KitchenAid GAS RANGE Installation Instructions Manual

A WARNING

l

ALL RANGES CAN

TIP

l

INJURY TO PERSONS

COULD RESULT

l

INSTALL ANTI-TIP

DEVICE PACKED

WITH RANGE

l

SEE INSTALLATION

INSTRUCTIONS

Reference

Contents:

m Before you start

q

1 Product dimensions

m Cabinet dimensions/requirements

z Gas supply requrrements

a -(61 Installation steps

m-j Gas conversions

‘Back1 If range does not operate

;v If you need assistance,‘service

Back Moving the range

If you need assistance:

Check your Use and Care Guide for a toil-free number to call or call the

dealer from whom you purchased this range. The dealer is listed in

the Yellow Pages of your phone directory under “Appliances Household - Major - ‘Service and Repair.”

Call when you:

:I Have questions about range installation or operation

2 Need to obtain the name and number of an authorized

service company.

When you call, you will need:

;,-. The range model number.

z The range serial number.

Both numbers are listed on the model/serial rating plate located on the

frame behind the broiler door.

Important: Observe all governing codes

and ordinances.

This installation must conform with

all local

codes and ordinances. In the absence of local

codes, installation must conform with American

National Standard, National Fuel Gas Code ANSI

2223.1 - latest edition**.

Proper installation is your responsibility. A

qualified technician must install this range. Make

sure you have everything necessary for correct

installation. It is the installer’s responsibility to

comply with installation clearances specified on

the gas information label. The gas information

label and model/serial rating plate are located on

the frame behind the broiler door.

Check location where range will be installed. The

range should be located away from strong draft

areas, such as windows, doors and strong

heating vents or fans. The range should be

located for convenient use in kitchen.

ALL OPENINGS IN THE WALL OR FLOOR WHERE

RANGE IS TO BE INSTALLED MUST BE SEALED.

