Page 1

TM TM

Load Disc LD3 /LD360s

Installation Manual

CAUTION

It is essential that all instructions in

this manual be followed precisely to

ensure proper operation of the equipment.

LD3 and LD360s are trademarks

of Venture Measurement Company , LLC

97-1137-01

Rev E

Feb 2006

Page 2

NOTICE

The content of this document is the intellectual property of Kistler-Morse. Any reproduction or translation

of this document without the written authorization of a Kistler-Morse officer is prohibited.

CAUTION

Follow these rules if welding is done on the vessel after installation of the Load Disc. The electrical current

of the welder may pass through the Load Disc, causing damage to the transducer and possibly to the signal

processor. To avoid damage, follow these precautions:

1. Disconnect the Load Disc cables from the signal processor.

2. Ground the welder as close to the welding joint as possible. The welding ground must be between the

Load Disc and the weld joint to prevent the welding current from going through the Load Disc to earth

ground.

Note

High temperatures can damage the Load Disc. If you are welding in the vicinity of a Load Disc,

monitor the temperature of the metal adjacent to the Load Disc. If it becomes too hot to touch, stop

welding immediately and remove the Load Disc before continuing. Prior to reinstalling the Load

Disc, verify that no damage has occurred by referring to the measurement procedures in Troubleshooting, Appendix C.

Page 3

Table of Contents

Table of Contents

Introduction ...................................................................................................i

Welcome ...........................................................................................................................................................i

About this manual ............................................................................................................................................ i

Manual Conventions.................................................................................................................................. i

Specifications...................................................................................................................................................ii

Chapter 1. Description of the Load Disc ................................................ 1-1

Introduction ..................................................................................................................................................1-1

General Description of Measurement System ........................................................................................1-1

Applications Description ................................................................................................. .......................1-1

Installation Option Description.....................................................................................................................1-2

Universal T op Adaptor Plate .................................................................................................................1-2

Leveling Top Plate Adapter (1,000 - 7,500 lbs ONLY).........................................................................1-3

Anyadapter Plate (1,000 - 7,500 lbs ONLY) ...................................................................................... ...1-3

Leveling Base Adapter Plate .................................................................................................................1-4

Chapter 2. Preparing for the Load Disc Installation ............................ 2-1

Check Shipment ............................................................................................................................................2-1

Check Load Disc Order Items ................................................................................................................2-1

Visual Check ...........................................................................................................................................2-1

Prepare Installation Equipment.....................................................................................................................2-2

Installation Equipment Needed .............................................................................................................2-2

Vessel Preparation ........................................................................................................................................2-2

Factors That Affect Performance..................................................................................................................2-3

Chapter 3. Mounting the Load Disc ....................................................... 3-1

General Information......................................................................................................................................3-1

Check Load Disc General Installation ..........................................................................................................3-2

Leveling and Shimming ................................................................................................................................3-5

Leveling/Shimming using Universal Top Adapter Plate (1,000 - 7,500 lbs ONLY) ...............................3-5

Leveling/Shimming using Leveling Top Adapter Plate (1,000 - 7,500 lbs ONLY) .................................3-6

Leveling/Shimming using Leveling Base Adapter Plate.........................................................................3-6

Leveling/Shimming using Anyadapter Plate...........................................................................................3-6

Stainless Steel Junction Box Mounting and Wiring......................................................................................3-7

Appendix A: Contact Information.............................................................................. A-1

Appendix B: System Calibration................................................................................. B-1

Appendix C: Troubleshooting ..................................................................................... C-1

Appendix D: Technical Drawings................................................................................ D-1

Page 4

Table of Contents

Page 5

Introduction

Introduction

This chapter describes the organization, manual conventions,

and provides specification information.

Welcome

About this manual

This manual describes the installation of the Load Disc load cell and its

various hardware options. It includes procedures for leveling and shimming

of the vessel if it is neccessary . Instructions for wiring the load cell to the

junction boxes and wiring the junction boxes together and to the signal

processor are also included. Refer to the signal processor manual for specific

information on wiring the junction boxes to the signal processor.

Contact KM at 1-800-426-9010 if you have any questions regarding the

installation. For outside the USA and Canada, call 864-574-2763.

The chapters are organized in the following way:

Chapter 1: Description of the Load Disc

Chapter 2: Preparing the Load Disc for Installation

Chapter 3: Mounting the Load Disc

Appendix A through D include contact info, system calibration, troubleshooting charts and technical drawings (TI’s).

Manual Conventions

Three kinds of special explanations appear throughout the manual —

Warning , Caution and Note. The format and significance of each is

defined below:

WARNING

Possible danger to people. Injury may result if this information is

ignored.

CAUTION

Possible risk to the product. The Load Disc or other equipment may

be damaged if this information is ignored.

Note

Contains additional information about a step or feature critical to the

installation or operation of the Load Disc.

i

Page 6

Introduction

Specifications

LD3 LD360s

Mechanical

Compression 4 x Rated Load

Tension 1 x Rated Load

Shear 0.5 x Rated Load

Functional Integrity 2 x Rated Load (compression)

Electrical

Excitation Voltage 10-14 VDC 10-14 VDC

Impedance 7.5K Ohms±1% 7.5K Ohms±1%

Maximum Current 3mA @ 12 VDC excitation 3mA @ 12 VDC excitation

Output (@ 12 VDC excitation

Non-Linearity/Hysteresis combined: 0.08% of standardized output 0.08% of standardized output

Return to Zero 0.05% of Rated Output 0.05% of Rated Output

Zero Balance 1% Rated Capacity 1% Rated Capacity

Rated Output (12 VDC excitation) 360 mV±1% (30mV/V nominal) 360 mV±1% (30mV/V nominal)

Environmental

T emperature Range

Standard Temperature Range 0° to 100°F (-18° to 38°C) 0° to 100°F (-18° to 38°C)

Mid Temperature Range 50° to 150°F (10° to 66°C) 50° to 150°F (10° to 66°C)

Temperature Sensitivity Change ±0.015% rated load per degree ±0.015% rated load per degree

Fahrenheit over the Fahrenheit over the compensated

compensated range, 0° to 100°F range, 0° to 100°

Temperature Zero Shift 0.006%/°F (0.011%/°C) 0.006%/°F (0.011%/°C)

Humidity 100% 100%

Storage Temp Range-Std and Mid -40° to 176° F (-40° to 80°C) -40° to 176°F (-40° to 80°C)

Rating NEMA -6P (include NEMA -4X NEMA -6P (include NEMA -4X

and NEMA -6); hermetically and NEMA -6); hermetically sealed

sealed for high pressure caustic for high pressure caustic washdown

washdown and prolonged and prolonged submergence in water

submergence in water. (Cable (Cable must be installed and

must be installed and tightened tightened to meet rating.)

Physical

Construction 17-4 PH 900 stainless steel 17-4 PH 900 stainless steel

Connection Nickel plated brass body with a 6P rated sealed 5-conductor 12mm

Shipping Weight 5.0 lbs (2.3 kg) 5.0 lbs (2.3 kg)

to meet rating.)

polymide insert and neoprene male receptacle Turck Eurofast

Grommet. 22 AWG 3 conductor compatible

unshielded with PVC sheath

(15’ standard)

4 x Rated Load

1 x Rated Load

0.5 x Rated Load

2 x Rated Load (compression)

ii

Page 7

Chapter 1: Description of the Load Disc

Chapter 1:

Description of the Load Disc

This chapter describes the Load Disc Compression Load Cell

and its installation options.

