Page 1

2006137 Rev.A www.kitchenaid.com

Panel models and wraparound

stainless steel door models

36"(91.4 cm), 42"(106.7 cm), 48"(121.9 cm)

bUILT-IN REfrigeratorS

For the way it’s made

®

®

Important:

Read and

save these

instructions.

Installation

requires

2 or more

people.

Tip Over Hazard

Refrigerator is top

heavy and tips easily

when not completely

installed.

Keep doors taped

closed until refrigerator

is completely installed.

Use two or more people

to move and install

refrigerator.

Failure to do so can

result in death or

serious injury.

WARNING

Page 2

Page 2

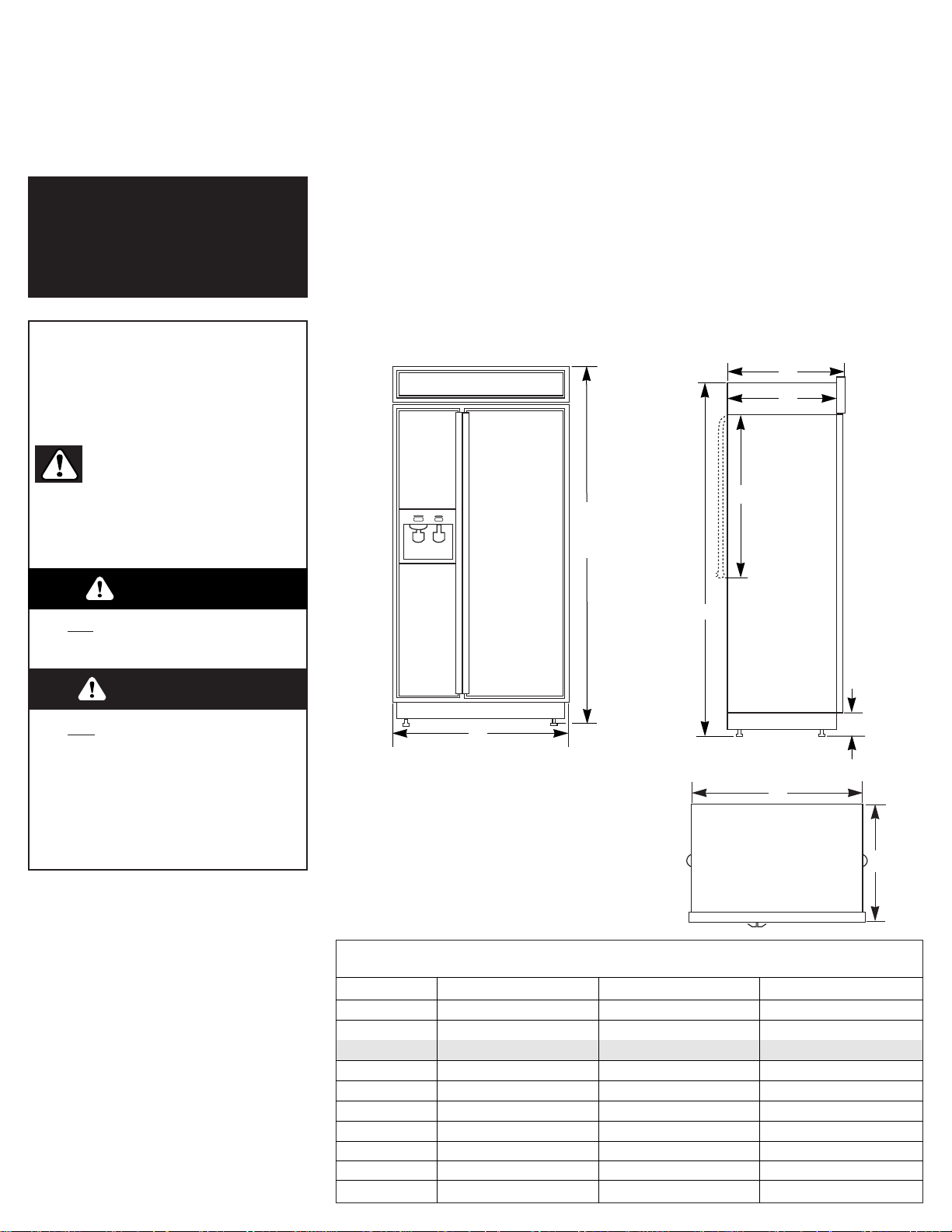

36" (91 cm) 42" (106 cm) 48" (122 cm)

A 36" (91 cm) 42" (106 cm) 48" (122 cm)

B

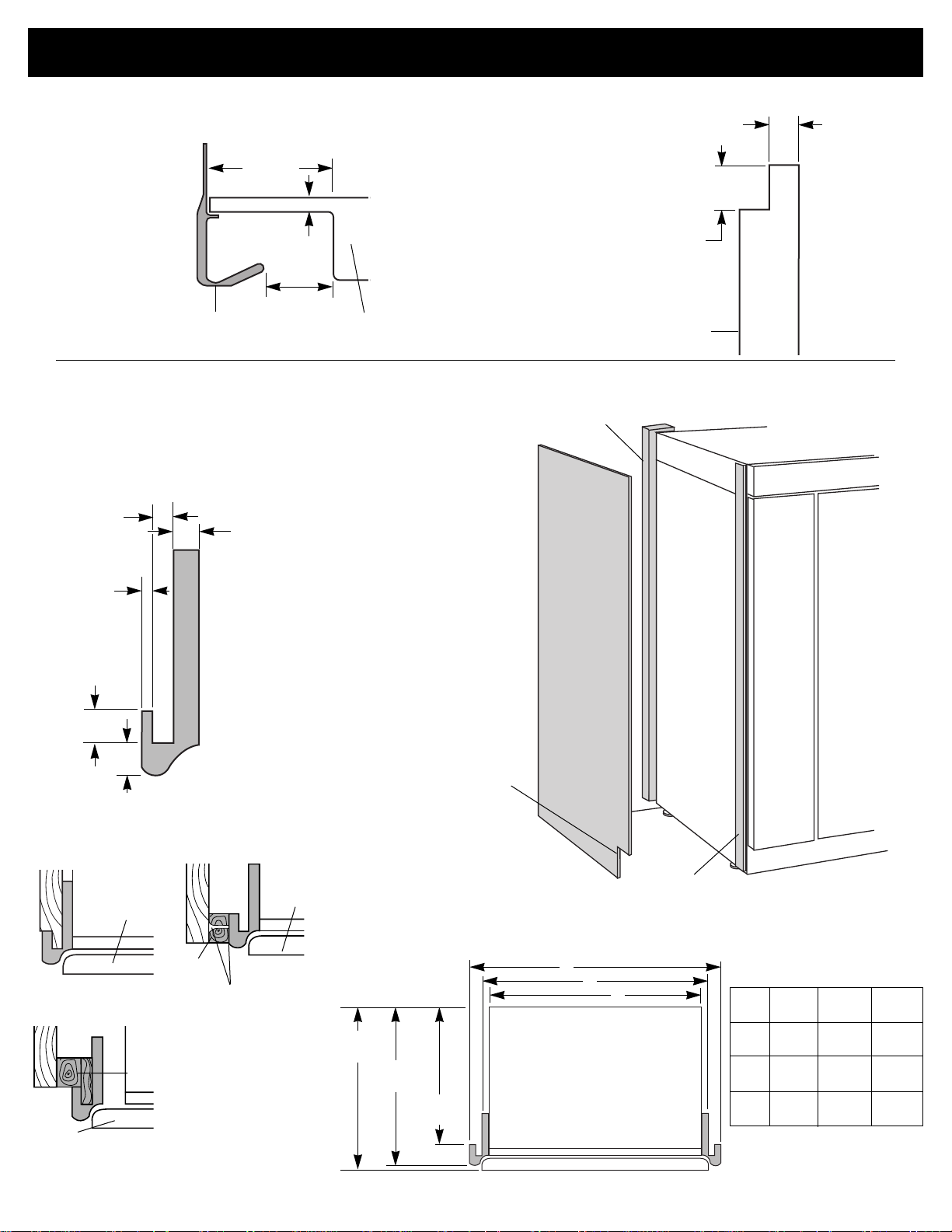

Panel model

83-5/8" (212 cm)* 83-5/8" (212 cm)* 83-5/8" (212 cm)*

B 83-1/8" (211 cm) 83-1/8" (211 cm) 83-1/8" (211 cm)

C 25-1/8" (64 cm) 25-1/8" (64 cm) 25-1/8" (64 cm)

D 23-1/2" (60 cm) 23-1/2" (60 cm) 23-1/2" (60 cm)

E 3-1/2" (9 cm)* 3-1/2" (9 cm)* 3-1/2" (9 cm)*

F 83-1/8" (211 cm)* 83-1/8" (211 cm)* 83-1/8" (211 cm)*

G 24" (61 cm) 24" (61 cm) 24" (61 cm)

H 35" (89 cm) 41" (104 cm) 47" (119 cm)

I 25" (63.5 cm) 25" (63.5 cm) 25" (63.5 cm)

Before you

start...

Keep cardboard shipping piece or

plywood under refrigerator until it is

installed in the operating position.

Front view

A

C

D

G

E

F

Product dimensions

* Dimensions shown are for leg levelers

extended 1/8" (3 mm) below rollers. For

levelers fully extended 1-1/4" (32 mm)

below rollers, add 1-1/8" (29 mm) to this

dimension.

Important:

Observe all governing codes and

ordinances.

It is your responsibility to:

• Comply with installation specifications

and dimensions.

• Properly install refrigerator.

• Remove any moldings or decorative

panels that prevent the refrigerator

from being serviced.

• Make sure that you have these

materials necessary for proper

installation:

1/4" (6 mm) copper tubing with

shutoff valve

Panel models only:

The “B” dimension can be increased or

decreased 1/2 inch (1.3 cm) by using

Grille Kits available from your dealer.

To increase: use “84-inch” Grille Kit

No. 4378788 (Silver Trim) or 4378789

(White Trim).

To decrease: use “83-inch” Grille Kit

No. 4378786 (Silver Trim) or 4378787

(White Trim).

Top view

H

I

Your safety and the safety of others

is very important.

We have provided many important

safety messages in this manual and

on your appliance. Always read and

obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to

hazards that can kill or hurt

you and others. All safety messages

will be preceded by the safety alert

symbol and the word “DANGER” or

“WARNING”. These words mean:

All safety messages will identify the

hazard, tell you how to reduce the

chance of injury, and tell you what can

happen if the instructions are not

followed.

You will be killed or seriously

injured if you don’t follow

instructions.

You can be killed or seriously

injured if you don’t follow

instructions.

Side view

1/4" (6 mm) compression fitting

6 – #8 x 3" (7.6 cm) wood screws

(Longer screws may be

required.)

2 – 2" x 4" x 32" (5 cm x 10 cm x

81 cm) min. wood boards

(See Page 4.)

• Assure that floor will support

refrigerator weight (more than

600 lb/272 kg), door panels,

and contents.

• Provide a properly grounded electrical

outlet.

• Assure that location will permit

appliance doors to open 90°

minimum.

B

See

Note.

WARNING

D ANGER

Panel models and wraparound stainless steel door models

Dispenser and Non-Dispenser

Wraparound

stainless steel model

Important:

• Installer: Leave Installation

Instructions with the homeowner.

• Homeowner: Keep Installation

Instructions for future reference.

• Save these Installation Instructions for

the local electrical inspector’s use.

