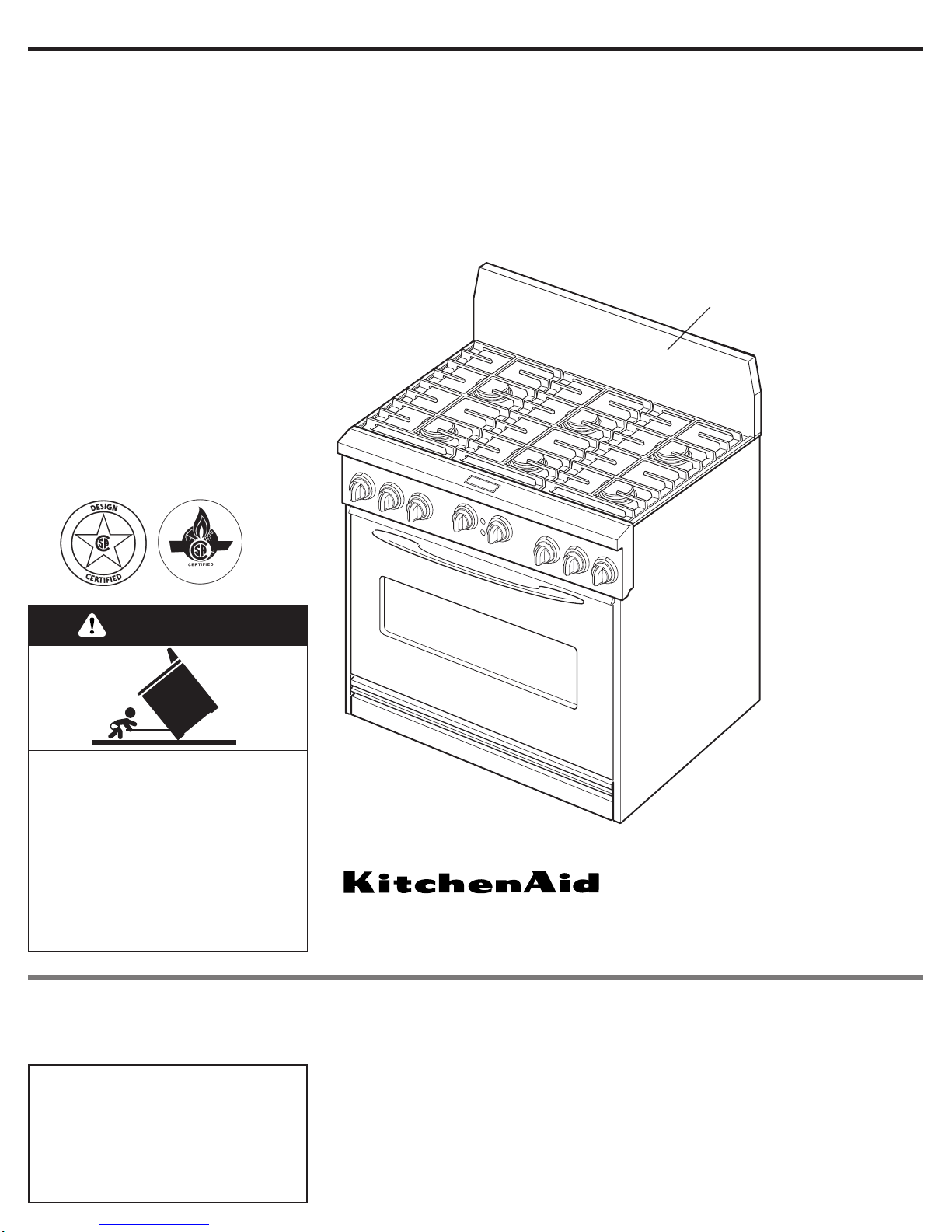

KitchenAid Architect Series KDRP462LSS, KDRP463LSS - 36"" Pro-Style Dual Fuel Range Installation Instructions Manual

Part No.8301169 Rev. A

Installation Instructions

IMPORTANT:

Installer: Leave Installation

Instructions with the homeowner.

Homeowner: Keep Installation

Instructions for future reference.

Save Installation Instructions for local

electrical inspector’s use.

Write down the model and serial numbers

before installing range.

Both numbers are on the model/serial

rating plate, located on the surface below

the control panel.

Model #___________________________

Serial # ___________________________

Questions regarding features,

operation, performance, parts or

service? Call 1-800-422-1230 or visit

our web site at www.kitchenaid.com.

IMPORTANT:

Read and save these

instructions.

36" (91.4 cm) Commercial Style Dual Fuel Range

with self-cleaning thermal/convection oven

for residential use only

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

backguard

(required for some installations)

For the way it’s made

®

®

Tip Over Hazard

A child or adult can tip the range

and be killed.

Connect anti-tip bracket to wall

behind range.

Reconnect the anti-tip bracket, if

the range is moved.

Failure to follow these instructions

can result in death or serious

burns to children and adults.

WARNING

O

FF

OFF

OFF

O

F

F

O

F

F

OFF

OFF

OFF

Before you start...

It is the customer’s responsibility:

• To contact a qualified electrical installer.

• To assure that electrical installation is

adequate and in conformance with

National Electrical Code, ANSI/NFPA

70 — latest edition**, or CSA Standard,

C22.1 Canadian Electrical Code, Part 1

— latest edition*, and all local codes

and ordinances.

Cabinet opening dimensions shown must

be used. Given dimensions are minimum

clearances.

When installing a range under existing

cabinets and installation does not meet

the minimum cabinet clearances, install a

range hood above the range to avoid burn

hazards.

NOTE: Some cabinet and building

materials are not designed to withstand

the heat produced by the oven for baking

and self-cleaning. Check with your builder

or cabinet supplier to make sure that the

materials used will not discolor,

delaminate or sustain other damage.

All openings in the wall or floor where the

range is to be installed must be sealed.

It is recommended that a range hood be

installed above this range.

