Page 1

Installation Instructions

30" Electric Range

with self-cleaning

thermal/convection

oven

Quick Reference

Table of Contents:

Pages

2

3

3-4

4

5-8

9

10

10

10

If you need assistance:

Check your Use and Care Guide for a toll-free number to

call or call the dealer from whom you purchased this

appliance. The dealer is listed in the Yellow Pages of your

phone directory under “Appliances — Household —

Major — Service and Repair.”

Call when you:

Have questions about range installation or operation.

Need to obtain the name and number of an authorized

service company.

When you call, you will need:

The range model number.

The range serial number.

Both numbers are listed on the model/serial rating plate

located on the oven frame behind the storage drawer

panel.

Before you start

Product dimensions

Cabinet dimensions/requirements

Electrical requirements

Installation steps

Check operation

If range does not operate

If you need assistance/service

Moving the range

IMPORTANT:

Installer: Leave Installation Instructions with the homeowner.

Homeowner: Keep Installation Instructions for future reference.

Save Installation Instructions for local electrical inspector's use.

Part No. 9757988

IMPORTANT:

Read and save these instructions.

®

HOME APPLIANCES

www.kitchenaid.com

Freestanding

Range

Slide-in

Range

Tip Over Hazard

A child or adult can tip the range

and be killed.

Connect anti-tip bracket to rear

range foot.

Reconnect the anti-tip bracket, if

the range is moved.

Failure to follow these instructions

can result in death or serious

burns to children and adults.

WARNING

Page 2

2

Before you start...

Mobile home installation

The installation of this range must

conform with the Manufactured Home

Construction and Safety Standard, Title

24 CFR, Part 3280 [formerly the Federal

Standard for Mobile Home Construction

and Safety, Title 24, HUD (Part 280)] or,

when such standard is not applicable, the

Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A*,

or with local codes.

When this range is installed in a mobile

home, it must be secured to the floor

during transit. Any method of securing

the range is adequate as long as it

conforms to the standards listed above.

Four-wire power supply cord or cable

must be used in a mobile home

installation. The appliance wiring will

need to be revised. See “Four-wire

electrical connection,” Page 4.

Tools needed:

• level

• flat-blade screwdriver

• 3/8" drive ratchet

• 3/8" and 5/16" nut driver

• hand or electric drill

• channel lock pliers

• safety glasses

• gloves

• measuring tape or ruler

• wood floors: 1/8" drill bit

• concrete/ceramic floors: 3/16" carbide-tipped

masonry drill bit (Hammer may be needed

for anchors.)

