Kirby Morgan 37, 57 Operation And Maintenance Manual

WARNING

Kirby Morgan® 37 & 57 Helmets

Operations and Maintenance Manual

KMDSI Part # 100-073

The KM37 helmet is covered by U.S. Patent #6,644, 307B2. Foreign and other patents pending.

™

Kirby Morgan Dive Systems, Inc.

1430 Jason Way

Santa Maria, CA 93455, USA

Telephone (805) 928-7772, FAX (805) 928-0342

E-Mail: KMDSI@KirbyMorgan.com, Web Site: www.KirbyMorgan.com

Manual prepared by KMDSI, Dive Lab, Inc. and Marine Marketing and Consulting.

NOTE: This manual is the most current for the Kirby Morgan 37 and 57 Helmet. It is page dated January 2013. Future changes will be shown on page IV and the changed pages will carry the date of change. Previous manuals may

not reect these updates.

Diving with compressed breathing gas is a hazardous activity. Even if you do everything

right there is always the danger that you may be killed or injured. No piece of diving

equipment can prevent the possibility that you may be killed or injured any time you

enter the water.

The Kirby Morgan 37 helmet is CE Approved and meets or exceeds all performance and testing requirements of all government and non-government testing agencies throughout the world. It is approved for

use on all commercial and military work underwater.

Kirby Morgan, SuperLite®, BandMask, Band Mask, KMB, KMB-Band Mask, DSI, Diving Systems International, EXO, REX®,

SuperFlow® and DECA are all registered trademarks of Kirby Morgan Dive Systems, Inc. Use of these terms to describe products

that are not manufactured by KMDSI is illegal.

The two dimensional images (such as photographs and illustrations) of our products are © copyrighted and trademarks of Kirby

Morgan Dive Systems, Inc. The three dimensional forms of our products are trademark, trade design and trade dress protected.

© ⅯⅯⅩⅡ Kirby Morgan Dive Systems, Inc. All rights reserved. This manual is made available for the express use of the owner of

this Kirby Morgan product. No part of this manual may be reproduced, stored in any retrieval system, or transmitted, or used in any

form or by any means, whether graphic, electronic, mechanical, photocopy, or otherwise by technology known or unknown, without

the prior written permission of Kirby Morgan Dive Systems, Inc.

Document Number 130108002

Kirby Morgan® 37 & 57

Warranty Information

KMDSI warrants every new Mask, Helmet, Scuba Regulator, Manifold Block or Kirby Morgan Air Control

System 5 (KMACS 5) (each, a Product) to be free from defects in workmanship for a period of three hun-

dred sixty ve (365) days from the date of purchase from a KMDSI authorized dealer. This warranty covers

all metal and plastic parts, but does NOT cover rubber parts, communications components, or head and chin

cushions. In addition, due to the electrolytic nature of underwater cutting and welding, chrome plating cannot be warranted when the diver engages in these activities.

Any defect of the product in workmanship or material covered by this warranty discovered within three

hundred sixty ve (365) days from the date of purchase must be promptly communicated in writing to the

nearest authorized KMDSI dealer or (if no such dealer in the buyer’s country) contact KMDSI directly

at (805) 928-7772. No Product returns will be accepted by KMDSI without a returned merchandise

authorization (RMA) number from KMDSI. Upon receipt of the RMA from KMDSI, the buyer should

return the defective Product or part, freight prepaid, to an authorized KMDSI dealer or the KMDSI plant, as

directed by the RMA. KMDSI will repair or replace the Product at no charge, within a reasonable time, as it

deems necessary.

This warranty becomes null and void if:

1) The Product is not registered with KMDSI within ten (10) days of purchase, or

2) The Product has not been properly serviced and/or maintained according to KMDSI factory recommended procedures described in the manual or Product updates have not been performed as

recommended by KMDSI, or

3) Unauthorized attachments or modications have been made to the Product, or

4) The Product has been used for purposes other than those for which it was designed, or otherwise

has been abused, misused, or subjected to unusual conditions, or the Product’s intended service has

been exceeded.

EXCEPT AS SPECIFICALLY PROVIDED HEREIN, THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES

FOR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE PRODUCT

COVERED BY THIS WARRANTY IS MARKETED AND SOLD BY KMDSI SOLELY FOR COMMERCIAL OR INDUSTRIAL USE AND IS NOT A CONSUMER PRODUCT INTENDED FOR

PERSONAL, FAMILY, OR HOUSEHOLD USE.

In purchasing any Product subject to this warranty, the buyer agrees that its sole and exclusive remedy and

KMDSI’s entire obligation in contract, tort, or otherwise under this contract will be repair or replacement at

KMDSI’s option of the Product or any parts which KMDSI determines during the applicable warranty period are defective in workmanship or material covered by this warranty. All exchanged parts are the property

of KMDSI. The buyer’s exclusive remedy and the KMDSI’s entire liability in contract, tort, or otherwise is

the payment by KMDSI of the buyer’s actual damages up to but not to exceed the amount paid by the buyer

for the Product.

In no event shall KMDSI be liable to the buyer for indirect, special, incidental or consequential damages (in-

cluding, but not limited to, damages for lost prots, lost sales, loss of business opportunity, or for injury to

persons or property arising out of the use of the Product). Any claim or action for breach of warranty must

II © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Kirby Morgan® 37 & 57

be commenced within one year following delivery of the Product to the buyer.

Buyer acknowledges that this warranty is the sole and exclusive warranty of the Product and that it supersedes any and all oral or written representations and undertakings between KMDSI, its dealers, and the

buyer relating to the Products. This warranty allocates the risks of product failure between KMDSI and the

buyer, which allocation is recognized by both parties and is reected in the price of the goods. The buyer

acknowledges that it has read this agreement, understands it, and is bound by its terms.

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 III

Kirby Morgan® 37 & 57

Record Of Changes

It is the responsibility of the owner of this product to register their ownership with Kirby Morgan Dive

Systems, Inc., by sending the warranty card provided. This card is to establish registration for any necessary

warranty work and as a means of communication that allows KMDSI to contact the user regarding this product.

The user must notify KMDSI of any change of address by the user or sale of the product.

All changes or revisions to this manual must be recorded in this document to ensure that the manual is

up to date. Quantities marked in parenthesis.

