Page 1

I_Jtc enAid _

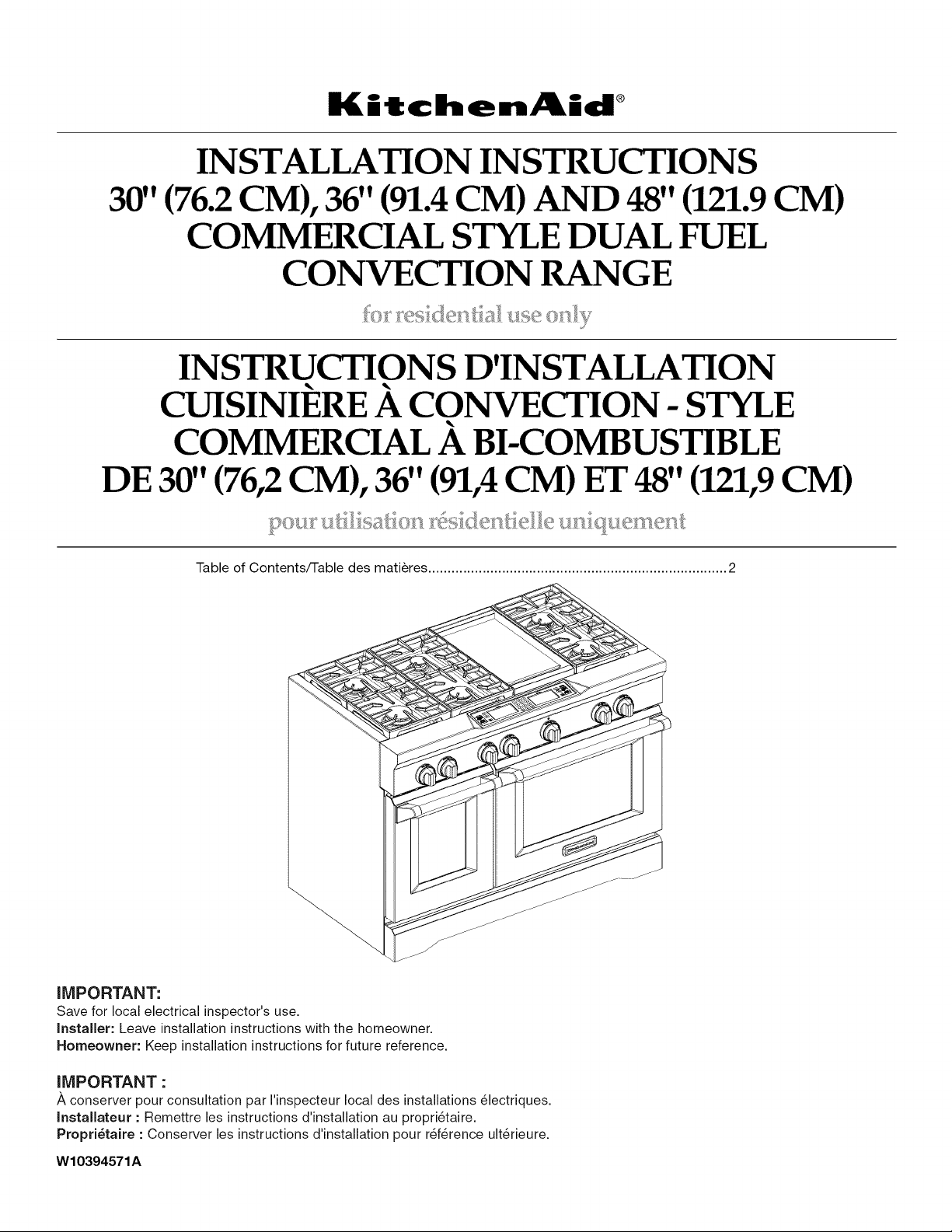

INSTALLATION INSTRUCTIONS

30"(76.2 CM), 36"(91.4 CM) AND 48"(121.9 CM)

COMMERCIAL STYLE DUAL FUEL

CONVECTION RANGE

INSTRUCTIONS D'INSTALLATION

CUISINIERE A CONVECTION- STYLE

COMMERCIAL A BI-COMBUSTIBLE

DE 30"(76,2 CM), 36"(91,4 CM) ET48" (121,9CM)

Table of Contents/Table des matieres ............................................................................. 2

iMPORTANT:

Save for local electrical inspector's use.

installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

iMPORTANT :

,&,conserver pour consultation par I'inspecteur local des installations 61ectriques.

Jnstallateur : Remettre les instructions d'installation au propri6taire.

Propri6taire : Conserver les instructions d'installation pour r6f@ence ult@ieure.

W10394571A

Page 2

TABLEOF CONTENTS

TABLEDES MATIERES

RANGE SAFETY ............................................................................. 3

INSTALLATION REQUIREMENTS ................................................ 4

Tools and Parts ............................................................................ 4

Location Requirements ................................................................ 5

Water Filtration System Location Requirements ......................... 7

Water Supply Requirements ........................................................ 7

Electrical Requirements- U.S.A. Only ......................................... 7

Electrical Requirements - Canada Only ....................................... 8

Gas Supply Requirements ........................................................... 9

INSTALLATION INSTRUCTIONS ................................................ 10

Unpack Range............................................................................ 10

Install Optional Backguard ......................................................... 11

Install Anti-Tip Bracket ............................................................... 11

Electrical Connection - U.S.A. Only ........................................... 12

Install Water Filtration System ................................................... 14

Make Gas Connection ............................................................... 15

Verify Anti-Tip Bracket Location ................................................ 16

Level Range................................................................................ 16

Install Grill Grease Trays ............................................................ 16

Install Griddle ............................................................................. 17

Electronic Ignition System ......................................................... 17

Reinstall Kick plate ..................................................................... 19

Complete Installation................................................................. 19

GAS CONVERSIONS .................................................................... 20

LP Gas Conversion .................................................................... 20

Natural Gas Conversion ............................................................. 22

Strip Circuits ............................................................................... 24

Wiring Diagrams ......................................................................... 25

SI_CURITI_ DE LA CUISINIF:RE ................................................... 30

EXIGENCES D'INSTALLATION ................................................... 31

Outillage et pieces ...................................................................... 31

Exigences d'emplacement ......................................................... 32

Exigences d'emplacement du systeme

de filtration de I'eau .................................................................... 34

Specifications de I'alimentation en eau ..................................... 35

Specifications de I'installation electrique .................................. 35

Specifications de I'alimentation en gaz ..................................... 35

INSTRUCTIONS D'INSTALLATION ............................................. 37

Deballage de la cuisiniere .......................................................... 37

Installation du dosseret facultatif ............................................... 37

Installation de la bride antibasculement .................................... 37

Installation du systeme de filtration de I'eau .............................. 38

Raccordement au gaz ................................................................ 40

Verification de I'emplacement de la bride

antibasculement ......................................................................... 40

Reglage de I'aplomb de la cuisiniere ......................................... 40

Installation des plateaux &graisse du gril.................................. 41

Installation de la plaque a frire ................................................... 42

Systeme d'allumage electronique .............................................. 42

Reinstallation du garde-pieds .................................................... 44

Achever I'installation .................................................................. 44

CONVERSIONS POUR CHANGEMENT DE GAZ....................... 45

Conversion pour I'alimentation au propane ............................... 45

Conversion pour I'alimentation au gaz naturel .......................... 47

Schemas des circuits du four .................................................... 50

Schemas de c&blage .................................................................. 51

2

Page 3

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death,

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance,

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or

the gas supplier,

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

In the State of Massachusetts, the following installation instructions apply:

m Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

m If using a ball valve, it shall be a T-handle type.

m A flexible gas connector, when used, must not exceed 3 feet.

Page 4

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to wail behind range.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

INSTALLATION REQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure • 1/4",3/8",%e" nut drivers

• #2 Phillips screwdriver • 3/W'carbide tip masonry bit

• %" x 41¼'' flat-blade • Marker or pencil

screwdriver

• Level resistant to LP gas

• Drill • Noncorrosive leak-detection

• Wrench or pliers

• Pipe wrench • Tubing cutter

• Adjustable wrench or For LP/Natural Gas

8/8"wrench Conversions

• 3/8"drive ratchet • Adjustable wrench

• 1/8"drill bit • 1/2"deep-well socket

• 1%6"combination wrench • 7 mm nut driver

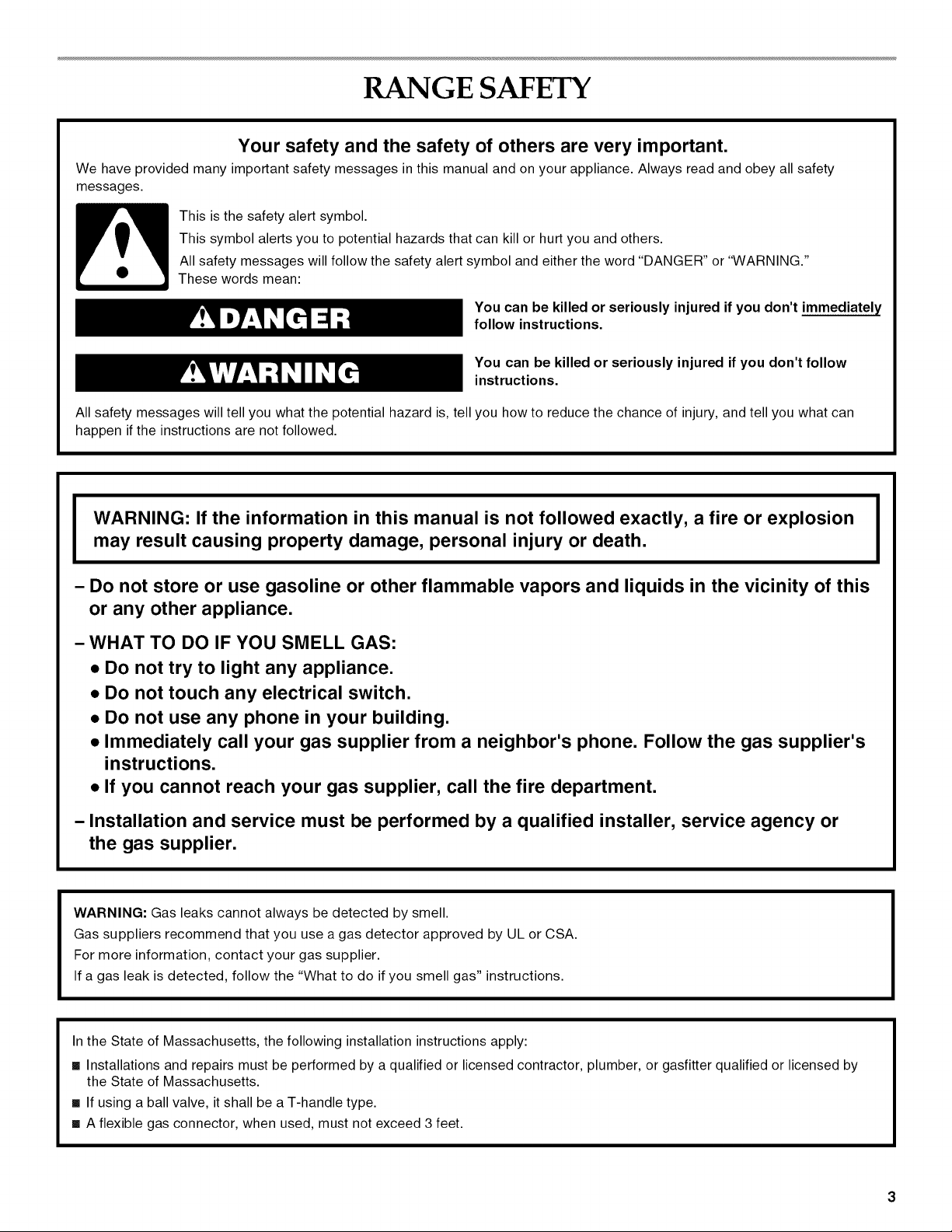

Parts supplied

Check that all parts are included.

• Anti-tip bracket kit

A. Anti-tip bracket

B. #8-18 x 111Phillips head screws (4)

NOTE: Anti-tip bracket must be securely mounted to

subfloor. Thickness of flooring may require longer screws to

anchor bracket to subfloor. Longer screws are available from

your local hardware store. See "Install Anti-Tip Bracket"

section.

Gas pressure regulator

• Burner grates

• Burner bases and caps

• Pipe-joint compound

solution

• Masking tape

• Grill grate (on grill models)

• Wave tray (on grill models)

• Flame spreader (on grill models)

• Burner assembly (on grill models)

• Grease trays (2) (on grill models)

• Griddle drip tray (on griddle models)

• Grill drip tray (on grill models)

• Island trim

• LP orifice package (W10393255)

• Conversion label (VV10393342)

NOTE: The cooktop is manufactured for use with Natural gas.

To convert to LP gas, see the "Gas Conversions" section.

Additional Parts Supplied on Steam-Assist Models

• Model W10049700 water filter kit

• 1¼.to 1¼.water supply union

Parts needed

• Power supply cord kit:

• 30" (76.2 cm) and 36" (91.4 cm) models - A UL listed

40 amp power supply cord kit

• 48" (121.9 cm) models - A UL listed 50 amp power supply

cord kit marked for use with nominal 13/8"(34.93 mm)

diameter connection openings

• A UL listed strain relief

• UL listed wire connectors

All models must be installed with a backguard if installing at

zero clearance to a combustible backwall. See "Cabinet

Dimensions" in the "Location Requirements" section for

installation requirements.

• 30" (76.2 cm) Adjustable Backguard

Order Part Number 8285148

• 36" (91.4 cm) Adjustable Backguard

Order Part Number 8284756

• 48" (121.9 cm) Adjustable Backguard

Order Part Number 8284755

• 9" (22.9 cm) Backguard for 30" (76.2 cm) Ranges

Order Part Number W10115773

• 9" (22.9 cm) Backguard for 36" (91.4 cm) Ranges

Order Part Number W10115776

• 9" (22.9 cm) Backguard for 48" (121.9 cm) Ranges

Order Part Number W10115777

Page 5

• 22"(55.9cm)BackguardwithShelffor30"(76.2cm)

Ranges

OrderPartNumberW10225950

• 22"(55.9cm)BackguardwithShelffor36"(91.4cm)

Ranges

OrderPartNumberW10225949

• 22"(55.9cm)BackguardwithShelffor48"(121.9cm)

Ranges

OrderPartNumberW10225948

Toorder,seethe"AssistanceorService"sectionoftheUse

andCareGuide.

