KitchenAid 3KUIS185V User Manual

Ki+chenAid,

Automatic Ice Maker

Model 3KUIS185V

INSTALLATION INSTRUCTIONS

CHANGING

TI-IE BIN DOOR AND LOWER PANEL

The slorage bin door and lower panel are deslgned to

accept an oplional decorative wood panel of your

choice.

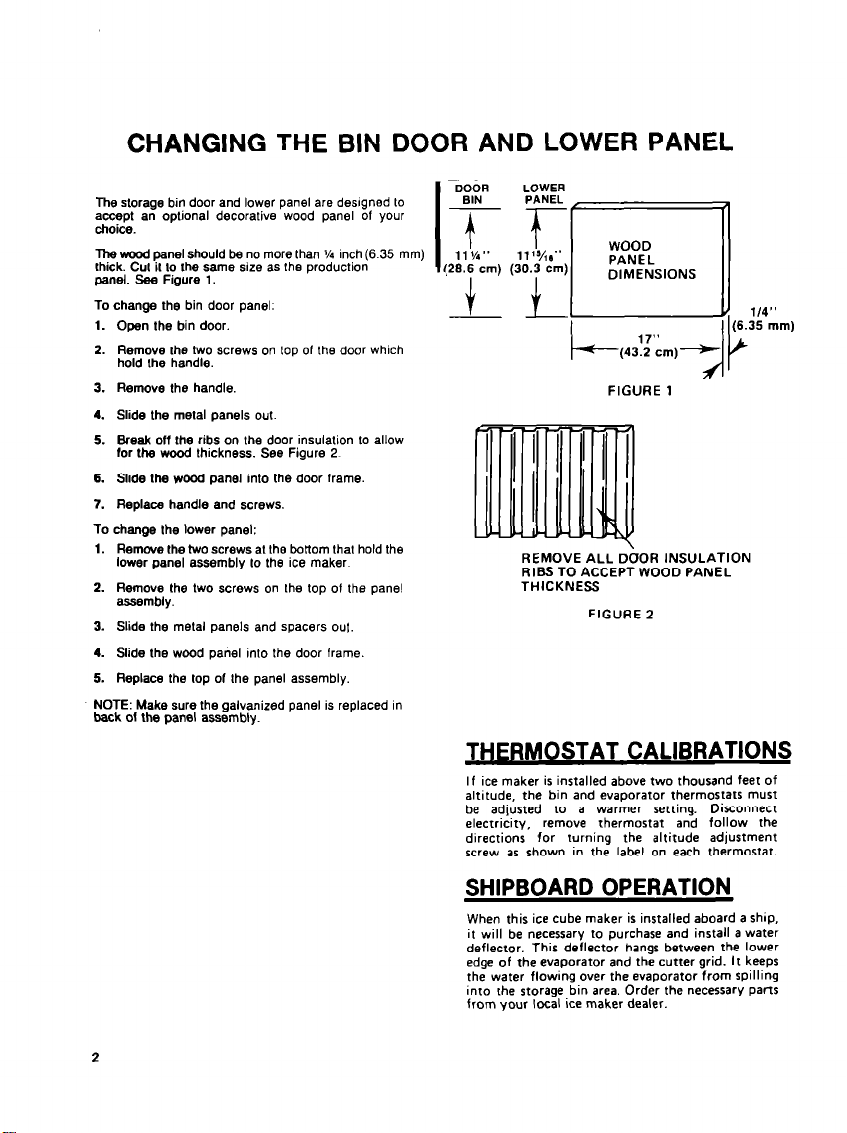

The wood panel should be no more than j/4 Inch (6.35 mm)

Ihick. GUI il lo the same size as Ihe production

panel. See Figure 1.

To change the bin door panel.

1. Open the bin door.

2. Remove the two screws on lop of the door which

hold Ihe handle.