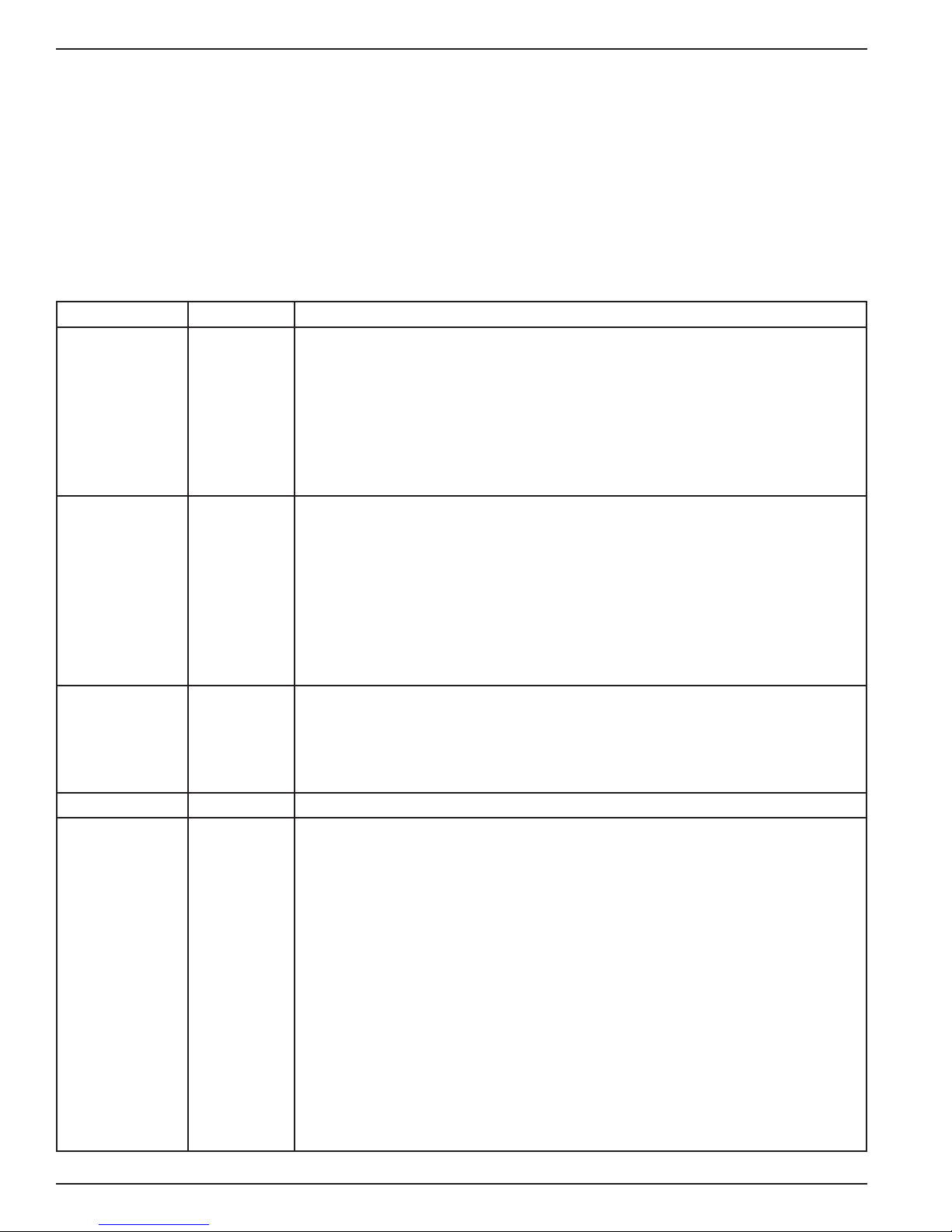

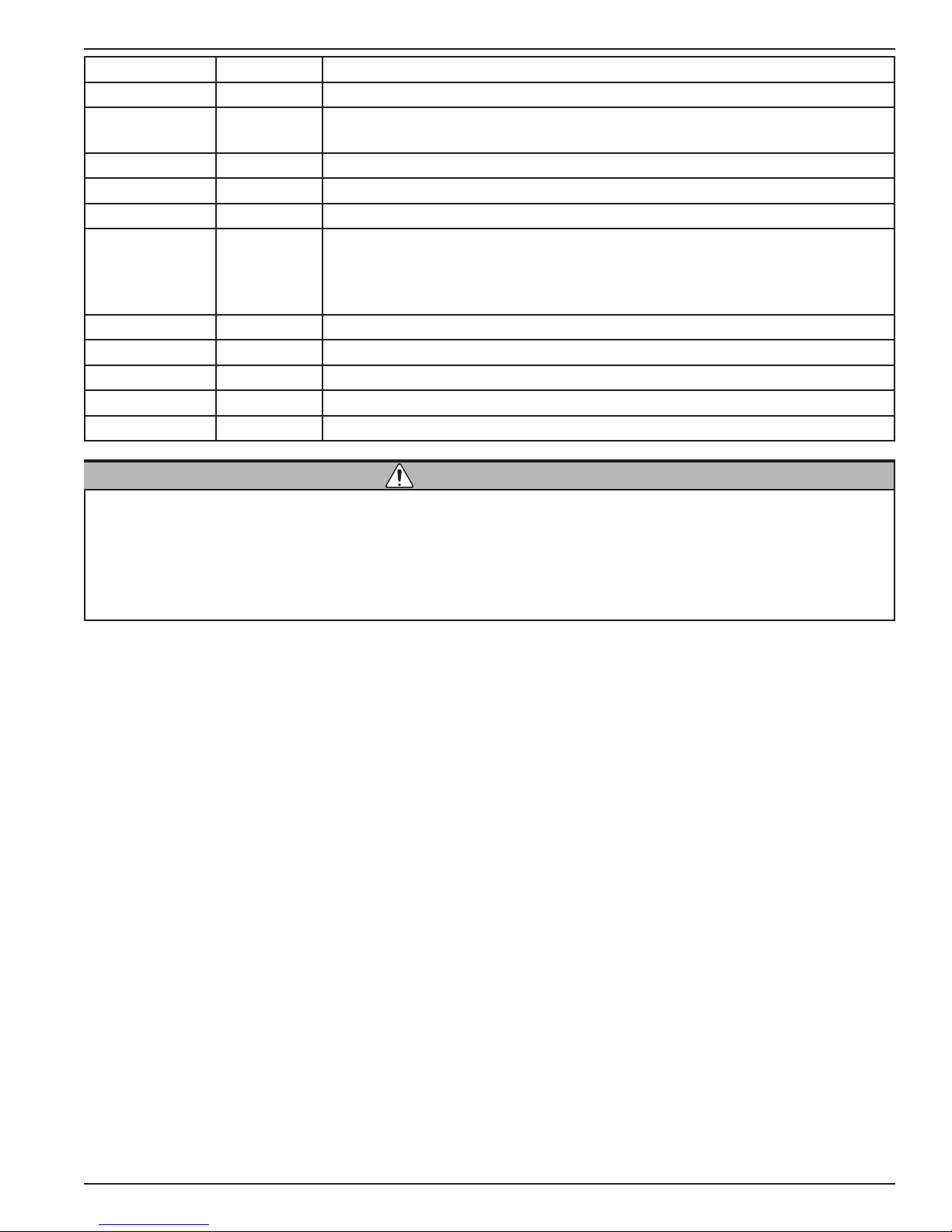

Change Number Date Description of Change

1 05/16/2008 Reworded: 2.1 Product Specications, 2.2.1 SuperFlow

Demand Regulators, 2.2.2 SuperFlow® 450 Performance Certication and 2.5

Operational Specications & limitations.

Reworded Warnings: Page 23 (2) and page 32.

Temperature limitations on page 24 changed from 36º F to 33º F.

Changed regulator adjustment knob to Flex Knob on page 102. Location number

in second NOTE on page 102 changed to reect correct location

Added: Appendix 3 and 4.

2 08/19/2008 Page III Removed page number column.

Page 17: Updated CE approved graphic on SL-17A/B

Page 18: Added CE approved graphic to KM-47 helmet. Updated CE approved

graphic on SL-27.

Page 20: Updated CE approved graphic on EXO-BR.

Pages 57-58: Moved chapter 5 into two columns.

Page 87: Added gasket warning on page 90 left column.

Page 158-159: Changed torque specications. Overset text arranged on next page

(159).

3 11/05/2008 Added D-Ring to Image on pages 17, 28, and 29.

Blowapart Image Updated with D-Ring on page 32, 38, 129, and 134.

Text Updated on pages 57-58, 131.

Rearranged pages 146-148, added diagram of earphone wire.

Appendix A1: Torque Specications updated on page 158.

4 02/25/2009 Text Updated on pages 144-145.

5 03/11/2009 Page 69, step 7; page 132 step 7; page 133 step 11; page 136 step 3; page 151

step 10: Changed kg cm to Newton Meters.

Page 71: Lacquer thinner changed to acetone.

Page 72: Corrected 35 inch pounds to 20 inch pounds in step 4. Lacquer thinner

changed to acetone.

Page 90: Corrected 75 inch pounds to 100 inch pounds in step 19.

Page 102: Section 7.12.2 “SuperFlow

®

450 Demand Regulator Test for Correct

Adjustment, Fully Assembled,” renumbered to aforementioned section number

from incorrect 7.12.1.

Page 117: Corrected 75 inch pounds to 100 inch pounds in step 8.

Page 121: Corrected 35 inch pounds to 20 inch pounds in step 3.

Page 123: Lacquer thinner changed to acetone.

Page 124: Corrected 35 inch pounds to 20 inch pounds in step 4. Lacquer thinner

changed to acetone.

Page 158: Added Location # 104a 530-020 Screw, exhaust ange.

Page 159: Added location # 176 550-533 Bent tube adapter, 450 Regulator.

®

and SuperFlow® 350

IV © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Kirby Morgan® 37 & 57

WARNING

6 07/27/2009 Added sections 2.1, 2.2, 2.2.1 and 2.2.2 for CE certication.

7 09/09/2009 Page 64 Section 6.4 step 5 text updated.

8 11/06/2009 Chapter 2: addition of CE conforming criteria.

2.3 Product Specications corrected weight to 32.6 lbs from 30.6 lbs.

9 03/17/2010 Updated images and diagrams with new whiskers

10 02/18/2011 Updated chapter 1.

11 03/23/2011 Updated earphones throughout manual

12 06/08/2011 Changed 61 meters to 67 meters in Appendix 3 Table 4 SuperFlow® / SuperFlow®

350 Regulator High Pressure Regulated Source and Appendix 3 Table 5 Supply

Pressure Guidelines SuperFlow® 450 Stainless Steel Balanced Regulators High

Pressure Regulated Source Supply Pressure Guidelines

13 10/17/2011 Updated CE notifying body number from 0496 to 2049

14 05/09/2012 Updated CE notifying body address

15 06/13/2012 Update copyright date to roman numerals

16 08/29/2012 Updated torque specs for updated BlowAparts

17 01/08/2013 Updated torque spec locations and copyright

Diving with compressed breathing gas is a hazardous activity. Even if you do everything

right there is always the potential for serious injury or death. No one piece of diving

equipment can prevent the possibility that you may be injured or killed any time you

enter the water. We do not herein make any effort to teach the principles of diving. The

information in this manual is intended for users of Kirby Morgan helmets and persons

that maintain or service Kirby Morgan helmets.

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 V

Kirby Morgan® 37 & 57

Table Of Contents

Warranty Information �������������������������������������������������������������������������������� II

Record Of Changes

Denition of Signal Words Used in this Manual

Chapter 1 General Information KMDSI Products ����������������������������������� 1

1.1 Introduction

1.2 Full-Face Masks and Manifolds

1.3 Kirby Morgan Diving Helmets

Chapter 2 Description & Operational Specications Kirby Morgan 37 &

57 �������������������������������������������������������������������������������������������������������� 9

2.1 CR Marking

2.2 CE Certication

2�2�1 CE Marking ���������������������������������������������������������������������������������� 9

2�2�2 Notied Body ������������������������������������������������������������������������������� 10

2.3 Product Specications

2.4 Regulator Performance

2�4�1 SuperFlow® and SuperFlow® 350 Demand Regulators �������������������������������������� 10

2�4�2 SuperFlow® 450 Performance �������������������������������������������������������������� 10

2.5 Cage Code �������������������������������������������������������������������������������������� 10

2.6 Operational Specications & Limitations ���������������������������������������������������� 10

2.7 Helmet Features

2.8 General Description

2�8�1 Helmet Shell �������������������������������������������������������������������������������� 14

2�8�2 Gas Flow Systems �������������������������������������������������������������������������� 14

2�8�3 Emergency Gas Supply System (EGS) ������������������������������������������������������ 18

2�8�4 Helmet Attachment to the Diver ������������������������������������������������������������� 19

2�8�5 Sealing Arrangement ����������������������������������������������������������������������� 20

2�8�6 Reducing Carbon Dioxide ������������������������������������������������������������������ 20

2�8�7 Communications ���������������������������������������������������������������������������� 20

2�8�8 Equalizing the Middle Ear ������������������������������������������������������������������� 20

2�8�9 Face Port or Viewing Lens ������������������������������������������������������������������ 21

2.9 Accessories

2�9�1 Eye Protection for Welding ������������������������������������������������������������������ 21

2�9�2 Hot Water Shroud for SuperFlow® 350 ������������������������������������������������������ 21

2�9�3 Special Regulator Tools for SuperFlow® 350 ������������������������������������������������ 22

2.10 Helmet Transport And Storage

2�10�1 Helmet Carrying Bag ���������������������������������������������������������������������� 23

2.11 Use of Kirby Morgan Original Replacement Parts ����������������������������������������� 24

Chapter 3 Operating Instructions �������������������������������������������������������� 25

3.1 Introduction

3.2 Design Purpose

3.3 First Use of Your Kirby Morgan Diving Helmet ���������������������������������������������� 26

3.4 Initial Adjustments to Your Helmet

3�4�1 Head Cushion ������������������������������������������������������������������������������ 27

3.4.1.1 Head Cushion Removal ������������������������������������������������������������������� 27

3.4.1.2 Clean and Inspect ������������������������������������������������������������������������ 27

3.4.1.3 Stufng ����������������������������������������������������������������������������������27

�������������������������������������������������������������������������������� IV

������������������������������������������������ XIII

�������������������������������������������������������������������������������������� 1

���������������������������������������������������������������� 2

������������������������������������������������������������������ 4

�������������������������������������������������������������������������������������� 9

���������������������������������������������������������������������������������� 9

������������������������������������������������������������������������� 10

������������������������������������������������������������������������ 10

�������������������������������������������������������������������������������� 11

���������������������������������������������������������������������������� 14

������������������������������������������������������������������������������������� 21

�������������������������������������������������������������� 22

������������������������������������������������������������������������������������� 25

��������������������������������������������������������������������������������� 25

������������������������������������������������������������ 26

VI © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Kirby Morgan® 37 & 57

3.4.1.4 Head Cushion Adjustment ����������������������������������������������������������������� 27

3.4.1.5 Foam Trimming tips ����������������������������������������������������������������������� 27

3.4.1.6 Foam Stufng Tips ������������������������������������������������������������������������ 28

3.4.1.7 Adding Earphone Holes to the Head Cushion ������������������������������������������������ 28

3�4�2 Head Cushion Foam Spacer (HCFS) �������������������������������������������������������� 28

3.4.2.1 Installation of Head Cushion Foam Spacer (HCFS) �������������������������������������������� 28

3.4.2.2 Donning the Head Cushion Foam Spacer (HCFS) ��������������������������������������������� 31

3.4.2.3 Maintenance of the Head Cushion Foam Spacer (HCFS) �������������������������������������� 32

3.4.2.3 Stufng the Head Cushion Foam Spacer (HCFS) ���������������������������������������������32

3�4�2 Trimming the Neck Dam �������������������������������������������������������������������� 32

3�4�3 Adjusting the Neck Pad ��������������������������������������������������������������������� 33

3.5 Pre Dress-In Procedure

������������������������������������������������������������������������ 34

3�5�1 Pre-Dive Visual Inspection ������������������������������������������������������������������34

3.6 Preparing the Helmet for Diving

��������������������������������������������������������������� 34

3�6�1 Clean Face Port ���������������������������������������������������������������������������� 34

3�6�2 Check Moving Parts ������������������������������������������������������������������������ 34

3�6�3 Check Communications �������������������������������������������������������������������� 36

3�6�4 One Way Valve Check ���������������������������������������������������������������������� 36

3.7 Emergency Gas System (EGS)

���������������������������������������������������������������� 36

3.8 Setting Up to Dive ������������������������������������������������������������������������������ 39

3�8�1 Flushing Out the Umbilical ������������������������������������������������������������������ 39

3�8�2 Connecting the Umbilical to the HelmetWhen you connect the hose to the helmet be sure

to use a wrench to hold the adapter, or inlet tting, and a second wrench to turn the swivel tting

on the hose� If this is not done, the adapter will turn inside the one way valve� If this happens

repeatedly the threads will wear and the valve will need to be replaced�

�������������������������� 40

3�8�3 Opening the Breathing Gas Supply to the Helmet�������������������������������������������40

3�8�4 Fogging Prevention �������������������������������������������������������������������������41

3�8�5 Donning The KM 37 or 57 ������������������������������������������������������������������� 41

3�8�6 Testing the Breathing System ���������������������������������������������������������������43

3�8�7 Adjust Regulator for Low Work Rates �������������������������������������������������������43

3�8�8 Sealing Integrity Check ��������������������������������������������������������������������� 43

