Kirby Morgan SuperLite 17B Operation And Maintenance Manual

WARNING

SuperLite® 17B Helmet

Operations and Maintenance Manual

KMDSI Part # 100-001

™

Kirby Morgan Dive Systems, Inc.

1430 Jason Way

Santa Maria, CA 93455, USA

Telephone (805) 928-7772, FAX (805) 928-0342

E-Mail: KMDSI@KirbyMorgan.com, Web Site:www.KirbyMorgan.com

Manual prepared by Marine Marketing and Consulting, Dive Lab, Inc., and KMDSI.

NOTE: This manual is the most current for the SuperLite® 17B Helmet. It is page dated June 2012. Future changes

will be shown on page III and the changed pages will carry the date of change. Previous manuals may not reect

these updates.

Diving with compressed breathing gas is a hazardous activity. Even if you do everything

right there is always the danger that you may be killed or injured. No piece of diving

equipment can prevent the possibility that you may be killed or injured any time you

enter the water.

The SuperLite®-17A/B helmet is CE Approved and meets or exceeds all performance and testing

requirements of all government and non-government testing agencies throughout the world. It is approved for use on all commercial and military work underwater.

Kirby Morgan, SuperLite®, BandMask, Band Mask, KMB, KMB-Band Mask, DSI, Diving Systems International, EXO, REX,

SuperFlow® and DECA are all registered trademarks of Kirby Morgan Dive Systems, Inc. Use of these terms to describe products

that are not manufactured by KMDSI is illegal.

The two dimensional images (such as photographs and illustrations) of our products are © copyrighted and trademarks of Kirby

Morgan Dive Systems, Inc. The three dimensional forms of our products are trademark, trade design and trade dress protected.

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. This manual is made available for the express use of the owner of

this Kirby Morgan product. No part of this manual may be reproduced, stored in any retrieval system, or transmitted, or used in any

form or by any means, whether graphic, electronic, mechanical, photocopy, or otherwise by technology known or unknown, without

the prior written permission of Kirby Morgan Dive Systems, Inc.

Document Number 120613005

SuperLite® 17B

Warranty Information

Kirby Morgan Dive Systems, Inc. warrants every new mask, helmet, or KMACS 5 Air Control

System to be free from defects in workmanship for a period of three hundred sixty ve (365) days

from date of purchase. This warranty covers all metal, berglass, and plastic parts. This warranty

does NOT cover rubber parts, communications components, or head cushions. In addition, due to

the electrolytic nature of underwater cutting and welding, chrome plating cannot be warranted when

the diver engages in these activities.

Should any part become defective, contact the nearest authorized KMDSI dealer. If there is no

dealer in your area, contact KMDSI directly at (805) 928-7772 x 229. You must have a return authorization from KMDSI prior to the return of any item, Upon approval from KMDSI, return the defective part, freight prepaid, to the KMDSI plant. The part will be repaired or replaced at no charge as

deemed necessary by KMDSI.

This warranty becomes null and void if:

1) The product is not registered with KMDSI within ten (10) days of purchase.

2) The product has not been properly serviced and/or maintained according to the appropriate

KMDSI manual. In addition, the user is responsible to ensure that all product updates as

recommended by KMDSI have been performed.

3) Unauthorized modications have been made to the product.

4) The product has been abused or subjected to conditions which are unusual or exceed the

product’s intended service.

NOTE: Be sure to complete the enclosed warranty card and return it to KMDSI immediately. No

warranty claims will be honored without a satisfactorily completed warranty card on le at KMDSI.

II © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

SuperLite® 17B

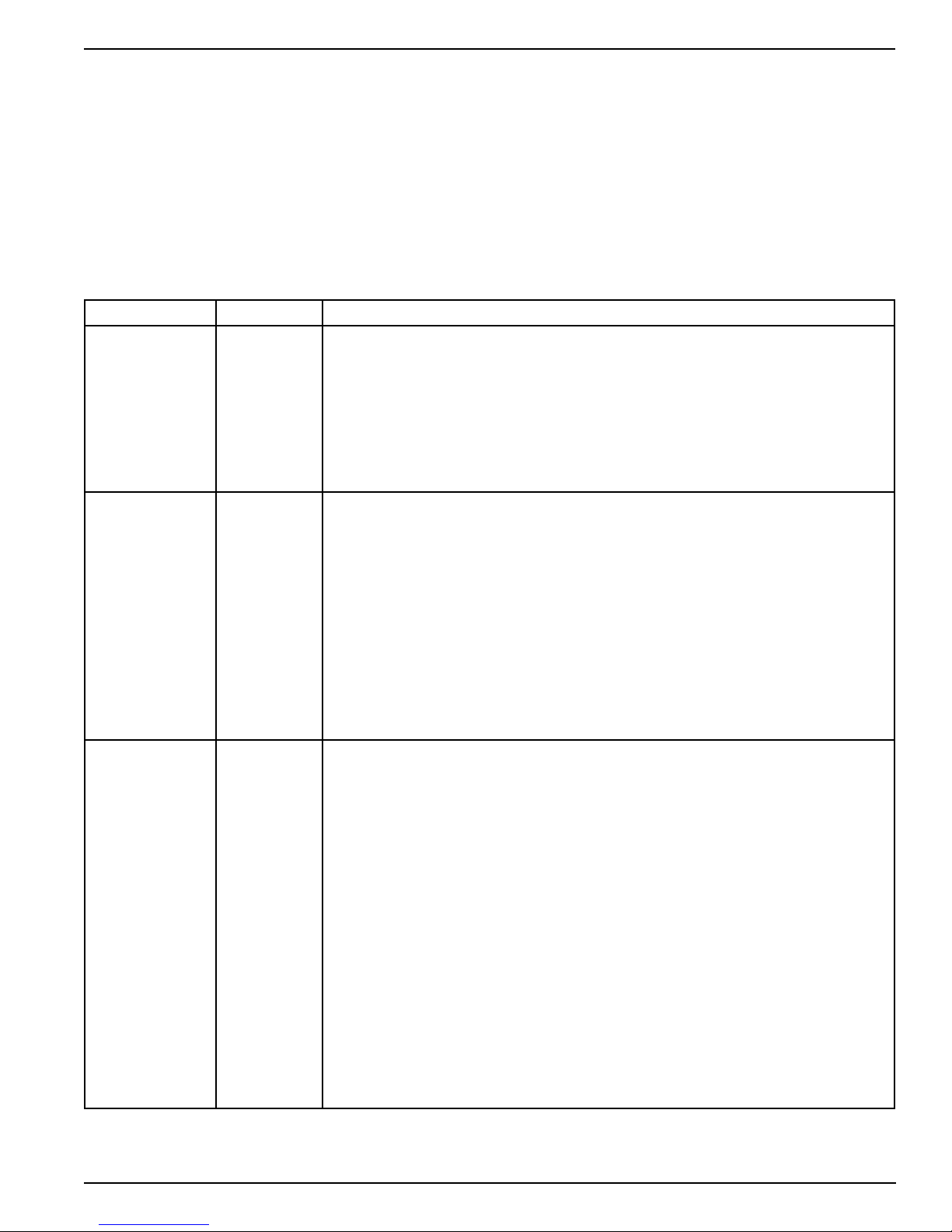

Record Of Changes

It is the responsibility of the owner of this product to register their ownership with Kirby Morgan Dive

Systems, Inc., by sending the warranty card provided. This card is to establish registration for any necessary

warranty work and as a means of communication that allows KMDSI to contact the user regarding this product.

The user must notify KMDSI of any change of address by the user or sale of the product.

All changes or revisions to this manual must be recorded in this document to ensure that the manual is

up to date. Quantities marked in parenthesis.

Change Number Date Description of Change

1 05/28/2008 Reworded: 2.1 Product Specications, 2.4 Operational Specications & Limitations,

Warnings Corrected, 7.12.1 to the correct 7.16.1 and Table of Contents Updated.

Added: Appendix A2, 3 and 4

®

Moved: 2.4 Operational Specications & Limitations, The SuperFlow

Regulator Image Rotated and Scaled to t.

Removed: Table 1 and Table 2 from chapter 2.

2 08/20/2008 Page III Removed page number column.

Page 16 First paragraph Part number added to Hard Shell.

Page 17 Second paragraph 77 added to list of helmets.

Chapter 1 rearranged and CE text added to KM-77 description.

Pg 63 and 64 Chapter 5 made to two columns format and font changed to lower

case instead of all caps.

Page 65 Added Whisker Clamp Replacement Kit: Part # 525-032.

Page 66 Corrected text to read “SL 17” instead of “KM 37 and 57” in 6.2, last

sentence and photo caption.

Page 102 step 17 corrected, "sssembly" to read "assembly."

Page 173 Torque Specication corrections.

Page 174 Added note about thread locking compound.

3 03/13/2009 Page 75: Space added between 6.5.1 Quad.

Page 77: Removed grammatical error beneath image.

Page 81: Corrected 40 inch pounds to 35 inch pounds in step 3. Lacquer thinner

changed to acetone.

Page 82: Corrected 40 inch pounds to 15 inch pounds in step 6. Lacquer thinner

changed to acetone.

Page 95: Corrected amount omitted inch pounds to 40 inch pounds in step 6.

Page 105: Corrected 75 inch pounds to 100 inch pounds twice in step 18. Corrected

30 inch pounds to 40 inch pounds in step 22.

Page 120: Corrected 75 inch pounds to 100 inch pounds in step 4.

Page 122: Corrected 75 inch pounds to 100 inch pounds in step 8. Corrected 35 inch

pounds to 40 inch pounds in step 9.

Page 124: Removed step 11 and merged SPECIAL CARE text with step 10. Corrected 75 inch pounds to 100 inch pounds in step 16.

Page 136: Corrected 35 inch pounds to 20 inch pounds in step 4.

Page 140: Corrected 30 inch pounds to 20 inch pounds in step 3.

Page 143: Corrected 35 inch pounds to 35-50 inch pounds in step 1.

Page 152: Corrected 15 inch pounds to 20 inch pounds in step 5.

Demand

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 III

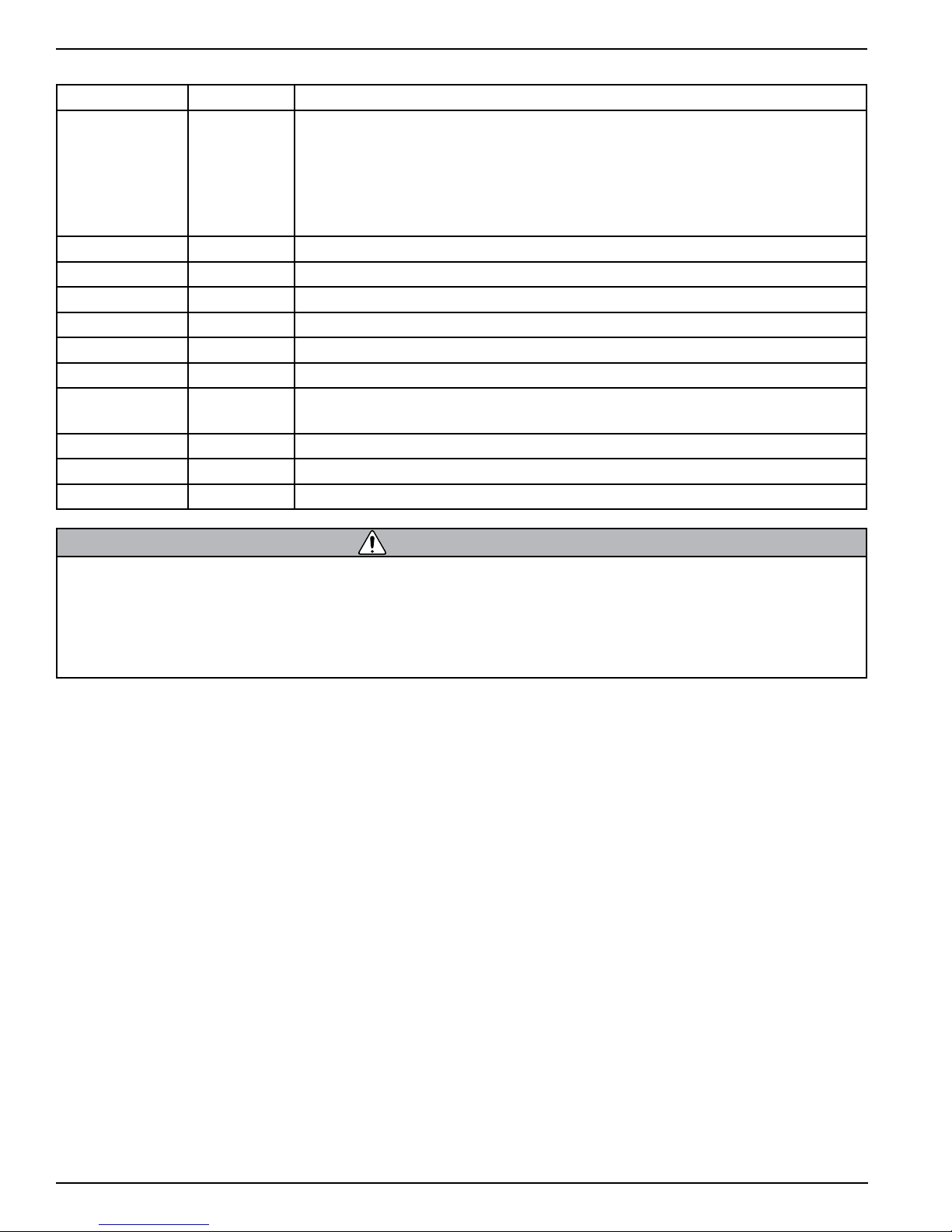

SuperLite® 17B

WARNING

Change Number Date Description of Change

3 (Continued) 03/13/2009 Page 154: Corrected 35 inch pounds to 25 inch pounds in step 5. Grammatical error,

"resuse" corrected to reuse in step 7. Corrected 35 inch pounds to 20 inch pounds

in step 1 of section 8.10.1.2. Corrected 35 inch pounds to 20 inch pounds in step 3

of section 8.10.1.2.

