Page 1

Page 2

TR850 Service Manual

Contents

1. OVERVIEW ............................................................................................................................................... 1

COPE OF MANUAL .................................................................................................................................. 1

1.1. S

AFEY PRECAUTIONS .............................................................................................................................. 1

1.2. S

2. PRODUCT CONTROL S AND LE D INDICATOR INTRODUCTION ........................................................ 2

RODUCT CONTROLS .............................................................................................................................. 2

2.1. P

2.2. LED

INDICATOR ....................................................................................................................................... 3

3. CIRCUIT DESCRIPTION .......................................................................................................................... 3

3.1. RF

3.1.1.

CIRCUIT ............................................................................................................................................. 3

Tx Circuit .................................................................................................................................................................. 4

3.1.2. RF Power Amplifier Module Circuit .................................................................................................................... 5

3.1.3. Rx Module Circuit ................................................................................................................................................... 6

3.2. GPS CIRUIT ............................................................................................................................................ 8

ASEBAND SECTION ................................................................................................................................ 9

3.3. B

Circuit Descrip ti on .................................................................................................................................................. 9

3.3.1.

3.3.2. Power Section ....................................................................................................................................................... 11

3.3.3. Audio Processing ................................................................................................................................................. 14

3.3.4. Ethernet Interface ................................................................................................................................................. 15

3.3.5. Boot Mode .............................................................................................................................................................. 15

3.3.6. Hardware V ers ion Enc ode ................................................................................................................................. 16

3.3.7. Baseband Board Interf ace and Indicator ........................................................................................................ 17

3.3.8. Tx Unit Interface Definition (J17) ...................................................................................................................... 18

3.3.9. RF Power Amplifier Module Interface (J18) ................................................................................................... 19

3.3.10.Rx Unit Interface D efinition (J15) .................................................................................................................... 20

3.3.11.Front Panel Interface Definition (J19) ............................................................................................................. 22

3.3.12.Serial Port Defin ition (J23) ................................................................................................................................ 22

3.3.13.JTAG Simulator Interface Def in it io n ( J 2) ....................................................................................................... 23

3.3.14.External Inter fac e Definition (J9) ..................................................................................................................... 24

3.3.15.Case External Int er face Definition .................................................................................................................. 26

4. FUNCTION AND PARAMETER SETTING............................................................................................. 28

ONVENTIONAL FUNCTIONS ................................................................................................................... 28

4.1. C

ARAMETER SETTING ............................................................................................................................ 28

4.2. P

4.2.1.

Parameters setting ............................................................................................................................................... 29

4.2.2. Install CPSp user programming softw are ....................................................................................................... 29

5. ASSEMBLY A ND DISA SSEMBLY INSTRUCTION ............................................................................... 32

UPLEXER ASSEMBLY ............................................................................................................................ 32

5.1. D

ISASSEMBLY INSTRUCTION ................................................................................................................... 34

5.2. D

XPLODED VIEW .................................................................................................................................... 36

5.3. E

ONNECTION ......................................................................................................................................... 41

5.4. C

I

Page 3

TR850 Service Manual

6. ADJUSTMENT ........................................................................................................................................ 44

REPARATION ........................................................................................................................................ 44

6.1. P

6.2. M

6.2.1.

ETHOD OF MODULATION AND TEST ...................................................................................................... 44

Local Oscillator Adjustment ................................................................................................................................ 44

6.2.2. Tx Adjustment........................................................................................................................................................ 45

6.2.3. Rx Adjustment ....................................................................................................................................................... 47

7. MAIN TECHNICAL FUNCTIONS AND SPECIFI CATIONS ................................................................... 49

8. MAINTENA NCE A ND TEST EQUIPMENT ............................................................................................ 51

9. TROUBLESHOOTING ............................................................................................................................ 52

APPENDIX1 400-470MHZ UHF BAND SPARE PART LIST..................................................................... 55

ABLE1 PARTS LIST (RX MODULE SECTION) .................................................................................................. 55

T

ABLE2 PARTS LIST (TX MODULE SECTION) ................................................................................................... 65

T

ABLE3 PARTS LIST (POWER AMPLIFICATION SECTION) .................................................................................. 72

T

ABLE4 PARTS LIST (BASEBAND MAINBOARD) ................................................................................................ 76

T

ABLE5 PARTS LIST (FRONT PANEL) .............................................................................................................. 84

T

ABLE6 PARTS LIST (POWER BOARD) ............................................................................................................ 84

T

ABLE7 PARTS LIST (ACCESSORY BOARD) ..................................................................................................... 85

T

IGURE 1 RX MODULE TOP BOARD PCB VIEW............................................................................................... 86

F

IGURE 2 RX MODULE BOTTOM BOARD PCB VIEW ........................................................................................ 87

F

IGURE 3 TX MODULE TOP BOARD PCB VIEW ............................................................................................... 88

F

IGURE 4 POWER AMPLIFIER MODULE TOP BOARD PCB VIEW ....................................................................... 88

F

IGURE 5 POWER AMPLIFIER MODULE BOTTOM BOARD PCB VIEW ................................................................ 89

F

IGURE 6 BASEBAND MAINBOARD TOP BOARD PCB VIEW ............................................................................. 90

F

IGURE 7 BASEBAND MAINBOARD BOTTOM BOARD PCB VIEW ....................................................................... 91

F

IGURE 8 FRONT PANEL TOP BOARD PCB VIEW ............................................................................................ 92

F

IGURE 9 FRONT PANEL BOTTOM BOARD PCB VIEW ..................................................................................... 92

F

IGURE 10 POWER BOARD TOP BOARD PCB VIEW ........................................................................................ 93

F

IGURE 11 ACCESSORY BOARD TOP BOARD PCB VIEW ................................................................................. 94

F

IGURE 12 ACCESSORY BOARD BOTTOM BOARD PCB VIEW .......................................................................... 94

F

IGURE 13 RX MODULE SCHEMATIC DIAGRAM ............................................................................................... 95

F

IGURE 14 TX MODULE SCHEMATIC DIAGRAM ............................................................................................. 102

F

IGURE 15 POWER AMPLIFIER MODULE SCHEMATIC DIAGRAM ..................................................................... 107

F

IGURE 16 BASEBAND MAINBAORD SCHEMATIC DIAGRAM ............................................................................ 110

F

IGURE 17 FRONT PANEL SCHEMATIC DIAGRAM........................................................................................... 125

F

IGURE 18 POWER BOARD SCHEMATIC DIAGRAM ........................................................................................ 126

F

IGURE 19 ACCESSORY SCHEMATIC DIAGRAM ............................................................................................. 127

F

APPENDIX2 136-174 MHZ VHF BAND SPARE P A RT LI ST .................................................................. 128

ABLE 1 PART LIST(RX MODULE SECTION) .................................................................................................. 128

T

ABLE 2 PART LIST(TX MODULE SECTION) .................................................................................................. 145

T

ABLE 3PART LIST(POWER AMPLIFICATION MODULE SECTION) ..................................................................... 151

T

II

Page 4

TR850 Service Manual

TABLE 4 PART LIST(BASEBAND BOARD) ....................................................................................................... 155

ABLE 5 PART LIST(FRONT COVER) ............................................................................................................. 163

T

ABLE 6 PART LIST(POWER BOARD) ............................................................................................................ 163

T

ABLE 7 PART LIST(ACCESSORY BOARD) ..................................................................................................... 164

T

IGURE 1 RX MODULE TOP BOARD POSITION MARK DIAGRAM ...................................................................... 165

F

IGURE 2 RX MODULE BUTTOM BOARD POSITION MARK DIAGRAM ............................................................... 166

F

IGURE 3 TX MODULE TOP BOARD POSITION MARK DIAGRAM ...................................................................... 167

F

IGURE 4 POWER AMPLIFIER MODULE TOP BOARD POSITION MARK DIAGRAM .............................................. 167

F

IGURE 5 POWER AMPLIFIER MODULE BUTTOM POSITION MARK DIAGRAM ................................................... 168

F

IGURE 6 BASEBAND MAINBOARD TOP BOARD POSITION MARK DIAGRAM .................................................... 169

F

IGURE 7 BASEBAND MAINBOARD BUTTOM BOARD POSITION MARK DIAGRAM ............................................. 170

F

IGURE 8 FRONT PANNEL TOP BOARD POSITION MARK DIAGRAM ................................................................. 171

F

IGURE 9 FRONT PANNEL BUTTOM BOARD POSITION MARK DIAGRAM .......................................................... 171

F

IGURE 10 POWER BOARD TOP BOARD POSITION MARK DIAGRAM .............................................................. 172

F

IGURE 11 ACCESSORY BOARD TOP BOARD POSITION MARK DIAGRAM ........................................................ 173

F

IGURE 12 ACCESSORY BUTTOM BOARD POSITION MARK DIAGRAM ............................................................. 173

F

IGURE 13 RX MODULE SCHEMATIC DIAGRAM .............................................................................................. 174

F

IGURE 14 TX MODULE SCHEMATIC DIAGRAM ............................................................................................. 181

F

IGURE 15 POWER AMPLIFIER MODULE SCHEMATIC DIAGRAM ..................................................................... 186

F

IGURE 16 BASEBAND MAINBOARD SCHEMATIC DIAGRAM ............................................................................ 189

F

IGURE 17 FRONT PANNEL SCHEMETIC DIAGRAM ........................................................................................ 204

F

IGURE 18 POWER BOARD SCHEMETIC ....................................................................................................... 205

F

IGURE 19 ACCESSORY SCHEMATIC DIAGRAM ............................................................................................. 206

F

III

Page 5

TR850 Service Manual

1. Overview

1.1. Scope of Manual

This manual is intended for use by trained engineers and professional technicians for the maintenance

and repair of TR850 Repeater. Data changes in this manual may occur with the improvement of

technology. To get the latest technology information, please contact us or your l oc al d ist ributors.

Before repairing the unit, please read this manual.

1.2. Safey Precautions

Electromagnetic Radiation

Radios generate and radiate electromagnetic energy, the security design of Kirisun radios’

electromagnetic radiat ion on human meets national and international standards.

Electromagnetic Interference

Installation should be i n accordance with local radio regulations.

Explosive and Harmful Gases

Do not install the repeater in areas with explosive and harmful gases, such as the lower deck of the hull,

fuel or chemical storage faci lities, area where the air contains chemicals or particles, dust or metal dust.

Do not install the repeat er when close to the blasting area, electric blasti ng detonators.

Replacement Parts

When replacing any replacement part, please be aware of the model. Do not arbitrarily replace the

component that does not matc h with the radio.

1

Page 6

TR850 Service Manual

2. Product Controls and LED Indicator

Introduction

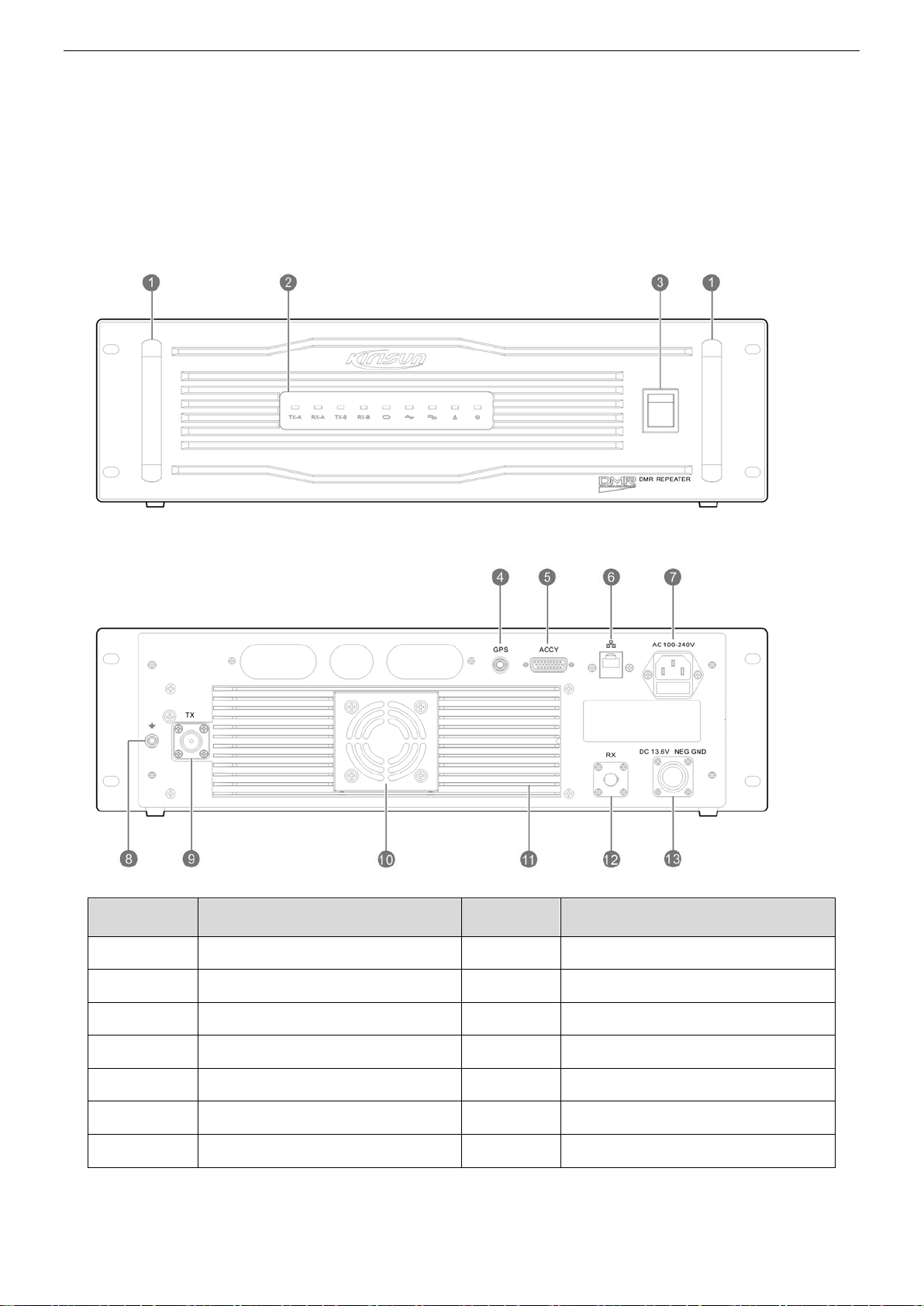

2.1. Product Controls

No. Part Name No. Part Name

1 Handle 2 Front Panel LED Indicator

3 Power Switch 4 GPS Atenna Co nnector

5 ACCY Connector 6 Internet Connector

7 AC Connector (with fuse) 8 Grouding Scew

9 Transmit Ante nna Connector (N) 10 Fan

11 Heat Sink 12 Receive Antenna Connector (BNC)

13 DC Connector - -

2

Page 7

TR850 Service Manual

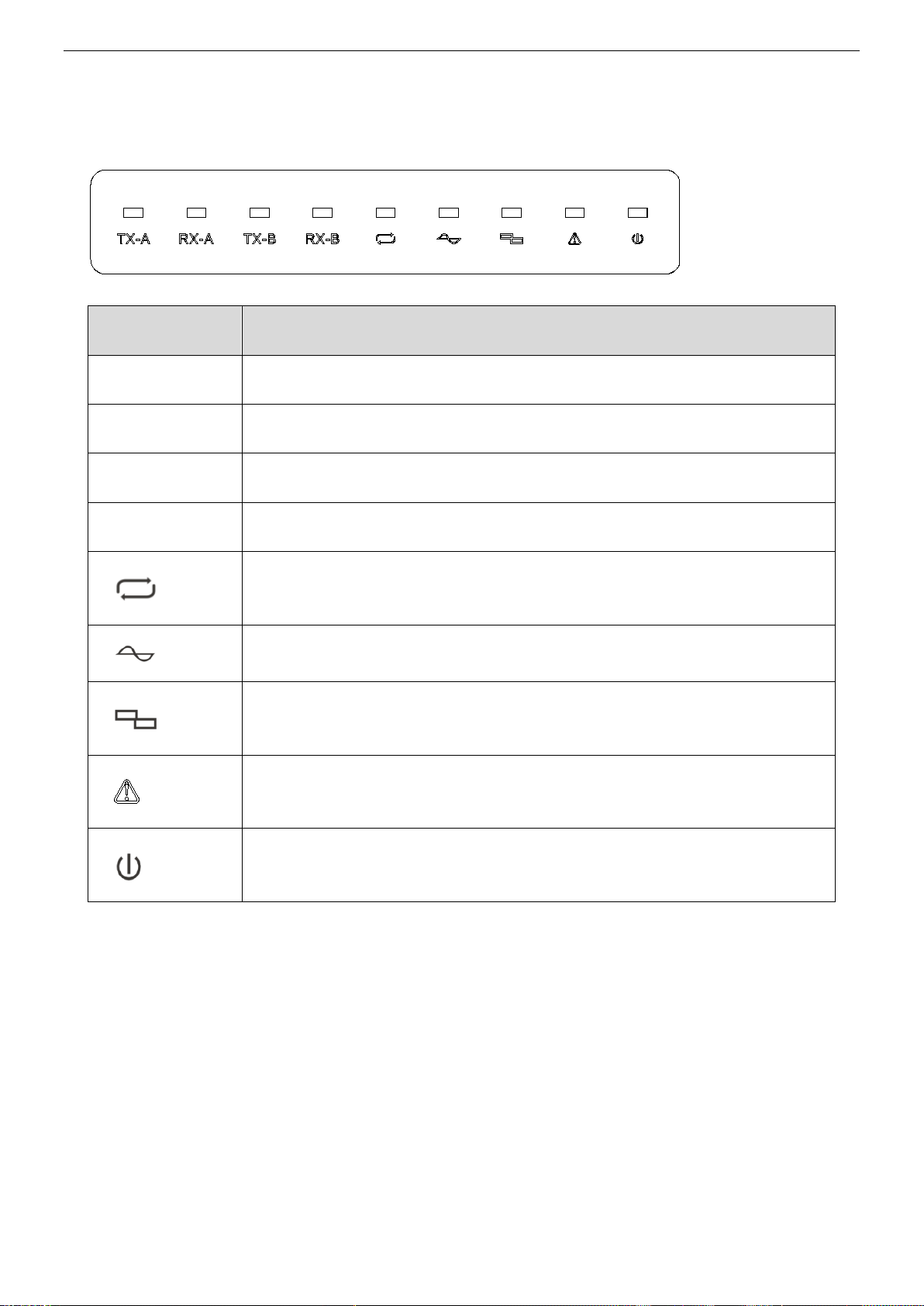

2.2. LED Indicator

LED Description

TX-A Indicates slot 1 is transmitting.

RX-A Indicates slot 1 is receivin g.

TX-B Indicates slot 2 is transmitting.

RX-B Indicates slot 2 is receivin g.

Repeater mode. When illuminated, the repeater is active. When the

repeater is inactive, the LED is o ff.

Analog mode. For analog or mixed signals the LED flashes when active.

The LED is off when inactive.

Digital mod e . F or di gi tal or m ix e d signals the LED flashes when active. The

LED is off when inactive.

Alarm mode. Illuminates when there is a problem with the repeater.

Illuminates when the repeater is switched on.

