TECHNICAL EDUCATION

KAR-15

BUILT-IN SIDE-BY-SIDE

REFRIGERATOR WITH VARIABLE

CAPACITY COMPRESSOR

2003 M MODEL

JOB AID 4317344

FORWARD

This KitchenAid Job Aid, “2003 M Model Built-In Side-By-Side Refrigerator With Variable Capacity

Compressor” (Part No. 4317344), provides the technician with information on the installation,

operation, and service of the Built-In Side-By-Side Refrigerator. It is to be used as a training Job

Aid and Service Manual. For specific information on the model being serviced, refer to the “Use

and Care Guide,” or “Tech Sheet” provided with the refrigerator.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Built-In Side-By-Side Refrigerator.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the refrigerator to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2003, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

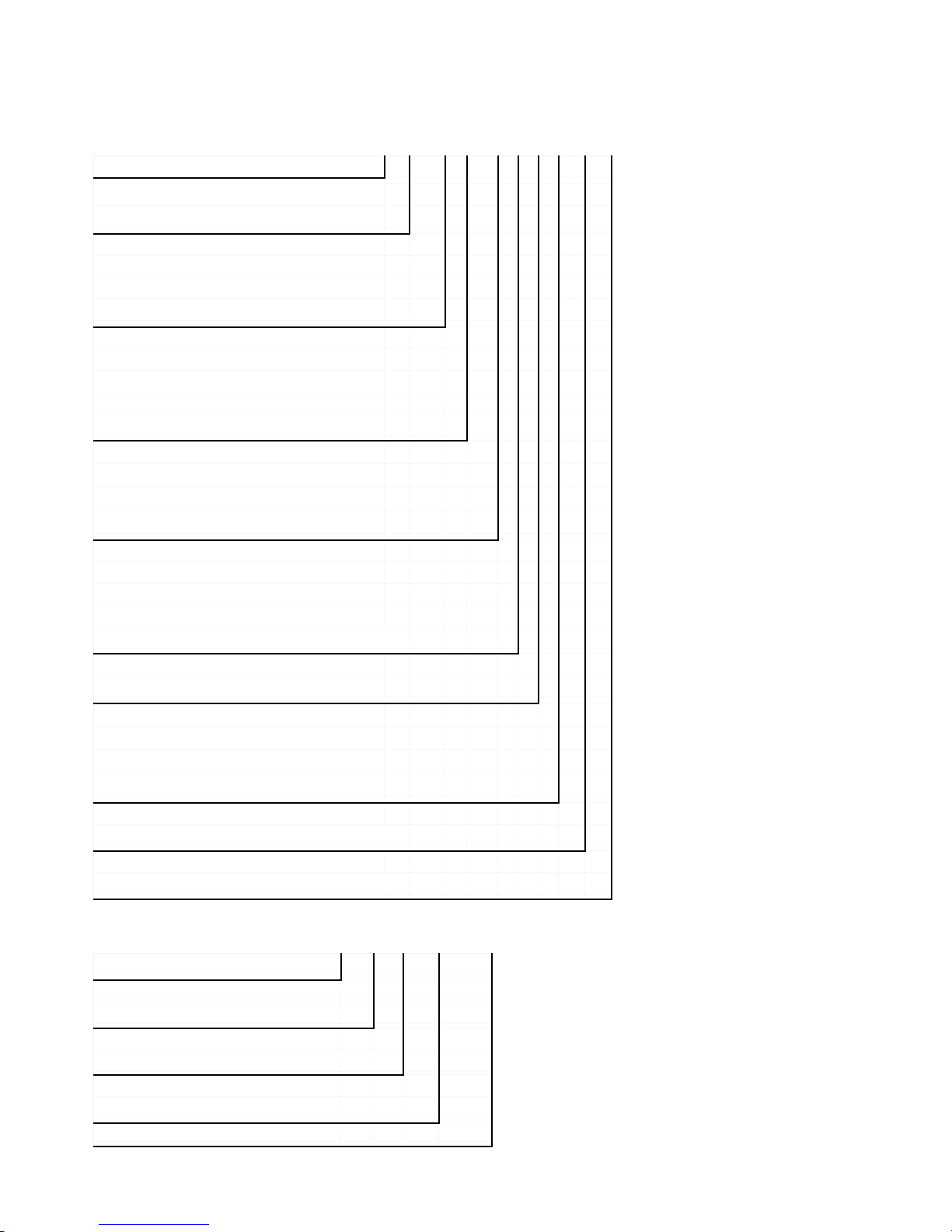

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

Model & Serial Number Designations ................................................................................ 1-3

Model & Serial Number Label And Tech Sheet Locations................................................. 1-4

KitchenAid Built-In Refrigerator Warranty .......................................................................... 1-5

INSTALLATION INFORMATION ........................................................................................... 2-1

THEORY OF OPERATION ..................................................................................................... 3-1

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing A Door Switch And The Power Switch ............................................................. 4-2

Removing The Inverter Assembly...................................................................................... 4-4

Removing The Condenser Fan Motor ............................................................................... 4-6

Removing The Ice Maker Inlet Heated Fill Tube ............................................................... 4-8

Removing The Main Control Board Assembly ................................................................... 4-9

Removing The Electronic Meat Pan Power Supply Board .............................................. 4-10

Removing The Compressor And Filter/Drier.................................................................... 4-12

Removing The Bimetal, The Evaporator Fan Motor,

The Defrost Heater, And The Evaporator ..................................................................... 4-14

Removing The Touch And Display Boards & The Motorized Air Door ............................ 4-18

Removing The Meat Pan Air Baffle & Thermistor, The Air Supply

Thermistor, And The Meat Pan Electronic Touch Control Assembly.......................... 4-20

Removing A Thermistor ................................................................................................... 4-23

Removing The Ice Maker, The Emitter, And The Receiver ............................................. 4-24

Removing The Auger Motor............................................................................................. 4-26

Removing The Water Reservoir And Water Valve .......................................................... 4-28

Removing A Light Socket ................................................................................................ 4-30

Removing The Water & Ice Dispenser ............................................................................ 4-31

Removing A Door ............................................................................................................ 4-34

COMPONENT TESTING ........................................................................................................ 5-1

Thermistor.......................................................................................................................... 5-1

Evaporator Fan Motor ........................................................................................................ 5-2

Condenser Fan Motor ........................................................................................................ 5-2

Compressor & Inverter....................................................................................................... 5-3

Motorized Air Door ............................................................................................................. 5-4

Defrost Heater & Bimetal ................................................................................................... 5-4

Main Control Board ............................................................................................................ 5-5

Power Switch ..................................................................................................................... 5-6

Door Switch ....................................................................................................................... 5-6

Air Supply Thermistor ........................................................................................................ 5-7

Water Valve Solenoid ........................................................................................................ 5-7

Checking The Auger Motor ................................................................................................ 5-8

Ice Maker Inlet Heated Fill Tube ...................................................................................... 5-10

Meat Pan Air Baffle Motor And Thermistor ...................................................................... 5-10

- iii -

Page

DIAGNOSTICS & TROUBLESHOOTING .............................................................................. 6-1

Diagnostics ........................................................................................................................ 6-1

Pre-Diagnostics Checks ................................................................................................. 6-1

Diagnostics Mode ........................................................................................................... 6-1

Service Diagnostics Mode Chart .................................................................................... 6-2

Water Filter Input (WFI) Test .......................................................................................... 6-2

Electronic Temperature-Controlled Meat Pan Diagnostics ............................................. 6-3

Troubleshooting Chart ....................................................................................................... 6-4

WIRING DIAGRAMS & STRIP CIRCUITS ............................................................................. 7-1

SXS Non Dispenser Wiring Diagram ................................................................................. 7-1

SXS Dispenser Wiring Diagram......................................................................................... 7-2

Bottom Mount Wiring Diagram........................................................................................... 7-3

Main Control Board Block Diagram ................................................................................... 7-4

Electronic Temperature-Controlled Meat Pan Diagram ..................................................... 7-5

SXS Tubing Joint Diagram ................................................................................................ 7-6

Bottom Mount Tubing Joint Diagram ................................................................................. 7-7

Strip Circuits ...................................................................................................................... 7-8

TECH TIPS ............................................................................................................................. 8-1

Servicing The Ice Bin Auger Assembly.............................................................................. 8-1

- iv -

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

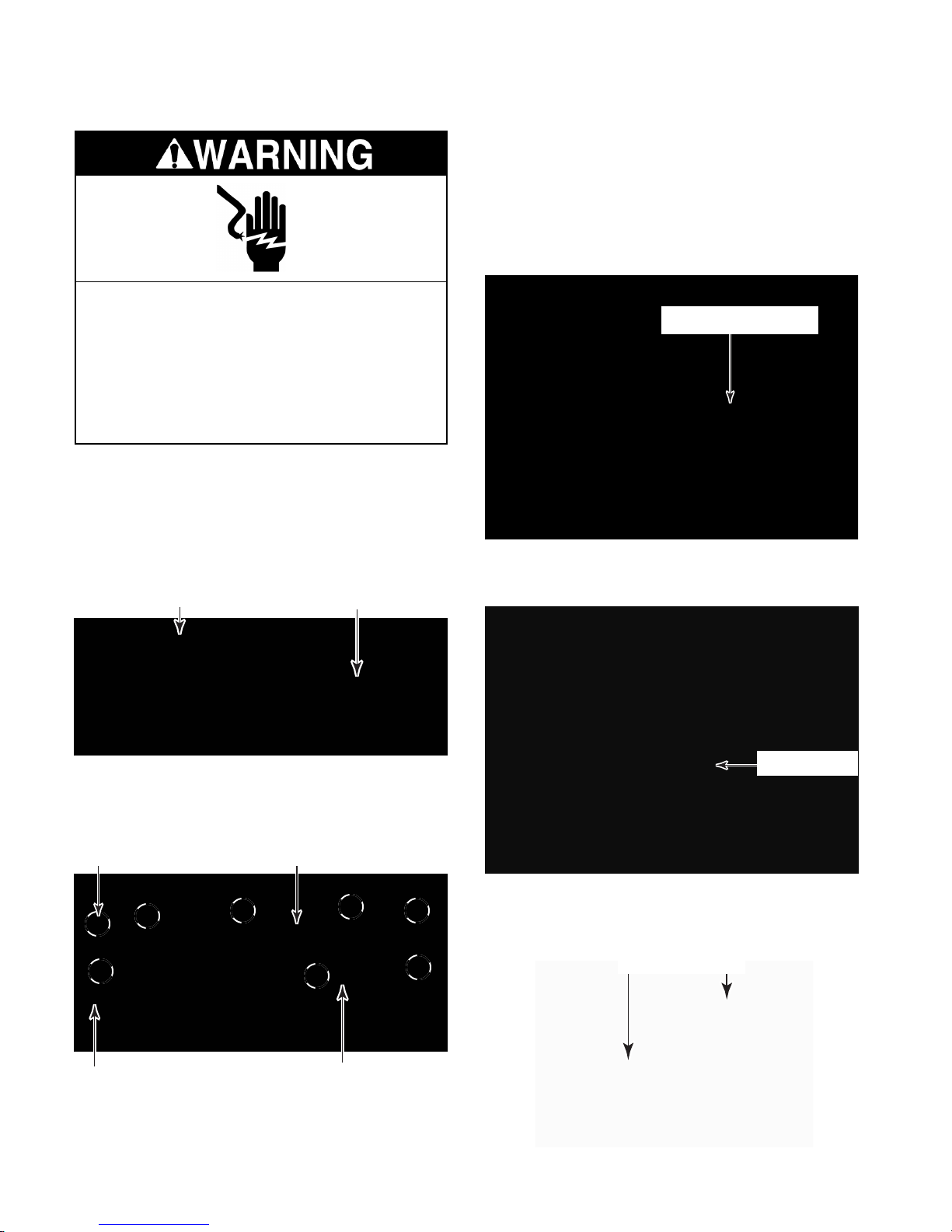

ELECTRICAL POWER SUPPLY &

GROUNDING REQUIREMENTS

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1-1

Electrical Shock Hazard

ELECTROSTATIC DISCHARGE

(ESD) SENSITIVE ELECTRONICS

ESD problems are present everywhere. ESD

may damage or weaken the electronic control

assembly. The new control assembly may appear to work well after repair is finished, but

failure may occur at a later date due to ESD

stress.

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

ANTI-TIP

REQUIREMENTS

Tip Over Hazard

Refrigerator is top heavy and tips easily

when not completely installed.

Keep doors taped closed until refrigerator is completely installed.

• Use an antistatic wrist strap. Connect the

wrist strap to a green ground connection

point or unpainted metal in the appliance; or

touch your finger repeatedly to a green ground

connection point or unpainted metal in the

appliance.

• Before removing the part from its package,

touch the antistatic bag to a green ground

connection point or unpainted metal in the

appliance.

• Avoid touching electronic parts or terminal

contacts. Handle the electronic control assembly by the edges only.

• When repackaging the failed electronic control assembly in an antistatic bag, observe

the above instructions.

Use two or more people to move and

install refrigerator.

Failure do so can result in death or

serious injury.