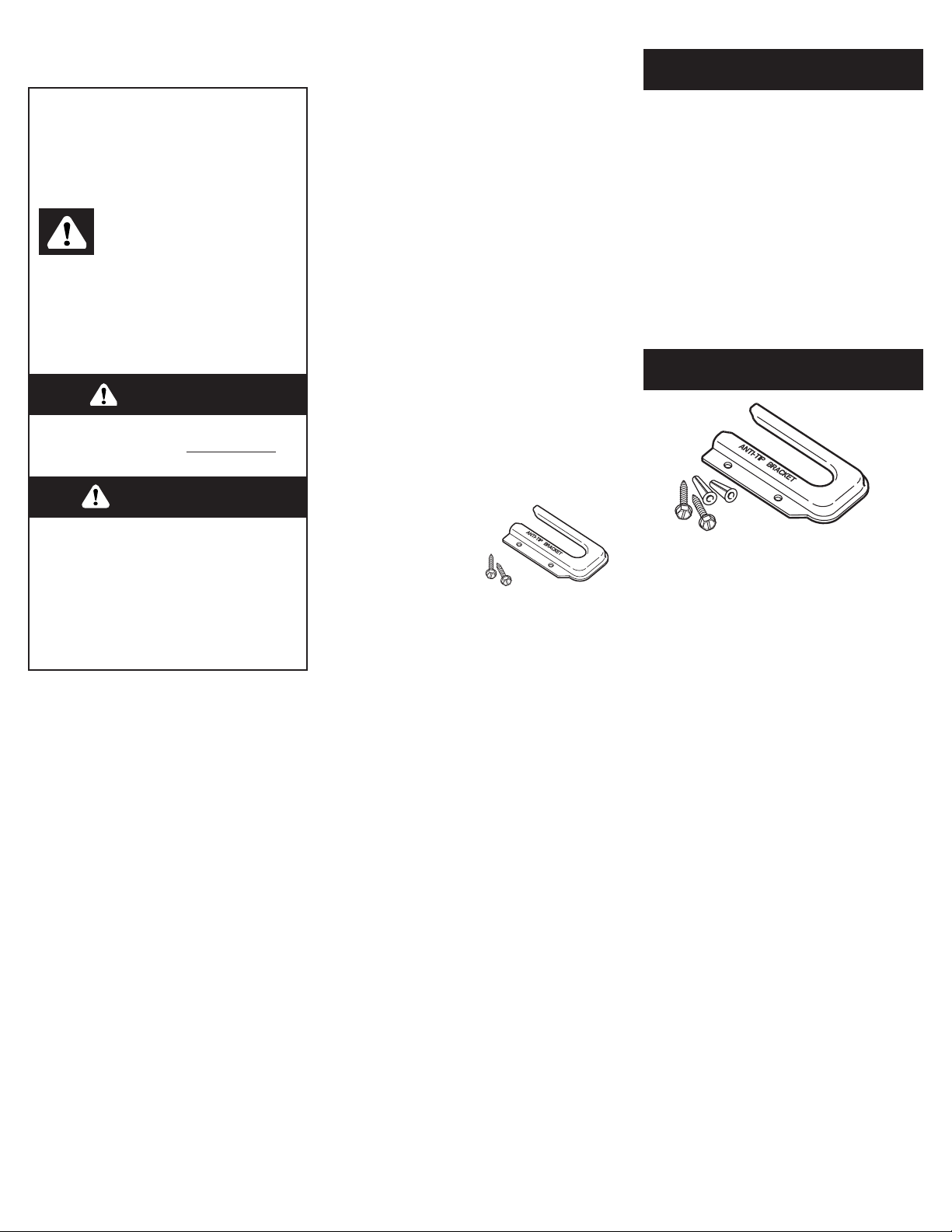

Parts supplied:

Brackets must be securely mounted to

sub-floor. Thickness of flooring may require longer

screws to anchor bracket to sub-floor. Longer

screws are available from your local hardware store.

Not shown:

literature pack

floor-mounted

anti-tip bracket

2 screws

(#10 x 1-1/2")

Copies of the standards listed may be obtained

from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts, 02269

The floor anti-tip

bracket MUST be

installed. To install

the anti-tip bracket

shipped with the

range, see Page 5 and the anti-tip

bracket template.

IMPORTANT: Observe all governing codes

and ordinances. Failure to meet codes

and ordinances could lead to fire or

electrical shock.

Proper installation is your responsibility.

A qualified technician must install this

range. Make sure you have everything

necessary for correct installation. It is the

installer’s responsibility to comply with

installation clearances specified on the

model/serial rating plate. The model/serial

rating plate is located on the oven frame

behind the storage drawer panel.

Check location where range will be

installed. The range should be located for

convenient use in kitchen.

When installing a range under existing

cabinets and the installation does not

meet the minimum cabinet clearances,

install a range hood above the cooktop to

avoid burn hazards.

All openings in the wall or floor where

ranges is to be installed must be sealed.

Cabinet opening dimensions that are

You can be killed or seriously

injured if you don’t follow

instructions.

DANGER

Your safety and the safety of

others are very important.

We have provided many important

safety messages in this manual and

on your appliance.Always read and

obey all safety messages.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

You can be killed or seriously

injured if you don’t immediatel

y

follow instructions.

WARNING

This is the safety alert

symbol.

This symbol alerts you to

potential hazards that can kill or hurt

you and others.

All safety messages will follow the

safety alert symbol and either the

word “DANGER” or “WARNING”.

These words mean:

2 plastic

anchors

shown must be used. Given dimensions

are minimum clearances.

Grounded electrical outlet is required.

See “Electrical requirements,” Page 4.