Page 3

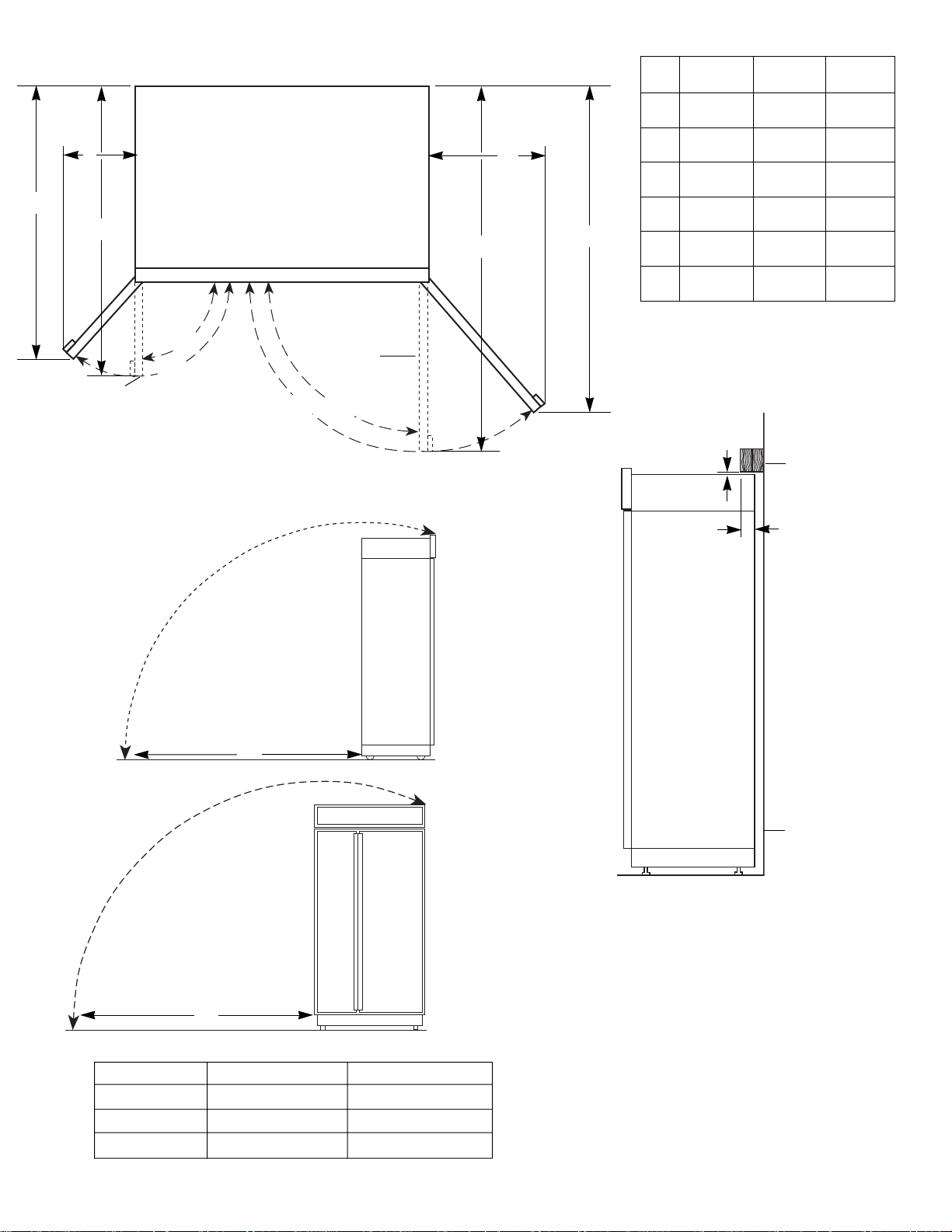

Model

Width min.

Height min.

Height max.

Depth min.

36" (91 cm)

35-1/2" (90 cm)

83-1/4" (211.5 cm)

84-3/4" (215 cm)

23-1/2" (60 cm)

42" (106 cm)

41-1/2" (105 cm)

83-1/4" (211.5 cm)

84-3/4" (215 cm)

23-1/2" (60 cm)

48" (122 cm)

47-1/2" (120 cm)

83-1/4" (211.5 cm)

84-3/4" (215 cm)

23-1/2" (60 cm)

Built-in opening

requirements &

dimensions

All dimensions ±1/8" (3 mm)

Grounded electrical

outlet location

Grounded electrical

outlet is required.

Mark stud

locations on

rear wall

80" - 90"

(203-229 cm)

above floor.

Floor: Must support refrigerator,

contents, and door panels.

Water line must

provide 15-100 psi

(103-690 kPa) water

pressure. Rough in

water line before

installing

refrigerator.

7"

(18 cm)

7"

(18 cm)

5-1/2"

(14 cm)

3"

(7.6 cm)

Install side panel (optional)

support board on rear wall

if opening depth is

25" (63.5 cm) or more.

Height

Depth

Opening dimensions

Page 3

Water line

location can be

through floor

or wall.

10"

(25 cm)

2" (5 cm)

1/2" (12 mm) hole for

plumbing can be

located anywhere

within shaded area.

The built-in refrigerator can be

installed:

• recessed in the cabinet opening.

• at the end of cabinets using a side

panel to enclose the refrigerator side.

Select one method and use dimensions

given. Dimensions shown provide 0"

(0 cm) clearance.

77"

(196 cm)

6"

(15 cm)

8"

(20 cm)

Width

A solid soffit or two, 2" x 4" x 32"

(5 cm x 10 cm x 81 cm) wood boards

to cover the width of the compressor

cover are required above the

refrigerator to prevent tipping

during use.

If solid soffit is more than 1 inch

(2.5 cm) above refrigerator, two

2"x 4" x 32" (5 cm x 10 cm x 81 cm)

wood boards must be installed on

the wall 1/4 inch (6 mm) above the

refrigerator cover. The bottom

surface of the boards should be

84 inches (213 cm) from floor. Boards

must be long enough to fully cover

width of compressor cover.

Page 4

Top front

of refrigerator

Freezer

door

Refrigerator

door

130°

C

D

B

A

Door swing dimensions

If boards are placed before installation of

refrigerator, locate boards so the bottom surface of

the boards are 84 inches (213 cm) from the floor.

During installation, raise the refrigerator up so there

is 1/4 inch (6 mm) maximum between top of

refrigerator and bottom of anti-tip boards.

If solid soffit is 1 inch (2.5 cm) above

refrigerator, anti-tip wood boards are not required.

If solid soffit is not available or soffit is more than

1 inch (2.5 cm) above cover, center wood boards

on rear wall 1/4 inch (6 mm) maximum above

refrigerator. Attach wood boards to wall studs with

wood screws — making sure that screws are

engaged in wall studs 1-1/2 inch (3.8 cm) minimum

and that boards extend 2 inches (5 cm) minimum

over the top rear of refrigerator compressor cover.

Two, 2" x 4" x

32" (5 cm x 10

cm x 81 cm)

anti-tip wood

boards

Attach to wall

studs with six,

#8 x 3" (76 mm)

(or longer)

wood screws.

Boards must be

long enough to

fully cover

width of

compressor

cover.

1/4" (6 mm) max.

2" (5 cm)

min.

rear

wall

Page 4

Anti-tip requirements

Tipping radius

Forward/backward

tipping radius

Side

tipping radius

Size A B

36" (91 cm) 87-1/4" (222 cm) 90-1/2" (230 cm)

42" (106 cm) 87-1/4" (222 cm) 93" (236 cm)

48" (122 cm) 87-1/4" (222 cm) 96" (244 cm)

A

B

A

B

C

D

E

F

36"

91 cm

38-1/2"

(98 cm)

36-1/16"

(92 cm)

43-1/2"

(110 cm)

40"

(102 cm)

19-3/4"

(50 cm)

14-1/2"

(37 cm)

42"

106 cm

41"

(104 cm)

38"

(97 cm)

47"

(119 cm)

42-9/16"

(108 cm)

23-1/4"

(59 cm)

17-1/4"

(44 cm)

48"

122 cm

43-1/2"

(110 cm)

40"

(102 cm)

50-1/2"

(128 cm)

45-1/4"

(115 cm)

26-3/4"

(68 cm)

19-3/4"

(50 cm)

Location must permit doors to open

to 90° min. Allow 4-1/2 inch

(11.4 cm) min. space between

refrigerator side and corner wall.

90°

130°

90°

E

F

Note: Dolly wheel height must be added to tipping

radius when a dolly is used.

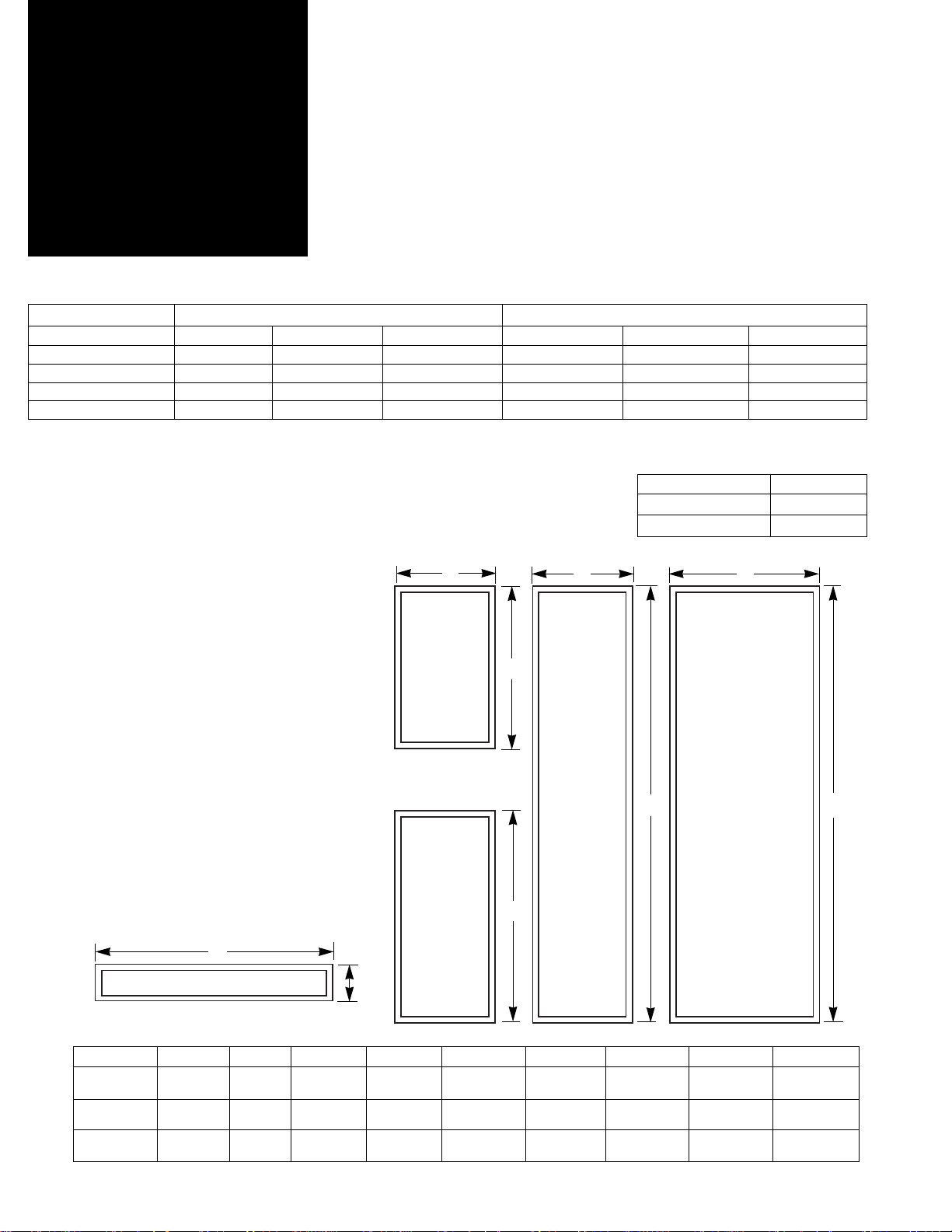

Page 5

Color Kit number

Matte Aluminum 4387989

White 4387990

Parts that

must be

ordered

separately or

custom made

1. Panel kits

Four kits, containing colored acrylic

or stainless steel door and top grille

panels, are available through your

KitchenAid dealer or by calling

Whirlpool Parts and Accessories at

1-800-442-9991. Follow the kit

instructions for installing the panels.

