Page 1

Page 2

DP770 Service Manual

Contents

1. General Introduction ................................................................................................................................... 3

1. Scope ....................................................................................................................................................................... 3

1.

1.2. Safety Precaution ................................................................................................................................................... 3

2. External Vie w and Functional Keys .......................................................................................................... 4

1. External View and Functional Keys ..................................................................................................................... 4

2.

2.2. LED Indicator .......................................................................................................................................................... 5

3. Circuit Description ...................................................................................................................................... 6

3.

1. RF Section ............................................................................................................................................................... 6

3.1.1. Transmitter Circuit.................................................................................................................................. 6

3.1.2. Receiver C ircuit ..................................................................................................................................... 8

3.1.3. Frequency Generation Unit ................................................................................................................... 9

3.1.4. GPS Circuit .......................................................................................................................................... 10

3.2. Baseband Section ................................................................................................................................................ 11

3.2.1. Power Section ...................................................................................................................................... 11

3.2.2. Audio Section ....................................................................................................................................... 11

4. Function Instruction and Parameters Setting ....................................................................................... 13

4.

1. General Functions ................................................................................................................................................ 13

4.2. Parameters Setting .............................................................................................................................................. 14

5. Assembly and Disassembly .................................................................................................................... 17

5.1. Attaching and Detaching the Battery ................................................................................................................. 17

5.2. Attaching and Detaching the Antenna ............................................................................................................... 18

5.3. Attaching and Detaching the Belt Clip ............................................................................................................... 19

5.4. Detaching the Chassis ......................................................................................................................................... 19

5.5. Removing the PCB board from the Chassis .................................................................................................... 20

5.6. Detaching the Keypad B oard from the Case.................................................................................................... 20

5.7. Exploded View ...................................................................................................................................................... 22

6. T une Mode ................................................................................................................................................. 25

6.

1. Required parts in adjust ment .............................................................................................................................. 25

6.2. Adjusting and checking method ......................................................................................................................... 25

Page 1 of 102

Page 3

DP770 Service Manual

6.2.1. Frequency description ......................................................................................................................... 25

6.2.2. Adjustment Equipments ....................................................................................................................... 26

6.2.3. Adjustment instruction o f TX ................................................................................................................ 26

6.2.4. Receiver section adjustm ent inst r uction .............................................................................................. 28

6.2.5. GPS Performance Test Instruction ...................................................................................................... 30

7. Main Specifications .................................................................................................................................. 31

8. R

epairing an d Testing Equi pments ......................................................................................................... 33

asic Tr oubles h ootin g ............................................................................................................................. 34

9. B

Appendix 1 Material List(Electrics Parts)400-470MHz ......................................................................... 36

Appendix 2 Material List (El ectrics Parts )136-174MHz ......................................................................... 54

Appendix 3 Material List ( Str uctural Section) ........................................................................................... 66

Appendix Figure 1 DP770 UHF Main Board Top Side PCB View ............................................................. 69

Appendix Figure 2 DP770 UHF Main Board Bottom Side PCB View ...................................................... 70

Appendix Figure 3 DP770 UHF Keypad Top Side PCB View ................................................................... 71

Appendix Figure 4 DP770 UHF Keypad Bottom Side PCB View ............................................................. 72

Appendix Figure 5 DP770 UHF Main Board Sche matic Diagram ............................................................ 73

Appendix Figure 6 DP770 UHF Keypad Schematic Diagram................................................................... 85

Appendix Figure 7 DP770 VHF Main Board Top Side PCB View ............................................................. 86

Appendix Figure 8 DP770 VHF Main Board Bott om Side PCB View ...................................................... 87

Appendix Figure 9 DP770 VHF Keypad Top Side PCB Vie w ................................................................... 88

Appendix Figure 10 DP770 VHF Keypad Bottom Side PCB View ........................................................... 89

Appendix Figure 11 DP770 VHF Main Board Schemat i c Diagram .......................................................... 90

Appendix Figure 12 DP770 VHF Keypad Schematic Diagram ............................................................... 102

Page 2 of 102

Page 4

DP770 Service Manual

1. General Introduction

1.1. Scope

This manual is used for maintenance and r epairin g of the DP770 di gita l handhel d radio, and inte nde d to be

used by experienced technicians and trained engineers. Changes may occur with the technology

development. To require latest technology development information, please contact our company or the

local dealer.

Before any repairing, please read this manual carefully.

1.2. Safety Precaution

Electromagnetic Radiation Energy of Radio

Radios will generate and radiate electromagnetic energy, and Kirisun Radios’ electromagnetic radiation

meets the demand of domestic and international standards. To ensure optimum efficiency of the radio and

reduce electromagnetic radiation, when using the radio, it should be perpendicular to the ground. Keep

your mouth 2-5cm away from the m icrophone.

Electromagnetic Interference

To avoid interference, please t urn of f the radio in the site which specifically forbids using radio, e.g. hospital,

airport, health center and etc.

Explosive harmful gases

In the place with explosive harmful gases, such as the lower deck of a hull, fuel or chemical storage,

transportation facilities, places that contain chemical s or dust particles or metal powder in the atmosphere,

radio should be shut down.

When getting close to the blast zone and detonator electric, radio sho uld b e t urn off.

Charging or replacing batt er y is not allowed in the place with potential explosive gases.

Antenna Damage

Do not use the radio when the ant enna is broken, which will cause a mild burn to your skin.

Replacing Spare Parts

Please try not to replace the spar e parts which are not contained in the spare part list.

Page 3 of 102

Page 5

2. External View and Functional Keys

accessories.

D

M

N

O

P

G

H

J

K

I

L

R

Q

E F

A

B

C

2.1. External View and Functional Ke ys

DP770 Service Manual

No. Part Name No Part Name

Volume/Channel Knob

Rotate the knob to adjust the

A Antenna B

LCD Display

C

160*128, 65K colors, 1.8 TFT

LCD.

D

volume.Short press the key, the

feature of the knob switches from

adjusting the volume to changing

the channel.

Universal Connector for

Accessories

Connect USB program ming cable,

earphone or some other

E

G

I Side Key 2 (SK2) J Left Key

Top Key (TK)

Programmable, default: short

press to enable emergenc y alarm,

long press to exit emergency

alarm.

Side Key 1 (SK1)

Programmable, default: none.

F LED Indicator

H PTT Key

Page 4 of 102

Page 6

Programmable, default: none. Press the key to select the ite ms

Dial Key

K

M

O Numeric keypad P MIC

Q Speaker

Press the key to send data or t ext

messages.

Right Key

Press the key to select the ite ms

shown at the bottom right of the

screen.

L 4-way Navigation Key

N

2.2. LED Indicator

DP770 Service Manual

shown at the bottom left of the

screen.

ON/OFF/Hookoff Key

Return to the standby screen.

Long press the key to turn on/off

the radio.

• Red LED glows: Radio is transmitting.

• Green LED glows: Radio is receiving (voice, short m essage, or data) or there is an activity on t

c

hannel.

• Orange LED glows: This means the call hang time period. That is, you can press PTT to talk while t

or

ange LED glows

• Orange LED flashes: Radio is in e m er gency status; or there is a missed call / incoming call aler t ; or t

radio is scanning.

• Red LED flashes: Radio is r ec eiv ing emergency alarm or "power on check" failed.

he

he

he

Page 5 of 102

Page 7

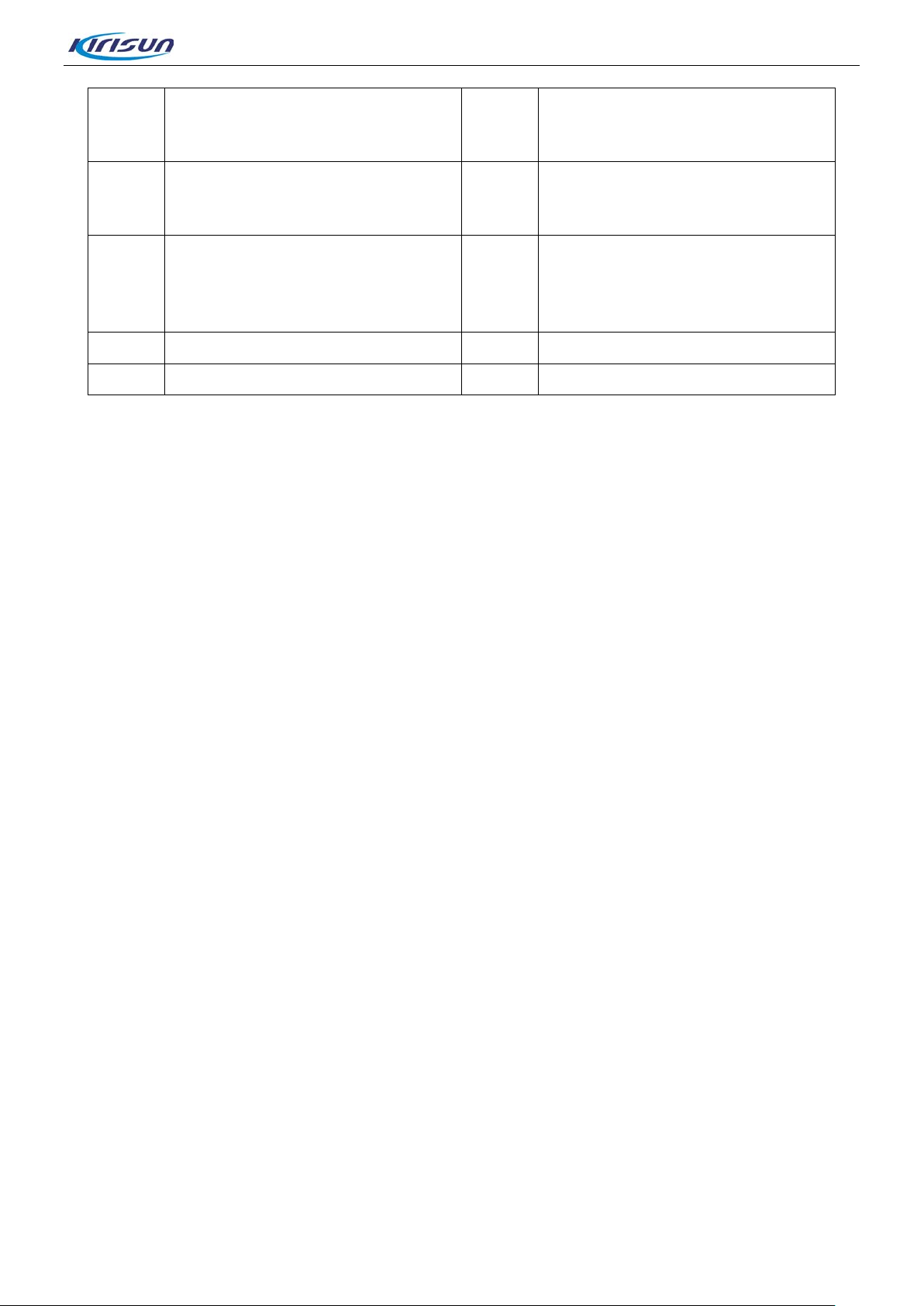

3. Circuit Description

Pre-Driver2 Drive-stage

Final-stage Tx/Rx Switch Low-pass Filter

Microstrip

Matcher

APC

To RX

Gate voltage control

Subtracter

Sampling

resistor

BATT+

I/V

convertor

Attenuator

To GPS

TEMP

Sensor

Close To Final PA

Temp Det Level

Antenna

FGU

Pre-Driver1

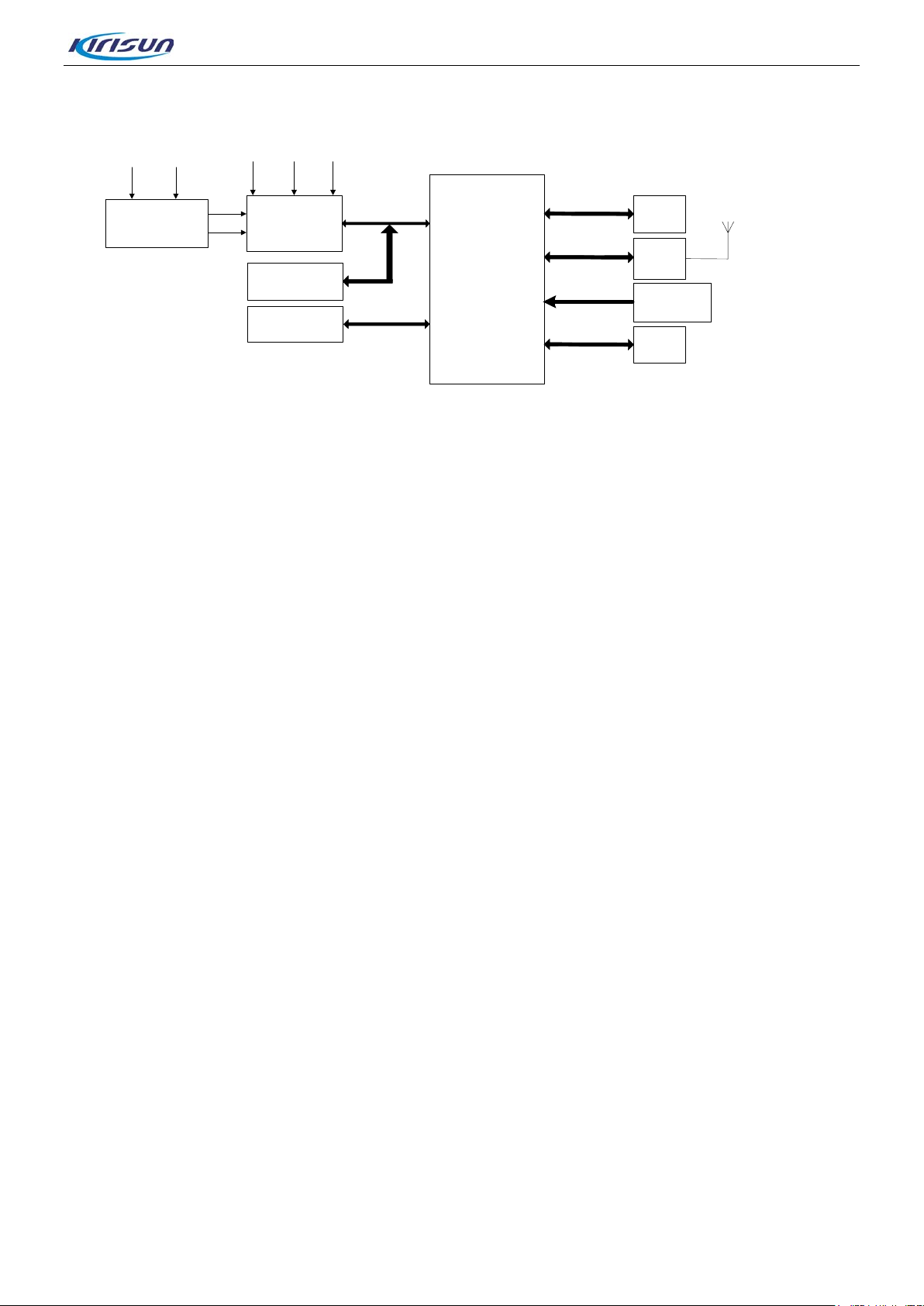

3.1. RF Section

Figure 3-1 RF Schematic Diagram

DP770 Service Manual

3.1.1. Transmitter Circuit

Figure 3-2 Transmitter Circ uit Diagram

Page 6 of 102

Page 8

DP770 Service Manual

The transmitter circuit includes three parts:

• Tran smitter Power Amplifier

T

he carrier signal generat ed by the TX VCO is mod ulate d and a mpl ified, and f eeds to t he tr ansm itter circuit

via the following steps.

Step1: The signal passes a Π-type attenuator, realizing segregative isolation between RF power amplifier

circuit and TX VCO.

Step2: The signal are pre-amplified by a pre-driver amplifier (UHF: Q301, VHF: Q72), providing further

segregative isolation bet ween itself and the next level amplifier.

Step3: The signal goes to the next pre-am plifier and drive amplifier (RD01) to obtain further amplification,

guarantying to provide enough driver power signal to the final-stage amplifier (RD07) and obtain the final

power amplification..

Step4: After amplified by multiple amplifiers, the transmitter signal is processed by a microstrip line to

complete output impeda nce match ing at the output of f inal-sta ge amplifier, to reduce the output loss caus ed

by impedance mismatch.

Step 5: The transm itt er signal goes through the RX/TX switch and enters to the low-pass filter.

• Low-pass Filter Circuit of suppressing t he harmonics

The low-pass filter is high-grade low-pass filter composed of lumped-parameter inductors and capacitors.

By this filter, the spurious signal within the stop band can be attenuated as much as possible while the

in-band ripple is within the required range.

• Auto Power C ont rol Circuit (APC includes temperature detection circuit

I

n the auto power control and temperature detection circuit, the drain current from the driver amplifier and

)

final-stage amplifier is converted to voltage via the sampling resistor and subtraction circuit which is

composed of the first operat ional amplifier.

This voltage is compare d w ith the APC control voltage of output by DA C at the seco nd o perati ona l ampl ifier.

Then the error voltage controls TX power by controlling the bias voltage at the gate of amplifier (including

the driver amplifier and the final-stage amplifier. The temperature sensor IC detects the surface

temperature of the final-stage amplifier, and converts it to DC voltage. Then the DC voltage is compared

with the voltage correspo nding to t he protectio n temper ature (generally 80% of the extreme temperature ) of

the amplifier. If the temperature is too high, the b ias v oltage o f the a mpl ifier w ill be redu ced unt il the sur fa c e

temperature falls below the prot ec t io n temperature.

