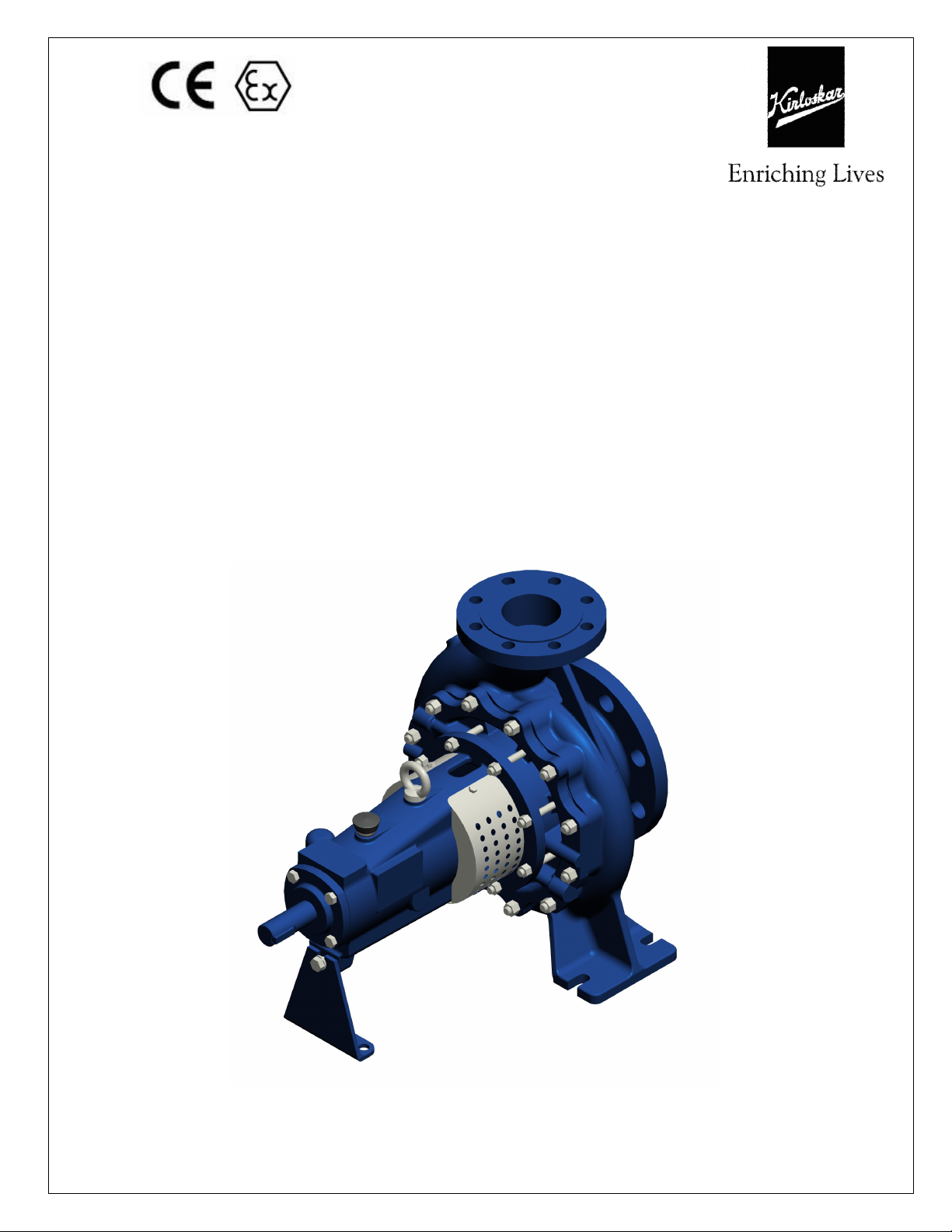

KIRLOSKAR GK Series, GKP Series, GK 7A, GKP 7A, GK 10 Instruction On Installation, Operation And Maintenance

...

INSTRUCTIONS ON

INSTALLATION,

OPERATION AND

MAINTENANCE FOR

KIRLOSKAR PUMP

TYPE GK(P)

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 1 LAST REV. DATE: 01.08.2019

KIRLOSKAR BROTHERS LIMITED

REGD. OFFICE UDYOG BHAVAN, TILAK ROAD PUNE-411002

WARRANTY

We warrant that the pump supplied from us is free from defective

material and faulty workmanship. This warranty holds good for a

period of 12 months from the date of commissioning the equipment

or 18 months from the date of dispatch from our factory, whichever

is earlier. Our liability in respect of any complaint is limited to

replacing part/parts free of charge ex-works or repairs of the

defective part/parts only to the extent that such replacement / repairs

are attributable or arise solely from faulty workmanship or defective

material.

This warranty holds good only for the products manufactured by us.

KIRLOSKAR BROTHERS LIMITED

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 2 LAST REV. DATE: 01.08.2019

CONTENTS

PART A: ATEX SAFETY MANUAL

PART B:

INSTRUCTIONS ON INSTALLATION, OPERATION AND

MAINTENANCE FOR KIRLOSKAR PUMP TYPE GK(P)

1. GENERAL

2. SAFETY INSTRUCTIONS

3. EQUIPMENT SCHEDULE

3.1 INSTALLATION

3.2 MOUNTING AND ALIGNMENT

4. OPERATION

4.1 EQUIPMENT DESCRIPTION

4.2 EQUIPMENT OPERATION

5. MAINTENANCE MANUAL

5.1 MAINTENANCE EHS INSTRUCTIONS

5.2 GENERAL MAINTENANCE DOCUMENTS

5.3 PREVENTIVE MAINTENANCE

5.4 CORRECTIVE MAINTENANCE

6. TECHNICAL DATA

Note: A copy of

maintenance of ‘Kirloskar pumps’

General instructions for installation, operation &

is attached at the end of this

manual.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 3 LAST REV. DATE: 01.08.2019

PART A: ATEX SAFETY MANUAL

TRAINING

It is recommended and a part of the CE regulations that users personnel who will be

involved in the installation, operation and/or maintenance of KBL products should

have the opportunity of an initial training period, which can be carried out either at

KBL works or customers premises by arrangement.

This training is offered by KBL in 3 different forms.

A. Informal training in your maintenance workshop by our Technical Sales

Representative on a Free of Charge basis.

B. Formal training in your training rooms by our skilled training personnel using

visual aids, ‘hands on’ equipment, etc., at an agreed cost to be confirmed.

C. Formal training at KBL Premises by our skilled training personnel using visual

aids, ‘hands on’ equipment, etc., at an agreed cost to be confirmed.

It is your responsibility to request your preferred training method now. KBL will not

consider responsibility for ongoing breakdowns, etc., if training has not been given.

KBL offer a friendly after sales policy but, reserve the right to charge for “call out”

visits that are found to be caused through operator/fitter error.

LIMITATIONS OF USE

KBL products are designed to provide performance generally, as shown in

accompanying literature associated with the individual models or series. All

performance Figures are given in good faith and are based on tests at KBL works

using water at ambient temperature.

Operating temperatures are governed by the materials of construction of parts i.e.

bearings, shaft gland, sealings, seals, etc., and it is the installer’s responsibility to

ensure that these maximum temperatures are not exceeded under any

circumstances.

Performance Figures provided by KBL against individual enquiries are estimates only

and are subject to variations depending upon atmosphere pressure and volumes of

liquid provided by client, and to head losses due to pipe work, valves, etc., which

may be unknown to KBL estimators.

All performance Figures, temperatures, flow rates, dimensions & other details are

subject to change without notice. Due to the wide variety of products handled by

KBL pumps, it is impossible for KBL to give a firm recommendation regarding

materials of construction for pump components. It is the users or specifiers

responsibility to determine the effect of corrosion & abrasion, and the general

suitability of any pump supplied for any individual application. KBL will, however,

give advice in such material selection as it may be able to do so in good faith.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 4 LAST REV. DATE: 01.08.2019

ESSENTIAL SAFETY REQUIREMENTS (ESR)

ATEX DIRECTIVE 2014/34/EU (EXPLOSION HAZARD SAFETY)

All KBL products that are certified to comply with the Directive also carry a specific

ATEX Safety Manual (Section 5) which must be referred to in conjunction with this

manual. It is the responsibility of the user to ensure that the equipment is correctly

rated for the environment in which it is to be used.

When handling KBL products, please refer weights given in KBL literature. Lifting

equipment may be required in certain cases. Note that all pumps dispatched from

our works are tested with water and during storage, packing and installation, some

water will have remained in the pump body. This water may cause spillage during

handling. Water could react with the products you wish to pump, and it is your

responsibility to check this before putting the pump into operation. Water may also

freeze if the pump is exposed to sub zero temperatures. Do not operate the pump

under these conditions as ice inside the pump may cause damage to working parts

of the pump.

