Kirby Morgan 77 User Manual

Kirby Morgan 77

WARNING

WARNING

Chapter 3.0

Operating Instructions

This manual is our effort to explain the operation, maintenance and use of the Kirby Morgan helmet. We do not herein make any effort to teach the principles of diving. It is our assumption the

reader is a qualified diver. We highly recommend that all divers should train, under controlled

conditions, in the use of any model of commercial diving helmet that they have not previously

used or trained in, prior to use on the job.

3.1 Introduction

This section provides advice on how to use your Kirby

Morgan helmet. The use of these diving helmets will

vary with the type of work and environmental conditions. The basic procedures of donning and removing

these helmets will be similar for every job.

A proper training program in a calm, clear body of

water should be undertaken. If the diver has not used

a particular Kirby Morgan helmet before, he must not

dive with the helmet without proper training.

However, divers that are familiar and trained in the

use of previous Kirby Morgan masks; i.e., KMB 8,

9, 10, 18, 28, the Navy MK. 1 Mask, Navy MK. 21

helmet, or the Navy MK. 22 mask or the SuperLite

helmets, will find that all Kirby Morgan diving helmets and masks have the breathing system controls

located in the same position. The operation of this

helmet will also be similar. The diver must be tended

at the surface at all times by a trained, qualified commercial diving tender.

The umbilical is the diver’s lifeline to the diving

control station.

Kirby Morgan diving helmets are not intended for use with a self contained gas

supply (scuba). There is no provision

for surface swimming once the scuba

air supply is depleted. This could lead

to suffocation or drowning, which could

be fatal.

3.2 Design Purpose

All Kirby Morgan diving helmets are designed for

use with an umbilical.

The umbilical is usually composed of at least a gas or

air supply hose and communication wire, assembled

with waterproof tape (and in some umbilicals wound

similar to strands in a rope) to form a single unit.

Some umbilicals also include a hose for hot water, a

pneumofathometer hose, and a strength member, such

as a cable or strong line.

It is strongly recommended that the air/gas umbilical

be married to a strength member in a manner that

allows the strength member to receive the strain.

This will help reduce the possibility of umbilical and

umbilical fitting fatigue and possible failure.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

The diver must be tended at the surface at all times by a

trained, qualified commercial diving tender.

41

Kirby Morgan 77

WARNING

WARNING

The diver must be tended at the surface at all times

by a trained, qualified commercial diving tender.

Never dive without a qualified tender holding your

diving hose.

The diving control station can be at the surface, in

a diving bell, or in a submerged habitat. The diving

control station is the center of the air/gas supply, communications with the diver, and diving procedures.

The station can be as simple as a tender with a set of

“phones” (communication amplifier), or as complex

as a control van in the midst of a saturation system.

All diving always involves the risk of

decompression sickness. Omitted decompression due to loss of gas supply or

other accidents can cause serious injury

or death. The use of the Kirby Morgan

helmets or masks cannot prevent this

type of injury.