3. Remove the handle.

4. Slide the metal panels out.

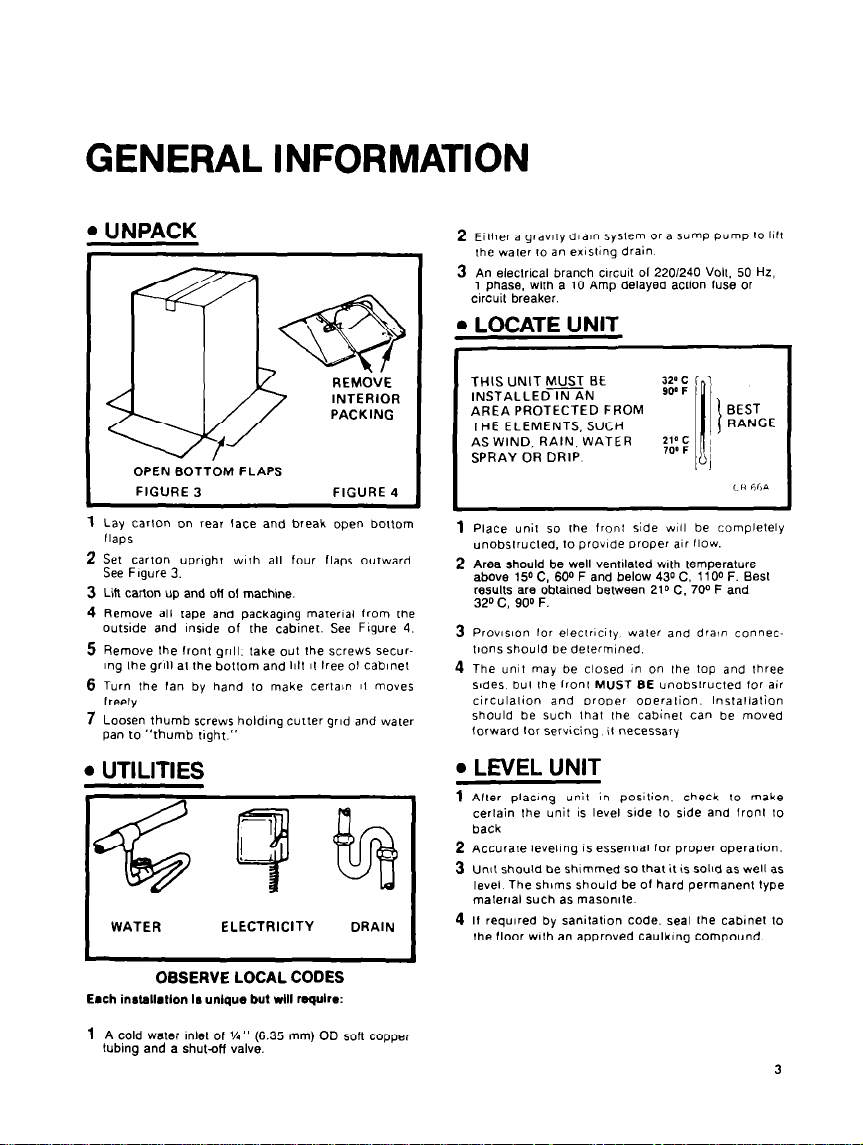

5. Break off the ribs on the door insulalion to allow

for the wood thickness. See Figure 2

6. Slide the wood panel into the door frame.

7. Replace handle and acraws.

To change the lower panel:

-

1. Hemwe the two screws at the txttom that hold the

lower panel assembly to the ice maker

2. Remove the Iwo acraws on the top of the pane!

assembly.

3. Slide the metal panels and spacers 01~1.

4. Slide the wood panel into Ihe door frame.

5. Replace the top of the panel assembly

NOTE: Make sure the galvanized panel is replaced I”

back of the panel assembly.

DOOR

BIN PANEL

Tf

11 %” 11’%8”

I

(28.6 cm) (30.3 cm:

LOWER

PANEL

DIMENSIONS

b(43.2 cm)-

FIGURE 1

REMOVE ALL DOOR INSULATION

RIBS TO ACCEPT WOOD PANEL

THICKNESS

FIGURE 2

If ice maker is installed above two thousand feet of

altitude, the bin and evaporator thermostats must

be adjusted to a warmer setting. Disconnect

electricity,

directions for turning the altitude adjustment

screw as shown in the label on each thermostat.

remove thermostat and follow the

SHIPBOARD OPERATION

When this ice cube maker is installed aboard a ship,

it will be necessary to purchase and install a water

deflector. This deflector hanas between the lower

edge of the evaporator and the cutter grid. It keeps

the water flowing over the evaporator from spilling

into the storage bin area. Order the necessary parts

from your local ice maker dealer.

2

GENERAL INFORMATION

. UNPACK

INTERIOR

OPEN BOTTOM FLAPS

FIGURE 3

1

Lay carlon on rear face and break open botlom

flaps

2

Set carton upnght wlrh all four flaps outward.

See Figure 3.

3 Lift carton up and ott 01 machme.

4

Remove all rape and packaglng material from rhe

outside and lnslde of the cabinet. See Flgure 4.

5R

emove Ihe front grill. lake out the screws secur-

1ng Ihe grlll at the botlom and 1111 It tree 01 c&net

6 Turn the fan by hand lo make terla~n II moves

freely

7 Loosen thumb screws holding cutter grid and water

pan to “thumb right.”

FIGURE 4

. UTILITIES

WATER

ELECTRICITY

DRAIN

2

ElIher a gravely drain

the waler 10 an exlsling drain

3 An eleclr~cal branch cwcuil 01 220/240 Volt, 50 Hz,

1 phase, with a 10 Amp delayed actlon fuse or

circuit breaker.

l

LOCATE UNIT

THIS UNIT MUST BE

INSTALLED IN AN

AREA PROTECTED FROM

THE ELEMENTS, SUCH

AS WIND, RAIN, WATER

SPRAY OR DRIP

1

Place unit so the fronl side WIII be complelely

unobstructed, to provide Draper air flow.

2 Area should be well ventllaled wth temperature

above 150 C, 600 F and below 430 C. 1100 F. Best

results are obtained between 210 C. 700 F and

320 C. 900 F.

3

Prov~slon lor eleclr#city water and drain conneclions should be delermlned.

4

The unit may be closed in on Ihe top and lhree

sndes. bul Ihe Iron1 MUST BE u”obs,r”c,ed lor air

circulalion and proper operalion. Inslallalion

should be such lhal Ihe cabinel can be moved

lorward lor servicing il

Syslem

or a sump pump t0 1111

necessary

. LEVEL UNIT

1 After placing unit in powlion. check to make

certain the unit IS level side lo side and front 10

back

2

Accurate leveling 1s eSsenlIal for proper OperaliOn.

3 Unit should be shimmed so that it !s solld as well as

level The shims should be of hard permanenl type

malerlal such as masonate

4 If required by sanitation code. seal rhe cabinet to

I

Ihe floor wlh an approved Caulking compound

OBSERVE LOCAL CODES

Emch installation 1~ unique but will require:

1

A cold water Inlet of l/4” (6.35 mm) OD

tubing and a shut-off valve.

sdi copper

3

Loading...

Loading...