Kirby Morgan 37 User Manual

Kirby Morgan 37 & 57

CAUTION

Breathing System Maintenance and Repairs

Chapter 7.0

7.1 Introduction

This chapter covers the maintenance and repair of all

components of the breathing system. The breathing

system includes the one way valve, the emergency

valve, the side block, the bent tube assembly, the

demand regulator, and the oral/nasal mask.

The breathing systems on all Kirby Morgan helmets

and masks are simple and highly reliable. The fact that

they can continue to operate when the components are

not in a well-maintained condition can cause divers

to become complacent about maintenance.

Your life depends on the correct function of this

equipment!

While Kirby Morgan helmets and masks are simple

to maintain, like any type of life support equipment,

they do require regular periodic maintena nce to f unction properly.

All parts disassembled should be thoroughly cleaned

using the methods described in the Appendix in the

rear of this manual. Components that require the use

of lubricants, sealing and thread locking compounds

should also be maintained.

Most fasteners have a torque value, it is imperative that

all fasteners which have a torque value be tightened

to the torque specifications as outlined by the procedure, or as listed in appendix 1. If in doubt as to the

proper torque setting, contact your local authorized

repair facility or KMDSI.

7.2 One Way Valve

NOTE: The one-way valve assembly should be disassembled, cleaned and the three O-rings should be

replaced at least annually. Damaged and/or corroded

parts should be replaced. A repair kit is available for

replacement parts (525-330).

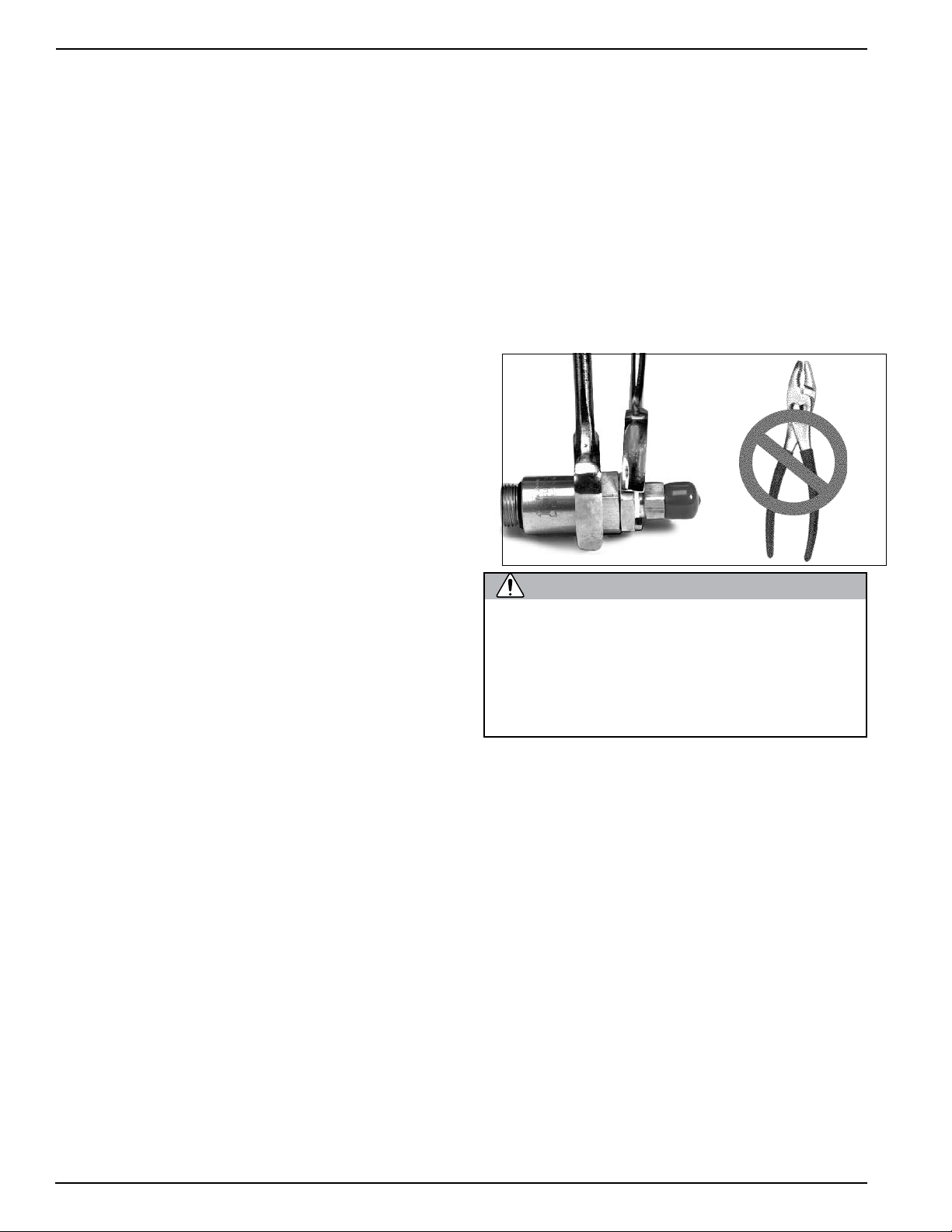

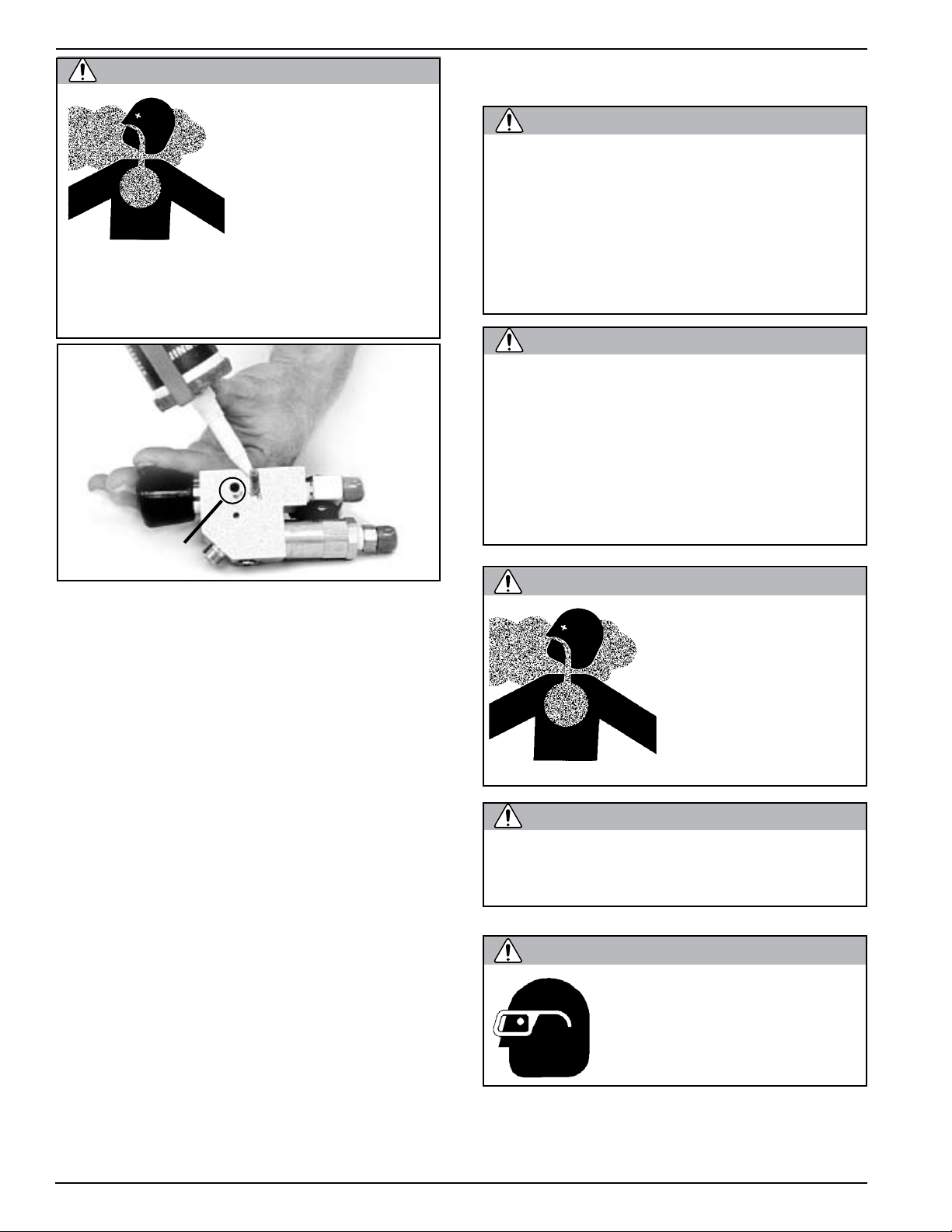

Use two wrenches or hold the hex part

of the body in a vise while removing or

turning the seat with a wrench. Do not

use pliers on the main body of the oneway valve. You may damage the valve if

pliers are used.