Page 7 of 102

Page 9

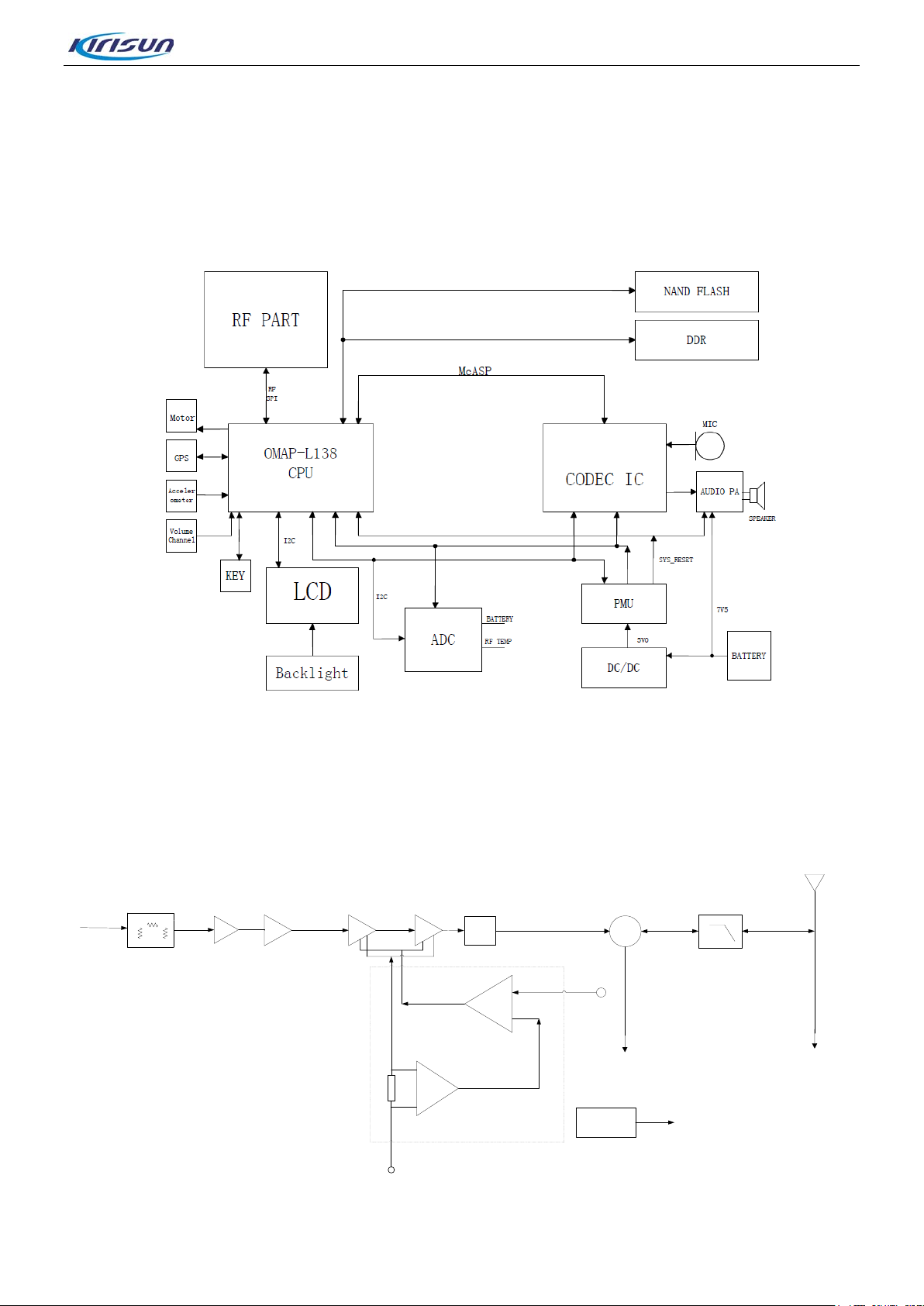

3.1.2. Receiver Circuit

AD986

Antenna

OMAP13

-120dBm

-106dBm

-121dBm

Clip at -24dBm

Figure 3-3 Receiver Circuit Diagram

DP770 Service Manual

Point A

Low-pass filter

Insertion los s = -1dB

-121dBm

-124dBm

Band-pass filter

Insertion los s = -3dB

Low noise amplifier

Gain = 18dB

Band- pass filte r

Insertion los s = -3dB

-109dBm

Lo: 0dBm

-115dBm

Mixer

Insertion los s = -6dB

he receiver circuit mainly com prises RF band-pass filter, low-noise amplifier, mixer, IF filter, IF amplifier

T

Crystal filter

sertion lo ss = -6dB

In

IF ampli fier

Gain = 25dB

Po-1dB = -24dBm

-96dBm

Point B

and IF processor.

• Receiver Front-end

The HF signal from the lo w-pass filter passes through the electrica lly t unab le band-pass filter controlled via

APC/TV1 level, to remove out-of–band interference signal and to send wanted band-pass signal to the

low-noise amplifier (UHF:Q205,VHF:Q62). The amplified signal goes to a band-pass fi lter controlled via

TFV level to remove out-of-band inter ference si gnal generat ed during a mplificat ion, and to send wante d HF

signal to the mixer (UHF:Z201,VHF:Z10).

Meanwhile, the first local oscillator signal generated by VCO passes through the low-pass filter and also

goes to the mixer (UHF: Z201, VHF: Z10). In the mixer, the wanted signal and the first local oscillator are

mixed to generate the first IF signal (UHF: 73.35MHz, VHF: 51.65MHz). The signal passes a frequency

selective network composed of LC, to suppress carrier other than the first IF signal , and to increase the

isolation between the mixer and the IF filter. After that, the first IF signal i s processed by the crystal filter

(UHF: Z202, VHF: Z11) and is sent to the two-stage IF amplifier circuit composed of 2SC5006 for

amplification. Then the amplified signal goes to the IF processor AD9864 (UHF: U201, VHF: U91) for

processing.

• eceiver Back-end

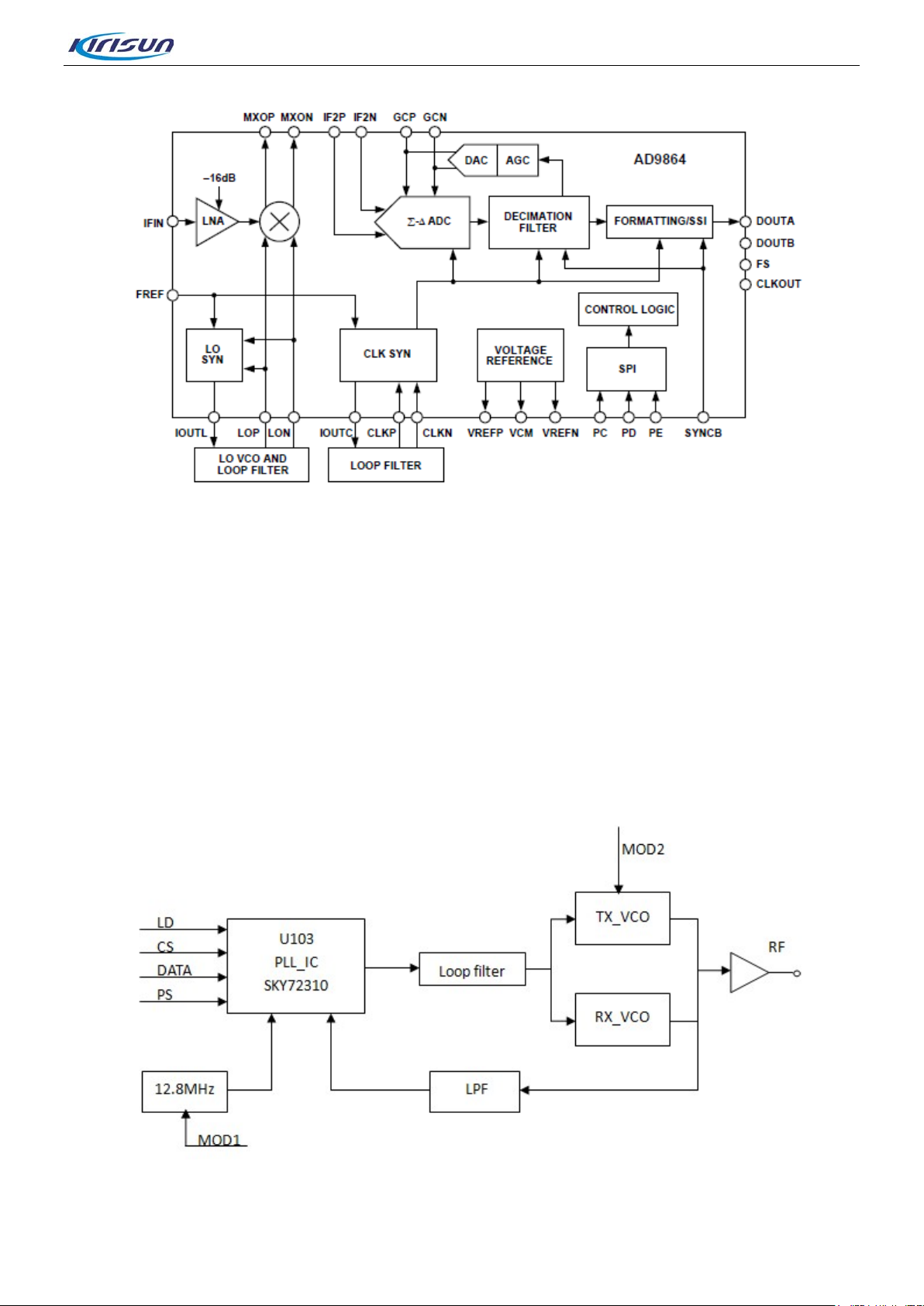

Figure 3-4 IF Processor Diagram

Page 8 of 102

Page 10

DP770 Service Manual

he first IF signal (73.35MHz) output by the IF amplifier goes into AD9864 (UHF: U201, VHF: U91) via Pin

T

47 and completes the second mixer, where the signal is converted to the second IF signal (2.25 MHz). The

second IF signal is converted to digital signal via ADC sampling, and output via the SSI interface. Finally,

the digital signal is sent to DSP (OMAP138) for demodulation.

AD9864 employs reference frequency of 12.8MHz. The second local oscillator is composed of an external

oscillator, a varactor and some other components, to provide the (UHF: 71.1MHZ, VHF: 49.4MHz)

71.1MHz LO signal. The 18MHz clock input frequency of AD9864 is generated by the LC resonance loo p.

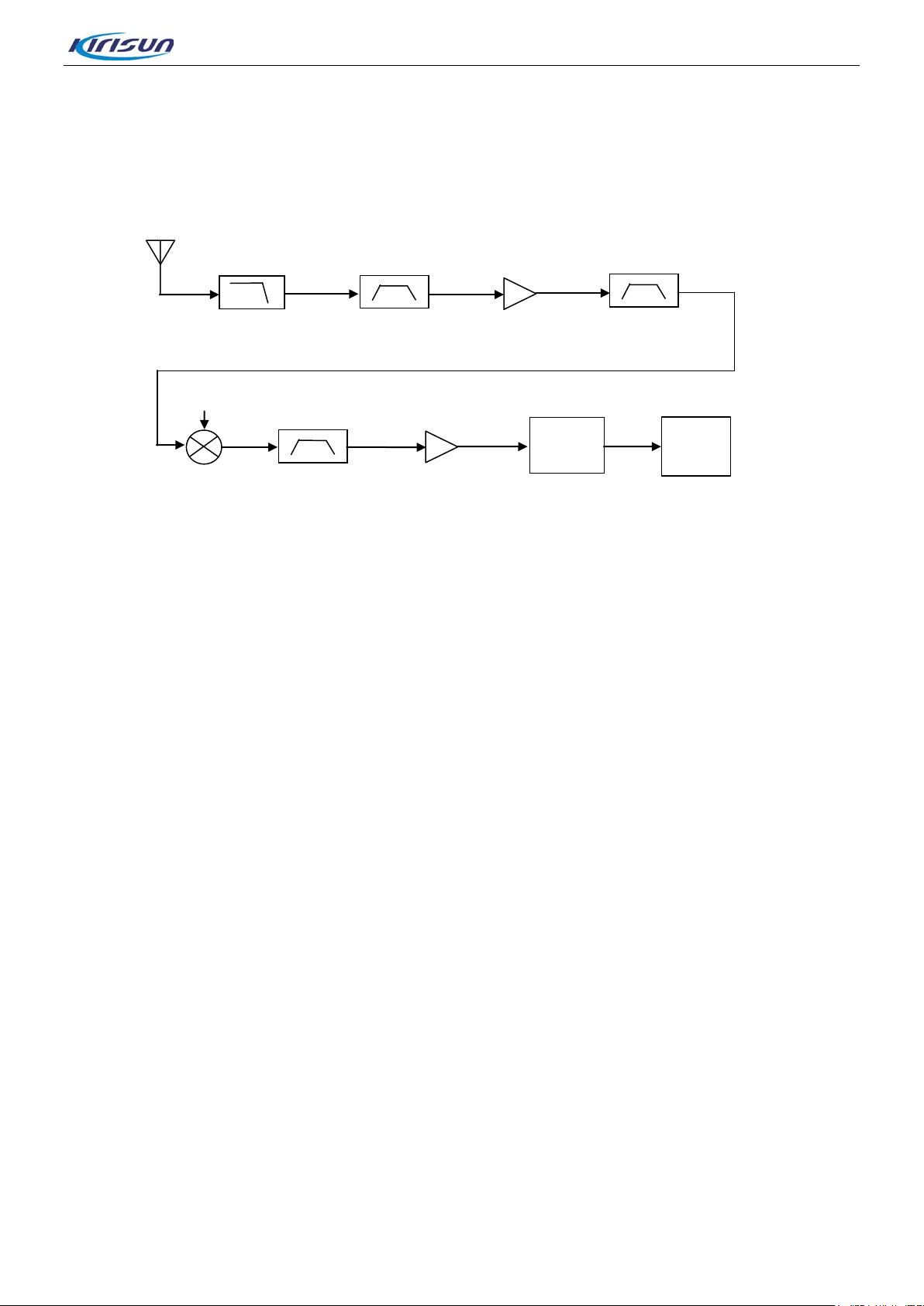

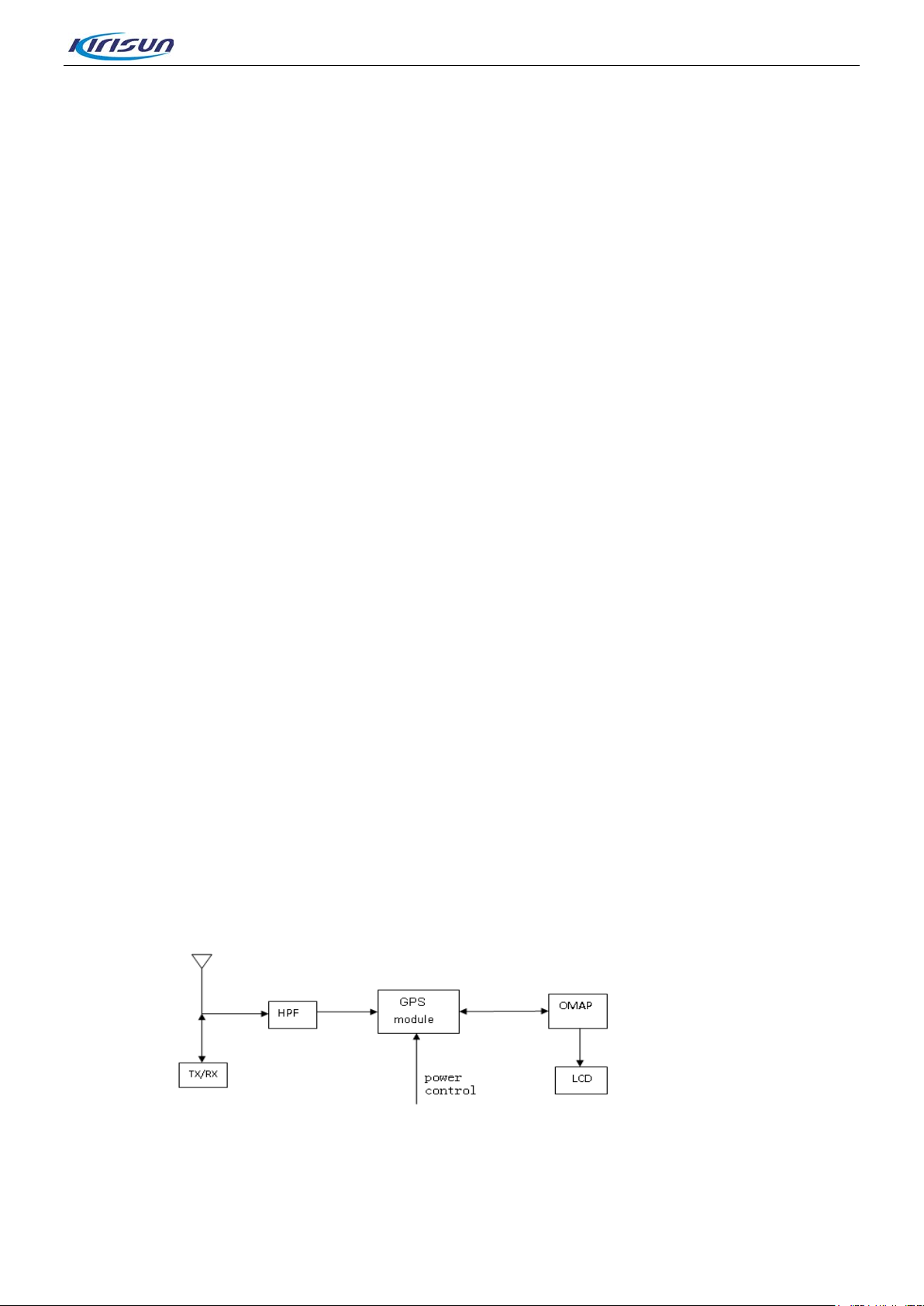

3.1.3. Frequency Generation Unit

Figure 3-5 Frequency Generation Circuit Diagram

Page 9 of 102

Page 11

DP770 Service Manual

The frequency generation circuit is composed of VCO and PLL. It is the core module of the whol e TX-RX

system. This circuit provides accurate carrier frequency during transmission; and provides stable local

oscillator signal during rec ept ion. It has a direct influence on the performance of the system.

• Workin g Pr inciple of PLL

The 12.8MHz frequency generated by the reference crystal oscillator goes to PLL for division, generating

the reference frequency (i.e step frequency f1). The frequency generated by VCO is filtered harmonic via

LPF and generates another frequency ( f2) through the freq uency div ider in PLL. Then freque ncies f1 an d f2

are compared in the phase detector (PD), to generate continuous pulse current. The pulse current goes to

the loop filter for RC integration and is then converted to CV voltage. Then the CV voltage is sent to the

varactor of VCO. It adjusts the output f requency of VCO directly unti l the CV voltage becomes constant.

Then the PLL is locked, and the stable frequency output by VCO goes to the TX-RX channel af ter passing

through two buffer a m pl ifiers.

• Workin g pr inciple of VCO

Voltage controlled oscillator applies oscillation mode of three-point capacitance, and gains different output

frequency through changing controlled voltage (C V) o f varactor. Rx VCO is composed of oscillating circuit

and Q24/Q29 and provides local oscillati on signal. Tx VCO is composed of oscillating circuit and Q27/Q28

and provides carrier of Tx signal.

Working principle employs colpitts oscillator circuit (the RX oscillator circuit is composed of D102, D103,

D106, D107 and L112 (VHF:D32, D33, D36, D34 and L23); the TX osci lla tor ci rcui t is com posed of D108,

D109, D110, D101and L117 (VHF:D38, D39, D40, D41 and L31). It obtains different output frequencies by

changing control voltage of varactor (i.e.CV voltage).RX VCO is composed of oscillator loop and Q104

(VHF:Q43), providing local oscillator signal. TX VCO is composed of oscillator loop and Q108 (VHF Q4 4)

and provides carrier of TX signa l.

• Two-point Modulation

To obtain higher modulatio n acc uracy and lower 4 F SK b it err or, it employs two-point modu lat ion tec hno logy

in the TX mode. MOD1 and MOD2 send the modulation signal to the modulation end of VCO and the

reference crystal oscillat or of PLL respectively to modulate TX VCO and the reference crystal oscillator.