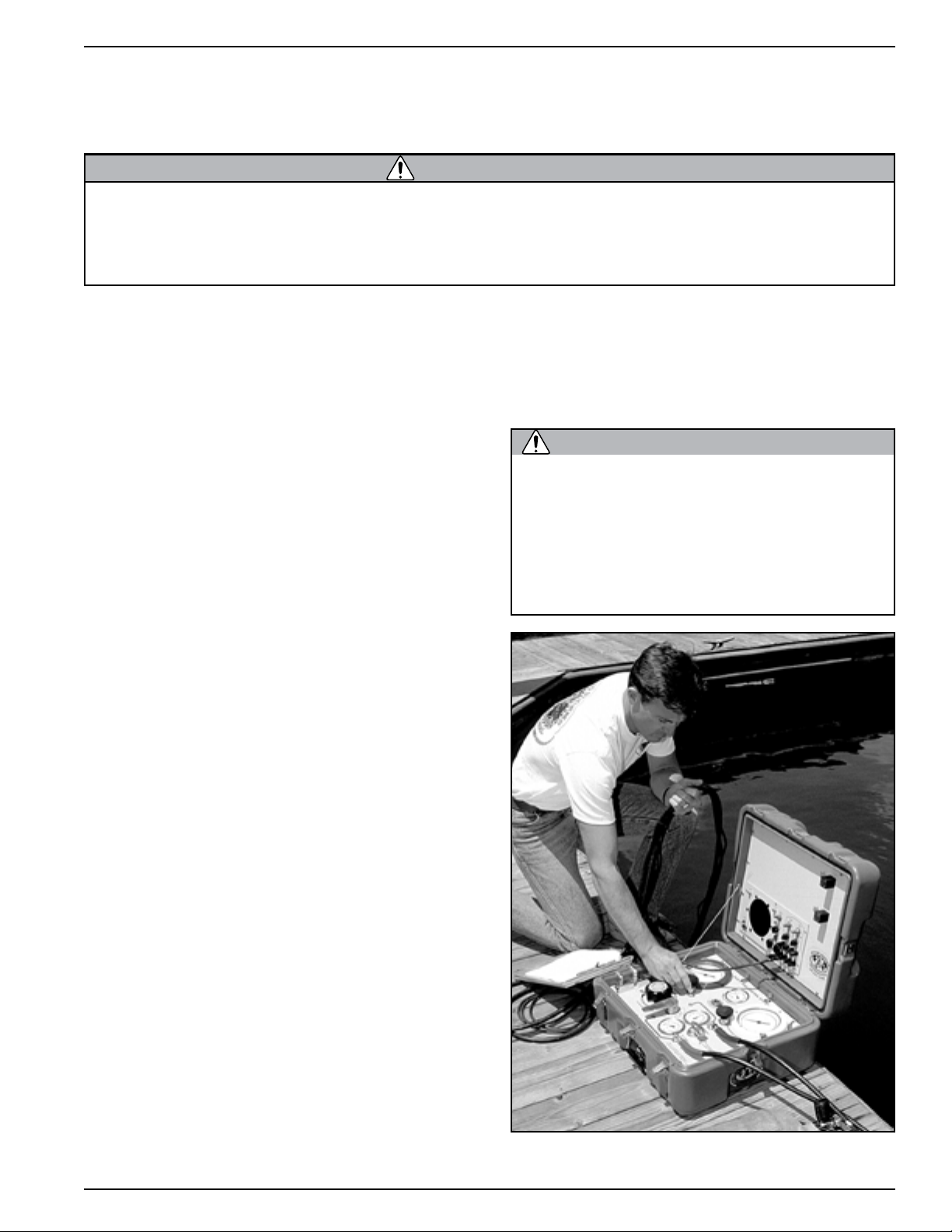

KMDSI manufactures a complete Air Control System,

the KMACS 5™ with integrated communications

and pneumofathometer. This portable system can be

operated on either a high pressure air supply or on a

low pressure compr essor. The Ai r Control System ha s

a specially designed high pressure regulator that reduces high pressure air and provides an adequate flow

to support divers to a depth of 130 fsw (40 msw)

The helmet demand regulator and side block assemblies have been designed to operate with a supply

pressure from 130 p.s.i.g. (8.8 bar) to 225 p.s.i.g.

(16 bar) over ambient pressure. This wide operating

range allows flexibility when using various gas supply systems.

For maximum breathing performance it is desirable

to maintain an over bottom supply pressure in accordance with the low-pressure and high-pressure

supply tables found in Chapter 2 of this manual. With

the many different gas supply console configurations

in use, it is important to ensure that the gas supply

system used, is capable of supplying the helmet with

the necessary pressure and flow of gas to allow the

diver to work safely and efficiently.

There are also detailed checklists for the set-up and

maintenance of your helmet on the Dive Lab web site

at www.divelab.com.

3.3 First Use of Your Kirby Morgan

Diving Helmet

When you first receive your Kirby Morgan diving

helmet, carefully unpack it and examine it for any

damage that may have occurred during shipment.

Use the inspection sheet provided to ensure that no

damage has occurred. The purchaser must contact

the freight carrier and/or the KMDSI dealer if the

helmet has been damaged in shipment.

Early production of the REX 77 helmet had a much

different surface finish than what is found on current

production runs.

Earlier helmets shells and components were finished

using a combination of glass and Stainless Steel

beads; this gave a dull or flat looking surface finish.

Later shipments have a surface finish with a much

smoother and almost shiny appearance. Although the

parts are not shiny, the surface finish is very smooth.

A Scotch-Brite

pad will remove buildup of unwanted surface deposits on both older, and newer REX 77 helmets. It can

also be used to give the main helmet components on

newer helmets, a satin (brushed ) finish.

®

, (or similar non metallic), scouring

High pressure supply regulators and associated piping systems for surface supplied diving with Kirby Morgan helmets

and masks must be capable of delivering

a minimum of 3.2 acfm to the diver at

depth. Only systems that can deliver the

required gas flow should be used.

42

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

Be sure to complete the enclosed warranty card

and return it to KMDSI immediately. No warranty

claims will be honored without a correctly completed warranty card on file at KMDSI.