1-2

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K SS S 4 2 Q M X 0 0

PRODUCT GROUP

K = KitchenAid Brand

PRODUCT IDENTIFICATION

BR = Bottom Mount Right Hand Hinge

BL = Bottom Mount Left Hand Hinge

SS = Side-By-Side Built-In

MERCHANDISING SCHEME/SERIES

C = Wrap Around Stainless Steel

P = Factory Installed Panel Kit

S = Framed Trim Kit (Panels Not Included)

V = VBL Pro Line Series

CAPACITY/ SIZE

36 = 36″ Width

42 = 42″ Width

48 = 48″ Width

FEATURES

D = Ice & Water Dispensing

F = Factory Installed Ice Maker w/Filter

M = Factory Installed Ice Maker wo/Filter

Q = Ice/Crushed Ice & Water Dispensing w/Filter

YEAR OF INTRODUCTION

M = 2003

COLOR CODE

S = Stainless

M = Meteorite

X = No Color Used

ENERGY POWER CONSUMPTION CHANGE

0 = Original, 1 = 1st Change, 2 = 2nd Change, Etc.

ENGINEERING CHANGE (NUMERIC)

0 = Original, 1 = 1st Change, 2 = 2nd Change, Etc.

SERIAL NUMBER

SERIAL NUMBER Q P 30 10003

MANUFACTURING SITE

Q = LaVergne, TN

YEAR OF PRODUCTION

P = 2003

WEEK OF PRODUCTION

30th WEEK

PRODUCT SEQUENCE NUMBER

1-3

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number Label and Tech Sheet locations are shown below.

Model & Serial Number Location

(Refrigerator Compartment)

Tech Sheet Location

(On Unit Compartment Cover)

1-4

KITCHENAID® BUILT-IN REFRIGERATOR WARRANTY

TWO-YEAR FULL WARRANTY

For two years from the date of purchase, when this refrigerator (excluding the water filter cartridges) is operated

and maintained according to instructions attached to or furnished with the product, KitchenAid will pay for factory

specified replacement parts and repair labor costs to correct defects in materials or workmanship. Service must

be provided by a KitchenAid designated service company.

Water filter cartridge: 30 day limited warranty on water filter. For 30 days from the date of purchase, when this

filter is operated and maintained according to instructions attached to or furnished with the product, KitchenAid

will pay for replacement parts to correct defects in materials and workmanship.

THIRD THROUGH SIXTH YEAR FULL WARRANTY ON

SEALED REFRIGERATION SYSTEM PARTS AS LISTED

In the third through sixth years from the date of purchase, when this refrigerator is operated and maintained according to instructions attached to or furnished with the product, KitchenAid will pay for factory specified replacement parts and repair labor costs to correct defects in materials or workmanship in the sealed refrigeration system. These parts are: compressor, evaporator, condenser, dryer, and connecting tubing. Service must be performed by a KitchenAid designated service company.

SEVENTH THROUGH TWELFTH YEAR LIMITED

WARRANTY ON SEALED REFRIGERATION SYSTEM

In the seventh through twelfth years from date of purchase, when this refrigerator is operated and maintained

according to instructions attached to or furnished with the product, KitchenAid will pay for factory specified replacement parts to correct defects in materials or workmanship in the sealed refrigeration system. These parts

are: compressor, evaporator, condenser, dryer, and connecting tubing.

LIFETIME LIMITED WARRANTY ON DOOR BINS

For the life of the product, when this refrigerator is operated and maintained according to instructions attached to

or furnished with the product, KitchenAid will replace all Door Bins due to defective materials or workmanship.

KitchenAid will not pay for:

1. Service calls to correct the installation of your refrigerator, to instruct you how to use your refrigerator, to replace house fuses or correct house wiring or plumbing, to replace light bulbs, or to replace water filters other

than as noted above.

2. Repairs when your refrigerator is used in other than normal, single-family household use.

3. Pickup and delivery. Your refrigerator is designed to be repaired in the home.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, improper installation, acts of God, or

use of products not approved by KitchenAid, or KitchenAid Canada.

5. Any food or medicine loss due to product failure.

6. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

7. Removal and replacement of trim or decorative panels that interfere with servicing the product.

8. Labor or parts installed by any non-designated service company during the full warranty period, unless approved by KitchenAid before service is performed.

9. In Canada, travel or transportation expenses for customers who reside in remote areas.

10. Any labor costs during the limited warranty periods.

KITCHENAID AND KITCHENAID CANADA SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states or provinces do not allow the exclusion or limitation of incidental or consequential damages, so this

exclusion or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state-to-state, or province-to-province.

Outside the 50 United States and Canada, a different warranty may apply. Contact your authorized KitchenAid

dealer to determine if another warranty applies.

If you need service, first see the “Troubleshooting” section of the Use and Care Guide. After checking “Troubleshooting,” additional help can be found by checking the “Assistance or Service” section, or by calling the

KitchenAid Customer Interaction Center, 1-800-422-1230 (toll-free), from anywhere in the U.S.A. In Canada,

contact your designated KitchenAid Canada service company, or call 1-800-807-6777.

1-5

— NOTES —

1-6

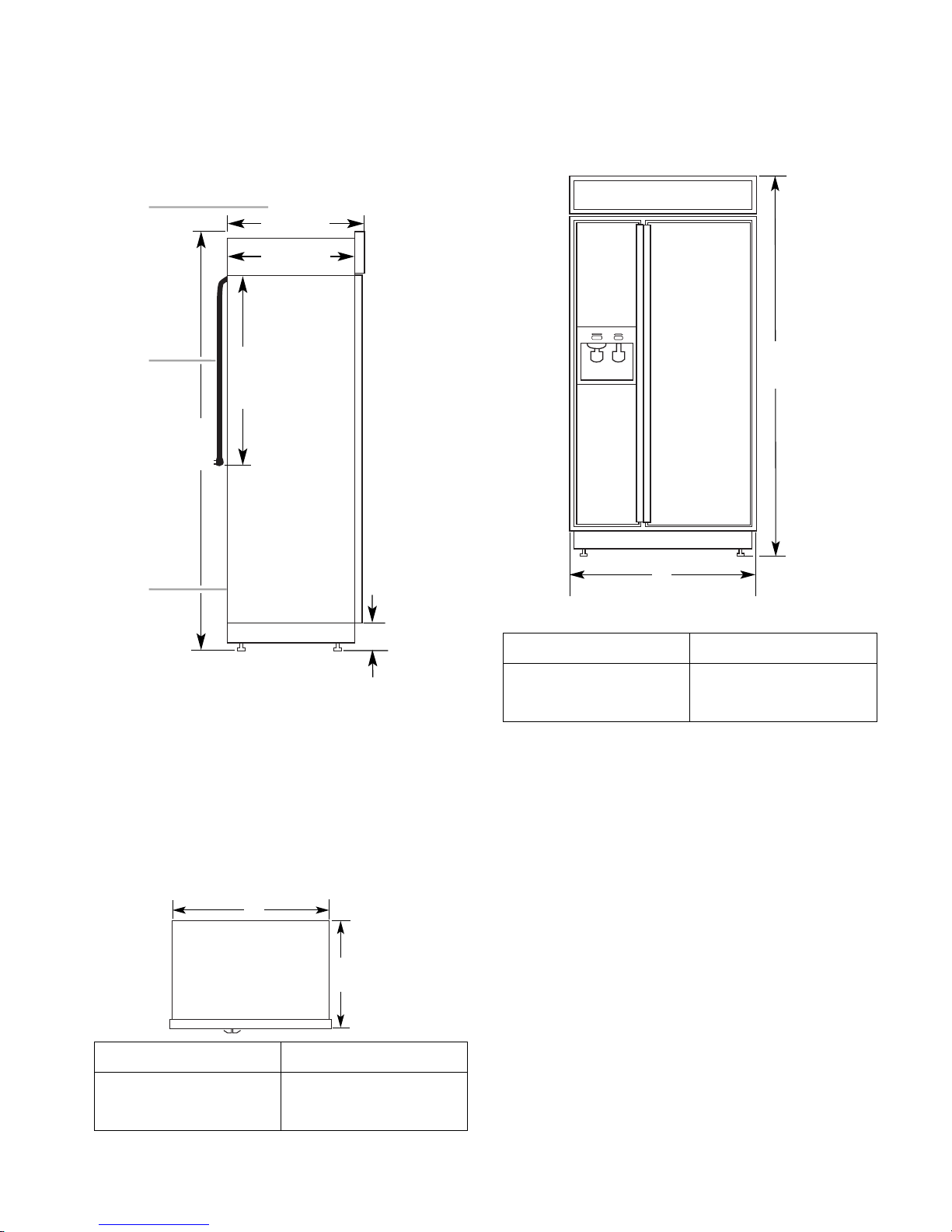

INSTALLATION INFORMATION

831/

8

"

(211 cm)

A

(see chart following)

Width of Refrigerator

36" (91 cm)

42

"

(106 cm)

48

"

(122 cm)

36-1/4

"

(92 cm)

42-1/4

"

(107 cm)

48-1/4

"

(123 cm)

Model Width A (as shown above)

PRODUCT DIMENSIONS

Side View

1

2

831/8"

(211 cm)*

3

251/8"

(64 cm)

231/2"

(60 cm)

24"

(61 cm)

Power Cord

Front View

NOTE: (*) Dimensions shown are for leg levelers extended 1/8″ (3 mm) below the rollers. For

levelers fully extended 1-1/4″ (32 mm) below

the rollers, add 1-1/8″ (29 mm) to this dimension.

Top View

Model Width A

36" (91 cm)

42

"

(106 cm)

"

(122 cm)

48

1

/2" (9 cm)*

3

1. 25-1/8" (64 cm) dimension is to front of top grille

2. Power cord (24") (61 cm)

3. 5 ft. (1.5 m) water line tubing taped to back

A

25-1/8"

(64 cm)

35

"

(89 cm)

41

"

(104 cm)

"

(119 cm)

47

NOTE: The width dimensions shown represent

the distance from outside trim to outside trim.

2-1

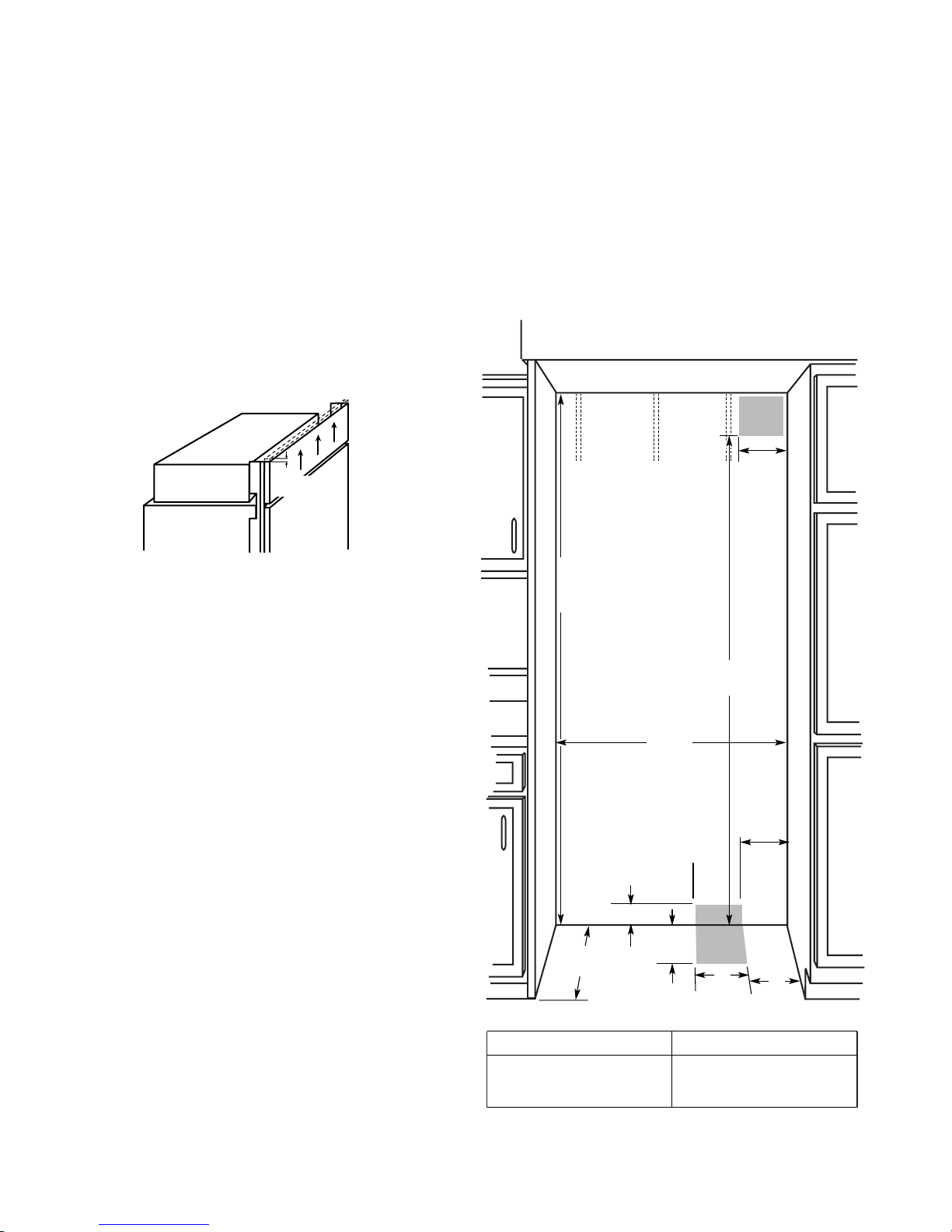

Opening Dimensions

(

)

Model

Width A (as shown above)

36 in. (91.4 cm)

42 in. (106.7 cm)

48 in. (121.9 cm)

35-1/2 in. (90.2 cm)

41-1/2 in. (105.4 cm)

47-1/2 in. (120.7 cm)

The solid soffit must be within 1″ (2.5 cm)

maximum above the refrigerator. If the solid

soffit is higher than 1″ (2.5 cm) or one is not

available, then the refrigerator must be braced

to prevent tipping during use.