NOTE: The range cooktop is

manufactured for use with Natural gas.To

convert to L.P./Propane gas, see the Gas

Conversion instructions provided in

literature package.

Proper gas and electrical supply

connections must be available. See “Gas

supply requirements,” Page 4 and

“Electrical requirements,” Page 5.

IMPORTANT: Observe all governing

codes and ordinances.

Do not obstruct flow of combustion and

ventilation air.

Proper installation is your responsibility.

Have a qualified technician install this

range. Make sure you have everything

necessary for correct installation. It is the

installer's responsibility to comply with the

installation clearances specified on the

gas information label.The gas information

label and model/serial rating plate are

located on the surface below the control

panel.

This installation must conform with all

local codes and ordinances. In the

absence of local codes, installation must

conform with American National

Standard, National Fuel Gas Code ANSI

Z223.1 — latest edition* or CAN/CGA —

B149 — latest edition* installation codes.

WARNING: If the

information in this manual

is not followed exactly, a

fire or explosion may result

causing property damage,

personal injury or death.

— Do not store or use

gasoline or other

flammable vapors and

liquids in the vicinity of

this or any other

appliance.

— WHAT TO DO IF YOU

SMELL GAS

• Do not try to light any

appliance.

• Do not touch any

electrical switch.

• Do not use any phone in

your building.

• Immediately call your

gas supplier from a

neighbor’s phone. Follow

the gas supplier’s

instructions.

• If you cannot reach your

gas supplier, call the fire

department.

— Installation and service

must be performed by a

qualified installer, service

agency or the gas

supplier.

2

Copies of the standards listed may be obtained

from:

* CSA Inter national

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

** National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

IMPORTANT: Observe all governing

codes and ordinances.

You can be killed or seriously

injured if you don’t follow

instructions.

DANGER

Your safety and the safety of

others are very important.

We have provided many impor tant

safety messages in this manual and

on your appliance.Always read and

obey all safety messages.

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

You can be killed or seriously

injured if you don’t immediatel

y

follow instructions.

WARNING

This is the safety alert

symbol.

This symbol alerts you to

potential hazards that can kill or hurt

you and others.

All safety messages will follow the

safety alert symbol and either the

word “DANGER” or “WARNING”.

These words mean:

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

3

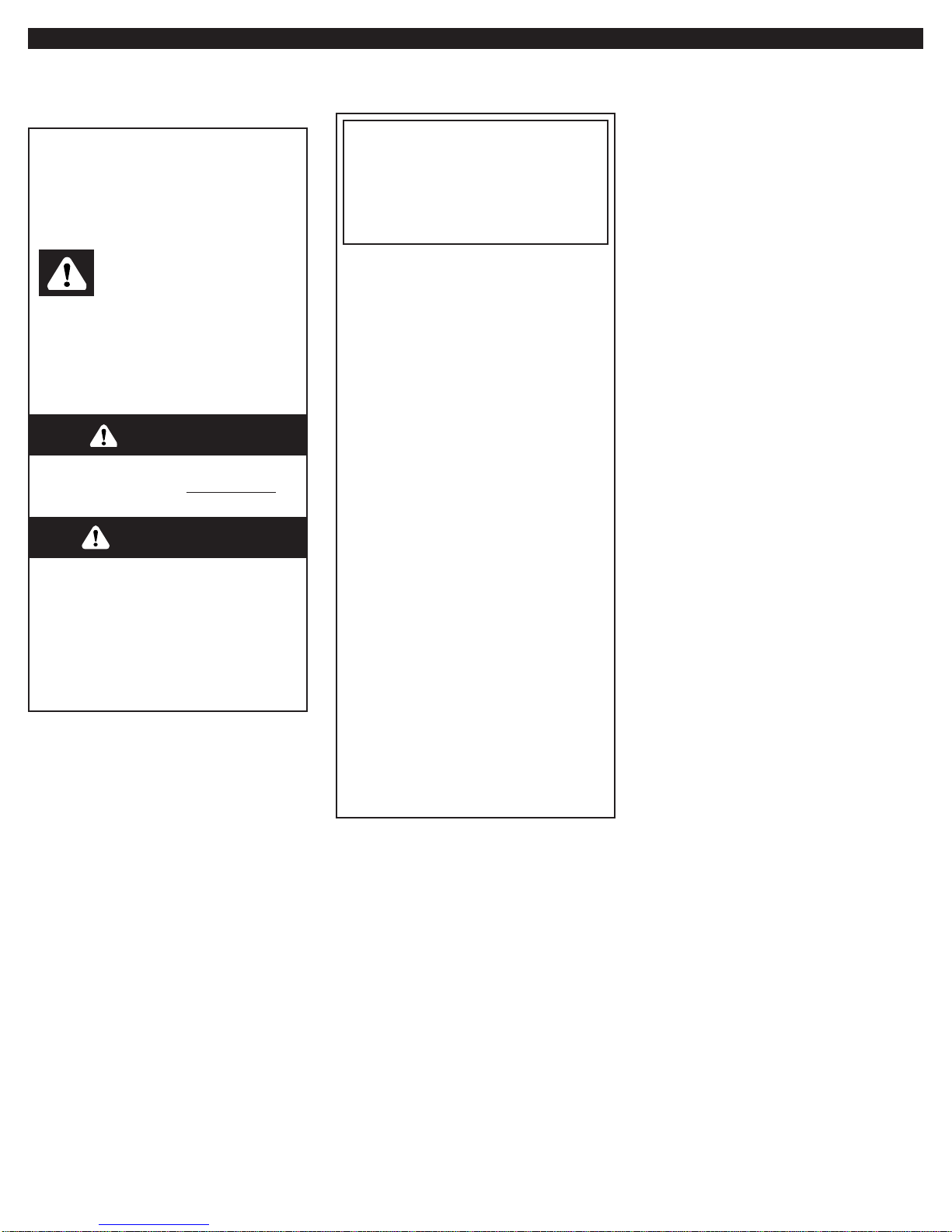

Parts supplied for

installation

Product

dimensions

36" (91.4 cm)

cooktop width

36" (91.4 cm)

width

9-1/4"

(23.5 cm)

anti-tip

brackets

1-3/4"

(4.4 cm)

1"

(2.5 cm)

2 - #10 x 2"

phillips head screws

36" (91.4 cm)

cooktop

height with

feet loosened

3/4 turns

NOTE: regulator

located at center

bottom of range.

