECTION

CAPACITY / SIZE / SERIES / CONFIGURATION

05 = 0.5 CU FT

08 = 0.8 CU FT

10 = 1.0 CU FT

13 = 1.3 CU FT

17 = 1.4 CU FT

FEATURES

2 = PLUS FEATURES

5 = DELUXE FEATURES

6 = MICRO-CONVECTION

7 = MICRO-CONVECTION WITH SENSOR

9 = MULTIMODE-HI SPEED-CONVECTION

S = CARRY-IN WARRANTY (EFFECTIVE 02/96)

X = IN-HOME WARRANTY (EFFECTIVE 02/96)

YEAR OF INTRODUCTION

H = 1999, J = 2000, K = 2001

COLOR CODE

WH = WHITE, BL = BLACK, SS = STAINLESS STEEL

ENGINEERING CHANGE (0, 1, 2, ETC.)

SERIAL NUMBER

SERIAL NUMBER X K 1 6 01004

MANUFACTURING SITE

X = OXFORD

YEAR OF PRODUCTION

K = 2000, L = 2001, M = 2002

WEEK OF PRODUCTION

16TH WEEK

PRODUCT SEQUENCE NUMBER

- v -

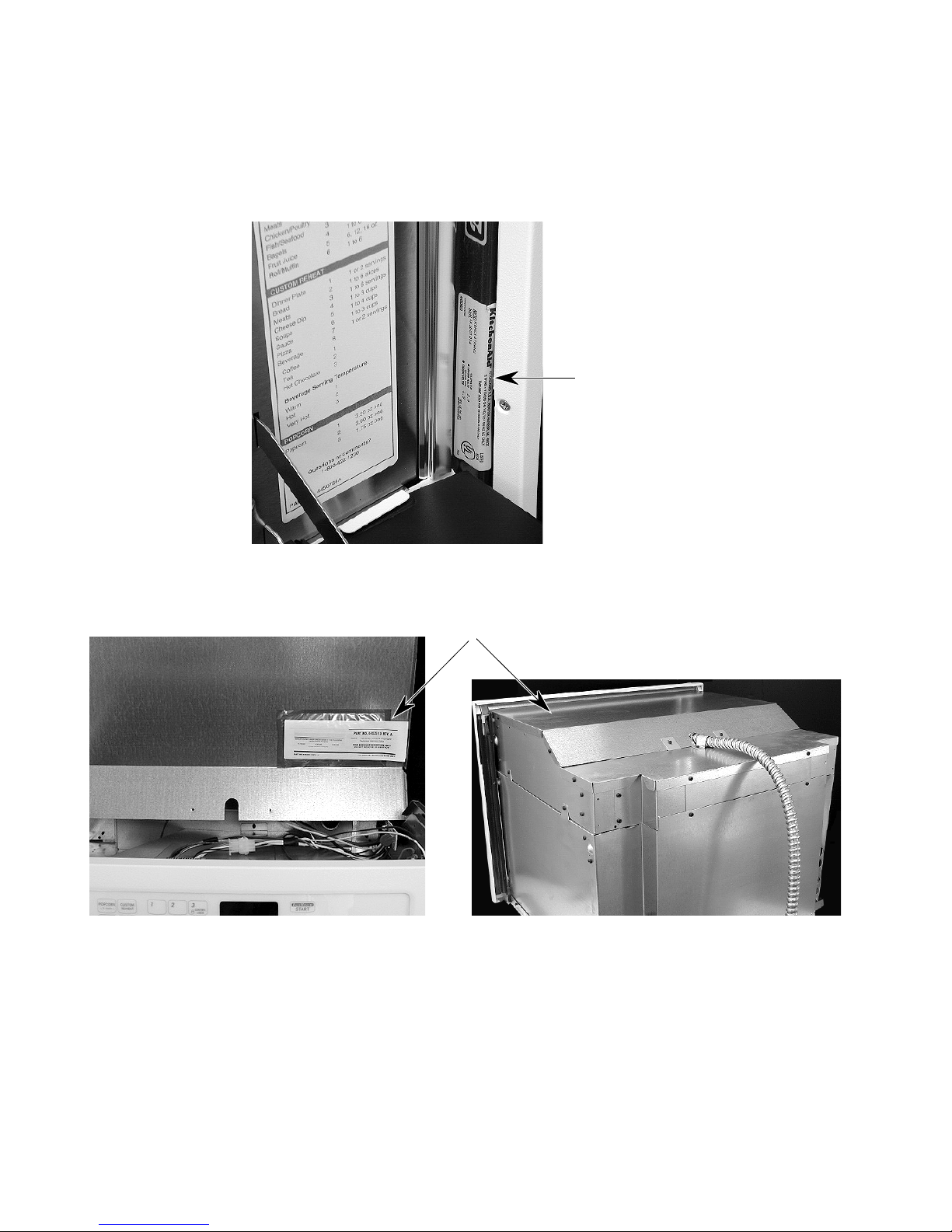

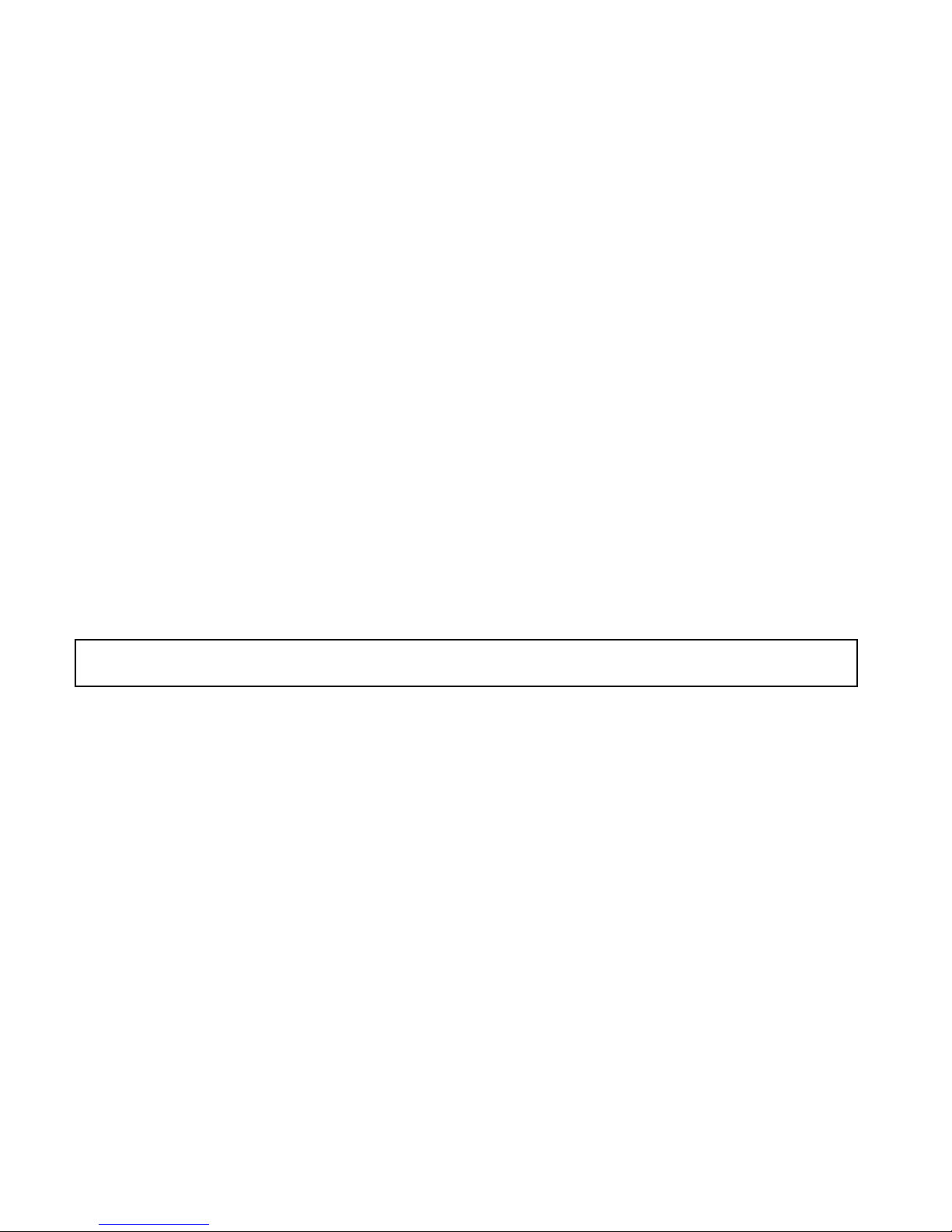

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model & Serial

Number Location

Tech Sheet Location

(Below Top Front Cover)

- vi -

IMPORTANT SAFETY INFORMATION

Your safety and the safety of others is very important.

Important safety messages have been provided in this Job Aid. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will be preceded by the safety alert symbol and the word

“WARNING.”

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

Grounding Instructions

CORD CONNECTED

The microwave oven must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electric shock by providing an escape wire for the electrical current. The

microwave oven is equipped with a cord having a grounding wire with a grounding plug. The plug