Page 3

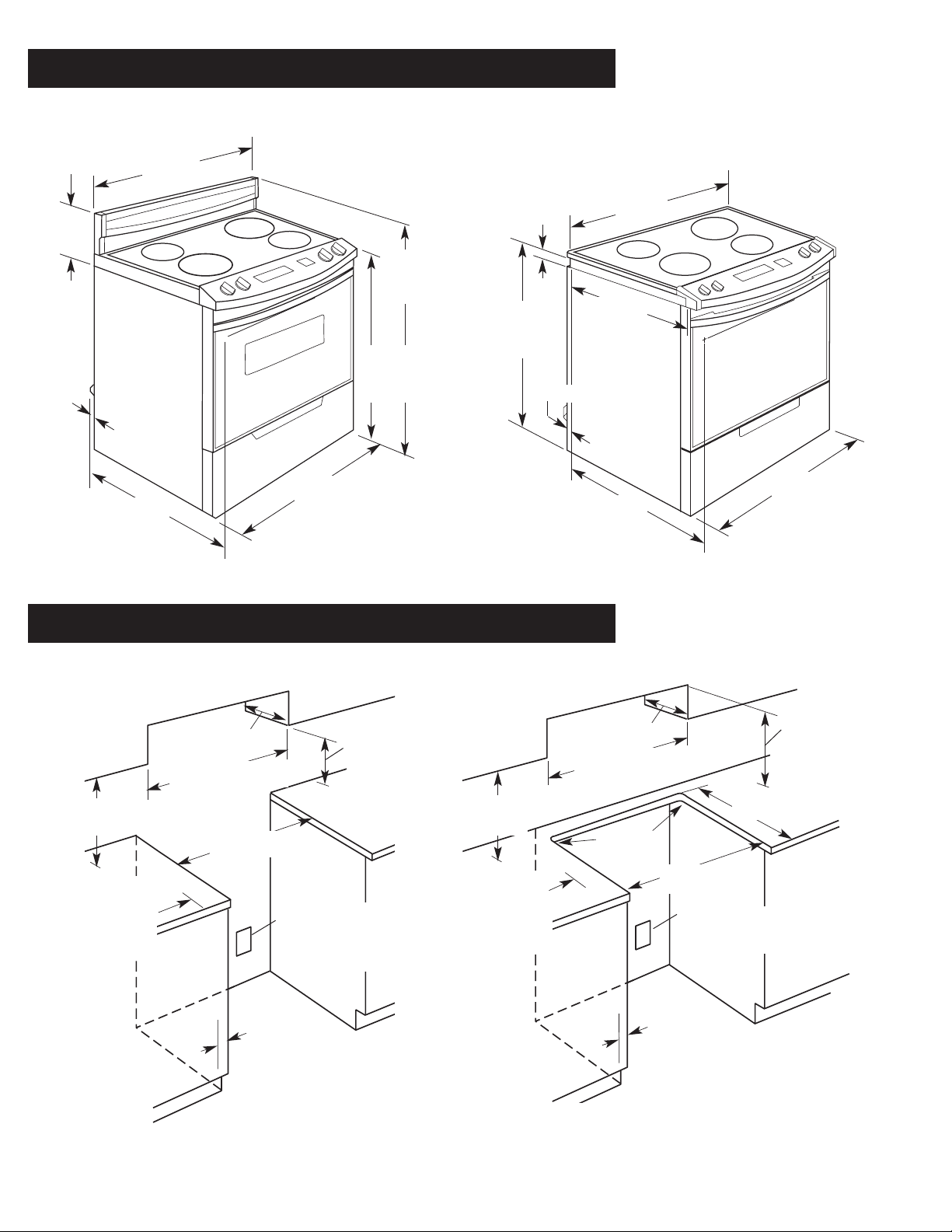

Product dimensions

Cabinet dimensions/requirements

3

Cabinet opening dimensions shown are for:

25" (63.5 cm) countertop depth, 24" (61 cm) base

cabinet depth, 36" (91.4 cm) countertop height

Freestanding Range

Slide-in Range

7/8" (2.2 cm)

min. required

between cutout

and cabinet

door or hinge.

junction box – 8" (20.3 cm) to

22" (55.9 cm) from either

cabinet, 7" (17.8 cm) max. from

floor.

30" (76.2 cm)

opening width

22-3/4" (57.8 cm)

opening depth

4" (10.2 cm)

min. clearance

from both sides

of range to side

wall or other

combustible

material.

***

NOTE: 24" (61 cm) min. when bottom of wood or metal cabinet is

protected by not less than 1/4" (0.64 cm) flame retardant millboard

covered with not less than No. 28 MSG sheet steel, 0.015" (0.4 mm)

stainless steel, 0.024" (0.6 mm) aluminum or 0.020" (0.5 mm) copper.

30" (76.2 cm) min. clearance between the top of the cooking platform

and the bottom of an unprotected wood or metal cabinet.

30" (76.2 cm) min.

cabinet opening width

1/2" (1.3 cm)

radius both

corners

For minimum

clearance to

the top of the

cooktop, see

NOTE.***

18" (45.7 cm)

upper cabinet

to countertop

13" (33 cm) max.

upper cabinet depth

7/8" (2.2 cm)

min. required

between cutout

and cabinet

door or hinge.

junction box –

8" (20.3 cm) to

22" (55.9 cm) from

either cabinet,

7" (17.8 cm) max.

from floor.

30" (76.2 cm)

opening width

4" (10.2 cm)

min. clearance

from both sides

of range to side

wall or other

combustible

material.

30" (76.2 cm) min.

cabinet opening width

For minimum

clearance to

the top of the

cooktop, see

NOTE.***

18" (45.7 cm)

upper cabinet

to countertop

13" (33 cm) max.

upper cabinet depth

Freestanding Range

Slide-in Range

1-1/2"

(3.8 cm)

25-3/4"

(65.4 cm)

depth with

handle

When installed in a 24"

(61 cm) base cabinet with 25"

(63.5 cm) countertop — front of

oven door protrudes 1-7/8" (4.8

cm) beyond 24" (61 cm) base

cabinet.