Page 175: Location #94's part number corrected from 530-045 to 530-040. Added

location #'s 6, 107 and 152a.

4 07/23/2009 CE material added

5 10/05/2009 Changed location # 82's part number from 550-372 to 550-038 in the torque specs.

6 11/06/2009 Chapter 2: addition of CE conforming criteria.

7 04/19/2010 Updated images and diagrams with new whiskers.

8 07/20/2010 Added wiring diagram to chapter 8.

9 04/06/2011 Updated earphones throughout manual

10 06/17/2011 Changed 61 meters to 67 meters in Appendix 3 Table 3 SuperFlow

High Pressure Regulated Source

11 10/17/2011 Updated CE notifying body number from 0496 to 2049

12 05/09/2012 Updated CE notifying body address

13 05/13/2012 Updated copyright date to roman numerals

®

350 Regulator

Diving with compressed breathing gas is a hazardous activity. Even if you do everything

right there is always the potential for serious injury or death. No one piece of diving

equipment can prevent the possibility that you may be injured or killed any time you

enter the water. We do not herein make any effort to teach the principles of diving. The

information in this manual is intended for users of Kirby Morgan helmets and persons

that maintain or service Kirby Morgan helmets.

IV © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

SuperLite® 17B

Table Of Contents

Warranty Information �������������������������������������������������������������������������������� II

Record Of Changes

Denition of Signal Words Used in this Manual

Chapter 1 General Information KMDSI Products ����������������������������������� 1

1.1 Introduction

1.2 Full-Face Masks and Manifolds

1.3 Kirby Morgan Diving Helmets

Chapter 2 Description & Operational Specications - SuperLite®-17B �� 9

2.1 CR Marking

2.2 CE Certication

2�2�1� CE Marking ��������������������������������������������������������������������������������� 9

2�2�2� Notied Body ������������������������������������������������������������������������������ 10

2.3 Product Specications �������������������������������������������������������������������������10

2.4 Regulator Performance ������������������������������������������������������������������������ 10

2.5 Cage Code �������������������������������������������������������������������������������������� 10

2.6 Operational Specications & Limitations

2.7 Helmet Features

2.8 General Description ���������������������������������������������������������������������������� 13

2�8�1 Helmet Shell �������������������������������������������������������������������������������� 13

2�8�2 Gas Flow Systems �������������������������������������������������������������������������� 13

2�8�3 Emergency Gas Supply System (EGS) ������������������������������������������������������18

2�8�4 Helmet Attachment to the Diver ������������������������������������������������������������� 18

2�8�5 Sealing Arrangement ����������������������������������������������������������������������� 18

2�8�6 Reducing Carbon Dioxide ������������������������������������������������������������������ 19

2�8�7 Communications ���������������������������������������������������������������������������� 20

2�8�8 Equalizing the Middle Ear ������������������������������������������������������������������� 20

2�8�9 Face Port or Viewing Lens ������������������������������������������������������������������ 21

2�8�10 Latch Catch Assembly, Pull Pin ������������������������������������������������������������ 21

2.9 Accessories ������������������������������������������������������������������������������������� 21

2�9�1 Eye Protection for Welding ������������������������������������������������������������������ 21

2�9�2 Hot Water Shroud ���������������������������������������������������������������������������22

2�9�3 Special Regulator Tools ��������������������������������������������������������������������� 22

2.10 Helmet Transport And Storage �������������������������������������������������������������� 23

2�10�1 Helmet Carrying Bag ���������������������������������������������������������������������� 24

2.11 Use of Kirby Morgan Original Replacement Parts

Chapter 3 Operating Instructions �������������������������������������������������������� 25

3.1 Introduction �������������������������������������������������������������������������������������25

3.2 Design Purpose

3.3 First Use of Your Kirby Morgan Diving Helmet

3.4 Initial Adjustments to Your Helmet

3�4�1 Head Cushion ������������������������������������������������������������������������������ 27

3�4�2 Adjusting the Neck Dam �������������������������������������������������������������������� 28

3.5 Pre Dress-In Procedure

�������������������������������������������������������������������������������� III

������������������������������������������������� XI

�������������������������������������������������������������������������������������� 1

���������������������������������������������������������������� 2

������������������������������������������������������������������ 4

�������������������������������������������������������������������������������������� 9

���������������������������������������������������������������������������������� 9

���������������������������������������������������� 10

�������������������������������������������������������������������������������� 11

����������������������������������������� 24

��������������������������������������������������������������������������������� 25

���������������������������������������������� 27

������������������������������������������������������������ 27

������������������������������������������������������������������������ 29

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 V

SuperLite® 17B

3�5�1 Pre-Dive Visual Inspection ������������������������������������������������������������������29

3.6 Preparing the Helmet for Diving���������������������������������������������������������������30

3�6�1 Clean Face Port ���������������������������������������������������������������������������� 30

3�6�2 Check Moving Parts ������������������������������������������������������������������������ 30

3�6�3 Check Communications �������������������������������������������������������������������� 30

3�6�4 One-Way Valve Check ���������������������������������������������������������������������� 30

3.7 Emergency Gas System (EGS) ���������������������������������������������������������������� 31

3.8 Setting Up to Dive ������������������������������������������������������������������������������ 35

3�8�1 Flushing Out the Umbilical ������������������������������������������������������������������ 35

3�8�2 Connecting the Umbilical to the Helmet ���������������������������������������������������� 35

3�8�3 Opening the Breathing Gas Supply to the Helmet ������������������������������������������36

3�8�4 Fogging Prevention �������������������������������������������������������������������������36

3�8�5 Donning The SuperLite®-17B ��������������������������������������������������������������� 37

3�8�6 Testing the Breathing System ���������������������������������������������������������������42

3�8�7 Sealing Integrity Check ��������������������������������������������������������������������� 42

3.9 Diving Procedures

3�9�1 Standing By to Dive ������������������������������������������������������������������������� 43

3�9�2 Attaching the Umbilical to the Harness ����������������������������������������������������� 43

3�9�3 Diver Dons Helmet �������������������������������������������������������������������������� 43

3�9�4 Diver Check Gas Flow Systems ������������������������������������������������������������� 43

3�9�5 Communications Check �������������������������������������������������������������������� 43

3�9�6 Diver Ready ��������������������������������������������������������������������������������� 43

3�9�7 Water Entry and Descent �������������������������������������������������������������������44

������������������������������������������������������������������������������ 43

3.10 Emergency Procedures ����������������������������������������������������������������������44

3�10�1 Flooding ����������������������������������������������������������������������������������� 44

3�10�2 Inhalation Resistance ���������������������������������������������������������������������� 44

3�10�3 Gas Flow Stops ��������������������������������������������������������������������������� 44

3�10�4 Demand Regulator Free Flow ��������������������������������������������������������������45

3.11 Post Dive Procedures ������������������������������������������������������������������������45

3�11�1 Removing the Equipment ������������������������������������������������������������������ 45

3�11�2 Removing the Helmet ��������������������������������������������������������������������� 45

3�11�3 Storage of the Helmet Between Dives ����������������������������������������������������� 46

Chapter 4 Troubleshooting ������������������������������������������������������������������47

4.1 General ������������������������������������������������������������������������������������������ 47

4.2 Communication Malfunction ������������������������������������������������������������������ 47

4.3 One Way Valve Malfunction ������������������������������������������������������������������� 47

4.4 Side Valve Malfunction �������������������������������������������������������������������������48

4.5 Water Leakage Into Helmet �������������������������������������������������������������������48

4.6 Demand Regulator Malfunction

4.7 Emergency Gas Supply Valve

��������������������������������������������������������������� 49

����������������������������������������������������������������� 49

Chapter 5 Inspection and Maintenance ����������������������������������������������� 51

5.1 Routine Maintenance �������������������������������������������������������������������������� 51

5�1�1 Daily Pre-Dive Maintenance A2�3 �����������������������������������������������������������51

5�1�2 Daily Post Dive Maintenance A2�6 ���������������������������������������������������������� 51

5�1�3 Supervisors Equipment Checks A2�4 and A2�5 ��������������������������������������������� 51

5.2 Monthly Maintenance �������������������������������������������������������������������������� 51

5.3 Yearly Maintenance ���������������������������������������������������������������������������� 51

VI © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

SuperLite® 17B

5�3�1 Overhaul/Inspection Checklist A2�1 ��������������������������������������������������������� 51

Chapter 6 General Preventative Maintenance �������������������������������������53

6.1 Introduction �������������������������������������������������������������������������������������53

6.2 Required tools, Cleaning Agents, Lubrication

6�2�1 Component and Parts Cleaning ������������������������������������������������������������� 54

6�2�2 Component and Parts Lubrication ��������������������������������������������������������� 54

6�2�3 Teon® Tape �������������������������������������������������������������������������������� 55

6�2�4 RTV Sealant ��������������������������������������������������������������������������������55

6�2�5 Thread Locker ������������������������������������������������������������������������������55

6.3 General Cleaning & Inspection Procedures

6�3�1 O-Ring Removal/Inspection/Cleaning and Lubrication �������������������������������������� 56

6�3�2 General Cleaning Guidelines ���������������������������������������������������������������� 56

6�3�2�1 Mild Soap Solution for ������������������������������������������������������������������� 57

General Cleaning and Leak Detector Use ��������������������������������������������������������� 57

6.3.2.2 Acidic Cleaning Solution and Procedures ����������������������������������������������������57

6.3.2.3 Germicidal Cleaning Solutions and Procedure ������������������������������������������������57

����������������������������������������������� 53

�������������������������������������������������� 55

6.4 Daily Maintenance ����������������������������������������������������������������������������� 59

6.5 Monthly Inspections ��������������������������������������������������������������������������� 61

6�5�1 Quad-Valve™ Exhaust System �������������������������������������������������������������61

6�5�2 Emergency Valve Assembly ����������������������������������������������������������������� 62

6�5�3 Steady Flow/Defogger Valve ����������������������������������������������������������������62

6�5�4 Bias Device Adjustable Section of Demand Regulator ������������������������������������� 62

6�5�5 Neck Clamp and Yoke Assembly ����������������������������������������������������������� 62

6�5�6 Latch Catch Mechanism �������������������������������������������������������������������� 62

Chapter 7 Breathing System Maintenance and Repairs �����������������������63

7.1 Introduction �������������������������������������������������������������������������������������63

7.2 One Way Valve ���������������������������������������������������������������������������������� 63

7�2�1 Disassembly Of The One Way Valve �������������������������������������������������������� 63