must be plugged into an outlet that is properly installed and grounded.

Improper use of the grounding plug can result in a risk of

WARNING

Consult a qualified electrician or serviceman if the grounding instructions are not completely

understood, or if doubt exists as to whether the microwave oven is properly grounded. Do not use

an extension cord. If the power supply cord is too short, have a qualified electrician or serviceman

install an outlet near the microwave oven.

electric shock.

PERMANENTLY CONNECTED

The microwave oven must be connected to a grounded, metallic, permanent wiring system, or an

equipment grounding conductor should be run with the circuit conductors and connected to the

equipment grounding terminal, or lead, on the microwave oven.

- vii -

Warning To Service Technicians

To avoid possible exposure to microwave radiation or energy, visually check the oven for damage

to the door and door seal before operating any oven. Use a microwave survey meter to check the

amount of leakage before servicing. In the event the R.F. Ieakage exceeds 4 mw/cm

appropriate repair must be made before continuing to service the unit. Check interlock function by

operating the door latch. The oven cook cycle should cut off before the door can be opened.

The door and latching assembly contains the radio frequency energy within the oven. The door is

protected by three safety interlock switches. Do not attempt to defeat them.

UNDER NO CIRCUMSTANCES SHOULD YOU TRY TO OPERATE THE OVEN WITH THE

DOOR OPEN.

