Kirchner und Tochter RA 65, FA 65 Installation And Operating Instructions Manual

VA Flow Meters

RA 65 / FA 65

Installation and Operating Instructions

Variable area flow meter

RA 65 / FA 65

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

Version 1.1

VA Flow Meters

2

RA 65 / FA 65

Contents

1. Foreword.................................................................................................................................................................. 3

2. Safety......................................................................................................................................................................... 3

2.1. Symbol and meaning................................................................................................................................3

2.2. General safety directions and exemption from liability ............................................................ 3

2.3. Intended use ................................................................................................................................................3

2.4. Special safety instructions concerning glass devices.............................................................. 4

2.5. Operator and operating personnel ................................................................................................... 4

2.6. Regulations and guidelines ...................................................................................................................4

2.7. Notice as required by the hazardous materials directive ...................................................... 4

3. Transport and storage......................................................................................................................................4

4. Installation ............................................................................................................................................................... 5

4.1. Installation RA 65...................................................................................................................................... 6

4.2. Installation FA 65 ......................................................................................................................................6

5. Start-up..................................................................................................................................................................... 6

6. Readings in operation........................................................................................................................................ 6

7. Limit contacts MSK-1, MSK-12, MSK-W................................................................................................. 7

7.1. Connection of limit contacts................................................................................................................. 7

7.2. Setting the limit contacts....................................................................................................................... 7

8. Maintenance and cleaning of the flow meter.........................................................................................8

8.1. Dismantling and installation .................................................................................................................8

8.2. Replacement of measuring glass ...................................................................................................... 8

9. Service ...................................................................................................................................................................... 9

9.1. Disposal.......................................................................................................................................................... 9

10. Technical data...............................................................................................................................................10

10.1. Materials ...............................................................................................................................................10

10.2. Dimensions........................................................................................................................................... 11

10.3. Technical data of limit contacts.................................................................................................. 13

10.3.1. Low-Voltage Directive............................................................................................................ 13

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

Version 1.1

VA Flow Meters

3

RA 65 / FA 65

1. Foreword

These Installation and Operating Instructions are applicable to devices of Series RA 65 and

FA 65. Please follow all instructions and information given for installation, operation,

inspection and maintenance. The Instructions form a component part of the device, and

should be kept in an appropriate place accessible to the personnel in the vicinity of the

location. Where various plant components are operated together, the operating instructions

pertaining to the other devices should also be observed.

2. Safety

2.1. Symbol and meaning

Safety notice

This symbol is placed against all directions/information relating to occupational health and

safety in these Installation and Operating Instructions, and draws attention to danger to life

and limb. Such notices should be strictly observed.

2.2. General safety directions and exemption from liability

This document contains basic instructions for the installation, operation, inspection and

maintenance of the variable-area flow meter. Failure to comply with these instructions can

lead to hazardous situations for Man and Beast and also to damage to property, for which

Kirchner und Tochter disclaims all liability.

The Operator is required to rule out potentially hazardous situations through voltage and

released media energy.

2.3. Intended use

The RA 65/FA 65 Series device is a variable-area flow meter for liquids and gases. It is

designed for installation in vertical pipe runs. Installation in the pipeline should be carried out

solely in accordance with these Instructions. The required version of the variable-area

flowmeter should be selected on the basis of the pipe diameter at the installation location of

the device. The limit values pertaining to the device are specified in Section 10 and must be

complied with. Any modifications or other alterations to the measuring device may be

carried out solely by Kirchner und Tochter. Installation in horizontal pipe runs is possible

using appropriate pipe bends. The direction of flow must always be from bottom to top.

Details of the process product together with the operating conditions are marked on the

measuring glass.

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

Version 1.1

VA Flow Meters

t

t

4

RA 65 / FA 65

2.4. Special safety instructions concerning glass devices

For safety reasons, we recommend fitting a protective shield in front of the

measuring tube when starting up flow meters fitted with glass measuring tubes.

The devices should not be operated where there is a risk of pressure surges (water

hammer)!

To avoid glass breakage, all fitting work between measuring glass and heads inside the

glass should be carried out by twisting and simultaneously pressing after having wetted the

packing rings/gaskets.

2.5. Operator and operating personnel

Authorized installation, operating, inspection and maintenance personnel should be suitably

qualified for the jobs assigned to them, and should receive appropriate training and

instruction.

2.6. Regulations and guidelines

In addition to the directions given in these Installation and Operating Instructions, observe

he regulations, guidelines and standards, such as DIN EN, and, for specific applications,

he codes of practice issued by DVGW (gas and water) and VdS (underwriters), or the

equivalent national codes, and applicable national accident prevention regulations.

2.7. Notice as required by the hazardous materials directive

In accordance with the law concerning handling of waste (critical waste) and the hazardous

materials directive (general duty to protect), we would point out that all flow meters

returned to Kirchner und Tochter for repair are required to be free from any and all

hazardous substances (alkaline solutions, acids, solvents, etc.).

Make sure that devices are thoroughly rinsed out to neutralize hazardous

substances.

3. Transport and storage

Always use the original packing for transport, handling and storage. Protect the device

against rough handling, impact, jolts, etc.