36" (91.4 cm) range with

all sealed burners shown

45" (114.3 cm)

overall height

13" (33 cm) max.

upper cabinet depth

1/4" (6.4 mm)

spacer

26-1/2" (67.3 cm)

width with

control panel

• Anti-tip bracket must be securely

attached to a wall stud.Thickness of

finished wall may require using

longer screws to anchor the bracket.

• L.P. conversion kit is included in

literature package.

• Backguard and island trim.The

backguard included with the range

must be installed when a standard

24" (61 cm) deep base cabinet is

used and there is zero clearance

between the back edge of range

and combustible rear wall.

For island installations or other

installations with more than 5"

(12.7 cm) clearance to back wall,

use the optional stainless steel

island trim, included with the range,

to cover the backguard mounting

flanges.

36" (91.4 cm) min.

upper cabinet width

36-1/4" (92.1 cm)

opening width

20"

(50.8 cm)

12"

(30.5 cm)

5-1/2" (14 cm)

8"

(20.3 cm)

18" (45.7 cm)

upper cabinet

to countertop

gas line opening to be

located in this area

junction box to be

located in this area

4" (10.2 cm) min.

clearance from both sides

of range to side wall or

other combustible material

above cooking surface

0" (0 cm) clearance from

both sides and back of

range to adjacent

combustible construction

below cooking surface

*NOTE: 42" (106.7 cm) min. when bottom of wood or

metal cabinet is protected by not less than 1/4" (6.4 mm)

flame retardant millboard covered with not less than

No. 28 MSG sheet steel, 0.015" (0.4 mm) stainless steel,

0.024" (0.6 mm) aluminum or 0.020" (0.5 mm) copper.

48" (121.9 cm) min. clearance between the top of the

cooking platform and the bottom of an unprotected wood

or metal cabinet.

For minimum

clearance to top of

range, see NOTE.*

28"

(71.1 cm)

4"

(10.2 cm)

3" (7.6 cm) maximum

gas line height

3-1/2" (8.9 cm)

maximum junction

box height

Cabinet opening

dimensions

O

FF

O

F

F

O

F

F

O

F

F

O

F

F

O

F

F

O

FF

O

F

F

4

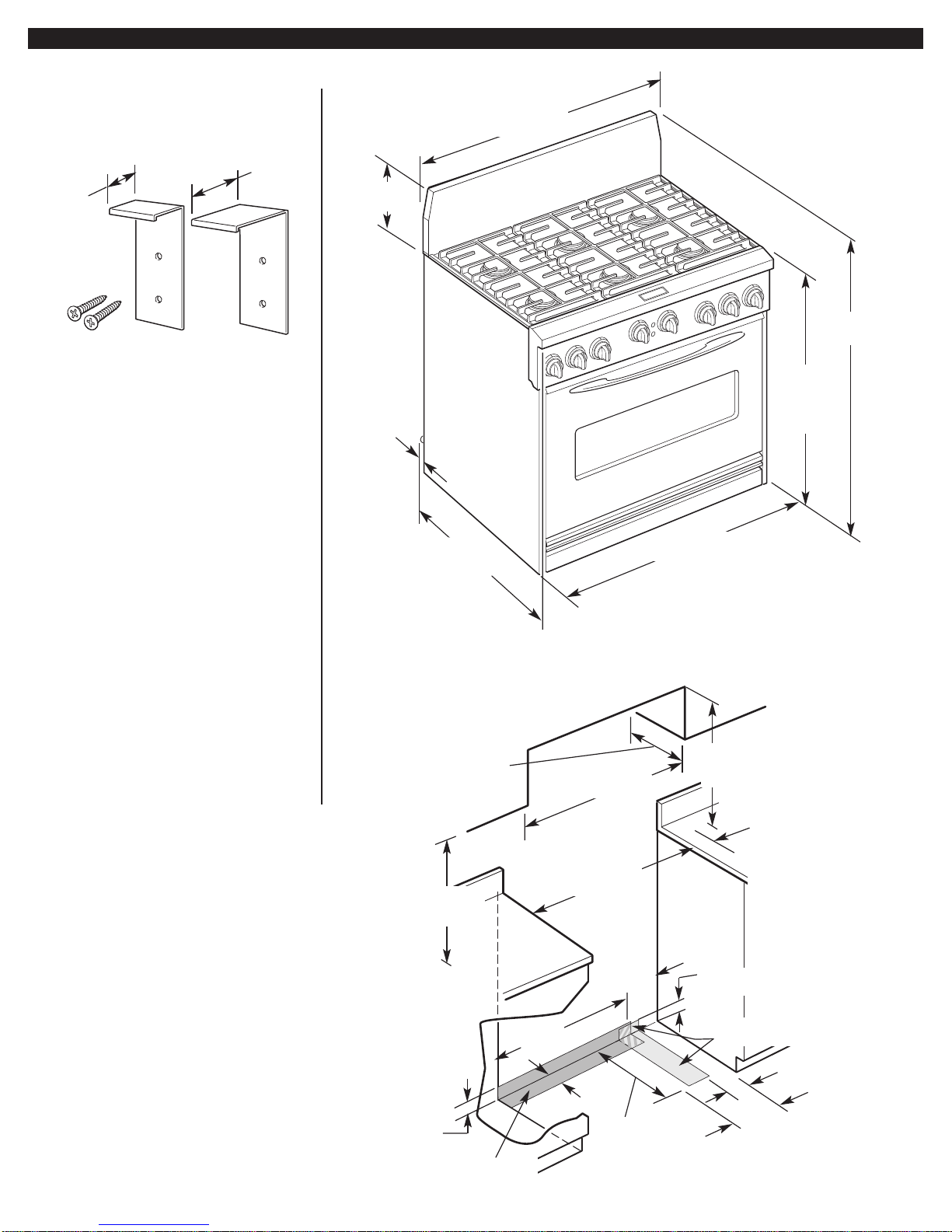

Gas supply

requirements

Observe all governing codes and

ordinances.