If the anti-tip boards are needed, they must be

attached to the rear wall studs 80″ to 90″ (203

- 229 cm) above the floor (see “Install Anti-Tip

Boards” for more information).

NOTE: A clearance of 1/2″ (1.3 cm) must be

maintained above the top grille in order for the

top grille to be removed.

1

/

2"

(1.3 cm)

A grounded 3 prong electrical outlet should be

placed within 4″ (10.2 cm) of the right side

cabinets or end panel.

The water shutoff should be located in the base

cabinet on either side of the refrigerator or

some other easily accessible area. If the water

shutoff valve is not in the cabinets, the plumbing for the water line can come through the floor

or the back wall (see “Water Supply Requirements” for more information).

80" - 90"

(203-229 cm)

4"

(10.2 cm)

831/4" (211.5 cm) min.

3

84

/4" (215 cm) max.

to bottom of solid soffit

Width

(see chart following)

3" (7.6 cm)

231/2"

(60 cm) min.

(28 cm)

A

11"

77"

(196 cm)

6"

(15.2 cm)

6"

(15.2 cm)

6"

15.2 cm

2-2

WATER SUPPLY REQUIREMENTS

r

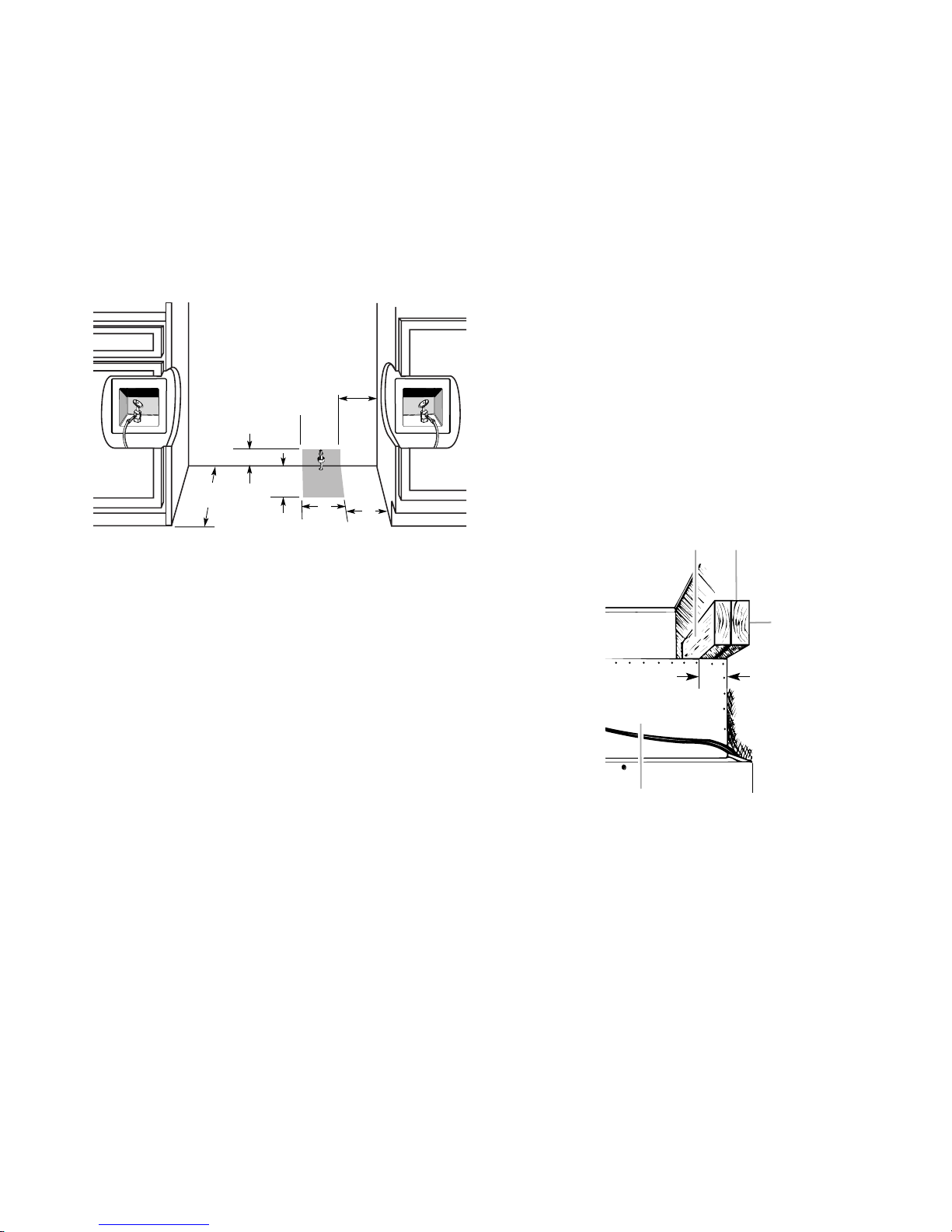

ANTI-TIP BOARDS

All installations must meet local plumbing code

requirements.

The water shutoff should be located in the base

cabinet on either side of the refrigerator or

some other easily accessible area. The righthand side is recommended. The access hole

through the right-hand side cabinet must be

within 1/2″ (12.7 mm) of the rear wall.

6"

(15.2 cm)

3" (7.6 cm)

11"

231/2"

(60 cm) m in.

(28 cm)

6"

(15.2 cm)

6"

(15.2 cm)

If the water shutoff valve is not in the cabinets,

the plumbing for the water line can come through

the floor or the back wall. A 1/2″ (12.7 mm) hole

for plumbing should be drilled 6″ (15.2 cm) to

12″ (30.4 cm) from the right-hand side cabinet

or panel. On the floor, the hole should be no

more than 11″ (28 cm) away from the back wall.

On the wall, the hole should be no more than 3″

(7.6 cm) up from the floor.

IMPORTANT:

• The solid soffit must be within 1″ (2.5 cm)

maximum above the refrigerator. If the solid

soffit is higher than 1″ (2.5 cm), or one is not

available, prevent the refrigerator from tipping during use, as shown.

• It is recommended that the boards be installed before the refrigerator is installed.

• Boards must be long enough to fully cover

the width of the compressor cover.

• Locate the boards so the bottom surface of

the boards are 84″ (213 cm) from the floor.

• During installation, raise the refrigerator up

so there is 1/4″ (6.4 mm) maximum between

the top of the refrigerator and the bottom of

the anti-tip boards. Do not crush the condenser cover when raising the rear leveling

legs.

21

3

2" (5 cm)

If this recommended water line location is

used, no additional plumbing must be purchased. If additional tubing is needed, use

copper tubing and check for leaks. Install the

copper tubing only in areas where the household temperatures will remain above freezing.

Do not use a piercing-type or 3/16″ (4.76 mm)

saddle valve, which reduces water flow and

clogs more easily. NOTE: Any refrigerator

dealer has a kit available with a 1/4″ (6.35 mm)

saddle-type shutoff valve, a union, and copper

tubing. Before purchasing, make sure a saddletype valve complies with your local plumbing

codes.

Cold Water Supply

Connect the ice maker to a cold water line with

water pressure between 15 and 100 psi (103 690 kPa).

4

1. Center board 1/4" (6 mm) max. above refrigerato

2. Two 2" x 4" x 32" (5 cm x 10 cm x 81 cm) boards

3. Attach to studs with 6-#8 x 3" (7.6 cm) screws

4. Compressor cover

To Install The Anti-Tip Boards:

1. Mark the stud locations on the rear wall

80″ to 90″ (203 - 229 cm) above the floor.

2. Securely attach one or two 2″ x 4″ x 32″

(5 cm x 10 cm x 81 cm) wood boards to the

wall studs behind the refrigerator. Use six

#8 x 3″ (7.6 cm) or longer wood screws.

The wood screws must be screwed into

the studs at least 1-1/2″ (3.8 cm). The

boards must overlap the compressor cover.

2-3

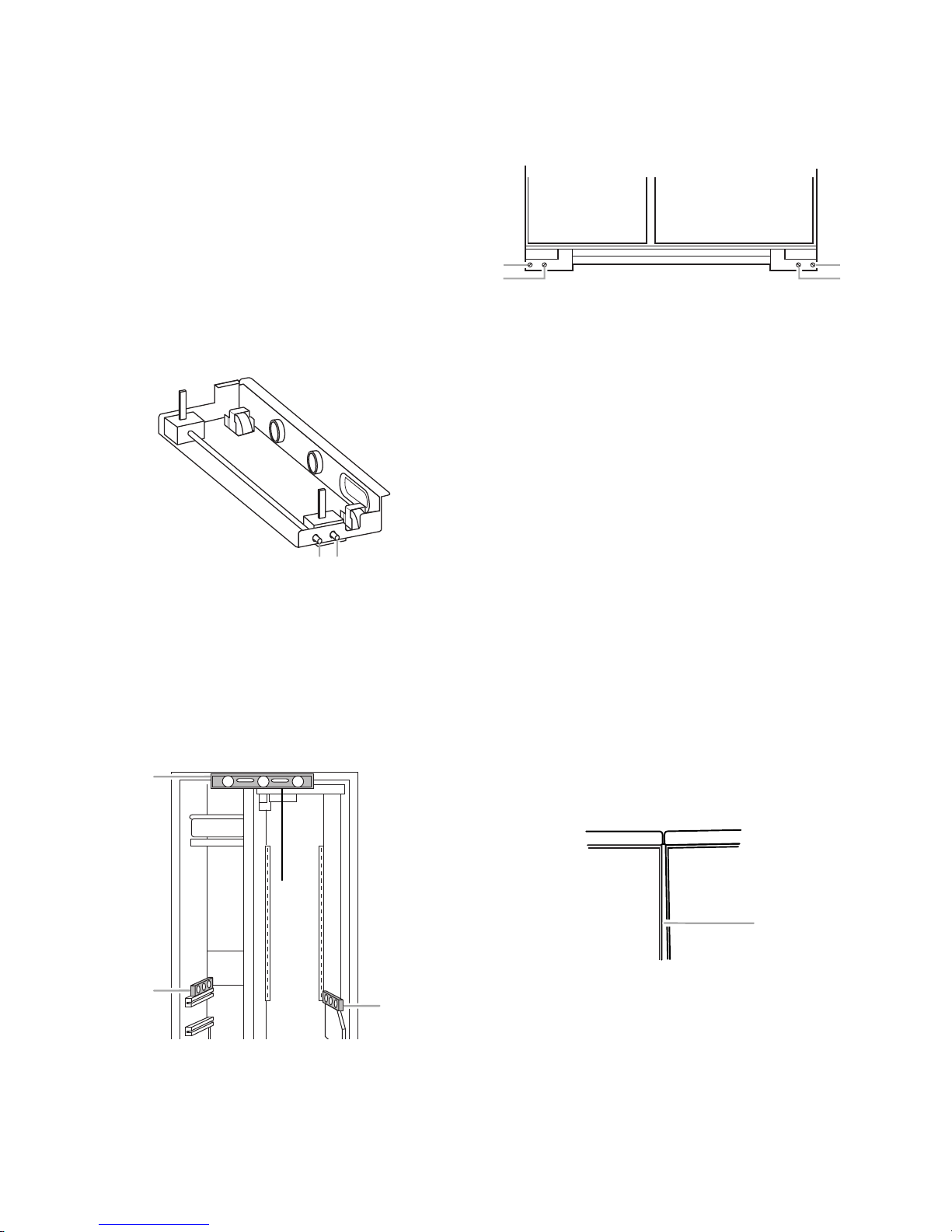

LOWERING THE LEVELING LEGS

All four leveling legs must contact the floor to

support and stabilize the full weight of the

refrigerator. Rollers are for moving the refrigerator, and not for permanent support.

Use a socket wrench to turn the leg levelers on

both sides of the refrigerator to the right (clockwise) until the refrigerator weight is supported

by the legs. The rollers should be off the floor.

To avoid cabinet damage, do not apply more

than 50 in/lbs (58 cm/kg) of torque to the

leveling legs.

