Kirchner und Tochter SMB Series, SMB-OE Series, SMB 80, SMB 150, SMB 200 Assembly And Operating Instructions Manual

...

Sprinkler measuring orifice

SMB

Assembly and operating instructions

Sprinkler measuring orifice

SMB/SMB-OE

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

SMB

Table of contents

1 General 1

1.1 Preface ......................................................................................................... 1

1.2 Exclusion of liability .......................................................................................... 1

2 Safety 1

2.1 General safety information .............................................................................. 1

2.2 Proper use .................................................................................................... 2

2.3 Explanation of pictographs and signs ............................................................... 2

2.4 Information on safety for owner and operators ................................................. 2

2.5 Regulations and guidelines .............................................................................. 2

2.6 VdS approval ................................................................................................. 2

3 Transport and storage 2

4 Description 3

4.1 Application .................................................................................................... 3

4.2 Design and function ....................................................................................... 3

4.3 Peculiarity SMB-OE ........................................................................................ 3

4.4 Installation variants ....................................................................................... 4

5 Installation 5

5.1 Preparation for installation ............................................................................. 5

5.2 Installation of the orifice ring .......................................................................... 5

5.3 Installation of the dial gauge ........................................................................... 6

6 Commissioning 7

6.1 Zero point adjustment .................................................................................... 7

6.2 Initial startup ................................................................................................ 7

7 Maintenance 8

8 Service 8

9 Disposal 8

10 Technical data 9

10.1 General technical data.................................................................................... 9

10.2 Models .......................................................................................................... 9

10.3 Measuring range ............................................................................................ 9

10.4 Inlet and outlet sections ................................................................................. 10

10.5 Dimensions .................................................................................................. 11

10.6 Installation kits ............................................................................................. 12

11 Spare parts 13

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

1

SMB

1. General

1.1 Preface

These assembly and operating

instructions apply to sprinkler

measuring orifices, type SMB with a

display of m3/min and to the SMB-OE

with percentage display.

All information contained in these

operating instructions on assembly,

operation, repairs and maintenance

have to be observed and adhered to.

The operating instructions form an

integral part of the sprinkler

measuring orifice; they have to be kept

at a suitable location in the vicinity of

the place of application and must be

accessible for the operators.

In case of interaction of different plant

components, the operating

instructions of those also have to be

observed.

1.2 Exclusion of liability

Kirchner und Tochter will not accept

any liability for damage or disruptions

caused by operating errors, nonobservance of these assembly and

operating instructions, inexpert

execution of assembly and repair work

or by the improper use of the sprinkler

measuring orifice.

2. Safety

2.1 General safety information

These assembly and operating

instructions contain important

information to be observed on the

assembly, the operation, on repairs

and maintenance of the sprinkler

measuring orifice. Each person

charged with the assembly, the

operation, repairs and maintenance

must have read and understood these

operation instructions.

Non-observance of these assembly and

operating instructions, or inexpertly

conducted assembly and repair work

may result in disruptions of the

sprinkler system. As a consequence,

man or animal may be at risk or

material assets may be damaged.

Hazards by electric energy or released

media energy must be prevented.

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

2

SMB

2.2 Proper use

The VdS approval of the sprinkler

measuring orifice is valid for the flow

measurement of water. Installation in

pipework may be effected only between

two flanges (intermediate flange

assembly).

Select the sprinkler measuring orifice

model in accordance with the pipe

cross-section at the location of

application for the sprinkler measuring

orifice.

The limit values of the sprinkler

measuring orifice are to be observed

as prescribed in chapter „Technical

data“. Rebuilding or other modifications

of the measuring device may be

effected by Kirchner und Tochter only.

2.3 Explanation of pictographs and

signs

Pictograph on work safety

This pictograph can be found at all hints

on work safety in these assembly and

operating instructions pointing out

hazards for life and limb of persons.

Further, this pictograph highlights

safety hints in these operating

instructions that point to regulations,

guidelines or operating sequences that

must be observed without fail. Nonobservance may result in damages to

or a destruction of the measuring

orifice and / or other parts of the

installation.

2.4 Safety information for the owner

and the operators

The personnel charged with the

assembly, the operation, repairs and

maintenance must be qualified to fulfill

the respective tasks and must have

been trained and instructed with

regards to the task in question.

2.5 Regulations and guidelines

Apart from the information contained

in these assembly and operating

instructions, the regulations, guidelines

and standards such as DIN EN, as well

as the DVGW and VdS guidelines in

case of branch-oriented applications

must be observed; the same is true for

the regulations on the prevention of

accidents valid in the destination

country.

2.6 VdS approval

The sprinkler measuring orifice has

been approved by the VdS. During the

installation, operation, repairs and

maintenance, the VdS guidelines have to

be adhered to.

