Kirby Morgan KMB-18 A/B, KMB-28B Operation And Maintenance Manual

Kirby Morgan Band Mask

KMB-18 A/B and KMB-28B

Operations and Maintenance Manual

KMB 18 & 28 MANUAL

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

This page not used at this time.

KMB 18 & 28 MANUAL

Kirby Morgan Band Mask

KMB 18A/B and KMB 28

Operations and Maintenance Manual

KMDSI Part # 100-002

Kirby Morgan Dive Systems, Inc.

425 Garden Street

Santa Barbara, CA 93101, USA

Telephone (805) 965-8538

FAX (805) 966-5761

E-Mail: Info@KMDSI.com

Web Site:www.KMDSI.com

DANGER: Diving with compressed breathing gas is a hazardous activity. Even

if you do everything right there is always the potential for serious injury or death.No one

piece of diving equipment can prevent the possibility that you may be injured or killed

any time you enter the water. We do not herein make any effort to teach the principles

of diving. It is our assumption the reader is a qualified diver.

Manual prepared by Marine Marketing and Consulting & Kirby Morgan Dive Systems, Inc.

SuperLite-17, SuperLite-27, SuperLite-17C, SuperLite-17K, Band Mask, Kirby Morgan, DCS-2A and KMB

are all registered trademarks of Kirby Morgan Dive Systems, Inc. Use of these terms to describe products that

are not manufactured by KMDSI is not permitted.

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. This manual is made available for

the express use of owner of this Kirby Morgan product. No part of this manual may be reproduced, stored in any

retrieval system, or transmitted, or used in any form or by any means, whether graphic, electronic, mechanical,

photocopy , or otherwise by technology known or unknown, without the prior written permission of Kirby Morgan Dive Systems, Inc.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

Document # 010518001

KMB 18 & 28 MANUAL

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

This page not used at this time.

KMB 18 & 28 MANUAL

Contents

DEFINITION OF SIGNAL WORDS .................................................................................................. 1

IMPORTANT SAFETY INFORMATION ........................................................................................... 2

WARRANTY INFORMATION ........................................................................................................... 4

Chapter 1 GENERAL INFORMATION......................................................................................... 7

1.1 INTRODUCTION ....................................................................................................................... 7

1.2 KMB 18A, KMB 18 B and KMB 28 BAND MASK CONFIGURATIONS ............................ 10

1.3 DESIGN PURPOSE ..................................................................................................................10

1.4 CONSTRUCTION SPECIFICATIONS .................................................................................... 11

1.5 GENERAL DESCRIPTION...................................................................................................... 11

1.5.1 Gas Flow Systems .................................................................................................................. 11

1.5.2 Auxiliary Gas Supply System................................................................................................. 13

1.5.3 Reducing Carbon Dioxide ...................................................................................................... 14

1.5.4 Main Exhaust System .............................................................................................................14

1.5.5 Communications..................................................................................................................... 15

1.5.6 Hood and Face Seal ................................................................................................................ 15

1.5.7 Hood and Face Seal Retainer Band ........................................................................................ 15

1.5.8 Head Harness or Spider ..........................................................................................................15

1.6 IMPORTANCE OF PROPER MAINTENANCE ..................................................................... 15

1.6.1 Special T ools........................................................................................................................... 15

Chapter 2 OPERATING INSTRUCTIONS.................................................................................. 17

2.1 INTRODUCTION ..................................................................................................................... 17

2.1.1 First Use of Kirby Morgan 18A/B & 28................................................................................. 17

2.2 PRE DRESS-IN PROCEDURE ................................................................................................ 18

2.2.1 Pre-dive Inspection ................................................................................................................. 18

2.2.2 Clean Face Port....................................................................................................................... 19

2.2.3 Check Moving Parts ............................................................................................................... 19

2.2.4 One Way V alve Check ............................................................................................................ 19

2.2.5 Connecting the Band Mask to the Diver’s Umbilical............................................................. 20

2.2.6 Gas Flow Systems Check ....................................................................................................... 21

2.2.7 Sealing Integrity Check .......................................................................................................... 22

2.2.8 Check Communications.......................................................................................................... 22

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

KMB 18 & 28 MANUAL

2.3 DIVING PROCEDURES .......................................................................................................... 22

2.3.1 Fogging Prevention ................................................................................................................ 22

2.3.2 Bleeding the Umbilical........................................................................................................... 23

2.3.3 Auxiliary Gas System ............................................................................................................. 23

2.3.4 Securing the Band Mask on the Diver.................................................................................... 26

2.3.5 Attaching the Umbilical to the Harness.................................................................................. 27

2.3.6 Diver Check Gas Flow Systems ............................................................................................. 28

2.3.7 Communications Check.......................................................................................................... 28

2.3.8 Diver Ready............................................................................................................................ 28

2.3.9 Water Entry and Descent ........................................................................................................ 28

2.4 EMERGENCY PROCEDURES ............................................................................................... 29

2.4.1 Flooding.................................................................................................................................. 29

2.4.2 Inhalation Resistance.............................................................................................................. 29

2.4.3 Gas Flow Stops....................................................................................................................... 29

2.4.4 Demand Regulator Free Flow................................................................................................. 30

2.5 POST DIVE PROCEDURES .................................................................................................... 30

2.5.1 Removing the Equipment ....................................................................................................... 30

Chapter 3 TROUBLESHOOTING................................................................................................ 31

3.1 GENERAL ................................................................................................................................ 31

3.2 COMMUNICATIONS MALFUNCTIONS .............................................................................. 31

3.3 ONE-WA Y VAL VE MALFUNCTION ..................................................................................... 32

3.4 SIDEBLOCK MALFUNCTION............................................................................................... 32

3.5 DEMAND REGULATOR MALFUNCTION........................................................................... 33

3.6 WATER LEAKAGE INTO BAND MASK............................................................................... 34

3.7 AUXILIAR Y VALVE MALFUNCTION.................................................................................. 34

Chapter 4 INSPECTION/MAINTENANCE TIMETABLE ....................................................... 35

4.1 DAILY MAINTENANCE ......................................................................................................... 35

4.2 MONTHLY MAINTENANCE ................................................................................................. 35

4.3 EVERY SIX MONTHS OR 200 OPERATING HOURS.......................................................... 35

4.4 YEARLY OR EVERY 400 OPERATING HOURS .................................................................. 36

Chapter 5 PREVENTATIVE MAINTENANCE .......................................................................... 37

5.1 INTRODUCTION ..................................................................................................................... 37

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

KMB 18 & 28 MANUAL

5.2 REQUIRED TOOLS, CLEANING AGENTS, AND LUBRICATING AGENTS.................... 37

5.2.1 Component and Parts Cleaning ............................................................................................. 38

5.2.2 Component and Parts Lubrication .......................................................................................... 38

5.2.3 Teflon Tape ............................................................................................................................. 38

5.2.4 RTV Sealant............................................................................................................................ 38

5.3 GENERAL ................................................................................................................................ 39

5.4 DAILY MAINTENANCE ......................................................................................................... 39

5.5 MONTHLY MAINTENANCE (OR BETWEEN JOBS).......................................................... 41

5.5.1 Communications Inspection ................................................................................................... 41

5.5.2 Lubricate Nose Block O-Rings............................................................................................... 41

5.5.3 ONE-WA Y VALVE ................................................................................................................ 42

5.5.3.1 Disassembly of the One-Way Valve .................................................................................... 42

5.5.3.2 Reassembly of the One-Way Valve ..................................................................................... 43

5.5.4 DEMAND REGULATOR ...................................................................................................... 44

5.5.4.1 Demand Regulator Test for Correct Adjustment, Fully Assembled .................................... 44

5.5.4.2 Inspection of Regulator Body Interior................................................................................. 45

5.5.5.1 Adjustment System Lubrication .......................................................................................... 45

5.5.5.2 Reassembly of Adjustment System .................................................................................... 47

5.6 DEMAND REGULATOR INTERNAL ADJUSTMENT ......................................................... 48

5.7 HOOD AND FACE SEAL ........................................................................................................ 50

Chapter 6 CORRECTIVE MAINTENANCE .............................................................................. 53

6.1 GENERAL ................................................................................................................................ 53