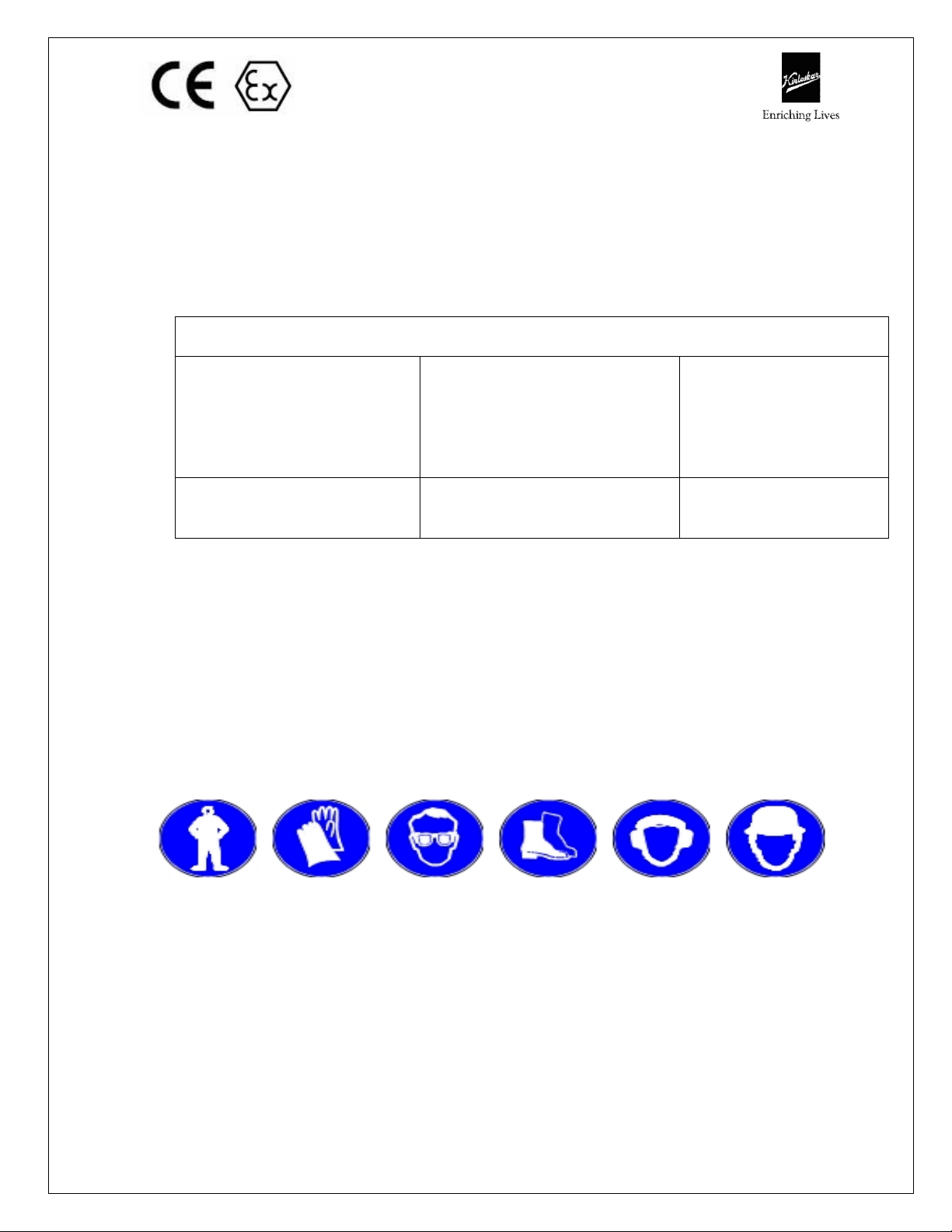

At all times the installer must wear suitable clothing, footwear, goggles, etc., for

personal protection. This particularly applies when the pump is being operated or

maintained.

If the product being processed is hazardous, then provision must be made by the

user to deal with this problem. This can be achieved by either specifying a guardian

or barrier system as part of the original pump specification and constructing pipe

work which can carry the leakage to a safe place.

ATEX SAFETY MANUAL

For Centrifugal GK(P) Pumps and Accessories.

User Instructions to ensure compliance with European Directive 2014/34/EU

1.0 GENERAL

These instructions must always be kept close to the product’s operating location or

directly with the Product. These instructions are intended to facilitate familiarization

with the product and its permitted use to help satisfy ATEX safety requirements.

The instructions may not have taken into account local regulations; ensure such

regulations are observed by all, including those installing the product. Always coordinate repair activity with operations personnel and follow all plant safety

requirements and applicable safety and health/law regulations. These instructions

should be read prior to installing, operating, using and maintaining the equipment in

any region worldwide and in conjunction with the main user instructions provided.

The equipment must not be put into service until all the conditions relating to safety

instructions have been met.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 5 LAST REV. DATE: 01.08.2019

A.1 DIRECTIVE 2014/34/EU

It is a legal requirement that machinery and equipment put into service within

certain regions of the world shall conform to the applicable CE Marking Directives

for Equipment for Potentially Explosive Atmospheres (ATEX).

Where applicable the Directive covers important safety aspects relating to the

equipment, its use and the satisfactory provision of technical documents. Where

applicable this document incorporates information relevant to these Directives. To

establish if the product itself is CE marked for a Potentially Explosive Atmosphere

check the name plate and the Certification provided.

A.1.1 Disclaimer

Information in these User Instructions is believed to be reliable. In spite of all the

efforts of KIRLOSKAR BROTHERS LTD. to provide sound and all necessary

information, the content of this Manual may appear insufficient and is not

guaranteed by KIRLOSKAR BROTHERS LTD. as to its completeness or accuracy.

A.2 Personnel qualifications and training

All personnel involved in the operation, installation, inspection and maintenance of

the unit must be qualified to carry out the work involved. If the personnel in

question do not already possess the necessary knowledge and skill, appropriate

training and instruction must be provided. If required, the operator may commission

the manufacturer/supplier to provide applicable training.

A.3 Maximum surface temperature (Temperature Class)

Special attention must be paid to the marking on the ATEX name plate as the use

of ‘pirate’ spare parts will invalidate the ATEX certification. It is essential to heed

the instruction prohibiting dismantling of the equipment in a flammable atmosphere

where applicable.

EQUIPMENT MUST BE EARTHED AND ONLY GENUINE KBL SPARES USED DO

NOT DISMANTLE IN FLAMMABLE ATMOSPHERE.

A.4 CE Marking & Approvals

General:

It is a legal requirement that the machinery & equipment put into service in certain

region of the world shall conform with the applicable CE marking directives

covering pump, accessories & instruments in the package for potentially Explosive

Atmosphere (ATEX). The applicable documents incorporating information relevant

to their directives will be provided separately e.g. CE marking & ATEX marking

certification, additional safety instructions & directives etc., as applicable.

Kirloskar pumps GK(P) range of pumps are certified to comply with the ATEX

directives 2014/34/EU & user is to ensure compliance with the European Directive

2014/34/EU.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 6 LAST REV. DATE: 01.08.2019

Check the product name plate & certification provided to establish that the product

itself is CE marked for Potentially Explosive Atmosphere.

Non CE/ATEX marked.