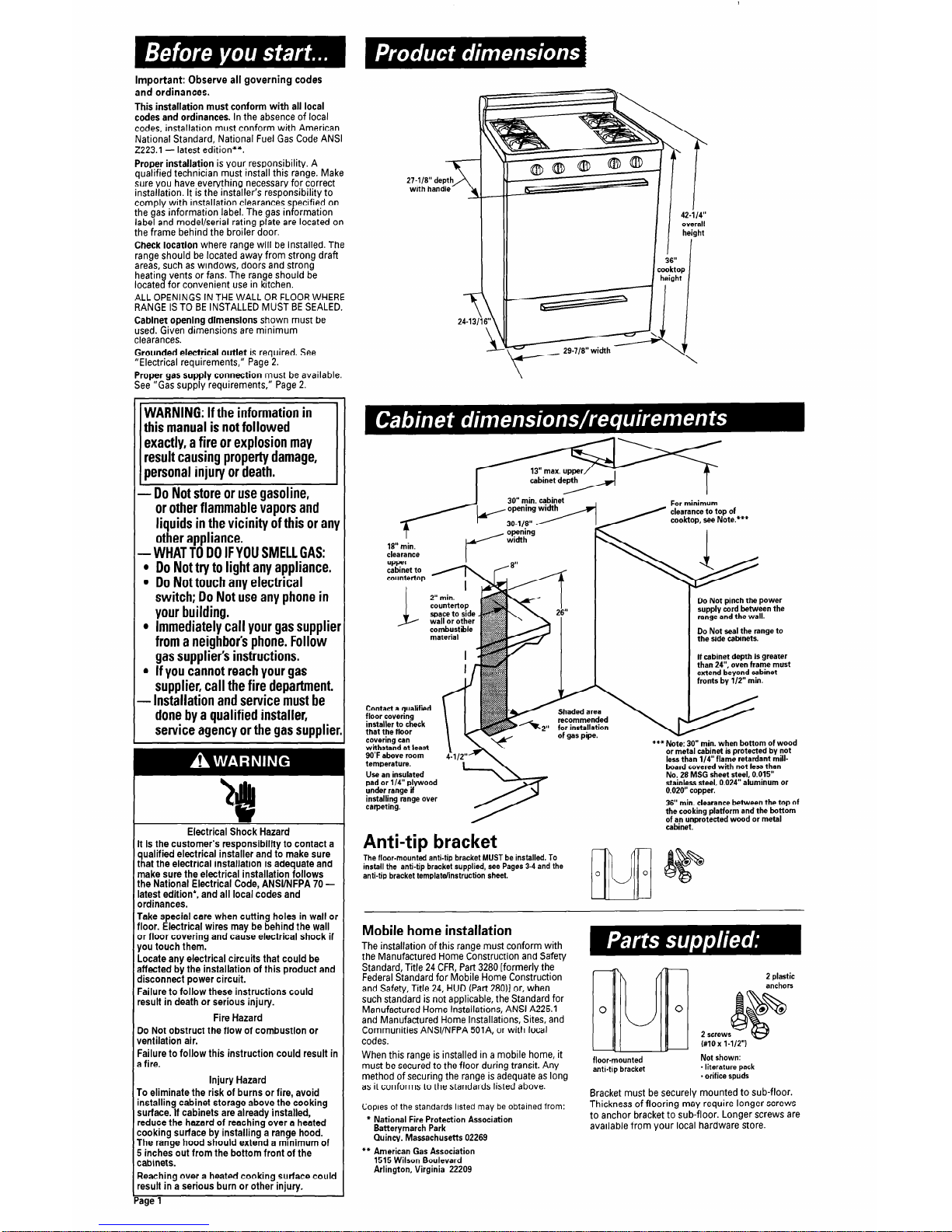

Cabinet opening dimensions shown must be

used. Given dimensions are minimum

clearances.

Grounded electrical outlet is required. See

“Electrical requirements,” Page 2.

Proper gas supply connection must be available.

See “Gas supply requirements,” Page 2.

24-13116”

3

i

42-i14"

overall

height

36”

cooktop

height

I

WARNING: If the information in

this manual is not followed

exactly, a fire or explosion may

result causing property damage,

personal injury or death.

- Do Not store or use gasoline,

or other flammable vapors and

liquids in the vicinity of this or any

other aooliance.

ia”

min.

-WHAT id DO IFYOU SMELL GAS:

l

Do Not try to light any appliance.

l

Do Not touch any electrical

switch; Do Not use any phone in

your building.

l

Immediately call your gas supplier

from a neighbor’s phone. Follow

gas supplier’s instructions.

l

If you cannot reach your gas

supplier, call the fire department.

- Installation and service must be

done by a qualified installer,

service agency or the gas supplier.

Do Not pinch the power

supply cord between the

range and the wall.

Do Not seal the range to

the side cabinets.

If cabinet depth is greater

than 24”, oven frame must

extend beyond cabinet

fronts by l/2” min.

Contact a qualified

floor covering

installer to check

that the floor

covering can

withstand at least

9O’F above room

temperature.

Use an insulated

pad or l/4” plywood

under range if

installing range over

carpeting.

Shaded area

recommended

for installation

-1 --- -I--

1

***Note: 30” min. when bottom of wood

or metal cabinet is protected by not

less than l/4” flame retardant mill-

board covered with not less than

No 28 MSG sheet steel, 0.015”

stainless steel, 0.024” aluminum or

0.020” copper.

36” min. clearance between the top of

the cooking platform and the bottom

of an unprotected wood or metal

Electrical Shock Hazard

It is the customer’s responsibility to contact a

qualified electrical installer and to make sure

that the electrical installation is adequate and

make sure the electrical installation follows

the National Electrical Code, ANSUNFPA 70 latest edition*, and all local codes and

ordinances.

Take special care when cutting holes in wall or

floor. Electrical wires may be behind the wall

or floor covering and cause electrical shock if

you touch them.

Locate any electrical circuits that could be

affected by the installation of this product and

disconnect power circuit.

Failure to follow these instructions could

result in death or serious injury.

Fire Hazard

Do Not obstruct the flow of combustion or

ventilation air.

Failure to follow this instruction could result in

a fire.

Injury Hazard

To eliminate the risk of burns or fire, avoid

installing cabinet storage above the cooking

surface. If cabinets are already installed,

reduce the hazard of reaching over a heated

cooking surface by installing a range hood.

The range hood should extend a minimum of

5 inches out from the bottom front of the

cabinets.

Reaching over a heated cooking surface could

result in a serious burn or other injury.

