Kistler-Morse Microcell Installation Manual

Microcell™

Installation Manual

CAUTION

It is essential that all instructions in this

manual be followed precisely to ensure

proper operation of the equipment.

97-1012-02

Revision G

March 2010

NOTICE

The content of this document is the intellectual property of Kistler-Morse® Corporation. Any

reproduction or translation of this document without the written authorization of a Kistler-Morse

corporate ofcer is prohibited.

®

CAUTION

Follow these rules if welding is done on the vessel after installation of the Microcell™ system. The

electrical current of the welder may pass through the Microcell™, causing damage to the sensor and

possibly to the signal processor. To avoid damage, follow these precautions:

1. Disconnect the Microcell™ cables from the signal processor.

2. Ground the welder as close to the welding joint as possible. The welding ground must be between

the Microcell™ and the weld joint to prevent the welding current from going through the Microcell™

to earth ground.

TABLE OF CONTENTS

CHAPTER 1. INTRODUCTION ................................................................................................................ 1

Equipment Description ......................................................................................................................... 1

Applications .......................................................................................................................................... 1

Manual Conventions ............................................................................................................................. 1

CHAPTER 2. PRE-CHECK PROCEDURES ............................................................................................ 2

Introduction ................................................................................................................................................ 2

Application Verication ............................................................................................................................... 2

Order Verication ........................................................................................................................................ 2

Microcell™ Order ................................................................................................................................. 2

Microcell™ Installation Equipment ....................................................................................................... 3

Junction Box and Field Wiring Equipment ........................................................................................... 3

Checking Equipment .................................................................................................................................. 3

Visual Check ......................................................................................................................................... 3

Functional Check .................................................................................................................................. 3

Testing with Kistler-Morse® Test Meter ........................................................................................... 3

Testing with Digital Multimeter (DMM) ............................................................................................. 4

CHAPTER 3. MICROCELL™ INSTALLATION ON VERTICAL COLUMN LEGS .................................... 5

Introduction ................................................................................................................................................ 5

Mounting Locations .................................................................................................................................... 5

Microcell™ Sets ................................................................................................................................... 5

Best Performance ........................................................................................................................... 5

Standard Performance ................................................................................................................... 5

Horizontal Distribution of Microcell™ Sets ........................................................................................... 6

Vertical Location of Microcell™ Sets .................................................................................................... 6

Column Legs without X-Braces ...................................................................................................... 6

Column Legs with X-Braces ........................................................................................................... 6

Installing Microcell™ Sets .......................................................................................................................... 8

Surface Preparation .............................................................................................................................. 8

Drill and Tap .......................................................................................................................................... 8

Mounting the Microcell™ Sets ............................................................................................................. 9

Mounting Junction Box ............................................................................................................................ 10

Mounting Location ............................................................................................................................. 10

Junction Box Installation .................................................................................................................... 11

Wiring Microcells™ to Junction Box ........................................................................................................ 11

Wiring Junction Boxes Together and to Signal Processor ....................................................................... 13

Installing Insulation for Outdoor Vessels (Optional) .................................................................................. 15

Insulation Order and Installation Equipment ...................................................................................... 15

Installing Brace Wrap ......................................................................................................................... 15

CHAPTER 4. MICROCELL™ INSTALLATION ON HORIZONTAL BEAMS .......................................... 17

Introduction .............................................................................................................................................. 17

Mounting Locations .................................................................................................................................. 17

Microcell™ Sets ................................................................................................................................. 17

Distribution of Microcell™ Sets .......................................................................................................... 17

Installing Microcell™ Sets ........................................................................................................................ 20

Surface Preparation ............................................................................................................................ 20

Drill and Tap ........................................................................................................................................ 20

Mounting Microcell™ Sets ................................................................................................................. 21

TABLE OF CONTENTS

Mounting Junction Box ............................................................................................................................ 22

Mounting Location.............................................................................................................................. 22

Junction Box Installation .................................................................................................................... 22

Wiring Microcell™ Sets to Junction Box .................................................................................................. 23

Wiring Junction Boxes Together and to Signal Processor ....................................................................... 24

CHAPTER 5. SYSTEM CALIBRATION .................................................................................................. 27

Introduction .............................................................................................................................................. 27

Live Load Calibration ............................................................................................................................... 27

Adding a Known Quantity of Material ................................................................................................. 27

Removing a Known Quantity of Material ............................................................................................ 28

Manual Calibration ................................................................................................................................... 28

CHAPTER 6. TROUBLESHOOTING ...................................................................................................... 29

Problem 1. Small Amplitude Changes or Erratic Fluctuations in Display Readings ............................... 29

Problem 2. Repeatable Drift Over a 24-hour Period ............................................................................... 30

Problem 3. Sudden Change in Weight Reading or System Requires Frequent Recalibration ................ 31

APPENDIX A. MICROCELL™ SPECIFICATIONS ................................................................................. 32

APPENDIX B. GLOSSARY ..................................................................................................................... 34

APPENDIX C. ALTERNATE METHOD FOR CHECKING OUTPUT ...................................................... 35

APPENDIX D. SPARE PARTS RECOMMENDATIONS ......................................................................... 36

APPENDIX E. TECHNICAL DRAWINGS ............................................................................................... 37

CHAPTER 1. INTRODUCTION

APPLICATIONS

The 3” Microcell™ can be installed on carbon

steel, stainless steel, or aluminum vessel supports.

The 2” Microcell™ can be installed on carbon steel

vessel supports only. Refer to Appendix A

(Microcell™ Specications) for stress limits on

each type of Microcell™.