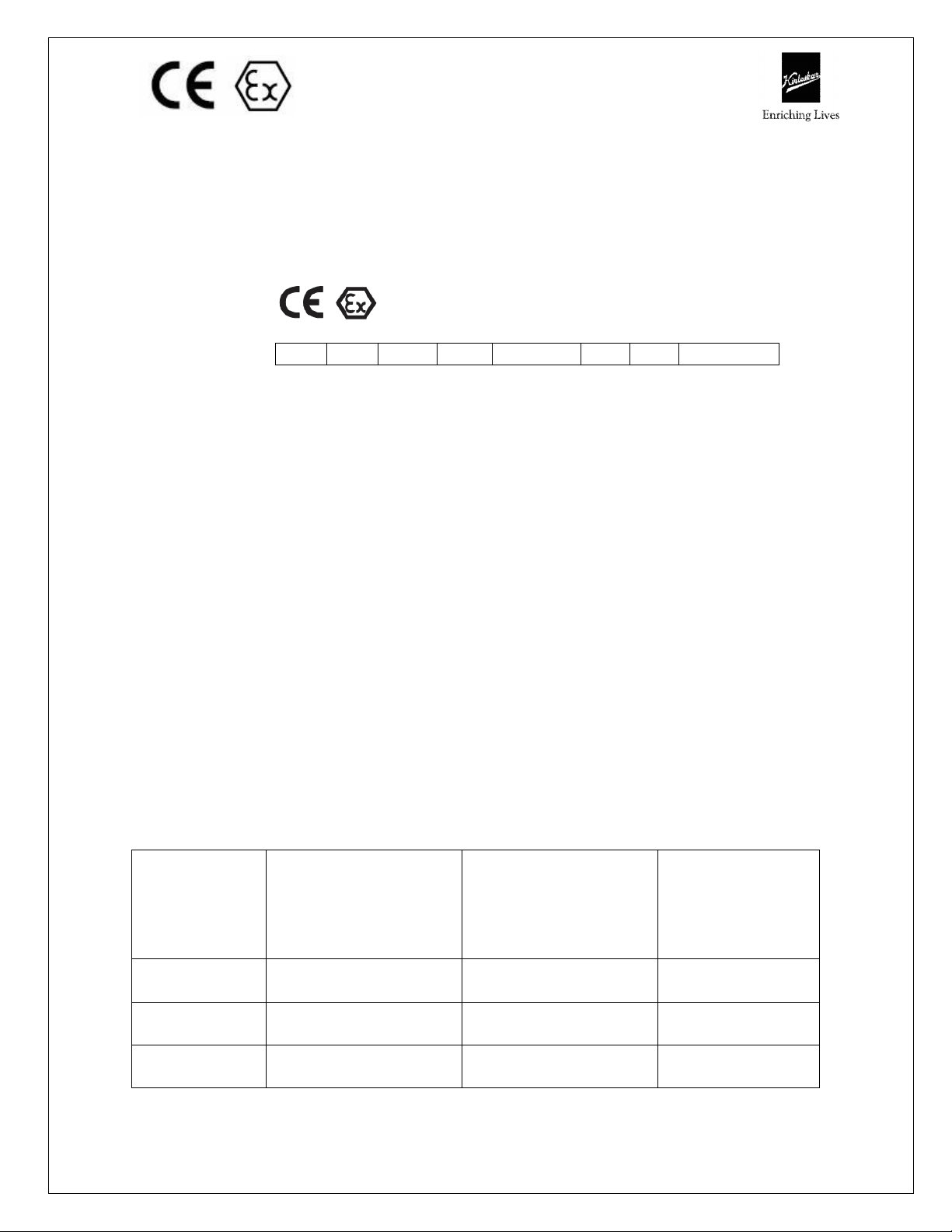

Marking: An example of ATEX equipment marking is shown below. The applicable

marking will be graved on name plate:

Example:

II 2/3 G/D h Tx Gb/Gc

1 2 3 4 5 6 7 8

1) CE marking

2) Use of equipment in potentially explosive atmosphere

3) Equipment group for surface application

4) Equipment Category 2 (Zone 1) or 3 (Zone 2)

5) G-Gas D-dust

6) Constructional Safety ‘h’ as per EN ISO 80079-36 & 37

7) Temperature Class –T1-450ᑻᑻᑻᑻC T2-300ᑻᑻᑻᑻC T3-200ᑻᑻᑻᑻC T4-135ᑻᑻᑻᑻC T5100ᑻᑻᑻᑻC T6-85ᑻᑻᑻᑻC

8) Equipment Protection Level – Gb (Zone 1) / Gc (Zone 2)

A.5 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE CLASS IS SUITABLE FOR THE HAZARD

ZONE

A.5.1 Pump liquid temperature

Pumps have a temperature class as stated in the ATEX Ex rating on the name plate.

These are based on a maximum ambient of 40ºC (104ºF). Refer to KIRLOSKAR

BROTHERS LTD. for higher ambient temperatures. The surface temperature of the

pump may be influenced by the temperature of the liquid handled. The maximum

permissible liquid temperature depends on the temperature class and must not

exceed the values in the table applicable below. The temperature rise at the seals,

bearings and due to the minimum permitted flow rate is taken into account in the

temperatures.

Maximum permitted liquid temperature for GK(P) pumps:

Temperature

Class to

EN 13463–1

Maximum

Surface temperature

Permitted

Temperature limit of

liquid handled

Depending on material

and Construction

variant.

T4 1350C (2750F) 1050C (2210F)

T3 2000C (3920F) 1750C (3470F)

T2

3000C (5720F)

2500C (4820F)

Else product to be treated as

Consult Kirloskar

Brothers Ltd.

Consult Kirloskar

Brothers Ltd.

Consult Kirloskar

Brothers Ltd.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 7 LAST REV. DATE: 01.08.2019

Where there is any risk of the pump being run for prolonged periods against a

closed or partially closed valve generating high liquid and casing external surface

temperatures, it is recommended that users fit an external surface temperature

protection device.

A.5.2 Additional requirements for self-priming conditions

Where the system operation does not ensure control of priming, and the maximum

permitted surface temperature of the T3 Class could be exceeded, it is

recommended for users to fit an external surface temperature protection device.

A.6 Preventing the build up of explosive mixtures

ENSURE PUMP IS PROPERLY FILLED WHENEVER POSSIBLE AND DOES NOT RUN

DRY FOR LONGER THAN 5 MINUTES CONTINUOUSLY

Ensure the pump and relevant suction and discharge pipeline system is totally filled

with liquid during the pumping operation, so that an explosive atmosphere is

prevented. If the operation of the system cannot avoid this condition, ensure that

the pump does not run dry for more than 5 minutes continuously.

To avoid potential hazards from fugitive emissions of vapour or gas to atmosphere

the surrounding area must be well ventilated.

A.7 Preventing sparks

To avoid the potential hazard from random induced current generating a spark, the

earth stud on the pump casing or foot must be connected. Avoid electrostatic

charge: Do not rub non-metallic surfaces with a dry cloth for cleaning, etc; ensure

the cloth is damp.

A.8 Preventing leakage

The pump must only be used to handle liquids for which it has been approved to

have the correct corrosion resistance. Avoid entrapment of liquid in the pump and

associated piping due to closing of suction and discharge valves, which could cause

dangerous excessive pressures to occur if there is heat input to the liquid. This can

occur particularly if the pump is stationary. Bursting of liquid containing parts due

to freezing, must be avoided by draining or protecting the pump and ancillary

systems. If leakage of liquid to atmosphere can result in a hazard, the installation of

a liquid detection device is recommended.

A.9 Maintenance of the GK(P) pump to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED TO AVOID POTENTIAL HAZARDS WHICH

GIVE A RISK OF EXPLOSION

The responsibility for compliance with maintenance instructions is with the plant

operator. To avoid potential explosive hazards during maintenance, the tools,

cleaning and painting materials used must not give rise to sparking or adversely

affect the ambient conditions. Where there is a risk from such tools or materials,

maintenance must be conducted in a safe area.

It is recommended that a maintenance plan and schedule is adopted, in line with

the user instructions provided, to include the following:

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 8 LAST REV. DATE: 01.08.2019

A. Any auxiliary systems installed must be monitored, if necessary, to ensure they

function correctly.

B. Check for any leaks from gaskets and seals. The condition of the mechanical

seal must be checked regularly to ensure correct functioning.

C. Check that the duty condition is in the safe operating range for the pump.

D. Check that dirt and dust is removed from operational areas of the pump.

E. Inspect the GK(P) pumps at least every 1000 running hours and renew if any

sign of damage is apparent.

A.10 Additional Safety Instructions

A) Pumps and ancillary equipment must be drained, cleaned and decontaminated

prior to any change of duty.

B) Where pumps and ancillary equipment contain non-conductive plastic wetted

components, dismantling for maintenance must take place in a safe area away

from the flammable hazard, or the equipment made safe by purging with

nitrogen.

C) When installing a pump either for the first time or after maintenance, a check

must be made to ensure that the earth connection terminal on the pump and

any external metalwork is at ground potential.

D) Where a counter or count and stop device is fitted, it is for indicating the

number of cycles run only, and not to use as a means of process flow control or

for performing a safety function.

E) Ensure nozzle forces and bending moments should not exceed the maximum

permissible values as specified in technical documents.

PART B: INSTRUCTIONS ON INSTALLATION, OPERATION AND

MAINTENANCE FOR KIRLOSKAR PUMP TYPE GK(P)

1. GENERAL:

1.1 ‘KIRLOSKAR’ make GK(P) pumps are used for handling various types of

chemical liquids. These pumps are manufactured to close tolerance and are

of rigid construction. However, proper installation, operation and

maintenance are equally important to ensure trouble free service. This

booklet covers important guidelines and instructions for installation,

operation and maintenance. These instructions should be followed carefully

for satisfactory performance of the pumping unit. Only mechanical aspects

are dealt within this booklet.