WARNING

3.4 Initial Adjustments to

WARNING

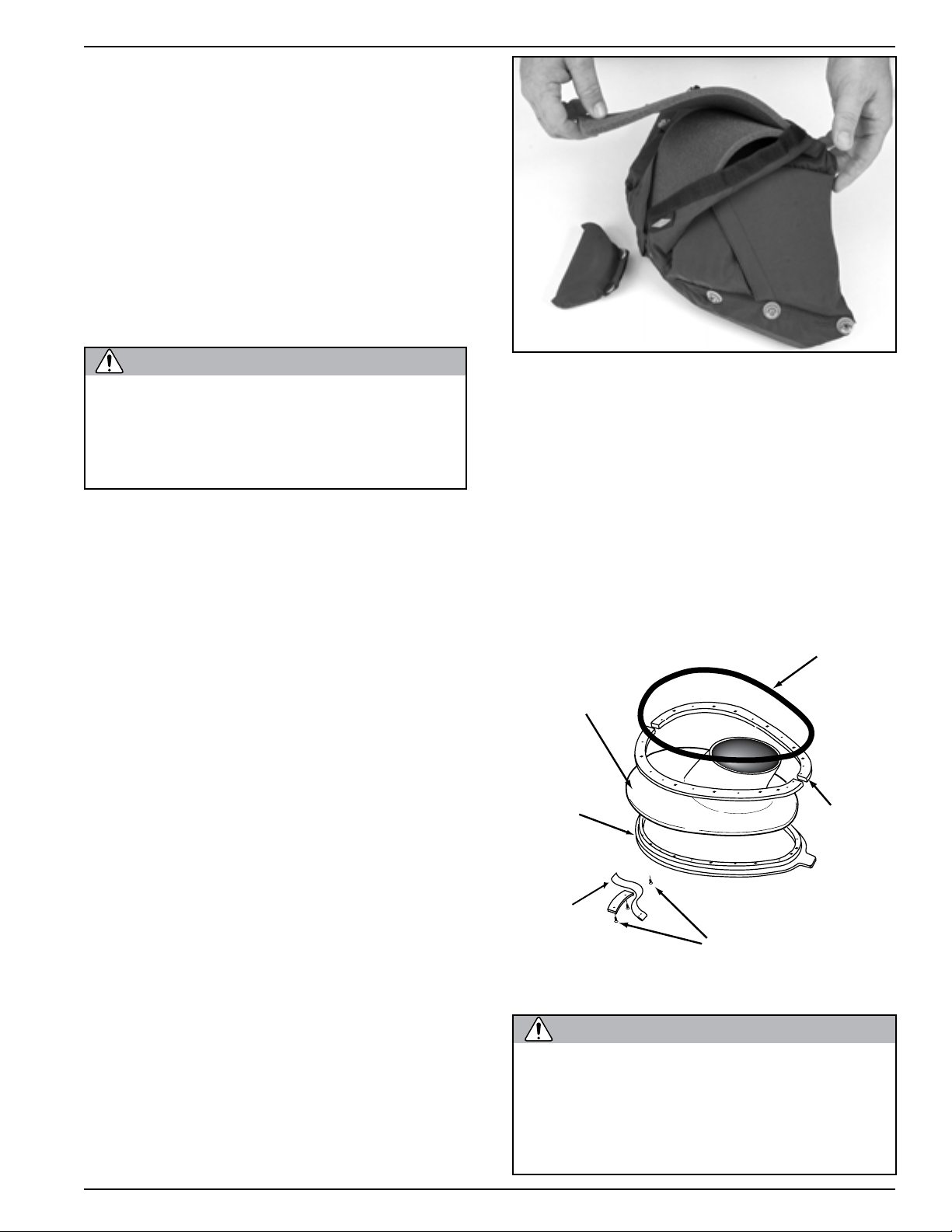

O-ring

Split

Ring

Neck

dam

Stepped

Ring

Pull

Strap

Screw

Your Helmet

Before using the helmet for the first time, it must be

checked and adjusted for proper fit. There are several

adjustments that must be made to provide a more

comfortable fit when wearing the helmet.

3.4.1 Head Cushion

The fit of the helmet is primarily determined by the

layers of open cell foam that fill the head cushion

bag.

The center top/rear foam is very dense to reduce

KMDSI must have your current address to

ensure that you receive all safety notices

and other important information concerning the helmet. Please notify KMDSI of

any change of address.

compression and spring-back. This reduces the tendency of the helmet to ride up when underwater. Do

not replace this rigid foam with a soft foam. A softer

foam is used on the sides and around the bottom of

the head cushion.

Kirby Morgan 77

The head cushion should be adjusted for best fit.

dam opening so that the two “edges” of the neck

dam are parallel. The neck dam must be under slight

tension but must not be stretched beyond its normal

length. Trim the neck dam with the largest, sharpest

scissors available, in order to make as few cuts as

possible. There must be no jagged edges on the neck

dam or it may tear.

Trim only 1/4 inch off the neck dam at a time. When

you are done, the neck dam must be just tight enough

The diver’s head can be moved forward into the oral

nasal mask by adding layers of additional foam at the

rear of the head cushion. Do not add to much foam to

the rear of the head cushion, as this may position the

diver’s chin too far into the oral/nasal mask and create

an uncomfortable fit. The diver’s head can be moved

up or down in the helmet by decreasing or increasing

the foam pads at the top of the head cushion.