7�2�2 Reassembly of the One Way Valve ���������������������������������������������������������� 64

7.3 Side Block Assembly���������������������������������������������������������������������������65

7�3�1 General ������������������������������������������������������������������������������������� 65

7�3�2 Side Block Assembly Removal �������������������������������������������������������������� 65

7�3�3 Separating the Side Block Assembly from the Helmet Shell ��������������������������������66

7�3�4 Side Block Assembly Replacement ��������������������������������������������������������� 68

7.4 Defogger Valve ���������������������������������������������������������������������������������69

7�4�1 Disassembly of the Defogger Valve ���������������������������������������������������������69

7�4�2 Cleaning and Lubricating ������������������������������������������������������������������� 69

7�4�3 Reassembly of the Defogger Valve ���������������������������������������������������������70

7.5 Emergency Valve Assembly

7�5�1 Disassembly of the Emergency Valve ������������������������������������������������������� 71

7�5�2 Cleaning and Lubricating ������������������������������������������������������������������� 71

7�5�3 Reassembly of Emergency Valve ����������������������������������������������������������� 72

7�5�4 Leak Testing the EGS Valve �����������������������������������������������������������������73

7.6 Bent Tube Assembly

7�6�1 General ������������������������������������������������������������������������������������� 74

7�6�2 Removal of the Bent Tube Assembly �������������������������������������������������������� 74

7�6�3 Inspection of Bent Tube Assembly ���������������������������������������������������������� 75

��������������������������������������������������������������������������� 74

������������������������������������������������������������������� 71

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 VII

SuperLite® 17B

7�6�4 Installation of the Bent Tube Assembly������������������������������������������������������ 75

7.7 Hose Assembly (SL-17A only) ����������������������������������������������������������������� 76

7�7�1 Hose Assembly Removal ������������������������������������������������������������������� 76

7�7�2 Hose Assembly Inspection “A” style Side Block �������������������������������������������� 76

7�7�3 O-Ring Replacement ����������������������������������������������������������������������� 76

7�7�4 Hose Assembly Replacement ��������������������������������������������������������������� 76

7�8�2 SuperFlow® Demand Regulator Test for Correct Adjustment, Fully Assembled �������������77

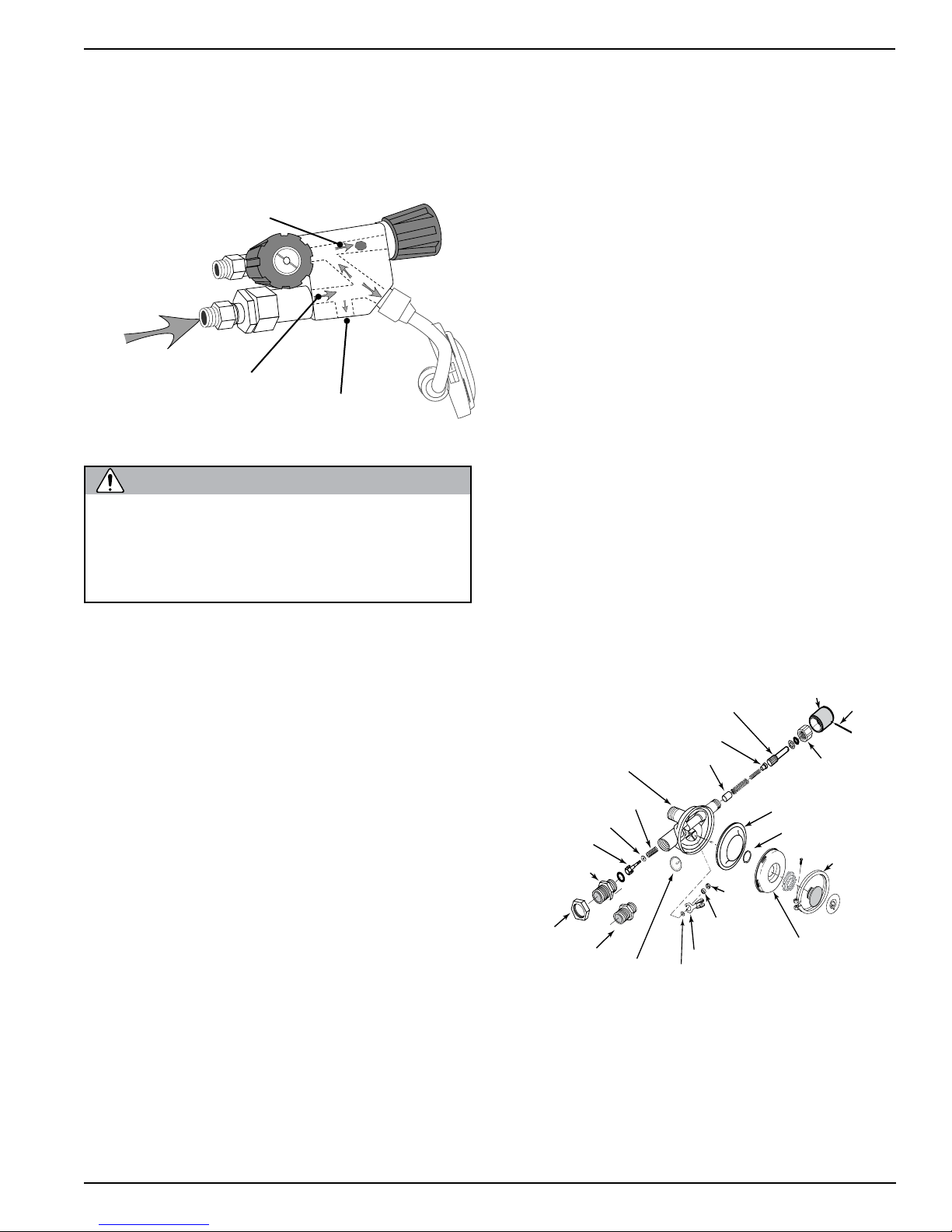

7.8 SuperFlow® Demand Regulator ��������������������������������������������������������������� 77

7�8�1 General Regulator Information �������������������������������������������������������������� 77

7�8�3 Inspection of SuperFlow® Regulator Body Interior ������������������������������������������ 78

7�8�4 SuperFlow® Demand Regulator Bias Adjustment Servicing, Demand Regulator on the Helmet

��������������������������������������������������������������������������������������������������� 79

7�8�5 Reassembly of the SuperFlow® Regulator Adjustment System������������������������������80

7�8�6 SuperFlow® Demand Regulator Removal from Helmet ��������������������������������������81

7�8�7 Disassembly of the SuperFlow® Demand Regulator�����������������������������������������82

7�8�8 Inspection of SuperFlow® Demand Regulator Parts ����������������������������������������� 85

7�8�9 Reassembly of the SuperFlow® 350 Demand Regulator ������������������������������������ 87

7�8�10 Tuning the SuperFlow® Regulator ���������������������������������������������������������� 91

7.8.10.1 Important Notes on Regulator Adjustment �������������������������������������������������� 92

7�8�11 SuperFlow® Regulator Steady Flows When Pressured Up: Special Tools Used ������������ 93

7�8�12 Regulator Steady Flows When Pressured Up ���������������������������������������������95

7�8�13 Regulator has Low or No Flow When Pressurized �����������������������������������������95

7�8�14 Unexplained Demand Regulator Free Flow ������������������������������������������������95

7.9 Oral Nasal ��������������������������������������������������������������������������������������� 96

7�9�1 Oral Nasal General Information ������������������������������������������������������������� 96

7�9�2 Oral Nasal Removal ������������������������������������������������������������������������ 96

7�9�3 Inspection of Oral Nasal �������������������������������������������������������������������� 96

7�9�4 Oral Nasal Replacement �������������������������������������������������������������������� 97

7.10 Quad-Valve™ Exhaust Assembly ������������������������������������������������������������98

7�10�1 Quad-Valve™ Assembly Removal ���������������������������������������������������������98

7�10�2 Quad-Valve™ Exhaust Valve Replacement ������������������������������������������������ 99

7�10�3 SuperFlow® Regulator Exhaust Valve Replacement �������������������������������������� 102

7�10�4 Quad-Valve™ Assembly Installation ���������������������������������������������������� 103

7.11 Water Dump Exhaust Body ���������������������������������������������������������������� 103

7�11�1 Water Dump Valve Removal ������������������������������������������������������������� 103

7�11�2 Water Dump Valve Replacement �������������������������������������������������������� 103

7�11�3 Water Dump Valve Body Removal ������������������������������������������������������ 103

7�11�4 Water Dump Valve Body Remounting ��������������������������������������������������� 103

7.12 Reinstalling the Quad-Valve™ Exhaust Assembly

�������������������������������������� 105

7�13 Standard Old Style Single Exhaust Whisker PN# 510-554 ��������������������������������� 106

7�13�1 Whisker Removal ������������������������������������������������������������������������ 106

7�13�2 Reinstalling the Whisker ����������������������������������������������������������������� 107

7.14 Double Exhaust Whisker

������������������������������������������������������������������� 108

7�14�1 Double Exhaust Whisker Cleaning and Overhaul, Whisker PN# 525-102 ���������������� 108

7.15 Tri-Valve Exhaust Whisker ������������������������������������������������������������������ 110

7�15�1 Demand Regulator Assembly Removal �������������������������������������������������� 110

7�15�2 Replacing the Regulator Exhaust Valve �������������������������������������������������� 110

VIII © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

SuperLite® 17B

7�15�3 Tri-Valve Exhaust Valve Replacement ���������������������������������������������������� 111

7�15�4 Installing the Tri-Valve Exhaust System onto the Regulator ������������������������������ 113

7.16 Overpressure Relief / Bleed Valve Overhaul Procedures �������������������������������� 114

7�12�1 Overpressure Relief Valve ��������������������������������������������������������������� 114

7�16�2 Overpressure Relief Valve Disassembly and Cleaning ����������������������������������� 114

7�16�3 Overpressure Relief Valve Reassembly �������������������������������������������������� 115

7�16�4 Overpressure Relief Valve Lift Check/Setting �������������������������������������������� 115

Chapter 8 Corrective Maintenance ���������������������������������������������������� 117

8.1 General

8.2 Yoke/Neck Clamp Assembly and Helmet Shell Inspection

8.3 Nose Block Assembly ������������������������������������������������������������������������ 119

8�3�1 Nose Block Assembly Removal ����������������������������������������������������������� 119

8�3�2 Nose Block Device Replacement ��������������������������������������������������������� 120

8.4 Handle and Weights

8�4�1 Handle Removal ������������������������������������������������������������������������� 121

8�4�2 Handle Replacement ��������������������������������������������������������������������� 122

8�4�3 Weight Removal �������������������������������������������������������������������������� 123

8�4�4 Weight Replacement ���������������������������������������������������������������������� 123

8.5 Chin Strap and Yoke Strap ������������������������������������������������������������������ 125

8�5�1 Chin Strap Removal ���������������������������������������������������������������������� 125

8�5�2 Chin Strap Replacement ������������������������������������������������������������������ 125

8�5�3 Removal of the Yoke Strap ���������������������������������������������������������������� 126

8�5�4 Replacement of the Yoke Strap ����������������������������������������������������������� 126

8.6 Alignment Sleeve ����������������������������������������������������������������������������� 128

8�6�1 Sleeve Removal and Inspection ����������������������������������������������������������� 128

8�6�2 Sleeve Replacement ���������������������������������������������������������������������� 128

8.7 Port Retainer ���������������������������������������������������������������������������������� 129

8.8 Face Port �������������������������������������������������������������������������������������� 129

8�8�1 General ����������������������������������������������������������������������������������� 129

8�8�2 Face Port and Nose Block Device Removal ����������������������������������������������� 129

8�8�3 Face Port and Nose Block Replacement �������������������������������������������������� 130

8�8�4 Special Note Regarding Ports ������������������������������������������������������������ 132

8.9 Communications System �������������������������������������������������������������������� 133

8�9�1 General ����������������������������������������������������������������������������������� 133

8�9�2 Earphone Inspection ���������������������������������������������������������������������� 133

8�9�3 Microphone Removal and Replacement �������������������������������������������������� 134

8�9�4 Earphone Removal and Replacement ����������������������������������������������������� 135

8�9�5 Waterproof Connector ������������������������������������������������������������������� 135

8�9�6 Communications Posts ������������������������������������������������������������������� 137