IMPORTANT: Range cooktop must be

connected to a regulated gas supply.

A.This installation must conform

with local codes and ordinances. In the

absence of local codes, installations must

conform with American National

Standard, National Fuel Gas Code

ANSI Z223.1 — latest edition* or

CAN/CGA-B149 — latest edition*

installation codes.

B.Input ratings shown on the

model/serial rating plate are for elevations

up to 2,000 feet (610 m). For elevations

above 2,000 feet (610 m), ratings are

reduced at a rate of 4% for each 1,000

feet (305 m) above sea level. (Not

applicable for Canada.)

Copies of the standards listed may be

obtained from:

* CSA Inter national

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

D.

Provide a gas supply line of 3/4"

(1.9 cm) rigid pipe to the range location. A

smaller size pipe on long runs may result

in insufficient gas supply. Pipe-joint

compounds, appropriate for use with L.P.

gas, must be used.With L.P. gas, piping or

tubing size can be 1/2" (1.3 cm) minimum.

L.P. gas suppliers usually deter mine the

size and materials used on the system.

L.P. Gas:

No attempt shall be made to convert the

cooktop from the gas specified on the

model/serial rating plate for use with a

different gas without consulting the

serving gas supplier. Conversion must be

done by a qualified service technician.To

convert to L.P. gas, use L.P. gas

conversion kit part no.8301439.The parts

for this kit are in the literature package

supplied with range.

E.If local codes permit, a new AGA

or CSA design-certified, 4-5 foot (122-

152.4 cm) long, 5/8" (1.6 cm) I.D., flexible

metal appliance connector is

recommended for connecting this range

to the gas supply line. Do not kink or

damage the flexible tubing when moving

the range. A 1/2

"

(1.3 cm) male pipe

thread is needed for connection to

pressure regulator female pipe threads.

F.The supply line shall be equipped

with an approved shutoff valve.This valve

should be located in the same room, but

external to the range, and should be in a

location that allows ease of opening and

closing. Do not block access to the

shutoff valve.

gas supply

line

shutoff valve

“open” position

G.If rigid pipe

is used as a gas

supply line, a combination of pipe

fittings must be used to obtain an in-line

connection to the range. All strains must

be removed from the supply and fuel lines

so range will be level and in line.

to range

H.The regulator must be checked at a

minimum 1-inch (25.4 mm) water column

above the set pressure.The inlet pressure to

the regulator should be as follows for

operation and checking the regulator setting:

NATURAL GAS:

Manifold pressure –

5 inches (12.7 cm) W.C.

Maximum pressure –

14 inches (35.6 cm) W.C.

L.P. GAS:

Manifold pressure –

10 inches (25.4 cm) W.C.

Maximum pressure –

14 inches (35.6 cm) W.C.

I.Line pressure testing:

Testing above 1/2 psi (3.5 kPa) (gauge):

The range and its individual shutoff valve

must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures

greater than 1/2 psig (3.5 kPa).

Testing at 1/2 psi (3.5 kPa) (gauge)

or lower: The range must be isolated from

the gas supply piping system by closing

its individual manual shutoff valve during

any pressure testing of the gas supply

piping system at test pressures equal to

or less than 1/2 psig (3.5 kPa).

C.

The range is equipped for use with

NATURAL gas. It is design-certified by

International Approval Services (I.A.S.) for

NATURAL and L.P. gases with appropriate

conversion.The model/ser ial rating plate,

located on the surface below the control

panel, has information on the type of gas

that can be used. If this information does

not agree with the type of gas available,

check with the local gas supplier.

WARNING

Explosion Hazard

Use a new AGA or CSA approved

gas supply line.

Install a shutoff valve.

Securely tighten all gas

connections.

If connected to LP, have a

qualified person make sure gas

pressure does not exceed 14"

(35.6 cm) water column.

Examples of a qualified person

include:

Licensed heating personnel,

Authorized gas company

personnel, and

Authorized service personnel.

Failure to do so can result in

death, explosion, or fire.