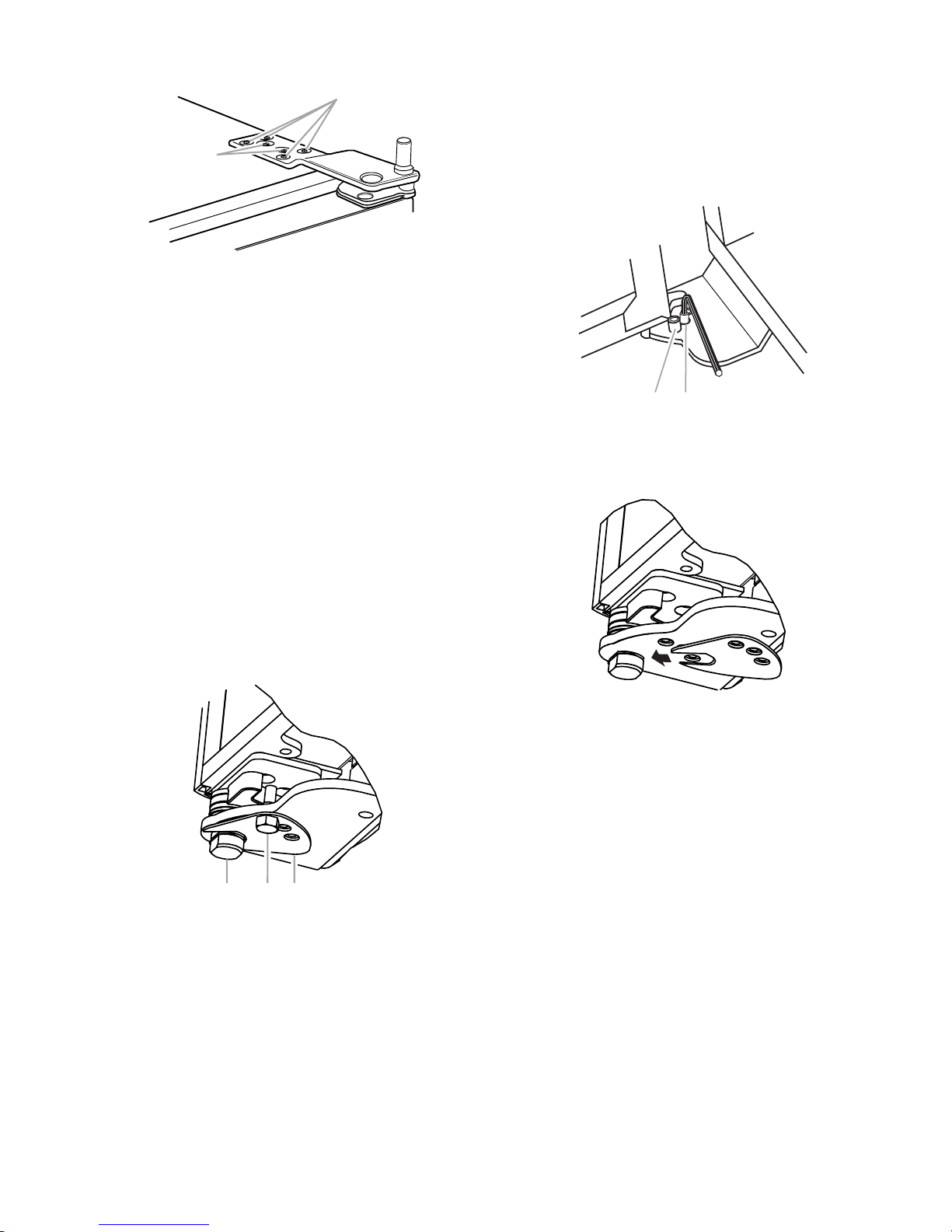

1. Rear leveling legs

2. Front leveling legs

1 2

LEVELING THE REFRIGERATOR

NOTE: Door panels must be installed before

leveling.

1. Open the doors and place a level on top of

the refrigerator frame. Check to see if the

refrigerator is level from left to right.

1

2. Use the leveling bolts to adjust the leveling

legs until the refrigerator is level from left

to right.

1

2

1. Rear leveling bolt

2. Front leveling bolt

1

2

3. Place a level on the shelves and check to

see if the refrigerator is level from front to

back.

4. Use the leveling bolts to adjust the leveling

legs until the refrigerator is level from front

to back.

5. Make sure that all four leveling legs contact the floor and support the full weight of

the refrigerator.

6. Make a final check to see that the refrigerator is level.

ADJUSTING THE DOORS

Door Alignment

Use the following steps to adjust the door

alignment to the left, right, in, or out.

1. Inspect the spacing of the gap between

the freezer and refrigerator doors. Make

sure that the spacing between the doors is

the same distance at the top and bottom.

2

1. Level to check left to right leveling

2. Level to check front to back leveling

1

1. Uneven door gap

2

2. If the door gap is uneven, loosen the four

T27 flat-head mounting screws on top of

both hinges. Loosen the screws to the

point that the hinge is movable, but there

is friction when trying to move the hinge.

NOTE: Do not loosen the two 1/4″ hexhead mounting screws.

2-4

1

2

1. T27 flat-head mounting screws

2. 1/4 in. hex-head mounting screws

3. Adjust the hinges so that the door gap is

the same distance at the top and bottom.

The bottom distance should be used as a

template for the top.

4. Tighten the screws on both hinges.

Door Height Adjustment

Overlay Models

Remove the two door stop screws: one

from the bottom side using a 3/8″ openend wrench, and one from the top side

using an Allen wrench.

12

1. Door stop screw from bottom

2. Door stop screw from top

Use the following steps to adjust the door

height up or down after the doors have been

leveled.

1. Open the freezer or refrigerator door and

locate the hinge assembly at the bottom of

the door, and remove the stop screw.

Classic & Architect® Models

Remove the door stop screw from the

bottom side of the hinge.

123

1. Locking plate

2. Door stop screw

3. Bushing

2. Remove the locking plate, as shown.

3. Turn the bushing located underneath the

bottom of the hinge using the open-end

wrench. Turning the bushing to the left

(counterclockwise) will raise the door.

Turning the bushing right (clockwise) will

lower the door.

4. After adjusting, check the doors to make

sure they are even at the top and bottom.

If the doors are not even, continue to turn

the bushing to adjust the door height.

5. Replace the locking plate.

6. Turn the bushing slightly to align the hinge

and locking plate screw holes.

7. Replace the door stop screw or screws

and tighten.

8. Make final recheck to make sure the doors

are aligned and even.

2-5

Door Swing Adjustment

1. Open the refrigerator and freezer doors

and make sure that they open freely. If a

door opens too wide, remove the door

stop screw(s) from the bottom hinge.

2. Hold the door open to a position that is less

than 90°.

3. Replace the door stop screw(s) in the

bottom hinge and tighten.

12 3

1. 130

°

2. 110

°

3. 90

°

2-6

THEORY OF OPERATION

Warmer

Power

On/Off

Colder

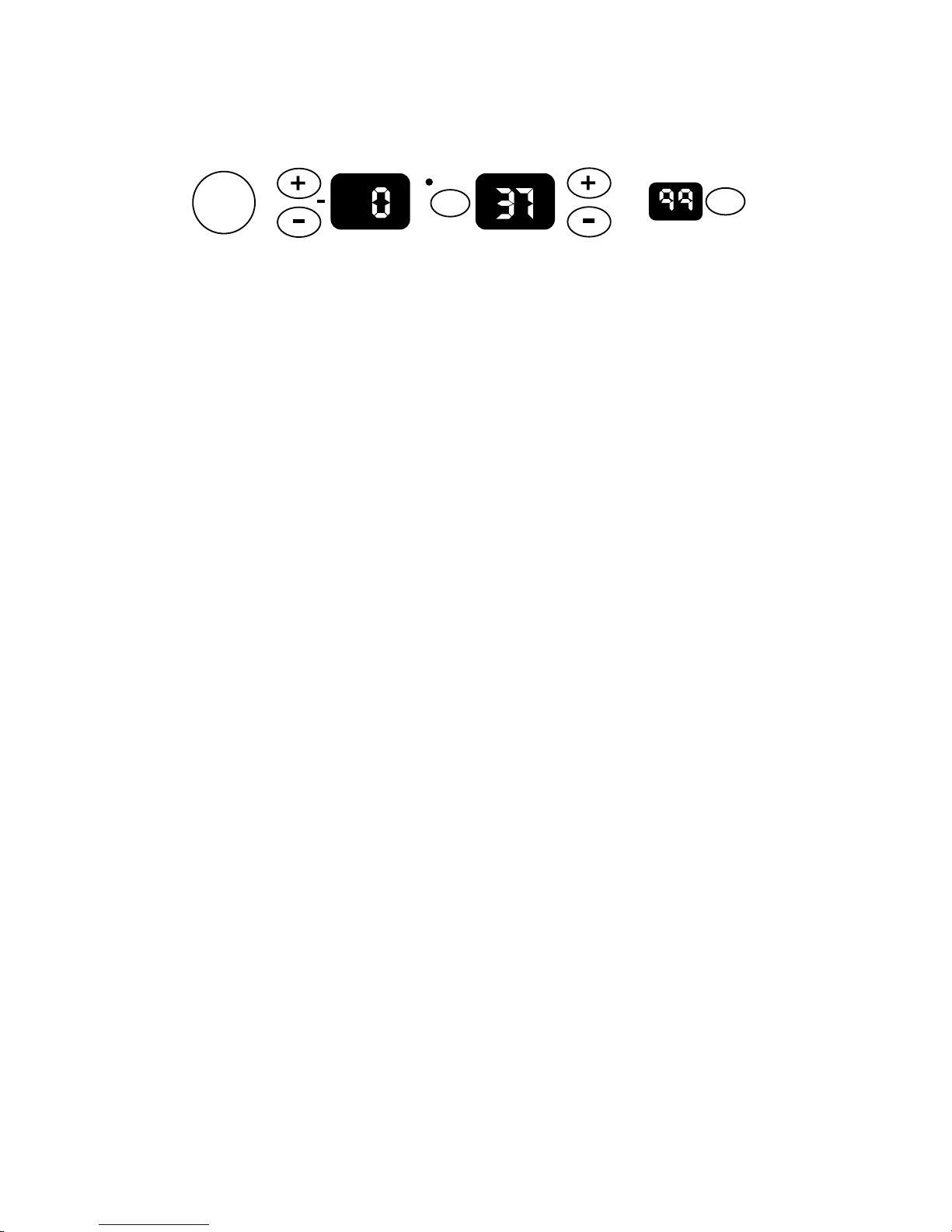

THE ELECTRONIC TEMPERATURE CONTROL PANEL

FREEZER REFRIGERATOR

°C

SELECT

OVERVIEW

The KitchenAid Built-In Refrigerator Constant

Flow Temperature Management System uses

two thermistors to monitor temperature changes

inside the refrigerator and freezer compartments. The electronic control manages the

operation of the variable capacity compressor

(VCC), a variable speed evaporator fan motor,

and a variable position air door. The air door

allows independent temperature control of the

refrigerator and freezer compartments.

The electronic control seeks the most efficient

means possible to maintain temperatures as it

controls the operation and speed of the compressor and the evaporator fan motor. Higher

fan speed is used before increasing the compressor speed to minimize power consumption. A nearly constant run time is sought at the

lowest possible fan and compressor speed.

Freezer temperatures can be set from 6°F to

–5°F (–14°C to –21°C). Refrigerator temperatures can be set from 46°F to 34°F, (8°C to

1°C).

The Adaptive Defrost Control (ADC) portion of

the electronic control utilizes “pulsed defrost”

technology to perform the defrost function (see

page 3-4).

Warmer

WATER FILTER

RESET

PERCENT LEFT

Colder

The electronic control monitors the water valve

for total elapsed time and gallons of water

used. The number displayed on the Water

Filter Indicator (WFI) is the percentage of filter

usage remaining.

The numeric display can be set for Fahrenheit

or Celsius and displays the actual temperatures. The display range for the refrigerator is

from 27° to 70°F (–2.8°C to 21°C). The normal

freezer display range is from –5°F to 70°F

(–21°C to 21°C). Temperatures above or below these limits will be displayed at the corresponding temperature limit. During Max Cool,

the freezer display will read –5°F (–21°C), and

the refrigerator will read 34°F (1°C).

The display will show the temperature setting

any time the actual temperature is within ±6°F

of the customer setting. This will prevent concern over temperature fluctuations when the

doors are opened. Press the temperature adjustment key to view the current temperature

setting, or to change the setting. When the

temperature adjustment key is used to change

the temperature setting, the display will brighten

for 5 seconds.

Available features include:

• Water Filter Indicator

• Max Cool

• Over-Temperature Alarm

• Holiday Mode

3-1

TEMPERATURE CONTROL

The electronic control checks the resistance of

the thermistors, and compares it to both the

customer temperature settings and the last

thermistor reading taken. This information is

used to determine when to begin a cooling

operation, and if a change is necessary in the

damper setting, or the evaporator fan or compressor speed.

When a warm refrigerator is first put into a

cooling mode, the air door partially opens, and

the compressor and evaporator fan motors

start to run at maximum rpm. The air door will

gradually move to its fully open position.

As the actual temperature in the refrigerator

nears the selected temperature setting, the

electronic control compares the temperatures

in both compartments. The compartment that

has the greatest need for cooling, will control

the speed of the evaporator fan motor.

