36” (91 cm),

42” (106 cm)

and 48” (122 cm)

Built-In

Refrigerators

Important:

Read and save

these instructions.

Installation

requires 2 or more

people.

Important:

l

Installer:

Instructions with the

homeowner.

l

Homeowner:

Instructions for future reference.

l

Save

Instructions for the local

electrical inspector’s use.

Leave Installation

Keep Installation

these Installation

/ I I I I I

/

I I

I

I

I I \

I

KitchenAPd”

\ \

I

\

\

Part No. 2004022

\

Personal Injury Hazard

. Because of the weight and size

of the refrigerator, two or

more people are required to

install it.

l Most of the refrigerator’s

weight is at the top. Extra care

is needed when moving the

refrigerator to prevent tipping.

Failure to follow these instructions

could result in personal injury.

Floor Damage

Keep cardboard shipping piece or

plywood under refrigerator until

it is installed in the operating

position.

Failure to do so may cause

damage to floor covering.

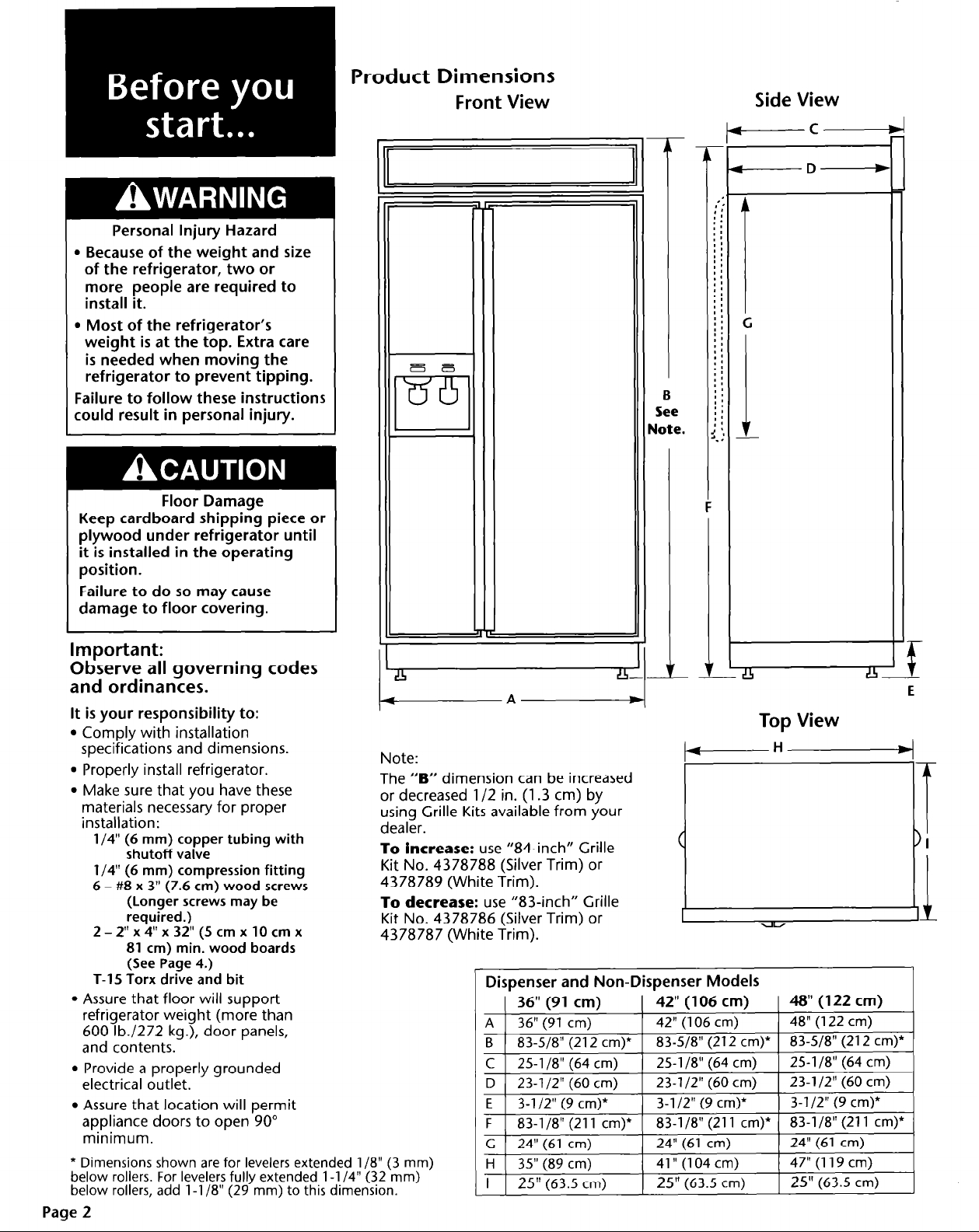

Product Dimensions

Front View

Side View

t------C

-D-

B

See

Jote.

Important:

Observe all governing codes

and ordinances.

It is your responsibility to:

l

Comply with installation

specifications and dimensions.

l

Properly install refrigerator.

l

Make sure that you have these

materials necessary for proper

installation:

l/4” (6 mm) copper tubing

shutoff valve

l/4” (6 mm) compression fitting

6 - #8 x 3" (7.6

cm) wood screws

(Longer screws may be

required.)

2 - 2" x 4" x 32"

(5 cm x 10 cm x

81 cm) min. wood boards

(See Page 4.)

T-15 Torx drive and bit

l

Assure that floor will support

refrigerator weight (more than

600 lb./272 kg.), door panels,

and contents.

l

Provide a properly grounded

electrical outlet.

l

Assure that location will permit

appliance doors to open 90”

minimum.

* Dimensions shown are for levelers extended l/B” (3 mm)

below rollers. For levelers fully extended l-l /4” (32 mm)

below rollers, add l-l /8” (29 mm) to this dimension.

Page 2

with

!I4

A-

Note:

The “B” dimension can be increased

or decreased l/2 in. (1.3 cm) by

using Grille Kits available from your

dealer.

To increase:

Kit No. 4378788 (Silver Trim) or

4378789 (White Trim).

To decrease:

Kit No. 4378786 (Silver Trim) or

4378787 (White Trim).

use “84-inch” Grille

use “83-inch” Grille

Dispenser and Non-Dispenser Models

( 36" (91 cm)

A 1 36” (91 cm)

I

B ) 83-518" (212 cm)* 1 83-518” (212 cm)* 1 83-518” (212 cm)*

C

25-1/8"(64 cm)

D 23-1/2"(60 cm)

E 3-l/2" (9 cm)*

I

F 1 83-118" (211 cm)* [ 83-118” (211 cm)* ( 83-l/8” (211 cm)*

c 24"(61 cm)

H 35"(89 cm)

I

25"

\ ,

(63.5 cm)

-

-

- LFhL

1 42"(106 cm)

1 42" (106 cm)

I

25-l /8” (64 cm)

23-1/2"(60 cm)

3-l /2” (9 cm)*

I

. ,

24" (61 cm)

41” (104 cm)

25"

(63.5 cm)

Top View

1 48” (122 cm)

1 48" (122 cm)

I

25-l /8” (64 cm)

23-1/2"(60 cm)

3-l/2" (9 cm)*

I

24" (61 cm)

47" (119 cm)

25" (63.5

‘f

E

1

cm)

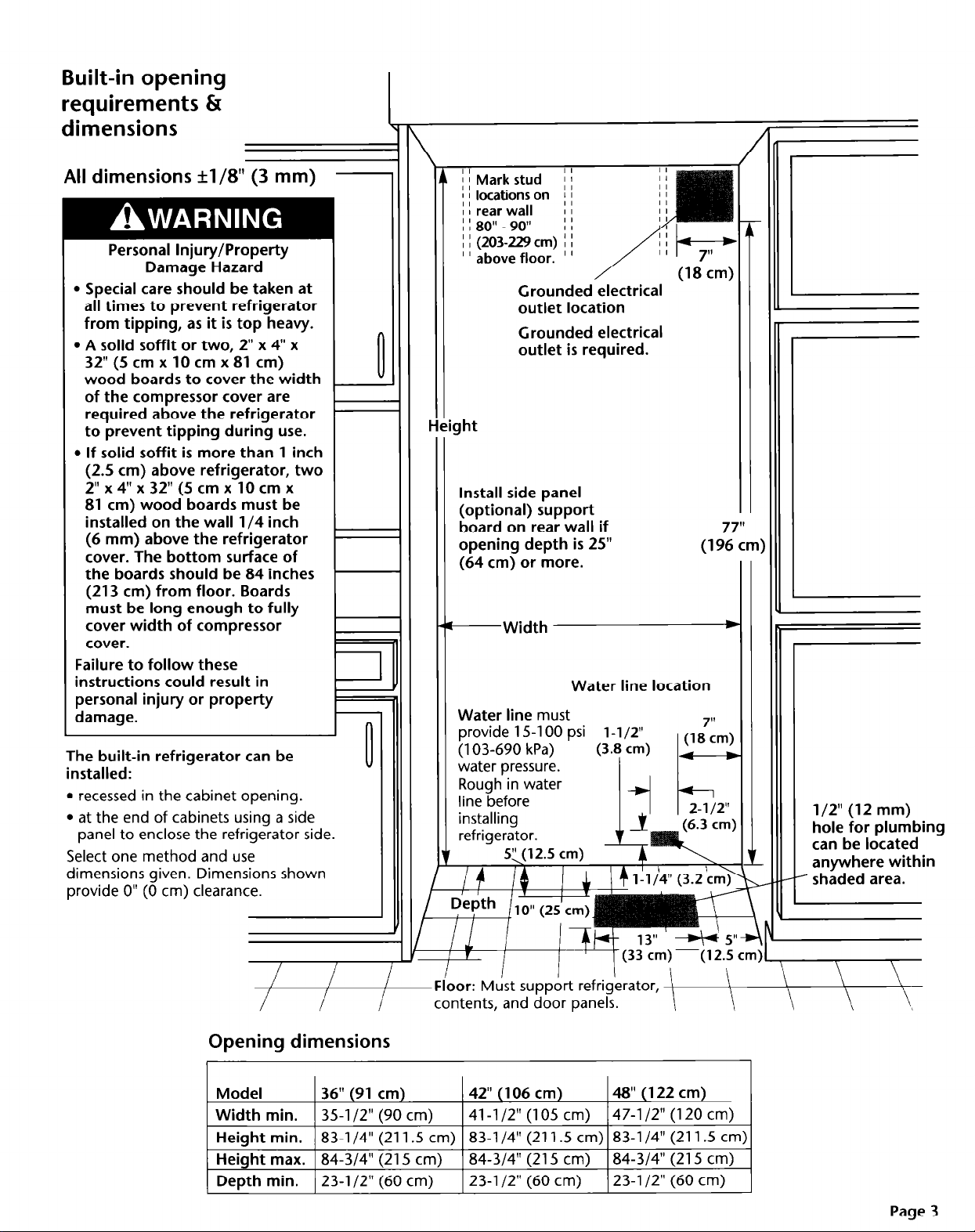

Built-in opening

requirements &

dimensions

All dimensions +1/8” (3 mm)

Personal Injury/Property

Damage Hazard

l Special care should be taken at

all times to prevent refrigerator

from tipping, as it is top heavy.

l A solid soffit or two, 2” x 4” x

32”

(5 cm x 10 cm x 81 cm)

wood boards to cover the width

of the compressor cover are

required above the refrigerator

to prevent tipping during use.

l If solid soffit is more than 1 inch

(2.5 cm) above refrigerator, two

2” x 4” x 32”

81 cm) wood boards must be

installed on the wall l/4 inch

(6 mm) above the refrigerator

cover. The bottom surface of

the boards should be 84 inches

(213 cm) from floor. Boards

must be long enough to fully

cover width of compressor

cover.

Failure to follow these

instructions could result in

personal injury or property

damage.

The built-in refrigerator can be

installed:

l

recessed in the cabinet opening.

l

at the end of cabinets using a side

panel to enclose the refrigerator side.

Select one method and use

dimensions given. Dimensions shown

provide 0” (0 cm) clearance.

(5 cm x 10 cm x

-

II

II

I I (203229

’ ’ above floor. ’ ’

cm) I I

Grounded electrical

outlet location

Grounded electrical

outlet is required.

