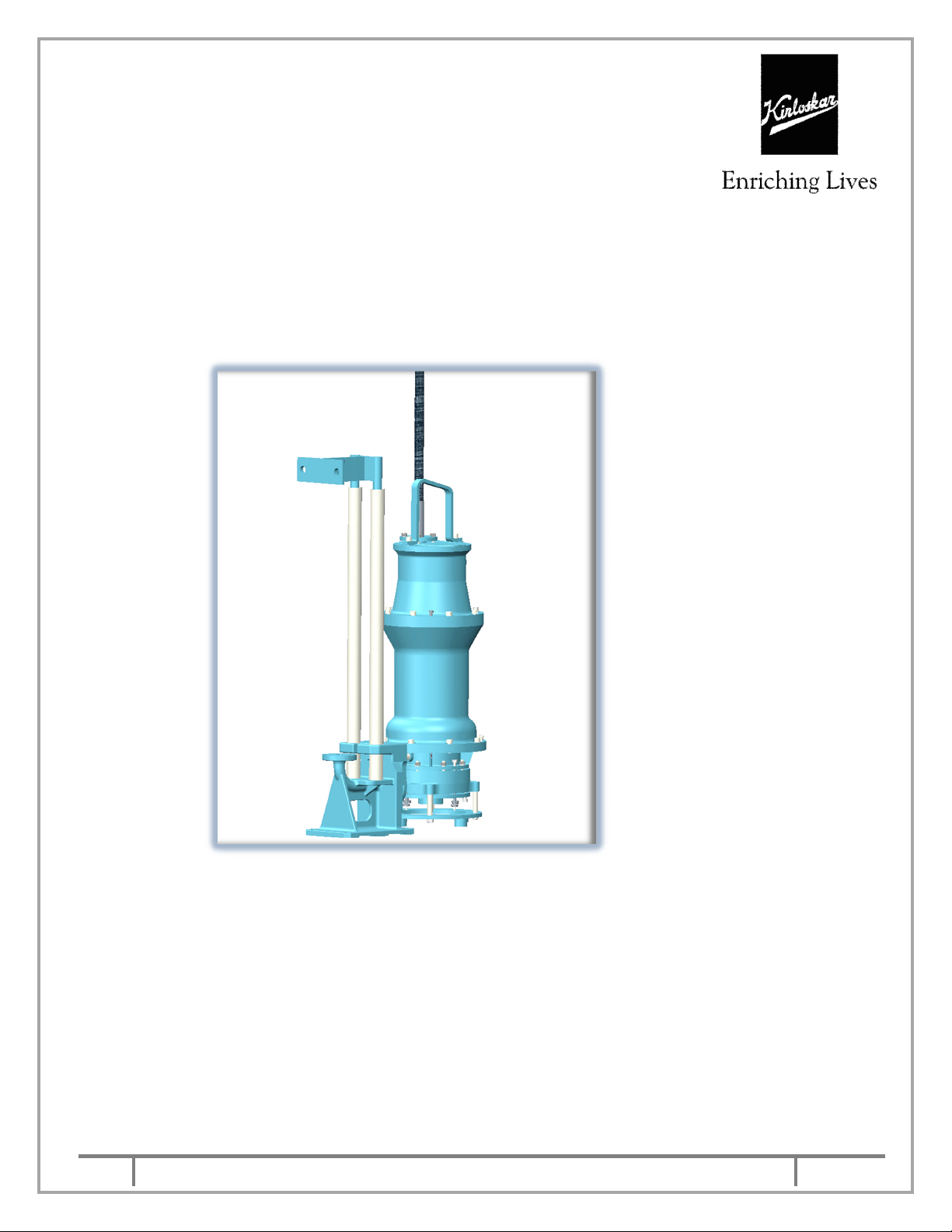

KIRLOSKAR NS100/26N, NS100/26Q, NS150/26QMB, NS150/26QM, NS100/26QM Instructions On Installation, Operation And Maintenance Manual

...Page 1

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

Instructions on Installation,

Operation and Maintenance

Manual for Kirloskar Non-Clog

Submersible series (IE2)

1

NS IOM MANUAL

Page 2

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

WARRANTY

We warrant that the pump supplied by us is free from defective

material and faulty workmanship. This warranty holds good for a

period of 12 months from the date of commissioning the equipment

or 18 months from the date of dispatch from our factory, whichever

is earlier. Our liability in respect of any complaint is limited to

replacing part/parts free of charge ex-works or repairs of the

defective part/parts only to the extent that such replacement/repairs

are attributable to or arise solely from faulty workmanship or

defective material.

This warranty holds good only for the products manufactured by us.

– KIRLOSKAR BROTHERS LIMITED –

2

NS IOM MANUAL

Page 3

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

1.

2.

3.

4.

5.

6.

7.

CAUTION

DO NOT LOWER OR LIFT THE PUMP WITH THE HELP OF

CABLES.

DO NOT FILL ANY LIQUID INSIDE THE MOTOR.

DO NOT MEGGER CONTROL PANEL CONTROL CIRCUIT

TERMINALS.

DO NOT RUN THE PUMP DRY OR IN REVERSE DIRECTION.

DO NOT RUN THE PUMP WITHOUT CONTROL PANEL.

DO NOT RUN THE PUMP WITH CONTROL UNIT IN BYPASSED

CONDITION.

DO NOT MEGGER CONTROL CABLE OF THE PUMP WITHOUT

DISCONNECTING FROM THE CONTROL PANEL.

3

NS IOM MANUAL

Page 4

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

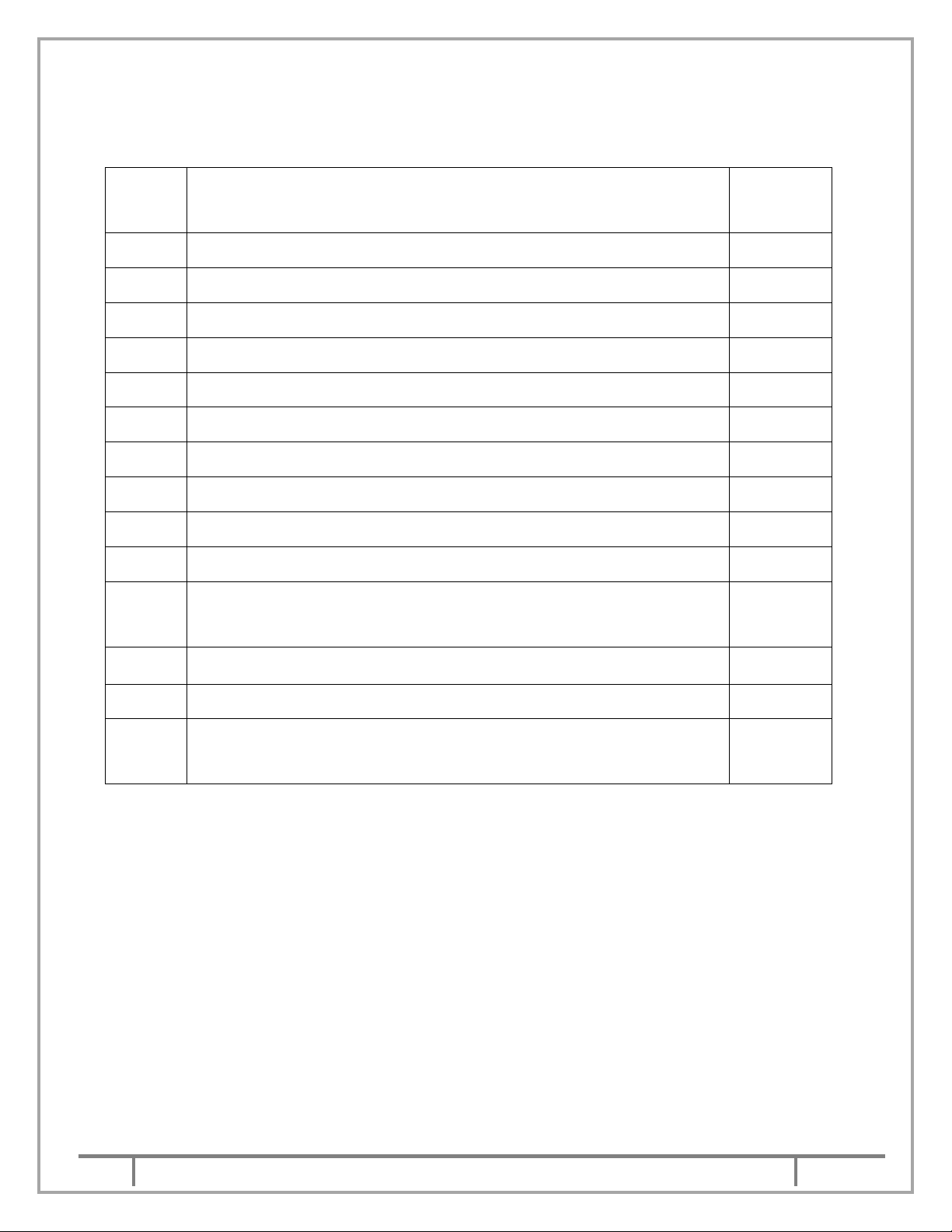

INDEX

SR.

CONTENTS

NO.

1 GENERAL 4

2 SAFETY INSTRUCTIONS 7

3 INSTALLATION 8

4 OPERATION 10

5 MAINTENANCE 11

6 SHUT DOWN / STORAGE / PRESERVATION 13

7 TECHNICAL DATA 14

8 OVERHAULING 18

9 CROSS SECTIONAL DRAWING AND PARTLIST 18

PAGE

NO.

10 OUTLINE DRAWING AND DIMENSIONS SHEET 23

GENERAL ARRANGEMENT DRAWING AND DIMENSIONS

11

SHEET

12 ANNEXURE: CONTROL PANEL / PMU SPECIFICATIONS 35

13 SPARE PARTS 36

ENVIRONMENTAL ASPECT AND PRODUCT RECYCLE

14

PROGRAM

NOTE:

• Please ensure these instructions are read fully before installation and

operation of the pump.

• Please furnish complete nameplate details, name of parts, part nos. and

material of construction while ordering spare parts for the pump

28

36

4

NS IOM MANUAL

Page 5

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

1. GENERAL :

* * * * *

* # * * *

* * * * * * *

* * * *

* * * *

* * * *

* * * *

* * * *

* * * *

* * * * * * *

* * * * * *

* * * * * *

1.1 KIRLOSKAR submersible sewage pumps type “NS” is available in the following types.

1. iNS series (1HS Series Code)

Unit kW Ratings in 2Pole kW Ratings in 4Pole kW Ratings in 6Pole

iNS unit - 1 0.75-1.1 0.55-0.75 iNS unit - 2 1.5-2.2 1.1-1.5 iNS unit - 3 3.7 2.2 iNS unit - 4 5.5-7.5 3.7-7.5 2.2-5.5

iNS unit - 5 9.3-18.5 9.3-15 iNS unit - 6 22 18.5-22 -

2. NS Series (192 Series Code)

Unit kW Ratings in 4Pole kW Ratings in 6Pole

NS unit - 1 - 7.5 -11

NS unit - 2 - 15

NS unit - 3 30 18.5-22

NS unit - 4 37-45

NS unit - 5 55 37

NS unit - 6 75 45

NS unit - 7 90 55

NS unit - 8 110-132

NS unit - 9 160-200

NS unit - 10 225

The following charts can be referred to know the pumps available in type of impellers ratings.