6.2 PORT RETAINER ..................................................................................................................... 53

6.3 FACE PORT .............................................................................................................................. 53

6.3.1 General.................................................................................................................................... 53

6.3.2 Face Port and Nose Block Device Removal........................................................................... 54

6.3.3 Face Port and Nose Block Replacement................................................................................. 55

6.4 COMMUNICATIONS SYSTEM............................................................................................. 57

6.4.1 General.................................................................................................................................... 57

6.4.2 Earphone Inspection ............................................................................................................... 57

6.4.3 Microphone Removal and Replacement................................................................................. 58

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

KMB 18 & 28 MANUAL

6.4.4 Earphone Removal and Replacement..................................................................................... 59

6.4.5 Waterproof Connector ............................................................................................................59

6.4.5.1 Waterproof Connector Removal .......................................................................................... 59

6.4.5.2 Connector Replacement....................................................................................................... 60

6.4.6 Communications Posts ........................................................................................................... 60

6.4.6.1 Communications Post Removal .......................................................................................... 60

6.4.6.2 Communications Post Replacement .................................................................................... 61

6.5 SIDEBLOCK ASSEMBL Y....................................................................................................... 61

6.5.1 General.................................................................................................................................... 61

6.5.2 Sideblock Assembly Removal ................................................................................................ 62

6.5.2.1 KMB 18A ............................................................................................................................ 62

6.5.2.2 KMB 18B & 28 ................................................................................................................... 62

6.5.2.3 Separating the Sideblock Assembly from the Band Mask Frame ....................................... 63

6.5.3 Sideblock Assembly Replacement.......................................................................................... 64

6.6 DEFOGGER VALVE ................................................................................................................ 66

6.6.1 Disassembly of the Defogger Valve ....................................................................................... 66

6.6.2 Cleaning and Lubricating ....................................................................................................... 67

6.6.3 Reassembly of the Defogger Valve ........................................................................................ 67

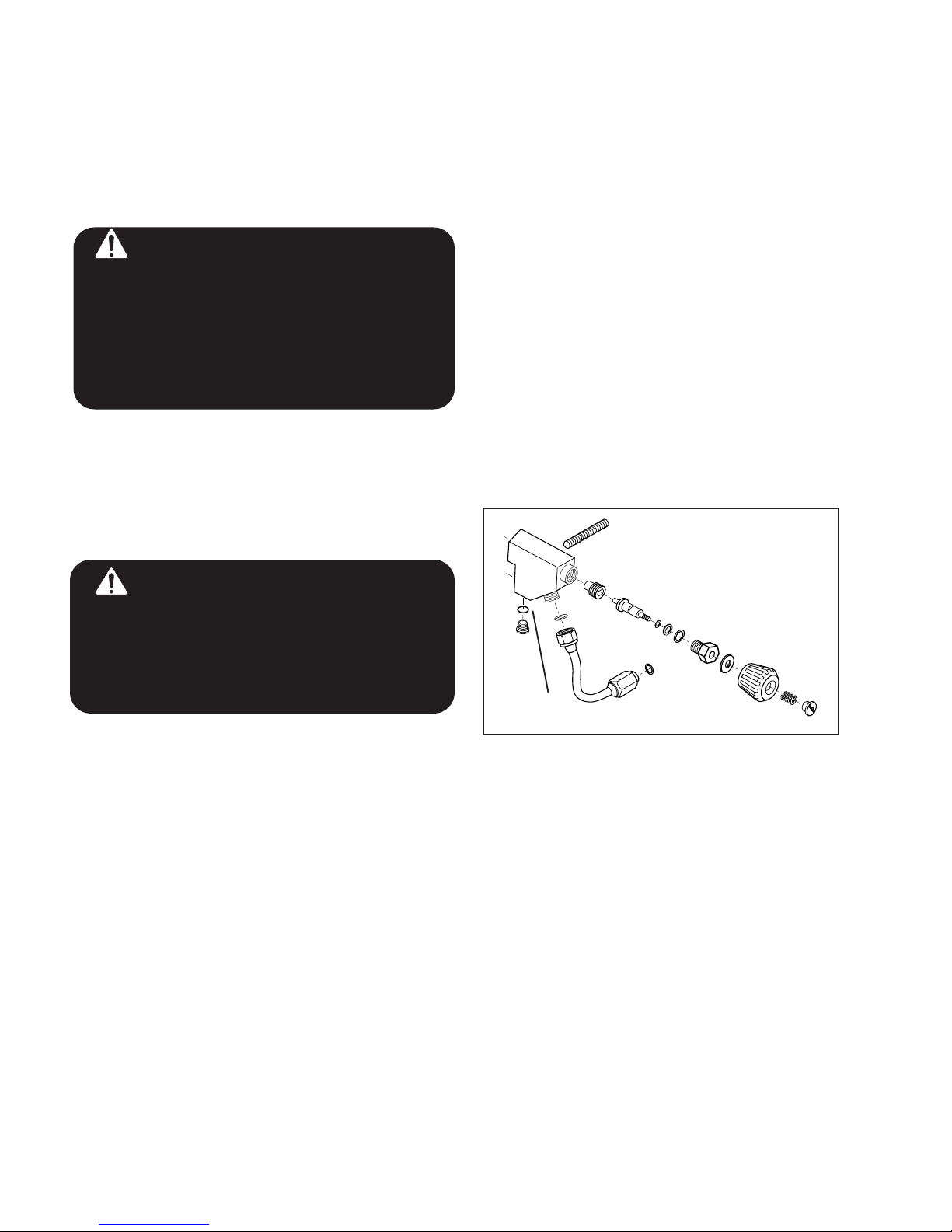

6.7 AUXILIARY GAS SUPPLY VALVE ASSEMBLY.................................................................. 68

6.7.1 Disassembly of the Auxiliary Valve Assembly....................................................................... 68

6.7.2 Cleaning and Lubricating ....................................................................................................... 68

6.7.3 Reassembly of Auxiliary Valve .............................................................................................. 69

6.8 MODEL "A" REGULATOR HOSE ASSEMBLY .................................................................... 70

6.8.1 Hose Removal ........................................................................................................................ 70

6.8.2 Inspection, Cleaning, and Lubricating.................................................................................... 70

6.8.3 Hose Replacement .................................................................................................................. 71

6.9 "B" BENT TUBE ASSEMBLY................................................................................................. 72

6.9.1 General.................................................................................................................................... 72

6.9.2 Removal of the Bent Tube Assembly ..................................................................................... 72

6.9.3 Inspection of Bent Tube Assembly ......................................................................................... 72

6.9.4 Replacement of the Bent Tube Assembly............................................................................... 73

6.10 NOSE BLOCK ASSEMBLY................................................................................................... 74

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

KMB 18 & 28 MANUAL

6.10.1 Nose Block Assembly Removal ........................................................................................... 74

6.10.2 Nose Block Device Replacement ......................................................................................... 74

6.11 BAND MASK FRAME KMB 18A/B..................................................................................... 74

6.12 RUBBER WHISKER .............................................................................................................. 75

6.12.1 Whisker Removal .................................................................................................................75

6.12.2 Whisker Replacement........................................................................................................... 76

6.13 MAIN EXHAUST ASSEMBLY ............................................................................................. 77

6.13.1 Exhaust Valve Removal........................................................................................................ 77

6.13.2 Main Exhaust Body Replacement ........................................................................................ 77

6.14 DEMAND REGULATOR ASSEMBLY ................................................................................. 78

6.14.1 General.................................................................................................................................. 78

6.14.2 Demand Regulator Assembly Removal................................................................................ 78

6.14.3 Disassembly of the Demand Regulator ................................................................................ 79

6.14.4 Inspection of Demand Regulator Parts................................................................................. 80

6.14.5 Reassembly of the Demand Regulator ................................................................................. 81

6.14.6 Unexplained Demand Regulator Steady Flow When Underwater....................................... 83

6.15 ORAL NASAL MASK............................................................................................................ 84

6.15.1 Oral Nasal Mask Removal.................................................................................................... 84

6.15.2 Inspection of Oral Nasal Mask ............................................................................................. 84

6.15.3 Oral Nasal Mask Replacement ............................................................................................. 84

6.15.4 Oral Nasal Valve Replacement ............................................................................................. 84

Chapter 7 ACCESSORIES ............................................................................................................. 85

7.1 INTRODUCTION ..................................................................................................................... 85

7.2 HOT WATER SHROUD INSTALLATION PROCEDURES ................................................... 85

7.3 LOW PRESSURE INFLATOR HOSE INSTALLATION ON THE “B” SIDEBLOCK ........ 87

7.4 WELD LENS ASSEMBLY INSTALLATION INSTRUCTIONS ........................................... 87

7.5 USE OF QUICK-DISCONNECT ............................................................................................. 88

7.6 MASK CARRYING BAG ........................................................................................................ 88

Appendix I Torque Specifictions ..................................................................................................... 89

Appendix 2 Maintenance Log.......................................................................................................... 90

Table of Equivalents ......................................................................................................................... 91

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

KMB 18 & 28 MANUAL

This page not used at this time

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

KMB 18 & 28 MANUAL

Definitions of Signal Words Used in this Manual

For your protection, pay particular attention to items identified by signal words in this manual. These

terms are identified as, CAUTION, WARNING AND DANGER. It is especially important for you to

read and understand these signal words.