Freezer Temperature Control —

Temperature Increasing

When the freezer calls for cooling, the compressor begins to run at minimum rpm, (see the

chart on page 3-3), and the evaporator fan

begins to run at 2000 rpm. The compressor

and evaporator speeds are continuously updated. Speed changes are made based on:

• The difference between the actual temperature and the selected temperature settings.

• The rate of temperature change.

If the temperature increases 4°F above the

selected temperature setting, the evaporator

fan speed begins to gradually increase. The

evaporator fan motor reaches the maximum

speed of 3000 rpm at 5°F above the selected

temperature setting, and the compressor speed

begins to gradually increase. A maximum compressor speed of 4500 rpm will be reached at

9°F above the selected temperature setting.

Freezer Temperature Control —

Temperature Decreasing

When the freezer temperature begins to decrease, the process will reverse. The compressor speed decreases, followed by the evaporator fan speed.

Refrigerator Temperature Control —

Temperature Increasing

When the refrigerator calls for cooling while

the freezer is satisfied, the air door begins to

open, and the evaporator fan starts to run at

minimum speed. If the temperature continues

to rise, the air door will continue to open. If the

temperature continues to rise after the air door

is fully open, the evaporator fan speed will

gradually increase to a maximum of 3000 rpm.

If the temperature continues to rise, the compressor starts to run, or if it has already been

running, begins to increase in speed.

Refrigerator Temperature Control —

Temperature Decreasing

As the refrigerator temperature approaches the

selected setting, the control compares the temperatures in both compartments to determine

which compartment will control the fan speed.

If the freezer is further from the selected temperature setting, it controls the fan speed, and

the air door begins to close, thus reducing the

airflow to the refrigerator.

If the freezer is satisfied, the air door remains

open, and the fan speed begins to decrease.

When the selected temperature setting is

reached, the air door closes.

3-2

COMPRESSOR

COMPRESSOR PROTECTION

The main control board supplies a 5 vdc, peakto-peak square wave, at 54 to 150 Hz, to the

inverter board. A standard VOM will read approximately 2.5 vdc. The inverter board supplies the variable capacity compressor with

three-phase 230 vac. Varying the frequency

to the inverter board, and not the voltage,

changes the speed of the compressor. The

compressor can run at speeds of 1620 to 4500

rpm.

NOTE: It is not necessary, nor is it recommended, to test the output of the inverter board.

While the compressor is running, its speed is

continuously updated. Speed is determined

after analyzing two factors:

• The difference between the actual tempera-

ture and the selected temperature settings.

• The rate of temperature change.

Minimum compressor speed is based on the

freezer’s selected temperature setting, as

shown in the following chart.

To protect the compressor and maintain efficiency, minimum compressor off time is programmed into the main control board. When

the compressor turns off, a minimum of 7 minutes must elapse before allowing a restart.

At the end of the 7 minute period, the condenser fan motor starts, and the main control

board sends the compressor speed signal to

the inverter. The compressor will not start for

an additional minute, due to the inverter delay.

The inverter board utilizes a current limiting

device and thermal protection that eliminates

the need for a compressor-mounted thermal

protector. The inverter will not allow a compressor restart for 8 minutes after the compressor

turns off. This inverter delay will not occur after a power interruption, because inverter

memory is lost (see “Power Interruption” on

page 3-4).

EVAPORATOR FAN MOTOR

The evaporator fan motor is a 12 vdc, variable

speed motor. The motor has four wires:

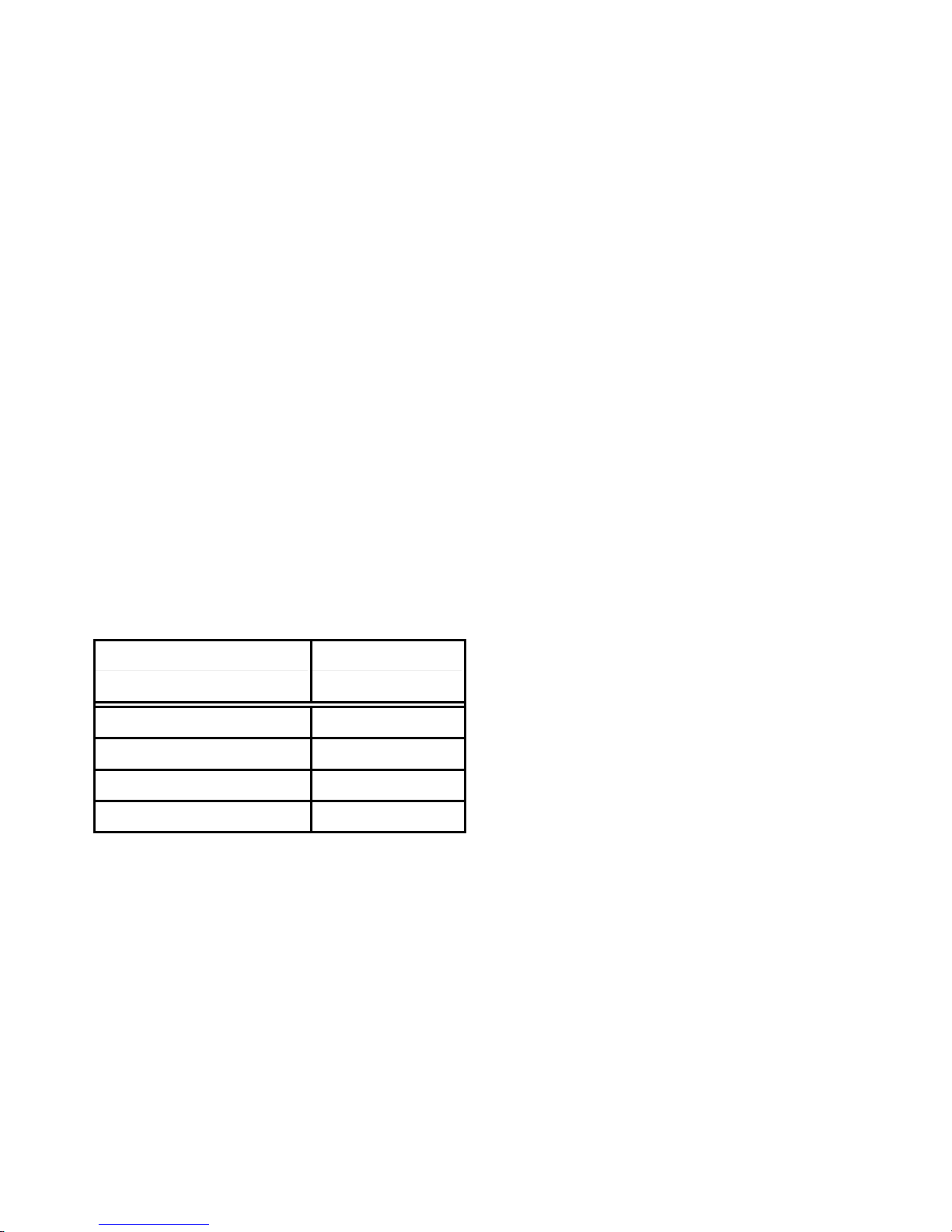

Freezer Temperature Compressor

Setting (°F)

Minimum Speed

6 to –2 1620 rpm

–3 1800 rpm

– 4 2000 rpm

–5 2200 rpm

The compressor generally cycles on and off

according to the cut-in and cut-out temperatures of the freezer, however, the refrigerator

can turn on the compressor if the evaporator

fan is at maximum speed and the refrigerator

temperatures are not dropping.

• A blue wire provides feedback to monitor the

speed of the motor.

• A red wire provides a constant 12 vdc.

• A yellow wire provides a variable voltage of

between 5 vdc and 17 vdc to control the

motor speed from 2000 to 3000 rpm.

• A white wire provides a common return.

EVAPORATOR FAN &

AIR DOOR DELAY

After defrost, an evaporator fan delay prevents

unnecessary movement of warm, moist air

through the refrigerator by chilling the evaporator prior to starting the fan. Immediately after defrost drip time, the compressor starts at

4500 rpm, but the evaporator fan is delayed

for 8 minutes. Also, the air door remains closed

during the 8 minute delay.

3-3

AIR DOOR

The air door is driven by a reversible DC

stepper motor. The motor operates on a 12

vdc, peak-to-peak square wave. Voltage is

delivered to the air door in a series of short

pulses. It is not possible to obtain a reliable

voltage reading with a VOM.

Separate windings are used to move the air

door open or closed. The door can be in any

one of 1800 positions from 0 to 90 degrees.

The air door is used to fine-tune the airflow to

the refrigerator.

The refrigerator temperature determines the

opening of the air door. When the refrigerator

requires cooling, if the evaporator fan motor is

already running for the freezer, the air door

partially opens, and then adjusts, if necessary.

While the refrigerator is cooling, the door will

be adjusting continuously to maintain or recover refrigerator temperature.

ADAPTIVE DEFROST

The adaptive defrost control allows the unit to

enter a defrost mode only when it is needed.

When powered up for the first time, the control

initiates a defrost cycle after 8 hours of compressor run time. By monitoring the duration of

defrost heating time and compressor run time,

the control will continuously adapt the time

between defrosts to optimize efficiency. Time

between defrost periods will vary between 8

and 100+ hours.

Defrost will occur immediately when the compressor has run at 4000 rpm or greater for 1

hour, and 8 hours have elapsed since the last

defrost.

PULSED DEFROST

For the first 2 minutes of defrost, the heater is

on continuously. It will then cycle off for 1

minute, and back on for 2 minutes. The heater

will continue to cycle at this ratio until the

bimetal opens, or until 33 minutes has elapsed.

At this point, heat is discontinued, and a

4-minute “drip time” begins. This allows the

water to drain before the unit returns to a

cooling mode. Maximum defrost time, (pulsed

heat on/off time + drip time) is 37 minutes.

When entering a defrost cycle, if the bimetal is

open, the time to defrost is reset to 8 hours, and

the control will time through the entire 37 minute

defrost period. During diagnostics this will allow a technician time to look for heater operation, and if necessary, bypass the bimetal.

POWER INTERRUPTION

After a power interruption, the following events

will occur:

• The unit returns to the same operating mode

and settings in use prior to the power interruption. If the unit was off, it remains off.

• Initially, the compressor, evaporator fan, and

condenser fan motors will be off.

• The air door will close, and then adjust to the

proper opening. The evaporator fan starts

when the air door opens.

• The adaptive defrost control resets the compressor run time counter to 0, and if the

freezer is above 20°F, the time to defrost is

set to 8 hours.

• If the freezer temperature is below 12°F

(–11.1°C), the compressor starts after a delay of 7 minutes. If the freezer temperature is

above 12°F, the compressor starts immediately.

FAILURE DEFAULTS

In the event of a thermistor, or keypad failure,

the control uses one of the following default

modes, which will continue until the failure is

corrected.

Refrigerator Thermistor

If the control senses an open or a shorted

thermistor, the air door and the evaporator fan

motor will begin to operate on a timed on and

off cycle, based on current selected temperature settings. The evaporator fan motor will run

when the air door is open.

At mid-settings of 37°F / 0°F, the air door will

open for 16 minutes, and close for 30 minutes.

Setting the freezer colder, or the refrigerator

warmer, will reduce the door-open time. Setting the freezer warmer, or the refrigerator

colder, will increase the door-open time.

3-4

Freezer Thermistor

MAX COOL MODE

If the control senses an open or a shorted thermistor, the compressor and the evaporator fan

motor will begin to operate on a timed on and

off cycle. The cycle time is based on current

selected temperature settings.

At mid-settings of 37°F / 3°C, the compressor

and the evaporator fan motors will run for 35

minutes, and be off for 25 minutes. Setting the

freezer colder will increase the run time. Setting the freezer warmer will decrease the run

time.

The compressor will run at minimum speed.

The evaporator fan will also run at minimum

speed, unless the refrigerator compartment

requests a higher speed.

Keypad

If the control detects that the keypad is not

working, it reverts to the default temperature

settings of 37°F (3°C) in the refrigerator, and

0°F (–18°C) in the freezer.

Max Cool changes the refrigerator temperature setting to 34°F (1 °C) and the freezer to

–5°F (–21°C) for 24 hours. During Max Cool,

the freezer and refrigerator temperature displays show the new temperature settings, not

the actual temperatures.

In most cases the motors run 100% for more

than 1 hour. The control returns to the previous

user setting after 24 hours, or any time the

temperature settings are changed.

AUTOMATIC MAX ICE

Automatic Max Ice operates any time the ice

maker water valve is energized. The duration

of Automatic Max Ice is 1-1/2 hours. During

Automatic Max Ice the following occurs:

• The freezer display shows the user tempera-

ture settings and not the actual temperature.

• The freezer temperature setting changes to

–5°F (–21°C).

• The evaporator fan runs at 3000 rpm.

Evaporator Fan Motor

If the evaporator fan motor malfunctions, the

compressor will run at 4500 rpm for an indefinite period, except during the defrost periods.

The “Call Service Alarm” will sound until the

failure has been corrected.

ELECTRONIC CONTROL

THERMAL SHUTOFF

The electronic control utilizes an on-board thermistor to shut the compressor off if the temperature rises above 160°F (71°C). When the

temperature drops to 130°F (55°C), the compressor returns to normal operation. This cycle

continues indefinitely until the cause of the high

temperature has been corrected.