• Proper operation of microwave ovens requires that the magnetron be properly assembled to

the waveguide and cavity. Never operate the magnetron unless it is properly installed.

• Be sure the “RF” seal is not damaged and is assembled around the magnetron dome properly

when installing the magnetron.

• Routine service safety procedures should be exercised at all times.

• Untrained personnel should not attempt service without a thorough review of test procedures

and safety information contained in this Job Aid.

KitchenAid microwave ovens have a monitoring system designed to assure proper operation of the

safety interlock systems.

2

at 5 cm,

The interlock monitor switch will immediately cause the oven fuse to blow if the door is opened and

the primary door interlock switch and/or the secondary interlock switch contacts fail in a closed

position.

CAUTION: REPLACE BLOWN FUSE WITH 20 AMPERE CLASS H FUSE ONLY

Test the upper and lower door interlock switches, cook relay and interlock monitor switch (middle

switch) for proper operation as described in the component test procedures, before replacing the

blown oven fuse.

DO NOT ATTEMPT TO REPAIR STICKING CONTACTS OF ANY INTERLOCK SWITCH,

SAFETY SWITCH OR COOK (LATCH) RELAY. THE COMPONENTS MUST BE REPLACED.

Any indication of sticking contacts during component tests requires replacement of that component

to assure reliability of the safety interlock system.

IF THE FUSE IS BLOWN, THE MONITOR, PRIMARY, AND SECONDARY INTERLOCK

SWITCHES MUST BE REPLACED. BE SURE THEY ARE PROPERLY CONNECTED.