CAUTION: This word indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

WARNING: This word indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

DANGER: This word indicates an imminently hazardous situation, which if not

avoided, will result in death or serious injury.

If English is not your native language and you have any difficulty understanding the language of any

warnings as they appear in the manual, please have them translated.

WARNING: Este é um aviso importante. Queira mandá-lo traduzir.

WARNING: Este es un aviso importante. Sirvase mandario traducir.

WARNING: Quest è un avviso importante. Tradurlo.

WARNING: Ceci est important. Veuillez traduire.

WARNING: Diese Mitteilung ist wichtig. Bitte übersetzen lassen.

If you have any questions regarding the information in this manual, or the operation of your mask,

call Kirby Morgan Dive Systems, Inc. at (805) 965-8538 or E-Mail: Info@KMDSI.com

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 1

KMB 18 & 28 MANUAL

IMPORTANT SAFETY INFORMATION

This Kirby Morgan Band Mask (KMB 18 A/B & 28) diving mask is intended for use only by trained

divers who have successfully completed a recognized training course in surface supplied diving.

WARNING: Follow all the instructions in this manual carefully and heed all safety

precautions. Improper use of this diving mask could result in serious injury or death.

DANGER: Kirby Morgan Dive Systems, Inc. (KMDSI) warns all divers who use the

Kirby Morgan Band Mask (KMB 18A/B & 28) to be sure to use only KMDSI original spare

parts from a KMDSI authorized dealer. Although other parts, O-rings and fittings may

appear to fit on the Kirby Morgan Band Mask (KMB 18A/B & 28), they may not to be

manufactured to the same standards maintained by KMDSI. The use of any parts other

than KMDSI original parts may lead to equipment failure and accidents.

DANGER: Diving in an environment that is chemically, biologically, or radiologically contaminated is extremely hazardous. Although the Kirby Morgan Band Mask

(KMB 18A/B & 28) may be adapted for use in some contaminated environments, special

training, equipment, and procedures are necessary. Do not dive in a contaminated

environment unless you have been thoroughly trained and equipped for this type of

diving.

Read this manual before using or maintaining the mask, even if you have experience with other

diving masks. If you have purchased the mask new from a dealer, be sure to send in the warranty

registration card so we may keep you informed regarding any safety notices that affect this

product. If you resell or loan this mask to another diver, be sure this manual accompanies the mask

and that the person reads and understands the manual.

DANGER: Diving is a life threatening occupation. Even if you do everything right

there is still the potential for serious injury or death. Diving a Kirby Morgan band mask

or helmet cannot prevent accidents, injuries, or death.

WARNING: This mask was completely checked and should be ready to dive as it

was shipped from the factory. However, it is always the diver's responsibility to check

all the components of the mask prior to diving.

page 2

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

KMB 18 & 28 MANUAL

This manual is supplied to the original purchaser of this mask. If you have any questions about the use,

maintenance, or operation of this mask, or you need another copy of this manual, Part Number 100-002,

contact your nearest KMDSI dealer or Kirby Morgan Dive Systems, Inc. (KMDSI). Telephone:(805)

965-8538, Fax: (805) 966-5761, E-Mail: Info@KMDSI.com

DANGER: Kirby Morgan masks and helmets are not cleaned or lubricated for

oxygen service. Using this mask with oxygen percentages above 50% by volume may

lead to fire or explosions that can result in serious injury or death.

All Kirby Morgan helmets and masks must not be used with oxygen breathing mixtures in excess of 50%

by volume without first insuring all gas transporting components have been cleaned and lubricated for

oxygen service. Only oxygen compatible lubricants such as Krytox® and Christo lube® should be used.

Lubricants must be used sparingly.

The information contained in this manual is intended to aid the user in optimizing the performance of

this helmet. Some of the information will depend on the diving situation and the use of associated

equipment. Many countries have specific laws and rules regarding commercial diving. The operating

and performance specifications listed in this manual on page 8 is separated into two charts. These

charts demonstrate different operation requirements, which are required or imposed by countries or

regulating bodies. It is important for the user to understand the rules, regulations, and philosophy

imposed by the governing regulating bodies whenever using commercial diving equipment. These

charts show the basic operating pressures, depths, and umbilical configurations as required by some

regulating bodies. Whenever Kirby Morgan helmets or masks are used in European Countries, which

have adopted the C.E. certification programs they must only be used with C.E. certified components.

Diving operations should only be conducted within the limits of the operational specifications, and in

accordance with the rules and regulations established by the governing authority in the specific country

or geographical location where the diving operations are being conducted. Please call Kirby Morgan Dive

Systems, Inc. (KMDSI) regarding any operational or performance questions.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 3

KMB 18 & 28 MANUAL

Warranty Information

Kirby Morgan Dive Systems, Inc. (KMDSI) warrants every new mask, helmet, or Dive Control System (DCS) to be free

from defects in workmanship for a period of ninety (90) days from date of purchase. This warranty does not cover rubber

parts or communications components.

Should any part become defective due to materials or workmanship during the warranty period, contact your nearest

authorized KMDSI dealer. If there is no dealer in your area, contact KMDSI directly at (805) 965-8538, E-Mail:

Info@KMDSI.com or Fax (805) 966-5761. You must have a return authorization number (RMA#) from KMDSI prior to

the return of any item. Upon approval from KMDSI, return the defective part, freight prepaid, to KMDSI, 425 Garden

Street, Santa Barbara, CA, 93101. The part will be repaired or replaced at no charge as deemed necessary by KMDSI.

This warranty becomes null and void if:

1. The product is not registered with KMDSI within ten (10) days of purchase.

2. The product has not been properly serviced and maintained according to the appr opriate KMDSI manual.

3. Unauthorized modifications have been made to the product.

4. The product has been abused or subjected to conditions which are unusual or exceed the product's

intended service.

page 4

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

This page not used at this time

KMB 18 & 28 MANUAL

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 5

KMB 18 & 28 MANUAL

Head protector

Spider

Free flow knob

Sideblock

Auxiliary valve

knob

Port retainer

Port

Equalizing

device

One-way valve

Hood

Regulator

adjustment knob

Regulator

The KMB 18B Band Mask

(shown with optional Hard Shell)

page 6

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

STOP!

KMB 18 & 28 MANUAL

BEFORE GOING FURTHER-

Locate the exploded view at the back of this manual. Fold it out and follow the numbers as you read. All

the numbers in parentheses in the text refer to the numbers on the exploded drawing. These numbers are

called “location” numbers on the parts list. They are used to find the referred to parts on the exploded

drawing only. They are not the part number. Always check the part number when ordering to make

sure it is correct. Always specify the mask model number as well. There is only one exploded view

drawing which includes both the Kirby Morgan Band Mask (KMB 18A) and Kirby Morgan Band Mask

(KMB 18B), as well as the Kirby Morgan KMB 28 Band Mask.

CHAPTER 1

GENERAL INFORMATION

1.1 INTRODUCTION

Kirby Morgan Dive Systems, Inc. (KMDSI) started

as the Kirby Morgan Corporation in 1965. Kirby

Morgan is a registered trademark for our products.

