Kirchner und Tochter SMB Series, SMB-OE Series, SMB 80, SMB 150, SMB 200 Assembly And Operating Instructions Manual

...

Sprinkler measuring orifice

SMB

Assembly and operating instructions

Sprinkler measuring orifice

SMB/SMB-OE

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

SMB

Table of contents

1 General 1

1.1 Preface ......................................................................................................... 1

1.2 Exclusion of liability .......................................................................................... 1

2 Safety 1

2.1 General safety information .............................................................................. 1

2.2 Proper use .................................................................................................... 2

2.3 Explanation of pictographs and signs ............................................................... 2

2.4 Information on safety for owner and operators ................................................. 2

2.5 Regulations and guidelines .............................................................................. 2

2.6 VdS approval ................................................................................................. 2

3 Transport and storage 2

4 Description 3

4.1 Application .................................................................................................... 3

4.2 Design and function ....................................................................................... 3

4.3 Peculiarity SMB-OE ........................................................................................ 3

4.4 Installation variants ....................................................................................... 4

5 Installation 5

5.1 Preparation for installation ............................................................................. 5

5.2 Installation of the orifice ring .......................................................................... 5

5.3 Installation of the dial gauge ........................................................................... 6

6 Commissioning 7

6.1 Zero point adjustment .................................................................................... 7

6.2 Initial startup ................................................................................................ 7

7 Maintenance 8

8 Service 8

9 Disposal 8

10 Technical data 9

10.1 General technical data.................................................................................... 9

10.2 Models .......................................................................................................... 9

10.3 Measuring range ............................................................................................ 9

10.4 Inlet and outlet sections ................................................................................. 10

10.5 Dimensions .................................................................................................. 11

10.6 Installation kits ............................................................................................. 12

11 Spare parts 13

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

1

SMB

1. General

1.1 Preface

These assembly and operating

instructions apply to sprinkler

measuring orifices, type SMB with a

display of m3/min and to the SMB-OE

with percentage display.

All information contained in these

operating instructions on assembly,

operation, repairs and maintenance

have to be observed and adhered to.

The operating instructions form an

integral part of the sprinkler

measuring orifice; they have to be kept

at a suitable location in the vicinity of

the place of application and must be

accessible for the operators.

In case of interaction of different plant

components, the operating

instructions of those also have to be

observed.

1.2 Exclusion of liability

Kirchner und Tochter will not accept

any liability for damage or disruptions

caused by operating errors, nonobservance of these assembly and

operating instructions, inexpert

execution of assembly and repair work

or by the improper use of the sprinkler

measuring orifice.

2. Safety

2.1 General safety information

These assembly and operating

instructions contain important

information to be observed on the

assembly, the operation, on repairs

and maintenance of the sprinkler

measuring orifice. Each person

charged with the assembly, the

operation, repairs and maintenance

must have read and understood these

operation instructions.

Non-observance of these assembly and

operating instructions, or inexpertly

conducted assembly and repair work

may result in disruptions of the

sprinkler system. As a consequence,

man or animal may be at risk or

material assets may be damaged.

Hazards by electric energy or released

media energy must be prevented.

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

2

SMB

2.2 Proper use

The VdS approval of the sprinkler

measuring orifice is valid for the flow

measurement of water. Installation in

pipework may be effected only between

two flanges (intermediate flange

assembly).

Select the sprinkler measuring orifice

model in accordance with the pipe

cross-section at the location of

application for the sprinkler measuring

orifice.

The limit values of the sprinkler

measuring orifice are to be observed

as prescribed in chapter „Technical

data“. Rebuilding or other modifications

of the measuring device may be

effected by Kirchner und Tochter only.

2.3 Explanation of pictographs and

signs

Pictograph on work safety

This pictograph can be found at all hints

on work safety in these assembly and

operating instructions pointing out

hazards for life and limb of persons.

Further, this pictograph highlights

safety hints in these operating

instructions that point to regulations,

guidelines or operating sequences that

must be observed without fail. Nonobservance may result in damages to

or a destruction of the measuring

orifice and / or other parts of the

installation.

2.4 Safety information for the owner

and the operators

The personnel charged with the

assembly, the operation, repairs and

maintenance must be qualified to fulfill

the respective tasks and must have

been trained and instructed with

regards to the task in question.

