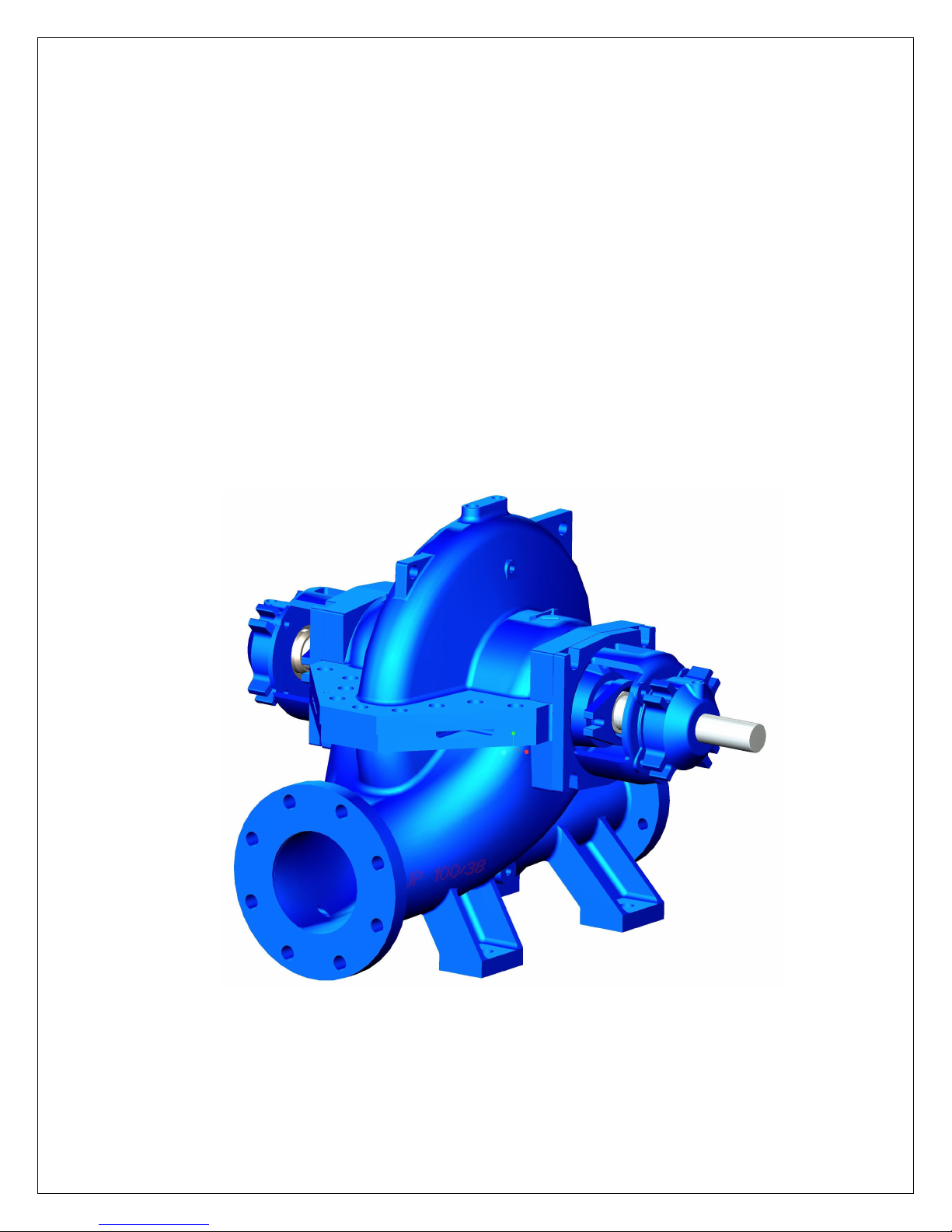

KIRLOSKAR UP 50/30B, UP 150/45, UP 65/24, UP 125/30B, UP 125/30A Instruction On Installation, Operation And Maintenance

...

INSTRUCTION ON

INSTALLTION,

OPERATION &

MAINTENANCE

FOR KIRLOSKAR PUMP

TYPE UP METRIC

KIRLOSKAR BROTHERS LIMITED

“Yamuna”S.No.98/3 to 7, Baner, Pune 411045

1.

GENERAL

2. SAFETY INSTRUCTIONS

3. INSTALLATION

4. OPERATION

CONTENTS

5. TECHNICAL DATA

6. MAINTENANCE

7. OVERHAULING

8. GENERAL OUTLINE DIMENSIONS

9. SPARE PART LIST AND CROSS-SECTIONAL DRAWINGS

10. EXPLODED VIEW.

Please ensure these instructions are read fully before installation and operation of the

pump.

Please furnish complete name plate details, part description, part nos, material construction

and quantity while ordering spare parts.

1. GENERAL

1.1 The booklet covers instructions for following types of UP (M) pumps.

UP 50/30A UP 125/24 UP 150/38BC

UP 50/30B UP 125/30A UP 150/45

UP 65/24 UP 125/30B UP 150/45 BC

UP 65/24A UP 100/35 UP 200/30

UP 80/24 UP 100/38 UP 200/38

UP 65/38 UP 125/35 UP 250/30

UP 65/38M UP 150/26N UP 250/38

UP 80/30 UP 150/30 UP 150/53A

UP 80/38 UP 150/30A(N) UP 150/53F

UP 100/24 UP 150/38A UP 200/42

UP 100/29 UP 150/38B

1.2 These are horizontal split casing type pumps with suction and discharge nozzles and

their supporting feet integrally cast in the lower half casing. This construction

enables to remove the rotating unit for inspection and repairs by just removing upper

half casing, and without disturbing alignment, pipe connection or prime mover.

1.3 Pumps when properly installed and given due care in operation and maintenance

should operate satisfactorily for a long period.

1.4 When the pump is received, sometime before the actual use of pump, it should be

inspected and located in dry place. The coupling should be rotated periodically (once

in a month) to prevent pitting of bearing surfaces.

1.5 Generally all the UP pumps mentioned above are similar in construction with minor

changes of some parts.

1.6 Pump Identification: All pumps are designated by serial number, model number, size

and type. This information is stamped on an identification plate which is fixed on the

pump.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 4 of 66

Last Revision: 12/06/2012

1.7 Nomenclature of the pump

Nomenclature for pump is as given below.

UP 100/35

UP- Basic pump type

100- Nominal Delivery size in mm

/ - Always slash

35- Nominal Impeller diameter in cm.

PUMP DESCRIPTION

Casing

Impeller

Shaft

- The casing is of axially-split volute design with suction and discharge flanges and

mounting feet cast integral with the lower half casing. Tapped and plugged holes are

provided for priming, vent, drain and gauge connections. Upper half casing is

removable without disturbing suction or discharge piping.

Suction and Discharge is on a common centerline in both the horizontal and vertical

planes.

- The impeller is of the enclosed double-suction (except UP 150/56 pump),

statically and hydraulically balanced. The impeller is keyed to the shaft and

positioned axially by the shaft sleeves. Hub shall have sufficient metal thickness to

allow machining for installation of casing wear rings.

- The shaft shall be of ample size to operate under load with of minimum deflection.

Shaft Sleeves

with the pumped liquid. An O-ring shall be furnished under sleeve to prevent

- The shaft sleeves should protect the shaft from wear and from contact

leakage.

Insert (Stuffing Box)

type gland to permit removal and access to packing. Ample space is provided for

repacking the insert.

Bearings

IOM/UP_METRIC Issue Date: 31/12/2007

Page 5 of 66

- The bearings are grease lubricated or oil lubricated. The inboard or coupling

end bearing is a single row ball bearing. The outboard bearing is a double row

cylindrical roller bearing which is retained by bearing locknut and lock washer.

- The insert is consisting of at least six packing rings and a split

Last Revision: 12/06/2012

Bearing Housings

and assure positive alignment of the rotating element. The housings provides a fit for

the inboard bearing that allows freedom for thermal expansion while the outboard

bearing is clamped in place to take all thrust loads and keep the rotating element in

its proper axial location.

- The bearing housings are bolted to the end of the lower half casing

Base plate

be provided with a drip pan beneath the pump. The drip pan contains a tapped drain

connection.

Coupling

- The base plate is sufficiently rigid to support the pump and driver and shall

- Coupling can be supplied – Snap-wrap / Pin-Bush / Spacer type

Coupling Guard

Rotation

- Pump can have clockwise or counterclockwise rotation when viewed from its

driving end

- The coupling guard can be in MS / AL / Bronze.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 6 of 66

Last Revision: 12/06/2012

2. SAFETY INSTRUCTIONS:

2.1: General Information

Before performing any actions detailed within this instruction, the Site Health and

Safety instructions must read and fully understood. The instructions in this

document also must be read and fully understood.

Whenever the equipment is operated, maintained or used in any way, the procedures

detailed within the Health and Safety Dossier (DHS) and any procedures detailed

within these instructions shall be followed. The pump supplied by Kirloskar Brothers

Limited (KBL) has been designed with safety in mind, where hazards cannot be

eliminated; the risk has been minimized by the use of guards and other design

features. Some hazards cannot be guarded against and the instructions below MUST

BE COMPLIED WITH for safe operation. These instructions cannot cover all

circumstances. It is the responsibility of the user of the equipment for maintaining

safe working practices at all times.

2.1.1 KBL products are designed for installation in designated areas, which are to be kept

clean and free of obstructions that may restrict safe access to the controls and

maintenance access points.

2.1.2 Pump nameplate is fitted to each unit and must not be removed. Loss of this plate

could make identification impossible. This in turn could affect safety and cause

difficulty in obtaining spare parts. Should accidental loss or damage occur, contact

KBL immediately.

2.1.3 Access to the equipment should be restricted to the personnel responsible for

installation, operation and maintenance and they must be trained, adequately

qualified and supplied with the appropriate tools for their respective tasks.

2.1.4 KBL firmly insists that all personnel responsible for installation, operation and

maintenance of the equipment must read safety instructions mentioned in the

manual before any work is done.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 7 of 66

Last Revision: 12/06/2012

2.1.5 Ear defenders should be worn where the specified equipment noise level exceeds

locally defined safe levels. Safety glasses or goggles should be worn where working

with pressurized systems and hazardous substances. Other personal protection

equipment must be worn where local rules apply.

2.2 DO NOT wear loose or frayed clothing or jewellery, which could catch on the

controls or becomes trapped in the equipment.

2.3 Operation of the equipment for the application other than for which it is supplied can

increase the risk from hazards. Please consult KBL before making such change in

the application of the equipment.

2.4 Improper installation, operation and maintenance of the product supplied by KBL

could result in injury or death.