30"

(76.2 cm)

cooktop

width

36" (91.4 cm)

cooktop

height with

feet loosened

1-1/2 turns

36" (91.4 cm)

cooktop

height with

feet loosened

1-1/2 turns

44-3/8"

(112.7 cm)

overall

height

30"

(76.2 cm)

cooktop

width

8-1/4"

(21 cm)

27-3/4"

(70.5 cm)

depth with

handle

22-5/8"

(57.5 cm)

30"

(76.2 cm)

width

30"

(76.2 cm)

width

1"

(2.5 cm)

1" (2.5 cm)

spacer

Page 4

4

Electrical requirements

Copies of the standards listed may be obtained from:

*National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts, 02269

A four-wire or three-wire, singlephase, 120/240-volt, 60-Hz, AC-only,

electrical supply (or three-wire or fourwire 120/208-volt if specified on the

model/serial rating plate) is required on a

separate, 40 amp circuit, fused on both

sides of the line.

A time-delay fuse or circuit breaker is

recommended.

The range can be connected directly

to the fused disconnect (or circuit breaker

box) through flexible armored conduit.

See “Direct wire method: Copper wire” or

“Direct wire method: Aluminum wire”

sections.

Allow two to three feet of slack in the line

so that it can be moved if servicing is

ever necessary.

A U.L.-listed conduit connector must be

provided at each end of the power supply

cable (at the range and at the junction

box).

Wire sizes and connections must conform

with the rating of the range (40 amps).

The wiring diagram is located on the

back of the range or on the inside of the

storage drawer in a clear plastic bag.

If connecting to a four-wire

system:

This range is manufactured with the

ground connected to the cabinet. The

ground must be revised so the green

grounding wire of the four-wire power

supply cord is connected to the cabinet.

See “Four-wire electrical connection,”

section, Page 6.

When a four-wire receptacle of NEMA

Type 14-50R is used (see Figure 1), a

matching U.L.-listed, four-wire, 250-volt,

40 amp, range power supply cord

(pigtail) must be used. This cord

contains four copper conductors with

ring terminals at the appliance end,

terminating in a NEMA Type 14-50P

plug on the supply end. The fourth

(grounding) conductor must be

identified by a green or green/yellow

cover and the neutral conductor by a

white cover. Cord should be Type SRD

or SRDT with a U.L.-listed strain relief

and be at least four feet long.

The minimum conductor sizes for the

copper four-wire power cord are:

40 amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

If connecting to a three-wire

system:

Local codes may permit the use of a

U.L.-listed, 250-volt, 40 amp range

power supply cord (pigtail). This cord

contains three, No.-10 copper wires and

matches a three-wire receptacle of

NEMA Type 10-50R, shown in Figure 2.

Connectors on the appliance end must

be provided at the point the power

supply cord enters the appliance.

If codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path and wire gauge are in

accordance with local codes.

This range must be connected to a

grounded metal, permanent wiring

system.

Check with a qualified electrician if you

are not sure range is properly grounded.

Do Not ground to a gas pipe.

Do Not have a fuse in the neutral or

ground circuit.

Recommended ground

method

It is the personal responsibility and

obligation of the customer to contact a

qualified electrician to assure that the

electrical installation is adequate and is in

conformance with the National Electrical

Code, ANSI/NFPA 70 — latest edition*

and all local codes and ordinances.

Power supply cord is not supplied, but is

available through your local electrical

supply house.

Range must be connected to the proper

electrical voltage and frequency as

specified on the model/serial rating plate.

(The model/serial rating plate is located

on the oven frame behind the storage

drawer panel.)

3-wire wall

receptacle (10-50R)

Figure 2

Figure 1

4-wire wall

receptacle (14-50R)