Introduction

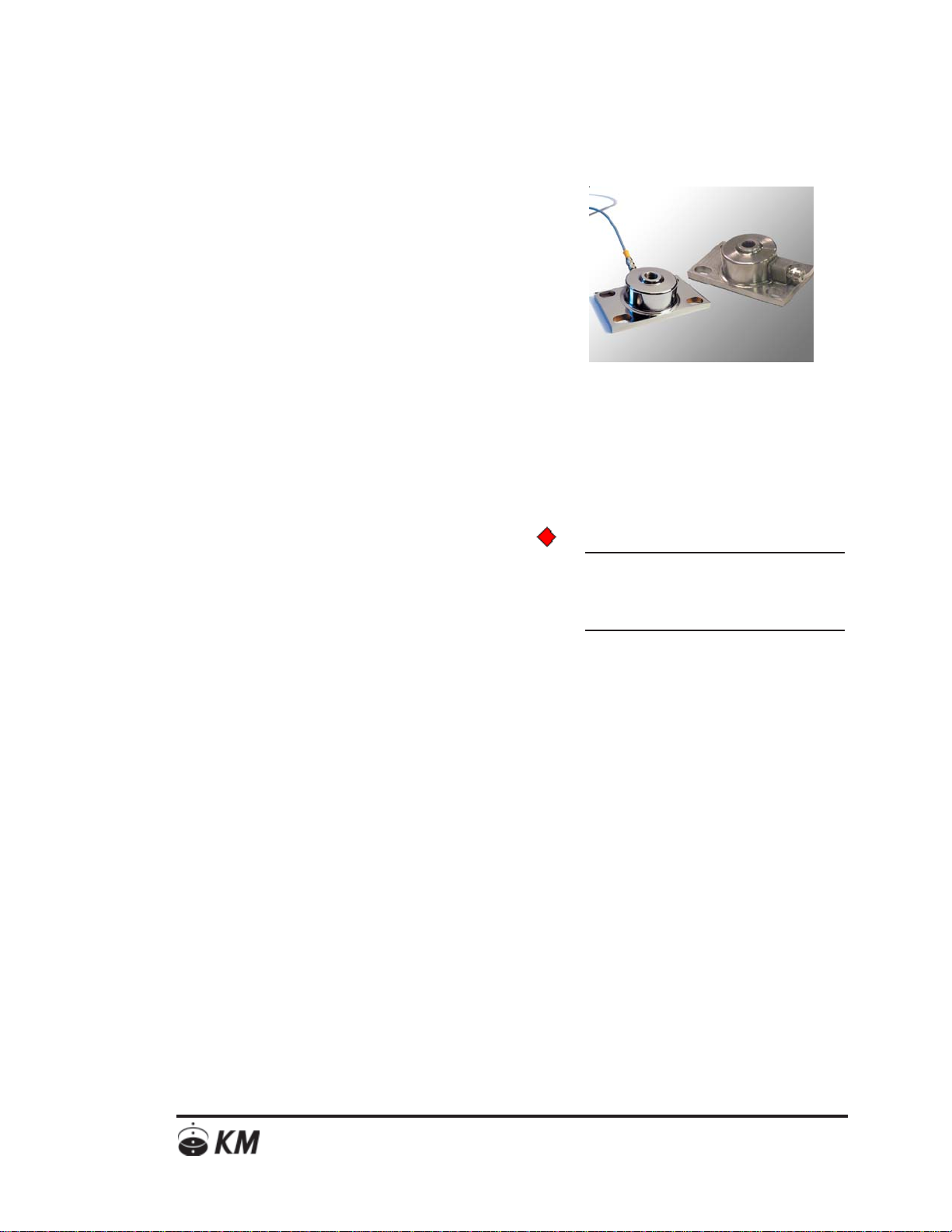

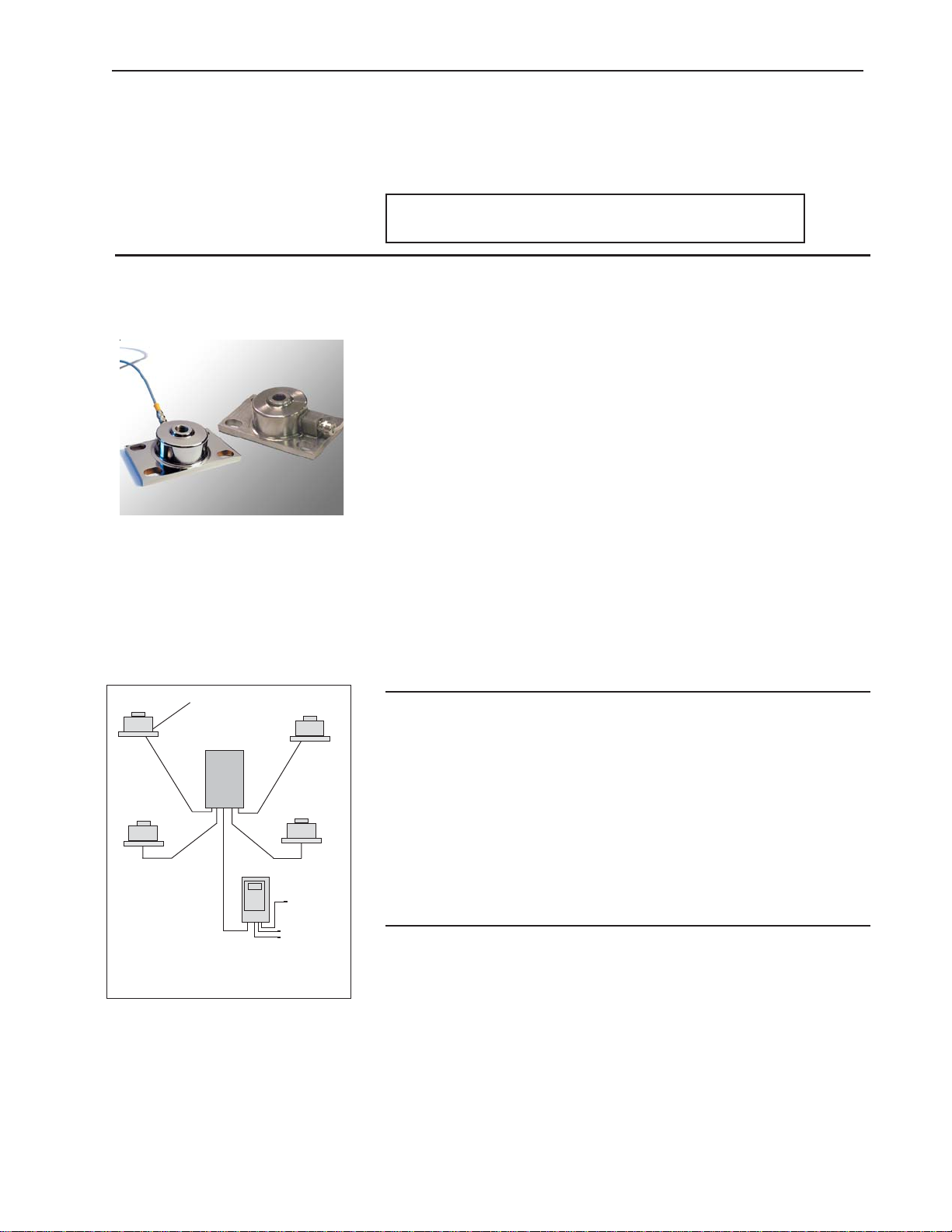

Figure 1-1:

Load Disc Compression Load

Cell with optional NEMA-6P

cable system

weight/4

weight/4

Figure 1-2:

General installation layout for Load Disc

using a junction box.

Load Disc

(x4)

junction box

signal

processor

weight/4

weight/4

Signal

transmission/

Serial Output

Setpoints for

signaling a change

in staus, such as

high and low

alarms

The Load Disc is a low profile load cell that is bolted to both the support

surface and the vessel supports, and is used to measure the weight of materials

in vessels and tanks. The sealed, stainless steel construction–NEMA-6P rated

unit with watertight cable system and cable entry–makes the Load Disc ideal

for use in high-pressure wash down and occasionally submerged environments.

The low-profile design for low clearance installations also keeps the vessel’s

center of gravity low and stable. Vessel tipping, walking or overturning while

agitating is eliminated. Installation and setup is simplified with less hardware.

No external vessel hold-downs are necessary, even in areas of high wind or

seismic activity. There are no moving parts that can wear out or require

replacement. The high output of the semiconductor sensor allows immunity to

industrial electrical noise and longer “load cell to signal processor” runs.

General Description of Measurement System

The deflection of the Load Disc load cell by the vessel weight is measured by

the semiconductor sensor, which is entirely sealed within the watertight cavity

of the transducer. The sensor converts the deflection into an electrical signal

which is directly proportional to the increase or decrease of the vessel

contents. Material movement and changes in material repose will not affect

the accuracy of the system. Accurate weight information is then sent to a

signal processor for display, information transmission and storage (See Figure

1-2).

Applications Description

The watertight design of the Load Disc load cell makes it ideal for measuring

bulk material in the sanitary and clean-in-place environments. It is particularly suitable for use on mixing and blending vessels, surge hoppers, and

agitated vessels. Rugged, solid, bolt-in-place mounting assures vessel

stability in outdoor storage vessels with gussets or legs used in all process

industries.

1-1

Page 8

Chapter 1: Description of the Load Disc

Installation Option Descriptions

This section will briefly describe the following hardware options

for the Load Disc:

Universal Top Plate Adapter, Leveling Top Plate Adapter,

Anyadapter Plate and Leveling Base Adapter Plate.

See Chapter 2 and 3 for more specific installation instructions and

refer to the TI drawings located in Appendix D.