Additional Parts Needed on Steam-Assist Models

• Tubing staples/retainers

• 1¼,,O.D. flexible codes approved water supply tubing (to

make water connection)

• Water connection device (to connect 1¼.O.D. tubing to

water source). Check local codes for type of connection

required.

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See "Electrical Requirements" and

"Gas Supply Requirements" sections.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

High Altitude Conversion

To convert the cooktop for elevations above 6,560 ft (1999.5 m),

order a High Altitude Conversion Kit.

• Part Number W10394296 - LP high altitude

• Part Number W10394295 - Natural gas high altitude

To order, see the "Assistance or Service" section of the Use and

Care Guide.

• Grounded electrical supply is required. See "Electrical

Requirements" section.

• Proper gas supply connection must be available. See "Gas

Supply Requirements" section.

• Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C). Use an

insulated pad or 1¼,,(0.64 cm) plywood over carpet and under

range if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194 ° (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-A240-1atest edition, or with local

codes.

Mobile home installations require:

• When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the standards

listed above.

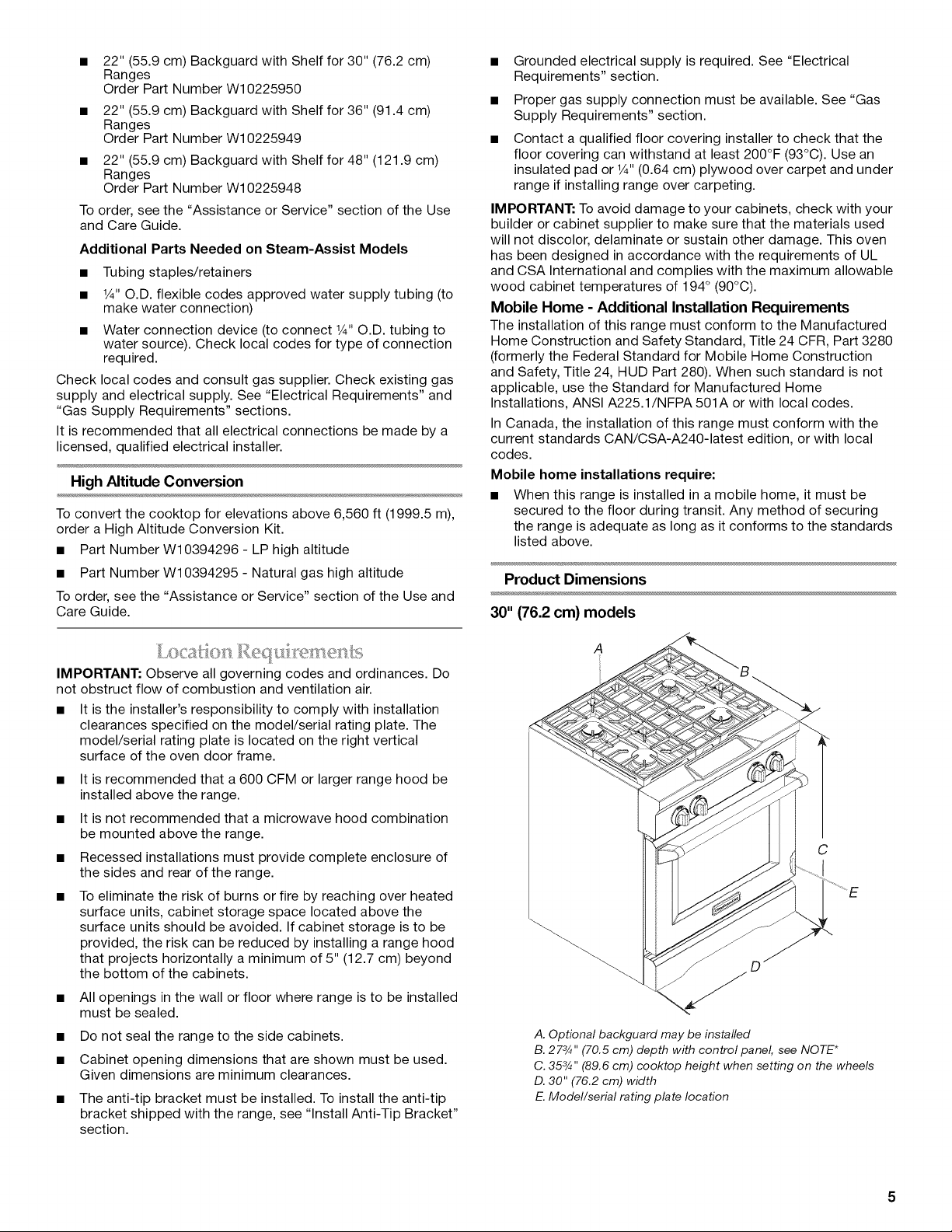

Product Dimensions

30" (76.2 cm) models

IiOQIl:J< I '_> "

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

• It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located on the right vertical

surface of the oven door frame.

• It is recommended that a 600 CFM or larger range hood be

installed above the range.

• It is not recommended that a microwave hood combination

be mounted above the range.

• Recessed installations must provide complete enclosure of

the sides and rear of the range.

• To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5 =(12.7 cm) beyond

the bottom of the cabinets.

• All openings in the wall or floor where range is to be installed

must be sealed.

• Do not seal the range to the side cabinets.

• Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

• The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see "Install Anti-Tip Bracket"

section.

A

C

D

A. Optional backguard may be installed

B. 273/4" (70.5 cm) depth with control panel, see NOTE*

C. 353/4" (89.6 cm) cooktop height when setting on the wheels

D. 30" (76.2 cm) width

E.Model/serial rating plate location

Page 6

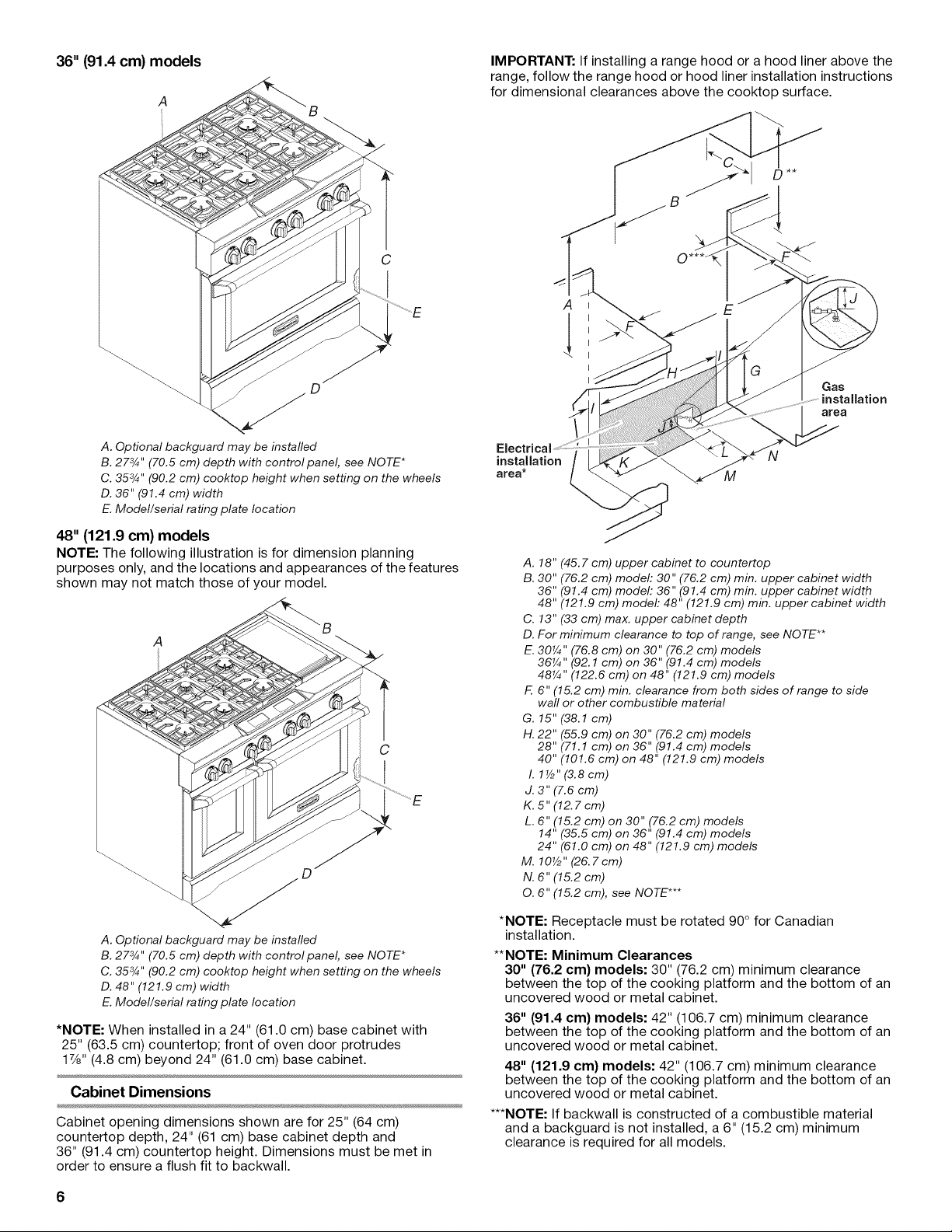

36" (91.4 cm) models

A

IMPORTANT: If installing a range hood or a hood liner above the

range, follow the range hood or hood liner installation instructions

for dimensional clearances above the cooktop surface.

B

C

A

Gas

area

A. Optional backguard may be installed

B. 273/4'' (70.5 cm) depth with control panel, see NOTE*

C. 353/4"(90.2 cm) cooktop height when setting on the wheels

D. 36" (91.4 cm) width

E. Model/serial rating plate location

48" (121.9 cm) models

NOTE: The following illustration is for dimension planning

purposes only, and the locations and appearances of the features

shown may not match those of your model.

A

C

installation

area*

A. 18" (45.7 cm) upper cabinet to countertop

B. 30" (76.2 cm) modeh 30" (76.2 cm) min. upper cabinet width

36" (91.4 cm) modeh 36" (91.4 cm) min. upper cabinet width

48" (121.9 cm) modeh 48" (121.9 cm) min. upper cabinet width

C. 13" (33 cm) max. upper cabinet depth

D. For minimum clearance to top of range, see NOTE**

E. 30¼" (76.8 cm) on 30" (76.2 cm) models

36¼" (92.1 cm) on 36" (91.4 cm) models

48¼" (122.6 cm) on 48" (121.9 cm) models

F. 6" (15.2 cm) min. clearance from both sides of range to side

wall or other combustible material

G. 15" (38.1 cm)

H. 22" (55.9 cm) on 30" (76.2 cm) models

28" (71.1 cm) on 36" (91.4 cm) models

40" (101.6 cm) on 48" (121.9 cm) models

I. 1V2" (3.8 cm)

J. 3" (7.6 cm)

K. 5" (12. 7 cm)

L. 6" (15.2 cm) on 30" (76.2 cm) models

14" (35.5 cm) on 36" (91.4 cm) models

24" (61.0 cm) on 48" (121.9 cm) models

M. 10V2" (26.7cm)

N. 6" (15.2 cm)

O. 6" (15.2 cm), see NOTE***

N

A. Optional backguard may be installed

B. 273/4'' (70.5 cm) depth with control panel, see NOTE*

C. 353/4"(90.2 cm) cooktop height when setting on the wheels

D. 48" (121.9 cm) width

E. Model/serial rating plate location

*NOTE: When installed in a 24" (61.0 cm) base cabinet with

25" (63.5 cm) countertop; front of oven door protrudes

17/8'' (4.8 cm) beyond 24" (61.0 cm) base cabinet.

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64 cm)

countertop depth, 24" (61 cm) base cabinet depth and

36" (91.4 cm) countertop height. Dimensions must be met in

order to ensure a flush fit to backwall.

6

*NOTE: Receptacle must be rotated 90° for Canadian

installation.

**NOTE: Minimum Clearances

30" (76.2 cm) models: 30" (76.2 cm) minimum clearance

between the top of the cooking platform and the bottom of an

uncovered wood or metal cabinet.

36" (91.4 cm) models: 42" (106.7 cm) minimum clearance

between the top of the cooking platform and the bottom of an

uncovered wood or metal cabinet.

48" (121.9 cm) models: 42" (106.7 cm) minimum clearance

between the top of the cooking platform and the bottom of an

uncovered wood or metal cabinet.

***NOTE: If backwall is constructed of a combustible material

and a backguard is not installed, a 6" (15.2 cm) minimum

clearance is required for all models.