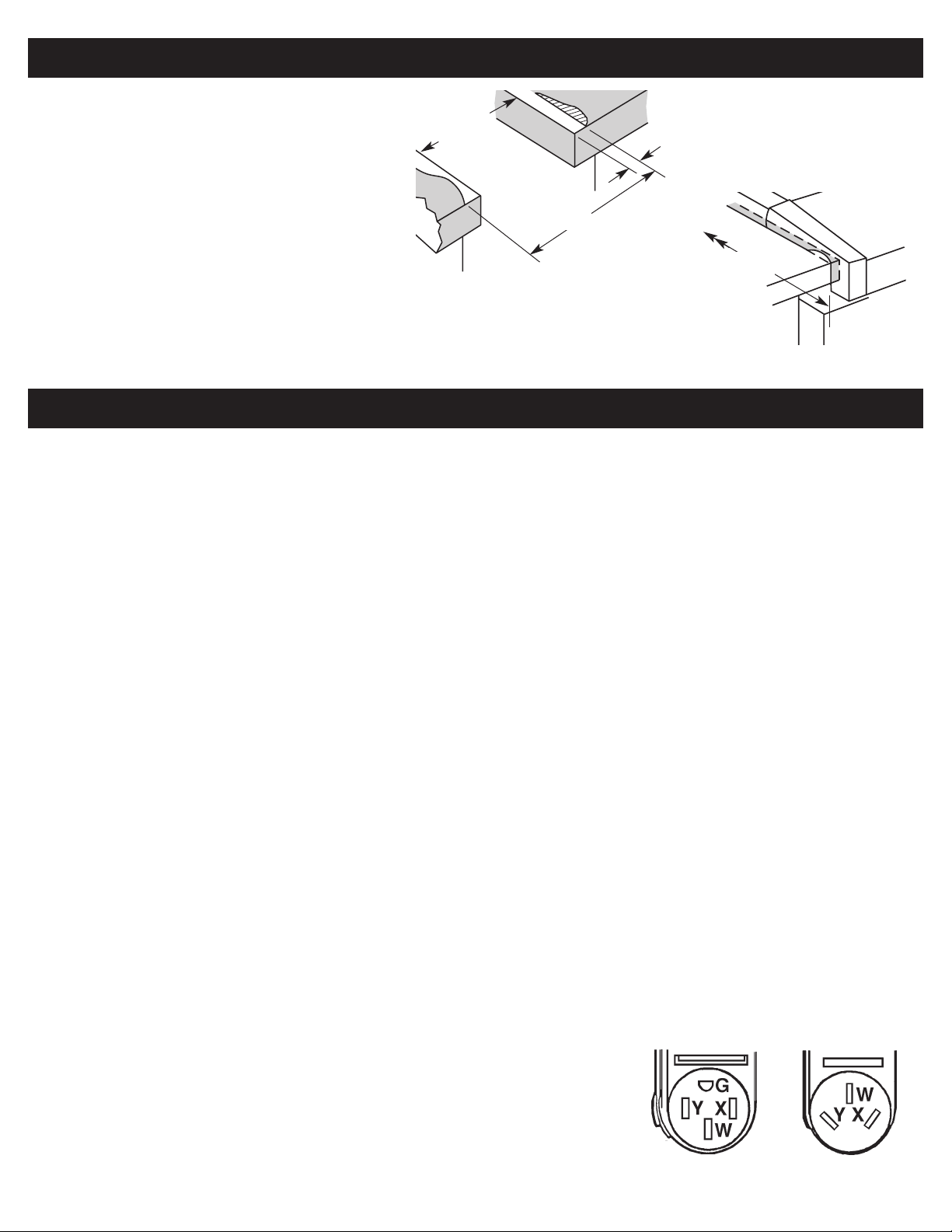

The cooktop sides of the slide-in range fit over the

cutout edge of your countertop.

If you have a square finish (flat) countertop and the

opening width is 30" (76.2 cm), no countertop

preparation is required.

Formed front-edged countertops: Must have molded

edge shaved flat 1/2" (1.3 cm) from each front corner

of opening.

Tile countertops may need trim cut back 1/2" (1.3 cm)

from each front corner and/or rounded edge flattened.

If countertop opening width is greater than 30" (76.2

cm), adjust the 1/2" (1.3 cm) dimension.

Countertop must be level. Place level on countertop,

first side to side; then front to back. If countertop is

not level, range will not be level. Oven must be level

for satisfactory baking conditions.

Formed or tiled countertop

trimmed 1/2" (1.3 cm) back

at front corners of

countertop opening.

30-7/8"

(78.4 cm)

1/2"

(1.3 cm)

22-5/8"

(57.5 cm)

30"

(76.2 cm)

opening

width

Cooktop sides of range fit over

edges of countertop opening.

Slide-in ranges: countertop preparation

Page 5

5

Now start...

Excessive Weight Hazard

Use two or more people to move and

install range.

Failure to do so can result in back or

other injury.

WARNING

1.

Put on safety glasses and gloves.

Remove shipping materials, tape and

protective film from range. Keep

cardboard bottom and shipping base

under range. Remove oven racks and

parts package from inside oven.

2.

Ta ke four

cardboard corners

from the carton.

Stack one cardboard corner on

top of another. Repeat with other two

corners. Place them lengthwise on the

floor behind the range — to support the

range when it is laid on its back. Firmly

grasp the range and gently lay it on its

back on the cardboard corners.