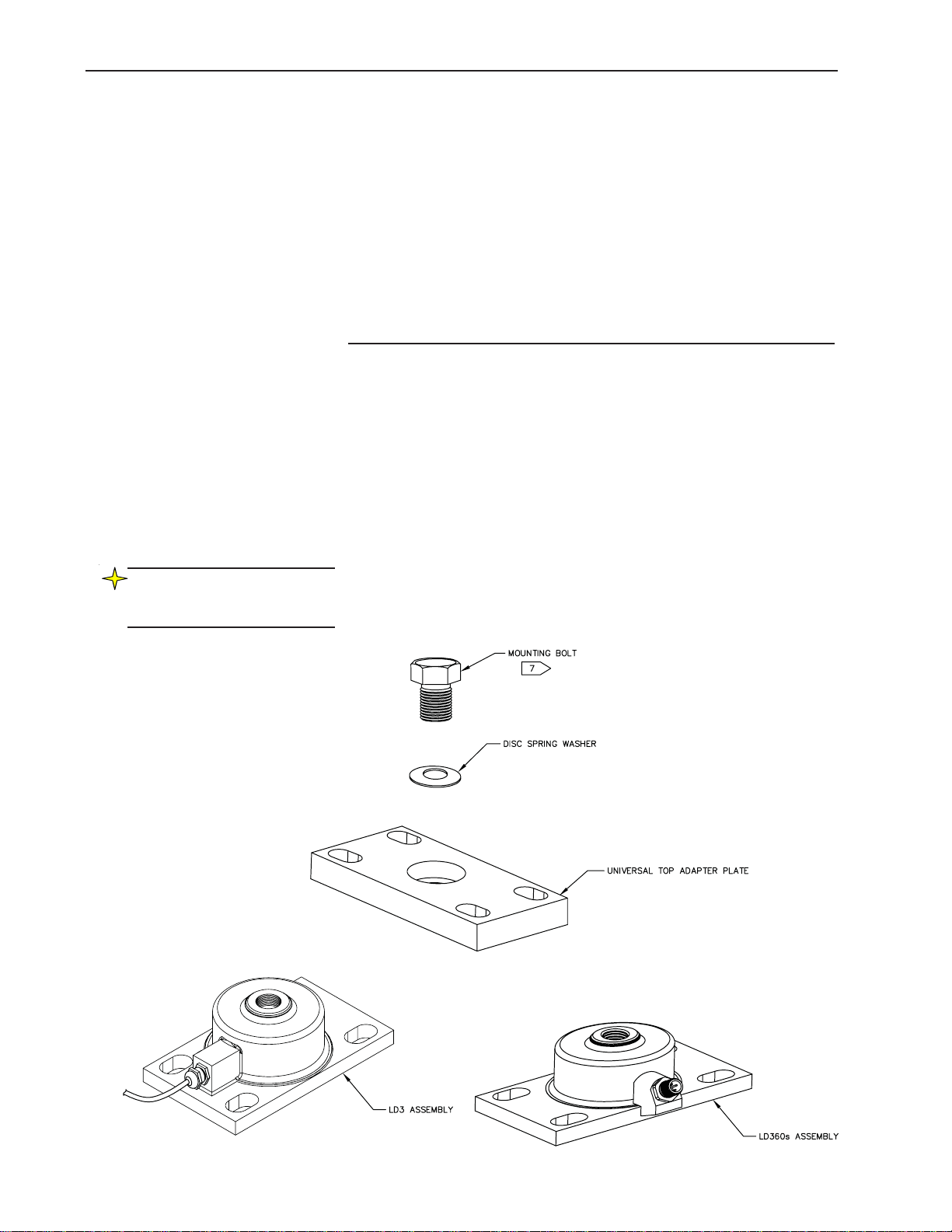

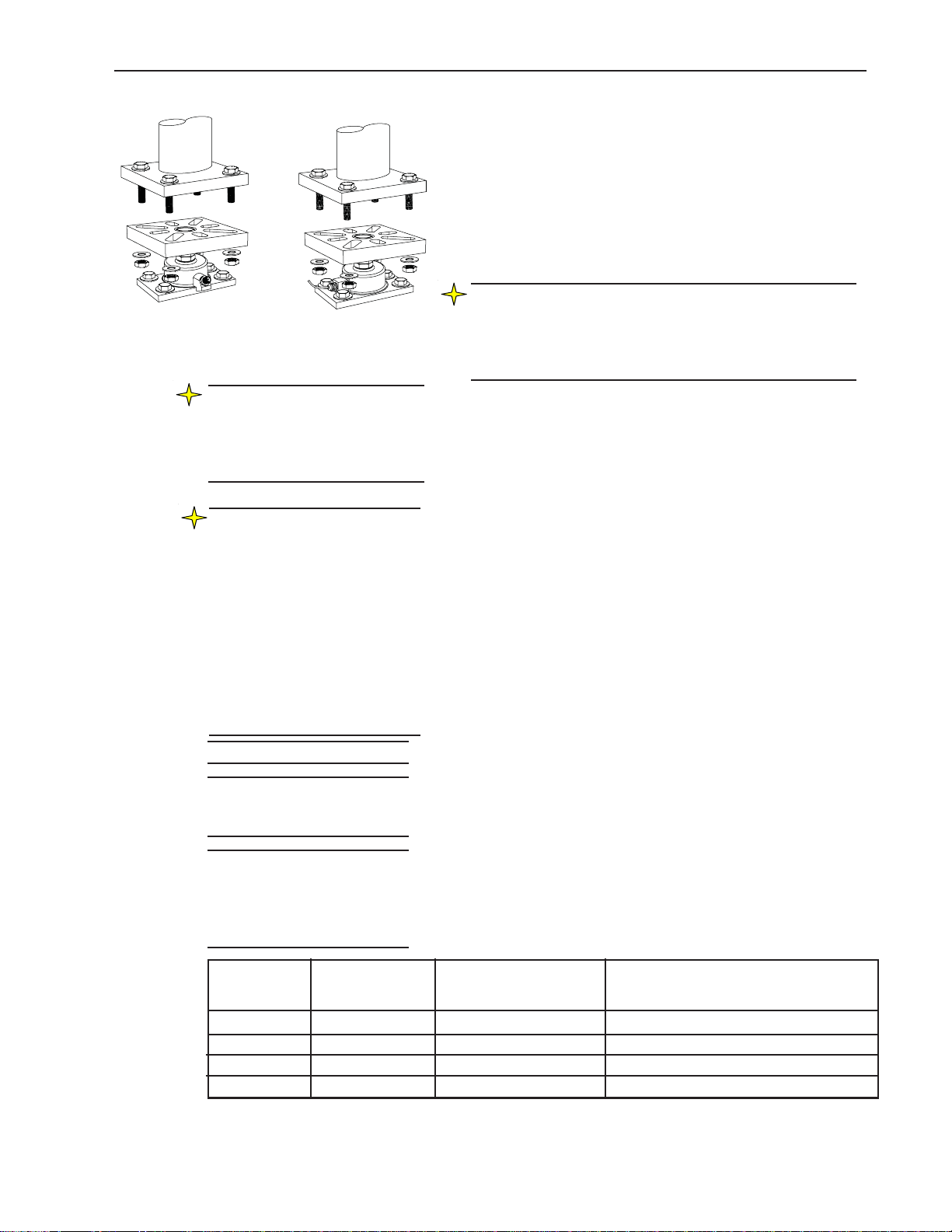

Universal T op Adapter Plate

This option consists of the Universal T op Adapter Plate, spring washer

and a hex head bolt. The adapter plate attaches to the load disc with the bolt

and washer. The adapter plate then bolts to a vessel gusset or a flat plate

welded to the vessel leg, using customer-supplied hardware.

Note: Accomodates up to thr ee

degrees of tilt in the floor or

vessel legs.

1-2

Page 9

Chapter 1: Description of the Load Disc

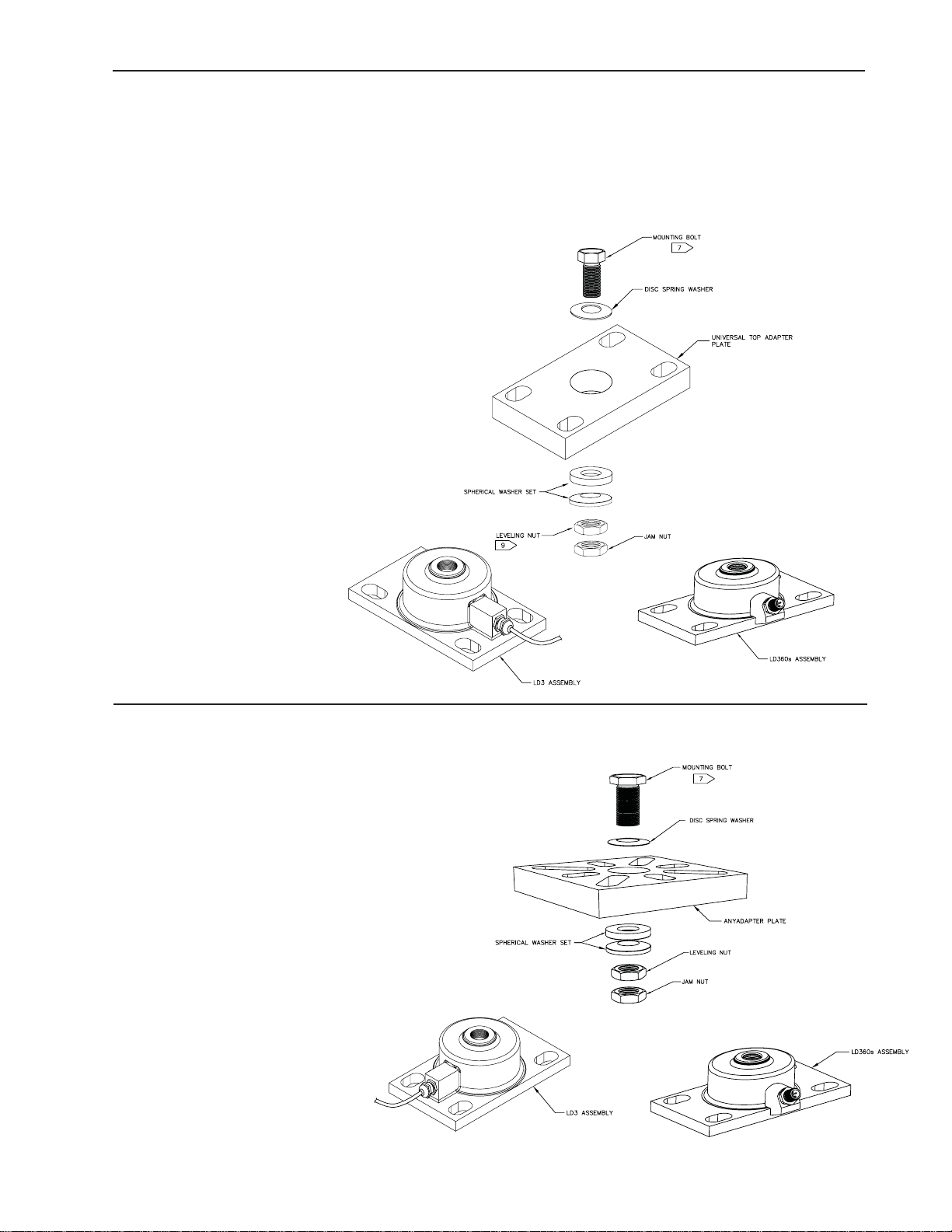

Leveling T op Plate Adapter

This option consists of the Universal T op Adapter Plate, a hex head bolt,

spherical washer set and jam nuts. The adapter plate attaches to the load disc

with the hex bolt and hardware. The adapter plate then bolts to a vessel gusset or

a flat plate welded to the vessel leg, using customer-supplied hardware.

This hardware arrangement allows 360

degree movement of the top plate and

angular misalignment of up to 3 degrees.

Additionally , there is a leveling feature that

allows vertical height adjustments. This

arrangement also incorporates a locking-jam

nut to insure the height remains unchanged.

(1,000 - 7,500 lb capacity ONLY)

Anyadapter Plate

This option consists of the unique Anydapter Plate which

has a universal bolt pattern (to fit a variety of vessel leg

flanges), and a hex head bolt. The plate attaches to the

load disc with the bolt and washers. The Anyadapter plate

then bolts to a vessel gusset or a flat plate welded to the

vessel leg, using customer-supplied hardware.

This hardware arrangement allows 360 degree movement of the top plate and angular misalignment of up to

3 degrees. Additionally, there is a leveling feature that

allows vertical height adjustments. This arrangement

also incorporates a locking-jam nut to insure that the

height remains unchanged.