I

Install side panel

(optional) support

board on rear wall if

opening depth is 25”

(64

cm) or more.

-Width

Water line

provide 15-l 00 psi l-1/2”

(103-690 kPa)

water pressure.

must

(1 !ZZm)

*

Water line location

(3.8 cm) V

I

l/2” (12 mm)

hole for plumbing

can be located

anywhere within

- shaded area.

Opening dimensions

Model

Width min.

Height min.

Height max. 84-3/4” (215 cm)

Depth min. 23-l /2” (60

36” (91

35-l/2” (90 cm)

83-l /4” (211.5 cm) 83-l /4” (211.5 cm) 83-l /4” (211.5 cm)

cm)

cm)

I I

I T

I I

Floor:

contents, and door panels.

, / 11 I

Must support refrigerator, l

42” (106

41-l /2” (105 cm)

84-3/4” (215 cm)

23-l /2” (60 cm)

cm)

1 (33 cm) -(12.5 cm)

\

48” (122 cm)

47-l /2” (120 cm)

84-3/4” (215 cm)

23-l /2” (60 cm)

\ \

\

Page 3

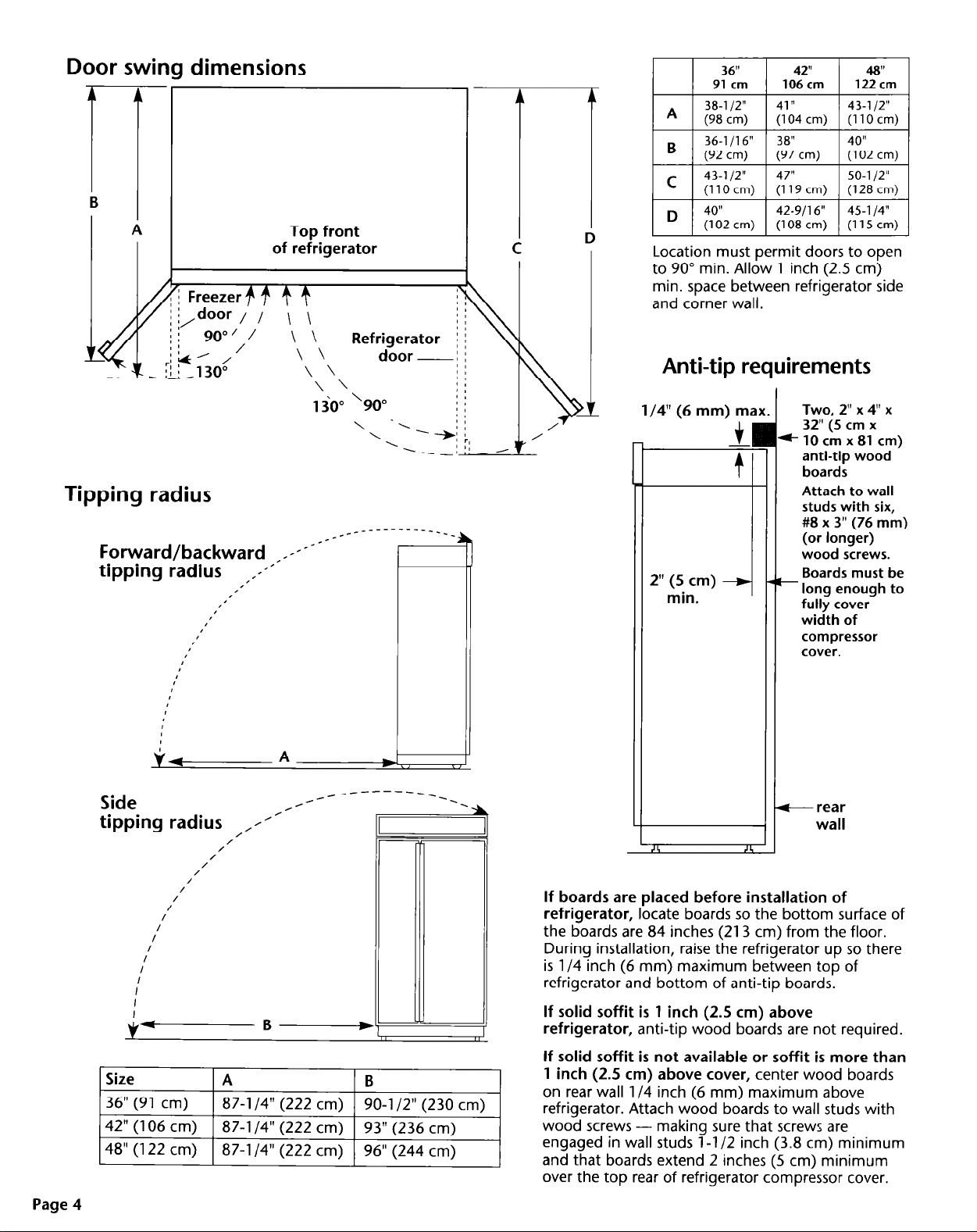

Door swing dimensions

B

1

A

Top front

of refrigerator

Location must permit doors to open

to 90” min. Allow 1 inch (2.5 cm)

min. space between refrigerator side

and corner wall.

Anti-tip requirements

Tipping radius

Forward/backward _x-xT-*--

tipping radius ,,1-’

,’

#’

I’

I

I

I

r’

I

I’

I’

Side

tipping radius ,/l’-

/

/

/

/

/

/

/

/

/I

/

I

I

V-B-

*’

_____-------____

_------_

__--

e3l

l/4” (6 mm) ma,

2” (5 cm)

min.

I

If boards are placed before installation of

refrigerator,

the boards are 84 inches (213 cm) from the floor.

During installation, raise the refrigerator up so there

is l/4 inch (6 mm) maximum between top of

refrigerator and bottom of anti-tip boards.

If solid soffit is 1 inch (2.5 cm) above

refrigerator,

locate boards so the bottom surface of

anti-tip wood boards are not required.

44

Two 2” x 4” x

32” (5 cm x

*lOcmx81 cm)

anti-tip wood

boards

Attach to wall

studs with six,

#8 x 3” (76 mm)

(or longer)

wood screws.

Boards must be

- long enough to

fully cover

width of

compressor

cover.

+ rear

wall

I

Page 4

87-l /4” (222 cm)

90-l /2” (230 cm)

If solid soffit is not available or soffit is more than

1 inch

on rear wall l/4 inch (6 mm) maximum above

refrigerator. Attach wood boards to wall studs with

wood screws - making sure that screws are

engaged in wall studs l-l /2 inch (3.8 cm) minimum

and that boards extend 2 inches (5 cm) minimum

over the top rear of refrigerator compressor cover.

(2.5 cm)

above cover,

center wood boards

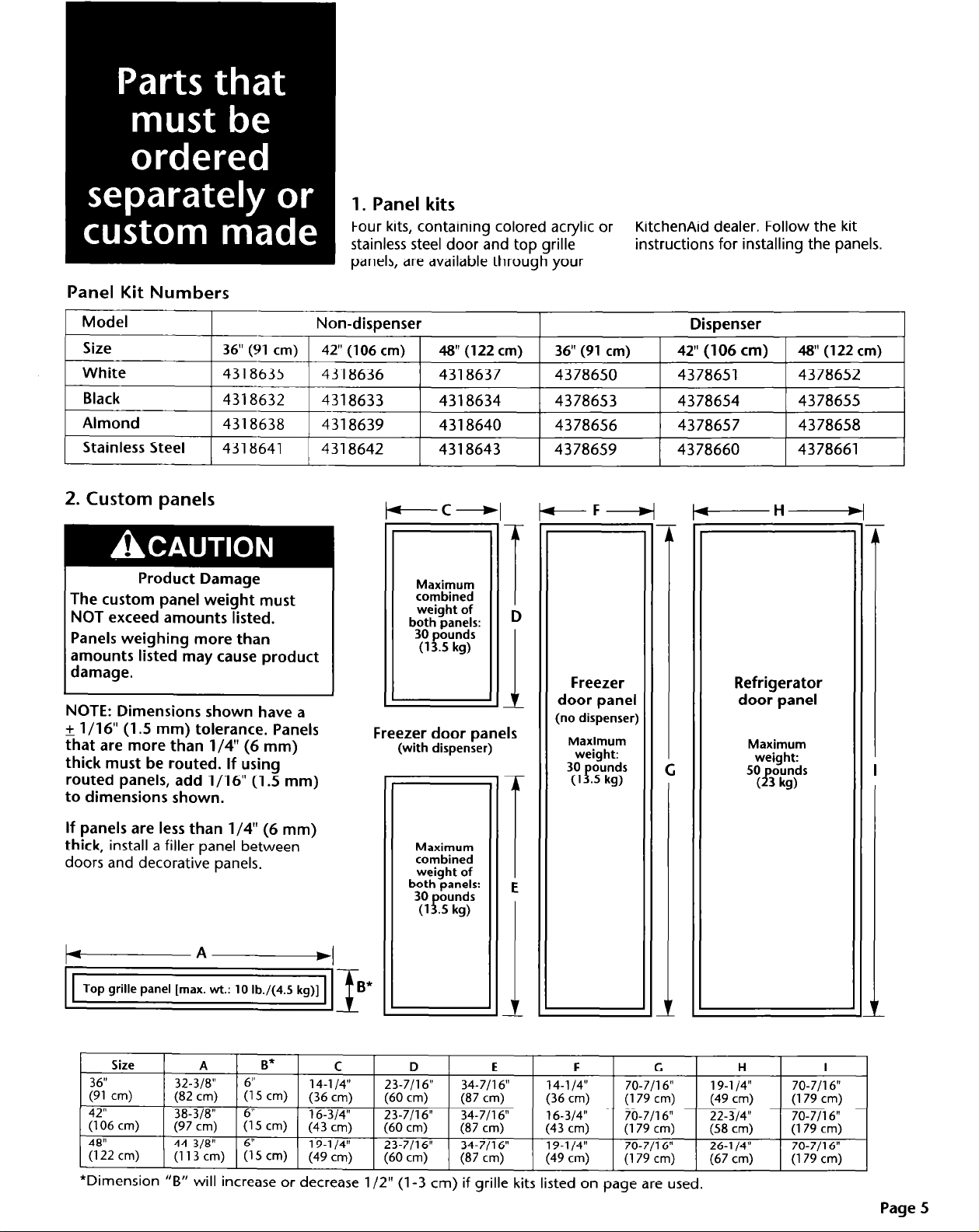

Panel Kit Numbers

1. Panel kits

Four kits, containing colored acrylic or

stainless steel door and top grille

panels, are available through your

KitchenAid dealer. Follow the kit

instructions for installing the panels.

Model

Size

White

Black

Almond

Stainless

Steel

36"

(91 cm)

4318635

4318632

4318638

4318641

2. Custom panels

Product Damage

The custom panel weight must

NOT exceed amounts listed.

Panels weighing more than

amounts listed may cause product

damage.

NOTE: Dimensions shown have a

+ l/16” (1.5 mm) tolerance. Panels

that are more than l/4” (6 mm)

thick must be routed. If using

routed panels, add l/16” (1.5 mm)

to dimensions shown.

Non-dispenser

42" (106

4318636

4318633

4318639

4318642

cm)

-C+

Freezer door panels

(with dispenser)

#I"(122

4318637

4318634

4318640

4318643

cm)

36"(91

4378650

4378653

4378656

4378659

Freezer

r

door panel

(no dispenser)

Maximum

weight:

30 ounds

(1 f.5 kg)

cm)

Dispenser

42"

(106 cm)

4378651

4378654

4378657

4378660

-H

W(122

4378652

4378655

4378658

4378661

Refrigerator

door panel

Maximum

weight:

50 ounds

33

kg)

cm)

If panels are less than l/4” (6 mm)

thick,

install a filler panel between

doors and decorative panels.

-A

Top grille panel [max. wt.:

Size

36"

(gl cm)

’

42"

(106

cm)

48"

(122 cm)

+

10 lb./(4.5 kg)]

A

32-318"

I^_ \ I- r \ ._ _

(t5.i cm)

38-318"

(97 cm)

44-3/8"

(113 cm) (15

B*

6"

(13 cm)

(6;‘5 cm) :&‘c$

6"

cm)

14-l/4"

(36

19-l 14”

(49 cm)

C

cm)

*Dimension “B” will increase or decrease l/2” (l-3 cm) if grille kits listed on page are used.