Usually, a diver with a small head will use all the foam

that comes with a new hat. A diver with a larger head

will need to remove a layer of foam in the center top

and back of the head cushion. The foam may be cut

with scissors to provide a better fit, or more foam can

be added to give a tighter fit.

The chin cushion can also be adjusted if necessary.

3.4.2 Trimming the Neck Dam

If your helmet is new, or any time you replace the

neck dam, it must be adjusted to fit you. New neck

dams are cone shaped and will probably be too tight

if not properly trimmed.

The neck dam must be trimmed to fit your neck. To

trim the neck dam, have your tender hold the neck

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

Neck Dam components.

Never dive with a neck dam that is too

tight. A neck dam that is too tight could

cause the diver to pass out due to pressure on the carotid artery in the neck.

This could lead to severe personal injury

or death.

43

Kirby Morgan 77

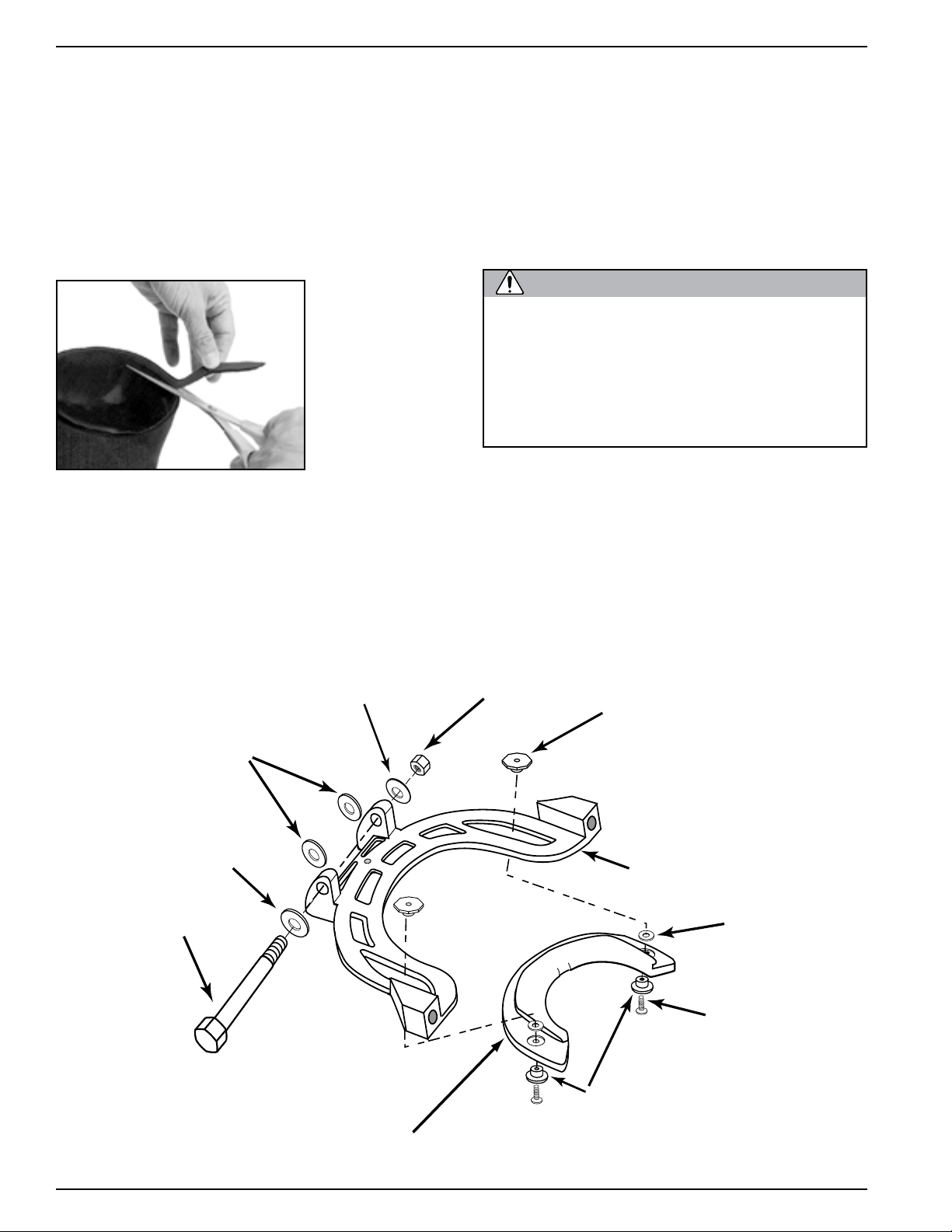

CAUTION

Hinge bolt

Nut

Locking collar

Neck pad

Adjustment nut

Washer

Screw

Washer

T-washer

Teflon

Washer

Washer

so that it does not leak. This may feel a bit snug out of

the water, but should be comfortable underwater.