If this cycle is repeated four times within 24

hours, the “Call Service” indicator lights, and

the alarm sounds.

• The compressor runs the entire 1-1/2 hour

mode. Speed is determined by the difference between actual freezer temperature

and –5°F (–21°C).

HOLIDAY MODE

The Holiday Mode may be used for the following occasions:

• On vacation.

• Religious observance (Sabbath Mode).

When the Holiday Mode is selected, the corresponding green LED flashes for 2 seconds,

and then remains on, to indicate that the feature is activated.

3-5

In the Holiday Mode the following occurs:

• Temperature selections remain at the current setting, but are not displayed.

• The Water Filter Indicator is not displayed,

but monitoring continues.

• The alarms are disabled.

• The ice maker is disabled.

• The interior lights are disabled.

MASTER ALARM RESET

Pressing the Over-Temperature Reset will turn

off the audio alarm, but does not affect the indicator light the first time the Over-Temperature Reset is pressed. The indicator light will

turn off once the Over-Temperature Reset is

pressed a second time. The audio alarm will

not sound again for the current condition that

caused the alarm until a new condition occurs.

• The temperature displays and all of the LEDs

will be off, except for the Holiday Mode LED.

The Holiday Mode LED will illuminate regardless of the door position.

• Keypad operation is disabled, with the exception of the Holiday Mode key, or the

Power On/Off key.

The Holiday Mode will be cancelled if one of the

following occurs:

• Pressing the Power On/Off, or Holiday Mode

keypads.

• Failure of both thermistors.

• No feedback from the evaporator fan motor.

• Temperatures that are 15°F above user settings in either compartment.

When the Holiday Mode is cancelled, the Holiday Mode LED turns off, and the control reverts to the settings in use prior to activation.

All inactive devices are restored, and the Water Filter Indicator is updated.

The Adaptive Defrost Control function is not

effected by use of the Holiday Mode.

OVER-TEMPERATURE ALARM

The Over-Temperature Alarm sounds, and the

indicator light flashes when either the refrigerator temperature exceeds 48°F (9°C), or the

freezer temperature exceeds 15°F (–9°C) for

over 1-1/2 hours. The appropriate temperature

display flashes to show the user which compartment is effected. The alarm stops if the

temperature(s) returns to normal, but the red

Over-Temperature indicator and temperature

display will continue to flash (refer to “Master

Alarm Reset” to reset the Over-Temperature

Alarm).

A Master Alarm Reset can be performed by

turning the power to the refrigerator off and on

again. The indicator light will turn on again after the Over-Temperature Reset is pressed, if

the condition that caused the alarm is still

present.

CALL SERVICE ALARM

Call Service is a visual and audio signal that

alerts the user that the refrigerator needs service. The Call Service Alarm will sound when:

• Both thermistors have failed.

• The evaporator fan motor loses its feedback

signal.

• An over-temperature condition occurs for 3

hours or more.

Reset using Master Alarm Reset.

DOOR OPEN ALARM

If either door is left open for more than 10 minutes, the interior lights will be disabled, the

Door Open icon will flash, and the alarm will

sound. If the door is closed during the alarm

operation, the alarm will reset, but the icon will

continue to flash until the temperature in the

refrigerator drops below 45°F (7°C) and the

freezer is below 15°F (–9°C)(refer to “Master

Alarm Reset” to reset the Door Open Alarm).

SALES DEMONSTRATION MODE

This mode provides a sequential display of the

temperature displays and feature LEDs. To

enter the Demonstration Mode, press and hold

the Max Cool and Power On/Off keys for 2

seconds. If the refrigerator or freezer door is open

for 10 minutes, the interior lights will turn off.

3-6

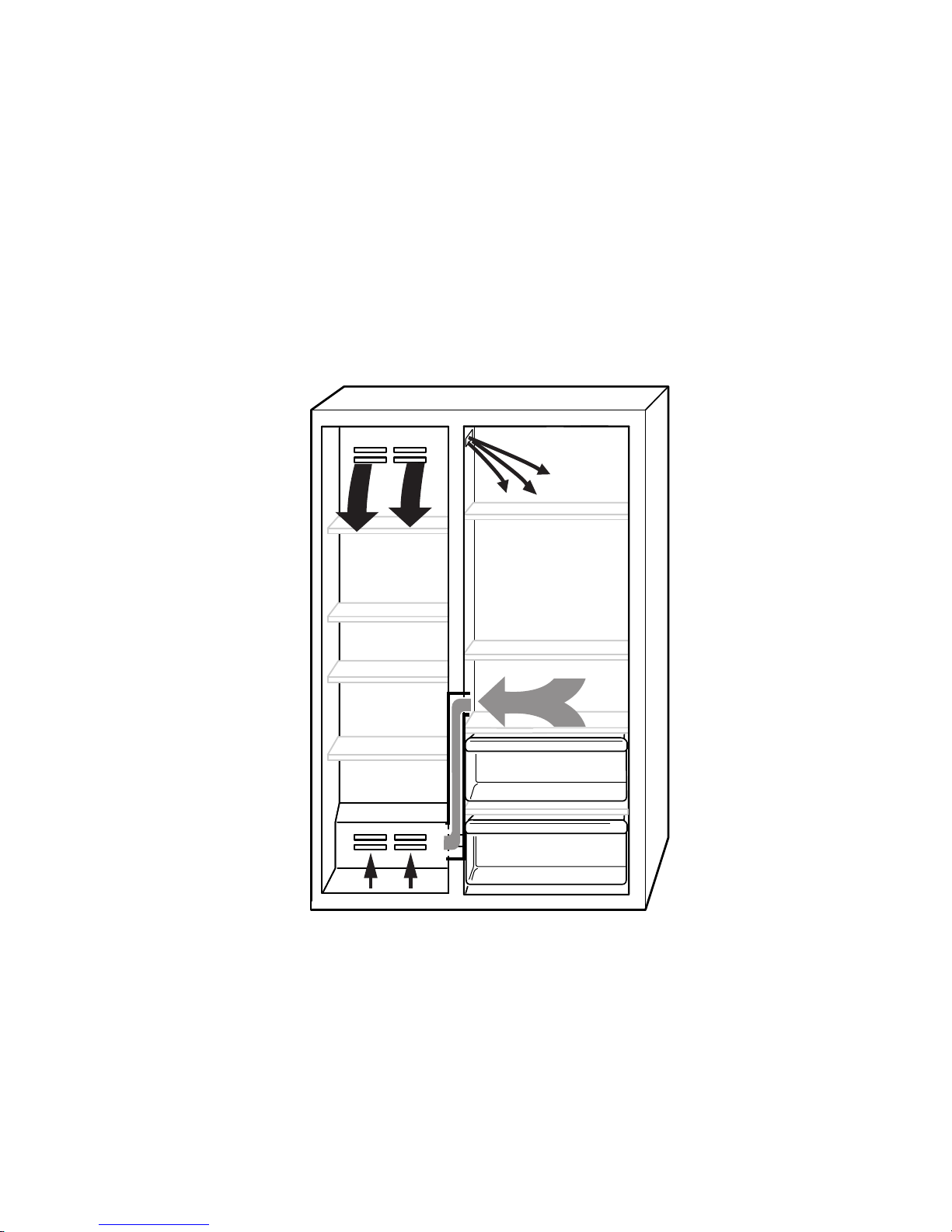

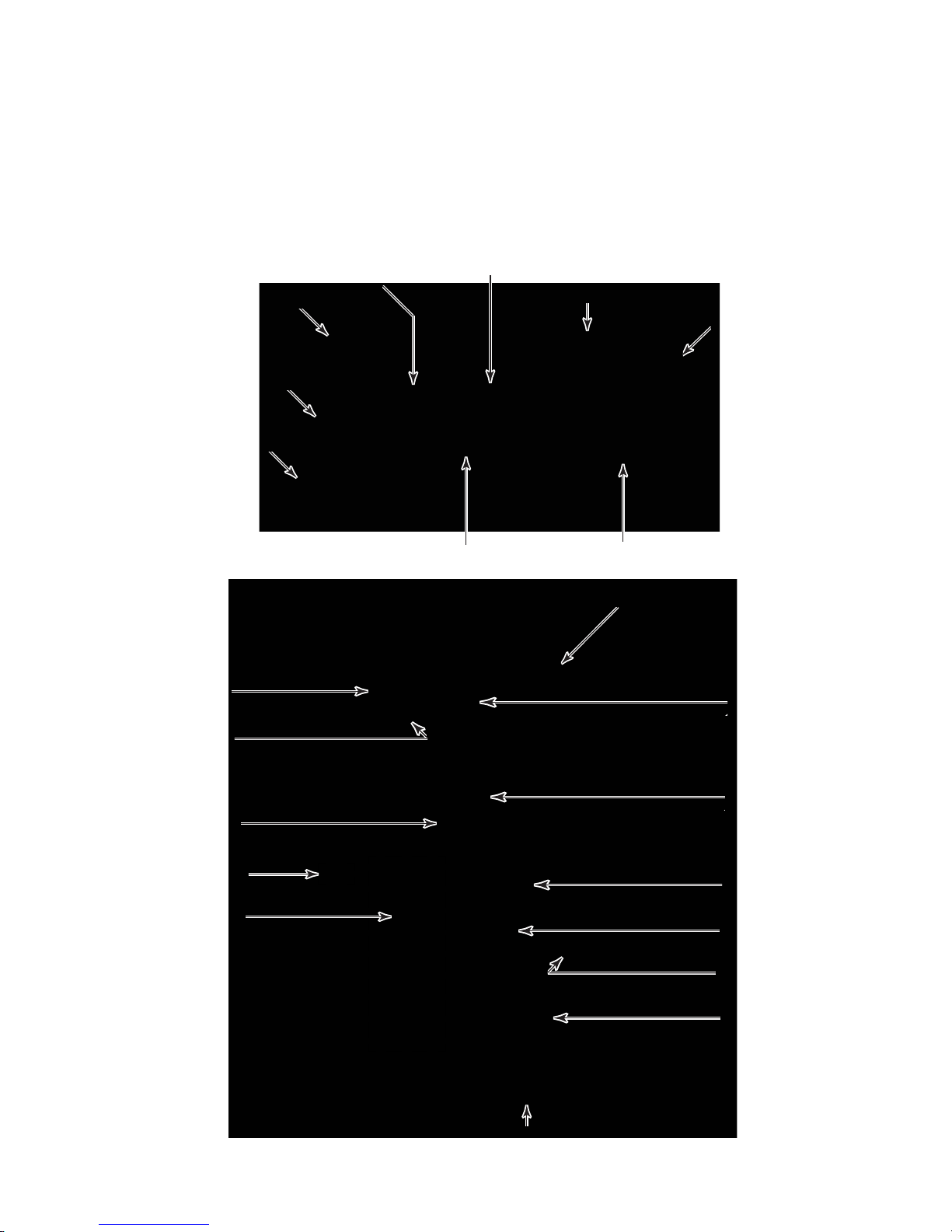

AIR CIRCULATION

In order to ensure the proper refrigerator and

freezer compartment temperatures, air must

be able to flow between the two sections.

Air enters the bottom of the freezer compartment and moves up through the evaporator.

Some of the cooled air from the evaporator is

directed back into the freezer, and the rest

goes into the refrigerator through the motorized air door. The refrigerator air then returns to

the freezer through the bottom air return (see

the illustration below).

It is important not to block any of the vents with

food items. If the vents are blocked, airflow will

be restricted, and the temperature management system will not function properly.

IMPORTANT: Because air circulates between

both sections, any odors formed in one section will transfer to the other. Keep both sections clean, and wrap or cover foods tightly to

prevent odors from occurring.