3.9 Removing the Helmet �������������������������������������������������������������������������� 44

3.10 Diving Procedures

3�10�1 Standing By to Dive ����������������������������������������������������������������������� 44

3�10�2 Attaching the Umbilical to the HarnessThe umbilical must now be hooked to the diver’s

harness by means of a suitable clip that is bound to the umbilical� Some divers and companies

prefer a quick release clip and others prefer a clip that is screwed together so the diver cannot

easily remove it from their harness� The securing of the umbilical keeps the pull of the hose at the

diver’s harness and not on the helmet�

3�10�3 Diver Dons Helmet ������������������������������������������������������������������������ 45

3�10�4 Diver Check Gas Flow Systems ����������������������������������������������������������� 45

3�10�5 Communications Check ������������������������������������������������������������������� 45

3�10�6 Diver Ready ������������������������������������������������������������������������������� 45

3�10�7 Water Entry and Descent ������������������������������������������������������������������45

3.11 Emergency Procedures

3�11�1 Flooding ����������������������������������������������������������������������������������� 45

3�11�2 Inhalation Resistance ���������������������������������������������������������������������� 46

3�11�3 Gas Flow Stops ��������������������������������������������������������������������������� 46

3�11�4 Demand Regulator Free Flow ��������������������������������������������������������������46

3.12 Post Dive Procedures

���������������������������������������������������������������������������� 44

����������������������������������������������������������� 44

���������������������������������������������������������������������� 45

������������������������������������������������������������������������ 46

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 VII

Kirby Morgan® 37 & 57

3�12�1 Removing the Equipment ������������������������������������������������������������������ 46

3�12�2 Removing the Helmet ��������������������������������������������������������������������� 46

3�12�3 Storage of the Helmet Between Dives ����������������������������������������������������� 46

Chapter 4 Troubleshooting ������������������������������������������������������������������ 49

4.1 General ������������������������������������������������������������������������������������������ 49

4.2 Communication Malfunction

4.3 One Way Valve Malfunction

4.4 Side Valve Malfunction

������������������������������������������������������������������������� 50

4.5 Water Leakage Into Helmet

������������������������������������������������������������������ 49

������������������������������������������������������������������� 49

������������������������������������������������������������������� 50

4.6 Demand Regulator Malfunction ��������������������������������������������������������������� 51

4.7 Emergency Gas Supply Valve

����������������������������������������������������������������� 51

Chapter 5 Inspection and Maintenance ����������������������������������������������� 53

5.1 Routine Maintenance

5�1�1 Daily Pre-Dive Maintenance A2�3 �����������������������������������������������������������53

5�1�2 Daily Post Dive Maintenance A2�6 ���������������������������������������������������������� 53

5�1�3 Supervisors Equipment Checks A2�4 and A2�5 ��������������������������������������������� 53

5.2 Monthly Maintenance

5.3 Yearly Maintenance ���������������������������������������������������������������������������� 53

5�3�1 Overhaul/Inspection Checklist A2�1 ��������������������������������������������������������� 53

�������������������������������������������������������������������������� 53

�������������������������������������������������������������������������� 53

Chapter 6 General Preventative Maintenance �������������������������������������55

6.1 Introduction

6.2 Required tools, Cleaning Agents, Lubrication �����������������������������������������������55

6�2�1 Component and Parts Cleaning ������������������������������������������������������������� 56

6�2�2 Component and Parts Lubrication ���������������������������������������������������������� 56

6�2�3 Teon® Tape �������������������������������������������������������������������������������� 57

6�2�4 RTV Sealant ��������������������������������������������������������������������������������57

6�2�5 Thread Locker ������������������������������������������������������������������������������57

6.3 General Cleaning & Inspection Procedures

6�3�1 O-Ring Removal/Inspection/Cleaning and Lubrication �������������������������������������� 58

6.3.1.1 O-Ring Removal: ������������������������������������������������������������������������ 58

6.3.1.2 O-Ring Inspection: ������������������������������������������������������������������������ 58

6.3.1.3 O-Ring Reuse: ���������������������������������������������������������������������������� 58

6�3�2 General Cleaning Guidelines ��������������������������������������������������������������� 58

6.3.2.1 Mild Soap Solution for General Cleaning and Leak Detector Use ������������������������������� 59

6.3.2.2 Acidic Cleaning Solution and Procedures ����������������������������������������������������59

6.3.2.3 Germicidal Cleaning Solutions and Procedure ������������������������������������������������59

6.4 Daily Maintenance

6.5 Monthly Maintenance (or between jobs) ����������������������������������������������������� 61

6�5�1 Locking Collar Assembly & Helmet Ring ��������������������������������������������������� 61

6�5�2 Neck Dam Ring Assembly ������������������������������������������������������������������ 61

6�5�3 Head Cushion and Chin Cushion ����������������������������������������������������������� 62

6�5�4 Communications Inspection ����������������������������������������������������������������62

6�5�5 Lubricate Nose Block O-Rings �������������������������������������������������������������� 62

6.6 Inspect the Exhaust Valve

6�6�1 For Helmets Equipped with the Tri-Valve™ �������������������������������������������������62

6�6�2 For Helmets Equipped with the Quad Valve™ Exhaust �������������������������������������63

������������������������������������������������������������������������������������� 55

�������������������������������������������������� 57

������������������������������������������������������������������������������ 60

��������������������������������������������������������������������� 62

Chapter 7.0 Breathing System Maintenance and Repairs ��������������������65

7.1 Introduction

7.2 One Way Valve

������������������������������������������������������������������������������������� 65

���������������������������������������������������������������������������������� 65

VIII © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Kirby Morgan® 37 & 57

7�2�1 Disassembly Of The One Way Valve �������������������������������������������������������� 65

7�2�2 Reassembly of the One Way Valve ���������������������������������������������������������� 66

7.3 Side Block Assembly

��������������������������������������������������������������������������� 67

7�3�1 General ������������������������������������������������������������������������������������� 67

7�3�2 Side Block Assembly Removal �������������������������������������������������������������� 67

7�3�3 Separating the Side Block Assembly from the Helmet Shell ��������������������������������67

7�3�4 Side Block Assembly Replacement ��������������������������������������������������������� 68

7.4 Defogger Valve

��������������������������������������������������������������������������������� 70

7�4�1 Disassembly of the Defogger Valve ���������������������������������������������������������70

7�4�2 Cleaning and Lubricating ������������������������������������������������������������������� 71

7�4�3 Reassembly of the Defogger Valve ����������������������������������������������������������71

7.5 Emergency Valve Assembly

������������������������������������������������������������������� 72

7�5�1 Disassembly of the Emergency Valve ������������������������������������������������������� 72

7�5�2 Cleaning and Lubricating ������������������������������������������������������������������� 73

7�5�3 Reassembly of Emergency Valve ����������������������������������������������������������� 74

7�5�4 Leak Testing the EGS Valve �����������������������������������������������������������������75

7.6 Bent Tube Assembly

��������������������������������������������������������������������������� 75

7�6�1 General ������������������������������������������������������������������������������������� 75

7�6�2 Removal of the Bent Tube Assembly �������������������������������������������������������� 76

7�6�3 Inspection of Bent Tube Assembly ���������������������������������������������������������� 76

7�6�4 Installation of the Bent Tube Assembly������������������������������������������������������ 76

7.7 SuperFlow® 350 Demand Regulator ���������������������������������������������������������� 77

7�7�1 General Regulator Information �������������������������������������������������������������� 77

7�7�2 SuperFlow® 350 Demand Regulator Test for Correct Adjustment, Fully Assembled ���������77

7�7�3 Inspection of SuperFlow® 350 Regulator Body Interior ������������������������������������� 78

7�7�4 SuperFlow® 350 Demand Regulator Bias Adjustment Servicing, Demand Regulator on the

Helmet

�������������������������������������������������������������������������������������������� 78

7�7�5 Reassembly of the SuperFlow® 350 Regulator Adjustment System ������������������������� 79

7�7�6 SuperFlow® 350 Demand Regulator Removal from Helmet ���������������������������������80

7�7�7 Disassembly of the SuperFlow® 350 Demand Regulator ������������������������������������ 81

7�7�8 Inspection of SuperFlow® 350 Demand Regulator Parts ������������������������������������ 82

7�7�9 Reassembly of the SuperFlow® 350 Demand Regulator ������������������������������������ 84

7�7�10 Tuning the SuperFlow® 350 Regulator ����������������������������������������������������� 88

7�7�11 SuperFlow® 350 Regulator Steady Flows When Pressured Up: Special Tools Used ������� 90

7.8 Oral Nasal ��������������������������������������������������������������������������������������� 92

7�8�1 Oral Nasal General Information ������������������������������������������������������������� 92

7�8�2 Oral Nasal Removal ������������������������������������������������������������������������ 92

7�8�3 Inspection of Oral Nasal �������������������������������������������������������������������� 92

7�8�4 Oral Nasal Replacement �������������������������������������������������������������������� 93

7.9 Quad Valve

7�9�1 Quad Valve™ Assembly Removal ������������������������������������������������������������ 94

7�9�2 Quad Valve™ Exhaust Valves ����������������������������������������������������������������95

7.9.2.1 Quad Valve™ Exhaust Valve Replacement ����������������������������������������������������95

7.9.2.2 SuperFlow® 350 Regulator Exhaust Valve Replacement ���������������������������������������96

7�9�3 Quad Valve™ Assembly Installation ��������������������������������������������������������� 96

7.10 Water Dump Exhaust Body

7�10�1 Water Dump Valve Removal ��������������������������������������������������������������� 97

7�10�2 Water Dump Valve Replacement ���������������������������������������������������������� 97

7�10�3 Water Dump Valve Body Removal ��������������������������������������������������������� 97

7�10�4 Water Dump Valve Body Remounting ����������������������������������������������������� 97

™

Exhaust Assembly �������������������������������������������������������������� 94

������������������������������������������������������������������ 97

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 IX

Kirby Morgan® 37 & 57

7.11 Reinstalling the Quad Valve™ Exhaust Assembly ������������������������������������������ 98

7�12 SuperFlow® 450 Stainless Balanced Regulator ���������������������������������������������� 99

7�12�1 General ������������������������������������������������������������������������������������ 99

7�12�2 SuperFlow® 450 Demand Regulator Test for Correct Adjustment, Fully Assembled �������� 99

7�12�3 Adjusting the SuperFlow® 450 ����������������������������������������������������������� 100

7�12�4 SuperFlow® 450 Demand Regulator Bias Adjustment Field Service with Demand Regulator

on Helmet

���������������������������������������������������������������������������������������101

7�12�5 SuperFlow® 450 Regulator Removal ����������������������������������������������������� 106

7�12�6 SuperFlow® 450 Disassembly ����������������������������������������������������������� 107

7�12�7 Assembly of the SuperFlow® 450 Regulator ��������������������������������������������� 109

7.12.7.1 Assembly of the Flex Knob�������������������������������������������������������������� 109

7.12.7.2 Assembly of SuperFlow® 450 Regulator ���������������������������������������������������110

7�12�8 SuperFlow® 450 Regulator Installation ����������������������������������������������������114

Chapter 8 Corrective Maintenance �����������������������������������������������������117

8.1 General �����������������������������������������������������������������������������������������117

8.2 Helmet Shell Inspection�����������������������������������������������������������������������117

8.3 Nose Block Assembly

8�3�1 Nose Block Assembly Removal ������������������������������������������������������������118

8�3�2 Nose Block Device Replacement ����������������������������������������������������������119

8.4 Handle and Weights �������������������������������������������������������������������������� 120

8�4�1 Handle Removal ������������������������������������������������������������������������� 120

8�4�2 Handle Replacement ��������������������������������������������������������������������� 120

8�4�3 Side Weight Removal ��������������������������������������������������������������������� 120

8�4�4 Port Weight Replacement ����������������������������������������������������������������� 122

8�4�5 Top Weight �������������������������������������������������������������������������������� 123