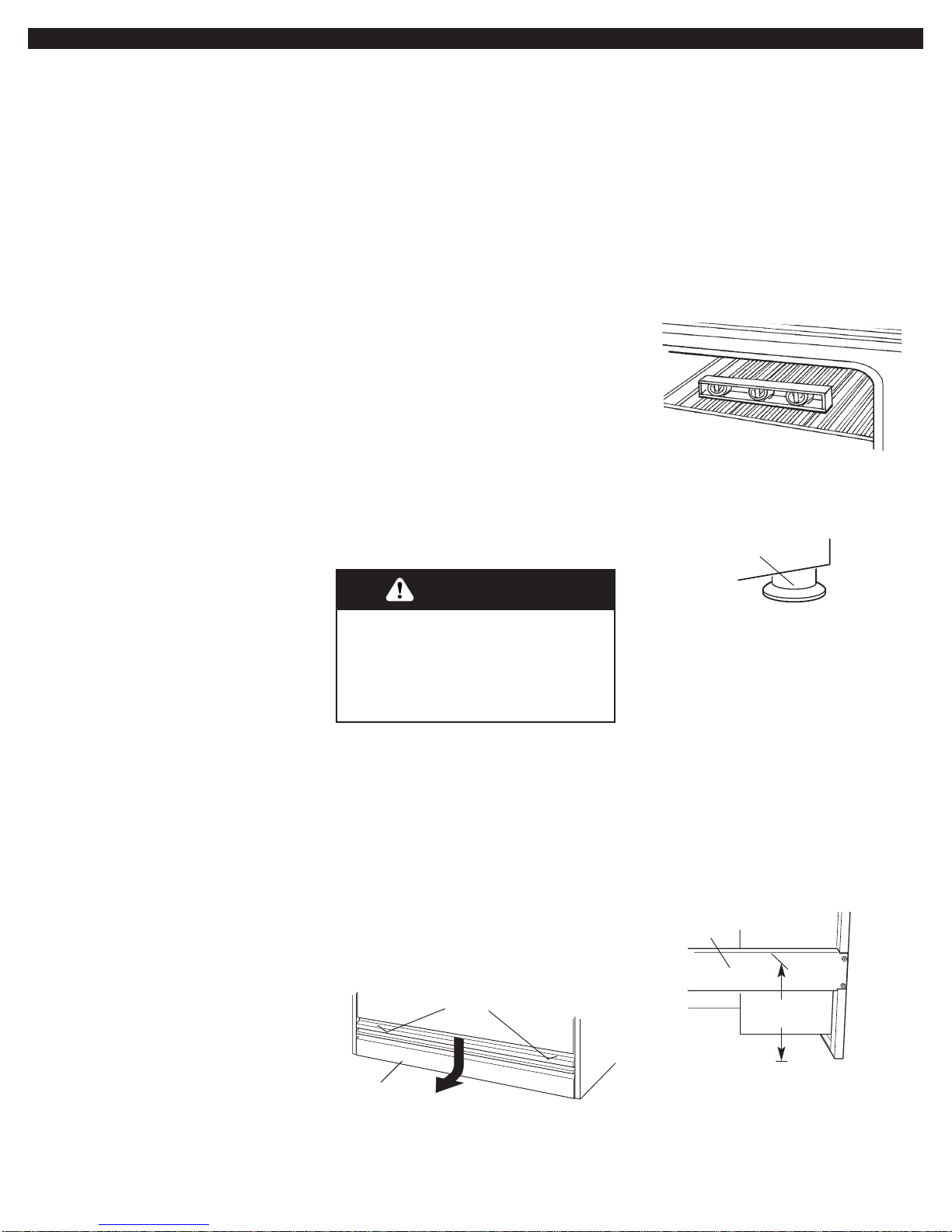

4.Carefully move range

close to the cabinet opening. Place the

rack in oven.Place level on rack, first side

to side; then front to back.

If the range is not level, adjust the feet up

or down.Tur n leveling leg sleeves to level

range and to raise or lower range to the

desired countertop height.

5

remove

screws

bottom

vent

leveling leg

sleeves

Electrical

requirements

F. Connection at connection block must

be copper wire only.

If the house has aluminum wiring, follow

the procedure below:

a) Connect the aluminum wiring to the

copper wiring using special connectors

designed and Underwriters

Laboratories-listed for joining copper to

aluminum. Follow the electrical

connector manufacturer’s recommended

procedure.

b) Aluminum/copper connection must

conform with local codes and industryaccepted wiring practices.

Copies of the standards listed may be obtained

from:

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

**CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

If codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path and wire gauge are in

accordance with local codes.

Do not ground to a gas pipe.

Check with a qualified electrician if you

are not sure the range is properly

grounded.

Do not have a fuse in the neutral or

ground circuit.

This range must be connected to a

grounded metal, permanent wiring

system.

A.A four-wire or three-wire, single

phase, 240-volt, 60-Hz, AC-only electrical

supply is required on a separate, 30ampere circuit, fused on both sides of the

line. A time-delay fuse or circuit breaker is

recommended.The fuse size must not

exceed the circuit rating of the range

specified on the model/serial rating plate

located on the horizontal surface below

the control panel.

B.Wire sizes and connections must

conform to the requirements of the

National Electrical Code ANSI/NFPA 70 –

latest edition*, or CSA Standards C22.194, Canadian Electrical Code, Part 1 and

C22.2 No.0-M91 - latest edition** and all

local codes and ordinances.

C.The range should be connected

directly to the fused disconnect or circuit

breaker box through flexible, armored or

non-metallic sheathed, copper cable.The

flexible, armored cable extending from the

fuse box or circuit breaker box should be

connected directly to the junction box.

D.Locate the junction box to allow

as much slack as possible between the

junction box and the range so that the

range can be moved if servicing is ever

necessary.Do not cut the conduit.

E.A U.L.- or CSA-listed conduit

connector must be provided at each end

of the power supply cable (at the cooktop

and at the junction box).

Installation

Excessive Weight Hazard

Use two or more people to move

and install range.

Failure to do so can result in back

or other injury.

WARNING

1.Put on safety glasses and gloves.

Remove shipping materials, tape and

protective film from range.Keep shipping

pallet under range. Unpack the burner

grates, burner caps, simmer plate, grille

grate, drip tray, spill guard, wave tray,

wave plate, tile bezels, regulator,

backguard and island trim. Items are

either packaged in the range or on the

range. Parts shipped with range depend

on model ordered.

2.Remove the bottom vent by

removing the 2 screws on each side of

the top of the bottom vent, Slide the vent

3.Lay a piece of cardboard from side

packing on the floor behind range.Using

2 people, firmly grasp each side of range.

Lift range up about 3 inches (8 cm) and

move it back until the range is off

shipping pallet. Set range on cardboard to

avoid damaging floor.

5.Choose the correct bracket for your

installation.

• If the wall behind the range has no

baseboard or a baseboard up to 3/8

"

(9.5 mm) thick, use the shorter 1

"

(2.5 cm) anti-tip bracket.

• If the wall behind the range has a

baseboard thicker than 3/8

"

(9.5 mm),

use the longer 1-3/4

"

(4.4 cm) anti-tip

bracket.

Locate a stud in wall behind range.

Measure distance from top of rear brace

to floor.Add 5/16

"

(7.9 mm) to

measurement to allow anti-tip bracket to

slide over rear brace.Use this final

measurement and mark a horizontal line

on wall where stud is located.

write down

this distance

rear

brace

down and pull toward you.Carefully lay

this part to the side to avoid scratching

the stainless steel.