Anti-tip bracket

-

The floor-mou& anti-tip bracket MUST be installed. To

install the anti-tip bracket supplied, see Pages 3-4 and the

anti-tip bracket templatelinstruction sheet.

Mobile home installation

The installation of this range must conform with

the Manufactured Home Construction and Safety

2 plastic

anchors

Standard, Title 24 CFR, Part 3280 [formerly the

Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD (Part 28011 or, when

such standard is not applicable, the Standard for

Manufactured Home Installations, ANSI A225.1

and Manufactured Home Installations, Sites, and

Communities ANSI/NFPA 501A, or with local

codes.

When this range is installed in a mobile home, it

i

must be secured to the floor during transit. Any

floor-m01

unted

method of securing the range is adequate as long

anti-tip bracket

0

L

2 screws

(#10x l-1/2")

Not shown:

- literature pack

* orifice spuds

as it conforms to the standards listed above.

Bracket must be securely mounted to sub-floor.

Copies of the standards listed may be obtained from:

* National Fire Protection Association

Batterymarch Park

Thickness of flooring may require longer screws

to anchor bracket to sub-floor. Longer screws are

available from your local hardware store.

Quincj, Massachusetts 02269

** American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

‘age

1

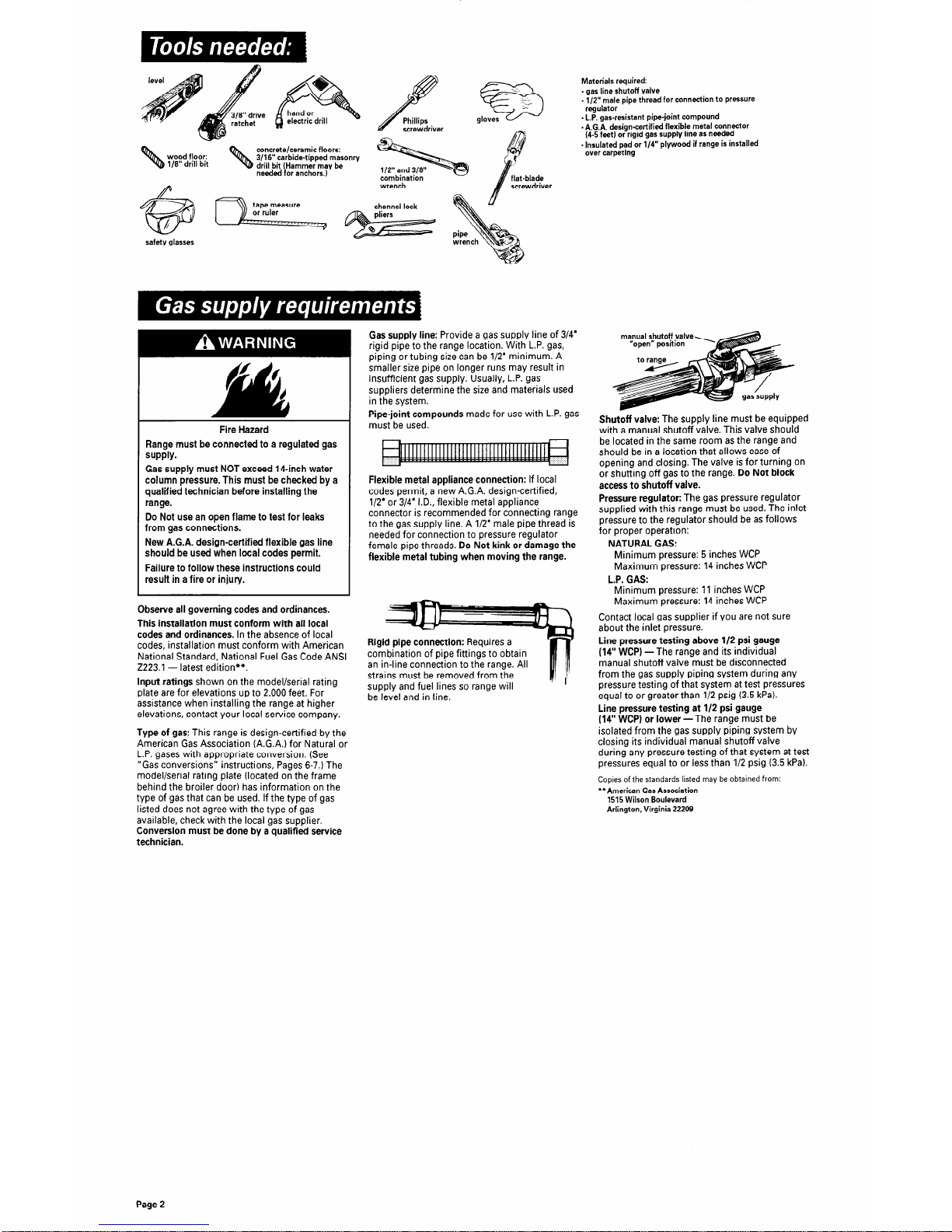

- A.G.A. design-certified flexible metal

connector

(4-5 feet) or rigid gas supply line as needed

- Insulated pad or l/4” plywood if range is installed

over carpeting

combination

wrench

wood floor:

l/8” drill bit

concrete/ceramic floors:

3/16” carbide-tipped masonry

drill bit (Hammer may be

needed for anchors.)

tape measure

or ruler

d

Fire Hazard

Range must be connected to a regulated gas

supply.

Gas supply must NOT exceed 1 Cinch water

column pressure. This must be checked by a

qualified technician before installing the

range.

Do Not use an open flame to test for leaks

from gas connections.

New A.G.A. design-certified flexible gas line

should be used when local codes permit.

Failure to follow these instructions could

result in a fire or injury.

Observe all governing codes and ordinances.

This installation must conform with all local

codes and ordinances. In the absence of local

codes, installation must conform with American

National Standard, National Fuel Gas Code ANSI

2223.1 - latest edition**.

Input ratings shown on the model/serial rating

plate are for elevations up to 2,000 feet. For

assistance when installing the range at higher

elevations, contact your local service company.

Type of gas: This range is design-certified by the