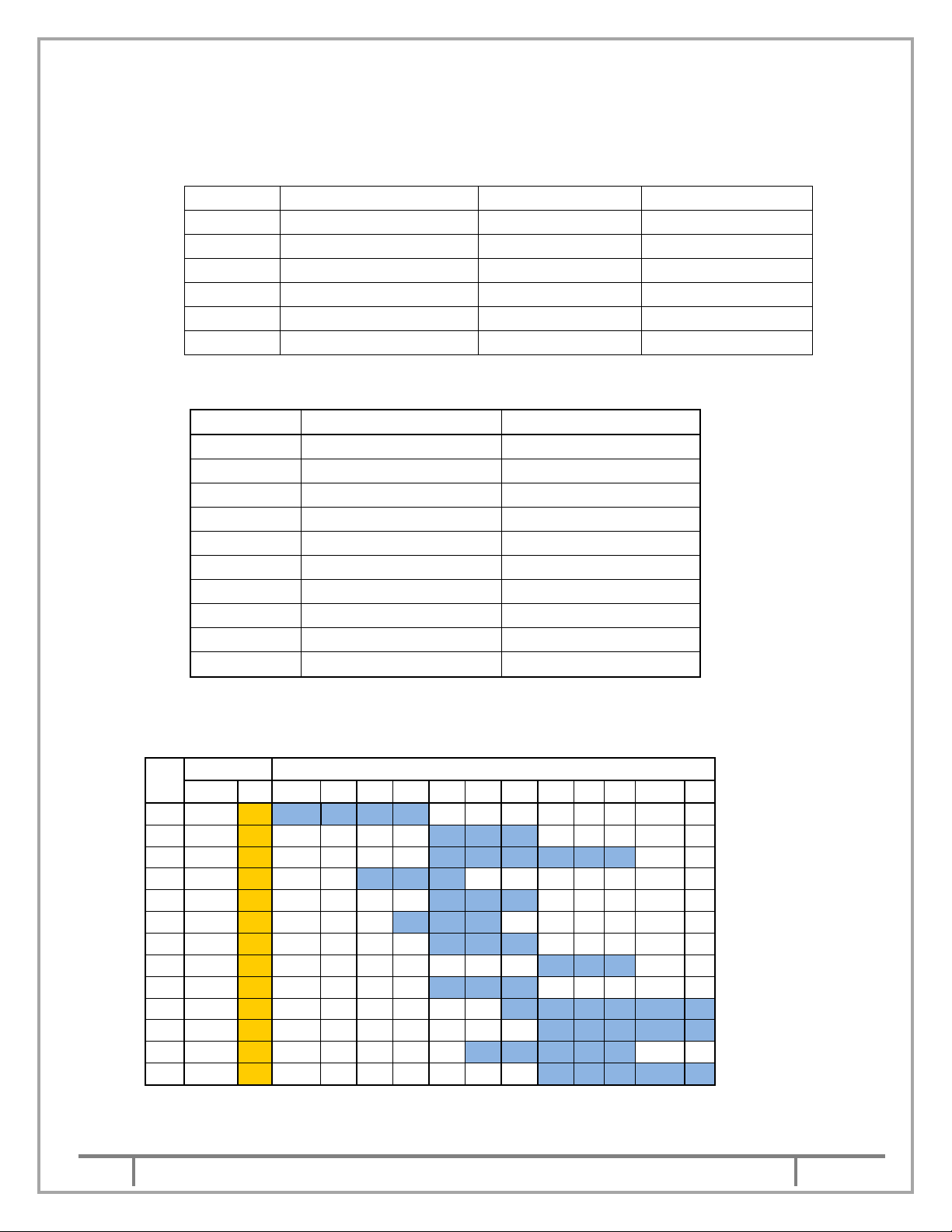

A. Refer below chart for 2 pole Models: (iNS)

IMPELLER kW RATING IN 2 POLE

Sr.

No.

PUMP QT 0.75 1.1 1.5 2.2 3.7 5.5 7.5 9.3 11 15 18.5 22

1 20/13

2 20/16

3 20/20

4 32/13

5 32/16

6 40/13

7 40/16

8 40/20

9 50/13

10 50/16

11 50/20

12 65/13

13 65/16

developed. #-yet to develop.

How to read – NS20/13QT 1.1/2 i (i-stands for iNS)

* * * * * *

30

75-110

132-180

-

*-design

5

NS IOM MANUAL

Page 6

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

B. Refer below chart for 4 pole Models: (iNS)

* * *

* * * *

* * * *

* * * * * * * * * *

* * * * * * * * *

* * * * *

* * * * * * * * * * * *

* * * * * * * * * *

* * * * * * * * * *

* * * * * * * *

* * * * * * * * * * * *

* * * * * *

* * * * * * * *

* * * * * * * *

* *

* * * *

* * *

* * * *

* * * *

* * * *

* * * * *

* * * *

* *

* * * *

* * * *

* * * * *

* * * *

* * * * * *

* * * *

* * * * * *

*

* * * * * * *

*

*

* * * * * * *

* * * * * *

Sr.

No.

PUMP N QM Q QT NB QMB NM QMM 2.2 3.7 5.5 7.5 9.3 11 15 18.5 22

1 40/20

2 40/32

3 50/20

4 50/26

5 50/32

6 50/36

7 65/32

8 80/26

9 100/26

10 100/32

11 150/26

12 150/32

13 80/40

IMPELLER TYPE kW Rating in 4 pole

C. Refer below chart for 6 pole Models: (iNS)

Sr.

No.

PUMP N QM Q QT NB QMB NM QMM 2.2 3.7 5.5

1 40/32

2 50/26

3 50/32

4 50/36

5 65/32

6 80/26

7 100/26

8 150/26

* * * * * *

* * * * * *

* * *

* * * * * * * * *

* * * * * *

* * * * * *

* * * * * * * * * *

IMPELLER TYPE kW Rating in 6 pole

*

*

* * *

D.

Refer below chart for 4 pole Models: (NS).

Sr.

No.

PUMP N QM Q QT NB QMB NM QMM X 30 37 45 55 75 90 110 132 160 180 200 225

1

150/26

2

100/32

3

150/32

4

200/32

5

80/40

6

100/40

7

150/40

8

200/40

9

250/40

10

150/50

11

250/34

IMPELLER TYPE kW RATING IN 4 POLE

How to read – NS150/26Q 30/4

6

NS IOM MANUAL

Page 7

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

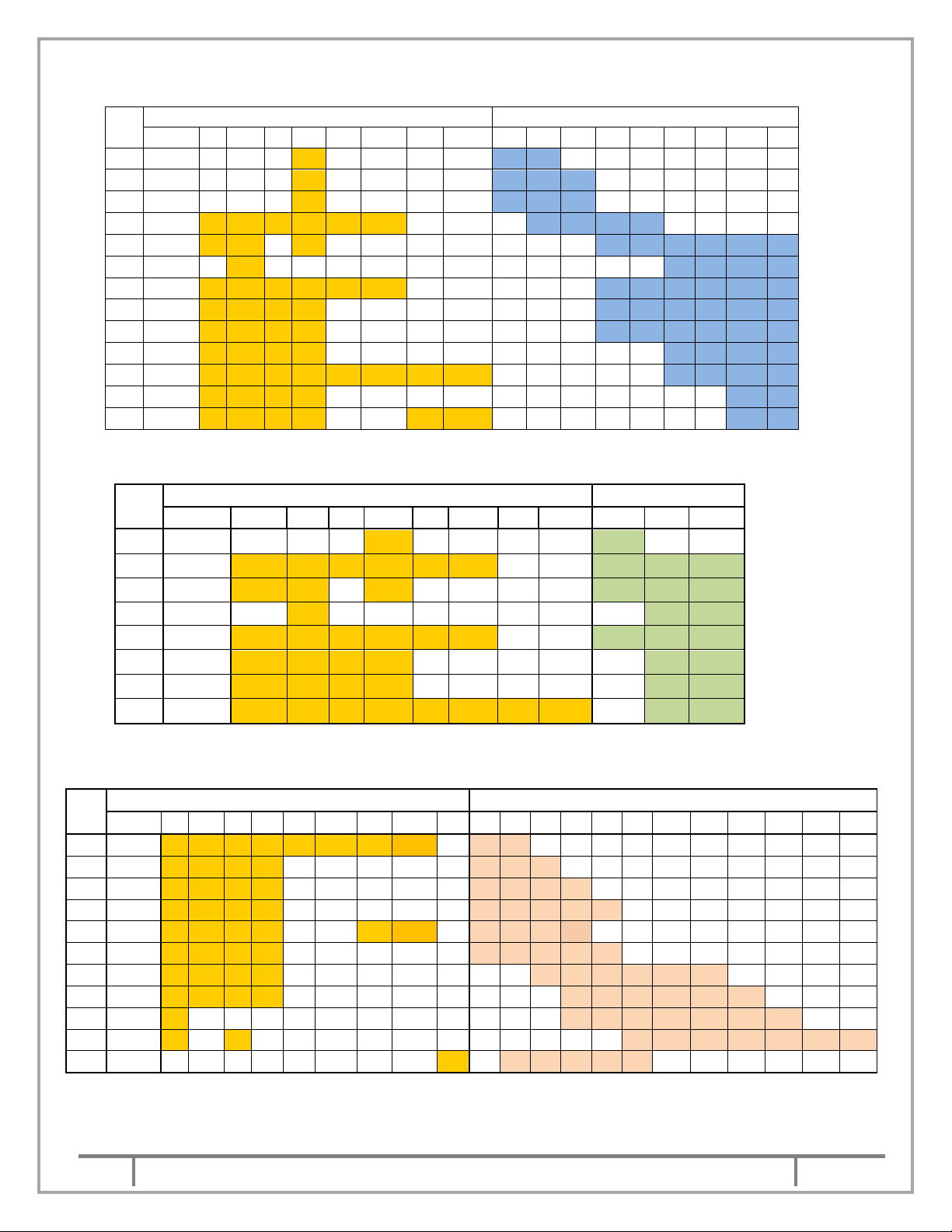

E.

Refer below chart for 6 pole Models: (NS)

PUMP N QM Q QT NB QMB NM QMM X 7.5 9.3 11 15 18.5 22 30 37 45 55 75 90 110 132 160 180

50/32 * * *

50/36 *

65/32 * * * * * *

80/40 * * * * *

100/26 * * * *

100/32 * * * *

100/40 * * * *

150/26 * * * * * * *

150/32 * * * *

150/40 * * * *

150/50 * * * *

200/32 * * * *

200/40 * * * *

250/34

250/40 *

250/50 * *

300/55 *

350/40

350/47

IMPELLER TYPE

*

*

*

*

* * * *

*

* * * * *

* * * * *

*

* *

* * * *

* * * * * *

* * * * *

* * * *

* * * * * *

* * * * *

* * *

* * * * * *

* * * *

* * * * * *

* * * * *

kW RATING IN 6 POLE

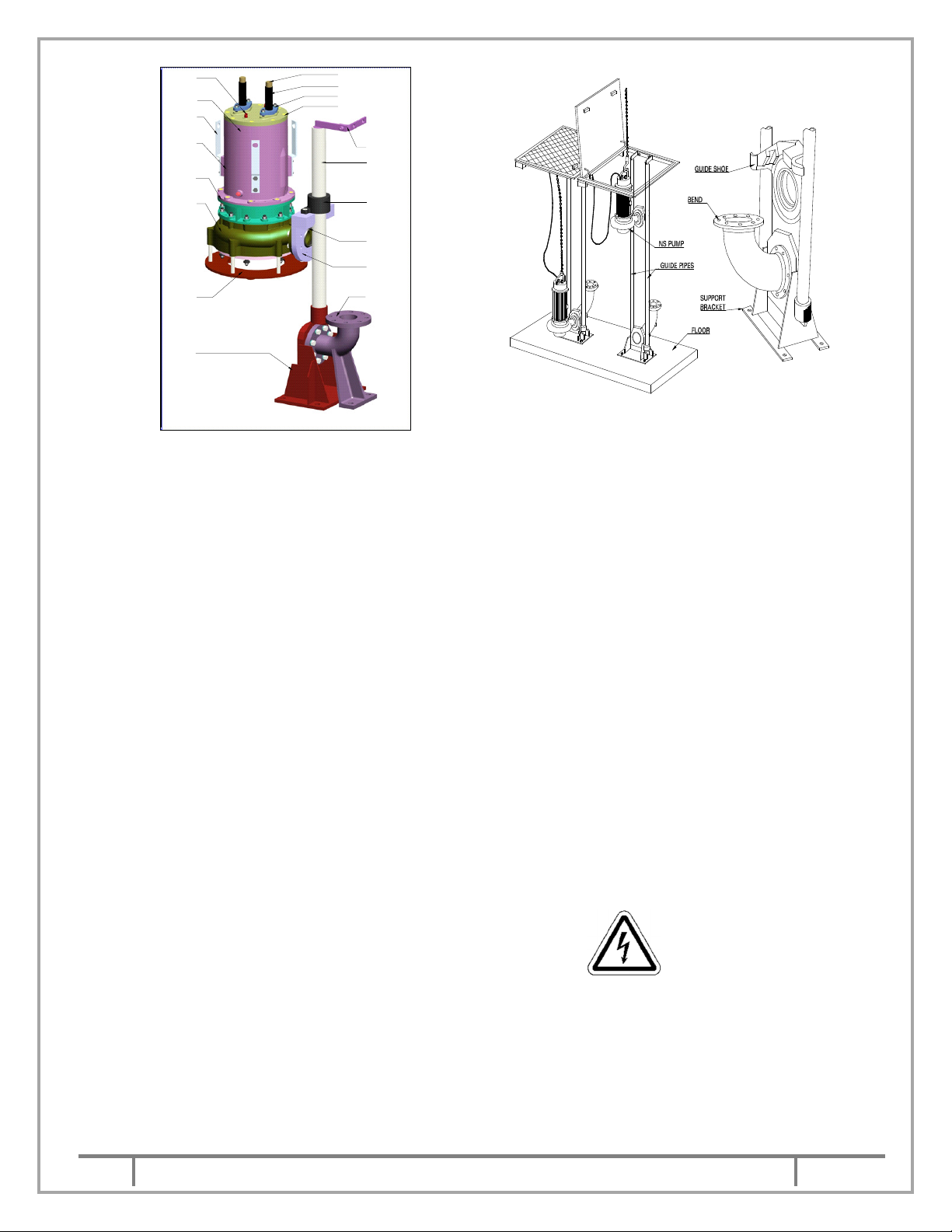

1.2

The pump comprises of three units:

I.