2.5 Within the manual, safety instructions are marked with safety symbols.

Hazard

This symbol refers to general mechanical aspects of safety.

Hazard

This symbol refers to electrical safety.

2.6: Transport handling and storage instructions:

2.6.1: Transport

Pumps are dispatched in duly assembled condition. Pumps are protected against

corrosion and packed for transport by normal road, rail and sea carriers.

2.6.2: Handling

Crushing hazard

When lifting the pump or pump set, use lifting equipment having a safe working load

rating suitable for the weight specified. Use suitable slings for lifting any pump not

provided with lifting points.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 8 of 66

Last Revision: 12/06/2012

The use of suitable forklift truck and four chain crane sling equipment is

recommended but locally approved equipment rating may be used.

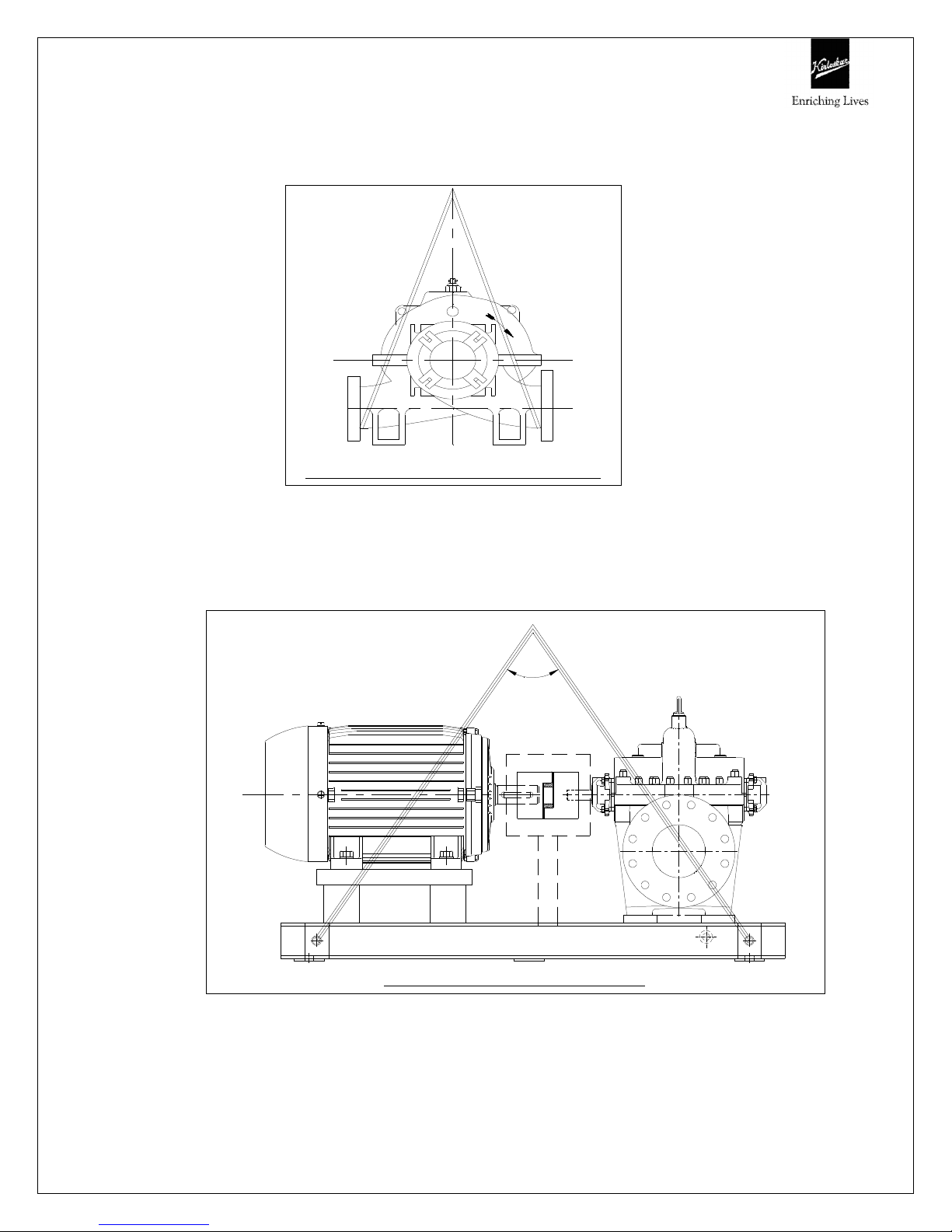

Pump should be slung as shown.

PU M P L IFT IN G A R R A N G EM ENT

Pump set must be lifted from the lifting holes provided on the pump by using

suitable four chain lifting equipment.

90°

Max.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 9 of 66

PUMP SET LIFTING ARRANGEMENT

Last Revision: 12/06/2012

2.6.3: Storage.

2.6.3.1: Temporary storage for up to six weeks.

If the pump unit is not be used immediately it should be stored carefully in a

horizontal position, in a sheltered, dry location. Additional rust preventive should be

applied to all unpainted carbon steel or cast iron parts, and should not be removed

until final installation.

2.6.3.2: Long Term Storage.

If the pump is not to be installed and operated soon after arrival, store it in a

clean, dry place, having slow, moderate changes in ambient temperature. Step

should be taken to protect the pump from moisture, dust, dirt, and foreign bodies. It

is recommended that the following procedure is taken:-

a) Ensure that the bearings are packed with the recommended grease, to prevent

moisture from entering around the shaft.

b) Remove the glands, packings and lantern rings from the stuffing box if the pump

is equipped in this manner. If the pump is equipped with mechanical seal, dismantle

and coat the seal with light oil.

c) Ensure that suction and discharge branches of the pump and all other openings

are covered with cardboard, wood or masking tape to prevent foreign objects

entering the pump.

d) If the pump is to be stored where there is no protective covering, it is advisable to

cover the unit with a tarpaulin or other suitable covering.

e) The shaft should be manually rotated periodically to prevent pitting of the bearing

surfaces by moisture.

Shearing Hazard.

Do NOT place fingers or hands etc. into the suction or discharge pipe outlets and do

NOT touch the impeller, if rotated this may cause severe injury. To prevent ingress

of any objects, retain the protection covers or packaging in place until removal is

IOM/UP_METRIC Issue Date: 31/12/2007

Page 10 of 66

Last Revision: 12/06/2012

necessary for installation. If the packaging or suction and discharge covers are

removed for inspection purposes, replace afterwards to protect the pump and

maintain the safety.

Fill the bearing housing with recommended grease to ensure that the shaft and

bearings remain rust free.

2.6.3.3: Exposed or Extreme Conditions Storage.

For exposed storage or extreme variants in atmospheric or environmental conditions,

please refer to KBL for special storage instructions to suit the conditions acceptable.

3 INSTALLATIONS

3.1 Receiving pump

Upon receipt of the pump, a visual check should be made to determine if any

damage occurred during transit or handling. The main items to look for are:-

a) Broken or cracked equipment, including base, motor or pump feet and flanges.

b) Bent shaft

c) Broken motor end bells, bent eyebolts or damaged boxes of motor

d) Missing parts.

e) Pump shaft rotates freely.

Parts or accessories are some times wrapped individually or fastened to the

equipment. If any damage or losses have been incurred; promptly notify your KBL

representative, KBL Dealer and the transport company who delivered the pump.

When unloading pump units, lift equally at four or more points from the base. DO

NOTLIFT ONLY THE DRIVER OR PUMP.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 11 of 66

Last Revision: 12/06/2012

3.2 Preparation

Before installing the pump, clean the suction and discharge flanges thoroughly.

Remove the protective coating from the pump shaft.

If the pump has been in storage and prepared for storage in the manner outlined

previously, remove all the grease from the bearings. The bearings should then be

flushed with carbon tetrachloride or kerosene and relubricated.

3.3 Location

The pump should be installed as near the suction supply as possible, with the

shortest and most direct suction pipe practical. The total dynamic suction lift (static lift

plus friction losses in suction line) should not exceed the limits for which the pump was

sold.

The pump must be primed before starting. Whenever possible, the pump should be

located below the fluid level to facilitate priming and assure a steady flow of liquid. This

condition provides a positive suction head on the pump. It is also possible to prime the

pump by pressurizing the suction vessel.

Pumps must be fully primed at all times during operation.

When installing the pump, consider its location in relation to the system to assure that

sufficient Net Positive Suction Head (NPSHA) is available at the pump inlet connection.

Available NPSH must always equal or exceed the required NPSH (NPSHR) of the pump.

The pump should be installed with sufficient accessibility for inspection and

maintenance. A clear space with ample head room should be allowed for the use of an

overhead crane or hoist sufficiently strong to lift the unit.

NOTE: Allow sufficient space to be able to dismantle pump without disturbing the

pump inlet and discharge piping.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 12 of 66

Last Revision: 12/06/2012

Select a dry place above the floor level wherever possible. Take care to prevent

pump from freezing during cold weather when not in operation. If the possibility of

freezing exists during a shut-down period, the pump should be completely drained, and

all passages and pockets where liquid might collect should be blown out with

compressed air.

Make sure there is a suitable power source available for the pump driver. If motor

driven, the electrical characteristics of the power source should be identical to those

shown on motor data plate.