Maximum

combined

weight of

both panels:

30

(1 p.5 kg)

D

23-7/16"

(60

cm)

23-7/l 6”

(60

cm)

23-7/l 6”

(60

cm)

ounds

L

E F G

34-7/16" 14-l/4" 70-7/16"

(87 cm) (36

34-7/l 6”

(87

cm)

34-7/l 6”

(87

cm) (49 cm) (179 cm)

cm) (179 cm)

16-314”

(43

cm) (179 cm)

19-l 14”

70-7/l 6”

70-7Jl6"

H

19-l 14”

(49 cm)

22-314"

(58

cm)

26-l/4"

(67

cm)

I

70-7/16"

(179 cm)

70-7116"

(179 cm)

70-7116"

(179 cm)

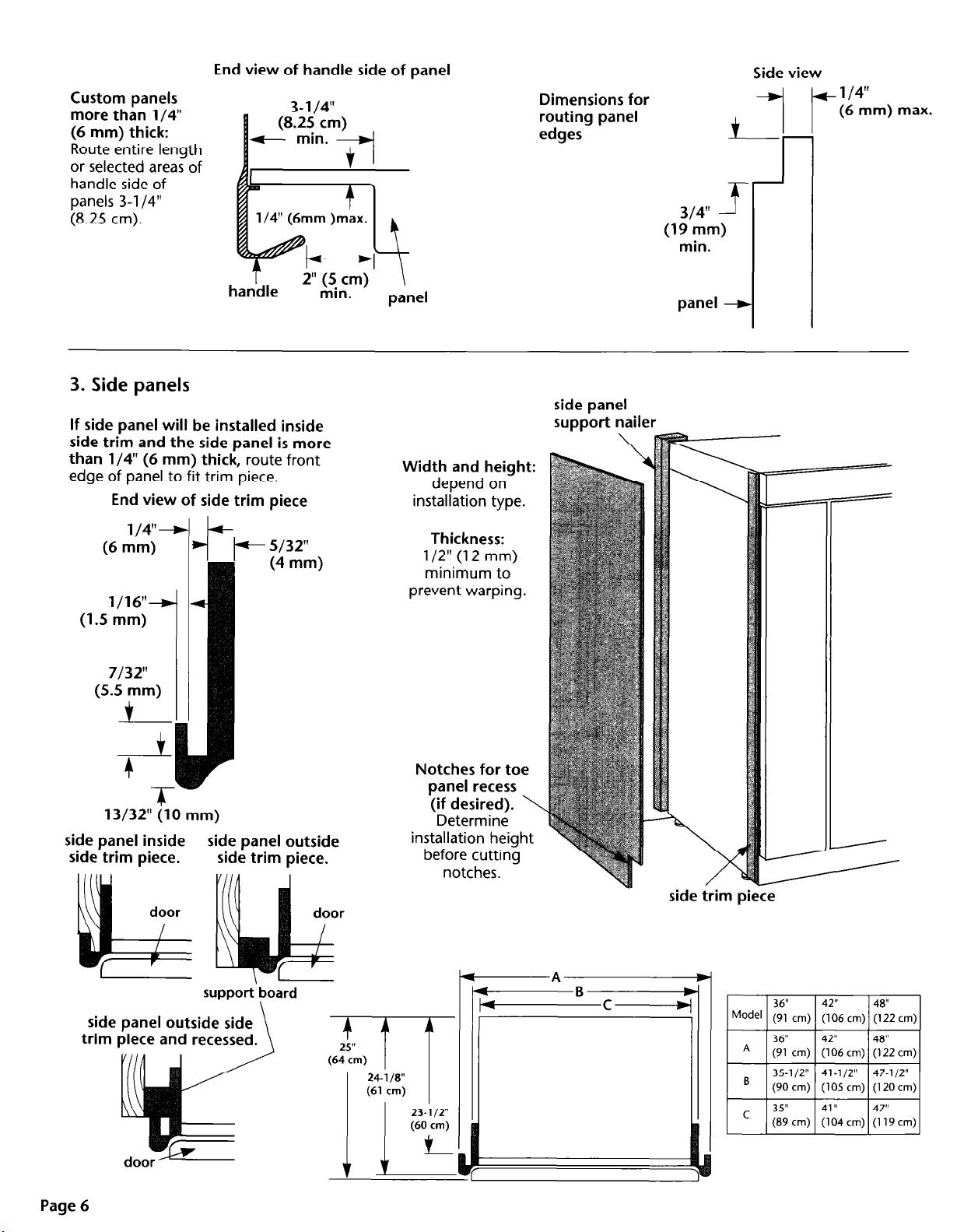

Custom panels

more than l/4”

(6 mm) thick:

Route entire length

or selected areas of

handle side of

panels 3-l /4”

(8.25

cm).

End view of handle side of panel

3- l/4”

l/4” (6mm )max.

Dimensions for

routing panel

edges

314” 314”

19 mm) 19 mm)

(

min. min.

L’ L’

f f

Side view

-7

+ l/4”

(6 mm) max.

nanare

3. Side panels

If side panel will be installed inside

side trim and the side panel is more

than l/4” (6 mm) thick,

edge of panel to fit trim piece.

End view of side trim piece

1/4”-D

(6 mm)

l/16”

(1.5 mm)

7132”

(5.5 mm)

$

--I+

+ s/32”

I I

route front

(4 mm>

min.

panel

Width and height:

depend on

installation type.

Thickness:

l/2” (12 mm)

minimum to

prevent warping.

panel panel

f f

side panel

su~~ort nailer

i

+

13/32” (10 mm)

side panel inside side panel outside

side trim piece. side trim piece.

support

side panel outside side

trim piece and recessed.

board

Notches for toe

panel recess

(if desired). \

Determine

installation height

before cutting

notches.

side trim piece

Page 6

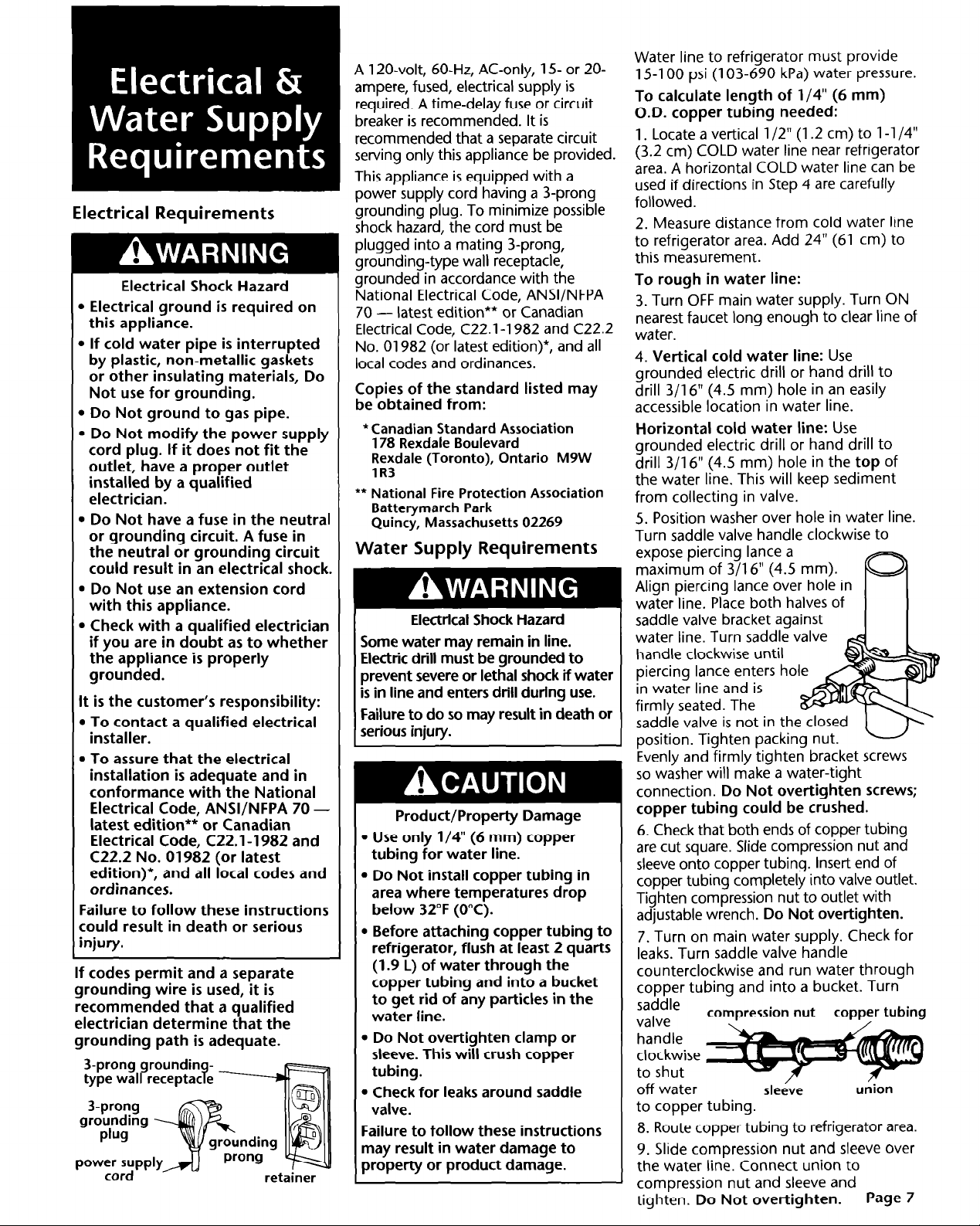

Electrical Requirements

Electrical Shock Hazard

b Electrical ground is required on

this appliance.

B If cold water pipe is interrupted

by plastic, non-metallic gaskets

or other insulating materials, Do

Not use for grounding.

b Do Not ground to gas pipe.

l Do Not modify the power supply

cord plug. If it does not fit the

outlet, have a proper outlet

installed by a qualified

electrician.

m Do Not have a fuse in the neutral

or grounding circuit. A fuse in

the neutral or grounding circuit

could result in an electrical shock.

m Do Not use an extension cord

with this appliance.

l Check with a qualified electrician

if you are in doubt as to whether

the appliance is properly

grounded.

It is the customer’s responsibility:

l To contact a qualified electrical

installer.

. To assure that the electrical

installation is adequate and in

conformance with the National

Electrical Code, ANWNFPA 70 latest edition** or Canadian

Electrical Code, C22.1-1982 and

C22.2 No. 01982 (or latest

edition)*, and all local codes and

ordinances.

Failure to follow these instructions

could result in death or serious

injury.

If codes permit and a separate

grounding wire is used, it is

recommended that a qualified

electrician determine that the

grounding path is adequate.

A 120-volt, 60-Hz, AC-only, 15 or 20ampere, fused, electrical supply is

required. A time-delay fuse or circuit

breaker is recommended. It is

recommended that a separate circuit

serving only this appliance be provided.

This appliance is equipped with a

power supply cord having a 3-prong

grounding plug. To minimize possible

shock hazard, the cord must be

plugged into a mating 3-prong,

grounding-type wall receptacle,

grounded in accordance with the

National Electrical Code, ANSVNFPA

latest edition** or Canadian

70 Electrical Code, C22.1-1982 and C22.2

No. 01982 (or latest edition)*, and all

local codes and ordinances.

Copies of the standard listed may

be obtained from:

*Canadian Standard Association

178 Rexdale Boulevard

Rexdale (Toronto), Ontario M9W

lR3

** National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Water Supply Requirements

I

Some water may remain in line.

Electric drill must be grounded to

prevent severe or lethal shock if water

is in line and enters drill during use.

Failure to do so may result in death or

serious injury.

l Use only l/4” (6 mm) copper

. Do Not install copper tubing in

l Before attaching copper tubing to

. Do Not over-tighten clamp or

l Check for leaks around saddle

Failure to follow these instructions

may result in water damage to

property or product damage.

Electrical Shock Hazard

Product/Property Damage

tubing for water line.

area where temperatures drop

below 32°F (0°C).

refrigerator, flush at least 2 quarts

(1.9 L) of water through the

copper tubing and into a bucket

to get rid of any particles in the

water line.

sleeve. This will crush copper

tubing.

valve.

Water line to refrigerator must provide

15-l 00 psi (103-690 kPa) water pressure.