Microcell™ sets can be installed on leg-supported

and beam-supported vessels. Refer Chapter 3

for installation details on installing Microcell™ on

vertical column legs. Refer to Chaper 4 for

installation details on installing Microcell™ on

horizontal beams.

Figure 1-1. The Kistler-Morse® Microcell™.

EQUIPMENT DESCRIPTION

The Microcell™ (Figure 1-1) is a highly sensitive

bolt-on strain gage sensor used to determine the

weight of material contained in storage vessels.

Microcell™ sets bolt onto a vessel’s metal support

structure. As weight is added to or removed from

the vessel, the vessel support structure

experiences strain changes proportional to the

weight changes. The Microcell™ detects the

strain changes and produces a voltage output

proportional to those changes, thus indicating the

change in weight. Kistler-Morse® signal

processors convert the Microcell™ voltage outputs

to weight or level. Refer to Appendix A for

specications.

The Microcell™ is easy to install. It mounts to the

surface of the structural support and never comes

in contact with the vessel contents. Used in many

different industries, it can weigh any type of

material stored in a vessel with metal support

members. The Microcell™ is rugged, can operate

in industrial environments, and requires no periodic

maintenance. It is immune to electrical noise due

to its high-level output voltage.

Contact Kistler-Morse® for information on

non-standard applications.

Be sure to read the entire installation procedure

pertaining to your application before beginning

installation.

MANUAL CONVENTIONS

Three kinds of special explanations appear

throughout the manual. The format and

signicance of each is dened below:

WARNING

Possible danger to people. Injury may result

if this information is ignored.

CAUTION

Possible risk to the product. The Microcell™

or other equipment may be damaged if this

information is ignored.

Note

Contains additional information about a step or

feature critical to the installation or operation of

the Microcell™.

1

CHAPTER 2. PRE-CHECK PROCEDURES

INTRODUCTION

This chapter describes the pre-check procedures

for Microcell™ sets. Verifying the application and

checking the Microcell™ sets before installation

will ensure installation of properly working

equipment that will provide accurate monitoring

of vessel contents.

APPLICATION VERIFICATION

Prior to ordering Microcell™ sets, be sure to have

read the Microcell™ Selection Guide

(Kistler-Morse® #97-5023) and completed the

appropriate Application Data Form (Kistler-Morse®

#97-5025 for Microcells™ on vertical column legs

or Kistler-Morse® #97-5024 for Microcells™ on

horizontal beams). A copy of the completed form

was returned with both the order acknowledgment

and equipment shipment. If you cannot locate the

form, contact Kistler-Morse® to get another copy

before proceeding. Review the information on the

form now to verify the application details.

Note

If the calculated stress on the Application Data

Form is outside the following ranges, this is a

special application:

3” Microcell™: 2,500 psi - 7,500 psi

(1.8kg/mm2 - 5.3kg/mm2)

2” Microcell™: 3,750 psi - 11,250 psi

(2.6kg/mm2 - 7.9kg/mm2)

ORDER VERIFICATION

Prior to beginning installation, verify the order is

complete and assemble additional equipment

needed for the installation.

MICROCELL™ ORDER

The following are included with the order

(quantities dependent on application):

STANDARD

Microcell™ set, each complete with:

Sensor

Environmental Cover

#8-32 socket head cap screws (2)

#8 hardened at washers (2)

JB1 or JB2 Junction Boxes, each complete with:

Terminal board

Watertight ttings (4)

Watertight plugs (for any cable openings that

will not be used)

Installation Kit, each complete with:

Microcell™ drill template with #8-32 socket

head cap screw

#29 drill bit

#8-32, 2-ute, spiral-point tap

Sikaex 1A polyurethane sealant or Dow

Corning RTV 738 or RTV 739 and Material

Safety Data Sheet (MSDS)

Rust-inhibiting silicone grease

OPTIONAL

Insulation and insulation hardware (if best

performance is required for an outdoor

installation on column legs)

Contact Kistler-Morse® before proceeding further

with a special application.

If any items are missing from the order, contact

Kistler-Morse® before proceeding. Substituting

parts without Kistler-Morse® approval may cause

system problems and will void the warranty.

Note

A signal processor and its manual are required

to calibrate the system. If using an existing

signal processor, this will not be included in

the order.

2

MICROCELL™ INSTALLATION EQUIPMENT

Tape measure

Marking pen

Kistler-Morse® Test Meter

Kistler-Morse® Microcell™ Sensor Drill Template

Drill motor

Tapping uid

Tap handle

Disk grinder, 4½” (114 mm) or larger, or belt

grinder

Sandpaper (coarse and ne)

Degreaser (isopropyl alcohol or acetone)

Level

Caulking gun

9

/64” hex T-handle driver

Digital Multimeter (DMM)

Tape (electrical or masking)

Note

If the Microcell™ sets will be install by

Kistler-Morse®, the service technician provided

by Kistler-Morse® will bring this equipment on

site with the tool kit. If the Microcell™ sets will

be installed by the customer, the purchase

of a Kistler-Morse® Test Meter is highly

recommended to simplify the installation.

CAUTION

Only use Sikaex 1A polyurethane sealant or

Dow Corning RTV 738 or RTV 739. Other

sealants may contain acetic acid, which is

harmful to sensors and electronics.

CHECKING EQUIPMENT

CAUTION

Handle Microcell™ sets with care. Dropping,

striking, etc. can damage the Microcells™.

VISUAL CHECK

Visually inspect all equipment in the order,

including Microcells™, junction boxes,

Installation Kit, and insulation (if provided), to verify

they were not damaged during shipment. If any

item was damaged, contact Kistler-Morse

immediately for a replacement.

FUNCTIONAL CHECK

Perform a functional check of the Microcells™

before installation to verify they were not damaged

during shipment. Two methods of performing the

check are described below.