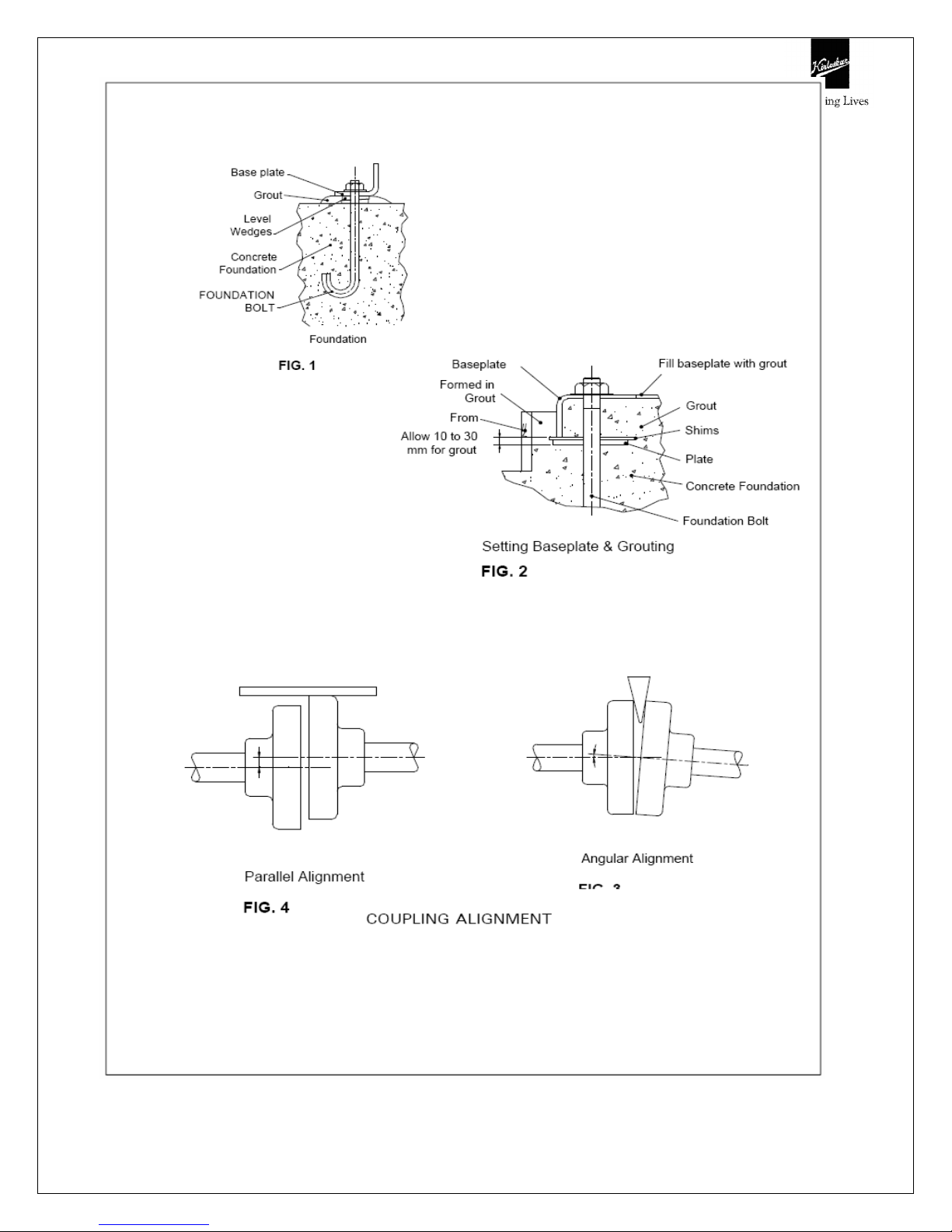

3.4 Foundation

The foundation should be strong enough to reduce vibrations and rigid enough to avoid

any twisting or misalignment.

The foundation should be poured without interruptions to within 20 to 40 mm of the

finished height. The top surface of the foundation should be well scored and glued

before the concrete sets. This provides a bonding surface for the grout. Foundation

bolts should be set in concrete as shown in Fig. 1. Allow enough bolt length for

grout,shims, lower base plate flange, nuts and washers. The foundation should be

allowed to cure for several days before the base plate is shimmed and grouted.

3.5 Baseplate setting

Use blocks and shims under base for support at foundation bolts and midway

between bolts, to position base approximately 25 mm above the concrete

foundation with studs extending through hole in the baseplate.

By adding or removing shims under the base, level the pump shaft and flanges. The

baseplate does not have to be leveled. Draw foundation bolt nuts tight against

baseplate and observe pump and motor shafts or coupling hubs for alignment.

Check to make sure the piping can be aligned to pump flanges without placing pipe

strain on either flange.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 13 of 66

Last Revision: 12/06/2012

Grout baseplate in completely and allow grout to dry thoroughly before attaching

piping to pump (24 hours is sufficient time with approved grouting procedure).

3.6 Grouting procedure

Grout compensates for uneven foundation, distributes weight of unit and prevents

shifting. Use an approved, non-shrinking grout as follows, after setting and leveling

unit See Fig. 2.

a) Build strong form around foundation to content grout.

b) Soak top of concrete foundation thoroughly, then remove surface water.

c) Baseplate should be completely filled with grout and, if necessary, drill vent holes

to remove trapped air.

d) After grout has thoroughly hardened, check the foundation bolts and tighten if

necessary.

e) Check the alignment after the foundation bolts are tightened.

f) Approximately 14 days after the grout has been poured or when the Grout has

thoroughly dried, apply an oil base paint to the exposed edges of the grout to

prevent air and moisture from coming in contact with the grout.

3.7 Alignment procedure

The pump driver, if supplied, is correctly aligned on its base plate at the factory. A

certain amount of deformation of the base plate is possible during transit and it is

therefore essential to check alignment, prior to final grouting.

A flexible coupling will only compensate for small amount of misalignment and

should not be used to compensate for excessive misalignment of the pump and

driver shafts.

Inaccurate alignment results in vibration and excessive wear on the bearings, sleeve

or shaft and wear rings.

Coupling alignment can be checked with dial gauge Indicator also. Alignment should

be performed after the base plate has been properly set and grout has dried

IOM/UP_METRIC Issue Date: 31/12/2007

Page 14 of 66

Last Revision: 12/06/2012

thoroughly according to instructions. Final alignment should be made by shimming

driver only.

Alignment should be made at operating temperatures.

After final alignment, it is necessary to dowel pump and driver feet to the baseplate.

FACTORS THAT MAY DISTURB ALIGNMENT

The unit should be periodically checked for alignment. If the unit does not stay in

line after being properly installed, the following are possible reasons:

a) Setting, Seasoning of the foundation.

b) Pipe strains, distorting or shifting of the machines.

c) Wear of the bearings.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 15 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 16 of 66

Last Revision: 12/06/2012

3.8 Suction and Discharge Piping

When installing the pump piping, make sure to observe the following precautions:-

Piping should always run to the pump. Do not move pump to pipe. This could make

final alignment impossible.

Both suction and discharge piping should be supported independently and close to

pump so that no strain is transmitted to the pump when the flange bolts are

tightened.

Use pipe hangers or other supports at necessary intervals to provide support. When

expansion joints are used in the piping system, they must be installed beyond the

piping supports close to the pump.

It is advisable to increase the size of both suction and discharge pipes at the pump

connection to decrease the loss of head from friction.

Install piping as straight as possible, avoiding unnecessary bends. Where necessary,

use 45 degree or long sweep 90 degree fitting to decrease friction losses.

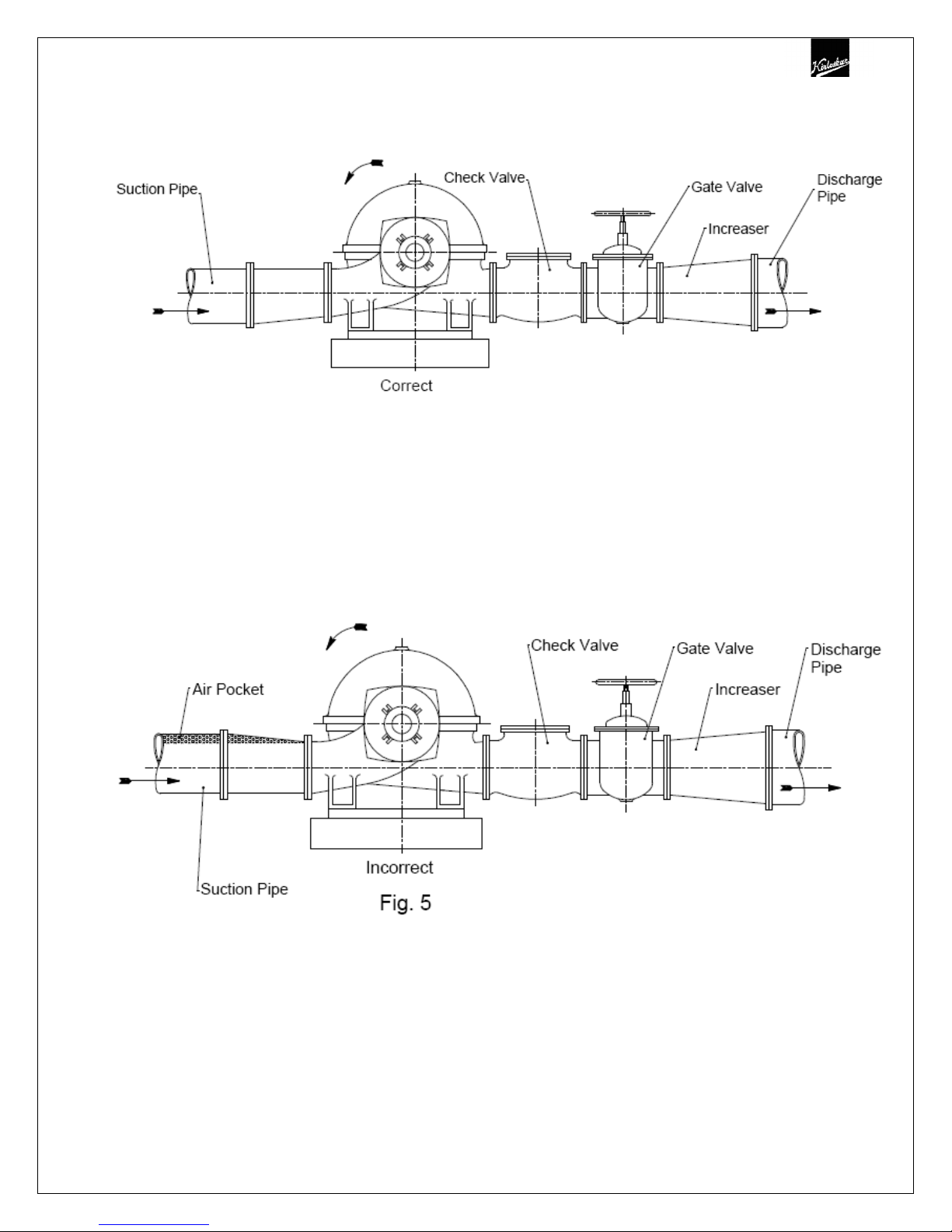

Make sure that all piping joints are air tight. Provide pipe expansions bellows when

hot fluids are to be pumped. Where reducers are used, eccentric reducers are to be

fitted in suction lines and straight taper reducers in discharge and vertical lines (See

Fig.5).

Misuse of reducers may cause the formation of air pockets in the pipe and thus

preventing the correct operation of the pump.

The suction pipe should be as short & direct as possible. Where suction lift is not

very high, it is advisable to use a foot valve. Horizontal suction line must have a

gradual rise to the pump.

The discharge pipe is usually preceded by a non-return valve or check valve and a

discharge gate valve (See Fig. 5). The check valve is to protect the pump from

excessive back pressure and reverse rotation of the unit and to prevent back flow

into the pump in case of stoppage or failure of the driver. The discharge valve is

used in priming, starting and when shutting down the pump.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 17 of 66

Last Revision: 12/06/2012

4 OPERATION

4.1 Before Starting

Before initial starting of the pump, make the following inspection:

4.1.1 The unit baseplate is grouted and bolted to the foundation.

4.1.2 Alignment between pump and motor.

4.1.3 Motor is correctly wired to starting device, check voltage, phase and frequency on

motor nameplate with line circuit. Ensure correct direction of rotation prior to

coupling to pump. Check by starting motor and switching off immediately. Observe

rotation is the same as the arrow direction on the pump casing.