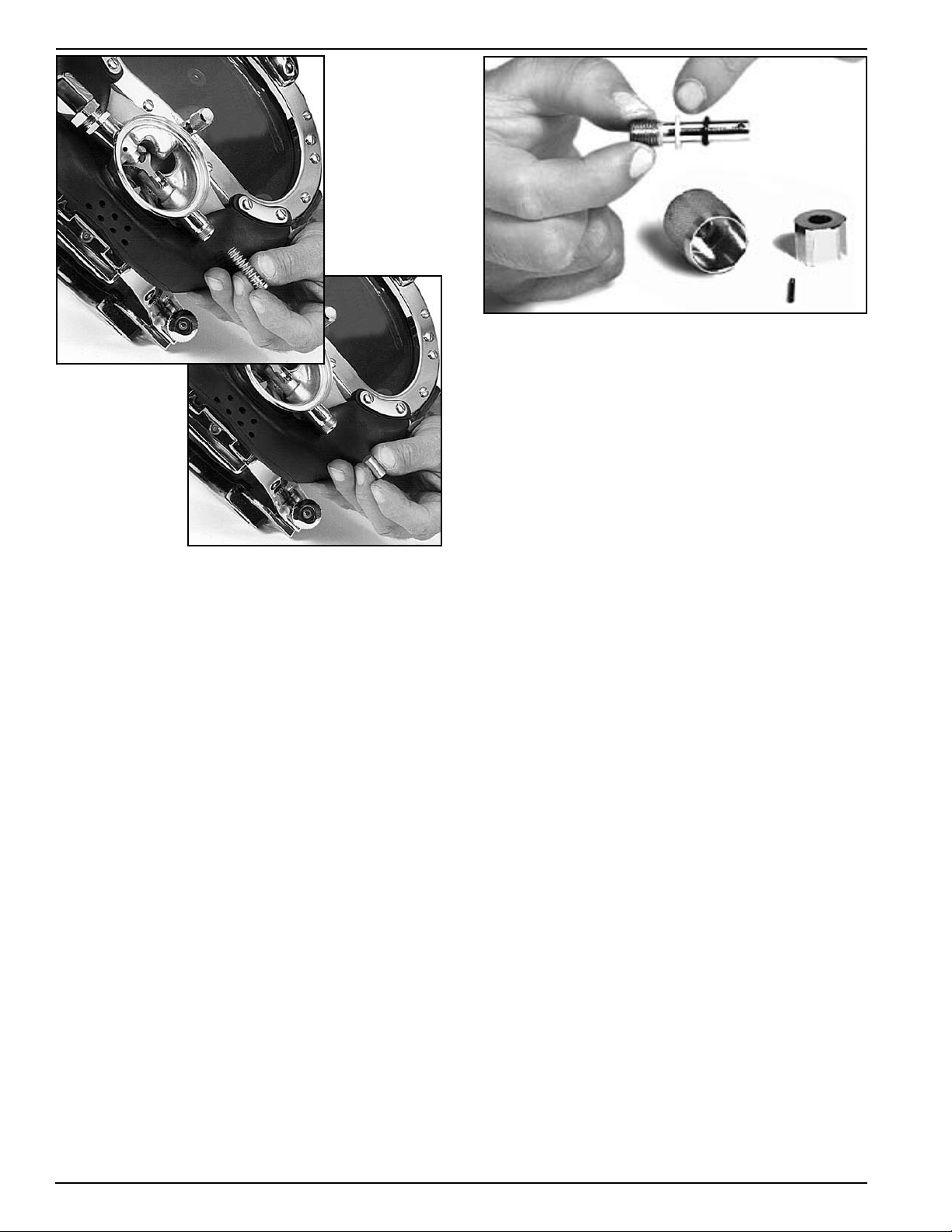

7.2.1 Disassembly Of The One Way Valve

Tools Required:

Soft Jaw Vice

1 inch Open End Wrench Attachment on Torque

Wrench

(If no vise is available use a backup 1 inch open end

wrench)

68

To disassemble and inspect the one way valve assembly:

1) The one way valve assembly must be removed

from the side block. Use the open end wrench to

remove it.

2) After the one way valve has been removed, use two

wrenches or hold the hex part of the body in a soft jaw

vise while removing the seat with a wrench.

As the seat is removed, the wiper and the O-ring

will slide out in place in a groove on the seat. The

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

WARNING

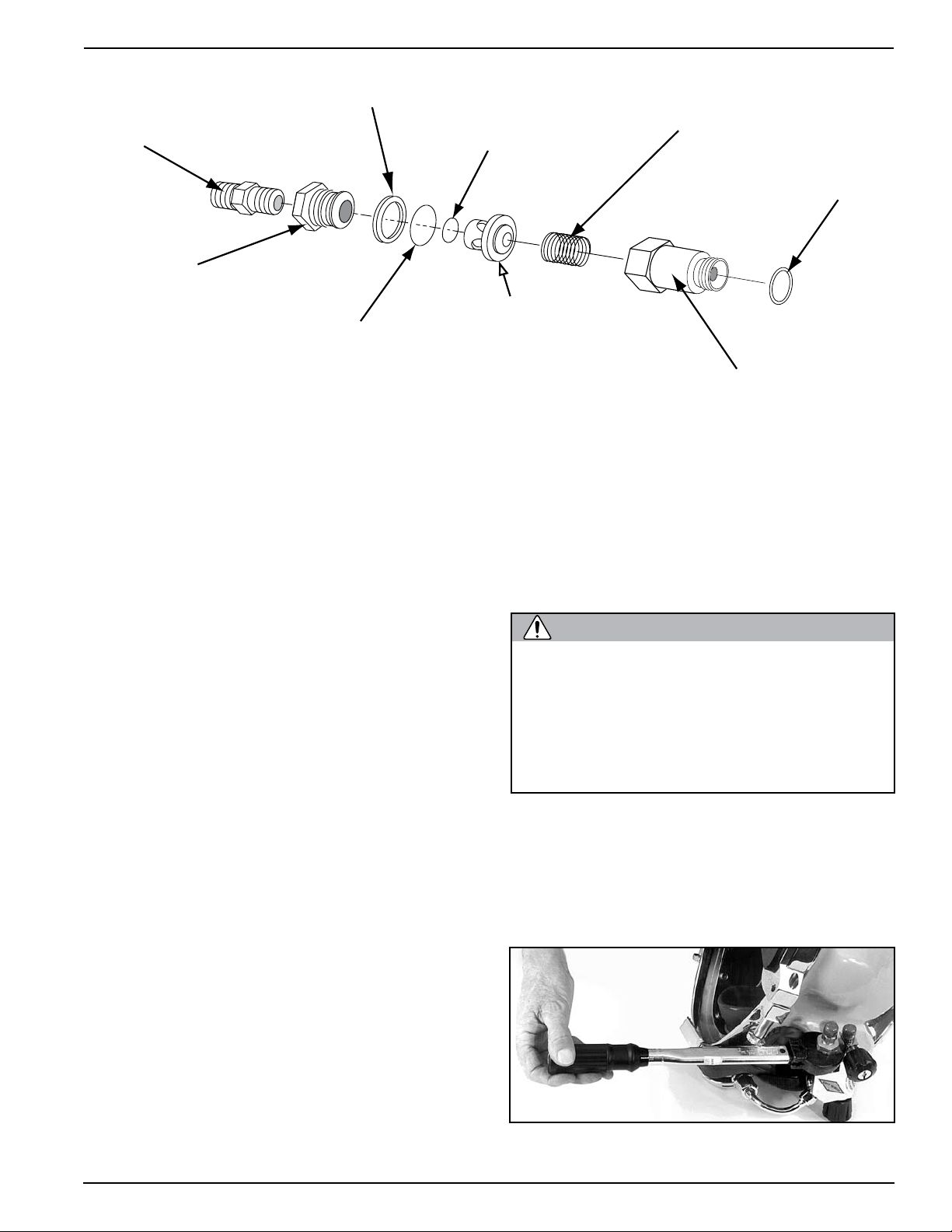

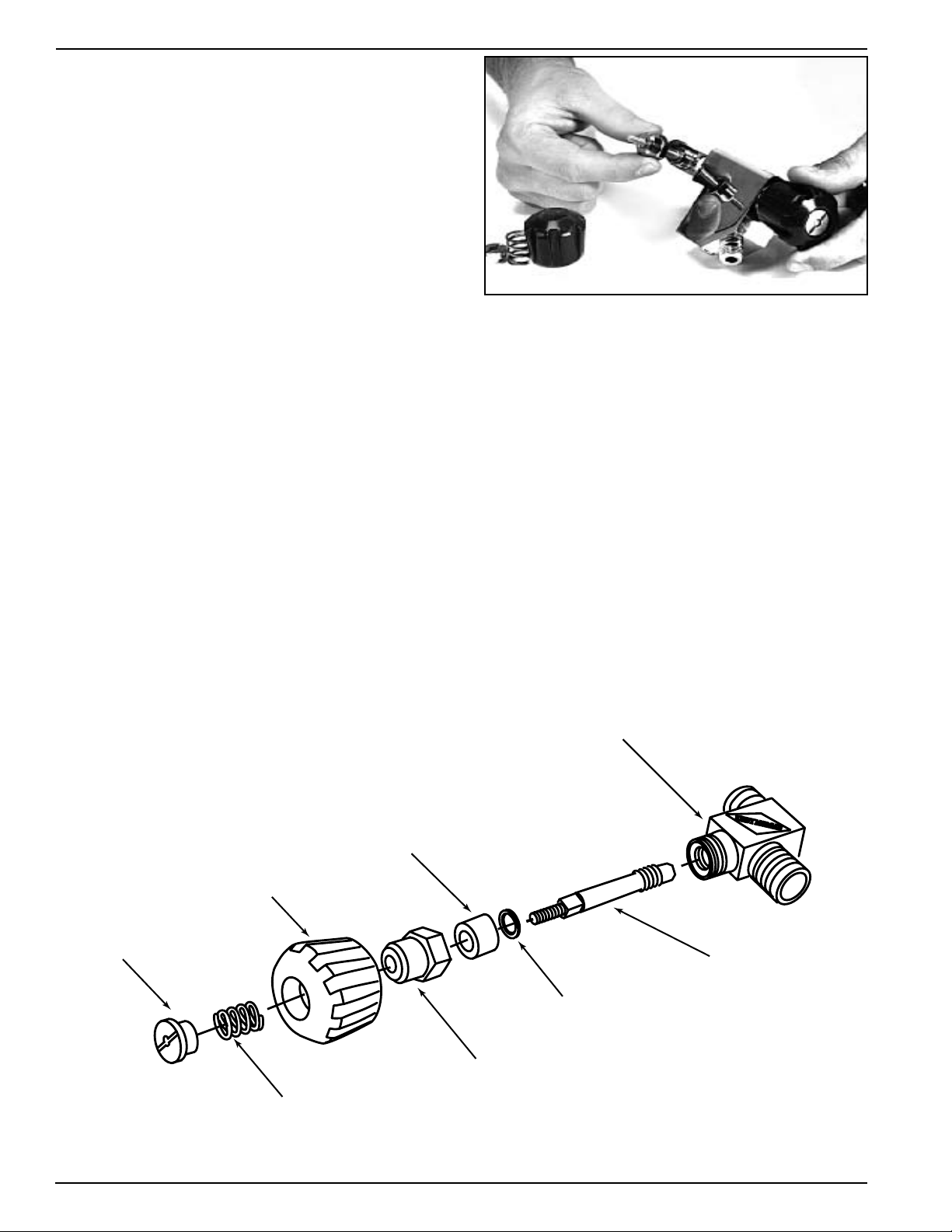

Correct assembly order of the one way valve.