1.2 Applications:

GK(P) pumps are mainly used in process industries like petrochemicals,

nuclear, refinery, fertilizer, paper, sugar, etc., and power plants. The pump

can handle corrosive acids, alkalies, salt solutions, caustics, hydro-carbons,

oils, liquefied gases, condensates, viscous liquids, etc.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 9 LAST REV. DATE: 01.08.2019

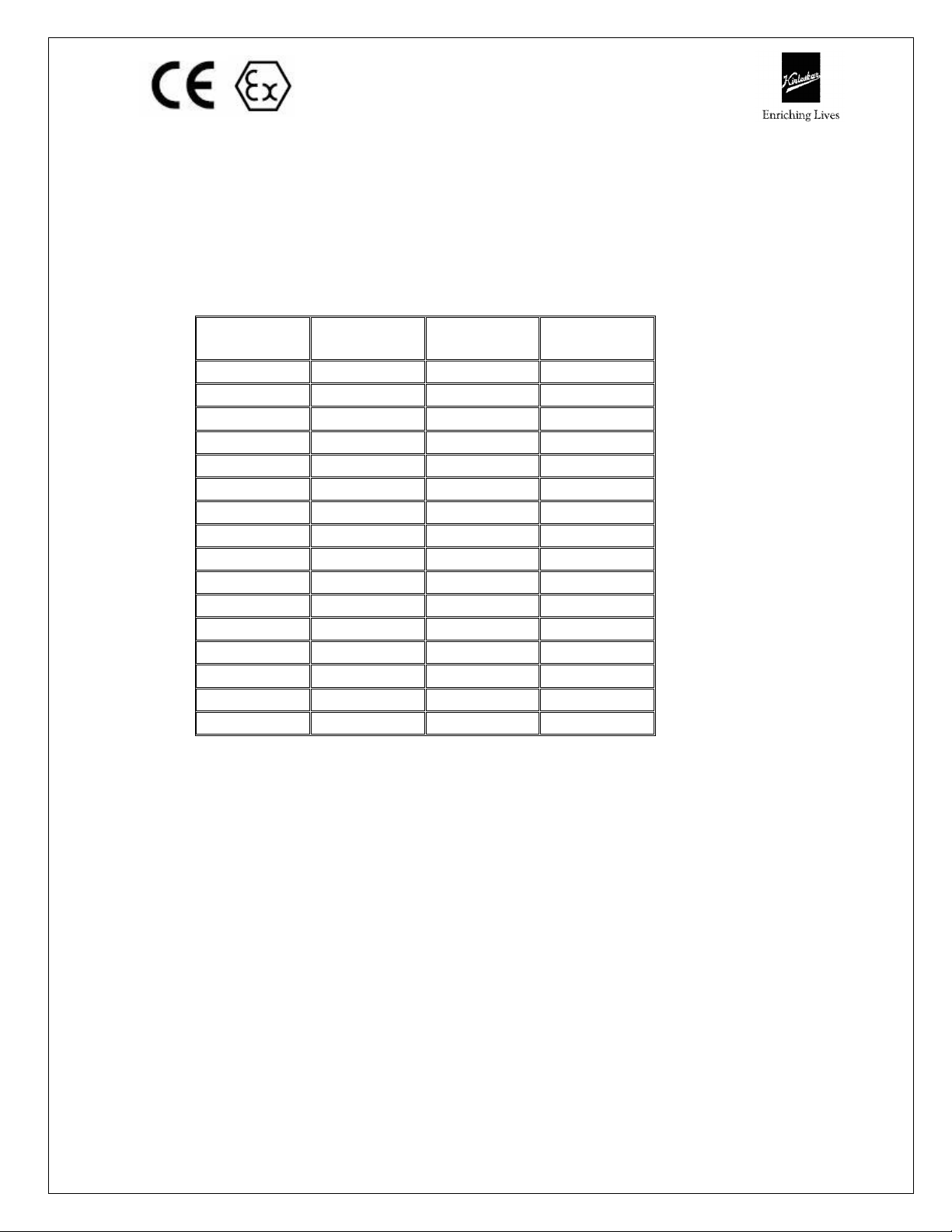

32/16

32/26

65/26NHS

65/32HS

40/13

50/26

80/40N

40/20A

65/20

100/32N

1.3 Nomenclature: GK(P)32/13

GK(P) - Global Kirloskar (Process) Pump.

32 - Delivery size in mm.

13 - Impeller diameter in cm.

1.4 This booklet covers instructions for following types GK(P), GK(P)J, GK(P)

CLM of GK(P) series.

GK(P)

UNIT – 7

32/13 25/26A 65/26HS 65/32

32/20 40/26 80/26HS 80/32

32/20A 40/32 50/32HS 80/40

40/16 50/32 100/26

40/20 65/16 100/32

50/13 65/26 100/40

50/16 65/26N 125/26

50/20 80/16 125/32

65/13 80/20 125/40

32/16A 80/26 125/40N

50/16A 100/16 150/32

100/20 150/32N

150/40

Description of GK(P) pumps.

GK(P)- GK(P) pumps with enclosed impeller.

GK(P)J- GK(P) pumps with jacketed delivery casing and casing cover or

only casing cover as per application / customer requirement.

GK(P)CLM GK(P) pumps with Centre Line Mounting arrangement.

1.5 The complete range of ‘GK(P)’ pumps is covered by 4 driving units thereby

reducing inventory and achieving interchangeability.

1.6 Name plate information:

Every pump has the name plate fitted to bearing housing provided with

necessary identification of the pump and its specific hydraulic characteristics.

The name plate must not be removed. Loss of this plate could make

identification impossible. This in turn could affect safety and cause difficulty in

obtaining spare parts.

GK(P)

UNIT – 7A

GK(P) UNIT

– 10

GK(P) UNIT

– 12

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 10 LAST REV. DATE: 01.08.2019

ENRICHING LIVES KIRLOSKAR BROTHERS LIMITED

1.7 Pumps when properly installed & given due care in operation & maintenance

should operate satisfactorily for a long period.

1.8 When the pump is received, sometime before the actual use of pump, it

should be inspected & located in dry place. The coupling should be rotated

once in a month to prevent pitting of bearing surfaces.

1.9

Contact Information

REGD. OFF:

UDYOG BHAVAN, TILAK ROAD,

PUNE-41102 (INDIA)

CORPORATE OFFICE: “YAMUNA”,

SURVEY NO-98/3-7,

PUNE-MUMBAI HIGHWAY,

BANER, PUNE -411 045 (INDIA)

WORKS:

KIRLOSKARWADI,

416308,

DIST.:SANGLI (INDIA)

TEL: 091 020- 2440 0770

FAX: 091 020- 2427 0156

Note: The information in this document may sometimes be of generic nature and

applicable to various company products irrespective of its specific application &

use. Additional instructions if any shall be specified on individual project

drawings & documents furnished to the buyer against specific order.

Where a conflict exists between the contents herein and the actual equipment

supplied, the user must make an engineering judgment, else contact KBL.

Kirloskar Brothers reserves the right to change the construction & design of the

products at any time without being obliged to change products already supplied

earlier.

2. Safety Instructions:

2.1 General Information

Before performing any actions detailed within this instruction, the Site Health

and Safety instructions shall be read and fully understood. The instructions in

this document shall also be read and fully understood.

TEL: 091 020- 2721 4444

FAX: 091 020- 2427 0879

TEL: 091 02346- 221 055

FAX: 091 02346- 222 311

Whenever the equipment is operated, maintained or used in any way, the

procedures detailed within the Health and Safety Dossier (DHS) and any

procedures detailed within these instructions shall be followed. The pump

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 11 LAST REV. DATE: 01.08.2019

supplied by Kirloskar Brothers Limited (KBL) has been designed with safety in

mind; where hazards cannot be eliminated, the risk has been minimized by the

use of guards and other design features. Some hazards cannot be guarded

against and the instructions below MUST BE COMPLIED WITH for safe

operation. These instructions cannot cover all circumstances. It is the

responsibility of the user of the equipment for maintaining safe working

practices at all times. The pumps are supplied with stickers for hazard, caution

and safety wherever these are applicable.

2.1.1 Within the manual, safety instructions are marked with safety symbols.

Hazard.

This symbol refers to general mechanical aspects of safety.

Hazard.

This symbol refers to electrical safety.

This symbol is used to introduce safety instructions whose nonObservance may lead to damage to the machine and its functions.

2.1.2 KBL products are designed for installation in designated areas, which are to

be kept clean and free of obstructions that may restrict safe access to the

controls and maintenance access points.

Pump name plate is fitted to each unit and must not be removed. Loss of

this plate could make identification impossible. This in turn could affect

safety and cause difficulty in obtaining spare parts. Should accidental loss or

damage occur, contact KBL immediately.

2.1.3 Access to the equipment should be restricted to the personnel responsible

for installation, operation and maintenance and they must be trained,

adequately qualified and supplied with the appropriate tools for their

respective tasks.

2.1.4 KBL firmly insists that all personnel responsible for installation, operation and

maintenance of the equipment must read the manual before any work is

done.

2.1.5 Ear defenders should be worn where the specified equipment noise level

exceeds locally defined safe levels. Safety glasses or goggles should be

worn where working with pressurized systems and hazardous substances.

Other personal protection equipment must be worn where local rules apply.

2.2

could catch on the controls or becomes trapped in the equipment.

DO NOT wear loose or frayed clothing or jewellery, which

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 12 LAST REV. DATE: 01.08.2019

2.3 Operation of the equipment for the application other than for which it is

supplied can increase the risk from hazards. Please consult KBL before

making such change in the application of the equipment.

2.4 Improper installation, operation and maintenance of the product supplied by

KBL could result in injury or death.

2.5

In case of GK(P)CLM pumps which are handling fluid at very

high temperature, the operator should avoid touching the pump in running

condition.

while operating GK(P)CLM pumps meant for High temperatures.

Use safety equipments like hand gloves and safety shoes

2.6 Transport handling and storage instructions:

2.6.1 Transport.

Pumps are dispatched in duly assembled condition. Lubricating oil in the

bearing housing is drained prior to dispatch of pump. Pumps are protected against

corrosion and packed for transport by normal road, rail and sea carriers.