4.1.4 Bearing lubrication is provided (see lubrication section), also check driver lubrication.

4.1.5 Mechanical seal has been fitted or stuffing box has been packed.

4.1.6 All rotating parts are found to be free when turned by hand.

4.1.7Pump is primed. Never run the unit dry. The liquid in the pump serves as a lubricant

for close running fits within the pump and the pump may be damaged if operated

dry. The pump may be primed by using an ejector, exhauster or vacuum pump. If a

foot valve is used in the suction line, the pump may be primed by venting and filling

the casing with liquid.

4.2 Starting

4.2.1 Close valve in discharge line.

4.2.2 Open fully all valves in the suction line.

4.2.3 Turn on seal water to the stuffing box where external pipe supplied.

4.2.4 Prime the pump.

4.2.5 Start the pump driver.

4.2.6 When the pump is operating at full speed, open the discharge valve slowly.

Do not operate pump for prolonged periods with closed discharge valve, so as to avoid

overheating.

The pump should be shut down at once and the trouble corrected if the pump is running at

its rated speed and found to have any of the following defects:

a) No liquid delivered.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 18 of 66

Last Revision: 12/06/2012

b) Not enough liquid delivered.

c) Not enough pressure.

d) Loss of liquid after starting.

e) Excess vibration.

f) Motor runs hot.

g) Pump bearing overheating.

4.3 Running

While the pump is running, a periodic inspection should be made of:

a) Stuffing box (soft packed pumps only). Ensure there is sufficient leakage to

lubricate the packing.

b) Bearings. Check the bearings for temperature, which should not exceed pumped

liquid temperature or 80 Deg. C whichever is the lower.

c) With mechanical seal fitted pumps, check that there is no leakage from the

stuffing box.

d) Suction and discharge gauge readings.

4.4 Stopping

a) Slowly close delivery valve and shut down driving unit in accordance with

manufacturer’s instructions.

b) Shut off external sealing liquid supply, if supplied, to relieve stuffing box pressure.

c) Successful operation of the pump depends on accurate alignment. It is

recommended to re-check the alignment after preliminary run.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 19 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 20 of 66

Last Revision: 12/06/2012

5 TECHNICAL DATA

5.1 Direction of Rotation

The standard direction of rotation is anticlockwise when viewed from driving side.

The pumps with reverse direction of rotation (Clockwise) can be supplied on request.

The direction of rotation can be reversed easily without changing any part.

5.2 Bearing Details

The pumps are fitted with antifriction heavy duty ball bearings at driving and non

driving ends. The details of the bearings are as under:

Bearing model

SR.NO PUMP TYPE

1 UP 50/30A

2 UP 50/30B

3 UP 65/24

4 UP 65/24A

5 UP 80/24

6 UP 65/38

7 UP 65/38M

8 UP 80/30

9 UP 80/38

10 UP 100/24

11 UP 100/29

12 UP 125/24

13 UP 125/30A

14 UP 125/30B

15 UP 100/35 MODULE IE 6309 FOR DE & NDE

16 UP 100/38

17 UP 125/35

18 UP 150/26N *

19 UP 150/30

20 UP 150/30A(N) *

21 UP 150/38A

22 UP 150/38B

23 UP 150/38BC *

24 UP 150/45

25 UP 150/45BC

26 UP 200/30

27 UP 200/38

28 UP 250/30

29 UP 250/38

30 UP 150/53A

31 UP 150/53F

32 UP 200/42

no.

MODULE 0 6305 FOR DE &NDE

MODULE I 6306 FOR DE & NDE

MODULE II 6309 FOR DE & NDE

MODULE III 6312 FOR DE & NDE

The designations of bearings are as per SKF catalogue. However, bearings of other

Ball bearing reference no. SKF or

equivalent

IOM/UP_METRIC Issue Date: 31/12/2007

Page 21 of 66

Last Revision: 12/06/2012

Make / equivalent are also used.

5.3 Special care for Bearings

These instructions do not supersede any information issued by the bearing

manufacturers, to whom application should be made for more comprehensive

literature by personnel responsible for bearing care, who with it to make a detailed

study.

Care and maintenance of bearings is a matter of ensuring that they are:

a) Correctly lubricated at intervals as laid down in routine maintenance chart.

b) Removed, cleaned and refitted with care.

c) Tools used and work areas should be cleaned.

To remove a bearing, use correctly suited withdrawal equipment.

CAUTION: Damage can be caused by exerting force against the outer ring of a ball

bearing. Ball bearings should not be dismantled. Clean bearings thoroughly with an

approved fluid. Dry the bearings by spinning with dry compressed air or by hand. Do

not spin a clean dry bearing. Inspect the bearing for wear, fractures, cracks,

corrosion or other damage which may necessitate bearing replacement. Pack both

sides of bearing with grease. Check that the bearing, shaft and housing are cleaned

and undamaged. Recharge with grease to a maximum of two thirds full. Refit the

bearing onto the shaft and press for tap into position.

5.4 Lubrication Details

Initially bearings are lubricated during assembly. In the regreasing period these

bearings should be repacked with a high quality, lithium soap base, ball and roller

bearing grease free from resin and acid, not liable to harden or crumble and

possessing rust preventive properties. Re-greasing interval depends upon the

operating speed of the unit.

Operating speed Regressing Interval

1450 RPM 4000 hours

2000 RPM 3000 hours

IOM/UP_METRIC Issue Date: 31/12/2007

Page 22 of 66

Last Revision: 12/06/2012

Manufacturer

Trade name

IOCL

SERVOGEM

-

3 OR EQ

IOCL

SERVOGEM

-

2 OR EQ

SHELL

ALVANIA EP 2

EXXON

POLYREX

CHEVRON

SRI GREASE NLGI 2

CHEVRON

BLACK PEARL NLGI 2

TEXACO

MULTIFAK EP2

PHILIPS

POLYTAC

HPCL

NATRA 3 OR LITHON 3

To recharge the bearings with fresh grease, use a grease gun and feed through the

two grease nipples provided.

DO NOT APPLY LUBRICANT WHEN PUMP IS RUNNING.

After 10,000 hours or two years whichever is earlier remove bearings from pumps,

degrease, thoroughly clean, recharge with fresh grease and refit in accordance with

reassembly instructions.

Recommended Grease specifications

5.5 Wearing Details

Pumps are supplied with casing wear rings. The Diametrical clearances between

Impeller and casing rings should be minimum: 0.25 mm and maximum 0.70 mm.

5.6 Impeller Details

Following pump types are fitted with single entry impeller UP 50/30A, UP 50/30B,

UP 80/38, UP 65/38 and UP 65/38M.

For other types, Double entry impellers are fitted.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 23 of 66

Last Revision: 12/06/2012

5.7 Stuffing Box Details

• Packing (Non Asbestos)

On packed pumps the packing is installed prior to shipment. All packing used are the

highest grade material. Before pump is put into operation check the condition of the

packing. If pump is installed within sixty (60) days after shipment the packing will be

in good condition with a sufficient supply of lubrication. If pump is stored for a

longer period it may be necessary to repack the stuffing box. In all cases, however,

we recommend an inspection of the packing before pump is started. The standard

pump packing is made from graphite solid plate cotton packing (non asbestos).

A soft, well-lubricated packing reduces stuffing box resistance and prevents

excessive wear on the shaft or shaft sleeve. Many brands of packing on the market

have the desired qualities.

NOTE: Eccentricity of the shaft or sleeve through the packing could result in excess

leakage that cannot be compensated for. Correction of this defect is very important.

Packing should be checked frequently and replaced as service indicates. Six months

might be a reasonable expected life, depending on operating conditions. It is

impossible to give any exact predictions. A packing tool should be used to remove

all old packing from the stuffing box. Never reuse old and lifeless packing or merely

add some new rings. Make sure the stuffing box is thoroughly cleaned before new

packing is installed. Also check the condition of the shaft or sleeve for possible

scoring or eccentricity, make replacements where necessary.

New packing (non-asbestos) should be placed carefully into the stuffing box. If

molded rings are used, the rings should be opened sideways and the joints pushed

into the stuffing box first. The rings are installed one at a time, each ring seated

firmly and the joints staggered at about a 90° rotation from each preceding joint.

Champion Style – 3116 – Graphited cotton greasy packing is used in the standard

supply. However packing suitable for liquid handled is also supplied against specific

requirement.

Size of gland packing and position of lantern ring

IOM/UP_METRIC Issue Date: 31/12/2007

Page 24 of 66

Last Revision: 12/06/2012

Gland packing are fitted with 2+L+2 arrangement L=Lantern Ring.

Module 0 - 8 mm

Module I& I E - 10 mm

Module II - 12 mm

Module III - 12 mm

2

2

2

2

• Mechanical Seal:

General instructions for operation of the various mechanical sealing arrangements

are included below. It is not feasible to include detailed instructions for all mechanical

seals in this booklet because of the almost unlimited number of possible combinations

and arrangements. Instead, seal manufacturer’s instructions will be included as a

separate supplement to this book, where required.

a. Mechanical seals are precision products and should be treated with care. Use special

care when handling seals. Clean oil and clean parts are essential to prevent scratching

the finely lapped sealing faces. Even light scratches on these faces could result in

leaky seals.

b. Normally, mechanical seals require no adjustment or maintenance except routine

replacement of worn or broken parts.

c. A mechanical seal which has been used should not be put back into service until the

sealing faces have been replaced or relapped. (Relapping is generally economical only

in seals two inches in size and above.)

