KitchenAid electric dryer Installation Instructions Manual

Installation Instructions

Electric

Dryer

Befotv you

start...

A

You need these tools to

n install your KItchenAid

electric dryer. Get them together in

one place to keep track of them.

B

n

Check the spot where you’re

going lo install the dryer...

proper mstallation is your responsibility.

C

w

Make sure you have

everything necessary for

proper inslallatron. You’ll need:

l

To meet code requirements: some

codes keep from or limit installation of

clothes dryers rn garages, closets,

mobile homes and sleeping quarters.

(Check with your local building

inspector.)

Important: observe all governing

codes and ordinances.

l

To check utilities: proper connectron

to electric supply should be available.

l

To check exhaust requirements:

a four inch metal exhaust duct is

required.

LOCATION

Size: Must be large enough to fully

open dryer door. For recessed or closet

installatron spacinq see Panel 8.

Support: The floor bust be able to

support the applrance weight of 175

pounds

Level Floor: Maximum floor slope

under dryer - 1 inch.

Protection from the weather: Proper

operation of drver cvcles reouires

temperatures above 45”F., o;~the dryer

may not shut off when automatic

cycles are used.

WARNING: Potential Fire Hazard

m It is the personal responsibility of the

customer to ensure fhat oasoline.

paint, thinners and other flammable

malerrals are not used or stored near

the dryer. Fumes from these

materials could result in fire or

explosion.

b Never install the dryer up against

draperies or curtains and be sure to

keep any and all items from fallmg

or collectmg behind the dryer

D Replace all access or service panels

belore operating dryer.

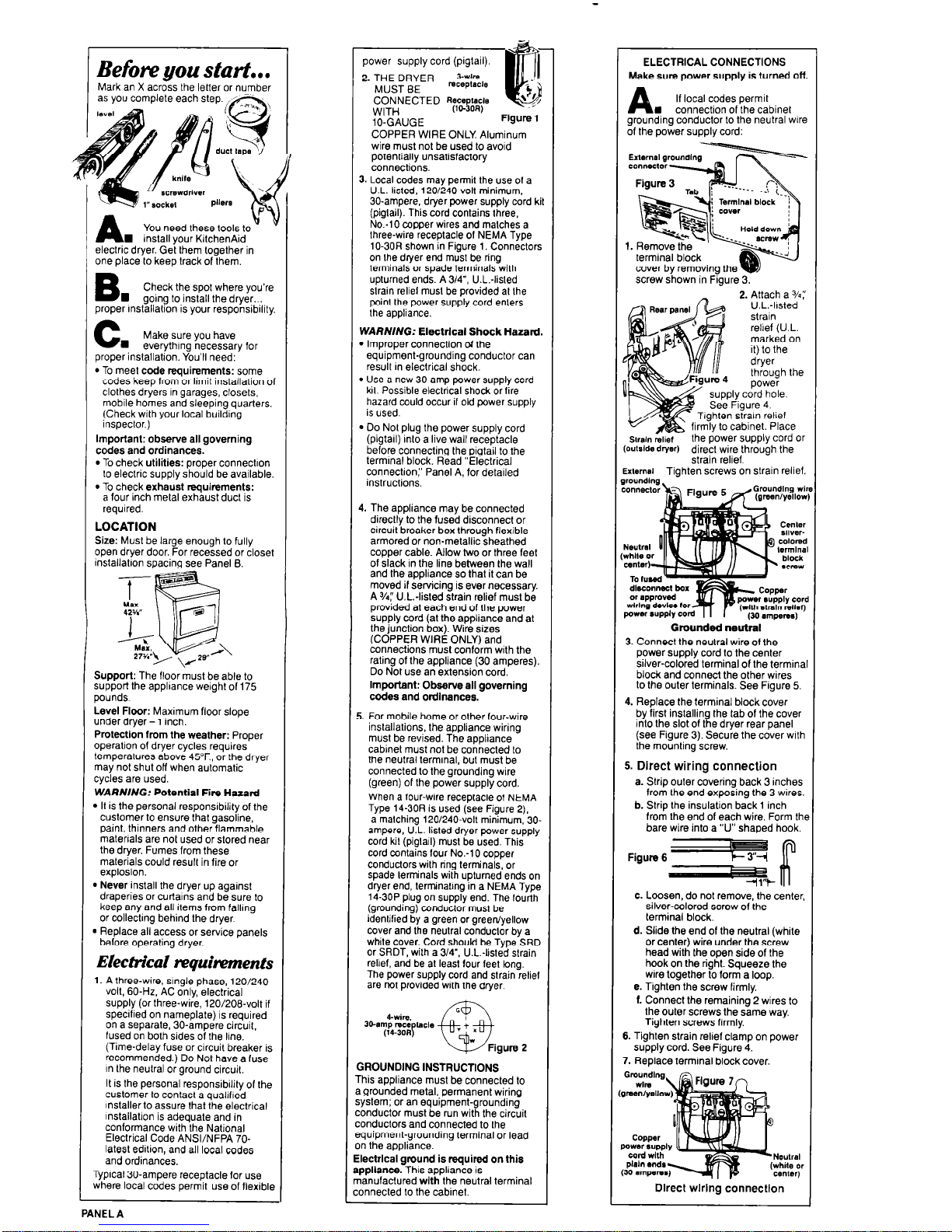

Electrical tvquhments

1. A three-wire, srngle phase, 120/240volt, 60.Hz. AC only, electrical

supply (or three-wire, 120/206volt if

specified on nameplate) is required

on a separate, 30-ampere circuit,

fused on both sides of the line.