To calculate length of l/4” (6 mm)

O.D. copper tubing needed:

1. Locate a vertical l/2” (1.2 cm) to l-l /4”

(3.2 cm) COLD water line near refrigerator

area. A horizontal COLD water line can be

used if directions in Step 4 are carefully

followed.

2. Measure distance from cold water line

to refrigerator area. Add 24” (61 cm) to

this measurement.

To rough in water line:

3. Turn OFF main water supply. Turn ON

nearest faucet long enough to clear line of

water.

4. Vertical cold water line:

grounded electric drill or hand drill to

drill 3/l 6” (4.5 mm) hole in an easily

accessible location in water line.

Horizontal cold water line:

grounded electric drill or hand drill to

drill 3/l 6” (4.5 mm) hole in the

the water line. This will keep sediment

from collecting in valve.

5. Position washer over hole in water line.

Turn saddle valve handle clockwise to

expose piercing lance a

maximum of 3/l 6” (4.5 mm).

Align piercing lance over hole in

water line. Place both halves of

saddle valve bracket against

I

water line. Turn saddle valve

handle clockwise until

piercing lance enters hol

in water line and is

firmly seated. The

saddle valve is not in th

position. Tighten

Evenly and firmly tighten bracket screws

so washer will make a water-tight

connection.

packing nut.

Do Not over-tighten screws;

Use

Use

top

copper tubing could be crushed.

6. Check that both ends of copper tubing

are cut square. Slide compression nut and

sleeve onto copper tubing. Inset-t end of

copper tubing completely into valve outlet.

Tighten compression nut to outlet with

adjustable wrench.

7. Turn on main water supply. Check for

leaks. Turn saddle valve handle

counterclockwise and run water through

copper tubing and into a bucket. Turn

saddle

valve

.-. -

handle

clockwise

to shut

off water

to copper tubing.

8. Route copper tubing to refrigerator area.

9. Slide compression nut and sleeve over

the water line. Connect union to

compression nut and sleeve and

tighten.

compression nut

Do Not over-tighten.

Do Not overtighten.

copper tubing

/

sleeve

u&on

Page 7

of

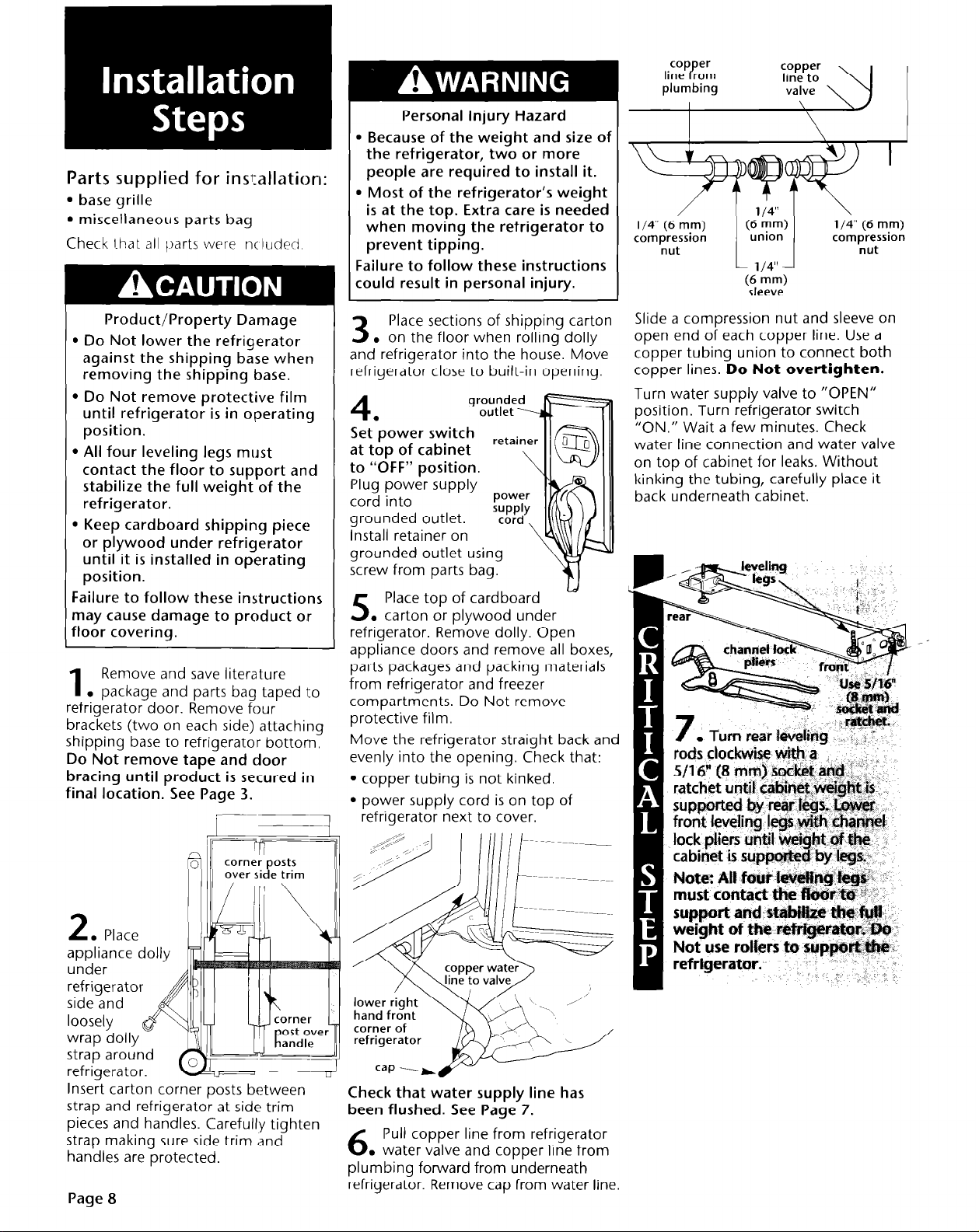

Parts supplied for ins:allation:

l

base grille

l

miscellaneous parts bag

Check l-hat all

Product/Property Damage

l

Do Not lower the refrigerator

against the shipping base when

removing the shipping base.

l

Do Not remove protective film

until refrigerator is in operating

position.

l

All four leveling legs must

contact the floor to support and

stabilize the full weight of the

refrigerator.

l

Keep cardboard shipping piece

or plywood under refrigerator

until it is installed in operating

position.

Failure to follow these instructions

may cause damage to product olr

floor covering.

Remove and save literature

1

. package and parts bag taped to

refrigerator door. Remove four

brackets (two on each side) attaching

shipping base to refrigerator bottorn.

Do Not remove tape and door

bracing until product is secured in

final location. See Page 3.

part, were nc ludetl

Personal Injury Hazard

l

Because of the weight and size of

the refrigerator, two or more

people are required to install it.

l

Most of the refrigerator’s weight

is at the top. Extra care is needed

when moving the refrigerator

prevent tipping.

Failure to follow these instructions

could result in personal injury.

Place sections of shipping carton

3

. on the floor when rolling dolly

and refrigerator into the house. Move

refrigerator close to built-in opening.

to

4

Set*power switc

at top of cabinet

to “OFF” position.

Plug power supply

cord into

grounded outlet.

Install retainer on

grounded outlet using

screw from parts bag.

Place top of cardboard

. carton or plywood under

5

refrigerator. Remove dolly. Open

appliance doors and remove all boxes,

parts packages and packing materials

from refrigerator and freezer

compartments. Do Not remove

protective film.

Move the refrigerator straight back and

evenly into the opening. Check that:

l

copper tubing is not kinked.

l

power supply cord is on top of

refrigerator next to cover.

I

\

\

l/4” (6 mm)

compression

nut

Slide a compression nut and sleeve on

open end of each copper line. Use a

copper tubing union to connect both

copper lines.

Turn water supply valve to “OPEN”

position. Turn refrigerator switch

“ON.” Wait a few minutes. Check

water line connection and water valve

on top of cabinet for leaks. Without

kinking the tubing, carefully place it

back underneath cabinet.

I I

Do Not overtighten.

(6

mm)

union

l/4”

(6

mm)

sleeve

Ye

l/4” (6 mm)

compression

nut

I

Insert carton corner posts between

strap and refrigerator at side trim

pieces and handles. Carefully tighten

strap making sure side trim and

handles are protected.

Paae 8

corner of

Check that water supply line has

been flushed. See Page 7.

Pull copper line from refrigerator

6

.

water valve and copper line from

plumbing forward from underneath

refrigerator. Remove cap from water line.

Filler panel

re uired if -

pane s are less

7

than l/4”

(6 mm) thick.

nylon

washers

(discard)

If panels are

more than

l/4” (6 mm)

thick, route

panel edges

on all sides.

/

assembiy

door

handle-

9

. Remove all taDe and door bracinq

from refrigerator and freezer doors.

Remove screws attaching handles to

door frames. Discard nylon washers

underneath screws. Slide decorative

door panels into door frames.

IGcorative

panel

If panels are less than l/4” (6 mm)

thick,

install a filler panel between

door and decorative panel.

If panels are more than l/4” (6 mm)

thick,

route panel edges on all sides.

are atigned and teveJ,

lf4~~~s iwsd ta be adjusted

kbr fight or bl or out,

bmen’&e 3/S” (9 mm) hex

hwfid screws in the tap hinge5

# dptws md to be adjusted

up or

down,

(9 rnmi~ hex head screws in

the b&torn hinges.

Adju$t doors. Tighten screws.

ftimk that doors are aligned

and levei.

loosen the 3/8

Remove door stop set screw

located in top and bottcvn

hinges using a f-7 4 Tom

wrench.

Hotd door in the desired position

and replrace ~?t crews. I# door

does not clear countertop after

door stop has been adjusted,

countertops may need to be

““mitered.

top grille

14 .

Slide top grille decorative panel

assembly up and off top grille

assembly. Release the two tethers

holding the decorative panel to the

top grille assembly.

Page 9

top grille decorative

panel assembly,

two small screws

and panel side

trim from one

side of the

decorative panel

assembly to allow

insertion of your

custom panel. Reassemble the side

trim, screws, and tethers in reverse

order. Reinstall decorative panel

assembly and pull down to secure.

---

If side panels are not used,

16

. go to Step 17.

If built-in area depth is 25” (63.5 cm)

or more,

inside the side trim or attached to the

outside of the side trim:

-

side panels can be installed

Top view

Top view

24-518”

(62 cm)

max.

L

l Outside side trim piece:

equally spaced holes into side trim

piece.

Do Not drill into side of

appliance.

to trim piece. Nail front and rear

edges of side panel to support

boards. Cover front support board

with a matching panel piece.

Attach a support board

Drill 6

Top view

\ rear wall

\

support board

- side panel

Open appliance doors and

. remove protective film from

17

door frame. Recheck water connections

at bottom of refrigerator for leaks.

Attach bottom grille to cabinet with

two screws. Install shelves and bins in

refrigerator and freezer compartments.

Set refrigerator and freezer

. compartment controls to the

18

midpoint between “COLD” and

“COLDEST.” Check that the

compressor is operating properly and

that all five lights are working.

I

24-518”

(62 ;m)

max.

l Inside side trim piece:

edge of routed side panel into trim

piece. Nail rear edge of panel to

support board.

Slide front

24-

side trim

door

If built-in area depth is less than

25” (63.5

installation according to site

restrictions. (One method is to install

a support nailer on the built-in

opening rear wall. Drill holes into side

trim. Then attach wood support to

trim. Attach side panel to wood

support and support nailer. Cover

wood support with a matching panel

piece.)

cm),

complete side panel

Part No. 2004022

0 1995 KitchenAid.

8 KitchenAid. Registered trademark

of KitchenAid.

KPtchenAid”

HOME APPLIANCES

Prepared by KitchenAid, St. Joseph, Michigan 49085

Printed in U.S.A.

Rkfrigkateurs

encastrks

91 cm (36 PO),

106 cm (42 po)

122 cm (48 po)

Important :

Lire et conserver

ces instructions.

L’installation

nbcessite

I’intervention de 2

personnes ou plus.

Important :

l

lnstallateur

instructions d’installation au

propriktaire.

l

PropriCtaire

instructions d’installation pour

rkfkrence ultk-ieure.

l

Conserver

d’installation pour consultation

par I’inspecteur local des

installations klectriques.