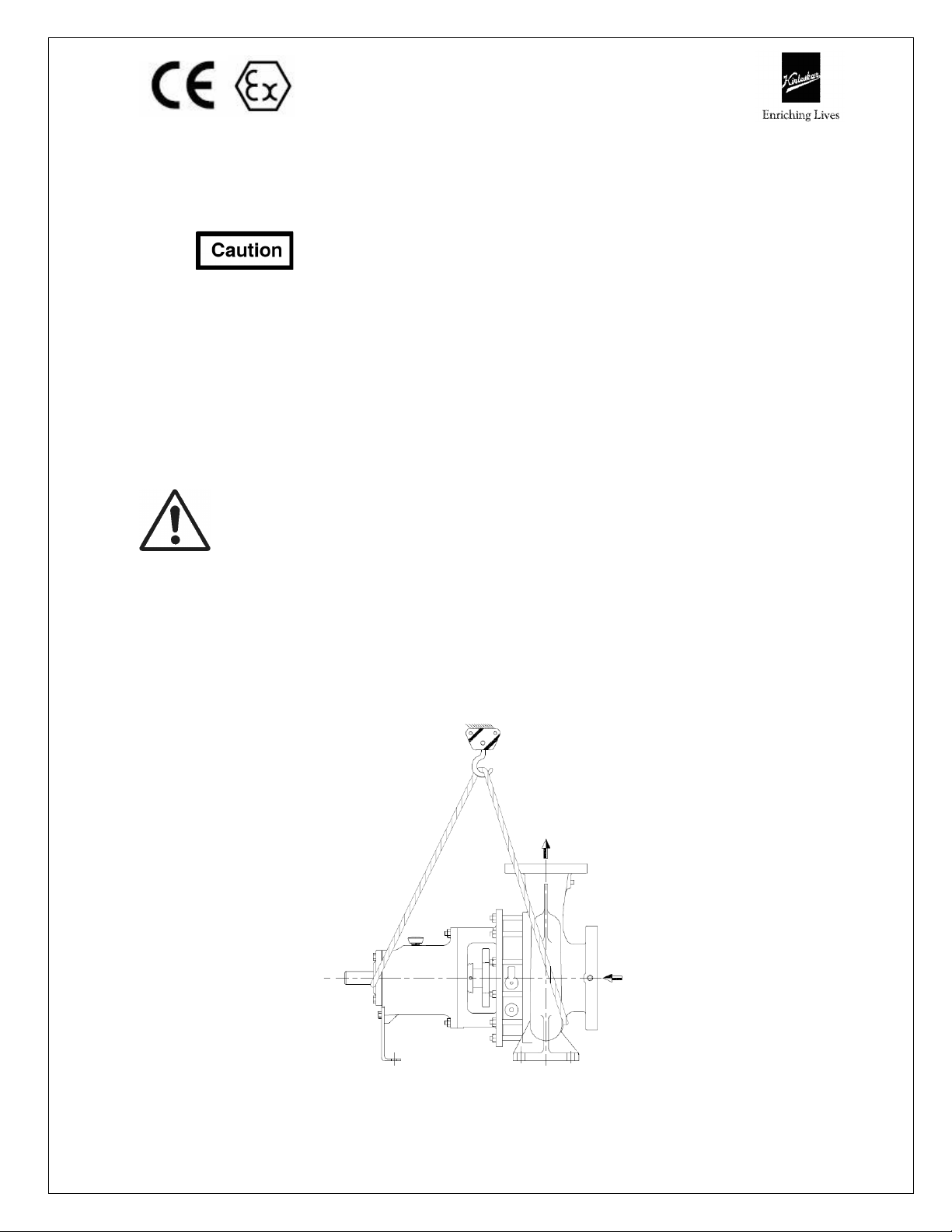

2.6.2 Handling

Crushing hazard

When lifting the pump or pump set, use lifting equipment having a safe working

load rating suitable for the weight specified. Use suitable slings for lifting any pump

not provided with lifting points.

The use of suitable forklift truck and four chain crane sling equipment is

recommended but locally approved equipment rating may be used.

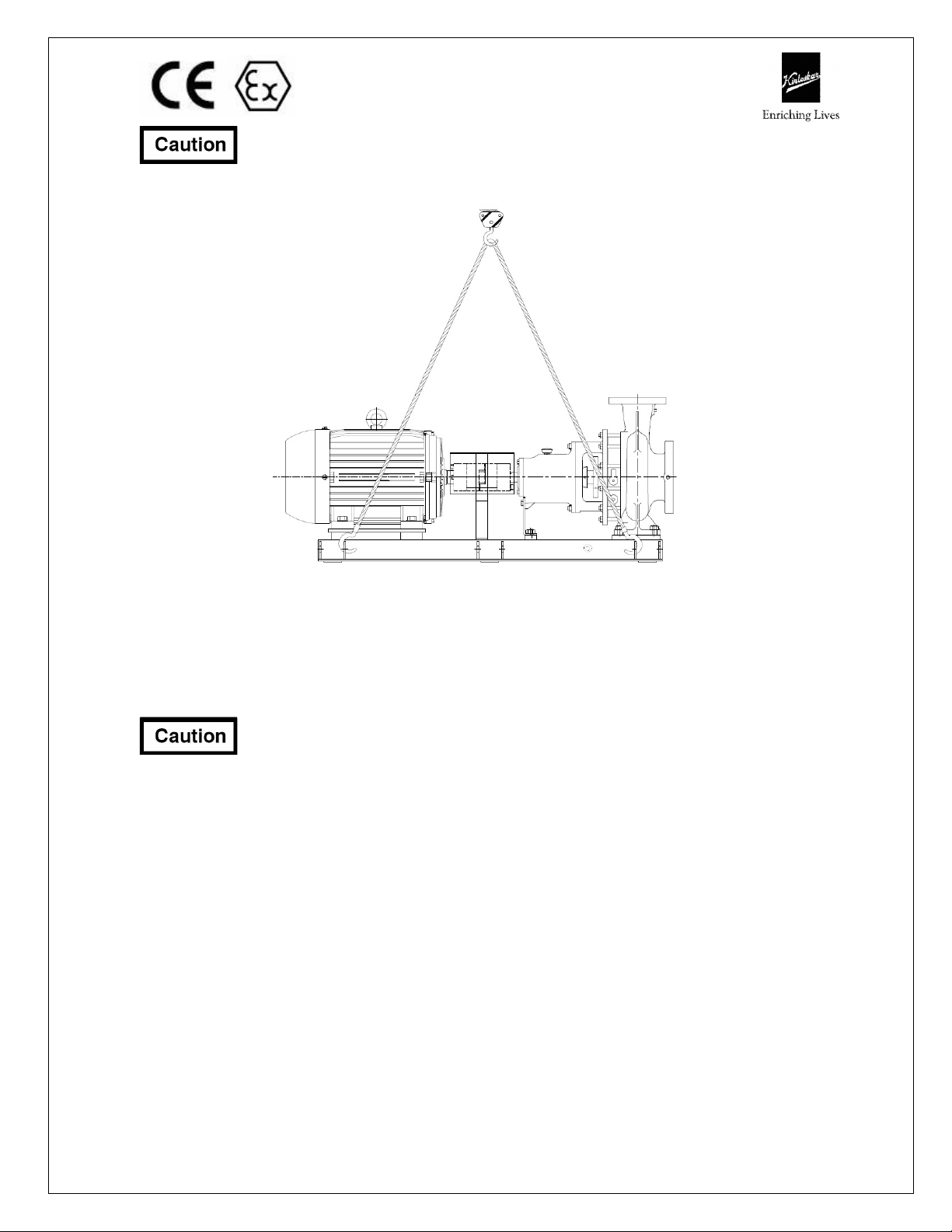

Pump should be slung as shown.

Lifting of bare shaft pump

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 13 LAST REV. DATE: 01.08.2019

Pump set must be lifted from the lifting holes provided using suitable four chain

lifting equipment.

Lifting of Pump set

2.6.3 Storage.

2.6.3.1 Temporary storage for up to six weeks.

If the pump unit is not to be used immediately it should be stored carefully in a

horizontal position, in a sheltered, dry location.

Additional rust preventive should be applied to all unpainted carbon

steel or cast iron parts and should not be removed until final installation.

2.6.3.2 Long Term Storage.

If the pump is not to be installed and operated soon after arrival, store it in a clean,

dry place, having slow, moderate changes in ambient temperature. Step should be

taken to protect the pump from moisture, dust, dirt, and foreign bodies. It is

recommended that the following precautions to be taken:

a) Ensure that the bearings are packed with the recommended grease, to prevent

moisture from entering around the shaft.

b) Remove the glands, packings and lantern rings from the stuffing box if the pump

is equipped in this manner. If the pump is equipped with mechanical seal,

dismantle and coat the seal with light oil.

c) Ensure that suction and discharge branches of the pump and all other openings

are covered with cardboard, wood or masking tape to prevent foreign objects

entering the pump.

d) If the pump is to be stored where there is no protective covering, it is advisable

to cover the unit with a tarpaulin or other suitable covering.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 14 LAST REV. DATE: 01.08.2019

e) The pump shaft should be manually rotated periodically to prevent pitting of the

bearing surfaces due to moisture.