William Bev Morgan started designing

and making diving equipment shortly

after becoming a breath-hold diver while

working as a beach lifeguard in the late

1940's. There was very little equipment

available in those early days so it was

necessary to make much of his own gear.

During the early 1950's he originated the Los

Angeles (California) Underwater Instructor

Program for teaching SCUBA divers/instructors, then started Dive 'N Surf, one of the first

diving equipment suppliers that integrated Scuba

diving instruction into the same operation as sales

and service of equipment. He, along with his

partners, Bill and Bob Meistrell, designed and

manufactured diving equipment that remains a

standard in the diving industry today.

In 1957 Morgan sold Dive 'N Surf to his partners.

In 1960 he started commercial diving along with

designing and making diving equipment for the

commercial market.

The Kirby Morgan Corporation was formed to

manufacture commercial diving helmets. The

copper and brass "heavy gear" or " Standard Dress"

helmets were the first manufactured by the com-

Bev Morgan, Chairman of the board,

Kirby Morgan Dive Systems, Inc.

pany. Over the years Kirby Morgan designed,

manufactured, and sold many different helmets

and masks for commercial divers.

Staying active in commercial diving has

contributed to the successful design innovations

of KMDSI products. This may be the primary reason for the acceptance of our designs by professional divers. Over the years,

Morgan has designed more than forty diving

helmets and forty five diving masks.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 7

KMB 18 & 28 MANUAL

All members of the KMDSI staff participate as part of the Kirby Morgan design

team. It would not be possible for us to

supply the commercial, military, scientific,

and public service diving industries with our

equipment without the team of people that

make up Kirby Morgan Dive Systems, Inc.

(KMDSI)

We feel it is important for the reader to

understand that we at KMDSI consider ourselves as only part of the process along the

path in diving equipment design. We welcome all input from our customers. The

thinking of many good divers, diving equipment engineers, diving medical specialists, diving organization administrators and

their supporting personnel has contributed

to the current state of the art of diving.

Each piece of gear we manufacture has in it some

of the thinking of those who have gone before us.

To all the people who give something of themselves to the men and women who work underwater, we express a thank you.

Our extensive dealer network makes it easy to

obtain genuine Kirby Morgan replacement parts

as well as technical assistance world wide. We

have a strong commitment to providing the best

diving equipment and service possible.

Kirby Morgan has always concentrated on designing and manufacturing diving equipment that

allows most repairs and routine maintenance to

be performed by the user. The KMB 18/28 full

face mask is no exception. Most routine preventative and corrective maintenance can be accomplished by the user utilizing this manual, the

KMDSI Tool Kit and common hand tools.

The side block and regulator are of a U.S. Navy

approved design, engineered to provide an optimum flow of breathing gas even under heavy

work conditions.

The mask has been tested and conforms to the

performance requirements as set forth in Annex

II of Directive 89/686/EEC and as far as applicable, the EN250 (edition Jan 2000) and the E

DIN 58 642 (edition Feb 1998). When the mask

is used for air diving in countries that conform to

C.E. regulations it may be used to a maximum

depth of 164fsw (50 msw). I.A.W. EN250.

Only equipment certified and tested according

to EN 250/E DIN 58 642 may be used with the

KMB 18/28 when conducting diving operations

in European EC compliant countries.

Performance of the mask is dependant on many

factors including type of breathing gas used, work

rate, delivery pressure, umbilical internal diameter, length and number of connections, diving

depth and capability of the gas delivery system

to provide breathing media at the required CFM

or LPM to maintain the optimum static over bottom pressure. Performance of this helmet is measured in volume averaged pressure, resistive effort, formally called work of breathing. Volume

averaged pressure is the measurement of average pressures contributed by resistive components within the UBA. This value is normally expressed in Joules/liter. The performance of this

mask can be expected to be less than 3.0 J/L when

used within the following guidelines.

Operational Specifications and Limitations:

- Maximum depth on air - 220 fsw (67 msw) with

the standard exhaust whisker assembly.

- Maximum depth on air - 100 fsw (30 msw) when

equipped with the double exhaust whisker

assembly*.

Work rate - moderately heavy - 62.5 lpm rmv.

-Umbilical minimum I.D. 3/8” (9.5 mm) of one

continuous length (no splice), total length not to

exceed 600 feet (182m).

-Required over-bottom supply pressure,

0-l00 fsw (0-30 msw), 1 15-135 psig (8-9.3 bar).

100-150 fsw (30-50 msw),135-225 psig (9.3-15.5 bar).

100-220 fsw (30-67 msw),175-225 psig (12.0-15.5

bar).

page 8

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

-Gas supply system capable of supplying 4.5

acfm (127.4 BL/min) to the side block assembly

at depth.

-T emperature limitations: Use at water temperatures below 36

o

F (2oC) requires use of hot water

shroud and hot water.

The umbilical assembly should be composed of

good quality diving hose that meets industry standards. Generally , gas hose will be married to the

communications wire, pneumofathometer hose,

and strength member in a manner that will allow

the strength member to receive all the strain.

There are also good quality umbilicals available

that are assembled at the factory using a twisted

method which does not require marrying. Regardless of the system used, the umbilical is the divers

life line and should always be of excellent quality and maintained carefully.

* This assembly has not been tested for CE

compliance. Hooded face masks should NOT be

used for diving in contaminated water situations.

The double exhaust is provided for the masks for

use during jetting operations. It has been found

that the use of a double exhaust assembly can

help in the prevention of inversion of the exhaust

valve during heavy jetting operations.

KMB 18 & 28 MANUAL

WARNING: High pressure regulators and associated piping systems for

surface supplied diving with Kirby Morgan helmets and masks must be capable

of delivering a minimum of 4.5 acfm to the

diver at depth. Only systems that can

deliver this required gas flow should be

used. The use of standard SCUBA style

regulators stationed top side is unacceptable as there is no provision for adjusting the intermediate pressure supplied to the diver. This can create a dangerous situation where the diver may not

receive an adequate supply of air. Only

regulators which allow a variable setting

for intermediate pressure should be used

for umbilical diving.

Many of the parts on the Kirby Morgan Band

Mask (KMB 18A/B) are interchangeable with

our SuperLite Helmets, and the Kirby-Morgan

Band Mask 28. This helps keep inventory costs

low for diving companies and independent divers.

The KMB 28 has a durable injection molded

plastic frame (17) rather than a fiberglass frame

as found in the KMB 18A/B.

The diving control station can be at the surface, in

a diving bell, or out of a submerged habitat. The

diving control station is the center of the air/gas

The KMB 28 uses the SuperFlow regulator, the

KMB 18 uses the large tube SuperFlow 350

regulator.

supply, communications with the diver, and diving procedures.

DANGER: Decompression diving

always involves the risk of decompression sickness. Omitted decompression

due to loss of gas supply or other accidents can cause serious injury or death.

Use of a KMB 18/28 mask cannot prevent

this type of injury.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 9

KMB 18 & 28 MANUAL

Additional differences between the Kirby Morgan Band Mask KMB 18A/B and the Kirby

Morgan Band Mask KMB 28 are as follows:

1) The face port (27) in the KMB 28 is a slightly

different size than the KMB 18A/B.

2) The main exhaust body (67) is molded into the

mask frame in the KMB 28.

3) The exhaust covers on the two masks are

slightly different.

4) There is a vacuum formed comfort insert (14)

in the KMB 18A/B.

5) The air train in the KMB 28 requires a special

standoff (24) for proper mounting of the side

block.

It is our hope that the Kirby Morgan Band Mask

(KMB 18A/B or KMB 28), will provide comfort

and safety to your diving. This manual is our

effort to explain the operation, maintenance and

use of the Kirby Morgan Band Mask (KMB 18A/

B & 28).

WARNING: We do not herein make

any effort to teach the principles of diving. It is our assumption the reader is a

qualified diver.

inlet nipple (61b) and jam nut (61c), the two

models are identical. The configuration of the

KMB 28 is almost identical to the KMB 18B.

The Kirby Morgan Band Mask A (KMB 18A)

side block assembly (120a) receives the main and

auxiliary gas supplies from hoses that run down

in front of the diver. The Kirby Morgan Band

Mask 18B (KMB 18B) side block assembly (120b)

receives the hoses from over the diver’s shoulder.