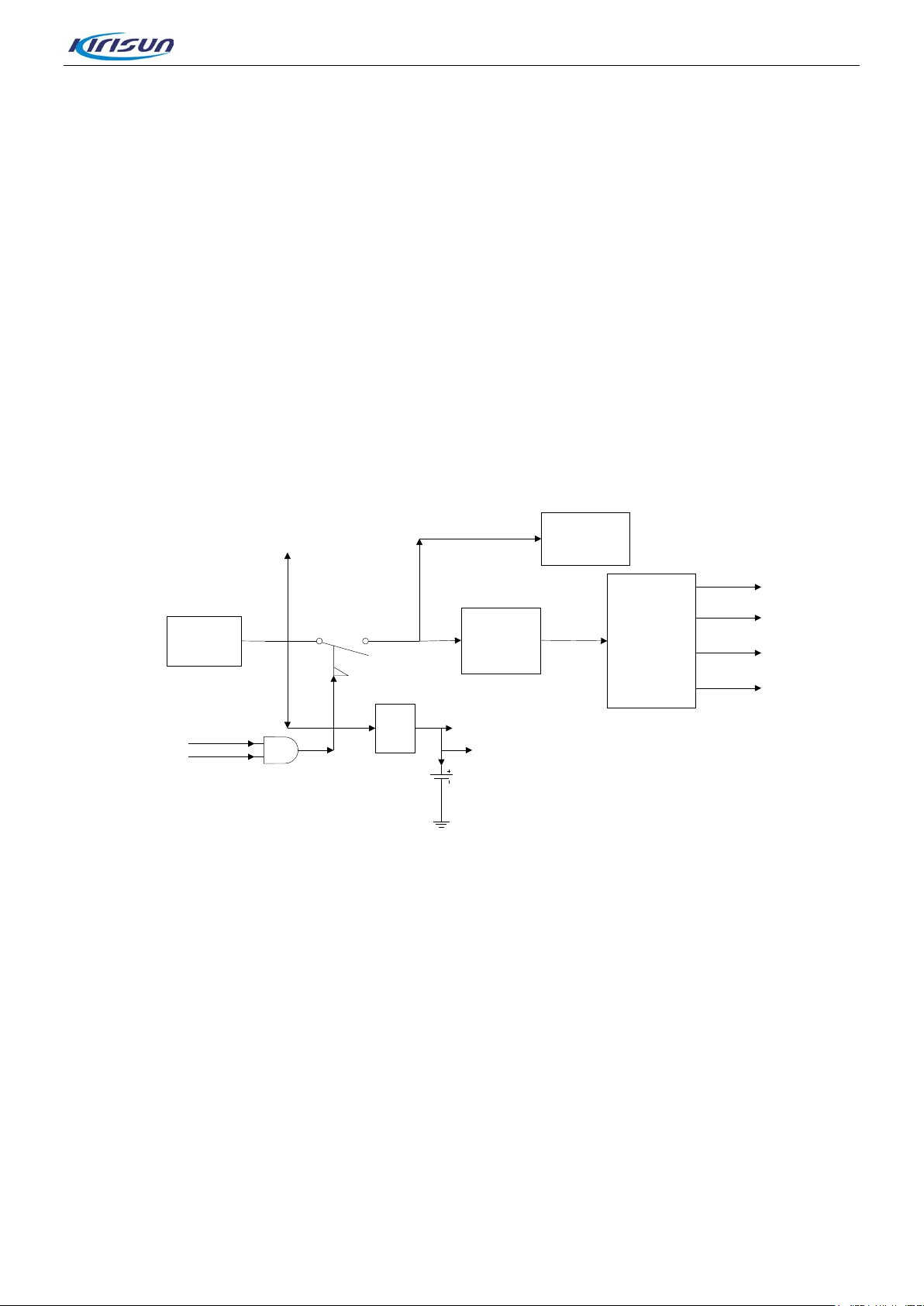

3.1.4. GPS Circuit

Figure 3-6 GPS Circuit Diagram

The GPS function is realized via REB-1315LPx (GPS module).The GPS module integrates a baseband

processor, a LAN and a SAW . The GPS function is realized via the foll ow ing steps:

Page 10 of 102

Page 12

DP770 Service Manual

PMU

VCC_3V3

VCC_1V8

VCC_1V2

LDO_3V3

V

C

C

_

5

V

0

Power switch

DC/DC

Battery

Audio PA

Soft_ctr

PWR_Key

RF_PWR

Logic OR

LDO

GPS_3v3

RTC_1v2

Step1: The 1575.42MHz GPS signal is received by the antenna, and then goes to HPF to remove the

in-band signals used for t r ansmission and reception.

Step2: The signal goes to GPS module for amplification and filtering after frequency selection via filter.

Then it will be sent to baseband section for cal culation.

Step3: The calculated GPS position information is sent to OMAP for processing via the UART interface.

Meanwhile, OMAP138 can send appropriate command information to the GPS module via the UART

interface.

Step4: Finally, the OMAP sends the proce ssed data information to the LCD.

3.2. Baseband Section

3.2.1. Power Section

Figure 3-7 Power Section Diagram

The radio adopts 7.4V li-i

on battery as power supply. The baseband and RF circuit are supplied by

independent power structure. The baseband power is composed of two stage conversion circuit. The first

stage reduces the batter y voltage to 5V by DC/DC, and the second stage converts the 5V voltage to power

required voltage for the system by the power management.

Power On/Off: Power On/Off is implemented through a PMOS component. When the Power On/Off key i s

pressed, PWR_Key signal becomes high level, and PMOS component becomes conducted. The system

will begin initialization and set Soft_ctr to be high level. Thus, the radio is powered up. During the power off

process, when the system detects that the Power On/Off key is pressed, the system will begin executing

the shut down operations, and finally set Soft_ctr to be low level, which will shut down the PMOS

component, thus the radio being powered off.

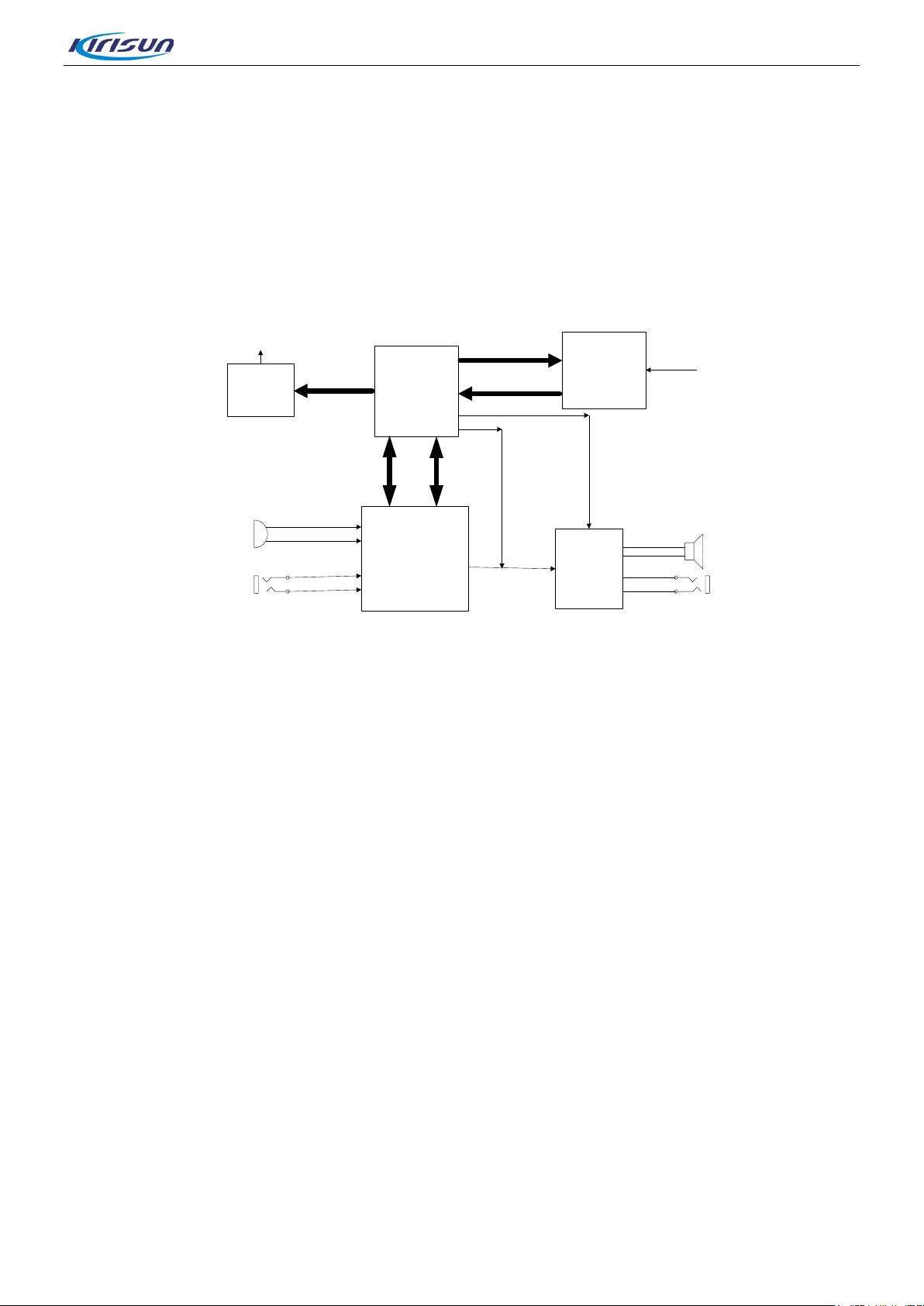

3.2.2. Audio Section

The audio module is mainly for audio input and outp ut. It uses TLV320AIC14 as audio codec to conv ert and

Page 11 of 102

Page 13

DP770 Service Manual

CODEC

Audio PA

OmapL138

AD9864

TLV5614

Baseband signal

Configure data

RX signal

RX

TX

IICIIS

INT_MIC

EXT_MIC

Voice signal

INT_SPK

Interface EXT-SPK

TONE

Mode

select

SPI

MIC

Input

PWM

Control

signal

process audio signal and digital signa l. The audio ampl ifier TDA854 7TS is used to amplify the analog audio

signal.

DSP processes digi tal signal (i.e audio signal encoding/decoding, digital I/Q signal decoding, digi tal audio

signal processing). The AD9864 converts and processes the RF IF, and sends un-demodulated serial

digital signal to the DSP fo r proces sing. The n DAC 5614 conv ert s the dig ital signa l output by DAS to analog

signal.

Figure 3-8 Audio Section Diagram

iagram of Signa l Flow

• D

The microphone convert s t he aud io sign al into e lectr ica l signa l, whic h is am plifi ed by PG A of the codec and

then sent to ADC of the codec for sampling. After digital audi o processing, the signal is output DSP for

processing. Then the s ign al is s ent t o DA C (TLV5614), which conver ts t he sig nal to modulat ion si gnal. After

modulated and amplified in the RF module, the signal is sent out from the antenna.

The RF signal receiv ed by the R F mo dule is conv ert ed to d igit al by ADC (AD9864), and is then sent t o D SP

for modulation and proces sing. Then the digital signal is sent to the digital audio process or of the codec for

digital audio processing, and is then converted into analog audio signal by DAC of the codec. Finally the

signal is amplified by the exter nal audio amplifier (TDA8547TS) to drive the speaker.

• System Peripheral Function Unit

The system peripheral consists of analog/digital converter module, vocoder encryption modul e, TF card

interface module, display module, key detection module and acceleration sensor module. These modules

are used to achieve human-radio interaction, state detection, communication encryption and feature

extension. The analog/digital converter is used for voice signal strength detection, power suppl y detection,

temperature detection, so as to realiz e VOX, low bat tery w arning and tem perature c ontrol. The ac celerati on

sensor is used to detect tilted state, realizing mandown function. The TF card module interface is used for

communication encrypt ion, to provide communicate security.

Page 12 of 102

Page 14

DP770 Service Manual

ADC

Voice level detect

Codec

Accelerometer

TF card

IIC0

INT_MIC

EXT_MIC

CVDECT

Voltage

Temperature

detect

IIC1

GPS

UART0

OmapL138

Key scan module

LCD

LCD

controler

Figure 3-9 The Composing of System Basic Peripheral

4. Function Instruction and Parameters Setting

4.1. General Functions

• Support P-Call, G-Call, A-Call in digit a l mod e.

• Support P-Call, G-Call, A-Call in analog mode.

• Support Transmit Interrupt function in digital mode.

• Support Encryption of both voice and data.

• Support Short message, st at us me ssage and GPS data information.

• Support Stun, Un-kill, Re mote Monitor, Call Alert digital signaling.

• Support Self-defined Ki ll digital signaling.

• Support CTCSS/CDCS S i n analog mode.

• Support MDC1200, 2 Tone, DTMF, 5Tone signaling system in analog mode.

• Support Emergency funct i on.

• Support scan function of digital channel, analog channel and mixed digital and anal og channel.

• Support the maximum of 1024 c hannels capacity.

• Support the maximum of 248 Z ones and the maximum of 128 channels in every zone.

• Support the maximum of 512 co ntacts.

• Support graphic menu operation interface.

• Support LED, choices of alert t ones and vibration indication.

• 12.5 kHz, 20 kHz or 25 kHz channel spaces can be chosen by PC software.

• Real-time display of signal strength.

• Support battery display and low bat t er y alarm alert functions.

Page 13 of 102

Page 15

DP770 Service Manual

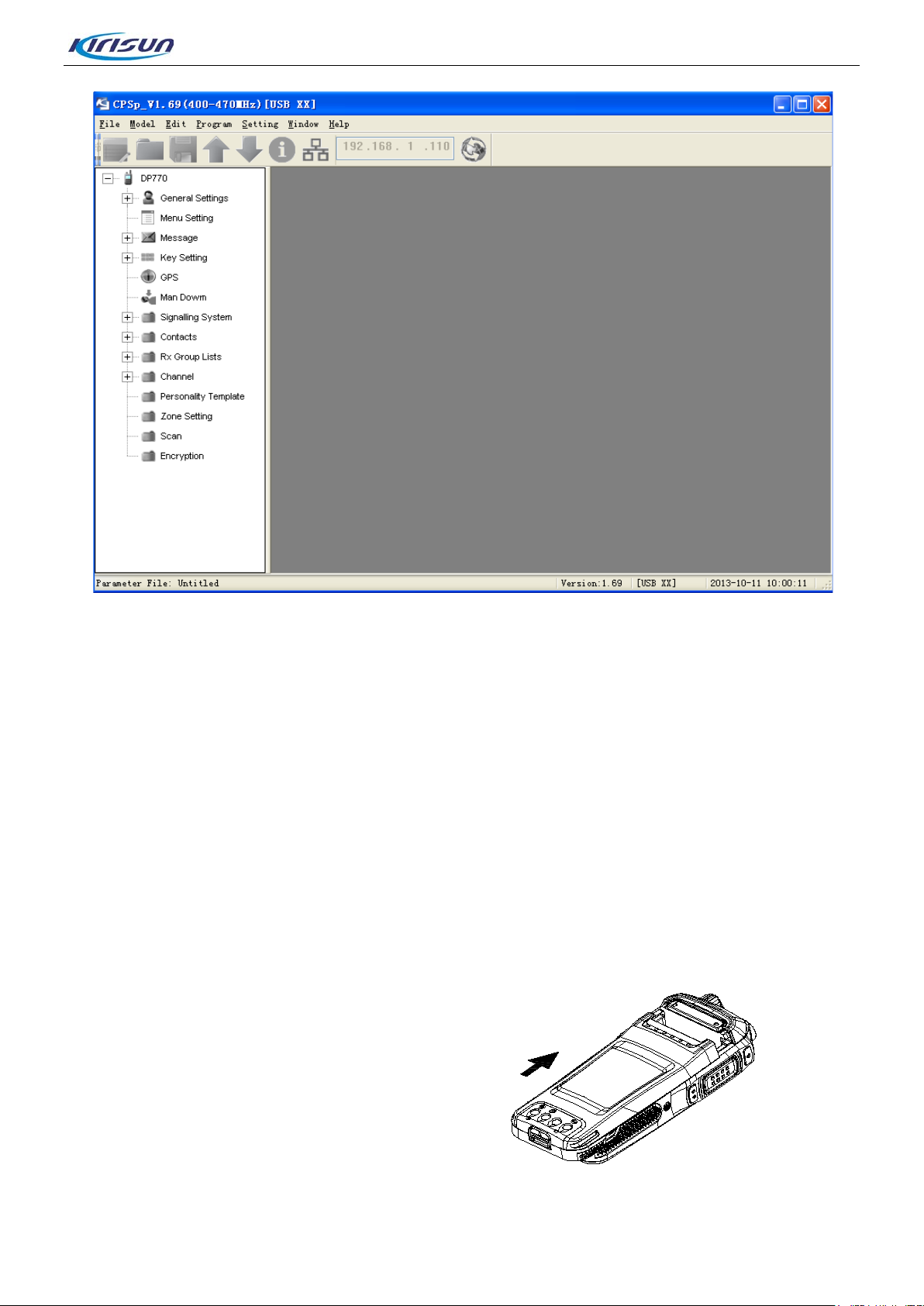

4.2. Parameters Setting

Radios have default parameters. While users can set parameters of frequency, channels, function of

scanning or encryption, etc according your own requirements.

• Parameters setting st eps as follow:

Step 1. Install the right version of Kirisun CPSp.

Step 2. Connect radio with compu t er by Kirisun programming cable.

Step 3. Make sure radio’s power is on.

Step 4. Execute CPSp and start oper at ion.

• CPSp installation st eps as follow:

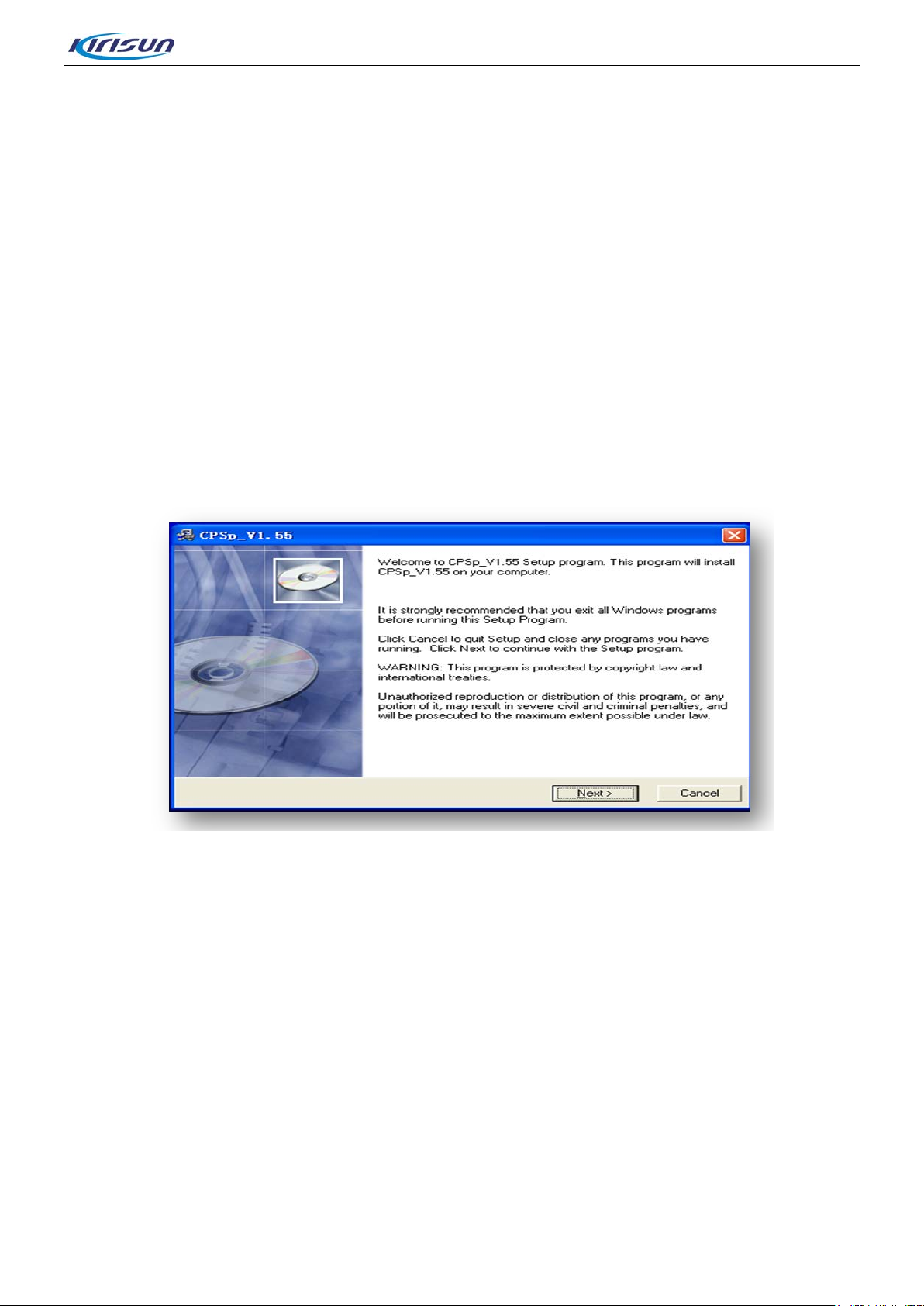

Step 1. Double click the installation file; pop-up interface as Figure 4-1.

