Page 1

2200139A

In the U.S. for questions about features,

accessories or service,

operation/performance, parts, call:

1-800-422-1230

In Canada, call:

for assistance

installation and service 1-800-807-6777

1-800-461-5681

or visit our website at...

www.kitchenaid.com

Page 2

TABLE OF

TABLE DES

CONTENTS

REFRIGERATOR SAFETY ............................................... 3

PARTS AND FEATURES................................... ....... ...... .. 4

INSTALLING YOUR REFRIGERATOR .............................. 5

Unpacking Your Refrigerator ............................................ 5

Space Requirements......................................................... 5

Electrical Requirements.................................................... 6

Removing the Doors......................................................... 6

Water System Preparation................................................ 7

Connecting the Refrigerator to a Water Source............... 8

Factory Trim Kit................................................................. 9

Base Grille....................................................................... 11

Door Closing ................................................................... 11

Understanding Sounds You May Hear........................... 12

USING YOUR REFRIGERATOR....................................... 12

Ensuring Proper Air Circulation....................................... 12

Setting the Controls ........................................................13

Adjusting Control Settings.............................................. 13

Food Storage Guide........................................................14

REFRIGERATOR FEATURES........................................... 15

Ice Maker Storage Bin .................................................... 15

Water and Ice Dispensers............................................... 16

Water Filtration and Monitoring System......................... 17

Refrigerator Shelves........................................................ 18

Deli Drawer...................................................................... 19

Convertible Vegetable/Meat Drawer and Cov er.......... ...19

Convertible Vegetable/Meat Drawer

Temperature Control....................................................... 20

Crisper and Crisper Cover.............................................. 20

Crisper Humidity Control................................................20

Door Rails........................................................................21

Door Accessories............................................................ 21

Freezer Shelf ................................................................... 22

Freezer Basket ................................................................ 22

CARING FOR YOUR REFRIGERATOR........................... 22

Cleaning Your Refrigerator ............................................. 22

Changing the Light Bulbs ............................................... 23

Power Interruptions......................................................... 24

Vacation and Moving Care ............................................. 24

TROUBLESHOOTING....................................................... 25

ASSISTANCE OR SERVICE ............................................. 29

WARRANTY....................................................................... 30

WATER FILTER CERTIFICATIONS ................................. 31

MATIÈRES

SÉCURITÉ DU RÉFRIGÉRATEUR.................................33

PIÈCES ET CARACTÉRISTIQUES.................................34

INSTALLATION DU RÉFRIGÉRATEUR .......................... 35

Déballage de votre réfrigérateur..................................... 35

Espacement requis......................................................... 35

Spécifications électriques............................................... 36

Enlèvement des portes................................................... 36

Préparation du système d’eau........................................ 37

Raccordement du réfrigérateur

à une canalisation d’eau................................................. 38

Ensembles décoratifs de l’usine..................................... 40

Grille de la base .............................................................. 41

Fermeture des portes ..................................................... 42

Les bruits de l’appareil que vous pouvez entendre ....... 42

UTILISATION DU RÉFRIGÉRATEUR .............................. 43

Pour s’assurer d’une circulation d’air approp riée.......... 43

Réglage des commandes............................................... 43

Ajustement des réglages de contrôle............................. 44

Guide d’entreposage des aliments................................. 44

CARACTÉRISTIQUES DU RÉFRIGÉRATEUR................ 46

Bac d’entreposage de la machine à glaçons................. 46

Distributeurs d’eau et de glaçons................................... 46

Système de filtration

et de contrôle d’eau........................................................ 48

Tablettes du réfrigérateur ............................................... 49

Casier pour petits aliments............................................. 50

Tiroir et couvercle convertibles

pour légumes/viande..................................................... 50

Réglage de la température

du tiroir convertible à légumes/viande ........................... 51

Bac à légumes et couvercle ........................................... 51

Réglage de l’humidité dans les bacs à légumes............ 52

Tringles dans la porte ..................................................... 52

Accessoires de porte...................................................... 52

Clayette de congélateur.................................................. 53

Panier du congélateur..................................................... 53

ENTRETIEN DE VOTRE RÉFRIGÉRATEUR ................... 53

Nettoyage du réfrigérateur.............................................. 53

Remplacement des ampoules d’éclairage.................... 54

Pannes de courant.......................................................... 55

Entretien avant les vacances

ou lors d’un déménagement........................................... 56

DÉPANNAGE..................................................................... 57

ASSISTANCE OU SERVICE ............................................. 61

GARANTIE......................................................................... 62

CERTIFICATIONS DE FILTRE À EAU............................. 63

2

Page 3

REFRIGERATOR SAFETY

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will be preceded by the safety alert symbol and the word “DANGER” or

“WARNING.” These words mean:

You will be killed or seriously injured if you don't

DANGER

WARNING

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

precautions:

■

Plug into a grounded 3 prong outlet.

■

Do not remove ground prong.

■

Do not use an adapter.

■

Do not use an extensio n cord.

■

Disco n n e c t po wer befo re s er v ic i n g .

■

Replace all panels before operating.

■

Remove doors from your old refriger a tor.

To reduce th e ris k of fire, electric shock , or injury whe n u sin g your refrigerator, follow thes e ba s ic

follow instructions.

can be killed or seriously injured if you don't

You

follow instructions.

■

Use nonflammable cleaner.

■

Keep flammable mater ia ls and vapors, such as

gasoline, aw ay from refr iger ato r.

■

Use two or mo re peop le to mov e and install

refrigerator.

■

Disconnect power before installing ice maker.

■

Use a sturdy glass when dispensing ice or water (on

some models).

SAVE THESE INSTRUCTIONS

Proper Disposal of

Your Old Refrigerator

W ARNING

Suffocation Hazard

Remove doors from your old refrigerator.

Failure to do so can result in death or

brain damage.

IMPORTANT – Child entrapment and suffocation are not

problems of the past. Junked or abandoned refrigerators

are still d a ngerous – even if th ey will sit for “just a few

days.” If you are getting rid of your old refrigerator, please

follow these instructions to help prevent accidents.

Before you throw away your old refrigerator or freezer:

■ Take off the doors.

■ Leave the shelves in place so that children may not

easily climb inside.

3

Page 4

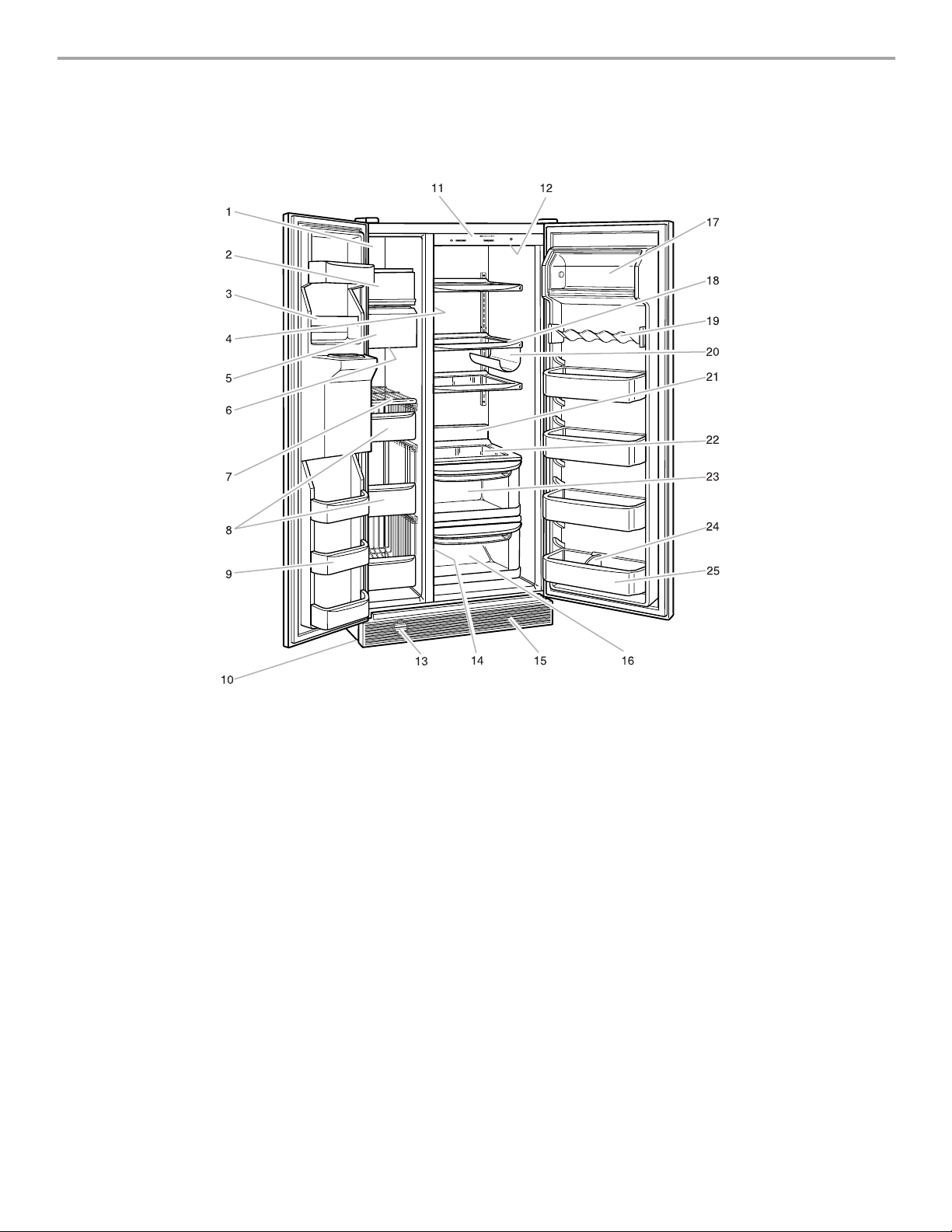

PARTS AND FEATURES

This manual covers sev eral diff erent models. The refrigerator you have purchased may hav e some or all of the items listed.

The locations of the features may not match your model.

Chrisper

Meat Locker

ExtendFreshExtendFresh

SuperbaSuperba

RefrigeratorRefrigerator

Freezer

4

Colder

3

1

2

Off

Automatic Exterior Moisture ControlAutomatic Exterior Moisture Control

ColderColder

4

3

1

2

ColdCold

1. Upper Freezer Light

2. Automatic Ice Maker (on some models)

3. Drop-in Door Rails

4. Model and Serial Number Label (on side wall)

5. Ice Maker Storage Bin (on some models)

6. Freezer Light (below Ice Maker Storage Bin)

7. Removable Freezer Shelf

8. Slide-out Freezer Baskets (number varies with model)

9. Snap-on Door Rails

10. Leveling Rollers (behind base grille)

11. Control Panel

12. Light

13. (AQUASENSE™) Water Filtration System

(on some models)

14. (FRESH CHILL™) Convertible Vegetable/Meat Drawer

Temperature Control (on side wall)

15. Base Grille

16. (FRESH CHILL™) Convertible Vegetable/Meat Drawer

with cover

17. Utility Compartment

18. (ROLLER TRAC™ SPILLCLEAN™) Shelves

19. Can Rack (number varies with model)

20. Wine Rack

21. Crisper Light

22. Crisper Cover with Humidity Control

23. Crisper Drawer

24. Door Bin with Stor-Lock

25. (SLIDE ‘N’ LOCK

TM

) Door Bins (on some models)

Other parts and features

(not shown in illustration above/optional on some

models)

Ice cube trays

Crisper humidity control

Egg/utility bin

4

Page 5

INSTALLING

Space Requirements

YOUR

REFRIGERATOR

Unpacking Y our Refrigerator

WARNING

Excessive Weight Hazard

Use two or more people to move and install

refrigerator.

Failure to do so can result in back or other injury.

Removing packa ging materials

■ Remove tape and any labels from your refrigerator

before using (except the model and serial numb er

label).

To remove any remaining tape or glue, rub the area

briskly with your thumb. Tape or glue residue can also

be easily removed by rubbing a small amount of liquid

dish soap over the adhesive with your fingers. Wipe

with warm water and dry.

■ Do not use sharp instruments, rubbing alcohol,

flammable fluids, or abrasive cleaners to remove tape

or glue. These products can damage the surface of

your refrigerat or. For more information, see the

“Important Safety Instructions” section.

IMPORTANT: Do not remove any permanent instruction

labels inside your refrigerator, or the Tech Sheet that is

fastened to the base grille.

Cleaning before use

After you remove all of the packaging materials, clean the

inside of your refrigerator before using it. See the cleaning

instructions in the “Caring for your Refrigerator” section.

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from refrigerator.

Failure to do so can result in death, explosion,

or fire.

■ To ensure proper ventilation for your refrigerator, allow

for .5" (1.25 cm) spa ce on each side and at the top.

.5" (1.25cm)

2" (5.08 cm)

■ If your refrigerator has an ice maker, make sure you

leave some extra space at the back for the water line

connections. The refrigerator can be flush against the

back wall if you do not have an ice maker installed.

■ If you are installin g your refr igerator n ext to a fixed wall,

leave 2" (5.08 cm) minimum on each side (depending

on your model) to allow for the door to swing open.

NOTE: Do not install the r efrig erator near an ove n, radiator,

or other heat source, nor in a location where the

temperature will fall below 55°F (13°C).