Shearing Hazard

DO NOT place fingers or hands etc., into the suction or discharge pipe outlets

and do NOT touch the impeller, if rotated this may cause severe injury. To prevent

ingress of any objects, retain the protection covers or packaging in place until

removal is necessary for installation. If the packaging or suction and discharge

covers are removed for inspection purposes, replace afterwards to protect the

pump and maintain the safety.

Fill the bearing housing with recommended oil to ensure that the shaft and bearings

remain rust free.

2.6.3.3 Exposed or Extreme Conditions Storage.

For exposed storage or extreme variants in atmospheric or environmental

conditions, please refer to KBL for special storage instructions to suit the conditions

acceptable.

3. Equipment schedule:

3.1 INSTALLATION:

3.1.1 For location, preparing foundation, installation, alignment, piping, general

maintenance, trouble shooting, etc., the instructions given in our publication

-’GENERAL INSTRUCTIONS FOR INSTALLATION, OPERATION AND

MAINTENANCE OF KIRLOSKAR CENTRIFUGAL PUMPS’ which is also

printed along with this booklet must be followed very carefully. If the pump

is drawing liquid from the vessel under vacuum, then vacuum equalizing

connection piping must be made as per instruction given in above

publication. The external sealing connection to the pump, if applicable, must

be made after installing and before commissioning the pump. Pump on hot

service must have final coupling alignment made with the unit at its

operating temperature.

3.1.2 Receiving pump

Upon receipt of the pump, a visual check should be made to determine if any

damage occurred during transit or handling. The main items to look for are:

a) Broken or cracked equipment, including base, motor or pump feet and

flanges.

b) Bent shaft.

c) Broken motor end bells, bent eyebolts or damaged boxes of motor.

d) Missing parts.

e) Pump shaft rotates freely.

Parts or accessories are sometimes wrapped individually or fastened to the

equipment. If any damage or losses have been incurred; promptly notify your

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 15 LAST REV. DATE: 01.08.2019

KBL representative, KBL Dealer and the transport company who delivered

the pump.

When unloading pump units, lift equally at four or more points from the

base.

DO NOT LIFT ONLY THE DRIVER OR PUMP.

3.1.3 Preparation

• Before installing the pump, clean the suction and discharge flanges

thoroughly.

• Remove the protective coating from the pump shaft.

• If the pump has been in storage and prepared for storage in the manner

outlined previously, remove all the grease from the bearings. The

bearings should then be flushed with carbon tetrachloride or kerosene

and relubricated. Make sure rust preventives on liquid wetted

components cleaned thoroughly prior to pump put into service. Failing to

this may result into hazardous condition by reaction with pumping media.

3.1.4 Location

• The pump should be installed as near the liquid source as possible, with

the shortest and most direct suction pipe practically. HIS Guidelines for

piping system arrangement should be followed for trouble free long life

service of pump.

• The pump should be installed with sufficient accessibility for inspection

and maintenance. Ample space and head room should be allowed for the

use of an overhead crane or hoist sufficiently strong to lift the unit.

• Make sure there is a suitable power source available for the pump driver.

If motor driven, electrical characteristics should be identical to those

shown on motor data / name plate.

3.1.5 Foundation

• The foundation should be strong enough to reduce vibrations and rigid

enough to avoid any twisting or misalignment.

• The foundation should be poured without interruptions to within 20 to

40 mm of the finished height. The top surface of the foundation should

be well scored and glued before the concrete sets. This provides a

bonding surface for the grout. Foundation bolts should be set in concrete

as shown in Foundation plan / General Arrangement drawing. Allow

enough bolt length for grout, shims, lower base plate flange, nuts and

washers. The foundation should be allowed to cure for several days

before the base plate is shimmed and grouted.

3.1.6 Base plate setting

• Use blocks and shims under base for support at foundation bolts and

midway between bolts, to position base approximately 25 mm above the

concrete foundation with studs extending through hole in the base plate.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 16 LAST REV. DATE: 01.08.2019

• By adding or removing shims under the base, level the pump shaft and

flanges. The base plate does not have to be leveled. Draw foundation

bolt nuts tight against base plate and observe pump and motor shafts or

coupling hubs for alignment.

• Check to make sure the piping can be aligned to pump flanges without

placing pipe strain on either flange.

• Grout base plate in completely and allow grout to dry thoroughly before

attaching piping to pump (24 hours is sufficient time with approved

grouting procedure).

3.1.7 Grouting procedure

Grout compensates for uneven foundation, distributes weight of unit and

prevents shifting. Use an approved, non-shrinking grout as follows, after

setting and leveling unit

• Build strong form around foundation to content grout.

• Soak top of concrete foundation thoroughly, then remove surface water.

• Base plate should be completely filled with grout and, if necessary, drill

vent holes to remove trapped air.

• After grout has thoroughly hardened, check the foundation bolts and

tighten if necessary.

• Check the alignment after the foundation bolts are tightened.

• Approximately 14 days after the grout has been poured or when the

Grout has thoroughly dried, apply an oil base paint to the exposed edges

of the grout to prevent from air and moisture coming in contact with the

grout.

3.1.8 Suction and Discharge Piping

When installing the pump piping, make sure to observe the following

precautions:

• Piping should always run to the pump. Do not move pump to pipe. This

could make final alignment impossible.

• Both suction and discharge piping should be supported independently and

close to pump so that no strain is transmitted to the pump when the

flange bolts are tightened.

• Use pipe hangers or other supports at necessary intervals to provide

support. When expansion joints are used in the piping system, they must

be installed beyond the piping supports close to the pump.

• It is advisable to increase the size of both suction and discharge pipes at

the pump connection to decrease the loss of head from friction.

• Install piping as straight as possible, avoiding unnecessary bends. Where

necessary, use long sweep 90 degrees bend to decrease friction losses.

• Make sure that all piping joints are air tight. Provide pipe expansions

bellows when hot fluids are to be pumped. Where reducers are used,

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 17 LAST REV. DATE: 01.08.2019

eccentric reducers are to be fitted in suction lines and straight taper

reducers in discharge and vertical lines.

• Misuse of reducers may cause the formation of air pockets in the pipe

and thus preventing the correct operation of the pump.

• The suction pipe should be as short & direct as possible. Where suction

lift is not very high, it is advisable to use a foot valve. Horizontal suction

line must have a gradual rise to the pump.

• The discharge pipe is usually preceded by a non-return valve or check

valve and a discharge gate valve. The check valve is to protect the pump

from excessive back pressure and reverse rotation of the unit and to

prevent back flow into the pump in case of stoppage or failure of the

driver. The discharge valve is used in priming, starting and when shutting

down the pump.