Adapter

Seat

Wiper

O-ring

O-ring

Poppet

Spring

Body

O-ring

Kirby Morgan 37 & 57

poppet and the poppet O-ring usually come out in

the seat being followed by the spring.

The only functional part remaining in the valve body

is a non-moving, pressed-in cage. The function of the

cage is to prevent the poppet O-ring from blowing out

of place during high flows. Do not remove the pressed

in cage. This can only be done at the factory.

3) Inspect the body interior for foreign matter of any

type and clean, if necessary. Clean in accordance with

the cleaning instructions in Chapter 6. If corrosion is

present, clean using the acidic solution as outlined

in Chapter 6.

4) Inspect the seat, wiper, O-ring, poppet O-ring and

poppet for wear, replace if necessary. Be sure each

part is clean and all components are lightly lubricated

with the appropriate lubricant. A repair kit is available

for replacement parts. (Part #525-330)

5) Be careful to wipe the poppet and poppet O-ring

thoroughly, removing nearly all silicone to prevent

foreign materials from sticking to these components.

6) Replace the spring.

seat. Thread the seat into the valve body.

4) Tighten the seat to 150 inch lbs. (17 Newton meters) with a torque wrench while holding the body

in a soft jaw vice or wrench.

5) If the adapter has been removed, it must be cleaned

and wrapped with Teflon tape.

Do not allow any Teflon tape to cover the

end of the adapter, or to enter the oneway valve. Loose pieces of Teflon tape

can interfere with the performance of the

one-way valve or the regulator and may

block the diver’s air supply. This could

lead to death through suffocation.

6) Test the operation of the valve.

7) Place the new O-ring on the end of the one way

valve assembly and reinstall the valve assembly in

the side block. Tighten to 150 inch lbs. (270 kg.cm.)

with a torque wrench.

7.2.2 Reassembly of the One Way Valve

1) Slide the new O-ring over the poppet.

2) Insert the new spring into the valve body, followed

by the poppet.

3) Next, install the new O-ring and new wiper on the

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Tighten to 150 inch lbs. (17 Newton Meters) with a

torque wrench.

69

Kirby Morgan 37 & 57

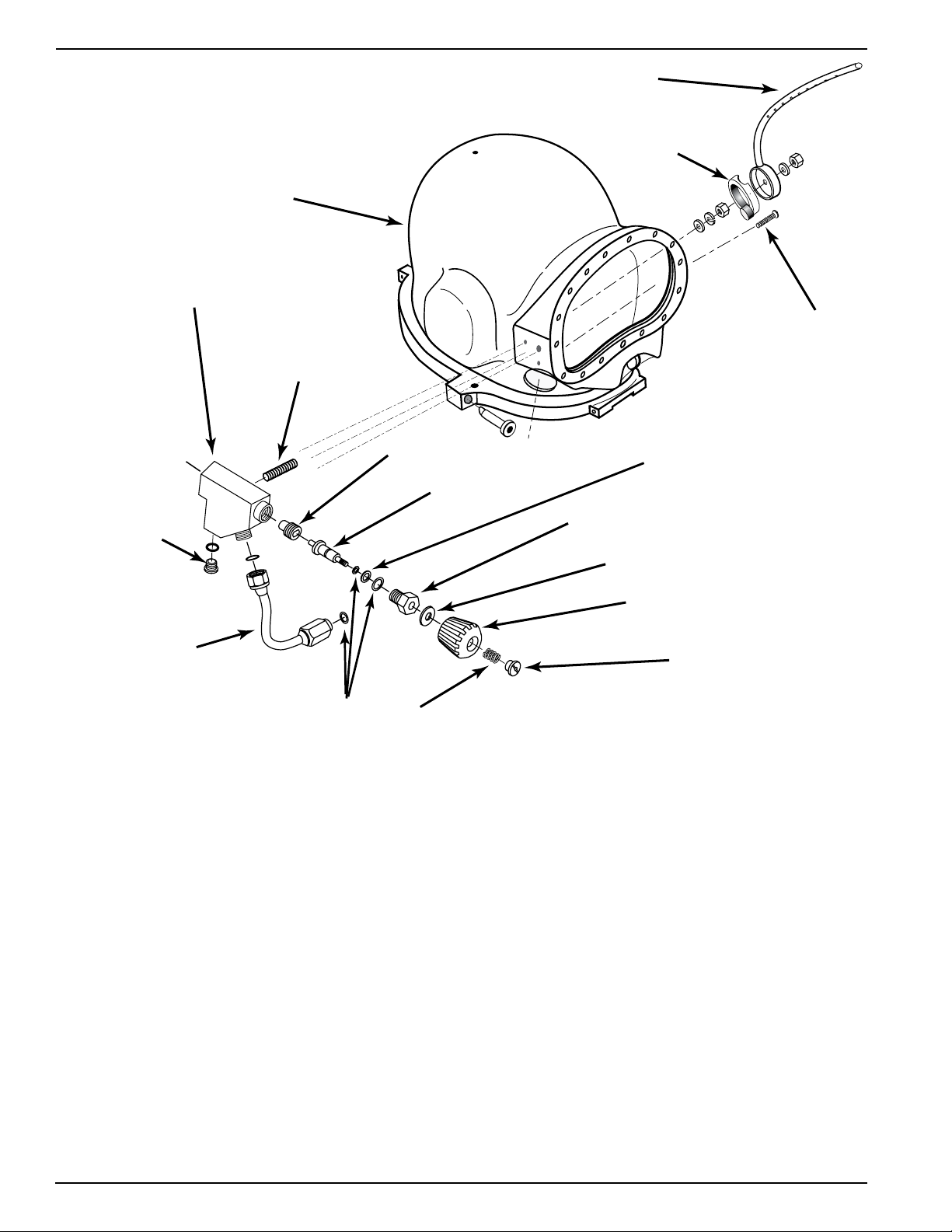

7.3 Side Block Assembly

7.3.1 General

The side block should be overhauled at least annually,

or whenever components show signs of wear, damage

or do not function smoothly or properly. Minimum

replacement components during overhaul includes

all O-rings. A repair kit is available for replacement

parts (Part #525-311).

The side block does not require removal from the

helmet each time an overhaul is being conducted

providing inspection of the internal passages does not

reveal contamination or excessive corrosion. However, the side block should be completely removed at

least every three years of active use to ensure fasteners

are not corroded or frozen.

The side block assembly is held in place on the helmet

shell by a stud, flat washer, lock washer, nut, and a

mach ine screw. T he screw does some securing but its

main function is to prevent rotation of the side block.

The stud also extends into the interior of the helmet

shell far enough to secure the air train by means of

the washer and nut.

The air train cup that fits over the stud is made of

soft brass and cannot be used for a bearing surface to

mount the side block. RTV silicone rubber compound

is used to form a gas tight seal between the side block

and the exterior of the helmet shell.

7.3.2 Side Block Assembly Removal

Tools Required:

