Page 1

WARNING

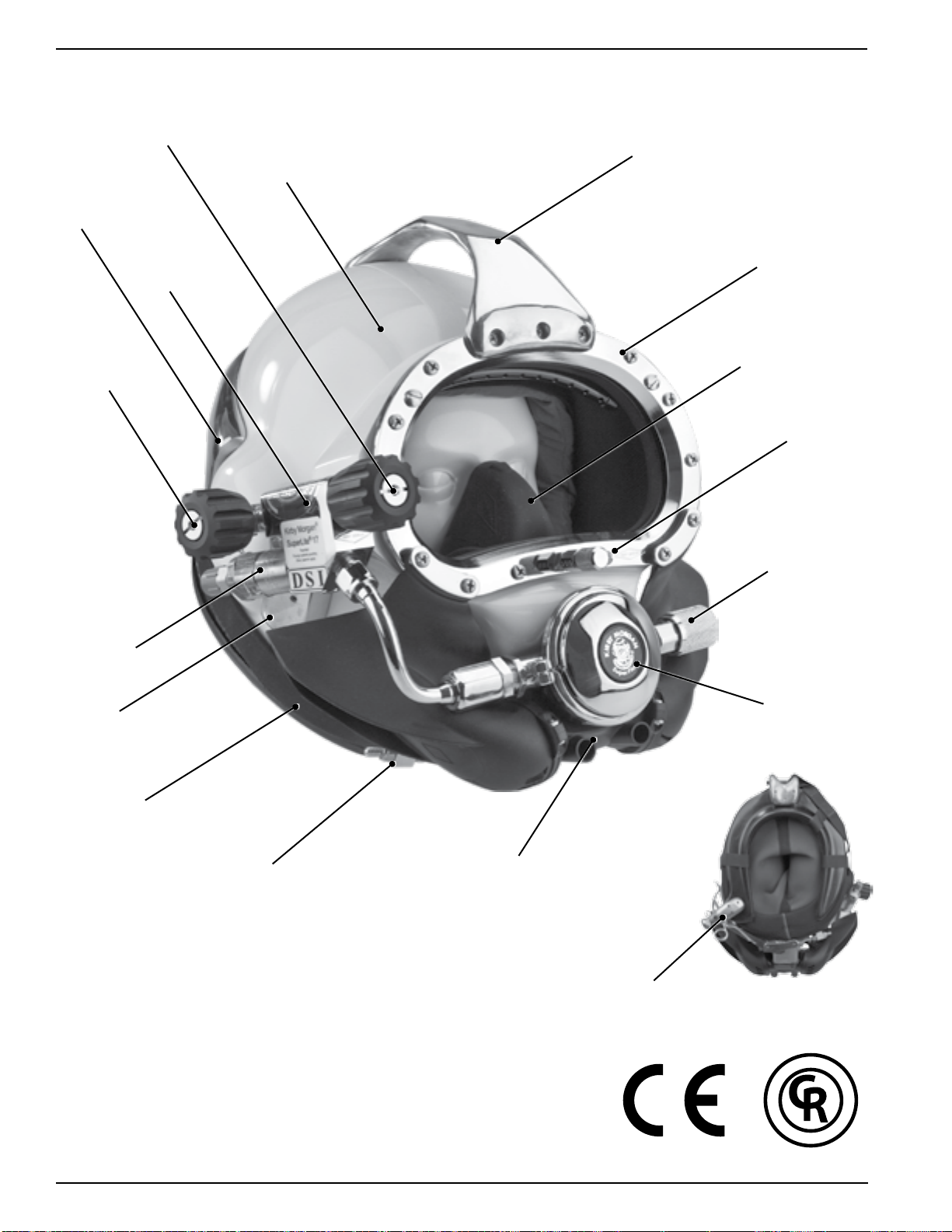

SuperLite® 17B Helmet

Operations and Maintenance Manual

KMDSI Part # 100-001

™

Kirby Morgan Dive Systems, Inc.

1430 Jason Way

Santa Maria, CA 93455, USA

Telephone (805) 928-7772, FAX (805) 928-0342

E-Mail: KMDSI@KirbyMorgan.com, Web Site:www.KirbyMorgan.com

Manual prepared by Marine Marketing and Consulting, Dive Lab, Inc., and KMDSI.