Figure 4-1

S

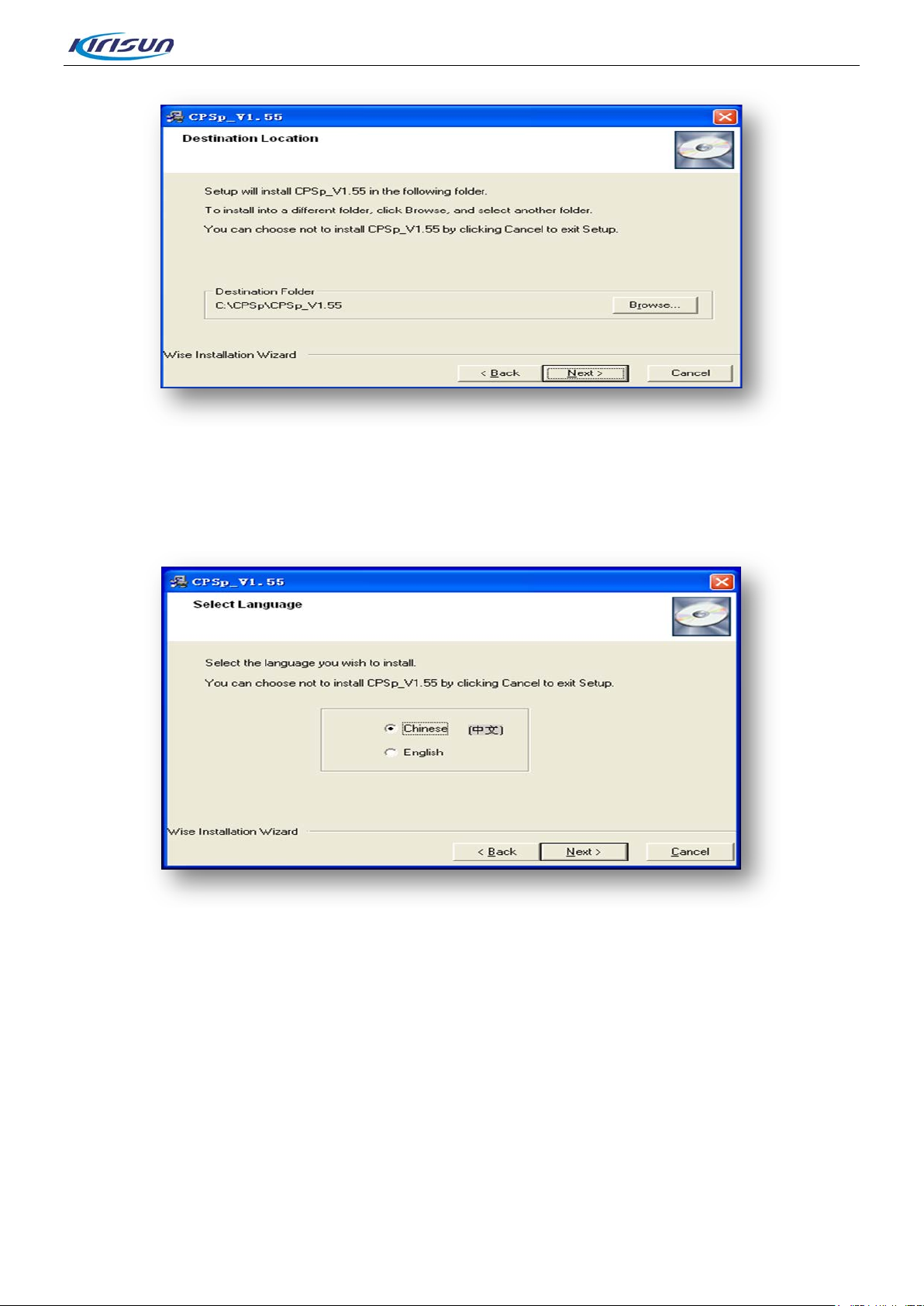

tep 2. Click “Next” and enter into t he nex t inter f ac e t o choose the installation route.

Step 3. In the interface shown in Figure 4-2, users can click “Browse” t o choose t h e ins tallat ion r oute, or

use the default route, and click ”Next” t o ent er t he next interface to choose language.

Figure 4-2

Page 14 of 102

Page 16

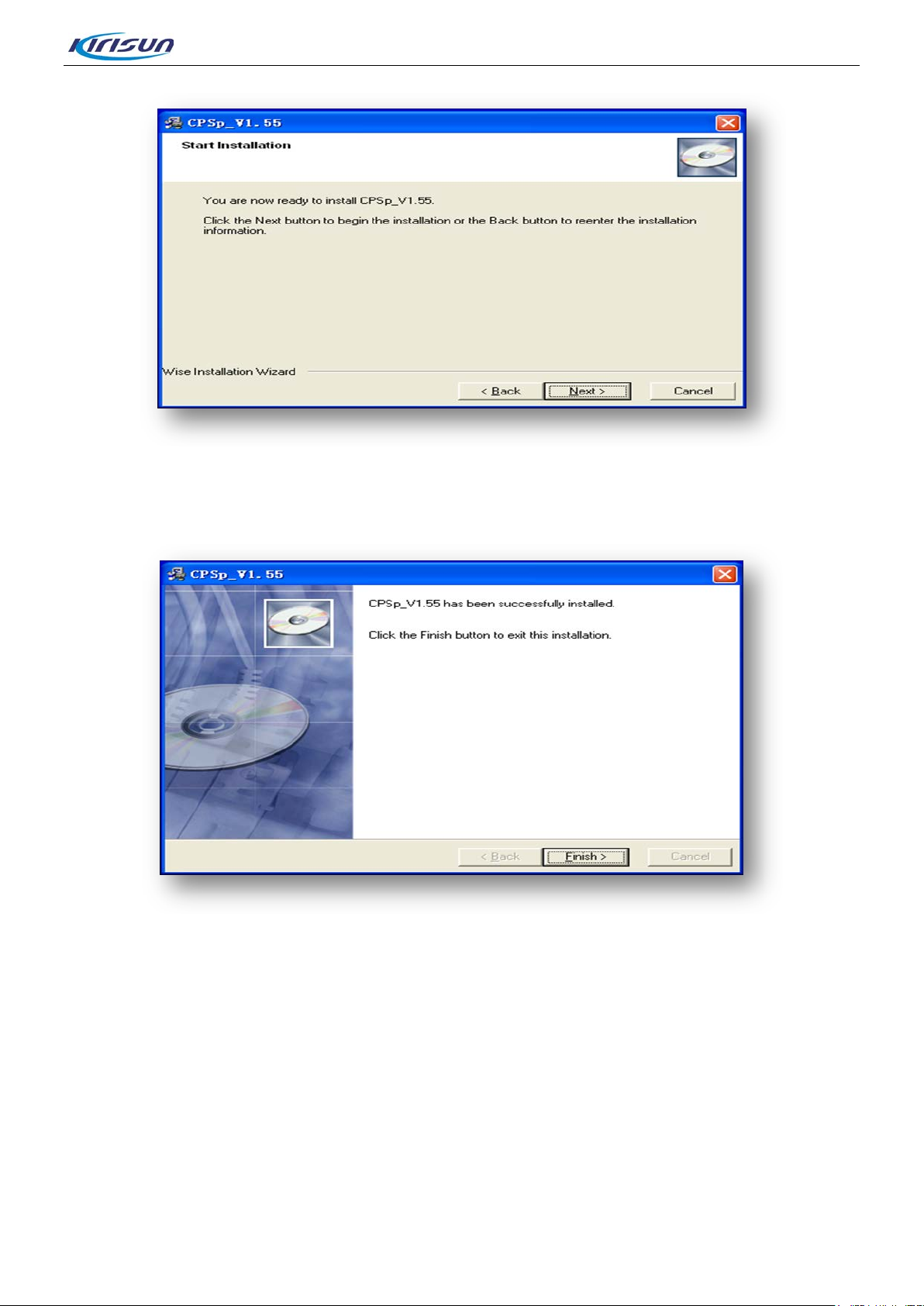

Step 4. Click “Next” to enter into installation information confirmation interface.

DP770 Service Manual

Figure 4-3

S

tep 5. Click “Next” to enter into the finished interface.

Figure 4-4

Page 15 of 102

Page 17

S

tep 6. Click “Finish” to finish installa tion.

DP770 Service Manual

Figure 4-5

tep 7. After successful install at io n, double click the software, as shown in Figure 4-6

S

Figure 4-6

Page 16 of 102

Page 18

DP770 Service Manual

sers can read the radio’s date, or revise the data and then write into the radi o.

U

Please refer to the help file in t he C PSp for the detailed operation instruction about K ir is un CPSp.

Notes:

Errors of parameter configuration may make certain functions cannot be used properly, in general, which

can be solved by writing the correct par ameters configuration.

Before parameter configuration modification, we strongly recommend backup the current parameters,

make sure that the radio can rest or e after an error occurs.

5. Assembly and Disassembly

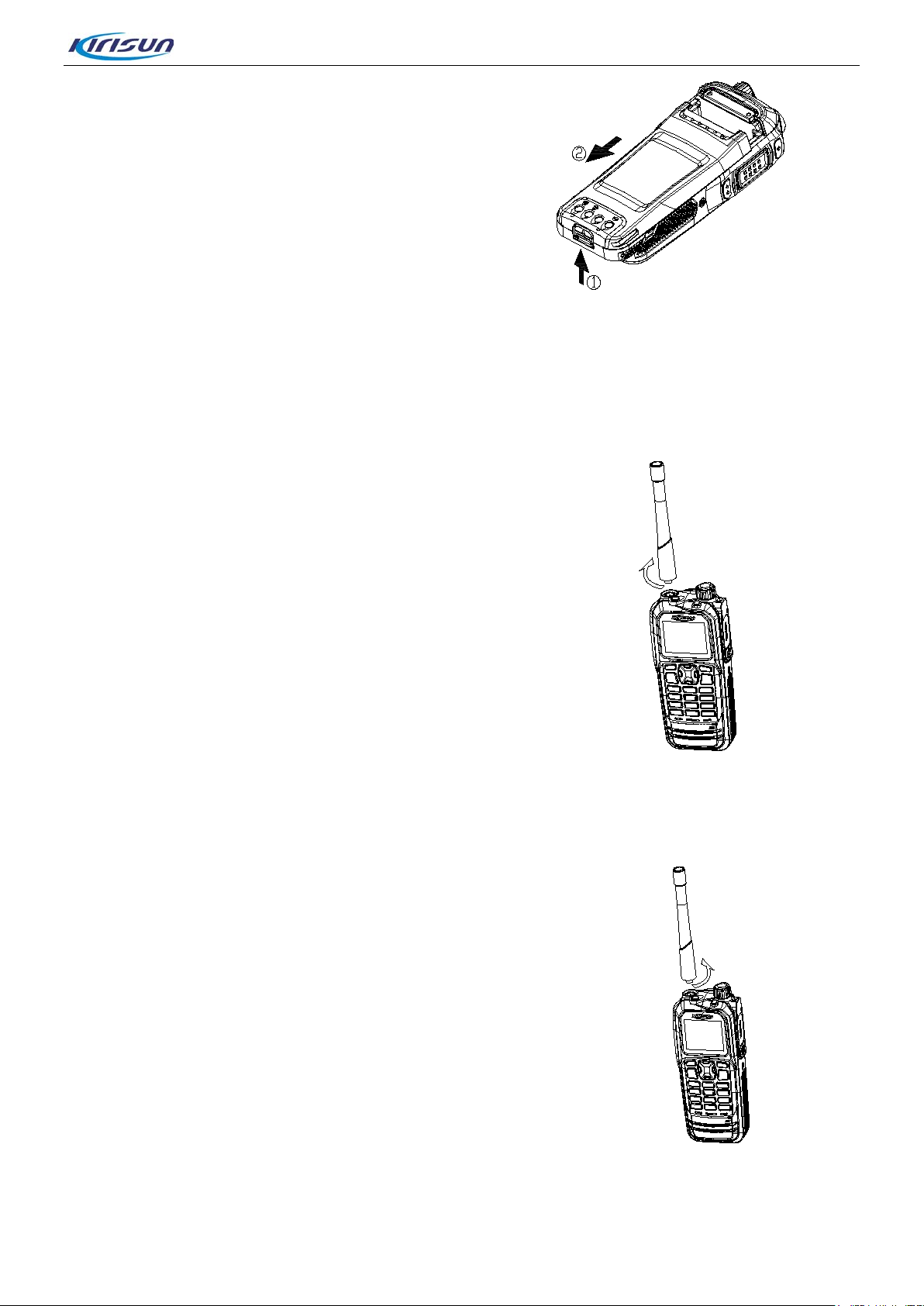

5.1. Attaching and Detaching the Battery

Attaching the battery as shown in figure 5-1.

Put the battery into radio’s aluminum alloy bracket slot.

Push up until a click is heard.

F

igure 5-1

Page 17 of 102

Page 19

Detaching the battery as shown in Figure 5-2

Push up the battery buckl e at the end of the battery.

Pull down to detach the bat t er y.

Figure 5-2

5.2. Attaching and Detaching the Antenna

As shown in Figure 5-3, put t he antenna into radio’ s t hread hole,

and rotate clockwise to fasten it.

DP770 Service Manual

As shown in Figure 5-4, rotate counter-cloc kwise to detach.

igure 5-3

F

igure 5-4

F

Page 18 of 102

Page 20

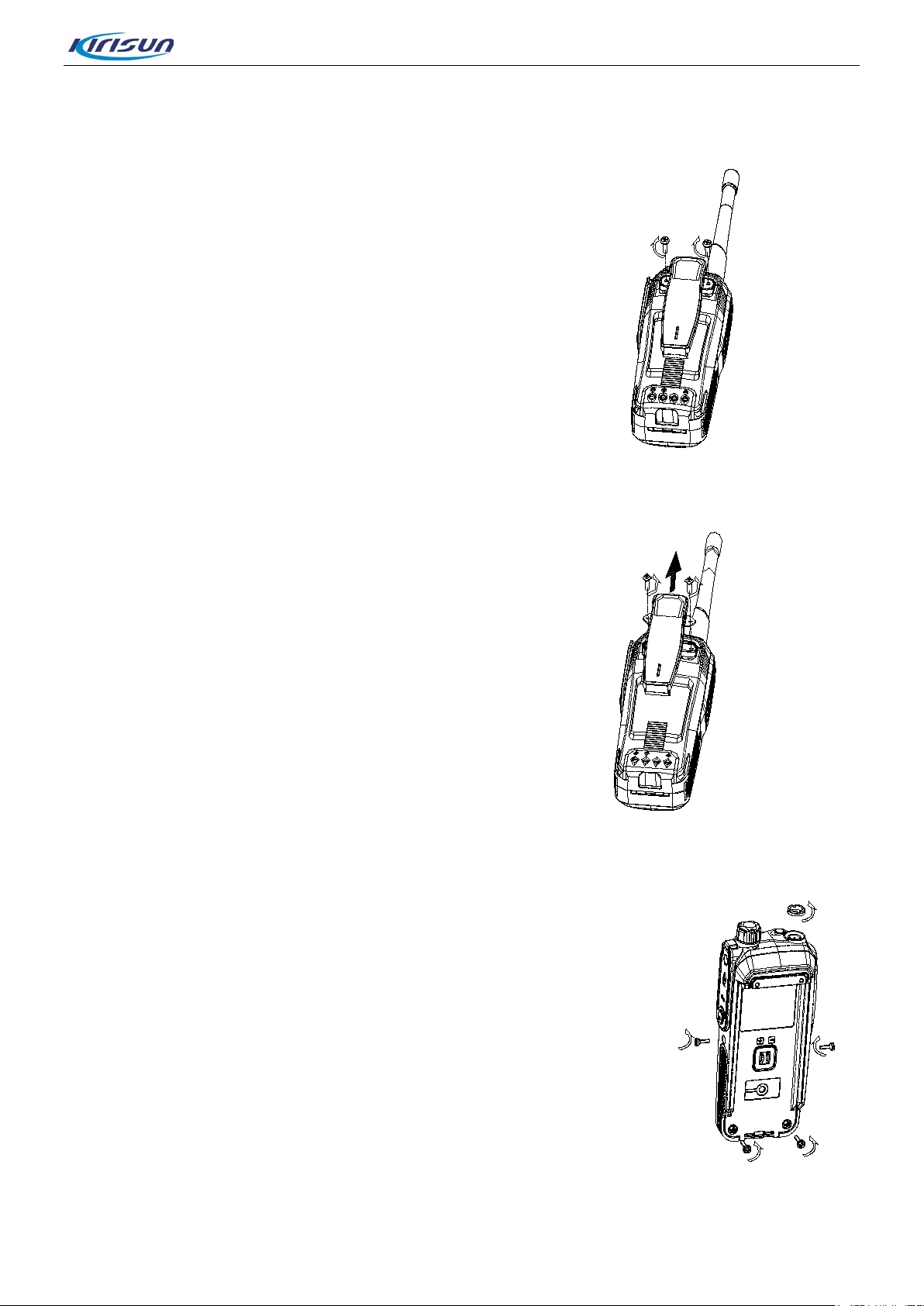

5.3. Attaching and Detaching the Belt Clip

As shown in Figure 5-5, align the screw holes on the belt clip, which is

located on the back of the r adio, and fasten them with the screwdriver.