: Remettre les

: Conserver les

ces instructions

I I I I I I

/ I I I I I I \ \ \ \i

Y

I I I

1 , I

I I

\ \

Piece no 2004022

\

”

Risque de blessures

l

A cause du poids et de la taille du

refrigerateur, son installation necessite

I’intervention de deux personnes ou

plus.

. La plus grande par-tie du poids du

refrigerateur se trouve a la pat-tie

superieure. Manipuler le refrigerateur

avec prudence lors des deplacements,

pour qu’il ne bascule pas.

Le non-respect de ces instructions peut

@tre la cause de blessures.

Risque de dommages pour le plancher

Conserver la plaque en carton ou en

contre-plaque de I’emballage sous le

refrigerateur jusqu’a ce qu’il soit install6 a

sa position de service.

Le non-respect de ces instructions peut

@tre la cause de dommages pour le

plancher.

Dimensions du produit

Vue avant

Vue lath-ale

-C

B

Voir

remarque.

Important :

Respecter les dispositions de tous

les codes et r+glements en

vigueur.

C’est a I’installateur qu’incombe la

responsabilite de :

l

Respecter les specifications et dimensions

d’installation.

l

Installer le refrigerateur convenablement.

l

Verifier que tout le materiel necessaire a

une installation convenable est disponible:

Tube en cuivre de 6 mm (l/4 po)

avec robinet d’arret

Raccord a compression, 6 mm (l/4 po)

6 vis a bois no 8 x 7,6 cm (3

(il peut @tre necessaire d’ub user des vis

plus longues)

2 morceaux de bois de 5 cm x 10 cm x

81 cm (2 po x 4 po x 32 po) min.

(voir page 4)

Tournevis - pointe Torx T-15

l

Verifier que la resistance du plancher lui

permet de soutenir le poids du

refrigerateur (plus de 272 kg/600 lb), des

panneaux de portes et du contenu.

l

Fournir une prise de courant

convenablement reliee a la terre.

l

Verifier que I’emplacement d’installation

permet I’ouverture de la Porte du

refrigerateur a au moins 90”.

l

Les dimensions indiquk correspondent B la situation oti

les pleds de r6glage de I’aplomb depassent de 3 mm

(l/8 po) au-dessous des roulettes. Lorsque les pieds sont

totalement deploy& de 32 mm (1 l/4 po) au-dessous des

roulettes, ajouter 29 mm (1 l/8 po) ti cette dimension.

Page 2

o)

if

k-----Ad

Remarque:

La dimension “B” peut @tre augmentee ou

diminuee de 1,3 cm (l/2 po) en employant

la trousse du panneau decoratif disponible

chez votre marchand.

Pour augmenter: employer la trousse de

panneau no 4378788 (garniture argent) ou

4378789 (garniture blanche).

Pour dlminuer: employer la trousse de

panneau (83 po) no 4378786

(garniture argent) ou 4378787

(garniture blanche).

I

I 91 c-m I36 00)

_ -...

\-- I--,

A 91 cm (36 po)

B

212 cm (83 5/8 PO)*

C 64 cm (25 l/B po)

D 60 cm (23 l/2 po)

I E I 9 cm (3 l/2 DO)* I 9cm

\

G 61 cm (24 poi ’ ’

H 89 cm (35 po)

I 63,5 cm (25 po)

’

106 c

212 cm i83 ‘5/8 PO)*

64 cm (25 l/8 po)

60 cm (23 l/2 po)

I

I

8 DO)*/ 211 cm (83 l/8 DO)* 1 211 cm (83 l/8

61 cm (i4 po) ’ ’

104 cm (41 po)

63,5 cm (25 po)

Vue de dessus

k-----“------d

IT

(

Mod+les avec et sans distributeur

212 cm i83 i/i PO)*

64 cm (25 l/8 po)

60 cm (23 l/2 po)

m2po)’

] 9 cm (3 l/2 PO)’ I

61 cm (;4 po) ’

119cm(47po)

63,5 cm (25 po)

>I

PO)’

Caract&istiques et

dimensions de la cavitk

d’encastrement

TolCrance de + 3 mm (l/8 po) E

pour toutes les dimensions

Risque de blessuresldommages

. Faire attention B ce que le

rCfrigCrateur ne bascule pas; la plus

grande partie du poids du

rkfrigkrateur se trouve B la pat-tie

supkrieure.

l

Pour kiter que le rkfrigkrateur ne

bascule en tours de service, installer

un soffite massif ou deux tales en

bois de 5 cm x 10 cm x 81 cm

(2 po x 4 po x 32 po) recouvrant la

largeur du couvercle du

compresseur.

l

Si le soffite massif est pIa& b plus

de 2,5 cm (1 po) au-dessus du

rkfrigkrateur, installer deux tales en

boisdeScmxlOcmx81 cm

(2 po x 4 po x 32 po) sur le mur, A

6 mm (l/4 po) au-dessus du

GfrigCrateur. La surface infkrieure

des tales doit Ctre A 213 cm (84 po)

du plancher. Les tales en bois

doivent Stre suffisamment longues

pour recouvrir compktement la

largeur du couvercle du

compresseur.

Le non-respect de ces instructions

peut @tre la cause de blessures ou

de dommages materiels.

Le rCfrigCrateur encastrk peut &re

install6 :

l

en retrait dans I’espace disponible entre

les placards.

l

ZI I’extr6mid de la rangCe d’armoires; on

utilise alors un panneau lateral pour

recouvrir le c&6 du rkfrigerateur.

Choisir l’une des methodes et utiliser les

dimensions indiqukes. Les dimensions

indiquees laissent un dkgagement de 0 cm

(0 PO).

matkriels

-

/ I

/

/

I

0

/

/

I

Marquer la 1

position des I

poteaux du I

colombage surl

le mur arrike, I

I I

I I

i 203-229

I I

(80-90

dessus du sol.

cm I

po) au-

(7

PO)

/

Emplacemknt de la prise

de courant Clectrique

reliee a la terre.

Une prise de courant

electrique relike b la terre

est rkcessaire.

Hau

teur

Installer des supports des

panneaux latkraux (facultatifs)

sur le mur arrike si la

profondeur de la cavitk est de

64 cm (25 po) ou plus.

Largeur

EmDlacement de la canalisation d’arrivbe

d’eh

La canalisation d’arrivke

d’eau

doit fournir de I’eau

sous une pression de

103-690 kPa (15-l 00

Ib/po2). Effectuer

I’installation

preliminaire de la

canalisation d’eau avant

d’installer le refrighateur.

_12,5 cm (5 po)

-Plancher : Le plancher doit pouvoir soutenir le poids du

rkfrigkrateur, des panneaux de portes et du contenu.

3,8

cm

(1 l/2 PO)

5

196 cm

(77 PO)

- 12Scm

L

Trou de 12 mm

(l/2 po) pour le

passage de la

canalisation (g un

emplacement

quelconque dans la

- zone ombragCe).

I

L

\

\

\

Dimensions de la cavitk

Modele

Largeur min.

Hauteur min.

Hauteur max.

Profondeur

min.

91 cm (36 po)

90

cm (35 l/2 po)

21 lg5 Cm

215 cm (84 3/4 po)

60

(83 114

cm (23 l/2 po)

106 cm (42 po)

105 cm (41 l/2 po)

Po) 211,5 cm (83 l/4 po)

215

cm (84 3/4

60

cm (23 l/2 po)

po)

122 cm (48 po)

120 cm (47

209 cm (82 l/2 PO)

215 cm (84 3/4 po)

60

cm (23 l/2 po)

l/2 po)

Page 3

Dimensions pour le pivotement des portes

I :

: :

: :

:::

7

congelateur

: :

90”’ / \ \

I ’

1: :

r;+ ’

x -130”

Devant du rCfrigCrateur

/

\ i

\ \

\ \

1 <oO ‘90”

\ ‘1

\

\

- *j j

.-.-_I#. -

Rayon de basculement

___------_____

*_--

__--

,’

.’

Rayon de basculement

avant/arrikre

1,’

,’

,’

i

-

r

L

4

/

91 cm 106 cm

(36

A

B

C

D

98

(38-l /2 po)

92

(36-l/1 6 po) (38

1lOcm

(43-l /2 po)

102 cm 108 cm

1

(40

PO)

cm

cm

po)

(42

104cm

(41

119cm

(47

I(42

PO)

PO)

97

cm

po)

PO)

9/l 6

PO)/ (45 l/4 po)l

D

L’emplacement d’installation doit

permettre I’ouverture des portes a un angle

de 90” au moins. Laisser un espace d’au

moins 2,5 cm (1 po) entre le c&C du

refrigerateur et le mur formant I’angle.

Prkvention du basculement

6

mm (l/4 po) max.

7

Scm

(2 po) min.

4-1

fl

-I

Deux tales en bois

de5cmxlOcmx

81 cm(Zpox4po

›- x

32

Fixer les tales en

bois aux poteaux

du colombage

mural avec six vis &

bois no 8 x 7,6 cm

(3

po) ou plus

longues.

Les tales en bois

- utilisCes doivent

@tre assez longues

pour couvrir

totalement la

largeur du

couvercle du

compresseur.

122 cm

(48 PO)

1lOcm

(43 l/2

102 cm

(40

PO)

128cm

(50 l/2 PO)

115cm

PO).

PO)

Page 4

Rayon de basculement

lateral

/

/

/

/

/

/

/

I

I

I

I

I

i-B.

*_v-----_

/-

-’

, ,/’

/

/

/

-.

-.

+ mur

arrikre

Si les tales sont mises en places avant I’installation du

rkfrigkrateur, positionner les tales de sorte que leur base

soit a 213 cm (84 po) du plancher. Pendant I’installation,

soulever le refrigerateur afin qu’il y ait un espace de 6 mm

(l/4 po) au plus entre le haut du refrigerateur et la base

des tales antibasculement.

Si un soffite massif est install6 a

2,5

cm (1 po) audessus du rkfrigkrateur, il n’est pas necessaire d’installer

les tales en bois pour prevenir le basculement.

Si un soffite massif n’est pas disponible ou si le soffite

est place a plus de 2,5 cm (1 po) au-dessus de la partie

supkrieure, centrer les tales en bois utilisees pour la

prevention du basculement sur le mur arriere a 6 mm

(l/4 po) max. au-dessus du refrigerateur. A I’aide des vis a

bois, visser les tales en bois aux poteaux du colombage

mural - veiller a ce que les vis p&-&rent dans les poteaux

du colombage d’au moins 3,8 cm (1 l/2 po) et a ce que la

surface frontale des tales en bois soit sit&e a au moins

5 cm (2 po) au-dela de la surface

arrihe

du

couvercle

du

compresseur du refrigerateur.

1. Ensembles de panneaux

Quatre ensembles de panneaux de portes

en acrylique colon? ou en acier inoxydable

sont disponibles de votre concessionnaire

Panneaux - Numkros des ensembles

KitchenAid. Utiliser les instructions

d’installation fournies avec chaque

ensemble pour I’installation des panneaux.

1 Modele Sans distributeur

Taille

Blanc

t-

91 cm (36 po) 106 cm (42 po)

4318635 4318636 4318637 4378650 4378651 4378652

14318632 14318633

I

I

122 cm (48 po)

14318634

I

IAvec distributeur

91 cm (36 po) 106 cm (42 po)

14378653

I

14378654

I

122 cm (48 po)

14378655

Amande 1 4318638 I431 8639 1 4318640 14378656 14378657 14378658

1 Acier inoxydable 1 4318641 14318642 1 4318643

I

4378659

14378660

14378661

2. Panneaux personnalisks

-H-

I-

Panneau de Porte

du rkfrigkrateur

Poids maximal :

23

kg (50 lb)

Risque de dommages pour le produit

Le poids des panneaux personnalisks

NE

doit PAS dCpasser les valeurs

indiqukes.

L’installation de panneaux dont le

poids dkpasse la limite indiquke peut

@tre la cause de dommages pour le

produit.

REMARQUE : Tolkrance de + 1,s mm

(l/16 po) pour les dimensions indiqukes.

Les panneaux dont I’kpaisseur est

supkrieure i 6 mm (l/4 po) doivent faire

I’objet d’un usinage. Lors de I’emploi de

panneaux dkji amincis par usinage,

ajouter 1,s mm (l/16 po) aux dimensions

indiqukes.