NOTE: This manual is the most current for the SuperLite® 17B Helmet. It is page dated August 2010. Future changes will be shown on page III and the changed pages will carry the date of change. Previous manuals may not reflect

these updates.

Diving with compressed breathing gas is a hazardous activity. Even if you do everything

right there is always the danger that you may be killed or injured. No piece of diving

equipment can prevent the possibility that you may be killed or injured any time you

enter the water.

The SuperLite®-17A/B helmet is CE Approved and meets or exceeds all performance and testing

requirements of all government and non-government testing agencies throughout the world. It is approved for use on all commercial and military work underwater.

Kirby Morgan, SuperLite®, BandMask, Band Mask, KMB, KMB-Band Mask, DSI, Diving Systems International, EXO, REX,

SuperFlow® and DECA are all registered trademarks of Kirby Morgan Dive Systems, Inc. Use of these terms to describe products

that are not manufactured by KMDSI is illegal.

The two dimensional images (such as photographs and illustrations) of our products are © copyrighted and trademarks of Kirby

Morgan Dive Systems, Inc. The three dimensional forms of our products are trademark, trade design and trade dress protected.

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. This manual is made available for the express use of

the owner of this Kirby Morgan product. No part of this manual may be reproduced, stored in any retrieval system, or transmitted,

or used in any form or by any means, whether graphic, electronic, mechanical, photocopy, or otherwise by technology known or

unknown, without the prior written permission of Kirby Morgan Dive Systems, Inc.

Document Number 100720003

Page 2

SuperLite® 17B

Warranty Information

Kirby Morgan Dive Systems, Inc. warrants every new mask, helmet, or KMACS 5 Air Control

System to be free from defects in workmanship for a period of three hundred sixty five (365) days

from date of purchase. This warranty covers all metal, fiberglass, and plastic parts. This warranty

does NOT cover rubber parts, communications components, or head cushions. In addition, due to

the electrolytic nature of underwater cutting and welding, chrome plating cannot be warranted when

the diver engages in these activities.

Should any part become defective, contact the nearest authorized KMDSI dealer. If there is no

dealer in your area, contact KMDSI directly at (805) 928-7772 x 229. You must have a return authorization from KMDSI prior to the return of any item, Upon approval from KMDSI, return the defective part, freight prepaid, to the KMDSI plant. The part will be repaired or replaced at no charge as

deemed necessary by KMDSI.

This warranty becomes null and void if:

1) The product is not registered with KMDSI within ten (10) days of purchase.

2) The product has not been properly serviced and/or maintained according to the appropriate KMDSI manual. In addition, the user is responsible to ensure that all product updates

as recommended by KMDSI have been performed.

3) Unauthorized modifications have been made to the product.

4) The product has been abused or subjected to conditions which are unusual or exceed the

product’s intended service.

NOTE: Be sure to complete the enclosed warranty card and return it to KMDSI immediately. No

warranty claims will be honored without a satisfactorily completed warranty card on file at KMDSI.

II © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

Page 3

®®

SuperLite® 17 A/B Helmet

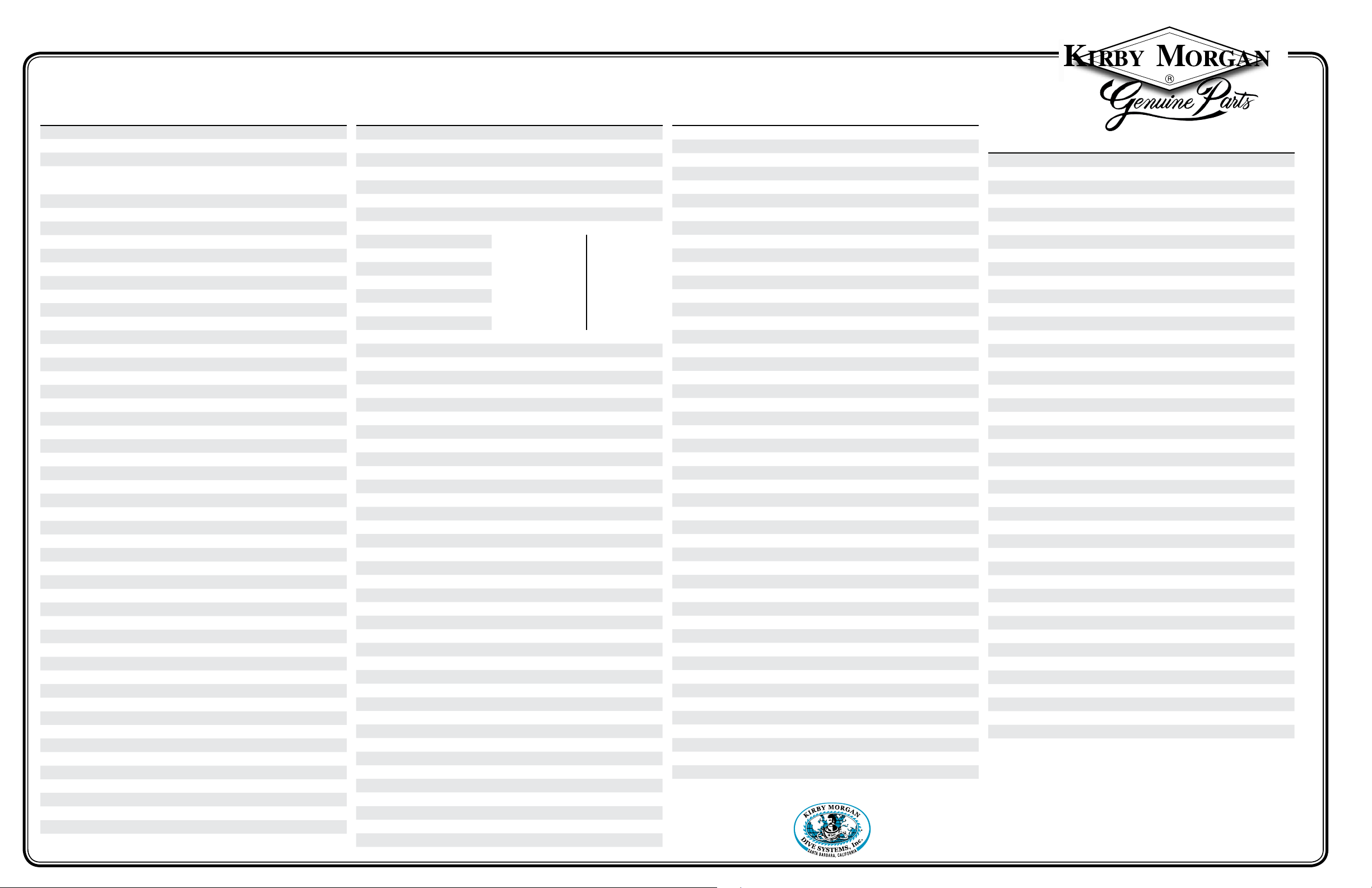

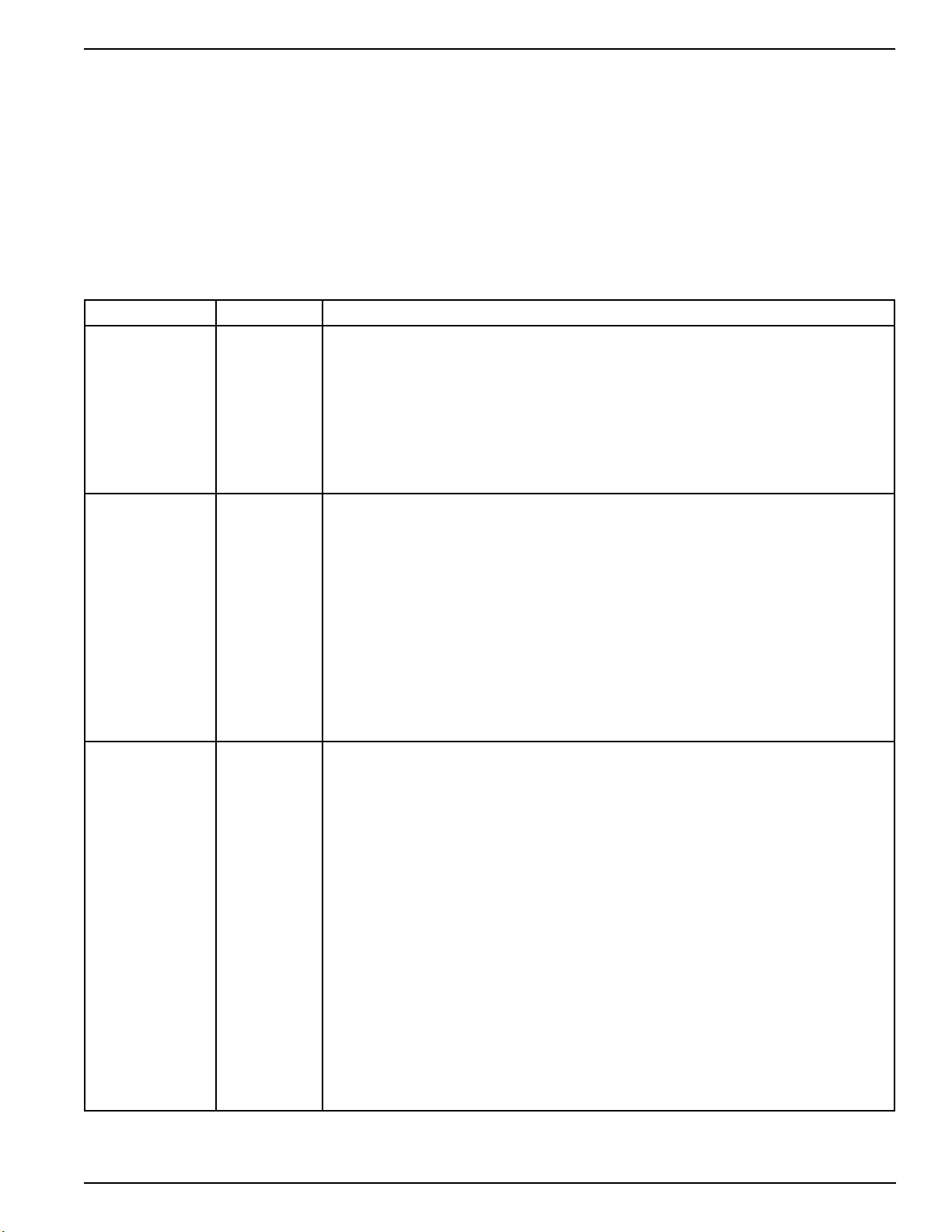

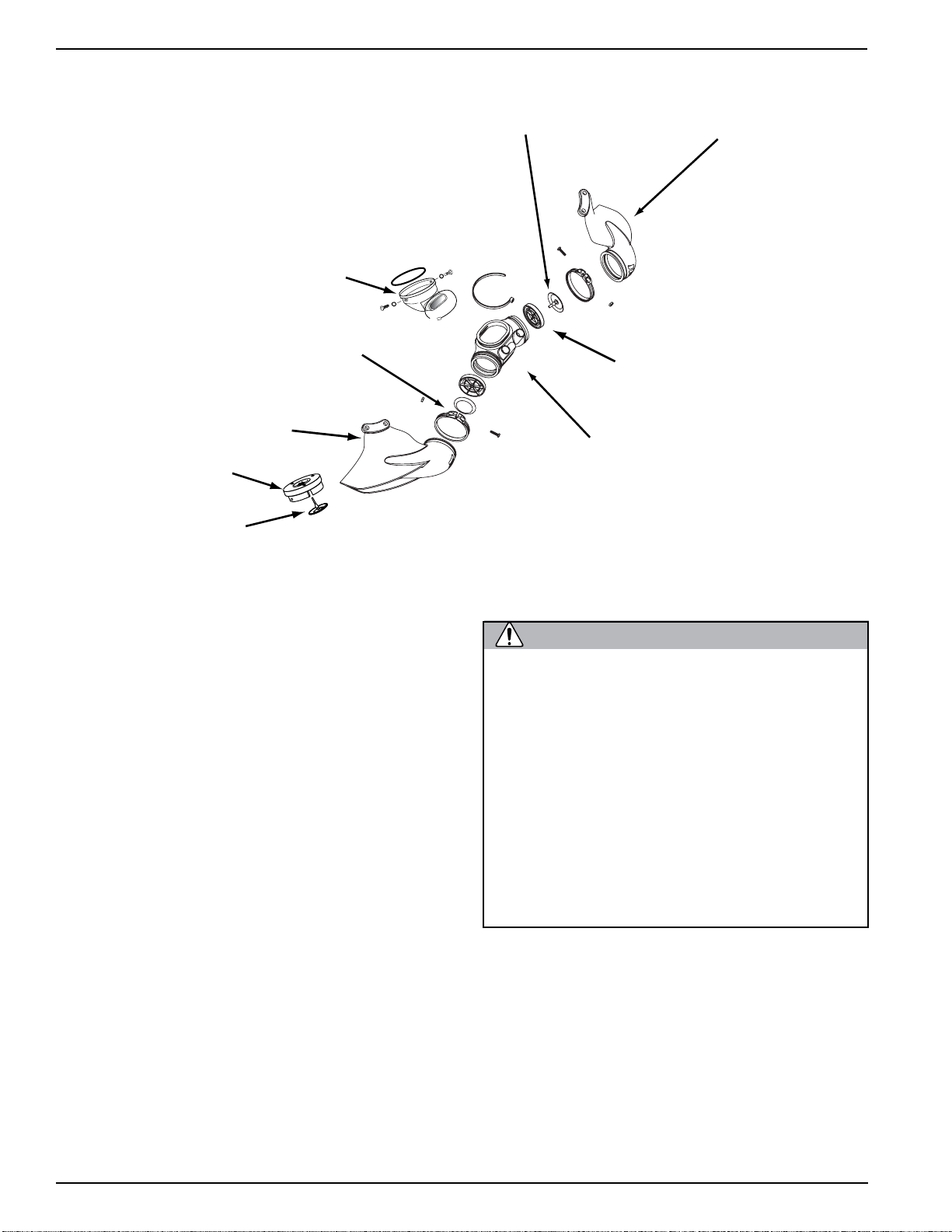

Location # Part # Description

1 510-521 Head Cushion

510-523 Replacement Foam

2 510-533 Drawstring Neck Dam

3 Neck Clamp

(Order Comp. see #7)

4 530-317 Nut

5 530-415 Washer

6 530-320 Nut, Lock

7 505-055 Neck Clamp Assembly

8-13 not used

14 505-008 Neck Clamp Yoke Assembly Comp.

