Electric Built-in

24” and 27” Thermal

Single and Double

Ovens

24” and 27” Thermal

Convection Single

and Double Ovens

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer:

Leave Installation Instructions with

the homeowner.

Homeowner:

Keep Installation Instructions

for future reference.

Save

Installation Instructions for local

electrical inspector’s use.

Part No. 3183659 Rev. B

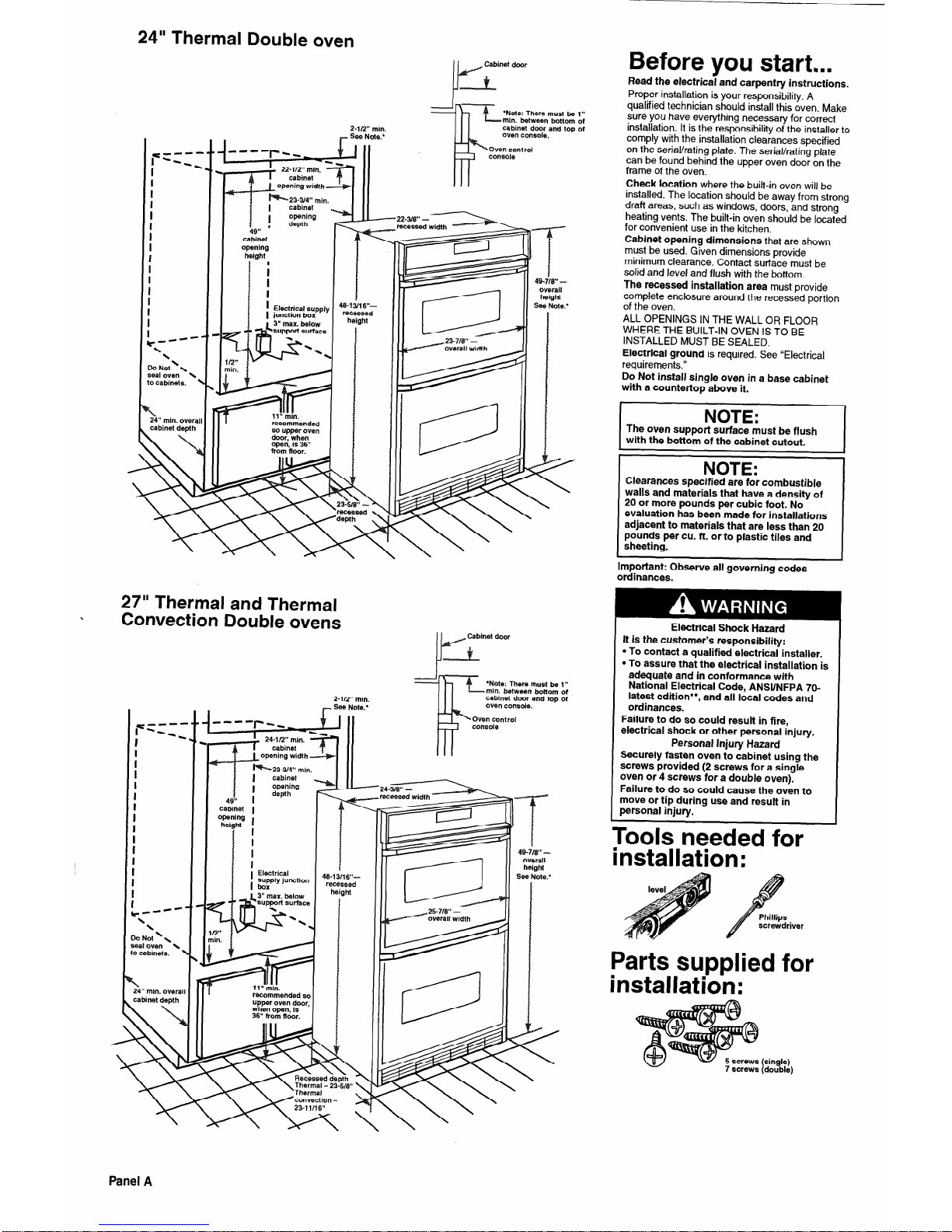

24” Thermal Double oven

Before

you

start...

Read the electrical and carpentry instructions.

Proper installation is your responsibility. A

qualified technician should install this oven. Make

sure you have everything necessary for correct

installation. It is the responsibility of the installer to

comply with the installation clearances specified

on the serial/rating plate. The serial/rating plate

can be found behind the upper oven door on the

frame of the oven.