7/16,11/16, and 7/8 inch Open End Wrenches

11/16 and 7/8 inch Open End Wrench Attachment on

Torque Wrench

1/4 inch Flat Blade Stubby Screwdriver

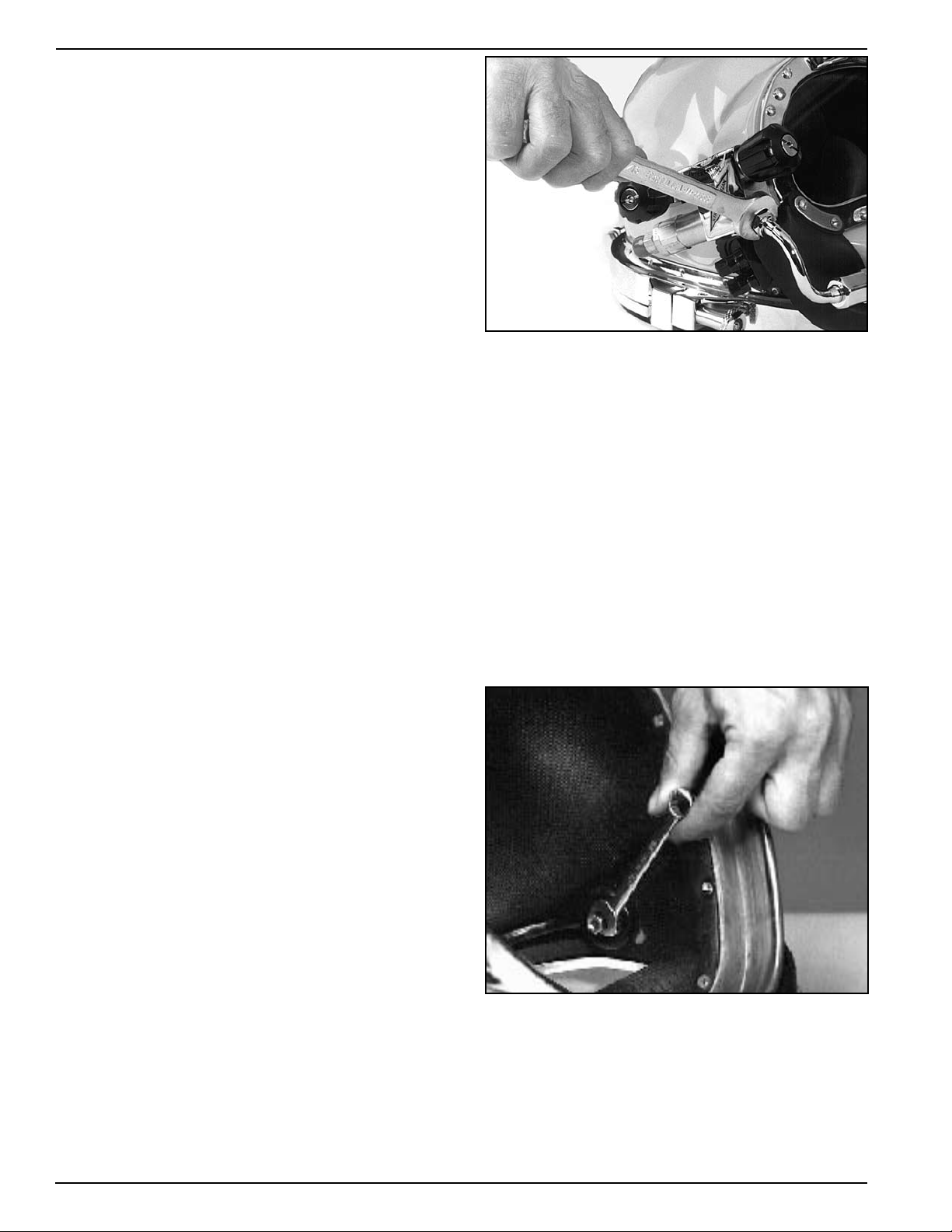

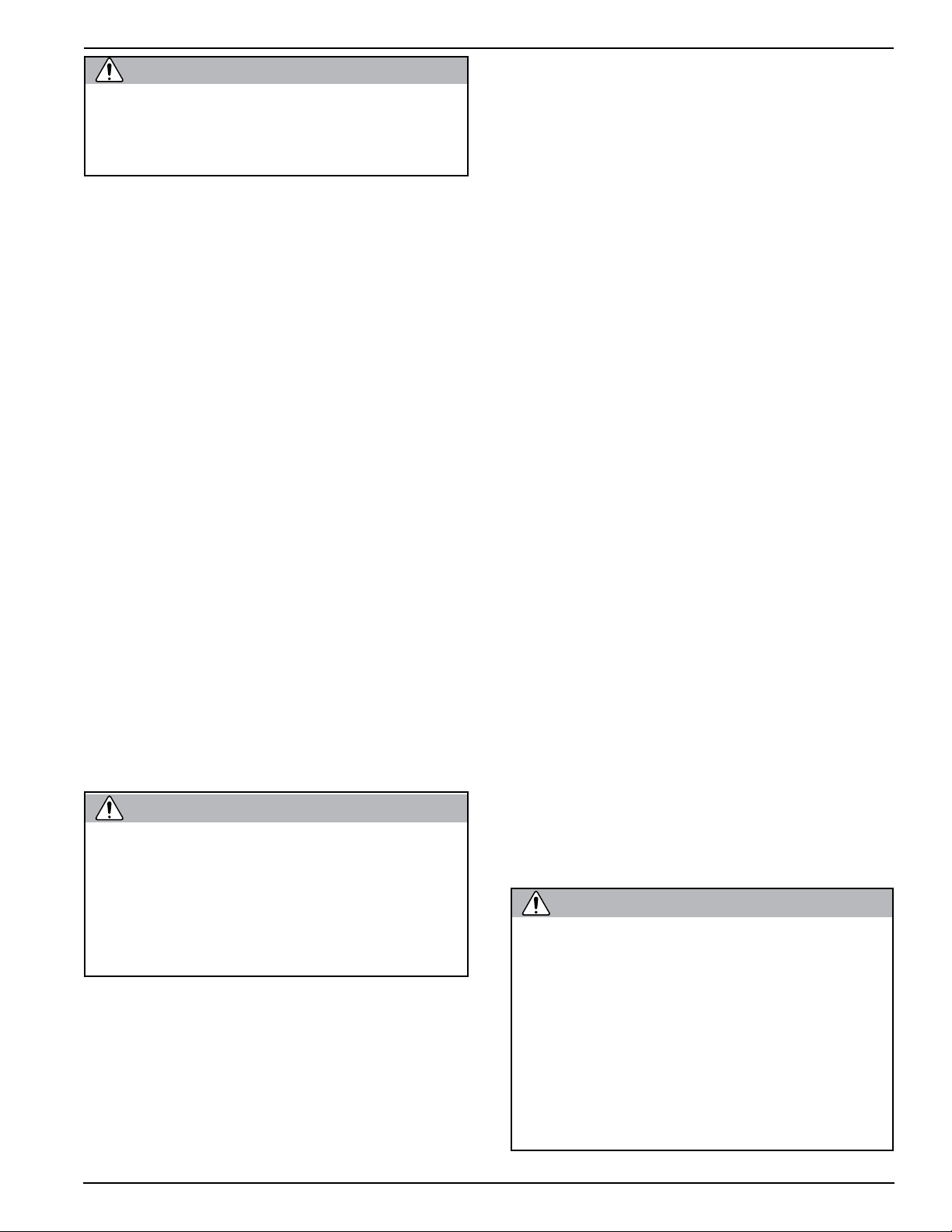

Loosening the bent tube from the side block.

7.3.3 Separating the Side Block Assembly

from the Helmet Shell

Tools Required:

Putty Knife

7/16 inch Open End Wrench

1/4 inch Flat Blade Stubby Screwdriver

1) Removal of the side block assembly requires removing the air train.

2) Remove the nut and washer that secure the air train,

then the air train itself.

3) The st ud nut is remove d next, with the lock washer

and flat washer.

The bent tube assembly must be ent irely removed before removal of the side block assembly is started.

1) Completely unscrew the bent tube assembly nut

(14) from the side block.

2) Using two wrenches, hold the nut at the regulator

end of the bent tube assembly with the first wrench.

With the other wrench, loosen the jam nut (100) by

turning the wrench DOWN.

3) Unscrew the bent tube nut until it comes free, then

pull the bent tube assembly straight out of the regulator inlet nipple.

4) The side block assembly is ready to be separated

from the helmet shell at this time.

70

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Loosening the nut that holds the air train.

4) Next, the alignment screw is removed.

NOTE: The alignment screw is located in a recess in

the fiberglass next to the stud. This recess is normally

filled with RTV. The RTV must be scraped free to reveal

the screw.