5

Page 6

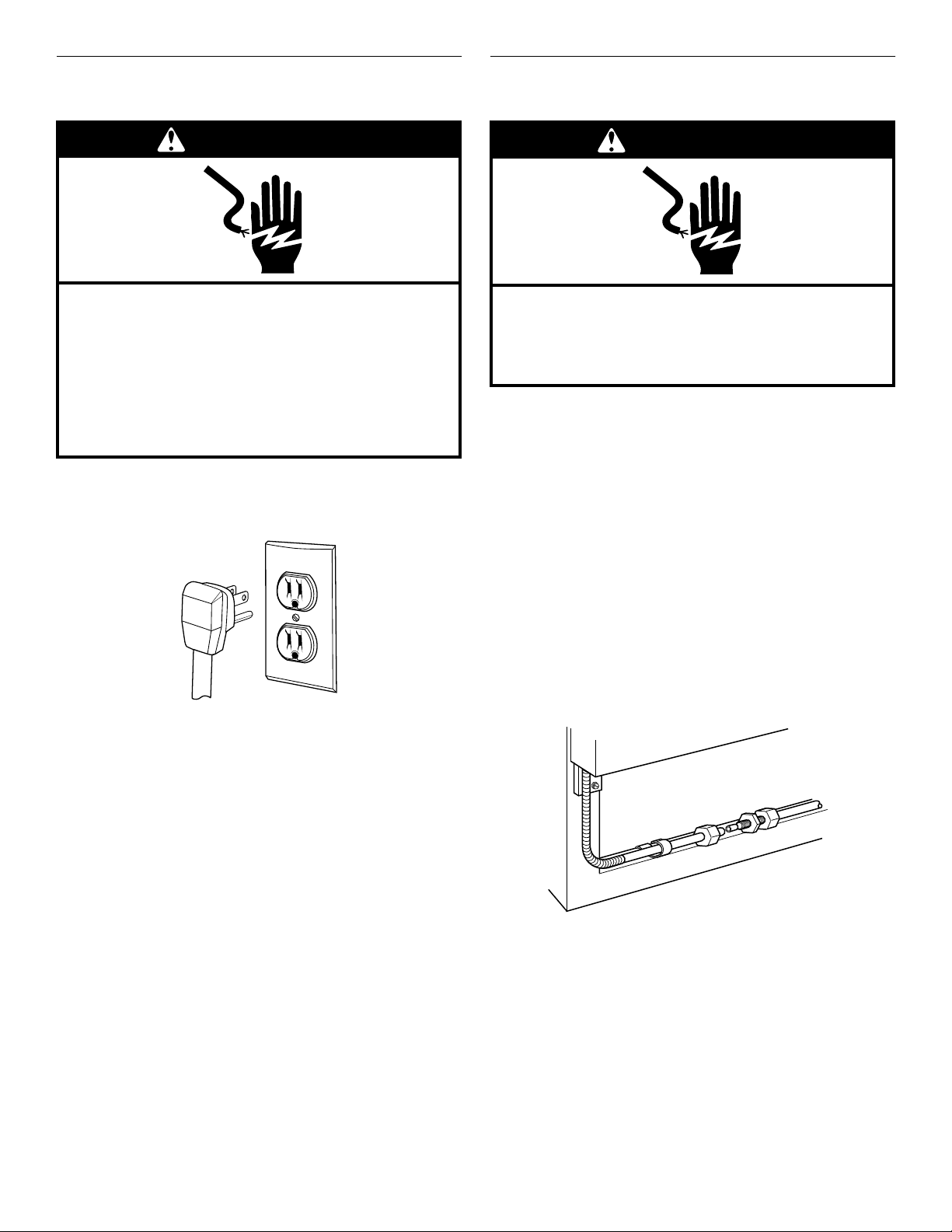

Electrical Requirements

Removing the Doors

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Before you move your refrigerator into its final location, it is

important to make sure you have the proper electrical

connection:

WARNING

Electrical Shock Hazard

Disconnect power before removing doors.

Failure to do so can result in death or

electrical shock.

NOTE: Before removing doors, open both doors and

remove base grille (see the “Base Grille” section).

Tools Needed:

¹⁄₄-inch hex-head socket wrench and ⁵⁄₁₆-inch hex-head

socket wrench.

1. Unplug refrigerator or disconnect power.

2. If you have a dispen ser ( ice or wa ter), di sconnect water

line (behind base grille).

Recommended Grounding Method

A 115 Volt, 60 Hz., AC only 15 or 20 ampere fused,

grounded electrical supply is required. It is recommended

that a separate circuit serving only your refrigerator be

provided. Use an outlet that cannot be turned off by a

switch. Do not use an extension cord.

NOTE: Before performing any t ype of installation, cleaning ,

or removing a light bulb, turn the control, (Thermostat,

Refrigerator or Fr eezer Contr ol dep ending on the mo del) t o

OFF and then disconnect the refrigerator from the

electrical source. When you are finished, reconnect the

refrigerator to the electrical source and reset the control

(Thermostat, Refrigerat or o r Fr e ezer Control depending on

the model) to the desired setting.

■ Remove hose from clip.

■ Disconnect union nut and slide it back onto tube.

■ Remove metal insert from tube.

■ Remove union nut and spring.

6

Page 7

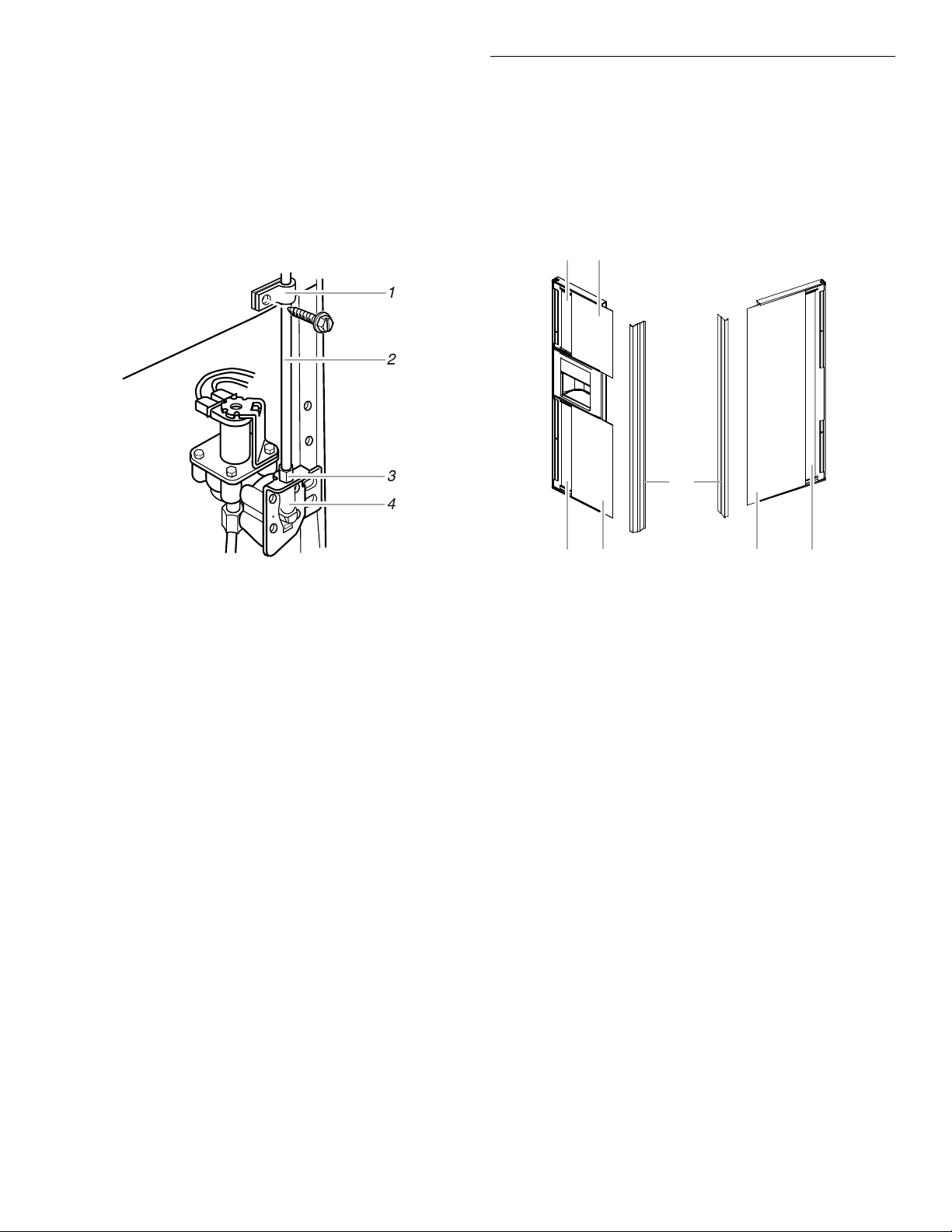

3. Remove left top hinge.

6. Replace doors.

■ Remove hinge cover and screws. DO NOT

REMOVE SCREW 1 AS SHOWN IN DIAGRAM.

■ Disconnect wiring plug and both ground wires.

■ Carefully lift door up off bottom hinge. Make sure

you protect water line from damage.

1

4. Disassemble right top hinge.

■ Remove hinge cover and screws. DO NOT

REMOVE SCREW 2 AS SHOWN IN DIAGRAM.

■ Lift door up off bottom hinge.

WARNING

Electrical Shock Hazard

Reconnect both ground wires.

Failure to do so can result in death or

electrical shock.

7. Reconnect wiring plug and both grounding wires.

8. Replace hinge cover and screws.

9. Plug in refrigerator or reconnect power.

W ater System Preparation

Please read before using the water system.

Immediately after installation, follow the steps below to

make sure that the water system is properly cleaned.

1. Turn off the ice maker by opening the freezer door and

lifting up the signal arm as shown.

2

5. Remove bottom hinge, if necessary. Both bottom

hinges have similar construction. DO NOT REMOVE

SCREW 3 AS SHOWN IN DIAGRAM.

NOTE: It may not be necessary to remove the bottom

hinge to move refrigerator through a doorway.

3

2. Flush the water system by dispensing and discarding

2-3 gallons (approximately 6-7 minutes) of water

through the dispenser. This will clean the system and

help clean air from the lines. Additional flushing may be

required in some households.

3. Turn on the ice maker by opening the freezer door and

lowering the signal arm as shown.

4. Allow 24 hours to produce the first batch of ice. Ice

maker should then produce approximately 7 to 9

batches of ice in a 24-hour period. Discard the first

three batches of ice produced.

7

Page 8

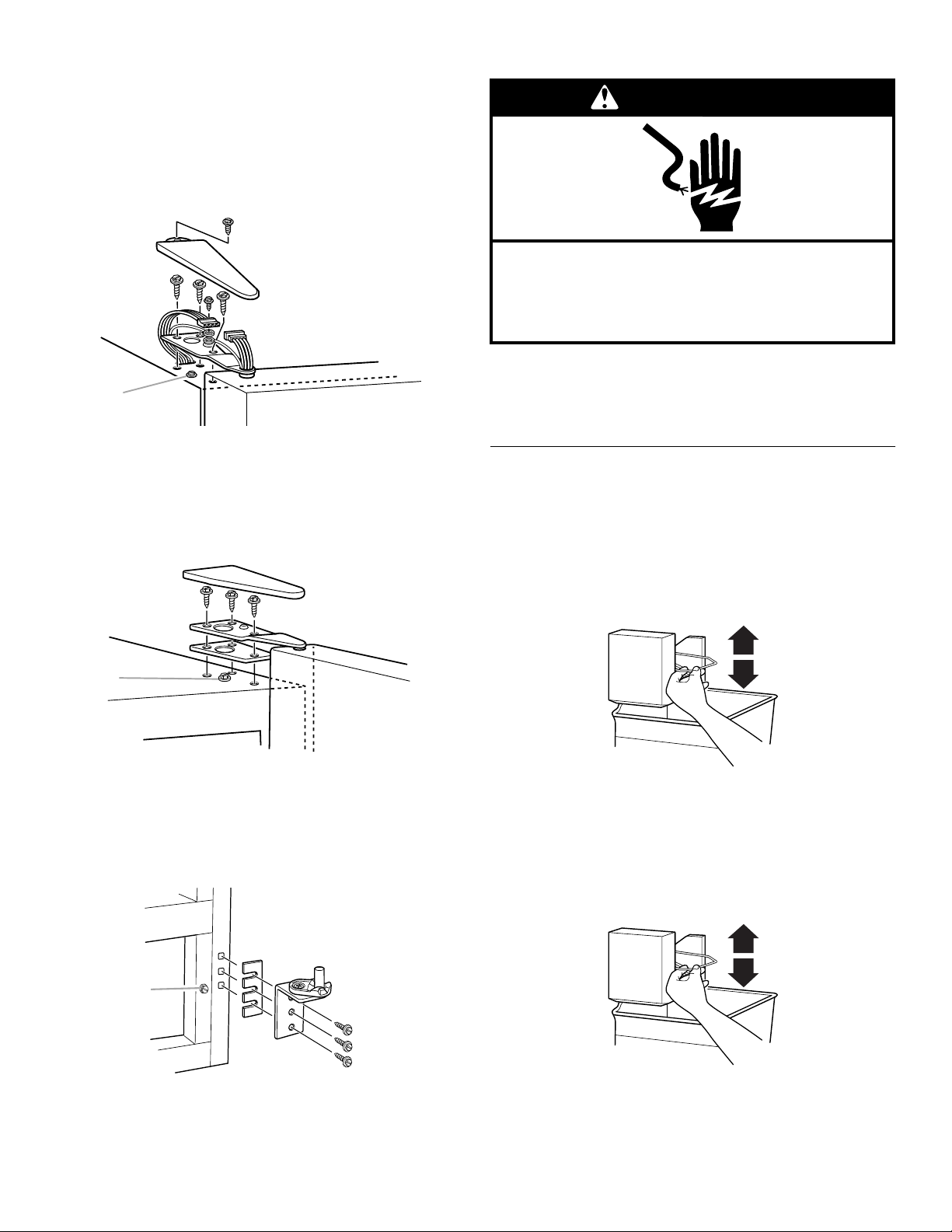

Connecting to water line:

Connecting the Refrigerator

to a Water Source

Read all directions carefully bef ore y ou begin.

IMPORTANT :

■ If operating the refrigerator before installing the water

connection, turn ice maker to the OFF position to

prevent operation without water.

■ All installations must be in accordance with local

plumbing code requirements.

■ Use copper tubing and check for leaks.

■ Install copper tubing only in areas wh ere temperatures

will remain above freezing.

■ It may take up to 24 hours for your ice maker to begin

producing ic e.

Tools required:

■ Standard screwdriver

■ ⁷⁄₁₆-inch and ¹⁄₂-inch open-end wrench es or two

adjustable wrenches

■ ¹⁄₄-inch nut driver

1. Unplug refrigerator or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet

long enough to clear line of water.

3. Find a ¹⁄₂-inch to 1¹⁄₄-inch vertical COLD water pipe

near the refrigerator.

NOTE: Horizontal pipe will work, but the following

procedure must be followed: Drill on the top side of the

pipe, not the bottom. This will help keep water away

from the drill. This also keeps normal sed iment from

collecting in the valve.

4. To determine the length of copper tubing you will need,

measure from connection on lower left rear of

refrigerator to water pipe. Add 7 feet (2.1 m) to allow for

moving refrigerator for cleaning. Use ¹⁄₄-inch O.D.

(outside diameter) copper tubing. Be sure both ends of

copper tubing are cut square.

5. Using a grounded drill, drill a ¹⁄₄-inch hole in the cold

water pipe you have selected.

■ ¹⁄₄-inch drill bit

■ Hand drill or electric drill (properly grounded)

NOTE: Your refrigerator dealer has a kit available with a

¹⁄₄-inch saddle-type shut-off valve, a union, and copper

tubing. Before p urchasing, make sure a saddle-type valve

complies with your local plumbing codes. Do not use a

piercing-type or ³⁄₁₆-inch saddle valve which reduces water

flow and clogs more easily.

Cold Water Supply

The ice maker wate r v al ve con t ains a fl ow was her wh ic h is

used as a water pressure regulator. The ice maker needs to

be connected to a cold water line with water pressure

between 30 and 120 psi. If a problem occurs, call your

utility company.

1. Cold Water Pipe

2. Pipe Clamp

3. Copper Tubing

4. Compression Nut

5. Compression Sleeve

6. Shut Off Valve

7. Packing Nut

6. Fasten shut-off valve to cold water pipe with pipe

clamp. Be sure outlet end is soli dly in the ¹⁄₄-inch drilled

hole in the water pipe and that washer is under the pipe

clamp. Tighten packing nut. Tighten the pipe clamp

screws carefully and evenly so washer makes a

watertight seal. Do not overtighten or you may crush

the copper tubing, especially if soft (coiled) copper

tubing is used. Now you are ready to connect the

copper tubing.

