KitchenAid Job Aid 4322312, G 4322312 Technical Education

TECHNICAL EDUCATION

KAR-8

25 cu. ft. TOP-MOUNT

REFRIGERATOR/FREEZER

G-MODEL

JOB AID 4322312

I

INTRODUCTION

This Job Aid, 1998 "G" Model, 25 cu. ft. TOP-MOUNT REFRIGERATOR/FREEZERS, (Part No.

4322312) provides specific information for the installation, service and repair of 1998 "G" Model 25 cu.

ft. Top Mount Refrigerator/Freezers.

1998 "G" Model, 25 cu. ft. T0P-MOUNT REFRIGERATOR/FREEZERS has been compiled to provide

the most recent information on design, features, troubleshooting, service and repair procedures.

Whirlpool-required sweep charge procedures are to be strictly adhered to when repairing the sealed

system. For a complete explanation of those procedures, refer to the Job Aid, SWEEP CHARGE

PROCEDURES FOR THE 90's, (Part No. 4321717) and its companion video (Part No. 4321718.)

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair 1998 "G" Model 25 cu. ft. Top-Mount Refrigerator/Freezers.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Follow proper refrigerant recovery procedures.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the refrigerator/freezer to proper operational status.

TO THE INSTRUCTOR/INDEPENDENT STUDENT

At the end of certain sections of this Job Aid you will find a "Confirmation of Learning Exercise." A

pencil will be necessary to complete these exercises. Certain exercises may require that service

procedures be performed if an appropriate appliance is available.

Inc.Inc.

Inc.

Inc.Inc.

For the way it's made.™

II

TABLE OF CONTENTS

INTRODUCTION ..................................................................................... II

TABLE OF CONTENTS ......................................................................... III

SAFETY ......................................................................................................... IV

R134a REFRIGERANT SERVICE INFORMATION ......................................... V

SECTION ONE

INSTALLATION CONSIDERATIONSINSTALLATION CONSIDERATIONS

INSTALLATION CONSIDERATIONS

INSTALLATION CONSIDERATIONSINSTALLATION CONSIDERATIONS

SECTION TWO

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

Temperature Control....................................................................................3

Refrigerant Flow ..........................................................................................3

Air Flow ......................................................................................................... 4

Defrost System .............................................................................................5

SECTION THREE

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

..............................................

....................... 1

..............................................

Accessing the Component Compartment .................................................7

Accessing the Heat Exchanger and Wiring Harness ................................8

Accessing Components in the Freezer Compartment .............................8

Accessing Component in the Refrigerator Compartment .....................12

SECTION FOUR

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

Troubleshooting Guide..............................................................................15

Diagnostic Information ..............................................................................17

SECTION FIVE

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

Typical External Sweat Patterns ...............................................................19

Wiring Harness Schematic ........................................................................20

Wiring Diagram .......................................................................................... 21

Strip Circuits ..............................................................................................22

Serial and Model Number Designators ....................................................24

KitchenAid Warranty .................................................................................. 25

III

SAFETY

! WARNING

To avoid the risk of electrical shock,

property damage, personal injury or death:

• The power cord must be plugged into a 3-prong, grounding-type

wall receptacle, grounded in accordance with the National Electrical

Code, ANSI/NFPA 70 - latest edition and local codes and

ordinances.

• It is the personal responsibility of the consumer to have a proper

3-prong wall receptacle installed by a qualified electrician.

• DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE THE

POWER CORD GROUNDING PRONG.

• A separate adequately fused and grounded circuit should be

available for this appliance.

• Do not remove any grounding wires

from individual components while

servicing, unless the component is

to be removed and replaced. It is

extremely important to replace all

grounding wires when components

are replaced.

Grounding Type

Wall Receptacle

Power Supply Cord

with 3-Prong

Grounding Plug

Disconnect the electrical power before servicing any components .

This unit has several sharp edges in areas where you will be working to

remove components for service. Wear protective gloves where sharp

! WARNING

ELECTRIC SHOCK HAZARD

Failure to do so can result in death or electrical shock.