Four important rules which should always be followed for optimum seal life are:

1. Keep the seal faces as clean as possible.

2. Keep the seal as cool as possible.

3. Assure that the seal always has proper lubrication.

4. If seal is lubricated with filtered fluid, clean filter frequently.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 25 of 66

Last Revision: 12/06/2012

IMPELLER

'A' 'B'

IN MM

IN MM

MECHANICAL SEAL FITTMENT CHART

MECHANICAL SEAL DETAILS

M EC H .S E A L

'A '

'M '

S E A L L O C A TIN G

D I S T A NC E N D E

C O F I M PE LL E R

L

'B '

'N '

S E A L L O C A TIN G

D I S T A NC E D E

S H O U L D E R R I N G

R E S T IN G F A CE

FITMENT OF MECH. SEAL (AS PER DIN 24960 STANDARD)

MOUNTED ON SHAFT

MODULE

PUMP TYPE

UP50/30A

UP50/30B 71 75 175 179

UP65/24 71 75 175 179

UP65/24A 71 75 175 179

UP80/24 71 75 175 179

UP65/38

UP65/38M 77 81 191 195

UP80/30 77 81 191 195

UP80/38 77 81 191 195

UP100/24 77 81 191 195

UP100/29 77 81 191 195

UP125/24 77 81 236.5 240.5

UP125/30A 77 81 236.5 240.5

UP125/30B 77 81 236.5 240.5

UP100/35 IE 40 148 152 231 235

UP100/38

UP125/35 97 101 245 249

UP150/26N

UP150/30 97 101 245 249

UP150/30AN 97 101 245 249

UP150/38A 97 101 245 249

UP150/38B 97 101 245 249

UP150/38BC 97 101 245 249

UP150/45 97 101 245 249

UP150/45BC 97 101 245 249

UP200/30 88.5 92.5 292 296

UP200/38 88.5 92.5 292 296

UP250/30 88.5 92.5 292 296

UP250/38 88.5 92.5 292 296

UP150/53A

UP 150/53F 181 185 444 448

UP200/42 181 185 444 448

NO SEAL SIZE NDE MM DE MM

71 75 175 179

0 30

77 81 191 195

I 35

97 101 245 249

II 50

181 185 444 448

III 65

LOCKING

DISTANCE

IOM/UP_METRIC Issue Date: 31/12/2007

Page 26 of 66

Last Revision: 12/06/2012

5.8 Coupling Details

Pumps will be supplied with snap wrap coupling as a standard scope of supply

however other types like pin bush, tyre type, spacer coupling can also be provide on

request.

5.9 Minimum safe flow

The pump should not run against closed discharge valve as this will cause an

increase in temperature/formation of steam in the pump. This may cause shaft

damage, impeller erosion, short life of bearings and damage to stuffing boxes or

mechanical shaft seals due to stress or vibration. The minimum flow rate must be at

least 30 % of the best efficiency point flow rate.

5.10 NPSHA (Net Positive Suction Head Available) and NPSHR (Net Positive Suction Head

Required)

NPSHA should be at least greater than 0.5m than NPSHR for satisfactory operation

of the pump. If NPSHA<NPSHR then pump cavitation may occurs which in turns

damage the impeller.

5.11 Pipe line velocities

For satisfactory operation of pumps and to minimize frictional losses, it is

recommended to maintain velocity in suction pipe line as 1.5 to 2 m/s and in

delivery pipe line it should be 2.5 to 3 m/s by providing higher pipe diameters than

pump suction / delivery size.

5.12 Tapping details:

Sr.No Tapping Description Size (in inch)

1

2

3

4

5

Air vent

Priming connection

(plugged)

Sealing connection

Suction & delivery

pressure gauge

connection (plugged)

Casing drain

Rp 3/8

Rp 1/2

Rp 1/4

Rp 3/8

Rp 1/2

IOM/UP_METRIC Issue Date: 31/12/2007

Page 27 of 66

Last Revision: 12/06/2012

NOZZLE

For

ces kg

Moment kg m

Fx Fy Fz Fx Fy Fz

150

133

334

267

204

102

102

5.13 Allowable forces and moments on pump flanges:

SIZE(mm)

200

250

300

350

400

450

500

600

178

210

226

241

256

270

286

317

445

525

566

603

641

680

717

792

356

420

453

483

513

540

573

634

272

320

345

368

391

420

437

483

136

160

172

184

195

215

218

241

136

160

172

184

195

215

218

241

IOM/UP_METRIC Issue Date: 31/12/2007

Page 28 of 66

Last Revision: 12/06/2012

5.14 Suction & Delivery Size:

SR.NO PUMP TYPE NOMINAL SUCTION

BORE mm

NOMINAL DELIVERY

BORE mm

1 UP 50/30A 65 50

2 UP 50/30B 65 50

3 UP 65/24 80 65

4 UP65/24A 80 65

5 UP 65/38 80 65

6 UP 65/38M 80 65

7 UP 80/24 100 80

8 UP 80/30 125 80

9 UP 80/38 100 80

10 UP 100/24 150 100

11 UP 100/29 150 100

12 UP 100/35 150 100

13 UP 100/38 150 100

14 UP 125/24 150 125

15 UP 125/30A 150 125

16 UP 125/30B 150 125

17 UP 125/35 150 125

18 UP 150/26 (N) 200 150

19 UP 150/30A 200 150

20 UP 150/30A(N) 200 150

21 UP 150/38A 200 150

22 UP 150/38B 200 150

23 UP 150/38BC 200 150

24 UP 150/45 200 150

25 UP 150/45BC 200 150

26 UP 200/30 250 200

27 UP 200/38 200 200

28 UP 250/30 250 250

29 UP 250/38 250 250

30 UP 150/53A 200 150

31 UP 150/53F 200 150

32 UP 200/42 250 200

IOM/UP_METRIC Issue Date: 31/12/2007

Page 29 of 66

Last Revision: 12/06/2012

5.15 Maximum allowable Speed and water fill capacity

SR.

NO.

1 UP 50/30A 5 1450 2000

2 UP 50/30B 5 1450 2000

PUMP TYPE WATER

FILL

CAPACITY

in LITRES

NOMINAL

SPEED IN RPM

3 UP 65/24 10 1450 1800

4 UP 65/24A 10 1450 1800

5 UP 65/38 11 1450 1500

6 UP 65/38M 11 1450 1800

7 UP 80/24 14 1450 1800

8 UP 80/30 14 1450 2000

9 UP 80/38 12 1450 1930

10 UP 100/24 14 1450 2000

11 UP 100/29 14.5 1450 2000

12 UP 100/35 20.5 1450 1500

13 UP 100/38 25.2 1450 2200

14 UP 125/24 25.2 1450 2000

15 UP 125/30A 24.5 1450 1760

16 UP 125/30B 24.5 1450 1760

17 UP125/35 30.0 1450 1500

18 UP 150/26N 28 2900 3000

19 UP 150/30 30 1450 1800

20 UP 150/30A(N) 30 2900 3000

21 UP 150/38A 28.5 1450 1800

22 UP 150/38B 28.5 1450 1800

23 UP 150/38BC 28.5 1450 2100

24 UP 150/45 48 1450 1800

25 UP 150/45BC 48 1450 1800

26 UP 200/30 50 1450 2000

27 UP 200/38 63 1450 1500

28 UP 250/30 58.5 1450 1500

29 UP 250/38 92 1450 1500

30 UP 150/53A 60 1450 1500

31 UP 150/53F 60 1450 1500

32 UP 200/42 98 1450 2100

MAX.ALLOWABLE

SPEED IN RPM

IOM/UP_METRIC Issue Date: 31/12/2007

Page 30 of 66

Last Revision: 12/06/2012

5.16 Starting Torque:

CASE 1 starting up with open isolating or regulating valve on delivery side.

CASE 2 starting up with closed isolating or regulating valve with opening the valve when

nominal speed is attained.

CASE 3 starting up with open isolating or regulating valve but against static delivery head

acting on non-return valve.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 31 of 66

Last Revision: 12/06/2012

5.17 Weights and GD^2 values:

Sr no Pump type Approx.net

weight (Kg)

GD^2 value In Kg-

cm^2

1 UP 50/30A 80 2080

2 UP 50/30B 80 2080

3 UP 65/24 84 1080

4 UP 65/24A 84 1080

5 UP 80/24 95 1003

6 UP 65/38 164 7500

7 UP 65/38 M 164 7500

8 UP 80/30 130) 3332

9 UP 80/38 158 9292

10 UP 100/24 158) 2092

11 UP 100/29 137 3572

12 UP 125/24 180 2816

13 UP 125/30A 182 4656

14 UP 125/30B 182 4656

15 UP 100/35 177 4948

16 UP 100/38 240 6976

17 UP 125/35

282

7450

18 UP 150/26N 262 6520

19 UP 150/30 253 6520

20 UP 150/30A (N)

270 5236

21 UP 150/38A 286 10040

22 UP 150/38B 286 10040

23 UP 150/38BC 286 10040

24 UP 150/45 308 18740

25 UP 150/45BC 308 18740

26 UP 200/30 372 8812

27 UP 200/38 350 12212

28 UP 250/30 348 7772

29 UP 250/38 420 21092

30 UP 150/53A 588 50650

31 UP 150/53F 588 50650

32 UP 200/42 560 50650

IOM/UP_METRIC Issue Date: 31/12/2007

Page 32 of 66

Last Revision: 12/06/2012

5.18 Interchangeability of Components

IOM/UP_METRIC Issue Date: 31/12/2007

Page 33 of 66

Last Revision: 12/06/2012

6. MAINTENANCE.

6.1 Maintenance EHS (Environmental Hazard Safety) Instructions

Following hazards may arise during maintenance work.

Fluid Pressure Jet Hazards

Check and ensure that the pump operates at below the maximum Working

Pressure specified.

Hazardous materials:

Wear a suitable mask or respirator when working with chemical material handling.

Hazardous Gases, Mists, Sprays and Leaks.

Be aware of the hazards relating to the pumped fluid, especially the danger from

inhalation from noxious and toxic gases, skin and eye contact or penetration. Obtain

and understand the hazardous substance data sheets relating to the pumped fluid

and note the recommended emergency and first aid procedures.

Before attempting any maintenance on a pump, particularly if it has been handling

any form of hazardous liquid; ensure that the unit is safe to work on. The pump

must be flushed thoroughly with suitable cleanser to purge away any of the product

left in the pump components. The plant operator should carry this out and a

certificate of cleanliness obtained before starting work. To avoid any risk to health it

is also advisable to wear protective clothing as recommended by the site safety

officer, especially when removing old packing that may be contaminated.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 34 of 66

Last Revision: 12/06/2012

Electric shock and accidental starting hazard:

Isolate the equipment before any maintenance work is done. Switch off the mains

supply, remove fuses, apply lockouts where applicable and affix suitable isolation

warning signs to prevent inadvertent re-connection.

In order to avoid the possibility of maintenance personnel inhaling dangerous fumes

or vapours, it is recommended that maintenance work be carried out away from the

pump location by removal of the rotating unit assembly to a suitable maintenance

area.

6.1 Routine Maintenance Chart

Preventive maintenance schedule is a periodical checks and precautions by which

possibilities of failure and breakdown will be rare.

EVERY WEEK

EVERY MONTH

EVERY 3

MONTHS

EVERY 6

MONTHS

EVERY YEAR

Visually check for leaks

Check for vibration.

Adjust gland as necessary to maintain slight leakage.