Check location

where the built-in oven will be

installed. The location should be away from strong

draft areas, such as windows, doors, and strong

heating vents. The built-in oven should be located

for convenient use in the kitchen.

Cabinet opening dimensions

that are shown

must be used. Given dimensions provide

minimum clearance. Contact surface must be

solid and level and flush with the bottom.

The recessed installation area

must provide

complete enclosure around the recessed portion

of the oven.

ALL OPENINGS IN THE WALL OR FLOOR

WHERE THE BUILT-IN OVEN IS TO BE

INSTALLED MUST BE SEALED.

Electrical ground

is required. See “Electrical

requirements.”

Do Not install single oven in a base cabinet

with a countertop above it.

2-l/2” min.

oven console.

recessed width

46-l 3/l 6’-

---I--

49-7/8” -

overall

height

See Note.’

‘<

+L-’

\

)o Not’,

eal oven \

3 cabinets. \

h” min. overall

cabinet depth

cabinet

opening

height

i

I

Electrical supply

junction box

re

I

sed

Iht

NOTE:

The oven support surface must be flush

with the bottom of the cabinet cutout.

so upper 0vG

door, when

open, is 36”

from floor.

I

I

I

NOTE:

Clearances specified are for combustible

walls and materials that have a density of

20 or more pounds per cubic foot. No

evaluation has been made for installations

adjacent to materials that are less than

20

pounds per cu. ft. or to plastic tiles and

sheeting.

Important: Observe all governing codes

ordinances.

27” Thermal and Thermal

\

Convection Double ovens

Electrical Shock Hazard

It is the customer’s responsibility:

l

To contact a qualified electrical installer.

l

To assure that the electrical installation is

adequate and in conformance with

National Electrical Code, ANSVNFPA 70latest edition**,

and all local codes and

ordinances.

Failure to do so could result in fire,

electrical shock or other personal injury.

Personal Injury Hazard

Securely fasten oven to cabinet using the

screws provided (2 screws for a single

oven or 4 screws for a double oven).

Failure to do so could cause the oven to

move or tip during use and result in

personal injury.

*Note: There must be 1”

-mm.

between bottom ot

cabinet door and top of

oven console.

2-l/2” min.

-\Oven control

R

console

I I I

cabinet

rL--

c

\

\

\

10 Not \

:eal oven \

o cabinets. ’

\

24” min. overal

cabinet depth

I

i

opening

49”

I

depth

cabinet I

opening

eight

I

P’

lin.

I

I

I’

I Electrical

I surly junction

43"

max. below

support surface

.

!Ds

\

‘.

IT

+ +

w

11” min.

Tools needed for

installation:

46-I 3/l 6”-

recessed

heigM

25-7/W’ -

/OVerall width

Parts supplied for

installation:

recommended so

upper oven door,

when open, is

36” from floor.