American Gas Association (A.G.A.) for Natural or

L.P. gases with appropriate conversion. (See

“Gas conversions” instructions, Pages 6-7.) The

model/serial rating plate (located on the frame

behind the broiler door) has information on the

type of gas that can be used. If the type of gas

listed does not agree with the type of gas

available, check with the local gas supplier.

Conversion must be done by a qualified service

technician.

Gas supply line: Provide a gas supply line of 3/4’

rigid pipe to the range location. With L.P. gas,

piping or tubing size can be l/2’ minimum. A

smaller size pipe on longer runs may result in

insufficient gas supply. Usually, L.P. gas

suppliers determine the size and materials used

in the system.

Pipe-joint compounds made for use with L.P. gas

must be used.

Flexible metal appliance connection: If local

codes permit, a new A.G.A. design-certified,

l/2’ or 3/4’ I.D., flexible metal appliance

connector is recommended for connecting range

to the gas supply line. A l/2’ male pipe thread is

needed for connection to pressure regulator

female pipe threads. Do Not kink or damage the

flexible metal tubing when moving the range.

rpe fittings to obtain

strains must be removed from the

supply and fuel lines so range will

be level and in line.

manual shutoff valve

Shutoff valve: The supply line must be equipped

with a manual shutoff valve. This valve should

be located in the same room as the range and

should be in a location that allows ease of

opening and closing. The valve is for turning on

or shutting off gas to the range. Do Not block

access to shutoff valve.

Pressure regulator: The gas pressure regulator

supplied with this range must be used. The inlet

pressure to the regulator should be as follows

for proper operation:

NATURAL GAS:

Minimum pressure: 5 inches WCP

Maximum pressure: 14 inches WCP

L.P. GAS:

Minimum pressure: 11 inches WCP

Maximum pressure: 14 inches WCP

Contact local gas supplier if you are not sure

about the inlet pressure.

Line pressure testing above l/2 psi gauge

(14” WCP) -The range and its individual

manual shutoff valve must be disconnected

from the gas supply piping system during any

pressure testing of that system at test pressures

equal to or greater than l/2 psig (3.5 kPa).

Line pressure testing at l/2 psi gauge

(14” WCPI or lower -The range must be

isolated from the gas supply piping system by

closing its individual manual shutoff valve

during any pressure testing of that system at test

pressures equal to or less than l/2 psig (3.5 kPa).

Copies of the standards listed may be obtained from:

**American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

Page 2

Loading...

Loading...