7. Slip compression sleeve and compression nut on

copper tubing as shown. Insert end of tubing into outlet

end squarely as far as it will go. Scr ew compr ession nut

onto outlet end with adjustable wrench. Do not

overtighten.

8. Place the free en d of the tubi ng into a cont ainer or sin k,

and turn ON main water supply and flush out tubing

until water is clear . Turn OFF shut-off valve on the water

pipe. Coil copper tubing.

8

Page 9

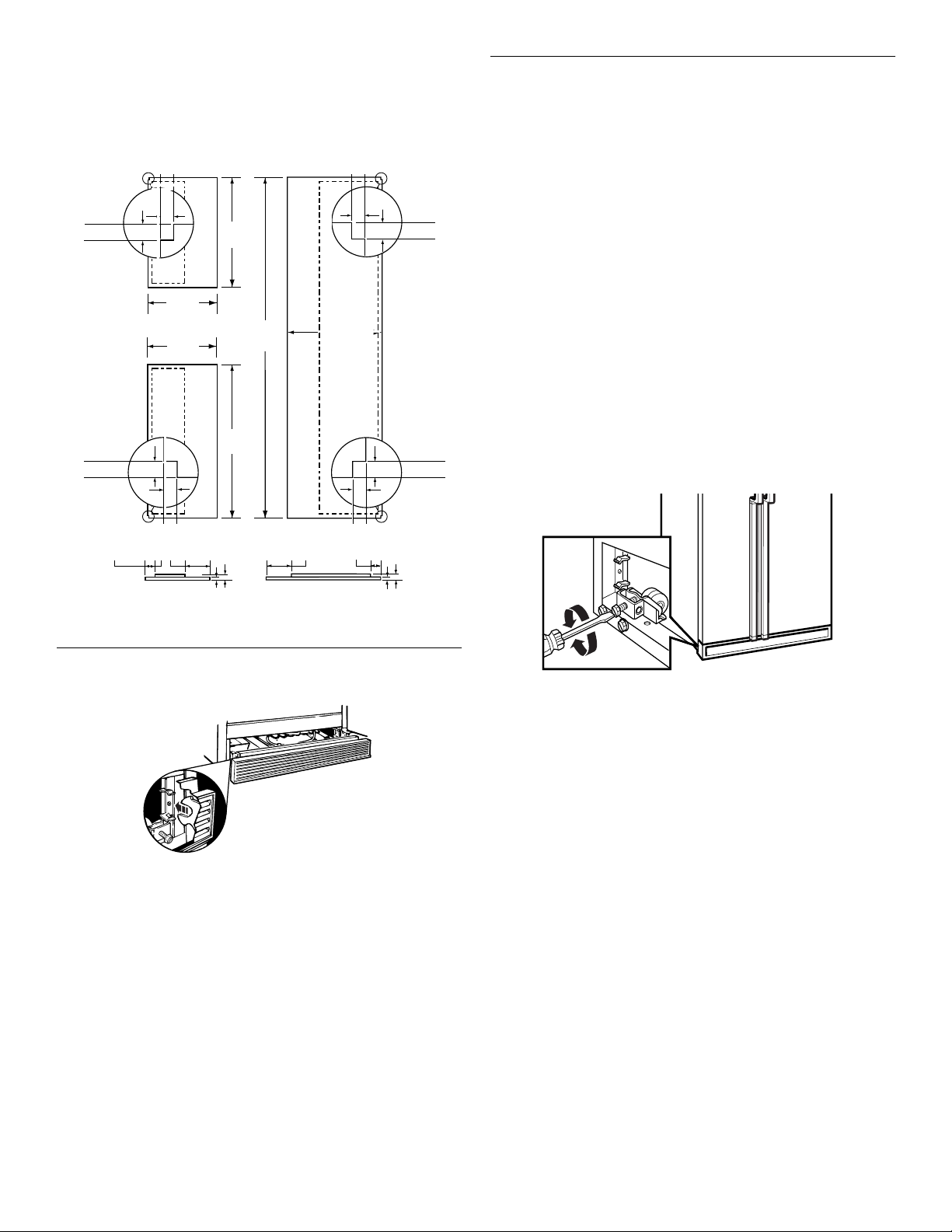

Connecting to refrigerator:

1. Attach the copper tube to the valve inlet using a

compression nut and sleeve as shown. Tighten the

compression nut. Do not overtighten. Use the tube

clamp on the back of the refrigerator to secure the

tubing to the refrigerator as shown. This will help

prevent damage to the tubing when the refrigerator is

pushed back against the wall. Move to step 2.

2. Turn shut-off valve ON. Check For Leaks. Tighten

any connections (including connections at the

valve) or nuts that leak.

Factory Trim Kit

(on some models)

There may be an occasion when you will need to remove

the factory-installed trim kit, such as moving the

refrigerator to a new home or installing custom-made

decorator panels. Please read all instructions carefully

before removing the trim kit and decorator panels.

2 1

3

1. Tube Clamp

2. Copper Tubing

3. Compression Nut

4. Valve Inlet

3. The ice maker is equipped with a built-i n water straine r.

If local water conditions require periodic cleaning or a

well is your source of water supply, a second water

strainer should be inst al le d in the ¹⁄₄-inch water line.

Obtain a water strainer from your nearest appliance

dealer. Install at either tube connection.

4. Plug in refrigerator or reconnect power.

2 1

Freezer Door Refrigerator Door

1. Decorator Panels

2. Filler Panels

3. Handles

1

2

Removing the Door P anels

NOTE: When removing and replacing decorator panels,

only the handle is removed. All other trim pieces remain

attached to the doors.

1. Remove the refrigerator and freezer handles:

■ Using a Phillips screwdriver, remove the screws that

hold each handle i n place.

■ Lift off handle. Make sure you keep screws for

reattaching handles.

2. Remove the door panels:

■ Open refrigerator or freezer door.

■ Slide out decorator panel and filler board.

■ Repeat process for other panels and filler boards.

■ Store panel and filler boards carefully to prevent

scratching.

9

Page 10

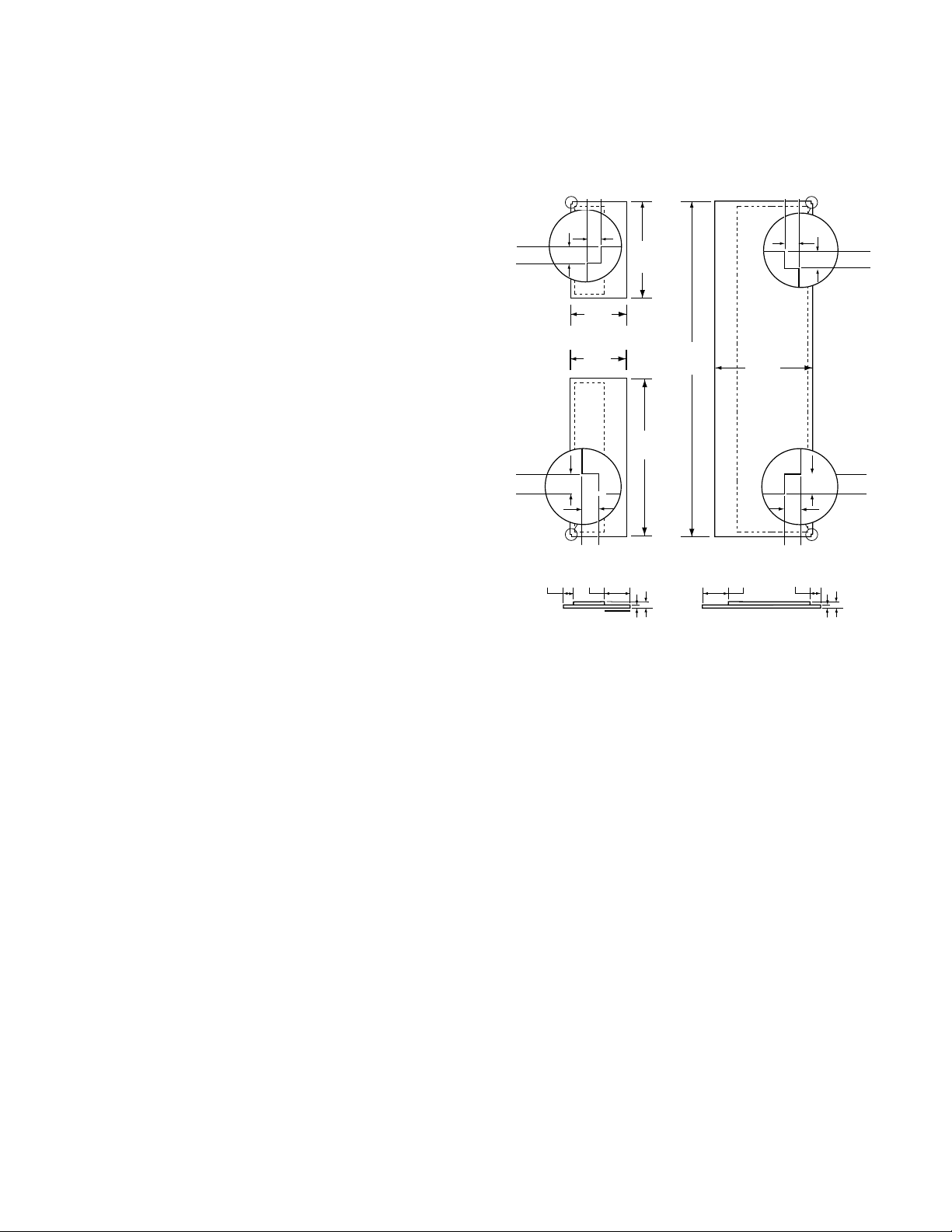

Replacing the Door Panels

17

7/16

"

12

3/16

"

28

1/2

"

60

3/8

"

1/4"

5/16"

TOP VIEW

3/4" min.

3/4"

1/4"

19

11/16

"

12

3/16

"

(7.93 mm)

(6.35 mm)

1/4"

5/16"

(7.93 mm)

1/4"

5/16"

(6.35 mm)

(7.93 mm)

(30.96 cm)

(

30.96 cm)

(

44.3 cm)

(

153.35 cm)

(

50.01 cm)

(

72.4 cm)

(19.05 mm min.)

(19.05 mm)

(6.35 mm)

(6.35 mm)

1/4"

5/16"

(6.35 mm)

(7.93 mm)

TOP VIEW

3/4" min.

(19.05 mm min.)

3 1/4"

3/4"

1/4"

(82.55 mm min.)

(19.05 mm)

(6.35 mm)

3 1/4"

(82.55 mm min.)

1. Replace the refrigerator or freezer door panels:

■ Open refrigerator or freezer door.

■ Carefully slide the ¹⁄₈" decorator panel into place

behind the side trim.

■ Push the filler boar d into pla ce behind the dec orator

panel.

■ Repeat process for other panels and filler boards.

2. Attach the handles:

NOTE: Freezer door handle is notched to fit around the

dispenser panel.

■ Align the top of the refrigerator or freezer handle

flush with the top trim. Fasten the handle to the

refrigerator or freezer door with the screws, using a

Phillips screwdriver.

■ Repeat the process for the other handle.

Care of Decorator Pa nels

1. Clean panels with an anti-static cleaner (available in

electronics or computer departments) or mild soap and

water with a clean, soft, damp cloth.

2. Rinse panels thoroughly and blot dry using a dry, soft

cloth or chamois.

Dimensions for Custom Wood Panels:

22 cu. ft. 22 cu. ft.

Freezer door Refrigerator door

panel dimensions panel dimensions

3. DO NOT use paper towels or cleaners which contain

solvents such as ammonia. They can damage the

surface of the panels.

4. If small scratches should appear on the panels, they

may be filled using an automotive paste wax (NOT a

cleaner/wax combinatio n). Apply wax sparingly and

buff lightly with a clean, soft cloth using a circular

motion.

Installing Custom Wood P anels

If you plan to install custom wood decorator panels, yo u

will need to create the panels yourself or consult your

cabinet maker or carpenter. See dimensional drawings for

wood panel inserts.

Flat panels:

You can create a custom flat panel ¹⁄₄" (6 mm) thick to

replace your decorator panels. Fl at wood panels less than

¹⁄₄" (6 mm) thick are not recommended.

Raised panels:

A raised panel design can be created by screwing or

gluing wood panels to ¹⁄₄" (6 mm) backing or by using ³⁄₄"

(19 mm) stock with routed edges.

Weight requirements for raised panel inserts:

■ Refrigerator door panel should not exceed 25 lbs

■ Freezer door panels should not exceed 18 lbs (6.80

(9.98 kg).

kg) combined weight.

10

Page 11

25 and 27 cu. ft. 25 and 27 cu. ft.

Freezer door Refrigerator door

panel dimensions panel dimensions

11/16

19

(50.01 cm)

1/4"

(6.35 mm)

"

5/16"

(7.93 mm)

1/4"

(6.35 mm)

14

(37.94 cm)

14

(37.94 cm)

15/16

15/16

"

"

7/16

20

"

(51.91 cm)

(160.97 cm)

3/8

63

"

5/16"

(7.93 mm)

Door Closing

Your r efrig erator has 2 fr ont adju stable r ollers — one o n the

right and one on the left. If your refrigerator seems

unsteady or you want the doors to close easier, adjust the

refrigerator's tilt using the instructions below:

1. Plug in refrigerator.

2. Move the refrigerator into its fina l position.

3. Remove the base grille (see “Base Grille” earlier in this

section). The two leveling screws are part of the front

roller assemblies which are at the base of the

refrigerator on either side.

4. Use a screwdriver to adjust the leveling screws. Turn

the leveling screw to the right to raise that side of the

refrigerator or turn the leveling screw to the left to lower

that side. It may take several turns of the leveling

screws to adjust the tilt of the refrigerator.

5/16"

(7.93 mm)

3/4" min.

(19.05 mm min.)

1/4"

(6.35 mm)

3 1/4"

(82.55 mm min.)

TOP VIEW

28

(72.4 cm)

3/4"

(19.05 mm)

1/4"

(6.35 mm)

Base Grille

To remove the base grille:

1/2

"

3 1/4"

(82.55 mm min.)

TOP VIEW

1/4"

(6.35 mm)

3/4" min.

(19.05 mm min.)

3/4"

(19.05 mm)

1/4"

(6.35 mm)

5/16"

(7.93 mm)

NOTE: Having someone push against the top of the

refrigerator takes some weight off the leveling screws

and rollers. This makes it easier to adjust the screws.

5. Open both doors again and check to make sure that

they close as easily as you like. If not, tilt the

refrigerator slightly more to the rear by turning both

leveling screws to the right. It may tak e several more

turns, and you should turn both leveling screws the

same amount.

6. Replace the base grille.

1. Open both refrigerator doors.

2. Place hands along the ends of the grille, with your

thumbs along the top. Push in with your thumbs and

pull up on the bottom.

NOTE: Be sure to refasten the Tech Sheet behind the base

grille after cleaning.

To replace the grille:

1. Open the doors.

2. Line up the grille support tabs with the metal clips.

3. Push the grille firmly to snap it into place.

11

Page 12

Understanding Sounds

You May Hear

USING YOUR

Your new refrigerator may make sounds that your old one

didn’t make. Because the sounds are new to you, you

might be concerned about them. Most of the new sounds

are normal. Hard surfaces, like the floor, walls, and

cabinets, can make the sounds seem louder than they

actually are. The following describes the kinds of sounds

and what may be making them.