®

JUNCTION BOX AND FIELD WIRING

EQUIPMENT

Drill motor

#29 drill bit

#8-32, 2-ute, spiral-point tap

Tap handle

Tapping uid

9/64” Allen wrench

#8-32 socket head cap screws

#8 at washers (3/16” inner diameter, 7/16” outer

diameter)

Belden™ 8791, 18 gauge, 3-conductor shielded

interconnect cable or equivalent (for up to

1,000 ft (305m) length)

Belden™ 8618, 16 gauge, 3-conductor shielded

interconnect cable or equivalent (for 1,000 ft

to 2,000 ft (305m to 610m) length)

Conduit and ttings or cable tray

Caulking gun

Sikaex 1A polyurethane sealant or Dow

Corning RTV 738 or RTV 739

TESTING WITH A KISTLER-MORSE

®

TEST METER

The Kistler-Morse® Test Meter (Figure 2-1) is

designed specically to test Kistler-Morse

®

sensors. If you do not have a test meter,

disregard this section and proceed to TESTING

WITH A DIGITAL MULTIMETER (DMM).

Note

The test meter display indicates a low battery or

behaves erratically when the batteries are weak.

When this occurs, replace the batteries before

testing.

1. See Figure 2-1. Connect the Microcell™

red, white, and black wires to the

corresponding test meter terminals. Place

the Microcell™ on a stable surface.

2. Turn on the power to the test meter and set

the Simulate/Test Switch to the Test

position. Verify the no-load output is

between +25mV and -25mV.

3. Repeat Steps 1 and 2 for each Microcell™.

If the no-load output for any Microcell™ is

outside these specications:

3

A. Proceed to TESTING WITH A DIGITAL

MULTIMETER (DMM) to determine the

resistance values for that Microcell™, and

B. Contact Kistler-Morse

®

for assistance

after determining the resistance values

and before proceeding with installation.

CAUTION

Replace Micrcells™ in packing tubes until ready

to install.

3. Put one DMM lead on the Microcell™ white

wire and the other lead on the black wire.

Place the Microcell™ on a stable surface.

Verify the resistance is within the following

limits:

3” standardized Microcell™ (light blue cover):

8,300Ω - 8,700Ω

2” standardized Microcell™ (dark blue cover):

1,800Ω - 2,200Ω

4. Repeat Steps 2 and 3 for each Microcell™. If

either reading for any Microcell™ is outside

these specications, contact Kistler-Morse® for

assistance before proceeding with installation.

CAUTION

Replace Micrcells™ in packing tubes until ready

to install.

Figure 2-1. Kistler-Morse® Test Meter.

TESTING WITH A DIGITAL MULTIMETER (DMM)

Follow this procedure to test the Microcell™ sets

®

if you do not have a Kistler-Morse

Test Meter or

the readings using the Test Meter were outside the

specications:

1. Set the DMM resistance scale to

accommodate a measured range up to

20,000Ω.

2. Put one DMM lead on the Microcell™ white

wire and the other lead on the red wire. Place

the Microcell™ on a stable surface. Verify the

resistance is within the following limits:

3” standardized Microcell™ (light blue cover):

8,300Ω - 8,700Ω

2” standardized Microcell™ (dark blue cover):

1,800Ω - 2,200Ω

4

CHAPTER 3. MICROCELL™ INSTALLATION

ON VERTICAL COLUMN LEGS

INTRODUCTION

Follow the instructions in this chapter only if

installing Microcells™ on vertical column legs.

This chapter describes the mounting locations,

installation details, and wiring details for

Microcells™ and junction boxes. Follow all

instructions carefully to ensure proper system

operation.

Note

Do not mix different types of Microcells™ on

one vessel. The three types (3” standardized,

3” non-standardized, and 2” standardized) are

not interchangeable.

MOUNTING LOCATIONS

Follow the procedures below to determine and

mark Microcell™ mounting locations prior to

beginning installation. Following these procedures

will ensure optimal system performance. Consult

Kistler-Morse® if special considerations prevent

you from installing Microcells™ at the designated

locations.