Panel A

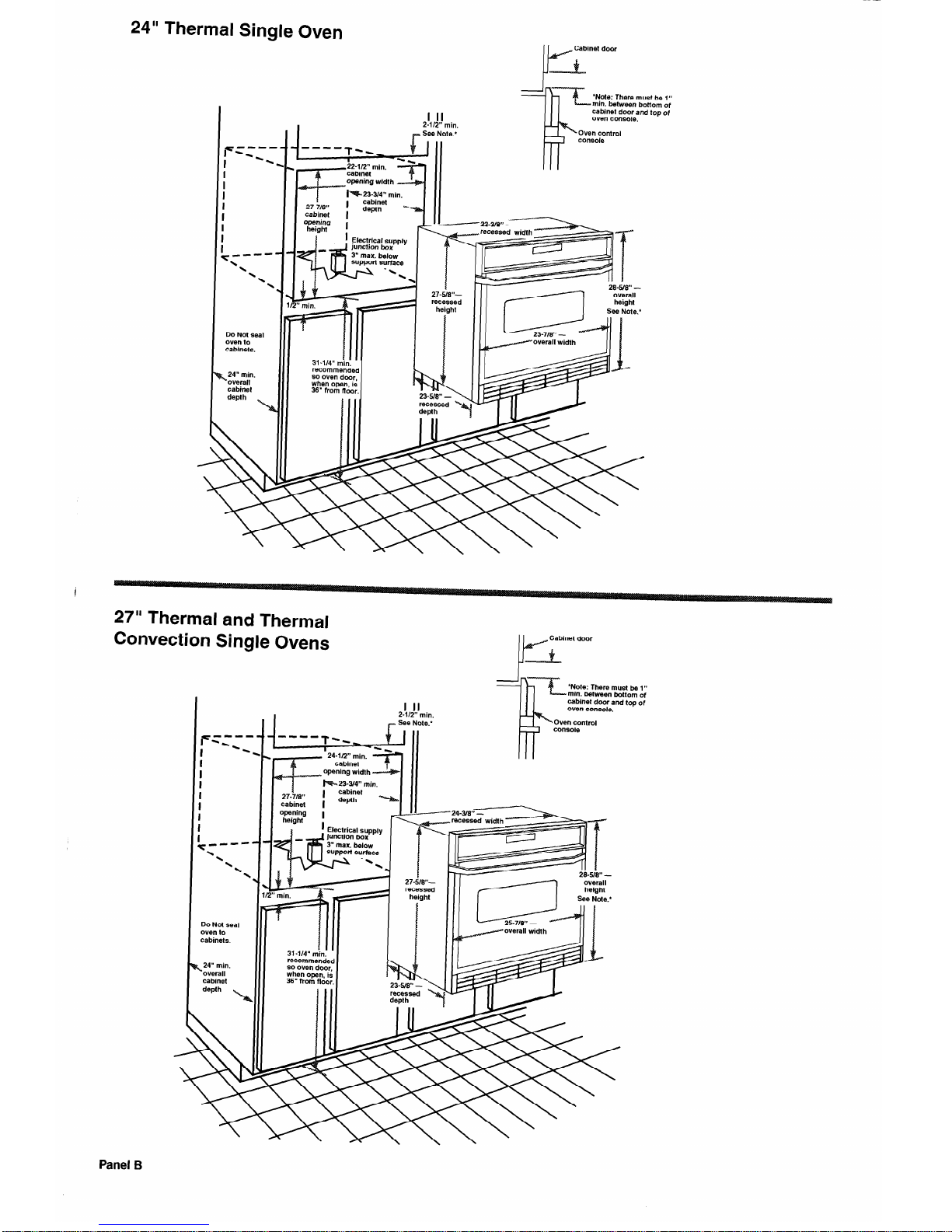

24” Thermal Single Oven

DO Not seal

oven to

cabinets.

24” min.

coverall

cabinet

depth

I II

2-l/2” min

cabinet door and top of

oven console.

F See Note.*

I

27-5/R”-

WV uven ooor,

when open, is

36” from floor.

I

recommended

_^ -..-- 2

‘\Oven control

R

console

-. -._

recessed

height

27” Thermal and Thermal

Convection Single Ovens

recommendec

so oven door,

when open,

is

36” from floor

2JLJ’lmin.

See Note.’

ssed

Mt

Cabinet door

Ik.

cabinet door and top of

oven console.

h-r

console

Panel B

Electrical

Electrical

requirements

connection

Electrical Shock Hazard

l

Electrical ground is required on this

appliance.

l

If cold water pipe is interrupted by

plastic, non-metallic gaskets, or other

insulating materials, Do Not use for

grounding.

l

Do Not ground to a gas pipe.

l

Do Not have a fuse in’the neutral or

grounding circuit. A fuse in the neutral

or grounding circuit could result in an

electrical shock.

l

Do Not use an extension cord with

this appliance.

l

Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

Failure to follow these in instructions

could result in serious injury or death.

If codes permit and a separate grounding

wire is used, it is recommended that a

qualified electrician determine that the

grounding path is adequate.

IMPORTANT:

Save Installation Instructions for the

local electrical inspector’s use.

This appliance

must

be connected to

the proper electrical voltage and

requency as specified on the serial/rating plate

located behind the oven door on the front

frame. Models rated at 7.0 kw on 240 volts (5.3

kw on 208 volts) or more require a separate 40ampere circuit. Models rated at 3.6 kw on 240

volts (2.7 kw on 208 volts) or less require a

separate 30-ampere circuit. Fuse both sides of

the line. A time-delay fuse or circuit breaker is

recommended.

I

OVEN MUST BE CONNECTED

WITH COPPER WIRE ONLY.

Wire sizes and connections must

conform to the reauirements of the

National Electrical Code, ANSI/NFPA 70 - latest

edition**, and all local codes and ordinances.

Wires sizes and connections must conform with

the rating of the appliance.