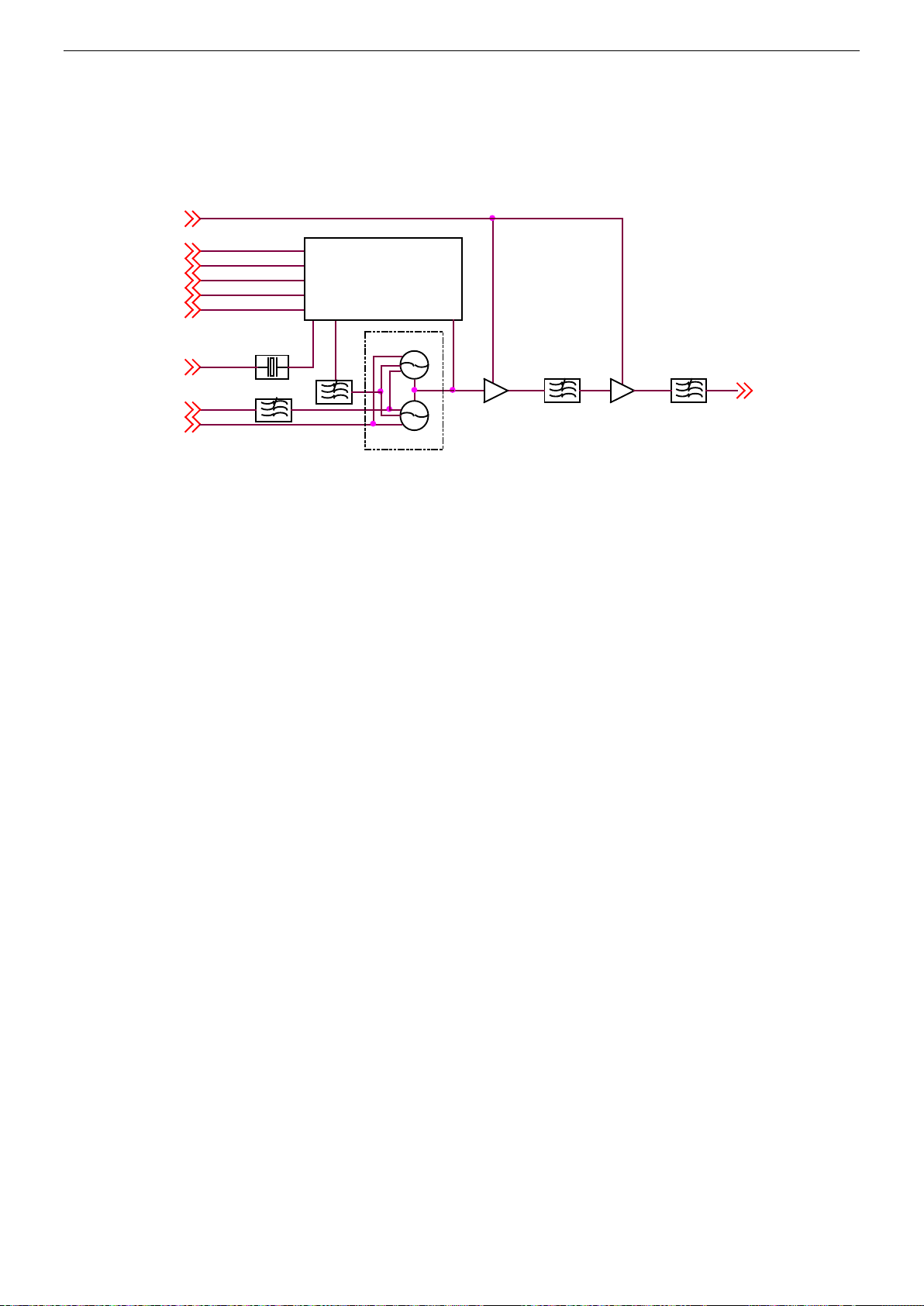

3. Circuit Description

3.1. RF Circuit

The RF part is compos ed of transmitter module, power amplifier mod ul e and receiver module.

3

Page 8

3.1.1. Tx Circuit

X100

MODE1

SDATA

TXPLLCS

SCLK

TXLD

MODEIN

Q2002

IC100 SKY72310

IC306

U402

TOTXPA

MODE2

TXVCOSELECT

TXVCO1+TXVCO2

Q105

Q106

TXENABLE

Figure 3-1 Transmitter Circuit

TR850 Service Manual

Transmitter circuit includes three parts:

Two Point Modulation Circuit

The RF center frequency cal ibrat ion from the baseband and the low frequency part of 4FSK signal will

be processed with addition algor it hm, then sent to the DAC to get MODE1 signal. The MODE1 directly

enters the reference cloc k X100, which is used for cent er frequenc y control a nd low fre quency modulation.

The MODE2 signal, which passes the two-level low pass filter which is composed of IC301s for DAC

sampling interference filter , will be sent into VCO for high frequency part modulation.

Transmitter Frequency Generation Unit Circuit

The transmitter PLL includes two VCOs,one PLL(IC100) IC SKY72310 and reference clock X100. The

transmitting frequencies of the two VCOs controlled by the TXVCOSELECT signal are 400~435M Hz a nd

435~470MHz respectively.(VHF is 136~ 155MHz and 155~174MHz)

a. Working Principle of Voltage Controlled Oscillator

The Tx Module employs two VCOs which cover the band of 400~435MHz and 435~470MHz (VHF is

136~155MHz and 155~174MHz). The switch of VCO is controlled by the TXVCOSELECT signal. VCO

employs thr ee point capac itanc e oscillation circuit. The VCO that c overs the band of 40 0~435M Hz (VHF is

136~155MHz) is composed of D106~D109、L119、Q106 and some other components, while the VCO

covers the band of 435~470MHz (VHF is 155~174MHz) is composed of D101~D104、L107、Q105 and

some other components .

The 12.8 MHz reference clock (X100) output signal which is controlled by MODE1 signal will enter the

reference input port of PLL IC (IC100 SKY72310), then according to the configuration of register, it will be

divided to get 3.2MHz reference frequency, and the frequency will be compared in phase difference with

the signal generated by t he frequenc y div ision which is resulted from the VCO’s enter into the input port of

PLL chip. The PLL (IC100 SKY72310) PD pin will output the positive or negative pulse current which is in

b. Working Principle of Frequency Generation Unit

output pulse width, is directly proportional to the aforementioned signal phase difference. When the pulse

4

Page 9

TR850 Service Manual

D103

SWR-R

IC100

POWERCONTROL

IC101

DS18B20

RFOUT

SWR-T

Q102

RF IN

U100

D104

current passes the loop f ilter, it will be converted to CV voltage via RC integral. The the CV voltage will be

sent to the VCO varactor to adjust and control the output frequency from the VCO until the CV voltage

becomes constant. The loop is locked in the meantime.

Buffer Amplifier Circuit

VCO outputs the modulated carrier signal to enter Q2002 for buffer amplication and then passes the LPF

U402 to eliminate the harmonic wave. A fter that, the signal will go into IC306 for pre-amplification, then

passes the LPF to filter the harmonic wave again, and the signal is output to the SMA connector which is

connected to the transmitt ing power amplification.

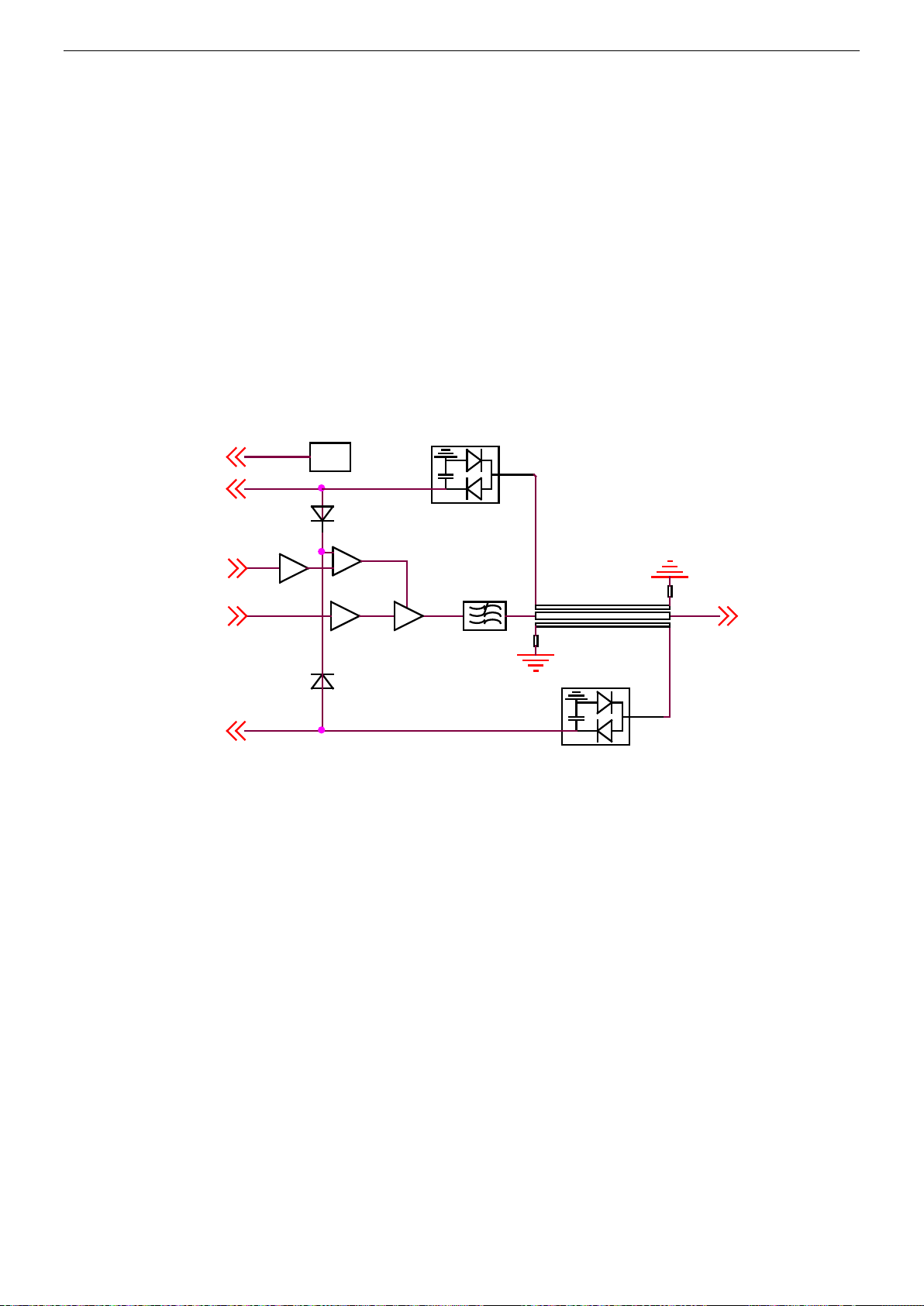

3.1.2. RF Power Amplifier Module Circuit

Figure 3-2 RF power amp lification module

The power amplifier module will amplify the modulated carrier signal from the transmitter module to a

certain power level, t hen send to the transmitter port.

The power amplifier modu le includes the three parts:

Power Amplification Part

The modulated carrier from the transmitter module will enter Q102 for pre-amplification, then the signal

will attenuate to a certain level to make the amplitude of the signal which will be input with U100 operates

between 17~20dBm. Under the control of POWERCONTROL signal, the RF signal output from U100 will

pass the LPF to suppress the harmonic wave and collect power stationary wave sample from the

directional coupler before being sent to the antenna port.

APC and Stat ion ar y Wave Protection Circuit

The directional coupler detects the forward and reverse directions RF signal and passes the Q103,Q104

to convert the signal to the DC voltage which is corresponding to the forwardand reverse direction power.

After the voltage division, the forward direction DC voltage with the reverse direction voltage pass the

selection switch which is composed of D201,D202 and enter IC100(NJM2904) for buffer amplification

before being sent to the reverse phase input port of the operational amplifier of IC100(NJM2904). The

5

Page 10

TR850 Service Manual

IC6003

FS

DATAOUTB

CLK

DATAOUTA

IC6001

AD9864SYNCB

IC1000

Q1009/1011

U5002

Q2002

PD

PC

PE

PLL

PLL CONFIG

12.8MHz

BPF AD J U ST

IC3000

L3006/8/9

L3000/1/2

Z3001

IC3005

L3010/11/12

Z3000

Q3001/2

U4000 AD9864

2rd LO

18MHz CLOCK

IC3003

RXVCOSELECT

POWERCONTROL control signal form the baseband will be sent to the identical phase input port of

IC100(NJM2904)’s operational amplifier. After the operational amplification and external circuit’s function

calculation, the signal is output as a conrol signal which controls the U100 gain control port to ensure that

the actual output power remains stable when the impedance matches and to decrease the output power

for power amplifier protection when the impedanc e mismatches.

Temperature Detection Circuit

The continuous temperature rise can lead to a decrease of transmitting power. The temperature detection

employs IC101(DS18B20) to collect the digital temperature sample.W hen the temperature exceeds the

threshold value, the fan wi ll be switched on for heat dissipation.

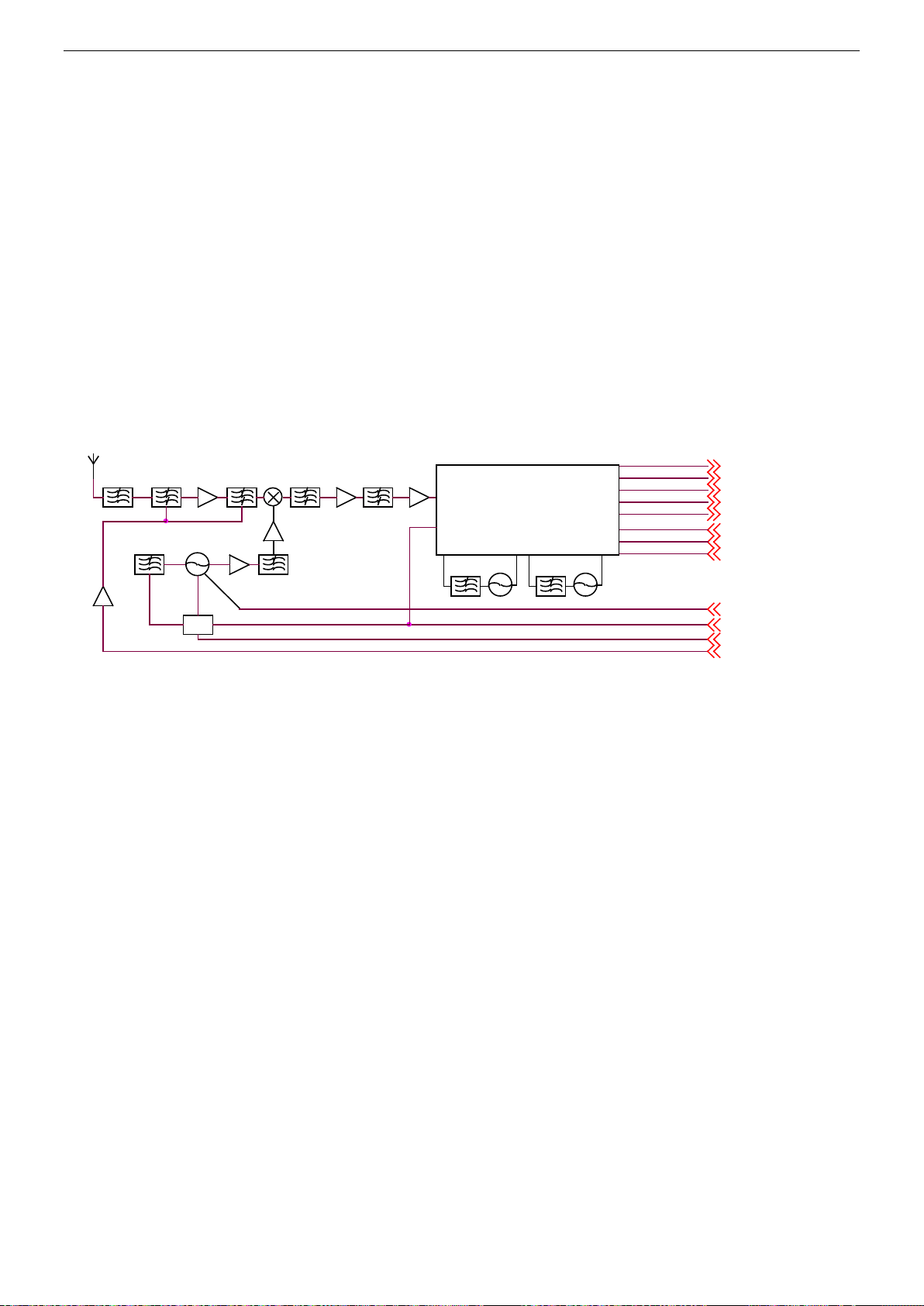

3.1.3. Rx Module Circuit

Figure 3-3 Receiver Module

Receiver Circu it

The receiver circuit includes RF Band pass filter, Low-noise amplifier, mixer, IF filter, IF ampli fier and IF

processor.

The signal from the receiving port first passes the low pass filter to suppress the high frequency

interference, and passes the electrical tuning BPF to suppress the image interference and the out-band

interference.The in-band signal is sent to the low noise amplifier (IC3000) and the amplified signal passes

the electrical tuning BPF contr olled by BPFADJUST to filter t he out-ba nd interf erence, so the ef fect ive high

frequency will be sent to the mixer(IC3005). Meanwhil e, the first loc al oscillation passes the LPF and gets

mixed with the effective signal in IC3005 to generate the first IF signal (51.65MHz). The first IF signal

passes the crystal filter (Z3001) to suppress the out-band signal. The signal is then sen t to IF amplif ier

(IC6003) for amplification before being sent to the crystal filter to strenghthen the suppression of the the

adjacent channel. After being sent to the limiting amplifier composed of Q3001 and Q3002, the signal

enters AD9864 (U4000) for the second freq uency mixing ,IF amplification and AD sampli ng. The digital IQ

signal will be finally output to the baseband for further processing.

6

Page 11

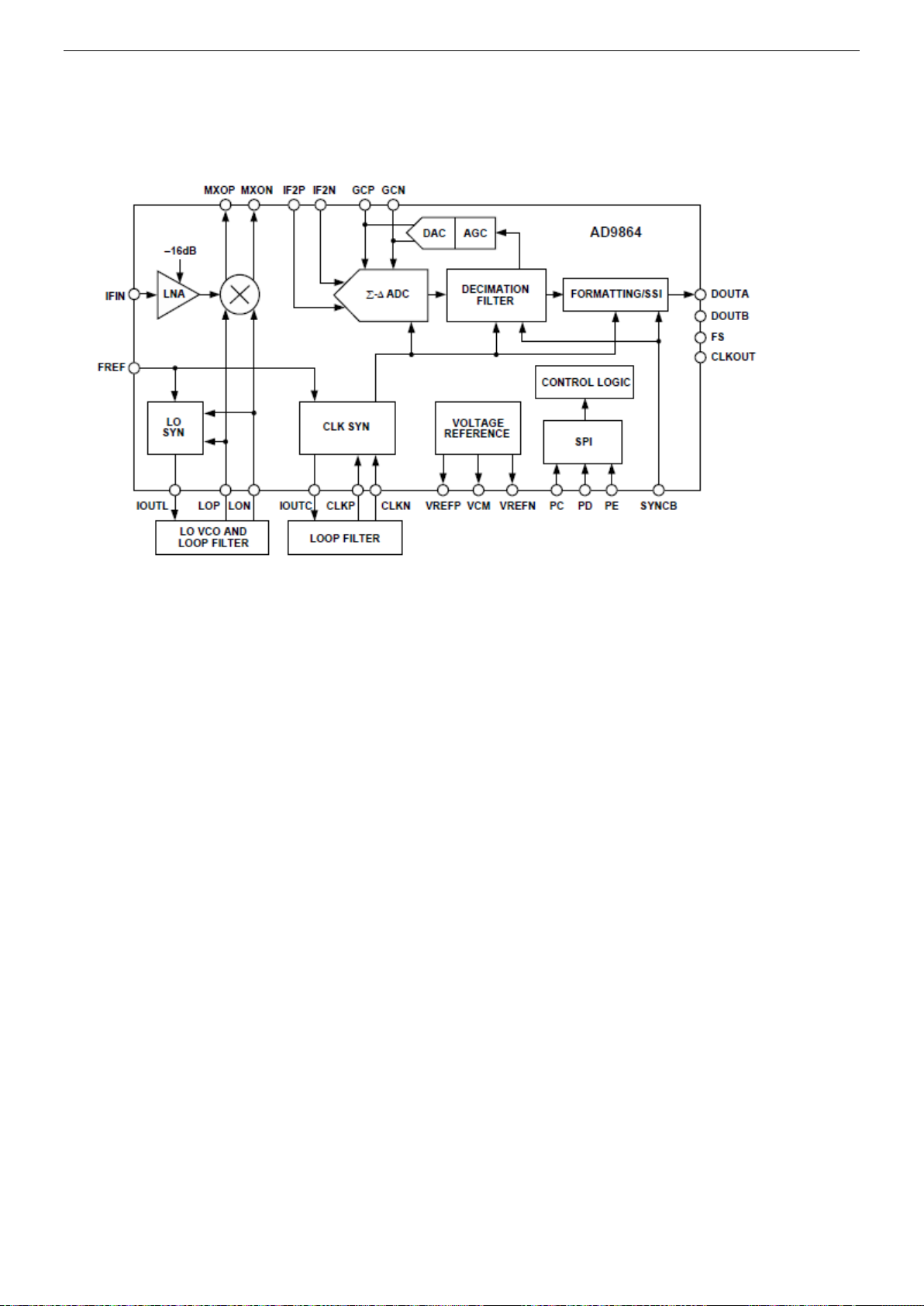

IF Processor Circuit

Figure 3-4 IF Processor

TR850 Service Manual

The 51.65MHz IF signal output from the IF amplifier enters the AD9864 via its pin 47, and it finishes the

second frequency mixing in the AD9864 to convert the fisrt IF to the second IF. The second IF signal is

converted to the digital signal through the ADC sampling and output from the SSI port, and the digital

signal is sent to FPGA f or demodulation.