Page 7

_el °t..__1o_! _s_e_ __..,oc_t,_o_

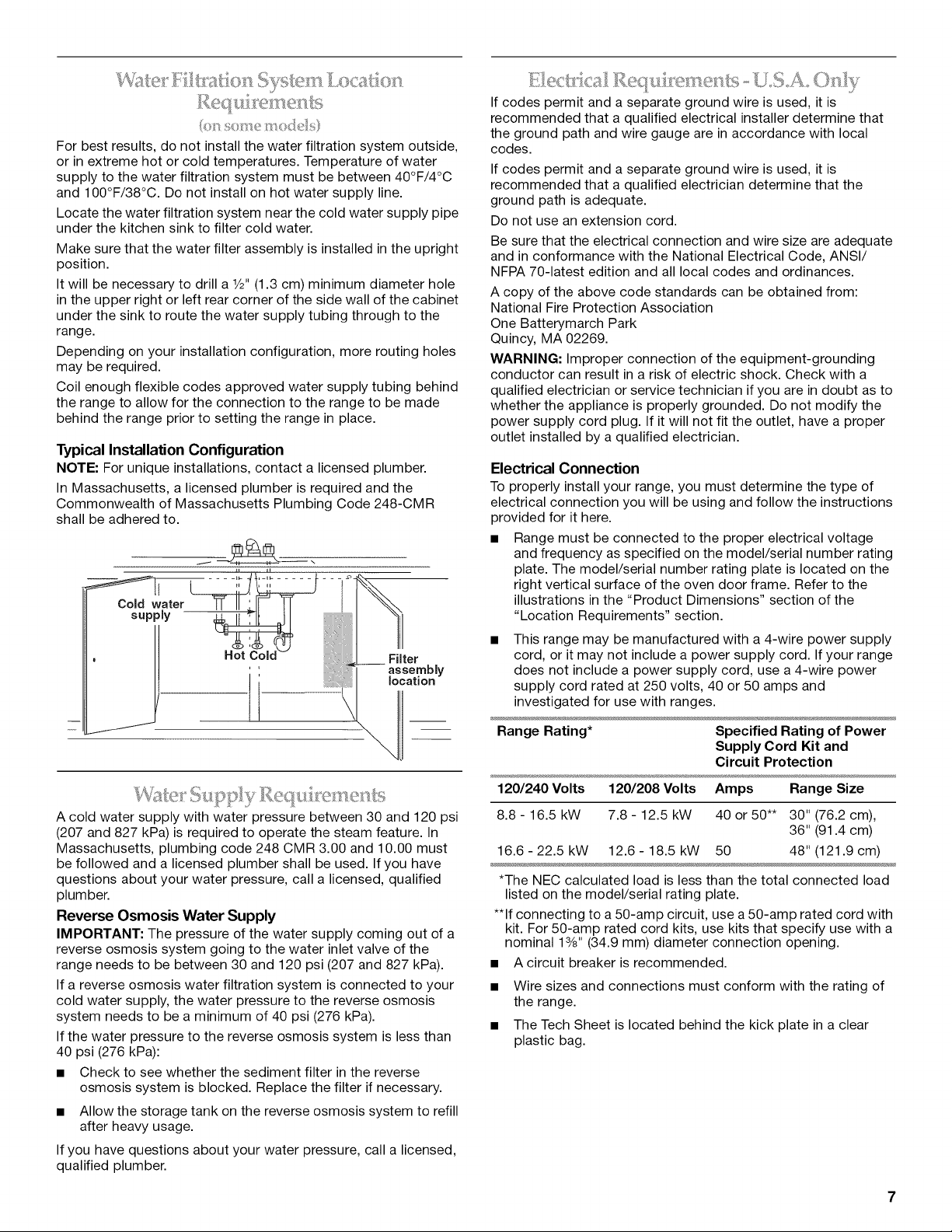

For best results, do not install the water filtration system outside,

or in extreme hot or cold temperatures. Temperature of water

supply to the water filtration system must be between 40°F/4°C

and 100°F/38°C. Do not install on hot water supply line.

Locate the water filtration system near the cold water supply pipe

under the kitchen sink to filter cold water.

Make sure that the water filter assembly is installed in the upright

position.

It will be necessary to drill a V2"(1.3 cm) minimum diameter hole

in the upper right or left rear corner of the side wall of the cabinet

under the sink to route the water supply tubing through to the

range.

Depending on your installation configuration, more routing holes

may be required.

Coil enough flexible codes approved water supply tubing behind

the range to allow for the connection to the range to be made

behind the range prior to setting the range in place.

Typical Installation Configuration

NOTE: For unique installations, contact a licensed plumber.

In Massachusetts, a licensed plumber is required and the

Commonwealth of Massachusetts Plumbing Code 248-CMR

shall be adhered to.

Fiter

assembly

location

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269.

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

• Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial number rating

plate. The model/serial number rating plate is located on the

right vertical surface of the oven door frame. Refer to the

illustrations in the "Product Dimensions" section of the

"Location Requirements" section.

• This range may be manufactured with a 4-wire power supply

cord, or it may not include a power supply cord. Ifyour range

does not include a power supply cord, use a4-wire power

supply cord rated at 250 volts, 40 or 50 amps and

investigated for use with ranges.

A cold water supply with water pressure between 30 and 120 psi

(207 and 827 kPa) is required to operate the steam feature. In

Massachusetts, plumbing code 248 CMR 3.00 and 10.00 must

be followed and a licensed plumber shall be used. Ifyou have

questions about your water pressure, call a licensed, qualified

plumber.

Reverse Osmosis Water Supply

IMPORTANT: The pressure of the water supply coming out of a

reverse osmosis system going to the water inlet valve of the

range needs to be between 30 and 120 psi (207 and 827 kPa).

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the reverse osmosis

system needs to be a minimum of 40 psi (276 kPa).

If the water pressure to the reverse osmosis system is less than

40 psi (276 kPa):

• Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

• Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

If you have questions about your water pressure, call a licensed,

qualified plumber.

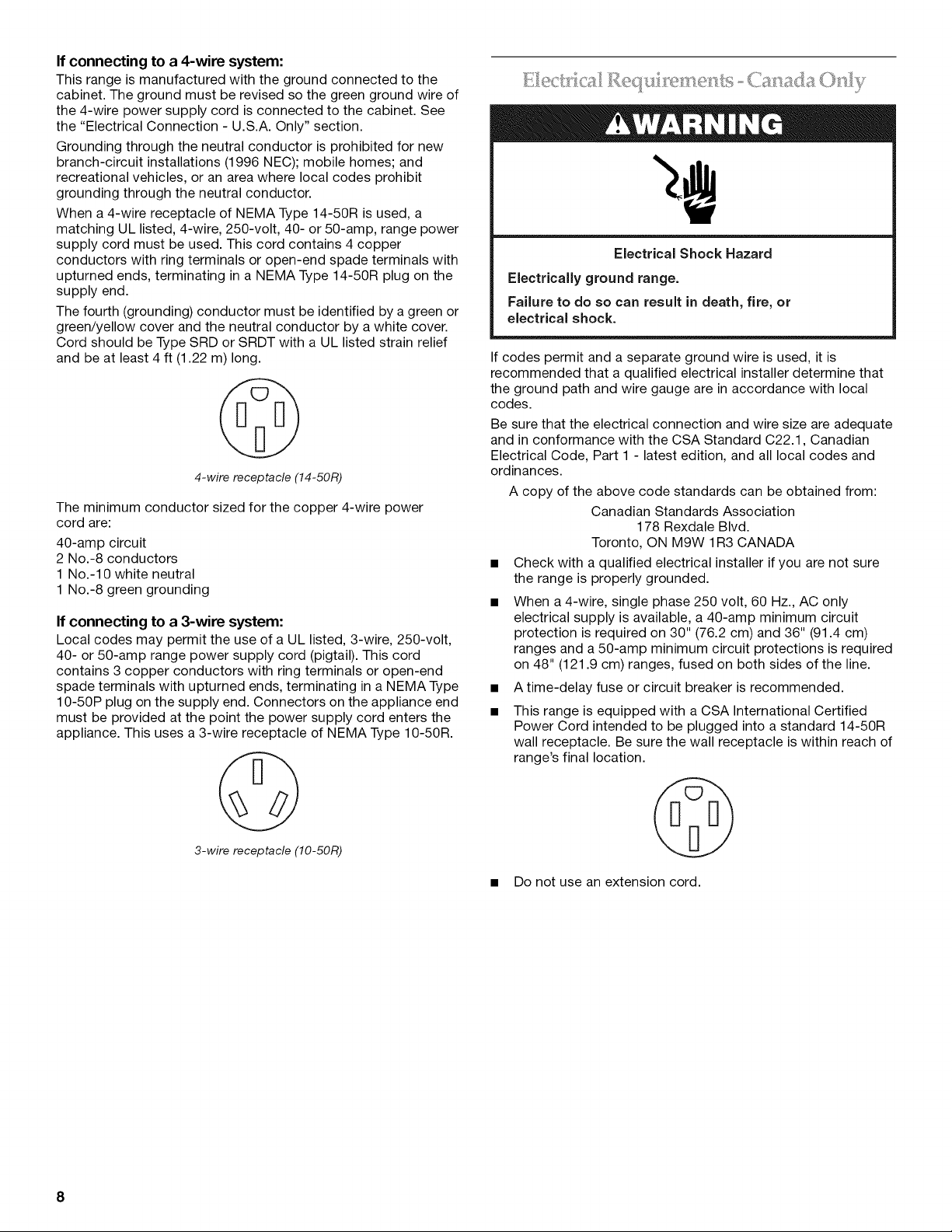

Range Rating* Specified Rating of Power

Supply Cord Kit and

Circuit Protection

120/240 Volts 120/208 Volts Amps Range Size

8.8 - 16.5 kW 7.8 - 12.5 kW 40 or 50** 30" (76.2 cm),

36" (91.4 cm)

16.6 - 22.5 kW 12.6 - 18.5 kW 50 48" (121.9 cm)

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

**If connecting to a 50-amp circuit, use a 50-amp rated cord with

kit. For 50-amp rated cord kits, use kits that specify use with a

nominal 13/8"(34.9 mm) diameter connection opening.

• A circuit breaker is recommended.

• Wire sizes and connections must conform with the rating of

the range.

• The Tech Sheet is located behind the kick plate in a clear

plastic bag.

Page 8

If connecting to a 4-wire system:

This range is manufactured with the ground connected to the

cabinet. The ground must be revised so the green ground wire of

the 4-wire power supply cord is connected to the cabinet. See

the "Electrical Connection - U.S.A. Only" section.

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL listed, 4-wire, 250-volt, 40- or 50-amp, range power

supply cord must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMA Type 14-50R plug on the

supply end.

The fourth (grounding) conductor must be identified by a green or

green/yellow cover and the neutral conductor by a white cover.

Cord should be Type SRD or SRDT with a UL listed strain relief

and be at least 4 ft (1.22 m) long.

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power

cord are:

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250-volt,

40- or 50-amp range power supply cord (pigtail). This cord

contains 3 copper conductors with ring terminals or open-end

spade terminals with upturned ends, terminating in a NEMA Type

10-50P plug on the supply end. Connectors on the appliance end

must be provided at the point the power supply cord enters the

appliance. This uses a 3-wire receptacle of NEMA Type 10-50R.

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with the CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

• Check with a qualified electrical installer if you are not sure

the range is properly grounded.

• When a 4-wire, single phase 250 volt, 60 Hz., AC only

electrical supply is available, a 40-amp minimum circuit

protection is required on 30" (76.2 cm) and 36" (91.4 cm)

ranges and a 50-amp minimum circuit protections is required

on 48" (121.9 cm) ranges, fused on both sides of the line.

• A time-delay fuse or circuit breaker is recommended.

• This range is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range's final location.

3-wire receptacle (10-50R)

• Do not use an extension cord.

8

Page 9

Explosion Hazard

Use a new CSA (nternational approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1/NFPA 54 - latest edition or CAN/CGA B149 -

latest edition.

IMPORTANT: Range cooktop must be connected to a regulated

gas supply.

IMPORTANT: Leak testing of the range cooktop must be

conducted according to the manufacturer's instructions.

Type of Gas

Natural Gas:

This range is design-certified by CSA International for use with

Natural gas or, after proper conversion, for use with LP gas.

• This range is factory set for use with Natural gas. The model/

serial rating plate located on the right vertical surface of the

oven door frame has information on the types of gas that can

be used. If the types of gas listed do not include the type of

gas available, check with the local gas supplier.

LP Gas conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the range cooktop from the

gas specified on the model/serial rating plate for use with a

different gas without consulting the serving gas supplier. To

convert to LP gas, use the LP gas conversion kit provided with

your range and see the "Gas Conversions" section. The parts for

this kit are in the literature package supplied with the range.

Gas Supply Line

• Provide a gas supply line of 3_,,(1.9 cm) rigid pipe to the

range location. A smaller size pipe on longer runs may result

in insufficient gas supply. With LP gas, piping or tubing size

can be V2" (1.3 cm) minimum. Usually, LP gas suppliers

determine the size and materials used in the system.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON ®ttape.

Flexible metal appliance connector:

• If local codes permit, a new CSA design-certified,

4 - 5 ft (122 - 152.4 cm) long, 5/8"(1.6 cm) or

3A,,(1.9 cm) I.D., flexible metal appliance connector may

be used for connecting range to the gas supply line.

• A 1/2"(1.3 cm) male pipe thread is needed for connection

to the female pipe threads of the inlet to the range

pressure regulator.

• Do not kink or damage the flexible metal tubing when

moving the range.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe

fittings to obtain an in-line connection to the range. The rigid

pipe must be level with the range connection. All strains must

be removed from the supply and fuel lines so range will be

level and in line.