3. Transport and storage

At the factory, the sprinkler measuring

orifice was suitably packed for transport

and storage. Transport and storage

should be effected while in the original

packing only.

The measuring device is to be

protected against shocks and

blows!

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

3

SMB

4. Description

4.1 Field of application

The sprinkler measuring orifice SMB is

a measuring device employed to measure

the flow rate in pipework of stationary

sprinkler systems.

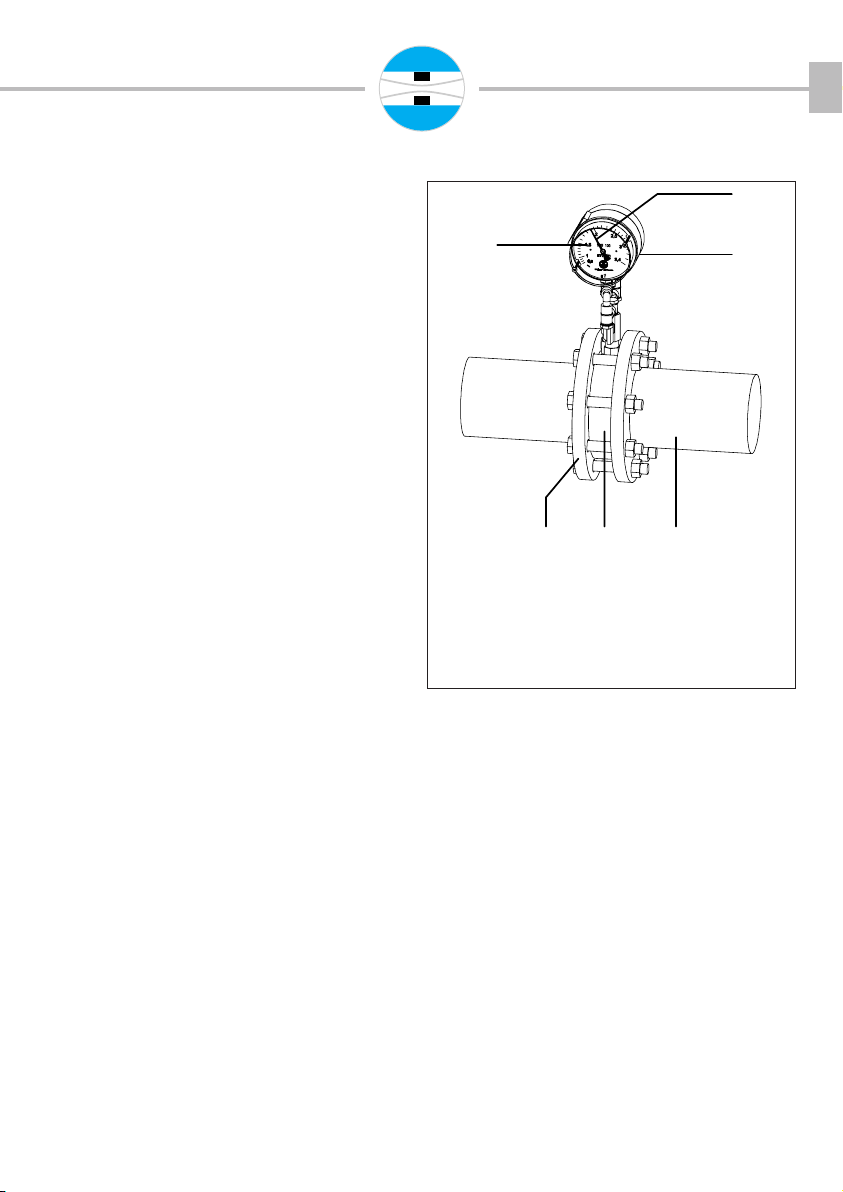

4.2 Design and function

Due to physical reasons, different

pressure potentials are found on both

sides of the orifice (5). This differential pressure acts quadratic proportional

to the volume flow inside the pipework

(4).

The scaling (1) of the dial gauge (3) is

realized in volume flow units (m³/min).

The dial gauge displays the present

volume flow inside the pipe via the

position of the hand (2).

4.3 Peculiarity SMB-OE

All information contained in these

assembly and operating instructions

are also valid for the measuring device

SMB-OE.

A peculiarity of the sprinkler measuring

orifice SMB-OE is the fact that the

scaling of the scale reading plate has

been subdivided in percent.

A label on the dial gauge serves to read

the effective flow values in m³/min for

the individual nominal cross-section of

the pipe.

This permits the combination of the dial

gauge with all nominal cross-sections

of the SMB-OE.

1 scaling

2 hand

3 dial gauge

4 pipe work

5 orifice

6 flange

Ill. 1

1

6 5 4

2

3

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Loading...

Loading...