Si I’Cpaisseur des panneaux est infkrieure 5

6

mm (l/4 PO),

remplissage entre les portes et les panneaux

decoratifs.

installer un panneau de

Si I’Cpaisseur des panneaux est supkrieure

a 6

mm (l/4 PO),

usinage.

amincir tous les bords par

-C+

Poids maximal

combine des

deux

panneaux :

13,5 kg (30 lb)

Panneaux de portes du

conoelateur (avec

d:stributeur)

Poids maximal

combine des

deux

panneaux :

135 kg

(30

7

lb)

E

Panneaux de

portes du

congklateur

(sans

distributeur)

Maximum

weight:

30 ounds

(1 g.5 kg)

I

-A

Panneau de la

L

[poids max. : 45 kg 60 lb)]

Size A

91 cm

(36 PO)

106 cm

(42 PO)

122

cm

(48 PO)

*La dimension “B” augmentera ou diminuera de 1,s cm (l/2

*La dimension “B” augmentera ou diminuera de 1,s cm (l/2

sont utilises. sont utilises.

4

grille

su erieure

82 cm 15cm

(32 3/8

PO) (6 PO)

97 cm

(38 318

113cm

(44 3/8

15cm

PO)

(6

PO)

15cm

po) (6 po)

B

B

C

36 cm

(14 l/4 PO)

43 cm

(16 314

PO)

49 cm

(19 l/4

PO) (23 7/16 po)

IL

L

60 cm

(23 7/16

60 cm 87 cm

(23 7/l 6

60 cm 87 cm

;I

D E

87 cm

(34 7/16

PO)

(34 7/l 6 po)

po)

(34 7/16 po)

po) si les trousses de panneaux d&or&ifs indiqu& 2 la page 2

po) si les trousses de panneaux dhratifs indiques 2 la page 2

-

F G

36 cm 179cm

(14 l/4

PO)

43 cm 179cm

(16 3/4 po)

49 cm 179cm

(19 l/4 po)

PO)

il.

(70 7/16

(70 7/l 6 po)

(70 7/16 po)

PO)

H

49 cm

(19 l/4

PO)

58 cm

(22 3/4 po)

67 cm

(26 l/4 po)

I

179cm

(70 7/l 6

179cm

(70 7/l 6 po)

179cm

(70 7/l 6 po)

PO)

I

-

Page 5

Vue de I’extrkmitb - c6tk poignke du panneau

Panneaux

personnalishs

d’kpaisseur supbrieure

2 6

mm (l/4 po) :

Amincir par usinage a la

toupie sur toute la

longueur ou a des

emplacements choisis

du cGtC poignke du

panneau, sur 8,25 cm

(3 l/4

PO).

8,25

cm

3. Panneaux latkraux

Si le panneau IatCral doit s’engager dans une

garniture latkrale, et si I’Cpaisseur du

panneau lateral est supkieure A 6 mm

(l/4 PO),

panneau pour qu’il puisse passer dans la piece

de garniture.

amincir par usinage le bord avant du

Vue de I’extrCmitC de la piece

de garniture laterale

Largeur et hauteur :

selon le type

d’installation.

Dimensions pour

I’usinage b la

peripherie des

panneaux

19 mm

(314

PO)

min.

panneau

tringle de clouage et

support du panneau lateral

Vue lath-ale

+6mm

(114

max.

PO)

6

mm+

(114

PO)

1,s mm j

l/16

po)

5,s mm

V/32

po)

3

10 mm (13/32 po)

panneau lateral

engage dans la piece

de garniture laterale.

4mm

(S/32

po)

panneau lateral

hors de la piece

de qarniture laterale.

Epaisseur :

Minimum 12 mm (l/2

po)

pour emp@cher le

gauchissement.

Encoches pour la

plinthe en retrait (le

cas echeant).

Determiner la hauteur

du refrigerateur

install6 avant de

decouper les

encoches.

\

-s

piece de garniture laterale

panneau lateral hors de

la piece de garniture

laterale, et en retrait.

Page 6

tringle d!app?

\

64cm

(25 PO)

I I

61011

(24

1 /a po)

I

(23 l/2

60cm

po)

Mode+ (36

91 cm 106cm

po)

(42 PO)

91 cm 106cm

A

(36 PO)

90 cm 105 cm

B

(35 l/2 po) (41 l/2 po) (47 l/2 po)

89 cm

C

(35 PO)

(42 PO)

104 cm

(41 PO)

122cm

(48 PO)

122 cm

(48 PO)

12Ocm

119cm

(47 PO)

klectrique

Risque de choc electrique

l

Cet appareil doit etre relic a la terre.

l

Si la canalisation d’eau froide comprend

des joints en plastique ou non

metalliques ou d’autres materiaux

isolants, ne pas les utiliser pour la liaison

a la terre.

l

Ne pas utiliser la canalisation de gaz

pour la liaison a la terre.

. Ne pas modifier la fiche du cordon

d’alimentation. Si la configuration de la

fiche de branchement ne correspond

pas a la configuration de la prise de

courant, demander a un Clectricien

qualifie d’installer une prise de courant

convenable.

l

Veiller a ce qu’aucun fusible ne soit

install6 en serie dans le conducteur

neutre ou le conducteur de liaison a la

terre. Cela pourrait etre la cause d’un

choc Clectrique.

l

Ne pas utiliser un cable de rallonge pour

I’alimentation de cet appareil.

. En cas de doute au sujet de la liaison a la

terre de cet appareil, consulter un

Clectricien qualifie.

C’est au client qu’incombe la responsabilite

de :

l

Contacter un Clectricien qualifie pour

I’installation.

9 S’assurer que I’installation Clectrique est

adequate et conforme aux dispositions

du Code National Electrique, ANSI/NFPA

70 - derniere edition** ou du Code

canadien des installations electriques

C22.1-1982 et C22.2 no 01982 (ou

derniere edition)‘, et tous les codes et

reglements locaux.

Le non-respect de ces instructions

pourrait causer la mar-t ou une blessure

serieuse.

Si les codes en vigueur le permettent et si un fil

distinct de liaison a la terre est utilise,. on

recommande qu’un electricien qualrfre

determine que le conducteur de liaison a la terre

prise de courant m

3 broches, reliee a

fiche de branchement

a 3 broches, reliee a la

terre

cordon d’alimentation

d’electricite

Une prise de courant de 120 V, 60 Hz, CA

seulement, 15 ou 20 A, avec fusible, doit etre

disoonible. On recommande I’emoloi d’un

fusjble temporise ou d’un disjonct’eur.

retenue

On recommande Cgalement que I’appareil

soit alimente par un circuit distinct

n’alimentant que cet appareil.

Cet appareil est equipe d’un cordon

d’alimentation dote d’une fiche de

branchement a 3 broches. Pour minimiser

le risque de choc electrique, le cordon doit

etre branche sur une prise de courant

murale correspondante, a 3 broches, reliee

a la terre, conformement aux dispositions

du Code National ilectrioue, ANSI/NFPA

70 - derniere edition*’ du bu Code

anadien des installations electriques

122.1-l 982 et C22.2 no 01982 (ou

erniere edition)*, et de tous les codes

)caux et reglements en vigueur.

In peut obtenir un exemplaire des codes

lentionnes a I’adresse suwante :

*Association canadienne de normalisation

178 Rexdale Boulevard

Rexdale (Toronto), Ontario M9W 1 R3

t National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts, 02269

;pkifications de

‘alimentation en eau

Risque de choc Clectrique

II peut rester de I’eau dans la

tuyauterie d’arrivee d’eau. Lors de

I’utilisation d’une perceuse Clectrique,

veiller a ce que la perceuse soit

convenablement reliee a la terre pour

kiter un choc Clectrique grave ou

meme mortel qui surviendrait si de

l’eau penetrait dans la perceuse.

Le non-respect de cette instruction

pourrait causer la mort ou une

blessure serieuse.

Risque de dommages pour le

produit/dommages materiels

. Utiliser uniquement un tube en

cuivre de 6 mm (l/4 po) pour

I’arrivee d’eau.

l

Ne pas installer le tube en cuivre

dans un endroit ou la temperature

peut s’abaisser a moins de 0 “C

(32 “F).

. Avant de connecter le tube en cuivre

au refrigerateur, le rincer en y

faisant passer au moins 1,9 L

(2 pintes) d’eau pour Climiner tous

les debris qui ont pu s’y introduire.

l

Ne pas serrer excessivement la bride

ou le raccord, ce qui pourrait ecraser

le tube en cuivre.

l

Rechercher les fuites autour du

robinet de prise en charge.

Le non-respect de ces instructions

peut Ctre la cause de dommages pour

le produit ou d’autres dommages

materiels sous I’effet d’une fuite d’eau.

La canalisation d’eau alimentant le

refrigerateur doit fournir de l’eau sous une

pression de 103-690 kPa (15-l 00 Ib/po2).

Calcul de la longueur necessaire de la

section d’un tube en cuivre de 6 mm

(l/4 po) de diam. ext. :

1. Identifier a proximite du refrigerateur une

canalisation d’eau FROIDE verticale de 1,2 cm a

3,2 cm (l/2 po a 1 l/4 PO). On peut Cgalement

utiliser une canalisation d’eau FROIDE horizontale

si les instructions de I’etape 4 sont

scrupuleusement observees.

2. Mesurer la distance entre la canalisation d’eau

froide et le refrigerateur. Ajouter 61 cm (24 po) a

cette dimension.

Pose preliminaire de la canalisation d’arrivee

d’eau :

3. FERMER le robinet principal d’alimentation.

OUVRIR le robinet le plus proche assez longtemps

pour purger toute l’eau des canalisations.

4. Canalisation d’eau froide vetticale : Utiliser une

perceuse Clectrique reliee a la terre ou une

perceuse manuelle pour perter un trou de

4,s mm (3/l 6 po) a un emplacement facilement

accessible de la canalisation.

Canalisation d’eau froide horizontale : Utiliser

une perceuse Clectrique reliee a la terre ou une

perceuse manuelle pour perter un trou de

4,s mm (3/l 6 po) dans la par-tie superieure de la

canalisation. Ainsi, des sediments ne

s’accumuleront pas dans le robinet de prise en

charge.

5. Placer le joint sur le trou perce de la canalisation.

Faire tourner la manette du robinet de prise en

charge dans le sens horaire pour faire depasser la

pointe percante d’un maximum de 4,s mm

(3/l 6 PO). Aligner la pointe percante avec le trou

per& dans la canalisation. Placer les deux moities

de la bride de fixation du robinet de m

prise en charge contre la

canalisation. Faire tourner la

Pi

manette du robinet dans le sens

horaire jusqu’a ce que la pointe

percante penetre dans le trou de

la canalisation et soit fermement

en place. Le robinet de prise en

charge n’est pas a la

position de fermeture.

Serrer I’ecrou autour de la

tige de commande. Serrer

uniformement et fermement les vis

de bridage, afin que le joint etablisse

une connexion etanche. Ne pas serrer

excessivement; le tube en cuivre pourrait

s’ecraser.

6. Veiller a ce que les deux extremites du tube en

cuivre soient toupees a I’equerre. Enfiler I’ecrou de

compression et la virole sur le tube en cuivre.

Enfoncer completement I’extremite du tube en

cuivre dans I’ouverture du robinet. Serrer I’ecrou

de compression sur le raccord avec une cle a

molette. Ne pas serrer excessivement.

7. Ouvrir le robinet principal d’alimentation.

Inspecter pour rechercher les fuites. Faire tourner

la manette du robinet de prise en charge dans le

sens antihoraire et laisser de I’eau s’ecouler a

travers le tube en

cuivre dans un seau. ecrou de

Faire tourner la

compression

,

tube en

cuivre

/

manette dans le

sens horaire pour

interrompre

I’ecoulement de I’eau a

travers le tube en cuivre.

virole

raccord

8. Acheminer le tube en cuivre jusqu’a la zone

d’installation du refrigerateur.

9. Enfiler I’ecrou de compression et la virole

sur la

canalisation d’eau. Visser I’ecrou sur le raccord et

serrer. Ne pas serrer excessivement.