8.4.5.1 Top Weight Removal �������������������������������������������������������������������� 123

8.4.5.2 Top Weight Replacement ���������������������������������������������������������������� 123

8.5 Face Port �������������������������������������������������������������������������������������� 124

8�5�1 General ����������������������������������������������������������������������������������� 124

8�5�2 Face Port and Nose Block Device Removal ����������������������������������������������� 124

8�5�3 Face Port and Nose Block Replacement �������������������������������������������������� 126

8�5�4 Special Note Regarding Ports ������������������������������������������������������������ 127

8.6 Neck Ring Assembly ������������������������������������������������������������������������ 128

8�6�1 General Information on Neck Dams ������������������������������������������������������� 128

8�6�2 Removal of the Neck Dam ���������������������������������������������������������������� 128

8�6�3 Neoprene Neck Dam Replacement ������������������������������������������������������� 128

8�6�4 Latex Neck Dam Replacement ������������������������������������������������������������ 131

8�6�5 Trimming a Latex Neck Seal �������������������������������������������������������������� 132

8.7 Pull Strap �������������������������������������������������������������������������������������� 133

8�7�1 Pull Strap Removal ����������������������������������������������������������������������� 133

8�7�2 Pull Strap Replacement ������������������������������������������������������������������� 133

8.8 Chin Strap

������������������������������������������������������������������������������������� 133

8�8�1 Chin Strap Removal ���������������������������������������������������������������������� 133

8�8�2 Chin Strap Replacement ������������������������������������������������������������������ 133

8.9 O-Ring Seal Replacement ������������������������������������������������������������������ 134

8.10 Helmet Ring ��������������������������������������������������������������������������������� 135

8�10�1 Helmet Ring Repairs ��������������������������������������������������������������������� 135

8.11 Sealed Pull Pins

8�11�1 Removal of Sealed Pull Pins ������������������������������������������������������������� 135

8�11�2 Replacement of Sealed Pull Pins �������������������������������������������������������� 135

�������������������������������������������������������������������������118

����������������������������������������������������������������������������� 135

X © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Kirby Morgan® 37 & 57

8.12 Swing Tongue Catch

8�12�1 Disassembly of the Swing Tongue Catch ������������������������������������������������ 136

8�12�2 Reassembly of the Swing Tongue Catch ������������������������������������������������� 136

����������������������������������������������������������������������� 136

8.13 Locking Collar/Neck Pad ������������������������������������������������������������������� 138

8�13�1 Locking Collar Removal ����������������������������������������������������������������� 138

8�13�2 Locking Collar Disassembly ������������������������������������������������������������� 139

8�13�3 Locking Collar Reassembly �������������������������������������������������������������� 140

8.15 Head Cushion (pre October 2012) ��������������������������������������������������������� 142

8�15�1 Head Cushion Foam ��������������������������������������������������������������������� 142

8.16 Chin Cushion Foam

8.15 Communications System

8�15�1 General ���������������������������������������������������������������������������������� 143

8�15�2 Earphone Inspection �������������������������������������������������������������������� 143

8�15�3 Removal of Communications Assembly ������������������������������������������������� 144

8�15�4 Replacement of Communications Assembly ��������������������������������������������� 144

8�15�5 Microphone Replacement ��������������������������������������������������������������� 145

8�15�6 Earphone And Wire Assembly Replacement ��������������������������������������������� 145

8�15�7 Waterproof Connector ������������������������������������������������������������������� 146

8.15.7.1 Connector Removal �������������������������������������������������������������������� 146

8.15.7.2 Connector Replacement ���������������������������������������������������������������� 147

8�15�8 Terminal Connections in the Waterproof Connector ������������������������������������� 147

8�15�9 Communications Posts ������������������������������������������������������������������ 149

8.15.9.1 Communications Post Removal ��������������������������������������������������������� 149

8.15.9.2 Communications Post Replacement ����������������������������������������������������� 149

������������������������������������������������������������������������� 142

������������������������������������������������������������������� 143

Chapter 9 Accessories for the Kirby Morgan 37 & 57 ������������������������ 151

9.1 Introduction ����������������������������������������������������������������������������������� 151

9.2 Hot Water Shroud for KM37 ����������������������������������������������������������������� 151

9�2�1 Hot Water Shroud Installation Procedures for KM37 �������������������������������������� 151

9.3 Low Pressure Inator Hose ������������������������������������������������������������������ 154

9�3�1 Installation of the Low Pressure Inator Hose ��������������������������������������������� 154

9.4 Weld Lens Assembly ������������������������������������������������������������������������� 155

9�4�1 Weld Lens Assembly Installation ���������������������������������������������������������� 155

9.5 Weld Shield Assembly ����������������������������������������������������������������������� 156

9�5�1 Weld Shield Assembly Installation �������������������������������������������������������� 156

9.6 Use of Quick Disconnect �������������������������������������������������������������������� 156

9.7 Accessory Mounting Brackets �������������������������������������������������������������� 157

9�7�1 Mount Bracket Installation ���������������������������������������������������������������� 157

Table of Equivalents �������������������������������������������������������������������������� 159

Appendix 1: Torque Specications ���������������������������������������������������� 160

Note on Torque Specications ���������������������������������������������������������� 161

Appendix 1: Torque Specications Continued������������������������������������ 161

Appendix A2 Maintenance and Inspection Procedures ���������������������� 162

Appendix 3 Supply Pressure Requirements & Tables ������������������������� 164

Appendix 3 Table 1 Work Rate Expressed as Respiratory Minute Volume (RMV)*

Appendix 3 Table 2 Compressor Supply Table SuperFlow® and SuperFlow® 350 ���������� 165

Appendix 3 Table 3 SuperFlow® 450 SS Balanced Regulator �������������������������������� 166

Appendix 3 Table 2 Compressor Supply Table SuperFlow® and SuperFlow® 350 Continued

����������������������������������������������������������������������������������������������������� 166

Appendix 3 Table 3 SuperFlow

®

450 SS Balanced Regulator Continued ������������������� 167

��������� 165

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 XI

Kirby Morgan® 37 & 57

Appendix 3 Table 4 SuperFlow® / SuperFlow® 350 RegulatorHigh Pressure Regulated

Source

Appendix 3 Table 3 SuperFlow

��������������������������������������������������������������������������������������������� 168

®

450 SS Balanced Regulator Continued ������������������� 168

Appendix 3 Table 5 Supply Pressure Guidelines SuperFlow® 450 Stainless Steel Balanced

Regulators High Pressure Regulated Source Supply Pressure Guidelines ����������������� 169

Appendix 4 Standard Kirby Morgan Surface Supply Pressure Formula Old Method

��������������������������������������������������������������������������������������� 169

XII © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Kirby Morgan® 37 & 57

CAUTION

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Definition of Signal Words Used in this Manual

For your protection, pay particular attention to items identied by signal words in this manual. These terms are identied

as, CAUTION, WARNING AND DANGER. It is especially important for you to read and understand these sections.

This word indicates an imminently hazardous situation, which if not avoided, could result in death or serious injury.

This word indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

This word indicates a potentially hazardous situation, which if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

If English is not your native language and you have any difficulty understanding the language of

any warnings as they appear in the manual, please have them translated.

Este é um aviso importante. Queira mandá-lo traduzir.

Este es un aviso importante. Sirvase mandario traducir.

Quest è un avviso importante. Tradurlo.

Ceci est important. Veuillez traduire.

Diese Mitteilung ist wichtig. Bitte übersetzen lassen.

If you have any questions concerning this manual or the operation of your helmet, contact KMDSI (805) 928-7772 or

by Email at kmdsi@KirbyMorgan.com or Dive Lab Inc. (850) 235-2715 or at Divelab@aol.com

IMPORTANT: A word about this manual. We have tried to make this manual as comprehensive and factual

as possible. We reserve the right however, to make changes at any time, without notice, in prices, colors, materials,

equipment, specications, models and availability. Since some information may have been updated since the time

of printing, please contact your local KMDSI dealer if you have any questions. Periodically KMDSI Operations and

Maintenance Manuals are reviewed. Any updates/changes will be posted on the KMDSI website and may be downloaded for insertion/correction.

Important Safety Information:

This Kirby Morgan diving helmet is intended for use by trained divers who have successfully completed a recognized

training course in surface supplied diving.

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 XIII

Kirby Morgan® 37 & 57

DANGER

WARNING

DANGER

DANGER

WARNING

WARNING

Follow all the instructions in this manual carefully and heed all safety precautions. Improper use of this diving helmet could result in serious injury or death.

Kirby Morgan Dive Systems, Inc. (KMDSI) warns all divers who use the Kirby Morgan

diving helmet to be sure to use only KMDSI original parts from a KMDSI authorized dealer. Although other parts, O-rings and fittings may appear to fit on Kirby Morgan diving

helmets, they may not be manufactured to the same standards maintained by KMDSI.

The use of any parts other than KMDSI original parts may lead to equipment failure and

accidents.

Diving in waters that are chemically, biologically, or radiologically contaminated is extremely hazardous. Although Kirby Morgan diving helmets may be adapted for use in

some contaminated environments, special training, equipment, and procedures are

necessary. Do not dive in a contaminated environment unless you have been thoroughly

trained and equipped for this type of diving.

Read this manual before using or maintaining the helmet, even if you have experience with other diving helmets. If

you have purchased the helmet new from a dealer, be sure to send in the warranty registration card so we may

keep you informed of any safety notices that affect this product. If you resell or loan this helmet to another diver,

be sure this manual accompanies the helmet and that the person reads and understands the manual. In addition to the

manual a log book should be used to log all repairs, maintenance and use.

Diving is a life threatening occupation. Even if you do everything right you can still be

killed or injured. None of the models of Kirby Morgan helmets or masks can prevent accidents, injuries or death due to improper training, poor-health, improper supervision,

improper job requirements, improper maintenance or acts of God.

This helmet was completely checked and should be ready to dive as it was shipped from

the factory. However, it is always the diver’s responsibility to check all the components

of the helmet prior to diving.

Any and all fiberglass repairs done to this helmet MUST be done by a KMDSI factory

trained repair facility. Painting is not recommended by KMDSI. Furthermore, many diving

companies will not allow painted helmets to be used because painting can mask previous fiberglass damage. KMDSI certified technicians are not responsible for certifying

helmets free from damage during annual overhauls.

Helmet shells can be re-gel coated by authorized/certified KMDSI trained technicians

that have received fiberglass training by KMDSI. Helmets that are to be painted for cosmetic purposes, should be first, certified free of fiberglass damage by an authorized

KMDSI technician certified in fiberglass repair. A log entry should be made in the helmet log that the helmet was free of damage prior to painting. Keep in mind other KMDSI

technician can refuse to work on helmet shells that have previously been painted or

repaired by non KMDSI certified persons.

This manual is supplied to the original purchaser of this helmet. If you have any questions about the use of the helmet

or you need another copy of this manual, Part Number 100-073, contact KMDSI or your nearest KMDSI dealer or

may be downloaded free from the KMDSI website at www.KirbyMorgan.com.

XIV © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Kirby Morgan® 37 & 57

DANGER

DANGER

WARNING

DANGER

WARNING

If you have any questions regarding the use, maintenance, or operation of this helmet, contact KMDSI at (805) 928-

7772, fax: (805) 928-0342, or e-mail: kmdsi@KirbyMorgan.com.

Kirby Morgan masks and helmets are cleaned and lubricated for oxygen service when they come from the factory. However, if the helmet is used with an

oil lubricated air compressor, contamination with hydrocarbons may result.

If the breathing system in the helmet is exposed to hdrocarbons, it must be

cleaned for oxygen service and lubricated with oxygen safe lubricants before

using it again with breathing mixtures containing a high percentage of oxygen. If this is not done, fires and explosions may result, exposing the user to

serious personal injury or death.

Components requiring lubrication, should only be lubricated with oxygen compatible lubricants such as Christo-

Lube®, Fluorolube®, or Krytox®. Lubricants must be used sparingly and should not be mixed with other lubricants.