DP770 Service Manual

Fi

gure 5-5

As shown in Figure 5-6, unfa s t en t he scr ews to detach the belt clip.

5.4. Detaching the Chassis

Step 1. Detaching the belt clip (Figure5.6);

Figure 5-6

Step 2. Removing the antenna (Figure 5.4);

Step 3. Removing the battery (Figure 5.2);

Step 4. Removing the two screws on the bottom of the chassis. Remove the

two screws on the side of shell, and remove the nut from antenna

connector.

Figure 5-7

Page 19 of 102

Page 21

DP770 Service Manual

Step 5. Refer to Figure 5-8. Insert the flat-bladed screwdriver

into the slot of Al alloy bracket; lift it s o as t o separ ate the Zinc

alloy bracket from the chassis, and then push the Al alloy

bracket away from the chassis, and take the soft flat cable

away from the socket. Separate the speaker connecting cable

by the soldering iron to.

Fi

gure 5-8

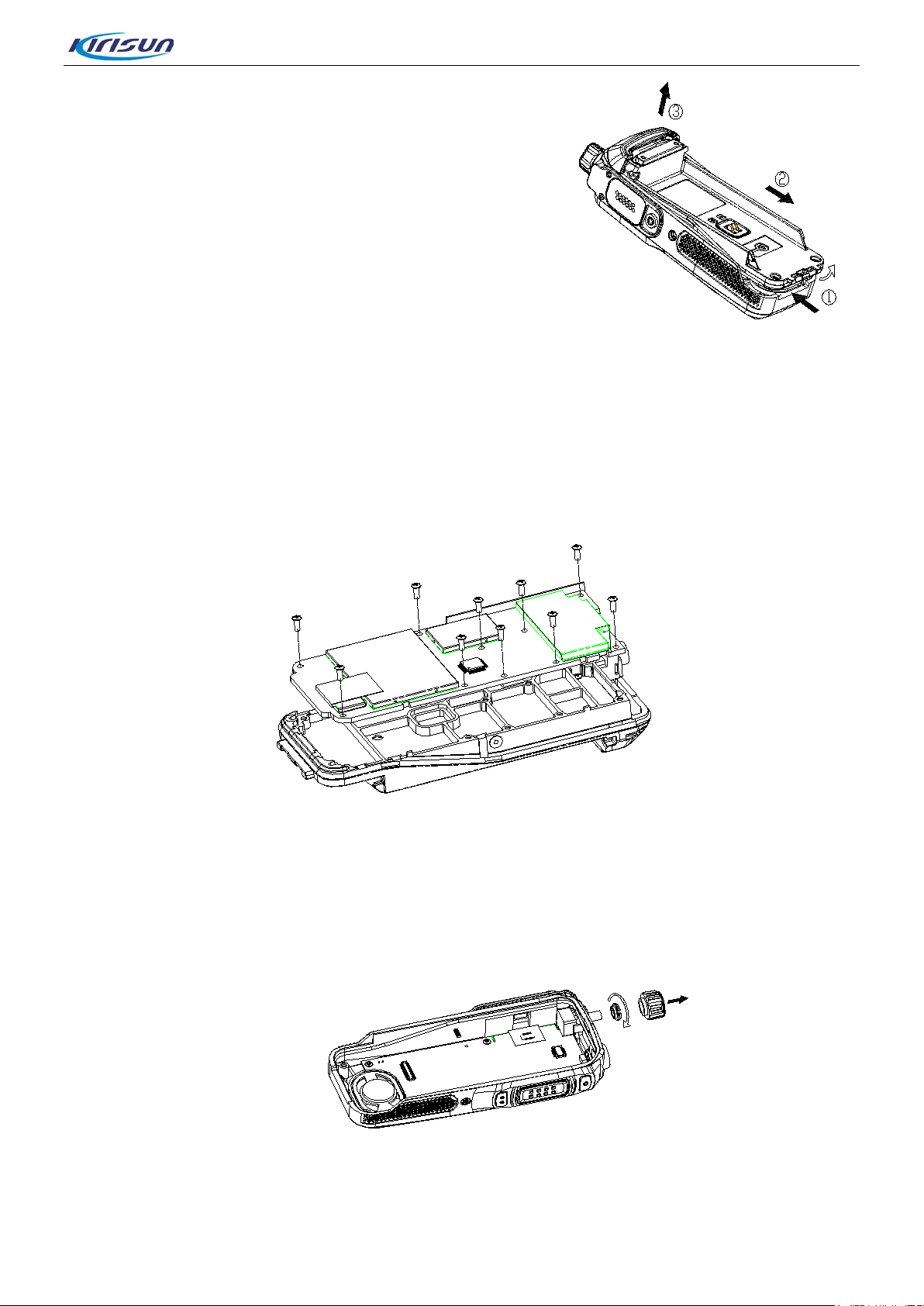

5.5. Removing the PCB board from the Chassis

Step 1. Remove the ten screws on the PCB board.

Step 2. Cut off the antenna connecting point by the soldering iron and then separate the PCB board

from the chassis.

Figure 5-9

5.6. Detaching the Keypad Board from the Case

Step 1. Insert the flat-bladed screwdriver into the slot between the volume knob and case, lift the

volume knob and take off it. Remove the volume knob nut by special tool in the clockwise direction.

Separate the volume soft f lat c able from the socket.

Figure 5-10

Step 2. Separate the speaker and M IC cable by soldering iron.

Page 20 of 102

Page 22

DP770 Service Manual

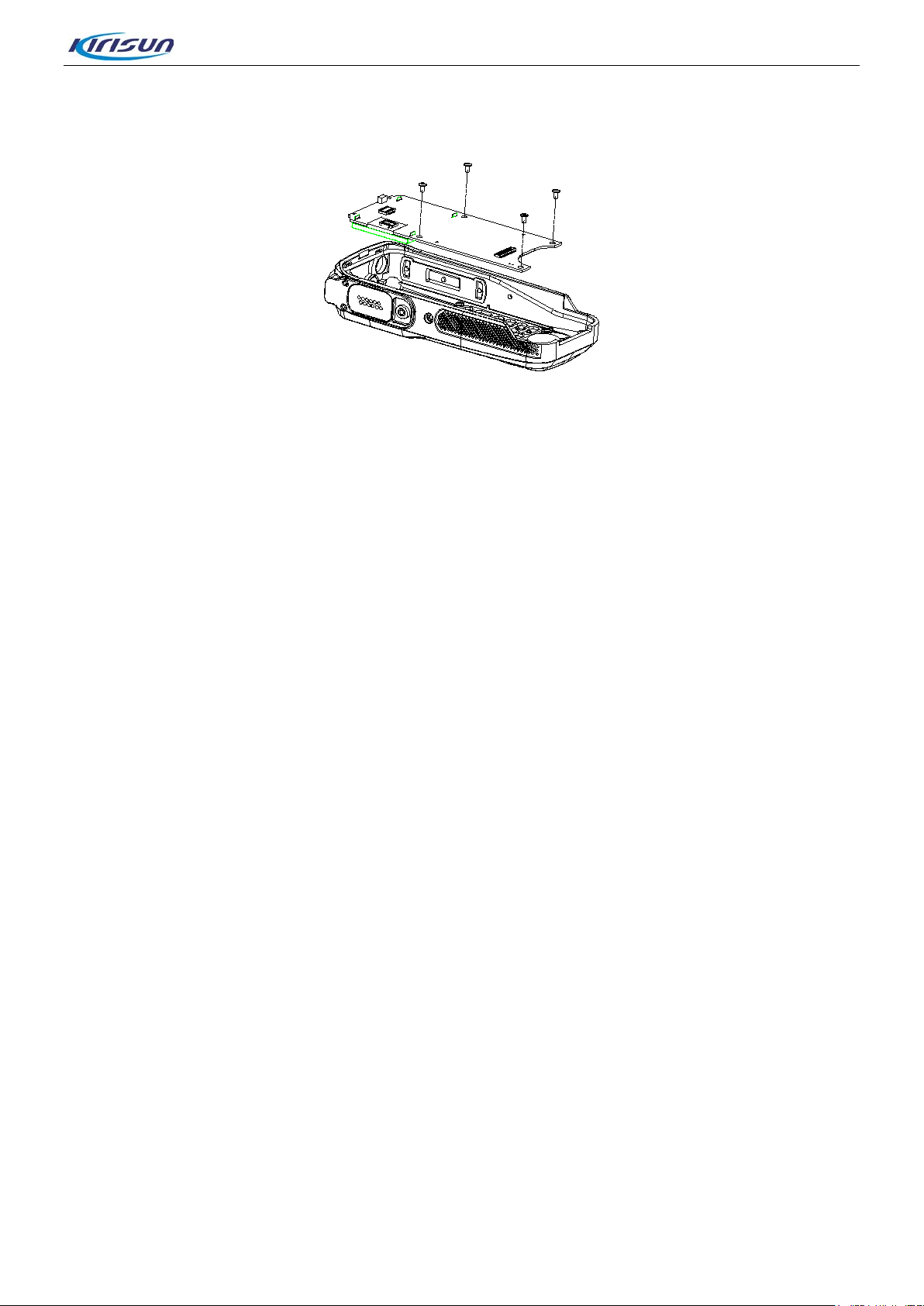

Step 3. Remove the four screws from keypad board and take off keypad PCB from case. (See Figure

5-11)

Figure 5-11

ep 4. After the detaching above, you can make the appropriate repairs and debug against fault

St

conditions.

Page 21 of 102

Page 23

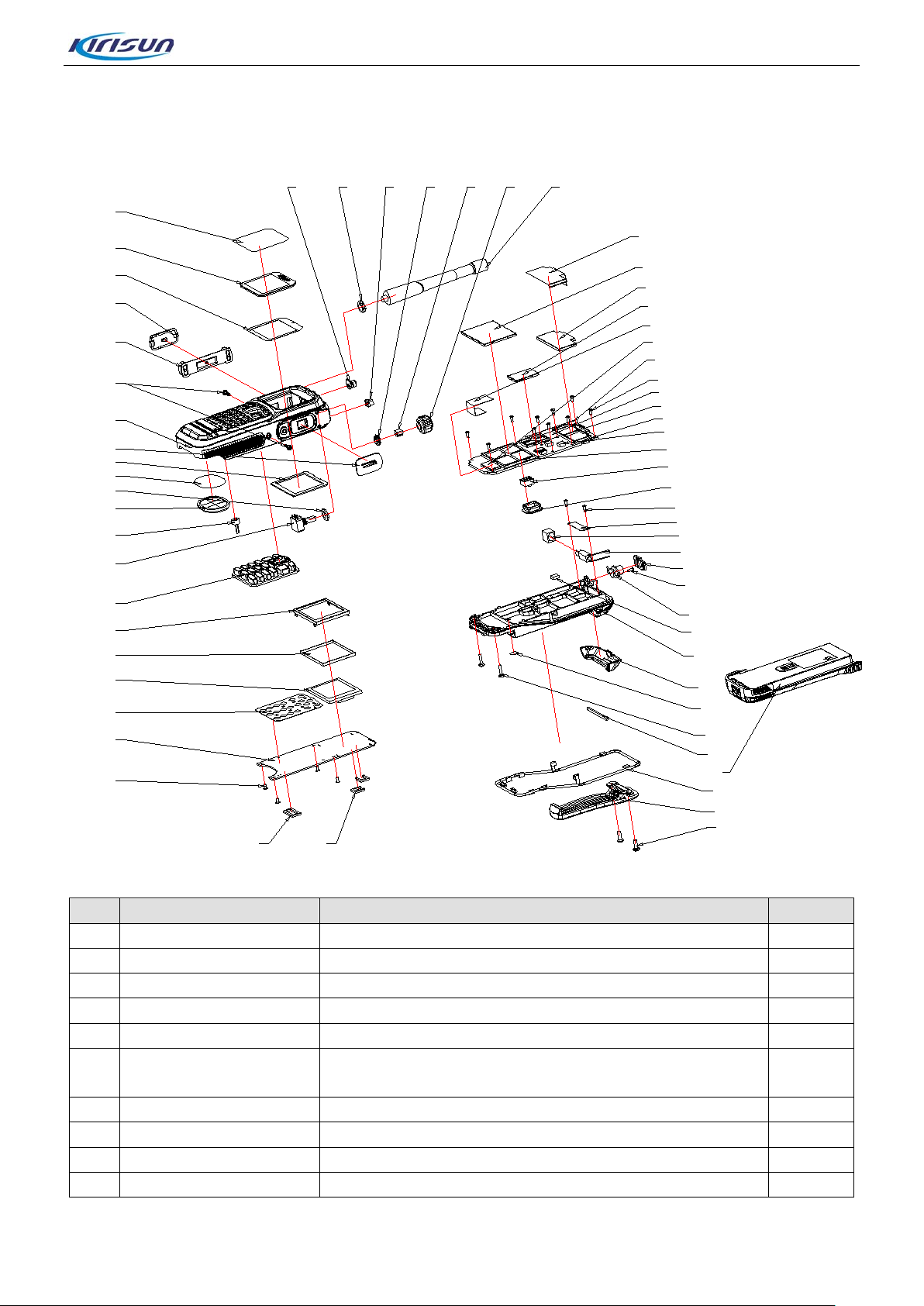

5.7. Exploded View

NO.

Part Number

Name, Specification

Quantity

1

7WFP-4002-01A

DP770lens protective fi l m PE T; transparent

1 2 7MHP-4002-02A-WC

DP770 LCD lens PC+PMM A, transparent

1 3 7GCJ-S4002-J

DP770 lens double sides adhesiv e t apeNITTO 57120B

1 4 7MHP-4002-04A-W9

DP770 PTT cover PC+ABS/TPU;black/PT2757C

1 5 7MHR-4002-10A-W6

DP770 Side silicone buttons silica gel; blue,PT654C

1

1

2.0X7.0 iron hardened tooth machine screw; Zinc

plating-black

7

7MHP-4002-01A-W0

DP770 front cover shell P C+ABS, texture, black

1 8 6SS1-4002-HL3C

Attachment plate strips ne s t ing

1 9 7MHM-4002-01A-W9

DP770 LCD Sponge bac k r ubber ; bla ck

1

57585960616263

53

54

55

56

52

46

45

47

48 49

50 51

44

42

41

18

40

43

38

37

36

35

18

39

32

33

34

29 30

31

27

26

25

24

28

22 23

21

20

19

18

17

16

15

13

14

12

11

9

8

7

10

30 6

5

3

2

1

4

DP770 Service Manual

Spare Parts List(Structure)

6

10 7GCB-S4002-01A DP770 T rumpet anti-dust mes h nylon; black 1

7SAF-020070M-SZYB-Z

2

Page 22 of 102

Page 24

DP770 Service Manual

11

7MHR-4002-16A-W9

DP770 Knob waterproof p ad silica gel; black

1

13

4SM7-4002-A40

Waterproof microphone with cover Φ7.0mm, height 2.8mm,

1

14

4SM7-4002-A40

Encoder switch RE11(Linjiwei)

1

PT432C/ character

DP770 display shielding cover 44.3*34.1*2.0MM,

21

7SMF-020040M-SZYB-N

M2*4 iron hardened tooth ma chine cross screw, Nylok

7

sided adhesive

1

M2.6*6 cross, machine ferrous hardened, Black zinc

machine teeth

25

6SS3-BJ4026-A

KBJ-15 Belt Clip PC+ABS

1

26

7MHR-4002-11A-W9

DP770 main waterproof ci r cle o f si li ca gel; black

1

1

2.0X11.0 tooth machine cross screws 5.3 harden iron; zi nc

plating-black

mesh

32

7MHP-4002-05A-W9

DP770 main unit top cover PC+ABS; texture; black

1

33

7MHL-4002-01-W

DP770 aluminum chasis ADC12; burnished

1

34

7MHR-7042-06B-W0

thermally conductive pad, blac k,3*6*9mm

1

DP770 Motor pressure pieces of stainless steel; natural

45

7MHC-4002-04A-W

DP770shielding cover ho lder 22.8*15.6mm; cupronickel

1

46

6PM7-4002-HMH

DP770-02 main board PC B ten -layer boar d

1

12 4SS7-3525-016-100A

15 7MHR-4002-09A-W9

DP770 speaker(waterproof)Φ=35mm,H=25mm,16Ω,

1W

DP770 The silicone number buttons;

with photopermeability

1

1

16 7MHS-4002-01A-W DP770 LCD Cupronickel stents; Xianfeng Hardware 1

17 7MHC-4002-11A-W

cupronickel

1

18 4PC7-4002H-A LCD display ZYW-T18CP-20PJ-B 1

19 7MHS-4002-03A-W

Numeric key METAL DO ME dia meter 4.0;SUS301

1

20 6PM7-4002-HKG DP770KEY-LCD PCB Four-layer board 1

22 7GCM-180090015-J

23 7GCM-100090015-J

24

7SMF-026060M-SZHT-B

DP770 main board double-s ided adhe sive f oam bl ack f oam

18*9*1.5

LCD Socket black foam doublefoam10*9*1.5

1

2

2

27 6SS3-DC7198-A KB-77B battery 1

28 7MHM-4002-02-W Aluminum chasis Poron , liner, Poron 36.5*2.5*1.0 1

29

7SAF-020110M-SZYB-Z

2

30 7MHR-4002-19A-W9 DP770 Screw waterproof r ubber r in g; black;polished 4

31 7GCB-070045005-J

Φ7 Microphone protection water perforated film with plastic

2

35 3CR7-SMA-50JF-4 Antenna connector SMA-J, Flange installation 1

36 7MHR-4002-15A-W9 DP770 antenna connector Waterproof pad silicone;blac k 1

37 4MV3-KFF081522 φ8Dc motor vibration KFF081522 1

38 7MHR-4002-17A-W9 DP770 Motor silicone pad sil ica gel; black 1

39 7MHS-4002-02A-W

color; Junyu, lead free

1

40 7MHR-4002-18A-W9 DP770 Discharge seatin g silicone; black 1

41 7MHP-4002-01A-W TD7700 battery connector BC-2P-41PH-6.8H 1

42 7MHC-4002-02A-W

DP770 shielding cover hol der一 43.4*32.3mm; cupronickel

1

43 7MBM-S4002-A EMI Gasket 12*7*7 With double-sided adhesive 3

44 7MHC-4002-16A-W1 GPS shielding cover base , c upronickel; Junyu; Lead free 1

Page 23 of 102

Page 25

DP770 Service Manual

M2*5 plum blossom iron hardened tooth machine screw,

49

7MHS-4002-04A-W

DP770 PTT key METAL DOME4.0; SUS301

1

50

7MHS-4002-05A-W

DP770

,0.6mm

1

51

7MDZ-1737-04A-J5

KB-58L sticker 1

,8*35*0.2

1

52

6SS1-4002-HL1G

Main flat cable

1

46.85x32.25x0.15mm

63

7MHR-4002-12A-W3

DP770 emergency key silica gel key;orange,PT021C

1

47

7SMF-020050M-MHHTN1

nickel plating

10

48 6PD7-4002-HPC DP770PTT board PCB double side board 1

Platooninsert tabletting stainless steel

Barley paper

53 7MHC-4002-05A-W DP770 shielding cover 23.3* 16. 1mm; cupronickel 1

54 7MHC-4002-17A-W1 GPS shielding cover cupronickel; Junyu; lead free 1

55 7MHC-4002-03A-W DP770 shielding cover 43.9* 32. 8mm; cupronickel 1

56 7MHJ-4002-01A-W

GPS

hielding cover conductive fabric

s

1

57 8ATX-400470-WC DP770 dual mode ant enna 400-470MHZGPS antenna 1

58 7MHP-4002-03A-W9 DP770 knob PC+ABS/TPU, grey 1

59 7MHS-1767-02B-W PT6800Knob circlip stainless steelSUS30 4-1/2H, hardened 1

60 7NRC-077107040-Z R 7200 Coding switch nut br ass , zinc plating-black 1

61 7MHR-4002-13A-WC DP770 Guide pillar silicon e; transparent 1

62 7NRC-090110025-W1 Ant enna connector copper nut 1

Page 24 of 102

Page 26

6. Tune Mode

Low

Frequency

Mid-frequen

cy

High

frequency

Low

Frequency

Mid-frequen

cy

High

frequency

It may need to check and adjust t he par ameters after parts replacement in maintenance.