(1,000 - 7,500 lb capacity ONLY)

1-3

Page 10

Chapter 1: Description of the Load Disc

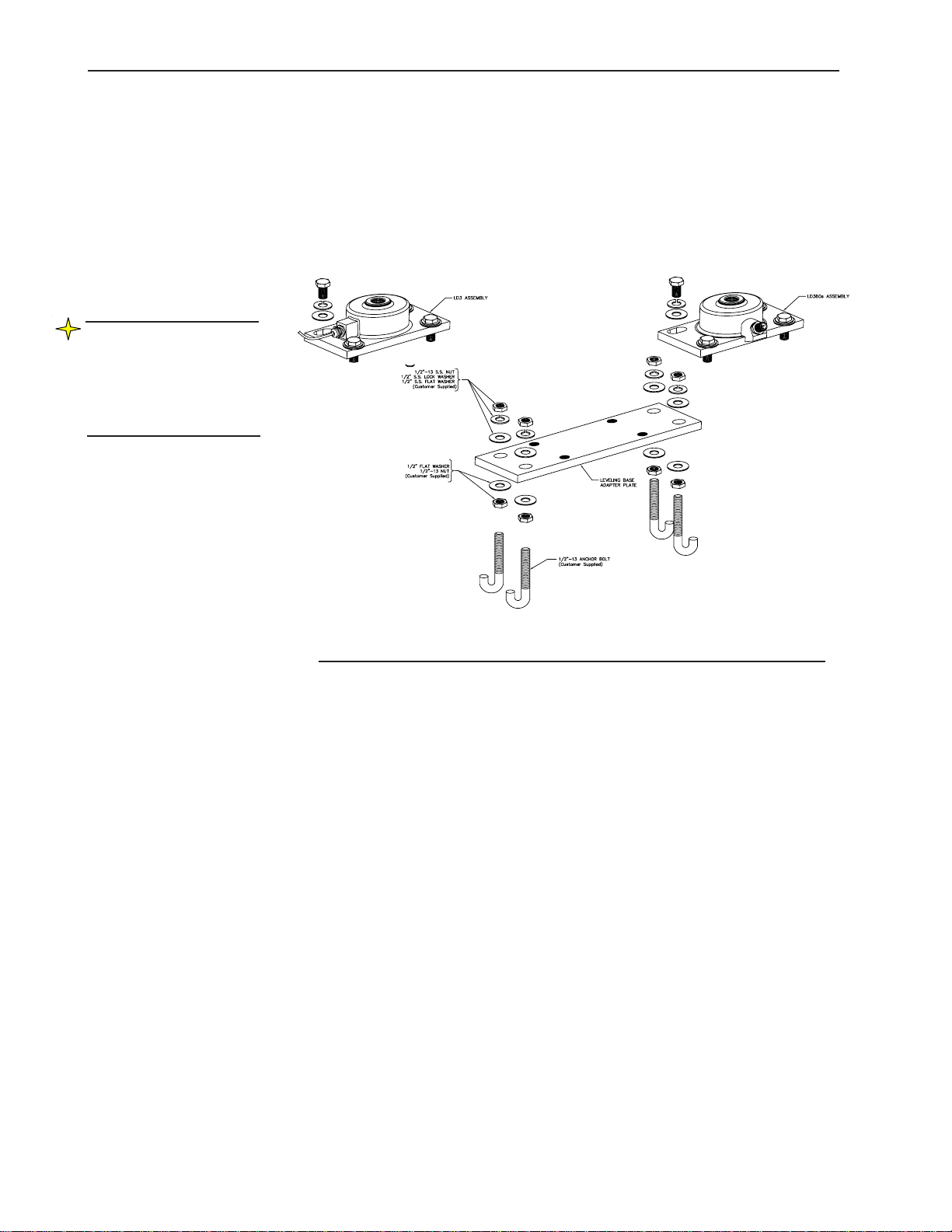

Leveling Base Adapter Plate

This kit consists of a Leveling Base Adapter Plate and four hex bolts, flat

washers, and lock washers. The Load Disc bolts onto the leveling base adapter

plate. This plate rests on four leveling nuts and washers screwed onto anchor

bolts installed in the foundation. By turning the leveling nuts, the height of the

load discs and thus the vessel, can be adjusted for proper load distribution.

Note:

Adapter plate not shown in

illustration at right.

This kit requires an adapter

plate for proper installation.

1-4

Page 11

Chapter 2: Preparing for the Load Disc Installation

Chapter 2:

Preparing for the Load Disc Installation

This chapter describes the pre-check procedures for the Load Disc.

Checking the Load Discs before installation will ensure properly

working equipment that will provide accurate monitoring of vessel

contents.

Check Shipment

Perform the following prior to installing the Load Disc:

Check Load Disc Order Items

The following items are included with a typical order for each vessel

(quantities dependent on application):

Load Disc Load Cell

Junction Boxes or Molded Junction Boxes

Top or Bottom Hardware

If any items are needed, contact KM before proceeding. Substituting

parts without KM approval may cause system problems and will void

the warranty.

Note:

A KM signal processor or a

KM Test Meter are required

to set up and install the

system.

V isual Check

Visually inspect all equipment in the order — including Load Discs,

junction boxes, and signal processors — to verify they have not been

damaged during shipment. If any item has been damaged, contact KM

for a replacement.

2-1

Page 12

Chapter 2: Preparing for the Load Disc Installation

Prepare Installation

Equipment

(Customer Supplied)

The following equipment is needed to install Load Discs:

Lifting equipment

Tape measure

Level

Pry bar

Marking pen

Wrenches

ASTM A-325 bolts (or equivalent strength), lock

washers, and flat washers to secure Load Disc to

vessel support (if applicable)*

ASTM A-325 (or equivalent strength) anchor

bolts, lock washers, flat washers, and nuts to

secure Load Disc to vessel foundation (if

applicable)*

Vessel Preparation

KM Test Meter or signal processor

Shims (if applicable)

Grout (if applicable)

Digital Multimeter (FLUKE™ or equivalent)

optional

* See TI drawings in Appendix D for the appropriate bolt size.

There are two aspects to successful use of Load Discs — properly

functioning Load Discs and appropriate vessel support

characteristics. Review the following list of error sources, and make

the recommended corrections before you install the Load Discs:

• An inadequate vessel foundation can allow excessive

movement. Ensure the foundation is concrete or steel.

• Hidden load-bearing structures, such as discharge chutes

or plumbing supported by the floor, can reduce loads on

the vessel supports. Install flexible couplings to minmize

this problem.

• Cross-connecting structures, such as catwalks and

manifolds, can transfer loads from adjacent vessels.

Install slip joint or flex couplings to minimize this

problem.

• Shock loads can damage the Load Disc. Install protective

barriers or stops to prevent vehicles from hitting the

vessel supports.

2-2

Page 13

Chapter 2: Preparing for the Load Disc Installation

Factors That Affect Performance

An independent, isolated vessel with no connection to any other vessel or adjacent structure provides the most accurate

results for a weight measurement system. Examples of this type of application are floor scales and truck scales. Connections to other vessels or structures affect accuracy because the transducers interpret strain changes caused by the connecting structures as being caused by changes in the material weight.

Some typical causes of error related to connecting structures and, where applicable, methods for reducing the errors

follow:

• Catwalk

• Hidden load bearing members

• Vessel goes through roof

• Tripper conveyors or deck plating

• Rigid piping connection between vessel and

another adjacent structure

• Poor Foundation

• Flexible Structure

• Uneven Loading

No horizontal run

No horizontal run

Flex coupling

Horizontal run too short for crosssectional area of pipe

Horizontal run length is ok for

cross-sectional area of pipe

Flex

2-3

Figure 2-1:

Examples of typical causes of error.

Page 14

Chapter 3: Mounting the Load Disc

Chapter 3: Mounting the Load Disc

This chapter describes installation and wiring of the

Load Disc and junction boxes. Follow all instructions

carefully to ensur e proper operation of the system.

General Information

The Load Disc has a variety of mounting hardware options that

accommodate almost all possible applications. These general requirements apply to all applications:

• Ensure the surfaces where the baseplates bolt down onto are clean,

smooth, flat, and level, with less than 1° of slope in any direction.

• Ensure vessel legs/gussets are clean, smooth, flat, and level, with

less than 1° of slope in any direction.

CAUTION: If you need to

raise the vessel or one

vessel leg after installation,

loosen the bolts on all Load

Discs to prevent overloading.

• Position Load Disc so the cable cannot be snagged or chafed and

can be easily routed to the junction box.

• When raising the vessel for Load Disc installation, use proper support to prevent the vessel from tipping or falling.

• During installation, carefully distribute the load to ALL Load

Discs evenly. PLACING THE LOAD ON ANY ONE LOAD DISC

MA Y CAUSE DAMAGE.

• Hardware and Bolts —

1. All bolts and hardware to attach the Load Disc to the vessel

and to the foundation are customer-supplied, ASTM A-325

or equivalent. (See TI drawings Appendix D)

2. Use specified hardware and bolt sizes. Using other than the

specified hardware can either reduce strength or overstress

the Load Disc during installation, voiding the warranty.

3. All bolts are kept loose until shimming and leveling is

complete.

• Securing Load Disc after Leveling/Shimming —

Once the weight distribution criteria has been satisfied

(page 3-4) through leveling and/or shimming, complete the installation by tightening the required bolts for your application.