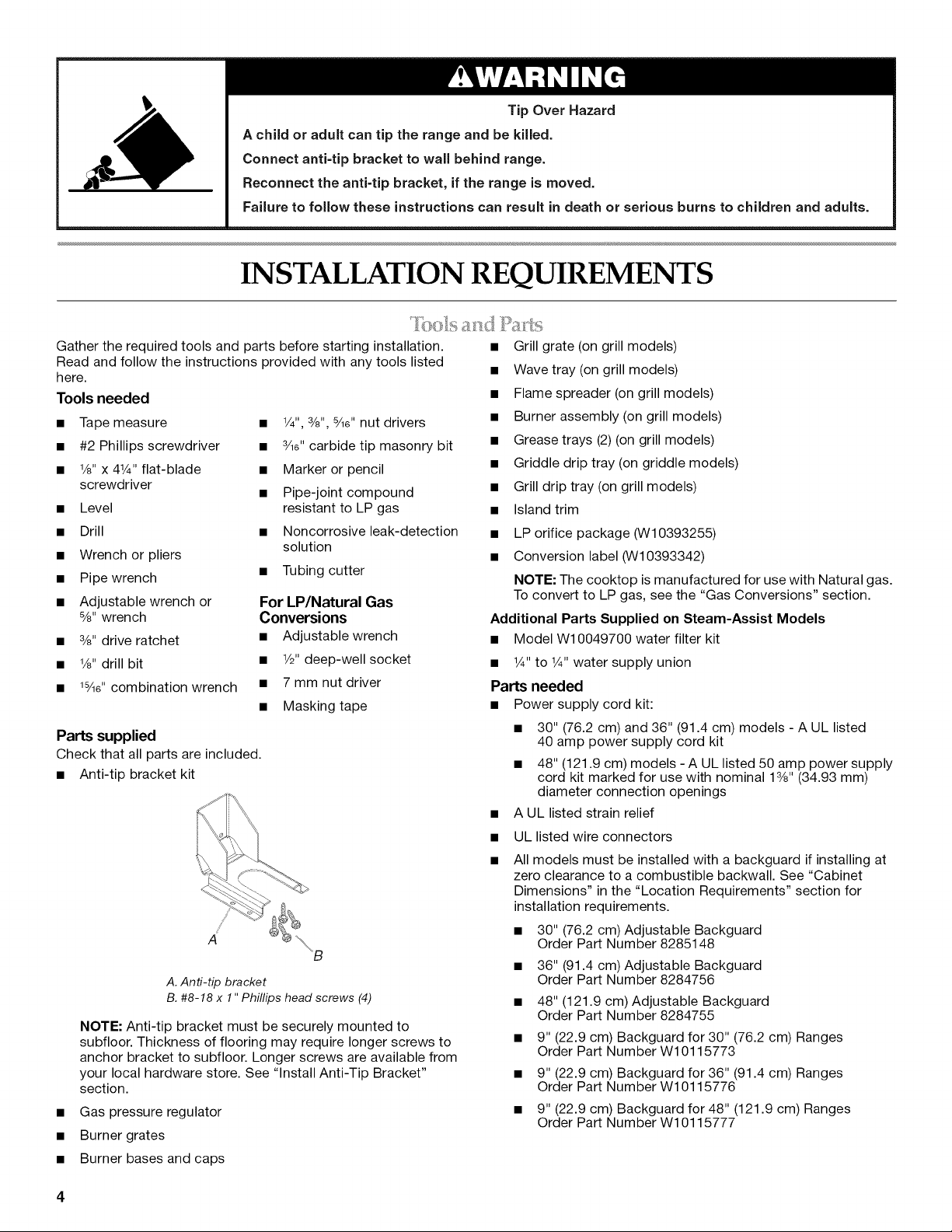

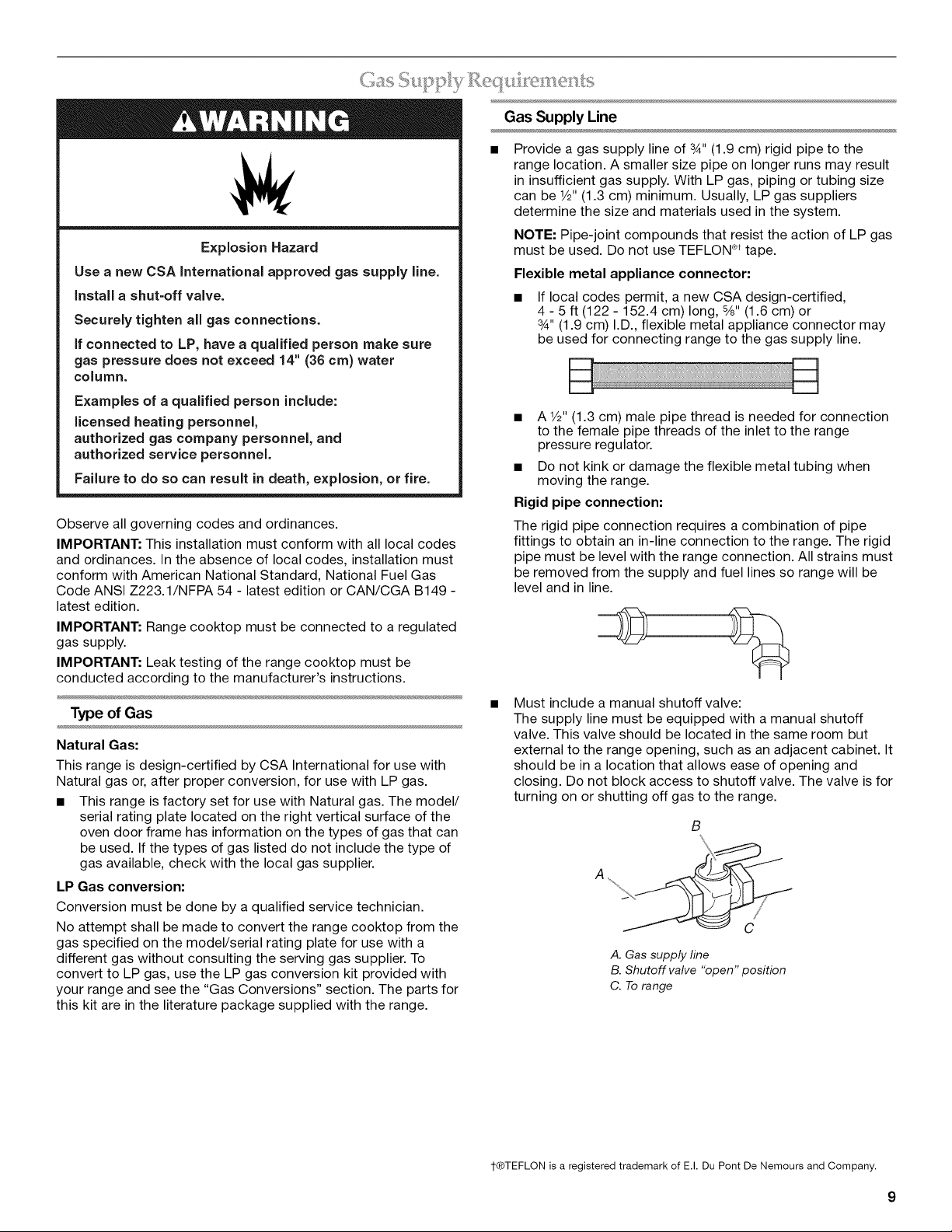

Must include a manual shutoff valve:

The supply line must be equipped with a manual shutoff

valve. This valve should be located in the same room but

external to the range opening, such as an adjacent cabinet. It

should be in a location that allows ease of opening and

closing. Do not block access to shutoff valve. The valve is for

turning on or shutting off gas to the range.

B

"%

A. Gas supply line

B. Shutoff valve "open" position

C. To range

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Page 10

Gas Pressure Regulator

Burner Input Rating - Altitude

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows for

proper operation:

Natural Gas:

Minimum pressure: 6" (15.2 cm) WCP

Maximum pressure: 14" (35.6 cm)WCP

LP Gas:

Minimum pressure: 11" (27.9 cm) WCP

Maximum pressure: 14" (35.6 cm)WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

INSTALLATION INSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings need to be

reduced at a rate of 4% for each 1,000 ft (304.8 m).

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" water column pressure above the manifold pressure shown

on the model/serial rating plate.

Line pressure testing above 1/2psi gauge (14" WCP)

The range and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2psi (3.5 kPa).

Line pressure testing at 1/2psi gauge (14" WCP) or lower

The range must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2psi (3.5 kPa).

3. Push down on kick plate to release plate from shoulder

screws.

4. Lay kick plate to the side to avoid scratching the stainless

steel.

5. For 48" (121.9 cm) models only, rotate center support

counterclockwise off the pallet until it stops.

1. Remove shipping materials, tape and film from range. Keep

shipping pallet under range. Remove oven racks, grates and

parts package from inside oven.

2. Remove screws from kick plate.

A. Kick plate

B. Remove these screws.

NOTE: This support is used only for shipping and is not

needed for installation.

6.

Lay a piece of cardboard from side packing on the floor

behind range. Using 2 or more people, firmly grasp each side

of range. Lift range up about 3" (8.0 cm) and move it back

until range is off shipping pallet. Set range on cardboard to

avoid damaging floor.

10

Page 11

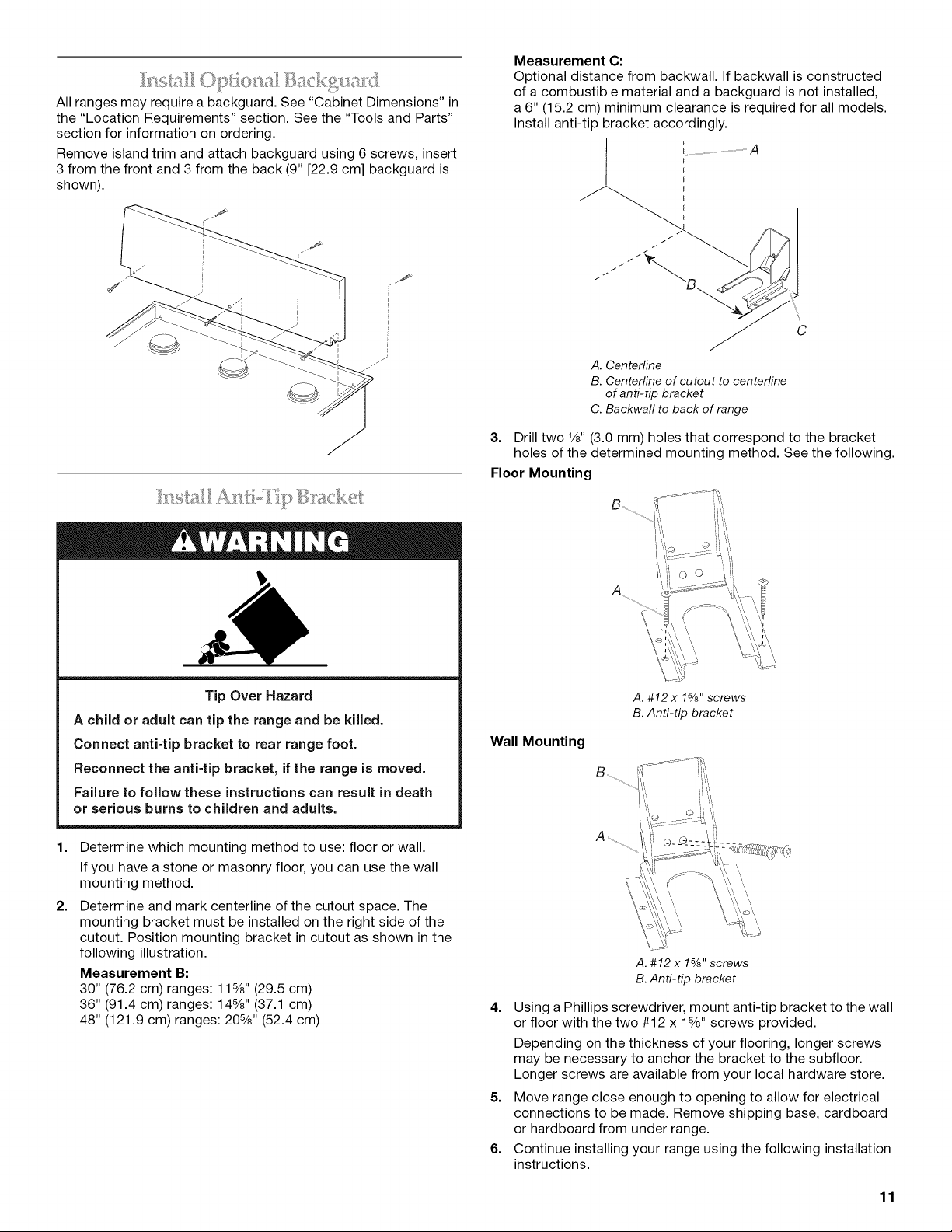

All ranges may require a backguard. See "Cabinet Dimensions" in

the "Location Requirements" section. See the "Tools and Parts"

section for information on ordering.

Remove island trim and attach backguard using 6 screws, insert

3 from the front and 3 from the back (9" [22.9 cm] backguard is

shown).

==I_=:_,,;=_ I!II _'II.I 1,11

....... i

Measurement C:

Optional distance from backwall. If backwall is constructed

of a combustible material and a backguard is not installed,

a 6" (15.2 cm) minimum clearance is required for all models.

Install anti-tip bracket accordingly.

;............................................................................A

I

I

I

t

c

A. Centerline

B.Centerlineof cutout to centerline

of anti-tip bracket

C. Backwall to back of range

3. Drill two %" (3.0 mm) holes that correspond to the bracket

holes of the determined mounting method. See the following.

Floor Mounting

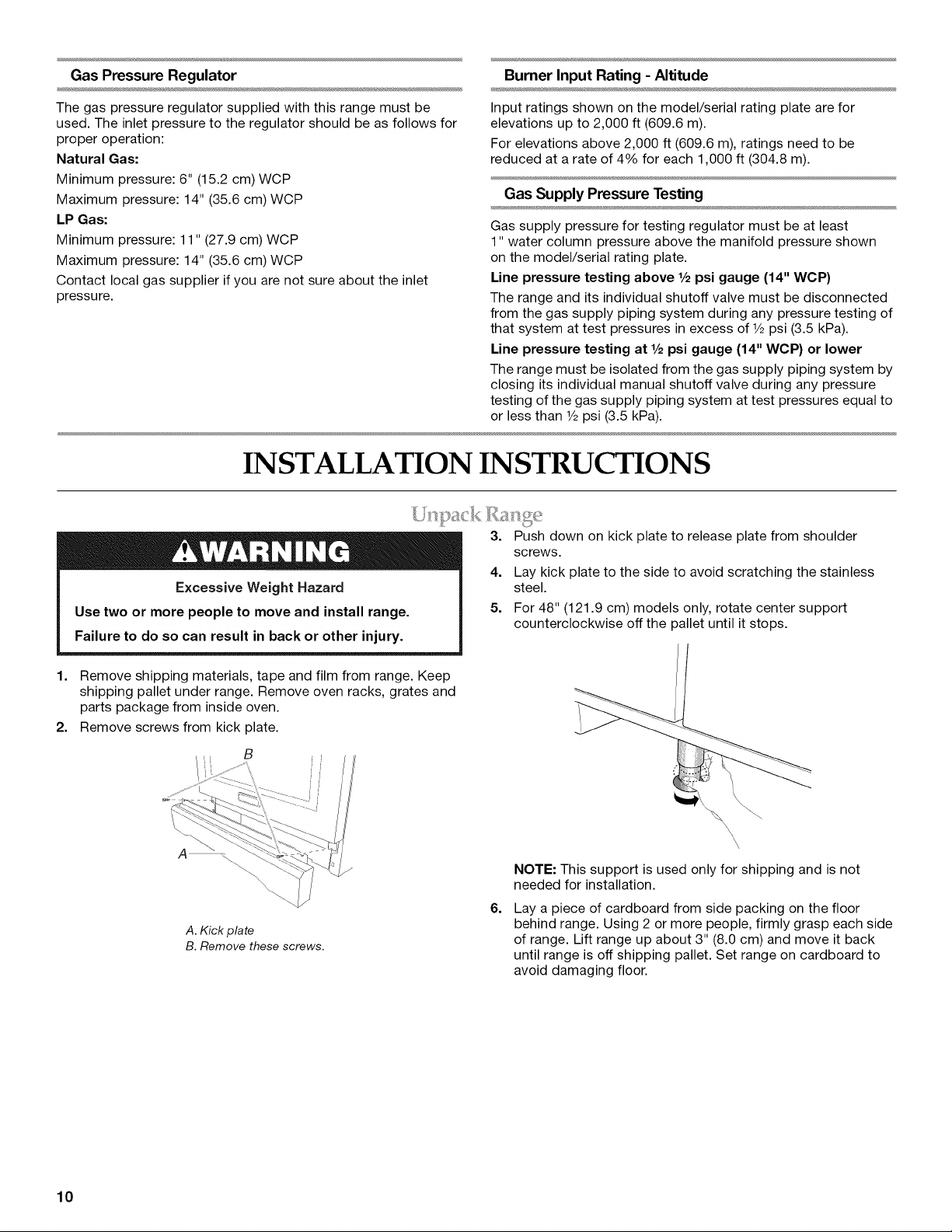

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1,

Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor, you can use the wall

mounting method.