If you have a neoprene neck dam, it may also need to

be stretched for it to fit properly. Trim the neck dam

until it is still snug, then stretch it by sliding it over

a scuba tank and allowing it to sit overnight. If you

still cannot get the proper fit by stretching the neck

dam, it must be trimmed further. Do not trim more

than 1/4 inch at a time.

Trimming the

neck dam.

As the neoprene

neck dam ages, it will become looser, due to a natural

breakdown of the cells. This is particularly true if

the helmet is locked in and out of a bell or saturation

system. As the neck dam becomes worn it will need

replacement to ensure that it seals properly.

3.4.3 Adjusting the Neck Pad

Another component that controls the fit of the Kirby

Morgan helmet is the adjustable neck pad. The neck

pad, which is mounted on the locking collar, slides

back and forth along the locking collar body for

adjustment to fit different divers. Two screws and

adjustment nuts lock the neck pad plate to the locking

collar. Loosening these screws from the mount nuts

allows the neck pad to be adjusted.

Avoid trimming neoprene neck dams too

much. Neoprene neck dams will loosen

over time as they are used and the cells of

the foam neoprene break down. If you trim

the neck dam too much it will be too loose

and will leak. Trim the neck dam until it is

snug, then stretch it before use.

The following procedure requires a diver and tender.

You do not need to have the air on to the helmet if

you do not use the neck dam ring assembly. If the

neck dam assembly is used, the diver must have air

to the helmet to breathe.

With the helmet face down on a suitable surface, pull

and turn each of the sealed pull pins until they are

locked open. Swing the locking collar/neck pad as-

Locking Collar components.

44

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

Kirby Morgan 77

WARNING

WARNING

sembly out away from the base of the helmet. Slightly

loosen the screws until the neck pad can slide back

and forth. Be sure each of the head cushion snaps

are attached to their corresponding fitting inside the

helmet.

Pick up the helmet and pull the nose block device

knob out fully. Position the helmet on your head so

the oral nasal is in the proper position on your face,

covering your nose and mouth. Turn the sealed pull

pins to the locking position with the ridge on the pins

engaging the notch in the sleeve and the pins fully

retracted.

Tilt your head forward so the lock i ng colla r/neck pad

assembly may be swung forward and locked up into

its closed position. The sealed pull pins must snap

into place on the locking collar.

Lift your head back up and slide the neck pad forward

until it is snug but comfortable. Mark the position of

the neck pad on the locking collar using an indelible

marker. Pull the sealed pull pins out to their unlocked

position and let the locking collar open.

3.5.1 Pre-Dive Visual Inspection

Visually inspect the exterior and interior of the helmet.

1) Inspect the regulator cover for any damage. The

purge button must work.

2) The neck dam must not be torn or punctured, and

properly trimmed to fit.

There must be no holes in the neck dam.

If there are any holes in the neck dam the

helmet could leak or flood. In addition,

the demand regulator will not operate

properly. Drowning could result.

3) Inspect the O-ring on the neck dam ring assembly. The O-ring must be in place, undamaged, and

lubricated.

Remove the helmet. Position the neck pad plate on the

locking collar at the marked position and tighten the

screws on each side. After the adjustment screws are

tightened, don the helmet again, tilt your head forward

and lock the locking collar/neck pad assembly. Move

your head in various positions to make sure the pad

is adjusted for comfort.

The helmet is now adjusted for your head. It should

need no further adjustment unless another diver uses

the helmet.