MICROCELL™ SETS

BEST PERFORMANCE

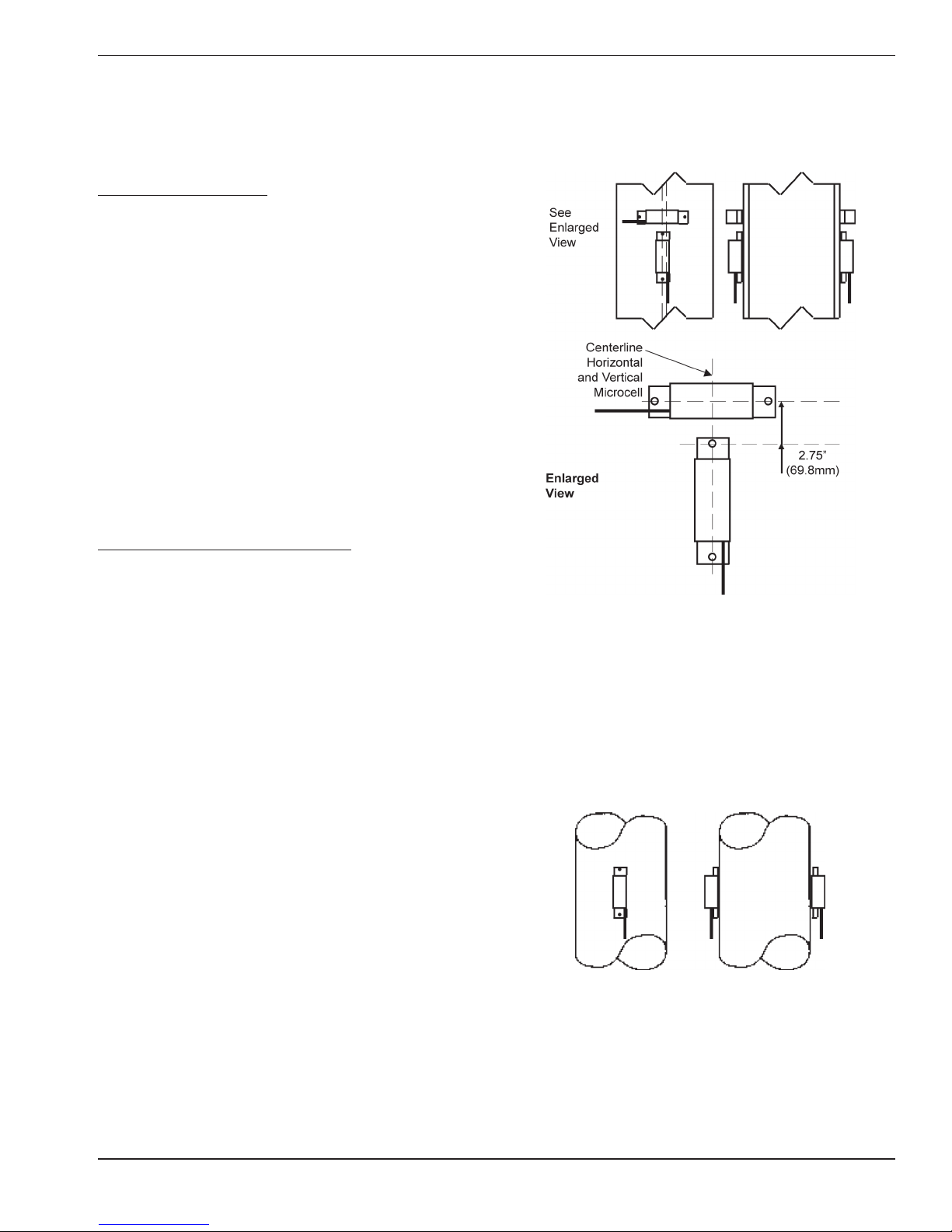

See Figure 3-1. For best performance,

Microcells™ are mounted in a rosette array — a

vertical Microcell™ with a horizontal Microcell™

above it in a “T” conguration. A Microcell™ set

consists of two rosette arrays (four Microcells™

total) mounted on opposite sides of a support leg,

at the same elevation.

Note

Best performance cannot be achieved if:

1. The leg is too narrow for the horizontal

Microcell™ and its environmental cover, or

2. Installation is on round legs.

See STANDARD PERFORMANCE.

Figure 3-1. Microcell™ Rosette Array for

Best Performance.

STANDARD PERFORMANCE

For standard performance, Microcells™ are

mounted vertically. A Microcell™ set consists of

two (2) Microcells™ mounted on opposite sides of

a support leg, at the same elevation.

Figure 3-2. Vertical Microcell™ for

Standard Performance.