All “location” numbers that are for the “A’ model

will have a small “a” and all “location” numbers

for the “B” only will have a small “b”.

Some divers prefer the hoses to go over their

shoulder to clear their front when working. Others prefer the hoses to go down their front to

prevent fouling. It depends on the type of work

and what the diver finds comfortable.

1.3 DESIGN PURPOSE

The Kirby Morgan Band Masks 18A/B & 28 are

designed for use with an umbilical.

WARNING: Only under very con-

trolled conditions, i.e., non-moving water

(such as swimming pools or calm lakes),

can this mask be used with a self contained gas supply. There is no provision

for surface swimming once the SCUBA

air supply is depleted.

If there is any information in this manual that is

not clear, contact Kirby Morgan Dive Systems,

Inc. at (805) 965-8538 for clarification.

1.2 KIRBY MORGAN BAND MASK A (KMB

18A), KIRBY MORGAN BAND MASK B

(KMB 18B), AND KIRBY MORGAN BAND

MASK 28 (KMB 28) CONFIGURATIONS

The Kirby Morgan Band Mask 18 (KMB 18) is

manufactured in two configurations. With the

exception of the side block assembly (120a/b),

the hose assembly (117a) with its inlet nipple

(61a), and the bent tube assembly (117b) with its

page 10

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

The umbilical is usually composed of at least a

gas or air supply hose and communication wire,

assembled with waterproof tape to form a single

unit. Some umbilicals also have included a hose

for hot water, a pneumofathometer hose, and a

strength member, such as a cable or strong line. It

is imperative that air/gas umbilicals be married to

a strength member in a manner that allows the

strength member to receive the strain. This will

help reduce the possibility of umbilical and umbilical fitting fatigue and possible failure. The

umbilical is the diver’s lifeline to the diving

control station.

KMB 18 & 28 MANUAL

The diving control station can be at the surface, in

a diving bell, or out of a submerged habitat. The

diving control station is the center of the air/gas

supply, communications with the diver, and diving procedures.

DANGER: Decompression diving

always involves the risk of decompression sickness. Omitted decompression

due to loss of gas supply or other accidents can cause serious injury or death.

Use of a KMB 18/28 mask cannot prevent

this type of injury.

WARNING: High pressure regulators for surface supplied diving with the

Kirby Morgan Band Mask 18A/B and KMB

28 mask must be capable of supplying an

over bottom pressure of between 115 and

225 PSI. The use of standard SCUBA style

regulators stationed top side is unacceptable as there is no provision for adjusting the intermediate pressure supplied to the diver. This can create a dangerous situation where the diver may not

receive an adequate supply of air. Only

regulators which allow a variable setting

for intermediate pressure should be used

for umbilical diving.

The surface supplied diver’s mask must provide

life support breathing systems, communications

components, viewing lens, and many other less

important, but vital systems. The Kirby Morgan

Band Masks 18A/B and 28 provides these systems in a convenient and comfortable way.

1.4 CONSTRUCTION SPECIFICATIONS

KIRBY MORGAN BAND MASK

KMB 18A/B & 28

Weight: 11 pounds

CONSTRUCTION:

Mask Frame KMB 18A/B, Fiberglass

Mask Frame KMB 28, Xenoy/Polycarbonate mix

HARDWARE:

Stainless Steel, Chromed Brass, Polished Brass

CONTROL KNOBS: ABS Plastic

LENS: Polycarbonate plastic

O-RINGS: Buna-N

HOOD: Foam, Open Cell Neoprene

RECOMMENDED LUBRICANTS:

Dow Corning #55 O-ring silicone lubricant.

Krytox, and Crysto Lube are also acceptable.

OPERATING PRESSURE: 115-225 PSI over

ambient.

Optimum 150 PSI over ambient

FLOW REQUIREMENTS: 3.2 CFM

COMMUNICATIONS:

Earphones - Mylar Cone 8 OHM

Oral Nasal Microphone - 8 OHM

1.5 GENERAL DESCRIPTION

1.5.1 Gas Flow Systems

The main gas supply flow from the umbilical

enters the system at the adapter (105) and flows

through the automatic one-way valve (104) to the

interior of the side block assembly (120a/b). The

one-way valve (104) or “non-return” is a very

important component. It must prevent the flow of

gas out of the mask to the umbilical in the event

of a sudden lowering of pressure in the supply

hose. This can happen due to an accidental break

in the hose or a fitting near the surface. Not only

would the auxiliary gas be lost if the one way

valve failed (concurrent with a hose or fitting

break on deck), but the diver would be “squeezed”,

a very serious accident. Although we have se-

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 11

KMB 18 & 28 MANUAL

lected the valve for its reliability and quality,

inspection and maintenance of this valve must be

done regularly. It is very easy to disassemble and

inspect. (A rebuild kit for this valve is available,

KMDSI Part #525-330).

WARNING: The one way valve must

be tested daily, prior to the commencement of diving operations. Failure of the

one way valve could cause serious injury

or death. Follow the procedures for testing the valve in chapter 2 (sec. 2.2.4) of

this manual.

The auxiliary gas comes from a tank of compressed gas worn by the diver. It enters the system

through the auxiliary valve (103) when the diver

turns the control knob (100) on. The flow then

enters the side block, (94a/b).

diver’s warmth and moisture. The flow continues

out through the mask main exhaust (66), or into

the oral nasal (9) by means of the valve (5), then

into the regulator and out through the regulator

exhaust (62). The diver can breathe from this

flow of gas if the demand regulator malfunctions.

Returning to the side block assembly (120a/b):

the other passage for gas is to the regulator (63a/

b). It goes to a hose assembly (117a) on the “A”

model or a bent tube assembly (117b) on the “B”

model. The flow of gas in the demand regulator

assembly (63a/b) is controlled by an automatic

valve that supplies gas to the diver on inhalation

“demand” only, and shuts off during the exhalation cycle.

The SuperFlow demand regulator (63a/b) senses

WARNING: Never connect the main

gas supply hose from the diving station

to the auxiliary valve (103). There is no

one way valve in the auxiliary valve. If this

mistake is made, any break in the supply

hose could possibly result in a “squeeze”.

The KMB 18A/B and KMB 28 use a stud (93) and

a machine screw (25) to mount the side block

assembly (120a/b).

The nut (20), lock washer (19), and flat washer

(18) bed solidly on the interior of the mask frame

(17) wall securing the side block assembly (120a/

b). Both sources of gas flow through the same

passage in the side block body (94a/b) to two

exits. One exit is always open to supply gas to the

demand regulator assembly (63a/b). The other

exit is to the defogger valve (free-flow valve)

assembly (83 through 92).

The diver controls the flow of gas through the

defogger system with the control knob (85). The

flow enters the mask and flows through the air

train (21) which directs the gas onto the face port

(27) to prevent fogging that forms there from the

Inflator hose connects here.

The “B” sideblock allows you to connect a low pressure

hose to your dry suit.

the start of the divers inhalation and opens the

flow valve, matching the diver’s need. The regulator continues to match the diver’s inhalation as

the rate increases, peaks, then ebbs and stops.

When the diver exhales, the supply gas stays off

as the exhalation gas flows through the regulator

body (39), out the regulator exhaust valve (62),

through the whisker (35), and out into the water.

The whisker (35) deflects the exhaust bubbles

away from the face port (27) to keep the diver’s

view clear.

page 12

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

All Kirby Morgan Helmets and Bandmasks are

equipped with a multi turn demand regulator

adjustment knob. The purpose of this adjustment

knob is to allow the diver the ability to compensate for variations in umbilical supply pressure.

This adjustment device operates by simply increasing or decreasing the amount of spring bias

tension on the demand regulator inlet valve. The

adjustment knob has a range of approximately 13

turns from full in to full out. The intent of this bias

adjustment device is strictly to allow the diver to

make adjustments for variations in umbilical supply pressure. This adjustment device is not intended as a minimum-maximum device. Minimum and maximum applies to supply pressure

only. The adjustment knob should be adjusted by

the diver to be at the easiest breathing setting at all

times. The exact number of turns required is

dependent on the supply pressure. Diving a

KMDSI helmet or bandmask with a bias setting

greater than that just necessary to keep the demand valve from free flowing increases the work

of breathing and reduces the diver's ability to

perform heavy work.