3-1

Page 15

Chapter 3: Mounting the Load Disc

Load Disc

General Installation

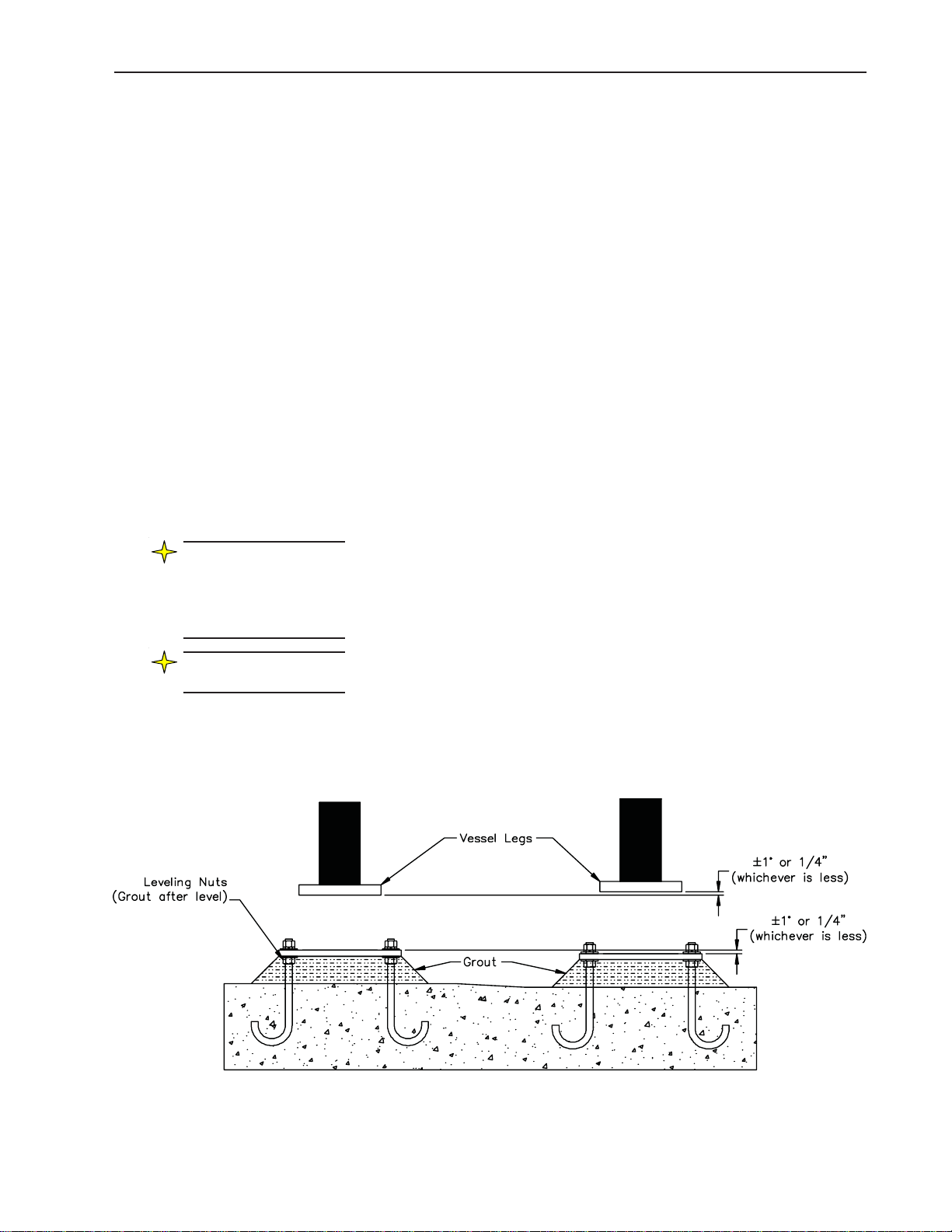

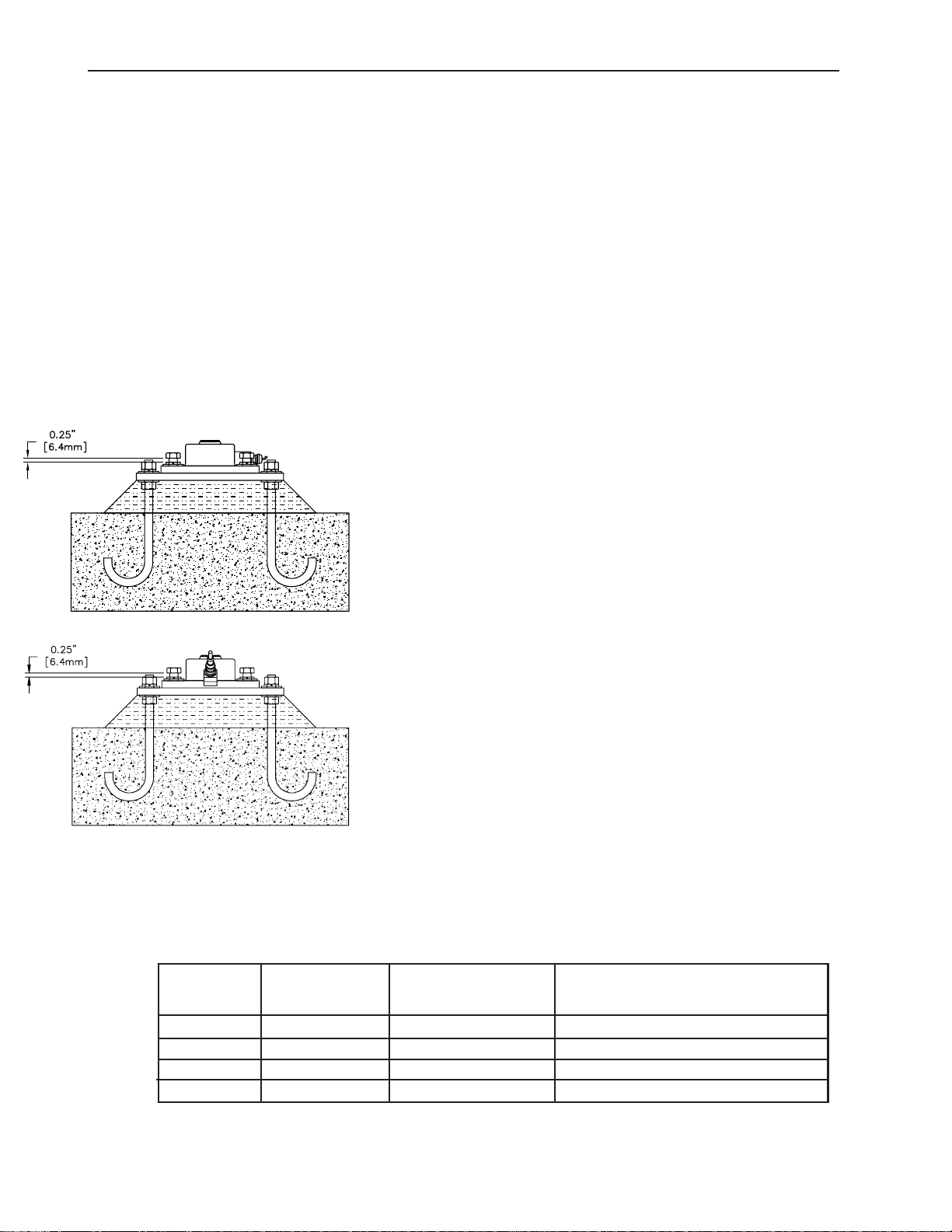

Note: Concrete foundation and grouting shown

for reference only. The

concepts apply to all

foundation types.

Anchor bolts supplied

by customer .

This section describes the Load Disc installation procedures for the

following hardware options:

Universal Top Plate Adapter , Leveling Top Plate Adapter , Anyadapter

Plate, and Leveling Base Adapter Plate.

1. Prior to installing the Load Discs, verify that they are the

correct capacity for your application by reviewing the

information engraved on the Load Disc baseplates.

2. If you have not already done so, connect the Load Disc cable to

the KM Test Meter (See pg. C-1). Measure the Load Disc

voltage output. W ith no-load, the preliminary measurement

should be +5mV and -5mV. (This measurement range is used

only to verify the condition of the Load Disc.) If the reading

is significantly outside of this range, consult the factory

before continuing the installation.

3. Raise the vessel.

4. Remove the cable from the KM Test Meter to the Load Disc.

5. Place bolt through center hole of adapter plate and install

hardware for your application

(See Appendix D:TI Drawings)

a. For Universal Top Plate Adapter, install bolt and

plate to the Load Disc, tightening bolt to 5-10 ft-lbs.

b. For Leveling and Anyadapter, install washers and

nuts to the bolt and plate, making sure the washers/

nuts are loosely tightened against plate. Install the

plate assembly to the Load Disc, tightening bolt to

5-10 ft-lbs.

6. For Leveling and Anyadapter applications, adjust plate to

lowest position by lowering jam nut to top of Load Disc and

tighten. Then lower leveling nut to the jam nut.

Figure 3-1: Angular misalignment

3-2

Page 16

Chapter 3: Mounting the Load Disc

7. Inspect the foundation and vessel mounting surfaces that

will mate to the Load Disc plates.

a. Check the mounting hole locations and size on both

the foundation base and the vessel foot pad. (Refer

to the TIdrawings, Appendix D.)

b. Check the surfaces for flatness and angular

misalignment. A baseplate with leveling nuts is

recommended. (See Figure 3-1 below)

8. Mount the Load Disc assembly to the foundation. (See TI

drawings, Appendix D)

a. Gently lower the Load Disc to the foundation. Take care

to align the mounting holes with the foundation

mounting holes/studs.

b. Install the bolts and nuts as required. DO NOT fully

tighten the bolts at this time. Leave a 1/4-inch gap

between the nut and the washer to allow positioning

of the Load Discs. (See Figure 3-2.)

c. Repeat Steps 8a and 8b for the remaining Load Discs.

Figure 3-2: Leave 1/4-inch gap for positioning

Load Disc # No-Load Output Dead Weight Output Output Change (mV)

(mV) (mV) (Dead Weight Output - No-Load Output)

9. Re-install the Load Disc cable and record the voltage output at

“no- load” condition now that it is in position.

a. If not already done, connect the Load Disc cable to

the KM Test Meter as seen in Figure C-1

Troubleshooting.

b. Turn on the power to the KM Test Meter and set the

Simulate/T est switch to the T est position.

c. Record the no-load output into Figure 3-3 below or

create your own similar table. See the example chart in

Figure 3-5.

d. Assign a number (1, 2, 3, etc.) to the Load Disc and note

it.

e. Repeat steps c and d for all the Load Discs.

1

2

3

4

Figure 3-3: W eight Distribution Chart: Record YOUR system’s Load Outputs

3-3

Page 17

Figure 3-4: Lower vessel onto

top plate.

Chapter 3: Mounting the Load Disc

10. Mount the vessel to the Load Disc.

a. Lower the vessel gently onto the Load Discs.

(Alignment pins may be used to help guide and

position the vessel.) (See Figure 3-4)

b. Center the Load Disc top mounting holes with the

vessel mounting holes, using the clearance

available from the bottom mounting holes.

Note: If the vessel hole pattern does NOT match up with

the Load Disc hole pattern, modify the mounting holes on

the vessel. DO NOT hammer or for ce the Load Disc into

position by tightening the mounting bolts. The vessel holes

will need to be resized or relocated.

Note: All output changes should

be positive! If you observe a

negative output change, check

wiring polarity and vessel load

shifting.

Note: The example below is an

ideal situation (load is centered). Offcenter loads caused

by offset mixers or gear boxes

will place weight on some

supports more than others. Do

not attempt to shim ALL

supports to ten percent of the

average output. Balance the

support weight between each

other making sure all legs carry

a load.