2.5 Regulations and guidelines

Apart from the information contained

in these assembly and operating

instructions, the regulations, guidelines

and standards such as DIN EN, as well

as the DVGW and VdS guidelines in

case of branch-oriented applications

must be observed; the same is true for

the regulations on the prevention of

accidents valid in the destination

country.

2.6 VdS approval

The sprinkler measuring orifice has

been approved by the VdS. During the

installation, operation, repairs and

maintenance, the VdS guidelines have to

be adhered to.

3. Transport and storage

At the factory, the sprinkler measuring

orifice was suitably packed for transport

and storage. Transport and storage

should be effected while in the original

packing only.

The measuring device is to be

protected against shocks and

blows!

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

3

SMB

4. Description

4.1 Field of application

The sprinkler measuring orifice SMB is

a measuring device employed to measure

the flow rate in pipework of stationary

sprinkler systems.

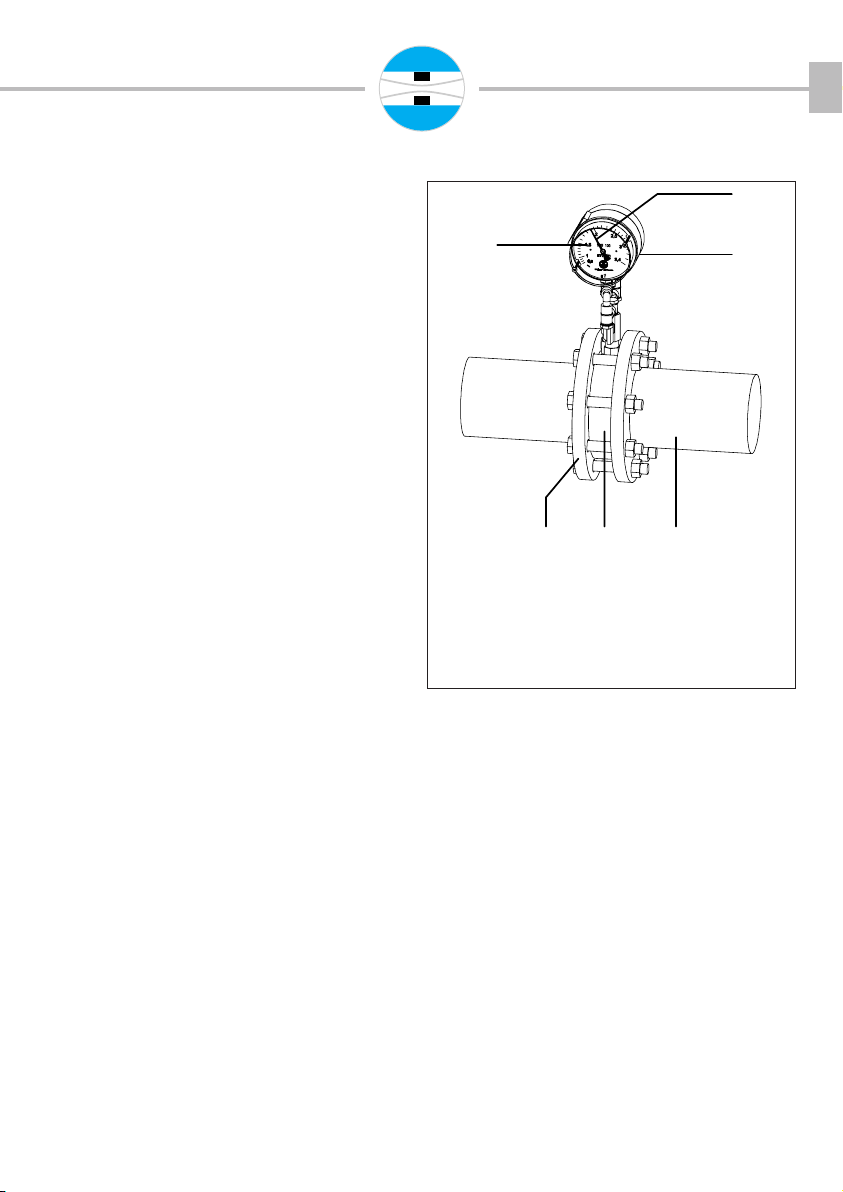

4.2 Design and function

Due to physical reasons, different

pressure potentials are found on both

sides of the orifice (5). This differential pressure acts quadratic proportional

to the volume flow inside the pipework

(4).