- viii -

Precautions To Be Observed Before And During

Servicing To Avoid Possible Exposure

To Excessive Microwave Energy

1. Do not operate or allow the oven to be operated with the door open.

2. Make the following safety checks on all ovens to be serviced before activating the magnetron

or other microwave source and make repairs as necessary.

a) Interlock Operation

b) Proper Door Closing

c) Seal and Sealing Surfaces (Arcing, Wear and Other Damage)

d) Damage to or Loosening of Hinges and Latches

e) Evidence of Dropping or Abuse

3. Before turning on the microwave power for any service test or inspection within the microwave

generating components, check the magnetron, wave guide or transmission line and cavity for

proper alignment.

4. Any defective or misadjusted components in the interlock, monitor, door seal and microwave

generation and transmission system shall be repaired by procedures described in the Job Aid

for the specific microwave oven being serviced before the oven is released to the owner.

5. A microwave leakage check to verify compliance with Federal Performance Standards should

be performed on each oven prior to release to the owner.

6. Do not attempt to operate the oven if the door glass is broken.

- ix -

CAUTION

• High voltages are present during the cook

cycle. Extreme caution should be observed at all times.

• Abrasive cleansers, steel-wool pads, gritty

wash cloths, etc. can damage the control

panel and the interior and exterior oven

surfaces. Use a sponge with mild detergent or paper towels with spray glass

cleaner. Apply spray glass cleaner to paper towel. Do not spray directly on oven.

• Before touching any oven component or

wiring, always unplug the oven from its

power source and discharge the capacitor by using a 20,000 ohm discharge

resistor or use an insulated plastic handle

screwdriver to short across the capacitor

terminals.

• Check that the unit is grounded before

troubleshooting. Be careful of the high

voltage circuits. Discharge any static

charge from your body by touching ground

before handling any part of the circuitry on

the control board. Electrostatic discharge

may damage the control circuit.

• Do not touch oven components or wiring

during operation. Attach meter leads with

alligator clips when making operational

tests.

• For continued protection against radiation emission, replace only with these

types of switches: Primary (Interlock)

Switch: SZM-V16-FA-63 or VP-533A-OF;

Secondary (Interlock) Switch: SZM-V01FA-32; Interlock (Monitor) Switch: SZMVI6-FA-62 or VP-532A-OF; Oven Lamp

Switch: SZM-V6-FA-31 or VP-331 A-OD.

• It is neither necessary nor advisable to

attempt measurement of high voltage.

• Attaching the adaptor ground terminal to

the wall receptacle cover screw does not

ground the appliance unless the cover

screw is metal and not insulated and the

wall receptacle is grounded through the

house wiring.

WARNING

• Disconnect the oven from electrical supply before servicing. Failure to do so could

result in electrical shock or death.

• Improper use of the grounding plug can

result in a risk of electrical shock. Do not,

under any circumstance, cut or remove

the third ground prong from the power

cord plug.

Fire, Electrical Shock, Excessive

Exposure to Microwave Energy,

Personal Injury & Product

Damage Hazard

• Do not block the rear air intake openings

or exhaust vents. Allow a few inches of

space at the back of the oven where

intake openings and exhaust vents are

located. Blocking the air intake openings

and exhaust vents can cause damage to

the oven and poor cooking results.

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD

may damage or weaken the electronic control assembly. The new control assembly

may appear to work well after repair is finished, but failure may occur at a later date

due to ESD stress.

• Use an antistatic wrist strap. Connect

wrist strap to green ground connection

point or unpainted metal in the appliance, or touch your finger repeatedly to

a green ground connection point or unpainted metal in the appliance.

• Before removing the part from its package, touch the antistatic bag to a green

ground connection point or unpainted

metal in the appliance.

• Avoid touching electronic parts or terminal contacts; handle electronic control assembly by the edges only.

• When repackaging failed electronic control assembly in antistatic bag, observe

above instructions.

- x -

R.F. LEAKAGE TEST

EQUIPMENT

• Electromagnetic energy leakage monitor

(NARDA 81 00B, HOLADAY H 1 501 ).

• 250 ml glass beaker.