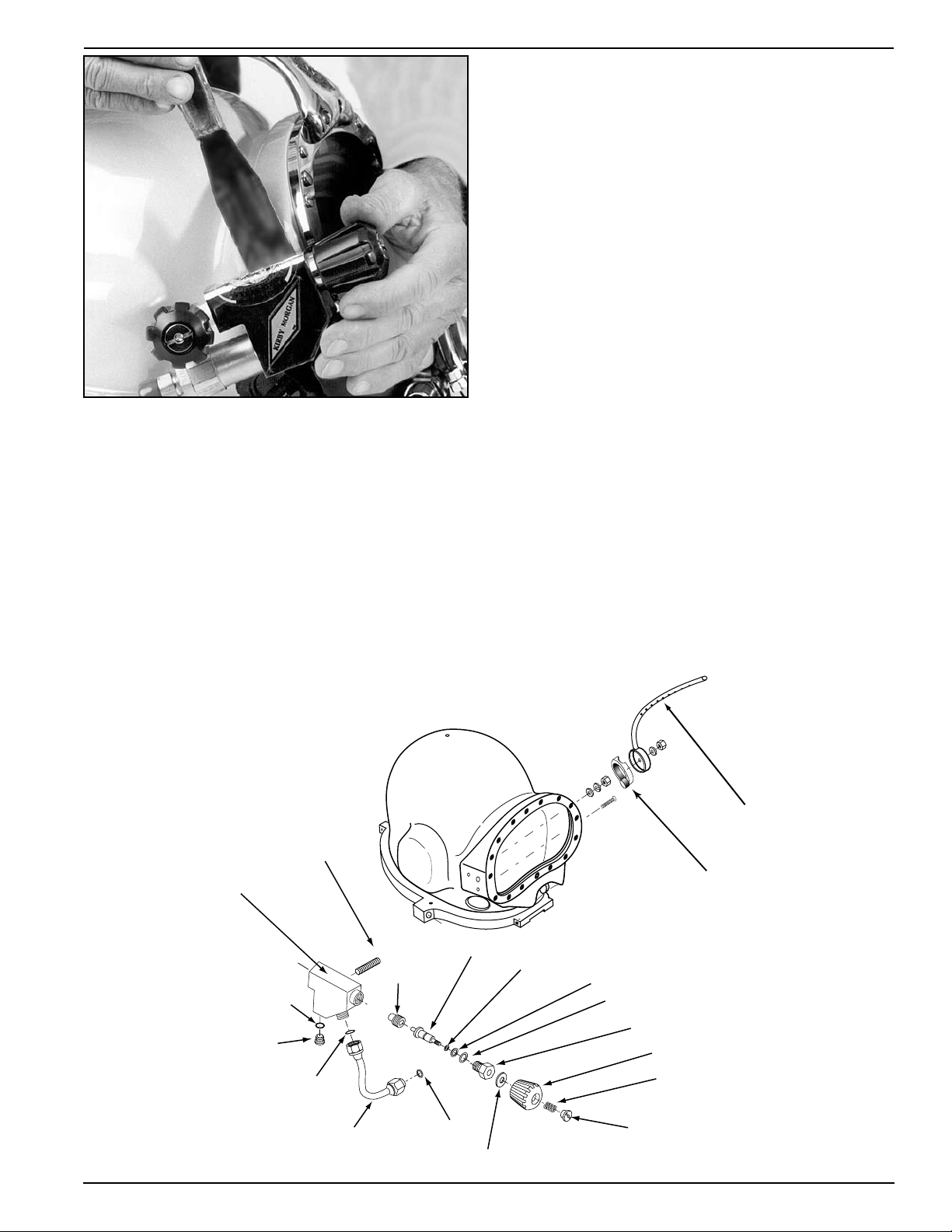

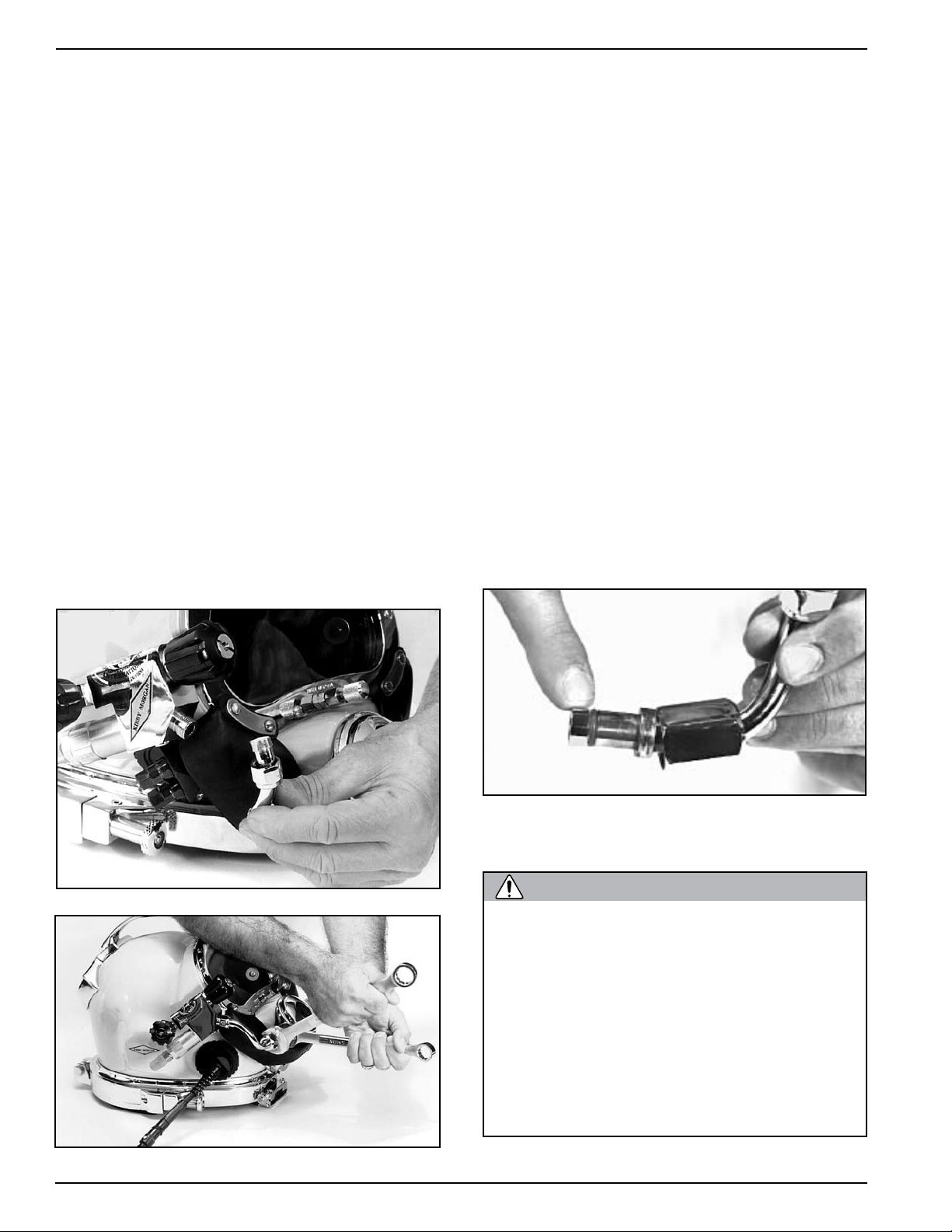

Knob

Spring

Washer

Locknut

Bonnet

Valve stem

O-ring

Washer

Side block

Stud

Bent tube

Seat

Plug

O-ring

O-ring

O-ring

O-ring

Air Train

Air Train

Gasket

A thin putty knife helps to remove the side block.

5) The side block assembly is now unfastened, but

held in place by the rubber sealing compound (silicone

sealant) that acts as a glue. It may be necessary to

rock just slightly, or pry the side block from the helmet shell. A thin putty knife can be pushed between

the side block and the helmet shell to help free it.

Do not use a screwdriver or chisel as damage to

the shell could result. Be sure to peel or scrape the

old silicone sealant away from both sealing surfaces

before reassembling. Acetone helps remove this, but

must be used sparingly since it will also remove the

Kirby Morgan 37 & 57

flat black finish inside the helmet.

6) If you plan to rebuild the side block assembly, it

should be done at th is ti me, while the side block is off

the helmet. Overhaul the defogger valve and emergency va lve i n accordance wit h th is chapter. O verhau l

the one-way valve in accordance with this chapter.

7.3.4 Side Block Assembly Replacement

If a new side block is being installed, make sure it

aligns correctly in the holes of the helmet shell before

applying RTV silicone sealant.

1) A generous application of silicone sealant must be

applied to the side block prior to installation on the

helmet shell. The sealant should surround the stud,

alignment screw, and air inlet on the block. Use only

Dow Corning

work must be done a well-ventilated area.

Care must be taken to avoid sealant entering the

air opening in the side block. Be sure to remove all

excess silicone sealant before it sets up. Lacquer

thinner can be used to dissolve uncured sealant, after

tightening.

2) Fit the side block to the helmet shell.

2) Thread the screw through the helmet shell and

lightly tighten into the side block body.

™ RTV 732 Multi Purpose sealant. This

Components of the Side Block & Air Train

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

71

Kirby Morgan 37 & 57

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Use silicone sealant in

a well ventilated area.

Do not breathe the

fumes from uncured

silicone sealant. These

fumes are dangerous

and can cause uncon-

sciousness. They can

also cause long term damage to body tissue. Read and follow all precautions listed

on the silicone sealant tube and Material

Safety Data Sheet.

DO NOT BLOCK

AIR OPENING!

If it is, it must be cleaned out prior to diving.

Do not dive the helmet until the sealant

has had time to cure. Check the directions on the tube of sealant for curing

time. If the helmet goes into the water

before the sealant has cured it could leak

through the side block mounting stud

hole, screw hole, or air flow hole. This

could lead to drowning.

If silicone sealant is blocking the air flow

into the helmet it must be cleaned out. If it

is not, the diver may not be able to properly defog the helmet or clear a flooded

helmet quickly. In addition, if the demand

regulator is not delivering air properly, the

diver cannot use the free flow system as

a source of breathing air. This could lead

to suffocation.

A generous application of silicone sealant must be

applied to the side block prior to installation on the

helmet shell. Use only Dow Corning™ RTV 732 Multi

Purpose sealant.

3) Slide the flat washer and the lock washer onto the

stud. Run the stud nut down the stud and tighten to

35 inch pounds (4 Newton meters). Do not over-

tighten!

4) Tighten the screw to the correct torque, 35 inch

pounds. Clean off all excess silicone sealant.

5) Place the air train gasket on the base of the air

train. The knob on the base of the air train gasket is

designed to cover the recessed hole where the bolt

that helps maintain the position of the air train is

installed. Slip the air train over the stud. Align the

air train with the upper edge of the view port opening

in the helmet shell.

6) Place the washer on the stud and tighten the nut

until the washer lays flush on the air train, 15 inch

pounds. Do not overtighten!

Avoid breathing

fumes from lacquer

thinner and use in a

well ventilated area.

Breathing fumes

can lead to nervous

system damage,

unconsciousness,

and death.

Avoid skin contact with lacquer thinner.

Wear rubber gloves. Lacquer thinner can

damage the nervous system.

Avoid eye contact with lacquer thinner. This chemical

is an irritant and may cause

tissue damage.

7) Test the side block prior to diving to ensure that no

silicone sealant is blocking the air flow to the helmet.

72

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Kirby Morgan 37 & 57

7.4 Defogger Valve

7.4.1 Disassembly of the Defogger Valve

Tools Required:

3/8 inch Slotted Flat Blade Screwdriver

13/16 inch Open End Attachment on Torque

Wrench

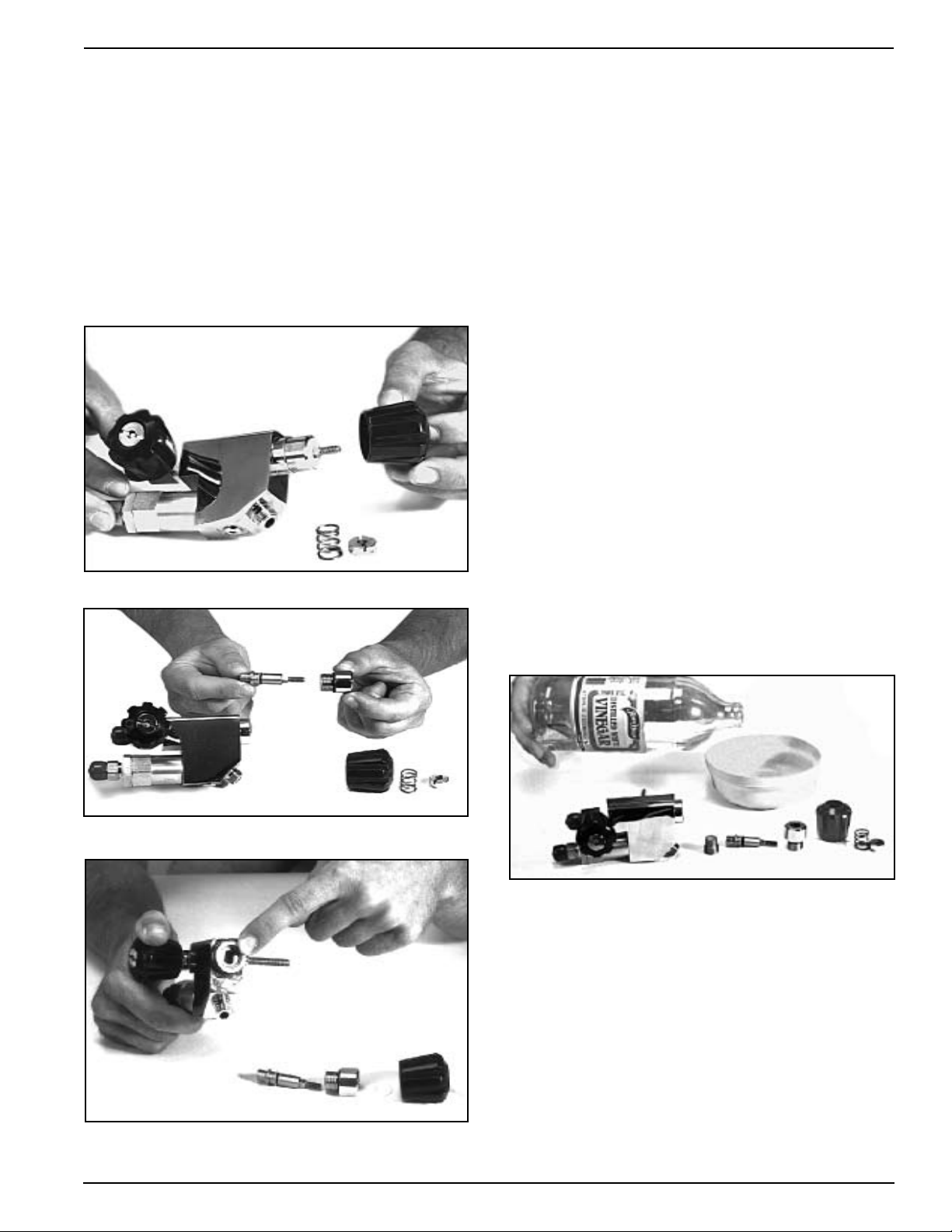

The defogger valve components are disassembled as

follows:

1) First, unscrew the control knob lock nut and remove the spring, control knob, and washer.