The scaling (1) of the dial gauge (3) is

realized in volume flow units (m³/min).

The dial gauge displays the present

volume flow inside the pipe via the

position of the hand (2).

4.3 Peculiarity SMB-OE

All information contained in these

assembly and operating instructions

are also valid for the measuring device

SMB-OE.

A peculiarity of the sprinkler measuring

orifice SMB-OE is the fact that the

scaling of the scale reading plate has

been subdivided in percent.

A label on the dial gauge serves to read

the effective flow values in m³/min for

the individual nominal cross-section of

the pipe.

This permits the combination of the dial

gauge with all nominal cross-sections

of the SMB-OE.

1 scaling

2 hand

3 dial gauge

4 pipe work

5 orifice

6 flange

Ill. 1

1

6 5 4

2

3

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

4

SMB

Ill. 2

4.4 Installation variants

Thanks to the special articulated design,

the dial gauge of the sprinkler measuring

orifice pivots by 180 degrees in both

directions. Therefore, an assembly in

various installation positions is possible

(refer to illustration 2).

Installation direction of flow

from left to right

Installation direction of flow

from top to bottom

Installation direction of flow

from right to left

Installation direction of flow

from bottom to top

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

5. Installation

Installation may be effected by

trained personnel only!

5.1 Preparation for installation

•Verify the local conditions and the

direction of flow inside the pipework

at the place of installation of the

sprinkler measuring orifice.

•Make sure that the sprinkler

measuring orifice is suitable for

installation at the planned location

with regards to nominal cross-section,

min. inlet and outlet distance,

maximum working pressure and medium (also refer to chapter 10).

• Shut off and secure the pipework in

accordance with regulations and

empty the circuit.

•Lay out the installation kit for the

delivered measuring orifice (refer to

chapter 10.6).

5.2 Installation of the orifice ring

For an intermediate flange

installation of the sprinkler

measuring orifice, two flanges

PN 16 have to be installed in accordance

with DIN EN 1092-1 and the VdS

guidelines. The flange distance required

for installation is 40 mm with an additional 2 mm each for both flange seals.

Sprinkler measuring orifice

5

SMB

Ill. 3

Pre-assemble the flanged connection in

such a way as to permit the insertion

of the measuring orifice with its seals

from the front (vertical piping) or from

above (horizontal piping), respectively.

Together with the seals attached on

both sides, place the measuring orifice

between both prepared flanges and

slide same all the way against the preassembled screws.

This serves to center orifice and seal.

The seals have to be in true alignment

with the entire circumference of the

measuring orifice.

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

6

SMB

The flow direction has to coincide with

the hand on the measuring orifice.

Insert the remaining screws and

uniformly tighten all screwed

connections crosswise.

Note

The best measuring accuracy is

obtained with smooth inside pipe joints

and pipe configurations in accordance

with the VdS guidelines.

5.3 Installation of the dial gauge

Remove the shipping protection plugs (1,

ill. 4) from the threads of the dial gauge

and the screwed connections of the

measuring orifice. The sealing rings (9)

required during assembly have been

attached to the dial gauge with cable

binders.

Use screws (4 and 7) to fix the dial

gauge with its inserted sealing rings (9)

to the ball valves of the measuring

orifice. In the process, connect the plus

line of the dial gauge with the plus line of

the measuring orifice and minus line of

the dial gauge with the minus line of the

measuring orifice. Observe the respective

markings at the dial gauge and on the

lable of measuring orifice.

Position the dial gauge in such a way, as

to permit an unimpeded reading of the

display.

Tighten the fixing screws (4 to 7) with

a torque of 15 Nm.

In order to prevent leaks, the joining

pieces (1 and 2) should not be tightened

with a torque.

When tightening the screwed

connections (4 and 7) immobilize the

joining pieces (1 and 2) with a wrench.

Ill. 4

1

5

6

7

8

9

1

4

3

2

Next follow the steps in chapter 6

„Commissioning“.