II.

III.

Pump unit – It comprises of a delivery casing having wide volute opening and non-clog

type of impeller. The casing is attached with connector unit or stand as per order.

Stuffing box unit – It comprises double mechanical seal and mechanical seal housing

filled with oil for lubricating the seals. The seal behind the impeller is having seat ring of

silicon carbide V/s silicon carbide and second seal comprises of carbon ring V/s stainless

steel ring.

Electrical motor unit – These pumps are provided with submersible three phase squirrel

cage induction motors in watertight housing. The entire motor unit is air tested to ensure

the leak tightness of the joints. Moisture sensor is provided in the mechanical seal housing

to give the indication to control panel which in turn trips the motor, when the seal near

impeller fails. The pump is provided with high and low liquid level controllers which avoids

dry running of pump

.

1.3 The NS pump can be supplied in portable or with fixed arrangement. When the pump is supplied

with portable type, hose, connection should be provided to avoid weight of pipe line on the pump

casing. The casing is provided with stand for support. For stationary application, the pump is

mounted on the support bracket and is connected to the delivery bend through a rubber diaphragm

and connector unit. The pump slides over the guide pipes without disconnecting/disturbing the

delivery pipe line

.

1.4 NS pump is supplied with wall mounted control panel. These control panels are supplied either with

DIRECT ON LINE, STAR DELTA, SOFT STARTER or ATS type starters. These panels are

designed for smooth running of pump-set. The pump gets switched off automatically and is

protected against the following.

a. Contamination of oil with pumped liquid.

b. Dry running of pump.

c. Single phasing/reverse phasing.

d. Over load.

e. Overheating of winding [against order].

The coding of leads of the cables is clearly marked on each lead and the connections to the control

panel should be made as per connections diagram of control panel and s per below shown Figure

(1) & (2).

7

NS IOM MANUAL

Page 8

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

ELECTRICAL CONNECTION DIAGRAM

( STAR DELTA STARTING )

CONTROL CABLE LEADS

M1 & M2 : FOR MOISTURE SENSOR

T1 & T2 : FOR THERMISTER

CABLES FROM PUMP

ELECTRICAL CONNECTION DIAGRAM

EARTHING

E

T2

T1

M2

M1

A1

POWER

B1

C1

B2

C2

CONTROL CABLE LEADS

M1 & M2 : FOR MOISTURE SENSOR

T1 & T2 : FOR THERMISTER

CABLE

LEADS

A2

( DOL STARTING )

CABLE FROM PUMP

M1

M2

EARTHING

E

T2

T1

A

POWER

B

CABLE

LEADS

C

Fig (1) SDS CONNECTION

Fig (2) DOL CONNECTION

1.5 As a standard scope of supply, NS pumps are supplied with 5 or 10 m long cable. This cable

consists of power cable having 4 and 3 core for Star Delta starting (for rating from 11kW to 22kW)

and 4 core cables for DOL (for rating upto 9.3kW) starting suitably designed for the voltage and

current. The control cable of 4 cores 1.5 sq.mm is used for thermistor and moisture sensor 2 wires

each.

2.

Safety Instructions:

2.1: General Information

Before performing any actions detailed within this instruction, the Site Health and Safety

instructions shall be read and fully understood. The instructions in this document shall also be read

and fully understood.

Whenever the equipment is operated, maintained or used in any way, the procedures detailed

within the Health and Safety Dossier (DHS) and any procedures detailed within these instructions

shall be followed. The pump supplied by Kirloskar Brothers Limited (KBL) has been designed with

safety in mind; where hazards cannot be eliminated, the risk has been minimized using guards and

other design features. Some hazards cannot be guarded against and the instructions below MUST

BE COMPLIED WITH for safe operation. These instructions cannot cover all circumstances. It is

the responsibility of the user of the equipment for maintaining safe working practices always. The

pumps are supplied with stickers for hazard, caution and safety wherever these are applicable.

2.1.1 Within the manual, safety instructions are marked with safety symbols.

Hazard.

a. This symbol refers to general

mechanical aspects of safety.

c.

This symbol refers to electrical

safety.

d.

b. This symbol is used to

introduce safety instructions

whose non- Observance may

lead to damage to the machine and its functions.

e.

This symbol refers to

magnetic field safety.

8

NS IOM MANUAL

Page 9

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

f. This symbol refers to restrict person having heart pacemaker to avoid contact

with magnetic components while pump is in running condition or while

carrying out maintenance work of pump.

2.1.2 KBL products are designed for installation in designated areas, which are to be kept clean and free

of obstructions that may restrict safe access to the controls and maintenance access points.

Pump nameplate is fitted to each unit and must not be removed. Loss of this plate

could make identification impossible. This in turn could affect safety and cause

difficulty in obtaining spare parts. Should accidental loss or damage occur, contact

KBL immediately.

2.1.3 Access to the equipment should be restricted to the personnel responsible for installation, operation

and maintenance and they must be trained, adequately qualified and supplied with the appropriate

tools for their respective tasks.

2.1.4 KBL firmly insists that all personnel responsible for installation, operation and maintenance of the

equipment must read the manual before any work is done.

2.1.5 Ear defenders should be worn where the specified equipment noise level exceeds locally defined

safe levels. Safety glasses or goggles should be worn where working with pressurized systems

and hazardous substances. Other personal protection equipment must be worn where local rules

apply.

2.2 DO NOT wear loose or frayed clothing or jewellery, which could catch on the

controls or becomes trapped in the equipment.

2.3 Operation of the equipment for the application other than for which it is supplied can increase the

risk from hazards. Please consult KBL before making such change in the application of the

equipment.

2.4 Improper installation, operation and maintenance of the product supplied by KBL could result in

injury or death.

2.5

2.6 In case of NS pumps which are handling fluid at high temperature, the operator

should avoid touching the pump in running condition. Use safety equipments like hand gloves and

safety shoes while operating NS pumps in such applications.

3. INSTALLATION:

3.1 The NS pumps of stationary arrangement are supplied with pump connector unit and this

connector unit is connected to pump support bracket with guide shoe & rubber diaphragm

to make it leak proof joint.

9

NS IOM MANUAL

Page 10

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

BOL TS

MOT OR E ND

CO VER

CAB LE

BRA CKET

STA TOR

HOU SING

STU FFIN G

BOX BUS H

CAS ING

STA ND

SUP POR T

BRA CKE T

EYE

CAB LE

CAB LE P ROT ECTIO N

TUB E

CAB LE G LAND

MOT OR E ND

COV ER

HO LDER

GUI DE

PIPE

GUI DE

PIPE

ADA PTER

RUB BER

DIAP HRA GM

GUI DE

SHO E

DUC K FO OT

BEN D

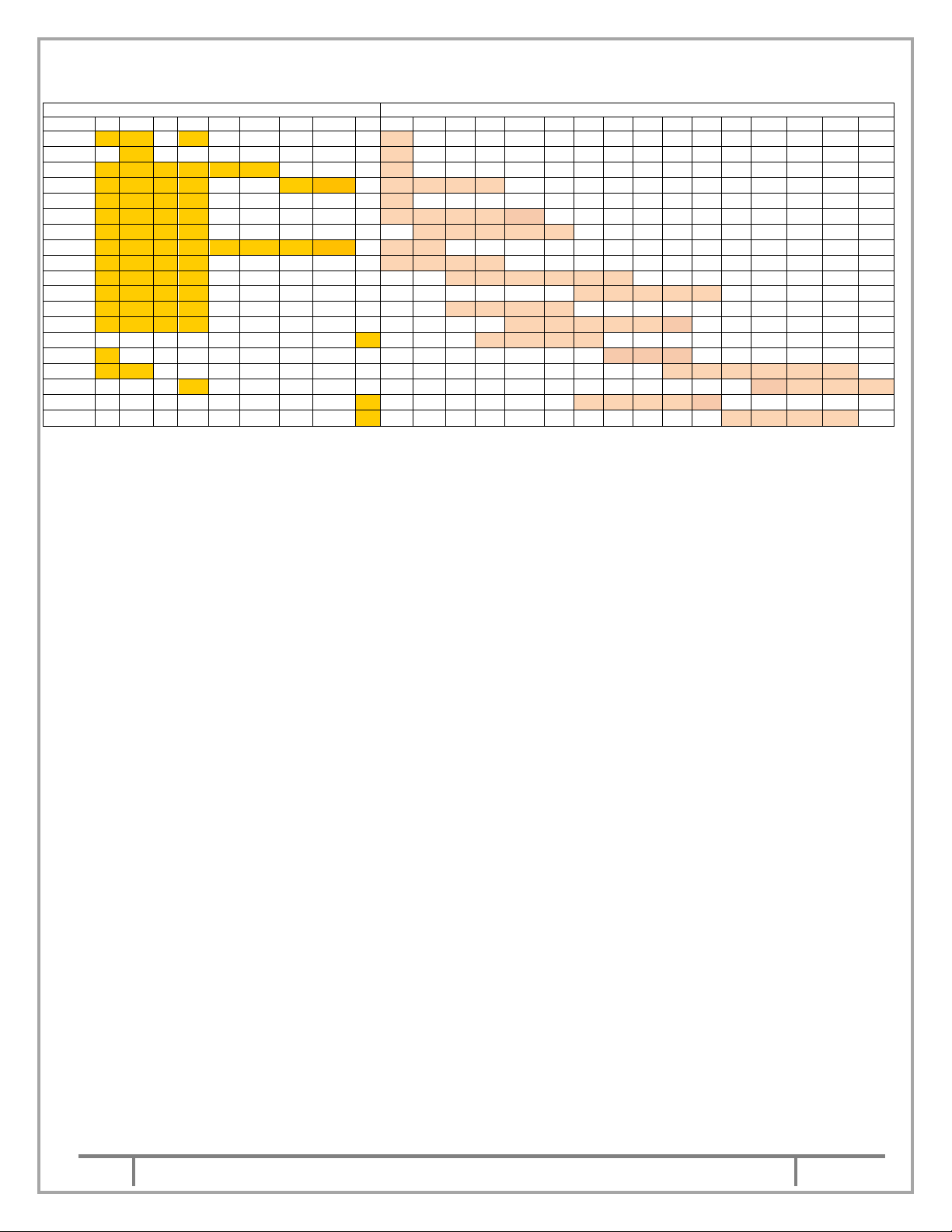

Single guide pipe arrangement (iNS) Double guide pipe arrangement

Stationary Installation view.

3.1.1 Installation of support bracket & bend –

Before installing the pump, ensure that sump bottom is flat and leveled. The support bracket &

bend should be attached and fixed to the sump bottom with foundation bolts, so that the guide pipe

shall be exactly vertical.