! WARNING

PERSONAL INJURY HAZARD

edges are present.

IV

R134a REFRIGERANT

Service Information

This product uses R134a refrigerant. This refrigerant requires synthetic Ester oil in the compressor.

This cooling system does not tolerate contamination from any of the following:

• Other Refrigerants

• Moisture

• Petroleum-based Lubricants

• Silicone Lubricants

• Cleaning Compounds

• Rust Inhibitors

• Leak Detection Dyes

• Any Other Type of Additive

As a result the following precautions should be observed:

• Use equipment dedicated to R134a sealed system service only.

• Do not leave a replacement compressor open to the atmosphere for more than 10 minutes.

• Always replace the filter-drier when performing any repairs on the sealed system.

• USE ONLY R134a REFRIGERANT FOR BACKFLUSHING AND SWEEP PROCEDURES.

• If the rubber plugs on the service replacement compressor appear to have been tampered

with or removed, DO NOT USE THE COMPRESSOR. Get another one.

• The filter-drier MUST be cut from the sealed system. Never unbraze the filter-drier from

system tubing. Applying heat will drive moisture back into the sealed system.

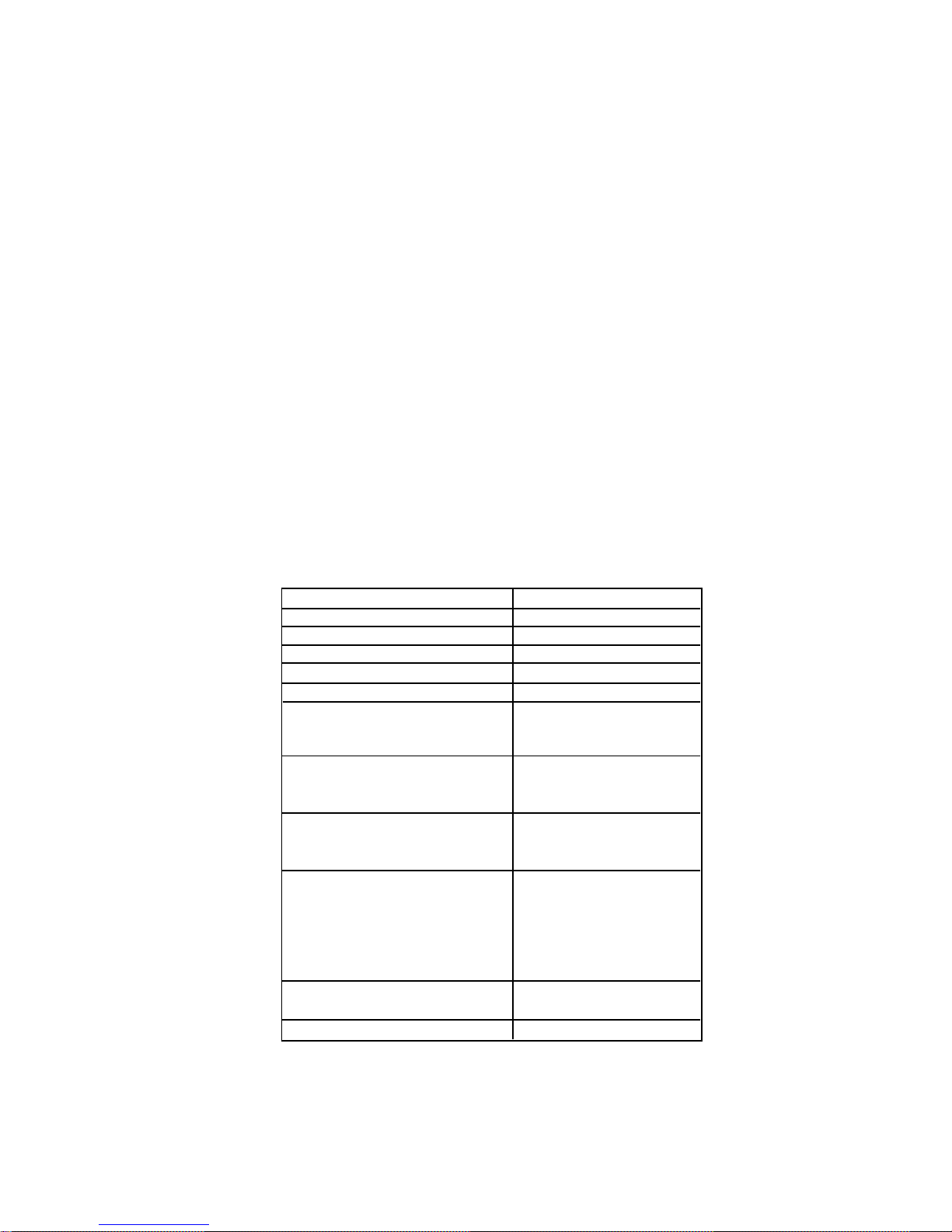

HEALTH AND SAFETY HANDLING

Allowable Overall Exposure Limit

Vapor Exposure to Skin

Liquid Exposure to Skin

Vapor Exposure to Eyes

Liquid Exposure to Eyes

Above Minimum Exposure Limit

Safety and Handling

Spill Management

Fire and Explosion Hazards

Storage Conditions

Disposal Procedure

R134a

1,000 ppm

No effect

Can cause frostbite

Very slight irritation

Can cause frostbite

Can cause asphyxiation,

tachycardia and cardiac

arrhythmias.

Wear appropriate skin and

eye protection. Use adequate

ventilation.

Remove or Extinguish Ignition

or Combustible Sources.

Evacuate or Ventilate Area.