Calculation Example:

A verage Output Change =

(86mV + 83mV + 69mV +

89mV) / 4 = 81.8mV

c. Place the four top bolts (customer supplied)

through the vessel and the Load Disc mounting

holes. The bolts must be able to pass freely

through the holes without interference.

d. Tighten the bolts, leaving a 1/4-inch gap for

positioning. (See Figure 3-2)

11. Check dead weight output.

a. Connect the Load Disc cable to the KM Test

Meter, if not already done.

b. Record the dead weight output on your Weight

Distribution Chart that was started on page 3-3.

See the example below in Figure 3-5.

c. Calculate the Output Change. (Change should be

positive.)

d. The output increase from no-load to dead weight

can be within ten percent of the AVERAGE

output increase. In the example below, the average

output change for Load Discs #1, #2 and #4 meet

this condition, while the output from Load Disc

#3 is too low indicating it is carrying less weight.

Allowable range for Output

Change = Average Output

Change ± 10% =

81.8mV ± (.1 x 81.8mV) =

e. Load disc #3 will require a shimming and/or

leveling procedure which will distribute the weight

more evenly over all of the supports. (See

page 3-5, Leveling/Shimming)

73.6 to 90.0 mV

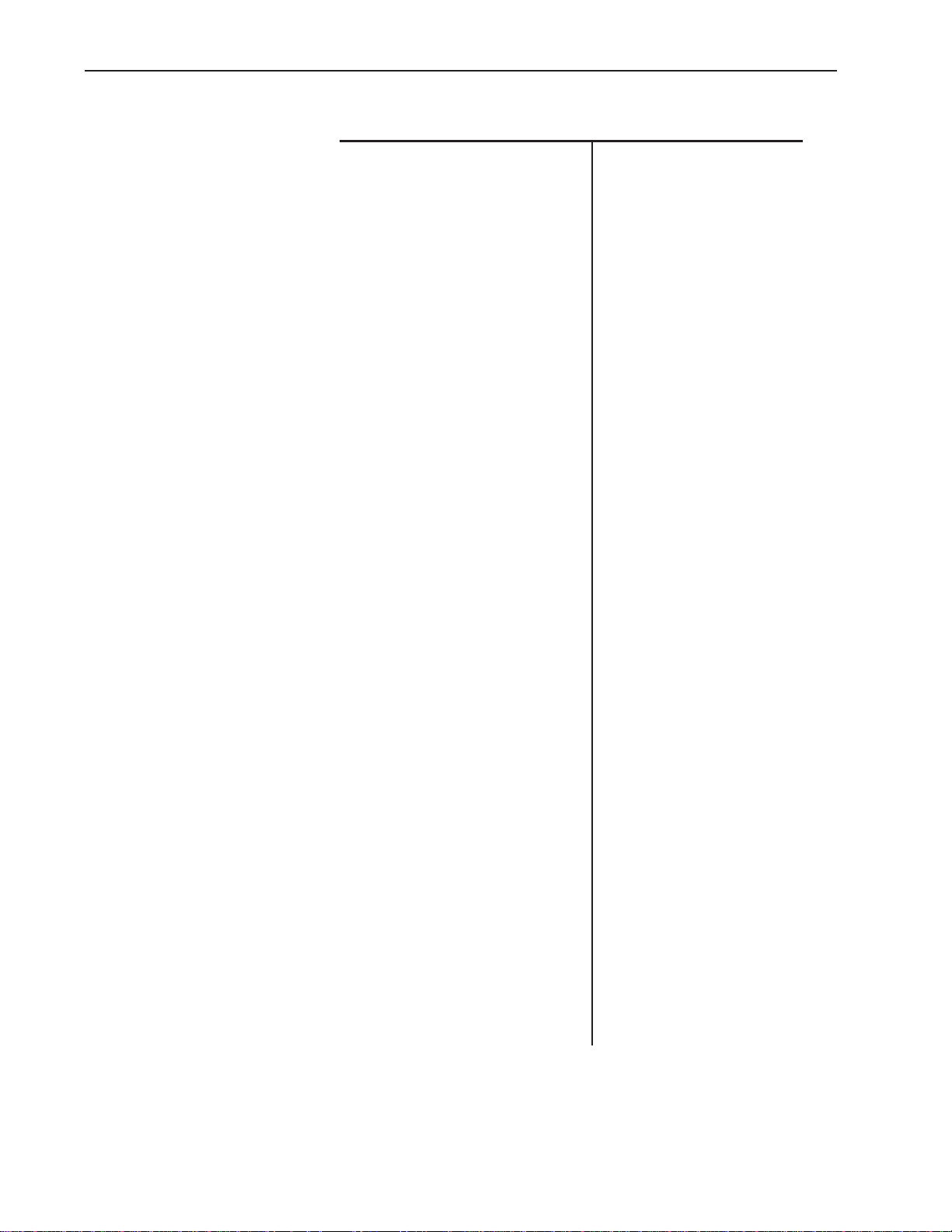

Load Disc # No-Load Output Dead Weight Output Output Change (mV)

(mV) (mV) (Dead Weight Output - No Load Output)

1 +3 +89 +86

2 +4 +87 +83

3 +2 +71 +69

4 -3 +86 +89

Figure 3-5: Example of Dead Weight Outputs and Output Change

3-4

Page 18

Chapter 3: Mounting the Load Disc

Leveling and Shimming

Note: For installations where

leveling nuts are not used, load

balancing on the Load Discs

must be achieved by adding or

removing shims. Adjusting the

Load Discs to distribute the

vessel weight evenly may

require adding shims (supplied

by customer) systematically to

all disc locations.

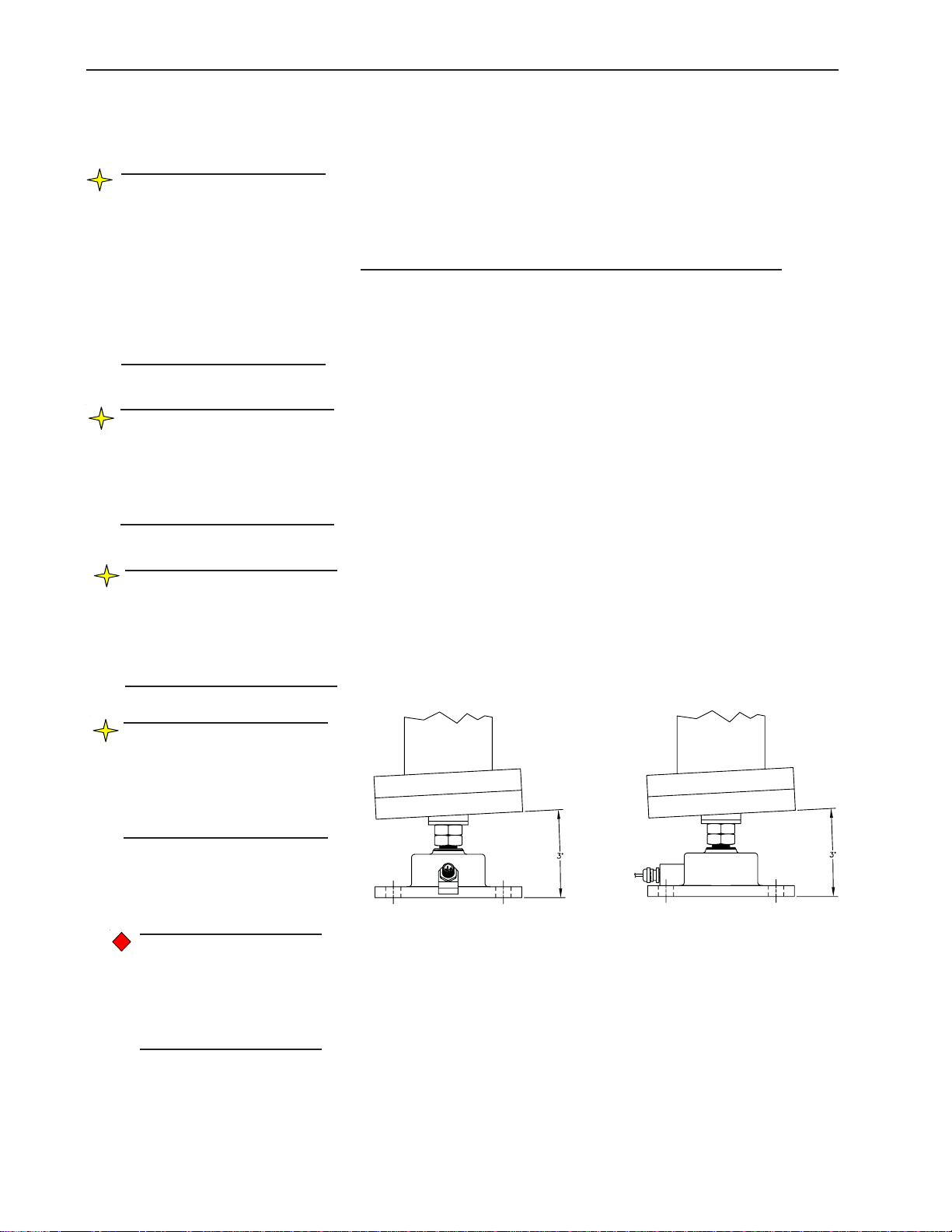

Note: The Universal T op

Plate will accomodate angular

misalignment up to three

degrees maximum (Figure 3-6 ).

Ideally, the load is distributed

evenly across the top plate.

Note: Shimming the plates of

one Load Disc will probably

affect the weight distribution

on the Load Disc located on the

opposite side. Keep this in mind

while shimming.

The main objective of leveling/shimming the vessel is to distribute

the weight evenly on all of the Load Discs. Uneven weight distribution will reduce the accuracy of the weight measurement system as

a whole and in extreme cases may cause Load Disc damage.

Once the general instructions have been completed (page 3-2

through 3-4), begin the leveling and shimming instructions in this

section.

Leveling/Shimming using Universal Top Adapter Plate

(1,000 to 7,000 lb capacity ONLY)

1. Based on the Weight Distribution Chart (Figure 3-3)

and visual inspection, raise the vessel and cut/place

shims as required to adjust the distribution of weight on

the Load Discs. Begin with the “lowest output”

support first!

2. Gently lower the vessel and measure the dead weight

output and the output change of all of the Load Discs

to see how they are affected. Record again into the

Weight Distribution Chart on page 3-3.

3. Repeat Steps 1 and 2 until you have achieved the

desired output change of all of the Load Discs.