The reference frequency of AD9864 is 12.8MHz. The second local oscillation VCO is composed of

external oscillation tube, varactor, and related components. The VCO provides the 49.4MHz local

oscillation signal. The clock frequency of AD9864 is18MHz and it is generated by external LC resonance

circuit.

Rx Module Frequency Generation Unit C irc uit

The Rx Module Frequency Generation Unit Circuit is composed of two VCOs and one PLL. Two VCOs

cover the band of 400~435M Hz and 435~470MHz respectively (VHF is 136~155MHz and 155~174MHz).

a. Working Principle of PLL

The 12.8MHz clock frequency provided by the baseband will enter the frequency divider for division, and

then the 3.2MHz phase detecting frequency will be generated. The signal generated by VCO enters the

PLL chip for frequency division, and goes into the PD to get compared in phase difference with the signal

generated by frequency division of reference clock, thus the continuous pulse current is generated. The

continuous pulse current p asses t he loop filter and w ill be conv erted t o CV volt age via R C integral. The C V

voltage will be sent to the varactor, and it controls and adjusts the VCO output frequency until the CV

becomes constant. In the mean time, the PLL is locked, and the stable output frequency from VCO

passes the two buffer amplifier to enter the frequency mixer.

b. Working Principle of VCO

The Rx module employs two VCOs which cover the band of 348.35~383.35MHz and 383.35~418.35MHz

7

Page 12

TR850 Service Manual

(VHF is 84.35~103.35MHz and 103.35~122.35MHz) respectively, and the switch of VCO is controlled by

the RXVCOSELECT sign al. VCO employs three point capacitance oscillation circu it. The VCO that covers

the band of 348.35~383.35MHz (VHF is 84.35~103.35MHz) is composed of D1006~D1009、L1017、

Q1011 and some other components, while while t he VCO covers the band of 383.35~418.35MHz (VHF is

103.35~122.35MHz) is composed of D1002~D1005、L1016、Q1009 and some other components.

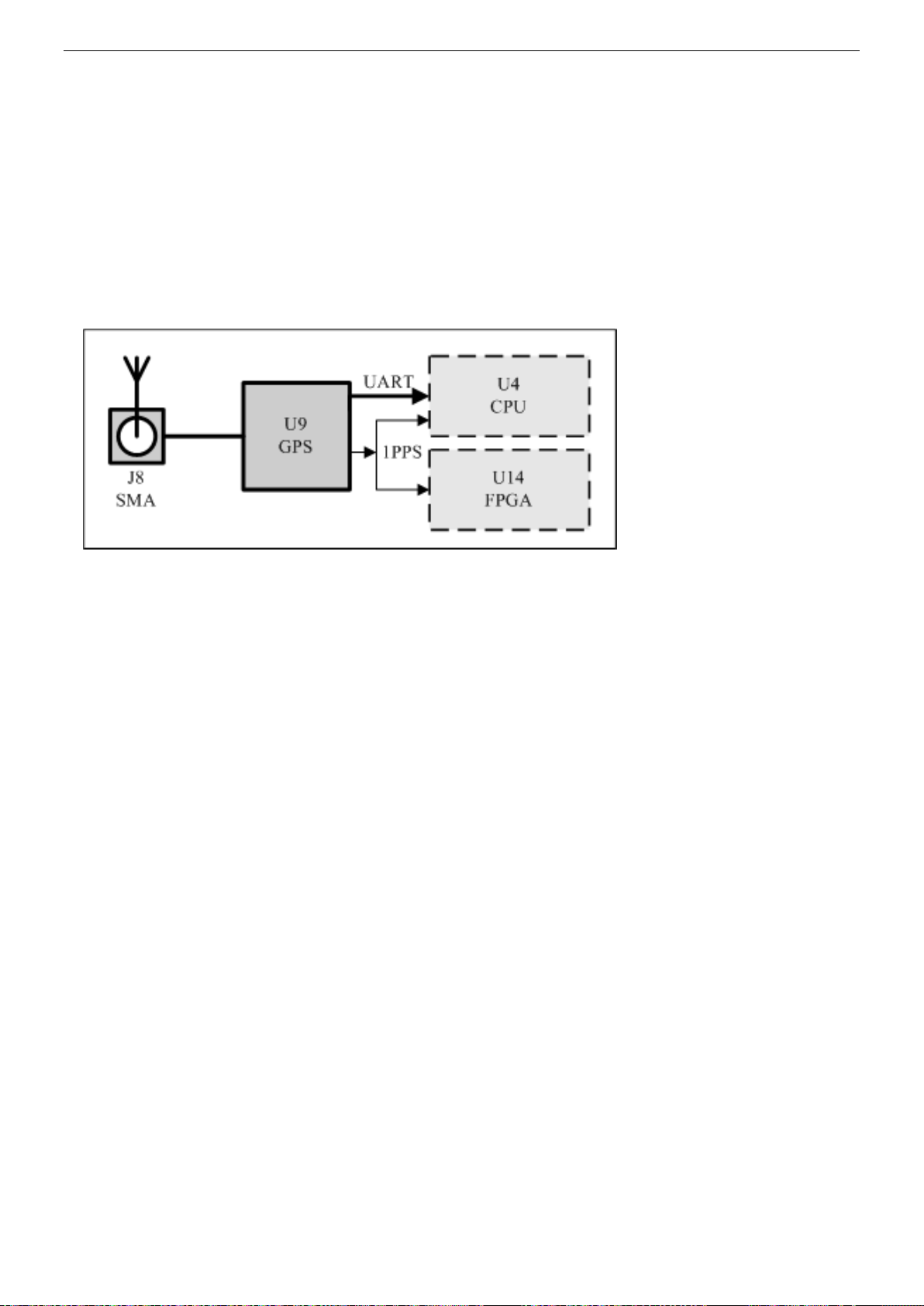

3.2. GPS Ciruit

Figure 3-5 GPS Schemat ic Diagram

As Figure 3-5 shows, the repeater baseband board includes the GPS module (U9) and the GPS an ten na

interface J8(SMA). The corresponding equipment box is also assembled with a GPS antenna interface

which supports the outdoor active antenna. The GPS module integrates a baseband processor, LNA and

SAW. The antenna receives the 1575.42M Hz GPS signal, a f ter t he inner a mpli ficati on and fi lter proce ss , it

will be sent to the baseband section for further calculating, to get the geographical location and time

information of the equipment. The output data information will be sent to processor (U4). M eanwhi le , the

GPS module hardware will provide the one-pulse-per-second signal (1PPS) for OMAP and FPGA

respectively.

8

Page 13

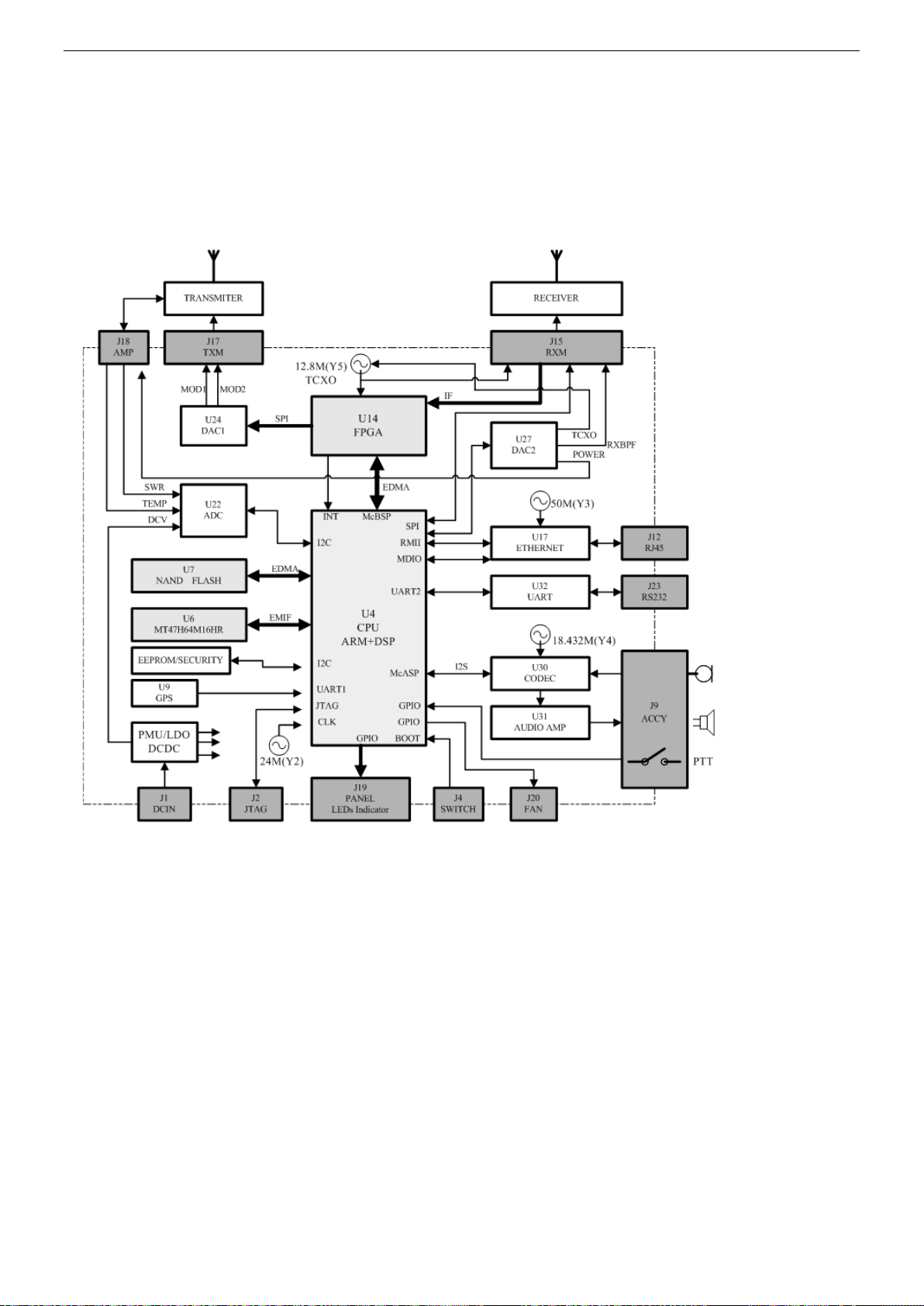

3.3. Baseband Section

3.3.1. Circuit Description

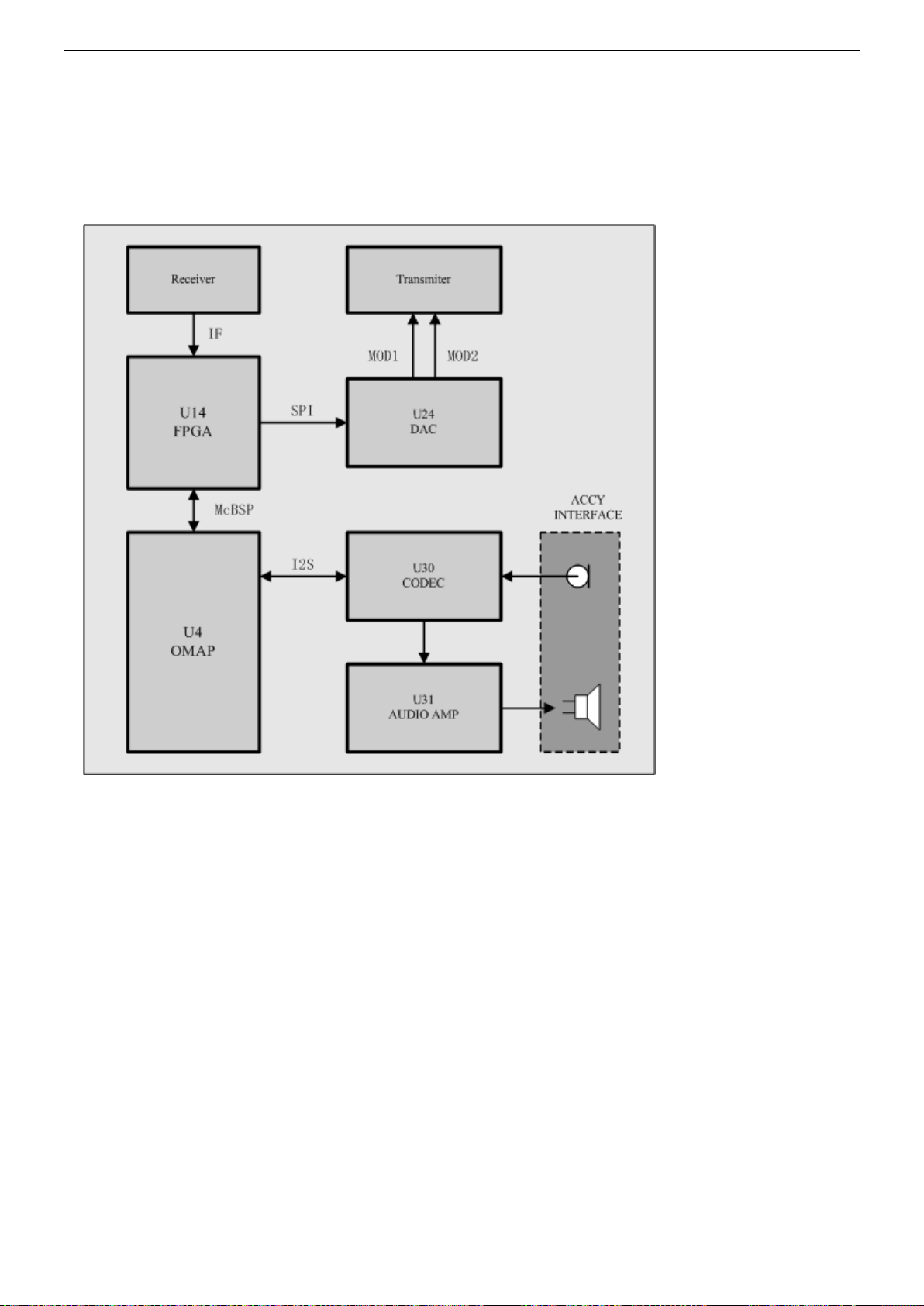

Figure 3-6 Baseband Circuit

TR850 Service Manual

As Figure 3-6 shows, inside the dotted line box is the baseband section circuits, which includes the four

major modules of dual core processor(U4), DDR2(U6), NAND FLASH(U7) and FPGA (U14). They are

used to run the Linux operation system with various drivers and protocols to achiev e call forwarding.

9

Page 14

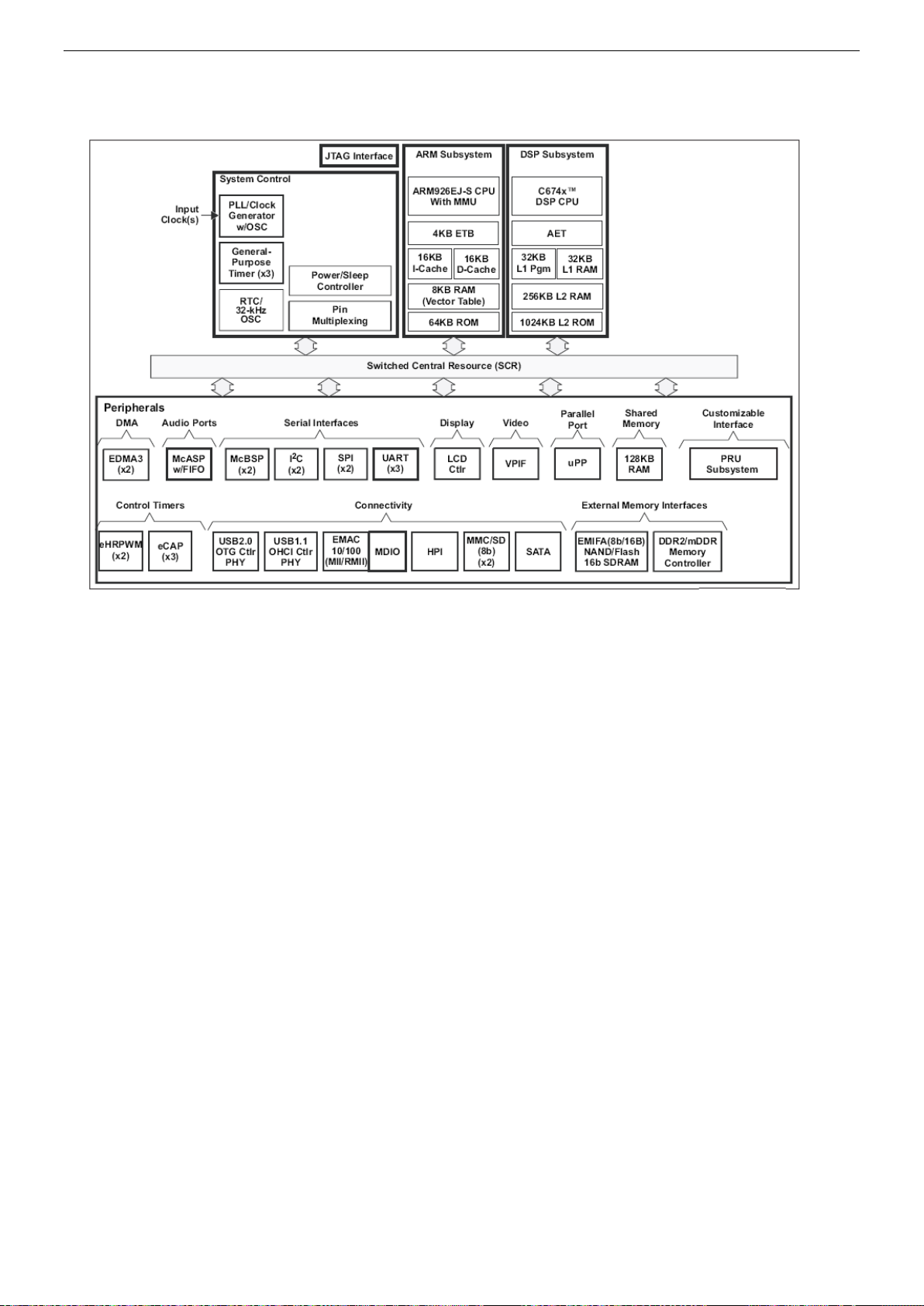

Figure 3-7 Processor Inter nal Circuit

TR850 Service Manual

The internal circuit of the proces sor is as Figure 3-7 shows, which is co mpos e d of variou s seri al inter fac es

such as 300MHz ARM926EJ MPU、300MHz C674x DSP、DMA controller、SDRAM EMIF interface、EMAC

Ethernet IC RMII interface、McASP digital audio interface and McBSP, SPI, I2C, UART.