8.10 Neck Clamp/Yoke Assembly

8�10�1 Yoke ������������������������������������������������������������������������������������ 138

���������������������������������������������������������������������������������������� 117

������������������������������� 117

�������������������������������������������������������������������������� 121

8.9.5.1 Connector Removal ��������������������������������������������������������������������� 135

8.9.5.2 Connector Replacement ����������������������������������������������������������������� 136

8.9.6.1 Communications Post Removal ���������������������������������������������������������� 137

8.9.6.2 Communications Post Replacement ������������������������������������������������������ 137

��������������������������������������������������������������� 138

8.10.1.1 Yoke Removal and Disassembly ��������������������������������������������������������� 138

8.10.1.2 Yoke Replacement and Reassembly ����������������������������������������������������� 140

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 IX

SuperLite® 17B

8�10�2 Latch Catch Assembly ������������������������������������������������������������������ 140

8.10.2.1 Latch Catch Mechanism Disassembly ���������������������������������������������������� 140

8.10.2.2 Latch Catch Mechanism Reassembly ���������������������������������������������������� 141

8�10�3 Neck Clamp Assembly ������������������������������������������������������������������ 141

8.10.3.1 Neck Clamp Assembly Adjustment /Inspection �������������������������������������������� 141

8�10�4 Neck Dam ������������������������������������������������������������������������������ 143

8.10.4.1 Neck Dam Replacement ���������������������������������������������������������������� 143

Pre-84 and Cold Water Type Neck Dam ��������������������������������������������������������� 144

Installation ������������������������������������������������������������������������������������ 144

8.10.4.2 Four Hole Method of Attaching Neck Dam to Hinge Tab ������������������������������������ 145

8.10.4.3 Patch Method of Attaching Neck Dam to Hinge Tab ��������������������������������������� 146

8.10.4.4 Drawstring Type Neck Dam Installation ��������������������������������������������������� 146

8.11 O-Ring Seal Replacement ������������������������������������������������������������������ 148

8.12 Head Cushion Foam Replacement �������������������������������������������������������� 148

Chapter 9 Accessories ���������������������������������������������������������������������� 149

9.1 Introduction ����������������������������������������������������������������������������������� 149

9.2 Hot Water Shroud General������������������������������������������������������������������� 149

9�2�1 Installation of the Hot Water Shroud ������������������������������������������������������ 149

9.3 Low Pressure Inator Hose Installation on the B Sideblock ����������������������������� 151

9.4 Weld Lens & Weld Shield Assemblies ������������������������������������������������������ 152

9.5 Use of Quick Disconnect �������������������������������������������������������������������� 154

9.6 Double Exhaust System ��������������������������������������������������������������������� 155

9�6�1 Double Exhaust Kit Installation ������������������������������������������������������������ 155

Table of Equivalents �������������������������������������������������������������������������� 159

Appendix 1: Torque Specications ���������������������������������������������������� 160

Note on Torque Specications ���������������������������������������������������������� 161

Checklist, Maintenance, and Pre-Dive Inspections ������������������������������������������� 161

Appendix A2 Maintenance and Inspection Procedures ���������������������� 162

Appendix 3 Supply Pressure Requirements & Tables ������������������������� 164

Appendix 3 Table 1 Work Rate Expressed as Respiratory Minute Volume (RMV)* ��������� 165

Appendix 3 Table 2 Compressor Supply Table SuperFlow® and SuperFlow® 350 ���������� 165

Appendix 3 Table 3 SuperFlow® 350 Regulator High Pressure Regulated Source ��������� 167

Appendix 4 Standard Kirby Morgan Surface Supply Pressure Formula Old Method ��������������������������������������������������������������������������������������� 167

X © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

SuperLite® 17B

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Denition of Signal Words Used in this Manual

For your protection, pay particular attention to items identied by signal words in this manual. These terms are identied

as, CAUTION, WARNING AND DANGER. It is especially important for you to read and understand these sections.

This word indicates an imminently hazardous situation, which if not avoided, could result in death or serious injury.

This word indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

CAUTION

This word indicates a potentially hazardous situation, which if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

If English is not your native language and you have any difculty understanding the language of any warnings as they appear in the manual, please have them translated.

Este é um aviso importante. Queira mandá-lo traduzir.

Este es un aviso importante. Sirvase mandario traducir.

Quest è un avviso importante. Tradurlo.

Ceci est important. Veuillez traduire.

Diese Mitteilung ist wichtig. Bitte übersetzen lassen.

If you have any questions concerning this manual or the operation of your helmet, contact KMDSI (805)

928-7772 or by Email at info@KMDSI.com or Dive Lab Inc. (850) 235-2715 or at Divelab@aol.com

IMPORTANT: A word about this manual. We have tried to make this manual as comprehensive and factual as possible. We reserve the right, however, to make changes at any time, without notice, in prices, colors, materials, equipment, specications, models and availability. Since some information may have been updated since the time of printing, please contact your local KMDSI dealer if you have any questions. Periodically KMDSI Operations and Maintenance Manuals are reviewed. Any updates/changes will be posted on the KMDSI website and may be downloaded for

insertion/correction.

Important Safety Information:This SuperLite® 17B diving helmet is intended for use by trained divers who have

successfully completed a recognized training course in surface supplied diving

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 XI

SuperLite® 17B

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Follow all the instructions in this manual carefully and heed all safety precautions. Improper use of this diving helmet could result in serious injury or death.

Kirby Morgan Dive Systems, Inc. (KMDSI) warns all divers who use Kirby Morgan diving helmets or masks to be sure to use only KMDSI original parts from a KMDSI authorized dealer. Although other parts, O-rings and ttings may appear to t your Kirby

Morgan diving helmet or mask, they may not be manufactured to the same standards

maintained by KMDSI. The use of any parts other than KMDSI original parts may lead to

equipment failure and accidents.

Diving in waters that are chemically, biologically, or radiologically contaminated is extremely hazardous. Although Kirby Morgan diving helmets may be adapted for use in

some contaminated environments, special training, equipment, and procedures are

necessary. Do not dive in a contaminated environment unless you have been thoroughly

trained and equipped for this type of diving.

Read this manual before using or maintaining the helmet, even if you have experience with other diving helmets. If

you have purchased the helmet new from a dealer, be sure to send in the warranty registration card so we may

keep you informed of any safety notices that affect this product. If you resell or loan this helmet to another diver,

be sure this manual accompanies the helmet and that the person reads and understands the manual. In addition to the

manual a log book should be used to log all repairs, maintenance and use.

This helmet was completely checked and should be ready to dive as it was shipped

from the factory. However, it is always the diver’s responsibility to check all the components of the helmet prior to diving.

Diving is a life threatening occupation. Even if you do everything right you can still be

killed or injured. None of the models of Kirby Morgan helmets or masks can prevent accidents, injuries or death due to improper training, poor-health, improper supervision,

improper job requirements, improper maintenance or acts of God.

Any and all berglass repairs done to this helmet MUST be done by a KMDSI factory

trained repair facility. Painting is not recommended by KMDSI. Furthermore, many diving companies will not allow painted helmets to be used because painting can mask

previous berglass damage. KMDSI certied technicians are not responsible for certifying helmets free from damage during annual overhauls.

Helmet shells can be re-gel coated by authorized/certied KMDSI trained technicians

that have received berglass training by KMDSI. Helmets that are to be painted for

cosmetic purposes, should be rst, certied free of berglass damage by an authorized

KMDSI technician certied in berglass repair. A log entry should be made in the helmet log that the helmet was free of damage prior to painting. Keep in mind other KMDSI

technicians can refuse to work on helmet shells that have previously been painted or

repaired by non KMDSI certied persons.

XII © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

SuperLite® 17B

WARNING

WARNING

WARNING

WARNING

This manual is supplied to the original purchaser of this helmet. If you have any questions about the use of the helmet

or you need another copy of this manual, contact KMDSI or your nearest KMDSI dealer. It may also be downloaded

free from the KMDSI website at www.KirbyMorgan.com.

KMDSI helmets and masks are intended for underwater use only and should only be

used by qualied divers that have received proper training in the use of this type of

equipment. KMDSI helmets and masks should not be used or worn without the appropriate life support systems, such as air or gas supplies and support personnel as described in this manual.

KMDSI helmets and masks should never be used for motor sport racing, aviation /

space craft use, or for chemical warfare use. The helmet must never be used by persons in poor physical condition, by persons with previous head, neck, or back injuries

which could be aggravated by its use. The helmet should not be used by persons under the inuence of drugs or alcohol. Furthermore, infants, children, or persons under

the age of 18 should never wear KMDSI helmets and masks. Failure to pay heed to the

above could result in serious injury or death.

Do not use KMDSI masks or helmets in currents exceeding 3.0 knots Use in currents

greater than 3 knots may allow water to enter the exhaust valve, possibly causing regulator ooding. This could lead to drowning.

Surface-supplied diving can be a strenuous activity. The SuperLite®-17B weighs approximately 30 lbs. KMDSI recommends that persons with a previous neck or back injury

seek professional medical approval prior to engaging in surface supplied diving operations using the SuperLite®-17B. Use of the SuperLite®-17B with a pre-existing physical/

medical condition may result in death or serious injury.

If you have any questions regarding the use, maintenance, or operation of this helmet, contact KMDSI at (805) 928-

7772, fax: (805) 928-0342, or e-mail: info@kirbymorgan.com.

Components requiring lubrication, should only be lubricated with oxygen compatible lubricants such as Christo-

Lube®, Flourolube, or Krytox®. Lubricants must be used sparingly and should not be mixed with other lubricants.

The information contained in this manual is intended to aid the user in optimizing the performance of this helmet.

The application of some of this information will depend on the diving situation and the use of associated equipment.

Many countries have specic laws and rules regarding commercial diving. It is important for the user to understand

the rules, regulations, and philosophy imposed by the governing, regulating bodies whenever using commercial diving

equipment.

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 XIII

SuperLite® 17B

WARNING

WARNING

Never use the helmet without rst completing all pre-dive maintenance and set up

procedures. Failure to complete all pre-dive checks could result in helmet failure due to

problems with the incorrect set-up of the equipment. This could lead to serious personal injury or death.

Always read the Material Safety Data Sheet (MSDS) for any chemical - adhesive, cleaning agent, or lubricant - used on your Kirby Morgan helmet. Some of these chemicals

may cause serious bodily injury or death if used improperly or without the proper personal protective equipment.

Whenever KMDSI helmets or masks are used in European Countries, which have adopted the C.E. certication

programs, they must only be used with C.E. certied components. Diving operations should only be conducted within

the limits of the operational specications, and in accordance with the rules and regulations established by the governing authority in the specic country or geographical location where the diving operations are being conducted. If

you have any questions concerning this manual or the operation of your helmet, contact KMDSI (805) 928-7772 or at

KMDSI@KirbyMorgan.com or Dive Lab Inc. (850) 235-2715 or at Divelab@aol.com

XIV © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

SuperLite® 17B

STOP!

BEFORE GOING FURTHER-

This manual will refer to location numbers in specic drawings, or in the exploded view, which is

in the back of this manual. These numbers are called “location” numbers. They are used to nd

the referred to parts in the drawings in this manual only. They are not the part number. Next to

the exploded drawing is a list of the “location” numbers that match the Kirby Morgan part numbers along with the name of the part. Always check the part number when ordering to make sure

it is correct. When ordering, always specify the helmet model number and serial number as well.

Chapter 1

General Information KMDSI Products

1.1 Introduction

The Kirby Morgan Corporation was started in 1965.

The copper and brass “Heavy Gear” or “Standard

Dress” helmets were the rst helmets manufactured

by the company. Over the years Kirby Morgan designed, manufactured and sold many different helmets and masks for commercial divers.

Staying active in commercial diving has contributed

to the successful design innovations of KMDSI

products. This may be the primary reason for the acceptance of our designs by professional divers.

Bev Morgan has designed more than fty-seven diving helmets and over 40 diving masks. All employees

of KMDSI participate as part of the Kirby Morgan

design team. It would not be possible for us to supply the commercial, military, scientic, and public

service diving industries with our equipment, without

the team of people that make up Kirby Morgan Dive

Systems, Inc. (KMDSI)

We feel it is important for the reader to understand

that we at KMDSI consider ourselves as only part

of the process along the path in diving equipment

design. We welcome all input from our customers.