3.

Pull cardboard shipping base

firmly to remove.

4.

Use an

adjustable

wrench to

loosen the

leveling legs four complete turns.

5.

Place cardboard or hardboard in

front of range. Stand range back up onto

cardboard or hardboard.

Electrical connection

8.

Depending on your electrical

supply, make the four-wire or three-wire

connection to the range following the

“Power supply cord method” or “Direct

wire method” instructions for copper

wire or aluminum wire depending on the

connection needed.

terminal

block cover

knockout

opening for

40 amp

power

supply cord

knockout

opening

for power

supply

cable

7.

Remove the terminal block cover

located on the back of range.

Contact a qualified floor covering installer

for the best procedure for drilling

mounting holes through your type floor

covering.

6.

Use the anti-tip bracket template to

install the anti-tip bracket.

Anti-tip bracket must be anchored

securely to the sub-floor.

Depending on the thickness of your

flooring, longer screws may be necessary

to anchor the bracket to the sub-floor.

Longer screws are available from your

local hardware store.

Check that range is on cardboard

shipping base to protect floor covering.

Tip Over Hazard

A child or adult can tip the range

and be killed.

Connect anti-tip bracket to rear

range foot.

Reconnect the anti-tip bracket, if

the range is moved.

Failure to follow these instructions

can result in death or serious

burns to children and adults.

WARNING

Page 6

6

Power supply cord method:

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can

result in death, fire, or electrical shock.

remove knockout

for 40 amp

power cord and

U.L. listed strain

relief

opening for

conduit

connector

1. Disconnect power.

2. Remove the knockout for the 40 amp

power supply cord.

3. Assemble a U.L.-listed strain relief in the

opening.

4. Insert the power supply cord through

the strain relief, allowing enough slack to

WARNING - Improper connection of the

equipment-grounding conductor can

result in a risk of electric shock. Check

with a qualified electrician or serviceman

if you are in doubt as to whether the

appliance is properly grounded. Do not

modify the power supply cord plug. If it

will not fit the outlet, have a proper outlet

installed by a qualified electrician.

This range is manufactured with the

neutral terminal connected to the cabinet.

Use a three-wire, U.L.-listed, 40 amp

power supply cord (pigtail); or if local

codes Do Not permit ground through the

neutral, use a four-wire power supply

cord rated at 250 volts, 40 amps and

investigated for use with ranges. (See

“Four-wire electrical connection.”)

WARNING

easily attach the wiring to the terminal

block.

5. Use only ring-type terminals to

connect the power supply.

6. Complete electrical connection

according to your type electrical

supply (“Four-wire electrical

connection” or “Three-wire electrical

connection.”)

Four-wire electrical

connection:

ground

link

ground-link

screw

Figure1

U.L. listed strain

relief and 40 amp

range power supply

cord

neutral wire

(center wire)

line 1

line 2

green

ground

wire

Figure 2

Use this method for new installations,

mobile homes, recreational vehicles and

whenever four-wire installation is

required.

7. R emove the ground-link screw from the

range frame. Save the ground-link

screw. Bend up the ground link so that

it does not contact the range. See

Figure 1.

8. Connect the green ground wire from

power supply cord to the range using

the ground-link screw. The ground wire

must be attached first and must not

contact any other terminal. See

Figure 2.

9. Use 3/8” nut driver and remove the

outside nuts on the terminal block

screws. Do not loosen the factorytightened nuts behind the outside nuts.

center

terminal

block screw

ground-link

screw

ground link

10. Connect the neutral wire (center wire)

to the center terminal screw on the

terminal block. See Figure 2.

11. Connect the other two wires (lines 1

and 2) to the outer screws on the

terminal block. See Figure 2.

12. Securely tighten nuts with 3/8" nut

driver for proper electrical

connection.

13. Tighten the strain relief screws.

14. Replace the terminal block cover.

15. Plug power supply cord into

grounded electrical outlet.

Three-wire electrical

connection:

U.L.-listed strain

relief and 40 amp

range power supply

cord

ground

link

neutral

(center wire)

line 2

line 1

Figure 3

Use this method only if local codes

permit connecting cabinet-ground

conductor to neutral wire of power

supply cord.

7. Use 3/8” nut driver and remove the

outside nuts on the terminal block

screws. Do not loosen the factorytightened nuts behind the outside nuts.

8. Connect the neutral wire (center wire)

to the center terminal screw on the

terminal block. See Figure 3.

9. Connect the other two wires (lines 1

and 2) to outer terminal screws on the

terminal block. See Figure 3.

10. Securely tighten nuts with 3/8" nut

driver for proper electrical connection.