KMDSI helmets and masks are intended for underwater use only and should only be

used by qualified divers that have received proper training in the use of this type of

equipment. KMDSI helmets and masks should not be used or worn without the appropriate life support systems, such as air or gas supplies and support personnel as described in this manual.

KMDSI helmets and masks should never be used for motor sport racing, aviation /

space craft use, or for chemical warfare use. The helmet must never be used by persons

in poor physical condition, by persons with previous head neck or back injuries which

could be aggravated by its use. The helmet should not be used by persons under the influence of drugs or alcohol. Furthermore, infants, children, or persons under the age of

18 should never wear KMDSI helmets and masks. Failure to pay heed to the above could

result in serious injury or death.

Never use the helmet without first completing all pre-dive maintenance and set up pro-

cedures.

Do not use KMDSI masks or helmets in currents exceeding 3.0 knots Use in currents

greater than 3 knots may allow water to enter the exhaust valve, possibly causing regulator flooding.

Surface-supplied diving can be a strenuous activity. Most Kirby Morgan helmets weigh

in excess of 27 pounds. KMDSI recommends that persons with a previous neck or back

injury seek professional medical approval prior to engaging in surface supplied diving

operations using any Kirby Morgan helmet. Use of any Kirby Morgan helmet with a preexisting physical/medical condition may result in death or serious injury.

The information contained in this manual is intended to aid the user in optimizing the performance of this helmet.

The application of some of this information will depend on the diving situation and the use of associated equipment.

Many countries have specic laws and rules regarding commercial diving. It is important for the user to understand

the rules, regulations, and philosophy imposed by the governing, regulating bodies whenever using commercial diving

equipment.

Whenever KMDSI helmets or masks are used in European Countries, which have adopted the C.E. certication programs, they must only be used with C.E. certied components. Diving operations should only be conducted within the

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 XV

Kirby Morgan® 37 & 57

limits of the operational specications, and in accordance with the rules and regulations established by the governing

authority in the specic country or geographical location where the diving operations are being conducted. If you have

any questions concerning this manual or the operation of your helmet, contact KMDSI (805) 928-7772 or at

kmdsi@KirbyMorgan.com or Dive Lab Inc. (850) 235-2715 or at Divelab@aol.com

XVI © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

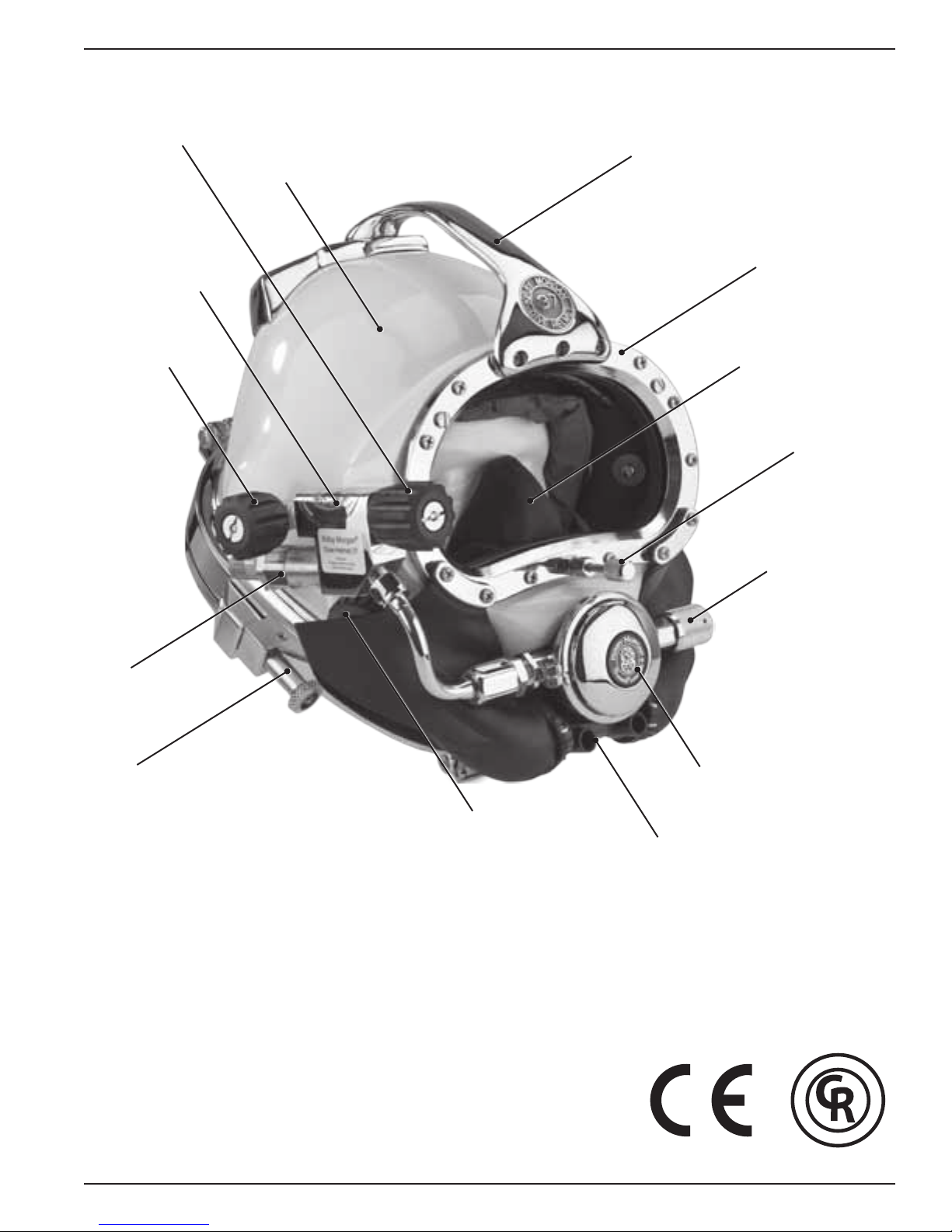

Defog Free Flow

Valve Knob

Helmet Shell

Sideblock

Kirby Morgan® 37 & 57

Handle

Port Retainer

EGS Valve

Non-Return Valve

Pull Pin

Oral Nasal Mask

Equalization Device

Regulator Adjustment

Knob

Purge Button

The Kirby Morgan 37 helmet

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 XVII

Communications Port

Quad Valve™ Exhaust

(standard on all Kirby Morgan 37

helmets from 2005 on)

A

R

T

Y

E

L

D

L

A

I

-

C

R

E

M

M

O

C

D

E

T

S

E

T

B

A

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

L

E

G

V

E

I

A

D

R

-

™

Kirby Morgan® 37 & 57

STOP!

BEFORE GOING FURTHER-

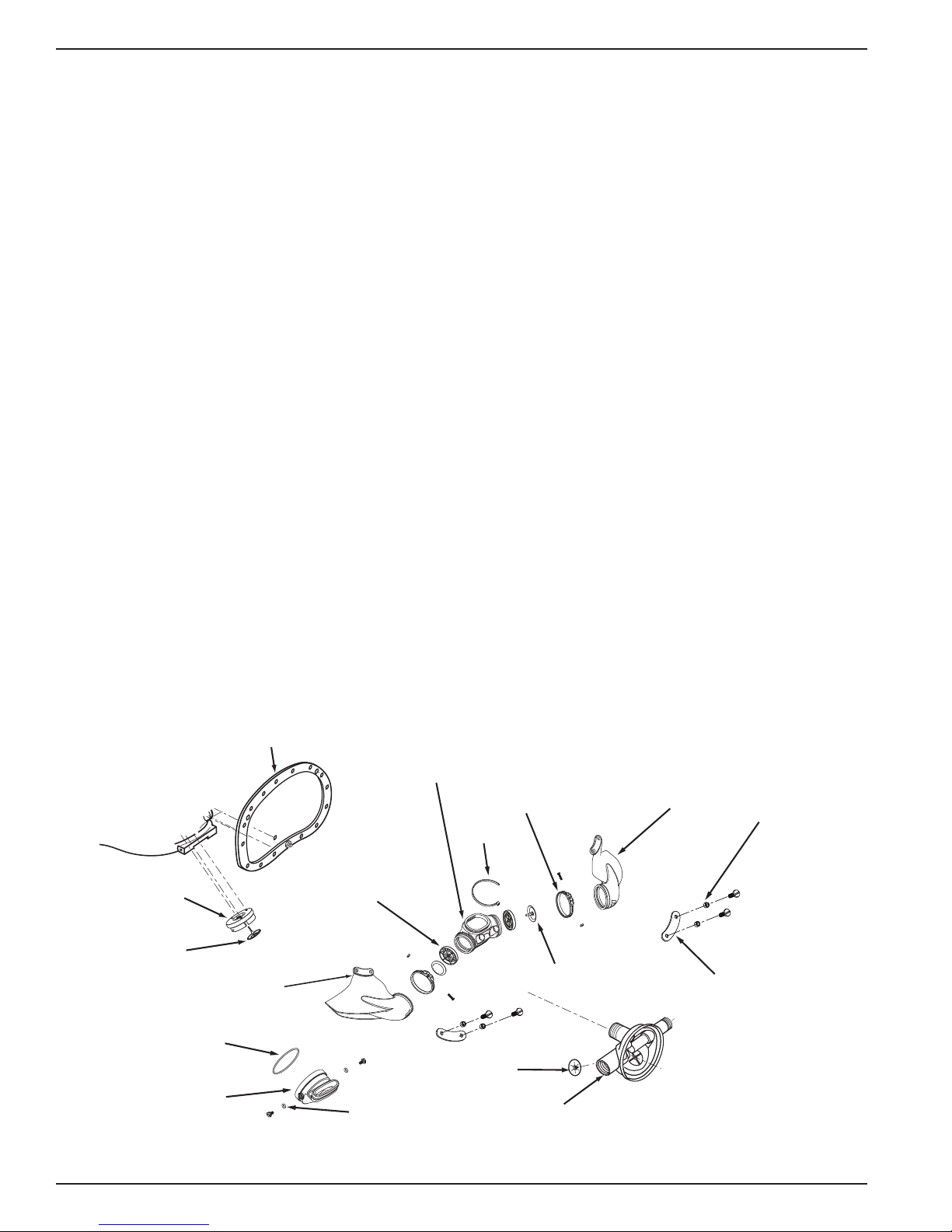

This manual will refer to location numbers in specic drawings, or in the exploded view, which is

in the back of this manual. These numbers are called “location” numbers. They are used to nd

the referred to parts in the drawings in this manual only. They are not the part number. Next to

the exploded drawing is a list of the “location” numbers that match the Kirby Morgan part numbers along with the name of the part. Always check the part number when ordering to make sure

it is correct. When ordering, always specify the helmet model number and serial number as well.

Chapter 1

General Information KMDSI Products

1.1 Introduction

The Kirby Morgan Corporation was started in 1965.

The copper and brass “Heavy Gear” or “Standard

Dress” helmets wer e the rst hel mets manufactu red by

the company. Over the years Kirby Morgan designed,

manufactured and sold many different helmets and

masks for commercial divers.

Staying active in commercia l d iving has contributed to

the successful design innovations of KMDSI products.

This may be the primary reason for the acceptance of

our designs by professional divers.

Bev Morgan has designed more than fty-seven diving hel mets a nd over 40 diving masks. All employees

of KMDSI participate as part of the Kirby Morgan

design team. It would not be possible for us to supply

the commercial, military, scientic, and public service

diving industries with our equipment, wit hout the team

of people that make up Kirby Morgan Dive Systems,

Inc. (KMDSI)

We feel it is important for the reader to understand

that we at KMDSI consider ourselves as only part

of the process along the path in diving equipment

design. We welcome all input from our customers.

The thinking of many good divers, diving equipment

engineers, d iving medical specia lists, diving organ ization administrators and their supporting personnel has

contributed to the current state of the art of diving.