Ensure that support bracket and bend are located correctly relative to descending pump vertical

guide pipe and discharge pipe.

3.1.2 Lowering the pump - Attach the guide shoe & guide pipe adapter to the pump. The unsupported

length of guide pipe should not exceed 6 m.

3.1.3 Fix the guide pipe in the support bracket and locate the vertical position of guide pipe holder at the

top of the pit. Now grout the guide pipe holder.

3.1.4 Insert the above assembly in the guide pipe by dismantling the guide pipe holder & refit the holder

in the guide pipe.

3.1.5 Check- Lower the pump with the help of chain. While sliding over the guide pipe into the sump,

check that the cable is not slagging and is not under tension.

3.1.6 Ensure that the pump position is exactly vertical on the support bracket. Check by giving a jerk.

3.1.7 Before taking the pumping station into use, check that there are no loose solid pieces or other

material on bottom of sump that would damage the pump.

3.1.8 DO NOT LIFT THE PUMP WITH THE HELP OF CABLES.

3.2 The NS pumps supplied for portable installation requires no foundation. Only ensure that the

delivery pipe line is well supported and its weight is not acting on pump casing directly.

3.3 Use chain with intermediate hooks for holding to lower or lift the pump. This type of chain is specially

designed to avoid the tendency of the operator to lift the pump with the help of cable causing

damage & replacement of the cable unit. While selecting size of the chain, refer weight of the pump

given in 7.6. and chain capacity as per chart in 3.4. We recommend use of non-return valve in

delivery pipe line located before sluice valve.

10

NS IOM MANUAL

Page 11

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

3.4 As per IS: 2429 the following sizes of chains can be used upto the weight as mentioned in the

Nom. Chain Size (mm)

Lifting capacity (Tonnes)

6

8

10

12

14

16

below chart.

0.44

0.8

1.25

1.8

2.4

3.2

4. OPERATION:

4.1 Prior to commissioning of the pump, check the following.

FILL THE OIL INSIDE THE MECHANICAL SEAL HOUSING WITH PROPER GRADE REFER CHART IN

7.5 OF CLEAN OIL FREE FROM MOISTURE. ENSURE THE MECHANICAL SEAL HOUSING OF THE

PUMP IS DULY FILLED AS PER CHART IN 7.6. CHECK THE OIL PLUG OF THE MECHANICAL SEAL

HOUSING IS INTACT.

4.1.1 Check the insulation resistance of winding by using 500 V megger. The insulation resistance of

winding should not be less than 10 mega-ohms for motor rating upto 45kW and 50 mega-ohms

beyond 45kW at phase to phase and phase to Earth. This test should be carried out at free end of

the cable. If the insulation resistance is found less than mentioned above then please consult our

service personnel.

For continuity test, connect the two wires of megger between the two ends of the same phase of

motor. It should show zero resistance. This test should be carried out for the phases.

The resistance across two moisture sensing wires M1 and M2 should be above 5 MΩ. Make sure

to remove control cable connections from terminal board [M1 and M2] before testing this. If the

resistance found less, please consult our service department. The megger test for phase to phase

and phase to Earth should be conducted serially. The megger test should show insulation

resistance above 10 MΩ for motor rating upto 45kW and 50 MΩ beyond 45kW

4.1.2 The control panel is provided with auto/manual switch. When the switch is on "Manual" position the

pumpset can be started manually by the start push button provided the liquid level is above the low

level electrode. If the switch is on "Auto" position it will start automatically if liquid level in the sump,

is above the high-level electrode. The pump set gets switched off automatically for any position of

Auto Manual switch if liquid level goes down just below the low-level electrode. This is indicated by

glowing of red lamp on control panel.

When the pumped liquid gets mixed up with the oil in the casing cover, it is indicated by glowing of

red lamp under name plate contamination. After rectification of the fault, resetting switch is to be

pressed first and then the pump set will get started by pressing "Starting switch" if it is operated on

"Manual position" or automatically if control panel is operating on "Auto position".

Before change over from star to delta connection, time delay should be sufficient to allow the motor

to attain its normal running speed. The same depends upon the load of the motor and it is generally

around 10 second.

4.1.3 LIQUID LEVEL CONTROLLERS ARE INCORPORATED IN THE PANEL TO PROTECT THE

PUMP FROM DRY RUNNING. THE LOW-LEVEL ELECTRODE SHOULD BE POSITIONED IN

SUCH A MANNER THAT LOWEST END OF ELECTRODE REMAINS ABOVE MOTOR BODY. IF

LOW LEVEL ELECTRODE IS NOT INSTALLED PROPERLY THE MOTOR BODY IS LIKELY TO

BE HEATED UP AS COOLING OF MOTOR IS DONE BY LIQUID IN THE SUMP AROUND THE

STATOR HOUSING. HENCE SUBMERGENCE UPTO FULL CORE LENGTH OF MOTOR IS

REQUIRED.

4.1.4 Before starting the pump, check the direction of rotation is as outlined below.

.

11

NS IOM MANUAL

Page 12

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

4.1.5 Hoist up the pump and momentarily switch on the power. If the connections are correctly made the

pump should jerk in anticlockwise direction when viewed from top. If the pump jerks in opposite

direction, change two phases of the incoming leads to the control panel. In no case the direction of

rotation should be changed by changing the leads of motor terminals. Do not run the pump dry.

Just check in which direction the pump jerks.

4.2 While putting the pump in operation, follow the procedure outlined below.

4.2.1 Start the pump. Let the motor pick-up its full speed.

4.2.2 Open the discharge valve slowly.

4.3 Check during running that –

4.3.1 The pump is running smooth.

4.3.2 Power consumption is within limit.

4.3.3 Head and capacity developed by the pump is as specified.

4.3.4 Stop the pump immediately if any defects are detected and must not be started unless they

are rectified. Report immediately to the supplier if it is not possible to rectify the defect.

4.4 STOPPING THE PUMP:

4.4.1

Pump should be switched off only after closing the delivery sluice valve.

5. MAINTENANCE:

Preventive maintenance schedule is the periodical checks and precautions by which possibilities

of failure and break-downs are minimized.

5.1 Daily checks –

5.1.1 An hourly record of the delivery pressure and power input to the pump should be maintained.

5.1.2 Noise and vibrations is the first sign of impending troubles like bearing failure, choking of impeller

or casing and such other operating troubles. The pump performance should be checked for noise

and vibration.

5.2 Periodical checks –

5.2.1 The lubrication of mechanical seals should be checked. The lubricant might get contaminated with

foreign material or get blackened due to overheating. In such cases, oil chamber should be flushed

and filled with fresh oil. Before filling, heat the oil [Servo system 317] to 140°C. This is required to

remove moisture present in the oil.

5.2.2 THE ELECTRODES/FLOAT SWITCHES SHOULD BE CLEANED WHENEVER POSSIBLE BUT

NOT LATER THAN 15 DAYS FOR SMOOTH WORKING OF PUMP.

5.2.3 Clean the sump if there are chances of deposition of the contents of liquid handled.

5.2.4 Replace the Oil from pump periodically after 2000 hrs.

5.3 Annual checks [after one year minimum] –

5.3.1 The pump portion of the motor pump set should be overhauled completely to check the clearance

and to replace the worn-out parts. Clearance between impeller and casing ring and casing cover

are very important.

5.3.2 The effect of liquid handled on pump components should be checked. If abnormal corrosion,

erosion is observed then the components should be replaced with that of suitable material.

12

NS IOM MANUAL

Page 13

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

6 SHUT DOWN / STORAGE / PRESERVATION

If operation is not required for some time after delivery, we recommend the following steps for storage

of the pump:

6.1 Storage of new pumps up to 3 months (Short storage)

i) Spray oil inside the pump housing, paying special attention to the area around the impeller

wear ring. Spray oil through inlet and outlet flanges of pump. It is then recommended to cover

the flanges with plastic caps or similar.

ii) Store the pump in an upright position in a dry place. Support all electrical cables at cable entry

points to avoid permanent distortion.

iii) Electric connecting cables are capped securely for protection purposes prior to delivery. This

protection must not be removed.

iv) Use weather-proof coverings such as flame-resistant sheeting or tarpaulins.

v) Tie coverings down to protect the pump from wind damage.

vi) Place the unit on skids, pallets or shoring higher than 5 inches from the ground for good air

circulation.

vii) Maintain an even temperature of 15 degree Celsius or higher above the dew point.

6.2 Pump long term storage requirements (Above 3 months)

Submersible units require proper preparation for storage and regular maintenance during storage.

The unit is considered in storage when it has been delivered to the job site and is awaiting

installation.

6.2.1 Storage preparation

i) Although this is a submersible pump, storage in a clean, dry area will help preserve the paint

and prevent corrosion. Hand rotation of the shaft every fifteen days is recommended to keep

the seals free and the bearings lubricated.

ii) Spray oil inside the pump housing, paying special attention to the area around the impeller

wear ring. Spray oil through inlet and outlet flanges of pump. It is then recommended to cover

the flanges with plastic caps or similar.

iii) Take care of all indoor storage requirements.

iv) Use weather-proof coverings such as flame-resistant sheeting or tarpaulins.

v) Tie coverings down to protect the pump from wind damage.

vi) Place the unit on skids, pallets or shoring higher than 5 inches from the ground for good air

circulation.

vii) Maintain an even temperature of 15 degree Celsius or higher above the dew point.

6.3 Site condition before installation of pump:

Pit in which pump is to be installed should be clean, free from hard particles such as nails, cement/

sand particles etc. Submersible pumps are designed only to handle the soft particles such as

clothes, plastic bags, etc.

6.4 Measures for prolonged shut down periods

i) The pump remains installed ready for operation when required.

ii) To maintain pump availability, the pump should be started for 10 second, once in every week.

iii) Always keep cable ends out of the sump to avoid leakage through cable ends to pump.

6.5 The pump is dismantled and stored

i) Prior to storage the pump should be checked and maintained in accordance operator must

ensure that all maintenance, inspection and repair work is carried out by qualified, authorized

staff who are familiar with the equipment and who have read the operating instructions.

ii) O-ring need to change after dismantling the pump. Do not use old O-rings for reassembly of

the pumps.

6.6 Rubber components storage ideal conditions

If the pumps are stored in below conditions, rubber components shelf life should be of 5 years

otherwise all rubber components need to be replaced after 1 year.

Condition:

a. store in cool, dry place with temperature below 15 degree Celsius.

13

NS IOM MANUAL

Page 14

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

b. keep away from direct heat or open flame.

1

2

3

4

5

6

7

8

9

2

10

2

11

12

13

14

15

c. store without stretch or tension including hanging.

d. keep product wrapped or sealed to minimize the absorption of moisture.

e. store in relaxed condition free from tension, compression or other deformation.

6. TECHNICAL DATA

7.1 Non-Clog Submersible pumps are supplied at maximum speed 1450 rpm having 4 pole motors.

However, the same pump can be offered at 980 rpm having 6 pole motor if fits in duty points. The

direction of rotation is clockwise when viewed from the motor top. We have newly introduced pump

series in iNS at 2950rpm having 2Pole.

7.2 SPECIFICATIONS OF BEARINGS:

The shaft is supplied with antifriction ball bearings at both ends. The bearing specifications are

given below. The designations of bearings are as per SKF catalogue. However, equivalent bearing

in type, capacity and dimensions are also can be used.

LUBRICATION:

Bearings of NS pumps are grease sealed for life. Re-lubrication of these bearings is not required.