■ If your product i s equipped with an ice maker, you will

hear a buzzing sound when the water valve opens to fill

the ice maker for each cycle.

■ The defrost timer will click when the automatic defrost

cycle begins and ends. Also, the thermostat refrigerator control, will click when cycling on and off.

■ Rattling noises may come from the flow of refrigerant,

the water line, or items stored on top of the refrigerator.

■ Your refrigerator is designed to run more efficiently to

keep your food items at the desired temperature. The

high efficiency compressor may cause yo ur new

refrigerator to run longer than your old one, and you

may hear a pulsating or high-pitched sound.

■ Water dripping on the defrost heater during a defrost

cycle may cause a sizzling sound.

■ You may hear the evaporator fan motor circulating the

air through the refrigerator and freezer compartments.

REFRIGERATOR

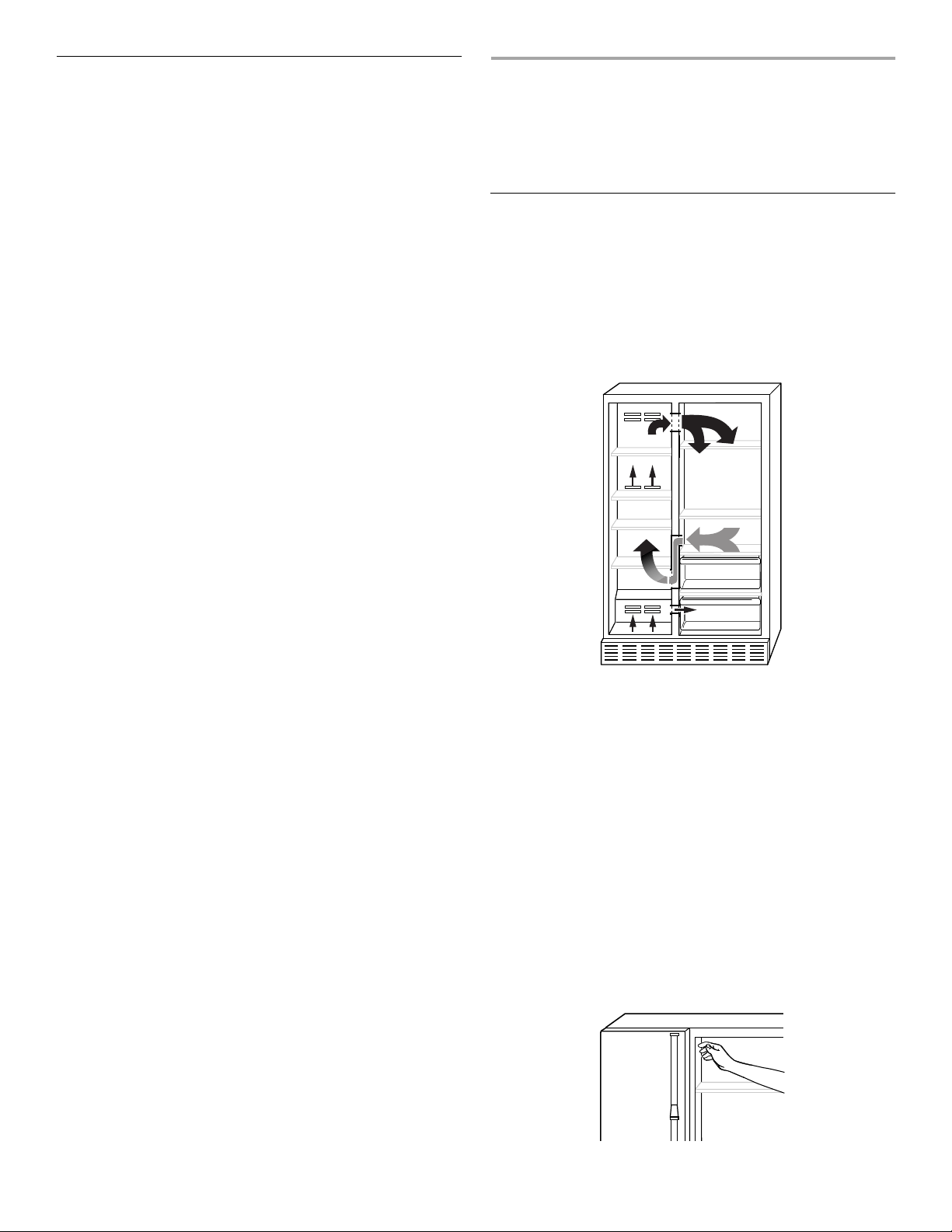

Ensuring Proper

Air Circul ation

In order to ensur e prop er temperatur es, you need to permi t

air to flow between the two sections. Cold air enters the

bottom of the fr e ezer se ction an d move s up. It th en en te rs

the refrigerator section through the top vent. Air then

returns to the freezer as shown.

■ As each cycle ends, you may hear a gurgling sound

due to the ref r igerant flowing in your refrigerator.

■ Contraction and exp a nsion of the inside walls may

cause a popping noise.

■ You may hear air being forced over the condenser by

the condenser fan.

■ You may hear water r unning into the drain pan dur ing

the defrost cycle.

Do not block any of these vents with food such as soda,

cereal, bread, etc. If the vents are blocked, airflow will be

prevented and the temperature controls will not function

properly.

IMPORTANT: Because air circulates between both

sections, any odors formed in one section will transfer to

the other. You must thoroughly clean both sections to

eliminate odors. To prevent odor transfer from food, wrap

or cover foods tightly.

Checking airfl ow

To measure the amount of cold air being directed from the

freezer compartment into the refrigerator section, hold

your hand in front of the top vent. You can adjust the Air

Balance Control to feel the different amounts of airflow.

For further information on temperatures inside your

refrigerator, refer to the “Troubleshooting” section.

12

Page 13

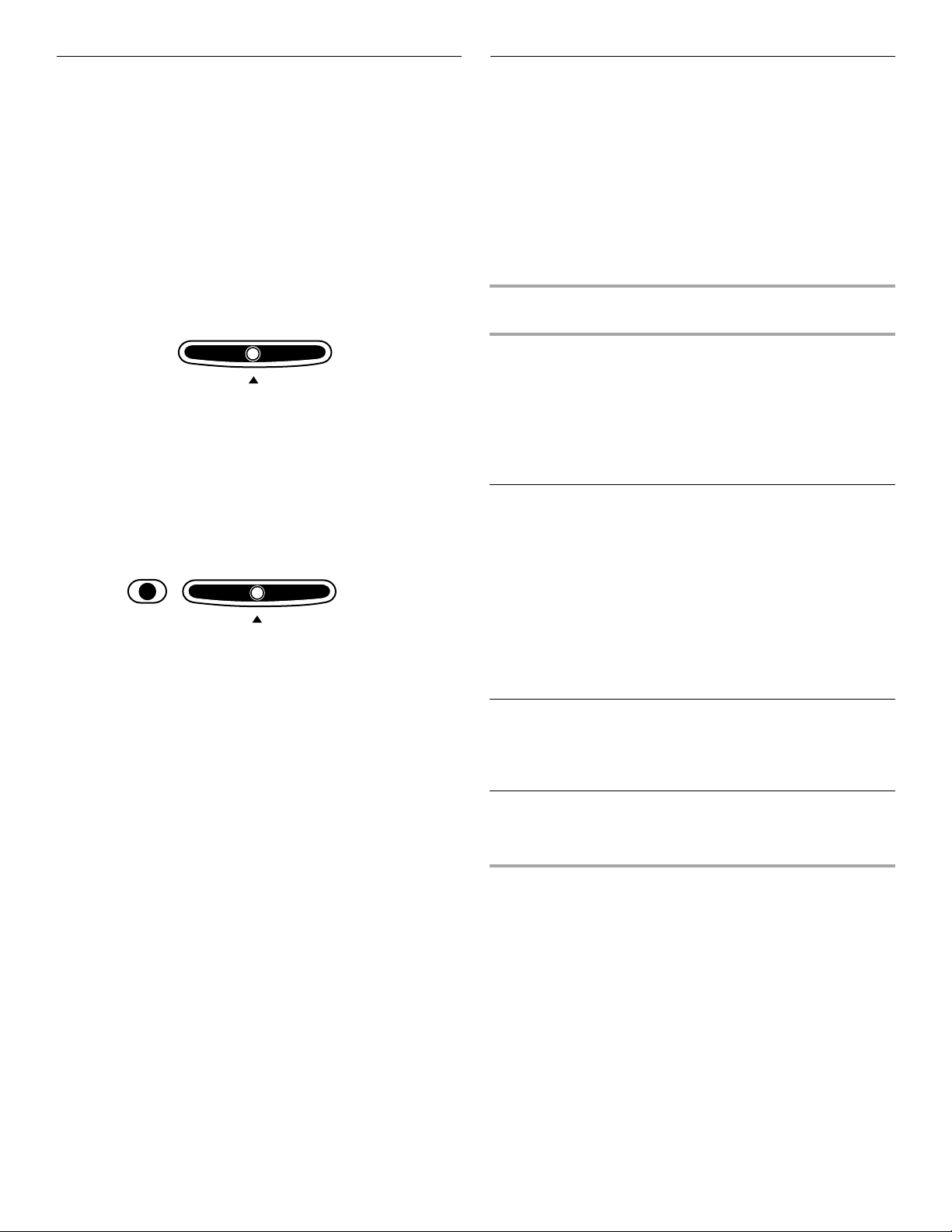

Setting the Controls

Adjusting Control Settings

For your convenience, your refrigerator controls are

preset at the factory. When you first install your

refrigerator, make sure that the controls are still preset.

The Refrigerator Control and the Freezer Control should

both be at the “mid-settings” as shown in the illustrations

below.

The Refrigerator Control adjusts the refrigerator

compartment temperature. Settings to the left of the

mid-setting make the temperature less cold. Settings to

the right of the mid-setting make the temperature colder.

Refrigerator

Colder

Cold

The Freezer Control adjusts the freezer compartment

temperature. Settings to the left of the mid-setting make

the temperature less cold. Settings to the right of the midsetting make the temperature colder.

NOTE: You r pr oduct w ill not cool when the Fre ezer Contr ol

is set to OFF.

1

2

4

3

Freezer

Give the refrigerator time to cool down completely before

adding food. It is best to wait 24 hours before you put food

into the refrigerator. The settings indicated in the previous

section should be correct for normal household

refrigerato r usage. The con trol s are set corr ectl y when milk

or juice is as cold as you like and when ice cream is firm.

If you need to adjust temp eratures in the refrigerator or

freezer, use the settings listed in the char t below as a

guide. Wait at least 24 hours between adjustments.

RECOMMENDED

CONDITION/REASON:

REFRIGERATOR section

too warm

■ Door opened often

■ Large amount of food added

■ Room temperature very warm

FREEZER section too warm/ice

not made fast enough

■ Door opened often

■ Large amount of food added

ADJUSTMENT:

Turn

REFRIGERATOR

Control one-half

setting higher,

wait 24 hours,

then check the

freezer

temperature

Turn FREEZER

Control one-half

setting higher

Off

Give your refri gerator time to coo l down co mpletely befor e

adding food. It is best to wait 24 hours before you put food

into the refrigerator.

IMPORTANT: If you ad d food before the refrigerator has

cooled completely, your food may spoil. Turning the

Refrigerator and Freezer Controls to a higher (colder)

than recommended setting will not cool the

compartments any faster.

NOTE: The Automatic Exterior Moisture control

continuously guards against moisture buildup on the

outside of your refrigerator cabinet. This control does not

have to be set or adjusted.

1

2

4

3

Colder

■ Very cold room temperature

(can’t cycle often enough)

■ Heavy ice usage

■ Air diffuser blocked by items

REFRIGERATOR section

too cold

■ Controls not set correctly for

your conditions

FREEZER section too cold

■ Controls not set correctly for

your conditions

Move packages

out of airstream

Turn

REFRIGERATOR

Control to next

lower number

Turn FREEZER

Control one-half

setting lower

13

Page 14

Food Storage Guide

Storing fresh food

Wrap or store food in the refrigerator in airtight and

moisture-proof material unless otherwise noted. Th is

prevents food odor and taste transfer throughout the

refrigerator. For dated products, check code date to

ensure freshness.

Butter or margarine

Keep opened butter in covered dish or closed

compartment. When storing an extra supply, wrap in

freezer packaging and freeze.

Cheese

Store in the original wrapping until you are ready to use

it. Once opened, rewrap tightly in plastic wra p or

aluminum foil.

Milk

Wipe milk cartons. For best storage, place milk on

interior shelf.

Eggs

Store in original carton on interior shelf.

Fruit

Wash, let dry, and st or e in r efr igerator in pl asti c bags or

crisper. Do not wash or hull berries until they are read y

to use. Sort and keep berries in original container in a

crisper, or store in a loosely closed paper bag on a

refrigerator shelf.

Leafy vegetables

Remove store wrapping and trim or tear off bruised and

discolored ar eas. Wash in cold water an d drain. Pl ace in

plastic bag or plastic conta i ne r an d sto re in crisp er.

Vegetables with skins (carrots, peppers)

Place in plastic bags or plastic container and store in

crisper.

Fish

Use fresh fish and shellfish the same day as purchased.

Meat

Store most meat in original wrapping as long as it is

airtight and moist ure-proof. Rewrap if necessary. See

the following chart for storage times. When storing meat

longer than the times given, freeze the meat.

Chicken.................. ....... ...... ............................ 1 -2 days

Ground beef.................................................... 1-2 days

V ariety meats (liver, heart, etc.)....................... 1-2 days

Cold cuts......................................................... 3-5 days

Steaks/roasts......... ....... ...... ....... ...... ....... ........ 3-5 days

Cured meats ........................................... ...... 7-10 days

Leftovers

Cover leftovers with pl astic wrap or aluminum foil.

Plastic containers with tight lids can also b e used.

Storing frozen food

NOTE: For further information a bout preparing food fo r

freezing or food storage times, check a freezer guide or

reliable cookbook.

Packaging

Successful freezing depends on the correct packaging.

When you close and seal the package you must not allow

air or moisture in or out. If you do, you could have food

odor and taste transfer throughout the refrigerato r, and

also dry out frozen food.

Packaging recommendations:

■ Rigid plastic containers with tight-fitting lids

■ Straight-sided canning/freezing jars

■ Heavy-duty aluminum foil

■ Plastic-coated paper

■ Non-permeable plastic wraps (made from saran

film)

■ Specified freezer self-sealing plastic bags

Follow package or container instructions for proper

freezing methods.

14

Page 15

Do not use:

■ Bread wrappers

■ Non-polyethylene plastic containers

■ Containers without tight lids

■ Wax paper or wax-coated freezer wrap

■ Thin, semi-permeable wrap

Freezing

Your freezer will not quick-freeze any lar ge quantity of

food. Put no more unfrozen food into the freezer than will

freeze within 24 hours (no more than 2 to 3 lbs of food per

cubic foot [907-1,350 g per liter] of freezer space). Leave

enough space in the freezer for air to circulate around

packages. Be careful to leave enough room at the fr ont so

the door can close tightly.