May decompose if contact is

made with flames and heating

elements. Container may

explode if heated due to

pressure rise. combustion

products are toxic.

The procedures / rules for R12

also apply to R134a.

Reclaim

SEE SWEEP CHARGE PROCEDURES FOR THE 90's,

Part No. 4321717 FOR COMPLETE INSTRUCTIONS ON

SERVICING THE SEALED SYSTEM.

V

VI

ANSWER SHEET

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

CONFIRMATION OF LEARNING

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

EXERCISESEXERCISES

EXERCISES

EXERCISESEXERCISES

Section One

True or False Statements:

F

1. ___

F

2. ___

T

3. ___

T

4. ___

5. ___

T

Section One

Label the Components:

Section Two

True or False Statements:

T

1. ___

F

2. ___

F

3. ___

T

4. ___

T

5. ___

Section Three

True or False Statements:

F

1. ___

T

2. ___

T

3. ___

F

4. ___

F

5. ___

Evaporator

Evaporator

Outlet

Capillary Tube

Heat

Loop

Compressor

Condenser

Process

Tube

Filter Dryer

Condenser

Outlet

VII

VIII

IX

SECTION TWO

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

TEMPERATURE CONTROL

Freezer temperature is regulated by an air-sensing thermostat inside the control box located at the top

front of the refrigerator compartment. This thermostat actuates the compressor to circulate refrigerant

through the sealed system to remove heat from the freezer and refrigerator sections. The thermostat

should be set to maintain 0° - 5°F freezer food temperature.

Refrigerator temperature is regulated by an automatic air damper control. The air damper control is a

thermostat that manually actuates the air damper door. This control governs the amount of refrigerated

air entering the refrigerator compartment. The control should be set to maintain 38°F to 40°F fresh

food temperature.