3-7

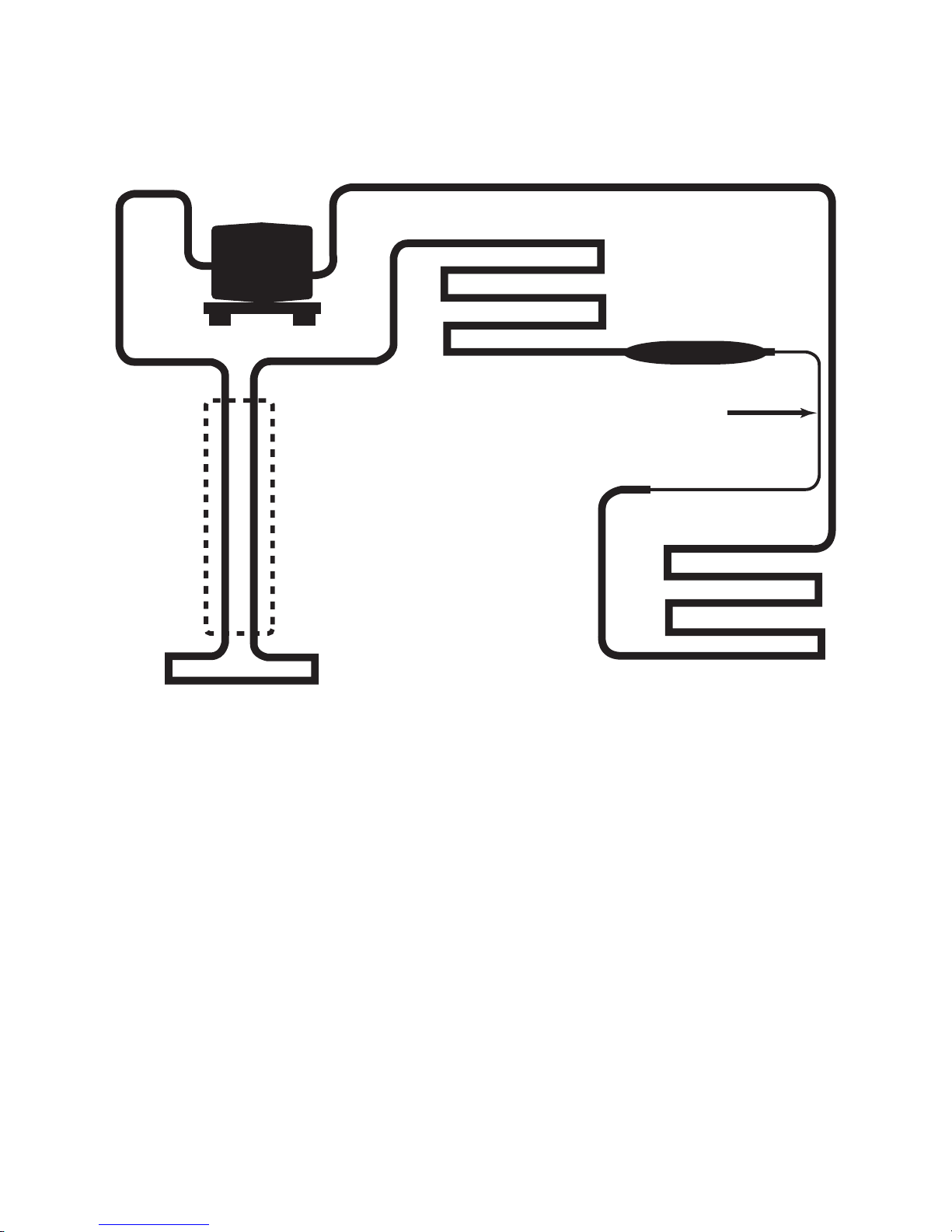

SEALED SYSTEM SCHEMATIC

Discharge

Freezer

Side

Compressor

Mullion

Refrigerator

Suction Line

Condenser

Drier

Heat Exchanger

Evaporator

Side

Condensate Loop

3-8

COMPONENT ACCESS

This section instructs you on how to service each component inside the refrigerator/freezer. The

components and their locations are shown below.

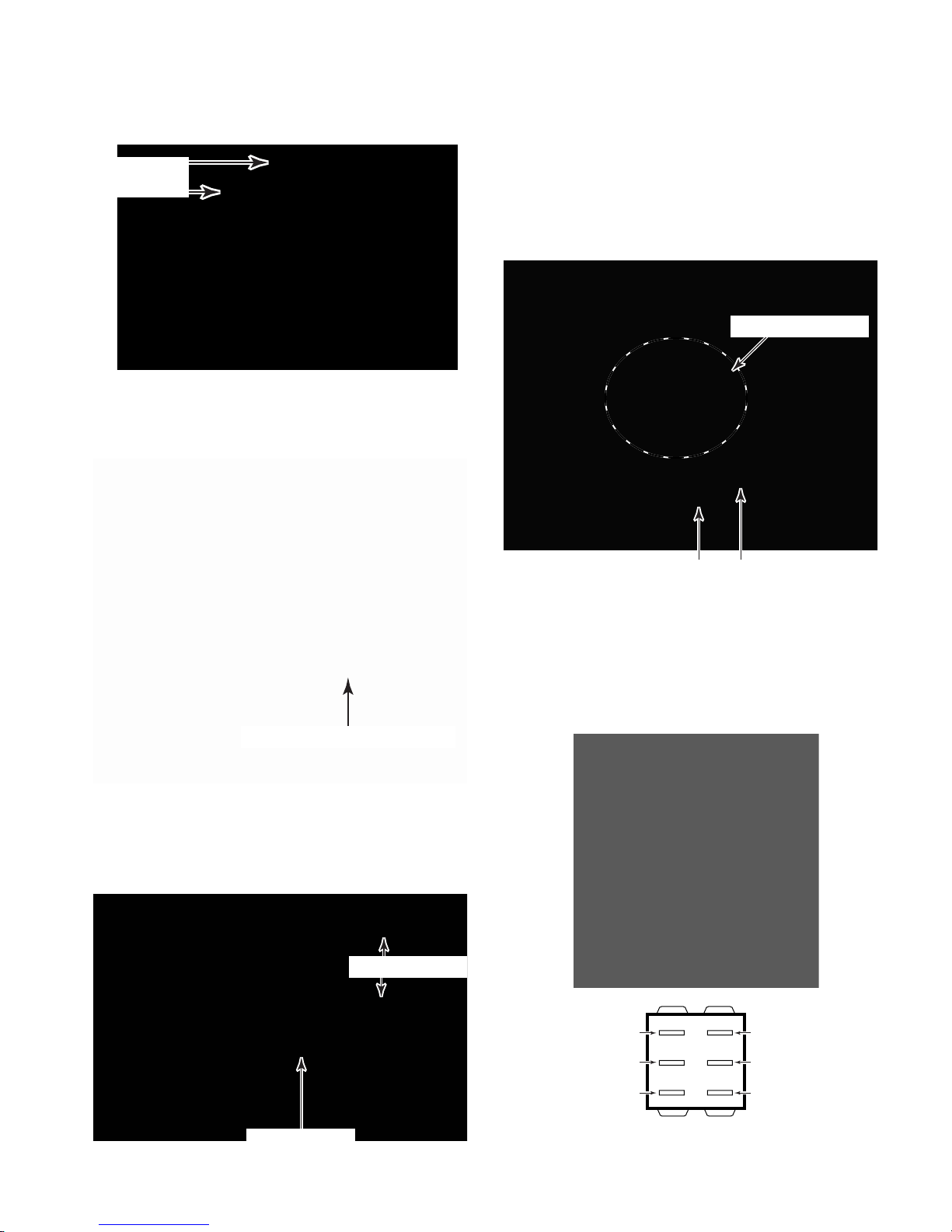

COMPONENT LOCATIONS

Compressor

Inverter Assembly

Freezer Door

Switch

Ice Maker

Filter/Drier

Ice Maker Inlet Heated Fill Tube

Condenser Fan Motor

Meat Pan Power Supply

Power Switch

Touch Control Assembly

Main Control

Board Assembly

Motorized

Air Door

Freezer Light

(1 of 2)

Freezer Thermistor

Auger Motor

Evaporator Fan

Motor Bimetal

Defrost Heater

Evaporator

Refrigerator

Thermistor

Refrigerator Light

Meat Pan Air Baffle

& Thermistor & Air

Supply Thermistor

Meat Pan Electronic

Touch Control Assy.

Water Reservoir

Water Valve

4-1

REMOVING A DOOR SWITCH AND THE POWER SWITCH

5. To remove a door switch:

a) With the door closed, remove the hex-

head screw from the door linkage at the

top of the door. NOTE: The door spring

will remain under slight tension when

the door is closed.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Lift the main decorative panel to unhook it

and remove the panel.

3. Lift and remove the louvered decorative

panel.

Main Decorative Panel Louvered Decorative Panel

Door Linkage Screw

b) Use a pair of pliers and lift the end of

the linkage off the square post.

4. Remove the eight screws from the unit

compartment front cover, and pull the cover

forward out of the way.

Screw (1 of 8) Unit Compartment Front Cover

Freezer Door Switch

(Refrigerator Door Switch

Shown In Right Column)

Power Switch

Square Post

c) Remove the two hex-head screws from

the door switch cover and remove the

cover.

2 Cover Screws

4-2

d) Disconnect the wire connectors from

1

2

3

4

5

6

Power Cord (Ribbed)

Power Cord (Smooth)

White Wire

Black Wire

N/CN/C

the door switch terminals.

2 Wire

Connectors

e) Press against the locking tab on the

switch body and push the switch out of

the bracket.

b) Disconnect the wire connectors from

the switch terminals. NOTE: Be sure

to reconnect the wires to the same terminal locations, as shown below.

c) Press against the four locking tabs on

the body of the power switch, and push

the switch out of the bracket.

4 Wire Connectors

Push Switch Out Of Bracket

6. To remove the power switch:

a) Remove the two hex-head screws from

the switch bracket and turn the bracket

over so you can access the wires.

Bracket Screws

Switch Locking Tabs

(2 of 4)

REASSEMBLY NOTE: When you reinstall the

power switch in the bracket, be sure to position

the switch with the On and Off markings as

shown below. The switch wiring is also shown

below. The terminal numbers are shown on the

switch body.

Power Switch

4-3

REMOVING THE INVERTER ASSEMBLY

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

Ground Screw

Inverter Mounting Screws

2. Remove the main and louvered decorative panels (see page 4-2).

3. Remove the eight screws from the unit

compartment front cover, and pull the cover

forward out of the way (see page 4-2).

4. Disconnect the two inverter assembly wire

connectors from the harness.

Inverter Assembly

2 Wire Connectors

5. Remove the two hex-head screws from

the inverter assembly (see the photo at the

top of the right column).

7. Using a large screwdriver, pry down on the

compressor terminal cover, and remove it

from the compressor.

8. Pull the inverter connector off the compressor pins.

9. Pull the green ground connector off the

compressor terminal.

Pry Down &

Unsnap Cover

Compressor

Ground Connector

6. Pull the inverter assembly forward and

remove it from the rear bracket, then position the assembly out of the way.

Inverter Connector

4-4

10. Remove the hex-head screw from the

inverter’s green ground wire, (see the photo

at the top of the right column on page 4-4),

and remove the inverter assembly.

Electrical Shock Hazard

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

11. Install the new inverter assembly and connect the green ground wire to the chassis

with its hex-head screw.

4-5

REMOVING THE CONDENSER FAN MOTOR

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the main and louvered decorative panels (see page 4-2).

3. Remove the eight screws from the unit

compartment front cover, and pull the cover

forward out of the way (see page 4-2).

Condenser Fan Motor

4. Remove the three hex-head screws (2 in

front and 1 in back) from the condenser

fan motor bracket (see the photo at the top

of the right column).

Condenser Fan Motor Screw (1 of 3)

6. Remove the speed nut from the condenser

fan blade and remove the fan from the

motor shaft. NOTE: Be sure to position the

fan blade with the “Nut Side” facing the

front end of the motor shaft when you

reinstall it.

Fan Blade Speed Nut

5. Move the condenser fan motor assembly

to the left and away from the condenser.

Rotate the bottom of the bracket toward

the rear of the unit, and move the condenser fan motor assembly to the front.

4-6

7. Disconnect the wire connector from the

condenser fan motor.

8. Remove the two hex-head screws from

the condenser fan motor and remove the

motor from the bracket.

Bracket Screws

Wire Connector

4-7

REMOVING THE ICE MAKER INLET HEATED FILL TUBE

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the main and louvered decorative panels (see page 4-2).

3. Remove the eight screws from the unit

compartment front cover, and pull the cover

forward out of the way (see page 4-2).

Screw (1 of 3)

Ice Maker Inlet Heated Fill

Tube Cover & Connector

6. Press the front locking ring on the John

Guest fitting and slide the fitting off the

inlet.

John Guest Fitting

Locking Ring

Ice Maker Inlet Heated Fill Tube

4. Disconnect the heated fill tube wire connector from the harness (see the photo at

the top of the right column).

5. Remove the three hex-head screws from

the ice maker inlet heated fill tube cover

and remove the cover.

7. Remove the two hex-head screws from

the ice maker inlet heated fill tube, and pull

the fill tube straight up and out of the unit.

Fill Tube Screws

4-8

REMOVING THE MAIN CONTROL BOARD ASSEMBLY

5. Slide the wire grommet out of the enclosure slot and position the assembly so that

you can access the board.

6. Remove the wire connectors from the

main control board assembly.

Wire Grommet Out Of Enclosure Slot

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the main and louvered decorative panels (see page 4-2).

3. Remove the eight screws from the unit

compartment front cover, and pull the cover

forward out of the way (see page 4-2).

4. Remove the two hex-head screws from

the main control board assembly enclosure.

Main Control Board Assembly

2 Screws

Main Control Board

Wire Connectors

7. Remove the main control board from the

five standoffs. Press the locking tab on

each standoff to release the board.

Press Locking Tab

On Standoff

4-9

REMOVING THE ELECTRONIC

MEAT PAN POWER SUPPLY BOARD

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

Electronic Meat Pan Power Supply

Enclosure Screw

Ground Wire Screw

7. Pull the meat pan power supply assembly

forward as far as it will go, and turn it over

so you can access the board.

1. Unplug refrigerator or disconnect power.

2. Remove the main and louvered decorative panels (see page 4-2).

3. Remove the eight screws from the unit

compartment front cover, and pull the cover

forward out of the way (see page 4-2).

Electronic Meat Pan Power Supply

8. Disconnect the two wire connectors from

the meat pan power supply board.

9. Remove the meat pan power supply board

from the three standoffs. Press in the

locking tab on each standoff to release the

board.