6.1. Required parts in adjustment

(1)Antenna adapter

(2)Universal interface

6.2. Adjusting and checking method

6.2.1. Frequency descri ptio n

Model 400~470MHz

DP770 Service Manual

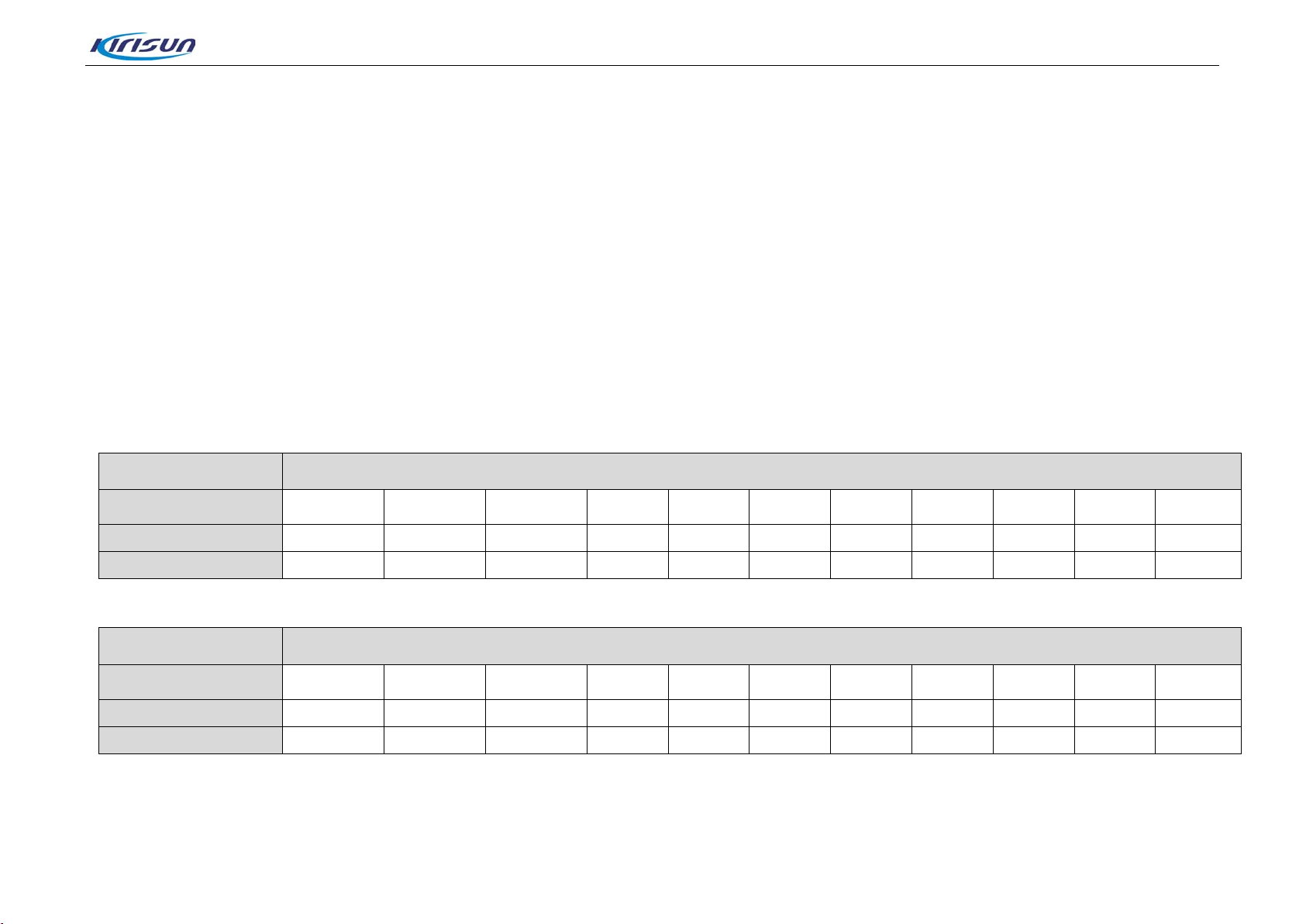

Channel

TX frequency(MHz) 400.00 435.00 470 400 410 420 430 440 450 460 470

RX frequency(MHz) 400.05 435.05 469.95 400.05 410.05 420.05 430.05 440.05 450.05 460.05 469.95

Model 136~174MHz

Channel

TX frequency(MHz) 136.00 158.00 174.00 136.00 140.00 146.00 152.00 158.00 164.00 170.00 173.975

RX frequency(MHz) 136.05 158.05 174.00 135.05 140.05 146.05 152.05 158.05 164.05 170.05 174.00

F1 F2 F3 F4 F5 F6 F7 F8

F1 F2 F3 F4 F5 F6 F7 F8

Page 25 of 102

Page 27

6.2.2. Adjustment Equipments

Test

equipment

1)Enter tune mode;

5) Click “Save” to save it.

1)Enter tune mode;

2)Double click TX high power, and enter

frequency F1 to F8 to adjust high power

3)Adjust the value in tune mode to make

frequency F1 to F8 to adjust low power

3)Adjust the value in tune mode to make

(1)Comprehensive t est inst r ument(HP8921 or similar equipment)

(2)Computer and CPSp software

(3)AEROFLEX 3920

(4)spectrum analyzer

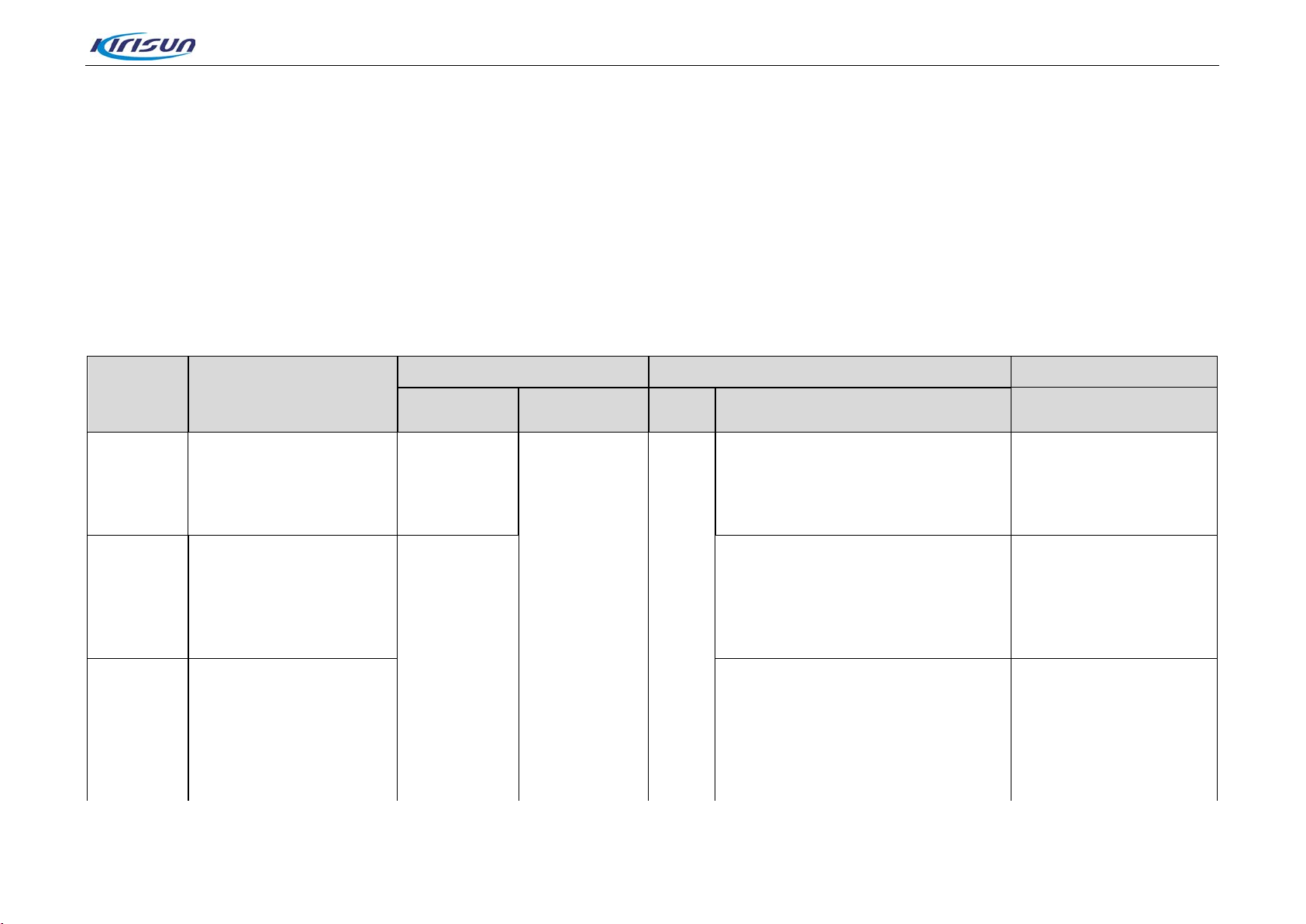

6.2.3. Adjustment instruction of TX

Test Tool and Method Remark

Item Configuration

Test Point Tool Method

DP770 Service Manual

Frequency

Stability

Tx High

Power

Tx Low

Power

Set comprehensive instrument

to tx mode

Set comprehensive instrument

to tx mode

Set comprehensive instrument

to tx mode

HP8921A or

similar

instrument

HP8921A or

similar

instrument

Connect the

antenna port to

RF IN/OUT port of

instrument by

antenna

connector adapter

PC

2)Double click frequency stability

3)Adjust the value in tune mode to make

the tx frequency to be within+/-480Hz

4) Observe TX current

output at different frequency.

the tx high power to be within 4W+/-0.2W

4) Click “Save” to save it.

1)Enter tune mode;

2)Double click TX low power, and enter

output at different frequency.

the tx high power to be within 1W+/-0.2W

4) Observe TX current

5) Click “Save” to save it.

≤±500Hz

1) Power:3.7W-4.5W;

2) Current:<1.8A

1)

Power:0.7W-1.5W;

2) Current:<1A

Page 26 of 102

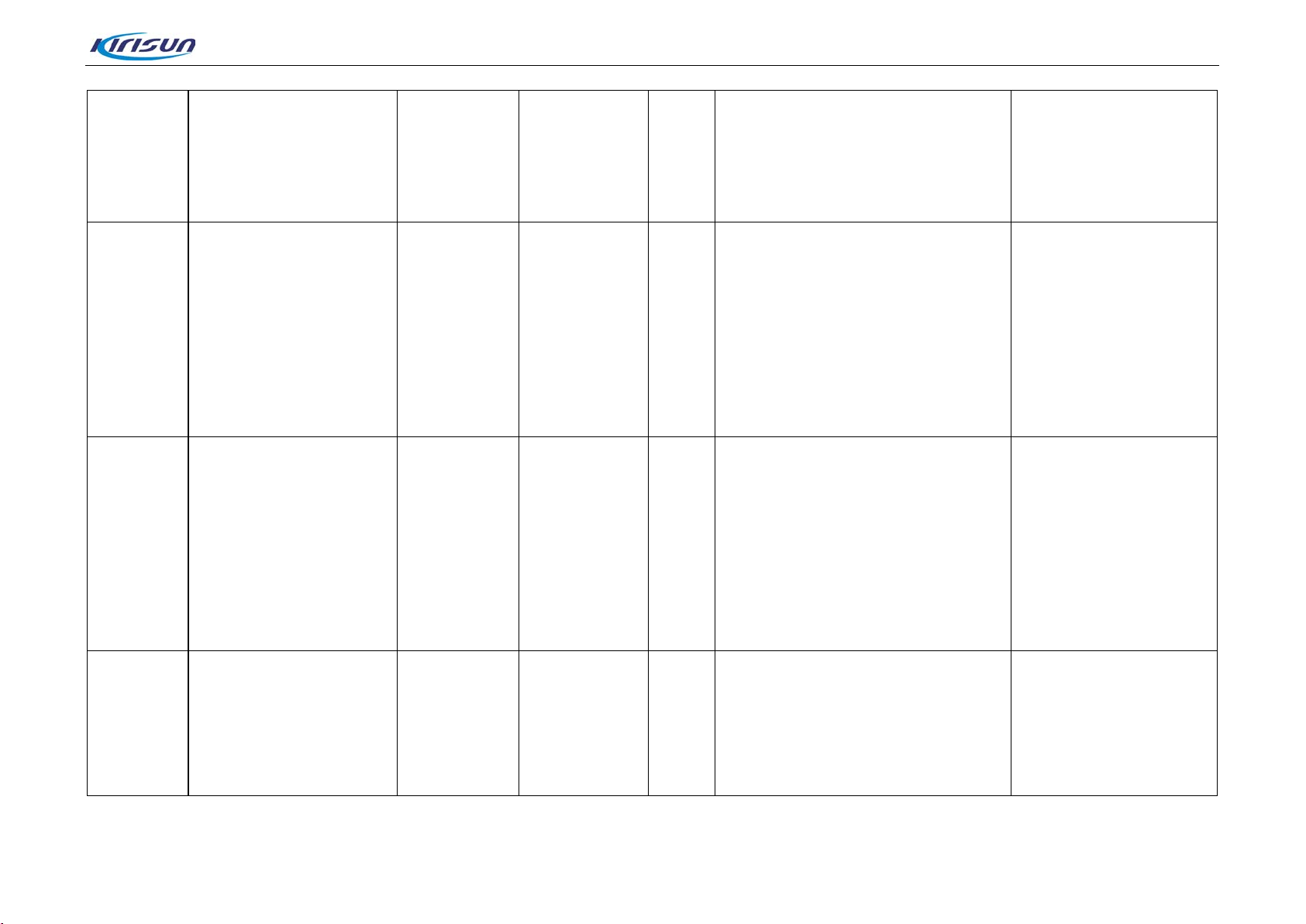

Page 28

DP770 Service Manual

1)Enter tune mode

Double click” Low frequency modulation

and enter to F1 to F8 to adjust

FM deviation on the instrument when AF

1)Enter tune mode

deviation” and enter to F1 to F8 to adjust

FM deviation on the instrument when AF

Click “Start”, the radio will enter vox

Maximum

Deviation

Low

frequency

modulation

deviation

High

Frqnecy

modulation

deviation

Set the test instrument to tx

mode.

Set HF(High filter) to 50Hz

and LF(low filter) to 15KHz

)

Set comprehensive

instrument to tx mode

Set comprehensive

instrument to tx mode

H

P8921A or

similar

instrument

HP8921A or

similar

instrument

HP8921A or

similar

instrument

Connect the

antenna port to

RF IN/OUT port

of instrument by

antenna

connector

adapter

Connect the

antenna port to

RF IN/OUT port

of instrument by

antenna

connector

adapter

Connect the

antenna port to

RF IN/OUT port

of instrument by

antenna

connector

adapter

PC

PC

PC

1) Enter tune mode;

2) Double click "Maximum Deviation".

3)Adjust the value in tune mode and view

the FM deviation on the test instrument

4) Make the FM deviation within 5.0±0.05kHz

5) Click confirm to save

2)

deviation”

different frequency.

)Adjust th e valu e in tun e mo de an d view the

3

Freq is 0.1kHz

4

)Make the FM deviation within

5.0±0.05kHz.

5)Click save to save the data.

2)Double click” high frequency modulation

different frequency.

)Adjust th e valu e in tun e mo de an d view the

3

Freq is 6.0kHz

4

)Make the FM deviation within

5.0±0.05kHz.

5)Click save to save the data.

4.95kHz-5.05kHz

4.95kHz-5.05kHz

4.95kHz-5.05kHz

Set comprehensive

VOX 1

instrument to tx mode 1)

AFGen1 Freq:1kHz;

2)AFGen1 Lvl:50mV

HP8921A or

similar

instrument

Connect mic

port of the radio

to audio out of

test instrument

PC

1)Enter tune mode

2)Double click”VOX1.

3)

adjustment automatically.

4

)Click “stop” when the value is stable.

5)Click save to save the data.

Test:

1)The vox will activate then

AFGen1 is set to50mV.

The vox will stop when

AFGen1 is below 15mV.