TEST

On every service call, checks for microwave

energy emission must be made according to

the following manner.

1. Remove the cooking rack from the oven

cavity, if the microwave oven is so

equipped.

2. Place a 250 ML (8.0 oz.) glass of water in

the center of the oven bottom.

3. Select "HIGH" cook power, turn the micro-

wave oven on, and test for R.F. Ieakage at

the following locations using the pattern

shown below:

a) Around the cabinet at the front.

b) Around the door.

c) Across the console panel.

d) Horizontally across the door.

e) Vertically across the door.

f) Diagonally across the door.

g) Across the air vents.

h) Across the rear air vent.

i) All lockseams.

j) Weld at bottom.

k) Bottom plate.

I) Oven feet.

NOTE: Enter leakage readings in space BEFORE and AFTER on the service document.

All microwave ovens exceeding the emission

2

level of 4 mw/cm

must be reported to Dept. of

Service for microwave ovens immediately and

the owner should be told not to use the microwave oven until it has been repaired completely.

If a microwave oven is found to operate with the

door open, report to Dept. of Service, the

manufacturer and CDRH* immediately. Also

tell the owner not to use the oven.

The interlock monitor switch acts as the final

safety switch protecting the customer from

microwave radiation. If the interlock monitor

switch operated to blow the fuse when the

interlocks failed, you must replace all interlock

switches with new ones, because the contacts

of those interlock switches may be melted and

welded together.

All repairs must be performed in such a manner

that microwave energy emissions are minimal.

Address for CDRH is:

Office of Compliance (HFZ-312) Center

for Devices and Radiological Health

1390 Piccard Drive

Rockville, Maryland 20850

* CDRH: Center for Device and Radiological Health,

Food and Drug Administration.

4. The scan speed is one inch per second.

When checking for R.F. Ieakage, use an approved R.F. measuring device to assure less

than 4 mw/cm2 emission at 5 cm distance with

a maximum scan rate of 2.5 cm/second, in

compliance with U.S. Government Department

of Health, Education and Welfare 21 CFR1030,

performance Standard for Microwave Ovens.

A properly operating door and seal assembly

will normally register small emissions, but they

must be no greater than 4 mw/cm2 to allow for

measurement uncertainty.