Storage times will vary a ccor ding to t he qu ality and t ype of

food, the type of packaging or wrap used (airtight and

moisture-proof), and the storage temp erature. Ice crystals

inside a sealed package are normal. This simply means

that moisture in the food and air inside the package have

condensed, creating ice crystals.

NOTE: Allow hot foods to cool at room temperature for 30

minutes, then package and freeze. Cooling hot foods

before freezing saves energy.

REFRIGERATOR

FEATURES

Ice Maker Storage Bin

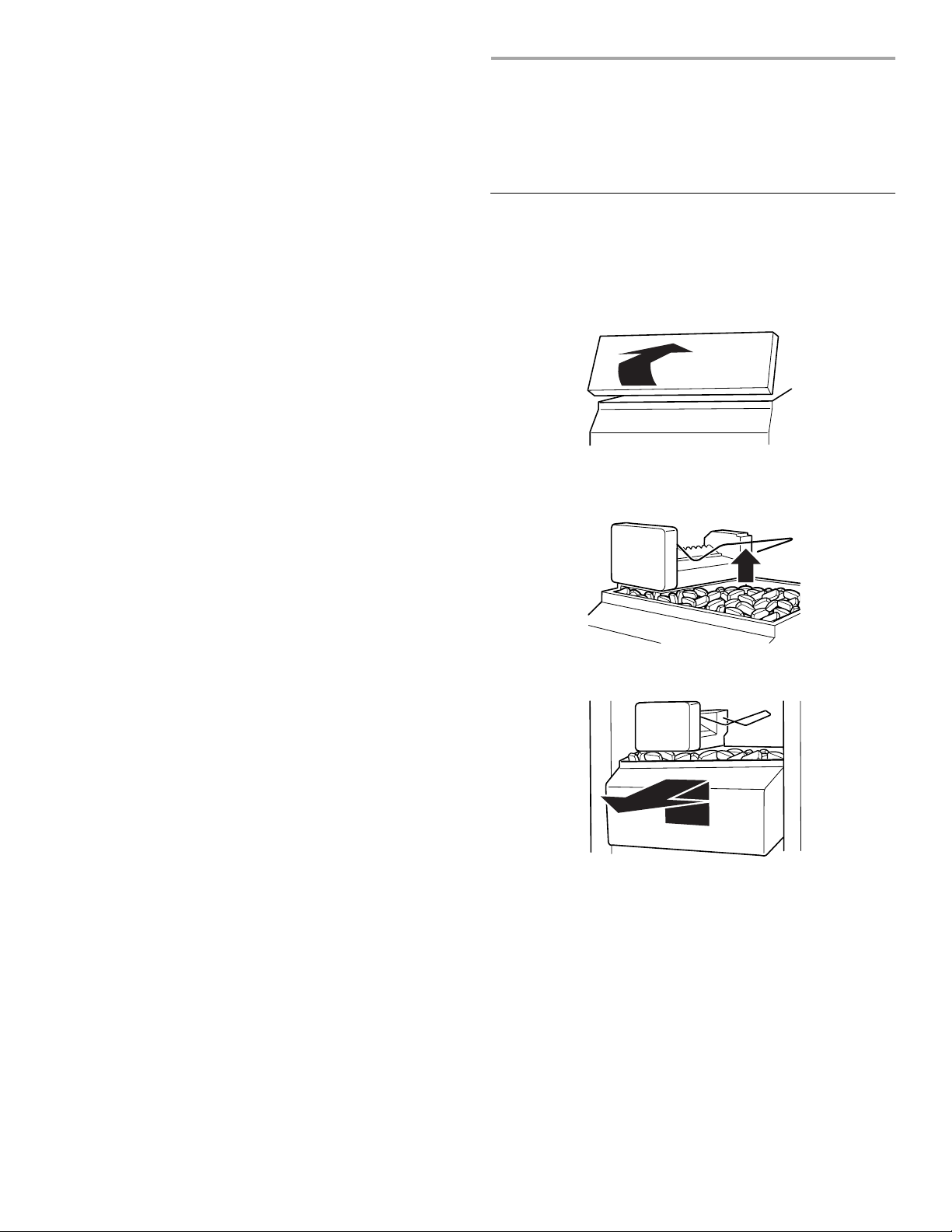

To remove the ice bin:

1. Pull the covering panel out from the bottom and then

slide it back toward the rear.

2. Lift the signal arm so it clicks into the OFF (up) position.

Ice can still be dispensed, but no more can be made.

3. Lift up the front of the storage bin and pull it out.

4. Empty the ice bin. Use warm water to melt the ice if

necessary. Never use anything sharp to break up the

ice in the bin. This can cause damage to the bin an d

the dispenser mechanism.

5. Wash with a mild detergent, rinse well and dry

thoroughly. Do not use harsh or abrasive cleaners or

solvents.

6. When you replace the bin, make sure it is pushed in

all the way or the dispenser will not work. Then push

the signal arm down to the ON position to restart ice

production. Make sure the door is closed tightly.

15

Page 16

To dispense ice:

W ater and Ice Dispensers

(on some models)

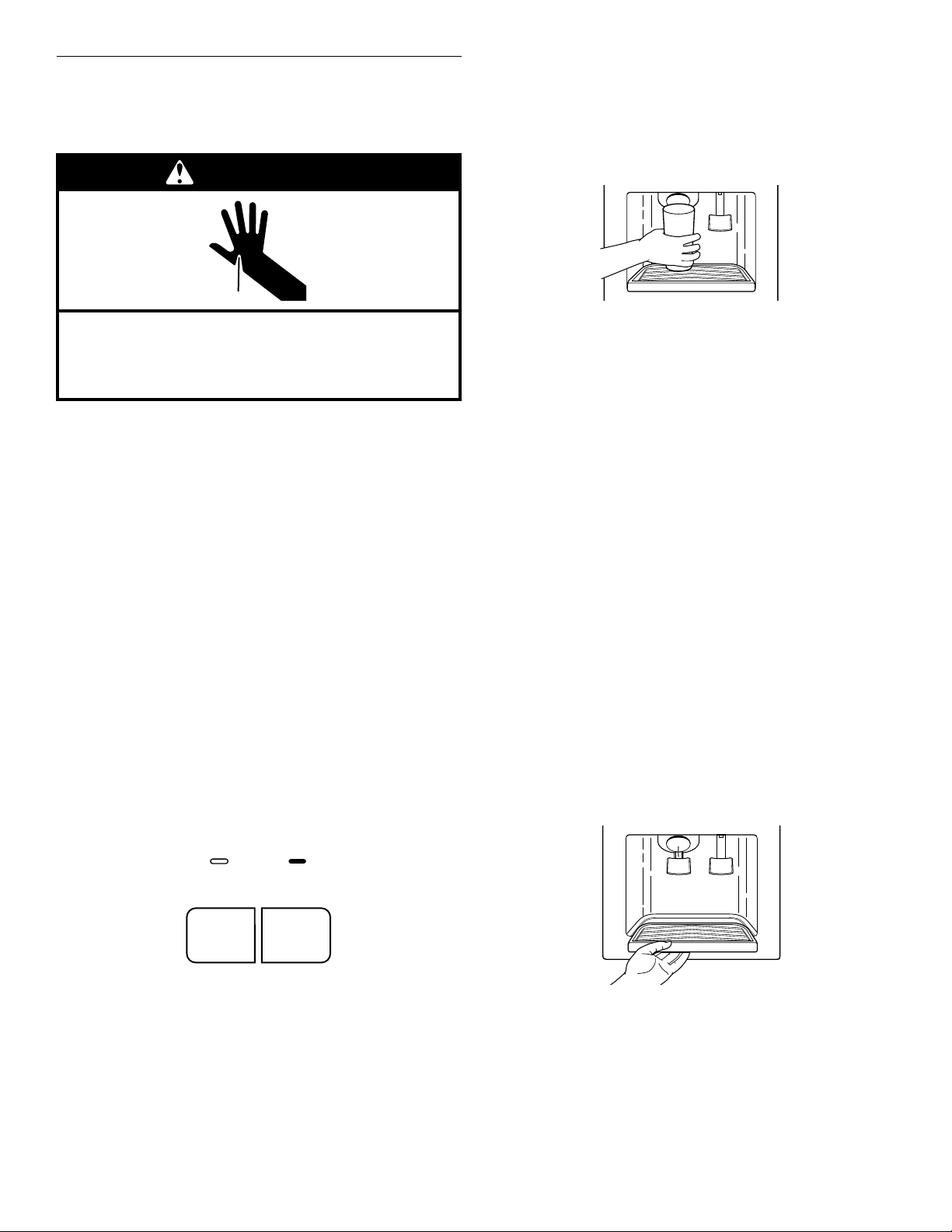

WARNING

Cut Hazard

Use a sturdy glass when dispensing ice or water.

Failure to do so can result in cuts.

Depending on your model, you may have one or more of

the following optio ns: The ability to select eit her crushed or

cubed ice, a special light that turns on when you use the

dispenser, or a lock option to avoid accidental dispensing.

The ice dispenser

Ice dispenses from t he ice maker storage bin in the freez er.

When the dispenser lever is pressed:

■ A trapdoor opens in a chute between the dispenser

and the ice bin.

■ Ice moves from the bin and falls through the chute.

■ When you release the dispenser lever, the trap door

closes and the ice dispensing stops. The dispensing

system will not operate when the freezer door is open.

Some models dispense both cu bed and crushed ice.

Before dispen sing ice, select which type of ice you prefer.

The button controls are designed for easy use and

cleaning.

■ For cubed ice, press the CUBE button until the red

indicator appears in the window above the CUBE

button.

1. Press button for the desired type of ice.

2. Press a sturdy glass against the ice dispenser lever.

Hold the glass close to the dispenser opening so ice

does not fall outside of the glass.

IMPORTANT: You do not need to apply a lot of

pressure to the lever in order to activate the ice

dispenser. Pr essing hard will not make the ice dispense

faster or in greater quantities.

3. Remove the glass to stop dispensing.

NOTE: The first few batches of ice may have an off-

flavor from new plumbing and parts. Throw the ice

away. Also, take large amounts of ice from the ice bin,

not through the dispenser.

The water dispenser

Chilled water comes from a container behind the meat

drawer. It holds approximately 1¹⁄₂ quarts (1.5 L).

When the refrigerator is first hooked up, press the water

dispenser bar with a glass or jar until you draw and discard 2 or 3 quarts (1.9 to 2.8 L). It will take three to four

minutes for the water to begin dispensing. The water you

draw and discard rinses the tank and pipes.

Allow several hours to chill a new tankful.

IMPORTANT: The small removable tray at the bottom of

the dispenser is d e signed to catch small spills and allow

for easy cleaning. Th ere is no drain i n the tray. Th e tray can

be removed from the dispenser and carried to the sink to

be emptied or cleaned.

ICE

CRUSH CUBE

■ For crushed ice, press the CRUSH button until the red

indicator appears in the window above the CRUSH

button.

For crushed ice, cubes are crushed before being

dispensed. This may cause a slight delay when dispensing

crushed ice. Noise from the ice crusher is normal, and

pieces of ice may vary in size. When changing from

CRUSH to CUBE, a few ounces of crushed ice will be

dispensed along with the first cubes.

16

Page 17

To dispense water:

1. Press a glass against the water dispenser lever.

2. Remove the glass to stop dispensing.

NOTE: Dispense enough water every week to maintain a

fresh supply.

The dispenser light

The dispenser area has a light. It can be turned on

manually by pressing the “ON” button at the right hand

side of the contr ol panel . The red indicator above the “ON”

button will appear. On some models: Whenever you use

the dispenser the lever will automatically turn the light on.

LIGHT

W ater Filtration and

Monitoring System

(on some models)

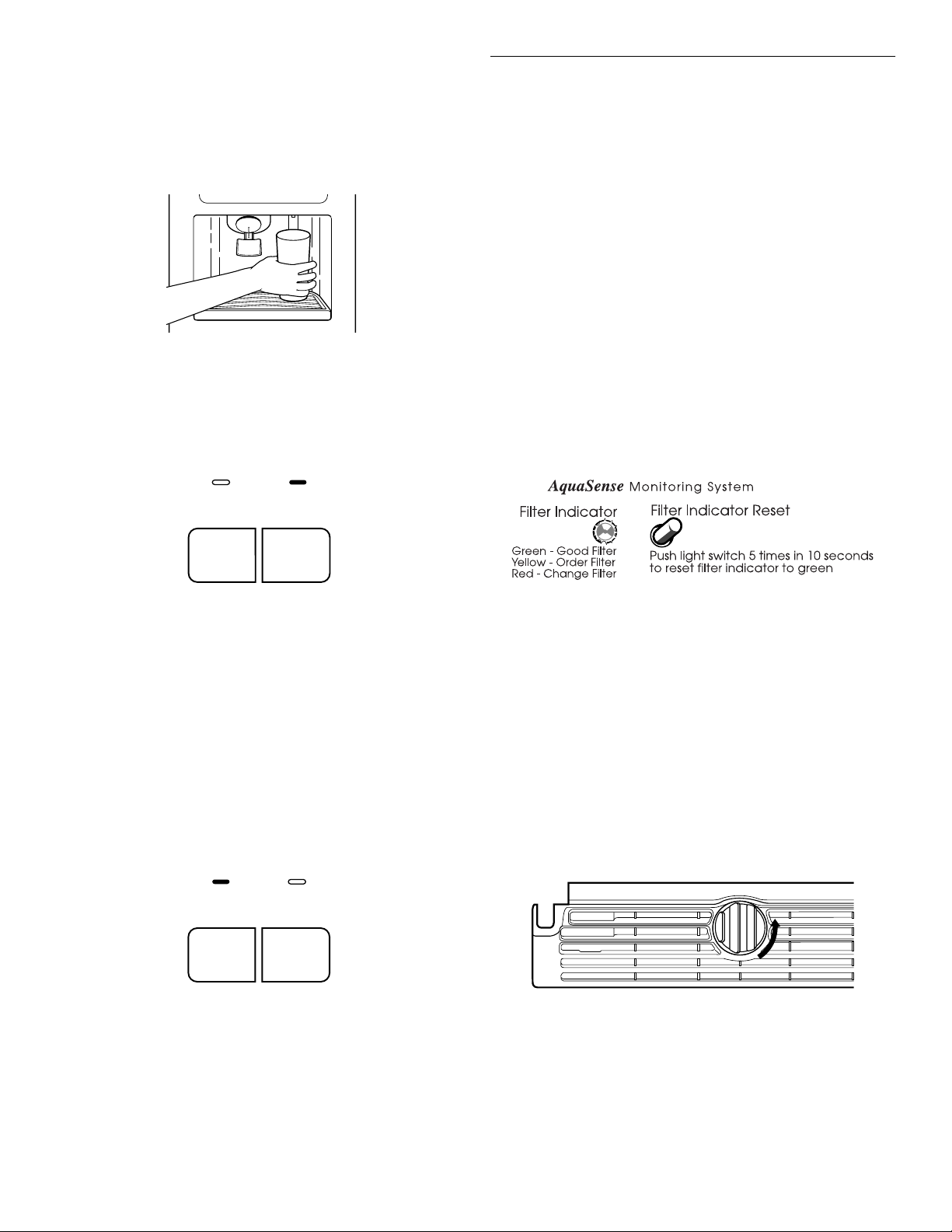

The water filter indicator light

The water filter indicator light will help you know when to

change your water filter cartridge. The light is located at

the top of the refrigerator compartment. The light will

change from green to yellow. This tells you that it is almost

time to change the water filter cartridge (90% of the filter

life has been used). It is recommended that you replace

the water filter car tridge when the wate r filter indic ator light

changes to red OR water flow to your water dispenser or

ice maker decreases noticeably. (See “Changing a water

filter cartridge ” la ter in thi s se c tio n. )

NOTE: Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

OFF ON

NOTE: See the “Changing the Light Bulbs” section for

information on changing the dispenser light bulb.