Copies of the standards listed may be obtained

from:

**National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

This appliance should be connected

directlv to the fused disconnect (or

circuit breaker box) through flexible, armored or

non-metallic sheathed, copper cable (with

grounding wire). The flexible armored cable

from the appliance should be connected directly

to the junction box.

Locate the junction box to allow as

much slack in the cable as possible

between the junction box and the appliance so

that the oven can be moved if servicing is ever

necessary.

Do Not cut the conduit.

A U.L.-listed conduit connector

must

be provided at the junction box.

A wiring diagram is included in the

Tech Sheet. The Tech Sheet is located

behind the control panel.

Electrical Shock Hazard

l

Electrical ground is required on this

appliance.

l

Do Not connect to the electrical supply

until appliance is permanently

grounded.

l

Disconnect power to the junction box

before making the electrical

connection.

l

This appliance must be connected to a

grounded, metallic, permanent wiring

system, or a grounding connector

should be connected to the grounding

terminal or wire lead on the appliance.

Failure to do so could result in a fire,

personal injury or electrical shock.

L

This appliance is manufactured with white

(neutral) power supply wire and a cabinetconnected green grounding wire twisted

toget her.

Connect the appliance cable to the junction box

through the U.L.-listed conduit connector.

Complete electrical connection according to

local codes and ordinances.

A. Where local codes permit...

connecting the cabinet-grounding conductor

to the neutral (white) junction box wire:

Cable from

Junction

power supply

box \

I

Bare or / II‘

green wire

conduit

Figure 1

Cablefrom oven

connect01

Grounded Neutral

1. Disconnect the power supply.

2. Remove the terminal block cover.

3. Connect together 3 wires: green and white

appliance cable wires and the neutral (white)

wire in junction box.

4. Connect the two black wires together; then

the two red wires together. See Figure 1.

B. Where local codes Do Not

permit...

connecting the cabinet-grounding conductor

to the neutral (white) junction box wire:

Red

wires

Cable from

Bare

green

wires

isted

Cable

conduit

from oven

connector

Figure 2

Ungrounded Neutral

1. Disconnect power supply.

2. Separate the green and white appliance

cable wires.

3. Connect the white appliance cable wire to the

neutral (white) wire in the junction box.

4. Connect the two black wires together; then

the two red wires together. See Figure 2.

5. Connect the green or bare grounding wire

from the appliance cable to a grounded wire in

the junction box.

C. If connecting to a fourwire electrical system...

Do Not connect the cabinet-grounding

conductor to the neutral (white) junction

box wire.

Cable from

Figure 3

conduit

connector

1. Disconnect the power supply.

2. Separate the green (or bare) and white

appliance cable wires.

3. Connect the white appliance cable wire to the

neutral (white) wire in the junction box.

4. Connect the two black wires together; then

the two red wires together. See Figure 3.

5. Connect the green appliance cable wire to

the green grounding wire in the junction box.

Panel C

Now start...

with oven in kitchen.

Remove shipping materials, tape, and

protective film from oven.

Do Not

remove shipping base at this time.

Remove the racks and other parts

from inside the oven.

Personal Injury/Product Damage Hazard

l

Use both hands to remove oven doors.

l

Grasp only the sides of oven doors.

l

Do Not use handle or any portion of the

trim for lifting.

l

Because of the weight and size of the

single or double oven, two or more

people are needed to move and safely

install the oven.

Failure to properly grasp the oven doors

or to lift ovens properly could result in

damage to the product or personal injury.

Completely open the lower oven door.

Remove the two oven door screws. (Not

all models have oven door screws.)

Close lower oven door to the broil position.

Grasp the sides of the oven door and pull the

door up and out of the hinge slots to remove

Set door aside.

Repeat Steps 3 and 4 for upper oven

door.

Product Damage

Before moving oven across floor, check

that oven is on shipping base or slide

single or double oven onto cardboard or

hardboard.

Failure to follow these instructions may

result in damage to floor covering.

Turn power supply off. Move oven close

to final oosition. Remove and discard

shipping base. ‘Feed appliance cable through

the opening in cabinet. Make electrical

connection. See “Electrical requirements” and

“Electrical connection” sections, Panel C.

Product Damage

Carefully push against the seal area of the

oven front frame when pushing the oven

into the cabinet.

Do Not push against outside edges.

Failure to follow these instructions can

result in damage to oven finish.

Remove and discard shipping base. Lift

oven up into cabinet cutout using the oven

opening as an area to grip.