6

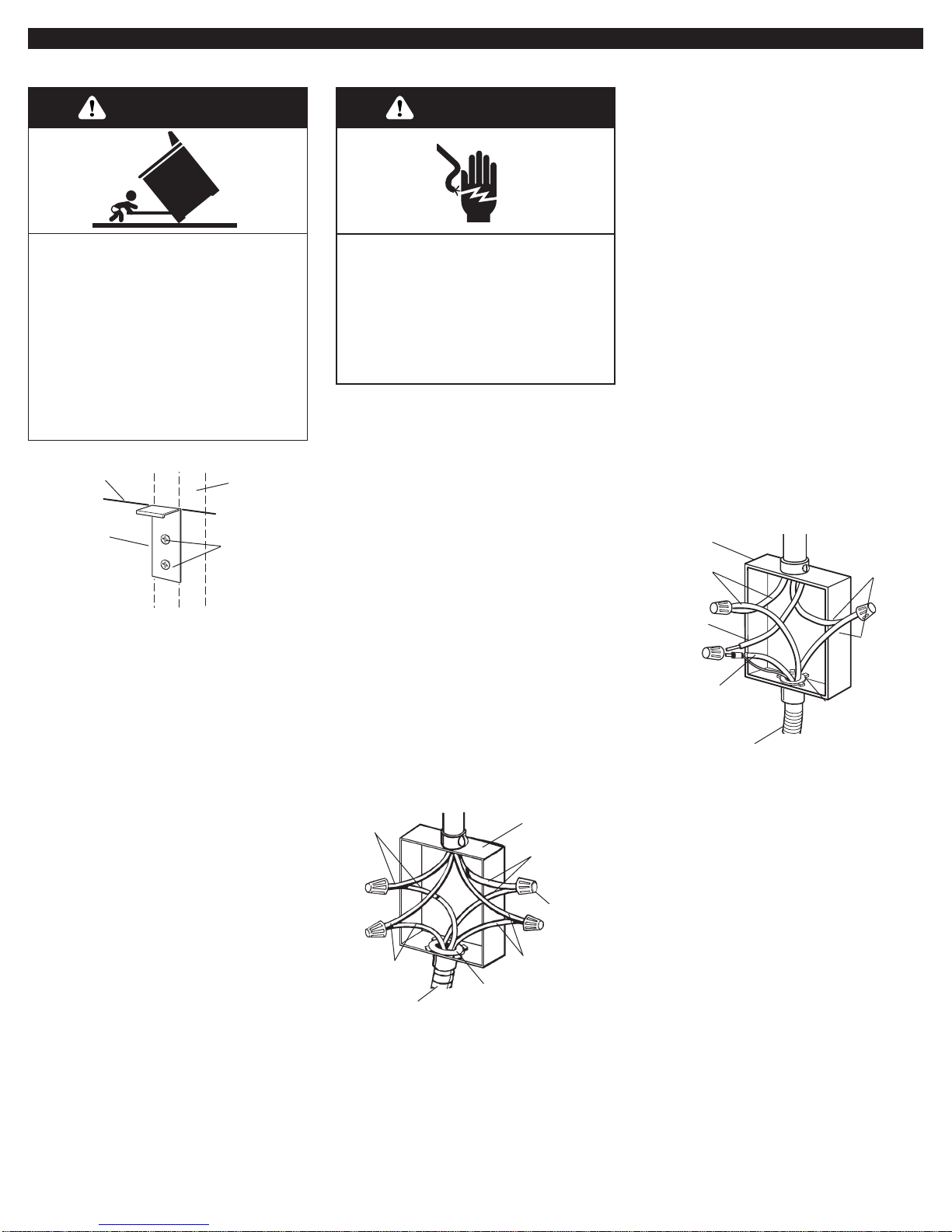

6.Position top of anti-tip bracket at

line marked in step 5 and mark holes.

Drill two 1/8" (3 mm) holes. Use screws

provided to fasten anti-tip bracket to wall.

NOTE: Anti-tip bracket must be mounted

securely to stud in wall behind the range.

Depending on thickness of the wall

covering, longer screws may be required.

7.Make electrical connection.

If your house has aluminum wiring, see

“Electrical requirements” page 5.

wall stud

line

mounting

screws

anti-tip

bracket

This range must be connected to a

grounded, metallic permanent wiring

system or a ground connector should be

connected to the ground terminal or wire

lead on the range.

This range is manufactured with a frameconnected, green or bare ground wire

factory-cr imped to the neutral (white)

wire. Connect the range cable to the

junction box through the U.L.- or CSAlisted conduit connector.Complete

electrical connection according to local

codes and ordinances.

7A.Where local codes Do Not

permit connecting the frame-ground

conductor to the neutral (white) junction

box wire (also used for Canadian

installations):

1. Disconnect power supply.

2. Connect the flexible, armored cable

from the range to the junction box

using a U.L.- or CSA-listed conduit

connector.Tighten screws on conduit

connector.

junction box

4-wire cable from power supply

twist-on

connector

black wires

U.L.- or CSA- listed

conduit connector

4-wire cable from range

bare or green

wires

white wires

red wires

Figure 1

Ungrounded neutral

7B.Where local codes per mit

connecting the frame-ground conductor to

the neutral (white) junction box wire (not

used for Canadian installations):

Figure 2

Grounded neutral

junction

box

red

wires

white

wire

white and bare grounding

oven cable wires —

factory crimped

3-wire cable from

power supply

black

wires

4-wire cable from range

U.L.- or CSA- listed

conduit connector

1. Disconnect power supply.

2. Connect the flexible, armored cable

from the range to the junction box

using a U.L.- or CSA-listed conduit

connector.Tighten screws on conduit

connector.

3. Connect the two black wires together;

the two red wires together; and the

factory-cr imped bare and white

cooktop cable wires to the white

(neutral) wire in the junction box using

twist-on connectors. (See Figure 2.)