Panel kit numbers

Size

White

Black

Almond

Stainless Steel

36" (91 cm)

4318635

4318632

4318638

4318641

36" (91 cm)

4378650

4378653

4378656

4378659

42" (106 cm)

4318636

4318633

4318639

4318642

42" (106 cm)

4378651

4378654

4378657

4378660

48" (122 cm)

4318637

4318634

4318640

4318643

48" (122 cm)

4378652

4378655

4378658

4378661

2. Extended door handle kits

Two kits, containing one freezer door handle and one refrigerator door handle, are

available through your KitchenAid dealer or by calling Whirlpool Parts and

Accessories at 1-800-442-9991. Use extended door handles when additional finger

clearance is needed between the door handle and custom panel. Follow the kit

instructions for installing the door handles.

3. Custom panels

The custom panel weight must NOT

exceed amounts listed.

Panels weighing more than amounts

listed may cause product damage.

C F H

D

G

I

E

Freezer door panels

(with dispenser)

Maximum

combined

weight of

both panels:

30 pounds

(13.5 kg)

Maximum

combined

weight of

both panels:

30 pounds

(13.5 kg)

Freezer door

panel

(non

dispenser)

Maximum

weight:

30 pounds

(13.5 kg)

Refrigerator door

panel

Maximum

weight:

50 pounds

(23 kg)

Page 5

Model Non-dispenser Dispenser

A

B*

Size

36"

(91 cm)

42"

(106 cm)

48"

(122 cm)

A

32-3/8"

(82 cm)

38-3/8"

(97 cm)

44-3/8"

(113 cm)

B*

6"

(15 cm)

6"

(15 cm)

6"

(15 cm)

C

14-1/4"

(36 cm)

16-3/4"

(43 cm)

19-1/4"

(49 cm)

D

23-7/16"

(60 cm)

23-7/16"

(60 cm)

23-7/16"

(60 cm)

E

34-7/16"

(87 cm)

34-7/16"

(87 cm)

34-7/16"

(87 cm)

F

14-1/4"

(36 cm)

16-3/4"

(43 cm)

19-1/4"

(49 cm)

G

70-7/16"

(179 cm)

70-7/16"

(179 cm)

70-7/16"

(179 cm)

H

19-1/4"

(49 cm)

22-3/4"

(58 cm)

26-1/4"

(67 cm)

I

70-7/16"

(179 cm)

70-7/16"

(179 cm)

70-7/16"

(179 cm)

Top grille panel [max. wt.: 10 lb./(4.5 kg)]

NOTE: Dimensions shown have a

±1/16 (1.5 mm) tolerance. Panels

that are more than 1/4" (6 mm) thick

must be routed. If using routed

panels, add 1/16" (1.5 mm) to

dimensions shown.

If panels are less than 1/4" (6 mm)

thick, install a filler panel between

doors and decorative panels.

*Dimension “B” can increase or decrease 1/2" (1.3 cm) if grille kits listed on page 2 are used.

Panel kits are not required for “factoryinstalled panel” models or wraparound

stainless steel door models.

Page 6

Dimensions for

routing panel

edges

Side view

3/4"

(19 mm)

min.

1/4"

(6 mm) max.

panel

End view of handle side of panel

panel

handle

2" (5 cm)

min.

1/4" (6mm )max.

Custom panels

more than 1/4"

(6 mm) thick:

Route entire length

or selected areas of

handle side of

panels 3-1/4"

(8.25 cm).

Thickness:

1/2" (12 mm)

minimum to

prevent warping.

Width and height:

depend on

installation type.

Notches for toe

panel recess

(if desired).

Determine

installation height

before cutting

notches.

If side panel will be installed inside

side trim and the side panel is more

than 1/4" (6 mm) thick, route front

edge of panel to fit trim piece.

side panel

support nailer

side trim piece

Page 6

End view of side trim piece

5/32"

(4 mm)

1/4"

(6 mm)

1/16"

(1.5 mm)

7/32"

(5.5 mm)

13/32" (10 mm)

side panel inside

side trim piece

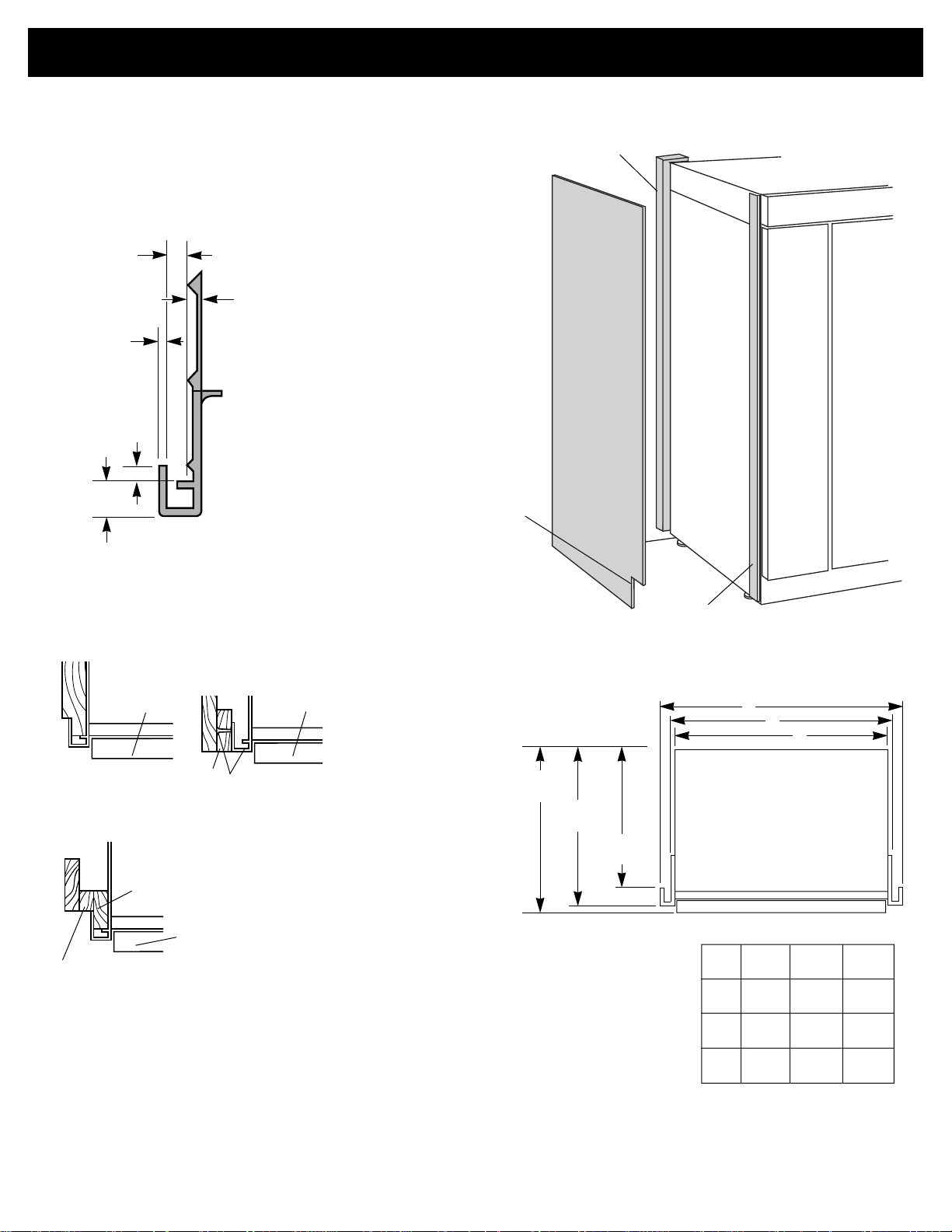

3. Side panels

recessed side panel

outside side trim piece

3-1/4"

(8.25 cm)

min.

A

B

C

Model

A

B

C

36"

(91 cm)

36"

(91 cm)

35-1/2"

(90 cm)

35"

(89 cm)

42"

(106 cm)

42"

(106 cm)

41-1/2"

(105 cm)

41"

(104 cm)

48"

(122 cm)

48"

(122 cm)

47-1/2"

(120 cm)

47"

(119 cm)

25"

(63.5 cm)

24-1/8"

(61.3 cm)

23-1/2"

(59.7 cm)

Panel models

Attach support

board with screw

or adhesive

compatible with

aluminum and

wood.

support

board

door

side panel outside

side trim piece

door

door

support

board

Rout front edge of support board or attach

1/4" board for retention in cabinet side trim.

Page 7

Page 7

Wraparound stainless steel door models

Thickness:

1/2" (12 mm)

minimum to

prevent warping.

Width and height:

depend on

installation type.

Notches for toe

panel recess

(if desired).

Determine

installation height

before cutting

notches.

If side panel will be installed inside

side trim and the side panel is more

than 1/4" (6 mm) thick, route front

edge of panel to fit trim piece.

side panel

support nailer

side trim piece

End view of side trim piece

5/32"

(4 mm)

1/4"

(6 mm)

1/16"

(1.6 mm)

3/16"

(4.8 mm)

13/32" (10.5 mm)

side panel inside

side trim piece

side panel outside

side trim piece

door

door

3. Side panels

door

recessed side panel

outside side trim piece

A

B

C

Model

A

B

C

36"

(91 cm)

36"

(91 cm)

35-1/2"

(90 cm)

35"

(89 cm)

42"

(106 cm)

42"

(106 cm)

41-1/2"

(105 cm)

41"

(104 cm)

48"

(122 cm)

48"

(122 cm)

47-1/2"

(120 cm)

47"

(119 cm)

25"

(63.5 cm)

23-3/8"

(59.4 cm)

22-13/16"

(57.9 cm)

Rout front edge of support board or attach

1/4" board for retention in cabinet side trim.

Attach support board with screw

or adhesive compatible with

aluminum and wood.

support

board

support

board

Page 8

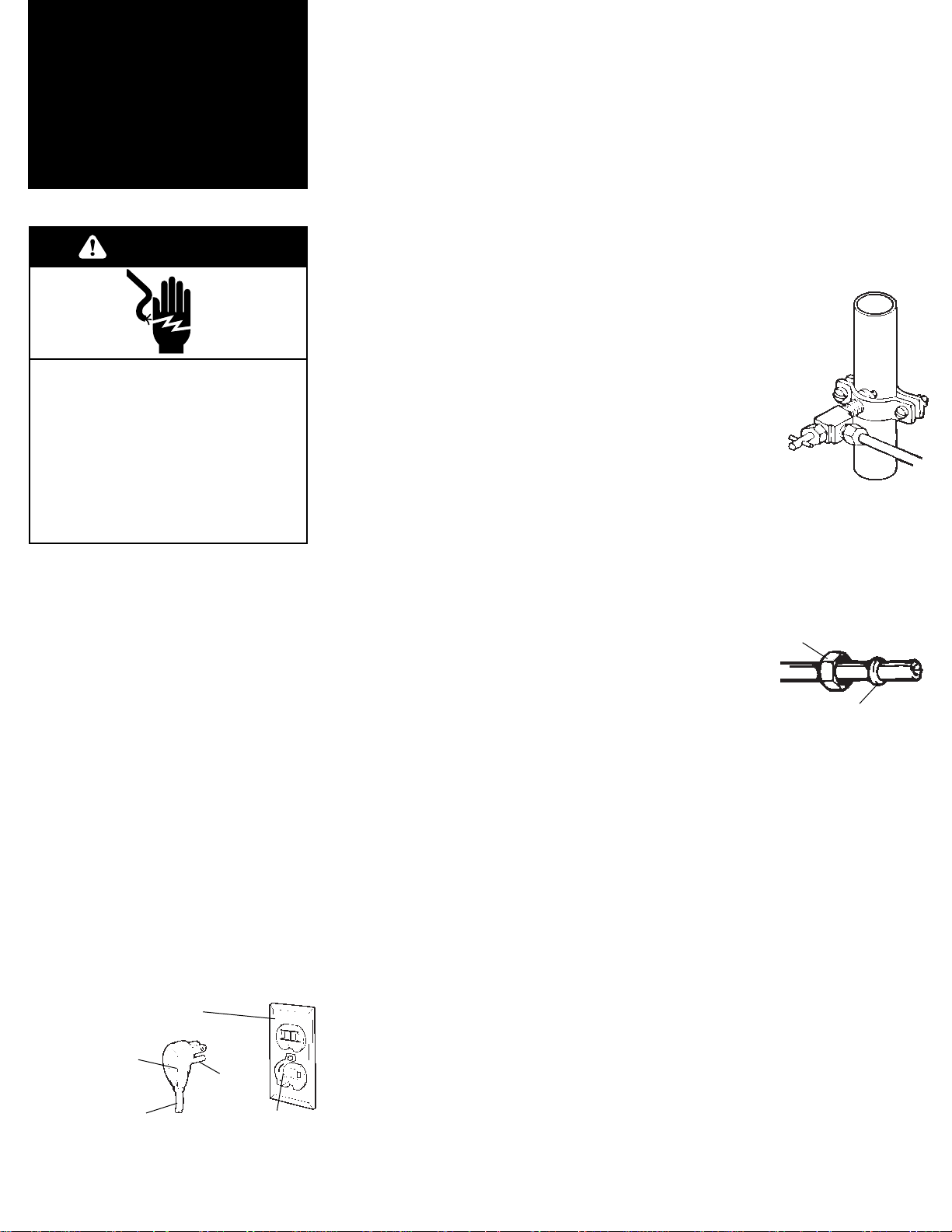

Electrical &

water supply

requirements

A 120-volt, 60-Hz, AC-only, 15- or 20ampere, fused, electrical supply is

required. A time-delay fuse or circuit

breaker is recommended. It is

recommended that a separate circuit

serving only this appliance be provided.