3.2 MOUNTING AND ALIGNMENT

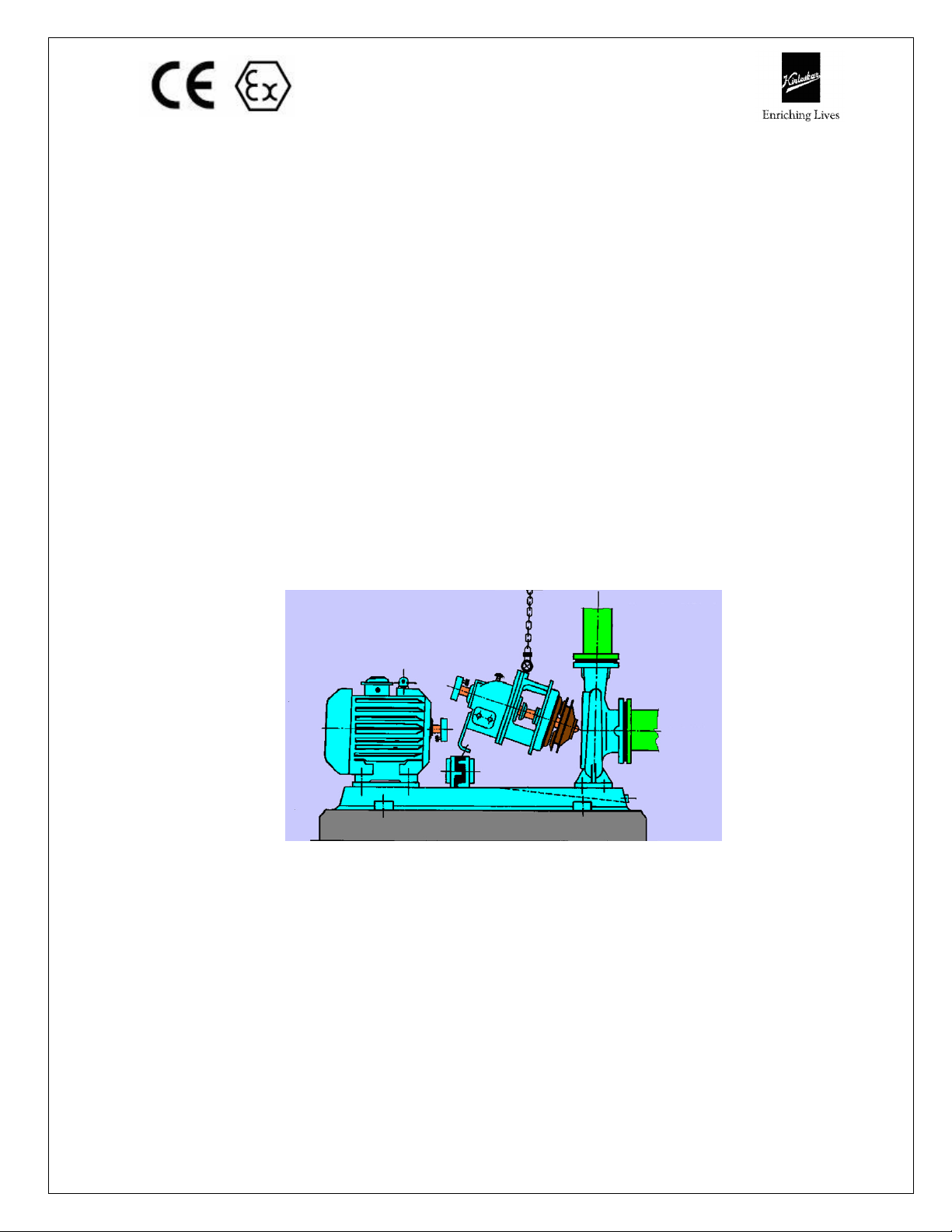

A spacer type flexible coupling is used to connect pump shaft to the driver.

By using spacer type of coupling, the complete rotating unit can be removed

from the volute without removing pump casing or rotor and without

disconnecting piping connections. This also avoids any realignment of pump

and motor after re-assembly of rotating unit. However, other types of

coupling can be supplied against request.

Back pull out assembly of GK(P) pump

3.2.1 ALIGNMENT

The pump driver, if supplied, is correctly aligned on its base plate at the

factory. A certain amount of deformation of the base plate is possible during

transit and it is therefore essential to check alignment, prior to final grouting.

A flexible coupling will only compensate for small amount of misalignment

and should not be used to compensate for excessive misalignment of the

pump and driver shafts.

Inaccurate alignment results in vibration and excessive wear on the bearings,

sleeve or shaft and wear rings.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 18 LAST REV. DATE: 01.08.2019

ALWAYS REMEMBER “A FLEXIBLE COUPLING IS NOT A UNIVERSAL

JOINT”

Correct alignment is essential for the smooth operation of the pump. There

are two types of misalignment between the pump shaft and the drive shaft,

which are:

1) Angular misalignment – shaft with axis concentric, but not parallel.

Maximum allowable misalignment is 1°.

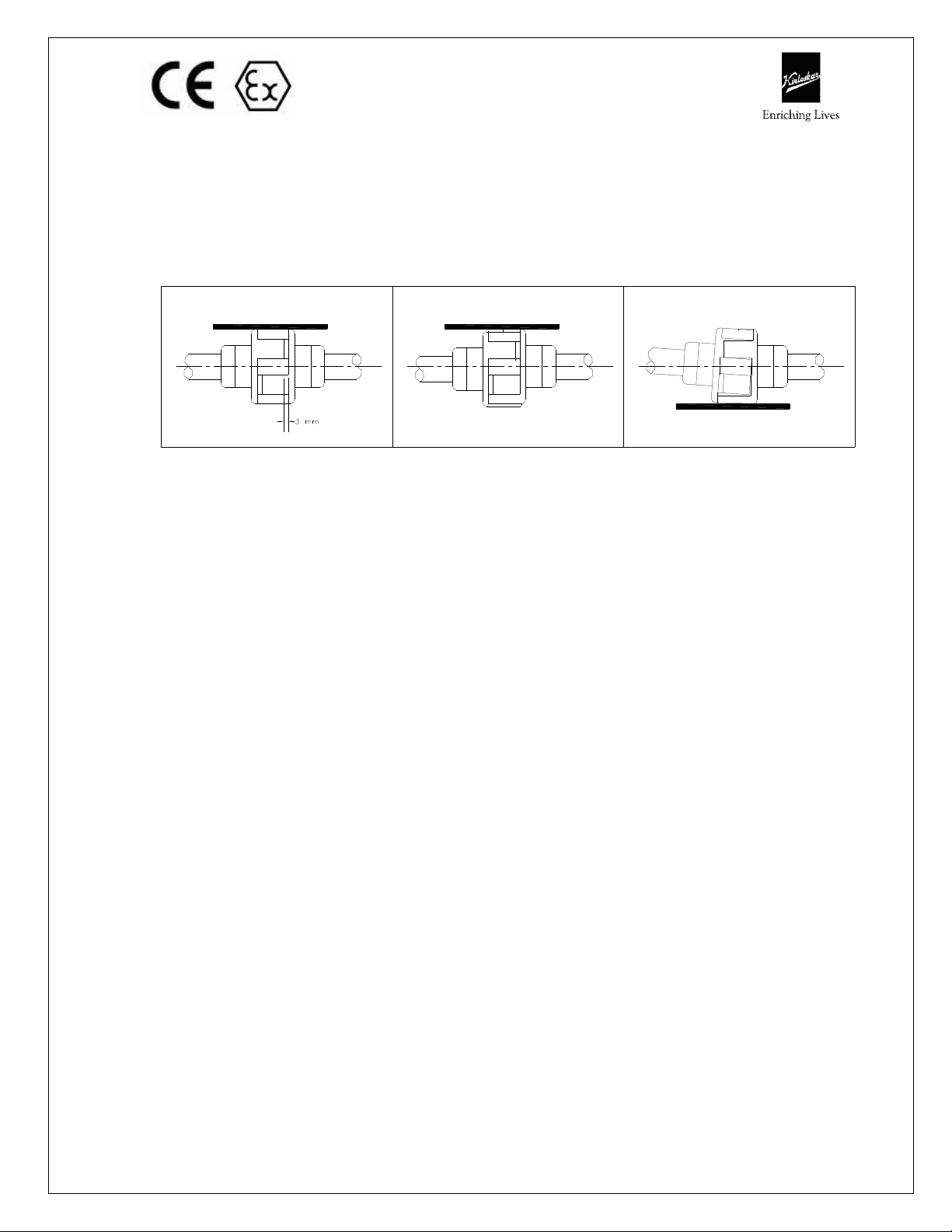

STEEL STRAIGHT EDGE

CORRECT

Checking coupling alignment with straight edge

STEEL STRAIGHT EDGE

INCORRECT PARALLEL

MISALIGNMENT

2) Parallel misalignment – shaft with axis parallel, but not concentric.

Maximum allowable misalignment is 0.1 mm.

This misalignment is checked by using a straight edge as shown in Figure

given above. Coupling alignment can be checked with dial gauge Indicator.

Alignment should be performed after the base plate has been properly set

and grout has dried thoroughly according to instructions. Final alignment

should be made by shimming under driver side only.

Alignment should be made at operating temperatures.

After final alignment, it is necessary to dowel pump and driver feet to the

baseplate.

FACTORS THAT MAY DISTURB ALIGNMENT

The unit should be periodically checked for alignment. If the unit does not

stay in line after being properly installed, the following are possible reasons:

a) Setting, Seasoning of the foundation.

b) Pipe strains, distorting or shifting of the machines.

c) Wear of the bearings.

3.2.1.1 Before commissioning the pump set, please ensure:

A) The pipe connections are flushed and tightened properly.

B) Alignment is proper.

C) Auxiliary piping connections such as sealing connections, cooling

connections, etc., are made. Details of sealing liquid are given in our

supply order.

Please refer to Figure given below for plugs and piping connections.

INCORRECT ANGULAR

MISALIGNMENT

STEEL STRAIGHT EDGE

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 19 LAST REV. DATE: 01.08.2019

H Air b

reather cap.

On beari

ng housing top.

J1 - St. box jacket he

ating steam inlet.

Casing cover top left.