2,

Determine and mark centerline of the cutout space. The

mounting bracket must be installed on the right side of the

cutout. Position mounting bracket in cutout as shown in the

following illustration.

Measurement B:

30" (76.2 cm) ranges: 11%" (29.5 cm)

36" (91.4 cm) ranges: 14%" (37.1 cm)

48" (121.9 cm) ranges: 20%" (52.4 cm)

A

A. #12 x 1%" screws

B.Anti-tip bracket

Wall Mounting

A. #12 x 1%" screws

B. Anti-tip bracket

4. Using a Phillips screwdriver, mount anti-tip bracket to the wall

or floor with the two #12 x 1%" screws provided.

Depending on the thickness of your flooring, longer screws

may be necessary to anchor the bracket to the subfloor.

Longer screws are available from your local hardware store.

5. Move range close enough to opening to allow for electrical

connections to be made. Remove shipping base, cardboard

or hardboard from under range.

6. Continue installing your range using the following installation

instructions.

11

Page 12

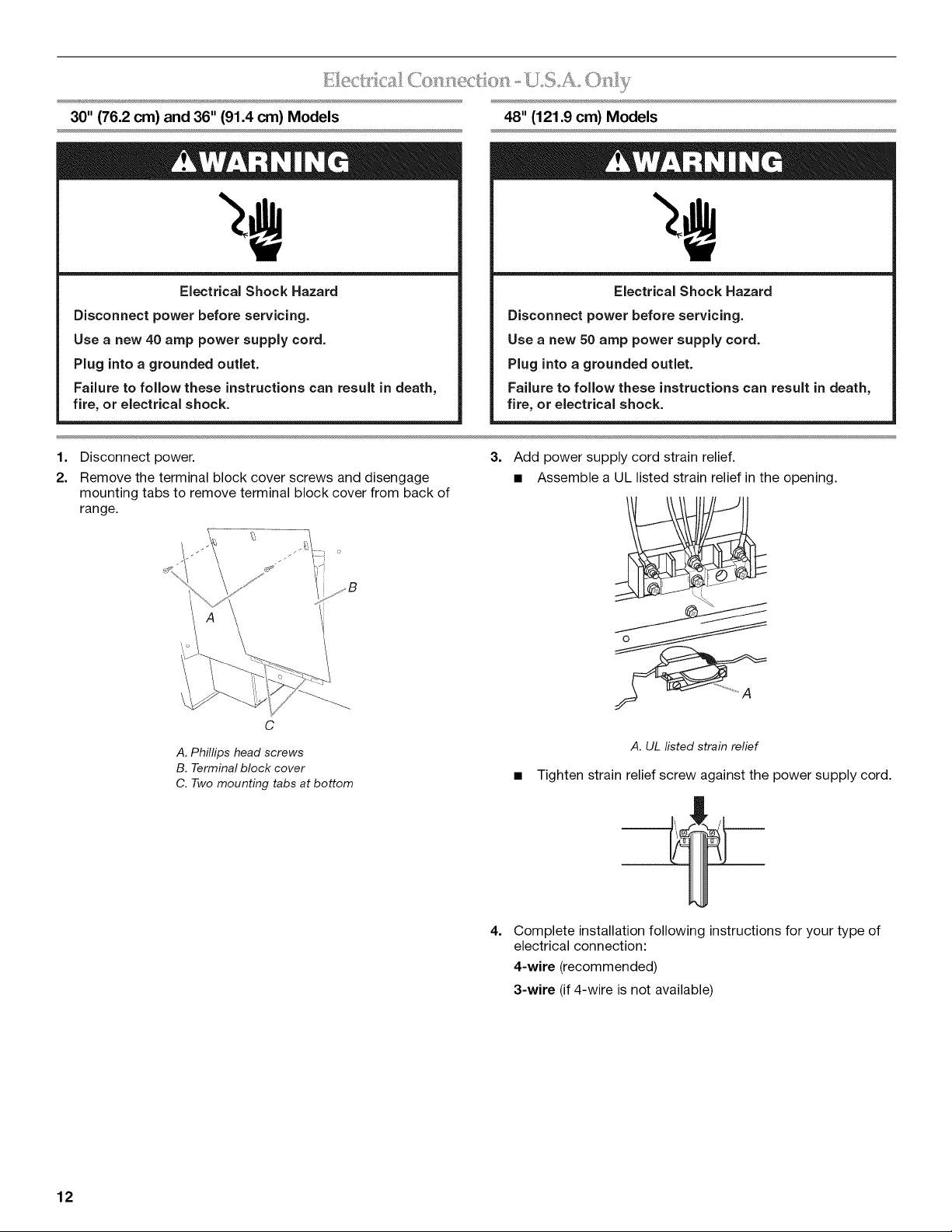

30" (76.2 cm) and 36" (91.4 cm) Models

48" (121.9 cm) Models

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Disconnect power. 3. Add power supply cord strain relief.

2. Remove the terminal block cover screws and disengage • Assemble a UL listed strain relief in the opening.

mounting tabs to remove terminal block cover from back of

range.

I A

Disconnect power before servicing.

Use a new 50 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Electrical Shock Hazard

€

A.Phillips headscrews

B. Terminalblock cover

C. Twomounting tabs at bottom

• Tighten strain relief screw against the power supply cord.

A. ULlisted strainrelief

12

4.

Complete installation following instructions for your type of

electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

Page 13

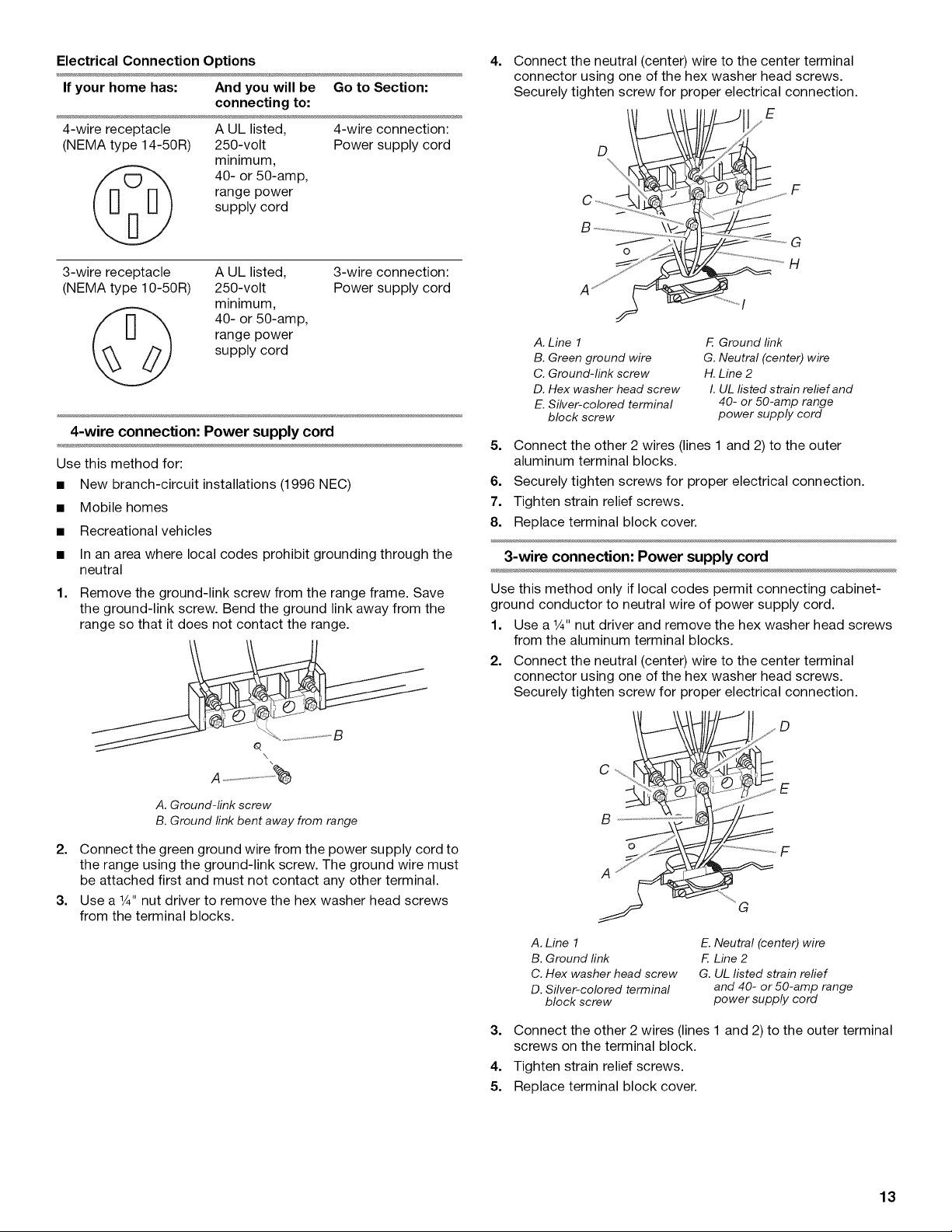

Electrical Connection Options

If your home has: And you will be Go to Section:

connecting to:

4-wire receptacle

(NEMA type 14-50R)

A UL listed,

250-volt

4-wire connection:

Power supply cord

minimum,

40- or 50-amp,

range power

supply cord

3-wire receptacle

(NEMA type 10-50R)

A UL listed,

250-volt

3-wire connection:

Power supply cord

minimum,

40- or 50-amp,

range power

supply cord

4-wire connection: Power supply cord

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1.

Remove the ground-link screw from the range frame. Save

the ground-link screw. Bend the ground link away from the

range so that it does not contact the range.

4.

Connect the neutral (center) wire to the center terminal

connector using one of the hex washer head screws.

Securely tighten screw for proper electrical connection.

E

D

J G

0

H

A. Line 1

B. Green ground wire

C. Ground-link screw

D. Hex washer head screw

E. Silver-colored terminal

block screw

F. Ground link

G. Neutral (center) wire

H. Line 2

I. UL fisted strain refief and

40- or 50-amp range

power supply cord

5. Connect the other 2 wires (lines 1 and 2) to the outer

aluminum terminal blocks.

6. Securely tighten screws for proper electrical connection.

7. Tighten strain relief screws.

8. Replace terminal block cover.

3-wire connection: Power supply cord

Use this method only if local codes permit connecting cabinet-

ground conductor to neutral wire of power supply cord.

1. Use a 1¼,,nut driver and remove the hex washer head screws

from the aluminum terminal blocks.

2. Connect the neutral (center) wire to the center terminal

connector using one of the hex washer head screws.

Securely tighten screw for proper electrical connection.

N

A. Ground-link screw

B. Ground rink bent away from range

2. Connect the green ground wire from the power supply cord to

the range using the ground-link screw. The ground wire must

be attached first and must not contact any other terminal.

3. Use a 1¼,,nut driver to remove the hex washer head screws

from the terminal blocks.

D

C

E

B

F

G

A. Line 1

B. Ground rink

C. Hex washer head screw

D. Silver-colored terminal

block screw

E. Neutral (center) wire

F. Line 2

G. UL listed strain refief

and 40- or 50-amp range

power supply cord

3. Connect the other 2 wires (lines 1 and 2) to the outer terminal

screws on the terminal block.