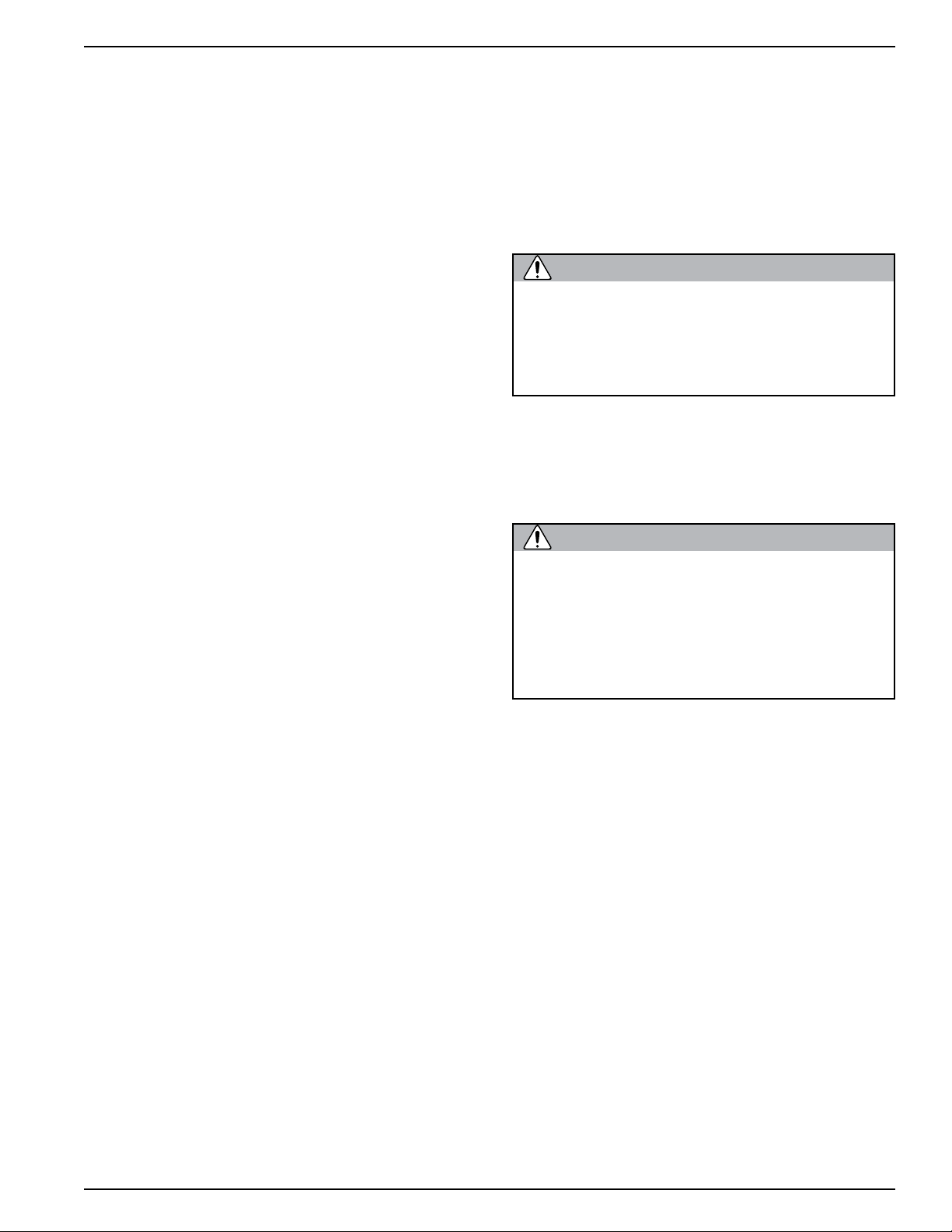

3.5 Pre Dress-In Procedure

Before dressing in for a dive, inspection of the helmet

systems must be made to be sure it is in proper working order. This must be done well in advance of the

dive so any problems can be fixed without delaying

the dive. The following steps are part of the recommended daily maintenance.

The O-ring on the neck dam ring assembly on the Kirby Morgan helmet must be

in place and in good condition. It must

be properly lubricated for smooth operation. Without a proper functioning O-ring

the helmet will leak and possibly flood.

Drowning could result.

4) Inspect the bent tube that supplies breathing gas

to the regulator. There must be no dents or kinks in

the assembly.

5) Inspect the face port. It must be in good condition.

6) Be sure the communications wires are hooked up

and tested.

7) Inspect the oral/nasal mask. Make sure it is on

the regulator mount nut properly and the valve is

installed properly.

8) Inspect the sealed pull pin on each side of the helmet. They must engage and disengage properly.

9) Make sure the head cushion and chin cushion are

properly fastened inside the helmet. The chin strap

should be open as wide as possible.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

45

Kirby Morgan 77

WARNING

10) Check the screws on the port retainer . They must

be adjusted to the proper torque setting specifications

noted in Appendix 1 of this manual. Binder head

screws are used in this application for their self locking characteristics.

All parts on Kirby Morgan diving helmets

must be adjusted to their proper torque

specifications. See Appendix 1 for a

complete listing of torque specifications

for each part. Failure to adjust parts to

the recommended specifications could

lead to helmet failure and accidents. This

could be fatal.

3.6 Preparing the Helmet for Diving

3.6.1 Clean Face Port

Thoroughly clean the face port with a soft cloth and

a mild liquid soap solution. DO NOT USE ANY

AEROSOL SPRAYS ON THE POLYCARBONATE

PORT!

3.6.2 Check Moving Parts

Check all moving parts, such as the regulator adjustment knob, the defogger control knob, emergency

(EGS) knob, and the nose block device knob and

all locking collar parts to ensure smooth and proper

operation.

3.6.3 Check Communications

Check the communications system for proper operation. Put the helmet on and talk to an assistant on the

amplifier. If you are by yourself, with the helmet off

take the helmet near the amplifier and tap on each

earphone and the microphone, listening to the taps

on the amplifier/speaker. Talk into the amplifier/

speaker feeling the vibration on each earphone and

the microphone with your fingertips. Check the fit

and tightness of the comm module mount nut.