The thinking of many good divers, diving equipment

engineers, diving medical specialists, diving organization administrators and their supporting personnel

has contributed to the current state of the art of diving.

Each piece of gear we manufacture has in it some of

the thinking of those who have gone before us. To

all those people who gave something of themselves

to the men and women who work underwater, we

express a thank you.

We have a strong commitment to providing the best

diving equipment and service possible. This thinking

has been the policy of Kirby Morgan Dive Systems,

Bev Morgan, Chairman of the Board Kirby Morgan

Dive Systems, Inc.

Inc. and we will continue to take this approach to

our work.

Our extensive dealer network makes it easy to obtain

genuine Kirby Morgan replacement parts, as well as

technical assistance worldwide.

KMDSI has always concentrated on designing and

manufacturing diving equipment that allows most

repairs, inspections, and all routine maintenance to

be performed by the user. Most routine preventative

and corrective maintenance can be accomplished by

the user utilizing this manual, the KMDSI Tool Kit

(P/N 525-620) and common hand tools. Technician

training is available through Dive Lab Inc. Information can be obtained on line at www.divelab.com or

by telephone at 850-235-2715.

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 1

SuperLite® 17B

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

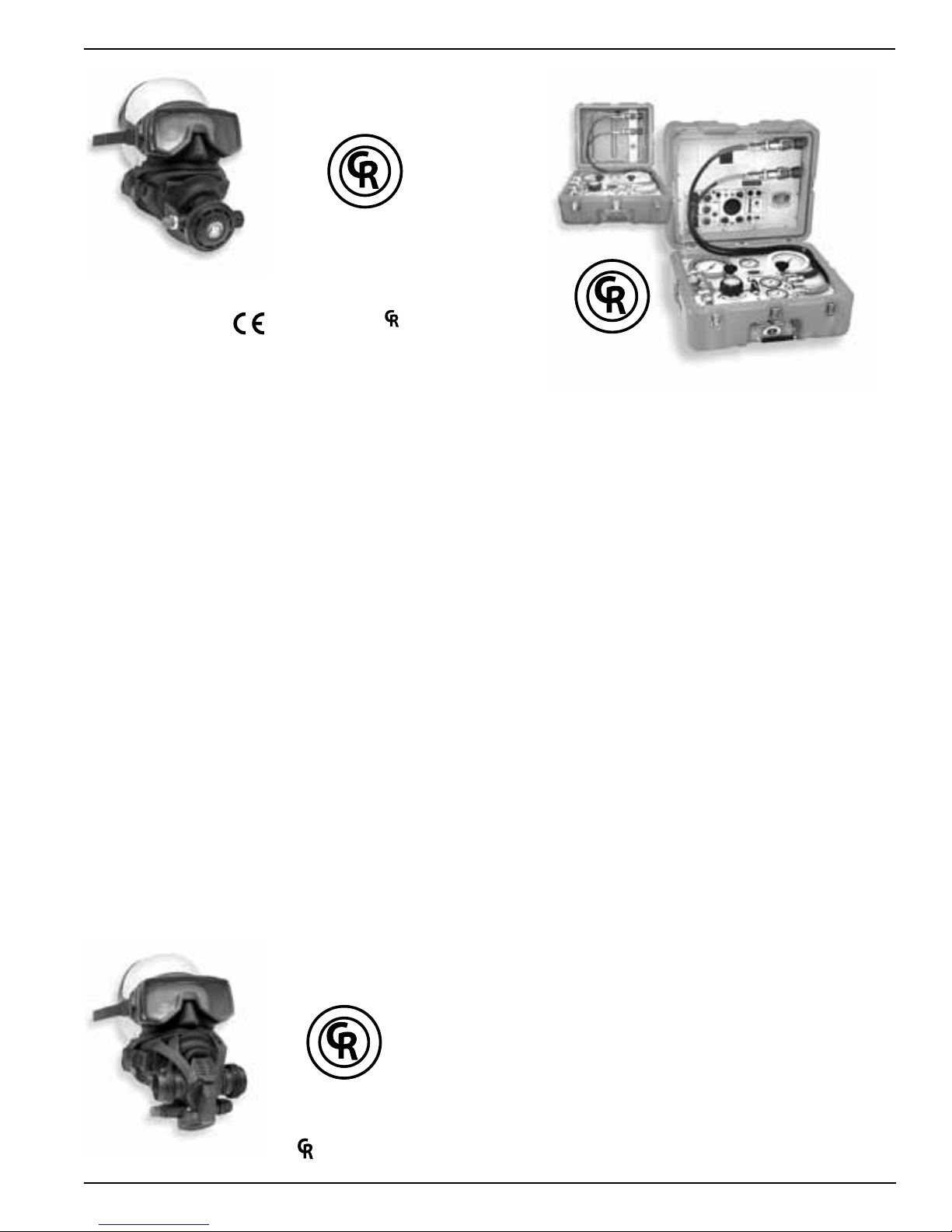

1.2 Full-Face Masks and Manifolds

KMB 18 A/B

approved and ™ marked

The EXO Full Face Mask is designed for both

surface supplied and scuba diving. By enclosing the

divers eyes, nose and mouth, the EXO permits nearly

normal speech when used in conjunction with most

wireless, and all hard wire underwater communication systems.

The EXO BR (BALANCED REGULATOR)

shown here is designed to meet or exceed recommended performance goals in both scuba and surface

supplied modes and is

approved. It meets and sur-

passes European standards for regulator performance.

The KMB 18B Band Mask frame is constructed of

hand laid berglass. The head harness is a molded,

strong tear resistant neoprene rubber.

The hood, which attaches to the mask frame with

welded stainless steel bands, provides warmth for

the divers head as well as pockets for the earphones.

The communications connections can be either a male

waterproof plug in type or bare wire posts. Both this

mask and the KMB 28B feature the new Tri-Valve™

Exhaust System.

The KMB 28B Band Mask (not shown) is very simi-

lar to the KMB 18, with many parts on the KMB 18B

being interchangeable with the KMB 28B. The major

difference between the 18 and 28 is the material of the

mask frame itself. The KMB 18 has a berglass frame

(yellow) while the KMB 28B frame is an extremely

durable injection molded plastic (black).

Other differences include:

1) The main exhaust body of the KMB 28 is part of

the frame itself and uses a #545-041 main exhaust

cover

2) no comfort insert is required on the 28

3) the face ports for the 18 and the 28 differ slightly

in size.

EXO BR

approved and ™ marked

The Balanced Regulator helps reduce the work of

breathing for the diver by balancing the intermediate

air pressure against the valve sealing pressure inside

the regulator. This enables the regulator to instantly

adjust to changes in line pressure. The balanced

regulator is adjustable for a wide range of intermediate pressures between 90 PSIG – 250 over ambient

pressure (6.2 – 17 bar).

Both models have a modular communications design that permits rapid and simple maintenance. The

optional Hard Shell provides surfaces for mounting

lights, cameras etc.

Both the KMB 18 and KMB 28 are

2 © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

approved.

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

SuperMask M-48

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

™

w/ Scuba Pod

SuperLite® 17B

KMACS-5

w/ No Communications

approved and ™ marked

The SuperMask M-48 is an innovative new design

in a full-face mask. It provides the diver with all the

comfort of a full-face mask with the convenience

of changeable second stage regulators as well as the

ability to use a snorkel without having to remove

the mask.

The mask is comprised of two major components,

the mask frame and the interchangeable lower pod.

The removable lower pod is a feature unique to the

SuperMask full-face mask. When diving, the pod is

easily removed and replaced on the mask, providing

the diver the capability to buddy-breathe, snorkel,

use an octopus or perform an “in water” gas switch.

With the pod sealed to the mask, the exible, silicone

pod cover allows the diver to quickly place the regulator mouthpiece into the mouth or dive with it free of

the mouth for communications. With the mouthpiece

in, the regulator may be used without the pod being

sealed to the mask.

KMACS-5

w/ Communications

The Kirby Morgan Air Control System-5 (KMACS)

is a lightweight, portable control box for use in surface supplied air diving operations. The KMACS-5

controls the diver’s air supply, communications and

monitors the diver’s depth. It allows two divers clear

push-to-talk (two wire) or round robin (four wire)

communications. The KMACS-5 is also available

without communications.

The air supply can be either from a low-pressure

compressor or high-pressure cylinders. The adjustable rst stage regulator reduces the high-pressure

air and supplies low pressure through the umbilical

to the diver’s breathing system.

High pressure yokes permit U.S. standard scuba

cylinders or DIN equipped cylinders to be used. Lowpressure air supply ttings allow for a compressor to

be used as the primary air source.

The mask may also be used surface supplied when

used with the proper accessories. We are currently

developing several different pod congurations for

both open circuit and rebreather use. For further

information, see the Frequently Asked Questions

(FAQ) area on

our web site at www.KirbyMorgan.

com/FullFaceMasks/M48.html.

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 3

SuperMask M-48

w/ Rebreather pod

A complete pneumo system with dual reading gauges

(both US Standard and Metric) is provided for each

diver’s air, as well as a shut-off/bleed system that uses

two high-pressure feed lines which allows changing

of used cylinders without interruption of the diving

operation. Optional shut off valves allow the isolation

of each diver’s air supply.

The Communication Set is a multipurpose intercommunication system that provides reliable and clear

communications between a topside operator (tender)

and one or more surface-supported divers, recompression chambers, or other submersible systems.

marked

SuperLite® 17B

1.3 Kirby Morgan Diving Helmets

All Kirby Morgan diving helmets and masks are

manufactured by Kirby Morgan Dive Systems, Inc.

(KMDSI). Each step of the manufacturing process is

carefully controlled to assure the customer of a high

quality, durable helmet that will function properly

for many years.

There are eight models of Kirby Morgan diving helmets currently in production. They are the SuperLite

17B, (MK-21- U.S. Navy version), SuperLite

the SuperLite

37SS, 47, 57, and 77. All are

The SuperLite

®

27, and Kirby Morgan models 37,

®

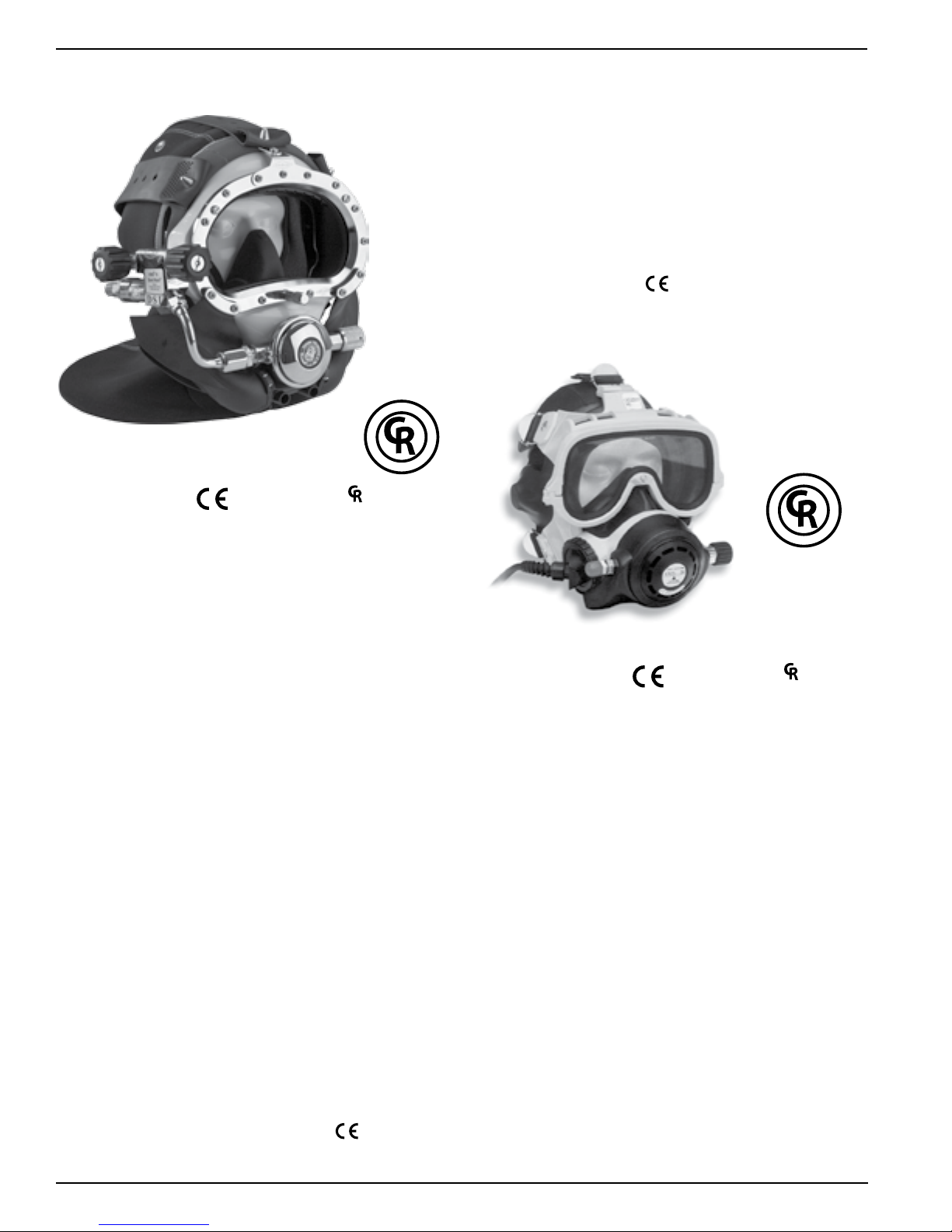

-17 A/B was rst developed in 1975

™

marked.

and quickly set a new standard for diving helmet

design. Many large and small commercial diving

companies, military organizations, scientic divers,

and public safety divers are successfully using this

design around the world. This helmet is

marked.