Each piece of gear we manufacture has in it some of

the thinking of those who have gone before us. To

all those people who gave something of themselves

to the men and women who work underwater, we

express a thank you.

We have a strong commitment to providing the best

diving equipment and service possible. This thinking

has been the policy of Kirby Morgan Dive Systems,

Bev Morgan, Chairman of the Board

Kirby Morgan Dive Systems, Inc.

Inc. and we will continue to take this approach to

our work.

Our extensive dealer network makes it easy to obtain

genuine Kirby Morgan replacement parts, as well as

technical assistance worldwide.

KMDSI has always concentrated on designing and

manufacturing diving equipment that allows most

repairs, inspections, and all routine maintenance to

be performed by the user. Most routine preventative

and corrective maintenance can be accomplished by

the user utilizing this manual, the KMDSI Tool Kit

(P/N 525-620) and common hand tools. Technician

training is available through Dive Lab Inc. Information can be obtained on line at www.divelab.com or

by telephone at 850-235-2715.

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 1

Kirby Morgan® 37 & 57

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

1.2 Full-Face Masks and Manifolds

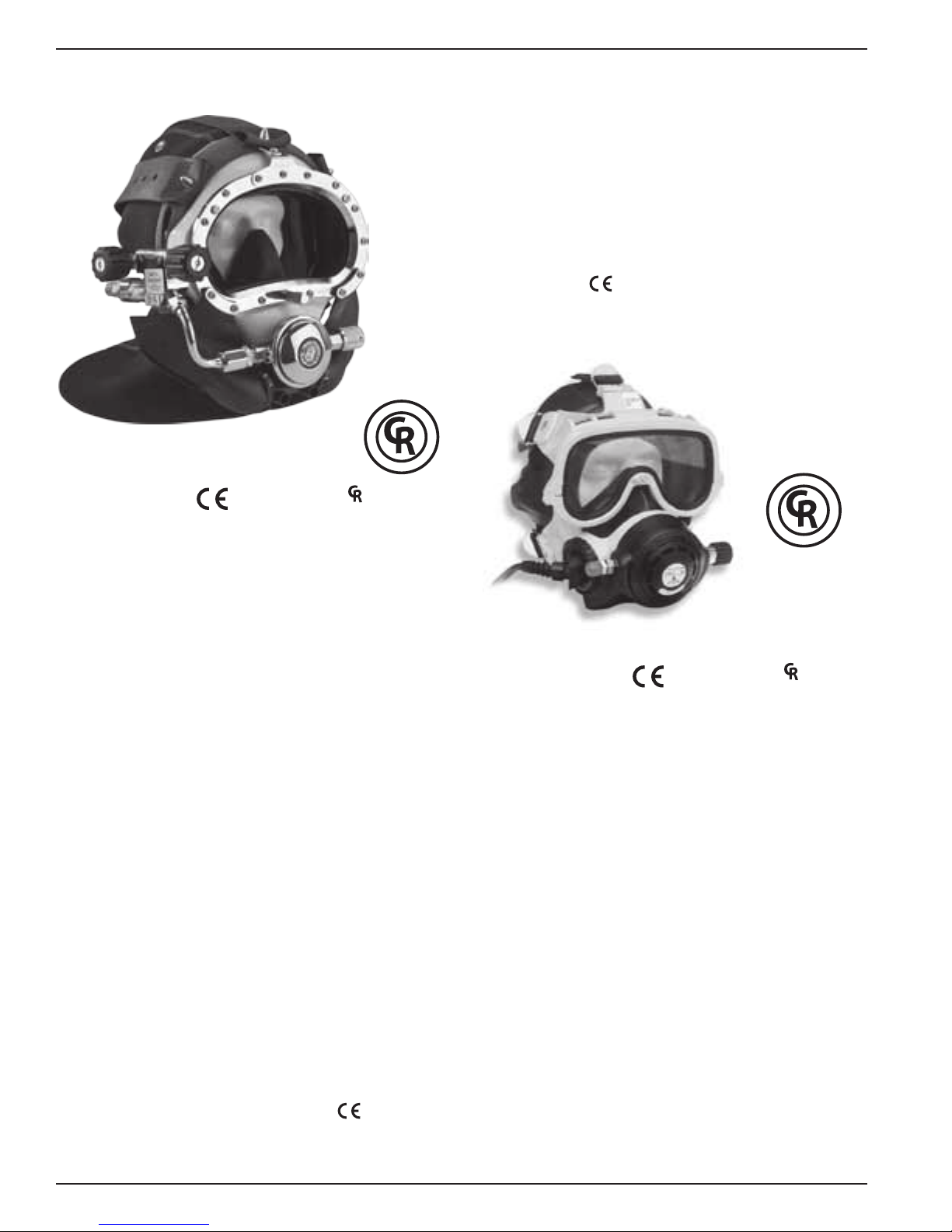

KMB® 18 A/B

approved and ™ marked

The EXO Full Face Mask is designed for both

surface supplied and scuba diving. By enclosing the

divers eyes, nose and mouth, the EXO permits nearly

normal speech when used in conjunction with most

wireless, and all hard wire underwater communication systems.

The EXO BR (BALANCED REGULATOR) shown

here is designed to meet or exceed recommended

performance goals in both scuba and surface supplied

modes and is

approved. It meets and surpasses

European standards for regulator performance.

The KMB 18B Band Mask frame is constructed of

hand laid berglass. The head harness is a molded,

strong tear resistant neoprene rubber.

The hood, which attaches to the mask frame with

welded stainless steel bands, provides warmth for the

divers head as well as pockets for the earphones. The

communications connections can be either a male

waterproof plug in type or bare wire posts. Both this

mask and the KMB 28B feature the new Tri-Valve™

Exhaust System.

The KMB 28B Band Mask (not shown) is very similar to the KMB 18, with many parts on the KMB 18B

being interchangeable wit h the KMB 28B. The major

difference between the 18 and 28 is the material of the

mask frame itself. The KMB 18 has a berglass frame

(yellow) while the KMB 28B frame is an extremely

durable injection molded plastic (black).

Other differences include:

1) The main exhaust body of the KMB 28 is part of the

frame itself and uses a #545-041 main exhaust cover

2) no comfort insert is required on the 28

3) the face ports for the 18 and the 28 differ slightly

in size.

EXO® BR

approved and ™ marked

The Balanced Regulator helps reduce the work of

breathing for the diver by balancing the i ntermediate

air pressure against the valve sealing pressure inside

the regulator. This enables the regulator to instantly

adjust to changes in line pressure. The balanced

regulator is adjustable for a wide range of intermediate pressures between 90 PSIG – 250 over ambient

pressure (6.2 – 17 bar).

Both models have a modular communications design that permits rapid and simple maintenance. The

optional Hard Shell provides surfaces for mounting

lights, cameras etc.

Both the KMB 18 and KMB 28 are

2 © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

approved.

SuperMask M-48

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

™

w/ Scuba Pod

Kirby Morgan® 37 & 57

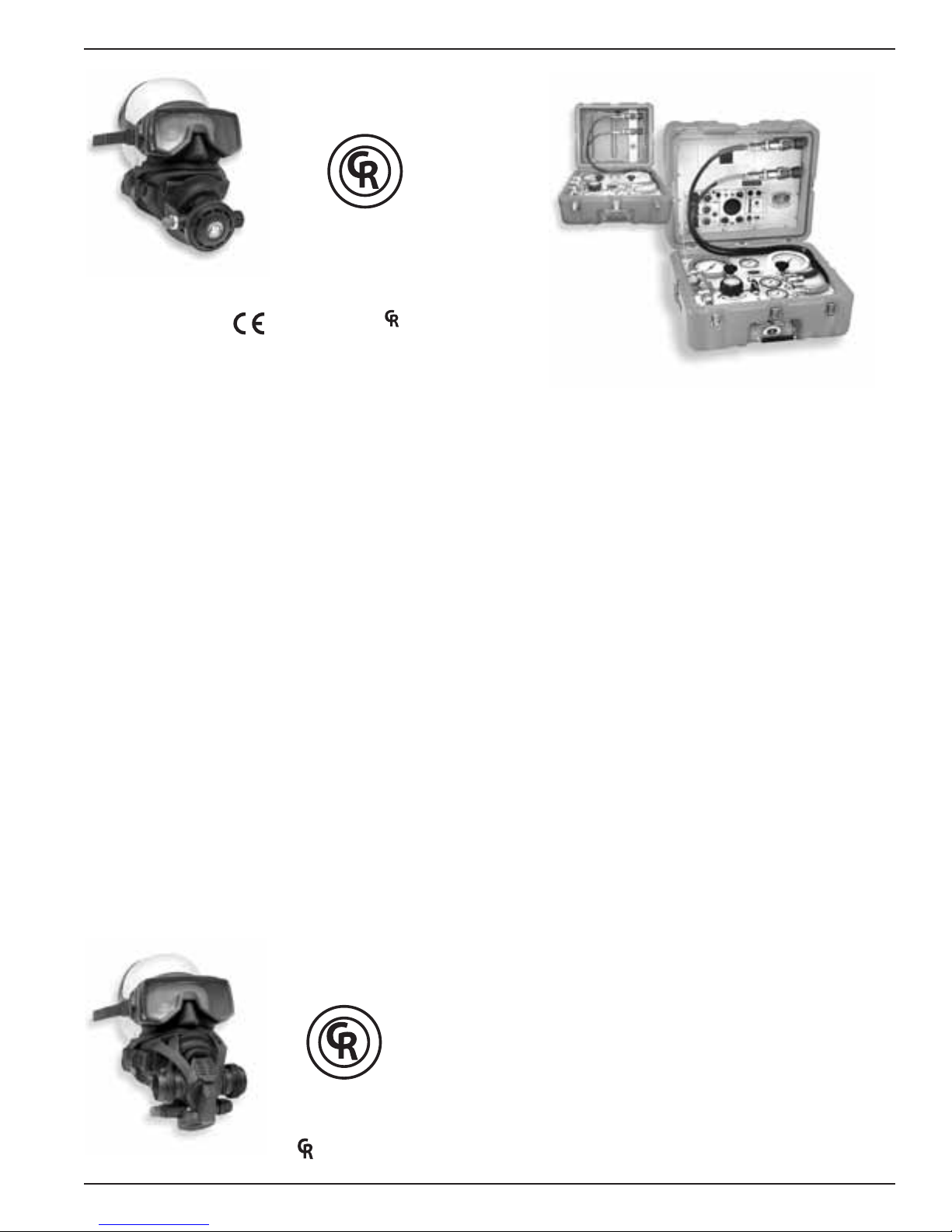

KMACS-5

w/ No Communications

approved and ™ marked

The SuperMask M-48 is an innovative new design

in a full-face mask. It provides the diver with all the

comfort of a full-face mask with the convenience of

changeable second st age regulators as well as the ability to use a snorkel wit hout having to remove the mask.

The mask is comprised of two major components,

the mask frame and the interchangeable lower pod.

The removable lower pod is a feature unique to the

SuperMask full-face mask. When diving, the pod is

easily removed and replaced on the mask, providing

the diver the capability to buddy-breathe, snorkel, use

an octopus or perform an “in water” gas switch.

With the pod sealed to the mask, the exible, silicone

pod cover allows the diver to quickly place the regulator mouthpiece into the mouth or dive with it free of

the mout h for com mun ications. With the mouthpie ce

in, the regulator may be used without the pod being

sealed to the mask.

The mask may also be used surface supplied when

used with the proper accessories. We are currently

developing several different pod congurations for

both open circuit and rebreather use. For further

information, see the Frequently Asked Questions

(FAQ) area on

our web site at www.KirbyMorgan.

com/FullFaceMasks/M48.html.

KMACS-5

w/ Communications

The Kirby Morgan Air Control System-5 (KMACS)

is a lightweight, portable control box for use in surface supplied air diving operations. The KMACS-5

controls the diver’s air supply, communications and

monitors the diver’s depth. It allows two divers clear

push-to-talk (two wire) or round robin (four wire)

communications. The KMACS-5 is also available

without communications.