4. Tighten strain relief screws.

5. Replace terminal block cover.

13

Page 14

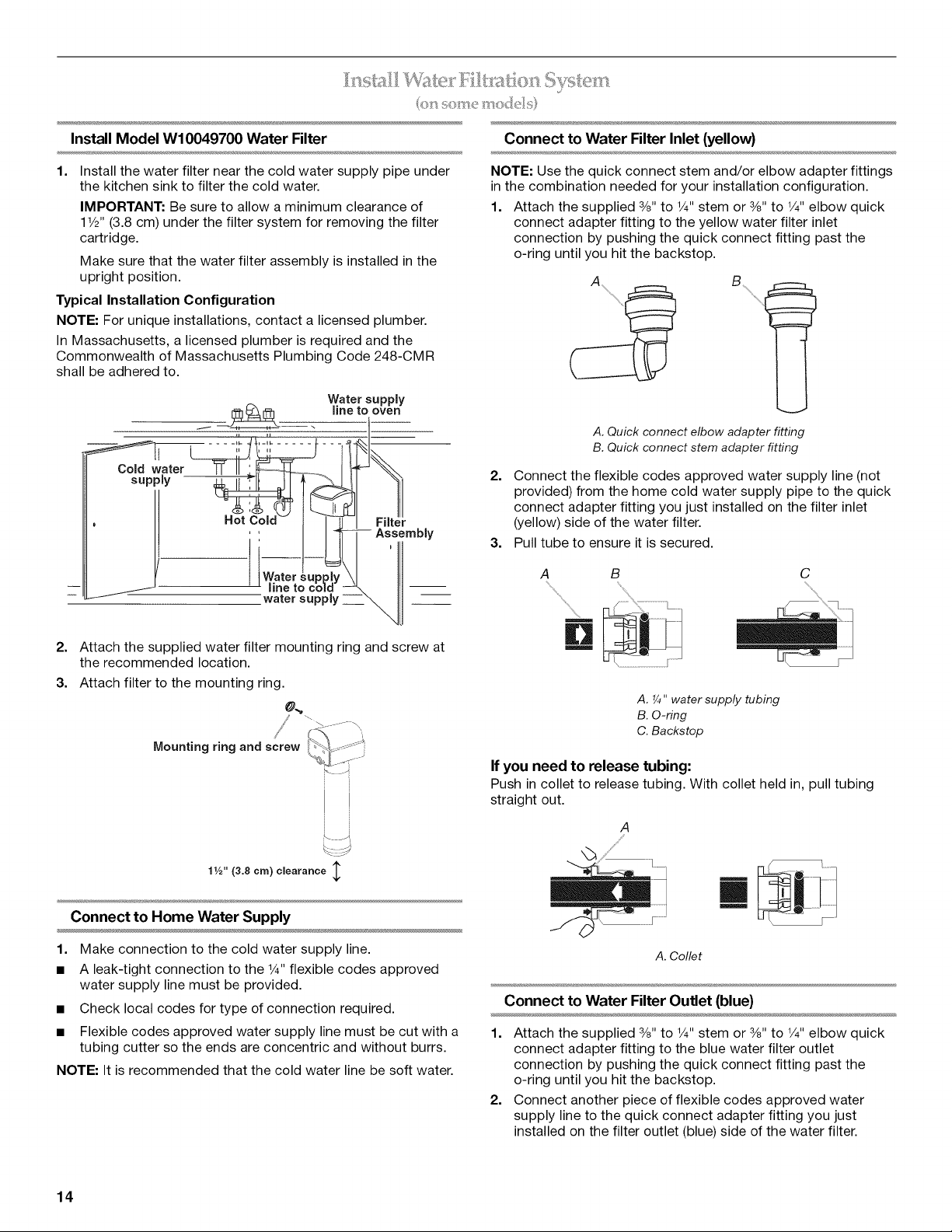

InstallModelW10049700WaterFilter

Connect to Water Filter Inlet (yellow)

1. Install the water filter near the cold water supply pipe under

the kitchen sink to filter the cold water.

IMPORTANT: Be sure to allow a minimum clearance of

11&" (3.8 cm) under the filter system for removing the filter

cartridge.

Make sure that the water filter assembly is installed in the

upright position.

Typical Installation Configuration

NOTE: For unique installations, contact a licensed plumber.

In Massachusetts, a licensed plumber is required and the

Commonwealth of Massachusetts Plumbing Code 248-CMR

shall be adhered to.

Water supply

_[_ line to oven

\

Cold water

supply

Hot Cold

er

y

water su

2.

Attach the supplied water filter mounting ring and screw at

the recommended location.

3.

Attach filter to the mounting ring.

J

/

Mounting ring and screw

NOTE: Use the quick connect stem and/or elbow adapter fittings

in the combination needed for your installation configuration.

1. Attach the supplied 3/8"to 1/4"stem or 3/8"to 1/4"elbow quick

connect adapter fitting to the yellow water filter inlet

connection by pushing the quick connect fitting past the

o-ring until you hit the backstop.

A. Quick connect elbow adapter fitting

B. Quick connect stem adapter fitting

2. Connect the flexible codes approved water supply line (not

provided) from the home cold water supply pipe to the quick

connect adapter fitting you just installed on the filter inlet

(yellow) side of the water filter.

3. Pull tube to ensure it is secured.

A

B C

=====m

N

m

A, ¼" water supply tubing

B, O-ring

C. Backstop

If you need to release tubing:

Push in collet to release tubing. With collet held in, pull tubing

straight out.

A

/

11/2"

(3.8 ore) clearance

Connect to Home Water Supply

1. Make connection to the cold water supply line.

• A leak-tight connection to the 1¼,,flexible codes approved

water supply line must be provided.

• Check local codes for type of connection required.

• Flexible codes approved water supply line must be cut with a

tubing cutter so the ends are concentric and without burrs.

NOTE: It is recommended that the cold water line be soft water.

14

m

|

m

A, Collet

Connect to Water Filter Outlet (blue)

1. Attach the supplied 3/8"to 1/4"stem or 3/8"to 1/4"elbow quick

connect adapter fitting to the blue water filter outlet

connection by pushing the quick connect fitting past the

o-ring until you hit the backstop.

2. Connect another piece of flexible codes approved water

supply line to the quick connect adapter fitting you just

installed on the filter outlet (blue) side of the water filter.

Page 15

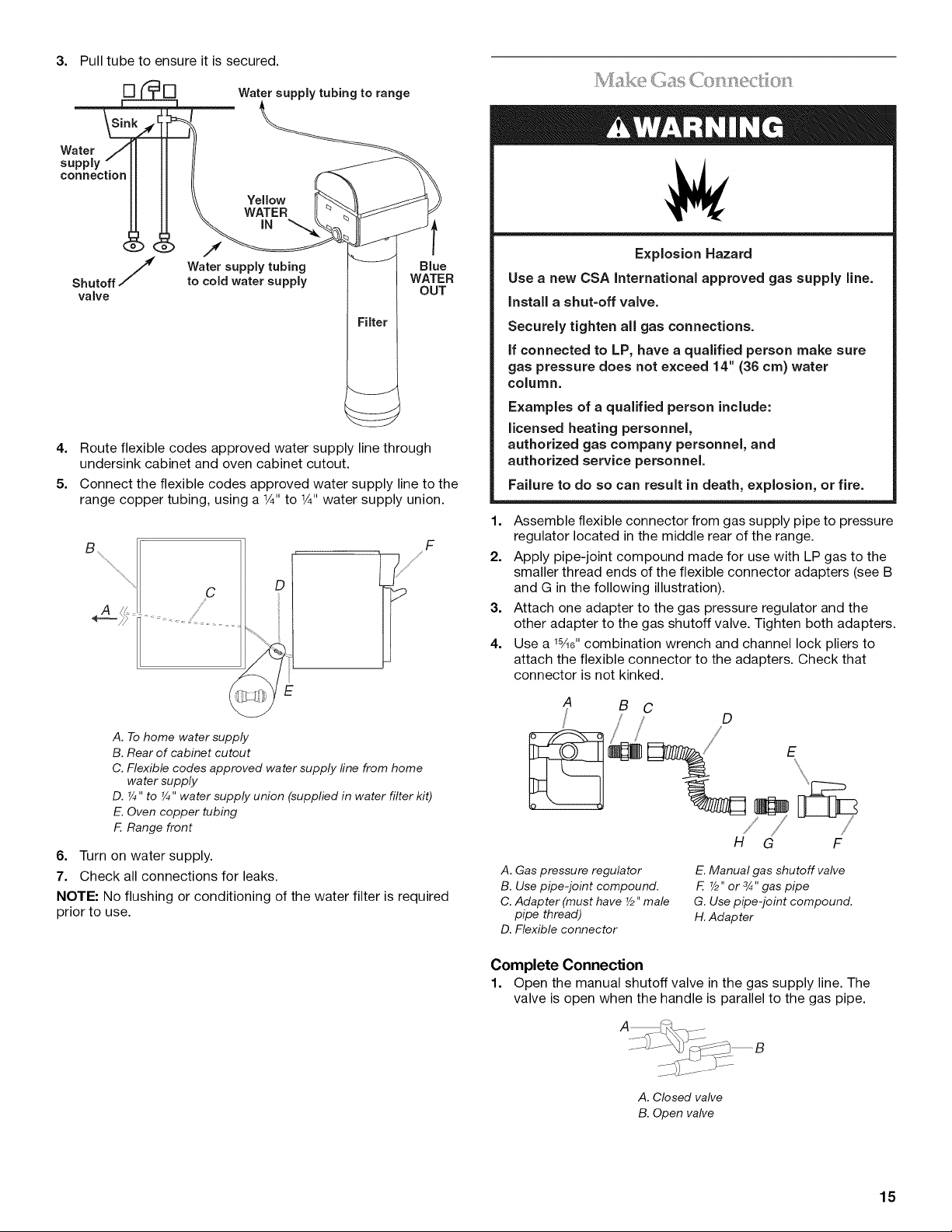

3. Pull tube to ensure it is secured.

[] ::1[] Water supply tubing to range

Water

supply

connection

Yellow

WATER

IN "-_

j Water supply tubing

Shutoff to cold water supply

valve

4. Route flexible codes approved water supply line through

undersink cabinet and oven cabinet cutout.

5. Connect the flexible codes approved water supply line to the

range copper tubing, using a ¼" to 1_,,water supply union.

C

,,¢

\

/

A. To home water supply

B. Rear of cabinet cutout

C. Flexible codes approved water supply fine from home

water supply

D. ¼" to ¼" water supply union (supplied in water filter kit)

E. Oven copper tubing

F Range front

6. Turn on water supply.

7. Check all connections for leaks.

NOTE: No flushing or conditioning of the water filter is required

prior to use.

Blue

WATER

OUT

F

%___,_ C_7__ _ __ _ _< _,__

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

1. Assemble flexible connector from gas supply pipe to pressure

regulator located in the middle rear of the range.

2. Apply pipe-joint compound made for use with LP gas to the

smaller thread ends of the flexible connector adapters (see B

and G in the following illustration).

3. Attach one adapter to the gas pressure regulator and the

other adapter to the gas shutoff valve. Tighten both adapters.

4. Use a _5/le"combination wrench and channel lock pliers to

attach the flexible connector to the adapters. Check that

connector is not kinked.

A B C

, // D

J

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have 7/2"male

pipe thread)

D. Flexible connector

H G F

E.Manual gas shutoff valve

F 7/2"or 3/4"gas pipe

G. Use pipe-joint compound.

H. Adapter

Complete Connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

15

Page 16

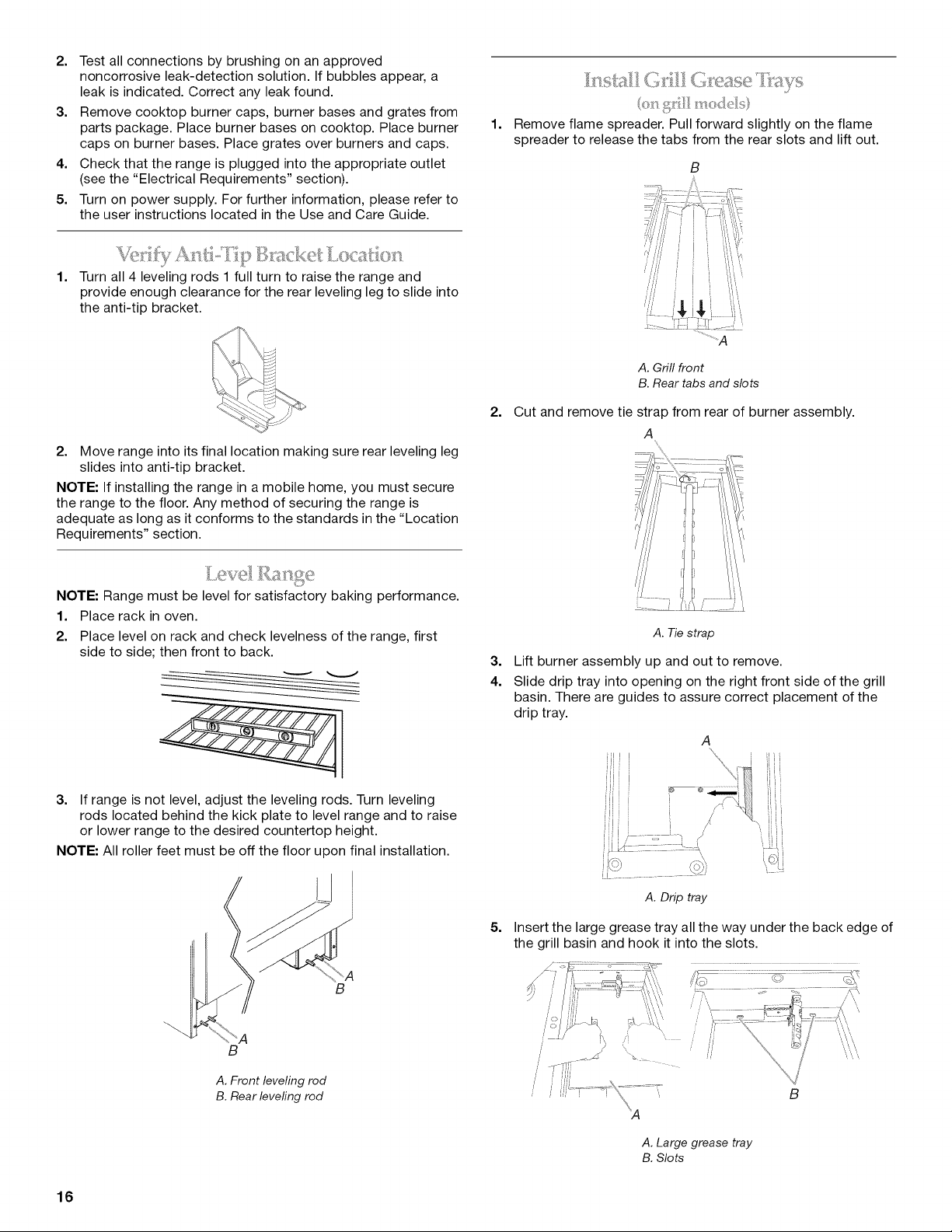

2. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear, a

leak is indicated. Correct any leak found.

3. Remove cooktop burner caps, burner bases and grates from

parts package. Place burner bases on cooktop. Place burner

caps on burner bases. Place grates over burners and caps.

4. Check that the range is plugged into the appropriate outlet

(see the "Electrical Requirements" section).

5. Turn on power supply. For further information, please refer to

the user instructions located in the Use and Care Guide.