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Ill. 5

Version 2.1

6. Commissioning

6.1 Zero-point adjustment

In case the hand of the dial gauge is not

within the range of the rest position

marked RP with the flow cut off, the

sprinkler measuring orifice has to be

readjusted as follows:

• Detach the screws (3) from the dial

gauge

• Remove the translucent cover lid

• With the zero-point adjustment screw

(4) adjust the hand to the center of the

rest postion (ill. 6)

• Put cover lid back on

• Insert screws and tighten same

6.2 Initial startup

The correct installation is a

prerequisite for commissioning.

The following steps have to be followed

for the initial startup:

• Close ball valves (1 and 2)

• Put conduit under pressure

• Simultaneously open the ball valves (1

and 2)

• Check tightness of all components of

the sprinkler measuring orifice.

Sprinkler measuring orifice

7

SMB

zero point Ok zero point not Ok

Adjust zero point concentric to

the rest position (RP)

Ill. 6

3

3

4

2

1

Ill. 7

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

8

SMB

7. Maintenance

The sprinkler measuring orifice is

maintenance-free. In order to warrant

a reliable operation and a long service

life of the device, we recommend

regular checks of the device, such as:

• check of the display

• remove deposits inside the nozzles of

the banjo bolts

• check of the joints between orifice ring

and dial gauge

The exact checking cycles are

determined by the VdS regulations and

are to be adjusted depending on the

operating and surrounding conditions.

8. Service

All defective or faulty devices are to be

returned directly to our repair shop.

In order to process complaints of our

customers as quickly as possible, kindly

contact our Sales Department tel. no.

+49 (0) 2065-96090 before returning

any parts.

9. Disposal

For a better environment.

Please help us protect our environment

by disposing of the parts used in

accordance with the relevant legislation

or by recycling same.

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

SMB

10. Technical data

10.1 General technical data

VdS approval G 4990049

Measuring principle Differential pressure metering at orifice

Materials:

Orifice hard-coated aluminum

Screwed connections nickel-plated brass, 1.4308

Ball valves nickel-plated brass

Dial gauge Aluminum

Scale in m³/min or % at SMB-OE

Measuring accuracy 2.5% FS

max. working pressure 16 bar

Installation intermediate flange installation in accordance with the VdS

guidelines

10.2 Models

The SMB is available in five different nominal cross-sections. The approved measuring

range of the SMB is at least 1:5. The SMB attains an accuracy of 2.5% at the approved

full-scale range and an accuracy of 5% at the approved measuring range start value.

10.3 Measuring range

Measuring range SMB

Model For pipes with Approved Max. deviation from the

inner diameter of measuring range full-scale range

[mm] / [DN] [m³/min] [m³/min] [%]

SMB 80 83.1 / 80 0,6 - 2.1 ±0.0525 ± 2,5

SMB 100 107.9 / 100 1 - 3.4 ±0.085 ± 2,5

SMB 150 160.3 / 150 2 - 7.25 ±0.18125 ± 2,5

SMB 200 210.1 / 200 4 - 12.35 ±0.30875 ± 2,5

SMB 250 264.0 / 250 4 - 18.12 ±0.453 ±2,5

9

Measuring range SMB-OE

DN80 DN100 DN150 DN200 DN250

Indication Indication Indication Indication Indication

% m³/min % m³/min % m³/min % m³/min % m³/min

100,00 2,10 100,00 3,40 100,00 7,25 100,00 12,35 100,00 18,12

90,00 1,89 90,00 3,06 90,00 6,53 90,00 11,12 90,00 16,31

80,00 1,68 80,00 2,72 80,00 5,80 80,00 9,88 80,00 14,50

70,00 1,47 70,00 2,38 70,00 5,08 70,00 8,65 70,00 12,68

60,00 1,26 60,00 2,04 60,00 4,35 60,00 7,41 60,00 10,87

50,00 1,05 50,00 1,70 50,00 3,63 50,00 6,18 50,00 9,06

40,00 0,84 40,00 1,36 40,00 2,90 40,00 4,94 40,00 7,25

30,00 0,63 30,00 1,02 30,00 2,18 30,00 3,71 30,00 5,44

28,57 0,60 29,41 1,00 27,59 2,00 32,39 4,00 22,08 4,00

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

10

SMB

10.4 Inlet and outlet paths

A B

Ill. 8

The optimum accuracy is obtained, if the pipe configuration conforms to the VdS guidelines.