The air supply can be either from a low-pressure

compressor or high-pressu re cylinders. T he adjustable

rst stage regulator reduces the high-pressure air and

supplies low pressure through the umbilical to the

diver’s breathing system.

High pressure yokes permit U.S. standard scuba cylinders or DIN equipped cylinders to be used. Lowpressure air supply ttings allow for a compressor to

be used as the primary air source.

A complete pneumo system with dual reading gauges

(both US Standard and Metric) is provided for each

diver’s air, as well as a shut-off/bleed system that uses

two high-pressure feed lines which allows changing

of used cylinders without interruption of the diving

operation. Optional shut off valves allow the isolation

of each diver’s air supply.

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 3

SuperMask M-48

w/ Rebreather pod

The Communication Set is a multipurpose intercommunication system that provides reliable and clear

communications between a topside operator (tender)

and one or more surface-supported divers, recompression chambers, or other submersible systems.

marked

Kirby Morgan® 37 & 57

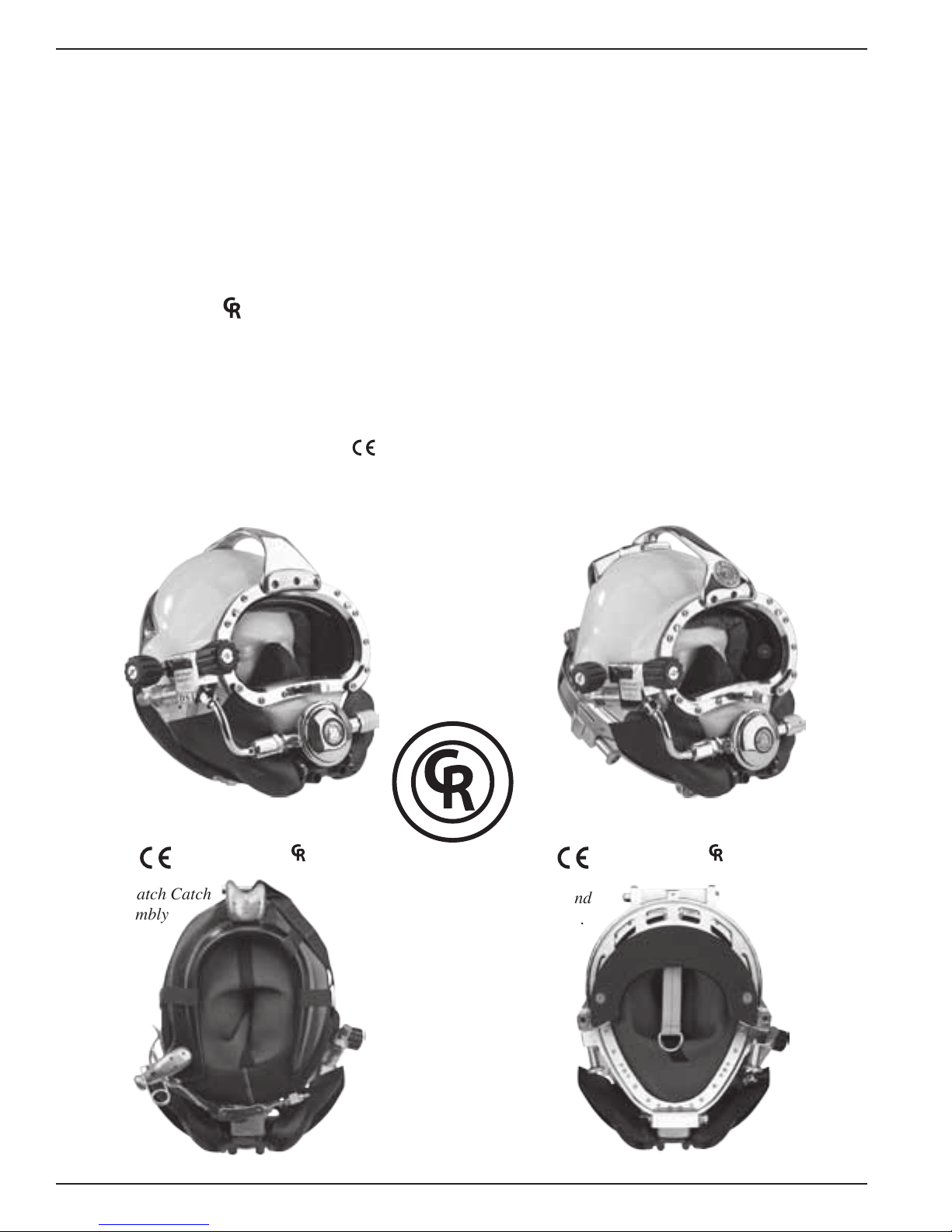

1.3 Kirby Morgan Diving Helmets

All Kirby Morgan diving helmets and masks are

manufactured by Kirby Morgan Dive Systems, Inc.

(KMDSI). Each step of the manufacturing process is

carefully controlled to assure the customer of a high

quality, durable helmet that will function properly for

many years.

There are eight models of Kirby Morgan diving helmets currently in production. They a re the SuperLite

17B, (MK-21- U.S. Navy version), SuperLite

SuperLite

47, 57, and 77. All are

The SuperLite

®

27, and Kirby Morgan models 37, 37SS,

®

-17 A/B was rst developed in 1975

™

marked.

®

and quickly set a new standard for diving helmet

design. Many large and small commercial diving

companies, military organizations, scientic divers,

and public safety divers are successfully using this

design around the world. This helmet is

marked.

®

17C the

The SL-17 A/B helmet system consists primarily of

two major components: the neck dam/yoke assembly,

and t he helmet. To don the helmet, the diver rst slips

the a ngled neck dam wit h t he attached yoke over thei r

head. The helmet is lowered onto the diver’s head

with the help of a tender, then the yoke hinge tab is

hooked onto the alignment screw on the rear weight.

The neck clamp is then slipped onto the helmet and

locked. The locking system not only seals the neck

-

dam to the helmet but also secures the front of the

yoke, fastening the helmet to the diver’s head.

The SuperLite

®

-17A /B shares many common breath-

ing system parts with all Kirby Morgan helmets

and masks. The breathing system was man-tested

to 1600 FSW by the University of Pennsylvania and

approved by the U.S. Navy for surface-supplied diving to 190 FSW with air and 300 FSW with mixed

gas. It surpasses all requirements of all governing

agencies and it is approved for commercial diving

through out the world.

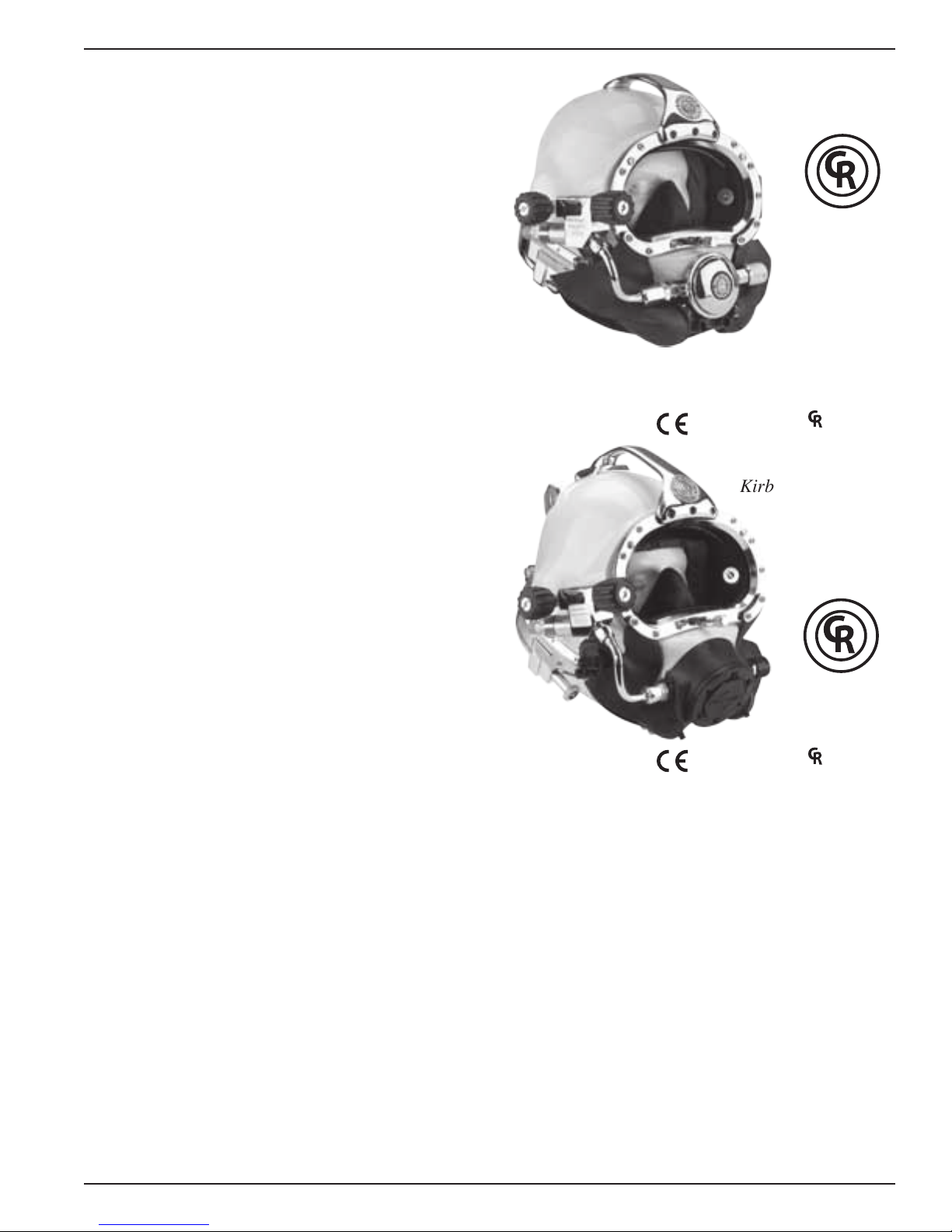

SuperLite® 17A/B

approved and ™ marked approved and ™ marked

Yoke and Latch Catch

Assembly

A

R

T

Y

E

L

D

L

A

I

C

R

E

M

M

O

C

D

E

T

S

E

T

B

A

L

E

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

V

E

I

A

D

R

-

™

Kirby Morgan

®

37

Neck Pad and

Sealed Pull Pins.

4 © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

Other features that are common to all Kirby Morgan

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

helmets include:

* Face port and retainer ring

* Communications components

* Oral/nasal mask

* Nose block device

* Air train defogger

Kirby Morgan® 37 & 57

The Kirby Morgan

®

37 Commercial Diver’s Helmet

represents what we at Kirby Morgan consider to be

a turning point in modern diving helmet design. The

helmet consists of two major assemblies: the helmet

shell/helmet ring assembly and the neck dam/neck

ring assembly.

The helmet comes with the large tube SuperFlow

350 adjustable demand regulator which provides an

easier breathing gas ow during peak work output.

A quick change communications module is available

with either bare wire posts or a waterproof connector.

The helmet ring houses the sealed pull pins and

provides protection for the bottom end of the helmet.

The diver is also provided with an internally adjustable chin support. This custom t and balance seats

the helmet comfortably for long periods of time even

when working in the face down position.

The SuperLite

®

27® Commercial Diver’s Helmet has

all the same features of the KM37 on a smaller, low

volume shell design. This helmet is often preferred

by persons with smaller heads.

®

®

SuperLite

27

®

approved and ™ marked

Kirby Morgan® 47

®

The chrome plated machined brass helmet neck ring

houses the sealed pull pins and provides protection

for the bottom end of the helmet. Like the SL-17K,

37 and 17C, the diver is provided with an internally

adjustable chin support. This support, along with the

adjustable neck pad on the locking collar, gives the

diver a comfortable, secure, custom t.