2) Next, unscrew the bonnet. Its o-ring will come off

with it. The valve stem, o-ring, and washer usually

come out with the bonnet and can be pushed out of

the bonnet once removed from the side block.

3) If the stem remains in the side block body it can

be lifted out after the bonnet is removed.

4) The seat a ssembly can be unscrewed from the side

block body with the stem or a screwdriver.

7.4.2 Cleaning and Lubricating

1) Clean all the metal first in the soapy water solution

and then in a 50/50 dilute solution of white vinegar/

water. Rinse in fresh water.

2) Check the Teflon

®

se at for wear a nd /or conta mination, and replace if necessary. Damage such as a rough

face or cuts to the seat indicate it must be replaced.

3) The Teflon

®

washer and O-ring must be replaced

if worn.

Remove the defogger control knob.

The valve stem usually comes out with the bonnet.

4) Be sure to place a light coating of silicone grease

on all internal moving parts, O-rings, and washers.

However, do not lubricate the Teflon

®

seat, as this will

attract dust and debris.

5) Inspect the seat area inside the side block and

replace the block if damaged.

Clean all the metal parts to remove salts.

The seat should be removed for inspection.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

73

Kirby Morgan 37 & 57

Side Block

Helmet

shell

Air Train

Air Train

Gasket

Stud

Bolt

Bent Tube

LP

Plug

Seat

Valve Stem

Bonnet

Washer

Knob

Spring

Nut

Teflon washer

O-ring

The Side Block assembly and it’s

associated parts.

7.4.3 Reassembly of the Defogger Valve

Tools Required:

3/8 inch Slotted Flat Blade Screwdriver

13/16” Open End Attachment on Torque Wrench

Minimum recommended replacement parts during

overhaul:

Washers, O-rings

1) Screw in the new seat assembly until it is even with

the front of the side block body.

2) Next, install the Teflon

the stem.

3) Insert the proper end of the stem into the seat

assembly and turn clockwise until the seat lightly

bottoms out. Leave the stem in place.

4) Lubricate the O-ring and install on the bonnet.

5) Slide the bonnet over the stem and thread the bon-

®

washer and O-ring onto

net into the side block.

6) Tighten the bonnet with a torque wrench to 100

inch lbs.

7) Place the new Teflon

on t he stem and rot ate t he stem counterclockwise until

the seat assembly tops out fully open. The control

knob must turn smoothly without any binding.

®

washer and the cont rol knob

Binding (or “hard spots”) in the rotation could be

an indication of a bent stem that should be replaced.

Replace the knob and or stem if the fit allows the valve

to rotate loosely more than 1/8

8) Install the new Teflon

the spring, and locknut. Tighten the locknut until it

is flush with the knob.

th

of a turn.

®

washer, new knob, and

74

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

7.5 Emergency Valve Assembly

WARNING

The Emergency valve control knob is not interchangeable with the defogger valve control knob.

The control knob for the emergency

valve and the defogger knob are not interchangeable. Use only the correct knob

for the appropriate valve.

Kirby Morgan 37 & 57

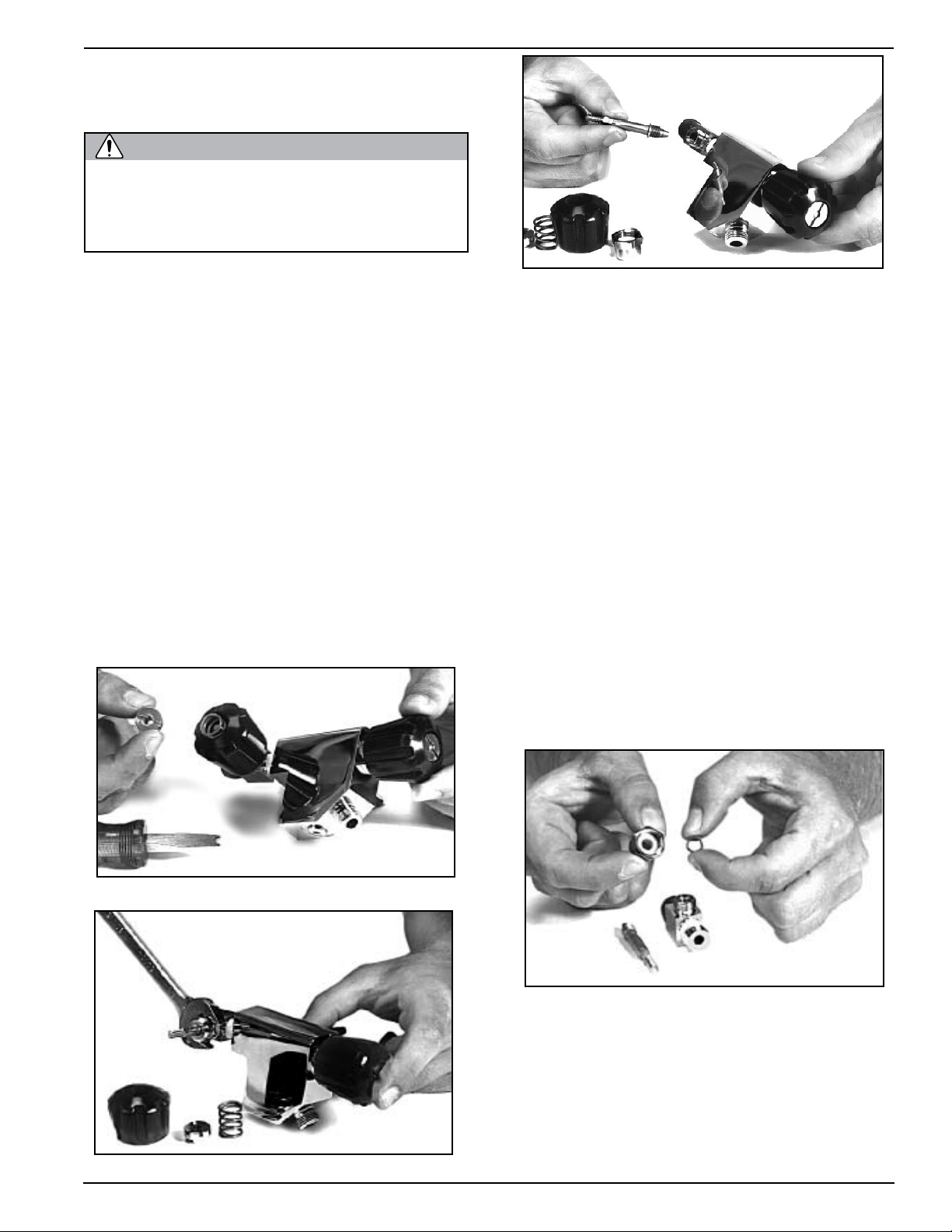

7.5.1 Disassembly of the Emergency Valve

Tools Required:

11/16 inch Open End Wrench

1 inch Open-end Wrench

Torque Wrench Attachments & Torque Wrench

3/8 inch Slotted Flat Blade Screwdriver

Soft Jaw Vice

Lubricant

Teflon Tape

1) Remove the lock nut, spring, and knob.

2) Undo the packing nut, and remove the packing,

and washer.

3) When the packing nut is free of the threads of the

emergency valve body, back out the stem until it is

free of the emergency valve body.

Remove the valve stem.

7.5.2 Cleaning and Lubricating

1) Clean all the metal parts in a soap and water solution, followed by cleaning with a 50 /50 dilute solution

of white vinega r/water. Rinse with fresh water. Clean

all parts. See the cleaning instructions in Chapter 6.

2) Inspect the packing and washer for wear and replace if necessary. Normally the packing will last a

very long time and does not require replacement as

long as the valve operates smoothly and does not leak.

To replace the packing place the packing nut in a vise

and carefully work the packing out with a small screw

driver, taking care not to damage the threads of the

packing nut. Replace the washer if needed.

3) Inspect the stem seat for unevenness or wear and

replace if necessary. It must also be replaced if the

stem is bent. Damage will include damaged threads,

rounded flats that engage the control knob. Also

inspect the shaft to ensure the conical seat surface is

smooth and free of corrosion or damage.

Remove the lock nut, spring and knob.

Inspect the packing and washer.

4) Check the seat in the emergency valve body for

wear or unevenness, galling and corrosion. Check

the seat on the emergency valve stem. To clean up the

seat surface use a pencil eraser to buff the surface.

Inspect all threaded surfaces for damage. Replace the

emergency valve body if any damage is found.

Undo the packing nut.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

75

Kirby Morgan 37 & 57

Valve Body

Valve Stem

Packing nut

Knob

Spring

Lock nut

Packing

Washer

5) To remove the emergency valve body from the

side block the one way valve assembly must first be

removed.

6) If the emergency valve body was removed, clean

and inspect the pipe thread and inspect for damaged

threads, cracking or distortion. Replace the emergency valve if any damage is present.