U6 is DDR2 S DRAM wi th the capacity of 1Gb(64Mx16), and it is used to store the running program

codes and various dynamic data.

U7 is NAND FLASH with the capacity of 2GB, and it is used to store the drive rs of all the devices,

operation system and application program code wh ich includes the program code of FPGA.

The digital IF signal sent from the FPGA processing receiving unit communicate with the processor U4

via EMA BUS, and it communicate with DAC via the analog SPI interface to process the transmitting and

receiving data, which includes the data framing, filter, interpolation, extracting and etc. to achieve the

calculation and synchronization of frame number. The PLL module inside the FPGA IC will process the

external 12.8MHz, +/-1.5ppm reference clock to generate a 61.44MHz master clock via 24/5 frequency

doubling and frequency division.

The external circuit includes the parts of ADC, DAC, CODEC, AUDIO AMP, ETHERNET, RS232 and etc.

The Analog-Digital Convertor ADC (U22) collects data such as stationary wave signal detection and

power supply voltage detection which are controlled by RF power.

Digital-Analog Convertor DAC (U24) is used for transmitter two point modulation output, and the other

DAC(U27) is used to achieve the band pass adjusting and the RF power amplification control of the RF

receiver, the tuning control of the receiver local oscillation reference clock.

CODEC(U30) achieves the digital-analog converting. It is connected to the OMAP processor via I2S

digital audio interface to achieve the local monitoring, output and input of interposed speech or audio

10

Page 15

TR850 Service Manual

Tx/Rx index testing.

The output power of audio power amplifier (U31) is 1W, which is used for local monitoring or tested

speech output.

Network interface (U17) is the TRx components of 10/100M single Ethernet physical layer , and it is used

to the tuning of various parameter setting and communication control.

UART- Universal Asynchronous Receiver/Transmitter(U32)achieve s the RS232 electrical level switch,

when it communicates with the PC, it can initiate the programming burning, programming tuning

information printing, and e tc.

3.3.2. Power Section

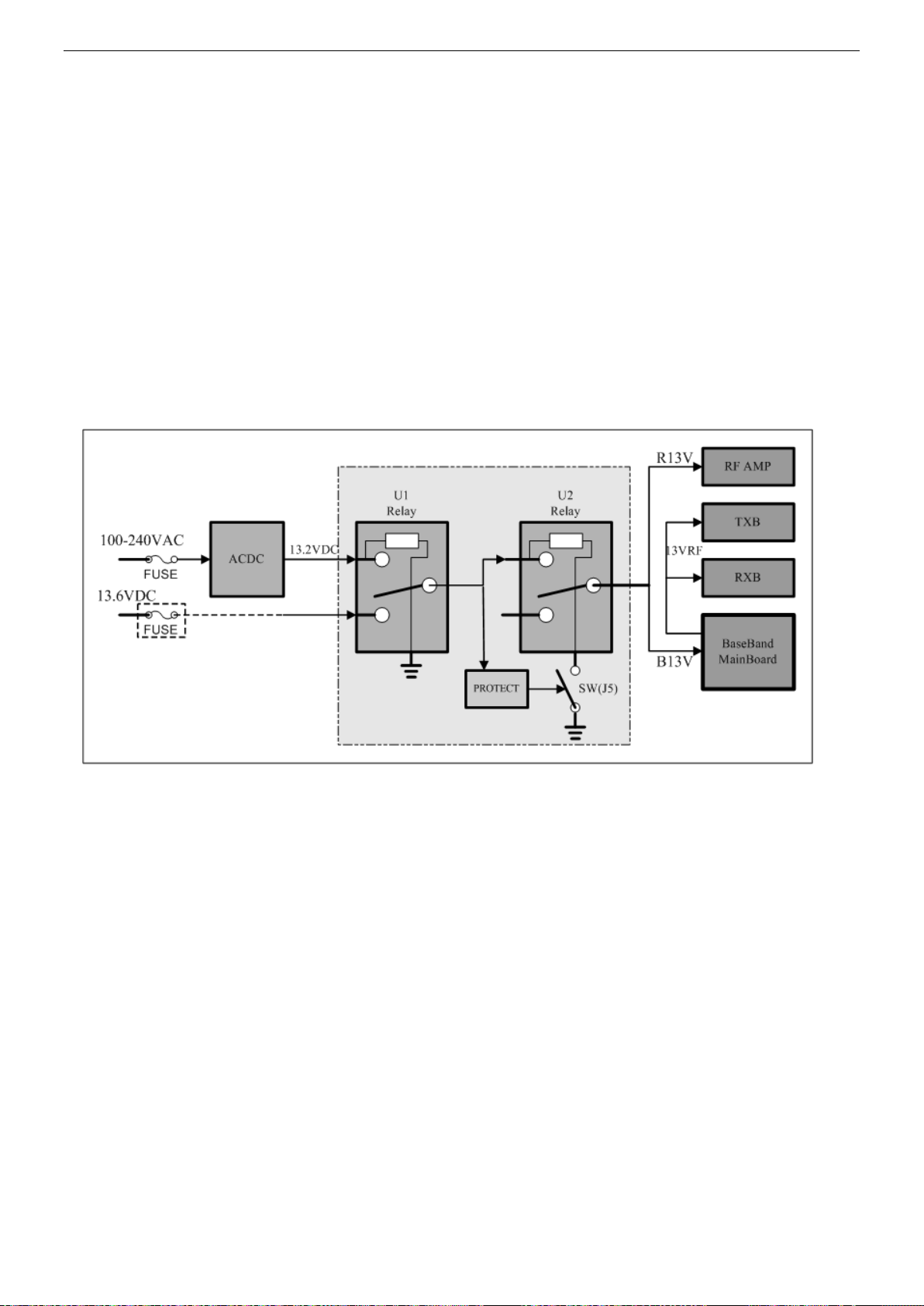

Figure 3-8 Whole Unit Power

As Figure 3-8 shows, the whole unit power supply employs adaptive ac/dc power supply with AC priority

and DC/AC auto switch. The output DC voltage which is switched and protected by the electric relay will

be divided into two paths. One path is for the RF power amplification, and the other is for banseband

mainboard. The switch in the front panel turns the power on/off via the electric relay U2. The protection

circuit wil l c u t off all the DC output when the DC exceeds 18V.

The AC/DC switching part employs an independent module power supply(320W), and it supports the AC

input range between 100V-240V, nominal output DC voltage is 12V, and the factory set is 13.2V.

The rated AC input voltage is between 100-240V, the socket is built in the dual protective tube.

Specification of the protective tube is 2.5A, 5x20mm cer amic tube, slow type.

The rated DC input voltage is 13.6V with the rated current being 15A. The protective tube is included in

the DC accessories.

Power Switch and AC/DC Switch

As the Figure 3-8 shows, t he elect ric re lay is sw itch ed on for t he AC power supply and it will cut off the DC

point. The 13.2VDC output from the ACDC m odule is c onnect ed to U2 thro ugh the U1 c ont a ct. If the panel

switch (J5) is on, the electric relay (U2) will be switched on, so is the repeater.

11

Page 16

TR850 Service Manual

When AC power supply is off, the electric relay (U1) is released. The DC is connected to U2 via the

electric relay (U1) contac t . I f t he panel switch (J5) is on, the electric relay U2 will be switch ed on, so is t he

repeater.

The panel switch (J5) is off, and U2 is released, which cut off the baseband DC power supply B13V

including the RF power supply R13V.

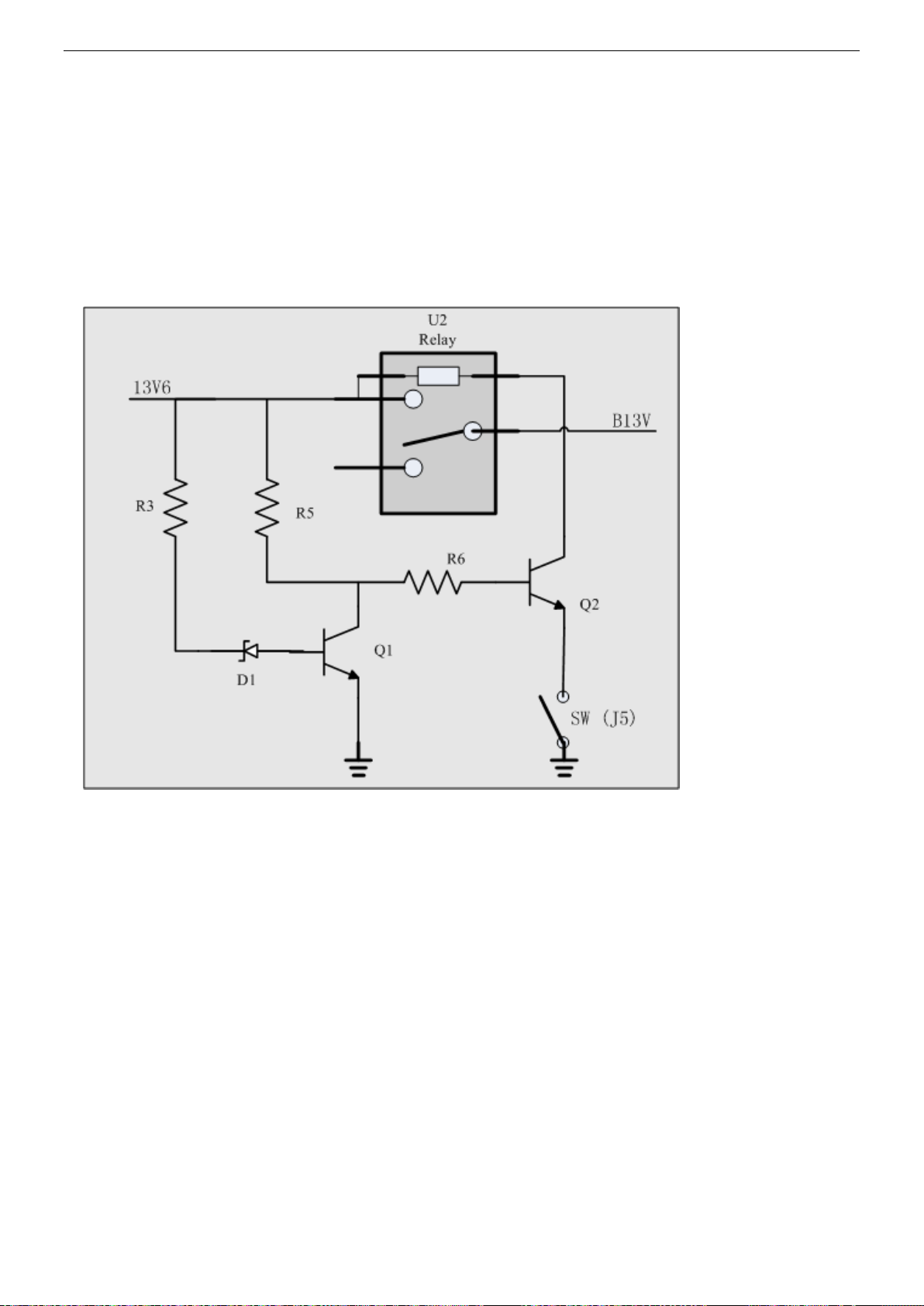

Over-voltage Prote ction

Figure 3-9 Over-voltage Circuit Protection

As the Figure 3-9 shows, the breakdown voltage of the voltage stabilizing diode is 18V+/-0.5V. If the input

DC volatage is over 18V+/-0.5V, the Q1 breaks over with Q2 being cut of f, and the electric relay U2 will be

released to cut off the DC power supply B13V, includ ing t he RF power supply R13V.

12

Page 17

TR850 Service Manual

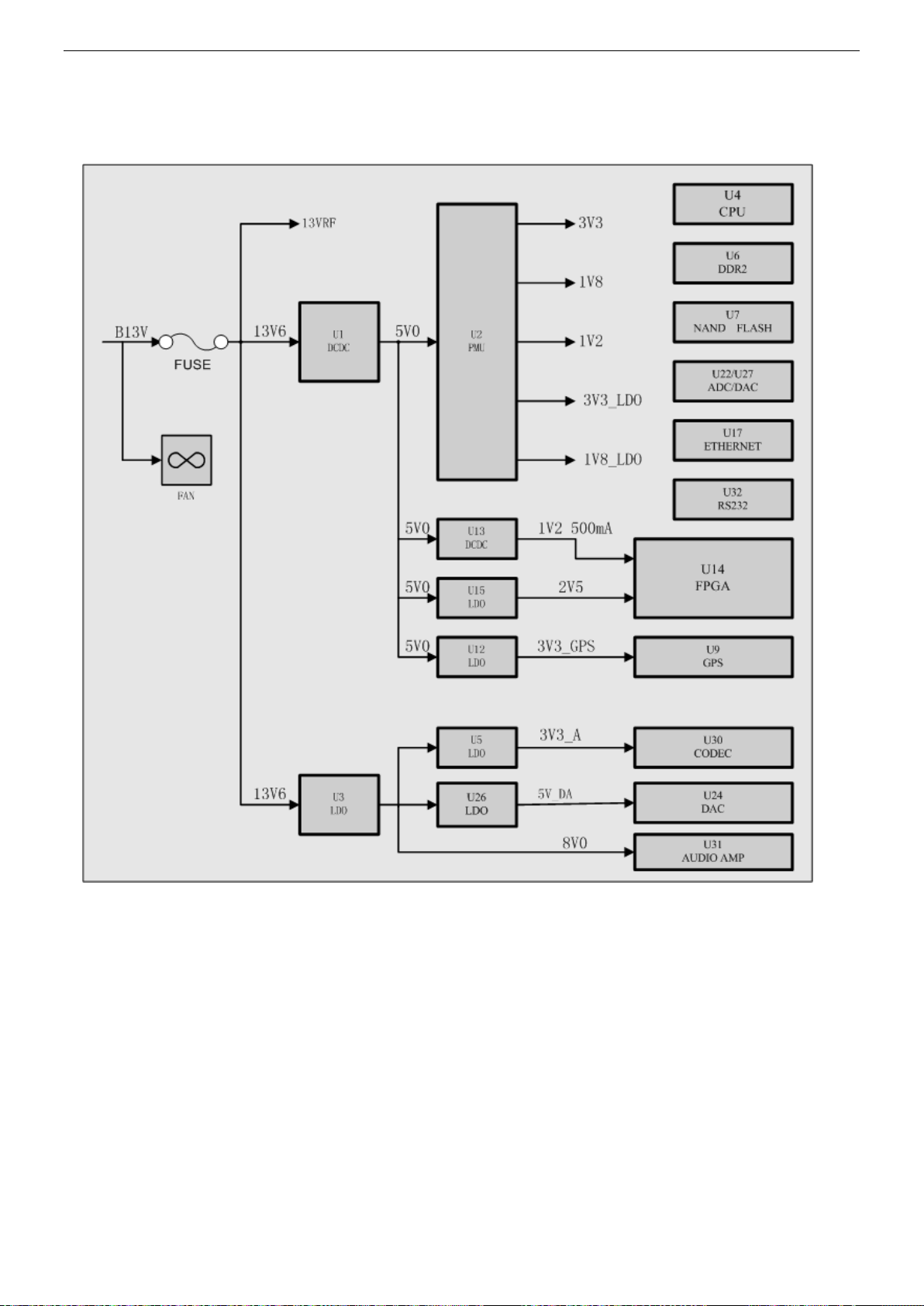

Baseband Board Power Supply

Figure 3-10 Baseband Board Power Supply Distribution Diagram

As Figure 3-10 shows, the baseband and RF employs isolated power supply. B13V will be divided into

three paths. One path provides power for baseband circuit, the second one is provided for Tx and Rx

module af ter being isolated by magnetic bead, and the last one is provided for heat dissipation fan after

being isolated by the ferrit e Inductor.

The digital and analog part of the baseband circuit own separate power supply.

The power supply of the digital circuit is composed of two-level switch circuit. The first level decreases

the B13V to 5V via DC/DC (U1) ; the second level switches 5V to 3.3V, 1.8V, 1.2V and etc.. wh ich are

isolated by various magne t ic beads before being supplied to the circuit modul es.

The analog circuit power supply will be directly supplied to analog audio power amplification circuit after

being switched to 8V via LDO. One power path outputs 5V_DA via the low voltage LDO (U26) and

provide it for the analog power of DAC(U24, U27), and the other oupts 3.3V_A via the low voltage LDO

13

Page 18

TR850 Service Manual

(U5) and provide it for the analog p ow er of CODEC (U30).

3.3.3. Audio Processing

Figure 3-11 Audio Proces s ing Schematic Diagra

As the Figure 3-11 shows, the audio processing module mainly achieves encoding and decoding with

ADC and DAC of the audio signal, including air audio forwarding and local audio TRx.

Air Audio Forwarding

The digi tal IF si gnal fr om the RF r ecei ver wil l be first sent to the FPGA(U14) for time slot processing and

achieving the framing, filtering and extracting of the data to realize the calculation and synchronization of

the frame number; the signal will be send to the DSP of CPU (U4)via the McBSP interface for 4FSK

decoding, digital audio signal decoding and etc.. Meanwhile, the internal DSP will send the digital audio

signal which achieves t he decodin g and enc oding to the FPGA(U14) for time slot processing and finishi ng

the framing, filtering and interpolation and other synchronization calculation of the data, and the digital

audio signal will then be sent to the DAC (U24) via the SPI interface for the audio digital/analog switch,

generating the analog speech two point modulation signal before being sent to the transmitter for the

audio forwarding.

Local Audio TRx

The internal DSP in the main processor(U4) connects to the CODEC(U30) via the I2S digital audio

interface. The CODEC(U30) will convert the analog audio input from the external to digital audio, then

14

Page 19

TR850 Service Manual

send into the internal DSP. In the meantime, converts the received digital audio from the internal DSP to

analog audio, then send t he audio t o audio pow er a mplifier( U31), be fore final ly send t o the ACCY external

interface, which is to drive the 1W, 16Ω speaker.

3.3.4. Ethernet Interface

Figure 3-12 Ethernet Interface

As Figure 3-12 shows, A RMII simpli fied interface is used between the CUP(U4) and network interface

chip(U17) . RMII inter fac e independent clock uses external clock mode and sh ar e 50MHz clock with U17.

CPU (U4) achieves the hardware information of internet interface U17 through the independent

configuration interface MDIO. CPU also initiate it and assi gn M AC and IP address.

The data transmitt ing and receiving bet ween netw ork inter face ch ip(U17) and interface connector(J12) are

achieved through connecting the transformer inside the connector jack RJ45 and LED through 2 pairs of

differential line.

The network interface can realize parameter adjustment and parameter conf igure, user programming and

firmware upgrade.