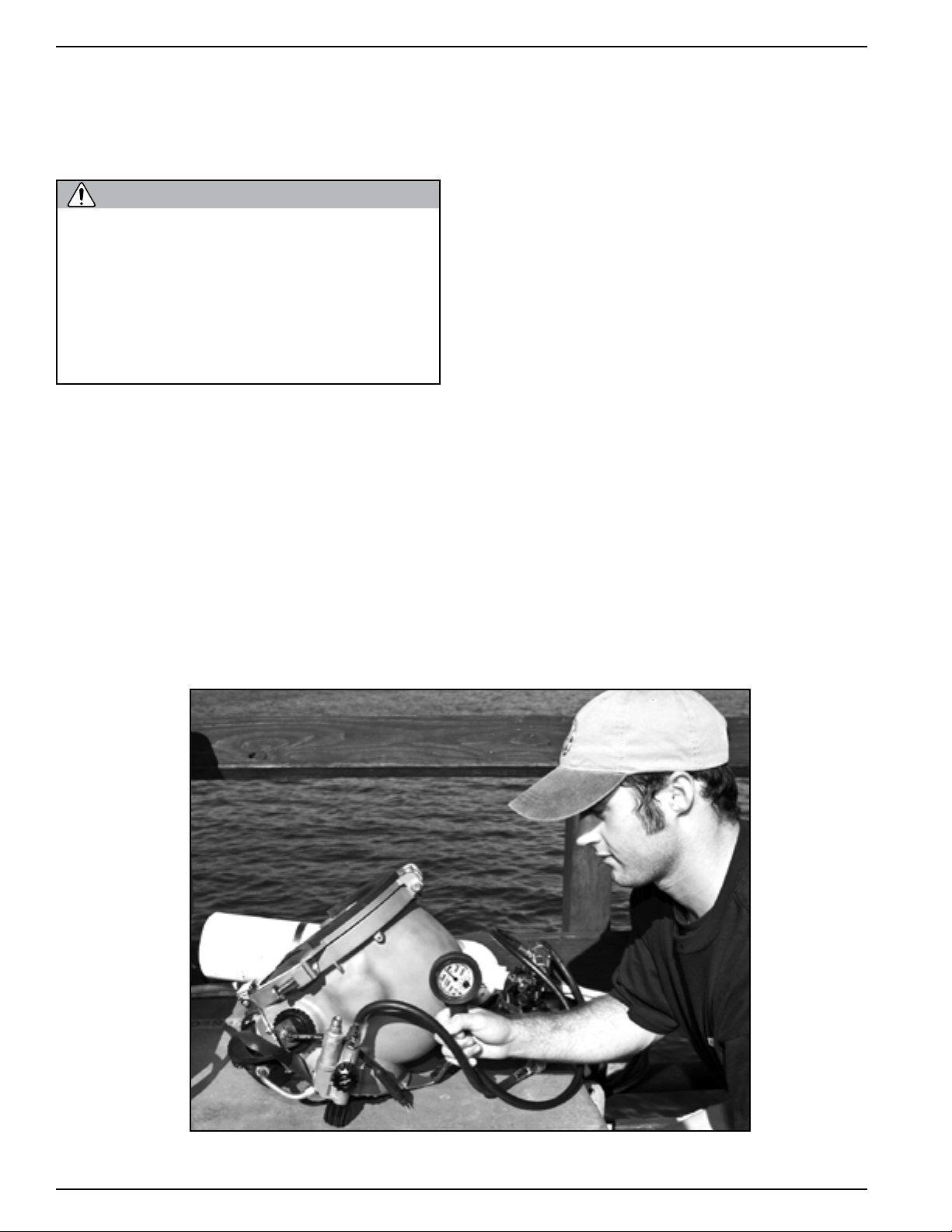

3.6.4 One Way Valve Check

The one way valve must be tested daily, prior to

commencement of diving operations.

1) Prior to attaching (or pressuring up) the umbilical,

close the emergency valve knob, attach and pressure

up the emergency hose. Shut off the defogger control

knob and screw in the adjustment knob on the regulator all the way.

2) With the emergency hose pressurized, turn on the

emergency valve knob. If any gas escapes out the end

of the adapter, the one way valve is faulty and must

be rebuilt or replaced. A one way valve repair kit is

available to rebuild these valves (Part # 525-330).

You can test the one way valve by connecting the bailout bottle to the emergency valve and pressurizing the

sideblock. There must be no gas leakage through the one way valve.

46

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

WARNING

WARNING

The one way valve must be tested daily,

WARNING

prior to commencement of diving operations. Failure of the one way valve could

cause serious injury or death.