Re-tape threads with Teflon tape, 11/2 wraps starting

two threads back, tighten using good engineering

practice. To reinstall the emergency valve body onto

the side block, the one-way valve assembly must be

removed first.

7.5.3 Reassembly of Emergency Valve

1) Lightly lubricate the stem threads in the body as

well as the bonnet threads.

2) Replace the washer and packing on the stem , then

lightly lubricate the stem shaft and threads.

NOTE: There are two different packing (s) and

washers supplied in the kit (525-311), for rebuilding both the older style and the newer high flow

emergency gas valve. Match the removed packing

and washers to the new ones supplied and discard

the others.

3) Holding these components in place on the stem,

screw the stem into the emergency gas valve body.

Installing the packing nut on the valve stem.

4) Rotate the stem until it is seated all the way in then,

back it out -1/2 turn.

5) T

hread the packing nut onto the emergency valve

body. Run the nut in and tighten slightly with a

wrench.

6) Inspect the emergency gas valve knob for wear and

damage. Ensure the flats that engage the valve stem

shaft are not rounded, cracked or damaged. The valve

knob should not have rotational play greater than 1/8th

of a turn.

NOTE: This knob is not interchangeable with the

defogger valve knob.

7) Place the emergency gas valve knob onto the stem

76

The emergency valve

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

WARNING

The control knob for the emergency

WARNING

WARNING

valve and the defogger knob are not interchangeable. Use only the correct knob

for the appropriate valve.

and rotate the stem all the way out, then back again.

The rotation must be smooth. If “hard spots” or unevenness are felt during the rotation, the stem may

be bent and could need replacement.

8) Tighten t he pack ing nut with a torque wrench until

moderate resistance is felt when turning the knob.

Torque to 50 inch pounds after seating.

Kirby Morgan 37 & 57

the first thread. Apply the tape with slight tension to

allow the tape to fill into the threads.

Hand tighten the valve, then continue an additional 1-1/2

to 2 turns with a wrench keeping in mind the proper

alignment of the control knob to the side block. Also,

there should be at least one male thread visible. Check

to be certain the valve is tight by trying to loosen the

fit by hand.

DO NOT TIGHTEN

TH

AN NECESSARY!

OVERSTRESS THE PART AND CAUSE THE PART

TO FAIL.

THE VALVE BODY TIGHTER

OVER TIGHTENING MAY

9) Place the spring, and locknut onto the stem securing the knob.

10) Tighten the locknut until its top is flush with the

top of the knob. The assembly is now complete and

ready for testing.

NOTE: If the valve was removed from the side block

testing of the emergency gas valve is easily accomplished by attaching the valve, by itself in the shut

position, on to the bail-out whip from the first stage.

Pressurized to a minimum 135 p.s.i.g. (9.3 bar) using the EGS Cylinder and dropping it into a bucket

of clean water a minimum 30 seconds to check for

leaks.

11) Before wrapping the threads with pipe tape, check

the fit of the valve assembly pipe threads to the mating

threads of the side block. There should be 2 turns of

hand make up before needing to use a wrench.

Use only thin Teflon tape when installing

the Emergency Gas Supply valve in the

side block. Thick tape can lead to thread

damage, which may make it impossible

to install the EGS valve in the side block

properly. This could lead to a loss of

breathing gas.

If there is less make up, then the threads will need to be

chased with a 1/4” NPT tap to obtain the proper make

up. If thread chasing is required, the bent tube assembly,

the one way valve assembly and steady flow components

must all be removed and the side block body must be

thoroughly cleaned to remove any loose particles.

12) Before installing the valve assembly, wrap the pipe

threads with 1-1/2 turns of Teflon tape starting after

It is NOT necessary to have the control knob for the

emergency gas supply valve perfectly “square,” i.e., at

a 90 degree angle to the side block. Any angle is acceptable provide d t hat 1) the valve handle ca n b e tu r ned

easily and 2) the diver can locate the handle easily.

7.5.4 Leak Testing the EGS Valve

a) Attach supply whip from the EGS first stage to EGS

helmet valve.

b) Ensure the defogger valve knob is open and the EGS

Valve is shut.

c) Pressurize EGS Valve to a minimum of 135 p.s.i.g.

(9.3 bar) using the EGS cylinder as supply. Allow system pressure to stabilize, and then shut the EGS supply

cylinder valve. Note time and final stabilized system

pressure.

d) Perform the leak check for minimum of five minutes, using the mild soapy solution, per Chapter 6.

Ensure there is no gas flowing or pressure drop in the

system. There should be no visible signs of external

leakage if the valve is operating properly.

A leaking Emergency Gas Valve assembly

can cause the diver to exhaust his entire

EGS (bailout) without his knowledge. This

may lead the diver to mistakenly assume

his EGS supply is available when it is

not. This could lead to panic or drowning

in an emergency. Any worn or damaged

components must be replaced.

A submersibl e pressure gaug e

should always be used with the EGS system to help minimize this risk.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

77

Kirby Morgan 37 & 57

WARNING

7.6 Bent Tube Assembly

7.6.1 General

The bent tube assembly provides breathing gas flow

from t he side block assembly to t he regu lator assembly

on the Kirby Morgan 37. Both ends of the bent tube

assembly disconnect for complete removal. The Oring and the Teflon O-ring should be replaced during

normal overhauls or any time these components are

deemed unserviceable.

These components do not require replacement during

field repairs providing a careful visual inspection does

not reveal wear or damage. All soft goods should be

carefully cleaned in accordance with Chapter 6 prior

to inspection for reuse.

7.6.2 Removal of the Bent Tube Assembly

Tools Required:

11/16 inch Open-end Attachment on Torque

Wrench

7/8 inch Open-end Attachment on Torque Wrench

7/8 inch Open-end Wrench

1) Always start removal of the bent tube at the side

block end. The free swiveling mount nut on this end

of the bent tube can be unthreaded completely and

can slide down the tube.

2) The inlet nipple has a jam nut that locks the mount

nut in place. With one wrench, hold the bent tube

mount nut. With another wrench, turn DOWN the

jam nut, backing it away from the mount nut. The

mount nut can then be rotated until free of the regulator inlet nipple threads. It can be pushed up the

bent tube.

3) With the two mount nuts free; the bent tube assembly can b e pul led straight out of the regulator in let

nipple. The bent tube assembly can be rotated back

and forth to aid removal.

7.6.3 Inspection of Bent Tube Assembly

Clean the bent tube in accordance with Chapter 6.

The O-ring at the regulator end should be clea ned and

inspected whenever the bent tube is removed.

Replace the bent tube if it is excessively scratched

dented or compressed deeper than 1/8 inch. If the

helmet has been used for burning jobs, carefully check

for erosion of the metal or severe corrosion. Replace

if any erosion is present or integrity is in question.

Keep in mind the bent tube is a critical component

that routs breathing gas to the helmet systems.

Always start removal at the side block end.

Loosening the jam nut.

78

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Replace the O-ring on the bent tube if it is worn or

damaged.

Do not wrap the bent tube with tape,

ropework, springs, hose wrap, or other

items. This will prevent daily inspection of

the bent tube. In addition, some of these

items may trap moisture, which could lead

to corrosion and failure of the bent tube.

If the tube fails, this could lead to a rapid

depletion of the diver’s breathing gas supply. This could lead to serious personal

injury or death.

7.6.4 Installation of the

Bent Tube Assembly

Tools Required:

11/16 inch Open-end Torque Wrench Attachment

7/8 inch Open-end Torque Wrench Attachment

7/8 inch Open-end Wrench

Normal minimum replacement parts during overhaul:

O-ring, Teflon

®

ring

1) Lightly lubricate the bent tube O-ring and install

in the O-ring groove at the regulator end of the bent

tube, then install new Teflon® O-ring at the side

block end.

2) Push the regulator end of the bent tube assembly

into the inlet nipple. Slide it in until the side block

end of the tube is aligned with the threads for the

mount nut.

Kirby Morgan 37 & 57

3) Be sure the Teflon

®

O-ring is in place on the side

block end of the bent tube, then engage the threads

on the tube to the side block and hand tighten.

4) Start the “regulator to bent tube” mount nut onto

the inlet nipple of the demand regulator and run it in

by hand as far as it will go.

NOTE: Run the mount nut up on the inlet nipple

hand tight only.

5) Using a torque w rench, t ight en t he bent tube assembly mount nut onto the side block to (100 inch lbs).

6) Hold the mount nut on the end of the bent tube

with a wrench and tighten the jam nut against it with

a torque wrench to 40 inch pounds.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

79

Kirby Morgan 37 & 57

7.7 SuperFlow 350

Demand Regulator

7.7.1 General Regulator Information

While the regulator systems on all K irby Morgan helmets a re simple a nd h ighly rel iable, the breat hing resistance will increase if the demand regulator on your

helmet is not maintained or adjusted properly. The

demand regulator must receive regular maintenance

to assure the best performance possible. However, in

the event the demand regulator is damaged, there is

always a backup supply of steady flow gas available

from the defogger valve.

If the regulator does not breathe easily, the diver cannot work hard and will tire rapidly. Simply put: If the

demand regulator does not work properly the diver

cannot work properly. This makes the maintenance

of the demand regulator assembly essential.

For the gas inlet valve and adjustment system to operate properly, the components in the demand regulator

MUST be in good condition and MUST be periodically inspected and adjusted.