Hand test bearing housing for any sign of temperature.

Voltage and current.

Check bearing temperature with thermometer.

Check grease lubricated bearings for saponification.

Check the packing and replace if necessary.

Check shaft or shaft sleeve for scoring.

Check alignment of pump and motor.

Check holding down bolts for tightness.

Check coupling bush/rubber star.

Check rotating element for wear.

Check wear ring clearances.

Clean and regrease bearings.

Measure total suction and discharge Head as a test of pipe

connection

IOM/UP_METRIC Issue Date: 31/12/2007

Page 35 of 66

Last Revision: 12/06/2012

7.0 OVERHAULING

With normal daily operating spell, the pump will be due for overhaul after about

5000 working hours. This work should be done by skilled personnel. Please refer to

the cross sectional drawing while dismantling and reassembling the pump. Please

also refer to chart given at end of this booklet.

7.1 Dismantling Procedure

Note – Store all loose components carefully in a wooden box. Remove sealing

connection given to lantern ring / mechanical seal, temperature indicator, etc.

7.1.1 For SOFT PACKED UP METRIC PUMPS:

7.1.1.1 Disengage pump coupling from motor coupling.

Drain the pump by removing drain plug (60100) and opening air vent valve (45000).

7.1.1.2 Remove the nuts (58001) and locating pin (61100) joining the upper half casing

and lower half casing.

7.1.1.3 Remove all insert joint nuts at both ends (58002).

7.1.1.4 Insert a screw driver or peg bar into the slot between the two halves and separate

two halves, lifting off the upper half casing (12200). Remove the upper half casing,

taking enough care not to damage the impeller and casing (wear) ring.

7.1.1.5 Tap the inserts (97900) with a soft hammer to break the seat between the insert

and lower half casing (12300) and lift the rotating unit out of the lower half casing

so that none of the parts will be damaged. Take out the rotating unit & keep it on

rubber or wooden sheet in clean & dry place for further dismantling purpose.

7.1.1.6 Remove the pump coupling and coupling key.

7.1.1.7 Remove four hex screws (57100) from each bearing housing (24001 and 24002)

and remove the bearing housing from bearings & take it off the shaft.

7.1.1.8 Remove bearing lock nut (33600) and lock washer (41500) from NDE side.

Remove NDE bearing (26000) from the shaft by the use of bearing puller. Remove

driving end bearing in the same manner.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 36 of 66

Last Revision: 12/06/2012

7.1.1.9 Remove oil seals (50000) from the insert from DE & NDE side. Remove shoulder

rings (19900) from the shaft by using puller.

7.1.1.10 Remove liquid deflector (23600) from the shaft.

7.1.1.11Remove gland nuts (58200) from each gland. Remove gland (22300) gland

packing (43000) & lantern rings (22700) from each insert.

7.1.1.12Slide inserts (97901, 97902) off the shaft.

7.1.1.13 Take out casing rings (19000) on DE & NDE side.

7.1.1.14 For counter clockwise (CCW) direction of rotation of pump viewed from driving

end, follow steps (i & ii) and then go to point no. 7.1.1.16:

i) Unscrew DE side shaft sleeve and slide it off the shaft from DE side.

Remove impeller from shaft. Remove impeller key.

ii) Unscrew the NDE side shaft sleeve and slide it off the shaft from NDE side.

7.1.1.15 For clockwise (CW) direction of rotation of pump viewed from driving end, follow

steps (i & ii) then go to point no. 7.1.1.16:

i) Unscrew NDE side shaft sleeve and slide it off the shaft from NDE side. Remove

impeller from shaft. Remove impeller key.

ii) Unscrew the DE side shaft sleeve and slide it off the shaft from DE side.

7.1.1.16 Store all parts of rotating assembly in clean and dry place and arrange to store

the parts in well oiled condition.

7.1.1.17 mechanical seal arrangement –

All UPM pumps are fitted with bare mechanical seal only.

a) Dismantling procedure for mechanical seal fitted pump is same as above except step

no. 7.1.1.11. After step no. 7.1.1.10, slide inserts (97901, 97902) off the shaft.

b) Remove grub screws holding mechanical seal & slide off mechanical seal on both

sides from the shaft.

c) Then follow steps 7.1.1.13 to 7.1.1.16.

This completes the dismantling of the pump.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 37 of 66

Last Revision: 12/06/2012

7.2 Reassembly Procedure -

7.2.1 For UPM pumps:

7.2.1.1 Check ‘O’ ring (52202) for cut or flaws, discard if faulty, lubricate and roll ‘O’

ring in groove of each shaft sleeve.

7.2.1.2 Wipe over shaft (18001) with clean light oil.

7.2.1.3 Keep shaft so that coupling end extension is in correct position looking from

position of suction and delivery branches.

7.2.1.4 For counter clockwise (CCW) direction of rotation of pump viewed from driving

end, follow steps (i, ii & iii) and then go to point no.7.2.1.6:

i) Locate the locking shaft sleeve (31000) at NDE side with the help of impeller

key (32000) and tighten it on the shaft. Please check that the “o” ring is fitted

in groove of sleeve.

ii) Check impeller vanes for correct direction of rotation. Slide the impeller on the

shaft. Check that keyway provided on shaft extends equally outside the hub of

impeller on both sides.

iii) Slide DE side adjusting sleeve in the shaft and tight it against impeller hub with

the help of set screw.

7.2.1.5 For clockwise (CW) direction of rotation of pump viewed from driving end, follow

steps (i, ii & iii) and then go to point no.7.2.1.6.

i) Locate the locking shaft sleeve (31000) at DE side with the help of impeller key

and tighten it on the shaft. Please check that the “o” ring is fitted in groove of

sleeve.

ii) Check impeller vanes for correct direction of rotation. Slide the impeller on the

shaft. Check that keyway provided on shaft extends equally outside the hub of

impeller on both sides.

iii) Slide the NDE side adjusting sleeve in the shaft and tight it against impeller hub

with the help of set screw.

7.2.1.6 Apply a hand of light oil on casing rings (19000) and place casing rings on the

impeller.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 38 of 66

Last Revision: 12/06/2012

7.2.1.7 Check ‘O’ rings (52201) for cracks or flaws, discard if faulty. Lubricate and roll

‘O’ ring (52201) into the groove in each insert (97901, 97902).

7.2.1.8 Slide inserts (97901, 97902) over shaft with guide vane at top position.

7.2.1.9 Slide glands (22300) over the shaft / slide bare mechanical seal over the shaft

and locate the same on the shaft with the help of grub screws.

7.2.1.10 Slide the liquid deflector on the shaft from DE & NDE side.

7.2.1.11 Fit shoulder ring (19900) onto shaft, then fit oil seal (50000) into insert.

Ensure that no foreign particle should enter in bearing assembly. See sectional

drawing.

7.2.1.12 Heat the ball bearing (26000) to approximately 100°C (212°F) using heating

oil bath.

NOTE: DO NOT EXCEED 120°C (250°F).

7.2.1.13 Use hand gloves while handling heated bearings.

Slide the heated bearing on to the shaft to about shoulder ring (19900) at non

driving end. Place locking washer (44500) onto shaft & screw bearing lock

nut (31500) using hook spanner. Tight the lock nut against bearing. Bend the

washer in the slot of bearing lock nut.

7.2.1.14 Cool the bearing to room temperature and coat both sides with grease.

7.2.1.15 Coat the inside of the bearing housing (24002) with grease and slide into

place over bearing. Secure bearing housing to insert with four hex head

screws (57100).

7.2.1.16 At coupling end heat the bearing (26000) to approximately 100°C (212°F)

using heating oil bath.

NOTE: DO NOT EXCEED 120°C (250°F).

7.2.1.17 Slide the heated bearing onto the shaft to about shoulder ring (19900) at

coupling end.

Use hand gloves while handling heated bearings.

7.2.1.18 Cool the bearing to room temperature and coat both sides with grease.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 39 of 66

Last Revision: 12/06/2012

7.2.1.19 Coat the inside of the bearing house (24002) with grease and slide into place

over bearing. Secure bearing housing to insert with four hex screws (57100).

7.2.1.20 Fit cylindrical pins (61000) in their respective holes.

7.2.1.21 Lift the rotating unit by means of crane. Set the rotating unit in the lower

casing half. Locate both insert tongues at top position. Correct any excessive

‘O’ ring buckling. Check whether Impeller is centrally placed in volute and

there is no rubbing between impeller and casing.

7.2.1.22 Ensure that casing rings are located in cylindrical pins fitted in lower half

casing. Install gasket (51900) between upper & lower half casing with a light

coat of grease on both gasket surfaces.

Carefully align the inner edge of gasket with the insert ‘O’ rings.

7.2.1.23 Lift upper half casing (12200) and place it on lower half casing and engage

casing joint nuts loosely.

NOTE: When installing casing half upper make sure that the ‘O’ rings (52201)

are not cut or punched.

7.2.1.24 Insert locating pins (61100) for upper & lower half casing and drive them

home. Tighten upper half casing to lower half casing by studs and nuts.

7.2.1.25 Fit insert at DE & NDE side & tight it to upper & lower half casing with the

help of hex screws.

7.2.1.26 Fill the gland packing along with lantern ring in the correct sequence as given

in technical data. Then fit gland to the insert with studs & hex nut. (This step

is not applicable for mechanical seal fitted pump.)

7.2.1.27 Mount all the accessories such as grease nipple, sealing / flushing connection

etc.

7.2.1.28 Rotate the shaft by hand to assure smooth rotation and that it is free from

rubbing or binding.

7.2.1.29 Mount the pump coupling key and fit the pump coupling on the shaft from DE

side.

7.2.1.30 Align motor coupling with pump coupling within 0.05 mm to each other.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 40 of 66

Last Revision: 12/06/2012

Note - UP150/56, UP200/56, UP200/64M, UP250/33, UP250/66, UP300/34

& UP300/39 pumps are fitted with bare mechanical seal only.

This completes the reassembly of the pump.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 41 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 42 of 66

Last Revision: 12/06/2012

JOINT FLANGE

TIGHTENING TORQUES AND SEQUENCE

Stud and Nut use in this main joint flange of UP pumps should be tightened to the

torques stated in table 1 and in the sequence stated in Fig.

STUD SIZE TIGHTENING TORQUES

M12

M16

M20

M24

250Kg-CM

650Kg-CM

1270Kg-CM

2200Kg-CM

2. Tightening sequence.

2.1 Tighten the four corner stud marked ‘X’ 1, 2, 3, and 4

2.2 Work outward along shaft axis towards the stuffing boxes in opposite quarters

tightening nut in regions 5, 6, 7 and 8.

2.3 Work outwards along the branch and in opposite quarters tightening nuts in regions

9, 10, 11, and 12.