1,

Turn all 4 leveling rods 1 full turn to raise the range and

provide enough clearance for the rear leveling leg to slide into

the anti-tip bracket.

2. Move range into its final location making sure rear leveling leg

slides into anti-tip bracket.

NOTE; If installing the range in a mobile home, you must secure

the range to the floor. Any method of securing the range is

adequate as long as it conforms to the standards in the "Location

Requirements" section.

1,

Remove flame spreader. Pull forward slightly on the flame

spreader to release the tabs from the rear slots and lift out.

B

A. Grifl front

B. Rear tabs and slots

2,

Cut and remove tie strap from rear of burner assembly.

A

NOTE; Range must be level for satisfactory baking performance.

1. Place rack in oven.

2. Place level on rack and check levelness of the range, first

side to side; then front to back.

3. If range is not level, adjust the leveling rods. Turn leveling

rods located behind the kick plate to level range and to raise

or lower range to the desired countertop height.

NOTE; All roller feet must be off the floor upon final installation.

B

A. Tie strap

3,

Lift burner assembly up and out to remove.

4.

Slide drip tray into opening on the right front side of the grill

basin. There are guides to assure correct placement of the

drip tray.

A

A. Drip tray

5,

Insert the large grease tray all the way under the back edge of

the grill basin and hook it into the slots.

i/ \ ',"'\

16

A. Front leveling rod

B. Rear leveling rod

_..z ,,_ ,, ,,, ',,t1

B

'A

A. Large grease tray

B.Slots

Page 17

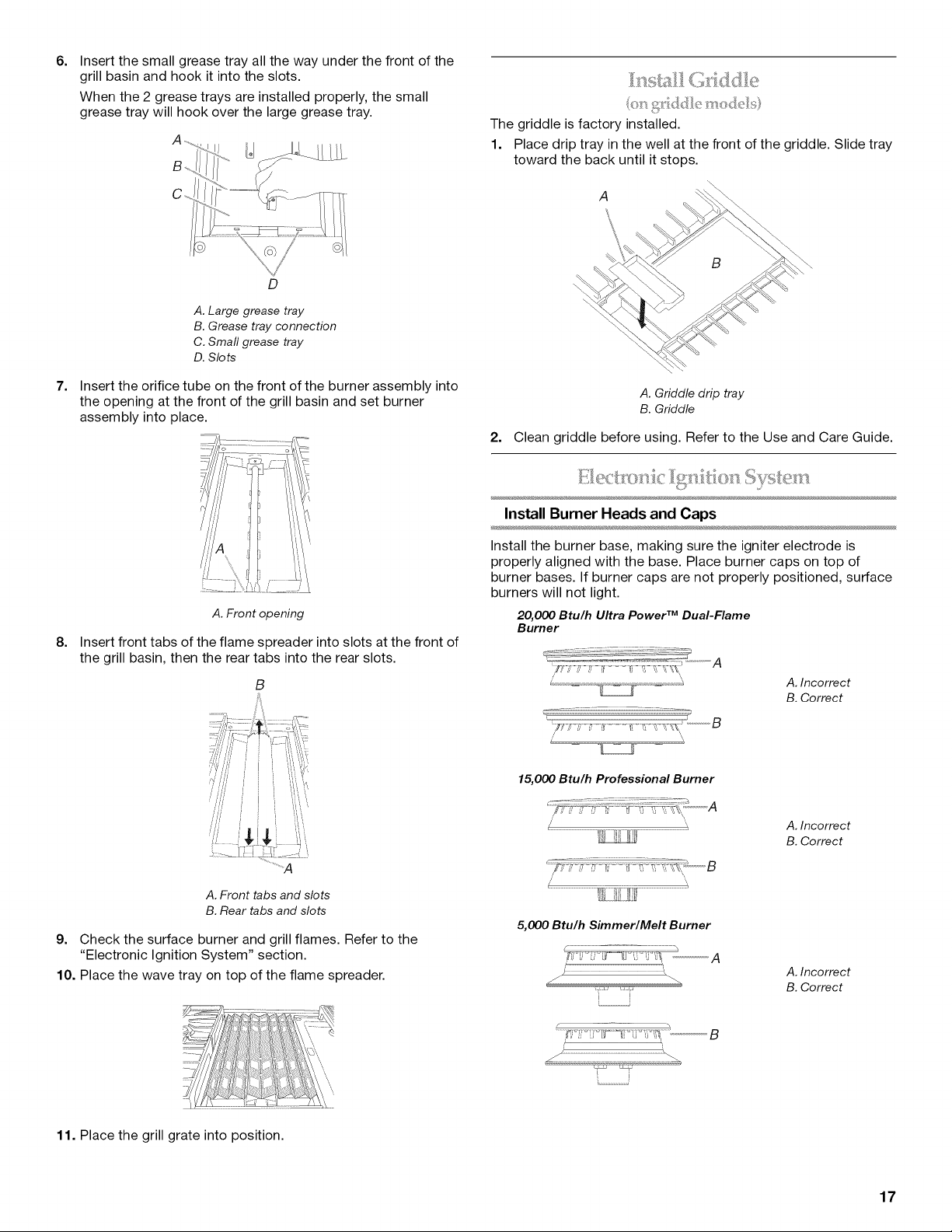

6.

Insert the small grease tray all the way under the front of the

grill basin and hook it into the slots.

When the 2 grease trays are installed properly, the small

grease tray will hook over the large grease tray.

D

A. Large grease tray

B. Grease tray connection

C. Small grease tray

D. Slots

7=

Insert the orifice tube on the front of the burner assembly into

the opening at the front of the grill basin and set burner

assembly into place.

The griddle is factory installed.

1. Place drip tray in the well at the front of the griddle. Slide tray

toward the back until it stops.

A

A. Griddle drip tray

B. Griddle

2. Clean griddle before using. Refer to the Use and Care Guide.

A. Front opening

8.

Insert front tabs of the flame spreader into slots at the front of

the grill basin, then the rear tabs into the rear slots.

B

........................A

A. Front tabs and slots

B. Rear tabs and slots

9. Check the surface burner and grill flames. Refer to the

"Electronic Ignition System" section.

10. Place the wave tray on top of the flame spreader.

Install Burner Heads and Caps

Install the burner base, making sure the igniter electrode is

properly aligned with the base. Place burner caps on top of

burner bases. If burner caps are not properly positioned, surface

burners will not light.

20,000 Btulh Ultra PowerTM Dual-Flame

Burner

A

A. Incorrect

B. Correct

15,000 Btu/h Professional Burner

A.Incorrect

' B. Correct

..........................................._1ii;i.]i_l_l!F...........................................

5,000 Btu/h Simmer/Melt Burner

/ _ A.Incorrect

-:,, ,:=:. g. Correct

11. Place the grill grate into position.

17

Page 18

Initial Lighting and Gas Flame Adjustments

Cooktop burners use electronic igniters in place of standing

pilots. When the cooktop control knob is turned to any position,

the system creates a spark to light the burner. This sparking

continues until the flame is lit or the knob is turned to Off.

Check Operation of Cooktop Burners

Push in and turn each control knob to the "LITE" position.

The surface burners and grill flames should light within

4 seconds. The first time a burner is lit, it may take longer than

4 seconds to light because of air in the gas line.

After verifying the proper burner operation, turn the control knobs

to OFF.

If burners do not light properly:

• Turn cooktop control knob to the "OFF" position.

• Check that the range is plugged in and the circuit breaker has

not tripped or the fuse has not blown.

• Check that the gas shutoff valves are set to the "open"

position.

• Check that burner caps are properly positioned on burner

bases.

Repeat start-up. If a burner does not light at this point, contact

your dealer or authorized service company for assistance.

4.

Open the oven door and remove the 2 screws on each side of

the range that hold the control console in place.

NOTE: Make sure to leave oven door open or the control

console will not rest in the side brackets properly once it is

detached.

5.

Pull up on the control console and let it drop forward into the

notched console brackets on each side.

Flame Height

The cooktop flame should be a steady blue flame approximately

1_" (0.64 cm) high.

Dual Flame Burner

A

A. Upper (simmer) flame

B. Lower flame

Single Flame Burner

// \

To Adjust Flame Height:

1. Unplug range or disconnect power.

2. Remove burner grates.

3. Remove the control knobs.

_A

A.Control console bracket

6.

Remove the round gasket from the valve stem.

7.

Put a control knob onto the valve stem of the burner you want

to adjust.

8. Turn the control knob to LO and using a butane extension

lighter, light the burner.

9. Remove the control knob.

18

Page 19

10. Use a 1/8"x 4W' flat-blade screwdriver to adjust the flame

height. Tighten screw to reduce flame height. Loosen screw

to increase flame height.

NOTE: When you are converting to LP gas, the screw should

be tightened down completely on the single output valves.

The dual output valve should not be adjusted.

/

A. Single flame burner adjustment screw (on right side of valve)

B.Dual flame burner adjustment screw (on left side of valve)

11. When finished adjusting the flame height, put a control knob

back onto the valve stem and turn off the burner.

12. Remove the control knob.

13. Replace the round gasket.

14. Repeat steps 6 through 13 for any other burners that need

adjustment.

15. Lift up on the control console and set it back into place. For a

proper fit, the flange of the control console must hook over

the lip on the front of the range cooktop.

Kick Male

1. Align shoulder screw mounting holes with shoulder screws on

range.

2. Push kick plate up against front of range until the top screw

holes are aligned with the mounting holes on the front of the

range.

3. Reattach screws to the top of the kick plate.

C

A. Kick plate

B. Reattach these screws.

C. Top screw hole

D. Shoulder screw mounting hole

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. For oven use and cleaning, read the Use and Care Guide.

/

B

A. Control console flange

B. Front lip of range cooktop

16. Check that the control console is flush with the top edge of

the range.

A

A. Flush with range top

17. Replace the 2 screws on each side of the control console.

18. Replace the control knobs.

19. Replace burner grates.

20. Test the flame by turning the control from LO to HI, checking

the flame at each setting.

Check Operation of Oven(s)

1. Turn power on.

2. Start a Bake cycle. See the Use and Care Guide for operating

instructions.

If oven(s) does not operate, check the following:

• Household fuse is intact and tight; or circuit breaker has

not tripped.

• Electrical supply is connected.

• See "Troubleshooting" section in the Use and Care Guide.

3. When oven has been on for 10-15 minutes, open the oven

door, and feel for heat.

If you do not feel heat or if an error code ("F" followed by a

number plus "E" followed by a number) appears in the display

turn off the oven and contact a qualified technician.

4. Touch OFE

To set the clock and other oven functions, refer to the Use and

Care Guide.

If you need Assistance or Service:

Please reference the "Assistance or Service" section of the Use

and Care Guide or contact the dealer from whom you purchased

your range.

19

Page 20

GAS CONVERSIONS

IMPORTANT: Gas conversions from Natural gas to LP gas must

be done by a qualified installer.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1.

Turn the manual shutoff valve to the closed position.

...................B

A

'_ ....................C

A. To range

B.Shutoff valve(closed position)

C. Gas supply line

To Convert Gas Pressure Regulator

1. Remove the access cap by using a wrench, turning the

access cap counterclockwise.

2. Remove spring retainer from the cap by pushing against the

flat side of the spring retainer. Look at the spring retainer to

locate the "NAT" or "LP" position. Turn over the spring

retainer so the "LP" is showing on the bottom. Snap the

spring retainer back into the cap. Reinstall the cap onto the

regulator.

.........S_

...... ¸¸%¸¸

E D

A. Access cap D. LP position

B. Gasket E.NAT position

C. Gas pressure regulator

3.

Test the gas pressure regulator and gas supply line.

C

The regulator must be checked at a minimum 1" (2.5 cm)

water column above the set pressure. The inlet pressure to

the regulator should be as follows for operation and checking

the regulator setting:

LP Gas:

Minimum pressure 11" (27.9 cm) WCP

Maximum pressure 14" (35.5 cm) WCR

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" water column pressure above the manifold pressure

shown on the model/serial rating plate.

Line pressure testing above 1/2psi gauge (14" WOP)

The range and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2psi (3.5 kPa).

Line pressure testing at 1/2psi gauge (14" WCP) or lower

The range must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2psi (3.5 kPa).

To Convert Surface Burners

1. If the burner grates are installed, remove them.

2. Remove burner cap.

2. Unplug range or disconnect power.

2O

Page 21

3. Remove the burner base.

A

C--_ ......B

_"_..........A Small Burner

--A

Large Dual Burner

A. Burner cap

B. Burner base

Medium Burner

A. Burner cap

B. Burner base

C. Choke (for use with medium

burner, LP gas only)

A.Burner cap

B. Burner base

To Convert Grill Burner (on some models)

1. Remove grill grate, wave plate, flame spreader and burner

assembly. See "Install Grill Grease Trays" section for removal

instructions. Set parts aside.

2. Use a _/2"deep-well socket to remove the Natural gas orifice

hood. Replace with correct grill LP gas orifice hood. See "LP

Gas Orifice Spud/Hood Chart."

A

4. Apply masking tape to the end of a 7 mm nut driver to help

hold the gas orifice spud in the nut driver while changing it.

Insert nut driver into the gas opening and press down onto

the gas orifice spud and remove by turning the gas orifice

spud counterclockwise and lifting out. Set gas orifice spud

aside.

5. Replace with correct LP gas orifice spud. See the "LP Gas

Orifice Spud/Hood Chart."

Use the following chart to find the exact orifice spud

placement.

Fully insert choke into bottom of medium burner base. Choke

should snap into place.

LP Gas Orifice Spud/Hood Chart

Burner

Color Size Burner Style

Rating

3,000 BTU Blue 0.55 mm

Small burners

11,000 BTU Yellow 0.97 mm Medium burners

14,000 BTU

Red/ 1.05 mm

Large burner - main

Green

Green 0.35 mm

Large burner - simmer

A. Grill orifice hood location

3. Turn LP gas orifice hood down tightly onto orifice base.

4. Place Natural gas orifice hoods in plastic parts bag for future

use and keep with package containing literature.

5. Before replacing the burner assembly, loosen the screw at the

front of the burner and rotate the shutter so that the opening

is s/16"(8.0 mm) wide.