Page 7

Pikes fournies pour

I’installation :

l

grille de ventilation basse

l

Sachet de pikes

Verifier que toutes les pikes sont prkentes

Risque de dommages pour le

produit/dommages materiels

. Ne pas abaisser le kfrigkrateur sur la

base utiliske pour I’expbdition, lors de

I’extraction de la base.

l

Ne pas Bter le film protecteur avant que

le rCfrigCrateur soit b la position de

service.

l

Les quatre pieds de kglage de I’aplomb

doivent @tre en contact avec le sol et

soutenir la totalitk du poids du

rbfrigkrateur pour le stabiliser.

l

Conserver la plaque en carton ou en

contre-plaquC sous le refrigkrateur lors

de I’expCdition, jusqu’h ce qu’il soit

install6 A la position de service.

Le non-respect de ces instructions peut

Ctre la cause de dommages que subirait le

produit ou le revetement du sol.

Enlever le sachet de documents et le

1

. sachet de pikes fix& sur la Porte du

rbfrigbrateur; conserver ces articles en lieu stir.

6ter les quatre brides (deux de chaque c6t.k)

fixant la base utilisCe pour le transport en bas

du rCfrigCrateur.

adhksifs et entretoises qui immobilisent les

portes avant que le rkfrigerateur ait ktk

solidement install6 a la

position de service

I. . . .

rmale. Volr page 3.

2

. Mettre le

chariot sous le c6tk

du rkzfrigerateur et

arrimer le

r6frigCrateur avec

la sangle du

chariot, sans

trop serrer.

Inskrer les cornkes

en carton pour

proteger les angles et les poigkes entre la

sangle et le r@frig@rateur. Serrer prudemment la

sangle en Grifiant que les pikes de garniture

latbrales et les poigkes sont protPg6es.

Page 8

Ne pas 6ter les rubans

cormere en

carton sur les

Risque de blessures

l

A cause du poids et de la taille du

rkfrigkrateur, son installation

nkcessite I’intervention de deux

personnes ou plus.

l

La plus grande partie du poids du

rCfrig&ateur se trouve & la partie

supkrieure. Manipuler le

rbfrigkrateur avec prudence lors

des dCplacements, pour qu’il ne

bascule pas.

Le non-respect de ces instructions peut

@tre la cause de blessures.

Avant de deplacer le refrigkrateur sur

3

3. le plancher de la maison, sur un

chariot, placer sur le plancher les sections

de I’emballage de carton. Approcher le

r6frigPrateur prPs de I’ouverture de

I’encastrement oti il sera instalk

prise

. Pousser le

4

commutateur

d’alimentation sit&

en haut de la caisse

B la position d’arkt

(OFF).

Brancher le

de

courant reliCe

cordon d’alimentation

sur une prise de

courant blectrique

reli6e 2 la terre. Fixer la bride d

retenue sur la prise de courant

avec la vis qu’on trouve dans le

sachet de petites pikes.

Mettre une plaque en contre-plaq&

. ou en carton sous le rkfrigkateur.

5

Retirer le chariot de manutention. Ouvrir

les portes de I’appareil et 6ter toutes les

boites, les sachets de pikes et les

matkiaux d’emballage qu’on trouve dans

le compartiment de refrig6ration et le

compartiment de congglation. Ne

la pellicule protectrice.

pas 6ter

InsCrer le rPfrig6rateur dans I’ouverture

d’encastrement, en ligne droite et

uniformement. Verifier que :

l

le tube en cuivre n’est pas deform@,

6cras6, etc.

l

le cordon d’alimentation electnque est au

sommet du rbfrigkateur, prk du

couvercle.

vers robinet

d’arrivee d’eau

VCrifier que la canalisation d’arrivke

d’eau a CtC purgke. Voir page 7.

Extraire la canalisation de cuivre du

. robinet d’alimentation en eau du

6

r@fng&ateur, et tirer vers I’avant pardessous le rPfrig6rateur la canalisation de

cuivre reGe au circuit de plomberie.

canalisation en

cuivre relike au

circuit de

plomberie de la -

maison ,

canalisation en

cuivre, vers le

robinet

\

6mm

(114

PO)

de6mm

Enfiler un 6crou de compression et sa virole

sur I’extr@mit@ libre de chaque canalisation

de cuwre. Utiliser un raccord droit pour

tubes de cuivre pour raccorder les deux

canalisations de cuivre. Ne

excessivement.

pas serrer

Ouvrir le robinet d’arrike d’eau (position

OPEN). Placer le commutateur

d’alimentation electrique du refrigkateur a

la position de marche (ON). Attendre

quelques minutes. Inspecter la connexion

de la canalisation d’eau et le robinet

d’arrivee d’eau au sommet de la caisse pour

identifier les fuites kentuelles. R&ns&er la

canalisation de cuivre sous le Gfrigkateur,

en veillant a ne pas I’kraser ou la deformer.

Panneau de

remplissage

kessaire si __

I’kpaisseur du

panneau

dkcoratif est

infkrieure 21

6

mm (l/4 PO).

rondelles

de nylon

(jeter)

n

. &er tous les rubans adhesifs et

7

;i

il

Si I’kpaisseur

du panneau

dkoratif est

supkrieure B

6mm

(1 I4 PO),

amincir tous

les bords par

bCcoratif

entretoises des pottes du refrigerateur et

du congelateur. &er les vis fixant les

poignees aux cadres de portes. Enfiler les

panneaux decoratifs des portes dans les

cadres de portes.

Si I’Cpaisseur du panneau dkoratif est

infCrieure a 6 mm (l/4 PO), installer un

panneau de remplissage entre la Porte et

le panneau decoratif.

Si I’kpaisseur du panneau dkcoratif est

supkrieure a 6 mm (l/4 PO), amincir tous

les bords par usinaqe a la toupie.

51 UR sdte ma& n’est pas

dispnble OLI si be soffite est ptaci B

plus de 2,5 an (1 po) audessus du

ri$fri#ra&2w, centrer &es tales en

Ws w-itibascutenent sur le mur

ati$re, ii 6 mm (IM PO) max. audews du r&ig&atew. A l’aide des

vis (3. tmis, visser ies tales en b&s aux

potearlx du colornbage mural - veiller

a ce que les vis p&&rent dans les

poteaux du colambage d’au mains

3,8 cm (1 l/2 po) et Z ce que la

s&ace fmntak ck tales en buis soit

i plack a au mains S cm (2 po) au-

de& de la surface arrike du couvercle

montage de la

Mbrieure

Faire coulisser le panneau decoratif de la

grille superieure vers le haut pour le &parer

de la grille superieure. Detacher les deux

cordons qui relient le panneau decoratif a la

grille superieure.

Page 9

Vue de dessus

panneau dkoratif de

la grille superieure

deux petites vis et la

garniture laterale du

panneau sur un

c&S du panneau

decoratif, pour

permettre I’inseftion

du panneau

personnalise. Reinstaller la garniture laterale,

les vis et les cordons de retenue, dans I’ordre

inverse du demontage. Reinstaller le

panneau decoratif et tirer vers le bas pour

I’immobiliser.

. Si aucun panneau IatCral n’est

16

utilisb, passer A I’btape 17.

Si la profondeur de la cavitb

d’encastrement est de 63,5 cm (25 po) ou

plus, on peut engager les panneaux lateraux

i I’interieur de la garniture laterale, ou les

fixer a I’exterieur de la garniture laterale.

lanchette d’appui lanchette d’appui

T T

II

62

cm

l

Pike de garniture laterale externe :

Perter 6 trous equidistants dans la piece

de garniture laterale. Ne pas perter

dans le cBtC de I’appareil. Fixer une

planchette d’appui sur la piece de

garniture. Clouer les bords avant et

arriere du panneau lateral sur les

planchettes d’appui. Recouvrir la face

avant des planchettes d’appui avec un

morceau de panneau assorti.

l\l I

Vue de dessus

Ouvrir les portes de I’appareil et

. oter la pellicule protectrice de

17

I’encadrement des portes. Inspecter de

nouveau les raccords de connexion de

tuyauterie situ& en bas du refrigerateur

pour rechercher les fuites.

Fixer la grille de ventilation de la base avec

deux vis. Installer les @tag&es et caissons

dans les compartiments de refrigeration et

de congelation.

Regler les thermostats du

. refrigerateur et du congklateur au

18

point median entre les rep&es FROID et

TEMPERATURE MINIMALE. Verifier que le

compresseur et les cinq lampes

fonctionnent normalement.

Vue de dessus

(24 ~0)

62 cm

(24 518 po)

max.

1L

l

Pike de garniture laterale interne :

Enfiler le bord avant aminci du panneau

lateral dans la piece de garniture. Clouer

le bord arriere du panneau sur la

planchette d’appui.

rniture laterale

planchette d’appui

Si la profondeur de la cavitC

d’encastrement est infkrieure 2 63,s cm

(25 PO), executer I’installation des

panneaux lateraux en tenant compte des

restrictions imposees par les

caracteristiques du site d’installation. (Une

methode consiste a installer une

planchette de clouage et d’appui sur le

mur arriere de la cavite d’encastrement.

Perter des trous dans la garniture laterale.

Fixer ensuite la planchette d’appui a la

garniture. Fixer le panneau lateral sur la

planchette d’appui et la planchette de

clouage. Recouvrir la planchette d’appui

avec un morceau de panneau assorti.)

Piece no 2004022

0 1995 KitchenAid

@ KitchenAid. Marque deposee de

KitchenAid.

KitchenAEcD”

APPAREILS MiNAGERS

Prepare par KitchenAid, St. Joseph, Michigan 49085

lmprime aux k-U.

36 pulg. [91 cm.]

42 pulg. [106 cm]

y 48 pulg. [122 cm]

Refrigerador

Empotrado

Importante:

Leer y guardar

estas instrucciones.

Se requiere 2 0 miis

personas para

instalar.

Importante:

l

Instalador: Dejar instrucciones

con el propietario.

l

Propietario: Cuardar

instrucciones para referencia en

el futuro.

l

Cuarde estas instrucciones de

instalacih para uso del inspector

elktrico.

I I I

I

I

I I

I

I

I

I

\ \

I \

Pieza No. 2004022

\

\ \

Peligro de Heridas

l

Por el peso y tamafio del

refrigerador, se requiere dos o mk

personas para su instalacibn.

l

La mayor parte del peso del

refrigerador se encuentra en la

secci6n superior. Se requiere de

cuidado especial al mover el

refrigerador, para prevenir su

inclinacibn.

La falta de atenci6n a estas

instrucciones pueden causan heridas.

Vista Frontal

DIMENSIONES

Vista Lateral

-C

B

Ver

Nota.

La falta de atenci6n a esta instrucci6n

puede daiiar la superficie del piso.

Observar todas las

disposiciones y regulaciones

del case.

Es su responsabilidad:

l

Observar las disposiciones sobre

instalaci6n y dimensiones

. lnstalar el refrigerador en forma

correcta.

l

Verificar que dispone de 10s siguientes

materiales necesarios para una

instalaci6n correcta:

tuberia de cobre de l/4 pulg. [6 mm]

con vilvula de cierre

accesorio de compresi6n de l/4 pulg.

b5

mm1

6 tornillos para madera #8 x 3 pulg.

[76 mm]

[es posible que requiera tornillos m&

largos]

2 tiras de madera de 2 pulg. x 4 pulg.

[S cm x 10 cm x 81 cm] min.

[ver p6gina

T-15 Tornillo Torx

l

Confirmar que el piso puede soportar un

refrigerador de un peso [mayor a 600

lbs.1272 kg.], paneles de puertas y su

contenido interior.

l

Proveer un enchufe el&trico con su

debida tierra.

l

Verificar que el lugar permite la apertura

de la puerta del refrigerador por lo

menos 90”.

l

Las dimensiones indicadas surten efecto para 10s

niveladores extendidos l/8 pulg. 3 mm] debajo de 10s

rodillos. Para niveladores extendidos 1 -l/4 pulg.

[32 mm] debajo de 10s rodillos, aumentar l-1/8 pulg.

[29 mm] a esta dimensi6n.

Pigina 2

Nota:

La dimensi6n “6” puede ser

aumentada o disminuida l/2 pulg.

(1,3 cm) usando 10s Juegos de Rejilla

disponibles de su distribuidor.

Para aumentar: use el Juego de

Rejilla de “84 pulgadas” N” 4378788

(Moldura Plateada) o 4378789

(Moldura Blanca).

Para disminuir: use el Juego de

Rejilla de “83 pulgadas” N” 4378786

(Moldura Plateada) o 4378787

(Moldura Blanca).