2.4 Repeat the whole sequence.

Sleeve Location

IOM/UP_METRIC Issue Date: 31/12/2007

Page 43 of 66

Last Revision: 12/06/2012

INSTALLING STUFFING BOX PACKING

1. Refer to stuffing box data to ascertain size and number of rings required.

2. If the packing is to be cut from a coil or long length:-

a) Wrap the packing around a dummy shaft, equal to the shaft sleeve diameter.

b) To assist in cutting rings, two guide lines parallel to the shaft axis and separated

by a distance equal to the packing section may be drawn on the spiral.

c) Cut the rings from the spiral at an angle of 45° diagonally across the guide lines

no gap is left between the ends.

3. Insert the first ring and tap it to the bottom of the stuffing box. Each following ring

should be installed in the same manner and positioned in the stuffing box so that the

split is advanced 90 Deg.

Install the lantern ring in its proper position to align with the sealing connection

allowing for movement of the ring deeper in to the box as the packing is

compressed.

4. When the correct number of rings have been inserted, the last packing ring should

not protrude past the stuffing box face, so that the gland may be properly seated in

the stuffing box bore.

5. Bring the gland follower up securely against the last packing ring and tighten the

nuts evenly to give pressure.

6. Turn the shaft to ensure it does not bind on the bore or the gland follower.

7. Pressurize the stuffing box, ensuring air is not trapped. A packed gland must leak

and leakage should take place commencing soon after the stuffing box is

pressurized.

8. Until steady leakage takes place, the pump may overheat. If this happens, the pump

must be stopped and allow to cool and, when restarted, leakage should take place.

If it does not, this operation should be repeated. Gland nuts should not be

slackened.

9. After the pump has been running for 10 minutes with steady leakage, tighten the

gland nuts by one sixth of a full turn. Continue to adjust at ten minute intervals,

each time

IOM/UP_METRIC Issue Date: 31/12/2007

Page 44 of 66

Last Revision: 12/06/2012

evenly by one sixth of a full turn, until leakage is reduced to an acceptable level.

There should be leakage of 60 to 80 drops per minute.

CAUTION:

Excessive gland pressure will cause damage by cutting off lubrication to the packing

and packing will burn and damage the sleeve.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 45 of 66

Last Revision: 12/06/2012

8.0 GENERAL OUTLINE DIMENSIONS

`

`

IOM/UP_METRIC Issue Date: 31/12/2007

Page 46 of 66

Last Revision: 12/06/2012

9.0 SPARE PART LIST AND CROSS SECTIONAL DRAWINGS

* marked part code nos. are recommended spares.

Part code no. Part description

12200

12300

15900*

19000*

19900

24001

24002

26000*

27000

27101

27102

32000*

32100

33600

41500

44101

45000

47101

47102

50000

51900

52200*

52202*

57100

57101

57102

58001

58002

59001

59002

60500

60600

61000

61100

64000

67000

69100

84901

84902

84903

60000

60100

CASING HALF UPPER

CASING HALF LOWER

IMPELLER

WEARING RING

SHOULDER RING

BEARING HOUSING DE

BEARING HOUSING NDE

BALL BEARING

BEARING COVER DE

BEARING COVER NDE

BEARING COVER DE & NDE

KEY (IMPELLER)

KEY (COUPLING)

LOCK NUT (BEARING)

LOCK WASHER (BEARING)

GREASE NIPPLE

VENT VALVE

PROTECTION COVER (SUC)

PROTECTION COVER (DEL)

OIL SEAL

GASKET (CASING)

O RING (INSERT)

ORING (SLEEVE)

SCREW (BRG.HOUSING)

SCREW (BRG. HSG & CASING)

SCREW (BRG. HSG & INSERT)

NUT (CASING)

NUT (INSERT)

STUD (CASING)

STUD (INSERT)

PIPE PLUG (BEARING HOUSING NDE)

PIPE PLUG (PRIMING)

LOCKING PIN (CASING RING)

LOCATING PIN (CASING)

RIVET (NAME PLATE)

DUTY NAME PLATE

NUT (LOCATING PIN)

WASHER (LOCATING PIN)

WASHER (INSERT)

WASHER (BEARING HOUSING)

GAUGE PLUG

DRAIN PLUG

IOM/UP_METRIC Issue Date: 31/12/2007

Page 47 of 66

Last Revision: 12/06/2012

Soft packed pump components

18001*

22300

22700

23600

31000*

43000*

58200

59200

59404

97901

97902

PUMP SHAFT (SOFT PACKED)

GLAND

LANTERN RING

DEFLECTOR

SHAFT SLEEVE (SOFT PACKED)

GLAND PACKING

NUT (GLAND)

STUD (GLAND)

WAHSER (GLAND)

INSERT DE(SOFT PACKED)

INSERT NDE(SOFT PACKED)

Common for Mechanical Seal & Gland Pack

a) Internal Flushing Components

55902

56002

STUD COUPLING

TUBE FLUSHING

b) External Flushing Components

60200 SEALING PLUG (CASING)

Soft Packed Components

Grease Sealing (If Ordered)

60200

44102

SEALING PLUG (CASING)

GREASE NIPPLE

Gauge and drain connection (If Ordered)

60000

60600

GAUGE PLUG

DRAIN PLUG

Mechanical Seal Components

18000*

23000*

31500*

97900

PUMP SHAFT (MECH.SEAL)

MECH.SEAL

SHAFT-SLEEVE(MECH.SEAL)AGAINST ORDER

INSERT (MECH.SEAL)

IOM/UP_METRIC Issue Date: 31/12/2007

Page 48 of 66

Last Revision: 12/06/2012

CROSS SECTIONALDRAWING FOR UP 50/30A, UP 50/30B, UP 65/38, UP 65/38M AND

UP 80/38 (SOFT PACKED)

IOM/UP_METRIC Issue Date: 31/12/2007

Page 49 of 66

Last Revision: 12/06/2012

CROSS SECTIONAL DRAWINGOF UP50/30A, UP 50/30B, UP 65/38, UP65/38M AND

UP80/38 (MECHANICAL SEAL)

IOM/UP_METRIC Issue Date: 31/12/2007

Page 50 of 66

Last Revision: 12/06/2012

CROSS SECTIONAL DRAWING FOR SOFT PACKED PUMP

IOM/UP_METRIC Issue Date: 31/12/2007

Page 51 of 66

Last Revision: 12/06/2012

CROSS SECTIONAL DRAWING FOR MECHANICAL SEAL PUMP

IOM/UP_METRIC Issue Date: 31/12/2007

Page 52 of 66

Last Revision: 12/06/2012

10.0 EXPLODED VIEW

IOM/UP_METRIC Issue Date: 31/12/2007

Page 53 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 54 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 55 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 56 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 57 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 58 of 66

Last Revision: 12/06/2012

IOM/UP_METRIC Issue Date: 31/12/2007

Page 59 of 66

Last Revision: 12/06/2012

GENERAL INFORMATION & SAFETY INSTRUCTIONS

1. The products supplied by KBL have been designed with safety in mind. Where hazards cannot be

eliminated, the risk has been minimized by the use of guards and other design features. Some hazards

cannot be guarded against and the instructions below MUST BE COMPLIED WITH for safe operation.

These instructions cannot cover all circumstances. Installation, operation and maintenance personnel

must use safe working practices at all the times.

1.1 KBL products are designed for installation in designated areas, which are to be kept clean and free

of obstructions that may restrict safe access to the controls and maintenance access points.

A pump duty nameplate is fitted to each unit and must not be removed. Loss of this plate could

make identification impossible. This in turn could affect safety and cause difficulty in obtaining

spare parts. If accidental loss or damage occur, contact KBL immediately.

1.2 Access to the equipment should be restricted to the person net responsible for installation,

operation and maintenance and they must be trained, adequately qualified and supplied with

appropriate tools for their respective tasks.

1.3 Most accidents involving product operation, maintenance and repair are caused by failure to

observe safety rules or precautions. An accident can often be avoided by recognizing potentially

situations before an accident occurs. A person must be aware of potential hazard associated in

activities of installation, operation and maintenance of equipments.

1.4 KBL requires that, all personnel that are responsible for installation, operation or maintenance of the

equipment, have access to and study the product instruction manual BEFORE any work is done and

that they will comply with all local and industry based safety instructions and regulations.

1.5 Ear defenders should be worn where the specified equipment noise level exceeds locally defined

safe levels. Safety glasses or goggles or face shield should be worn where working with pressurized

systems and hazardous substances. Other personal protection equipment must be worn where local

rules apply. Wear safety shoes, helmets and cotton overall [Apron] when you enter pump house.

Noise level should not exceed 90 dbA and 110 dbA for motor driven and engine driven pumps,

respectively.

1.6 Do not wear loose clothing or jewelry, which could catch on the controls or become trapped in the

equipment.

1.7 Read the instruction manual before installation, operation or maintenance of the equipment. Check

and confirm that you are referring relevant copy of the manual by comparing pump type on the

nameplate and with that on the manual.

1.8 Note the “Limits of product application permissible use” specified in the manual. Operation of the

equipment beyond these limits will increase the rist from hazards noted below and may lead to

premature and hazardous pump failure.

1.9 Clear and easy access to all controls, gauges and dials etc must be maintained at all times.

Hazardous or flammable materials must not be stored in pump rooms unless safe areas or racking

and suitable container have been provided.

1.10 Use suitable earthing and tripping devices for electrical equipments.

2. IMPROPER INSTALLATION, OPERATION, MAINTENANCE,

LUBRICATION, REPAIR OF THIS KBL PRODUCT COULD

RESULT IN INJURY OR DEATH.

If any tool, procedure, work method and operation technique is not recommended by KIRLOSKAR

BROTHERS LIMITED is used or followed, it should be ensured that it is a safe for personnel around and

others. It should also be ensured that the product will not be damaged or made unsafe by the

operation, lubrication and maintenance or repair procedures you choose.

3. SAFETY INSTRUCTIONS WHILE HANDLING AND STORAGE

IOM/UP_METRIC Issue Date: 31/12/2007

Page 60 of 66

Last Revision: 12/06/2012

When lifting the pump, use the lifting points specified on general arrangement drawing, if provided. Use

lifting equipment having a safe working load rating suitable for the weight specified. Use suitable slings

for lifting pump, which is not provided, with lifting points. The use of forklift truck and chain crane sling

equipment is recommended but locally approved equipment of suitable rating may be used. While

lifting, the equipment adjusts the center of gravity, so that it is balanced properly.