This appliance is equipped with a power

supply cord having a 3-prong ground

plug. To minimize possible shock hazard,

the cord must be plugged into a mating

3-prong, ground-type outlet, grounded

in accordance with the National

Electrical Code, ANSI/NFPA 70 — latest

edition* or Canadian Electrical Code,

C22.1-1982 and C22.2 No. 01982 (or

latest edition)**, and all local codes and

ordinances.

Copies of the standard listed may be

obtained from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** Canadian Standard Association

178 Rexdale Boulevard

Etobicoke, Ontario M9W 1R3

Electrical requirements

ground

prong

power supply

cord

retainer

Water supply requirements

Use only 1/4" (6 mm) copper tubing

for water line.

Do Not install copper tubing in area

where temperatures drop below

32°F (0°C).

Before attaching copper tubing to

refrigerator, flush at least 2 quarts

(1.9 L) of water through the copper

tubing and into a bucket to get rid

of any particles in the water line.

Do Not overtighten clamp or sleeve.

This will crush copper tubing.

Check for leaks around saddle valve.

3. Turn OFF main water supply. Turn ON

nearest faucet long enough to clear line

of water.

4. Vertical cold water line: Use

grounded electric drill or hand drill to

drill 3/16" (4.5 mm) hole in an easily

accessible location in water line.

Horizontal cold water line: Use

grounded electric drill or hand drill to

drill 3/16" (4.5 mm) hole in the top of

the water line. This will keep sediment

from collecting in valve.

5. Position washer over hole in

water line. Turn saddle valve

handle clockwise to expose

piercing lance a maximum of

3/16" (4.5 mm). Align

piercing lance over hole in

water line. Place both

halves of saddle valve

bracket against water

line. Turn saddle

valve handle

clockwise until piercing lance

enters hole in water line and is

firmly seated. The saddle valve is not in

the closed position. Tighten packing nut.

Evenly and firmly tighten bracket screws

so washer will make a water-tight

connection. Do Not overtighten

screws; copper tubing could be

crushed.

6. Check that both

ends of copper

tubing are cut

square. Slide

compression nut

and sleeve onto copper

tubing. Insert end of copper tubing

completely into valve outlet. Tighten

compression nut to outlet with adjustable

wrench. Do Not overtighten.

7. Turn on main water supply. Check for

leaks. Turn saddle valve handle

counterclockwise and run water through

copper tubing and into a bucket. Turn

saddle valve handle clockwise to shut off

water to copper tubing.

8. Route copper tubing to refrigerator

area.

compression nut

sleeve

Page 8

3-prong ground-type

outlet

3-prong

ground plug

If codes permit and a separate

ground wire is used, it is

recommended that a qualified

electrician determine that the

ground path is adequate.

Do not ground to gas pipe.

Check with a qualified electrician if

you are not sure the appliance is

properly grounded.

Do not have a fuse in the neutral or

ground circuit.

It is the customer’s responsibility:

To contact a qualified electrical

installer.

To assure that the electrical

installation is adequate and in

conformance with the National

Electrical Code, ANSI/NFPA 70 —

latest edition* or Canadian Electrical

Code, C22.1-1982 and C22.2 No.

01982 (or latest edition)**, and all

local codes and ordinances.

WARNING

Electrical Shock Hazard

Plug into a grounded 3-prong

outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these

instructions can result in death,

fire, or electrical shock.

Water line to refrigerator must provide

15-100 psi (103-690 kPa) water

pressure.

To calculate length of 1/4" (6 mm)

O.D. copper tubing needed:

1. Locate a vertical 1/2" (1.2 cm) to

1-1/4" (3.2 cm) COLD water line near

refrigerator area. A horizontal COLD

water line can be used if directions in

Step 4 are carefully followed.

2. Measure distance from cold water

line to refrigerator area. Add 24" (61

cm) to this measurement.

To rough in water line:

Page 9

1/4" (6 mm)

compression

nut

copper line

to valve

ferrule

Check that water supply line has

been flushed. See Page 7.

6.Pull water supply line out from

underneath refrigerator. Carefully make

a 3-1/2" or less (180°) hook-shaped end

in the water supply line. Do not kink

water supply line.

1.Remove and save literature

package and parts bag taped to

refrigerator door. Remove four brackets

(two on each side) that attach shipping

base to refrigerator bottom.

Do not remove tape and door bracing

until refrigerator is in final position.

Installation

steps

Do Not lower the refrigerator

against the shipping base when

removing the shipping base.

Do Not remove protective film until

refrigerator is in operating position.

All four leveling legs must contact

the floor to support and stabilize the

full weight of the refrigerator.

Keep cardboard shipping piece or

plywood under refrigerator until it is

installed in operating position.

Parts supplied for installation:

• base grille

• miscellaneous parts bag

Check that all parts were included.

3.Place pieces of shipping carton

on the floor when rolling dolly and

refrigerator into the house. Move

refrigerator close to built-in opening.

corner

post over

handle

Page 9

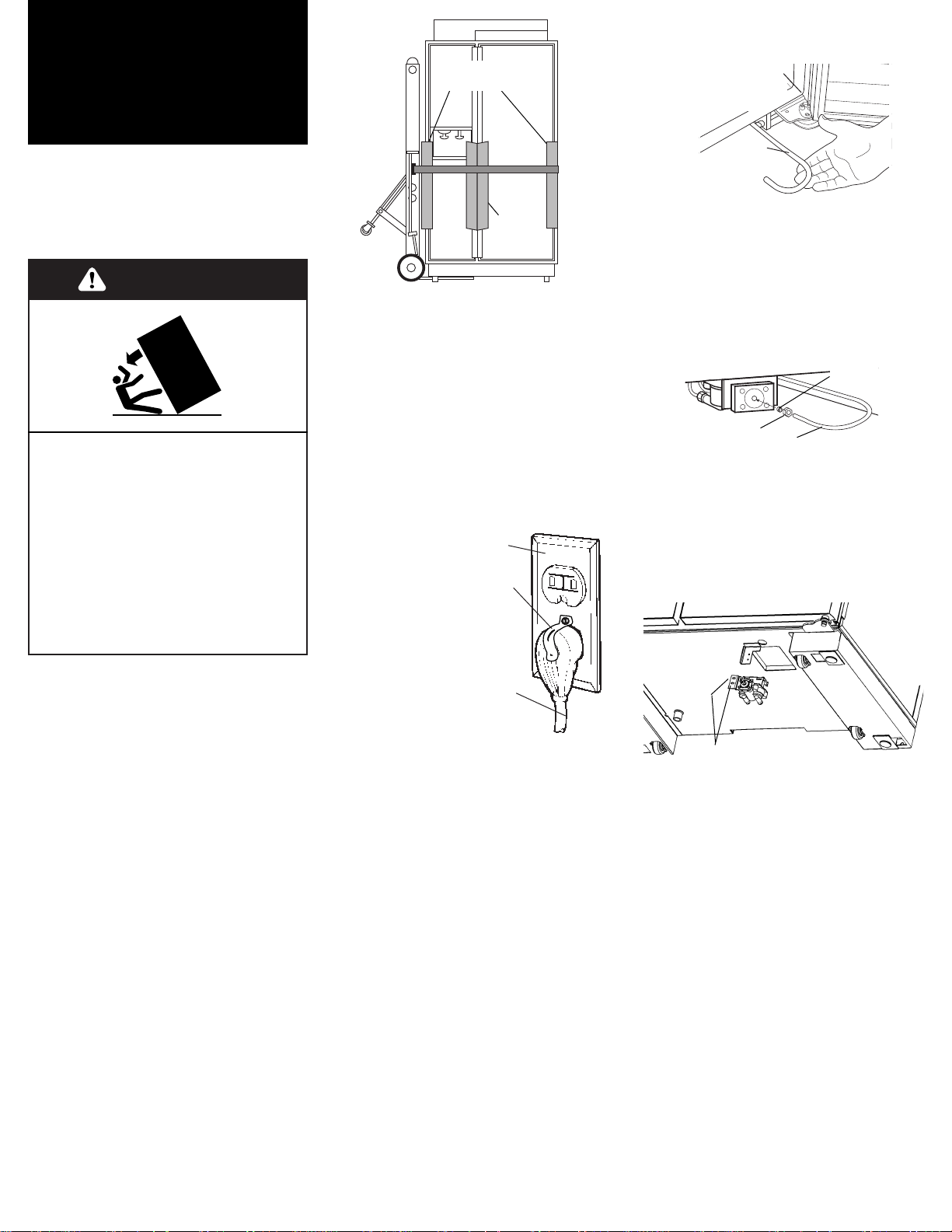

4.Set power

switch at top of

cabinet to “OFF”

position.

Plug power supply cord

into grounded outlet.

Install retainer on

grounded outlet

using screw from

parts bag.

5.Place top of cardboard

carton or plywood under refrigerator.

Remove dolly. Open appliance doors

and remove all boxes, parts packages

and packing materials from refrigerator

and freezer compartments. Do Not

remove protective film.

To prevent floor damage make sure

levelers are raised (not touching the

floor) and refrigerator is on rollers

before moving.

Move the refrigerator straight back and

evenly into the opening. Check that:

• copper tubing is not kinked.

• power supply cord is on top of

refrigerator next to cover.

retainer

grounded

outlet

power

supply

cord

2.Place appliance dolly under the

freezer side of refrigerator and loosely

wrap dolly strap around refrigerator.

Insert carton corner posts between

strap and side trim and handles.

Carefully tighten strap, making sure

side trim and handles are protected.

corner posts

over side trim

copper

water line to

valve

lower right hand

front corner of

refrigerator

Remove cap from water valve. Slide

compression nut, then ferrule, onto

water supply line. Insert water supply

line completely into water valve.

Tighten compression nut to water

valve. Do not overtighten.

Note: Connecting the water supply line

to the water valve is easier if the water

valve is removed from the mounting

bracket. Remove the two screws

attaching the water valve and pull

forward. Connect the water supply line.

Reattach water valve to mounting

bracket.

Turn water supply line valve to “Open”

position. Turn refrigerator switch to

“On” position. Wait a few minutes.

Check water line connections for leaks.

Tip Over Hazard

Refrigerator is top heavy and tips

easily when not completely

installed.

Keep doors taped closed until

refrigerator is completely

installed.