Page 27 of 102

Page 29

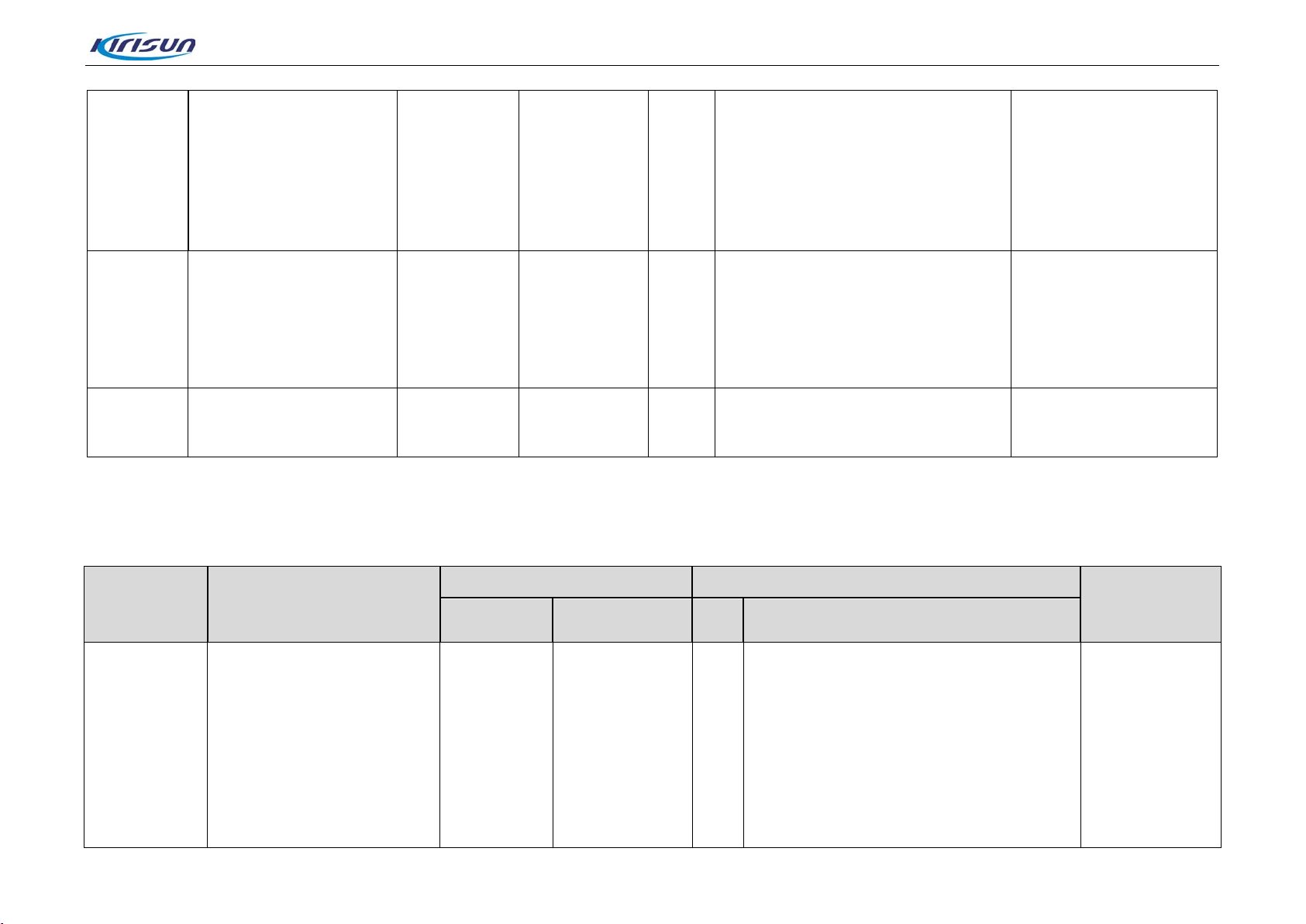

VOX 10

The low battery starts to

the voltage is above 7.2V.

1)Enter tune mode.

4) After adjustment, click save

Equipment

Connect the

by test cable

Low battery

warning

Set comprehensive

instrument to tx mode 1)

AFGen1 Freq:1kHz;

2)AFGen1 Lvl: 5mV

HP8921A or

similar

instrument

* multimeter

Connect mic

port of the radio

to audio out of

test instrument

Battery

connector

PC

*

1)Enter tune mode

2)Double click”VOX10”.

3) Click “Start”, the radio will enter vox

adjustment automatically.

4)Click “stop” when the value is stable.

5)Click save to save the data.

1)Enter t tune mode

2)Set the power supply voltage to 6.8V;

3)Click save when value is stable.

DP770 Service Manual

*

work when the voltage is

below 6.5V.

The radio will power off

when the voltage is below

5.8V.

The radio can work when

CV Curve PC

6.2.4. Receiver section adjustment instruction

Item Configuration

Receiver

sensitivity

1)Set comprehensive

instrument to RX mode

2)Set RF Gen Freq to F1、

F2、…、F8,Eg:Set RF Gen

Freq to 469.95MHz when

testing F8

3)Set AFGen1 Freq to 1kHz

Set AFGen1 to 3kHz

4)Set HF(High filter) to 300Hz

and LF(low filter) to 3KHz

2)Double click “TX CV Curve”

Click “Start”

3)

Test Tool and Method

Test

Test point Tool Method

antenna port to

HP8921A or

similar

instrument

RF IN/OUT port

of instrument by

antenna

connector

adapter, Connect

universal

connector

of

radio to audio in

PC

1) Enter tune mode

2) Double click “receiver sensitivity”. Enter F1

to F8 to adjust different frequency.

3)Set input signal strange to -119dBm, adjust

pc value to max the SINAD and the SINAD

is above 12dB .

4)Click save to save it.

of test instrument

Low point:>=0.5V

High point:<4.5V

Standard

Requirement

SINAD>=12dB

W:-119dBm;

N:-118dBm。

Page 28 of 102

Page 30

SQL1 Open

1)Set comprehensive

1.5kHz(N)

1)Set comprehensive

1.5kHz(N)

1)Set comprehensive

1.5kHz(N)

1)Set comprehensive

1.5kHz(N)

SQL1 Close

SQL9 Open

SQL9 Close

instrument to RX mode

2

)Set RF Gen Freq to test

frequency

3)Set Amplitude t

-123d

Bm1(25KHz)or -121dBm

o

(12.5KHz)

4)Set AFGen1 Freq to 1kHz

5)Set FM to 3kHz(25KHz)

instrument to RX mode

2

)Set RF Gen Freq to test

frequency

3)Set Amplitude t

-125d

Bm(25KHz)or -123dBm

o

(12.5KHz)

4)Set AFGen1 Freq to 1kHz

5)Set FM to 3kHz(25KHz)

instrument to RX mode

2

)Set RF Gen Freq to test

frequency

3)Set Amplitude to -116dBm

4)Set AFGen1 Freq to 1kHz

5) Set FM to 3kHz(25KHz)

instrument to RX mode

2

)Set RF Gen Freq to test

frequency

3)Set Amplitude to -119dBm

4)Set AFGen1 Freq to 1kHz

5)Set FM to 3kHz(25KHz)

or

HP8921A or

similar

or

instrument

or

or

Connect the

antenna port to

RF IN/OUT port

of instrument by

antenna

connector

adapter

PC

DP770 Service Manual

1. Enter tune mode

2. Double click”SQL1 Open”and enter to F

o F8 to adjust different frequency

t

1

3. Click “Start”.

4. Click “Stop” when the value is stable.

5. Click save

1.Enter tune mode

2.Double click”SQL1 Open”and enter to F1 t

8 to adjust different frequency

F

3. Click “Start”.

4. Click “Stop” when the value is stable.

5. Click save

1.Enter tune mode

2.Double click”SQL9 Open”and enter to F1 t

F

8 to adjust different frequency

. C

3

lick “Start”.

4.Click “Stop” when the value is stable.

5.Click save

1.Enter tune mode

2.Double click”SQL9 Close”and enter to F1 to

F8 to adjust different frequency

. C

3

lick “Start”.

4. Click “Stop” when the value is stable.

5.Click save

Open:-119dBm

Close -127dBm

o

o

Open:-115dBm

Close -120dBm

Page 29 of 102

Page 31

RSSI 1

Connect the

adapter

Install standard double

、

RSSI 4

1)Set comprehensive

instrument to RX mode

2) Set RF Gen freq to 400MHz

3)Set Amplitude to -110dBm

1)Set comprehensive

instrument to RX mode

2) Set RF Gen freq to 400MHz

3)Set Amplitude to -80dBm

HP8921A or

similar

instrument

HP8921A or

similar

instrument

Connect the

antenna port to

RF IN/OUT port

of instrument by

antenna

connector

adapter

antenna port to

RF IN/OUT port

of instrument by

antenna

connector

PC

PC

1.Enter tune mode

2.Double click ”RSSI1”

. C

3

lick “Start”.

4.Click “Stop” when the value is stable.

5.Click save

1.Enter tune mode

2.Double click ”RSSI4”

3. Click “Start”.

4.Click “Stop” when the value is stable.

5.Click save

DP770 Service Manual

The RSSI is

displayed one

bar when input

signal is

-107dBm The

RSSI is

displayed 4 bars

when input

signal is

-70dBm.

1.Enter tune mode

2.Double click ”CV Curve”

. C

3

CV Curve

Test the VCO voltage

PC

lick “Start”.

4.Click “Stop” when the value is stable.

5.Click save

6.2.5. GPS Performance Test Instruction

Item Test Environm e nt Test Equipment Test Method Standard Requireme nt

1、 TTFF(cold start)Time to first fix

GPS

Position

Time

1) Change the radio to

digital channel

2)

mode antenna

3) Put the radio in the

outside area without high

building surround it.

1) DP770

2) Timing tool

1) Remove the battery

2) Install the battery

3) Open GPS function in the menu and

enter “gps information menu”

4) Activate timing tool

5) Check the time when gps positions

successful.

<1minute

2

TTFF(hot start)Time to first fix

<10 seconds

3、

Horizontal Accurancy

<10 meters

Low point:>

=0.5V;

High point:<

4.5V。

Page 30 of 102

Page 32

7. Main Specifications

General Specifications

Frequency

UHF1: 400-470MHz, VHF: 136-174MHz

Channel Capacity

1024

Channel Spacing

12.5kHz/20kHz/25kHz

Dimension

138mm*62mm*38mm

Display

1.8 Inches 65535 Color Display

Battery Capacity

7.4V 2000mAH Li-ion

Digital: 15 Hours

Environmental Operating Conditions

Working Temperature

-30℃~+60℃

Storage Temperature

-40℃~+85℃

Waterproof/Dustproof

IP67

MILST

Humidity

Shock and Vibration

Receiver Part

Frequency St a bi lity

±1.5ppm

DP770 Service Manual

Weight

Working Time(5-5-90)

Electrostatic Defending

362g(with battery and antenna)

Analog: 13.5 Hours

IEC 61000-4-2(Level 4)

±8kV (Touch)

±15kV (Air)

MIL-STD-810 C/D/E/F/G

MIL-STD-810 C/D/E/F/G

MIL-STD-810 C/D/E/F/G

Analog Sensitivity

0.3uV(12dB SINAD)/0.22uV(12dB SINAD,Typical)

Page 31 of 102

Page 33

DP770 Service Manual

Intermodulation

Spurious Response Rejection

Conducted Spurious Emission

Block

Rated Audio Power

Hum and Noise

Audio Respons e

Transmitter

Frequency St a bi lity

Hum and Noise

FM Modulation

Modulation Limit

Audio Respons e

+1dB~-3dB

Digital Sensitivity

Adjacent Channel Selectivity

Rated Audio Distortion

RF Power output

0.3uV(5% BER)

ETSI: 65dB TIA603: 70dB

ETSI/TIA603: 60dB@12.5kHz,70dB@20/25kHz

ETSI/TIA603: 70dB

-57dBm

ETSI: 84dB TIA603: 80dB

0.5W

<3% (Typical)

-40dB@12.5kHz/-43dB@20kHz/-45dB@25kHz

+1dB ~ -3dB

±1.5ppm

Low: 1W, High: 4W(UHF)/5W(VHF)

Conducted/Radiated Em issi on

Adjacent Channel Po we r

4FSK Modulation

-40dB@12.5kHz/-43dB@20kHz/-45dB@25kHz

-36dBm@<1GHz,-30dBm@>1GHz

60dB@12.5kHz,70dB@20/25kHz

11K0F3E@12.5kHz,14K0F3E@20kHz,16K0F3E@25kHz

12.5kHz(data only): 7K60FXD

12.5kHz(data and voice ): 7K60FXE

±2.5kHz@12.5kHz, ±4kHz@20kHz, ±5kHz@25kHz

Page 32 of 102

Page 34

DP770 Service Manual

Vocoder

Digital Data Protocol

GPS

Horizontal Accuracy

<10meters

Installations

Main Specifications

Frequency: 10MHZ to 3G Hz

Output:-127dBm/0.1uv---47dBm/1mv

Frequency Deviation Meter

Input Impedance:10Mega Ohm Impedance

Oscillograph

Frequency Stability: ≤ 0.2ppm

Ammeter

5A

Audio Distorti on

TTFF(cold start) Time to first fix

TTFF(Hot start)Time to first fix

3% (Typical)

AMBE++

ETSI TS 102 361-1, -2, -3

<1min

<10s

8. Repairing and Testing Equipments

RF Standard Signal Gen erat or (SSG)

Modulation: Frequency modu lation and externa l mode m

Dynamometer Instruments

Digital RMS Multimeter

High Sensitive Frequency Counter

Input Impedance: 50Ω

Operating Frequency : 100MHZ-1000MHz

Range: 10W

Frequency: 100MHZ-1000MHz

Range: DC 10mv-10v

30MHz- 100MHz

Frequency: 100-1000MHz

Page 33 of 102

Page 35

DP770 Service Manual

Output: 0-1v

Input PWL: 50mv-10vms

Spectrum analyzer

Range:100-3GHz or higher

16Ω Dummy Load

Power Supply

Output Voltage 5v- 30v, current:5A

No.

Problem

Causes and Solutions

You cannot communicate with

During receiving, LED is green

Audio Frequenc y Voltmeter

Tone Generator

Distortion Meter

9. Basic Troubleshooting

A.The battery may be used up. Recharge it or change the battery to try again.

1 The radio cannot be powered on.

B.The power ON/OFF key may suffer from poor contact. Clear the metal dome with alcohol and try again.

C.The power binding post isn’t connected with battery. Re-install it and try again.

D.The power is connected inversely which leads to the pow er prote ctive t ube F901 op en. R eplace t he pr otectiv e tube F901 and try again .

Frequency: 50Hz-10KHz

Voltage: 1mv-10v

Frequency: 50Hz - 5K Hz or higher

Power: when 1KHz, ≤3%

16Ω, 3W

2

3 The radio cannot receive signals

4

other members

but no voice.

A.The frequency settings may be different from others. Set your TX/RX frequencies to be the same as others.

B.The CTCSS/CDCSS signaling may be different from others. Set your CTCSS/CDCSS signaling to be the same as others.

C.Your place may be too far away from the others, beyond the radio’s coverage area.

A.The antenna may get looser or may be improperly installed. Re-inst all the ant e nna.

B.The frequency settings may be different from others. Set your TX/RX frequencies to be the same as others.

C. Your place may be too far away from the others, beyond the radio’s coverage area.

A.Check whether the volume is smallest or not. If so, increase the volume.

B.Check whether the speaker is broken or not. If so, change the s peaker.

Page 34 of 102

Page 36

5 GPS cannot locate your position.

DP770 Service Manual

A. Check whether the antenna is GPS+UHF dual band or not. If not, use a GPS+UHF dual band antenna to replace the old one.

B. Check whether the GPS setting is correct or not. If not, set it correctly.

C. Maybe there is some other RF interference around the radio’s place. Go to an open sky place and try again.

6

CPS programming failed.

A.Connection between the radio and PC is not good enough. Check and try again.

B.Earphone interface board has poor contact with external programming cable. If so, change the Earphone interface board.

Page 35 of 102

Page 37

Appendix 1 Material List(Electrics Parts)400-470MHz

BD+GPS)

main board SMD

4

1DR1-1SR154-400

R SMD commutation diode

1

D903

12

1DV1-HVC376B

R SMD varactor

9

D101,D102,D105,D106,D202,D203,D204,D205,D206

B

,

NO. Part Number Name Quantity Position Mark

DP770 Service Manual

1 6SS2-4002B-HMD

2 6SS1-4002B-HMC

3 0SS1-4002B-HME

5 1DS1-DA2S10100L R SMD switch diode 9

6 1DS1-DAN222 R SMD switch diode 1 D904

7 1DS1-HSC277 R SMD switch diode 1 D112

8 1DS1-HVC131 R SMD switch diode 4

9 1DV1-1SV278 R SMD varactor 1 D109

10 1DV1-1SV305 R SMD varactor 1 D201

11 1DV1-HVC350B R SMD varactor 4 D103,D104,D107,D108

DP770 Main Board suite(BD+GPS)

DP770-02 main board SMD suite

(

DP770-02

units(BD+GPS)

1

1

1

D110,D111,D113,D701,D702,D703,D704,D15,D506

D301,D302,D303,D304

13

14

15

16 1DZ1-PESD5V0S1U

1DZ1-MMSZ4678T1

G

1DZ1-PESD12VS1U

B

1DZ1-PESD3V3S1U

SMD voltage regulated diode 1 D905

SMD voltage regulated diode 2 D901,D902

SMD voltage regulated diode 1 D907

SMD voltage regulated diodeDP770

1 D906

Page 36 of 102

Page 38

B

DP780,STP,KH620

19

1IL1-TDA8547TS

E

IC

1

U802

WT3

29

1IS1-TLV5614

DA convertor IC

1

U105

DP780,KH620D,STR,STP

1IS1-XC6204B502M

35

1TF1-2SK3019TL

R SMD FET

2

Q902,Q4

17 1ID1-MXD2020ML

SMD general logic IC(accelerated

sensor)