5

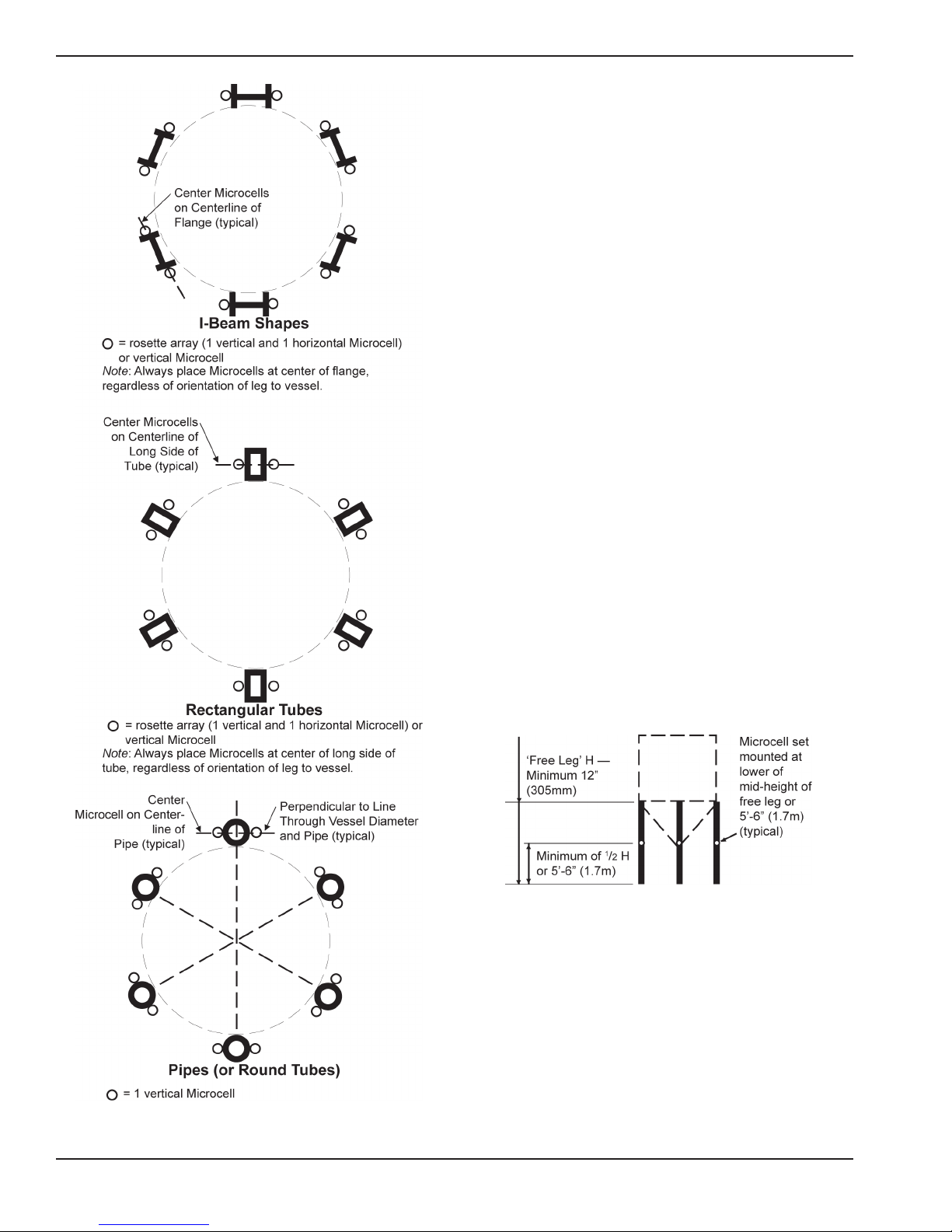

HORIZONTAL DISTRIBUTION OF

MICROCELL™ SETS

Microcell™ sets are placed on each support leg.

Refer to Figure 3-3 for the mounting locations for

each shape.

VERTICAL LOCATION OF MICROCELL™

SETS

Note

Microcell™ locations may be adjusted up to

12 in (305mm) vertically to avoid obstacles. If

adjusting locations, maintain the conguration

of the Microcell™ set (i.e., if one Microcell™ in

the set is moved from its ideal location, move

the other(s) as well).

COLUMN LEGS WITHOUT X-BRACES

See Figure 3-4.

If the free leg distance is between 12 in (305mm)

and 11 ft (3.4m), mount the Microcell™ sets at

mid-height of the free leg.

If the free leg distance is more than 11 ft (3.4m),

mount the Microcell™ sets at 5 ft 6 in (1.7m) above

the foundation.

If the free leg distance is less than 12 in (305mm),

this is a special application situation. Consult

Kistler-Morse® before proceeding further.

Figure 3-4. Vertical Location of Microcell™

Sets for Legs Without X-Braces.

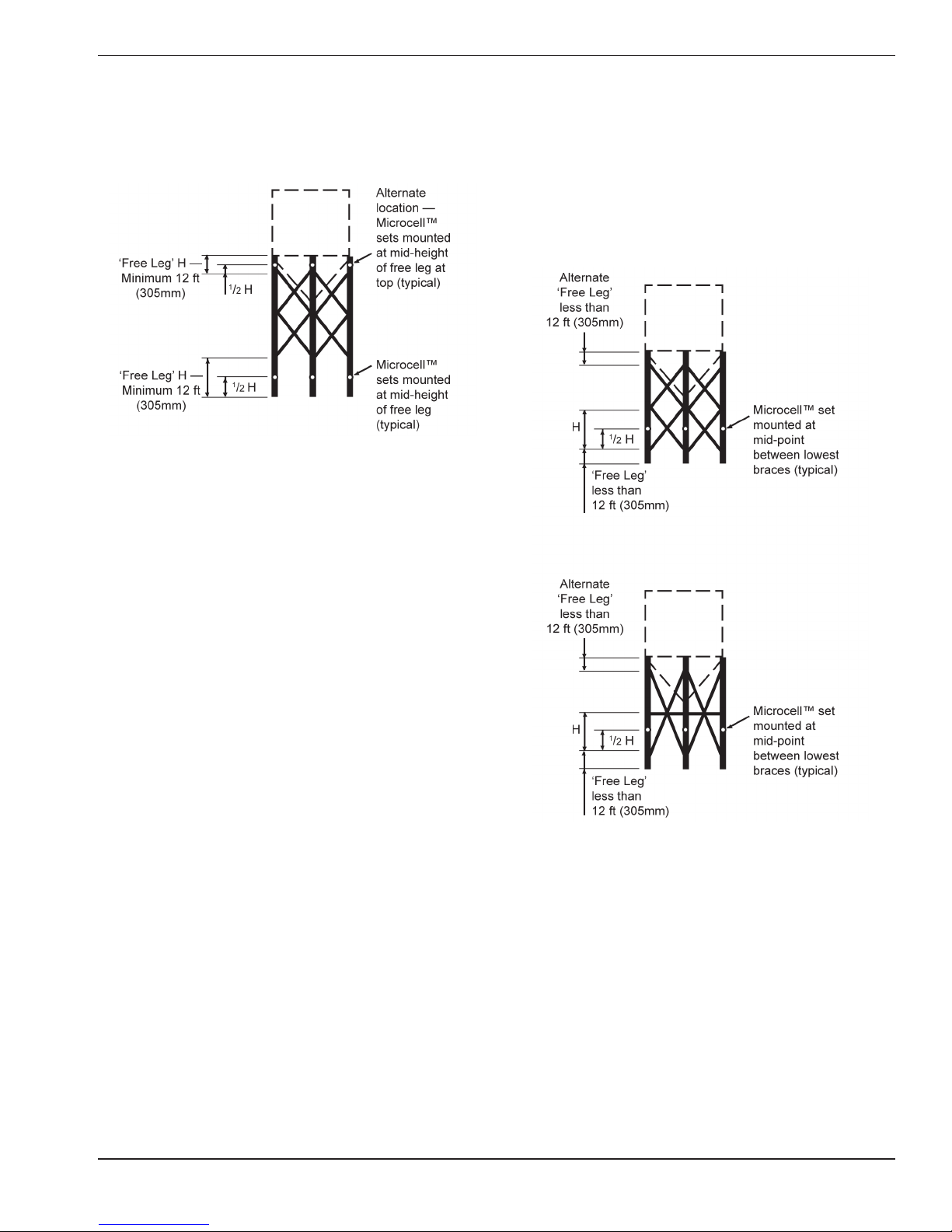

COLUMN LEGS WITH X-BRACES

See Figure 3-5.