Use two or more people to move

and install refrigerator.

Failure to do so can result in

death or serious injury.

WARNING

screws

Page 10

decorative

panel

Filler panel

required if

panels are less

than 1/4"

(6 mm) thick.

If panels are

more than

1/4" (6 mm)

thick, route

panel edges

on all sides.

door

handle

nylon

washers

Page 10

13.If solid soffit is 1 inch

(2.5 cm) above refrigerator, anti-

tip wood boards are not required.

If solid soffit is not available or

soffit is more than 1 inch

(2.5 cm) above refrigerator,

locate wall studs in refrigerator

opening. Center one wood board

on rear wall 1/4 inch (6 mm)

maximum above refrigerator.

Attach wood board to wall studs

with wood screws — making sure

that screws are engaged in wall

studs 1-1/2 inches (3.8 cm)

minimum. Attach second wood

board to the front of the first

board. Wood boards must extend

2 inches (5 cm) minimum over the

top rear of the refrigerator

compressor cover.

8.Wraparound stainless steel

door models: go to step 9.

Panel models: Remove all tape and

door bracing from refrigerator and

freezer doors. Remove screws attaching

handles to door frames. Slide decorative

door panels into door frames.

If panels are less than 1/4" (6 mm)

thick, install a filler panel between door

and decorative panel.

If panels are more than 1/4" (6 mm)

thick, route panel edges on all sides.

two, 2" x 4" x 32"

(5 cm x 10 cm x 81 cm)

anti-tip wood boards

Center

board 1/4"

(6 mm) max.

above

refrigerator.

cover

2" (5 cm)

Attach to

wall studs

with six,

#8 x 3"

(7.6 cm)

(or longer)

wood

screws.

Boards

must be long

enough to

fully cover

width of

compressor

cover.

11.Replace door handles.

Check that the top of both door

handles are aligned.

If door handles are not

aligned, loosen all handle screws

and adjust door handles up or

down. Tighten screws.

If any of the white door screws

are damaged, replace them with

additional screws provided in the

parts package.

C

R

I

T

I

C

A

L

S

T

E

P

S

door stop set screw

(130° position)

90° position

bottom hinge

12. Check that

doors can open freely. If doors

open too wide, remove door

stop screw from bottom door

hinge. Hold door open to a

position that is less than 90°.

Replace door stop screw in the

90° door stop position in

bottom hinge and tighten

screw. If door does not clear

countertop after door has been

adjusted, countertops may need

to be mitered.

C

R

I

T

I

C

A

L

S

T

E

P

S

9.

Open

doors. Place

a level

against

underside of

door trim,

on refrigerator

crisper

guide and

on freezer

basket

guide as shown. Adjust leveling

legs until refrigerator is level.

Check that all four leveling legs

contact floor and support the full

weight of the refrigerator. Door

panels need to be installed before

leveling.

Check that

refrigerator is

level.

C

R

I

T

I

C

A

L

S

T

E

P

leveling

legs

Use 5/16" (8 mm)

socket and ratchet.

7.Use socket wrench to turn leg

levelers on both sides of

refrigerator to the right (clockwise)

until refrigerator weight is

supported by leveling legs. The

rollers should be off the floor.

To avoid cabinet damage, do not

apply more than 50 in/lb (58 cm/kg)

of torque to the leveling legs.

Note: All four leveling legs must

contact the floor to support and

stabilize the full weight of

refrigerator. Rollers are for

moving refrigerator and not for

permanent support.

rear

front

10.Check that both

refrigerator and freezer doors are

aligned and level.

If doors need to be adjusted left

or right or in or out, loosen the

3/8" hex head screws in top

hinges.

If doors need to be adjusted up

or down, remove door stop screw

from bottom door hinge. Remove

locking plate. Use 1/2" open-end

wrench or channel-lock pliers to

turn bushing to the left

(counterclockwise) to move door

up, to the right (clockwise) to

move door down. Check that

doors are level. Replace locking

plate and door stop screw.

You may need to turn bushing

slightly to align locking plate so

that door stop screw can be

inserted.

Page 11

To get the most efficient use

from your new built-in

refrigerator, read your

KitchenAid Use and Care Guide.

Keep Installation Instructions

and Guide close to built-in

refrigerator for easy reference.

Part No. 2006137 Rev. A

© 1999 KitchenAid.

® Registered Trademark/Trademark of

KitchenAid U.S.A., KitchenAid

Canada licensee in Canada

Prepared by KitchenAid, Benton Harbor, Michigan 49022

19. Open refrigerator doors and

remove protective film from door

frame. Recheck water connections at

bottom of refrigerator for leaks.

Attach bottom grille to cabinet with

two screws. Install shelves and bins in

refrigerator and freezer compartments.

20. Set refrigerator and freezer

compartment controls to the midpoint

between “COLD” and “COLDEST.”

Check that the compressor is operating

properly and that all five lights are

working.

screws

bottom grille

HOME APPLIANCES

Printed in U.S.A.

remove 2

screws

top grille decorative

panel

grille panel

cabinet

side trim

cabinet

side trim

louver

assembly

grille panel

screws

15. Panel models: Remove

screws and side trim from one side of

the decorative panel. Insert your panel.

Reattach side trim and screws.

16. Panel models: Slide

decorative panel down to reattach to

top grille.

17. Wraparound stainless steel

models: If additional ceiling clearance is

required for tipping the refrigerator, the

top grille and cabinet side trim can be

removed. Slide the louver assembly up to

remove from the top grille. Remove two

screws from the grille panel and slide the

grille panel down to remove from the

refrigerator. Remove the screws (six each

side) attaching the cabinet side trim to

the refrigerator. Reassemble after dolly

has been removed from refrigerator.

18. If side panels are not used,

go to Step 19.

If built-in area depth is 25"

(63.5 cm) or more, side panels can be

installed inside the side trim or attached

to the outside of the side trim.

• Inside side trim piece: Slide front

edge of routed side panel into trim

piece. Nail rear edge of panel to

support board.

NOTE: KitchenAid is not responsible

for the removal or addition of

molding or decorative panels that

would prevent the refrigerator from

being serviced.

A

B

Panel Wraparound

models (shown) stainless steel

door models

24" 23"

(61 cm) (58.4 cm)

24-5/8" 23-3/8"

(62.5 cm max.) (59.4 cm)

side panel

side trim

support board

rear wall

door

Top view

B

A

®

14. Wraparound stainless steel

door models: go to step 17.

Panel models: Slide decorative panel

assembly up to remove from top grille

assembly.

top grille

assembly

decorative panel

assembly

Page 12

Pièce n° 2006137 Rév. A www.kitchenaid.com

BIEN PENSé, BIEN fabriqué

®

®

Important :

Lire et

conserver ces

instructions.

L’installation

nécessite

l’intervention

de 2 personnes

ou plus.

Risque de basculement

Le réfrigérateur est lourd au

sommet et bascule

facilement lorsqu’ il n’est pas

complètement installé.

Garder les portes fermées

avec un ruban adhésif

jusqu’à l’installation

complète du réfrigérateur.

Deux personnes ou plus

doivent déplacer et installer

le réfrigérateur.

Le non-respect de ces

instructions peut causer un

décès ou une blessure grave.

AVERTISSEMENT

Modèles à panneaux et modèles à portes en

acier inoxydable

91 cm (36 po), 106 cm (42 po),122 cm (48 po)

Réfrigérateurs encastrés

Page 13

Page 2

Avant de

commencer...

Conserver la plaque en carton ou en

contreplaqué de l’emballage sous le

réfrigérateur jusqu’à ce qu’il soit installé à

sa position de service.

Vue avant

A

C

D

G

E

F

Dimensions du produit

* Les dimensions indiquées correspondent

à la situation où les pieds de réglage de

l’aplomb dépassent de 3 mm (1/8 po) audessous des roulettes. Lorsque les pieds

sont totalement déployés de 32 mm

(1 1/4 po) au-dessous des roulettes, ajouter

29 mm (1 1/8 po) à cette dimension.

Important :

Respecter les dispositions de tous les

codes et règlements en vigueur.

C’est à l’installateur qu’incombe la

responsabilité de :

• Respecter les spécifications et dimensions

d’installation.

• Installer le réfrigérateur convenablement.

• Enlever toutes moulures ou panneaux

décoratifs qui préviennent l’entretien du

réfrigérateur.

• Vérifier que tout le matériel nécessaire

à une installation convenable est

disponible:

Tube en cuivre de 6 mm

(1/4 po) avec robinet d’arrêt

Modèles à panneaux seulement :

La dimension ”B” peut être augmentée ou

diminuée de 1,3 cm (1/2 po) en employant la

trousse du panneau décoratif disponible chez

votre marchand.

Pour augmenter: employer la trousse de

panneau (84 po) n° 4378788 (garniture argent)

ou 4378789 (garniture blanche).

Pour diminuer: employer la trousse de

panneau (83 po) n° 4378786 (garniture argent)

ou 4378787 (garniture blanche).

Vue de dessus

H

I

Votre sécurité et celle des autres

sont très importantes.

Nous donnons de nombreux

messages de sécurité importants dans

ce manuel et au sujet de votre

appareil ménager. Assurez-vous de

toujours lire tous les messages de

sécurité et de les respecter.

Ce symbole d’alerte de

sécurité vous signale les

dangers susceptibles de causer un

décès et des blessures graves. Tous

les messages de sécurité seront

précédés du symbole d’alerte de

sécurité et du mot «DANGER» ou

«AVERTISSEMENT». Ces mots

signifient :

Tous les messages de sécurité

identifient le danger et vous indiquent

comment réduire le risque de blessure

et ce qui peut se produire en cas de

non-respect des instructions.

Risque certain de décès ou de

blessure grave si vous ne suivez

pas les instructions.

Risque possible de décès ou de

blessure grave si vous ne suivez

pas les instructions.

Vue latérale

Raccord à compression, 6 mm

(1/4 po)

6 vis à bois n° 8 x 7,6 cm (3 po)

(il peut être nécessaire d’utiliser

des vis plus longues)

2 morceaux de bois de 5 cm x 10 cm x

81 cm (2 po x 4 po x 32 po) min.

(voir page 4)

• Vérifier que la résistance du plancher lui

permet de soutenir le poids du

réfrigérateur (plus de 272 kg/600 lb), des

panneaux de portes et du contenu.

• Fournir une prise de courant

convenablement reliée à la terre.

• Vérifier que l’emplacement d’installation

permet l’ouverture de la porte du

réfrigérateur à au moins 90°.

91 cm (36 po) 106 cm (42 po) 122 cm (48 po)

A 91 cm (36 po) 106 cm (42 po) 122 cm (48 po)

B 212 cm (83 5/8 po)* 212 cm (83 5/8 po)* 212 cm (83 5/8 po)*

B 211 cm (83-1/8 po) 211 cm (83-1/8 po) 211 cm (83-1/8 po)

C 64 cm (25 1/8 po) 64 cm (25 1/8 po) 64 cm (25 1/8 po)

D 60 cm (23 1/2 po) 60 cm (23 1/2 po) 60 cm (23 1/2 po)

E 9 cm (3 1/2 po)* 9 cm (3 1/2 po)* 9 cm (3 1/2 po)*

F 211 cm (83 1/8 po)* 211 cm (83 1/8 po)* 211 cm (83 1/8 po)*

G 61 cm (24 po) 61 cm (24 po) 61 cm (24 po)

H 89 cm (35 po) 104 cm (41 po) 119 cm (47 po)

I 63,5 cm (25 po) 63,5 cm (25 po) 63,5 cm (25 po)

B

Voir

remarque.

AVERTISSEMENT

DANGER

Modèles à panneaux et modèles à portes en acier inoxydable

Avec et sans distributeur

Modèle à portes en

acier inoxydables

Modèle à

panneaux

Important :

• Installateur : Remettre les instructions

d’installation au propriétaire.

• Propriétaire : Conserver les

instructions d’installation pour

référence ultérieure.

• Conserver ces instructions

d’installation pour consultation par

l’inspecteur local des installations

électriques.