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

Version 1.1

VA Flow Meters

5

RA 65 / FA 65

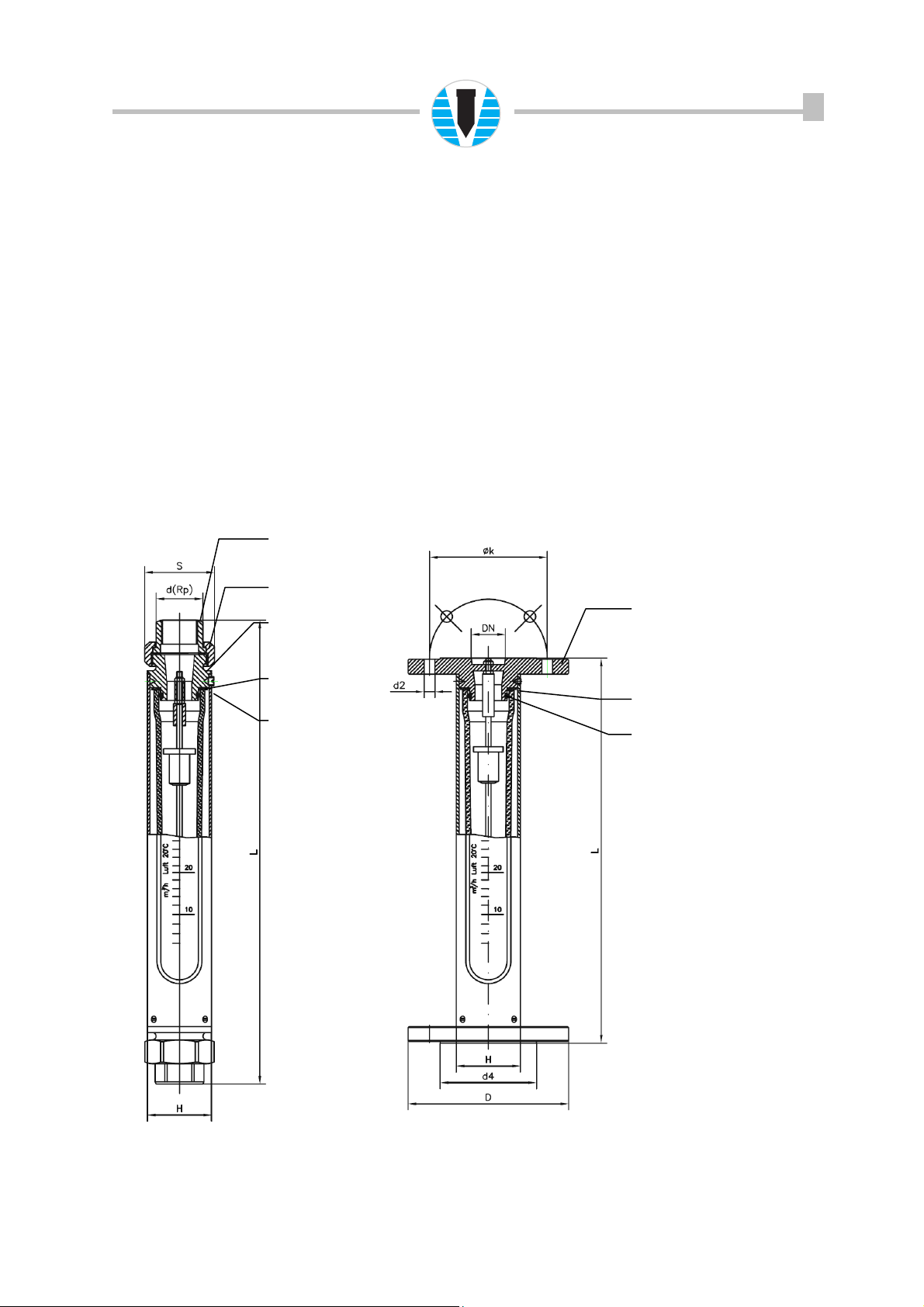

4. Installation

Variable-area flow meters are suitable only for vertical installation, with the direction of flow

being from bottom to top . For all other installation situations, appropriate pipe bends need

to be fitted in the existing pipeline in order to ensure upward vertical flow through the device.

Before installing, remove all protective caps, transport locks and any foreign bodies found.

Make sure the pipes are correctly spaced and in true alignment at the installation location of

the flow meter. For Type RA 65, additionally fit pipe unions to both open ends of the pipeline

before installing the flow meter.

Straight unimpeded pipe runs upstream and downstream of the meter’s installation location

should each have a length equal to 5 x DN (= meter size). Any control equipment, particularly

in the case of gaseous media, should always be located downstream of the flow meter.

The type FA 65 flow meter is sealed off from the pipeline by gaskets. After it has been

installed, the flow meter should not be turned any more. Avoid drawing the ends of the

pipelines together and do not tighten down the device excessively.

Insert with internal

thread

Union nut

Device head with

external thread

Gasket

O-ring

Device head with

flanged connection

Gasket

O-ring

RA 65 FA 65

A. Kirchner & Tochter GmbH Dieselstraße 17 · D-47228 Duisburg

Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Internet: www.kt-web.de · e-mail: info@kt-web.de

Version 1.1

Loading...

Loading...