The following inlet and outlet sections that must not contain any valves, knees, elbows,

changes in cross-section or similar, apply to the various SMB models.

When using pumps creating fluctuations in the volume flow (possible with centrifugal

pumps driven by a diesel engine), we recommend to extend the inlet section from 10 d to

18 d.

Model Min. inlet path Min. outlet path

SMB 80 800 400

SMB 100 1000 500

SMB 150 1500 750

SMB 200 2000 1000

SMB 250 2500 1250

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

AB

[mm] [mm]

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

10.5 Dimensions

Sprinkler measuring orifice

11

SMB

104

2

2,5

1,5

SMB 100

3

3

m

/min

1

0,6

3,4

RP

0

P+

P-

SMB 100

3

q : 3,3m /min

max

3

q : 0,6m /min

min

P : 16bar

max

VdS Anerkennung

Nr.: G XXXXXXX

Ser. Nr.: 100000000

Kirchner und Tochter

D-47228 Duisburg

URL www.kt-web.de

40

Ill. 9

Model A B E

SMB 80 144 84.1 311

SMB 100 164 108.9 321

SMB 150 220 161.8 349

SMB 200 275 211.8 377

SMB 250 331 264.5 406

[mm] [mm] [mm]

96

E

B

A

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

12

SMB

10.6 Installation kits

SMB Quantity Designator

installation kit

DN 80 8 hexagon bolt DIN 933 - M16 x 110 - 8.8 galvanized

DN 100 8 hexagon bolt DIN 933 - M16 x 110 - 8.8 galvanized

DN 150 8 hexagon bolt DIN 933 - M20 x 110 - 8.8 galvanized

DN 200 12 hexagon bolt DIN 933 - M20 x 110 - 8.8 galvanized

DN 250 12 hexagon bolt DIN 933 - M24 x 110 - 8.8 galvanized

1)

Use rubber seals or water-resistant seals.

8 nut DIN 934 - M16 - 8

8 washer DIN 125 - 17 - A2

2 seals

8 nut DIN 934 - M 16 - 8

8 washer DIN 125 - 17 - A2

2 seals

8 nut DIN 934 - M20 - 8

8 washer DIN 125 - 21 - A2

2 seals

12 nut DIN 934 - M20 - 8

12 washer DIN 125 - 21 - A2

2 seals

12 nut DIN 934 - M24 - 8

12 washer DIN 125 - 25 - A2

2 seals

1)

Ø 133 x Ø 86 x 2

1)

Ø 162 x Ø 109 x 2

1)

Ø 211 x Ø 162 x 2

1)

Ø 265 x Ø 223 x 2

1)

Ø 328 x Ø 274 x 2

Ill. 10

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

11. Spare parts

Sprinkler measuring orifice

13

SMB

1

10

7

5

11

6

4

9

6

8

3

2

Bill of parts

Pos. Qty. Designator Material

1 1 Dial gauge AI

2 1 Measuring orifice hard-coated AI

3 2 Joining piece CuZn nickel-plated

4 2 Straight joint 1.4308

5 2 L-type joint 1.4308

6 4 Screw CuZn nickel-plated

7 2 Double-threaded nipple CuZn nickel-plated

8 2 Ball valve CuZn nickel-plated

9 12 Sealing ring CuZn nickel-plated/NBR

10 1 Clear-view cover Perspex

11 2 Screw with damping insert CuZn nickel-plated

12 1 Assembly and operating instructions -

Spare parts’ list

A) 1 orifice with joining pieces (Pos. 2, 3, 8, 9)

B) 1 set pre-assembled fittings (Pos. 4, 5, 6, 9, 11)

C) 1 dial gauge (Pos. 1, 7, 10)

D) 1 set of sealing rings (Pos 9)

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Sprinkler measuring orifice

SMB

The equipment from Kirchner und Tochter has been tested in compliance with

the applicable CE-regulations of the

European Community.

The respective declaration of

conformity is available on request.

The Kirchner und Tochter QM-System

will be certified in accordance with

DIN-EN-ISO 9001:2000. The quality is

systematically adapted to the

increasing demands.

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Version 2.1

Loading...

Loading...