Kirby Morgan 77

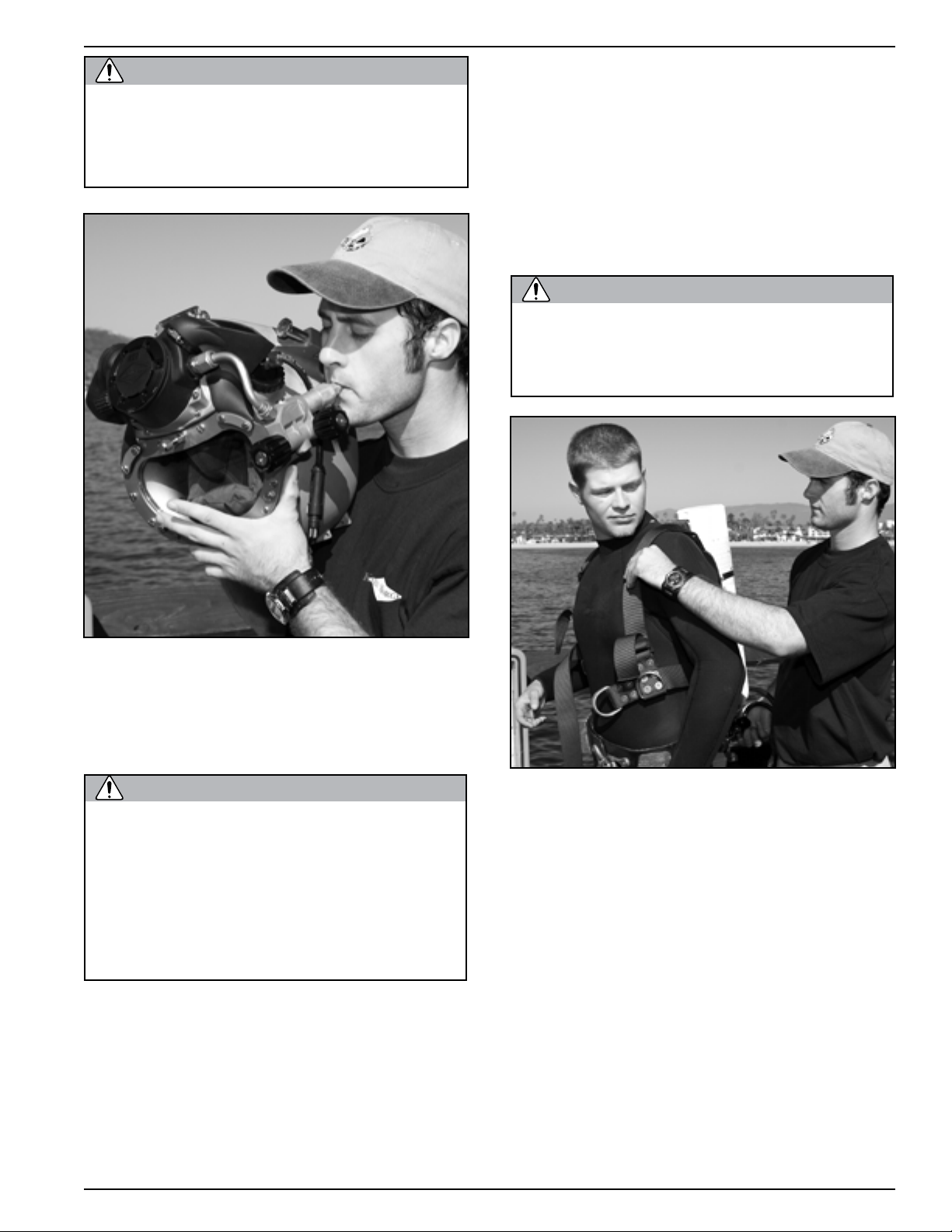

3.7 Emergency Gas System (EGS)

If the diver’s main gas supply fails, the diver must

have another source of gas that will enable him to

return to the dive station or to a point where a normal gas supply can be reestablished. For this reason,

an emergency gas supply (bailout) cylinder must be

used on all dives. The bailout cylinder is normally

worn on the back using a combination backpack and

lifting harness.

Do not dive without a diver worn Emergency Gas System. If the main gas supply

is lost, you will have nothing to breathe

and may drown.

You can also test the one way valve by attempting

to suck air through the valve. The emergency valve

must be open for this test to work properly. If you

are able to suck any air through the valve it is not

working properly.

Never dive if the one way valve is not operating properly. If the hose or breathing

gas/air fitting breaks near the surface a

serious injury could result to the diver’s

lungs and/or eyes. In extreme cases this

could be fatal. The one way valve must be

tested daily prior to the commencement

of diving operations.

Diver donning a complete bail-out system.

Most commercial divers wear a harness (separate

from the weight belt) that is used for several purposes. The harness is fitted with large metal rings

(usually brass or stainless steel). The umbilical is

hooked into one of these rings to keep any strain off

the helmet. In addition, the rings on the harness are

used to hang tools and other equipment. Usually the

harness is also designed to provide a means of lifting

an unconscious diver from the water. This harness is

the best method of securing the emergency breathing

gas to the diver.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #080626002

47

Loading...

Loading...