If the free leg distance is 12 in (305mm) or more, mount

the Microcell™ sets at mid-height of the free leg.

Figure 3-3. Microcell™ Mounting Arrangements on Legs.

Measure the free leg between the bottom of the bottom

X-brace or horizontal brace and the top of the

foundation.

6

For an alternate location, measure the free leg

between the top of the top X-brace or horizontal

brace and the beam supporting the vessel.

Figure 3-5. Vertical Location of Microcell™

Sets for Legs With Braces and with Free

Leg Greater Than 12 in (305mm).

See Figure 3-6. If the free leg distance is less than

12 in (305mm), mount the Microcell™ sets at the

mid-height between the lowest braces. When

mounting between the braces, insulation around

the adjacent braces is required for best

performance. This insulation will reduce the effect

of sun-induced stresses on the support metal.

Figure 3-6. Vertical Location of Microcell™

Sets for Legs With Braces and with Free

Leg Less Than 12 in (305mm).

7

INSTALLING MICROCELL™ SETS

Note

1. Use lubricating uid (Relton RapidTap®

Heavy Duty Cutting Fluid or equivalent)

when drilling and tapping.

2. Drilling and tapping instructions assume

metal thickness greater than ¾” (19mm).

If the thickness is less, drill all the way

through the metal and tap until cutting

complete threads through the other side.

Minimum metal thickness is 0.1875” (5mm),

which provides six thread engagement.

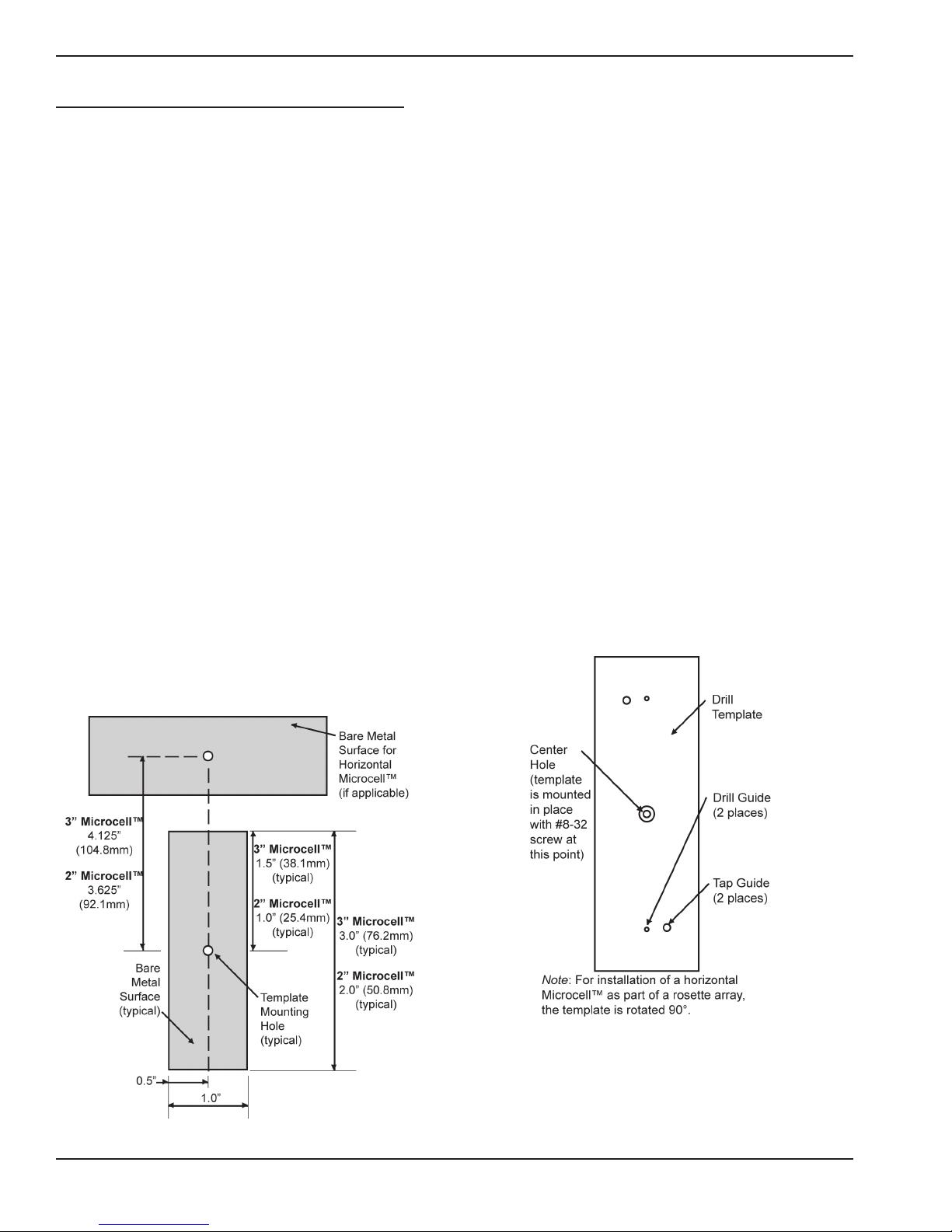

SURFACE PREPARATION

1. See Figure 3-7. At the center of the

vertical Microcell™ mounting location, drill a

¾” (19mm) deep hole with the #29 drill bit.