3.3.5. Boot Mode

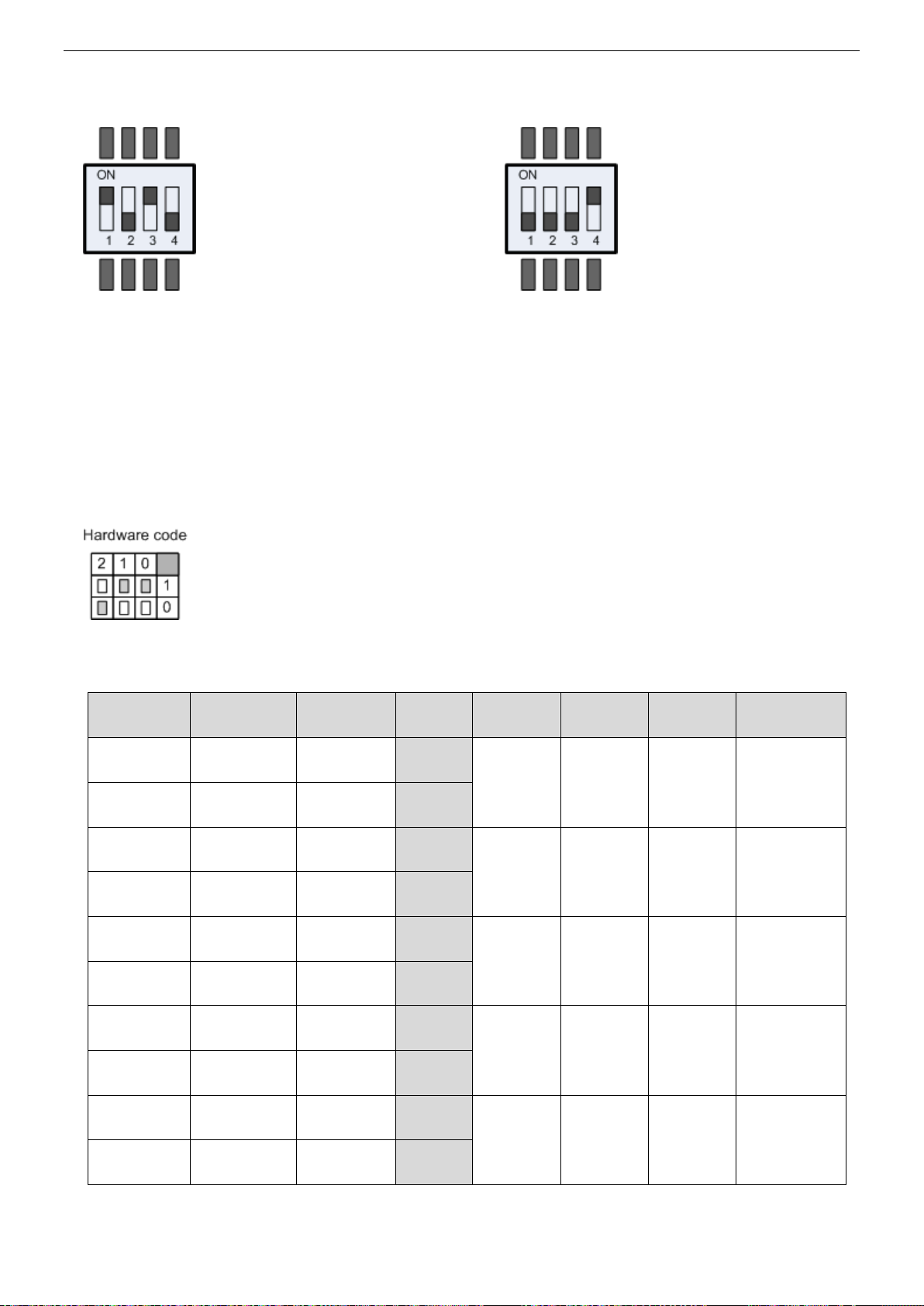

A boot mode selection switch (J4) is provided on the baseband. The four position 1 to 4 of DIP encode

switcher are correspondingly connected with boot 1 to boot 4 of OMAP (U4), so the boot operation mode

will be changed after being powered on.

The level of position “ON” of encode switcher corresponding to boot which is connected to GND is

“0”.Conversely, the level of position “OFF” is “1”.

As showing in Figure 3-13, the level of boot1 to boot4 of switcher is 0101, and it enters to firmware

download mode after power on. It can upgrade the guide program and the low driver program by booting

from serial port(UART2).

15

Page 20

TR850 Service Manual

Figure 3-13 Firmware Download Mode Figure 3-14 User Mode

As showing in Figure 3-14, the level of boot 1 to boot4 is 1110, and it enters to normal running user mode

after power on. It starts from NAND FLASH. In this mode, it can upgrade operation system kernel, device

driver program, files syst em an d application program by network interfac e.

Please configure the boot mo de as user mode as shown in Figure 3-15 in normal use.

3.3.6. Hardware Version Encode

Figure 3-15 Hardware V er sion Enc ode

According to the position of chip resistor in Figure 3-15 the encoder is “001” and the corresponding

version is Ver3. 0.

2 1 0 D2 D1 D0 Version

NULL NULL 0R

0R 0R NULL

NULL 0R NULL

0R NULL 0R

NULL 0R 0R

0R NULL NULL

1

0 0 1 Ver1.0

0

1

0 1 0 Ver2.0

0

1

0 1 1 Ver3.0

0

0R NULL NULL

NULL 0R 0R

0R NULL 0R

NULL NULL NULL

1

1 0 0 Ver4.0

0

1

1 0 1 Ver5.0

0

16

Page 21

TR850 Service Manual

0R 0R 0R

1

1 1 0 Ver6.0

NULL NULL NULL

0R 0R 0R

0

1

1 1 1 Ver7.0

NULL NULL NULL

0

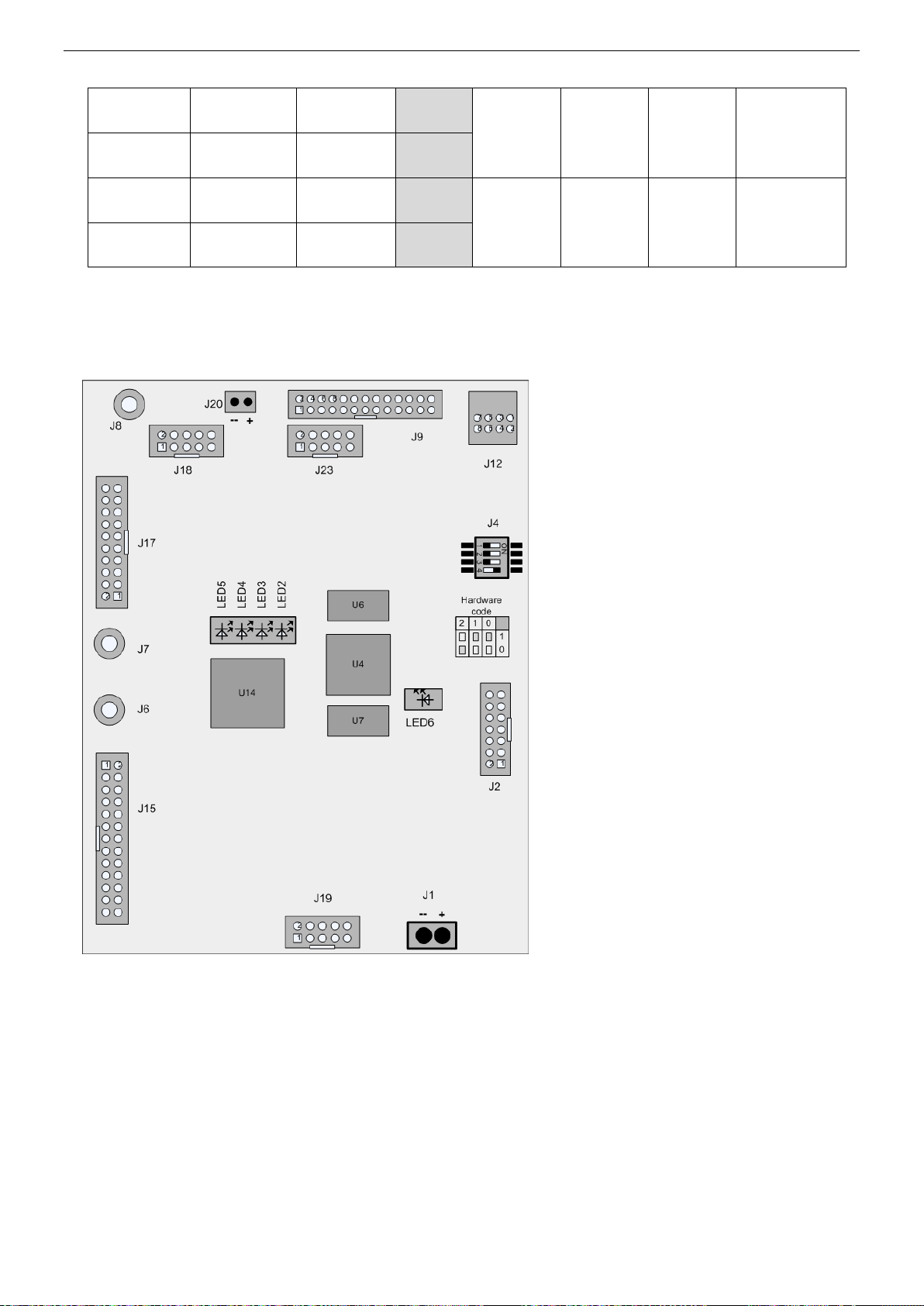

3.3.7. Baseband Board Interface and Indicator

Figure 3-16 Baseband Board I nt er fac e and I ndicator

See Figure 3-16, Th e int erfaces and indicators of banseband are as follows:

J1 is the 13.2V(+/-20%) DC input interface of the whole banseband mainboard, and the polarity

should be noted. The input circuit includes isolating magnetic inductor (L12) and chip insurance resistor

(F1).

J2 is the JTAG adjustment interface of main processor, and it is used for program simulation

adjustment.

J4 is the switch for boot mode. See“3.3.5Boot Mode” for details.

J6、J7 are 12.8MHz clock and SMA offered by main board to other p art s. The two signals are the same

17

Page 22

TR850 Service Manual

and either one of them can be selected.

J8 is the interface and SMA of GPS interface, and it supp orts active antenna with 3.3V feed output.

J9 is the ACCY external interface provided by baseband, and it is used for function expansion or test.

It includes the input and output of loc al speech, external PTT, and pr ogramm able exp ans ion IO. It provides

12V/1A DC output.

J15 is the interface of Rx board, including digital IF, SPI interface signal, 12C interface sig nal for storing

data of test and adjust m e nt, etc.

J17 is the interface of Tx board, includ ing two point modulation si gnal, SPI int erface of Tx circu it PLL, Tx

control signal, etc.

J18 is the control interface of RF power amplifier, including SWR , TEMP_DET, POWER_CONTROL,

TX_ENABLE, etc.

J19 is the interface of LED status display board.

J20 is the 12VDC fan interface.The fan will be switched on when the r adio tr ansmits or the temperature

goes beyond the set range.

J23 is the serial port UART2.

LED2、LED3、LED4、LED5 indicates program operation status.

LED6 indicates CPU power.