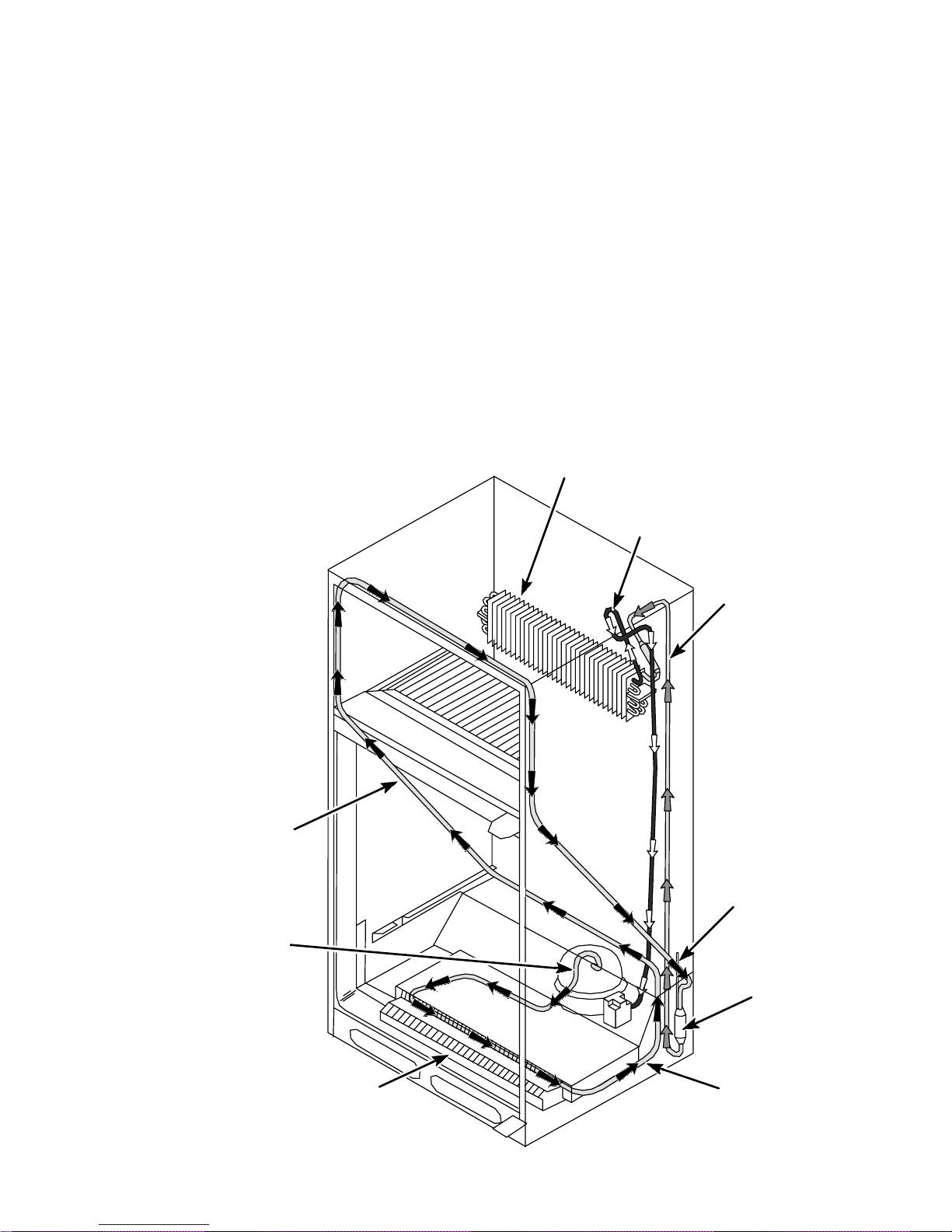

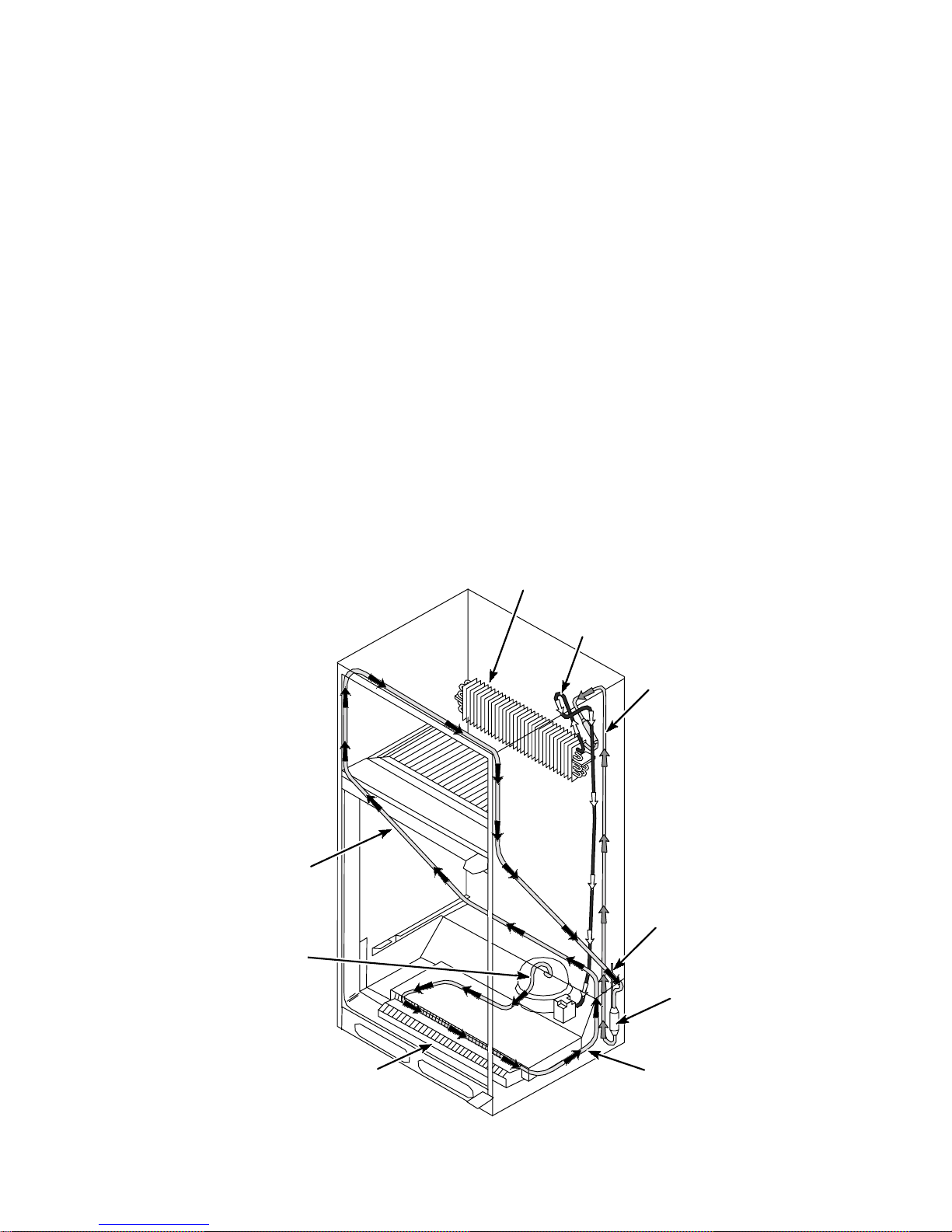

Refrigerant Flow

Refrigerant is pumped from the compressor and passes through the condenser, the heat loop around

the freezer compartment opening, the filter drier, capillary tube, evaporator and the suction line back to

the compressor.

The heat loop is made of a continuous piece of copper tubing with no brazed joints.