Push against seal area of front frame to push

oven into cabinet.

-

0

c

0

\

: 4 screws

Center oven into cabinet cutout. Use

two screws (four screws for a double

oven) through the mounting holes in the front

frame of the oven to secure the oven to the

cabinet. Do Not overtighten screws.

Iv-

y

\

B

this position.

Install the lower vent grille using the

three screws provided.

Replace the oven racks.

Replace the single oven or

upper double oven door

by

partially fitting the door

hinges into the hinge slots.

Pull door slightly toward you;

then slide door completely in

place. Reinstall the two

oven-door screws (if required

for your oven door). If door does not close, you

have not pushed hinges completely into frame.

Repeat for lower oven door.

11.

Numbers

correspond

to steps.

Panel D

Thermal convection double oven control panel

Turn on the power supply. “88:88”

should aopear in the clock disDlav.

Check the operation of the BROIL

element.

Press the “CLOCK SET” button. “TIME, H’R AND

MIN” will light in the display. “0:OO” will appear

and ‘7 will be flashing. Press the numbers pads

for the correct time of day. Press the

‘START/ENTER” pad to start the clock.

Check the operation of the BAKE

element.

Thermal-only single or double ovens, or the

lower oven on the thermal convection

double oven:

Press the “BAKE” pad and

“350”” will appear in the display. Press the

“START/ENTER” pad to start the bake

operation. “Lo”” and the ON, Bake Element,

Outer Broil Element and Oven Cavity symbols

will light in the display. In 1-2 minutes, the

bottom element should glow red. The upper

element should become hot, but not glow red

and the oven should be heating.

Press the “CANCEUOFF’ pad.

Thermal convection single or upper ovens:

Press the “CONVECTION BAKE” pad and

“325”” will appear in the display. Press the

“START/ENTER” pad to start the bake

operation. “Lo”” aiid the ON, Convection

Element and Convection Fan symbols will light

in the display. In 1-2 minutes, the bottom

element should glow red. The upper element

should become hot, but not glow red and the

oven should be heating.

Press the “CANCEUOFF pad.

Thermal convection single or double ovens:

Press the “BROIL” pad once and “500”” and

“MAXI BROIL” (if model is so equipped) will

appear in the display. Press the

“START/ENTER” pad to start the broil

operation. The ON, Inner and Outer Broil

Elements, and Oven Cavity symbols will light in

the display (if model is so equipped). In l-2

minutes, the upper element should glow red.

Press the “CANCEL/OFF’ pad.

Thermal-only single or double ovens:

Press the “BROIL” pad and “500”” will appear in

the display. Press the ‘START/ENTER” pad to

start the broil operation. The ON, Inner and

Outer Broil Elements, and Oven Cavity symbols

will light in the display. In l-2 minutes, the upper

element should glow red.

Press the “CANCEL/OFF’ pad.

To get the most efficient use

from your new oven,

read your KitchenAid Use &

Care Guide. Keep lnstalla tion

Instructions and Guide close to

oven for easy reference.

If the range does

not operate...

l

Check that the circuit breaker is not

tripped or the house fuse blown.

l

See Use and Care Guide for

troubleshooting checklist.

NOTE:

Refer to Use and Care Guide for

operating instructions and cleaning

instructions.

Part No. 3183659 Rev. B

0 1992 KitchenAid

If you need

assistance...

The KitchenAid Consumer Assistance Center

will answer any questions about operating or

maintaining your oven not covered in the

Installation Instructions. The KitchenAid

Consumer Assistance Center is open 24 hours

a day, 7 days a week. Just dial 1-800-422-l 230

-the call is free.

When you call, you will need the oven model

number and serial number. Both numbers can

be found on the seriaVrating plate located

behind the oven door on the front frame.

Prepared by

KitchenAid

@,

St. Joseph, Michigan 49085

Printed in U.S.A.

If you need

service...

In the event that your KitchenAid appliance

should need service, call the dealer from whom

you purchased the appliance or a KitchenAidauthorized service company. A KitchenAidauthorized service company is listed in the

Yellow Pages of your telephone directory under

“Appliances - Household - Major - Service

or Repair.” You can also obtain the service

company’s name and telephone number by

dialing, free, within the continental United

States, the KitchenAid Consumer Assistance

Center telephone number, 1-800-422-l 230. A

special operator will tell you the name and

number of your nearest KitchenAid-authorized

service company.

Loading...

Loading...