Note: Shims are typically

applied between the Load Disc

Top Plate and mating vessel

plate, but the gap condition

may exist at either the top or

bottom plates.

CAUTION: If you need to

raise the vessel or one

vessel leg after installation,

loosen the bolts on all Load

Discs to prevent overloading.

Figure 3-6: Angular misalignment

up to 3 degrees.

3-5

Page 19

Chapter 3: Mounting the Load Disc

Leveling/Shimming using Leveling Top

Adapter Plate, Leveling Base Adapter Plate,

and the Anyadapter Plate

1. Based on the Weight Distribution Chart and visual

inspection, raise the leveling nut to adjust the top plate

until the weight distribution falls within the weight

distribution guidelines (See page 3-4). Check for gaps and

use shims as required.

2. Gently lower the vessel and measure the dead weight

output and the output change of all of the Load Discs

to see how they are affected. (See Weight Distribution

Chart page 3-3.)

3. Repeat Steps 1and 2 until you have achieved the

desired output change of all of the Load Discs.

Note: Shimming the plates of

one Load Disc will probably

affect the weight distribution

on the Load Disc located on

the opposite side. Keep this in

mind while shimming.

CAUTION: If you need to

raise the vessel or one

vessel leg after installation,

loosen the bolts on all Load

Discs to prevent overloading.

3-6

Page 20

Chapter 3: Mounting the Load Disc

Stainless Steel Junction Box Mounting and Wiring

Mounting Junction Box

1. See Figure 3-7. Hold the junction box at the desired

mounting location. Mark the four mounting holes.

2. Mount the junction box with #8-32 socket head cap

screws and flat washers per your application. Tighten the

screws until snug.

Figure 3-7: Plastic and

Stainless Steel Junction Box

Mounting

Wiring Load Discs to Junction Box

See Figure 3-8. The stainless steel junction box accommodates up to

eight Load Discs, with up to two Load Disc wires at each terminal.

Note that the junction box has no pre-cut holes for conduit or fittings.

Follow this procedure:

1. Prepare junction box —

a. Remove the junction box cover.

b. Remove the terminal board from the junction box.

c. Carefully lay out the conduiting configuration —

the Load Disc cables connect to the terminals on

the left and the signal processor cable connects

on the right. Several Load Disc cables may enter

the box through the same conduit.

d. Cut the required fitting holes in the bottom and/or

sides of the junction box.

e. Install liquid tight fittings.

f. Seal fittings with Sikaflex™ or electrical grade

sealant.

Figure 3-8: Wiring Load Discs to Stainless

Steel Junction Box

3-7

Page 21

Note: Ground the cable

shield only at the signal

processor.

Chapter 3: Mounting the Load Disc

2. Thread the Load Disc cable through the desired conduit

fitting. (See Figure 3-8).

3. Estimate the required length of cable to the terminal strip,

allowing a little extra for strain relief. Cut the excess cable.

4. Strip back 3” (76mm) of the cable sheathing to expose the

three wires inside. Strip back 1/4” (6mm) of insulation from

the end of each of the wires.

5. Connect the Load Disc wires to the selected TB3 terminals

on the left side of the junction box: brown or red wir e

to R, white wire to W, and black wire to B.

6. Perform Steps 2 through 5 for each Load Disc you wire to

this junction box. Up to two Load Discs can be wired to

each terminal.

7. Replace the junction box cover if not ready to begin

wiring the junction boxes together.

Wiring Junction Boxes Together and to Signal Processor

Notes:

1. The procedure below assumes the conduit fitting and

conduit for wiring the junction box to the other junction boxes

and to the signal processor has been installed.

2. Seal all conduit fittings against water entry. Install drain holes

at conduit’s lowest elevation(s) to allow condensation to drain.

3. Use Belden™ 3-conductor shielded interconnect cable or

equivalent to wire junction boxes together and to the signal

processor. For lengths up to 1,000’ (305m) use 18-gage

Belden™ 8791 cable. For lengths from 1,000’ to 2,000’ (305m to

610m) use 16-gage Belden™ 8618 cable.

4. When wiring cable to junction box terminals, strip back 3”

(76mm) of cable sheathing to expose the three conductor wires

and shield wire inside. Strip 1/4” (6mm) of insulation from the

end of each of the conductor wires.

5. All spliced wiring routed between junction boxes and signal

processor must be soldered and encapsulated in waterproof

heatshrink.

1. Remove the junction box cover.

2. See Figure 3-9. Route the 3-conductor cable through the fitting

into the junction box farthest from the signal processor.

Connect wires from the cable to the TB1/TB2 terminal in the

junction box: black wire to B, white wire to W, and

brown or red wire to R.

3. Route the cable through conduit to the next junction box.

Estimate the required length of cable to the terminal strip,

allowing a little extra for strain relief. Cut the excess cable.

Connect wires from the cable to the TB1/TB2 terminal in the

junction box: black wire to B, white wire to W, and

brown or red wire to R.

3-8

Page 22

Chapter 3: Mounting the Load Disc

CAUTION: Only use

Sikaflex™ 1A polyur ethane sealant or Dow

Corning™ RTV 739

or RTV 738. Other

sealants may contain

acetic acid, which is

harmful to sensors

and electronics.

4. Route another 3-conductor cable through the fitting into

this junction box, and attach wires to the TB1 TB2 terminal:

black wire to B, white wire to W, and brown or red wire

to R.

5. Repeat Steps 3 and 4 until all junction boxes on the

vessel are wired together.

6. Route the cable from the last junction box through

conduit to the signal processor. Refer to the signal

processor manual for wiring the junction box to the signal

processor. One vessel takes up one channel in the signal

processor — the channel shows the average value from

all the Load Discs under the vessel.

Figure 3-9: Wiring Stainless Steel Junction Boxes Together and to Signal Processor

3-9

Page 23

Appendix A: Contact Information

Appendix A: Contact Information

Contact Information

Technical Service

You may reach Kistler-Morse headquarters at the

following:

Mail: Kistler-Morse

150 Venture Boulevard

Spartanburg, SC 29306 USA

Telephone: 1-800-426-9010

(864) 574-2763

Fax: (864) 574-8063

E-mail: sales@kistlermorse.com

Website: http://www.kistlermorse.com

A complete, unabridged copy of our product warranty is available

upon request from KM. A summary of the warranty, subject to the

terms and conditions listed fully in the warranty, follows:

KM warrants the equipment to be free from defects in material and

workmanship for two years from date of shipment to original user.

KM will replace or repair, at our option, any part found to be

defective. Buyer must return any part claimed defective to KM,

transportation prepaid.

KM maintains a fully trained staff of field service personnel who

are capable of providing you with complete product assistance.

Phone Consultation

Our Customer Service staff provides the following services by

telephone, via our regular and toll free number (toll free in U.S.A.

and Canada only):

• Technical, application, and troubleshooting assistance

• Spare parts assistance

• Warranty (replacement) assistance

A-1

Page 24

Appendix A: Contact Information

On-Site Consultation

KM’s Field Service staf f can provide additional services at your request.

Contact KM for rate and scheduling information for the following

services:

• Technical, application, startup, and troubleshooting assistance

on-site

• Training on-site or at our production facility

• Service calls

• Equipment updates to our latest configuration

Note: Load Disc installation, field

wiring, conduit installation, and

junction box and signal processor

mounting must be performed by the

customer. The AC power must be

connected to the signal processor,

but not energized, prior to KM

beginning work.

General descriptions of some of these standard services follow. Of

course, if your service needs vary from those described, we are

available to discuss them with you.

Installation, Startup Assistance, and On-Site Training

The system will be powered up and checked for proper electrical

operation. For best results, KM requires moving a known amount of

material, such as a truckload, for Live Load calibration. Live Load

calibration will be performed if actual material or weight devices can be

moved. If it is not possible to move material, a Manual calibration will

be performed. Recommendations for the optimal performance of the

system will be provided.

On-site training will include simulation of the Live Load calibration

process (if Live Load calibration can not be performed while KM is on

site) and instruction covering operation and maintenance of the system.

Troubleshooting

KM will troubleshoot systems for mechanical, electrical, calibration,

and wiring errors. Normal component repairs will be made and wiring

errors will be corrected, including replacement of non-repairable

printed circuit boards. (To troubleshoot your own equipment, see

Appendix C for Equipment Troubleshooting charts)

Service Calls

KM will perform on-site repair/replacement services.

Return Material Authorization

If a part needs to be sent to the factory for repair, contact KM and

request a Return Material Authorization (RA) number. The RA number

identifies the part and the owner and must be included with the part

when it is shipped to the factory.

A-2

Page 25

Appendix B: System Calibration for the Load Disc

Appendix B: System Calibration for the

Load Disc

This chapter describes general procedur es

for calibrating the Load Disc system.

Calibration Methods

Before calibrating, install a signal processor. Refer to the signal

processor manual for the procedures to input calibration parameters.

There are two calibration methods:

• Live Load calibration — set lo span and hi span while moving

material into or out of the vessel. This is the preferred method.

• Manual calibration — set scale factor counts, scale factor weight,

and zero calibration value without moving material.

Live Load calibration requires you to move a known quantity of

material into or out of the vessel while performing the procedure. The

quantity of material moved must be at least 25% of the vessel’s total

capacity to provide the best accuracy . Live Load calibration is also

based on the material weight currently in the vessel.

Manual calibration allows you to start using the system as soon as the

Load Discs, junction boxes, and signal processor are installed and

wired, even if you cannot move any (or enough) material now. Manual

calibration values are based on system parameters, including rated load,

and signal processor A/D converter sensitivity. These values are known,

can be calculated, or can be obtained from the signal processor. Manual

calibration is also based on the material weight currently in the vessel.

Note that Manual calibration does not take into account the actual

response to changes in weight. Theoretically , a change in weight results

in a proportional change in digital counts. However, the structure’s

actual response to weight and interaction with piping, catwalks, roof,

discharge chutes, etc. prevents the system from achieving theoretical

values. Manual calibration is a good start, but to obtain the highest

accuracy, perform a Live Load calibration when scheduling permits you

to move material into or out of the vessel.

Refer to the indicator manual(s) for detailed calibration instructions.