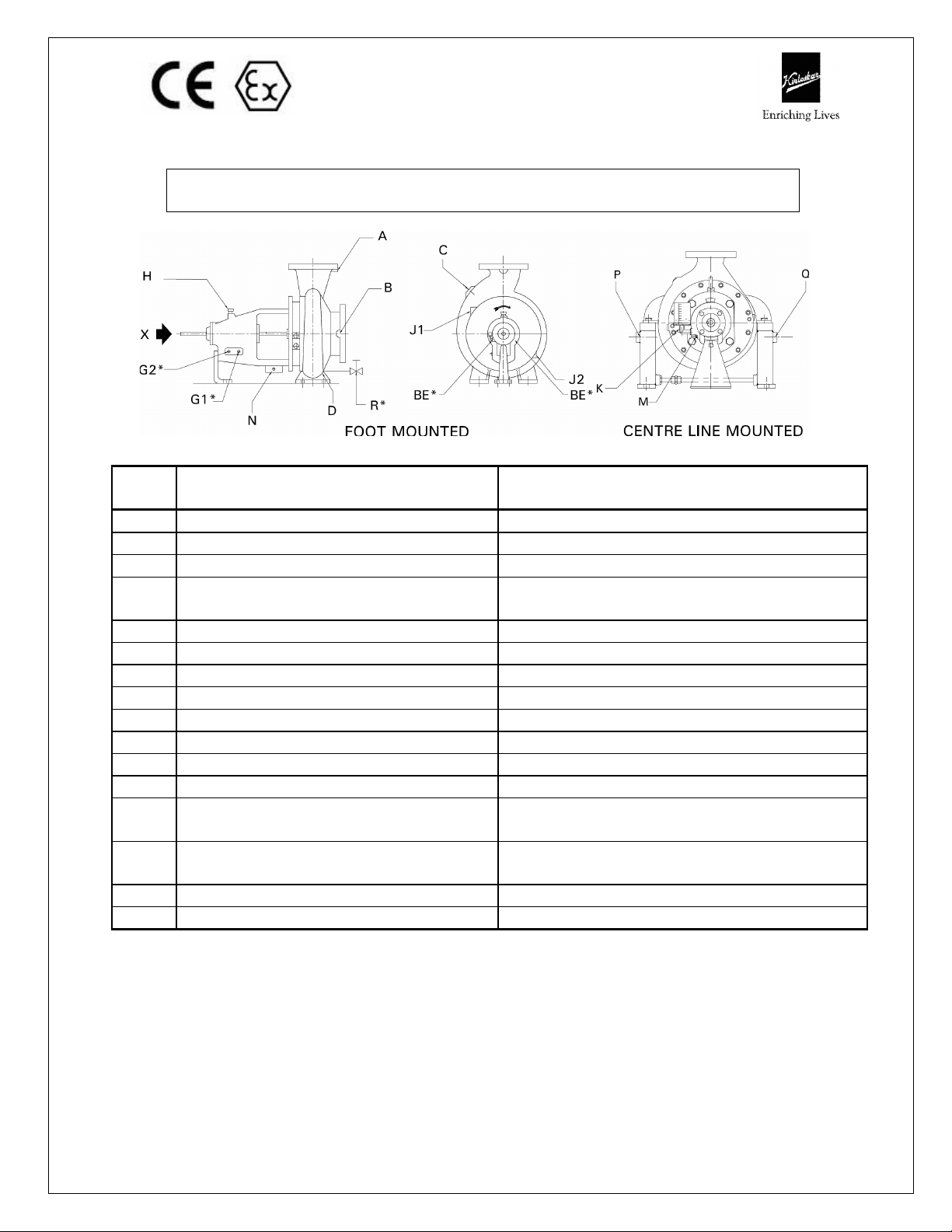

Code Description Location of connection when viewed from

A Gauge connection discharge side. On pump discharge flange.

B Gauge connection suction side. On suction flange right.

C Flushing line connection. On casing top left.

D Pump casing drain. On pump casing bottom side towards

G1* Bearing housing cooling water inlet. On bearing housing right.

G2* Bearing housing cooling water outlet. On bearing housing right.

GK(P) PUMPS – TAPPINGS CONNECTIONS CHART

driving end

suction.

J2 - St. box jacket heating steam outlet. Casing cover bottom right.

K Constant level oiler. On bearing housing left.

M Bearing housing oil drain. On bearing housing left.

N* Drip pan drain. On bearing housing bottom right.

P Pad cooling water inlet for centre line

mounted pumps.

Q

Pad cooling water outlet for centre

line mounted pumps.

On pad for centre line mounted pump

casing.

On pad for centre line mounted pump

casing.

R* For drain cock and piping. On pump casing bottom.

BE* For bulls eye indicator. On bearing housing both sides.

*

This special provision on request / application requirement only.

– Will be applicable only for jacketed pump.

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 20 LAST REV. DATE: 01.08.2019

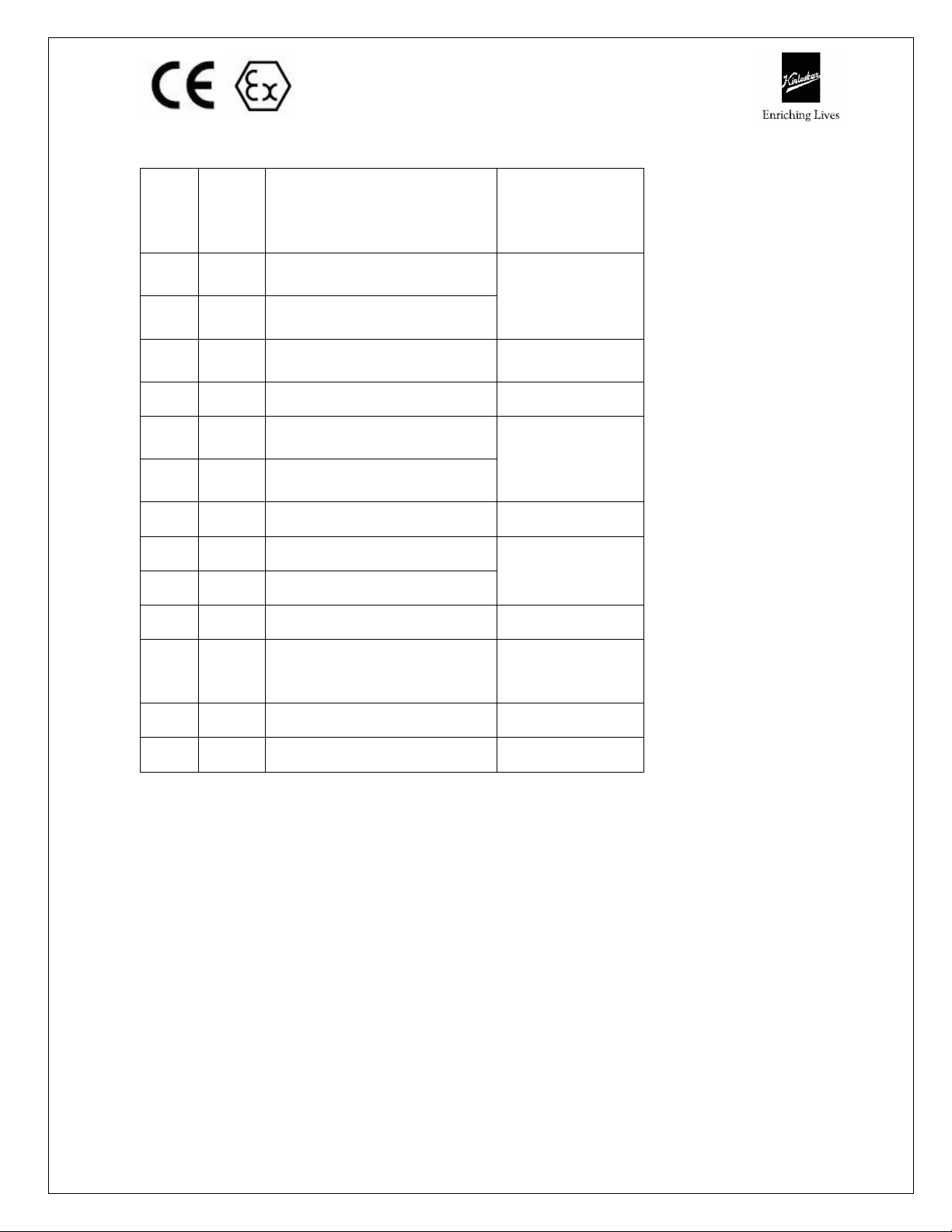

Tapping size details for GK(P) pump:

SR.

NO.

CODE

DESCRIPTION

OF

PIPE

CONN

1 A

2 B

3 C

Gauge connection

discharge side.

Suction Gauge / Vacuum

equalising connection.

Flushing/Sealing conn.

from pump casing.

CONNECTION

4 D Pump casing drain. 1/2

SIZE OF

1/4

1/4

5 G1*

6 G2*

Bearing housing cooling

water inlet.

Bearing housing cooling

water outlet.

1/2

7 H Air breather cap. 20 mm hole

8 K Constant level oiler.

1/4 BSP

9 M Bearing housing oil drain.

10 N* Drip pan drain. 1/2

11

P

Q

Pad cooling water for

centre line mounted pump

inlet & outlet.

1

12 R* Drain cock and piping. 1/2

13 BE* Bulls eye indicator. 1/2 BSP

Notes:

All tappings are in inches and location of connections are specified looking from

arrow “X”.

* This special provision on request / application requirement only and at extra cost.

All connections are NPT except specified.

3.2.1.2 CONSTANT LEVEL OILER

GK(P) pumps are oil lubricated as standard scope of supply. Pump is

provided with constant level oiler.

Procedure for standard KBL make constant level oiler is as given below.

For other than KBL make refer respective make work instruction supplied.

Fix the constant level oiler and fill the oil. Procedure for fitting the

constant level oiler and the method of filling oil is given below.

Constant level oiler has plastic container in Aluminium body as a

standard supply. Connection stem is ¼ inch BSP tapped and its capacity

IOM/GK(P)/CONICAL ISSUE DATE: 10.11.2015

Page 21 LAST REV. DATE: 01.08.2019

Loading...

Loading...