- xi -

— NOTES —

- xii -

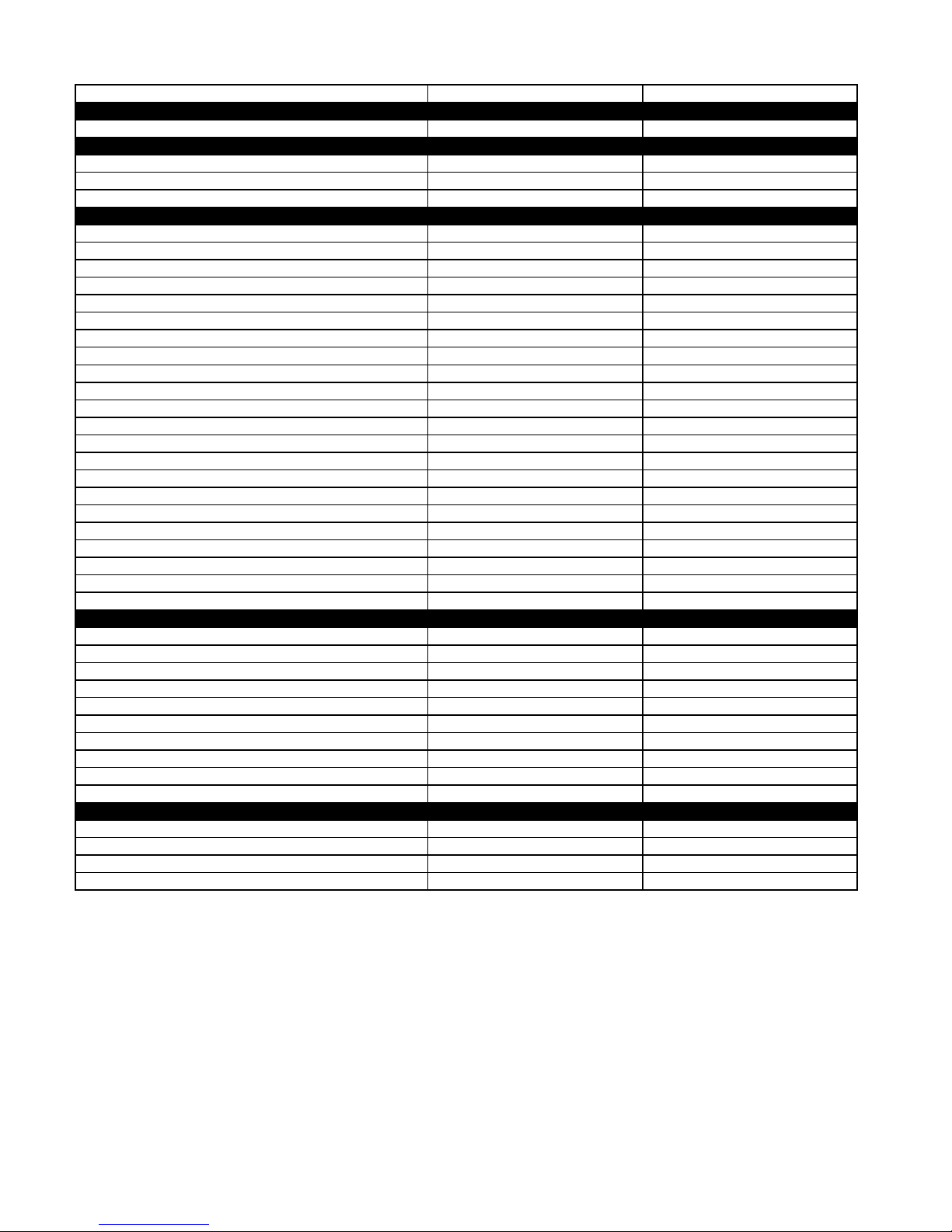

SPECIFICATIONS

Model Number

Release Info

Model Description

Size-Configuration

Feature Level/Series

Dimensions/Specifications

Exterior Dimensions

Overall Height (in)

Overall Width (in)

Cutout Height (in) (Measure Or Min/Max)

Cutout Width (in) (Measure Or Min/Max)

Cutout Depth (in) (Measure Or Min/Max)

Other Dimensions

Conduit Size (in) (Length/Diameter)

Total Connected Load in kW

240 Volts

208 Volts

Circuit Amps

Exterior

Oven Control Type

Microwave Controls

Membrane Touch

Probe

Microwave Timer

Diagnostics

Error Indication

MW Power (Watts)

Off/Cancel

Programming Tone

Staged Cooking # Levels/Type

Start/Enter

Stoppable Turntable

Broil Element Output (Watts)

Broil Heat-Up Time

Crisp Turntable Performance # IEC Pts/Min for Release

Crisp Pan Size/Type

MW Cavity Volume (cu ft)

MW Cavity Material

Miscellaneous

Product Literature

Installation Instructions Part/Comment

Tech Sheet Part/Comment

Use & Care Guide Microwave Part/Comment

Other

Agency Approvals

Installation Hardware

Residential Use Only

Warranty

Full (Months)

Extended

Electronic Controls (Months)

Electrical Elements (Months)

Magnetron (Months)

KBMC140H KBMC147H

Built In Microwave Built In Microwave

30" 27"

Crisp Convection Crisp Convection

20 1/2" 20 1/2"

29 3/4" 26 3/4"

19 7/16" 19 7/16"

28 1/2" 25 1/2"

23 1/4" 23 1/4"

57"; 1/2" 57"; 1/2"

3 kw 3 kw

3 kw 3 kw

20 AMP 20 AMP

Electronic Electronic

VFD (Blue,Green,Red) VFD (Blue,Green,Red)