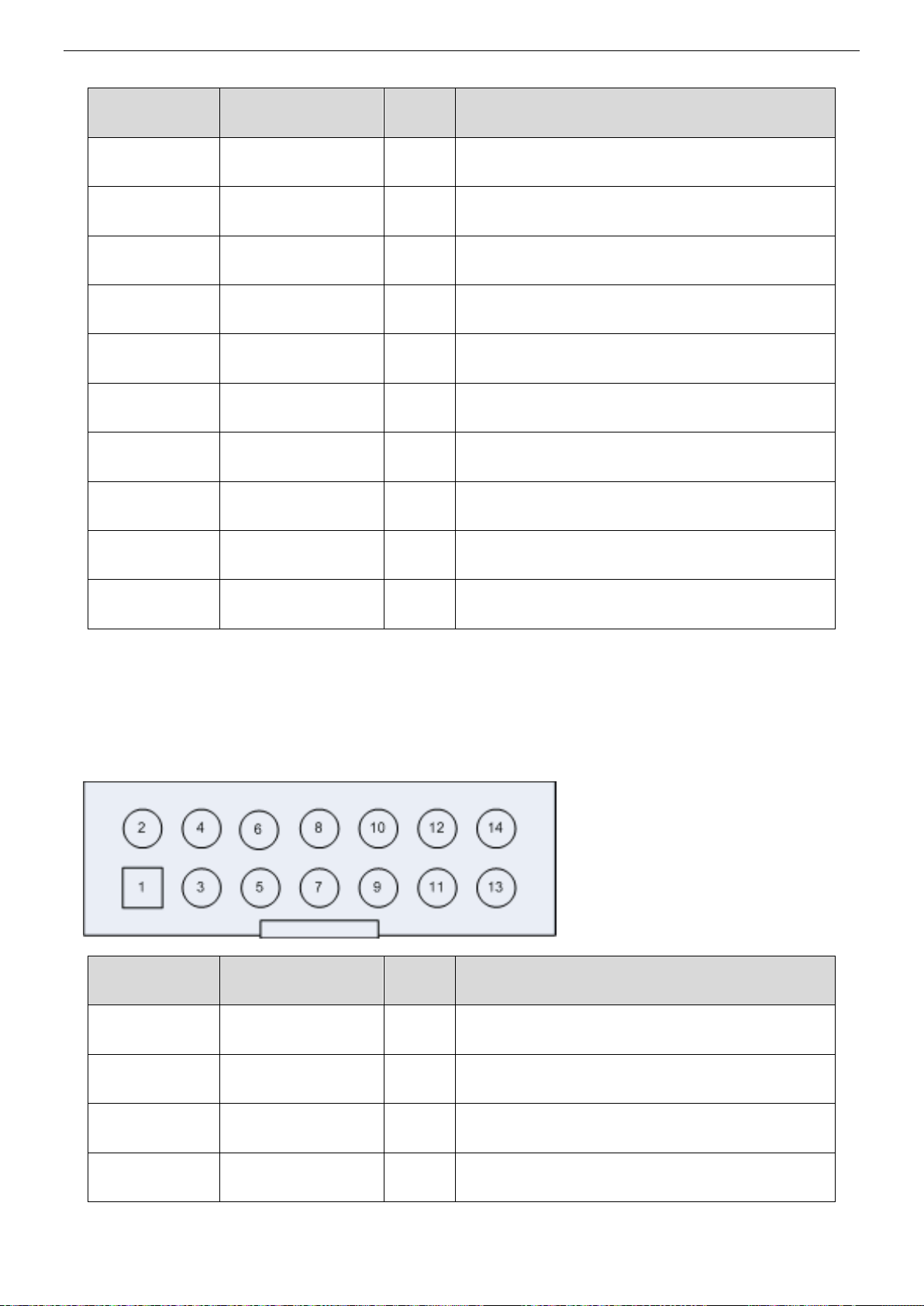

3.3.8. Tx Unit Interface Definition (J17)

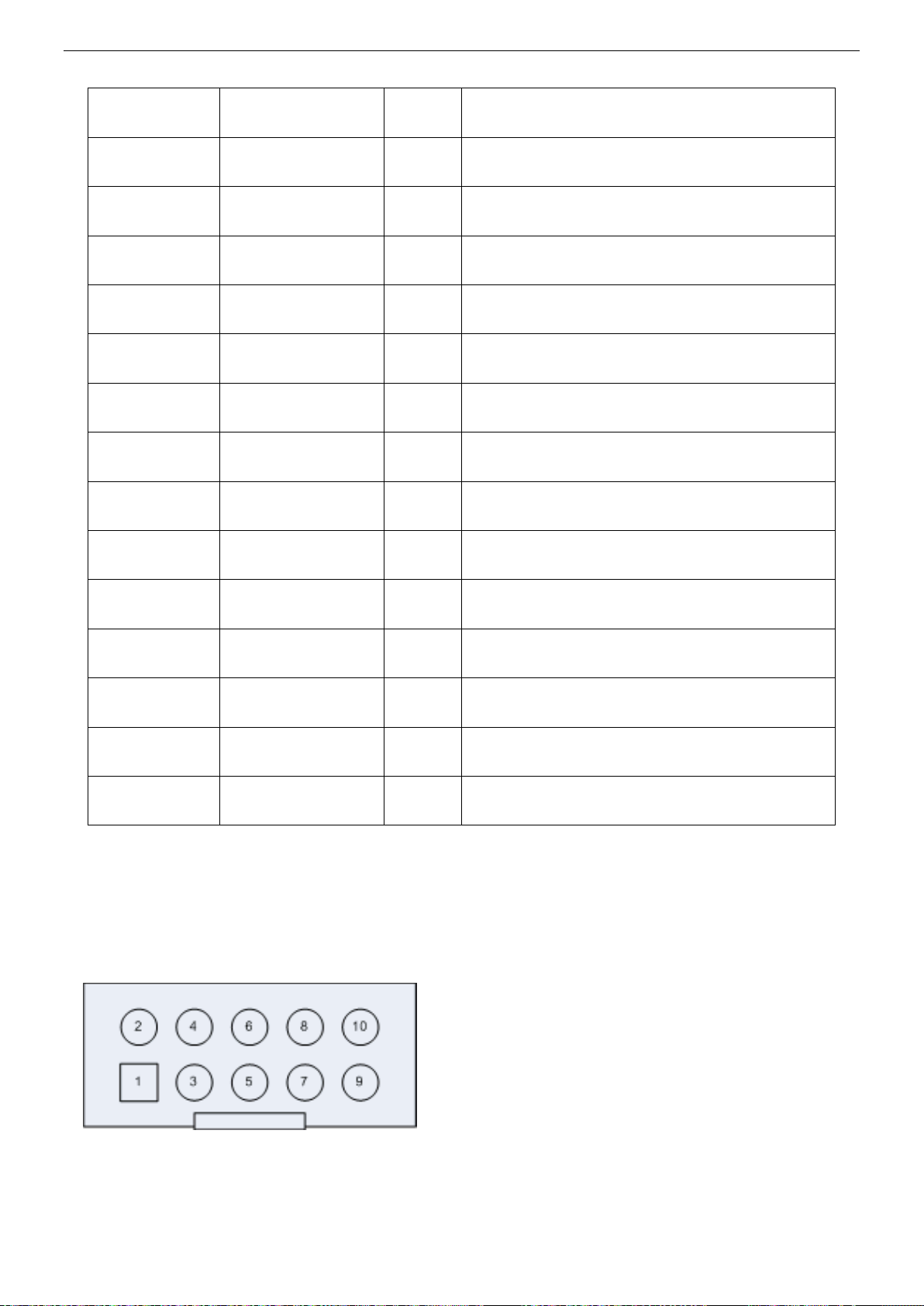

Figure 3-17 Tx Unit Interface Definitio n

Ter minal NO. Terminal Name I/O Function

1 GND - Ground

2 MOD1 O TX Modulate signal output1

3 GND - Ground

4 MOD2 O TX Modulate signal output2

5 GND - Ground

18

Page 23

TR850 Service Manual

6 NC - -

7 GND - Ground

8 NC - -

9 TX_LD O PLL locked indicate,active high

10 TX_VCO_SEL O Select VCO band

11 SPI_CLK O SPI clk

12 GND - Ground

13 VCCTX O Open TX Power,active high

14 GND - Ground

15 SPI_MOSI I/O SPI data

16 GND - Ground

17 PLL_CS O PLL chip selected,,active low

18 TX_ENABLE O Enable TX PLL,,ac t iv e high

19 VCC O 13.2V output

20 VCC O 13.2V output

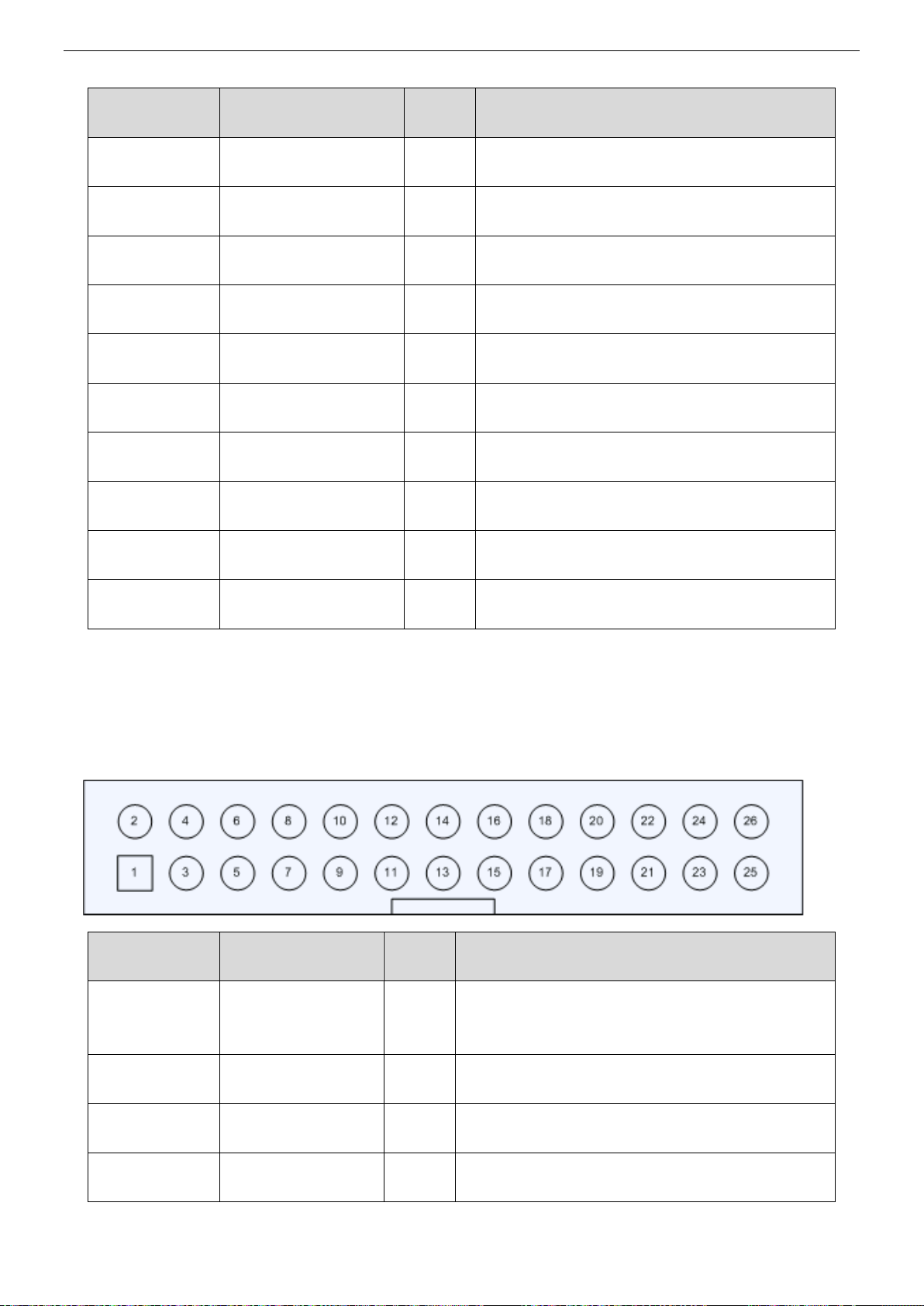

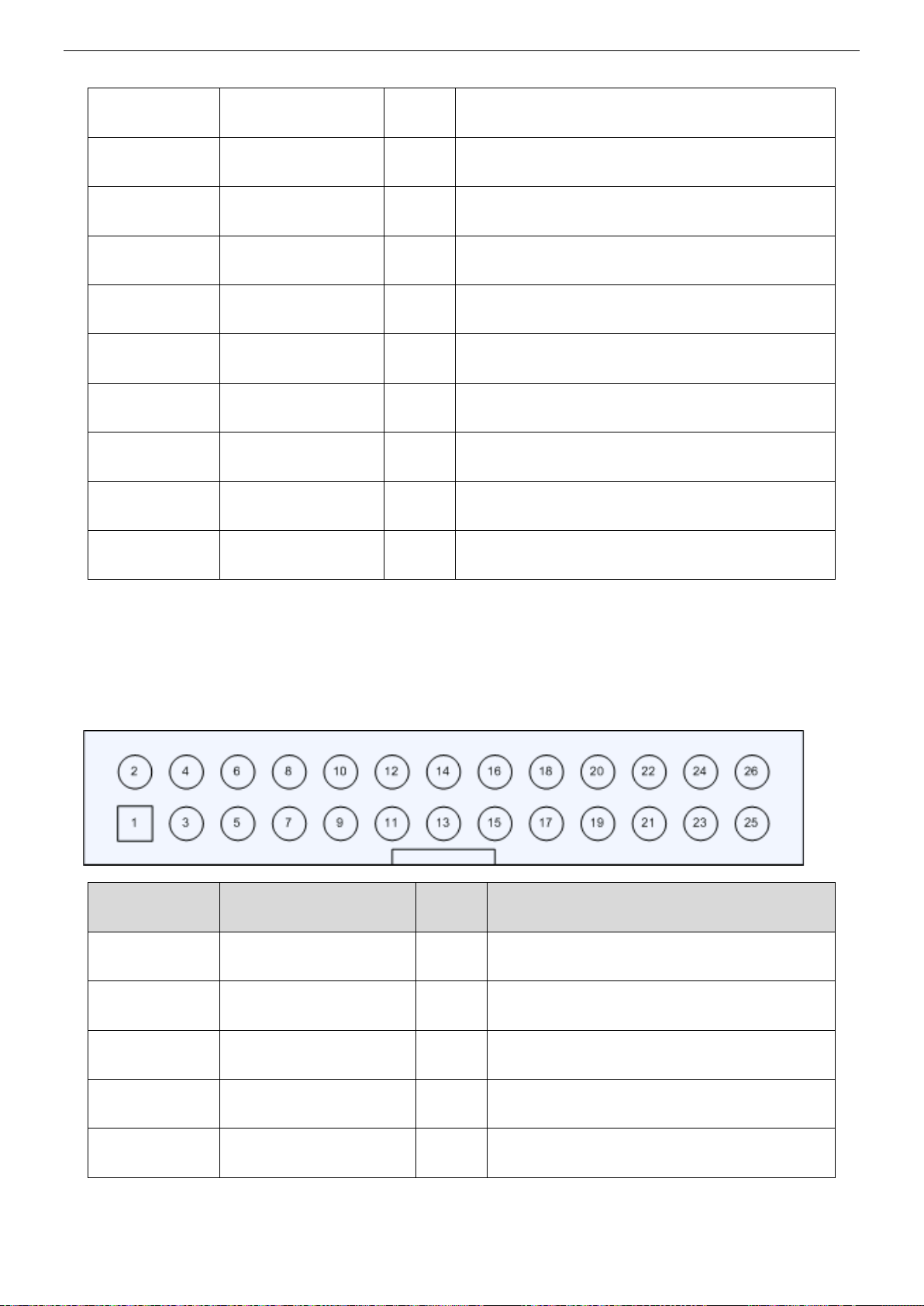

3.3.9. RF Power Amplifier Module Interface (J18)

Figure 3-18 RF Power Amplifier Module Interface

19

Page 24

TR850 Service Manual

Resets AD9864 SSI and DecimatorCounters;