11. Tighten the strain relief screws.

12. Replace the terminal block cover.

13. Plug power supply cord into grounded

electrical outlet.

center

terminal

block screw

NOTE: The bag containing three

aluminum terminal lugs is not used

when connecting the range using a

power supply cord.

Page 7

7

Direct wire method: Copper or Aluminum wire

1. Disconnect power.

2. Remove the knockout as needed for

conduit connection.

3. Assemble a U.L.listed conduit

connector in

opening.

This range may be connected directly to

the fuse disconnect or circuit breaker box;

or with a U.L.-listed, 40 amp range power

supply cable. Depending on your

electrical supply, make the required threewire or four-wire connection.

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge

aluminum wire.

Electrically ground range.

Failure to follow these instructions can

result in death, fire, or electrical shock.

WARNING

4. Strip the insulation back 1 inch from

the end of each wire.

5. Allow enough slack in the wire to

easily attach the wiring terminal block.

6. Use 3/8” nut driver and remove the

outside nuts on the terminal block

screws. Do not loosen the factorytightened nuts behind the outside nuts.

1”

Use this method only if local codes

permit connecting ground conductor to

neutral supply wire.

10. Loosen (do not remove) the 3 slotted

set screws. Insert the neutral (white)

wire into the hole at the bottom of the

center position lug (attached to center

terminal screw of terminal block). See

Figure 3. Connect the other two wires

(lines 1 and 2) to the outer aluminum

lugs. Securely tighten the set screws.

For 8 gauge copper wire, tighten to

25 in/lbs of torque, and for 6 gauge

aluminum wire, tighten to 35 in/lbs of

torque to make a proper electrical

connection. See Figure 3.

11. Tighten the locking ring of the conduit

connector.

12. Replace the terminal block cover.

Figure 3

Three-wire electrical

connection:

Four-wire electrical

connection:

ground

link

Figure 1

Figure 2

Use this method for new installations,

mobile homes, recreational vehicles and

whenever four-wire installation is

required.

10. Remove the ground-link screw from

the range frame. Save the ground-link

screw and cup washer. Bend up the

ground link so that it does not contact

the range. See Figures 1 and 2.

11. Connect the bare ground wire to the

range using the ground-link screw and

cup washer. The ground wire must be

attached first and must not contact any

other terminal. See Figure 2.

12. Loosen (do not remove) the 3 slotted

set screws. Insert the neutral (white)

wire into the hole at the bottom of the

center position lug (attached to center

terminal screw black terminal block).

See Figure 2. Connect the other two

wires (line 1 and 2) to the outer

aluminum lugs. Securely tighten the

set screws. For 8 gauge copper wire,

tighten to 25 in/lbs of torque, and for

ground

screw

aluminum

lug

terminal

screw

set screw

must face out

slotted

set screw

green

ground

wire

line 1

line 2

neutral

(center

wire)

slotted

set screw

line 1

line 2

neutral

(center

wire)

7. IMPORTANT: the aluminum lugs must

be assembled to the terminal posts

with the set screws facing out as

shown.

6 gauge aluminum wire, tighten to

35 in/lbs of torque to make a proper

electrical connection. See Figure 2.

13. Tighten the locking ring of the

conduit connector.

14. Replace the terminal block cover.

NOTE:The bag containing three

aluminum terminal lugs must be used

when making a direct wire connection.

U.L.-listed

conduit

connector

8. Attach three aluminum lugs to

terminal posts.

Use a 3/8” nut driver and tighten the

nuts securely. Nuts must be tightened

to 20 in/lbs of torque for proper

electrical connection.

9. Complete electrical connection

according to your type electrical

supply (“Four-wire electrical

connection” or “Three-wire electrical

connection.”)

Page 8

8

9.

Move range close to cabinet

opening.

10.

Remove cardboard or

hardboard from under range. Carefully

move range into final position.

11.

Pull drawer open to first stop

position. Lift front of drawer to clear

white wheels in drawer guides. Remove

drawer and set it aside on a protected

surface.

Operating position

13.

If installing the range in a

mobile home, you must secure the range

to the floor. Any method of securing the

range is adequate as long as it conforms

to the standards in the “Mobile home

installation” instructions, Page 2.

14.

Place rack in oven. Place level

on rack, first side to side; then front to

back.

If range is not level, pull range forward

until rear leveling leg is removed from

the anti-tip bracket. Use 3/8" drive ratchet

and channel lock pliers to adjust leveling

legs up or down until range is level. Push

range back into position. Check that rear

leveling leg is engaged in anti-tip bracket.

NOTE: Oven must be level for satisfactory

baking conditions.

15.

Replace the storage drawer or

lower panel.

16.

Reconnect power.

anti-tip

bracket

range foot

12.