The adjustment knob (47) allows the diver to

control the regulator for a wide range of incoming

gas pressures. Normally, this would be from 115

P.S.I. to 225 P.S.I. over ambient (diver) pressure.

It is important to have this control at the diver for

the least breathing resistance.

The Kirby Morgan Band Mask 18B and KMB 28

side block is drilled and tapped to accept low

pressure inflator hoses. This allows the diver the

capability to inflate variable volume dry suits or

buoyancy compensators. It is tapped with a 3/8"24 thread orifice, standard for American first

stage scuba regulator low pressure auxiliary fittings. The port is shipped plugged at delivery.

KMB 18 & 28 MANUAL

WARNING: When using the side

block low pressure inflator port. The Operator should only use high quality hoses

with an integrated flow restrictor or a

KMDSI flow restrictor PN# 555-720. All

hoses must have an in-line restrictor to

reduce the gas flow in the event of hose

failure. Do not use fitting adapters, standard adapters do not provide an adequate

flow restriction. The use of many off the

shelf adapters on the side block assembly could expose the low pressure hose

fittings to excessive stress. Any failure of

an inflation hose will subject the diver to

a decreased supply pressure.

1.5.2 Auxiliary Gas Supply System

All divers using Kirby Morgan surface supplied

helmets and masks must always have a diver

worn auxiliary gas cylinder fitted with a first stage

regulator and hose that is connected to the inlet

of the auxiliary supply valve (103). The size of

the cylinder should be such that will allow the

diver to safely ascend to the surface or to a point

where the normal gas supply can be restored. The

first stage regulator should always be fitted with

the KMDSI overpressure relief valve.

WARNING: Be sure the auxiliary

air/gas first stage regulator is fitted with

an overpressure relief valve. A leaky first

stage can overpressure the hose, bursting it and causing a loss of the entire

auxiliary air/gas supply and possible

physical injury to the diver as the hose

whips about. Do not use a high pressure

hose as the system on the helmet is not

designed for high pressure.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 13

KMB 18 & 28 MANUAL

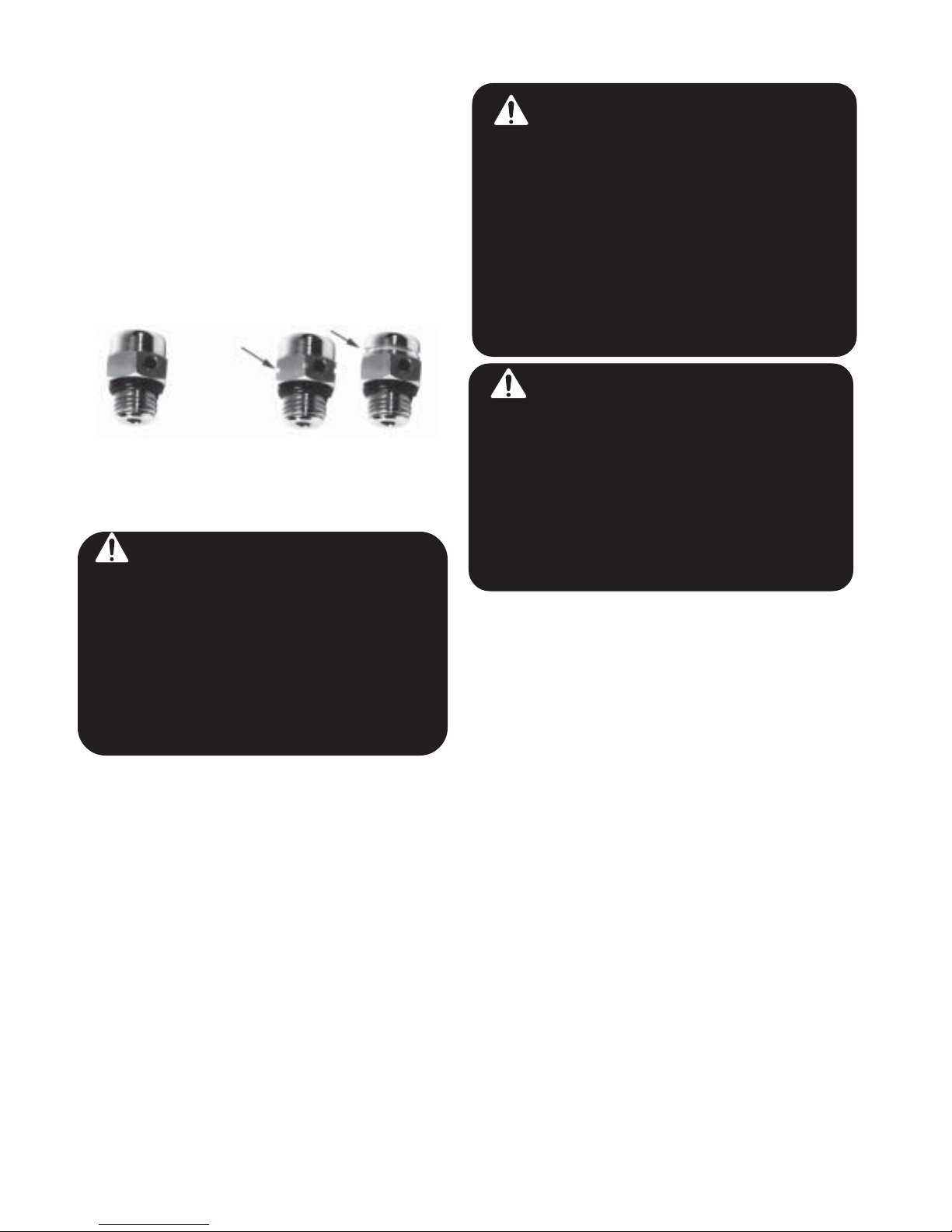

The KMDSI Overpressure relief valve, part

number 200-017, has been manufactured in two

different flow rates. The original valve had a

lower flow rate that the current valve. The current

valve has been marked in two ways, the first

being a groove around the flats of the hex. Currently the valve is marked with a groove around

the top of the body. These are the same valve, just

different marks.

Shown are the three versions of the over pressure relief

valve

DANGER: Your auxiliary air/gas

supply on a deep mixed-gas dive is extremely limited. All divers must be aware

of exactly how long their bailout bottle

will last at depth. For example, a diver

breathing one cubic foot of air a minute at

the surface will use a 50 cubic foot bailout

bottle in approximately 7 minutes at 198

FSW while at rest.

1.5.3 Reducing Carbon Dioxide

It is important to reduce the internal volume of the

mask that the diver is breathing through. Carbon

dioxide (CO2) can build up if proper flushing does

not occur. A rubber oral nasal mask (9) is located

inside the mask to fit over the diver’s nose and

mouth. The oral nasal (9) attaches to the regulator

mount nut (8). This separates the breathing gas

flow from the larger gas space on the interior of

the mask, and this in turn reduces carbon dioxide

buildup.

WARNING: Always be sure the oral/

nasal valve is properly mounted in the

oral nasal mask. If the valve is mounted

improperly or absent this can lead to a

higher CO2 level inside the mask. A higher

CO2 level can cause dizziness, nausea,

headaches, shortness of breath, or blackout. This can also increase the probability

of decompression sickness. The correct

flow of gas is from the mask into the oral

nasal.

DANGER: Do not confuse the oral/

nasal valve with the main exhaust valve.

They are not the same thickness. The

main exhaust valve is much thicker. Using the main exhaust valve in the oral

nasal valve body will restrict the air flow

to the diver. Using the oral nasal valve in

the main exhaust could cause water to

leak into the mask.

1.5.4 Main Exhaust System

The main exhaust system (64,65,66,67) is located

at the bottom of the mask frame (17). Breathing

gas exiting through this valve automatically purges

water from the interior of the mask. This happens

naturally because the valve (66) is the lowest part

of the mask during normal working or swimming

conditions. The cover (65) may be removed by

unscrewing the two screws (64) . Removal of the

cover (65) permits access to the rubber mushroom valve (66). The main exhaust body (67) on

the KMB 18 is held in place by three screws (69).