®

17C

®

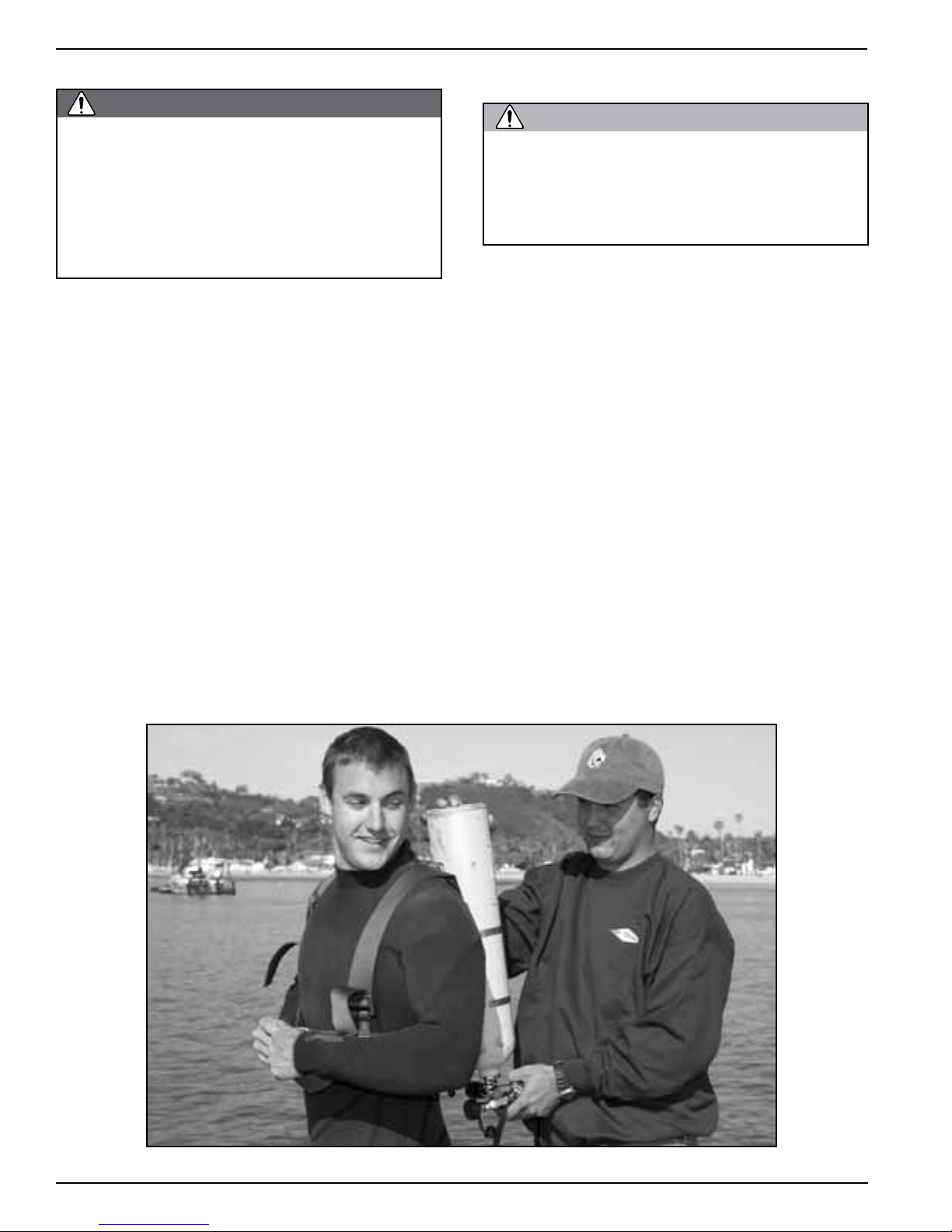

The SL-17 A/B helmet system consists primarily of

two major components: the neck dam/yoke assembly, and the helmet. To don the helmet, the diver

rst slips the angled neck dam with the attached

yoke over their head. The helmet is lowered onto

the diver’s head with the help of a tender, then the

yoke hinge tab is hooked onto the alignment screw

on the rear weight. The neck clamp is then slipped

onto the helmet and locked. The locking system

-

not only seals the neck dam to the helmet but also

secures the front of the yoke, fastening the helmet

to the diver’s head.

The SuperLite

®

-17A/B shares many common breath-

ing system parts with all Kirby Morgan helmets and

masks. The breathing system was man-tested to

1600 FSW by the University of Pennsylvania and

approved by the U.S. Navy for surface-supplied diving to 190 FSW with air and 300 FSW with mixed

gas. It surpasses all requirements of all governing

agencies and it is approved for commercial diving

through out the world.

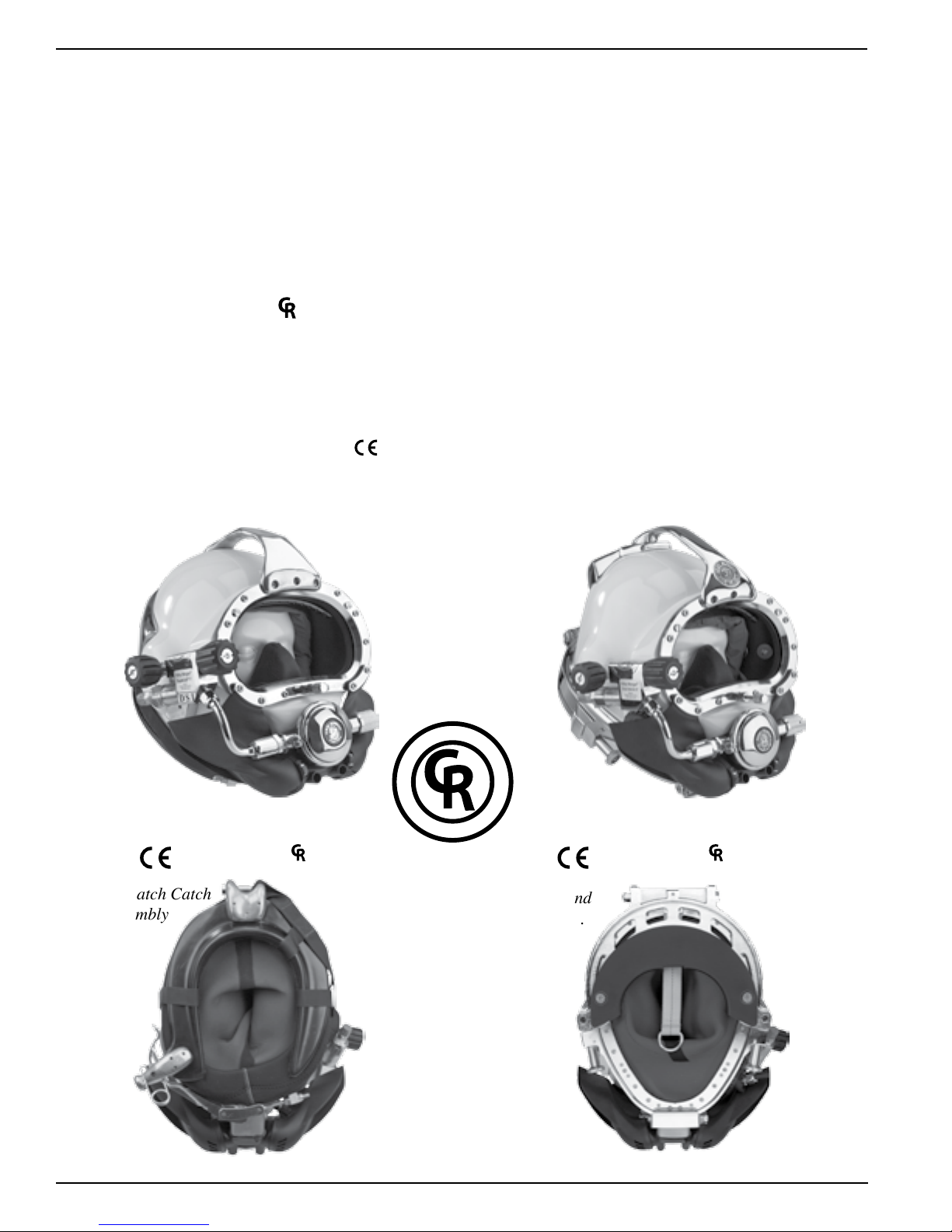

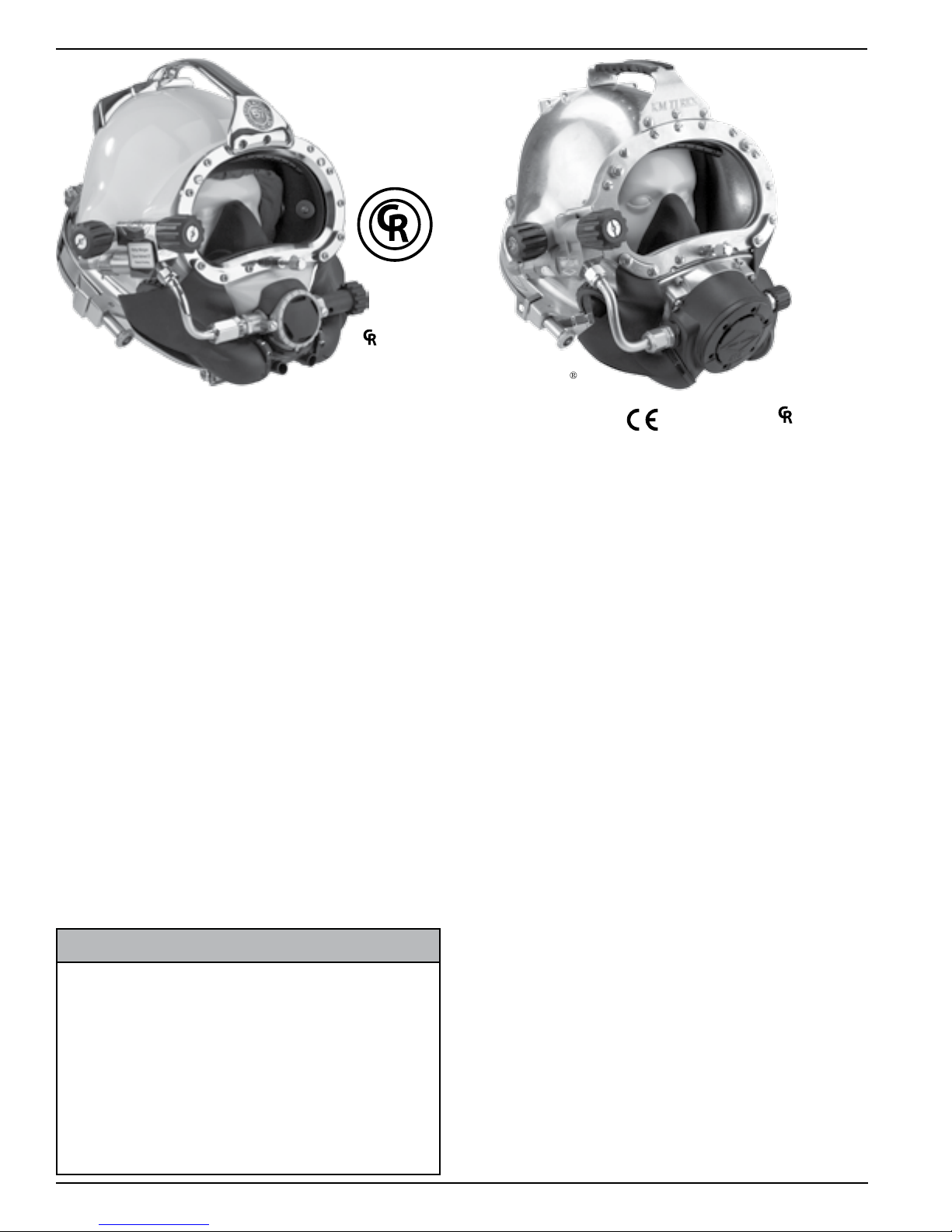

SuperLite® 17A/B

approved and ™ marked approved and ™ marked

Yoke and Latch Catch

Assembly

A

R

T

Y

E

L

D

L

A

I

C

R

E

M

M

O

C

D

E

T

S

E

T

B

A

L

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

E

G

V

E

I

A

D

R

-

™

Kirby Morgan 37

Neck Pad and

Sealed Pull Pins.