The quick-cha nge communications module, available

with either bare wire posts or a waterproof connector,

allows for easy, efcient maintenance of the helmets

communications.

The helmet also features the SuperFlow

tube adjustable demand regulator. The helmet is

available in the umbilical over the shoulder, “B”

conguration only.

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 5

®

350 large

approved and ™ marked

The Kirby Morgan® 47 offers the ultimate in a high

performance breathing regulator. This helmet has an

entirely new breathing system, oral nasal mask, and

water ejection system. T he REX

®

Demand Valve, wit h

it’s fully adjustable balanced piston is a breakthrough

design that exceeds the requirements of all government or other testing agencies.

It has the best work-of-breathing performance when

compared to ANY other commercial diving helmet.

The Kirby Morgan 47 Dive Helmet has been tested

and meets or exceeds European CE requirements and

is fully commercially rated. In all other respects, this

helmet is nearly identical to the Kirby Morgan 37.

Kirby Morgan® 37 & 57

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

™

marked

®

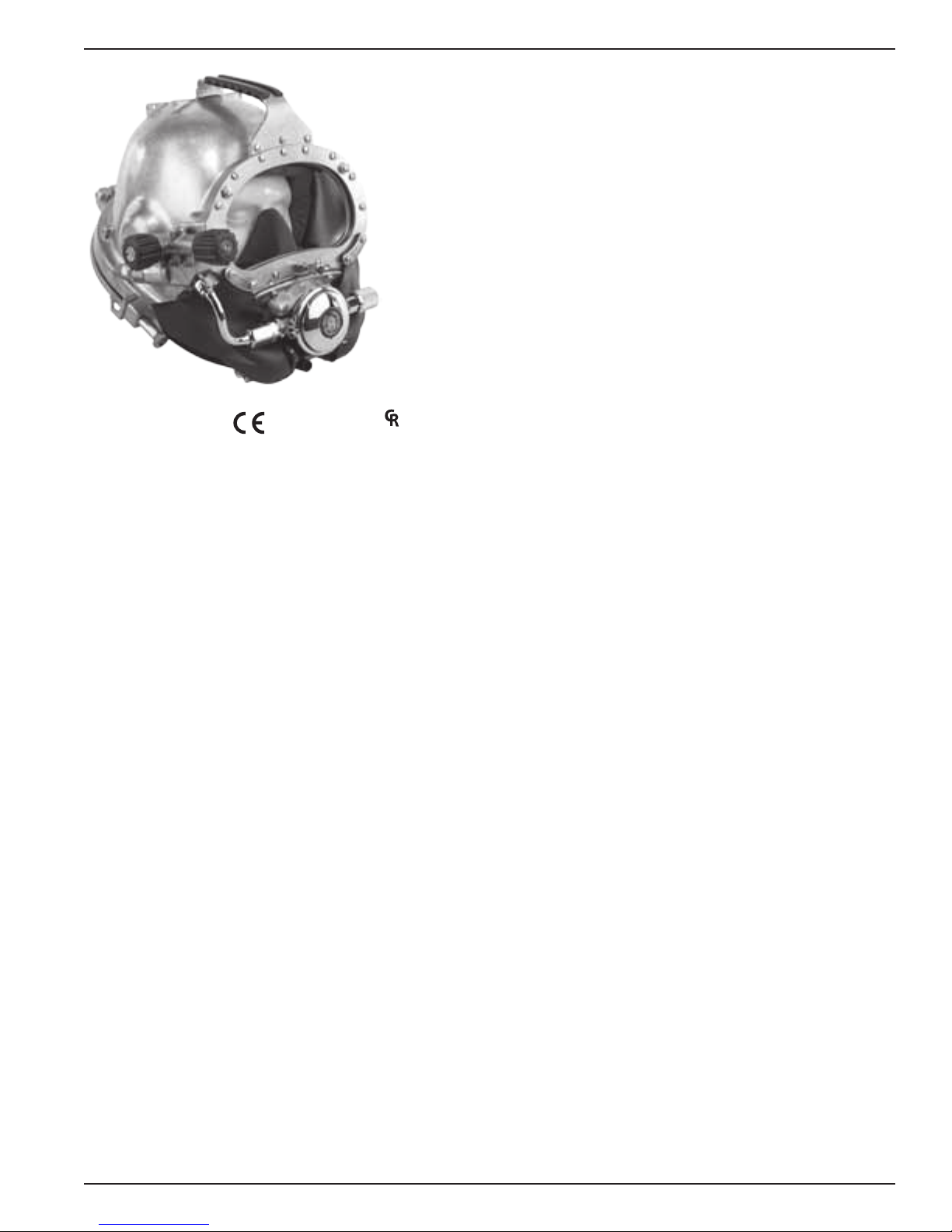

The Kirby Morgan® 57 helmet features our revolutionary new SuperFlow

®

450 Stainless Balanced

Regulator. It's machined from a stainless steel casting

for the ultimate in performance and reliability.

Like all KMDSI regulators on our helmets and

Band Masks

®

, we use only regulators that are specically designed for surface-supplied diving, that will

perform over the wide range of pressures delivered

by low pressure compressors. An ordinary SCUBA

regulator mounted on a diving helmet is not capable

of delivering the gas you need at heavy work loads.

This commercially rated fully diver adjustable regulator delivers all the breathing gas you might require

for the most demanding work underwater.

The Kirby Morgan

™

Valve

Exhaust System. It's recommended for div-

®

57 also includes our Quad

ing in biologically contaminated water, when you're

properly trained and equipped, using recommended

procedures. This new exhaust has exceptionally low

exhalation resistance that you must experience to

appreciate.

®

approved and ™ marked

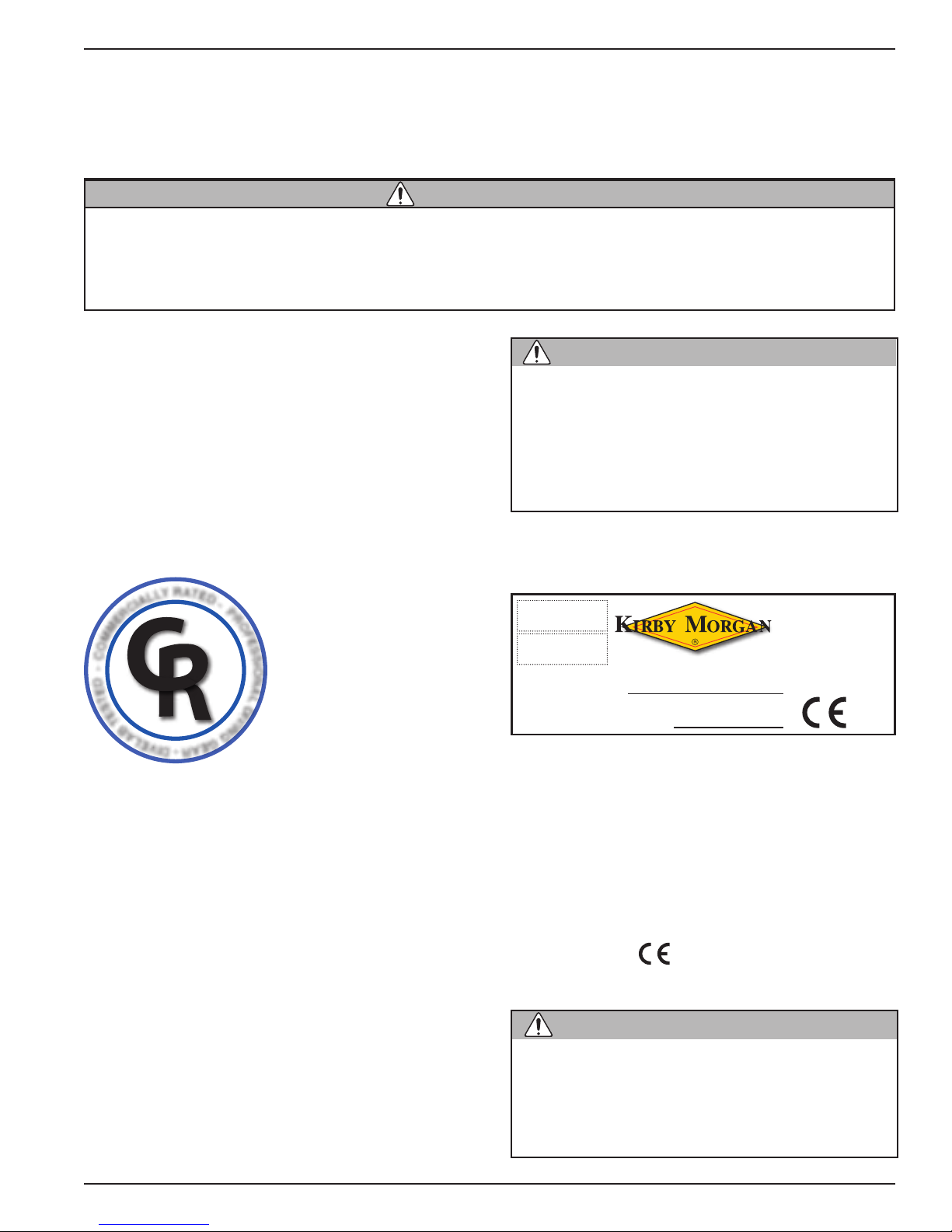

The Kirby Morgan® 77 represents the rst in a new

generation of stainless steel diving helmets that provide an alternative for the diver who prefers a metal

helmet. The helmet features a stainless steel version

of our new REX

®

regulator, which offers the best

performance of any Kirby Morgan system.

It has the best work-of-breathing performance when

compared to ANY other commercial diving helmet.

The Kirby Morgan 77 Dive Helmet has been tested

and meets or exceeds European CE requirements and

is fully commercially rated.

The advantages of this all stainless steel helmet include the following:

• No renishing required if the surface is scratched

or gouged.

• Faster production of helmets for customer delivery.

B WARNING

Before attempting any diving in any

type of contaminated water, a complete diving and topside course in

hazardous materials emergencies

should be completed. The divers and

the topside team must be properly

trained and have the proper safety

equipment. All helmets and suits can

leak water under certain conditions.

Divers should use extreme caution

when diving in contaminated waters.

6 © ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002

• Elim ination of th readed inserts for securing the port

retainer to the helmet shell.

• No need to remove the handle to remove the port

retainer.

• One piece sideblock includes both the free-ow valve

and the Emergency Gas System valve.

• The helmet ring is an integral part of the helmet.

Kirby Morgan® 37 & 57

®

approved and ™ marked

The Kirby Morgan

®

37SS features an all stainless

steel shell, as well as a stainless sideblock, helmet

ring, bent tube, handle, and other key components.

The SuperFlow

®

350 is standard on this helmet.

The K i rby Morgan 37SS featur es a quick change communications module, available with either bare wire

posts or a waterproof connector, and allows for easy,

efcient maintenance of the helmet's communications.

The advantages of this stainless steel helmet include

the following:

• Rugged helmet shell and other components

• No renishing required if the surface is scratched

or gouged

• Elimination of threaded inserts for securing port

retainer to helmet shell

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document #130108002 7

Kirby Morgan® 37 & 57

WARNING

CAUTION

WARNING

Chapter 2

Description & Operational Specifications

Kirby Morgan 37 & 57

This manual is our effort to explain the operation, maintenance and use of the KM 37 & 57. We do

not herein make any effort to teach the principles of diving. It is our assumption the reader is a

qualified diver. We highly recommend that all divers should train, under controlled conditions, in

the use of any model of commercial diving helmet that they have not previously used or trained in,

prior to use on the job, until they have mastered the skills required to use their helmet correctly.

This section includes detailed descriptions of the

Kirby Morgan 37 and 57, as well as important operational specications. With the exception of the

regulators, all parts are interchangeable.

2.1 CR Marking

The helmet meets or excee ds all standards established

by Dive Lab of Panama City, Florida, and is CR

(Commercially Rated) rated with the SuperFlow

with SuperFlow

SuperFlow

L

A

I

C

R

E

M

M

O

C