On models without crushed ice, the light switch is a

rocker-style type. Push the switch to turn the light on, and

push again to turn the light off.

The dispenser lock

Your dispenser can be turned of f for easy cleaning or to

prevent accidental dispensing by small children and pets.

To turn off the dispenser, press the LOCK button. The

indicator will appear above the LOCK button and the ice

and water dispensers will not work. To unlock the

dispenser, press the UNLOCK button until the indicator

appears. Then continue to dispense ice or water as usual.

(on some mode ls)

DISPENSER

LOCK

NOTE: The lock feature does not shut off power to the

product, to the ice maker, or to the dispenser light. It

simply deactivates the dispenser levers.

UNLOCK

After changing the water filter cartridge, reset the water

filter indicator light by pressing the light switch 5 times

within 10 seconds. The in dica to r li gh t wi ll chan ge from red

to green when the system is reset.

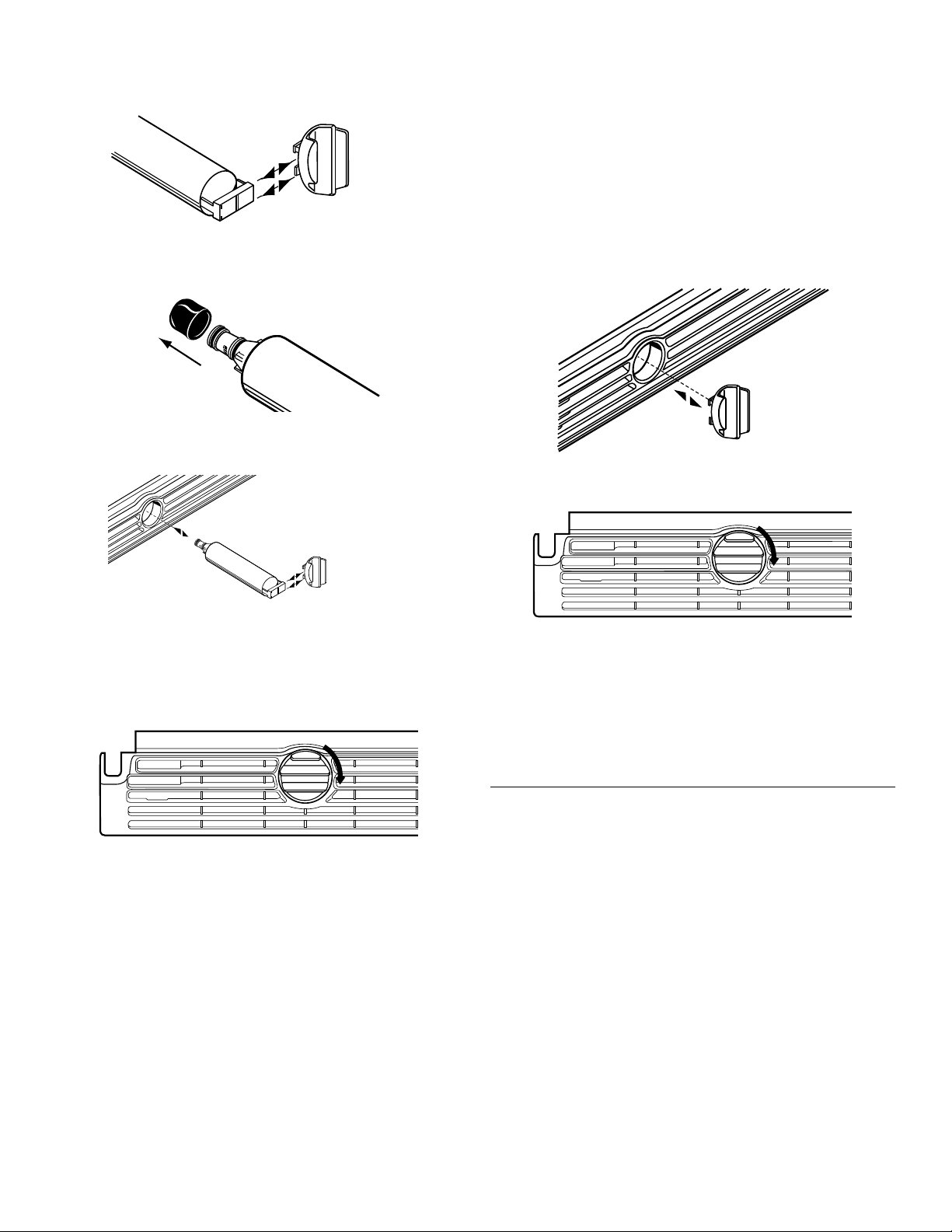

Changing a water filter cartridge

The water filter is located below the freezer comp artment

door.

1. Locate the water filter cartridge cap in the front base

grille below the freezer compartment door. Rotate the

cap counterclockwise to a vertical position and pull the

cap and filter cartridge out through the base grille.

NOTE: There will be water in the cartridge. Some

spilling may occur.

17

Page 18

2. Remove the cartr idge cap b y sliding i t of f the end of the

old cartridge. The cap will slide to the left or right. DO

NOT DISCARD THE CAP.

Using the dispenser without the water filter

You can run the dispenser without a water filter cartridge.

Your water will not be filtered. If you run the dispenser

without a water filter cartridge, keep the cartridge cap and

replace it in the base grille for future use.

1. Remove the water filter cartridge (See “Changing a

water filter cartridge” earlier in this section.) Then slide

the cartridge ca p off the end of the filter cartridge. DO

NOT DISCARD THE CAP.

3. Take th e new cartridge out of it s packaging and r emove

protective cover from o-rings.

4. Slide the cartrid ge cap onto the new cartridge as

shown.

5. With cartridge cap in the vertical position, push the

new filter cartridge into the base grille until it stops.

Rotate the cartridge cap clockwise to a horizontal

position.

2. With the cartridge cap in the ver tical pos ition, i nsert the

cap into the base grille until it stops.

3. Rotate the cartridge cap to a horizontal position.

NOTE: The cartridge cap may not be even with the

base grille.

Ordering replacement filter s

To order more water filter cartridges, call 1-800-422-1230

and ask for accessory Part #4392857 or contact your

authorized KitchenAid dealer.

6. RUN WATER THROUGH THE DISPENSER UNTIL THE

WATER RUNS CLEAR (about 2-3 gallons or 6-7

minutes). This will clean the system and clear air from

the lines. Additional flushing may be required in some

households.

NOTE: As air is cleared from the system, water may

spurt out of the dispenser.

18

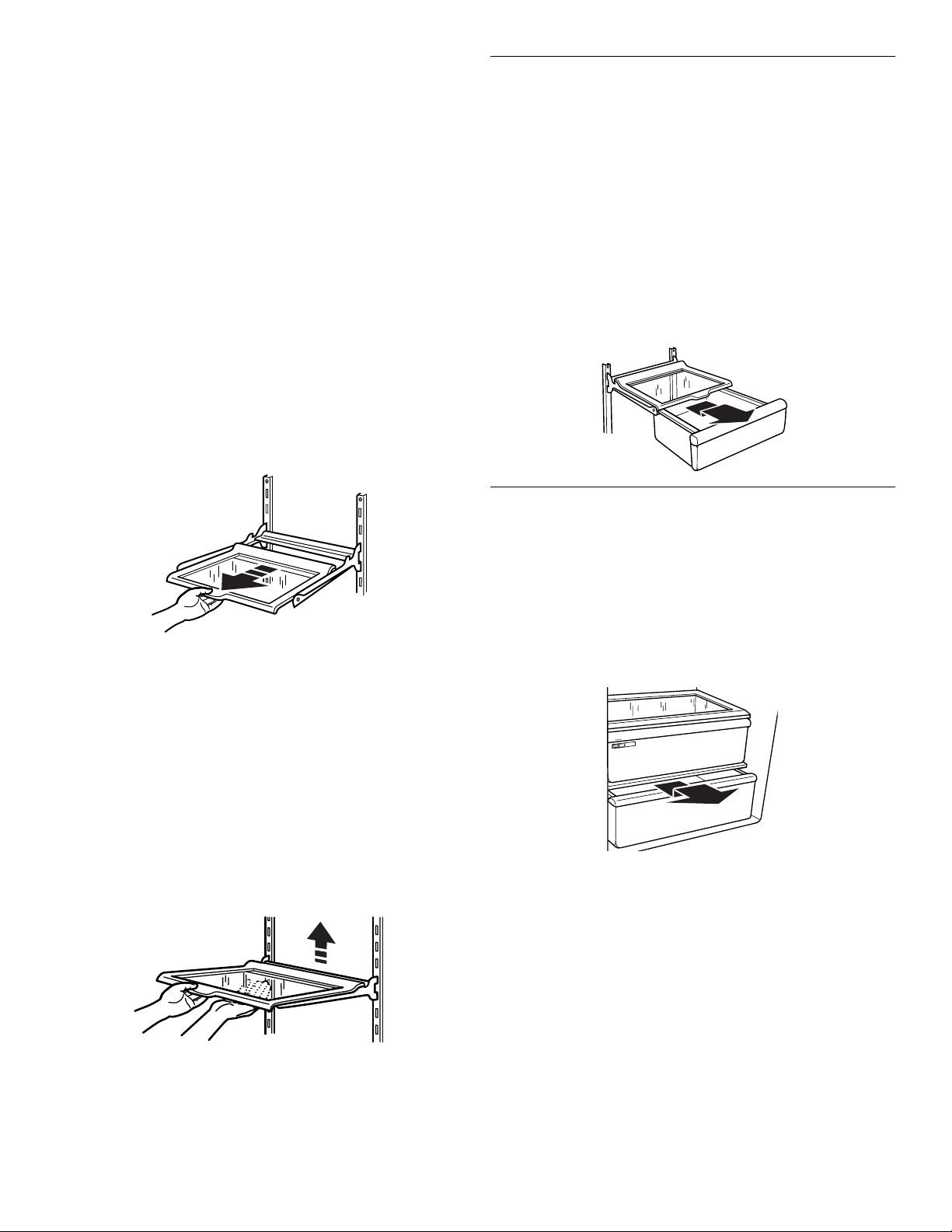

Refrigerator Shelves

The shelves in y our r efrigera tor ar e adju stable t o meet y our

individual storage needs. Your model may have glass or

wire shelves.

Storing similar food items together in your refrigerator and

adjusting the shelves to fit different heights of items will

make finding the exact item you want easier. It will also

reduce the amount of ti me the refrigerator door is open,

and save energy.

IMPORTANT: Do not clean glass shelv es with warm water

when they are col d. Shelves may break if exp o sed to

sudden temperature changes or impact. For your

protection tempere d glass is d esigned to sh atter into many

small pebble-size pieces. This is normal.

NOTE: Glass shelves are heavy. Use special care when

removing them to avoid impact from dropping.

Page 19

To remove shelves from the shipping position (shelves

LOWLOW

HIGH

are shipped upside down):

1. Grasp front of upper shelf with one hand and use other

hand to remove packing material from shelf area.

2. Lower front of upper shelf until shelf hooks can be

removed from slots in shelf supports on the back

refrigerator wall. Pull shelf forward to remove.

3. Flip shelf over.

4. Insert rear shelf hooks into slots in shelf supports.

5. Tilt front of shelf up until rear hooks drop into slots.

6. Lower front of shelf. Check to make sure that shelf is

securely in position.

Slide-out shelves (on some models)

Some shelves slide out, providing easier access to foods

stored in back.

To slid e out shelf, carefully pull front of shelf toward

you.

To slide in shelf, push shelf in until it stops.

Deli Drawer

(on some models)

The deli drawer provides a convenient place to store

raisins, nuts, spreads, and other small items at normal

refrigerator temperatures.

To remove the deli drawer:

1. Slide the deli drawer straight out to the stop.

2. Lift the front and slide the drawer out the rest of the

way.

Replace the deli drawer by sliding it back in fully past

the drawer stop.

To remove a shelf from the metal frame:

1. Pull shelf out to the stop.

2. Tilt front of the shelf up and pull it out a little further.

3. Lift up shelf so that it moves through the slot in the

frame.

Replace the shelf in the reverse order.

Shelves and shelf frame s

To remove a shelf/frame:

1. Tilt up front of the shelf/frame.

2. Pull shelf/frame.

Convertible Vegetable/Meat

Drawer and Cover

To remove the drawer:

1. Slide the drawer straight out to the stop.

2. Lift the front slightly and slide it out t h e rest of the way.

3. Replace the drawer by sliding it past the drawer stop.

To remove the cover:

1. Remove the drawer and the crisper.

2. Lift the front of the cover off of the supports and

remove it by pulling up and out.

To replace the cover:

1. Fit the back of the cover into the notch supports on the

walls of the refrigerator and lower it into place.

2. Replace the drawer and crisper.

To replace a shelf/frame:

1. Guide the rear shelf hooks into the slots in the shelf

supports on the back refrigerator wall.