4 © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

Other features that are common to all Kirby Morgan

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

helmets include:

* Face port and retainer ring

* Communications components

* Oral nasal mask

* Nose block device

* Air train defogger

The Kirby Morgan 37 Commercial Diver’s Helmet

represents what we at Kirby Morgan consider to be

a turning point in modern diving helmet design. The

helmet consists of two major assemblies: the helmet

shell/helmet ring assembly and the neck dam/neck

ring assembly.

The helmet comes with the large tube SuperFlow

®

350 adjustable demand regulator which provides an

easier breathing gas ow during peak work output.

A quick change communications module is available

with either bare wire posts or a waterproof connector.

SuperLite® 17B

®

SuperLite

27

®

approved and ™ marked

Kirby Morgan 47

The helmet ring houses the sealed pull pins and provides protection for the bottom end of the helmet. The

diver is also provided with an internally adjustable

chin support. This custom t and balance seats the

helmet comfortably for long periods of time even

when working in the face down position.

The SuperLite

®

27® Commercial Diver’s Helmet has

all the same features of the KM37 on a smaller, low

volume shell design. This helmet is often preferred

by persons with smaller heads.

The chrome plated machined brass helmet neck ring

houses the sealed pull pins and provides protection

for the bottom end of the helmet. Like the SL-17K,

37 and 17C, the diver is provided with an internally

adjustable chin support. This support, along with the

adjustable neck pad on the locking collar, gives the

diver a comfortable, secure, custom t.

The quick-change communications module, available

with either bare wire posts or a waterproof connector,

allows for easy, efcient maintenance of the helmets

communications.

The helmet also features the SuperFlow

®

350 large

tube adjustable demand regulator. The helmet is

available in the umbilical over the shoulder, “B”

conguration only.

approved and ™ marked

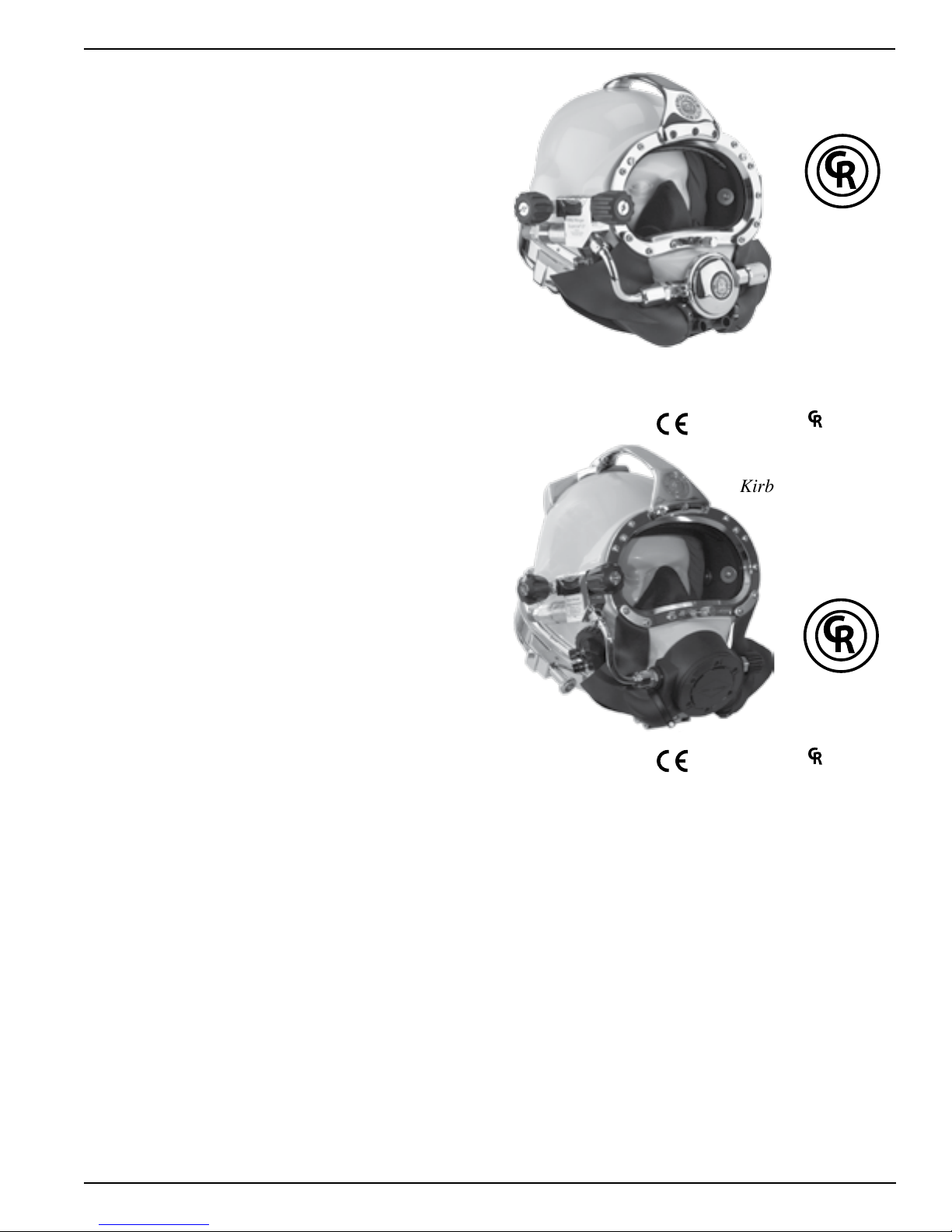

The Kirby Morgan 47 offers the ultimate in a high

performance breathing regulator. This helmet has an

entirely new breathing system, oral nasal mask, and

water ejection system. The REX Demand Valve, with

it’s fully adjustable balanced piston is a breakthrough

design that exceeds the requirements of all government or other testing agencies.

It has the best work-of-breathing performance when

compared to ANY other commercial diving helmet.

The Kirby Morgan 47 Dive Helmet has been tested

and meets or exceeds European CE requirements and

is fully commercially rated. In all other respects, this

helmet is nearly identical to the Kirby Morgan 37.

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 5

SuperLite® 17B

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

™

marked

®

The Kirby Morgan 57 helmet features our revolutionary new SuperFlow

®

450 Stainless Balanced

Regulator. It's machined from a stainless steel casting

for the ultimate in performance and reliability.

Like all KMDSI regulators on our helmets and

Band Masks, we use only regulators that are specically designed for surface-supplied diving, that will

perform over the wide range of pressures delivered

by low pressure compressors. An ordinary SCUBA

regulator mounted on a diving helmet is not capable

of delivering the gas you need at heavy work loads.

This commercially rated fully diver adjustable regulator delivers all the breathing gas you might require

for the most demanding work underwater.

The Kirby Morgan 57 also includes our QuadValve™ Exhaust System. It's recommended for diving in biologically contaminated water, when you're

properly trained and equipped, using recommended

procedures. This new exhaust has exceptionally low

exhalation resistance that you must experience to

appreciate.

approved and ™ marked

®

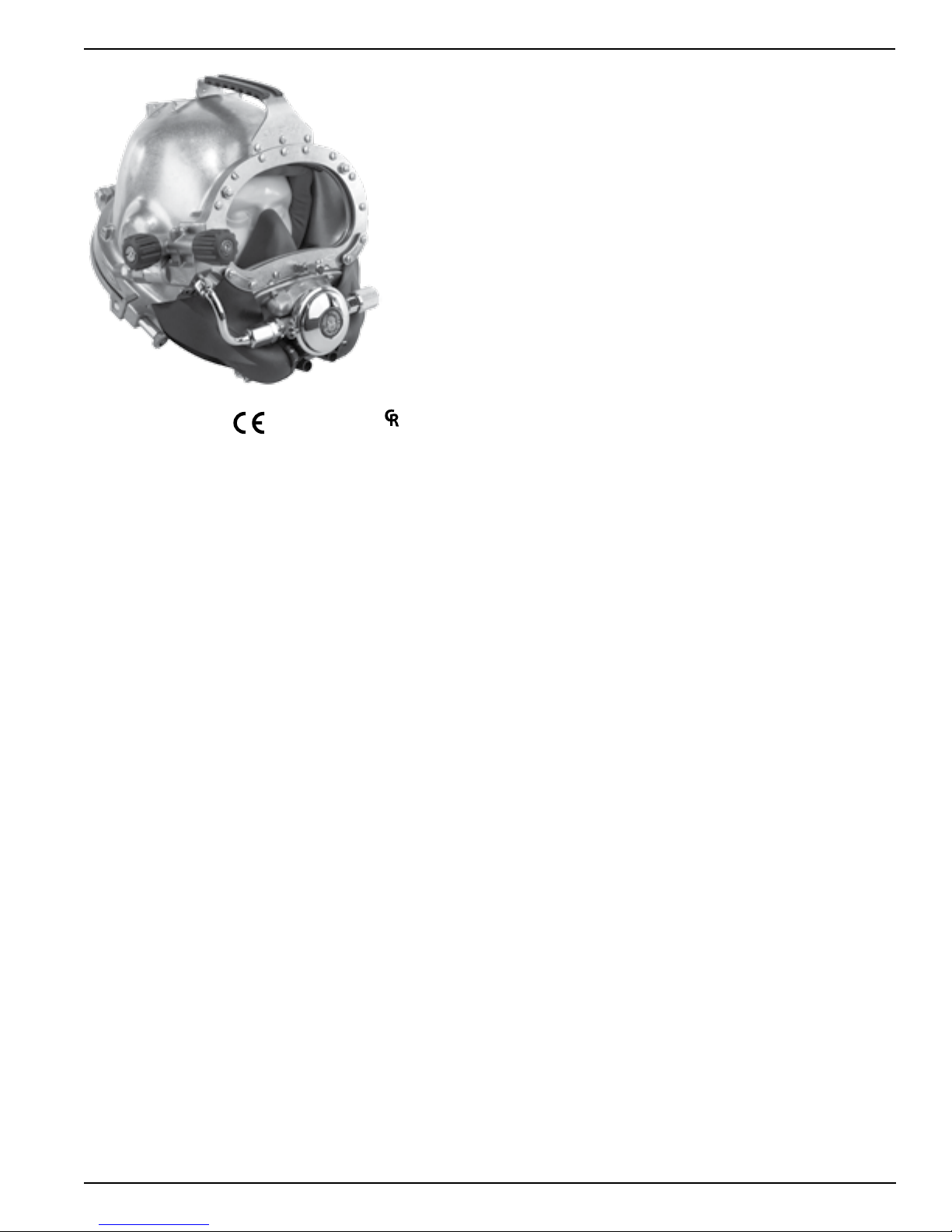

The Kirby Morgan

77 represents the rst in a new

generation of stainless steel diving helmets that provide an alternative for the diver who prefers a metal

helmet. The helmet features a stainless steel version

of our new REX

®

regulator, which offers the best

performance of any Kirby Morgan system.