This produces the template mounting hole.

Repeat for the horizontal Microcell™

(if applicable).

2. See Figure 3-7. Mark the surface preparation

area for the vertical Microcell™ and horizontal

Microcell™ (if applicable).

3. Attach the coarse grit sandpaper to the

grinder. Remove heavy paint and rust with

the grinder until a bare metal surface is

achieved. Due to the use of coarse grit, the

resulting surface is somewhat coarse.

4. Replace the coarse grit sandpaper with the

ne grit sandpaper. Grind until the surface(s) is

completely down to bare metal and smooth to

the touch.

Note

The Microcell™ must be mounted against

smooth, bare metal. Remove all paint and rust

from the area where the Microcell™ is to be

fastened.

DRILL AND TAP

1. Using the #8-32 tap, thread the template

mounting hole for the vertical Microcell™

(drilled during Surface Preparation) to a

minimum

Remove any burrs from the hole.

2. See Figure 3-8. Position the drill template

so the center hole lines up with the template

mounting hole.

3. Fasten the drill template to the template

mounting hole through the center hole, using

the captive #8-32 socket head cap screw. Use

a level to ensure correct orientation.

4. Using the #29 drill bit, drill two ¾” (19mm)

deep holes in the leg through the template drill

guides.

5

/8” (16mm) depth, full threads.

Figure 3-7. Prepared Mounting Surface.

Figure 3-8. Drill and Tap Template.

8

5. Loosen the screw securing the template and

rotate the template until the two tap guides line

up with the drilled holes. Push the #8-32 tap

into one of the tap guide holes to align the

template. Retighten the screw securing the

template.

6. Using the #8-32 tap, thread the two holes

through the template tap guides. Tap to a

minimum

5

/8” (16mm) depth, full threads.

Remove the template from the leg.

7. If installing a rosette array, repeat Steps 1

through 6 for the horizontal Microcell™.

8. Remove burrs from all the holes created.

MOUNTING MICROCELL™ SETS

CAUTION

Do not install Microcells™ in the rain. Do not

trap moisture under the environmental cover.

1. Wipe down a 5 in by 2¼ in (127mm by 57mm)

surface, centered on the template mounting

hole, with degreaser. This cleans the bare

metal and adjacent mounting surface for the

environmental cover.

2. Apply a thin coat of Kistler-Morse

inhibitor to the bare metal surface for the

vertical Microcell™.

CAUTION

Do not apply rust inhibitor beyond this area, or

the environmental cover will not adhere

properly.

3. Connect the Microcell™ red, black, and white

wires to the corresponding terminals on the

®

Kistler-Morse

Test Meter. Turn on the power

to the Test Meter and set the Simulate/Test

Switch to the Test position.

Note

If a Kistler-Morse® Test Meter is not available,

refer to Appendix C (Alternate Method for

Checking Output) before proceeding.

®

rust

Note

3” Microcells™ for vertical and horizontal

installation are slightly different. 3” Microcells™

for horizontal installation are labeled

“Horizontal.” 3” Microcells™ for vertical

installation are not labeled.

CAUTION

For proper installation, tighten each screw until

the T-handle driver exes in torsion ¼ turn past

the point where the screw stops turning.

Repeat this exing procedure several times to

ensure the screw is tight. When both screws

are tight, the voltage must be in the range

-100mV to +100mV. Follow the procedure in

Steps 5 through 7 to achieve this goal.

5. Using the T-handle driver, slowly tighten the

top screw. While turning the T-handle driver,

monitor the test meter carefully. If the

voltage goes outside the range -100mV to

+100mV while tightening, stop immediately

and evaluate the following:

A. If the voltage jumped outside the range

-100mV to +100mV, it may indicate a burr

or rough surface. Remove the screws

holding the Microcell™ to the leg. Check

for and remove burrs and surface

roughness (refer to SURFACE

PREPARATION for removing surface

roughness). Repeat Steps 1through 5.

B. If the voltage gradually moved outside the

range -100mV to +100mV, slowly loosen

the screw until the voltage is within range

again and proceed to Step 6.

6. Repeat Step 5 for the bottom screw. If the

voltage is outside the range -100mV to

+100mV, attempt to bring the reading within

range by loosening the screw being torqued,

tightening the other screw, or some

combination of loosening and tightening. If

you have difculty staying within the range, try

turning each screw ¼ turn at a time until both

screws are tightened.

4. With the cable end down, align a vertical

Microcell™ with its mounting holes. Fasten the

Microcell™ loosely to the leg using the two

#8-32 x

5

/8” socket head cap screws and

washers. Do not tighten the screws. If the

voltage goes outside the range -100mV to

+100mV, immediately loosen the screw(s).

9

Note

If the following occurs while tightening screws,

check Microcell™ resistance using a DMM

(described in Problem 1 in Chapter 6):

A. Voltage does not change or changes less

than 25mV as you turn a screw, or

B. Voltage changes randomly as you turn a

screw (i.e., not in a consistent direction).

7. To complete installation, ensure that both

screws are tightened until the T-handle driver

exes in torsion, ¼ turn past the point where

the screw stops turning, with this exing

procedure repeated several times to ensure the

screw is tight, and the voltage is in the range

-100mV to +100mV.

8. Repeat Steps 1 through 7 for the horizontal

Microcell™ (if applicable).