Sr. No. Motor rating in kW Lower bearing Qty. Upper bearing Qty.

i-NS unit - 1 6305-2RS1 1 6303 2RSH 1

i-NS unit - 2 6305-2RS1 1 6303 2RSH 1

i-NS unit - 3 6307 2RS1 1 6305 2RS1 1

i-NS unit - 4 6307 2RS1 1 6305 2RS1 1

i-NS unit - 5 6307 2RS1 1 6306 2RS1 1

i-NS unit - 6 6307-2RS1 1 6306 2RS1 1

NS unit - 1 6309-2RS1 1 6306-2RS1 1

NS unit - 2 6309-2RS1 1 6306-2RS1 1

NS unit - 3 7312 BG Back to Back

NS unit - 4 7312 BG Back to Back

NS unit - 5 7315 BG Back to Back 2 6311-2RS1 1

NS unit - 6 7318 BG Back to Back 2 6313-2RS1 1

NS unit - 7 7318 BG Back to Back 2 6313-2RS1 1

NS unit - 8 7318 BG Back to Back 2 6313-2RS1 1

NS unit - 9 7320 BG Back to Back 2 6318-2RS1 1

6309-2RS1 1

6309-2RS1 1

7.3 EBXL CABLE CURRENT CARRYING CAPACITY

Cable size (sq.mm)

8C X 1.5 20 4C X 4 + 4C X 1.5 53/22

8C X 2.5 39 4C X 10 + 4C X 1.5 96/22

4C X 25 174 4C X 16 + 4C X 1.5 133/22

4C X 35 191 4C X 25 + 4C X 1.5 174/22

4C X 50 239 4C X 35 + 4C X 1.5 191/22

3C X 4 53 4C X 50 + 4C X 1.5 239/22

3C X 10 96 4C X 70 + 4C X 1.5 295/22

3C X 16 133 4C X 120 + 4C X 1.5 414/22

3C X 25 174 4C X 95 + 4C X 1.5 355/22

3C X 35 191

3C X 50 239

3C X 70 295/22

3C X 95 355/22

3C X 120 414/22

Approx. Current carrying

capacity (amp)

Cable size (sq.mm)

Approx. Current carrying

capacity (amp)

14

NS IOM MANUAL

Page 15

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

Note: These values are for reference only.

Inboard

Outboard

1

2

3

4

5

6

7

8

ELF

IOC

HPCL

CASTROL

GULF

SHELL

Model

kW

Pole Oil Qty

Pump & connector

Model

kW

Pole Oil Qty

Pump & connector

NS100/26N

7.5 4 3 Litre

240 120

NS150/26NM

15 4

3 Litre

340 155

NS100/26N

9.3 4 3 Litre

265 120

NS150/26NM

18.5 4 3 Litre

345 155

NS100/26N

11 4

3 Litre

268 120

NS150/26NM

22 4

3 Litre

355 155

NS100/26N

15 4

3 Litre

315 120

NS150/26Q

11 4

3 Litre

335 155

NS100/26N

18.5 4 3 Litre

320 120

NS150/26Q

15 4

3 Litre

340 155

NS100/

26N 22 4 3 Litre

330 120

NS150/26Q

18.5 4 3 Litre

345 155

NS100/26Q

7.5 4 3 Litre

240 120

NS150/26Q

22 4

3 Litre

355 155

NS100/26Q

9.3 4 3 Litre

307 120

NS150/26QMB

11 4

3 Litre

335 155

NS100/26Q

11 4

3 Litre

310 120

NS150/26QMB

15 4

3 Litre

340 155

NS100/26Q

15 4

3 Litre

315 120

NS150/26QMB

18.5 4 3 Litre

345 155

NS100/26Q

18.5 4 3 Litre

320 120

NS150/26QMB

22 4

3 Litre

355 155

NS100/26Q

22 4

3 Litre

330 120

NS150/26QM

11 4

3 Litre

335 155

NS100/26QM

7.5 4 3 Litre

240 120

NS150/26QM

15 4

3 L

itre 340 155

NS100/26QM

9.3 4 3 Litre

265 120

NS150/26QM

18.5 4 3 Litre

345 155

NS100/26QM

11 4

3 Litre

268 120

NS150/26QM

22 4

3 Litre

355 155

NS100/26QM

15 4

3 Litre

315 120

NS150/26QNM

11 4

3 Litre

335 155

NS100/26QM

18.5 4 3 Litre

320 120

NS150

/26QNM

15 4

3 Litre

340 155

NS100/26QM

22 4

3 Litre

330 120

NS150/26QNM

18.5 4 3 Litre

345 155

NS100/26QT

7.5 4 3 Litre

240 120

NS150/26QNM

22 4

3 Litre

355 155

NS100/26QT

9.3 4 3 Litre

307 120

NS150/26QT

11 4

3 Litre

335 155

NS100/26QT

11 4

3 Litre

310 120

NS150/26QT

15 4

3 Litre

340 155

NS100/26QT

15 4

3 Litre

315 120

NS150/26QT

18.5 4 3 Litre

345 155

NS100/26QT

18.5 4 3 Litre

320 120

NS150/26QT

22 4

3 Litre

355 155

NS100/26QT

22 4

3 Litre

330 120

NS150/32N

18.5 4 4 Litre

350 155

Consider factor of safety as 0.87 if ambient temperature is 45 degree Celcius.

7.4 MECHANICAL SEALS

:

Sr.

Motor ratings in kW Seal size in

No.

iNS all 2 Pole ratings 22

iNS 4 Pole ratings upto 7.5kW 22

iNS 4 Pole ratings above 7.5kW 40

UNIT-I & II 40

UNIT-III 55

UNIT – IV 65

UNIT – V & VI 80

UNIT – VII, VIII & IX 90

mm

SiC Vs SiC Carbon Vs St. Steel

SiC Vs SiC Carbon Vs Ceramic

SiC Vs SiC Carbon Vs St. Steel

Mechanical seal type

7.5 LUBRICATION FOR MECHANICAL SEALS:

The upper mechanical seal faces are lubricated by oil provided in casing cover. The lubricating oil

should conform to the following grades of oil available in the market.

Note: The oil used should be highly refined straight mineral product of high demulsibility free from running and acid forming

tendencies. Detergent Oil may cause foaming and should not be used.

NAME OIL SPECIFICATION NAME OIL SPECIFICATION

7.6

WEIGHTS OF PUMPS AND OIL QUANTITY:

ACANTIS HM 68 VEEDOL ATLINE 68

SERVOSYSTEM 57/68/317 PENNZOIL PENNZBELL AW 68

ENKLO 57 BPCL HYDRO 68

HYSPIN EP 68 ESSO AW68

HARMONY 68 MOBIL AW68

TELLUS 68

(approx)

15

Wt. (kg) (approx)

NS IOM MANUAL

(approx)

Wt (kg) (approx)

Page 16

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

Model

kW Pole Oil Qty

(approx)

Pump & connector

Model

kW

Pole Oil Qty

Pump & connector

NS100/32N

11 4

4 Litre

330 120

NS150/32N

22 4

4 Litre

360 155

NS100/32N

15 4

4 Litre

335 120

NS150/32Q

18.5 4 4 Litre

350 155

NS1

00/32N

18.5 4 4 Litre

340 120

NS150/32Q

22 4

4 Litre

360 155

NS100/32N

22 4

4 Litre

350 120

NS150/32QM

18.5 4 4 Litre

350 155

NS100/32Q

11 4

4 Litre

330 120

NS150/32QM

22 4

4 Litre

360 155

NS100/32Q

15 4

4 Litre

335 120

NS150/32QT

18.5 4 4 Litre

350 155

NS100/32Q

18.5 4 4 Litre

340 120

NS150/32QT

22 4

4 Litre

360 155

NS100/32Q

22 4

4 Litre

350 120

NS40/20QT

2.2 4 1.7 Litre

145 55

NS100/32QM

11 4

4 Litre

330 120

NS40/20QT

3.7 4 1.7 Litre

155 55

NS100/32QM

15 4

4 Litre

335 120

NS40/20QT

1.5 4 1

.7 Litre

143 55

NS100/32QM

18.5 4 4 Litre

340 120

NS40/32QT

2.2 4 4 Litre

147 55

NS100/32QM

22 4

4 Litre

350 120

NS40/32QT

3.7 4 4 Litre

150 55

NS100/32QT

11 4

4 Litre

330 120

NS40/32QT

5.5 4 4 Litre

165 55

NS100/32QT

15 4

4 Litre

335 120

NS40/32QT

7.5 4 4 Litre

165 55

NS100/32QT

18.5 4 4 Litre

340 120

NS50/20QT

2.2 4 1.7 Litre

150 65

NS100/32QT

22 4

4 Litre

350 120

NS50/20QT

3.7 4 1.7 Litre

170 65

NS150/26NB

11 4

3 Litre

335 155

NS50/20QT

5.5 4 1.7 Litre

165 65

NS150/26NB

15 4

3 Litre

340 155 NS50/26NB

9.3 4 3 Litre

225 65

NS150/26NB

18.5 4 3 Litre

345 155

NS50/26NB

3.7 4 3 Litre

185 65

NS150/26NB

22 4

3 Litre

355 155

NS50/26NB

5.5 4 3 Litre

180 65

NS150/26N

11 4

3 Litre

335 120

NS50/26NB

7.5 4 3 Litre

180 65

NS150/26N

15 4

3 Litre

340 155

NS50/26N

9.3 4 3 Litre

225 65

NS150/26N

18.5 4 3 Litre

345 155

NS50/26N

3.7 4 3 Litre

180 65

NS150/26N

22 4

3 Litre

355 155

NS50/26N

5.5 4 3 Litre

180 65

NS150/26NM

11 4

3 Litre

335 155

NS50/26N

7.5 4 3 Litre

180 65

NS50/26Q

9.3 4 3 Litre

225 65

NS65/32Q

11 4

4 Litre

280 75

NS50/26Q

3.7 4 3 Litre

185 65

NS65/32Q

15 4

4 Litre

285 75

NS50/26Q

5.5 4 3 Litre

180 65

NS65/32Q

18.5 4 4 Litre

290 75

NS50/26Q

7.5 4 3 Litre

180 65

NS65/32Q

22 4

4 Litre

300 75

NS50/26QMB

9.3 4 3 Litre

225 65

NS6

5/32Q

7.5 4 4 Litre

230 75

NS50/26QMB

3.7 4 3 Litre

175 65

NS65/32QMB

9.3 4 4 Litre

275 75

NS50/26QMB

5.5 4 3 Litre

180 65

NS65/32QMB

11 4

4 Litre

280 75

NS50/26QMB

7.5 4 3 Litre

180 65

NS65/32QMB

15 4

4 Litre

285 75

NS50/26QM

9.3 4 3 Litre

225 65

NS65/32QMB

18.5 4 4 Litre

290 75

NS50/26QM

3.7 4 3 Litre

185 65

NS65/32QMB

22 4

4 Litre

300 75

NS50/26QM

5.5 4 3 Litre

180 65

NS65/32QMB

7.5 4 4 Litre

230 75

NS50/26QM

7.5 4 3 Litre

180 65

NS65/32QM

9.3 4 4 Litre

275 75

NS50/26QT

9.3 4 3 Litre

225 65 NS65/32QM

11 4

4 Litre

280 75

NS50/26QT

3.7 4 3 Litre

185 65

NS65/32QM

15 4

4 Litre

285 75

NS50/26QT

5.5 4 3 Litre

180 65

NS65/32QM

18.5 4 4 Litre

290 75

NS50/26QT

7.5 4 3 Litre

180 65

NS65/32QM

22 4

4 Litre

300 75

NS50/32N

9.3 4 4 Litre

275 65

NS65/32QM

7.5 4 4 Litre

230 75

NS50/32N

11 4

4 Litre

280 65

NS65/32QT

9.3 4 4 Litre

275 75

NS50/32N

15 4

4 Litre

285 65

NS65/32QT

11 4

4 Litre

280 75

NS50/32N

18.5 4 4 Litre

290 65

NS65/32QT

15 4

4 Litre

285 75

NS50/32N

22 4

4 Litre

300 65

NS65/32Q

T 18.5 4 4 Litre

290 75

NS50/32N

7.5 4 4 Litre

220 65

NS65/32QT

22 4

4 Litre

300 75

NS50/32QM

9.3 4 4 Litre

275 65

NS65/32QT

7.5 4 4 Litre

230 75

NS50/32QM

11 4

4 Litre

280 65

NS80/26N

9.3 4 3 Litre

250 85

NS50/32QM

15 4

4 Litre

285 65

NS80/26N

11 4

3 Litre

253 85

NS50/32QM

18.5 4 4 Litre

290 65

NS80/26N

15 4

3 Litre

290 85

NS50/32QM

22 4

4 Litre

300 65

NS80/26N

18.5 4 3 Litre

295 85

NS50/32QM

7.5 4 4 Litre

220 65

NS80/26N

22 4

3 Litre

305 85

NS50/32QT

9.3 4 4 Litre

275 65

NS80/26N

7.5 4 3 L

itre 220 85

NS50/32QT

11 4

4 Litre

280 65

NS80/26N

5.5 4 3 Litre

220 85

NS50/32QT

15 4

4 Litre

285 65

NS80/26Q

9.3 4 3 Litre

250 85

NS50/32QT

18.5 4 4 Litre

290 65

NS80/26Q

11 4

3 Litre

253 85

NS50/32QT

22 4

4 Litre

300 65

NS80/26Q

15 4

3 Litre

290 85

NS50/32QT

7.5 4 4 Litre

220 65

NS80/26Q

18.5 4 3 Litre

295 85

NS50/36QM

11 4

4 Litre

270 65

NS80/26Q

22 4

3 Litre

305 85

NS50/36QM

15 4

4 Litre

275 65

NS80/26Q

7.5 4 3 Litre

220 85

NS50/36QM

18.5 4 4 Litre

280 65

NS80/26Q

5.5 4 3 Litre

220 85

NS50/36QM

22 4

4 Litre

290 65

NS80/26QM

9.3 4 3 Litre

250 85

NS65/32NB

9.3 4 4 Litre

275 75

NS80/26QM

11 4

3 Litre

253 85

Wt. (kg) (approx)

(approx)

Wt (kg) (approx)

16

NS IOM MANUAL

Page 17

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

Model

kW

Pole Oil Qty

(approx)

Pump & connector

Model

kW

Pole Oil Qty

Pump & connector

NS65/32NB

11 4

4 Litre

280 75

NS80/26QM

15 4

3 Litre

290 85

NS65/32NB

15 4

4 Litre

285 75

NS80/26QM

18.5 4 3 Litre

295 85

NS65/32NB

18.5 4 4 Litre

290 75

NS80/26QM

22 4

3 Litre

305 85

NS65/32NB

22 4

4 Litre

300 75

NS80/26QM

7.5 4 3

Litre 220 85

NS65/32NB

7.5 4 4 Litre

230 75

NS80/26QM

5.5 4 3 Litre

220 85

NS65/32N

9.3 4 4 Litre

275 75

NS80/26QT

9.3 4 3 Litre

250 85

NS65/32N

11 4

4 Litre

280 75

NS80/26QT

11 4

3 Litre

253 85

NS65/32N

15 4

4 Litre

285 75

NS80/26QT

15 4

3 Litre

290 85

NS65/32N

18.5 4 4 Litre

290 75

NS80/26QT

18.5 4 3 Litre

295 85

NS65/32N

22 4

4 Litre

300 75

NS80/26QT

22

4 3 Litre

305 85

NS65/32N

7.5 4 4 Litre

230 75

NS80/26QT

7.5 4 3 Litre

220 85

NS65/32Q

9.3 4 4 Litre

275 75

NS80/40NM

18.5 4 8 Litre

287 85

NS50/26QM

3.7 6 3 Litre

180 65

NS80/40NM

22

4 8 Litre

297 85

NS50/26QM

5.5 6 3 Litre

180 65

NS80/40Q

22

4 8 Litre

287 85

NS50/26QM

2.2 6 3 Litre

185 65

NS80/40Q

18.5 4 8 Litre

297 85

NS50/26QT

2.2 6 3 Litre

185 65

NS80/40QM

18.5 4 8 Litre

287 85

NS50/26QT

3.7 6 3 Litre

180 65

NS80/40QM

22

4 8 Litre

297 85

NS50/26QT

5.5 6 3 Litre

180 65

NS80/40QNM

18.5 4 8 Litre

287 85

NS50/32N

2.2 6 4 Litre

225 65

NS80/40QNM

22

4 8 Litre

297 85

NS50/32N

3.7 6 4 Litre

220 65

NS80/40QT

18.5 4 8 Litre

287 85

NS50/32N

5.5 6 4 Litre

220 65

NS80/40QT

22

4 8 Litre

297 85

NS50/32QM

2.2 6 4 Litre

225 65

NS100/26N

3.7 6 3 Litre

240 120

NS50/32QM

3.7 6 4 Litre

220 65

NS100/26N

5.5 6 3 Litre

240 120

NS50/32QM

5.5 6 4 Litre

220 65

NS100/26Q

3.7 6 3 Litre

240 120

NS50/32QT

2.2 6 4 Litre

225 65

NS100/26Q

5.5 6 3 Litre

240 120

NS50/32QT

3.7 6 4 Litre

220 65

NS100/26QM

3.7 6 3 Litre

240 120

NS50/32QT

5.5 6 4 Litre

220 65

NS100/26QM

5.5 6 3 Litre

240 120

NS50/36QM

3.7 6 4 Litre

220 65

NS100/26QT

3.7 6 3 Litre

240 120

NS50/36QM

5.5 6 4 Litre

220 65

NS100/26QT

5.5 6 3 Litre

240 120

NS65/32NB

2.2 6 4 Litre

235 75

NS150/26NB

3.7 6 3 Litre

310 155

NS65/32NB

3.7 6 4 Litre

230 75

NS150/26NB

5.5 6 3 Litre

310 155

NS65/32NB

5.5 6 4 Litre

230 75

NS150/26N

3.7 6 3 Litre

310 155

NS65/32N

2.2 6 4 Litre

235 75

NS150/26N

5.5 6 3 Litre

310 155

NS65/32N

3.7 6 4 Litre

230 75

NS150/26NM

3.7 6 3 Litre

310 155

NS65/32N

5.5 6 4 Litre

230 75

NS150/26NM

5.5 6 3 Litre

310 155

NS65/32Q

2.2 6 4 Litre

235 75

NS150/26Q

3.7 6 3 Litre

310 155

NS65/32Q

3.7 6 4 Litre

230 75

NS150/26Q

5.5 6 3 Litre

310 155

NS65/32Q

5.5 6 4 Litre

230 75

NS150/26QMB

3.7 6 3 Litre

310 155

NS65/32QMB

2.2 6 4 Litre

235 75

NS150/26QMB

5.5 6 3 Litre

310 155

NS65/32QMB

3.7 6 4 Litre

230 75

NS150/

26QM

3.7 6 3 Litre

310 155

NS65/32QMB

5.5 6 4 Litre

230 75

NS150/26QM

5.5 6 3 Litre

310 155

NS65/32QM

2.2 6 4 Litre

235 75

NS150/26QNB

3.7 6 3 Litre

310 155

NS65/32QM

3.7 6 4 Litre

230 75

NS150/26QNM

5.5 6 3 Litre

310 155

NS65/32QM

5.5 6 4 Litre

230 75

NS150/26QT

3.7 6 3 Litre

310 155

NS65/32QT

2.2 6 4 Litre

235 75

NS150/26QT

5.5 6 3 Litre

310 155

NS65/32QT

3.7 6 4 Litre

230 75

NS40/32QT

2.2 6 4 Litre

170 55

NS65/32QT

5.5 6 4 Litre

230 75

NS50/26NB

3.7 6 3 Litre

180 65

NS80/26N

3.7 6 3 Litre

220 85

NS50/26NB

5.5 6 3 Litre

180 65

NS80/26N

5.5 6 3 Litre

220 85

NS50/26NB

2.2 6 3 Litre

180 65

NS80/26Q

3.7 6 3 Litre

220 85

NS50/26N

3.7 6 3 Litre

180 65

NS80/26Q

5.5 6 3 Litre

220 85

NS50/26N

5.5 6 3 Litre

180 65

NS80/26QM

3.7 6 3 Litre

220 85 NS50/26N

2.2 6 3 Litre

180 65

NS80/26QM

5.5 6 3 Litre

220 85

NS50/26Q

3.7 6 3 Litre

180 65

NS80/26QT

3.7 6 3 Litre

220 85

NS50/26Q

5.5 6 3 Litre

180 65

NS80/26QT

5.5 6 3 Litre

220 85

NS50/26Q

2.2 6 3 Litre

185 65

NS80/26QT

5.5 6 3 Litre

220 85

N

S50/26QMB

3.7 6 3 Litre

180 65

NS80/40N

18.5 4 8 Litre

287 85

NS50/26QMB

5.5 6 3 Litre

180 65

NS80/40N

22 4

8 Litre

297 85

NS50/26QMB

2.2 6

3 Litre

185 65

Wt. (kg) (approx)

(approx)

Wt (kg) (approx)

NOTE: change oil after every 5000 hrs of pump operation.

17

NS IOM MANUAL

Page 18

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

8 OVERHAULING:

Overhauling of the pump or any part of it, at site, is not permitted. In case of doubt, please consult

our service division.

Do not handle the pump with the use of cable.

9 CROSS SECTIONAL DRAWING

9.1 (UNIT 1,2,3,4,5,6- iNS Connector Unit)

New modified Duck Foot Bend integrated with

Support Bracket is supplied for stationary

Arrangement.

PU MP C ONNEC TO R U N IT

9.2 (UNIT 1- iNS with QT Type Impeller and DOL type of starting)

92 800

94 100

28 300

91 800

91 900

91301

97802

91500

22501

84501

84504

91401

90902

52306

25700

16401

91100

18900

50900

27100

26001

23000

52301

10700

52304

62100

33000

52305

91200

26002

52302

13001

52302

93200

23200

OIL

48600

44400

51100

35000

15300

46500

32000

34100

38300

18

SUC.

NS IOM MANUAL

Page 19

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

9.3 (UNIT 2,3,4,5,6- iNS with QT Type Impeller and DOL type of starting)

52305

26002

91200

13001

52302

27100

51100

23200

48600

OIL

35000

15300

46500

34100

38300

32000

93200

91500

91301

22501

97802

91401

84504

84501

90902

25700

52302

16401

18900

91100

50900

26001

44400

9.4 (UNIT 2,3,4,5,6- iNS with Q Type Impeller and SDS type of starting)

91302

97803

52305

22502

91402

84505

84502

91200

13001

26002

52302

27100

23200

52301

23000

51100

48600

OIL

52304

33000

62100

10700

15300

35000

32000

UNIT 2,3,4,5,6- iNS with QT Type Impeller and DOL type of starting

46000

91500

91301

84504

84501

22501

97802

19

93200

90902

91401

25700

52302

NS IOM MANUAL

16400

18900

91100

50900

26001

52301

23000

44400

10700

52304

66900

UNIT 2,3,4,5,6- iNS with Q Type Impeller and SDS type of starting

Page 20

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

9.5 (UNIT 2,3,4,5,6- iNS with N Type Impeller and SDS type of starting)

97803

91302

22502

52305

91402

84505

84502

13001

26002

91200

52302

27100

23200

35000

15100

32000

51100

48600

19000

OIL

91500

91301

84504

84501

90902

91401

22501

97802

25700

52302

91100

16400

18900

9.5 CROSS SECTIONAL VIEW OF NS PUMP

CROSS SECTIONAL VIEW OF NS PUMP QT TYPE IMPELLER UNIT I (DOL)

93200

50900

26001

52301

23000

44400

66900

10700

6.5 (UNIT 2,3,4,5,6- iNS with N Type Impeller and SDS type of starting)

20

NS IOM MANUAL

Page 21

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

9.7 CROSS SECTIONAL VIEW OF NS PUMP N TYPE IMPELLER UNIT II (SDS)

9.8 CROSS SECTIONAL VIEW OF NS PUMP UNIT III – N TYPE IMPELLER (SDS)

DEL.

OIL

SUC.

21

NS IOM MANUAL

Page 22

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

9.9 CROSS SECTIONAL VIEW OF NS PUMP UNIT III – Q TYPE IMPELLER (SDS)

DEL.

OIL

SUC.

9.10 CROSS SECTIONAL VIEW OF NS PUMP UNIT IV & ABOVE (SDS)

22

NS IOM MANUAL

Page 23

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

9.10. Pump Part list

PARTCD

PARTDESC

PARTCD

PARTDESC

10700 PUMP CASING

59005 STUD FOR BEARING COVER

13001 STATOR HOUSING

59006 STUD FOR PUMP CASING AND SUCTION PLATE

15100*

ENCLOSED IMPELLER

59008 STUD FOR UPP BRG HOLDER AND ST HOUSING

15300*

SEMIOPEN IMPE

LLER 62100 WASHER FOR IMPELLER NUT

16401 ROTOR WITH SHAFT

63001 RELEASE SCREW FOR MECH SEAL HSG/LOW BRG HOLDER/MOT END COV

18900 SHAFT 63002 HEX RELEASE SCREW FOR SUCTION PLATE

19000*

CASING RING

64001 RIVET FOR OIL NAME PLATE

20900 SPACER FOR SUCTION

PLATE 64002 RIVET FOR DUTY NAME PLATE

22401 HOSE CLIP FOR POTTING CUP FOR POW+CON CABLE

66900*

SCREW FOR IMPELLER

22402 HOSE CLIP FOR POTTING CUP FOR POWER CABLE

67000 DUTY NAME PLATE

22501 BUSH FOR POWER+CONTROL CABLE

-

DOL 67300 OIL NAME PLATE

22503 BU

SH FOR POWER CABLE

-

SDS 68200*

GASKET FOR IMPELLER SCREW

23000*

DOUBLE MECHANICAL SEAL

69200 HEX NUT FOR FOUNDATION BOLT

24600 CABLE BRACKET

70101 SPRING WASHER FOR NUT OF LOW BEARING HOLDER AND CASING

25600 LOWER BEARING HOLDER/MECH SEAL HOUSING

70102 S

PRING WASHER FOR NUT OF LOW BRG HOLDER AND ST HOUSING

25700 UPPER BEARING HOLDER

70103 SPRING WASHER FOR MOTOR END COVER AND STATOR HOUSING

26001*

DEEP GROOVE BALL BEARING LOWER

70105 SPRING WASHER FOR BEARING COVER

26002*

DEEP GROOVE BALL BEARING UPPER

70107 SPRING WASHER FOR STAND NUT

27100 BEARING COVER FOR LOWER BEARING

82800 STUD FOR GUIDE SHOE

28300 DUCK FOOT BEND

84000 WASHER FOR NUT FOR FOUNDATION BOLT

30400 FOUNDATION BOLT

84501 WAHSER FOR POWER+CONTROL CABLE

32000*

KEY FOR IMPELLER

84502 WA

SHER FOR POWER CABLE

33000*

IMPELLER NUT

84504 WASHER FOR PROTECTION TUBE POWE+CONT CABLE

34100 TIE ROD FOR STAND

-

PORTABLE

84505 WASHER FOR PROTECTION TUBE POWE CABLE

35000 STUFFING BOX BUSH

84900 WASHER FOR EARTHIN SCREW

38300 SUPPORT PLATE FOR STAND

-

PORTABLE

84901 WASHER FOR TERMINAL BOARD

44001 POTTING CUP FOR POWER+CONTROL CABLE

-

DOL 85600 SPRING WASHER FOR HEX SCREW FOR PUMP CASING AND GUIDE SHOE

44003 POTTING CUP FOR POWER CABLE

-

SDS 85700 NUT FOR GUIDE SHOE

44400 PLUG FOR INSPECTION

88400 TIE FO

R CABLE

46000*

WEAR PLATE

88501 PIN TYPE LUG

-

FOR CONTROL CABLE

46500*

SUCTION PLATE

88502 PIN TYPE LUG FOR POWER CABLE

47100 PROTECTION COVER FOR DELIVERY

88504 CRIMPING RING TERMINALS FOR CONTROL CABLE

47101 PROTECTION CAP FOR SCREW

88505 CRIMPING RIN

G TERMINAL FOR POWER CABLE

47900 HELICOIL LOCK INSERT FOR IMPELLER SCREW

90901 MOTOR END COVER

48600 EXTERNAL CIRCLIP FOR LOWER BEARING

91100 STATOR

-

F CLASS STD

50900 CABLE BRACKET

91201 TERMINAL BOARD

51100*

GASKET FOR PUMP CASING & LOW BRG HOLDER/MEC

H SEAL HSG

91301 POWER+CONTROL CABLE

52301*

O-

RING FOR UPPER BEARING HOLDER / STATOR HOUSING

91302 POWER CABLE

52302*

O-

RING FOR LOWER BEARING HOLDER / STATOR HOUSING

91401*

CABLE SEAL FOR POWER+CONTROL CABLE

52303*

O-

RING FOR OIL FILLING PLUG/INSPECTIO

N 91402*

CABLE SEAL FOR POWER CABLE

52304*

O-

RING FOR SUCTION PLATE/WEAR PLATE

91500 HANDLE

52305*

O-

RING FOR FOR MOTOR END COVER

91800 GUIDE SHOE

52306*

O-

RING FOR STUFFING BOX BUSH

91900 RUBBER DIAPHRGAM

52307*

O-

RING FOR COOLING CHAMBER

92000 STAND

52308*

O-

RING FOR INSPECTION PLUG

92800 GUIDE PIPE HOLDER

55901 GUIDE PIPE ADAPTOR

93200 MOISTURE SENSOR

55902 ADAPTOR PIECE FOR GUIDE PIPE

93800 THERMISTOR

58201 HEX NUT FOR STUD OF PUMP CASING AND LOW BRG HOLDER

94100 GUIDE PIPE

58202 HEX NUT FOR LO

W BRG HOLDER AND STATOR HOUSING

94300 HEX NUT FOR TERMINAL BOARD

58203 HEX NUT FOR MOTOR END COVER AND STAT HOUSING

97801*

PROTECTION TUBE FOR POWER+CONTROL CABLE

58204 HEX NUT FOR BUSH AND MOTOR END COVER

-

SDS 97802*

PROTECTION TUBE FOR POWER CABLE

58205

NUT OF BEARING COVER

98900 HEX. SOCKET HEAD CAP SCREW FOR STUFFING BOX BUSH

58206 NUT FOR SUCTION PLATE

98901 HEX SOC CAP SCREW FOR EARTHING

58207 NUT FOR STAND

98903 HEX SOC CAP SCREW FOR GUIDE PIPE ADAPTOR

58208 HEX NUT FOR STUD OF UPPER BEARING HOL

DER 98904 HEX SOC CAP SCREW FOR ST HOUSING AND LOW BRG HOLDER

59001 STUD FOR PUMP CASING AND LOW BRG HOLDER

98905 HEX SOC CAP SCREW FOR ST HOUSING AND MOTOR END COVER

59002 STUD FOR LOW BRG HOLDER AND STATOR HOUSING

98906 HEX SCREW FOR CABLE BRACKET

59003

STUD FOR STATOR HOUSING AND MOTOR END COVER

98907 HEX SCREW FOR BEARING COVER

59004 STUD FOR BUSH AND MOT END COVER

-

SDS

* Marked part code nos. are recommended spares.

23

NS IOM MANUAL

Page 24

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

10 OUTLINE DRAWING & DIMENSIONS SHEET

10.1

!

(Unit 1 & 2- iNS)

TO BE SUSPENDED

FROM SUITABLE

SUPPORT.

CHAIN

A

OIL FILLING

B

PLUG

DEL.

C

SUC.

ØH

L

FRONT VIEW

D

E F

PLAN

Pump UNIT A B C E F D H L

NS20/13QT 1 580 80 150 145 150 290 290 450

NS20/13QT 2 625 80 150 145 150 290 290 500

NS32/13QT 2 762 133 203 175 150 350 350 550

NS40/13QT 2 610 81 150 180 150 360 360 500

24

NS IOM MANUAL

Page 25

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

10.2 (Unit 3,4,4a,5,6- QT, QM, QMB type Impeller iNS)

NS65/32QT

Pump UNIT A B C E F D H L

NS20/16QT 3 910 159 227 175 180 350 350 600

NS20/20QT 3 920 81 150 175 180 350 350 550

NS32/13QT 3 915 133 203 175 150 350 350 600

NS32/16QT 3 940 132 227 175 180 350 350 600

NS40/13QT 3 915 81 150 180 150 360 360 500

NS40/16QT 3 940 170 290 230 190 460 460 800

NS50/13QT 3 950 135 235 175 180 350 350 600

NS20/16QT 4 1005 159 227 175 180 350 350 600

NS20/20QT 4 1015 81 150 175 180 350 350 600

NS32/16QT 4 1035 132 227 175 180 350 350 700

NS40/13QT 4 1010 81 150 180 150 360 360 600

NS40/16QT 4 1035 132 228 175 190 350 350 700

NS50/13QT 4 1040 135 235 175 180 350 350 700

NS65/13QT 4 1040 145 245 225 200 450 450 700

NS20/16QT 4 1005 159 227 175 180 350 350 600

NS20/20QT 4 1015 81 150 175 180 350 350 600

NS32/16QT 4 1035 132 227 175 180 350 350 700

NS40/16QT 4 1035 132 228 175 190 350 350 700

NS50/13QT 4 1040 135 235 175 180 350 350 700

NS50/16QT 4 1003 135 195 175 200 350 350 650

NS65/13QT 4 1040 145 245 225 200 450 450 700

NS40/20QT 3 932 75 150 213 200 425 425 550

NS40/32QT 3 960 175 290 275 275 550 550 800

NS50/20QT 3 935 175 250 213 230 425 425 650

NS40/20QT 4a 1025 75 150 213 200 425 425 550

NS40/32QT 4a 1055 80 200 260 275 520 520 650

NS50/20QT 4a 1030 175 250 213 230 425 425 650

NS50/26QM 4a 1065 180 250 250 245 500 500 700

NS50/26QMB 4a 1065 180 250 250 245 500 500 700

NS50/26QT 4a 1065 180 250 250 245 500 500 700

NS40/32QT 4 1055 80 200 260 275 520 520 700

NS50/20QT 4 1030 175 250 213 230 425 425 650

NS50/26QM 4 1065 180 250 250 245 500 500 750

NS50/26QMB 4 1065 180 250 250 245 500 500 750

NS50/26QT 4 1065 180 250 250 245 500 500 750

NS80/26QM 4 1085 160 265 250 245 500 500 750

NS80/26QT 4 1085 160 265 250 245 500 500 750

NS40/32QT 4 1055 80 200 260 275 520 520 700

NS50/26QM 4 1065 180 250 250 245 500 500 750

NS50/26QMB 4 1065 180 250 250 245 500 500 750

NS50/26QT 4 1065 180 250 250 245 500 500 750

NS50/32QM 4 1077 155 254 270 280 540 540 750

NS50/32QT 4 1077 155 254 270 280 540 540 750

NS65/32QM 4 1070 158 250 270 275 540 540 750

NS65/32QMB 4 1070 158 250 270 275 540 540 750

NS65/32QT 4 1070 158 250 270 275 540 540 750

NS80/26QM 4 1085 160 265 250 245 500 500 750

NS80/26QT 4 1085 160 265 250 245 500 500 750

NS100/26QM 4 1105 175 290 275 275 550 550 800

NS100/26QT 4 1105 175 290 275 275 550 550 800

NS100/26QM

NS100/26QM

NS100/26QT

NS40/32QT

NS50/26QM

NS50/26QMB

NS50/26QT

NS50/32QM

NS50/32QT

NS65/32QM

NS65/32QMB

4 1105 175 290 275 275 550 550 800

4 1105 175 290 275 275 550 550 800

4 1105 175 290 275 275 550 550 800

4a 1055 80 200 260 275 520 520 700

4a 1065 180 250 250 245 500 500 750

4a 1065 180 250 250 245 500 500 750

4a 1065 180 250 250 245 500 500 750

4a 1077 155 254 270 280 540 540 750

4a 1077 155 254 270 280 540 540 750

4a 1070 158 250 270 275 540 540 750

4a 1070 158 250 270 275 540 540 750

4a 1070 158 250 270 275 540 540 750

CHAIN

A

L

OIL FILLING

PLUG

B

D

Pump UNIT A B C E F D H L

NS150/26QM

NS150/26QMB

NS150/26QMB

NS150/26QT

NS50/26QM

NS50/26QMB

NS50/26QT

NS50/32QM

NS50/32QT

NS50/36QM

NS65/32QM

NS65/32QMB

NS65/32QT

NS80/26QM

NS80/26QT

NS100/26QT

NS150/26QM

NS150/26QMB

NS150/26QNM

NS150/26QT

NS50/26QM

NS50/26QMB

NS50/26QT

NS50/32QM

NS50/32QT

NS50/36QM

NS65/32QM

NS65/32QMB

NS65/32QT

NS80/26QM

NS80/26QT

SUC.

ØH

FRONT VIEW

E F

PLAN

4 1150 165 325 275 350 550 550 750

4 1150 165 325 275 350 550 550 750

4 1150 165 325 275 350 550 550 750

4 1150 165 325 275 350 550 550 750

4 1065 180 250 250 245 500 500 750

4 1065 180 250 250 245 500 500 750

4 1065 180 250 250 245 500 500 750

4 1077 155 254 270 280 540 540 750

4 1077 155 254 270 280 540 540 750

4 1115 130 250 308 330 615 615 1250

4 1070 158 250 270 275 540 540 750

4 1070 158 250 270 275 540 540 750

4 1070 158 250 270 275 540 540 750

4 1085 160 265 250 245 500 500 750

4 1085 160 265 250 245 500 500 750

4 1105 175 290 275 275 550 550 800

4 1150 165 325 275 350 550 550 750

4 1150 165 325 275 350 550 550 750

4 1150 165 325 275 350 550 550 750

4 1150 165 325 275 350 550 550 750

4 1065 180 250 250 245 500 500 750

4 1065 180 250 250 245 500 500 750

4 1065 180 250 250 245 500 500 750

4 1077 155 254 270 280 540 540 750

4 1077 155 254 270 280 540 540 750

4 1115 130 250 308 330 615 615 1250

4 1070 158 250 270 275 540 540 750

4 1070 158 250 270 275 540 540 750

4 1070 158 250 270 275 540 540 750

4 1085 160 265 250 245 500 500 750

4 1085 160 265 250 245 500 500 750

DEL.

C

25

NS IOM MANUAL

Page 26

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

10.2.1 (Unit 3,4,4a,5,6- Q, N, NM, NB type

Impeller iNS)

CHAIN

A

OIL FILLING

PLUG

B

ØH

DEL.

C

FRONT VIEW

Pump UNIT A B C E F D H L

NS50/26N 4a 1080 165 250 230 245 460 460 700

NS50/26NB 4a 1080 165 250 230 245 460 460 700

NS50/26Q 4a 1080 165 250 230 245 460 460 700

NS50/26N 4 1080 165 250 230 245 460 460 750

NS50/26NB 4 1080 165 250 230 245 460 460 750

NS50/26Q 4 1080 165 250 230 245 460 460 750

NS80/26N 4 1095 150 265 230 245 460 460 750

NS80/26Q 4 1095 150 265 230 245 460 460 750

NS100/26N 4 1110 170 290 230 275 460 460 800

NS50/26N 4 1080 165 250 230 245 460 460 750

NS50/26NB 4 1080 165 250 230 245 460 460 750

NS50/26Q 4 1080 165 250 230 245 460 460 750

NS50/32N 4 1087 145 254 250 280 500 500 750

NS65/32N 4 1050 138 250 250 275 500 500 750

NS65/32NB 4 1050 138 250 250 275 500 500 750

NS65/32Q 4 1050 138 250 250 275 500 500 750

NS80/26N 4 1095 150 265 230 245 460 460 750

NS80/26Q 4 1095 150 265 230 245 460 460 750

NS100/26Q 4 1110 170 290 230 275 460 460 800

NS100/26N

NS100/26N

NS100/26Q

NS100/26Q

NS50/26N

L

NS50/26NB

NS50/26Q

NS50/32N

NS65/32N

NS65/32NB

NS65/32Q

NS150/26N

NS150/26NB

NS150/26NM

NS150/26Q

NS50/26N

NS50/26NB

NS50/26Q

NS50/32N

NS65/32N

NS65/32NB

NS65/32Q

NS80/26N

NS80/26Q

NS150/26N

NS150/26NB

NS150/26NM

NS150/26Q

NS50/26N

NS50/26NB

NS50/26Q

NS50/32N

NS65/32N

NS65/32NB

NS65/32Q

NS80/26N

NS80/26Q

4 1110 170 290 230 275 460 460 800

4 1110 170 290 230 275 460 460 800

4 1110 170 290 230 275 460 460 800

4 1110 170 290 230 275 460 460 800

4a 1080 165 250 230 245 460 460 750

4a 1080 165 250 230 245 460 460 750

4a 1080 165 250 230 245 460 460 750

4a 1087 145 254 250 280 500 500 750

4a 1050 138 250 250 275 500 500 750

4a 1050 138 250 250 275 500 500 750

4a 1050 138 250 250 275 500 500 750

4 1170 175 325 230 350 460 460 900

4 1170 175 325 230 350 460 460 900

4 1170 175 325 230 350 460 460 900

4 1170 175 325 230 350 460 460 900

4 1080 165 250 230 245 460 460 750

4 1080 165 250 230 245 460 460 750

4 1080 165 250 230 245 460 460 750

4 1087 145 254 250 280 500 500 750

4 1050 138 250 250 275 500 500 750

4 1050 138 250 250 275 500 500 750

4 1050 138 250 250 275 500 500 750

4 1095 150 265 230 245 460 460 750

4 1095 150 265 230 245 460 460 750

4 1170 175 325 230 350 460 460 900

4 1170 175 325 230 350 460 460 900

4 1170 175 325 230 350 460 460 900

4 1170 175 325 230 350 460 460 900

4 1080 165 250 230 245 460 460 750

4 1080 165 250 230 245 460 460 750

4 1080 165 250 230 245 460 460 750

4 1087 145 254 250 280 500 500 750

4 1050 138 250 250 275 500 500 750

4 1050 138 250 250 275 500 500 750

4 1050 138 250 250 275 500 500 750

4 1095 150 265 230 245 460 460 750

4 1095 150 265 230 245 460 460 750

26

NS IOM MANUAL

Page 27

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

10.3 (Unit 1&2- Q, N type Impeller NS)

27

NS IOM MANUAL

Page 28

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

10.4 (Unit 3 & 4 - Q, N type Impeller iNS)

28

NS IOM MANUAL

Page 29

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

11 GENERAL ARRANGEMENT DRAWING & DIMENSIONS SHEET

11.1 For iNS QT type model unit 1 & 2

!

TO BE SUSPENDED

FROM SUITABLE

SUPPORT.

GUIDE PIPE

(QTY- 02)

CHAIN

OD-V1

LENGTH ' V'

A

OIL FILLING

PLUG

B

D

SUC.

E

G.L.

G

F

FRONT VIEW

M

N

J

DEL.

L

C

G.L.

K

PLAN OF PUMP AND CONNECTOR UNIT ONLY

Pump UNIT A B C D E F G J K L M N P Q1 Q2 R1 R2 R3 S T1 T2 U V1 W1 W2 W3 W4 W5

NS20/13QT 1 580 80 250 285 143 254 150 110 200 450 300 105 19 150 400 125 250 500 100 100 50 250 43 150 200 23 200 38

NS20/13QT 2 625 80 250 285 143 254 150 110 200 500 300 20 19 150 400 125 250 500 100 100 50 250 43 150 200 23 200 38

NS32/13QT 2 762 80 290 285 143 254 150 150 210 500 340 40 19 160 410 145 290 540 100 100 50 250 43 150 200 23 200 38

NS40/13QT 2 610 130 350 285 143 264 150 170 250 550 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38

29

NS IOM MANUAL

Page 30

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

11.2 For iNS N, Q type model unit 3,4,5,6

200

CHAIN

A

OIL FILLING

PLUG

B

G.L.

LENGTH ' V'

FRONT VIEW

M

N

GUIDE PIPE

(QTY- 02)

OD-V1

DEL.

C

L

G.L.

D

G

E

PLAN OF PUMP AND CONNECTOR UNIT ONLY

30

K

JF

NS IOM MANUAL

Page 31

This is a proprietary document of Kirloskar Brothers Limited,

YAMUNA’ Survey No. 98/ 3 to 7, Baner, Pune

– 411045, India.

1

Sept

2018

Pump UNIT A B C D E F G J K L M N P Q1 Q2 R1 R2 R3 S T1 T2 U V1 W1 W2 W3 W4 W5 W6 W7 BS LEN

NS150/26QMB

NS150/26QMB

NS150/26QMB

NS150/26QNM

NS150/26QNM

NS150/26QNM

NS100/26QM

NS100/26QM 5 1215 175 468 450 225 399 275 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS100/26QM 6 1240 175 468 450 225 399 275 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS100/26QT

NS100/26QT 5 1215 175 468 450 225 399 275 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS100/26QT 6 1240 175 468 450 225 399 275 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS100/32QM 5 1210 180 468 490 245 434 310 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS100/32QM 6 1235 180 468 490 245 434 310 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS100/32QT 5 1210 180 468 490 245 434 310 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS100/32QT 6 1235 180 468 490 245 434 310 210 320 900 540 170 19 220 470 220 440 690 100 100 50 250 43 200 300 23 200 50 100 140 16 250

NS150/26QM

NS150/26QM 5 1240 130 553 450 225 474 350 260 390 900 560 165 19 340 590 255 510 760 100 100 50 250 43 200 300 23 200 38 75 140 16 250

NS150/26QM 6 1295 130 553 450 225 474 350 260 390 900 560 165 19 340 590 255 510 760 100 100 50 250 43 200 300 23 200 38 75 140 16 250

NS150/26QT

NS150/26QT 5 1240 130 553 450 225 474 350 260 390 900 560 165 19 340 590 255 510 760 100 100 50 250 43 200 300 23 200 38 75 140 16 250

NS150/26QT 6 1295 130 553 450 225 474 350 260 390 900 560 165 19 340 590 255 510 760 100 100 50 250 43 200 300 23 200 38 75 140 16 250

NS150/32QM 6 1260 165 553 490 245 519 395 260 390 900 560 165 19 340 590 255 510 760 100 100 50 250 43 200 300 23 200 38 75 140 16 250

NS150/32QT 6 1260 165 553 490 245 519 395 260 390 900 560 165 19 340 590 255 510 760 100 100 50 250 43 200 300 23 200 38 75 140 16 250

NS20/16QT 3 910 8 2 250 340 170 284 180 110 200 500 300 105 19 150 400 125 250 500 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS20/16QT 4 1005 82 250 340 170 284 180 110 200 600 300 105 19 150 400 125 250 500 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS20/20QT 3 920 8 1 250 355 178 284 180 110 200 550 300 105 19 150 400 125 250 500 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS20/20QT 4 1015 81 250 355 178 284 180 110 200 600 300 105 19 150 400 125 250 500 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS20/20QT 5 1105 81 250 405 203 284 180 110 200 700 300 105 19 150 400 125 250 500 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS32/13QT 3 915 8 2 290 340 170 254 150 150 210 650 340 40 19 160 410 145 290 540 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS32/16QT 3 940 5 5 290 340 170 284 180 150 210 550 340 40 19 160 410 145 290 540 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS32/16QT 4 1035 55 290 340 170 284 180 150 210 600 340 40 19 160 410 145 290 540 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/13QT 3 915 130 350 340 170 264 150 170 250 650 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/13QT 4 1010 130 350 340 170 264 150 170 250 650 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/16QT 3 940 105 350 340 170 304 190 170 250 600 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/16QT 4 1035 105 350 340 170 304 190 170 250 700 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/16QT 5 1125 105 350 405 203 304 190 170 250 800 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/20QT 3 932 125 350 380 190 314 200 170 250 600 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/20QT 4a 1025 125 350 380 190 314 200 170 250 600 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/20QT 5 1100 125 350 405 203 314 200 170 250 700 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/32QT 3 960 9 8 350 495 248 389 275 170 250 600 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/32QT 4 1055 98 350 495 248 389 275 170 250 700 370 115 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS40/32QT

NS50/13QT 3 950 150 425 340 170 270 180 170 250 650 370 25 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS50/13QT 4 1130 150 425 405 203 270 180 170 250 750 370 25 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS50/16QT 4 1003 188 425 340 170 290 200 170 250 700 370 25 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250

NS50/16QT 5 1090 188 425 405 203 290 200 170 250 800 370 25 19 200 450 160 320 570 100 100 50 250 43 150 200 23 200 38 75 100 16 250