It has the best work-of-breathing performance when

compared to ANY other commercial diving helmet.

The Kirby Morgan 77 Dive Helmet has been tested

and meets or exceeds European CE requirements and

is fully commercially rated.

The advantages of this all stainless steel helmet include the following:

• No renishing required if the surface is scratched

or gouged.

• Faster production of helmets for customer delivery.

B WARNING

Before attempting any diving in any

type of contaminated water, a complete diving and topside course in

hazardous materials emergencies

should be completed. The divers and

the topside team must be properly

trained and have the proper safety

equipment. All helmets and suits can

leak water under certain conditions.

Divers should use extreme caution

when diving in contaminated waters.

6 © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

• Elimination of threaded inserts for securing the port

retainer to the helmet shell.

• No need to remove the handle to remove the port

retainer.

• One piece sideblock includes both the free-ow

valve and the Emergency Gas System valve.

• The helmet ring is an integral part of the helmet.

approved and ™ marked

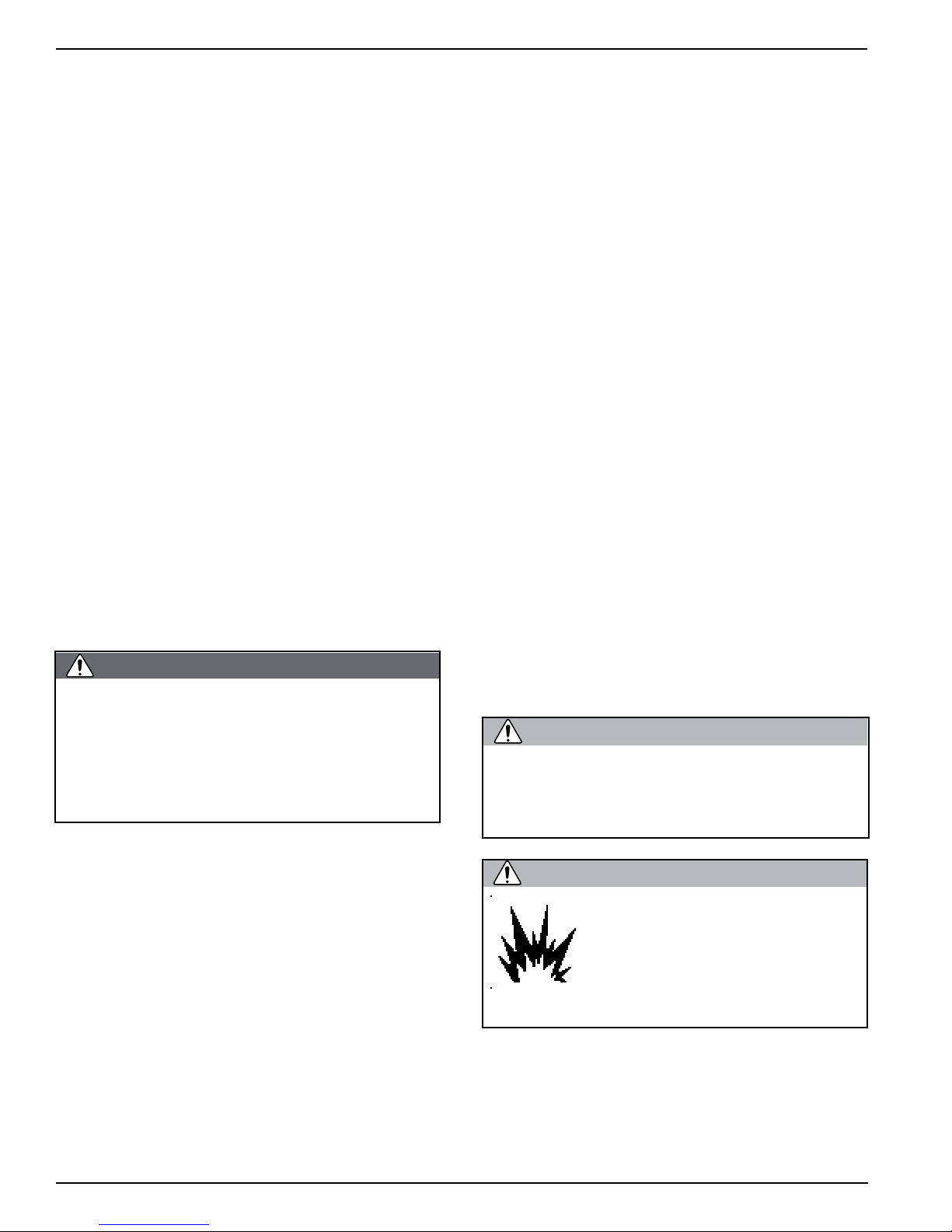

The Kirby Morgan 37SS features an all stainless

steel shell, as well as a stainless sideblock, helmet

ring, bent tube, handle, and other key components.

The SuperFlow

®

350 is standard on this helmet.

SuperLite® 17B

The Kirby Morgan 37SS features a quick change

communications module, available with either bare

wire posts or a waterproof connector, and allows

for easy, efcient maintenance of the helmet's communications.

The advantages of this stainless steel helmet include

the following:

• Rugged helmet shell and other components

• No renishing required if the surface is scratched

or gouged

• Elimination of threaded inserts for securing port

retainer to helmet shell

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 7

SuperLite® 17B

WARNING

CAUTION

CAUTION

WARNING

Chapter 2

®

Description & Operational Specications - SuperLite

This manual is our effort to explain the operation, maintenance and use of the SL 17. We do

not herein make any effort to teach the principles of diving. It is our assumption the reader is a

qualied diver. We highly recommend that all divers should train under controlled conditions, in

the use of any commercial diving helmet that they have not previously used, or trained in, prior

to use on the job.

-17B

This section includes a detailed description of the

SuperLite

®

-17 as well as important operational

specications.

2.1 CR Marking

The helmet meets or exceeds all standards established

by Dive Lab of Panama City, Florida, and is CR

(Commercially Rated) marked.

A

R

T

Y

E

L

L

A

I

C

R

E

M

M

O

C

-

D

E

T

S

E

T

B

A

L

E

V

D

-

P

R

O

F

E

S

S

I

O

N

A

TM

L

D

I

V

I

N

G

G

E

A

I

R

D

-

TM

2.2 CE Certication

The helmet has been tested and conforms to the

performance requirements as set forth in Annex II

of Directive 89/686/EEC and, as far as applicable,

the EN 250:2000, EN 250/A1:2006 and EN 153331:2008 (class B). It is fully CE marked with demand

regulator SuperFlow

and P/N 510-747.

Category of PPE: III

®

and oral nasals P/N 510-690

2.2.1. CE Marking

On the frame of the helmet the CE mark is afxed.

EN250:2000

EN250/A1:2006

EN15333-1:2008

CLASS B

HELMET MODEL:

YEAR OF PRODUCTION:

CE Mark

KIRBY MORGAN

DIVE SYSTEMS, INC.

1430 Jason Way,

Santa Maria, CA 93455

2049

In the mark the data reported are the following:

1. the name and the address of the manufacturer;

2. harmonized reference standard: EN 250:2000,

EN 250/A1:2006 and EN 15333-1;

3. Helmet model;

4. the year of production;

5. CE marking:

;

6. number of notied body.

The user cannot:

• remove the mark from the frame of the

helmet;

• modif y or count er feit the da ta r eported

on the mark.

The helmet has been tested with air and CE

certicates for use with air up to 50 meters.

Compressed air must be compliant with the

EN 12021.

All the tables reporting the technical data

and the pressure of use are relative to compressed air.

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005 9

The mark must be visible and legible

throughout the life of the PPE. If the mark

deteriorates or is not legible the user

should contact the manufacturer.

SuperLite® 17B

DANGER

WARNING

WARNING

2.2.2. Notied Body

The Notifying Body is: Eurons-Modulo Uno

S.p.A.

Address: Via Cuorgne,

21-10156 Torino,

ITALY

Identication number: 2049

2.3 Product Specications

Weight: 29.03 pounds

Helmet Shell: Fiberglass, polyester resin, and carbon

bers

Control Knobs: Polyurethane

Lens: Clear polycarbonate

Neck Dam: Neoprene

O-Rings: Buna-N

Head Cushion: Nylon bag lled with #4 Polyester

foam

The recommended lubrication type for breathing

gas mixtures containing oxygen percentages greater

than 50% is Christo-Lube

Halocarbon. Helmet gas train components being used

with gas mixtures containing less than 50% oxygen

can be lubricated with food grade silicone lubricant

such as Dow Corning

Never use aeros ol-pr opell e d s prays n ear the

fac e p or t of a ny Kir by Morga n d iving helmet .

The propellant used in these aerosols can

invisibly damage the face port and cause it

to shatter on impact from any strong blow.

If the face port fails underwater, injury or

death may result.

®

, Krytox®, Tribolube® and

®

111.

2.5 Cage Code

The cage code for identifying KMDSI products for

U.S. government purchase purposes is 58366.

2.6 Operational Specications &

Limitations

-Umbilical minimum I.D. 3/8” (9.5 mm) of not more

than two sections, total length not to exceed 600 feet

(183m).

Every model of KMDSI helmets and masks undergo

extensive type testing to fully document the performance capability and required supply pressures when

using various umbilical and pressure combinations.

All users should take the time to become knowledgeable on supply requirements to insure proper performance and for the comfort and safety of the diver.

The required supply pressures for the SL-17 equipped

with the SuperFlow

appropriate supply pressure tables in Appendix 3.

The supply pressures listed in the supply tables were

derived by breathing simulator trials. There are two

tables used for the SuperFlow

regulators. It is important that users understand how

to use the tables. For further information on supply

requirements for the SL-17 or any Kirby Morgan

helmet or mask check the Kirby Morgan website at

www.kirbymorgan.com.

When the helmet is used for air diving in

countries that conform to C.E. regulations it

must be used to a maximum depth of 164fsw

(50msw). I.A.W. EN 15333-1.

®

350 regulators are listed in the

®

and SuperFlow® 350

If you have any questions regarding proper set-up,

operation, or maintenance of your SuperLite

contact KMDSI (850) 928-7772 or at salesinfo@

KirbyMorgan.com or Dive Lab Inc. (850) 235-2715

or at Divelab@aol.com

2.4 Regulator Performance

The regulator on the SuperLite®-17B offers very good

performance. The helmet has been tested at Dive

Lab in Panama City, Florida, as well as by other the

United States Navy’s Experimental Diving Unit and

other independent testing laboratories.

10 © ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 120613005

®

-17

The demand regulator and side

block assemblies have a maximum design pressure of 250

psig (17.2 bar) over the ambient pressure, higher pressures

could lead to component failure

resulting in serious injury.

Decompression diving always involves the

DANGER

WARNING

WARNING

risk of decompression sickness. Omitted

decompression due to a loss of the breath-

ing gas supply or other accidents can cause

seri ous in jury or death . U se of a SL 17 c a nnot

prevent this type of injury.

It is important for the user/diver to take

excessive currents into consideration. The

Quad-Valve™ Exhaust PN#525-759 is now

standard on the SuperLite 17B. Unlike the

old latex double exhaust, the quad system

is not limited to a maximum depth of 150

FSW (46 msw) due to exhalation pressure.

-Temperature Limitations: Use at water temperatures

below 33°F (1°C) requires the use of hot water shroud

PN# 525-100 and hot water to help prevent icing of

the demand regulator.

SuperLite® 17B

The umbilical assembly should be composed of good

quality diving hose that meets industry standards.

Generally, gas hose will be married to the communications wire, pneumofathometer hose, and strength

member in a manner that will allow the strength

member to receive all the strain. There are also good

quality umbilicals available that are assembled at

the factory using a twisted method which does not

require marrying.

Regardless of the system used, the umbilical is the

diver’s life line and should always be of excellent

quality and maintained carefully.

Gas systems used to supply Kirby Morgan

helmets and masks must be capable of supplying gas to the diver at the required pressure and ow rates as stated in the operational specications. The use of unregulated

gas sources is extremely dangerous.

NOTE The Hot Water Shroud (Part #525-100) in

conjunction with hot water to the diver should be

used whenever diving operations are conducted

using HEO