Yes Yes

No No

Yes Yes

Yes Yes

Yes Yes

900 Watts 900 Watts

Yes Yes

Yes Yes

3 Level 3 Level

Yes Yes

No No

1200 Watts 1200 Watts

<1 minute <1 minute

3.5 3.5

322 mm OD 322 mm OD

1.4 1.4

Stainless Stainless

4452615 4452615

4452613 4452613

4452614 4452614

Cooking Tips - 3191638 Cooking Tips - 3191638

UL & CSA UL & CSA

Yes Yes

Yes Yes

12 12

60 60

60 60

60 60

1-1

Model Number KBHC179J KBHC109J

Release Info

Colors Black, White, Stainless, Biscuit Black, White, Stainless, Biscuit

Model

Model Description Built-In High Speed Built-In High Speed

Size-Configuration 27" 30"

Feature Level/Series Crisp Convection Crisp Convection

Dimensions/Specifications

Exterior Dimensions

Overall Height (in) 20 1/2" 20 1/2"

Overall Width (in) 26 3/4" 29 3/4"

Overall Depth Inc Hrdwr/Hndl (in) 25 1/8" 25 1/8"

Depth W/O Handle (in) 23 7/8" 23 7/8"

Other Dimensions

Conduit Size (in) (Length/Diameter) 57"; 1/2" 57"; 1/2"

Weight

Net Weight (lbs) 110 117

Total Connected Load in kW

240 Volts 4.4 kw 4.4 kw

208 Volts 3.8 kw 3.8 kw

Circuit Amps 30 Amp 30 Amp

Probe No No

Microwave Timer Yes Yes

Diagnostics Yes Yes

Error Indication Yes Yes

MW Power (Watts) 900 Watts 900 Watts

Stoppable Turntable No No

Broil Element Type Quartz Quartz

Broil Element Output (Watts) 1200 Watts 1200 Watts

Broil Heat-Up Time <1 minute <1 minute

Interior

MW Cavity Volume (cu ft) 1.4 1.4

MW Cavity Material Porcelain Enamel Steel Porcelain Enamel Steel

Other

Agency Approvals UL UL

Residential Use Only Yes Yes

Warranty

Full (Months) 12 12

Electronic Controls (Months) 60 60

Electrical Elements (Months) 60 60

Magnetron (Months) 60 60

Miscellaneous

Installation Instructions Yes Yes

Installation Instructions Part 4452615 4452615

Tech Sheet Part 4452613 4452613

Use & Care Guide Microwave Part 4452614 4452614

1-2

COMPONENT ACCESS

This section instructs you on how to service each component inside the Model KBMC147H BuiltIn Microwave Oven. The components and their locations are shown below.

OVEN CABINET COMPONENT LOCATIONS

Blower Motor

Suppressor Board

Light Power Supply

Oven Control &

Display Boards

MICROWAVE OVEN COMPONENT LOCATIONS

Convection

Temperature

Sensor

Air Pressure

Relief Valve &

Secondary

Interlock Switch

Convection Fan Motor

Convection Element

Halogen Lamp

Convection

Thermal Fuse

Thermal Fuse

Low Voltage

Transformer

High Voltage Rectifier

Line Fuse

Cavity

High Voltage

Capacitor

High Voltage

Transformer

Magnetron

Mag. Thermal Fuse

Air Vent

Solenoid

Primary

Interlock Switch

Monitor

Interlock Switch

Cooling Fan

Motor

Grill Element

Assembly

Turntable

Motor

2-1

Grill

Thermal Fuse

REMOVING THE MICROWAVE OVEN ASSEMBLY

WARNING

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so could result in death or

electrical shock.

CAUTION: When you work on the microwave

oven, be careful when handling the sheet metal

parts. Sharp edges may be present, and you

can cut yourself if you are not careful.

5. To remove the side trim, pull the bottom

out approximately 2˝ and slide the top

down to disengage it from the front panel.

Slide Down

Side Trim

1. Disconnect the electrical power to the

microwave oven.

2. Remove the glass turntable and roller

assembly from inside the oven cavity.

Turntable &

Roller Assembly

3. Completely open the microwave oven door.

4. Remove the screws from the side trim.

Pull Out

6. Remove the two cabinet mounting screws.

Cabinet Mounting

Screw (1 On Each

Side)

Side Trim Screw

(1 On Each Side)

Excessive Weight Hazard

Use two or more people to remove and

reinstall the microwave oven.