2. Tilt up front of shelf/frame.

3. Lower the front of the shelf into position.

19

Page 20

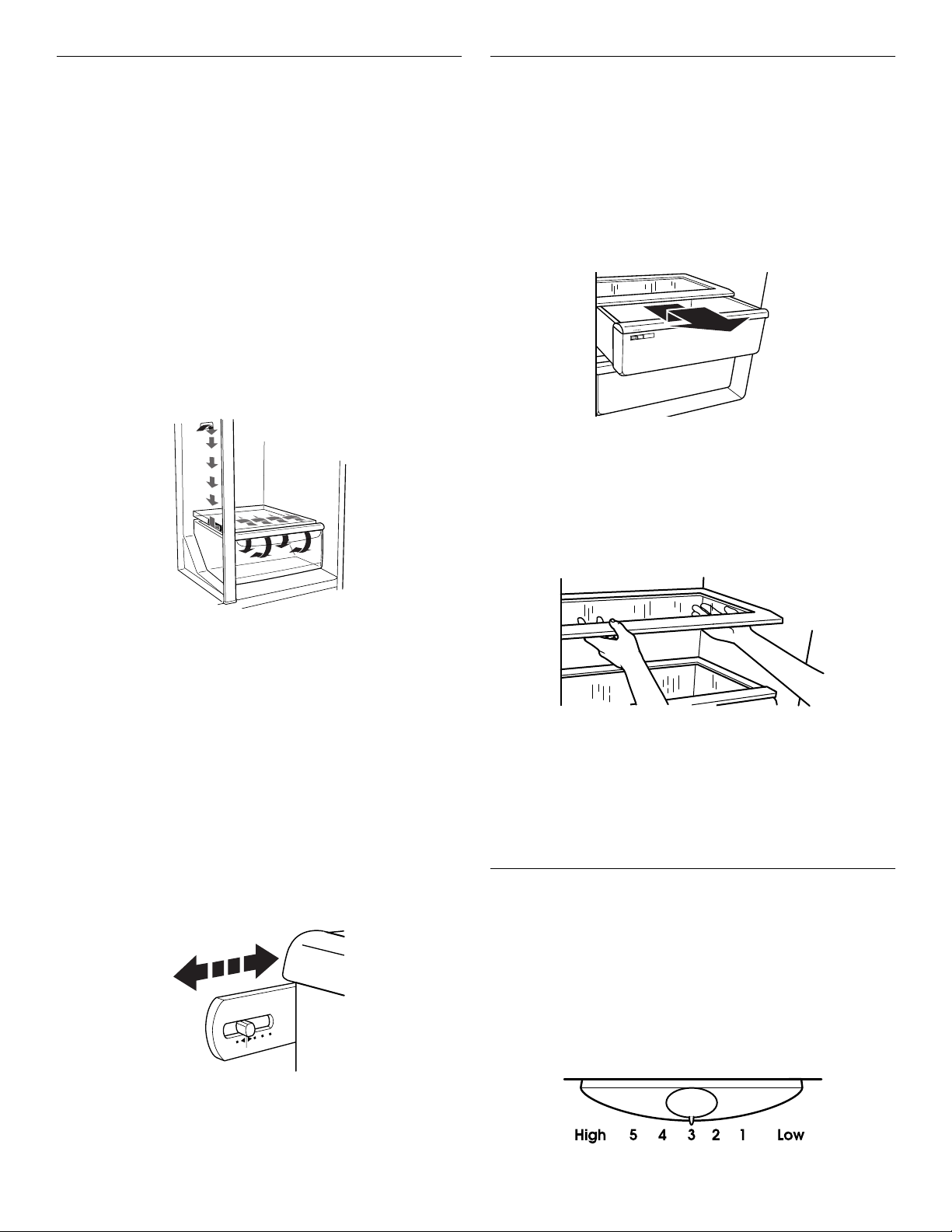

Convertible Vegetable/Meat

LOW

HIGH

Crisper and Crisper Cover

Drawer Temperature Control

The convertible v egeta ble/mea t dr awer can be ad justed to

properly chill meats or vegetables. Unlike most chilled

meat drawer systems, the Temperature Control cools the

air inside the pan. (Most systems chill only the pan itself,

which doesn’t cool the air inside the pan evenly).

Chilling the air inside the pan provides more even cooling

and reduces “sp ot ” freezing. The Temperature Control can

be set to keep meats at the recommended storage

temperatures (28°F-32°F are the recommended storage

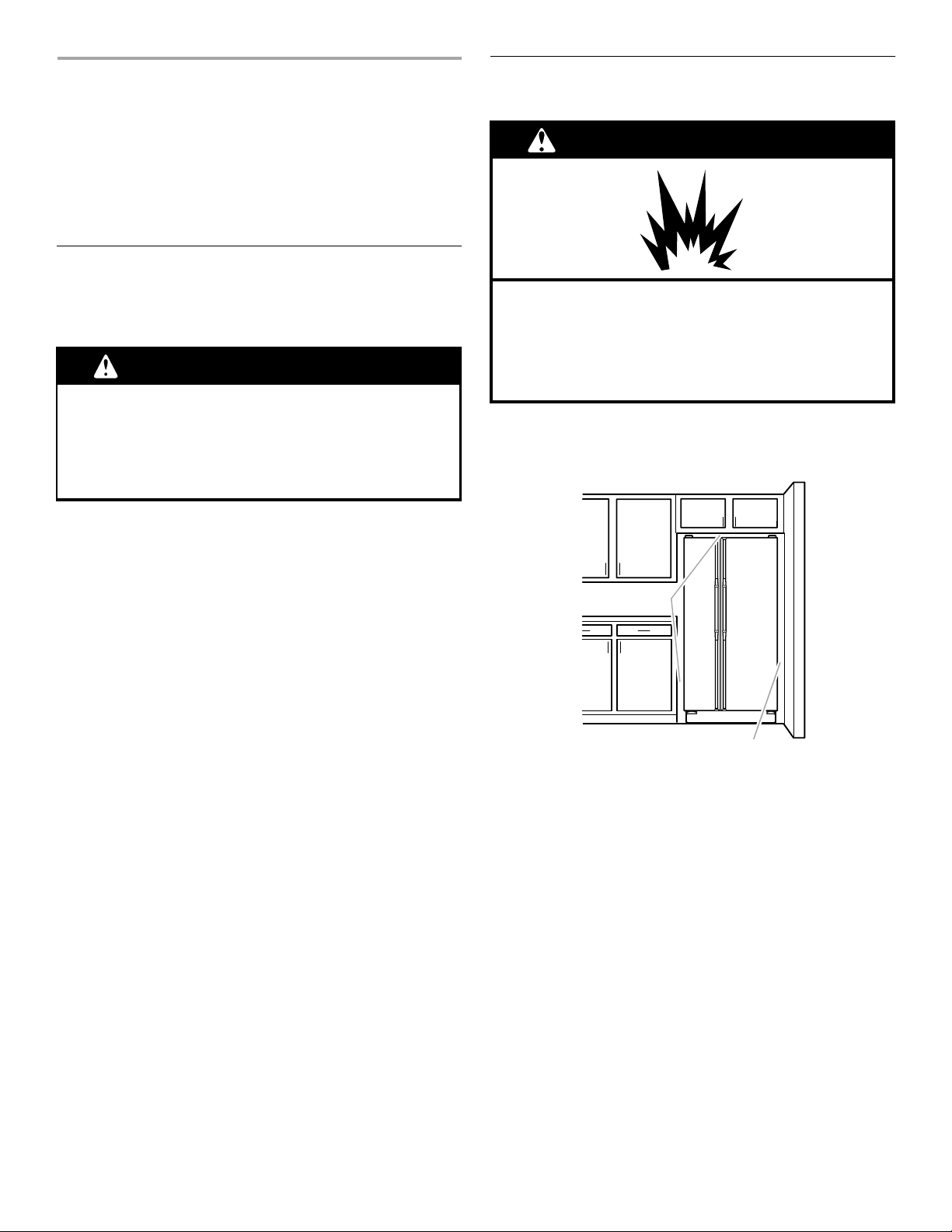

temperatures from the National Livestock and Meat

Board).

To store vegetables at their optimal storage temperatures

(which need to be warmer than those for meat), set the

control at the Vegetable setting, all the way to the left.

To remove the crisper:

1. Slide crisper straight out to the stop.

2. Lift the front.

3. Slide crisper out the rest of the way.

Replace the crisper by sliding it back in ful ly past the

drawer stop.

To remove the crisper cover:

1. Remove crisper.

2. Holding glass insert firmly, grasp one side of crisper

cover and lift the other side up from the bottom.

3. Slide the glass insert out to remove.

4. Lift cover frame up and remove.

IMPORTANT: To extend freshness even more, remember

to wrap meats in airtight, moisture-proof materials before

storing. Always store meat as recommended by the

National Livestock and Meat Board. See “Storing Fresh

Food” in the “Food Storage Guide” section for more

information.

Adjusting the control

The convertible co nt rol comes preset f or yo u a t th e lo west

meat setting. Move it to the mid-setting or “colder” as

desired.

To ch ange a c ontr o l setti ng: Move the control to the right

(colder) or to the left (less cold).

To store vegetables: Move the control all the way to the

left to the VEG setting.

Veg/Meats Veg/Meats

Temperature Temperature

MEATS

VEG

To replace the crisper cover:

1. Fit back of cover frame into supports on side walls of

the refrigerator.

2. Lower front of the cover frame into place.

3. Slide rear of glass insert into cover frame and lower

front into place.

Crisper Humidity Control

You can control the amount of humidity in the moisturesealed crisper. Adjust the control to any setting between

LOW and HIGH.

■ LOW (open) lets moist air out of the crisper for best

storage of fruits and vegetables with skins.

■ HIGH (closed) keeps moist air in the crisper for best

storage of fresh, leafy vegetables .

IMPORTANT: If food starts to freeze, move the control to

the left (less cold). Remember to wait 24 hours between

adjustments. Doing so gives the temperature of the food

time to change.

20

Page 21

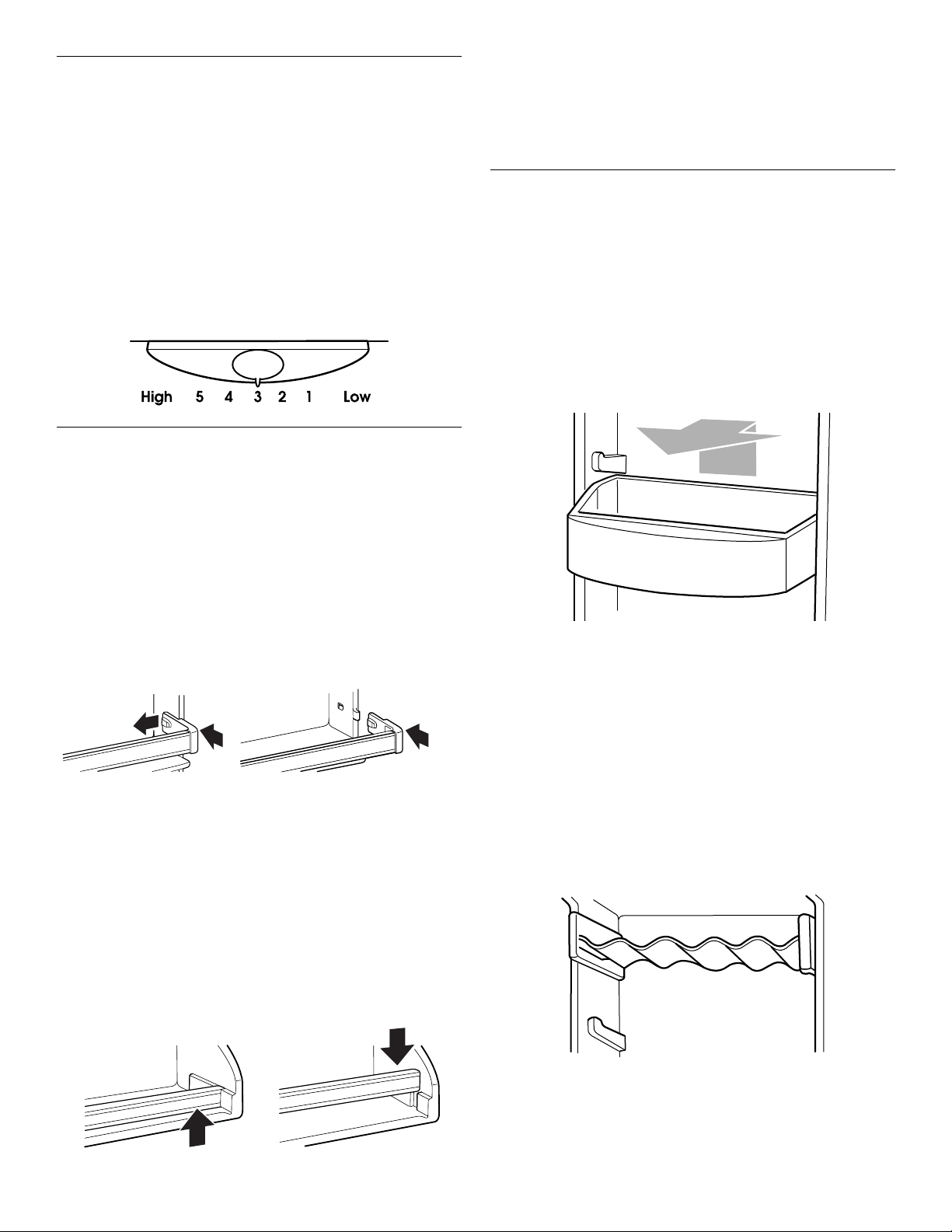

Door Rails

The door rails may be removed for easier cleaning.

Snap-on Door Rails

To remove the rails:

1. Remove all items from the shelf.

2. Push in slightly on the front of the bracket while pulling

out on the inside tab.

3. Repeat these steps for the other end of the rail.

To replace the rails:

1. Line up the ends of the brackets with the buttons on

the sides of the door liner.

2. Firmly snap bracket and rail assembly onto the tabs

above the shelf as shown.

Drop-in Door Rails

To remove the rails:

1. Remove all items from the shelf.

2. Pull straight up on each end of the rail.

Door Accessories

Door Bins

The door bins are removable for easy cleaning and

adjusting.

1. To remove the bin, simply lift the bin up and pull

straight out.

2. To replace the bin, slide it in above the desired

support button and push down until it stops.

Can Rack

To remove the rack:

1. Remove all items from the rack.

2. Lift the rack up.

3. Pull the rack strai ght out.

To replace the rails:

1. Slide the shelf rail into the slots on the door.

2. Push the rail straight down until it stops.

To replace the rack:

1. Hold the back of the rack above the desired guide.

2. Push the back of the rack back and down until it stops.

21

Page 22

Freezer Shelf

(number varies with model)

To remove the shelf:

1. Lift the shelf off of the supports.

CARING FOR

YOUR

2. Slide it out of the shelf support holes.

Replace shelf in the reverse order.

Freezer Basket

(plastic bin on some models)

The freezer basket can be used to store bags of frozen

fruits and vegetables that may slide off freezer shelves.

To remove the freezer basket:

1. Slide it out to the stop.

2. Lift the front and slide it out the rest of the way.

REFRIGERATOR

Cleaning Y our Refrigerator

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion,

or fire.

Both the refrigerator and free zer sections defrost

automatically. However, clean both sections about once a

month to prevent odors from building up. Wipe up spills

immediately.

To replace the basket:

1. Position it on the slides, making sure that the wire

stops are clear of the front of the slides.

2. Slide it back in all the way.

Energy Saving Tip:

Clean the condenser coils regularly, as described i n the

cleaning chart in this section.

To clean your refrigerator:

■ Unplug refrigerator or disconnect power.

■ Remove all removable parts from inside, such as

shelves, crispers, etc.

■ Use a clean sponge or soft cloth and a mild deter gent in

warm water. Do not use abrasive or harsh cleaners.

■ Hand wash, rins e, and dry all sur f ace s thoroughl y.

■ Plug in refrigerator or reconnect power.

22

Page 23

■ Additional cleaning tips are listed below:

Light behind control panel:

PART COMMENTS

Outside

■ Waxing external painted metal

surfaces helps provide rust

protection. Do not wax plastic

parts. Wax painted metal surfaces

at least twice a year using

appliance wax (or auto paste wax).

Apply wax with a clean, soft cloth.