Evaporator

Evaporator Outlet

Capillary

Tube

Heat

Process

Compressor

Tube

Filter Drier

Condenser

Condenser

Outlet

Fig. 2

3

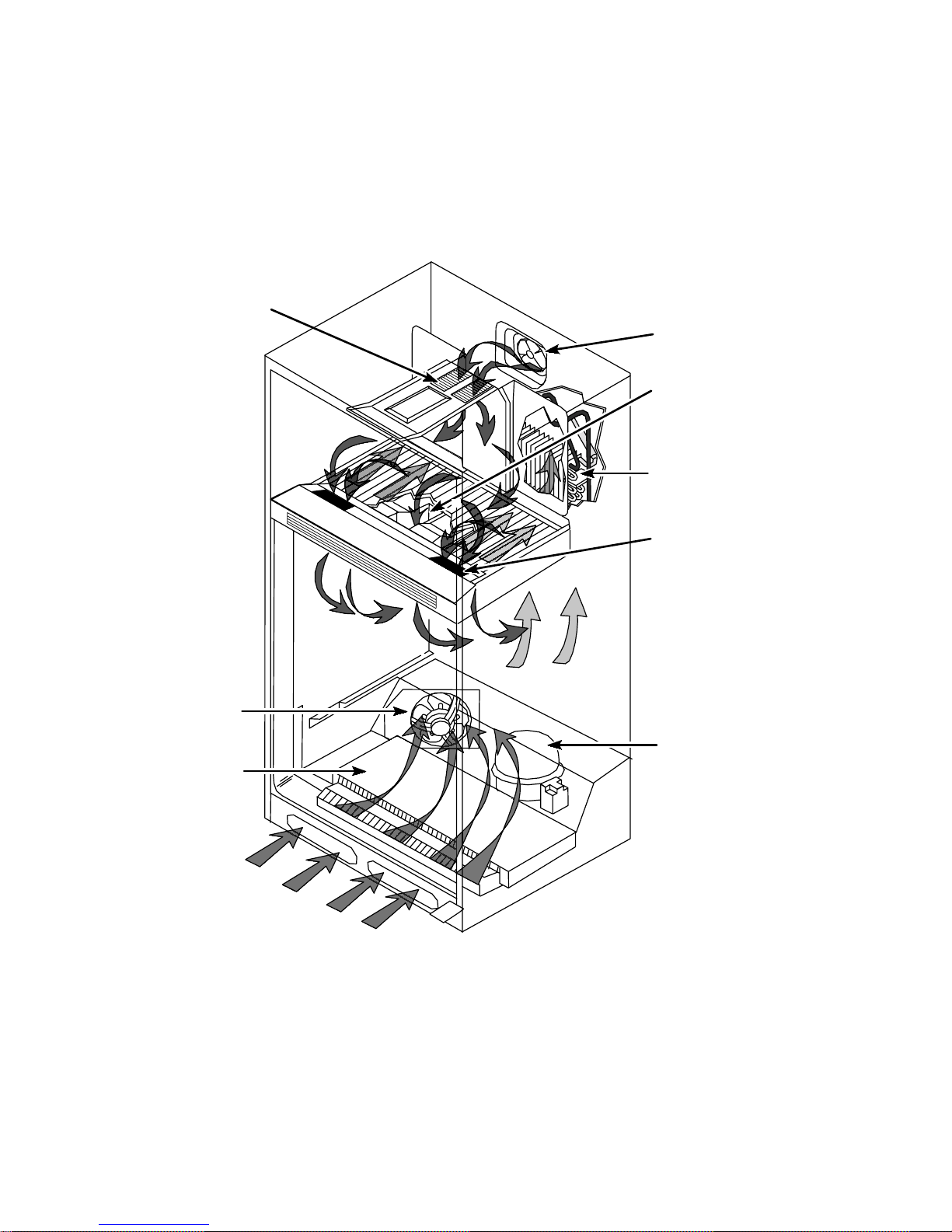

Air Flow

Air inside the freezer section is cooled when it is drawn across the evaporator and circulated through

the freezer compartment.

Cold freezer air is also drawn into the refrigerator compartment and circulated to remove heat.

Freezer Air

Supply Grille

Evaporator Fan

Assembly

Refrigerator Air

Supply Duct

Evaporator

Freezer Return Air

Through Bottom of

Freezer Floor

Condenser Fan

Condenser

Compressor

Fig. 3

4

Loading...

Loading...