(Note: The main exhaust body is molded directly

into the mask frame on the KMB 28.)

The rubber mushroom valve (66) is designed to

present a resistance to the flow of exhaust gasses.

This is necessary to prevent the demand regulator

(63a/b) from turning on a steady flow when the

diaphragm (52) is positioned lower than the main

exhaust (66) during a dive. The diver does not

encounter this resistance as he exhausts out of the

regulator exhaust.

page 14

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

KMB 18 & 28 MANUAL

1.5.5 Communications

The Kirby Morgan Band Mask (KMB 18A/B and

28) communications system is very simple. For

two wire (push to talk) communications systems,

the left earphone (11) with the longer wire, and

the right earphone (10) with the shorter wire, are

wired in parallel with the microphone (12) to the

communications posts (73). These posts (73) are

also known as “bare wire” connectors. The wire

that is part of the umbilical bundle is connected to

these connectors.

The KMB 18A/B & 28 may also be fitted with a

waterproof connector (80). This system comes

standard with a terminal block (82) that is used

with four wire communications, also known as

“round-robin” systems. The terminal block can

also be wired for two wire systems if preferred.

Electrical signals are sent to, and received from,

the surface through the umbilical wires. An amplifier boosts the signals to the desired volume for

the surface and the diver. The diver is always

“on” in a two wire system, except when the

tender pushes a switch to talk to the diver. In a

four wire system, both top side and the diver can

speak at the same time, just as you would on a

telephone.

1.5.7 Hood and Face Seal Retainer Bands

(15, 16, 68)

The top band (16) and the bottom band (68) fit

around the hood and face seal combination (2)

and clamp it firmly to the mask frame (17). Two

screws (15) hold these bands in place. Five spider

“hooks” consisting of stainless steel posts welded

to the retainer bands (16,68) are located on the top

and bottom bands. The top band (16) has three

stainless steel posts. The bottom band (68) has

two stainless steel posts.

DANGER: The bands must be tightened properly or the mask frame may

separate from the hood and face seal. If

this happens the diver can drown and

death may result.

1.5.8 Head Harness or “Spider”

The five legged head harness or “spider” (1) is a

simple and convenient method of keeping the

mask in place against the diver’s face. The multiple holes punched in each leg allow adjustment

to fit any size head. It will be more comfortable if

the lower rear or neck area is as low as possible on

the diver’s neck. If this lower portion of the spider

(1) is too high, it will cause the face seal to push

up on the chin causing discomfort.

1.5.6 Hood and Face Seal

The hood and face seal (2) is fabricated from

foam neoprene and open cell foam. The open cell

foam forms a comfortable cushion that pushes the

sealing surface of the foam neoprene against the

diver’s face.

1.6 IMPORTANCE OF PROPER

MAINTENANCE

Although the Kirby Morgan Band Mask KMB

18A/B is a rugged piece of equipment, proper

care and maintenance is essential. The demand

breathing system is simple in design but subject

to malfunction if not properly maintained. Nor-

The hood incorporates built-in pockets that are

open to the interior of the mask frame (17). These

pockets retain the earphones (10,11). It is very

mal wear requires periodic internal adjustment to

the regulator. This will assure the diver of easy

breathing.

easy to remove the earphones for maintenance.

1.6.1 Special Tools

If the standard hood does not fit your head comfortably, other sizes are available from your

KMDSI dealer.

A Regulator Adjustment Tool Kit (KMDSI Part

#525-620) containing four special adjustment

tools is available for internal adjustment of the

demand regulator assembly (63a/b). These tools

make regulator adjustment much easier. The tool

kit comes in a convenient, wallet sized pouch

with instructions.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 15

KMB 18 & 28 MANUAL

DANGER: Without correct, regular

maintenance, your mask will not function

properly. A poorly functioning mask can

cause a fatal accident.

WARNING: When purchasing

spare parts, always insist on Kirby Morgan Genuine Parts. Although other parts

may look the same, they may not be

manufactured to the same standards of

quality. Improperly manufactured parts

can cause accidents.

page 16

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

CHAPTER 2

OPERATING INSTRUCTIONS

2.1 INTRODUCTION

This section provides the manufacturer’s advice

on how to use the Kirby Morgan 18A/B and 28

Band Masks. The use of these diving Band Masks

will vary with the type of work and environmental conditions.

DANGER: The basic procedures of

donning and removing the Kirby Morgan

18A/B or 28 will be similar for every job. A

proper training program in a calm, clear

body of water must be undertaken. If the

diver has not used the Kirby Morgan 18A/

B or KMB 28 before, he must not go on a

job without proper training. Death could

result due to a lack of familiarity with the

mask.

KMB 18 & 28 MANUAL

Be sure to complete the enclosed warranty card

and return it to KMDSI immediately. No warranty claims will be honored without a satisfactorily completed warranty card on file at KMDSI.

The card enables KMDSI to know what unit you

have so we can contact you in the event of a safety

notice being issued for this product. It is your

responsibility to keep the factory notified of any

change of address you may experience.

CAUTION: It is the responsibility

of the end user to register their ownership

of this mask with Kirby Morgan. If the

mask is not registered KMDSI has no way

to contact you regarding product upgrades.

Divers that are familiar and trained in the use of

WARRANTY INFORMATION

previous mask designs of Kirby and Morgan

(Models 8, 9, 10, the Navy MK. 1, the SuperLite17A/B, or the SuperLite-27) will find the Kirby

Morgan 18A/B and 28 to have the breathing

system controls located in the same position and

the operation of the Band Mask will be similar.

Kirby Morgan Dive Systems, Inc. warrants every

new mask, helmet, or Dive Control System (DCS),

to be free of defects in workmanship for a period

of ninety (90) days from date of purchase. This

warranty covers all metal, fiberglass, and plastic

parts. This warranty does not cover rubber parts,

communications components, or Band Mask

The numbers appearing in parentheses are “loca-

hoods.

tion” numbers on the parts list, which appear on

the “blowapart” illustration at the end of this

manual. You should fold out the blowapart illustration to view while you read this section.

Should any part become defective, contact your

nearest authorized KMDSI dealer for a replacement.

This warranty becomes null and void if:

2.1.1 First Use of Kirby Morgan 18A/B & 28

1) The product is not registered with KMDSI

within ten (10) days of purchase.

When you first receive your Kirby Morgan KMB

18A/B or KMB 28, carefully unpack it and examine it for any damage that may have occurred

during shipment. Use the inspection sheet provided to ensure that no damage has occurred

during shipment. The purchaser must contact the

freight carrier and/or the KMDSI dealer if the

2) The product has not been properly serviced and

maintained according to the appropriate KMDSI

manual.

3) Unauthorized modifications have been made

4) The product has been abused or subjected to

conditions which are outside normal diving conditions or exceed the product’s intended service.

Band Mask has been damaged in shipment.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 17

KMB 18 & 28 MANUAL

2.2 PRE DRESS-IN PROCEDURE

Before dressing in for a dive, inspection of the

Band Mask system must be made to be sure it is

in proper working order. This must be done well

in advance of the dive, so any problems can be

fixed without delaying the dive. The following

steps are part of the recommended daily maintenance which is also in Section 4.1.

DANGER: All parts on the Kirby

Morgan 18A/B must be adjusted to their

proper torque specifications. See Appendix 1 for a complete listing of torque

specifications for each part. Failure to

adjust parts to the recommended specifications could lead to Band Mask failure

and accidents. This could be fatal.

2.2.1 Pre-Dive Inspection

Inspect the exterior and interior of the Band

Mask.

1) The demand regulator cover assembly (51)

must not be dented.

2) Inspect the regulator hose assembly (117a) on

the “A” model, and the bent tube assembly (117b)

on the “B” model. There must be no dents or kinks

in the bent tube assembly. The hose assembly

must be in good shape.

3) Inspect the face port (27). It must be in good

condition.

4) Check the inside of the Band Mask. Be sure the

communications wires are hooked up and there

are no loose nuts. Check the wire lugs to make

sure they are not touching each other. This would

cause a short (no communications).

5) Inspect the oral nasal mask (9). Make sure it is

on the regulator mount nut (8) properly.

6) Check the screws (29) on the port retainer (28).