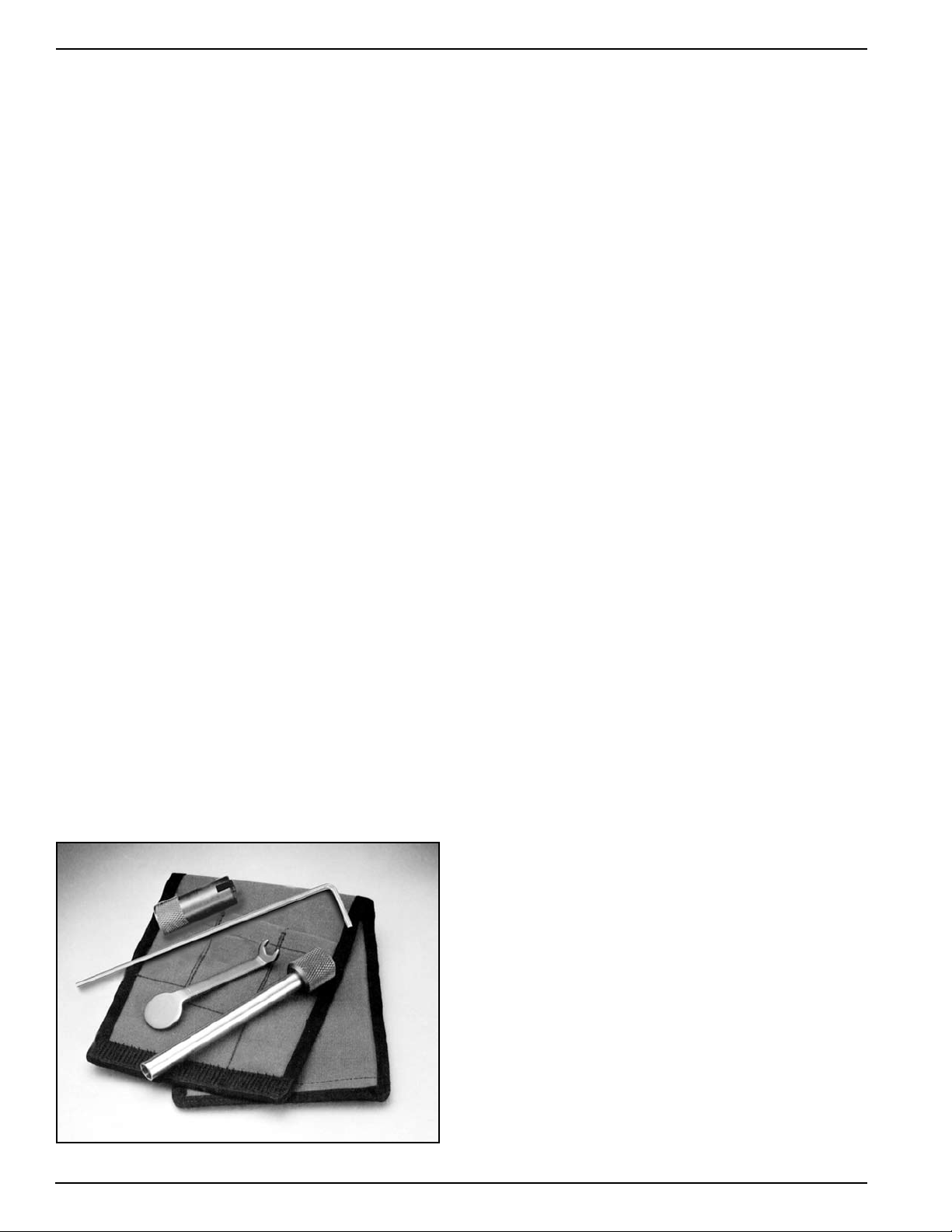

Four special tools, the inlet valve holder (Part #525-

616), the regulator adjustment wrench (Part #525-611),

the socket wrench (Part #525-612), and the castle

wrench (Part #525-618) should be used to work on

the SuperFlow 350 regulator whenever possible.

Disassembly, assembly, and adjustment can be done

without these tools, but the work is much easier and

the adjustment is better if these tools are used. The

above 4 tools are available together along with a tool

case. The “Tool Kit with Pouch” is Part #525-620.

This kit is included with each new Kirby Morgan

helmet that is equipped with the SuperFlow 350

regulator.

7.7.2 SuperFlow 350 Demand Regulator Test

for Correct Adjustment, Fully Assembled

To maintain optimum performance of the demand

regulator, it should be checked for proper function

and adjustment prior to commencement of diving

each diving day, in accordance with the KMDSI Daily

Set Up and Functional Checklist. See the Dive Lab

website (www.divelab.com) for the latest procedures

for set-up.

Check the regulator for adjustment and proper function with the assembly complete, and supplied with a

breathing gas supply pressure of 135 to 150 p.s.i.g.

NOTE: 135 to 150 p.s.i.g. over ambient is the standard supply pressure to be used when adjusting

all KMDSI helmets and band-mask equipped with

the SuperFlow 350 regulator. See Section 2.5 for

recommended pressures during use.

NOTE: When storing the helmet for any length of

time, ensure that the regulator adjustment knob is

turned “out ” fully cou nterclockwise to avoid st ressing

the bias springs. This will prolong the life of both the

inlet valve, seat, and bias springs.

1) Rotate the regulator adjustment knob in, towards

the regulator body.

2) Ensure the supply pressure is connected and properly adjusted to 135 to 150 p.s.i.g.

3) Turn on the gas supply.

4) Rotate the adjustment knob out counterclockwise

slowly, until a slight steady flow develops.

5) Slowly rotate the adjustment knob in clockwise,

until the free flow stops. Lightly depress the purge

button several times and ensure the gas flow has

stopped.

80

6) Lightly depress the purge button. There should be

bet ween 1/16” and 1/ 8” free travel i n the button before

gas flow starts. When the button is fully depressed, a

strong surge of gas must be heard.

7) If the purge button travels less than 1/16” or greater

than 1/8” before free flow is heard, the demand regulator requires internal adjustment, per this chapter.

Tool Kit with pouch - Part #525-620.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Kirby Morgan 37 & 57

WARNING

7.7.3 Inspection of SuperFlow 350

Regulator Body Interior

Tools Required:

1/4 inch Flat Blade Attachment on Torque Screwdriver

Remove the demand regulator clamp.

1) Remove the demand regulator clamp by removing

the clamp screw.

2) Lift off the regulator cover and diaphragm.

3) Clean the diaphragm with the soapy solution, per

Chapter 6 and wipe dry. Inspect the diaphragm for

holes, tears or any signs of deterioration by holding it

up to a white light and stretching and pulling. Check

for a good bond between the metal disc and the silicone. Replace diaphragm if any doubt exists.

NOTE: Older regulator clamps, when properly

torqued, had a gap of approximately 1/32” to

1/16” between the retaining clamp surfaces when

fully tightened. All new clamps when properly

torqued, have little or no gap between the retaining clamp surfaces.

7.7.4 SuperFlow 350 Demand Regulator

Bias Adjustment

Servicing, Demand Regulator

on the Helmet

Note: This procedure should be used when replacing the O-ring on the adjustment shaft and or

cleaning and lubricating the shaft threads during

field repairs of the demand regulator on the helmet.

Start at the adjustment knob end of the regulator:

To ols Required:

3/4 inch Open-end Wrench Attachment on Torque

Wrench

3/32 inch Punch & Small Block of Wood

Ball-Peen Hammer

Regulator Adjustment Tool Kit, Part #525-620

Torque Wrench

1) Unscrew the regulator adjustment knob until it

stops. If the knob wobbles as you turn it, or is extremely hard to turn, the shaft is bent and needs to

be replaced.

4) Inspect the interior of the demand regulator body

for damage, corrosion and cleanliness. Clean the interior of the regulator body if necessary per Chapter

6.

6) Reinstall the diaphragm, cover, and clamp. Tighten

the clamp screw to the recommended torque to 12

inch pounds using a torque screwdriver.

Use only replacement diaphragms manufactured by Kirby Morgan. Use of other

diaphragms may degrade performance

and may cause increased breathing resistance. This can lead to fatigue and the

inability to work at full capacity.

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Screw the regulator adjustment knob out for

removal.

2) Loosen the nut, then rotate the adjustment knob

counterclockwise until the adjustment knob and the

adjustment shaft are free.

3) Remove the spacer, springs, and piston. At this

point the threads can be cleaned and lubricated as

well as the adjustment shaft.

4) Punch out the roll pin using a 3/32 punch. Use a

block of wood with a 1/4” hole drilled through it to

support the knob. Position the knob so the roll pin

81

Kirby Morgan 37 & 57

Shake out the spacer, spring set, and piston.

is over the hole. The adjustment knob can be held

against the wood block allowing the roll pin to be

driven into the 1/4” hole.

5) Remove the adjustment knob, the washer and Oring.

Inspect the washer and o-ring.

9) Inspect the inside of the adjustment tube on the

regulator body to be sure there is no corrosion and

the adjustment assembly can travel freely. Ensure the

alignment t ube is not bent or misaligned from impact,

and that the threads are clean.

NOTE: If the inside of the adjustment tube is corroded, this indicates saltwater intrusion into the

adjustment tube and assembly. The demand regulator requires removal from the helmet and cleaning

per this Chapter.

7.7.5 Reassembly of the SuperFlow 350

Regulator Adjustment System

Tools Required:

3/4 inch Open-end Wrench Attachment on Torque

Wrench

Silicone grease, or oxygen compatible grease if used

for oxygen service.

NOTE: If the spacer and the spring set are stuck,

this could indicate corrosion or possible saltwater

intrusion into the adjustment tube and assembly,

or that the adjustment tube is bent. The demand

regulator should be removed from the helmet and

cleaned and inspected, per this Chapter..

6) Carefully inspect all parts for corrosion, paying

particular attention to threaded surfaces and the

spring set. Clean and lightly lubricate parts per the

instructions in this chapter.

NOTE: Carefully inspect the adjustment shaft to

ensure it is straight, Check for damaged threads.

Replace the adjustment shaft if any damage is

found. Replace the O-ring.

7) Replace washer.

8) Replace the O-ring.

82

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

1) Lightly lubricate the piston and spacer and place

the piston back in the regulator adjustment tube, followed by the spring set, and spacer.

2) Lightly lubricate the adjustment shaft end and

threads, install the washer and the lightly lubricated

O-ring on the adjustment shaft.

3) Slip the packing nut over the adjustment shaft followed by the adjustment knob.

4) Hold the shaft and rotate the knob until the pin

holes line up. Use the inlet valve holder from the

regulator tool kit to accurately align these holes. Using a small hammer drive the retaining pin back into

place, until it is flush with the surface of the adjustment knob.

5) Screw the adjustment knob assembly clockwise

back into the regulator body leaving enough packing

nut exposed to get the wrench on it.

Loading...

Loading...