Do not place fingers or hands etc into the suction or discharge pipe outlets and do not touch the

impeller, if rotated this may cause severe injury. To prevent ingress of any objects, retain the protection

covers or packaging in place until removal is necessary for installation. If the packaging or suction and

discharge covers are removed for inspection purposes, replace afterwards to protect the pump and

maintain safety.

4. SAFETY INSTRUCTIONS WHILE ASSEMBLY & INSTALLATION

Shaft alignment must be checked again after the final positioning of the pump unit and connection to

pipework as this may have disturbed the pump or motor mounting positions. If hot liquids [above 80°C]

are being pumped, alignment should be checked and reset with the pump and motor at their normal

operating temperature. If this is not possible, KBL can supply estimated initial offset figures to suit

extreme operating temperatures. Failure to support suction and delivery pipework may result in

distortion of the pump casing, with the possibility of early pump failure.

5. SAFETY INSTRUCTIONS WHILE COMMISSIONING & OPERATION

Never attempt adjustments while the pump is running, unless otherwise specified in the operation,

maintenance manual.

Do not touch any moving or rotating parts. Guards are provided to prevent access to these parts,

where they have been removed for maintenance they must be replaced before operating the equipment.

Check that pump is primed. Pump should never be run dry as the pumped liquid acts as lubricant for the

close running fits surrounding impeller and damage will be incurred.

Failure to supply the stuffing box or mechanical seal with cooling of flush water may result in damage

and premature failure of the pump.

Do not touch surfaces, which during normal running will be sufficiently hot to cause injury. Note that

these surfaces remain hot after the pump has stopped, allow sufficient time for cooling before

maintenance. Be cautious and note that other parts of the pump may become hot if a fault is

developing.

Do not operate water pumps in temperatures below freezing point, without first checking that the

pumped fluid is not frozen and the pump is free to turn. Pumps in these environments should be drained

down during inactivity and re-primed before starting.

In addition to local or site regulations for noise protection, KBL recommend the use of personal ear

protection equipment in all enclosed pump rooms and particularly those containing diesel engines. Care

must be taken to ensure that any audible alarm or warning signal can be heard with car defenders

worn.

Be aware of the hazards relating to the pump fluid, especially the danger from inhalation of noxious and

toxic gases, skin and eye contact or penetration. Obtain and understand the hazardous substance data

sheets relating to the pumped fluid and note the recommended emergency and first aid procedures.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 61 of 66

Last Revision: 12/06/2012

6. SAFETY INSTRUCTIONS WHILE MAINTENANCE & SERVICING

Do not attempt repairs of the pump or its accessories which you do not know. Use proper tools.

Before attempting any maintenance on a pump particularly if it has been handling any form of

hazardous liquid, it should be ensured that the unit is safe to work on. The pump must be flushed

thoroughly with suitable cleaner to purge away any of the product left in the pump components.

This should be carried out by the plant operator and a certificate of cleanliness obtained before starting

work. To avoid any risk to health it is also advisable to wear protective clothing as recommended by

the site safety officer especially when removing old packing, which may be contaminated.

Isolate the equipment before any maintenance work is done. Switch off the main supply, remove fuses,

apply lockouts where applicable and affix suitable isolation warning signs to prevent inadvertent

reconnection. In order to avoid the possibility of maintenance personnel inhaling dangerous fumes or

vapours locations by removal of bearing housing and shaft assembly to a suitable maintenance area.

Check and ensure that the pump operates at below the maximum working pressure specified in the

manual or on the pump namepate and before maintenance, ensure that the pump is drained down.

Wear a suitable mask or respirator when working with packing and gasket contain fibrous material, as

these can be hazardous when the fibrous dust is inhaled. Be cautious, if other supplier’s components

have been substituted for genuine KBL parts, these may then contain hazardous materials.

Store all oily rags or other flammable material in a protective container in a safe place. Do not weld or

flame cut on pipes/tubes that contents flammable fluids. Clean them thoroughly with nonflammable

solvent before welding or flame cutting on them. Use solvent/chemical resistant gloves for hand

protection.

Dispose of all wastes like gaskets, gland packing, oil, batteries, packing material etc in accordance with

local regulation.

Adequacy of suitable crane should be checked before lifting the pump/pump components. Also

condition of pulleys, chain and lifting shackles should be checked before use.

IOM/UP_METRIC Issue Date: 31/12/2007

Page 62 of 66

Last Revision: 12/06/2012

ADRESSES OF REGIONAL OFFICE

AHMEDABAD

11, Mill Officers Colony,

Behind La Gajjar Chambers,

Ashram Road, Ahmedabad 380 009

Tel: +91-79-26583739, 26580376,

26583615, 26583258, 26574500, 26574802

Fax: +91-79-26583786

EMAIL ID: ahmedabad@kbl.co.in

BANGALORE

No.5, Lakshmi Complex, II floor, 10th Cross,

RMV Extension, CV Raman Road Bangalore 560

080

Tel: +91-80-23619914, 23619915, 23610027,

23610028

Fax: +91-80-23610095

EMAIL ID: bangalore@.kbl.co.in

BHOPAL

E-1, Shankarnagar, 6 1/2 Bus Stop,

Opposite Parul Hospital,Bhopal 462 016

Tel: +91-0755-4218341

EMAIL ID: bhopal@kbl.co.in

BHUBANESHWAR

Plot No. 969, Part A, Uttam Tower, Block B,1st

Floor, Ashok Nagar, Unit 2,

Bhubaneshwar 751 009

Tel: +91-0674-2536188, 2536421, 2535371

Fax: +91-0674-2534965

EMAIL ID: bhubaneshwar@kbl.co.in

CHENNAI

RAJ PARIS,Trimeni Towers,2nd Floor,

147 GN Chetty Road,T Nagar,

Chennai 600 017

Tel: +91-044-28157769, 28156546 / 7 /8

Fax: 044-28156549

EMAIL ID: chennai@kbl.co.in

JAIPUR

B-8, Durga Das Colony,

Behind Neelkanth Tower,

Bias Godam Circle,

Bhawani Singh Road,

Jaipur - 302001 - Rajasthan

Tel: +91-0141 - 2223830

EMAIL ID: jaipur@kbl.co.in

KOCHI

Veejay Towers, 38/239 A, Salim Rajan Road,

Gandhinagar, Ernakulam,

Kochi - 682 017

Tel: +91-0484-2206651, 2206652

Fax: +91-0484-2206653

EMAIL ID: kochi@kbl.co.in

JAMSHEDPUR

No. 4, 4th Floor, Meghdeep Building,

Q road, Bistupur, Beside Hotel South Park,

Jamshedpur - 834001

KOLKATA

KCI Plaza, 1st Floor,

23 C, Ashutosh Chowdhary Avenue

Kolkata 700 019

Tel: +91-033-2461 4040, 4050, 4060, 5065,

5934, 5325, 4615

Fax: +91-033-2461 4519

EMAIL ID: kolkata@kbl.co.in

LUCKNOW

B-1/7, Sector A, Aliganj

Lucknow 226 024

Tel: +91-0522-2326367, 2326374,

2326387

Fax: +91-0522-2326365

EMAIL ID: lucknow@kbl.co.in

MUMBAI

10, Corporate Park,

Swastik Mills Compound,

Sion-Trombay Road, Chembur

Mumbai 400 071

Tel: +91-022-25289320 to 28

Fax: +91-022-25289329

EMAIL ID: mumbai@kbl.co.in

NEW DELHI

Jeevan Tara Building,

5, Parliament Street,

New Delhi 110 001

Tel: +91-011-41501055 to 62

Fax: +91-011-23342002

EMAIL ID: delhi@kbl.co.in

IOM/UP_METRIC Issue Date: 31/12/2007

Page 63 of 66

Last Revision: 12/06/2012

NAGPUR

Flat No. 7, Sagar Palace, Laxmi Nagar,

Behind 'Bal Jagat', East High Court Road,

Nagpur - 440 022

Tel: +91-0712-2234275, 2234276

Fax: +91-0712-2234276

EMAIL ID: nagpur@kbl.co.in

PUNE

Udyog Bhavan, Tilak Road,

Pune 411 002 (India)

Fax: +33 (0) 1 34 66 07 33

EMAIL ID: pune@kbl.co.in

Tel: +91-020-2444 0770

SECUNDERABAD

P.O. Box. No. 1580, 403, Jade Arcade,

126 MG Road, Paradise Circle,

Secunderabad - 500 003

Tel: +91-040-66874700, 66874712 to 37, 27816075

Fax: +91-040-27894598

EMAIL ID:

secunderabad@kbl.co.in

IOM/UP_METRIC Issue Date: 31/12/2007

Page 64 of 66

Last Revision: 12/06/2012

GLOBAL PRESENCE OF KBL

KIRLOSKAR BROTHERS LIMITED

Thuduea Rd, Near Simoung Shell Gas

Station, Ban Thatkhao, Sisattank Dist

Vientiane-Lao PDR

Tel: +856-21-219761

Fax: +856-21-213058

: kbllaos@laotel.com

: Tamil Selevan

: C.A.J. Vinodh

KIRLOSKAR BROTHERS LLC

15251 SW 108 Terrace

Miami,– FL – 33196

United States of America

Tel : +1 305-484-9509

: santoshk.kulkarni@kbl.co.in

: Santosh Kulkarni

KIRLOSKAR BROTHERS (THAILAND)

LIMITED

Kirloskar Brothers (Thailand) Limited 18/8,

8th Floor,

Fico Place Building, Sukhumvit 21 (Soi

Asoke), Klong

toey Nua, Wattana, Bangkok 10110,

Thailand

Tel : +66 2 665 2781/2

: pumps@kirloskarthailand.com

: Shreekanth Ramaswami

BRAYBAR PUMPS (PTY) LIMITED

5 Indiana Street, Apex Industrial Area,

Benoni, Gauteng, Republic of South Africa

Tel: +27 (0)11 421 5903/ +27 (0)11

421 5904

Fax: +27 (0)11 421 6793

:ajeet@braybar.co.za/

braybar@global.co.za

Website: www.braybar.edx.co.za

: Ajeet Kulkarni

SPP PUMPS, INC.

6716 Best Friend Road,

Norcross, GA 30071,

United States of America

Tel: +1(770) 409-3280

Fax: +1(770) 409-3290

: john_kahren@spppumps.com

: John Kahren

(Business Manager)

SPP PUMPS LIMITED

P O Box 61491,

Jebel Ali,Dubai

United Arab Emirates

Tel: +971 (0) 4 8838 733

Fax: +971 (0) 4 8838 735

: general@spppumps.com

: Steven Keen

(General Manager)

SPP PUMPS FRANCE

2, rue du Chateau d'eau, 95450 US

France

Tel: +33 (0) 1 30 27 96 96

Fax: +33 (0) 1 34 66 07 33