They must be adjusted to the proper torque setting

(12 inch pounds (13 kg cm)) per the specifications in Appendix 1 of this manual. Binder head

screws are used in this application for their self

locking characteristics. Overtightening will strip

out the threaded inserts in the Band Mask frame

(17).

page 18

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

DANGER: Never use RTV to glue

on the port retainer or to hold the threaded

inserts in the mask if they are loose. If the

RTV fails it could cause the mask to flood

and lead to drowning. This can be fatal.

7) Check the spider (1) to ensure there are no tears

or cracks in the material. If the spider is worn or

cracked it must be replaced. All five “legs” of the

spider must be present.

DANGER: The spider must be in

good condition. If it is worn or cracked it

could fail during the dive. This could cause

the mask to flood or come off the diver’s

head. This could lead to drowning.

8) Check the hood and face seal (2). The hood

must be in good condition with no tears or rips.

The face seal must be properly glued to the hood.

If it is not, or there are tears in the face seal this

will cause the regulator to free flow.

CAUTION: A torn face seal will

cause the regulator to free flow. This could

lead to a rapid consumption of the diver’s

air supply if bottled breathing gas is being used.

9) Check the screws (15) that hold the bands (16

& 68) in position. They must be adjusted to the

proper torque setting (see torque specs pg. 89)

When the screw are adjusted properly, the hood

and face seal cannot be moved from under the

bands.

10) Be sure to inspect the bands themselves (16 &

68). The welds must show no signs of cracking or

parting.

DANGER: If the bands become

loose the hood and face seal could separate from the mask. This would cause the

mask to flood which could cause drowning.

2.2.2 Clean Face Port (27)

Remove any sand or dirt on the interior of the face

port (27) which might cause scratches when antifogging solution is applied prior to the next dive.

KMB 18 & 28 MANUAL

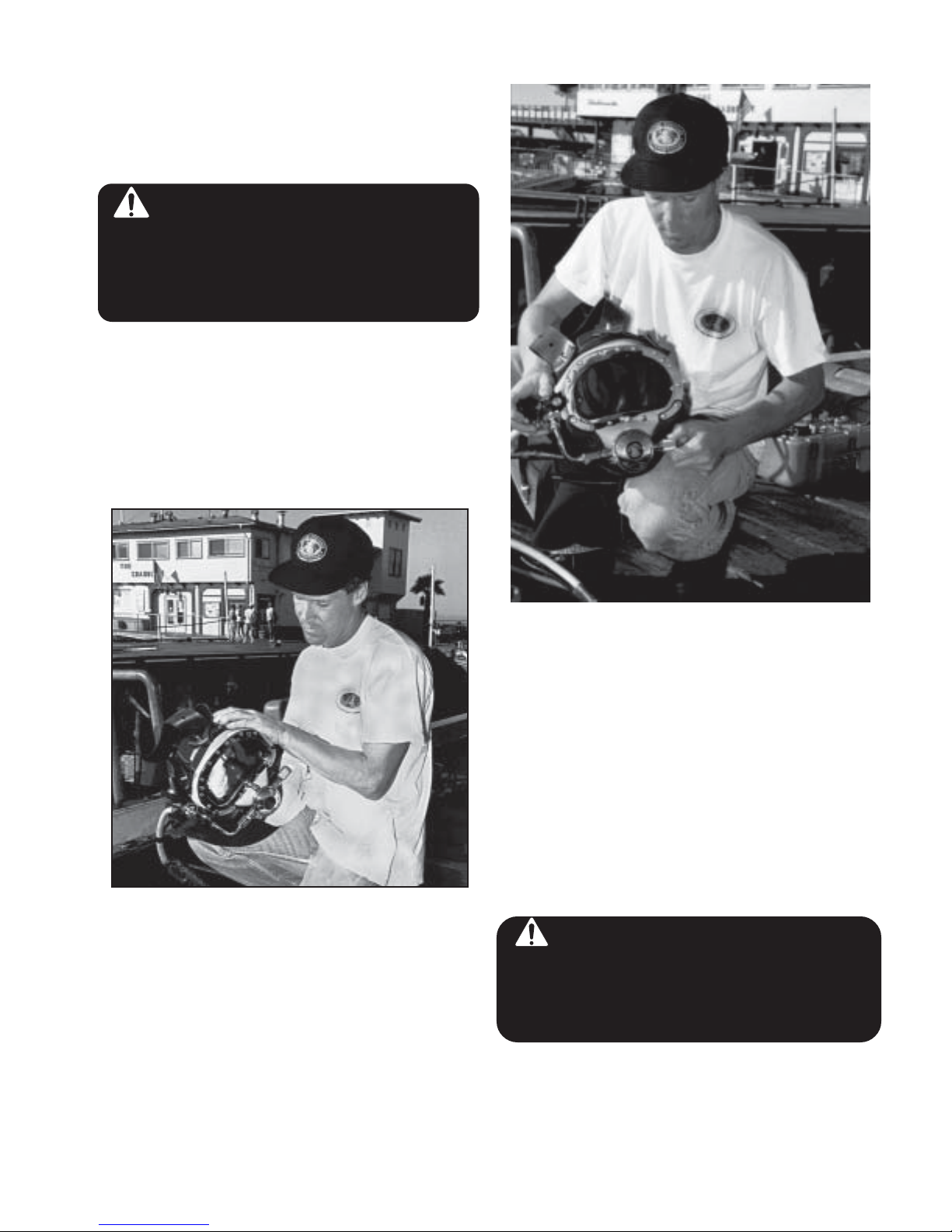

Fig. 2.1 Clean the face port prior to use.

2.2.3 Check Moving Parts

Check all moving parts, such as the regulator

adjustment knob (47), the defogger control knob

(85), auxiliary knob (100), and the nose block

device knob (34) to ensure smooth and proper

operation.

Fig.2.2 Moving parts, such as the regulator adjustment

knob must be checked before the Band Mask is put on

line.

2.2.4 One-Way Valve (104) Check

There are two ways to check the one-way valve

(104). Check both ways if possible.

1) Leaving the auxiliary knob (100) open (on) and

not hooked up to the supply hose, try to suck air

out of the adapter (105). If any air comes out, the

one-way valve must be replaced.

WARNING: The one way valve must

be tested dailly, prior to commencement

of diving operations. Failure of the one

way valve could cause serious injury or

death.

Document # 010518001 © Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved.

page 19

KMB 18 & 28 MANUAL

2) Prior to attaching (or pressuring up) the umbilical, close the auxiliary valve (103), and attach and

pressure up the auxiliary hose. Shut off the defogger control knob (85) and screw in the adjustment

knob (47) on the regulator all the way. With the

auxiliary hose pressurized, turn on the auxiliary

valve knob (100). If any gas escapes out the

adapter (105) or (if attached) into the unpressurized umbilical hose, the one-way valve (104) is

faulty and must be replaced. Flow into the unpressurized umbilical hose can be heard. A

one-way valve repair kit is available for rebuilding these valves (KMDSI Part # 525-330). Contact KMDSI at (805) 865-8538 if you have any

questions regarding rebuilding your one-way

valve.

2.2.5 Connecting the Band Mask to the Diver’s

Umbilical

When you connect the hose to the Band Mask, be

sure to use a wrench to hold the adapter, or inlet

fitting, (105), and a second wrench to turn the

fitting on the hose. If this is not done, the adapter

(105) will turn inside the one-way valve (104). If

this happens repeatedly the threads will wear and

the valve will need to be replaced. The connection between the hose and the Band Mask must

only be made up “snug”. Excessive force will

deform and ruin the adapter (105). A second

wrench must be used when the Band Mask is

disconnected as well, otherwise the adapter (105)

and/or the one-way valve assembly (104) may

become loose and fail to make a seal. If this

happens it is necessary to remove the adapter,

clean off all the thread tape, and reseal it using

Teflon tape.

Fig. 2.3 Always check the one-way valve prior to diving.

WARNING: Never dive if the oneway valve is not operating properly. If the

hose breaks near the surface a serious

injury could result to the diver’s lungs

and/or eyes. In extreme cases this could

be fatal.

page 20

© Copyright 1970-2003 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 010518001

Fig. 2.4 Always use two wrenches to connect the umbilical

to the KMB 18A/B or 28.

Loading...

Loading...