Ter minal NO. Terminal Name I/O Function

1 POWER_CTRL O PO WER contr ol o utput

2 GND - Ground

3 POWER_SWITCH O POWER switch,active high

4 NC - -

5 TX_ENABLE O Power modul e enbale,active high

6 NC - -

7 SWR_R I Power SWR_R detector

8 TEMP_DET I Power tempreture detect or

9 SWR_T I Power SWR_T dete ct or

10 NC - -

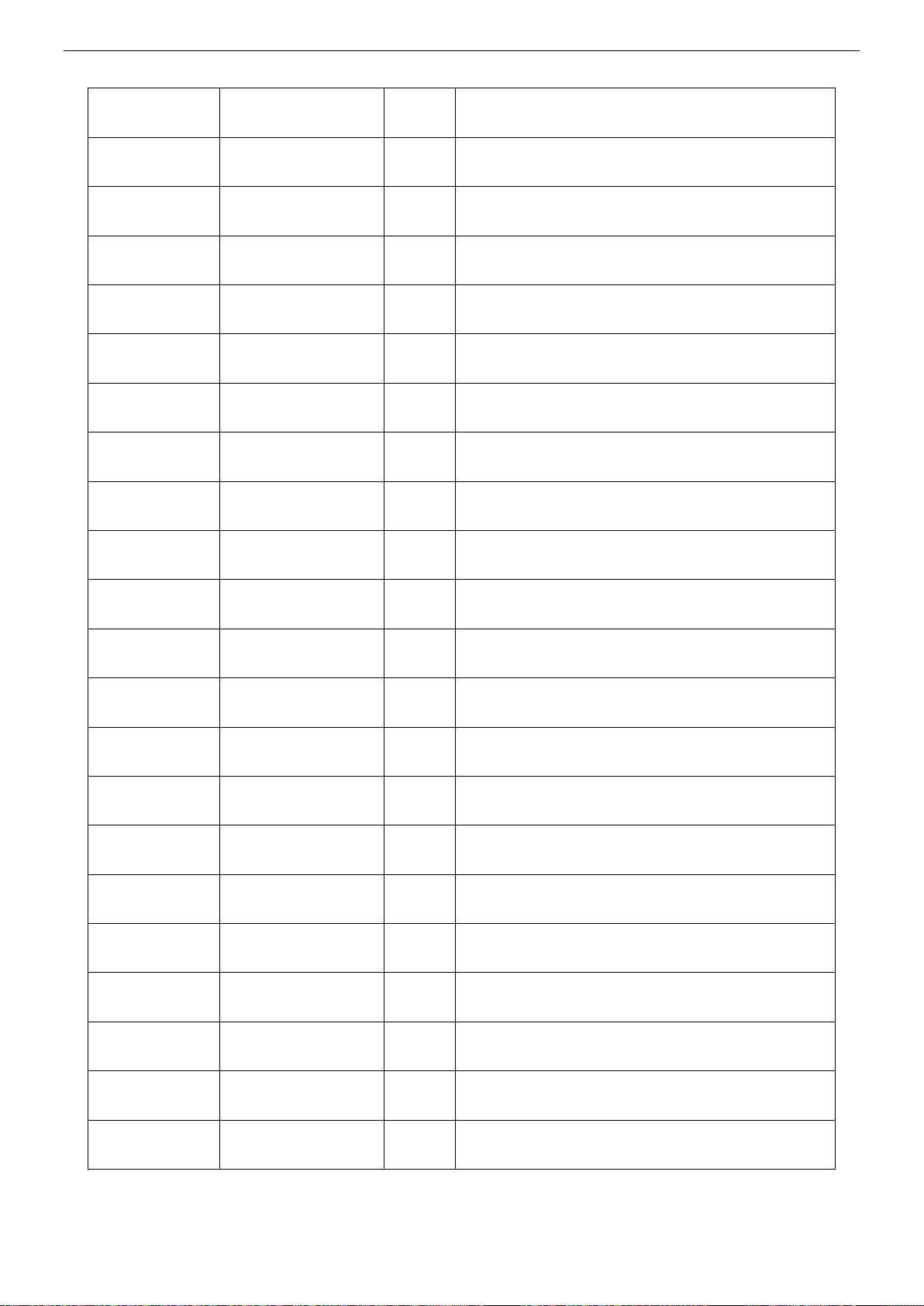

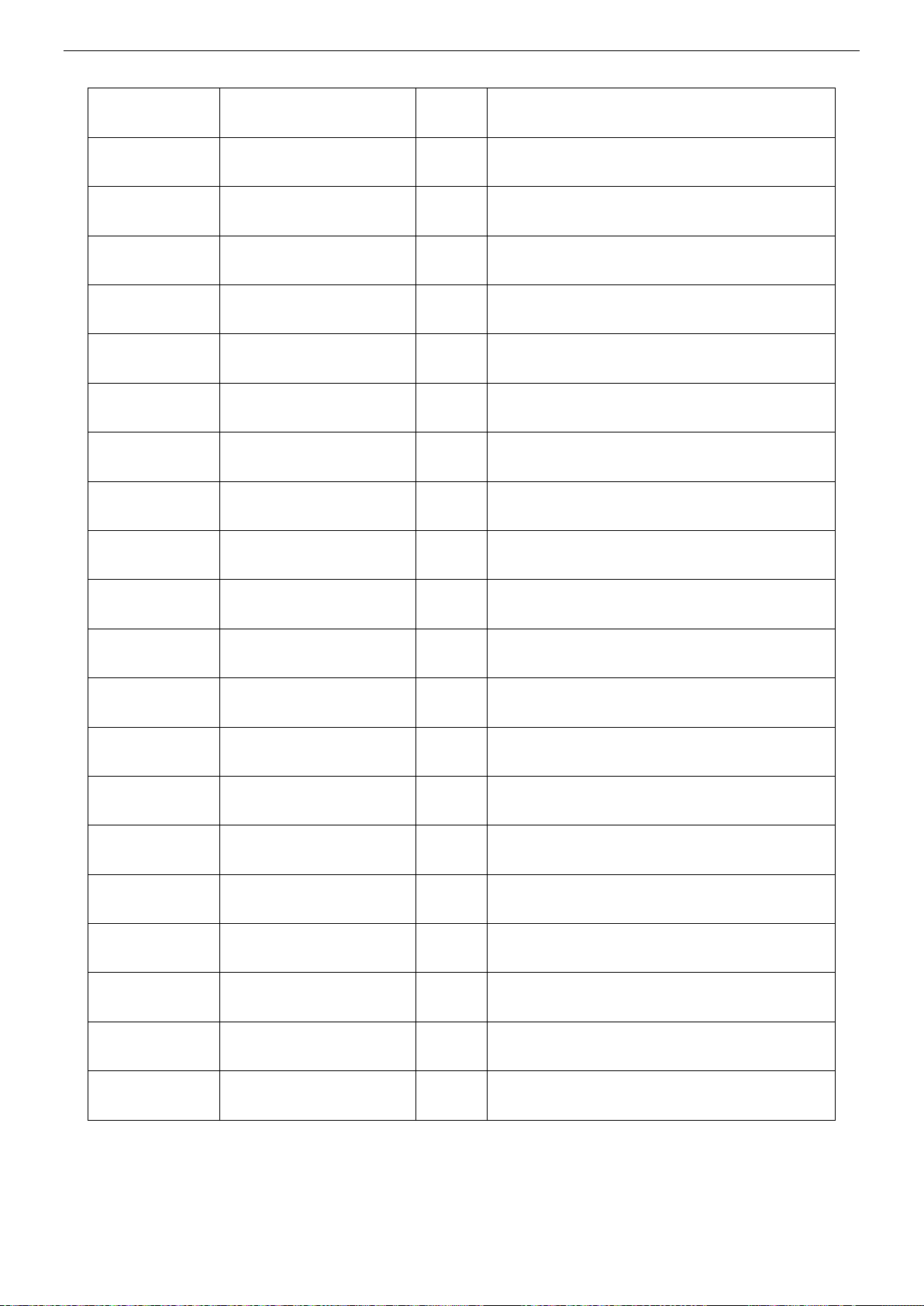

3.3.10. Rx Unit Interface Definition (J15)

Figure 3-19 Rx Unit Interface

Ter minal NO. Terminal Name I/O Function

1 SYNCB O

2 SPI_MISO I Data for AD9 864 SPI

3 AD9864_DATAOUT I Data for AD9864 SSI

4 AD9864_CLK I Clock for AD9864 SSI

Active Low

20

Page 25

TR850 Service Manual

5 AD9864_FS I Frame synchronous for AD9864 SSI

6 SPI_CLK O Clock for AD9864 SPI

7 SPI_MOSI O Data for A D9864 SPI

8 AD9864_SPI_CS O Enable for AD9864 SPI

9 RX_VCO_CTRL O VCO tunner

10 RX_PLL_CS O PLL chip selected, active low

11 I2C_SDA I/O EEPROM data

12 I2C_SCL O EEPROM clock

13 RX_LD O PLL locked ind icate,active high

14 GND - Ground

15 RX_BPF_CTRL O Output for RX BPF filter tunner

16 NC - -

17 VCCR8X O Open RX Power,active high

18 GND - Ground

19 RX_VCO_SEL O select VCO band

20 NC - -

21 I2C_A0 O EEPROM address

22 NC - -

23 GND - Ground

24 NC - -

25 VCC O 13.2V output

26 VCC O 13.2V output

21

Page 26

TR850 Service Manual

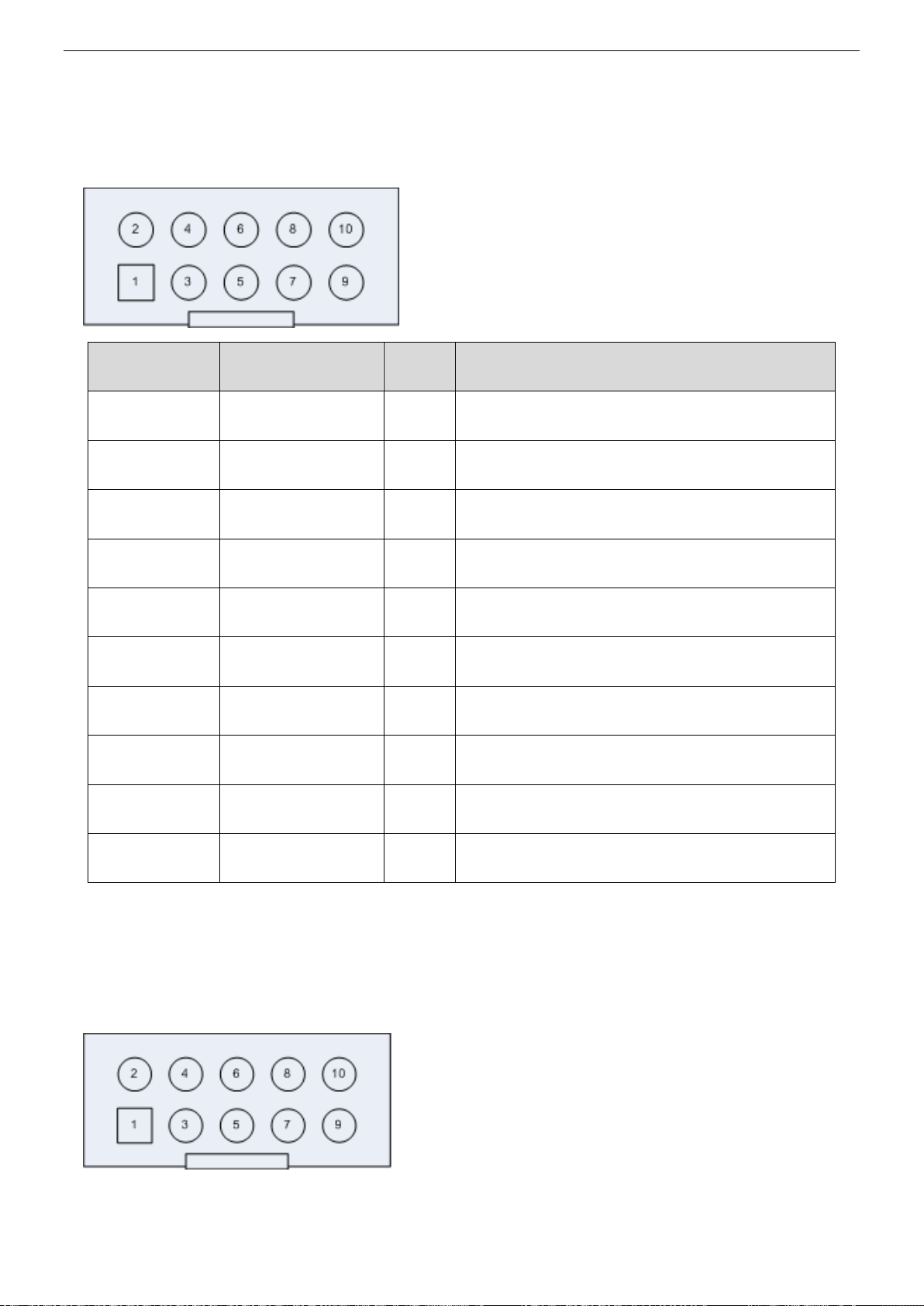

3.3.11. Front Panel Interface Definition (J19)

Figure 3-20 Front PanelInter fac e Definition

Terminal NO. T erminal Name I/O Function

1 3V3 - 3.3V

2 GND - Ground

3 LED0 O TX_A slot indicate, active high

4 LED4 O REPEATER mode indicate,active high

5 LED1 O RX_A slot indicate, act ive high

6 LED5 O ANALOG mode indicate,active high

7 LED2 O TX_B slot indicate,active high

8 LED6 O DIGITAL mode indicate,active high

9 LED3 O RX_B slot indicate,active high

10 LED7 O ALARM indicate,active high

3.3.12. Serial Port Definition (J23)

Figure 3-21 Serial Port Definition

22

Page 27

TR850 Service Manual

Ter minal NO. Terminal Name I/O Function

1 NC - -

2 NC - -

3 TXOUT O RS232 TX output

4 NC - -

5 RXIN I RS232 RX input

6 NC - -

7 NC - -

8 NC - -

9 GND - Ground

10 NC - -

3.3.13. JTAG Simulator Interface Definition (J2)

Figure 3-22 JTAG Simulator Interface Definit ion

Ter minal NO. Terminal Name I/O Function

1 TMS - TMS

2 TRST - TRST

3 - - -

4 - - -

23

Page 28

TR850 Service Manual

5 - - -

6 NULL - NULL

7 - - -

8 - - -

9 - - -

10 - - -

11 - - -

12 - - -

13 - - -

14 - - -

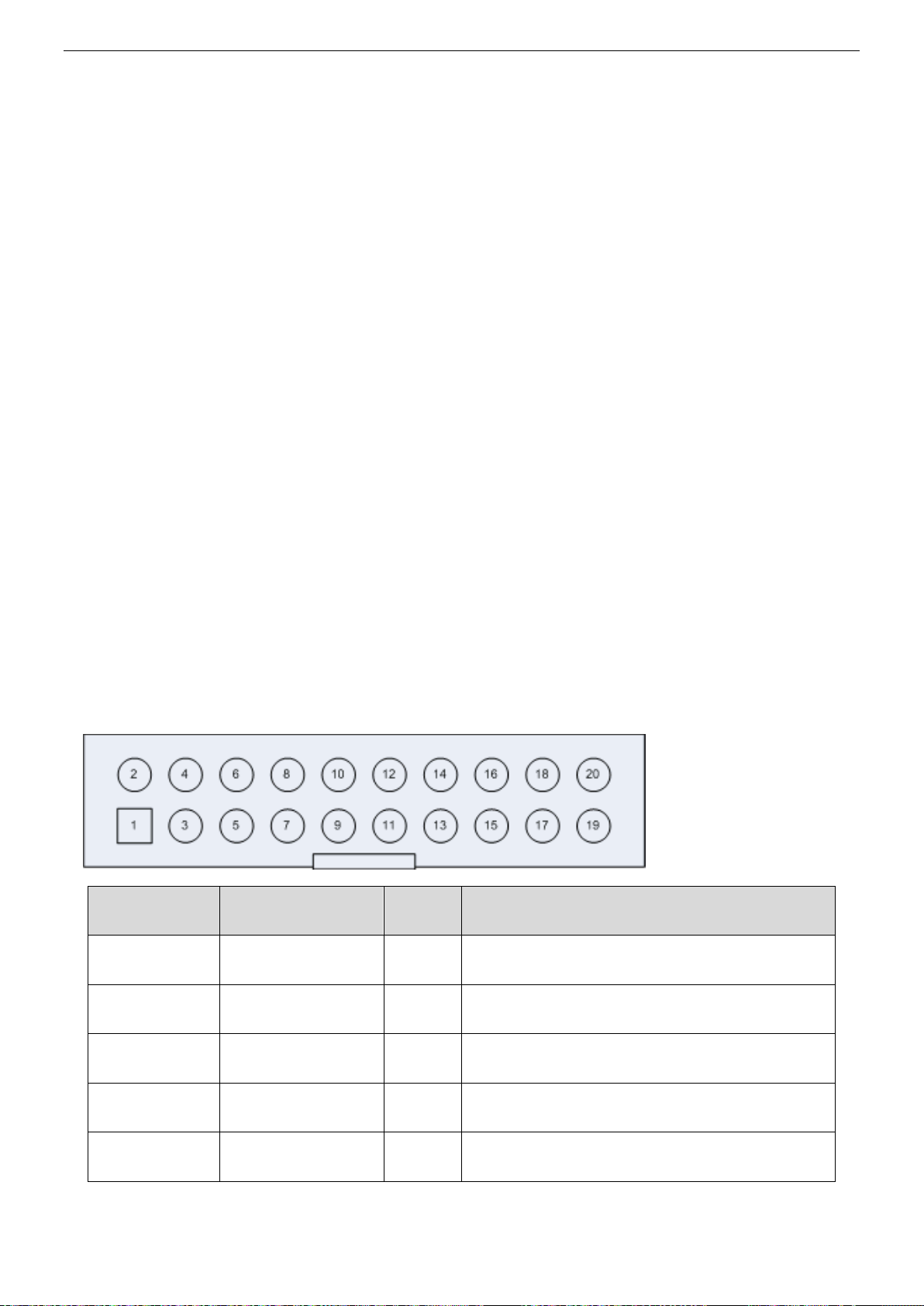

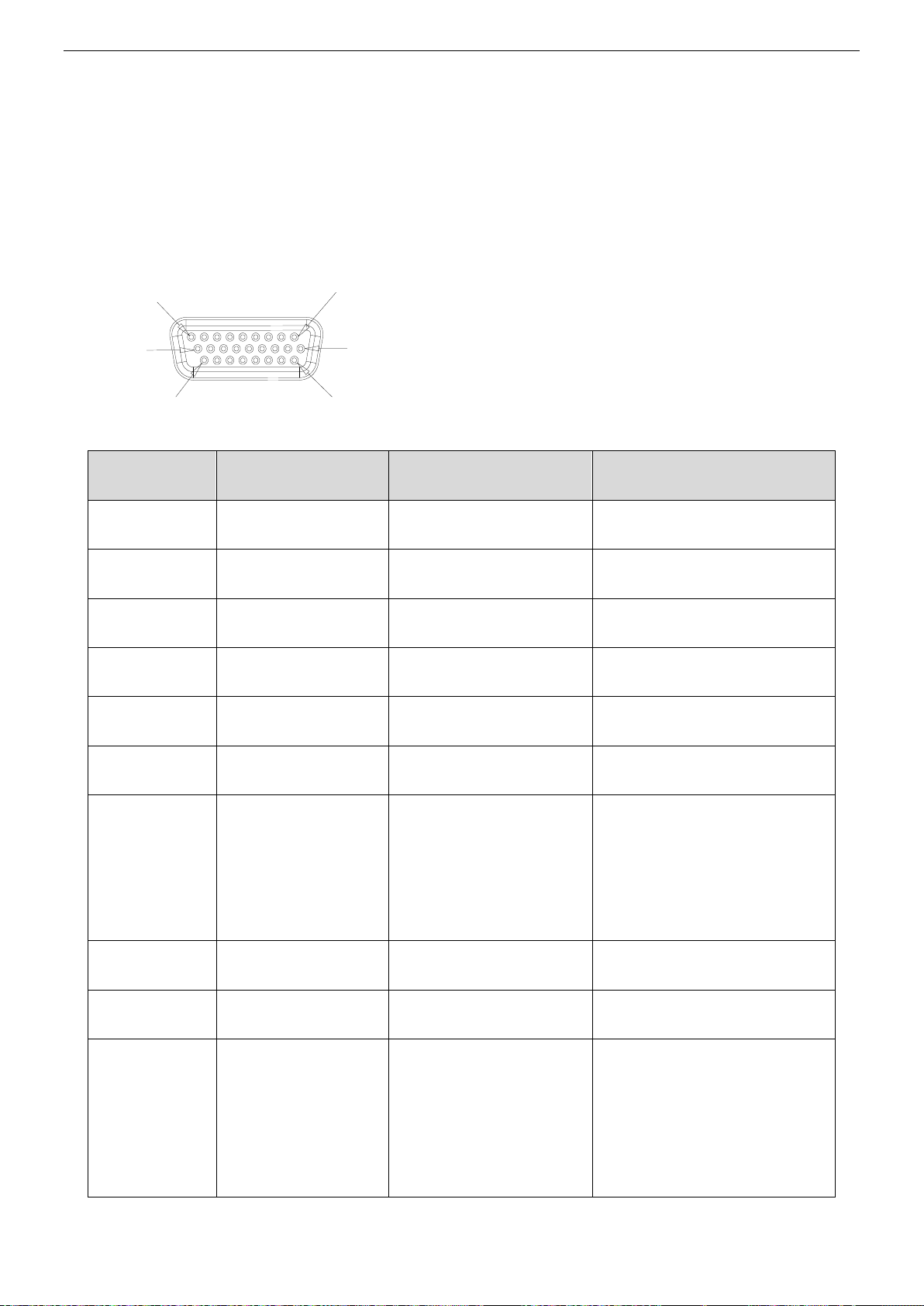

3.3.14. External Interface Definition (J9)

Figure 3-23 Externa Interface D ef in it io n

Ter minal NO. Terminal Name I/O Function

1 USB_D+ I/O Reserved

2 USB_D- I/O Reserved

3 V_BUS O Reserved

4 USB_GND - Ground

5 ACC_ID2 I Reserved

24

Page 29

TR850 Service Manual

6 ACC_ID1 I Reserved

7 EXT_SWB+ O Power 13.2VDC switched out put

8 POWER_GND - Ground

9 EXT_SPK- O Annalog output speaker-

10 EXT_SPK+ O Analog output speaker+

11 TX_AUDIO I Analog audio input

12 AUDIO_GND - Ground

13 AUX_AUDIO_OUT1 O Reserved

14 RX_AUDIO I Reserved

15 AUX_AUDIO_OUT2 O Reserved

16 GND - Ground

17 PRGM_IO_1 I PTT input,high active

18 GND - Ground

19 PRGM_IO_2 I/O Reserved

20 PRGM_IO_6 I/O Reserved

21 PRGM_IO_3 I/O Reserved

22 PRGM_IO_7 O Output high level(2.8V)

23 PRGM_IO_4 I/O Reserved

24 PRGM_IO_8 I/O Reserved

25 PRGM_IO_5 I/O Reserved

26 PRGM_IO_9 I/O Reserved

25

Page 30

TR850 Service Manual

10

18

19

26

9

1

3.3.15. Case External Interface Definition

Extended interface (J9) of base ban d is conn ected t o access ory board by a flat gray cable, t hen connect ed

to the ACCY connector at the rear of repeater after conversion through accessory board. The ACCY

connector is as following Figure 3-24.

Figure 3-24 ACCY Interface

Ter minal NO. T erminal Name I/O Function

1 Ext_SWB+ +13V Output +13.8V output(Imax<1A)

2 GND Ground Ground

3 USB_D+ Reserved

4 USB_D- Reserved

5 USB_VBUS Reserved

6 USB_GND USB Ground

External PTT Signal

input, High level

7 Program_IN_1 (PTT)

8 Ext_Spk- External Speaker output 8 Ω /16Ω, 0.8W Max

active .when connected

with Pin20, enter

transmission mode

Digital Input:

(2.5V<VIH<3.3V,0V<VIL<0.4V)

9 Ext_Spk+ External Spea ker out put 8 Ω /16Ω, 0.8W Max

Accessory ID input Line 2

Control signal, when

10 ACC_MAP_ID_2

connected with Pin20,

mode of analog RX

performance testing

26

Digital Input:

(2.5V<VIH<5V,0V<VIL<0.4V)

Page 31

TR850 Service Manual

Accessory ID input Line 1

11 ACC_MAP_ID_1

12

Squelch

(Program_IO_6)

13 RXD

14 TXD

Control signal, when

connected with Pin20, the

IP address will be set t o

the default address:

192.168.1.100.

Digital Input. High lev el

will enable opening

squelch when connecte d

with Pin20.

Output.

Receive signal from

repeater to PC

Input.

Transmit signal from PC

to repeater

Digital Input:

(2.5V<VIH<5V,0V<VIL<0.4V)

Digital Input

(2.5V<VIH<5V,0V<VIL<0.4V)

RS232 Level:

-3V ~ -15V

+3V ~ +15V

RS232 Level:

-3V ~ -15V

+3V ~ +15V

15 GND Ground -

16 Rx_Audio NULL -

17 Audio_Ground Ground -

18 Tx_Audio

External Audio signal

input

19 GND Ground -

Output high level, used

with Pin7 (PTT functi on) ,

20 Program_IO_7

Pin10 (analog Rx

function) and Pin11 (IP

address reset function)

and pin23(open squelch)

21

Program_IO_4

(Emergency)

NULL -

Analog input:0V<VIL<0.5V

Digital Output

2.5V<VOH<3.3V

22 Program_IO_8 NULL -

27

Page 32

23 Program_IN_5

TR850 Service Manual

Digital Input

High level active Opening

squelch when connected

with Pin20

Digital Input:

(2.5V<VIH<5V,0V<VIL<0.4V)

24

Program_Out_9

(Ext_Alarm)

Reserved -

25 Aux_Audio_Out1 NULL -

26 Aux_Audio_Out2 NULL -

4. Function and Parameter Setting

4.1. Conventional Functions

Conventional DMR functions:

Supports DMR dual slot mode

Supports DMR private call , group calla and all call transfer

Supports short Message, status mes sage transfer

Supports end to end voice and dat a encryption

Supports GPS

Supports interruption and monitor function

Supports stun, activation, kill signal ing tr ansfer

Supports IP connection

Supports S tandard AIS Interface

Support Analo g and Digital Mode

Supports Pseudo Trunkin g

4.2. Parameter Setting

Repeater is set with default par ameters when l eaving t he factory. Parameters such as operatio n frequency,

channel paramenters, scan and encryption may be changed according to different requirement by

users.Therefore, Kirisun specially designed programmable software CPSp, which is interface-friendly,

easy to operate and display-friendly, to realize the setting for repeater function para meters.

28

Page 33

TR850 Service Manual

4.2.1. Parameters setting

Parameter settings steps are as follows

Step 1. Install the right versio n of the CPSp user programming software.

Step 2. Using RJ45 ethernet cable to connect the repeater with Ethernet port of computer through

HUB/switchboard.

Step 3. Make sure the repeater is power ed on.

Step 4. Operate CPSp user programming soft w ar e f or t he settings of related parameters.

The user can read parameter configuration through CPSp user programming software.

4.2.2. Install CPSp user programming software

Installation steps of CPSp user programming software:

Step 1. Double click the installation file of CPSp user programming software, and the interface below will

pop up.

Step 2. Click “Next” and enter the next interface.

Step 3. (Option) Click browse and select the inst allation route.

This step can be skipped if using t he default route.

29

Page 34

TR850 Service Manual

Step 4. Select the language you wish to install.

Step 5. Click “Next” and install the software.

30

Page 35

TR850 Service Manual

Step 6. Click “Finish” to finish the installation.

Step 7. Please double click the CPSp user programming so ftwar e to operate after acquiring authorization.

See the figure below.

31

Page 36

TR850 Service Manual

Please refer to the help file in the CPSp user programming software for more details.

Note:

1. Errors of parameter configuration may cause malfunctions, but normally you can rewrite the

correct parameter configuration.

2. Before parameter configuration modification, we strongly recommend a backup for the current

parameters to make sure that the parameters can be restored after an error occurs.

5. Assembly and Disassembly Instruction

5.1. Duplexer Assembly

Step 1. Loosen the four screws on the top and the three screws on both sides of the top shell, and

remove the shell upwards.

32

Page 37

TR850 Service Manual

Step 2. Loosen the two screws on the duplex baffle, and remove the duplex baf fle.

Step 3. Loosen the two screws which fix the duplex bracket till the bracket can be slided in the track

groove.

33

Page 38

TR850 Service Manual

Step 4. Use screws to fix the rear part of the duplex on the bracket, and push the duplex into the box till

the duplex can be properly fit into the three corresponding holes in t he box before fixing the screws on

the duplex bracket.

5.2. Disassembly Instruction

The repeater is divided into the two parts below:

Area allowed for users to assemble and disasse mble: I nternal area of the t op shell. Us ers can assemble

duplex.

34

Page 39

TR850 Service Manual

Area allowed for dealers with maint enance permit to assemble and disassemble: Internal area of the top

shell and internal area of t he lower shell.

35

Page 40

5.3. Exploded View

1

2

3

4

5

6

7

10

11

13

14

12

15

16

17 18

19

20

21

8

9

22

2

20

23

24

25

26

27

28

29

30

31

32

33

34

13

35

36

29

40

37

38

39

41

42

43

44

45

46

47

48

49

50

57

58

30

59

28

27

38

52

41

51

53

54

55

56

9

13

TR850 Service Manual

No. Part No. Description Quantity

1 7WOZ-4100-01A Top panel, 1mm color zinc-plated board, dusting, with

decorative stripes.

1

2 7SMF-030050M-SZC

T-N1

3 7SAF-040080M-SZH

T-N

M3*5 cross sunk machine screws. Mat er ial: stainless

steel, φ3mm*5mm cross sunk machine thread,

metric coarse thread, blac k nickel-plated

M4*8 cross thick head combination machine screw

Material: hardened iron,w i th flat spacer and spring

36

24

6

Page 41

TR850 Service Manual

spacer, pb-free.

4 7MBF-4027-02A-X0 DR550 50W duplex bracket, zinc-plated boar d, 1.5mm

1

thick, color zinc-plated, pb-free.

5 7NHF-040008030-N1 M4*3 hexagonal nut mate rial: iron, internal diameter

6

M4mm, maximum external diameter 8mm, 3mm thick,

hexagonal nickel-plated nut.

6 Duplex, self-purchase

7 0ADY-4071-D STR-U pow er module, SP-320-12, 12V, 320W, ROHS,

10

1

with fan.

8 7SAF-030050M-SZY

B-Z1

M3*5 cross round flat head co mb ination machine

screw. Material: hardeded iron, Φ3mm*5mm with flat

10

spacer and spring spacer, pb-free

9 3CB1-151007-B Cable tie holder NYLON 66, 15X10X7, pb-free 10

10 7SAF-040060M-SZH

M4*6 cross thick head combination machine screw. 4

T-N

11 7WOZ-4071-03A Intermediate board 2, 1mm thick color zinc-plated

1

board.

12 6SS2-4071-HWA STR-U repeater power board jacking 1

13 7SAF-030080M-SZY

B-Z1

M3*8 cross round flat head co mb ination machine

screw. Material: hardeded iron, Φ3mm*8mm, with flat

28

spacer and spring spacer, pb-free.

14 7NHC-055070306-LJ M3*7+6 Hexagonal Copper Cylinder 19

15 6SS2-4071-HBA

STR-U/V Repeater Base Band Board Jack in g 1

16 7MHF-4100-01A-W TR850 DMR front panel, 5mm thick aluminum

1

material, oxidized black, l aser car ving, with copper

cylinder

17 7MHP-4071-01-W0 Handle, aluminum, oxidized black 2

18 7MBP-4100-01A-W TR850 lens 2mmthick, PMMA, transparent, screen

1

printing

37

Page 42

TR850 Service Manual

19 3SB3-YB-S1-Q AC power switch. 1

20 7GCR-4071-01A-W0 Repeater foot pad (4 pieces) silica gel, with screws (4

1

pieces)

21 7GCJ-S4071-J STR-U lens double side ta pe, NITTO 57120B double

1

side tape, pb-free

22 7WOZ-4100-02A Down panel, 1mm thick color zinc-plated boar d,

1

dusting.

23 6SS2-4071-HFB STR-U/V repeater front panel jacking 1

24 7SMF-030050M-SZY

B-N

M3*5 cross round flat head machine screw

Material: hardened iron, Φ3mm*5mm cross round

5

flat head nickel-plated machine thread, metric coars e

thread

25 7WOZ-4071-02A Intermediat e boar dm 1, 2mm thick color zinc-plated

1

board, rivet screw column

26 7SMF-030250M-SZC

T-N1

27 7SMF-030180M-SZC

T-N1

28 7MHL-4071-03A-W STR-U receive module aluminium shield down case

M3*25 cross sunk machine screw

metric coarse thread, whit e nickel-plated

M3*18 cross sunk machine screw

metric coarse thread, whit e nickel-plated

8

16

1

Aluminum

29 7SMF-030060M-SZY

B-N

M3*6 cross round flat head machine screw

Material: hardeded iron,Φ3mm*6mm metr i c c oar se

61

thread

30 6SS2-4067-HRB DR650-02receiving board jacking 1

31 7MHL-4071-02A-W STR-U receive module aluminium shield down case

1

32 3CB1-004071-A

Aluminum

STR-U Power Amplifier Board fixed socket processed

with aluminum alloy

38

1

Page 43

TR850 Service Manual

33 7SAF-030050M-SZY

B-Z1

M3*5 cross round flat head machine screw

Material: hardeded iron, with flat spacer and spring

10

spacer, pb-free.