3. Connect the two black wires

together; and the two red wires

together using twist-on connectors.

(See Figure 1.)

4. Separate the factory-crimped bare

and white range cable wires.

5. Connect the two white wires together

using twist-on connector.

6. Connect the bare ground wire from

the range cable to the grounded wire

in the junction box or other grounded

connector using twist-on connector.

(See Figure 1.) Do not connect bare

ground wire to neutral (white) wire in

junction box.

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground range.

Failure to follow these instructions

can result in death, fire, or

electrical shock.

WARNING

Tip Over Hazard

A child or adult can tip the range

and be killed.

Connect anti-tip bracket to wall

behind range.

Reconnect the anti-tip bracket, if

the range is moved.

Failure to follow these instructions

can result in death or serious

burns to children and adults.

WARNING

7

8.Remove cardboard or hardboard

from under range.

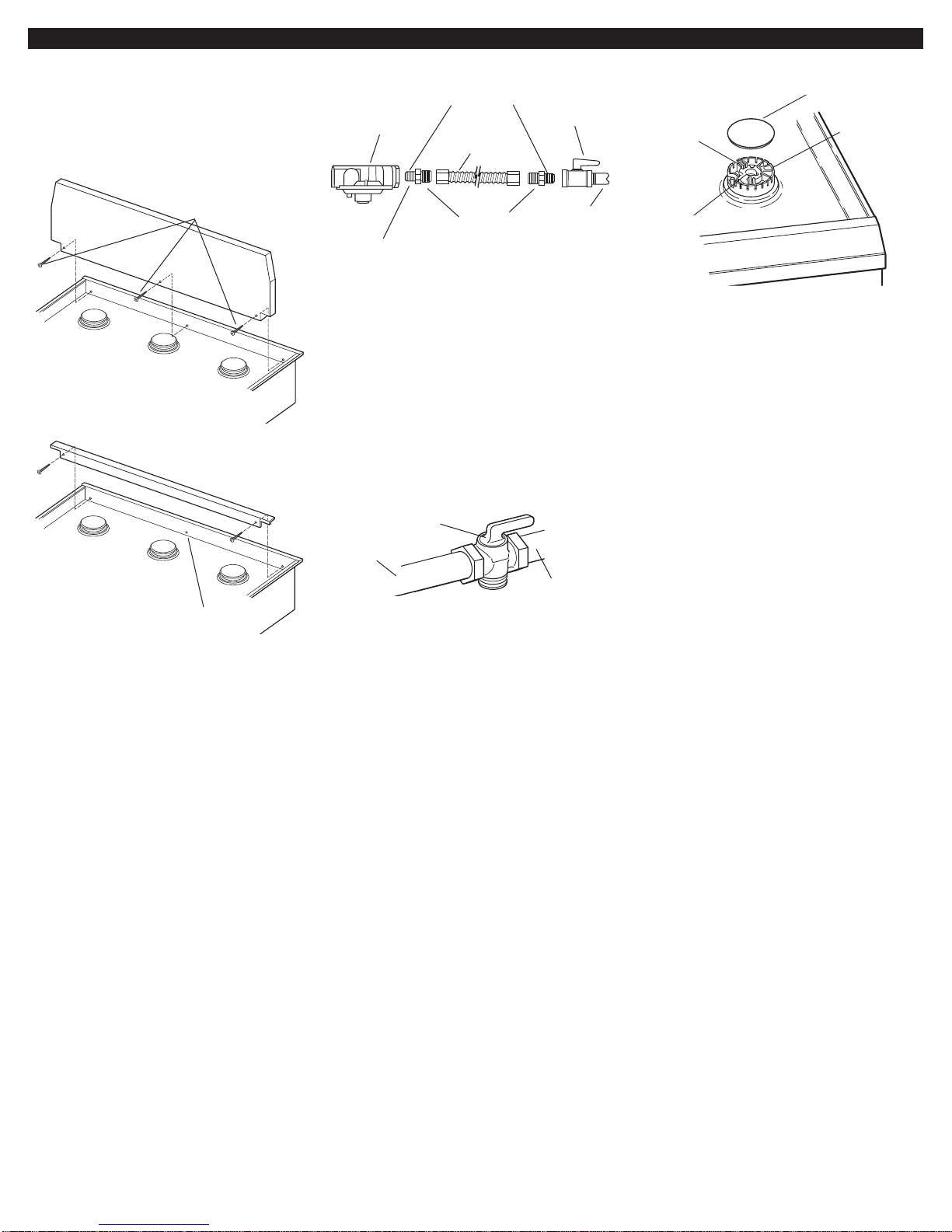

9.Attach the backguard or island trim

as required for your installation.

Attachment screws are in the literature

package.

10.Slide range completely back so

anti-tip bracket is over rear brace of

range.

11. Make gas connection. Assemble

flexible connector from gas supply pipe to

pressure regulator located in the middle

front of the range. Apply pipe-joint

compound made for use with L.P. gas to

the smaller thread ends of the flexible

connector adapters. Attach one adapter

to the pressure regulator elbow and the

other adapter to the gas shutoff valve.

Tighten both adapters.

13. Leak testing of the appliance

shall be conducted according to the

following instructions:

Use a brush and liquid detergent to test

all gas connections for leaks.Bubbles

around connections will indicate a leak. If

a leak appears, shut off gas valve

controls and adjust connections.Then

check connections again. Clean all

detergent solution from range.

14. Put a burner cap on each

burner base. Place burner grates over

burner bases and caps.

If your model has only surface burners

(no grille or griddle), go to “Check the

operation of the surface burners, grille

and griddle” on Page 9.

If your model was shipped with a grille or

griddle, go to “Installing the grille or

griddle” on Page 8 to complete the

installation.

15.Turn on power supply. “PF”

should appear in the clock display. (Refer

to your Use and Care Guide for

instructions on using the electronic

control.)