Wire

Connectors

Meat Pan Power

Supply Board

4. Remove the main control board assembly

from the unit (see page 4-9 for the procedure).

5. Remove the hex-head mounting screw

from the meat pan power supply board

enclosure (see the photo at the top of the

right column).

6. Remove the hex-head screw from the

meat pan power supply green ground wire

at the chassis.

4-10

Electrical Shock Hazard

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

10. Install the electronic meat pan power supply assembly in the unit, and connect the

green ground wire to the chassis with its

hex-head screw.

4-11

REMOVING THE COMPRESSOR AND FILTER/DRIER

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Remove the main and louvered decorative panels (see page 4-2).

TIP OVER HAZARD

Refrigerator is top heavy and tips easily

when not completely installed.

Keep door taped closed until refrigerator is completely installed.

Use two or more people to move and

install refrigerator.

Failure to do so can result in death or

serious injury.

3. Remove the eight screws from the unit

compartment front cover, and pull the cover

forward out of the way (see page 4-2).

4. Use the leveling screws and lower the

refrigerator onto the four rollers.

Leveling Screws

Rear Front

5. Pull the refrigerator out of its mounting

location.

6. Remove the eight screws from the unit

compartment cover (two on the left side,

four on the right side, and one in each of

the rear corners).

7. Lift the unit compartment cover up and off

the unit.

Right Rear

Cover Screw

Unit Compartment Cover

4 Cover Screws

4-12

8. Remove the compressor terminal cover.

To remove the cover, insert a flat-bladed

screwdriver into the top slot, push down on

the screwdriver to release the catch, and

then rotate the cover forward at the top,

and lift it off the bottom catch.

9. Loosen the strain relief from the compressor terminal cover and remove the wire.

Terminal Cover

& Strain Relief

11. Access the sealed system and discharge

the refrigerant into an approved recovery

system.

12. Unbraze the suction and discharge lines

from the compressor.

13. Cut the filter/drier from the system (do not

use a torch to remove the filter/drier).

Suction Line

10. Disconnect the green ground wire and the

3-pin inverter output connector from the

compressor pins.

Ground Wire

Filter/Drier

Discharge Line

14. Remove the four mounting bolts and the

rubber grommets from the compressor.

15. Lift the old compressor from the refrigerator and replace it.

Inverter Connector

4-13

REMOVING THE BIMETAL, THE EVAPORATOR FAN

MOTOR, THE DEFROST HEATER, AND THE EVAPORATOR

Cover

Screws

(2 of 10)

Light Lens

Cover Tabs

And Slots

Evaporator

Cover

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Open the freezer door.

Shelf Studs

(1 of 8)

Bin Glide

(1 of 4)

Refer to the photo at the top of the right column.

3. Unhook the tabs on the lens of the lower

freezer light and remove it from the liner.

4. Remove the bins and shelves from in front

of the evaporator cover.

5. Remove all of the shelf mounting studs.

6. Remove the two screws from each of the

four bin glides and remove the glides from

the sides of the freezer liner.

7. Remove the ten hex-head screws from

the evaporator cover.

8. Lift and unhook the two evaporator cover

slots from the chassis tabs, and pull the

cover out of the freezer.

9. To remove the bimetal:

a) Unclip the bimetal from the evaporator

inlet tubing.

b) Follow the instructions that were sup-

plied with the replacement bimetal to

connect the wires.

Bimetal

Clip

4-14

10. To remove the evaporator fan motor:

11. To remove the defrost heater:

a) Pull the fan blade off the motor shaft.

b) Unclip the motor.

c) Disconnect the wire connector from the

harness.

Pull Fan Blade Off Motor Shaft

Evaporator

Fan Motor

a) Remove the two hex-head screws from

the evaporator fan motor shroud.

b) Unclip the bimetal from the evaporator

inlet tubing.

c) Disconnect the defrost heater and

evaporator fan motor connectors from

the wiring harness.

d) Remove the evaporator fan motor

shroud and the two side foam blocks.

Foam Blocks

Unclip Motor

Wire Connector

d) Remove the isolator from the motor.

Isolator

Evaporator Fan Motor

Shroud Screws

Defrost Heater

Connector

Bimetal

Evaporator

Fan Motor

Connector

Continued on the next page.

4-15

e) 36″ Models Only: Remove the hex-

head screws from the right evaporator

cover mounting bracket and remove

the bracket. Be careful not to drop the

screws down the drain hole at the bottom of the liner. Cover the hole with a

cloth.

Right Evaporator Cover

Mounting Bracket

NOTE: Be very careful not to over-bend

the refrigerant tubing.

g) Bend the two hangers at the bottom of

the evaporator and remove the heater

from the hangers.

Defrost Heater

f) Lift the evaporator up slightly and un-

hook it from the liner, then pull the

bottom of the evaporator toward the

front of the unit.

Bend The Two Hangers

h) Remove the foam block from the right

side of the evaporator.

Foam Block

Lift & Pull Out

4-16

i) Unfasten the defrost heater from the

two metal clips on the right side of the

evaporator, and slide the defrost heater

down and off the evaporator.

12. To remove the evaporator:

a) Remove the defrost heater from the

evaporator (see step 11).

b) Access the sealed system and dis-

charge the refrigerant into an approved

recovery system.

c) Remove and replace the evaporator.

NOTE: Refer to the “Defrost Heater

Reassembly Notes” to the left when

reinstalling the evaporator.

Heater Clip

(1 of 2)

DEFROST HEATER

REASSEMBLY NOTES:

1. The evaporator fan motor shroud has a

foam block on each side. Note the position

of these blocks in the photo and make sure

that you reinstall them correctly.

Foam Blocks

Defrost Heater

Evaporator

Evaporator Fan Motor Shroud

2. Be sure to reinstall the foam block on the

right side of the evaporator, as shown in

the photo in step 11h on the previous

page.

Lift & Pull Out

4-17

REMOVING THE TOUCH AND DISPLAY BOARDS

& THE MOTORIZED AIR DOOR

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Open the refrigerator door and remove the

items from the top shelf. If necessary,

remove the top shelf so you can easily

access the touch control assembly or the

motorized air door. The locations are shown

below.

Touch Control Assembly

b) Disconnect the two wire connectors

from the touch control assembly and

remove the assembly from the refrigerator.

Wire Connectors

c) Remove the two screws from the plas-

tic cover and remove the cover from the

touch control panel.

Cover

Screws

Motorized Air Door

3. To remove the touch and display

boards:

a) Remove the three hex-head screws

from the back of the touch control assembly and lower the assembly.

3 Screws At Back Of Control

d) Disconnect the wire connector from the

end of the display board.

Display Board

Wire

Connector

e) Unclip the touch board from the locking

tabs and remove the board.

Board Tabs

Touch Board

4-18

4. To remove the motorized air door:

a) Remove the hex-head screws from the

motorized air door cover and remove

the cover.

Screw

Motorized Air Door Cover

Screw

b) Pull the motorized air door out of the

refrigerator liner opening.

c) Disconnect the wire connector from the

motorized air door and remove it.

REASSEMBLY NOTE: Be sure to position

the motorized air door with the motor and

wires as shown in the bottom left photo.

Motorized Air Door

Wire Connector

Motorized Air Door

Pull Out

4-19

REMOVING THE MEAT PAN AIR BAFFLE & THERMISTOR,

THE AIR SUPPLY THERMISTOR, AND THE MEAT PAN

ELECTRONIC TOUCH CONTROL ASSEMBLY

3. To remove the meat pan air baffle &

thermistor:

a) Remove the two screws from the baffle

housing assembly, then tilt the top of

the assembly forward, and pull the bottom tab from the slot.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

Meat Pan Air Baffle

Housing Assembly

2. Remove the meat pan and glass cover

from the refrigerator.

Meat Pan W/Glass Cover

Screws

b) Disconnect the two wire connectors

from the harness, and remove the air

baffle housing assembly from the refrigerator.

Wire Connectors

4-20

c) Remove the screw from the cover and

remove the cover from the baffle housing.

Housing Cover

4. To remove the air supply thermistor:

a) Remove the meat pan air baffle assem-

bly from the unit (see steps 3a & 3b).

b) Remove the four screws from the meat

pan air duct and remove the duct.

Housing

Screw

d) Pull the meat pan air baffle assembly

and thermistor out of the housing.

Meat Pan Air Baffle

Assembly

Thermistor

Housing

e) Disconnect the meat pan thermistor

connector from the harness.

f) Disconnect the four connector harness

assembly from the housing. NOTE: Make

sure that you reconnect the harness to

the indicated meat pan air baffle assembly connector shown below.

Screw (1 of 4)

Meat Pan Air Duct

c) Remove the screw from the air supply

thermistor.

d) Disconnect the air supply thermistor

connector from the harness and remove the thermistor.

Air Supply Thermistor

Meat Pan Air Baffle Assembly

Thermistor Connector

Harness Connector Here

4 Connector

Harness

Assembly

Screw

Harness Connector

Continued on the next page.

4-21

5. To remove the meat pan electronic

touch control assembly:

a) Remove the meat pan air baffle assem-

bly from the unit (see steps 3a & 3b on

page 4-20).

b) Remove the two screws from the bin

glide and remove the glide.

c) Remove the two screws from the deco-

rative cover and remove the cover.

Bin Glide Screws

Decorative Cover

Cover Screws

e) Lift the assembly from the bottom and

pull it out, then unclip the top and pull it

out so you can access the wiring.

f) Disconnect the two harness connec-

tors from the board and remove the

assembly.

2 Wire

Connectors

d) Remove the two screws from the meat

pan electronic touch control assembly.

Electronic Touch

Control Assembly

Screws

4-22

REMOVING A THERMISTOR

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

3. Remove the hex-head screw from the

thermistor cover. Pull the cover forward at

the screw end, and unhook the tab from

the slot at the other end of the thermistor

cover.

Screw

Refrigerator / Freezer

Thermistor Cover

NOTE: The refrigerator and freezer thermistors

are identical and are removed in the same

manner.

2. Depending on the thermistor, open the

freezer or refrigerator door, and remove

any items from the shelf that are in front of

the thermistor. It may be necessary to

remove the shelf as well. The thermistor

locations are shown below.

Refrigerator Thermistor

4. Disconnect the 2-wire connector and remove the thermistor.

Connector

Refrigerator / Freezer

Thermistor

Freezer Thermistor

4-23

REMOVING THE ICE MAKER,

THE EMITTER, AND THE RECEIVER

4. To remove the ice maker:

a) Close the spring-loaded emitter door

and open the ice maker door.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

2. Open the freezer door.

3. Remove the ice bin from the freezer door

by pressing in on the latch button, and

lifting the bin off the door shelf.

Ice Bin

Emitter Door

Ice Maker Door

b) Push the ice maker door to the left so

that the right pin disengages from the

pivot arm, then lift the pin out of the

pivot, and remove the left pin.

Ice Maker Door

Pivot & Pin

NOTE: The ice bin disassembly is shown in the

“Tech Tips” in Section 8.

Latch

Button

c) Remove the three screws from the left

side of the ice maker bracket, and the

single screw from the right side.

Left Bracket Screws

Right Bracket Screw

4-24

d) Disconnect the two ice maker connec-

tors from the freezer wiring harness

and remove the ice maker from the

freezer.

2 Wire

Connectors

e) Remove the three hex-head screws

from the bottom of the ice maker bracket

and remove the bracket from the ice

maker

Bottom 3 Bracket Screws

b) Disconnect the harness connector from

the emitter module board and remove

the module.

Emitter

Connector

6. To remove the receiver module:

a) Remove the three screws from the re-

ceiver module and pull it out of the

freezer liner opening.

5. To remove the emitter module:

a) Remove the three screws from the emit-

ter module and pull it out of the freezer

liner opening.

Screw (1 of 3)

Emitter

Module

Receiver

Module

Screw (1 of 3)

b) Disconnect the harness connector from

the receiver module board and remove

the module.

Receiver

Connector

4-25

REMOVING THE AUGER MOTOR

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

6. Remove the spring from the top of the hex

drive shaft.

Spring

7. Remove the containers from the freezer

door so you can access the motor housing

cover.

2. Open the freezer door.

3. Remove the ice bin from the freezer door

(see page 4-24).

4. Remove the two screws from the hex drive

shaft coupling holder and remove the coupling assembly.

5. Pull the coupler, seals, and bushing from

the hex drive shaft.

Coupler

Seals

Bushing

8. Remove the two screws from the motor

housing cover and remove the cover.

Screws

Motor Housing Cover

9. Disconnect the harness connector from

the motor terminals.

10. Remove the four screws from the auger

motor bracket.

Screw (1 of 4)

Screw (1 of 2)

Coupling Holder

Motor Connector

4-26

11. Allow the motor and hex drive shaft to drop

down and remove them from the unit, then

pull the hex drive shaft out of the motor.

Hex Drive

Shaft

Auger Motor

4-27

REMOVING THE WATER RESERVOIR AND WATER VALVE

5. Unclip the wires and remove the dispenser

wiring terminal cover, then disconnect the

dispenser wiring connectors.

Dispenser Wiring

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug refrigerator or disconnect power.

Terminal Cover

Bottom Trim

2. Turn off the water supply to the refrigerator.