Failure to follow this instruction can result in

back, or other injury.

7. Slide the microwave oven out of its mounting location.

2-2

REMOVING THE OVEN CONTROL & DISPLAY BOARDS

AND THE TOUCH PANEL ASSEMBLY

4. To remove the oven control panel, pull it

WARNING

Electrical Shock Hazard

out at the bottom, and lift and unhook it

from the oven cabinet support at the top.

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so could result in death or

electrical shock.

CAUTION: When you work on the microwave

oven, be careful when handling the sheet metal

parts. Sharp edges may be present, and you

can cut yourself if you are not careful.

1. Disconnect the electrical power to the

microwave oven.

2. Pull the microwave oven assembly forward several inches so that you can access the sides of the front panel (see page

2-2 for the side trim and mounting screw

removal procedure).

3. Remove the screws from the oven control

panel.

Oven

Control

Panel

Lift Off

Top

Support

Pull Out

5. Pull the ground clip on the end of the green

wire from the edge of the metal panel, and

disconnect the wire connectors from the

board. Set the panel face down on a

padded surface to protect the finish.

Ground Clip

Oven Control Panel Screw

(1 On Each Side)

Wire Connectors

Continued on the next page.

2-3

6. To remove the oven control & display

boards:

a) Remove the seven mounting screws.

b) Lift the ends of the locking arm and

disconnect the ribbon cable from its

connector.

NOTE: The control and display boards are

designed to be replaced as an assembly.

Lift Ends Of

Locking Arm

Screws

7. To remove the touch panel assembly:

a) Remove the standoffs and spacers from

over the mounting studs.

Touch Panel

Assembly

Standoffs & Spacers

Mounting Screws

b) Remove the six mounting screws.

c) Lift the touch panel assembly off the

front of the oven cabinet.

REASSEMBLY NOTE: When you reinstall the

oven control panel, use the following procedure (refer to the photos on the previous page,

as necessary):

Screws

1. Reconnect the wiring to the control board

terminals.

2. Clip the ground wire to the metal edge of

the control panel.

3. Hook the ends of the control panel over

the rubber tips of the brackets.

4. Push the bottom of the control panel in and

position the plastic air duct

under the lip of

the panel.

Air Duct

Bottom Lip Of Control Panel

5. Align the mounting holes and install the

two side screws in the control panel.

2-4

REMOVING THE LOW VOLTAGE TRANSFORMER,

THE LIGHT POWER SUPPLY, & SUPPRESSOR BOARD

5. To remove the low voltage transformer:

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so could result in death or

electrical shock.

CAUTION: When you work on the microwave

oven, be careful when handling the sheet metal

parts. Sharp edges may be present, and you

can cut yourself if you are not careful.

1. Disconnect the electrical power to the

microwave oven.

2. Remove the microwave oven assembly

from its mounting location (see page 2-2

for the procedure).

3. Remove the screw from the power conduit

clamp and remove the clamp.

4. Remove the 10 screws from the top front

and top rear oven cabinet covers.

a) Disconnect the 10-hole connector from

the control board at P17.

b) Remove the mounting screw at the top

and unhook the bottom transformer tab

from the oven cabinet slot.

Screw LV Transformer Connector P17

6. To remove the light power supply:

a) Disconnect the four wires from the LINE

and LOAD terminals. Note that the LINE

terminals are smaller than the LOAD

terminals to prevent miswiring.

b) Remove the mounting screw and un-

hook the tab from the oven cabinet slot.

Conduit

Clamp

Top Front Cover

(4 Screws)

Line & Load

Wires

Top Rear Cover

(6 Screws)

Screw

Light Power

Supply

Continued on the next page.

2-5

7. To remove the suppressor board:

a) Remove the hex nuts from the black

and white wires and remove the wires

from the screw terminals.

b) Remove the mounting screw holding

the suppressor board to the terminal

strip.

Suppressor Board

White Wires Black Wires

Screw

2-6

Loading...

Loading...