12. Open manual shutoff valve in

gas supply line.Wait a few minutes for

gas to move through the line.

attaching the

backguard

attaching the island

trim

center hole

not used

3 front screws

(4 rear screws required

but not shown)

use pipe-joint

compound

flexible

connector

1/2" flare union

adapter

manual gas

shutoff valve

1/2" to 3/4" gas

pipe

a 1/2" male pipe thread is needed for connection

to pressure regulator female pipe threads

regulator

gas supply

line

shutoff valve

“open” position

to range

burner cap

burner

base

ignitor

electrode

gas tube

opening

8

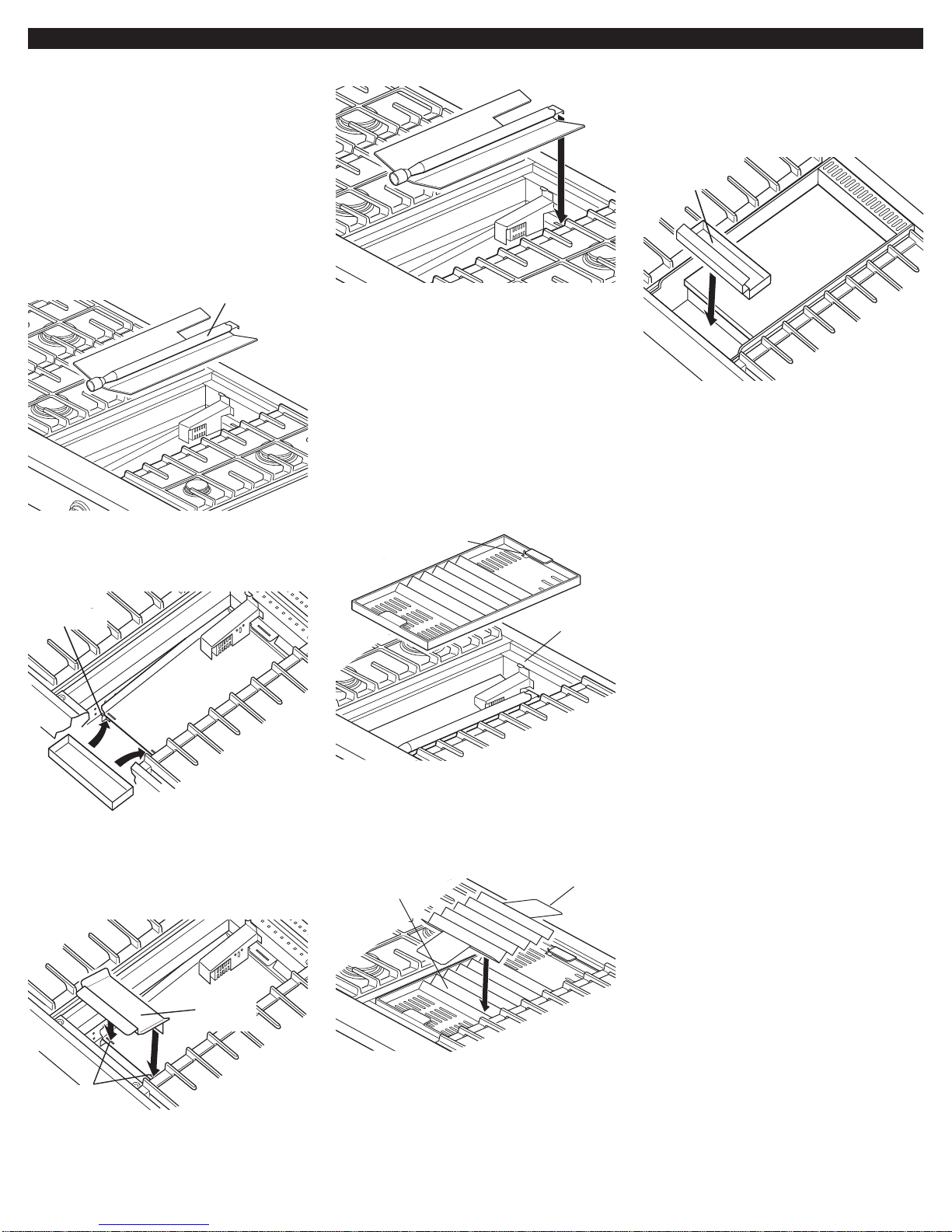

Installing the grille

or griddle.

Grille installation: Go to Step 16.

Griddle installation: The griddle is factory

installed.To complete the installation, go

to Step 17.

16.Installing the grille:

17.Completing the griddle

installation:

A. Lift the log burner up out of the bay

and set aside.

B. Place drip tray on bottom of grille

bay and slide the tray forward so that it is

located side-to-side and against the

locating feet of the rear spill guard.

C. Insert the front spill guard feet into

the slots in the rear spill guard as shown.

The rear flange will rest on the burner box.

D. Reinstall the log burner.Make sure

burner’s rear flange is seated in slot.

G. Install the wave tray into the grille

bay. The tab in the left rear cor ner of the

bay must fit through the slot in the left

rear corner of the wave tray.

H. Place the wave plate on the wave

tray as shown.The wave plate must be

centered on the wave tray.

E. Plug power supply cord into

grounded outlet.

C. Plug power supply cord into

grounded outlet.

I. Install the grille grate.

A. Place drip tray in the well at the

front of the griddle. Slide tray forward until

it stops.

B. Refer to the Use and Care Guide

that came with your Cooktop for

instructions on cleaning and seasoning

the griddle before using.

D. Check the surface burner and

griddle flames. Go to “Check the

operation of the surface burners, grille

and griddle” on Page 9.

F. Check the surface burner and grille

flames. Before completing the grille

installation, go to “Check the operation of

the surface burners, grille and griddle” on

Page 9.

locating feet

rear spill

guard

drip

tray

log burner

griddle drip

tray

griddle

front spill

guard

insert feet

into slots

locating

tab

wave

plate

wave

tray

slot for

locating tab

Loading...

Loading...