Inside walls

(allow freezer

to warm up so

cloth won’t

■ To help remove odors, you can

wash with a mixture of warm water

and baking soda (2 tbs to 1 qt [26 g

to .95 L] of water).

stick)

Door liners

and gaskets

■ Do not use cleaning waxes,

concentrated detergents, bleaches,

or cleaners containing petroleum

on plastic parts.

Plastic parts

(covers and

panels)

Condenser

coils

■ Do not use paper towels, window

sprays, scouring cleansers or

flammable fluids. These can

scratch or damage material.

■ Remove base grille. (See the

“Base Grille” sec tio n.)

■ Use a vacuum with an extended

attachment to clean condenser

coils.

■ Vacuum coils when dusty or dirty.

Coils may need to be cleaned as

often as every other month.

■ Replace base grille.

1. Unplug refrigerator or disconnect power.

2. Reach behind the Control Panel and remove the bulb.

3. Replace the bulb with a 40-watt appliance bulb.

4. Plug in refrigerator or reconnect power.

Crisper light (on some models):

1. Unplug refrigerator or disconnect power.

2. Remove the light shield by grasping the top center of

the shield and pullin g forwa r d while turning it slig htly to

one side.

3. Replace the bulb with a 40-watt appliance bulb.

4. Replace the light shield by gra sping the top center of

the shield and inserting the tabs on one end into the

slotted holes in the refrigerator liner. Then, carefully

bend the shield at the center to insert the tabs on the

other end.

Changing the Light Bulbs

NOTE: Not all appliance bulbs will fit your refrigerator. Be

sure to replace the bulb with one of the same size and

shape.

Refrigerator Light Bulbs

Dispenser area light (on some models):

1. Unplug refrigerator or disconnect power.

2. Reach through the dispenser area to remove the bulb.

3. Replace the bulb with a heavy-duty 10-watt bulb,

which can be purchased from your d ealer.

4. Plug in refrigerator or reconnect power.

5. Plug in refrigerator or reconnect power.

NOTE: To clean the light shield, wash it with warm water

and a liquid detergent. Rinse and dry the shield well.

Freezer Light Bulbs

Light below the ice bin:

1. Unplug refrigerator or disconnect power.

2. Push in the sides of the light shield and pull down until

the shield snaps free.

3. Replace the bulb with a 40-watt appliance bulb.

4. Replace the light shield.

5. Plug in refrigerator or reconnect power.

23

Page 24

Upper freezer light (on some models):

1. Unplug refrigerator or disconnect power.

2. Remove the light shield by grasping the top center of

the shield and pull ing for war d w hile tu rning it slig htl y to

one side.

3. Replace the bulb with a 40-watt appliance bulb.

4. Replace the light shield by grasping the top center of

the shield and inserting the tabs on one end into the

slotted holes in the freezer liner. Then, carefully bend

the shield at the center to insert the tabs on the other

end.

5. Plug in refrigerator or reconnect power.

Power Interruptions

If the electricity in your house goes off, call the power

company and ask how long it will be off.

1. If the power will be out for 24 hours or less , keep both

refrigerator door s closed to help foods stay cold and

frozen.

2. If the power will be out for more than 24 hours:

a) Remove all frozen food and store it in a frozen food

locker.

Vacation and Moving Care

V acations

If you choose to leave the refrigerator on while you’re

away, use these steps to prepare your refrigerator before

you leave.

1. Use up any perishables and freeze other items.

2. If your refrigerator has an automatic ice maker:

■ Raise ice maker arm to OFF (up) position.

■ Shut off water supply to the ice maker.

3. Empty the ice bin.

If you choose to turn the refrig erator off before you

leave, follow these steps.

1. Remove all food from the refrigerator.

2. If your refrigerator has an automatic ice maker:

■ Turn off the water supply to the ice maker at least

one day ahead of time.

■ When the last load of ice drops, raise the ice maker

arm to the OFF (up) position.

3. Depending on yo ur model, turn the Th erm ostat C ontr o l

(or Refrigerator Contr ol, depending on the model) to

OFF. See the “Setting the Controls” section.

4. Clean refrigerator, wipe it, and dry well.

5. Tape rubber or wood blocks to the tops of both doors

to prop them open far enough for air to get in. This

stops odor and mold from building up.

OR

b) Place 2 lbs (907 g) of dry ice in the freezer for every

cubic foot (28 L) of freezer space. This will k eep th e

food frozen for two to four days . While hand li ng dry

ice, wear gloves to protect your hands from ice

burns.

OR

c) If neither a food locker nor dry ice is available,

consume or can perishable food at once.

REMEMBER: A full freezer stays cold longer than a

partially filled one. A freezer full of meat stays cold longer

than a freezer full of baked goods. If you see that food

contains ice cry stals, it may be safely refrozen, although

the quality and flavor may be affected. If the condition of

the food is poor, or if you feel it is unsafe, dispose of it.

24

Page 25

Moving

When you are moving your refrigerator to a new home,

follow these steps to prepare it for the move.

1. If your refrigerator has an automatic ice maker:

■ Turn off the water supply to the ice maker at least

one day ahead of time.

TROUBLE-

SHOOTING

■ Disconnect the water line from the back of the

refrigerator.

■ When the last load of ice drops, raise the ice maker

arm to the OFF (up) position.

2. Remove all food from the refrigerator and pack all

frozen food in dry ice.

3. Depending o n your mode l, t urn the Th erm ostat Contr o l

(or Refrigerator Control, depending on the model) to

OFF. See the “Setting the Controls” section.

4. Unplug the refrigerator.

5. Empty water from the defrost pan.

6. Clean, wipe, and dry thoroughly.

7. Take out all removable parts, wrap them well, a nd tape

them together so they don’t shift and rattle during the

move.

8. Depending on the model, raise the front of the

refrigerator so it rolls easier OR screw in the leveling

legs so they don't scrape the floor. See the "Door

Closing" section.

9. Tape the doors shut and the power cord to the

refrigerator cabinet.

When you get to your new home, put everything back

and refer to the “Installing Your Refrigerator” section for

preparation instructions. Also, if your refrigerator has an

automatic ice maker, remember to reconnect the water

supply to the refrigerator.

Try the solutions suggested here first in order to

avoi d the cost of an unnecessary service call.

Your refrigerator will not operate

Is the power supply cord unplugged?

■■■■

Firmly plug the cord into a live outlet with proper voltage.

Has a household fuse or circuit breaker tripped?

■■■■

Replace the fuse or reset the circuit.

Is the refrigerator control turned to the “OFF”

■■■■

position?

Refer to the “Setting the Controls” section.

Is the refrigerator defrosting?

■■■■

Recheck to see if the refrigerator is operating in 30

minutes. Your refrigerator will regularly run an automatic

defrost cycle.

The lights do not work

Is the power supply cord unplugged?

■■■■

Firmly plug the cord into a live outlet with proper voltage.

Is a light bulb loose in the socket?

■■■■

Turn the refrigerator control to “OFF”. Disconnect the

refrigerator from the electrical supply . Gently remove the

bulb and reinsert. Then reconnect the refrigerator to the

electrical supply and reset the refrigerator control.

Is a light bulb burned out?

■■■■

Replace with an appliance bulb of the same wattage,

size, and shape. See the “Changing the Light Bulbs”

section.

There is water in the defrost drain pan

Is the refrigerator defrosting?

■■■■

The water will evaporate. It is normal for water to drip

into the defrost pan.

Is it more humid than normal?

■■■■

Expect that the water in the defrost pan will take longer

to evaporate. This is normal when it is hot or humid.

25

Page 26

The motor seems to run too much

Is the room temperature hotter than normal?

■■■■

Expect the motor to run longer under warm conditions.

At normal room temperatures, expect your motor to run

about 40% to 80% of the time. Under warmer conditions,

expect it to run even more of the time.

Has a large amount of food just been added to the

■■■■

refrigerator?

Adding a large amount of food warms the refrigerator. It

is normal for the motor to run longer in order to cool the

refrigerator back down.

Is the door opened often?

■■■■

Expect the motor to run longer when this occurs. In

order to conserve energy, try to get everything you need

out of the refrigerator at once, keep food organized so it

is easy to find, and close the door as soon as the food is

removed.

Are the controls not set correctly for the

■■■■

surrounding conditions?

Refer to the “Setting the Controls” section.

Are the doors not closed completely?

■■■■

Push the doors firmly shut. If they will not shut all the

way, see “The doors will not close completely” later in

this section.

Are the condenser coils dirty?

■■■■

This prevents air transfer and makes the motor work

harder. Clean the condenser coils. Refer to the

“Cleaning Your Refrigerator” section.

Are the door gaskets not sealed all the way around?

■■■■

Contact a qualified person or a technician.

NOTE:

If the problem is not due to any of the above,

remember that your new refrigerator will run longer than

your old one due to its high efficiency motor.

The refrigerator seems to ma ke too m uc h

noise

The sounds may be normal for your refrigerator.

■■■■

Refer to the “Understanding Sounds You May Hear”

section.

The ice maker is not producing ice

Is an ice cube jammed in the ejector arm?

■■■■

Remove the ice from the ejector arm with a plastic

utensil. Refer to the “Ice Maker Operation” section.

Does the ice maker mold have water in it?

■■■■

Check to see if your refrigerator has been connected to

your home water supply and the supply shut-off valve is

turned on. Refer to the “Connecting the Refrigerator to a

Water Source” section.

NOTE:

If not due to any of the above, there may be a

problem with the water line. Call for service.

The ice maker is producing too little ice

Has the ice maker just been installed?

■■■■

Wait 72 hours for full ice production to begin. Once your

refrigerator is cooled down, the ice maker should begin

producing 70-120 cubes every 24 hours.

Has a large amount of ice has just been removed?

■■■■

Allow 24 hours for ice maker to produce more ice.

Are the controls set correctly?

■■■■

Refer to the “Setting the Controls” section.

Is the water shut-off valve turned completely on?

■■■■

Turn valve on fully. Refer to the “Connecting the

Refrigerator to a Water Source” section.

Is there a water filter installed on the refrigerator?

■■■■

This filter may be clogged or installed incorrectly. First,

check the filter installation instructions to ensure that the

filter was installed correctly and is not clogged. If

installation or clogging is not a problem, call a qualified

person or a technician.

Off-taste, odor or grey color in the ice

Are the plumbing connections new , causing

■■■■

discolored or off-flavored ice?

Discard the first few batches of ice.

Have the ice cubes been stored for too long?

■■■■

Throw old ice away and make a new supply.

Do the freezer and ice bin need to be cleaned?

■■■■

See the “Cleaning Your Refrigerator” section.

■ Has food in the freezer or refrigerator been

wrapped properly?

Refer to the "Food Storage Guide" section.

Is the freezer temperature not cold enough to

■■■■

produce ice?

Wait 24 hours after ice maker hook-up for ice production.

Refer to the “Setting the Controls” section.

Is the ice maker arm in the “OFF” (arm up) position?

■■■■

Lowe r arm to the “ON” (arm down ) pos ition . See t he ”Ic e

Maker Operation” section.

Is the water line shut-off valve to the refrigerator not

■■■■

turned on?

Turn on the water valve. See the “Connecting the

Refrigerator to a Water Source” section.

26

Does the water contain minerals (such as sulfur)?

■■■■

A filter may need to be installed to remove the minerals.

Is there a water filter installed on the refrigerator?

■■■■

Grey or dark discoloration in ice indicates that the water

filtration system needs additiona l flus hing. Run

additional water through the water dispenser to flush the

water filtration system more thoroughly (at least 2-3

gallons or 6-7 minutes initially). Discard discolored ice.

Page 27

The ice dispenser will not operate properly

Is the freezer door closed completely?

■■■■

Push the door firmly shut. If it will not shut all the way,

see “The doors will not close completely” later in this

section.

Is the ice bin installed correctly?

■■■■

Push the ice bin in all the way. If the ice bin does not go

in all the way, it may not be put in straight. Pull it out and

try again.

Has the wrong ice has been added to the bin?

■■■■

Use only cubes produced by the current ice maker. If

other cubes have been added, remove all cubes and

check to see that none have become stuck in the

delivery chute.

Has the ice frozen in the ice bin?

■■■■

Shake the ice bin to separate cubes. If cubes do not

separate, empty bin and wait 24 hours for ice to restock.

Has the ice melted around the auger (metal spiral) in

■■■■

the ice bucket ?

Dump the ice cubes and clean the ice bucket completely.

Allow 24 hours for the ice maker to restock. Do not try to

remove the melted ice with a sharp object. You could

damage the ice bucket.

Is ice stuck in the delivery chute?

■■■■

Clear the ice from the delivery chute with a plastic

utensil. Do not use anything sharp to remove the ice.

You could cause damage.

Is there ice in the bucket?

■■■■

See “The ice maker is not producing ice” earlier in this

section.

Has the dispenser arm been held in too long?

■■■■

Release dispenser arm. Ice will stop dispensing when

the arm is held in too long. Wait three minutes for

dispenser motor to reset before using again. (For future

use, take large amounts of ice directly from the ice

maker so that the dispenser arm is not held in too long.)

The water dispenser will not operate properly

Is the freezer door not closed completely?

■■■■

Push the door firmly shut. If it will not shut all the way,

see “The doors will not close completely” later in this

section.

Has the water tank not filled?

■■■■

The water tank needs to be filled the first time it is used.

Depress the water dispenser bar with a large container

until you draw two or three quarts (1.9 to 2.8 L) of water.

Discard water. (Refer to the “Water and Ice Dispensers”

section for further instructions on filling the water tank.)

Is the water shut-off valve clogged or incorrectly

■■■■

installed?

Refer to the “Connecting the Refrigerator to a Water

Source” section. If clogging or installation is not a

problem, call for service or a contact a plumber.

Is there a kink in the home water source line?

■■■■

If you find or suspect a kink in the water line, call for

service.

Is there a water filter installed on the refrigerator?

■■■■

This filter may be clogged or incorrectly installed. First,

check the filter installation instructions to ensure that the

filter was installed correctly and is not clogged. If

installation or clogging is not a problem, call for service.

W ater or ice is le aking fr om the dispenser

Is the glass not being held under the ice dispenser

■■■■

long enough, causing the ice to spill?

Hold the container under the ice chute for two to three

seconds after releasing the dispenser lever. A small

amount of ice may dispense after the lever is released.

Is the glass not being held under the water

■■■■

dispenser long enough, causing water to drip?

Hold the container under the water dispenser two to

three seconds a fter rele asing the di spenser le v er . Wat er

may continue to dispense during this time.

Is an ice cube stuck in the chute and holding the

■■■■

trap door open?

Remove the cube.

Is there a water filter installed on the refrigerator?

■■■■

The water filtration system may have air in the lines,

causing water to drip. Additional flushing may help clear

air from the lines. Normal dispenser use should flush air

from the lines within 24-72 hours.

The dispenser water is not cool enough

Has the refrigerator been newly installed?

■■■■

Allow 24 hours for the tank to cool completely.

Has a large amount of water been recently

■■■■

dispensed?

Allow 24 hours for the tank to cool completely.

Has water not been recently dispensed?

■■■■

The first glass of water may not be cool. Discard the first

glass of water.

Is the water shut-of f v alve n ot turned on or the water

■■■■

line connected at the source?

Check to be sure the water shut-off valve is turned on