(Time-delay fuse or circuit breaker is

recommended.) Do Not have a fuse

rn the neutral or ground circuit.

It is the personal responsibility of the

customer to contact a quaIlfred

k-staller to assure that the electrical

lnstallatlon is adequate and in

conformance with the National

Electrical Code ANSVNFPA 70latest edition, and all local codes

and ordinances,

Typical 30-ampere receptacle for use

rvhere local codes permit use of flexible

power supply cord (pigtail).

2. THE DRYER ,Ls+$,.

MUST BE

CONNECTED

Recep1(1cIn

WITH

(104OR)

IO-GAUGE

COPPER WIRE ONLY Aluminum

wire must not be used to avord

potentially unsatisfactory

connections.

I ..-.

3 Local codes may permit the use of a

U L Iksted. 120/240-volt minimum.

30.ampere. dryer power supply cord kit

(piglail). This cord contains three,

No:10 copper wires and malches a

three-wire receptacle of NEMA Type

10.30R shown in Figure 1. Conneclors

1 onl~edryerendmustbertng 1

lermmals or soade termrnals with

upturned ends. A 3/4”, U.L.-listed

slrain reliel musl be provided at Ihe

poinl the power supply cord enlers

the appliance.

WARNING: Electrical Shock Hazard.

l

Improper connection d the

equipment-grounding conductor can

result in electrical shock.

l

Use a new 30.amp power supply cord

kil. Possible electrical shock or fire

hazard could occur il old power supply

is used.

l

Do Not plug the power supply cord

(pigtall) rnlo a live wall receptacle

before connecting the pigtail to the

termrnal block. Read “Electrical

connection:’ Panel A, for detailed

instructions.

4. The appliance may be connected

direclly to the fused disconnect or

circuit breaker box throuqh flexible

armored or non-metallicsheathed

coooer cable. Allow two or three feet

of siack in the line between the wall

and the appliance so that it can be

moved if servicing is ever necessary.

A%:’ U.L.-listed strain relief must be

provided at each end of the power

supply cord (at the appliance and at

the junction box). Wire sizes

(COPPER WIRE ONLY) and

connections must conform with the

rating of the appliance (30 amperes).

Do Not use an extension cord.

Important: Observe all governing

codes and ordinances.

5. For mobile home or other four-wire

inslallations, the appliance wiring

must be revised. The appliance

cabinet must not be connected to

the neutral terminal, but must be

connected to the grounding wire

(green) of the power supply cord.

When a four-wire receptacle of NEMA

TVD~ 14.30R is used fsee Fioure 21.

a ‘malching 120/240-volt mir&um:30-

ampere, U.L. listed dryer power supply

cord kil (piglarl) must be used. This

cord contains four No.-1 0 copper

conductors with nng terminals, or

spade terminals with uplurned ends on

drver end. terminatkta in a NEMA Tv~e

14.30P plug on supply end. The lou’rih

(grounding) conductor must be

identified by a green or green/yellow

cover and the neutral conduclor by a

white cover. Cord should be Type SRD

or SRDT, wilh a 3/4’. U.L.-listed slrain

relief. and be at least (our feet long.

The power supply cord and strain relief

are nol provided wilh the dryer.

GROUNDING INSTRUCTIONS

This appliance must be connected to

a grounded metal, permanent wirinq

or an equipment-grounding

conductor must be run with the circuit

conductors and connected to Ihe

equipment-grounding terminal or lead

on the aooliance.

I

Electrlc~l’ground is required on this

aoollanm. This aooliance is

manufactured wlih’the neutral terminal

connected lo the cabinet.

ELECTRICAL CONNECTIONS

Make sure power supply is turned off.

A

If local codes permit

n connection of the cabinet

grounding conductor to the neutral wire

of the power supply cord:

screw shown in Fygure 3:

2. Attach a %:

the power supply cord or

(outsrde drlsrt direcl wire through the

strain relief

External Tiahten screws on strain relief.

Groundedneutml

3. Connect the neutral wire of the

power supply cord to the center

silver-colored lerminal of the terminal

block and connect the other wires

to the outer terminals. See Figure 5.

4. Replace the terminal block cover

by first installing the tab of the cover

into the slot of the dryer rear panel

(see Figure 3). Secure the cover wilh

the mounting screw.

5. Direct wiring connection

a. Strip outer covering back 3 inches

from the end exposing the 3 wires.

b. Strip the insulatron back 1 inch

from the end of each wire. Form the

bare wire into a “U” shaped hook.

FigureSw

----_a

-ll”t

C. Loosen, do

not

remove, the center,

silver-colored screw of the

terminal block.

d. Slide the end of the neutral (white

or center) wire under the screw

head with the open side of the

hook on the right. Squeeze the

wire together to form a loop.

e. Tiahten the screw firmlv.

1. C&nect the remaining’2 wires to

the outer screws the same wav.

’ Tighten screws firmly.

6. Tighten strain relief clamp on power

supply cord. See Figure 4.

7. Replace terminal block cover.

I

Direct wlrlng connectlon

PANEL A

Loading...

Loading...