Page 14

Page 3

Modèle

Largeur min.

Hauteur min.

Hauteur max.

Profondeur

min.

91 cm (36 po)

90 cm (35 1/2 po)

211,5 cm (83 1/4 po)

215 cm (84 3/4 po)

60 cm (23 1/2 po)

106 cm (42 po)

105 cm (41 1/2 po)

211,5 cm (83 1/4 po)

215 cm (84 3/4 po)

60 cm (23 1/2 po)

122 cm (48 po)

120 cm (47 1/2 po)

211,5 cm (83 1/4 po)

215 cm (84 3/4 po)

60 cm (23 1/2 po)

Caractéristiques et

dimensions de la cavité

d’encastrement

Tolérance de + 3 mm (1/8 po) pour

toutes les dimensions

Pour éviter que le réfrigérateur ne bascule

en cours de service, installer un soffite

massif ou deux cales en bois de 5 cm x

10 cm x 81 cm (2 po x 4 po x 32 po)

recouvrant la largeur du couvercle du

compresseur.

Si le soffite massif est placé à plus de

2,5 cm (1 po) au-dessus du réfrigérateur,

installer deux cales en bois de 5 cm x

10 cm x 81 cm (2 po x 4 po x 32 po) sur le

mur, à 6 mm (1/4 po) au-dessus du

réfrigérateur. La surface inférieure des

cales doit être à 213 cm (84 po) du

plancher. Les cales en bois doivent être

suffisamment longues pour recouvrir

complètement la largeur du couvercle du

compresseur.

Le réfrigérateur encastré peut être

installé :

• en retrait dans l’espace disponible entre les

placards.

• à l’extrémité de la rangée d’armoires; on

utilise alors un panneau latéral pour

recouvrir le côté du réfrigérateur.

Choisir l’une des méthodes et utiliser les

dimensions indiquées. Les dimensions

indiquées laissent un dégagement de 0 cm

(0 po).

Emplacement de

la prise de courant

électrique reliée à la

terre.

Une prise de courant

électrique reliée à la terre

est nécessaire.

Marquer la

position des

poteaux du

colombage sur

le mur arrière,

à 203-229 cm

(80-90 po) audessus du sol.

Plancher : Le plancher doit pouvoir soutenir le

poids du réfrigérateur, des panneaux de portes et

du contenu.

La canalisation

d’arrivée d’eau doit

fournir de l’eau sous

une pression de 103690 kPa (15-100

lb/po2). Effectuer

l’installation

préliminaire de la

canalisation d’eau

avant d’installer le

réfrigérateur.

18 cm

(7 po)

14 cm

(5 1/2 po)

7,6 cm

(3 po)

Installer des supports des

panneaux latéraux (facultatifs) sur

le mur arrière si la profondeur de

la cavité est de 63.5 cm (25 po) ou

plus.

hauteur

profondeur

Emplacement de la

canalisation

d’arrivée d’eau.

25 cm

(10 po)

5 cm (2 po)

Trou de 12 mm

(1/2 po) pour le

passage de la

canalisation (à un

emplacement

quelconque dans la

zone ombragée.

15 cm

(6 po)

20 cm

(8 po)

largeur

18 cm

(7 po)

Dimensions de la cavité

196 cm

(77 po)

Page 15

Page 4

Si les cales sont mises en place avant l’installation du

réfrigérateur, positionner les cales de sorte que leur base soit à

213 cm (84 po) du plancher. Pendant l’installation, soulever le

réfrigérateur afin qu’il y ait un espace de 6 mm (1/4 po) au

plus entre le haut du réfrigérateur et la base des cales

antibasculement.

Si un soffite massif est installé à 2,5 cm (1 po) au-dessus du

réfrigérateur, il n’est pas nécessaire d’installer les cales en bois

pour prévenir le basculement.

Si un soffite massif n’est pas disponible ou si le soffite est

placé à plus de 2,5 cm (1 po) au-dessus de la partie

supérieure, centrer les cales en bois utilisées pour la prévention

du basculement sur le mur arrière à 6 mm (1/4 po) max. audessus du réfrigérateur. À l’aide des vis à bois, visser les cales en

bois aux poteaux du colombage mural - veiller à ce que les vis

pénètrent dans les poteaux du colombage d’au moins 3,8 cm

(1 1/2 po) et à ce que la surface frontale des cales en bois soit

située à au moins 5 cm (2 po) au-delà de la surface arrière du

couvercle du compresseur du réfrigérateur.

Prévention du basculement

Rayon de basculement

Remarque : Il faut ajouter la hauteur des roues du chariot

au rayon de basculement, le cas échéant.

Rayon de basculement

avant/arrière

Rayon de basculement

latéral

Taille A B

91 cm (36 po) 222 cm (87 1/4 po) 230 cm (90 1/2 po)

106 cm (42 po) 222 cm (87 1/4 po) 236 cm (93 po)

122 cm (48 po) 222 cm (87 1/4 po) 244 cm (96 po)

A

B

A

B

C

D

E

F

91 cm

(36 po)

98 cm

(38-1/2 po)

92 cm

(36-1/16 po)

110 cm

(43-1/2 po)

102 cm

(40 po)

50 cm

(19-3/4 po)

37 cm

(14-1/2 po)

106 cm

(42 po)

104 cm

(41 po)

97 cm

(38 po)

119 cm

(47 po)

108 cm

(42 9/16 po)

59 cm

(23-1/4 po)

44 cm

(17-1/4 po)

122 cm

(48 po)

110 cm

(43 1/2 po)

102 cm

(40 po)

128 cm

(50 1/2 po)

115 cm

(45 1/4 po)

68 cm

(26-3/4 po)

50 cm

19-3/4 po)

L’emplacement d’installation doit permettre

l’ouverture des portes à un angle de 90° au

moins. Laisser un espace d’au moins 11,4 cm

(4 1/2 po) entre le côté du réfrigérateur et le

mur formant l’angle.

Deux cales en

bois de 5 cm x

10 cm x 81 cm

(2 po x 4 po x 32

po).

Fixer les cales en

bois aux poteaux

du colombage

mural avec six vis

à bois n° 8 x

7,6 cm (3 po) ou

plus longues.

Les cales en bois

utilisées doivent

être assez longues

pour couvrir

totalement la

largeur du

couvercle du

compresseur.

6 mm (1/4 po) max.

5 cm

(2 po) min.

mur

arrière

Devant du réfrigérateur

Porte du

congélateur

Porte du

réfrigérateur

130°

C

D

B

A

Dimensions pour le pivotement des portes

90°

130°

90°

E

F

Page 16

Couleur Numéro de kit

Aluminium mat 4387989

Blanc 4387990

2. Kits de poignée de porte prolongée

Deux kits, contenant une poignée de porte de congélateur et une poignée de porte

de réfrigérateur sont disponibles par l’entremise de votre concessionnaire KitchenAid

ou en téléphonant à Pièces et Accessoires Whirlpool au 1-800-442-9991. Utiliser les

poignées de porte prolongées lorsqu’un dégagement supplémentaire pour les doigts

est nécessaire entre la poignée de la porte et le panneau personnalisé. Suivre les

instructions du kit pour l’installation des poignées de porte.

C F H

D

G

I

E

Panneaux de portes du

congélateur

(avec distributeur)

Poids

maximal

combiné des

deux

panneaux :

13,5 kg

(30 lb)

Poids maximal

combiné des

deux

panneaux :

13,5 kg (30 lb)

Panneaux de

portes du

congélateur

(sans

distributeur)

Poids

maximal

13,5 kg

(30 lb)

Panneau de porte

du réfrigérateur

Poids maximal :

23 kg (50 lb)

A

B*

Panneau de la grille supérieure

[poids max. : 4,5 kg (10 lb)]

Page 5

Pièces à

commander

séparément ou

à faire fabriquer

sur mesure

1. Ensembles de panneaux

Quatre ensembles de panneaux de portes et

de grille supérieure en acrylique coloré ou en

acier inoxydable sont disponibles de votre

concessionnaire KitchenAid ou en

téléphonant à Pièces et Accessoires Whirlpool

au 1-800-442-9991. Utiliser les instructions

d’installation fournies avec chaque ensemble

pour l’installation des panneaux.

Panneaux - Numéros des ensembles

Taille

Blanc

Noir

Amande

Acier inoxydable

91 cm (36 po)

4318635

4318632

4318638

4318641

91 cm (36 po)

4378650

4378653

4378656

4378659

106 cm (42 po)

4318636

4318633

4318639

4318642

106 cm (42 po)

4378651

4378654

4378657

4378660

122 cm (48 po)

4318637

4318634

4318640

4318643

122 cm (48 po)

4378652

4378655

4378658

4378661

3. Panneaux personnalisés

Le poids des panneaux personnalisés NE

doit PAS dépasser les valeurs indiquées.

L’installation de panneaux dont le poids

dépasse la limite indiquée peut être la

cause de dommages pour le produit.

Les ensembles de panneaux ne sont pas

requis pour les modèles à “panneaux

installés à l’usine” ou les modèles à portes

en acier inoxydable.

Modèle Sans distributeur Avec distributeur

Taille

91 cm

(36 po)

106 cm

(42 po)

122 cm

(48 po)

A

82 cm

(32 3/8 po)

97 cm

(38 3/8 po)

113 cm

(44 3/8 po)

C

36 cm

(14 1/4 po)

43 cm

(16 3/4 po)

49 cm

(19 1/4 po)

D

60 cm

(23 7/16 po)

60 cm

(23 7/16 po)

60 cm

(23 7/16 po)

E

87 cm

(34 7/16 po)

87 cm

(34 7/16 po)

87 cm

(34 7/16 po)

F

36 cm

(14 1/4 po)

43 cm

(16 3/4 po)

49 cm

(19 1/4 po)

H

49 cm

(19 1/4 po)

58 cm

(22 3/4 po)

67 cm

(26 1/4 po)

G

179 cm

(70 7/16 po)

179 cm

(70 7/16 po)

179 cm

(70 7/16 po)

I

179 cm

(70 7/16 po)

179 cm

(70 7/16 po)

179 cm

(70 7/16 po)

B*

15 cm

(6 po)

15 cm

(6 po)

15 cm

(6 po)

REMARQUE : Tolérance de + 1,5 mm

(1/16 po) pour les dimensions indiquées.

Les panneaux dont l’épaisseur est

supérieure à 6 mm (1/4 po) doivent faire

l’objet d’un usinage. Lors de l’emploi de

panneaux déjà amincis par usinage,

ajouter

1,5 mm (1/16 po) aux dimensions

indiquées.

Si l’épaisseur des panneaux est inférieure à

6 mm (1/4 po), installer un panneau de

remplissage entre les portes et les panneaux

décoratifs.

*La dimension “B” peut augmenter ou diminuer de 1,3 cm (1/2 po) si les trousses de panneaux décoratifs indiquées

à la page 2 sont utilisées.

Page 17

Page 6

Dimensions pour

l’usinage à la

périphérie des

panneaux

Vue latérale

6 mm

(1/4 po)

max.

panneau

Vue de l’extrémité - côté poignée du panneau

panneau

poignée

5 cm

(2 po)

min.

6 mm

(1/4 po) max.

Panneaux

personnalisés

d’épaisseur supérieure

à 6 mm (1/4 po) :

Amincir par usinage à la

toupie sur toute la

longueur ou à des

emplacements choisis

du côté poignée du

panneau, sur 8,25 cm

(3 1/4 po).

Épaisseur :

Minimum 12 mm

(1/2 po) pour

empêcher le

gauchissement.

Largeur et hauteur :

selon le type

d’installation.

Encoches pour la

plinthe en retrait (le

cas échéant).

Déterminer la hauteur

du réfrigérateur installé

avant de découper les

encoches.