34 7MBC-4071-01A-W

STR-U power amplifier module big shield cover ,

stainless steel,

0.5mm thick

1

35 7MMC-1943-01A-N PT8200 power module shield cover; pb-free 1

36 1MR3-RA55H4047M UHF RF amplifier IC 8200-02, DR550H STU 1

37 6SS2-4071-HPC STR-U power amplifier jacking (130722) 1

38 7SMF-030060M-SZC

T-N1

M3*6 cross sunk machine screw

Material: hardened iron, φ3mm*6mm cross sunk

8

machine thread, metric co ar se t hr ead, black

nickel-plated.

39 7MHL-4071-01A-W STR-U radiator; processed with aluminum alloy 1

40 3CR7-N-KKF1 RF connector 1

41 7SMF-030100M-SZC

T-N1

M3*10 cross sunk machine screw

Material: hardened iron, φ3mm*10mm cross sunk

12

machine thread, metric co ar se t hr ead, black

nickel-plated.

42 4MF7-DFB602512HM Fan DFB602512HM, Specification: 12V/0.3A,

1

60X60X25mm

43 7MHF-4027-02A-Z DR550 Fan-fixing bracket, zinc-plated board,

1

0.8mm thick , black dusting on surface

44 7STF-050120A-SZHT

-N

45 7WOZ-4100-04A Duplex baffle 1mm, thick color zinc-plated board,

M5*12 cross thick head self-t apping screws.

Hardened iron

4

1

dusting

46 7WOZ-4100-03A Rear pan el (part no. cancelled) 1.5mm thick color

1

zinc-plated board, dusting

47 7SAF-040100M-SZLJ M4*10 Cross external hexagonal combination 4

39

Page 44

TR850 Service Manual

-Z1 machine screw. Material: har dened iron

48 7MHS-4027-06A-W M4*8 grounding screw; stainless steel, M4.0*8 1

49 3CR7-SMA-160 RF coaxial line-1 SMA-C-KY1.5-1 to SMA-C-JW1.5,

1

type: RG141A/U, line length 160mm

50 3CR7-BNC-440 BNCcoaxial line SMA-C-J1.5 to BNC(rectangular

1

flange plate 24*24),RG141A/U, line length: 440mm

51 3CP3-YB-B2-Q1 Power socket, 2.5A T 20mm HRC 250V type 1

52 3WPC-WS20K2Z Two core aviation socket, WS20K2Z 1

53 7NHF-030062025-Z1 M3*2.5 hexagonal nut. Mat erial: iron, inter nal diamet er

10

M3mm, maximum external diameter 6.2mm, 2.5mm

thick, hexagonal and zinc-plated, metric coarse

thread.

54 6SS2-4071-HL1A STR-U repeater accessory board plug-in material 1

55 3WPC-812028-A STR-U Network port connecting wire 8pin, wire length

1

120mm, 28AWG, with network port and crystal head.

56 7WOZ-4100-05A Network port ba ffle, 1mm thick color zinc-plated board 1

57 7MHL-4071-04A-W STR-U Tx module aluminum alloy shield bottom cover 1

58 6SS2-4067-HTB DR650-02 Tx module jacking DR650-02 Tx module

1

jacking, pb-free

59 7MHL-4071-05A-WA STR-U Tx module aluminum al loy s hie ld up cover 1

40

Page 45

5.4. Connection

1

2

3

4

6

8 7

5

9

10

13

14

15

16

18

17

11

12

TR850 Service Manual

41

Page 46

TR850 Service Manual

23

22

+ -

+ -+-

24

28 29

25

26

27

31

30

32

34

35

33

Part no. Description Connect mode

Power connecting line-1 3 Pin, 135mm long, wire

3WPD-S4071-A

size16AWG. one e nd with cold-press sockets

terminal, one end round term inal.

6—31

3WPD-S4071-B

Power connecting line-2, 2Pin,red length 950mm

long, black wire 415mm, wire size 12AWG, both

ends with two round terminals.

42

28—30

Page 47

TR850 Service Manual

3WPD-S4071-C

3WPD-S4071-D

3WPD-S4071-E

3WPD-S4071-F

3CR7-SMA-160

3CR7-SMA-110A

Power connecting line -3 2Pin, 665mm lon g, wire

size 12AWG

Power connecting line -4 2Pin, 315mm lon g, wire

size 12AWG. One end with two round terminals, an d

the other a base.

Power connecting line-5 2 pin, 575mm long, wire size

18AWG, 3.96 interval, with soc ket and round

terminal.

Power connecting line-6 2pin, wire lengt h 550mm,

wire size 20AWG, inter val 2.54, with socket and

cold-press sockets t erminal

RF coaxial wire-1 SMA-C-KY1.5-1 to SMA-C-JW1.5,

wire type: RG141A/U, wire length 160mm

RF coaxial wire -2 SMA-C-J1.5 to

SMA-C-JW1.5,wire type: RG141A/U, wire length

110mm

7—29

24—35

18—25

2—26

3—13

15—21

3CR7-BNC-440

3WPC-812028-A

3WPT-P26050PH25420P

3WPT-P26050PH25426P

3WPD-S4071-G

3CR7-SMA-350

BNC coaxial wire, SMA-C-J1.5 to BNC(rectangular

flange plate 24*24), RG141A/U, wire length: 440mm

STR-U internet port connecting wire 8pin, wire length

120mm, 28AWG, with internet port and crystal head,

With dual-plugged flat cable AWG26#, 2.54 interval,

wire length 50mm, 20P socket, dual-headed soc ket

With dual-plugged flat cable AWG26#, 2.54 interval,

double flat cable, wire len gth 50mm, 26Psocket,

dual-headed socket

Power connecting line-7 2pin, w ire l ength 350mm,

wire size 20AWG, 2.54 interval, with socket and

cold-press sockets t er m in al

RF coaxial wire -3 SMA-C-JW1.5 to SMA-C-JW1.5,

wire type:RG141A/U, wier length 350mm

8—20

5—9

14—23

16—19

2—27

22—34

3WPT-P26155PH25426P

With three-plugged flat cable, AWG26#, 2.54

interval, three flat cable, 155mm long

43

4—10

Page 48

TR850 Service Manual

3WPT-P26350PH25410P

3WPT-P26080PH25410P

3WPD-160140-1PIN

Fan wire Come with fan

With dual-plugged flat cable, AWG26#, 2.54 interval,

double flat cable, wire len gth 350mm, 10P socket.

With dual-plugged flat cab le, AWG26#, 2.54

interval, double flat cab le, wire length 80mm, 10P

socket, double-headed s ocket.

Connected to ground wire 1Pin, blue wire, 140mm

length,wire siz e ,:16AWG.; two ends with r ound

terminal

1—12

17—33

31(ground

terminal)—

machine case

11—32

6. Adjustment

During maintenance, the repeater may needs some testing and modulation for technical index after

changing the components.

6.1. Preparation

Please prepare the tools and equipment before testing the DMR repeat er:

Integrated tester

PC and CPSp software

AEROFLEX 3920

Spectrum analyzer FSU

Antenna interface converter

Universal interface

6.2. Method of Modulation and Test

6.2.1. Local Oscillator Adjustment

Subject Test Point Test Procedure Standard

12.8M

Clock

base band

board J6

1. Enter test mode “12.8M Cl ock”.

2. Set HP8921 to TX mode; connect the reference

frequency port to HP8921 RF high power input

port.

3. Enter computer modulation mode.

44

≤±1Hz

Page 49

Rx

localoscilla

tor power

Tx central

frequency

&power

Rx board

test point

TP3005

Tx module

J200

TR850 Service Manual

4. Adjust to 12.8MHz±1Hz.

1. Enter test mode “Receiver BPF”.

2. Set HP8921 to TX mode.

3. Connect the TP3005 test poit on the RX board

to HP8921RF high power input por t .

4. Check the frequency: (Rx frequency

-51.65MHz)±100Hz; output power >10dBm.

1. Enter test mode “Low Freq.M od Deviatio n”.

2. Set HP8921 to TX mode.

3. Connect Tx module RF output to HP8921 RF

high power input port.

4. 4. Adjust to :±100Hz, Chec k: out put pow er>

15dBm.

1. Turn on the repeater.

Frequnency

tolerance≤±

200Hz

Output power>

10dBm

Frequency

tolerance≤±

200Hz

Output power>

15dBm

2. Set HP8921 to TX mode.

Tx lock

voltage

testing

Rx lock

voltage

test

Tx board

TP100

Rx board

TP100

3. Connect TX por t t o HP8921 RF high power input

port.

4. Enter computer modulat io n mo de.

5. Click Tx low pow er tes t po int s to test lock v olt ag e

1. Turn on the repeater.

2. Set HP8921 to TXmode.

3. Connect TX por t t o HP8921 RF high power input

port

4. Enter computer modulat io n mo de.

5. Click Rx sensitivity test point s to t est lock volt ag e

0.5V≤CV voltage

≤4.5V

0.5V≤CV voltage

≤4.5V

6.2.2. Tx Adjustment

Subject Modulation Procedure Standard

Tx high

power

Tx low

power

1. Enter pc tuning mode.

2. Enter modulation mode”High Power”.

3. Adjust PC software val ue; observe power value on the

integrated tester.

4. Adjust to test power: 40±2W.

5. Modulate the frequency one by one.

1. Enter computer modulation mode.

2. Enter modulation mode “Low Power”.

3. Adjust PC software valu e; obser ve power value on the

45

40±5W

20W±1.5db

Page 50

Low

frequency

modulation

frequency

deviation

High

frequency

modulation

frequency

deviation

TR850 Service Manual

integrated tester.

4. Adjust to test power: 20W.

5. Modulate the frequency one by one.

1. Enter computer modulat io n mo de.

2. Click frequency F1 to F6.

3. When AF Freq is 0.1kHz, observe FM Deviation on the

integrated tester, and modulate PC soft w ar e value.

4. Adjust FM Deviation to 5.0±0.05kHz.

5. Click “ok” to save.

1. Enter computer modulat io n mo de.

2. Click Frequency F1 to F6.

3. When AF Freq is 6.0 kHz, observe FM Deviation on the

integrated tester, and modulate PC software value.

4. modulate FM Deviationto5.0±0.05kHz.

5. Click “ok” to save.

4.95kHz-5.05kHz

4.95kHz-5.05kHz

4FSK EER

test

Maximum

audio

frequency

deviation

test.

QT/DQT

frequency

deviation

and wave

form test.

1. Enter computer modulat io n mo de.

2. Modulate PC software value to make repe at er transmit

O.153.

3. Check 4FSK EER≤5%.

4. Modulate frequenciesone by one.

5. Observe FSK EER value on the integrated test er.

6. Check 4FSK EER≤5%.

1. Connect the audio input wire to repeater.

2. Output audio signal 1KHz RMS 120 mV to repeater and make it

transmit.

3. The audio frequency deviation should be: N: 2000±100Hz,

W:4000±100Hz.

4. Test frequencies one by one.

1. Observe frequency deviation of QT.

2. Observe frequency deviation and wave form of DQT.

FSK EER≤5%

N: 2000±200Hz

W: 4000±400Hz

N: 350±150Hz

W: 750±250Hz

Modulationdi

stortion

Observe distortion for m v alue.

Tx SNR Observe SNR form value

<3%

W: >45dB

N: >40dB

46

Page 51

TR850 Service Manual

Analog&digit

al ACP

Spurious

emission

Observe ACP display value.

Observe spectrum analyzer display value.

6.2.3. Rx Adjustment

Modulation

Subject

Modulation Procedure Standard

W: <-70dB

N: <-60dB

<1GHz: <

-36dBm

>1GHz: <

-30dBm

Rx Sensitivity

Narrow band

squelch level

9 on

Narrow band

squelch level

9 off

1. Enter computer modulation mode.

2. Enter modulation mode ”Receiver BPF”, and clic k the six

frequencies one by one.

3. Make SINA>12dB.

4. Set the four Rx frequencies as -25.825MHz(*1、*2、*3、*4),

and signal strength as -40dBm; the SINA should be<7dB.

1. Enter computer modulat io n mo de

2. Set the channel to the current modulation frequency.

3. Enter modulation mode “SQL9 Open (N)”, and click “start”,

and change to the next frequen cy after the value is stable.

4. Modualte the frequency of nar r ow band and wide band in

turn.

1. Enter computer modulation mode.

2. Set the channel to the current modulation mode.

3. Enter the modulation mode ”SQL9 Close(N)”, and click

“start”, and change to the next frequency after the value is

stable.

-

-

-

4. Modulate the frequency of narrow band and wide band in

turn.

47

Page 52

Narrow band

squelch level

1 on

Narrow band

squelch level

1 off

TR850 Service Manual

1. Enter computer modulation.

2. Set the channel to the current modulation mode.

3. Enter the modulation mode “SQL1 Open(N)”, and click

“start”, and change to the next frequency after the value is

stable.

4. Modulate the frequency of narrow band and wide band in

turn.

1. Enter computer modulation.

2. Set the channel to the current modulation mode.

3. Enter the modulation mode “SQL1 Close(N)”, and click

“start”, and change to the next frequency after the value is

stable.

4. Modulate the frequency of narrow band and wide band in

turn.

1. Enter computer modulat io n mo de.

-

-

Wide band

squelch level

9 on

Wide band

squelch level

9 off

Wide band

squelch level

1 on

2. Set the channel to the curr ent mo dulation mode.

3. Enter the modulation mode “SQL9 Open( W)” , and click

“start”, and change to the next frequency after the value is

stable.

4. Modulate the frequency of nar row band and wide band in

turn.

1. Enter computer modulation mdoe.

2. Set the channel to the current modulation mode,

3. Enter modulation mode “SQL9 Close(W)”, and click “start”,

and change to the next frequen cy after the value is stable.

4.Modulate the frequency of narrow band and wide band in

turn.

1. Enter the computer modulation mode.

2. Set the channel to the current modulation mode.

3. Enter the modulation mode “SQL1 Close(N)”, and click

“start”, and change to the next frequency after the value is

stable.

-

-

-

Wide band

squelch level

1 off

4. Modulate the frequency of nar row band and wide band in

turn.

1. Enter the the computer modulation mode.

2. Set the channel to the current modulation mode,

3. Enter the modulation mode “SQL1 Close(N)”, and click

“start”, and change to the next frequency after the value is

stable.

4. Modulate the frequency of nar row band and wide band in

turn.

48

-

Page 53

TR850 Service Manual

Rx distortion Observe the distorti on value,

Rx SNR Observe SNR value

CTCSS/CDC

SS

BER Test

-

1. Set the output range of 3920 as -118dBm.

2. Enter BER test mode.

3. Click “Start”, and observe BER.

<3%

W: >45dB

N: >40dB

Can transmit

EER≤5%

7. Main Technical Functions and Specifications

General Specificatio n

Frequency Range

UHF: 400-470MHz VHF:136-174MHz

Channel Capaci t y

Channel Spacing

Weight

Dimension(H*B*D)

Environment Index

Operating

Temperature

Storage Temperature -40℃~+85℃

Rx Parameter

Frequency Stability ±1.5ppm

16

12.5kHz/20kHz/25kHz

11.5kg

138mm*62mm*38mm

-30℃~+60℃

Analog Rx Sensitivity

Digital Rx Sensitivity

Intermodulation

-118dBm(12dB)/-121dBm(12dB)

-120dBm(5%)

ETSI: 70dB TIA603: 75dB

49

Page 54

TR850 Service Manual

Adjacent Channel

Selectivity

Spurious Res pons e

Rejection

Conducted Sp uri ous

Emission

Impedance

Rated Audio

Distortion

Hum and noise

Audio Respons e

Tx Parameter

ETSI/TIA603: 60dB@12.5kHz, 70dB@20/25kHz

ETSI/TIA603: 70dB

-57dBm

ETSI: 84dB TIA603: 80dB

<3%

-40dB@12.5kHz/-43dB@20kHz/-45dB@25kHz

+1dB ~ -3dB

Frequency Stability ±1.5ppm

Tx Power

Hum and noise

Conducted Radiated

Emission

Adjacent Channel

Power

FM Modulation

Low: 25W, high: 40W

-40dB@12.5kHz/-43dB@20kHz/-45dB@25kHz

-36dBm@<1GHz, -30dBm@>1GHz

60dB@12.5kHz, 70dB@20/25kHz

11K0F3E@12.5kHz, 14K0F3E@20kHz, 16K0F3E@25kHz

12.5kHz(Only data): 7K60FXD

4FSK Modulation

12.5kHz(data+speech): 7K60FXE

Modulation Limiting ±2.5kHz@12.5kHz, ±4kHz@20kHz, ±5kHz@25kHz

Audio Respons e

+1dB~-3dB

Audio Distorti on 3%

Vocoder

AMBE++

50

Page 55

TR850 Service Manual

High Sensitivity Frequency

Digital Protocol

GPS Index

TTFF(cold start)Time

to First Fix

TTFF(hot start)T ime to

First Fix

Horizontal A ccuracy

ETSI TS 102 361-1, -2, -3

<1 miniute

<10 seconds

<10 meters

8. Maintenance and Test Equipment

Equipment Major Specification

Frequency Range: 10MHz~3GHz

RF Signal Generator

Power meter

Deviation Meter Frequency Range: 100MHz~1000MHz

DVM

Oscilloscope 30 ~100MHz

Modualtion: frequency mo dulation and external modulation.

Output: -127dBm/0.1uV - >-47dBm/1mV

Input Impedance: 50Ω

Operating Frequency : 100MHz~1000MHz

Measurement Range: about 10W

Measurement Range: D C 10mV~20V

Input Impedance: minimu m c ircuit load high input impedance

Frequency Range: 100 ~1000MHz

Counter

Ammeter 5A

Audio voltmeter

Frequency Stabilization : 0.2ppm or lower

Measurement Range: 50Hz~10KHz

Volt age Range: 1mV~10V

51

Page 56

TR850 Service Manual

Voltage Stabilization Power

Measurement Range: 50Hz~5KHz or higher

Audio Generator

Output: 0~1V

Capacity: 3% or lower at 1KHz

Spectrum Tester

Input Level: 50mV~10Vms

Spectrum Analyzer Measurement Rnage: 100~3GHz or higher

5Ω dummy load

Supply

Integrated Tester HP8921, IFR3920

100W

Output Voltage: 5V~30V; Current: 20A

9. Troubleshooting

No. Problems Causes and Solut i on

1. Check the duplexer isolation, and whether the insertion loss

meets the requirement .

2. Check if there is any feeder connectin g damage or abnormal ity.

1 Short coverage

3. Check if the antenna frequency range matches with the

repeater, and check if the antenna is broken.

2 Unable to repeat

3 Unable to receive

Rx green light is on

4

without being able to

repeat

4. Check if there is high power radio antenna beside the repeater

1. Check if the settings such as terminal frequency, CTCSS,

CDCSS, color code, repeater slot are correct.

2. Check if there is interference on the uplink frequency.

3. Beyond the communication scope.

1. Bad antenna contact. Please fix the antenna tightly.

2. Inconsistent frequency between Tx and Rx. P lease select the

same frequency.

3. Beyond the communicat io n scope.

Check if the settings such as termina l frequency, CTCSS, CDCSS,

color code, repeater slot ar e cor r ect .

52

Page 57

TR850 Service Manual

baseband fail to light