Modelos Con Expendedor

36 pulg (91 cm)

A 36 pulg (91 cm)

B

83-5/8 oula (212 cm)* 83-5/8 oulq (212 cm)* 83-5/8 pulq (212 cm)*

C 25-l/8 pulg (64 cm)

D

23-l /2 pulg (60 cm)

E 3-l /2 pulg (9 cm)*

1 F 1 83-l I8 oula (211 cm)‘1 83-l I8 PUIIJ (211 cm)*183-l/8 pulq (211 cm)*

c

24 pulg (61 cm)

H

I

25 oula (63.5 cm)

I .,.

35 pulg (89 cm)

42 pulg (106 cm)

42 pulg (106 cm)

25-l /8 pulg (64 cm)

23-l /2 pulg (60 cm)

3-l /2 pulg (9 cm)*

24 pulg (61 cm)

41 pulg (104 cm)

25 oula (63.5 cm)

--+

. -.

Vista Superior

-

48 pulg (122 cm)

48 pulg (122 cm)

25-l /8 pulg (64 cm)

23-l /2 pulg (60 cm)

3-l /2 pulg (9 cm)*

-

24 pulg (61 cm)

47 pulg (119 cm)

25 oulq (63.5 cm)

J

I

,I

DIMENSIONES Y

REQUERIMIENTOS PARA

EMPOTRAR

Todas las dimensiones + l/8

pulg. [3 mm]

Peligro de heridas/Daiios

a la propiedad

l

Se debe poner atenci6n en todo

moment0 para evitar que el

refrigerador se incline, puesto que

la parte superior soporta la mayor

parte del peso.

l

un sofito o dos de 2 pulg. x 4 pulg.

x 32 pulg. [5 cm x 10 cm x 81 cm]

de madera s6lida para cubrir el

ancho de la tapa del compresor

para prevenir inclinacirk durante el

uso.

l

Si el sofito s6lido sobresale m6s de

1 pulg. [2.5 cm] encima del

refrigerador, se requiere entonces

instalar dos Gras de madera de 2

pulg. x 4 pulg. x 32 pulg. [S cm x 10

cm x 81 cm] en la pared, l/4 pulg.

[6 mm] sobre la tapa del

refrigerador. La superficie inferior

de las tiras de madera debe

permanecer 84 pulgadas [213 cm]

del piso. Las Gras de madera deben

ser lo suficientemente largos para

cubrir el ancho de la tapa del

compresor.

La falta de observancia a estas

instrucciones puede causar heridas o

dafios a la propiedad.

El refrigerador empotrado puede

instalarse:

9 dentro de la cavidad de 10s gabinetes

l

al final de 10s gabinetes utilizando un

panel lateral para cubrir el lado del

refrigerador.

Elija un mCtodo y utilice las dimensiones

adjuntas. Estas dimensiones permiten una

6rea libre de 0 pulg. [0 cm].

-

1

II

I I Marque el

I I sitio de la

I I columna en I I

I ! la Dared

I I posterior II

” 80 - 90 pulg. ”

[203-229 cm]

desde el piso.

I

Utu Ira

lnstalar el soporte del

panel lateral [optional]

en la pared posterior si la

apertura tiene una

profundidad mayor de

i5 pulg. [64 cm]*o m6s.

+

PAncho

Tuberia de

agua debe

disponer de una

presih de 15-l 00

psi [103-690 kPa].

Efectuar instalacih (3*8 cm)

de la tuberia de

agua antes ae

I I

I i

II

Enchufe elkctrico con

tierra

Se requiere un enchufe

ektrico con tierra

Seiial de tuberia de agua

.

I/ r7

(18 cm)

/

77 pulg

(196 cm)

l

Ranura para

plomeria de

l/2 pulg. [12 mm]

puede ser situada

en cualquier lugar

- dentro del Circa

sombreada.

-

_i/.,

/ I I

Dimensiones de apertura

Modelo

Ancho min.

Altura min.

Altura max.

Profundidad min.

36 pulg (91 cm)

35-l /2 pulg (90 cm)

83-l /4 pulg (211.5 cm) 83-l /4 pulg (211.5 cm)

84-3/4 pulg (215 cm)

23-l /2 pulg (60 cm)

Piso: Debe soportar el refrigerador, w--

contenldo y puertas.

42 pulg (106 cm)

41-I /2 pulg (105 cm)

84-3/4 pulg (215 cm)

23-l /2 pulg (60 cm)

48 pulg (122 cm)

47-l /2 pulg (120 cm)

83-l /4 pulg (211.5 cm)

84-3/4 pulg (215 cm)

23-l /2 pulg (60 cm)

I

\

P6gina 3

Dimensih de Puertas

/I \\

90"' / \ \

/

Puerta del

congelador

Angulo de inclinacih

Angulo de inclination

Adelante/atras .--*

I

I

I

I

r’

,’

,’

I

I

I

I

I

A

A

36

91 cm

38-l/2

A (98

cm)

36-l/1 6

B (92cm)

43-l/2

’ (1lOcm)

D 40

PUlLI

(102 cm)

pulg

pulg

pulg 38 pulg

pulg 47 pulg

42

pulg

106

41 pulg

(104 cm)

(97

cm)

cm

48 Pub

122

cm

43-l /2 pulg

(1lOcm)

40

pulg

(102 cm)

50-l 12 pulg

(119 cm)

(128 cm)

42-9/l 6 pulg 45-1 I4 pulg

(108 cm)

(115 cm)

La instalaci6n permanente debe permitir

un angulo de apertura para las puertas de

minim0 90”. Dejar un espacio minim0 de

1 pulg. [2.5 cm] entre la pared lateral del

refrigerador y la pared esquinera.

Preventivo de inclinacih

l/4 [6 mm] max.

DOS tiras de

madera para

* prevenir la

inclination de

2 pulg. x 4 pulg.

x 32 pulg. [5 cm x

10 cm x 81 cm 1.

Fijar a las

columnas

mediante seis

tornillo para

- madera #8 x 3

pulg. [76 mm]

[o m6s largos].

Las tiras de

madera deben

ser

suficientemente

largas para cubrir

completamente

el ancho de la

tapa del

compresor.

48

pulg (122 cm)

P6gina 4

Angulo de inclination /‘-

Lateral

/

/

/

/

/

/

I

I

87-l/4

//’

/

/

/

/

/

pulg (222 cm) 90-l /2 pulg

87-l /4 pulg (222 cm)

(230

cm)

e Pared

trasera

Si se coloca las tiras de madera antes

a instalar el

refrigerador, sitlie las tiras de tal manera que la superficie

inferior de las mismas se encuentren a 84 pulg. [213 cm]

desde el piso. Durante el proceso de instalacirk, levante el

refrigerador hasta dejar un espacio maxim0 de l/4 pulg. [6

mm] entre la patte superior del refrigerador y la superficie

inferior de las tiras de madera.

Si se encuentra un sofito solid0 de 1 pulg. [2.5 cm] sobre

el refrigerador, no se requiere tiras de madera para prevenir

la inclination del refrigerador.

Si no existe un sofito solido, o si el sofito es mayor a 1

pulg. [2.5 cm] sobre la cubierta, centre las tiras de madera

en la pared trasera a l/4 pulg. [6 mm] maxim0 sobre el

refrigerador. Fije las tiras a las columnas de la pared

mediante tornillos para madera, verificando que 10s tornillos

se encuentran dentro de las columnas por lo menos l-1 /2

pulg. [3.8 cm], y que las tiras de madera sobrepasan por lo

menos 2 pulg. [5 cm] sobre la secci6n superior del area

posterior de la cubierta del compresor del refrigerador.

Nlimero del juego de paneles

Modelo

Tamaiio

Blanc0

36 Pulg (91 cm) 42 pulg (106 cm) 48 pulg (122 cm) 36 pulg (91 cm) 42 pulg (106 cm)

4318635

r4318632

I I

Almendra 4318638 4318639

(Acero lnoxidable 1 4318641

Sin expendedor

4318636

14318633 14318634

14318642

1. Juegos de Paneles

Su distribuidor KitchenAid dispone de

cuatro juegos de paneles acrilicos a color

acero inoxidable para puettas y la rejilla

Con expendedor

4318637

I

4318640 4378656 4378657

14318643

4378650

14378653

I

14378659

superior. Siga 10s pasos indicados en las

instrucciones de 10s paneles su instalacion.

0

48 pulg (122 cm)

4378651

(4378654

I

4378652

1 4378655

4378658

14378660

( 4378661

2. Paneles a medida

Daiio al product0

El peso de 10s paneles fabricados

a medida NO DEBE EXCEDER 10s pesos

indicados.

El sobrepeso de 10s paneles puede

causar dafios al producto.

NOTA: Las dimensiones indicadas

permiten una

tolerancia de +- l/16 pulg. [1.5 mm].

Paneles de m6s de l/4 pulg. [6 mm]

deben tupirse. Si se utiliza paneles

tupidos, aumente l/16 pulg. [1.5 cm] a

las dimensiones indicadas.

Si 10s paneles son de un grosor inferior

a l/4 pulg. [6

relleno entre las puertas y 10s paneles

decorativos.

Si 10s paneles son de un grosor mayor a

l/4 pulg. [6

filos del panel, en todos sus lados.

mm],

instale un panel de

mm],

pase el tupi sobre 10s

Peso m6ximo

combinado

de

10s dos

aneles:

0 libras

D

[13.5 kg]

Panel de puerta del

congelador

[sin expendedor]

Peso mhimo

combinado

de

10s dos

aneles:

P

0 libras

[13.5 kg]

Paneles de las

puertas del

con elador

con

P

expendedor]

Peso m6ximo:

30 libras

[13.5 kg]

-HH

Panel de puerta

del refrigerador

Peso m6ximo:

50 libras

t23 kg1

r

I

Panel superior de la rejilla [peso miximo:

10 lbV4.5 kg]

l

La dimension “B” aumentara o disminuira l/2 pulgada (1,3 cm) si se usan 10s juegos de rejillas indicados en la pagina 2.

P6gina 5

Carte del filo del panel lado de la manija

Corte lateral

Paneles a medida con un

rosor mayor a l/4 pulg.

6

mm]:

a

Pasar el

tupi sobre la

3-l/4 pulg

totalidad

del lar 9 o o sobre irreas

especi icas

de 10s paneles

del lado de la

!??apul~. [8.25 cm]

3. Paneles laterales

5

el panel lateral se instala

dentro de la moldura lateral y si

el panel tiene un grosor mayor a

l/4 pulg. [6 mm], pase el tupi sobre

el filo frontal del panel para fijar la moldura.

Corte del filo del panel latera

1/16pul +

(1.5 mm

3

Ancho y altura

depende del tipo

de instalacih

Crosor

l/2 pulg [12 mm]

minim0 para

prevenir

deformidades

Dimensiones para

tupir 10s filos

del panel

Dimensiones para

tupir

filbs del pan<1

314

pul

(19 mm

min.

Panel

f I/4

3

(6

mm) max.

pulg

7132

pul

(5.5 mm

Moldura interior

del panel lateral

Moldura exterior ahuecada

7

13/32 pulg (10 mm)

del panel lateral

Moldura exterior

del panel lateral

Tira de sopotte

Ranura para el

list6n del z6calo

[si se desea] \

Determinar la altura

antes

de efectuar 10s

tortes

I

.

LB-

;--c-;

v

Corte lateral

Mode'o (91

A

B

C

36

36

pulg

(91

35-l/2

(90cm)

35

pulg

(89

pulg

cm)

cm)

cm)

pulg

42

(106

42

(106

41-l/2

(105

41

(104

pulg

cm)

pulg

cm)

cm)

pulg

cm)

pulg

48

(122

40

(122

47-l/2

(120

47

(119

pulg

cm)

pulg

cm)

pulg

cm)

pulg

cm)

Pigina 6

Conexiones Ektricas

Peligro de choque electric0

l

Esta unidad requiere conexion a

tierra

9 Si la tuberia de agua fria se

encuentra cubierta por material

plastico, sell0 no-medlicos u otro

tipo de aislamiento, NO UTILIZAR

corn0 tierra.

l

No utilizar la tuberia de gas coma

tierra.

l

No modificar el alambre electric0 de

la unidad. Si este no se adapta al

enchufe, cambie el enchufe con la