A

B

A. Shutter opening

B. Screw

6. Reinstall the burner assembly, flame spreader, wave plate,

and grill grate. See "Install Grill Grease Trays" section for

installation instructions.

7. Open shutoff valve in the gas supply line. The valve is open

when the handle is parallel to the gas pipe.

REMEMBER: Once you have completed converting the grill,

test the range for leaks by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show,

indicating a leak. Correct any leaks found.

8. Plug in range or reconnect power.

14,500 BTU Black 1.18 mm Grill burner

Burner orifice spud Grill orifice hood

A

A. Size stamp or color A. Size stamp

6. Place Natural gas orifice spuds in plastic parts bag for future

use and keep with package containing literature.

7. Replace the burner base.

8. Replace burner cap.

9. Repeat steps 2 through 8 for the remaining burners.

Complete Installation

1. Refer to the "Make Gas Connection" section for properly

connecting the range to the gas supply.

2. Refer to the "Electronic Ignition System" section for proper

burner ignition, operation, and burner flame adjustments.

IMPORTANT: You may have to adjust the "LO" setting for

each cooktop burner.

Checking for proper cooktop burner flame is very important.

The small inner cone should have a very distinct blue flame

1_" (0.64 cm) to V2" (1.3 cm) long. The outer cone is not as

distinct as the inner cone. LP gas flames have a slightly

yellow tip.

3. Refer to "Complete Installation" in the "Installation

Instructions" section of this manual to complete this

procedure.

21

Page 22

_i,-+_ _t/_,Jo,,1 _ ....._ A ...._,_ _,_t_

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shutoff valve to the closed position.

...................S

3,

Test the gas pressure regulator and gas supply line.

The regulator must be checked at a minimum 1" (2.5 cm)

water column above the set pressure. The inlet pressure to

the regulator should be as follows for operation and checking

the regulator setting:

Natural Gas:

Minimum pressure 6" (15.2 cm) WCP

Maximum pressure 14" (35.6 cm) WCP

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" water column pressure above the manifold pressure

shown on the model/serial rating plate.

Line pressure testing above V2psi gauge (14" WCP)

The range and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2psi (3.5 kPa).

Line pressure testing at V2psi gauge (14" WCP) or lower

The range must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than _/2psi (3.5 kPa).

J .............. < ......................C

A. Torange

B.Shutoff valve(closed position)

C. Gas supply line

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator

1,

Remove the access cap by using a wrench, turning the

access cap counterclockwise.

2.

Remove spring retainer from the cap by pushing against the

flat side of the spring retainer. Look at the spring retainer to

locate the "LP" or "NAT" position. Turn over the spring

retainer so the "NAT" is showing on the bottom. Snap the

spring retainer back into the cap. Reinstall the cap onto the

regulator.

A ¸P

To Convert Surface Burners

1. If the burner grates are installed, remove them.

2. Remove burner cap.

3. Remove the burner base.

_j ...........A

............_ .....

Large Dual Burner

A. Burner cap

B. Burner base

Medium Burner

A. Burner cap

B. Burner base

C. Choke (for use with medium

burner, LP gas only)

Small Burner

_ A.Burner cap

L....]

4,

Apply masking tape to the end of a 7 mm nut driver to help

B. Burnerbase

hold the gas orifice spud in the nut driver while changing it.

Insert nut driver into the gas opening and press down onto

the gas orifice spud and remove by turning the gas orifice

spud counterclockwise and lifting out. Set gas orifice spud

aside.

22

E D C

A. Access cap D. NAT position

B. Gasket E. LP position

C. Gas pressure regulator

Page 23

5=

Replace with correct Natural gas orifice spud. See the

"Natural Gas Orifice Spud/Hood Chart."

Use the following chart to find the exact orifice spud

placement.

Remove choke from medium burner base.

Natural Gas Orifice Spud/Hood Chart

Burner Rating Size Burner Style

5,000 BTU 1.01 mm Small burners

15,000 BTU 1.75 mm Medium burners

20,000 BTU 2.10 mm Large burner - main

0.52 mm Large burner - simmer

18,000 BTU 1.93 mm Grill burner

Burner orifice spud

Grill orifice hood

3. Turn Natural gas orifice hood down tightly onto orifice base.

4. Place LP gas orifice hoods in plastic parts bag for future use

and keep with package containing literature.

5. Before replacing the burner assembly, loosen the screw at the

front of the burner and rotate the shutter so that the opening

is 3/8"(9.0 mm) wide.

A

B

A. Shutter opening

B. Screw

6. Reinstall the burner assembly, flame spreader, wave plate,

and grill grate. See "Install Grill Grease Trays" section for

installation instructions.

7. Open shutoff valve in the gas supply line. The valve is open

when the handle is parallel to the gas pipe.

\

REMEMBER: Once you have completed converting the grill,

test the range for leaks by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show,

indicating a leak. Correct any leaks found.

8. Plug in range or reconnect power.

x

A

A

A. Sizestamp A. Size stamp

6. Place LP gas orifice spuds in plastic parts bag for future use

and keep with package containing literature.

7. Replace the burner base.

8. Replace burner cap.

9. Repeat steps 2 through 8 for the remaining burners.

To Convert Grill Burner (on some models)

1. Remove grill grate, wave plate, flame spreader and burner

assembly. See "Install Grill Grease Trays" section for removal

instructions. Set parts aside.

2. Use a 1/2"deep-well socket and remove the LP gas orifice

hood. Replace with correct grill Natural gas orifice hood. See

"Natural Gas Orifice Spud/Hood Chart."

Complete Installation

1. Refer to the "Make Gas Connection" section for properly

connecting the range to the gas supply.

2. Refer to the "Electronic Ignition System" section for proper

burner ignition, operation, and burner flame adjustments.

IMPORTANT: You may have to adjust the "LO" setting for

each cooktop burner.

Checking for proper cooktop burner flame is very important.

The small inner cone should have a very distinct blue flame

1¼.(0.64 cm) to 1/2"(1.3 cm) long. The outer cone is not as

distinct as the inner cone. LP gas flames have a slightly

yellow tip.

3. Refer to "Complete Installation" in the "Installation

Instructions" section of this manual to complete this

procedure.

A. Grill orifice hood loca#on

23

Page 24

The following individual circuits are for use in diagnoses, and are shown in the ON position. Do not continue with the diagnosis of the

appliance if a fuse is blown, a circuit breaker is tripped, or if there is less than a 240 +10%/-15% volt power supply at the wall outlet.

Griddle 240V Control Wiring Diagram To Cooktop Stand-Alone and Freestanding

--_> R

w

).

>1 BK

Grill Reignition Wiring Diagram To Cooktop Stand-Alone and Freestanding

P2-1 P1-1

P1-3

Rotary Control

P1-4

P2-6 P1-6

c?_ j

ZJ_

m 1

Reignition Module

BU/W 1320W/240V BU/W

RTD

BU/W

BU

i]

) w

S

24

Page 25

Caution: Label all wires prior to disconnection when servicing controls.Wiring errors cancause improper anddangerous operation.

Verifyproper operation after servicing.

Cooktop Schematics

4 Burner Cooktop

Griddle Spare j : W

R_o BU

R,.._r....."% BR

R,LoJoY

o

-o SW1

C)

o 0 SW2

o

o Z SW3 __

o _ SW4

o _

--_ L i55

o

R

OR

6 Burner Cooktop

Grill Spare

Lw,___4.___

R

....... iw ,,.

_o_I.'-_ I_

f_GND Mpa_nerHa_nreeSs

Power Cord Only To

Cooktop Stand Alone

Version

Griddle Spare_ o

GND

BR o

Y _ 3- sw3

_e.....i G =

o

o

C)

_ sw2 m

s_ g

_ _ SW4 0

° _

= L

o N

o

4( !....................

Cooktop

FrontView

i-;,l.....

I

:

I

:

OR !

i

:

Y I

i '-

:

I

:

I

Gdll Spare B_ GND _ --_

= Po,_r I-"_

I Cord = U I I

_GND Main- Harness

fTL_ Power Spare

Power Cord Only To

Cooktop Stand-Alone

Version

25

Page 26

30"/36" (76.2 cm/91.4 cm) Oven Schematic for KDRS and YKDRS Models

NOTES:

• End of line tester is for manufacturing purpose only. • Circuit shown in STANDBY/OFF mode with oven door closed.

• Dots indicate connections or splices.

N L2 L1

W _R )BK

Control Panel

Spare

CooMop

Keypad

Spare

Communication

Control Power Transformer

BK

BK BK

BK BK

Latch Switch

(Operated By Motor)

BK Lalch

R

to

LEGEND

Appliance Manager P7-1

P2-1 Ps-_

P2-5 _,--0 T3-:

P2-6 T34

BR

P1-4 _ _ P8-4

i

P9-5 P]-"

L_P14

T1-2

T2-2 O___.__3I

P74 3 R

sW

0____@ Cony Fan

Cony- 1600W

3 R

Bake - 3000W

T3-z

30R OR

BU In Broil- 3500WBu

" "( )" The ma Ou o

36" (914 cm)- 3000W (Non-ResettaNe

R R W

Haloen Lihis

I 2_w?42ov%

OperateIn All Modes

Pl-_

_ _Exce t Sell-Clean

_-On somemodels

R/W

R/W

GND

338T (170°C)

Blower

BK_K_w

/

[2

f-

Ground

(Chassis)

---<

PlugWith

Female

Connector

Receptacle

WithMale

Connector

Light

ACDrive

Motor

RelayCoil

RelayContact

oQZ2S2SDo

Heating

Element

Enclosed

Thermistor

Operated

By Door

rhermalCutoff

(Non-

Resettable)

Thermostat

26

Page 27

48" (121.9 cm) Oven Schematic for KDRS Models

NOTES:

• End of line tester is for manufacturing purpose only. • Circuit shown in STANDBY/OFF mode with oven door closed.

• Dots indicate connections or splices.

Control Panel

GND

Thermal Cutoff

R_V

Blower

Spare

Cooktop

Right 30"

Oven

Spare

Communication

L2

R

BK

I KeypadI

I_lP40

Userlntedace Board

Io o oPl_ o c_l

30" Door Lock Latch

R

TempSensor

1080_'lAt21°C (7Oh) _

1654 _'?At177°0 (350°F)

Meat Probe

78KEIAt 156% (60T) _ W-. W.

37KOA 322°C 90T

) BK

BR

B _O R

LatchSwitch

(OperatedBy Motor)

Y

BK

P8-1Appliance Manager

p1-7 'r _ P8-6

_1-4 I P1-1

_8-5 P1-3

P9-5 o___ _>_

T1-2

[2-2

P1-2

T1-1

_Conv. Fan

y Cony.- 1600W y

OOW OR Non-Resettable

_ooow BU

R BK B

BKI:_ _1 Halogen Lights

,R R_

BK Except Self-Clean

R/W

R/W f

25W/120VBub

Operate In All Modes

"1 338T (170°C)

Left18"

Oven

Ground

(Chassis)

BK BK c

BK BK

BK b_

, _ Y

BK BK

18" Door Lock Latch

R

TempSensor

10800 At21% (TO°F) ( %,A

1654E_At 177%(350°F)

Meat Probe W OR

78K£)At 15.6%(6Oh) _

37K¢_At322% (9Oh}

LEGEND

___>

PlugWith

Female

Connector

Receptacle

WithMale

Connector

Light

ACDrive

Motor

RelayCoil

B BR _T_ OR OR

Latch Switch

(OpelatedBy Moto/)

_Lo

€

RelayContact

Appliance P7-3

P8-1 Manager P7-1

_2-5

BR

] P1-2

=9-5

)2-3

P2-4

T1-2

c@222_

Heating

Element

OR _ Cony.Fan W

y Conv.-1600W y

W OR Non-Resettabb

,BU

=_ _- I Halogen Lights

KI_ I 25W/120V Bulb

P1-3

BK

R/W

R/W

Enclosed

Thermistor

Operate In All Modes

Except Self-Clean

Operated

By Door

ThermalCutoff

1338T (170'C)

rhermalCutoff

(Non-

Resettable)

Bbwer

Thermostat

27

Page 28

30"/36" (76.2 cm/91.4 cm) Oven Schematic for KDRU and YKDRU Models

NOTES:

• End of line tester is for manufacturing purpose only. • Circuit shown in STANDBY/OFF mode with oven door closed.

• Dots indicate connections or splices.

L2 L1

W

R

b Control Panel

BK(

Spare

Cooktop

eee,nte_aceeeard II I

P2-1 (

' -- ' BK _'" spare 1080QAt21°C 70_F [ _¢)_^, _,

_" _"(-_'_-_1 C........ ication11654flAt177°C(350°F__

L_____J I I w _O>O_R

3K Control PowerTransformer I Msel_P,_ble5.6°C (6C°F)_

aI3K 37K fl At 32.2°0 9C°F _>W<W

3K BK

_qBK BK

/ DoorSwitch

(OnLatchAssy)

BK (OperatedByMotor)BK

_--->_<< Y

DoorLock Latch

d BK

BoilerNTC _ BRY _

100K_At25°C(7TF) I l

6.8K_ At 100°O(212T) BK ,> __ __

R

LatchSwitch

D8-1 PL_6 °P__5 P7-3

::::

r4-4 J. _#-"_'_

1111;

F_ <*-z_a

)1-4

r4-2 , ,

P9-5 P1-1

_3-5 / P1-3

3-4 1

P2-8

rl-2

r2-2 o___'F''_

€---_

o--- T2-1

_R

_W

> LR_Conv. Fan1

, [_Conv. Fan 2y

InBroil- 3500W | _.X4,.._

OR al_:#_t_o1_>

o?w +;

3K

P1-2

R

R/W

R/W

Halogen.25W/120.VBull

OperatemAll Mooes

IExceptSelf-Clean

Fi_ve W

Blower

R<#

BK

( W,

28

---<

PlugWith Receptacle

Female With Male

Connector Connector

Spare Steam

LEGEND

ACDrive _ H Enclosed

hig_ht @ RelayCoil melav_Contact_ °_

Motor Thermistor

Operated

By Door

o

Thermostat

F Vave

Page 29

48" (121.9 cm) Oven Schematic for KDRU Models

NOTES: