KIRLOSKAR KOSN Series Installation, Operation & Maintenance Manual

Kirloskar “KOSN Series”

Centrifugal Submersible Pump

A Kirloskar Group Company

KIRLOSKAR BROTHERS LIMITED

INSTALLATION, OPERATION & MAINTENANCE MANUAL

KOSN Series

CM - 9862

WORKS :

Ujjain Road, Dewas - 455 001 (M.P.)

Phone : +91 7272 227401/2/5/9 Fax : +91 7272 228747

Toll Free No. 1800 103 4443

CORPORATE OFFICE :

“YAMUNA”, Survey No. 98 (3-7), Baner,

Pune 411 045 (India)

Phone : +91 20 27214444

E-mail : kblin@kbl.co.in Visit us at : www.kirloskarpumps.com

REGISTERED OFFICE :

Udyog Bhavan, Tilak Road,

Pune - 411 002 (India)

Tel. : +91 20 24444444 Fax : +91 20 24444198

E-mail : kbl@kbl.co.in

KIRLOSKAR BROTHERS LIMITED

A Kirloskar Group Company

A View of KBL Dewas Manufacturing Plant

06019860

FOR PROMPT SERVICE & SPARES

Register on our website : www.kirloskarpumps.com

Our products are meant for pumping

water and they do not have any significant effect

on environment during their use, if properly

selected and used as per instructions

given in this manual.

Customers are advised to dispose unusable

components through appropriate disposal agencies to

avoid the impact on work environment.

CONGRATULATIONS........... .

Congratulations.... ..... on you r acqui ring one of t he finest pumps in t he

country.

The Kirloskar Openwell Submersible New- version Series in your

possession is scientifically designed by using the state of art design software

(Pro/E, ANSYS, CFD) for better a esthetics, performance, optimum material

Contents etc. These pumps are reliable, robust, compact in size and cheaper in

their class. Ca reful selection of materials, manufacturing and testing assur es

you a satisfactory performance over a long period of time.

These pumps will give you years of trouble free performance if it is

handled with due care. This booklet is a step in this direction. It covers general

instructions on installation, operation and maintenance of KOSN Pumps. Please

read this booklet comply with the instructions and your pump is bound to serve

you well.

1. HANDLING 01

2. PUMP DESIGNATION KEY 01

3. FEATURES & APPLICATION 01

4. OPERATING CONDITION 02

5. INSTALLATION 02

6. ELECTRICAL CONNECTION 04

7. PRIMING 05

8. MAINTENANCE 05

9. TROUBLE SHOOTING CHART 06

10. CAUSE AND REMEDY CHART 07

11. DISMENTLING PROCEDURE 12

12. DISPOSAL 12

13. EXPLODED VIEW 13

14. PART LIST 14

15. OUTLINE DRAWING 15

16. PUMP MODELS 16

17. PRODUCT RANGE 17

18. WARRANTY CERTIFICATE 18

CONT ENTS

1. Handling : When the entire pump is to be lifted in vertical direction, th en it is

recommended to lift the pump at the Lifting bolt by means of straps/ropes as shown in

figure 1.1 If pump to be moved from one place to another place then it is recommended to

lift the pump at mounting casing by means of hand.

figure 1.1

2. Pump designation key : Following 7 key characters designate Kirloskar KOSN

series monoblocs.

Example KOSN-128

K O S N 1 28

Name of Type of Type of Version Power Head at 0

firm pump pump rating in HP discharge

Kirloskar Open Well Submersible New 1 for 1 HP Sh ut of

1.5 for 1.5 head

HP etc

3. Features:

Kirloskar Openwell Submersible New version Pumps of designed for a wide

range of applications.

Designed for underwater applications - No need of priming and foot valve.

Easy installation - Foundation and installation platform or pump house not

required .

Can withstand wide voltage fluctations from 160-260 V.

Desined to prevent overloading and motor burning.

1

LIFTING ROPE

Dynamically balanced rotating parts to ensure minimum vibrations during

running .

Replacable wearing parts and hence longer life .

Easy maintenance and spares availability .

Applications :

Submerged pump in Fountains, Wells, Sumps and Water tanks .

Water supply for domestic use in high rise Apartments, Buildings and Hotels.

Gardening and sprinklers/conventional irrigation .

Industries, for clear water handling .

2

4. Operating Conditions :

4.1 Pumped Liquids :

Kirloskar Openwell Submersible New version Pumps are suitable only to pump

thin, non-explosive liquids, not containing solid particles. The liquid must not attack the

pump materials chemically. When pumping liquids with density and/or viscosity higher

than that of water, suitability of motor winding with correspondingly higher outputs must

be checked, if required.

4.2 Submerged Condition :

The pump must be submerged in water more than 1 meter .

4.3 Technical Data :

Maximum Liquid Temperature - 500 C

Rated voltage - 210 volt for single phase

- 380 volt for three pahse

Voltage Range - 160-260 for single phase

350-415 for three phase

Type of Duty - S 1 continuos

Direction of rotation - Anti-clock wise form suction side.

Frequency - 5 0Hz

Sound Level - 80dB

Degree of protection - I P-68

Class of Insulation - ‘P P’

5. INSTALLATION

5.1 G uidelines :

For avoiding the un-necessary troubles in Installation, Operation Ma i nt en an c e

and for Utmost Performance of the Pump, we are suggesting few guidelines. We hope by

following these guidelines our customer will able to install the pump easily and operate

the pump at optimum performance.

3

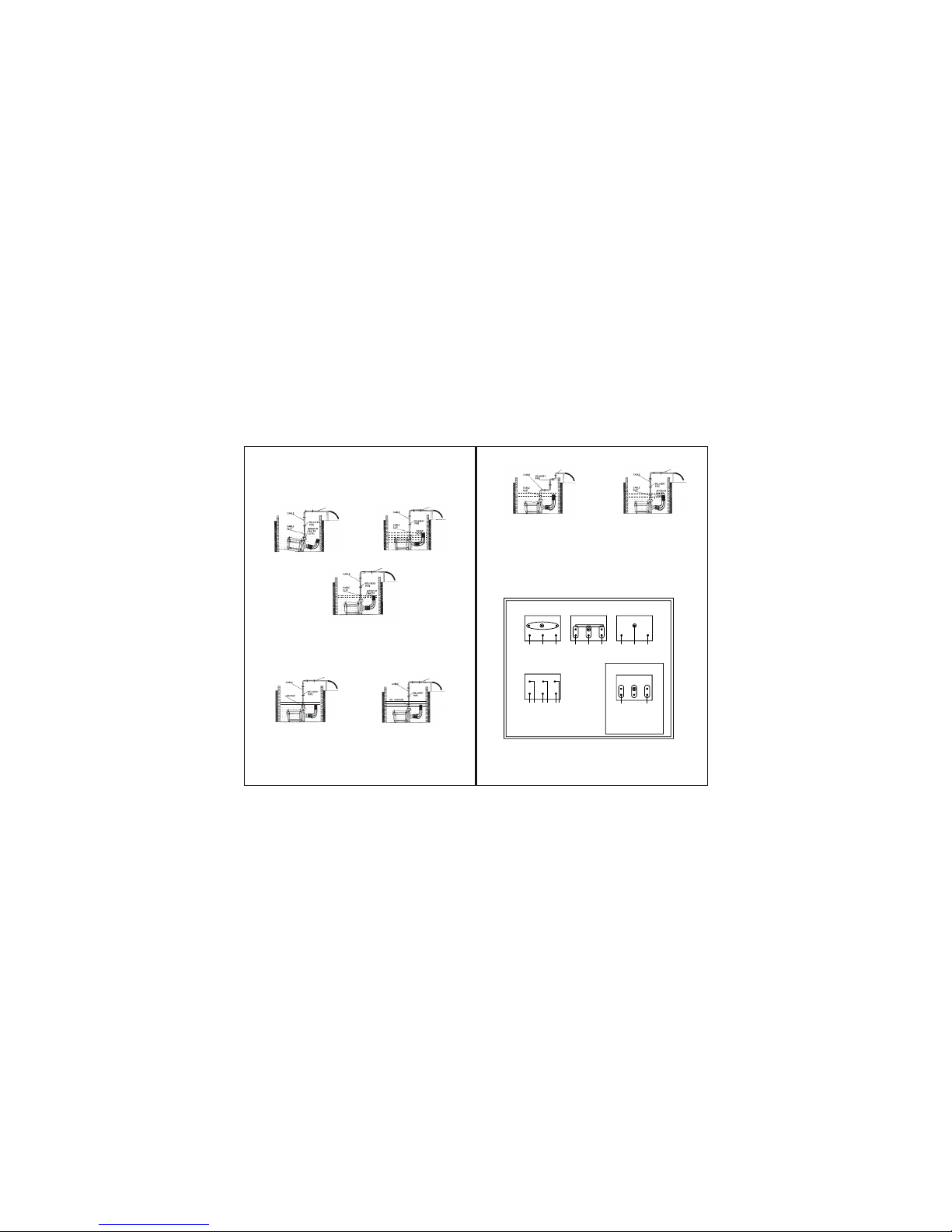

WRONG WRONG

Fig. 5.1

5.2 Guideline for Installation :

5.2.1 Location : The pump should be installed in horizontal position and submerged in

the water more than 1 meter . This will eliminate dry run and pump will give better

performance. The pump does not require any foundation ; however if installing dug

cum borewell , surface should be plain . The pump should not be installed in tilted

position. (Ref. fig. 5.1)

5.2.2 Guideline for Piping :

ØPipe size should be as per flange size to g et h igher dischar ge. It i s n ot

recommended to reduce pipe size. If length of delivery pipe is more than 3 m., use

hig her p ipe (P leas e refe r tabl e 1.1 a nd 1. 2 for pr oper pipe s ize) .

ØThe pi ping shoul d be airt ight . A ny leak age in p ipe may d rast icall y

affect the performance of the pump. ( ref. fig. 5.2 )

ØThe suction pipe should be as short as possible for getting better dischar ge.

( in case of dug cum borewell type arrangement. )

ØNo. of bends and other fittings should be as minimum as possible to reduce

frictional losses. ( ref. fig. 5.3 )

ØAdequate supports should be provided to pipes so that its dead weight should

not fall on delivery casing completely.

RIGHT

Fig. 5.2

RIGHT

6 Guideline for Electrical Connections :

ØProper earthing connection should be made at the bolts provided for earthing.

ØProper size of cable should be used between supply and motor terminals to

minimize voltage drop and to carry full load current (FLC) as well as the maximum

current in the operating voltage range specified.

4

ØFor delivery pressure more than 20 meters, it is recommended to install a check

( non-return ) valve in the discharge line. The check valve placed near the pump

is to protect the pump from excessive backpressure to prevent the water running

back through the pump in case of sudden failure of prime mover .

No. OF LEADS 3

V1 U1

W1

U1

V2

W2

CONNECTION

STAR OR DELTA

No. OF LEADS 3

V

U

W

TO LINES

STAR DELTA STARTING

No. OF LEADS 6

V2U2V1W2

W2 U1

CONNECTION DIAGRAM OF

THREE PHASE MOTORS

LEADS FROM

MOTOR

SINGLE PHASE 50 Hz

SUPPLY

CONNECTION DIAGRAM OF

SINGLE PHASE MOTOR

PHASE NEUTRAL

ØNuts at terminal should be tightened properly.

ØNo. of joints in cable should be less as possible, preferably joints should be

avoided.

Fig. 5.3

WRONG

CORRECT

Loading...

Loading...