Making sure the anti-tip bracket

is installed:

• Look for the anti-tip bracket securely

attached to floor.

• Slide range back so rear range foot is

under anti-tip bracket.

Page 9

9

Check operation

17. Push in and turn each

surface unit control knob to "HI"

position. Check the operation of the

cooktop elements and indicator

lights.

BAKE

BAKED

GOODS

OTHER

FOODS

COOK

TIME

CONVECT

FULL

MEAL

STOP

TIME

OVEN

LIGHT

MEATS

CLEAN

BROIL

• MAXI

• • ECONO

BAKE

BROIL ROAST

EASY CONVECT CONVERSION

CONVECTION

SET•START

CANCEL

CANCEL

OFF

CLOCK

SET • START

START

TIMER

1

2

3

4

56

7

8

0

9

CONTROL

LOCK

888

8:88

18:88

18:88

ON

EASY CONVECT

NIGHT LIGHT DELAY

DEHYDRATE

CONVECTION

ENTER STAND ARD COOK TIME

COOK TEMP

CLEAN TIME

RAISING

BREAD

CHECK

FOOD AT

CLOSE

DOOR

CONTROL

LOCKED

LOCK

START ?

START

TIME

STOP

TIME

O

F

SET PROBE TEMP

18:88

HR MIN

MIN SEC

Control panels may vary.

To get the most efficient use from

your new electric range, read

your KitchenAid Use and Care

Guide. Keep Installation

Instructions and Guide close to

the electric range for easy

reference.

18. Check the operation of the

oven element. Press the “BAKE” pad.

“350°F” will appear in the

temperature display. Press the

“START” pad. “Lo” will appear in the

display; then “170°F” (when oven

reaches 170°F).

The bottom element should glow red

and the indicator light should be on.

The upper element should become

hot but not glow red. As the oven

temperature rises, the temperature in

the display will increase in 5°F

increments until the oven reaches

the set temperature.

Press “CANCEL/OFF” pad.

OFF

LO

HI

MED LO

MED

MED HI

19. Check the operation of the

broil element. Close the oven door.

Press the “BROIL” pad. “500°F” will

appear in the temperature display.

Press the “START” pad.

Look through the oven window. The

top element should glow red. Press

the “CANCEL/OFF” pad.

Page 10

10

If range does not

operate:

Check that the circuit breaker is

not tripped or the house fuse

blown.

Check that the power supply cord

is plugged into the outlet.

See Use and Care Guide for

troubleshooting list.

If you need

assistance:

If you have questions about operating,

cleaning or maintaining your range:

Refer to Use and Care Guide.

The KitchenAid Consumer

Assistance Center will answer any

questions about operating or

maintaining your range not covered

in the Installation Instructions. The

KitchenAid Consumer Assistance

Center is open 24 hours a day, 7

days a week. Just dial 1-800-4221230 – the call is free within the

continental United States.

When you call, you will need the

range model number and serial

number. Both numbers can be

found on the model/serial rating

plate located on the oven frame

behind the door.

If you need

service:

In the event that your KitchenAid

appliance should need service, call

the dealer from whom you

purchased the appliance or a

KitchenAid- authorized service

company. A KitchenAid- authorized

service company is listed in the

Yellow Pages of your telephone

directory under “Appliances –

Household – Major – Service &

Repair." You can also obtain the

service company’s name and number

by dialing, free within the continental

United States, the KitchenAid

Customer Interaction Center

telephone number, 1-800-422-1230. A

special operator will tell you the

name of your nearest KitchenAidauthorized service company.

Maintain the quality built into your

KitchenAid appliance — call a

KitchenAid-authorized service

company.

Moving the range:

When moving range, slide range onto

cardboard or hardboard to prevent

damaging the floor covering.

If removing the range is necessary for

cleaning or maintenance:

1. Unplug range or disconnect power.

2. Slide range forward to complete

cleaning or maintenance.

3. Make sure the anti-tip bracket is

installed:

• Look for the anti-tip bracket

securely attached to floor.

• Slide range back so rear range

foot is under anti-tip bracket.

4. Check that range is level.

5. Plug in range or reconnect power.

anti-tip

bracket

range foot

Tip Over Hazard

A child or adult can tip the range

and be killed.

Connect anti-tip bracket to rear

range foot.

Reconnect the anti-tip bracket, if

the range is moved.

Failure to follow these instructions

can result in death or serious

burns to children and adults.

WARNING

Page 11

11

Notes

Page 12

Printed in U.S.A.

Part No. 9757988

© 2003 KitchenAid

® Registered Trademark

of KitchenAid.

Prepared by KitchenAid, Benton Harbor, Michigan 49022

®

HOME APPLIANCES

Loading...

Loading...