1 U702

18 1IL1-NJM2904V R SMD linear IC 2 U106,U303

General linear

20 1IM1-MT47H64M16 SMD memorizer IC 1 U905

21

1IP1-OMAPL138EZ

Dual core CPU 1 U906

22 1IS1-AD9864 IF Digital System 1 U201

23 1IS1-ADE1L SMD passive mixer 1 Z201

24 1IS1-ADS1015 AD convert IC 1 U701

DP770 Service Manual

25

1IS1-MC74VHC1GT66 Hig

26 1IS1-SKY72310 PLL Chip 1 U103

27 1IS1-TC75W51FU R SMD Specialized IC 1 U703

28 1IS1-TLV320AIC14K CODEC IC 1 U801

30 1IS1-TPS62110 Power Chip 1 U901

31 1IS1-TPS65023

32

33

1IS1-XC6204B302M

R

R

34 1TC1-UMC4 R SMD multiunit tube 4

36 1TF1-RD01MUS2 E R SMD FET 1 Q303

h-speed CMOS simulated switch

IC

Power management Chip DP770,

2 U

110,U111

1 U902

SMD voltage regulated 1 U112

R SMD voltage regulated 2 U101,U202

U107,U108,U109,U301

Page 37 of 102

Page 39

37 1TF1-RD07MUS2B E R SMD FET 1 Q304

41

1TT1-2SC5006

SMD triode

6

Q201,Q203,Q204,Q206,Q207,Q301

45

1TT1-FMMT720

SMD triode

1

Q906

0J

,C315,C321,C327,C346

2CC1-10-C0G500-1R

38 1TF1-ST2301 R SMD FET 4 Q905,Q907,Q908,Q901

DP770 Service Manual

39 1TT1-2SC3356-R24 R SMD triode 4

Q103,Q104,Q302,Q305

40 1TT1-2SC4617-R R SMD tr io de 3 Q102,Q105,Q107

42 1TT1-AT41511 Low Noise NPN triode 1 Q205

43 1TT1-DTC144EE R SMD triode 8 Q903,Q1,Q801,Q805,Q30,Q202,Q306,Q309

44 1TT1-FMMT717TA R SMD triode 2 Q106,Q307

46 1TT1-MMBT3904 SMD triode 1 Q904

C903,C925,C928,C932,C935,C938,C941,C956,C959,C962,C965

,C968,C971,C974,C977,C980,C981,C987,C990,C993,C996,C99

9,C1002,C1006,C1008,C1012,C1015,C1017,C1020,C1023

47

2CC1-10-C0G500-10

0D

R flake multi-layer capacitor 30

C110,C141,C201,C202,C203,C204,C205,C222,C223,C227,C229

48

2CC1-10-C0G500-10

1J

R flake multi-layer capacitor 71

,C244,C909,C926,C929,C931,C934,C937,C940,C955,C958,C96

3,C966,C969,C973,C975,C978,C988,C992,C994,C997,C1001,C

1004,C1005,

49

50

51

2CC1-10-C0G500-12

2CC1-10-C0G500-15

0J

2CC1-10-C0G500-15

1J

R flake multi-layer capacitor 6 C215,C216,C305,C311,C312,C356

R flake multi-layer capacitor 2 C245,C246

C116,C123,C139,C148,C157,C158,C159,C162,C163,

R flake multi-layer capacitor 24

C164,C166,C168,C177,C178,C257,C258,C260,C262,C302,C309

52

53

2CC1-10-C0G500-18

1J

0C

R flake multi-layer capacitor 1 C221

R flake multi-layer capacitor 7 C118,C150,C301,C945,C947,C949,C952

Page 38 of 102

Page 40

DP770 Service Manual

0J

0J

0D

,

,

,

0D

0B

68

2CC1-10-C0G500-4R

R flake multi-layer capacitor

1

C901

54

55

56

57

58

59

60

61

62

63

2CC1-10-C0G500-1R

5C

2CC1-10-C0G500-20

2CC1-10-C0G500-22

2CC1-10-C0G500-27

0J

2CC1-10-C0G500-27

1J

2CC1-10-C0G500-2R

2CC1-10-C0G500-30

0J

2CC1-10-C0G500-33

0J

2CC1-10-C0G500-3R

0B

2CC1-10-C0G500-3R

R flake multi-layer capacitor 2 C117,C149

R flake multi-layer capacitor 1 C320

R flake multi-layer capacitor 2 C124,C268

R flake multi-layer capacitor 2 C213,C214

flake multi-layer capacitor 9

C842,C358,C359,C613,C810,C811,C818,C819,C828

flake multi-layer capacitor 1 C266

flake multi-layer capacitor 1 C248

C1027,C1028,C1029,C1030,C1031,C1032,C1033,C1034

R flake multi-layer capacitor 64

C1035,C1036,C1037,C1038,C1039,C1040,C1041,C1042

C1043,C1044,C1045,C1046,C1047,C1048,C1049,C1050

C1051,C1052,C1053,C1054,C1055,C1056,

flake multi-layer capacitor 1 C269

flake multi-layer capacitor 2 C252,C263

64

65

66

67

2CC1-10-C0G500-47

0J

2CC1-10-C0G500-47

1J

2CC1-10-C0G500-4R

2CC1-10-C0G500-4R

0D

R flake multi-layer capacitor 13

C236,C267,C271,C707,C709,C943,C944,C946,C948,C950,C951

,C953,C954

flake multi-layer capacitor 9 C314,C340,C341,C345,C354,C614,C615,C617,C621

flake multi-layer capacitor 2 C251,C330

flake multi-layer capacitor 3 C254,C255,C265

Page 39 of 102

Page 41

69

2CC1-10-C0G500-5R

0C

2CC1-10-C0G500-8R

0C

5K

4K

81

2CC1-10-X7R160-47

R flake multi-layer capacitor

1

C357

7C

2CC1-10-C0G500-56

0J

DP770 Service Manual

R flake multi-layer capacitor 2 C317,C328

70

71

72

73

74

75

76

77

78

79

6B

2CC1-10-C0G500-6R

2CC1-10-C0G500-7R

0B

0B

2CC1-10-C0G500-9R

2CC1-10-X5R100-10

2CC1-10-X5R100-47

4K

2CC1-10-X5R6R3-22

5K

2CC1-10-X7R100-22

2CC1-10-X7R160-10

4K

flake multi-layer capacitor 2 C250,C283

R flake multi-layer capacitor 3 C129,C130,C264

flake multi-layer capacitor 2 C253,C277

flake multi-layer capacitor 1 C274

flake multi-layer capacitor 1 C307

flake multi-layer capacitor 10 C36,C38,C411,C412,C703,C710,C1136,C612,C812,C814

R flake multi-layer capacitor 1 C154

R flake multi-layer capacitor 11

C964,C970,C972,C989,C991,C995,C1000,C1007,C1009,C1013,

C1014

R flake multi-layer capacitor 2 C704,C712

C107,C119,C120,C121,C133,C134,C135,C136,

C137,C140,C147,C155,C156,C160,C165,C167,C179,C217,C218

R flake multi-layer capacitor 56

,C224,C225,C230,C232,C233,C235,C238,C240,C297,C344,C4,C

701,C705,C708,C906,C982,C983,C986,C1061,C1135,C616,C80

3,

80

2CC1-10-X7R160-33

3K

R flake multi-layer capacitor 2 C815,C816

Page 40 of 102

Page 42

82

C153,C212,C5,C6,C25,C927,C930,C933,C936,C939,C942,C957,

1025,C1026,C916

6,C322,C353,C355,C802,C807,C823,C831,C824

0D

2CC1-16-C0G500-13

0J

0J

95

2CC1-16-C0G500-24

R flake multi-layer capacitor

1

C339

3K

2CC1-10-X7R250-22

3K

DP770 Service Manual

R flake multi-layer capacitor 2 C706,C711

83

84

85

86

87

88

89

90

2CC1-10-X7R500-10

2K

2CC1-10-X7R500-10

3K

2CC1-10-X7R500-27

3K

2CC1-10-X7R500-33

2K

2CC1-16-C0G500-10

2CC1-16-C0G500-12

0J

0J

2CC1-16-C0G500-15

R flake multi-layer capacitor 25

C960,C967,C976,C979,C984,C985,C998,C1003,C1018,C1021,C

C122,C125,C171,C173,C206,C207,C208,C209,

R flake multi-layer capacitor 38

C210,C211,C219,C220,C226,C228,C234,C237,C239,C243,C247

,C249,C256,C272,C275,C276,C278,C280,C287,C288,C306,C31

R flake multi-layer capacitor 1 C342

R flake multi-layer capacitor 1 C152

R flake multi-layer capacitor 4 C111,C113,C114,C115

R flake multi-layer capacitor 1 C326

R flake multi-layer capacitor 1 C146

R flake multi-layer capacitor 1 C338

91

92

93

94

2CC1-16-C0G500-1R

0B

2CC1-16-C0G500-1R

5B

2CC1-16-C0G500-20

0J

2CC1-16-C0G500-22

flake multi-layer capacitor 1 C151

flake multi-layer capacitor 1 C335

R flake multi-layer capacitor 1 C349

R flake multi-layer capacitor 1 C145

Page 41 of 102

Page 43

0J

2CC1-16-C0G500-3R

0J

2CC1-16-C0G500-4R

0J

DP770 Service Manual

96

97

98

99

100

101

102

103

104

2CC1-16-C0G500-27

0J

2CC1-16-C0G500-2R

0B

2CC1-16-C0G500-3R

0B

5C

2CC1-16-C0G500-43

2CC1-16-C0G500-47

0J

0B

CC1-16-C0G500-4R

2

5B

2CC1-16-C0G500-56

R flake multi-layer capacitor 1 L304

flake multi-layer capacitor 2 C332,C337

flake multi-layer capacitor 1 C169

R flake multi-layer capacitor 1 C333

R flake multi-layer capacitor 1 C325

R flake multi-layer capacitor 1 C176

flake multi-layer capacitor 2 C334,C350

flake multi-layer capacitor 1 C112

R flake multi-layer capacitor 1 C331

105

106

2CC1-16-C0G500-5R

0B

2CC1-16-C0G500-68

0JQ

flake multi-layer capacitor 2 C142,C170

flake multi-layer capacitor 1 C175

Page 42 of 102

Page 44

DP770 Service Manual

0B

6K

M

M

C184,C360

107

108

109

110

111

112

113

2CC1-16-C0G500-6R

0C

2CC1-16-C0G500-R5

2CC1-16-X7R6R3-10

6K

2CC1-16-Y5V100-22

5Z

2CC1-16-Y5V160-10

5Z

2CC1-20-Y5V160-10

6Z

2CC1-32-X5R100-47

R flake multi-layer capacitor 2 C161,C144

R flake multi-layer capacitor 1 C336

SMD ceramic capacitor 7 C702,C804,C805,C821,C826,C809,C37

flake multi-layer capacitor 1 C921

R flake multi-layer capacitor 6 C323,C801,C806,C820,C907,C919

flake multi-layer capacitor 3 C915,C917,C923

SMD flake multi-layer capacitor 10

C101,C102,C105,C106,C241,C242,C352,C902,C904,C2

114

115

116

117

2CT1-TP20-100-100

2CT1-TS32-100-220

M

2CT1-TS32-100-4R7

M

2CT1-TS32-160-100

R SMD tantalum capac itor 2

SMD tantalum capacitor 3

C911,C143

C1,C830,C913

R SMD tantalum capac itor 1 C839

R SMD tantalum capacitor 11

C103,C104,C108,C109,C172,C180,C181,C182,C183,

118 2CT1-TS32-250-2R2 SMD tantalum capacitor 2 C127,C138

Page 43 of 102

Page 45

119

2CT1-TS32-350-R33

5

2LH1-R401R5-R04-0

5

5

L301,L302,L305,L317,L209

130

2LL1-16-27NGA

Laminated inductance

1

L206

134

2LL1-16-R82K

Laminated inductance

2

L101,L109

00M

136

2LW1-16UC-150J

R SMD coil induc ta n ce

1

L112

M

2CT1-TS32-350-R10

M

DP770 Service Manual

R SMD tantalum capac itor 1 C126

120

121

122

123

124

125

M

2LH1-R401R5-R02-0

2LH1-R401R5-R03-0

5

5

2LH1-R401R5-R08-0

2LH1-R501R5-R05-0

R SMD tantalum capac itor 1 C128

SMD air-core inductance 1 L310

R SMD air-core i nductance 2 L311,L312

R SMD air-core i nductance 6 L207,L208,L211,L212,L313,L314

R SMD air-core i nductance 1 L309

SMD air-core inductance 1 L306

126 2LL1-16-10NJ Laminated inductance 4 L225,L226,L228,L230

127 2LL1-16-18NG Laminated inductance 2 L108,L2

128 2LL1-16-1R0K R Laminated inductance 1 L218

129 2LL1-16-22NJ R Laminated inducta nce 5

131 2LL1-16-3N9S R Laminated inductance 3 L234,L235,L308

132 2LL1-16-3R3K R Laminated inductance 1 L204

133 2LL1-16-R10JB Laminated inductance 5 L213,L224,L227,L229,L231

135

2LL1-30-VLS3012T1

137 2LW1-16UC-181J SMD coil inductance 3 L210,L214,L318

138 2LW1-16UC-270G SMD coil inductance 2 L221,L222

139 2LW1-16UC-330G SMD coil inductance 2 L102,L220

Laminated inductance 4

L901,L902,L903,L904

Page 44 of 102

Page 46

140

2LW1-16UC-R33G

SMD coil inductance

7

L104,L105,L107,L110,L111,L114,L217

141 2LW1-20UC-120GA SMD coil inductance 1 L103

144

2LW1-20UC-8R2J

SMD coil inductance

1

L113

148

2RE1-10-2003

SMD precision resistor

1

R702

634,R905

155

2RS1-10-121J

R flake resistor

3

R114,R135,R136

142 2LW1-20UC-221J R SMD coil ind uc ta n ce 1 L316

143 2LW1-20UC-331J SMD coil inductance 1 L201

145 2LW1-25UC-103J R SMD coil ind uc ta n ce 2 L202,L203

146 2LW1-25UC-332K SMD coil inductance 1 L205

R31,R32,R830,R822,R706,

147 2RE1-10-1003 SMD precision resistor 26

R133,R134,R138,R207,R222,R223,R228,R229,R316,R317,R334

,R339,R37,R38,R626,R628,R635,R705,R711,R722,R928

R30,R812,R710,R721,R725,R802,R803,R805,R814,R815,

149 2RS1-10-000O R flake resistor 51

R816,R869,R926,R927,R40,R41,R115,R116,R119,R123,R144,R

146,R151,R152,R153,R156,R161,R164,R179,R183,R184,

R185,R197,R198,R199,R206,R217,R241,R242,

DP770 Service Manual

150 2RS1-10-100J R flake resistor 3 R826,R868,R911

151 2RS1-10-101J R flake resistor 21

152 2RS1-10-102J R flake resistor 13

153 2RS1-10-103J R flake resistor 48

154 2RS1-10-105J R flake resistor 2 R715,R718

156 2RS1-10-123J R flake resistor 2

R117,R118,R120,R129,R224,R253,R268,R271,R272,R274,R277

,R286,R290,R293,R294,R296,R304,R810,R819,R829,R901

R158,R159,R203,R205,R208,R341,R17,R39,R624,R625,R627,R

R823,R827,R33,R34,C231,R121,R124,R127,R128,R139,R142,R

147,R148,R204,R209,R210,R225,R243,R325,R813,R817,R825,

R916,R917,R918,R919,R920,R921,R923,R924,

R925,R929,R9,R141,R187,R188,R189,

R190,R263,R264,R269,R270,R276,R321,R910,R912,R915,R922

R130,R907

Page 45 of 102

Page 47

157

2RS1-10-124J

R flake resistor

2

R167,R236

158 2RE1-10-2200 SMD precision resistor 2 R305,R307

161

2RS1-10-153J

R flake resistor

2

R713,R716

171

2RS1-10-225J

flake resistor

2

R318,R332

172

2RS1-10-243J

R flake resistor

1

R302

175

2RS1-10-273J

R flake resistor

2

R714,R720

179

2RS1-10-333J

R flake resistor

1

R327

159 2RS1-10-151J R flake resistor 1 R233

160 2RS1-10-152J R flake resistor 1 R323

DP770 Service Manual

162 2RS1-10-154J R flake resistor 2

R104,R906

163 2RS1-10-182J R flake resistor 1 R132

164 2RS1-10-183J R flake resistor 2 R712,R719

165 2RS1-10-184J R flake resistor 3 R213,R221,R23

166 2RS1-10-202J R flake resistor 4

R106,R192,R808,R903

167 2RS1-10-203J R flake resistor 5 R122,R202,R232,R336,R701

168 2RS1-10-220J R flake resistor 9

R306,R175,R176,R177,R178,R180,R181,R342,R343

169 2RS1-10-222J R flake resistor 5 R27,R345,R804,R806,R245

170 2RS1-10-224J R flake resistor 4 R103,R168,R315,R333

173 2RS1-10-271J R flake resistor 2

R344,R811

174 2RS1-10-272J R flake resistor 6 R360,R1,R200,R259,R260,R261

176 2RS1-10-330J R flake resistor 1 R100

177 2RS1-10-331J R flake resistor 1 R238

178 2RS1-10-332J R flake resistor 2 R125,R909

Page 46 of 102

Page 48

180 2RS1-10-363J R flake resistor 1 R335

184

2RS1-10-472J

R flake resistor

12

R4,R143,R234,R703,R704,R801,R807,R913,R914,R12,R15,R36

187

2RS1-10-511J

R flake resistor

1

R201

181 2RS1-10-392J R flake resistor 3 R108,R226,R227

182 2RS1-10-470J R flake resistor 3 R113,R215,R219

DP770 Service Manual

183 2RS1-10-471J R flake resistor 2

185 2RS1-10-473J R flake resistor 15

186 2RS1-10-510J flake resistor 4 R191,R230,R308,R329

188 2RS1-10-514J flake resistor 1 R904

R340,R611

R137,R322,R171,R172,R173,

R174,R279,R280,R283,R284,R287,R288,R297,R298,R908

Page 47 of 102

Page 49

189 2RS1-10-562J R flake resistor 2 R107,R235

R110,R111,R112,R145

196

2RS1-10-823J

R flake resistor

1

R328

200

2RS1-16-271J

R flake resistor

1

R330

190 2RS1-10-680J R flake resistor 2 R109,R809

191 2RS1-10-682J R flake resistor 2 R310,R338

192 2RS1-10-684J R flake resistor 1 R214

193 2RS1-10-6R8J flake resistor 4

DP770 Service Manual

194 2RS1-10-753J R flake resistor 1 R220

195 2RS1-10-822J R flake resistor 3 R126,R131,R231

197 2RS1-16-000O R flake resistor 6 L216,L219,L303,L307,R170,R157

198 2RS1-16-102J R flake resistor 2 R348,R707

199 2RS1-16-181J R flake resistor 1 L215

201 2RS1-16-302J flake resistor 1 R708

Page 48 of 102

Page 50

202 2RS1-20-000O R flake resistor 1 FB901

,

RN22,RN24,RN25,RN26,RN27,RN28,RN29

SMD board-to-board connector

209

3FW1-42932-302320

R SMD fuse

1

F901

N1D

FB911,FB912,FB913,FB914,FB915,FB917,FB919

SMD temperature compensated

203 2RS1-32-R39J R flake resistor 3 R319,R320,R337

RN1,RN2,RN3,RN4,RN5,RN6,RN8,RN9,RN10,

204 2RS2-20-101J08B SMD Network resistor 25

RN11,RN14,RN15,RN16,RN17,RN18,RN19,RN20,RN21

DP770 Service Manual

205

2RT1-NTH5G16P40B

333J

206 3CB1-DF23C-50DS

SMD thermistor 1 R326

DP770 DP780

1 J902

207 3CM1-TFC-008-J Flat TF clutch base 1 J4

208 3CP1-TPS76301 LDO power regulat or 3 U102,U113,U5

210 5FE1-BLM11A601S R SMD EMI suppression f ilter 4

211

212

5FE1-BLM18AG121S

5FE1-BLM18PG181S

N1

SMD EMI suppression filter 15

SMD EMI suppression filter 10

213 5FE1-BLM21P300S R SMD EMI suppression f ilter 3

214

215

216

5FE1-BLM21PG221S

N1

5OT1-12R8-CEC3-05

03

5XC1-19R2-TKL3056B SMD crystal oscillator

SMD EMI suppression filter 4 FB808,FB921,R902,R932

R

crystal oscillator

1 U104

1 U114

FB202,FB203,FB204,FB301

FB701,FB801,FB802,FB803,FB806,FB908,FB909,FB910,

FB101,FB102,FB702,FB703,FB905,FB906,

FB907,R193,R194,FB201

FB302,FB303,FB304

DP770 STP KH620

217 5XC1-73R4-D73312 crystal oscillator 1 Z202

Page 49 of 102

Page 51

GQ12

,

GPS/BEIDOU dual module (DP770

DP780

0C

218

5XT1-MC146-32R76

K

219 6BLS-4814-03327U

E SMD

Ceramic Resonator 1 X503

SMD button battery (DP770,DM890

PT7800,219,620D)

1 BT1

220 7MHP-4002-01A-W TD7700 bat t er y connector 1 J901

221

2CC1-16-C0G500-10

1J

R flake multi-layer capacitor 1 C26

222 2RS1-16-222J R flake resistor 1 FB920

223 2LL1-16-2N2S R Laminated inductance 2 L1,L3

224

225

2CC1-10-C0G500-2R

5B

2CC1-10-C0G500-2R

0B

R flake multi-layer capacitor 2 C1134,C1153

flake multi-layer capacitor 2 C1132,C1143

226 1DR1-BAT54C SMD schottky diode 1 D17

227 1TF1-BSH203 SMD FET 1 Q2

DP770 Service Manual

228 1MR1-MC-1010B

229 1IS1-SKY65709-81

230 7MHC-4002-02A-W DP770 shield cover brac ket 1 1 S2

231 7MHC-4002-04A-W DP770 shield cover brac ket 2 1 S3

232 7MHC-4002-16A-W1 GPS shield cov er base 1 S4

234