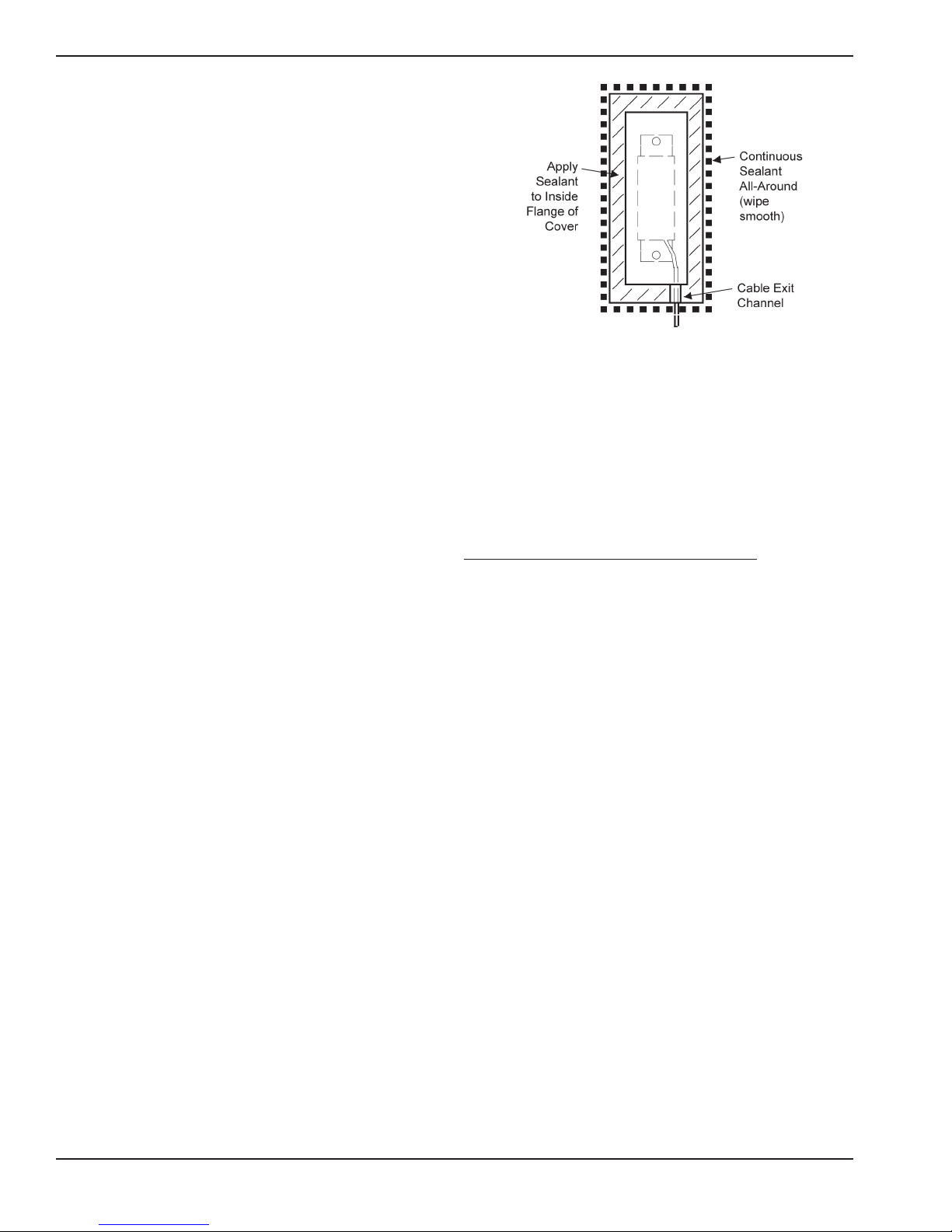

9. Prior to installing the environmental cover(s),

ensure the mating surface(s) on the leg is free

of dirt and grease. Reclean if necessary, being

careful not to remove the rust inhibitor on the

bare metal.

10. See Figure 3-9. Apply a generous bead of

sealant to the inside ange of the

environmental cover. Add extra sealant to the

cable exit channel.

A. Align the environmental cover over the

installed Microcell™, with the cable through

the cover’s exit channel.

B. Press the cover against the web,

squeezing out the sealant around the

edges. Be careful not to squeeze too

much sealant out.

C. Use your nger to smooth the sealant

around all edges and joints, eliminating

areas where moisture may pool, especially

along the top edge. Verify the sealant

forms a continuous, watertight seal. Ensure

the cable exit channel is completely sealed.

D. Repeat Step 10 for the horizontal

Microcell™ (if applicable).

CAUTION

Only use Sikaex 1A polyurethane sealant or

Dow Corning RTV 738 or RTV 739. Other

sealants may contain acetic acid, which is

harmful to sensors and electronics.

Figure 3-9. Environmental Cover.

11. If you created any holes that go completely

through the support metal, spread sealant

(Sikaex 1A polyrethane sealant or Dow

Corning RTV738 or RTV 739) over the open

holes. Use your nger to press sealant into

each hole.

MOUNTING JUNCTION BOX

MOUNTING LOCATION

Each junction box can be wired to a maximum of

two Microcell™ sets (four Microcells™ total):

1. Microcell™ rosette arrays - the four

Microcells™ on a support leg (two sets, each

cosisting of a vertical and a horizontal

Microcell™) are wired to one junction box.

2. Vertical Microcells™ - one junction box can be

wired to Microcells™ from two support legs

(two Microcells™ on each support leg) if the

legs are sufciently close to each other to allow

the Microcell™ cables to reach.

See Figure 3-10. Locate the junction box on the

support leg web or on a brace. Vertically, locate

junction boxes at a convenient height,

approximately 4 ft (1.2m) from the ground. The

exact location of the junction box is not critical,

but ensure you have sufcient cable length and

that a drip loop will be formed by the Microcell™

cables when wired to the junction box.

10

Loading...

Loading...