Si le panneau latéral doit s’engager dans une

garniture latérale, et si l’épaisseur du panneau

latéral est supérieure à 6 mm (1/4 po), amincir

par usinage le bord avant du panneau pour qu’il

puisse passer dans la pièce de garniture.

tringle de clouage et

support du panneau latéral

pièce de garniture latérale

Vue de l’extrémité de la pièce

de garniture latérale

4 mm

(5/32 po)

6 mm

(1/4 po)

1,5 mm

(1/16 po)

5,5 mm

(7/32 po)

10 mm (13/32 po)

tringle

d’appui

tringle

d’appui

porte

porte

3. Panneaux latéraux

porte

panneau latéral hors de

la pièce de garniture

latérale, et en retrait.

8,25 cm

(3 1/4 po)

min.

A

B

C

Modèle

A

B

C

91 cm

(36 po)

91 cm

(36 po)

90 cm

(35 1/2 po)

89 cm

(35 po)

106 cm

(42 po)

106 cm

(42 po)

105 cm

(41 1/2 po)

104 cm

(41 po)

122 cm

(48 po)

122 cm

(48 po)

120 cm

(47 1/2 po)

119 cm

(47 po)

63,5 cm

(25 po)

61,3 cm

(24 1/8 po)

59,7 cm

(23 1/2 po)

panneau latéral

hors de la pièce

de garniture latérale.

19 mm

(3/4 po)

min.

panneau latéral engagé

dans la pièce de garniture

latérale.

Modèles à panneaux

Fixer la tringle

d’appui au

moyen

de vis ou d’un

adhésif

compatible avec

l’aluminium et le

bois.

Amincir par usinage le bord avant de la

tringle d’appui ou fixer une tringle de

6 mm (1/4 po) pour rétention dans la pièce

de garniture latérale du placard.

Page 18

Page 7

Modèles à portes en acier inoxydable

Si le panneau latéral doit s’engager dans une

garniture latérale, et si l’épaisseur du panneau

latéral est supérieure à 6 mm (1/4 po), amincir

par usinage le bord avant du panneau pour qu’il

puisse passer dans la pièce de garniture.

3. Panneaux latéraux

Vue de l’extrémité de la pièce

de garniture latérale

Épaisseur :

Minimum 12 mm

(1/2 po) pour

empêcher le

gauchissement.

Largeur et hauteur :

selon le type

d’installation.

Encoches pour la

plinthe en retrait (le

cas échéant).

Déterminer la hauteur

du réfrigérateur installé

avant de découper les

encoches.

tringle de clouage et

support du panneau latéral

pièce de garniture latérale

Modèle

A

B

C

91 cm

(36 po)

91 cm

(36 po)

90 cm

(35 1/2 po)

89 cm

(35 po)

106 cm

(42 po)

106 cm

(42 po)

105 cm

(41 1/2 po)

104 cm

(41 po)

122 cm

(48 po)

122 cm

(48 po)

120 cm

(47 1/2 po)

119 cm

(47 po)

panneau latéral hors de

la pièce de garniture

latérale, et en retrait.

panneau latéral

hors de la pièce

de garniture latérale.

panneau latéral engagé

dans la pièce de garniture

latérale.

Fixer la tringle

d’appui au

moyen

de vis ou d’un

adhésif

compatible avec

l’aluminium et le

bois.

Amincir par usinage le bord avant de la

tringle d’appui ou fixer une tringle de

6 mm (1/4 po) pour rétention dans la pièce

de garniture latérale du placard.

4 mm

(5/32 po)

6 mm

(1/4 po)

1,5 mm

(1/16 po)

4,8 mm

(3/16 po)

10 mm (13/32 po)

porte

porte

porte

tringle

d’appui

tringle

d’appui

A

B

C

63,5 cm

(25 po)

59,4 cm

(23 3/8 po)

57,9 cm

(22 13/16 po)

Page 19

Spécifications de

l’alimentation

électrique

et en eau

Une prise de courant de 120 V, 60 Hz, CA

seulement, 15 ou 20 A, avec fusible, doit être

disponible. On recommande l’emploi d’un

fusible temporisé ou d’un disjoncteur. On

recommande également que l’appareil soit

alimenté par un circuit distinct n’alimentant

que cet appareil.

Cet appareil est équipé d’un cordon

d’alimentation doté d’une fiche de

branchement à 3 broches. Pour minimiser le

risque de choc électrique, le cordon doit être

branché sur une prise de courant murale

correspondante, à 3 broches, reliée à la terre,

conformément aux dispositions du Code

National Électrique, ANSI/NFPA 70 —

dernière édition* ou du Code canadien des

installations électriques C22.1-1982 et C22.2

n° 01982 (ou dernière édition)**, et de tous

les codes locaux et règlements en vigueur.

Spécifications de l’alimentation

électrique

Spécifications de l’alimentation

en eau

Utiliser uniquement un tube en cuivre de

6 mm (1/4 po) pour l’arrivée d’eau.

Ne pas installer le tube en cuivre dans un

endroit où la température peut s’abaisser

à moins de 0 °C (32 °F).

Avant de connecter le tube en cuivre au

réfrigérateur, le rincer en y faisant passer

au moins 1,9 L(2 pintes) d’eau pour

éliminer tous les débris qui ont pu s’y

introduire.

Ne pas serrer excessivement la bride ou

le raccord, ce qui pourrait écraser le tube

en cuivre.

Rechercher les fuites autour du robinet

de prise en charge.

Pose préliminaire de la canalisation

d’arrivée d’eau :

3. FERMER le robinet principal

d’alimentation. OUVRIR le robinet le plus

proche assez longtemps pour purger toute

l’eau des canalisations.

4. Canalisation d’eau froide verticale : Utiliser

une perceuse électrique reliée à la terre ou

une perceuse manuelle pour percer un trou

de 4,5 mm (3/16 po) à un emplacement

facilement accessible de la canalisation.

Canalisation d’eau froide horizontale :

Utiliser une perceuse électrique reliée à la

terre ou une perceuse manuelle pour percer

un trou de 4,5 mm (3/16 po) dans la partie

supérieure de la canalisation. Ainsi, des

sédiments ne s’accumuleront pas dans le

robinet de prise en charge.

5. Placer le joint sur le trou

percé de la canalisation. Faire

tourner la manette du robinet

de prise en charge dans le sens

horaire pour faire dépasser la

pointe perçante d’un

maximum de 4,5 mm

(3/16 po). Aligner la

pointe perçante

avec le trou percé

dans la canalisation. Placer les

deux moitiés de la bride de

fixation du robinet de prise en charge contre

la canalisation. Faire tourner la manette du

robinet dans le sens horaire jusqu’à ce que la

pointe perçante pénètre dans le trou de la

canalisation et soit fermement en place. Le

robinet de prise en charge n’est pas à la

position de fermeture. Serrer l’écrou autour

de la tige de commande. Serrer

uniformément et fermement les vis de

bridage, afin que le joint établisse une

connexion étanche. Ne pas serrer

excessivement; le tube en cuivre pourrait

s’écraser.

6. Veiller à ce que les

deux extrémités du

tube en cuivre soient

coupées à l’équerre.

Enfiler l’écrou de

compression et la virole sur le

tube en cuivre. Enfoncer complètement

l’extrémité du tube en cuivre dans l’ouverture

du robinet. Serrer l’écrou de compression sur

le raccord avec une clé à molette. Ne pas

serrer excessivement.

7. Ouvrir le robinet principal d’alimentation.

Inspecter pour rechercher les fuites. Faire

tourner la manette du robinet de prise en

charge dans le sens antihoraire et laisser de

l’eau s’écouler à travers le tube en cuivre dans

un seau. Faire tourner la manette dans le sens

horaire pour interrompre l’écoulement de

l’eau à travers le tube en cuivre.

8. Acheminer le tube en cuivre jusqu’à la

zone d’installation du réfrigérateur.

On peut obtenir un exemplaire des codes

mentionnés à l’adresse suivante :

*National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts, 02269*

**Association canadienne de normalisation

178 Rexdale Boulevard

Etobicoke, Ontario M9W 1R3

La canalisation d’eau alimentant le

réfrigérateur doit fournir de l’eau sous une

pression de 103-690 kPa (15-100 lb/po2).

Calcul de la longueur nécessaire de la

section d’un tube en cuivre de 6 mm

(1/4 po) de diam. ext. :

1. Identifier à proximité du réfrigérateur une

canalisation d’eau FROIDE verticale de

1,2 cm à 3,2 cm (1/2 po à 1 1/4 po). On

peut également utiliser une canalisation

d’eau FROIDE horizontale si les instructions

de l’étape 4 sont scrupuleusement

observées.

2. Mesurer la distance entre la canalisation

d’eau froide et le réfrigérateur. Ajouter

61 cm (24 po) à cette dimension.

écrou de compression

virole

Page 8

Risque de choc électrique

Brancher l’appareil sur une prise

à 3 alvéoles, reliée à la terre.

Ne pas enlever la broche de

liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de

rallonge.

Le non-respect de ces

instructions peut causer un

décès, un incendie ou un choc

électrique.

AVERTISSEMENT

Si les codes en vigueur le permettent et si

un fil distinct de liaison à la terre est utilisé,

on recommande qu’un électricien qualifié

détermine que le conducteur de liaison à la

terre est adéquat.

Ne pas utiliser une canalisation de gaz pour

la liaison à la terre.

En cas de doute au sujet de la liaison à la

terre de cet appareil, consulter un

électricien qualifié.

Veiller à ce qu’aucun fusible ne soit installé

en série dans le conducteur neutre ou le

conducteur de liaison à la terre.

C’est au client qu’incombe la responsabilité

de :

Contacter un électricien qualifié pour

l’installation.

S’assurer que l’installation électrique est

adéquate et conforme aux dispositions du

Code National Électrique, ANSI/NFPA 70 —

dernière édition* ou du Code canadien des

installations électriques C22.1-1982 et

C22.2 n° 01982 (ou dernière édition)**, et

tous les codes et règlements locaux.

cordon d’alimentation

d’électricité

broche de

liaison à la

terre

bride de

retenue

fiche de branchement

à 3 broches, reliée à la

terre

prise de courant murale à

3 broches, reliée à la terre

Page 20

Étapes de

l’installation

Ne pas abaisser le réfrigérateur sur la base

utilisée pour l’expédition, lors de

l’extraction de la base.

Ne pas ôter le film protecteur avant que le

réfrigérateur soit à la position de service.

Les quatre pieds de réglage de l’aplomb

doivent être en contact avec le sol et

soutenir la totalité du poids du

réfrigérateur pour le stabiliser.

Conserver la pièce de carton ou de

contreplaqué d’expédition sous le

réfrigérateur jusqu’à ce qu’il soit installé à

la position de service.

Pièces fournies pour

l’installation :

• grille de ventilation basse

• Sachet de pièces

Vérifier que toutes les pièces sont présentes.

Page 9

tube de cuivre

vers robinet

d’arrivée

angle inférieur

du réfrigérateur,

côté droit

Vérifier que la canalisation d’arrivée d’eau

a été purgée. Voir page 7.

6.Tirer la canalisation d’arrivée d’eau par-

dessous le réfrigérateur. Former avec

précaution une extrémité en forme de

crochet de 9 cm (3 1/2 po) au moins (180º)

dans la canalisation d’arrivée d’eau. Ne pas

plier la canalisation d’arrivée d’eau. Ôter le

capuchon du robinet.

4.Pousser le

commutateur

d’alimentation situé en

haut de la caisse à la

position d’arrêt (OFF).

Brancher le cordon

d’alimentation sur une

prise de courant électrique

reliée à la terre. Fixer la bride de

retenue sur la prise de courant avec

la vis qu’on trouve dans le sachet de

petites pièces.

bride de

retenue

prise de

courant reliée

à la terre

cordon

d’alimentation

3.Avant de déplacer le réfrigérateur sur le

plancher de la maison, sur un chariot, placer

sur le plancher les sections de l’emballage de

carton. Approcher le réfrigérateur près de

l’ouverture de l’encastrement où il sera

installé.