B-1

Page 26

Appendix C: Troubleshooting the Load Disc System

Appendix C: Troubleshooting the

Load Disc System

This section describes an output check and some common

problems. For each problem, one or more possible explanations are listed. For each explanation, suggested solutions

are provided.

Functional Check: Measuring Output

Note: The “no-load”

condition is when the

Load Disc stands

alone without any

weight applied.

SENSOR

ON

TEST

METER

OFF

SIMULATE TEST

+EX SIGNAL -EX

Red White Black

Brown White Black

or

Red

ADJUST

Load Disc

Figure C-1: Load Disc

connection to the KM

Test Meter.

1. Connect the brown or red, white and black wires of the Load

Disc to the corresponding T est Meter terminals, as shown in

Figure C-1. Place the Load Disc on a stable surface.

2. Turn on the power to the Test Meter and set the

Simulate/T est switch to the Test position.

3. Verify the no-load output is between + 5mV and -5mV.

(This preliminary measurement specification simply

determines the condition of the Load Disc. If the output

reading is outside +/- 5mV, consult KM.)

4. Repeat Steps 2 and 3 for each Load Disc.

Functional Check:Measuring Resistance

Follow this procedure to test the Load Discs if you do not have a KM

Test Meter or if the no-load output using the Test Meter was out of

range for a Load Disc.

1. Set the ohmmeter resistance scale to accommodate a measured

range up to 20K ohms.

2. Put one DMM lead on the Load Disc’s black wire and the

other lead on the brown wire. Verify the brown-to-black

resistance is between 4.0K ohms and 6.0K ohms.

3. Place the Load Disc on a stable surface. Put one DMM lead

on the Load Disc’s white wire and the other lead on the brown

wire. Verify the brown-to-white resistance is between 8.5K

ohms and 9.0K ohms.

4. Put one DMM lead on the Load Disc’s white wire and the

other lead on the black wire. Verify the black-to-white

resistance is between 8.5K ohms and 9.0K ohms and within

40 ohms of the brown-to-white reading from Step 3.

5. Repeat Steps 2 through 4 for each Load Disc. If any reading is

outside the above ranges, contact KM for assistance before

proceeding with installation.

C-1

Page 27

Appendix C: Troubleshooting the Load Disc System

Problem Problem Details Solution

Small Amplitude

Changes or Erratic

Fluctuations in display

readings

Fluctuations can be caused

by moisture in cable conduit,

junction boxes, or PCBs.

Fluctuations can be caused

by damaged Load Disc.

Check conduit, junction boxes, and PCBs for

water contamination. Find water entry source

and correct problem. Dry with a hair drier.

Remove/replace corroded parts and materials.

CAUTION

If using sealant to eliminate water entry, use

Sikaflex ™ 1A polyurethane sealant or Dow

Corning™ RTV 739 or RTV 738. Other

sealants may contain acetic acid, which is

harmful to electronics.

Using Digital Multimeter (DMM), check

resistance for individual Load Discs:

1. Set meter resistance scale to accommodate measured range up to 20,000 ohms.

2. Remove one Load Disc’s wires from

junction box terminal.

3. Put one DMM lead on Load Disc’s white

wire and other lead on brown wire.

Record resistance reading, and verify it is

8,750 ± 250 ohms and stable. If reading is

outside this range, Load Disc is damaged

and must be replaced.

4. Put one DMM lead on Load Disc’s white

wire and other lead on black wire. Record

resistance reading, and verify it is 8,750 ±

250 ohms and stable. If reading is outside

this range, Load Disc is damaged and

must be replaced.

5. V erify readings from Steps 3 and 4 are

within 400 ohms of each other . If not,

Load Disc is damaged and must

be replaced.

6. Repeat Steps 2 through 5 for each suspect

Load Disc, until damaged Load Disc is

located.

C-2

Page 28

Appendix C: Troubleshooting the Load Disc System

Problem Problem Details Solution

Small Amplitude

Changes or Erratic

Fluctuations in

display readings

Sudden Change in

Weight Reading or

System Requires

Frequent

Recalibration

Fluctuations can be caused

by problems with signal

processor.

One broken Load Disc can

cause indicated weight to

shift up or down by large

amount, up to 100% of fullscale live load.

Check signal processor excitation voltage

and incoming AC voltage for accuracy and

stability (refer to signal processor manual).

Using Digital Multimeter (DMM), check

resistance for individual Load Discs:

1. Set meter resistance scale to accommodate

measured range up to 20,000 ohms.

2. Remove one Load Disc’s wires from

junction box terminal.

3. Put one DMM lead on Load Disc’s white

wire and other lead on brown wire. Record

resistance reading, and verify it is 8,750

± 250 ohms and stable. If reading is outside

this range, Load Disc is damaged and must

be replaced.

4. Put one DMM lead on Load Disc’s white

wire and other lead on black wire. Record

resistance reading, and verify it is 8,750

± 250 ohms and stable. If reading is outside

this range, Load Disc is damaged and must

be replaced.

5. V erify readings from Steps 3 and 4 are

within 400 ohms of each other. If not, Load

Disc is damaged and must be replaced.

6. Repeat Steps 2 through 5 for each suspect

Load Disc, until damaged Load Disc is

located.

Sudden change in weight

reading can be caused by

problems with signal processor.

Check signal processor excitation voltage

and incoming AC voltage for accuracy and

stability (refer to signal processor manual).

C-3

Page 29

Appendix D: Technical Drawings

Appendix D. Technical Drawings (TI)

This appendix contains the following technical drawings for the Load Disc:

Drawing No. Drawing T itile

TI-LC.LD360s-(revC) Installation Arrangements, 1K-25K, Load Disc 360s (14 Pages)

Installation Instructions Page 1-4

LD360s with Leveling Top Universal Adapter Plate 5

LD360s with Universal Top Adapter Plate 6

LD360s with Anyadapter Plate 7

Mounting hole patterns for Anyadapter 8

LD360s with Leveling Base Adapter Plate 9

LD360s Mounting Dimensions 10

LD360s Mounting to Floor and I-beam 11

LD360s with Gusset Leg Attachment on I-Beam 12

LD360s Cabling using Molded Junction Conn, J-Box 13

LD360s Conduit/Non-conduit Cable Layout 14

RF-LC.LD360s-(revA) Retrofit TI-DWG, 1K-25K, Load Disc 360s (1 Page)

LD360s/UA360 Retrofit from LDII/UA1 1

TI-LD360s-01(revB) LD360s Typical Cabling Diagram (1 Page) 1

TI-LD360s-FM-01 FM Approved Installation Drawings (3 Pages) 1-3

TI-LC.LD3-(revA) Installation Arrangements, 1K-25K, LD3 (14 Pages)

Installation Instructions Page 1-4

LD3 with Leveling Top Universal Adapter Plate 5

LD3 with Universal Top Adapter Plate 6

LD3 with Anyadapter Plate 7

Mounting hole patterns for Anyadapter 8

LD3 with Leveling Base Adapter Plate 9

LD3 Mounting Dimensions 10

LD3 Mounting to Floor and I-beam 11

LD3 with Gusset Leg Attachment on I-Beam 12

LD3 Cabling using Molded Junction Conn, J-Box 13

LD3 Conduit/Non-conduit Cable Layout 14

RF-LC.LD3-(revA) Retrofit TI-DWG, 1K-25K, LD3 (1 Page) 1

TI-LC.LD3&LD360-01 Load Block to Load Disc Retrofit Installing (1 Page) 1

D-1

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

ELECTRONICS

ELECTRONICS

OPTION 3OPTION 2OPTION 1

LD360s TYPICAL CABLING DIAGRAM

J BOX

ELECTRONICS

Page 46

C

INSTALLATION,

(FM APPROVED)

TI-LD360s.FM-01

STAHL SAFETY BARRIER

JUNCTION BOX

TYPICAL JUNCTION BOX WIRING

TYPICAL FOUR CHANNEL INSTALLATION

NON-HAZARDOUS LOCATION HAZARDOUS LOCATION

MODEL SBMVS-N4 INTRINSIC SAFETY BARRIER ASSEMBLY (4 CHANNELS MAX.)

Page 47

TYPICAL JUNCTION BOX WIRING

C

Kistler-Morse

Bothell, WA

TI-LD360s.FM-01

B

MODEL SBMVS-N4 INTRINSIC SAFETY BARRIER ASSEMBLY (8 CHANNELS MAX.)

NON-HAZARDOUS LOCATION HAZARDOUS LOCATION

TYPICAL MULTI CHANNEL INSTALLATION

Page 48

I.S. BARRIERS

I.S. BARRIERS (CHAN. 1)

C

Kistler-Morse

Bothell, WA

TI-LD360s.FM-01

B

MVS INTERFACE

TYPICAL CONNECTION

FOR STX SYSTEMS, MVS RESIDENT.

MVS

TYPICAL CONNECTION

FOR TRANSDUCERS (SENSORS)

TYPICAL STAHL BARRIER CONNECTIONS TO MVS FOR DIFFERENT APPLICATIONS

I.S. BARRIERS

STX

TYPICAL CONNECTION

FOR STAND-ALONE STX SYSTEMS.

Page 49

Page 50

Page 51

Page 52

Page 53

MOUNTING DIMENSIONS

1Klb-7.5Klb LOAD DISC LD3 TRANSDUCER

WITH LEVELING TOP UNIVERSAL ADAPTER PLATE

Page 54

MOUNTING DIMENSIONS

WITH UNIVERSAL ADAPTER PLATE

1Klb-25Klb LOAD DISC LD3 TRANSDUCER

Page 55

MOUNTING DIMENSIONS

WITH ANY ADAPTER TOP ADAPTER PLATE

1Klb-7.5Klb LOAD DISC LD3 TRANSDUCER

Page 56

vESSEL MOUNTING HOLE PATTERNS

FOR ANY ADAPTER TOP ADAPTER PLAT E

(MINIMUM (4) 1/2” HEX HEAD BLOTS REQUIRED)

Page 57

MOUNTING DIMENSIONS

WITH LEVELING BASE ADAPTER PLATE

1Klb-25Klb LOAD DISC LD3 TRANSDUCER

Page 58

Page 59

WITH LEVELING BASE ADAPTER PLA TE

1Klb-25Klb LOAD DISC LD3 TRANSDUCER

Page 60

Page 61

Page 62

Page 63

Page 64

Loading...

Loading...