2.Mettre le chariot sous le côté

congélateur du réfrigérateur et arrimer le

réfrigérateur avec la sangle du chariot, sans

trop serrer. Insérer les cornières en carton

pour protéger les angles et les poignées entre

la sangle et le réfrigérateur. Serrer

prudemment la sangle en vérifiant que les

pièces de garniture latérales et les poignées

sont protégées.

écrou de

compression

de 6 mm (1/4 po)

virole

Remarque : Il est plus facile de connecter la

canalisation d’eau au robinet si le robinet est

enlevé du support de montage. Ôter les

deux vis qui retiennent le robinet et tirer

vers l’avant. Connecter la canalisation d’eau.

Réinstaller le robinet sur le support de

montage.

Ouvrir le robinet d’arrivée d’eau (position

OPEN). Placer le commutateur

d’alimentation électrique du réfrigérateur à

la position de marche (ON). Attendre

quelques minutes. Inspecter la connexion de

la canalisation d’eau.

canalisation en cuivre,

vers le robinet

5.Mettre une plaque en contreplaqué ou

en carton sous le réfrigérateur. Retirer le

chariot de manutention. Ouvrir les portes de

l’appareil et ôter toutes les boîtes, les sachets

de pièces et les matériaux d’emballage

qu’on trouve dans le compartiment de

réfrigération et le compartiment de

congélation. Ne pas ôter la pellicule

protectrice.

Pour éviter d’endommager le plancher,

s’assurer que les pieds de mise d’aplomb

sont soulevés (ne touchent pas le

plancher) et que le réfrigérateur repose

sur les roulettes avant le déplacement.

Insérer le réfrigérateur dans l’ouverture

d’encastrement, en ligne droite et

uniformément. Vérifier que :

• le tube en cuivre n’est pas déformé, écrasé,

etc.

• le cordon d’alimentation électrique est au

sommet du réfrigérateur, près du

couvercle.

1.Enlever et conserver le sachet de

documents et le sachet de pièces fixé sur la

porte du réfrigérateur avec du ruban adhésif.

Ôter les quatre brides (deux de chaque côté)

fixant la base d’expédition au-dessous du

réfrigérateur.

Ne pas ôter les rubans adhésifs et

entretoises qui immobilisent les portes

avant que le réfrigérateur ait été

solidement installé à la position de service

finale.

Risque de basculement

Le réfrigérateur est lourd au

sommet et bascule facilement

lorsqu’ il n’est pas complètement

installé.

Garder les portes fermées avec

un ruban adhésif jusqu’ à

l’installation complète du

réfrigérateur.

Deux personnes ou plus doivent

déplacer et installer le

réfrigérateur.

Le non-respect de ces

instructions peut causer un

décès ou une blessure grave.

AVERTISSEMENT

cornière

en

carton

sur les

poignées

cornières en carton

sur les pièces de

garniture latérales

vis

Enfiler l’écrou de compression, puis la virole

sur la canalisation d’arrivée d’eau. Enfoncer

complètement la canalisation d’arrivée d’eau

dans l’ouverture du robinet. Serrer l’écrou de

compression sur le robinet. Ne pas serrer

excessivement.

Page 21

Deux cales en bois

de 5 cm x 10 cm x

81 cm

(2 po x 4 po x

32 po).

Butée

antibasculement :

6 mm (1/4 po) max.

au-dessus du

réfrigérateur

couvercle

5 cm

(2 po)

Fixer ces cales

en bois aux

poteaux du

colombage

mural avec six

vis à bois n° 8 x

7,6 cm (3 po)

ou

plus longues.

Les cales doivent être suffisamment longues

pour couvrir entièrement la largeur du

couvercle du compresseur.

panneau

décoratif

Panneau de

remplissage

nécessaire si

l’épaisseur du

panneau

décoratif est

inférieure à

6 mm (1/4 po).

Si

l’épaisseur

des

panneaux

est

supérieure à

6 mm

(1/4 po),

amincir tous

les bords

par usinage

à la toupie.

poignée

de porte

rondelles

de nylon

Page 10

13.Si un soffite massif est

installé à 2,5 cm (1 po) au-dessus du

réfrigérateur, il n’est pas nécessaire

d’installer des cales en bois

antibasculement.

Si un soffite massif n’est pas

disponible ou si le soffite est placé à

plus de 2,5 cm (1 po) au-dessus du

réfrigérateur, trouver les poteaux du

colombage mural dans l’ouverture

d’encastrement du réfrigérateur.

Centrer une cale en bois sur le mur

arrière à 6 mm (1/4 po) max., audessus du réfrigérateur. À l’aide des vis

à bois, visser la cale en bois aux

poteaux du colombage mural - veiller

à ce que les vis pénètrent dans les

poteaux du colombage d’au moins

3,8 cm (1 1/2 po). Fixer la deuxième

cale sur l’avant de la première. Les

cales en bois doivent être en surplomb

d’au moins 5 cm (2 po) au-delà de la

surface arrière supérieure du couvercle

du compresseur du réfrigérateur.

10.Vérifier que la porte du

réfrigérateur et celle du congélateur sont

alignées et d’aplomb.

S’il est nécessaire d’ajuster la position

des portes vers la gauche ou vers la

droite, vers l’intérieur ou vers l’extérieur,

desserrer les vis à tête hexagonale de 9

mm (3/8 po) des charnières supérieures.

S’il est nécessaire d’ajuster la position

des portes vers le haut ou vers le bas

ôter la vis de la butée de porte de la

charnière inférieure. Ôter la plaque de

verrouillage. Utiliser une clé à fourches de

12 mm (1/2 po)

ou une pince multiprise

pour faire tourner la douille vers la

gauche (sens antihoraire) pour déplacer

la porte vers le haut, ou tourner vers la

droite (sens horaire) pour déplacer la

porte vers le bas. Vérifier que les portes

sont d’aplomb. Remettre en place la

plaque de verrouillage et la vis de la

butée de porte.

Il peut être nécessaire de tourner la

douille légèrement pour aligner la plaque

de verrouillage de telle sorte que la vis de

la butée de porte puisse être insérée.

11.Réinstaller les poignées des

portes. Vérifier que les deux poignées

de porte sont alignées.

Si les poignées de porte ne sont pas

alignées, desserrer toutes les vis des

poignées et ajuster la position des

poignées de porte vers le haut ou vers

le bas. Serrer les vis.

Si des vis blanches de la porte sont

endommagées, remplacer ces vis par

des vis qu’on trouve dans le sachet de

pièces.

É

T

A

P

E

S

C

R

I

T

I

Q

U

E

S

12.Vérifier que les portes

peuvent s’ouvrir librement. Si les

portes s’ouvrent trop grand, ôter la vis

de la butée de porte de la charnière

inférieure de la porte. Tenir la porte

ouverte à une position inférieure à 90º.

Replacer la vis de la butée de porte

dans la position de butée de 90º dans

la charnière inférieure et serrer la vis.

S’il y a encore une interférence entre le

comptoir et la porte après le réglage, il

peut être nécessaire d’usiner le

panneau du comptoir.

É

T

A

P

E

S

C

R

I

T

I

Q

U

E

É

T

A

P

E

S

C

R

I

T

I

Q

U

E

S

9.

Ouvrir les

portes. Mettre

un niveau en

contact avec

la face

inférieure de

la garniture

de la porte,

aux endroits

indiqués sur

l’illustration.

Ajuster les

pieds de mise d’aplomb, jusqu’à ce que

le réfrigérateur soit d’aplomb. Vérifier

que les quatre pieds sont en contact

avec le sol et soutiennent tout le poids

du réfrigérateur. Il faut que les portes

aient été installées avant cette

opération de réglage de l’aplomb.

Contrôler

l’aplomb du

réfrigérateur.

8.Modèles à portes en acier inoxydable :

passer à l’étape 9.

Ôter tous les rubans adhésifs et entretoises des

portes du réfrigérateur et du congélateur. Ôter

les vis fixant les poignées aux cadres de portes.

Enfiler les panneaux décoratifs des portes dans

les cadres de portes.

Si l’épaisseur des panneaux est inférieure à

6 mm (1/4 po), installer un panneau de

remplissage entre la porte et le panneau

décoratif.

Si l’épaisseur des panneaux est supérieure à

6 mm (1/4 po), amincir tous les bords par

usinage à la toupie.

pieds de

mise

d’aplomb

Utiliser une clé à

cliquet avec une

douille de

8 mm (5/16 po).

arrière

avant

7.Utiliser une clé à douille pour

faire tourner les pieds de réglage de

l’aplomb sur les deux côtés du

réfrigérateur vers la droite (sens

horaire) jusqu’à ce que le poids du

réfrigérateur soit en appui sur les pieds

de réglage de l’aplomb. Les roulettes

ne devraient pas être en contact avec

le plancher.

Pour éviter d'endommager la caisse, ne

pas serrer les pieds de nivellement à un

couple supérieur à 58 cm/kg (50 lb/po)

Remarque : Pour que le réfrigérateur

soit convenablement soutenu et

stable, il faut que les quatre pieds de

réglage de l’aplomb soient en

contact avec le plancher. Les

roulettes servent au déplacement du

réfrigérateur et non à son soutien

permanent.

vis de la butée de porte

(position de 130º)

position

de 90º

charnière inférieure

Page 22

Pour pouvoir utiliser au mieux

ce nouveau réfrigérateur

encastré, lire le guide

d’utilisation et d’entretien

KitchenAid. Conserver les

instructions d’installation et le

guide d’utilisation et d’entretien

près du réfrigérateur encastré,

pour référence.

Pièce nº 2006137 Rév. A

© 1999 KitchenAid.

® Marque déposée de KitchenAid

U.S.A., Emploi licencié par

KitchenAid Canada

Préparé par KitchenAid, Benton Harbor, Michigan 49022

19.Ouvrir les portes de l’appareil et

ôter la pellicule protectrice de l’encadrement

des portes. Inspecter de nouveau les raccords

de connexion de tuyauterie situés en bas du

réfrigérateur pour rechercher les fuites.

Fixer la grille de ventilation de la base avec

deux vis. Installer les étagères et caissons

dans les compartiments de réfrigération et

de congélation.

vis

grille inférieure

APPAREILS MÉNAGERS

Imprimé aux É.-U.

ôter les 2 vis

panneau décoratif de

la grille supérieure

15.Modèles à panneaux : Ôter les vis

et la garniture latérale du panneau sur un

côté du panneau décoratif. Réinstaller la

garniture latérale, et les vis.

16.Modèles à panneaux : Glisser le

panneau décoratif vers le bas pour le fixer de

nouveau à la grille supérieure.

18.Si les panneaux latéraux ne sont

pas utilisés, passer à l’étape 18.

Si la profondeur de la cavité

d’encastrement est de 63,5 cm (25 po) ou

plus, on peut engager les panneaux latéraux

à l’intérieur de la garniture latérale, ou les

fixer à l’extérieur de la garniture latérale.

panneau latéral

garniture

latérale

planchette d’appui

mur arrière

porte

Vue de dessus

B

A

• Pièce de garniture latérale interne :

Enfiler le bord avant aminci du panneau

latéral dans la pièce de garniture. Clouer le

bord arrière du panneau sur la planchette

d’appui.

REMARQUE : KitchenAid n’est pas

responsable de l’enlèvement de moulures

ou de panneaux décoratifs qui

préviendraient l’entretien du

réfrigérateur.

20.Régler les thermostats du

réfrigérateur et du congélateur au point

médian entre les repères FROID et

TEMPÉRATURE MINIMALE. Vérifier que le

compresseur et les cinq lampes fonctionnent

normalement.

A

B

Modèles à Modèles à portes

panneaux (illustrés) en acier inoxydable

61 cm 58,4 cm

(24 po) (23 po)

62,5 cm max. 59,4 cm

(24 5/8 po) (23 3/8 po)

®

14. Modèles à portes en acier

inoxydable : passer à l’étape 17.

Modèles à panneaux : Faire glisser le

panneau décoratif vers le haut pour le retirer

du montage de la grille supérieure.

montage de la

grille supérieure

panneau décoratif

de la grille

supérieure

Panneau de

la grille

Garniture

latérale de la

caisse

Garniture