15 530-066 Screw

16 530-601 Retaining Pin

17 550-255 Knob

18 535-900 Safety Pin

19 560-051 Latch Catch Body

20 535-808 Spring

21 550-257 Plunger

22 505-010 Latch Catch Assem., Pull Pin

23 530-034 17B Hinge Bolt, Electropolished

24 560-026 Hinge

25 530-028 Nut

26 540-157 Rear Hinge Tab, Electropolished

27 530-406 Washer

28 530-025 Screw

29 530-080 Screw

30 530-530 Washer

31 520-117 Urethane Yoke

520-060 Fiberglass Yoke

32 550-019 Locknut

33 535-802 Spring

34 520-524 Knob, Control

35 520-030 Washer

36 550-020 Bonnet

37 510-015 O-ring

38 520-031 Washer

39 510-010 O-ring

40 550-022 Valve Stem

41 550-023 Seat Assembly

42 550-024 Stud

43a 550-026 A Side Block

43b 550-029 B Side Block

44a 510-011 O-ring

44b 520-033 O-ring (teflon)

45b 555-154 Bent Tube Assembly

46a 510-010 O-ring

46b 510-012 O-ring

47a 555-152 Reg. Hose Assem. w/O-rings

47b 555-155 Bent Tube Assem. w/O-rings

48 550-095 L.P. Plug, w/O-ring

49 310-003 O-ring

50 550-140 Emergency Valve Body

51 550-138 Stem

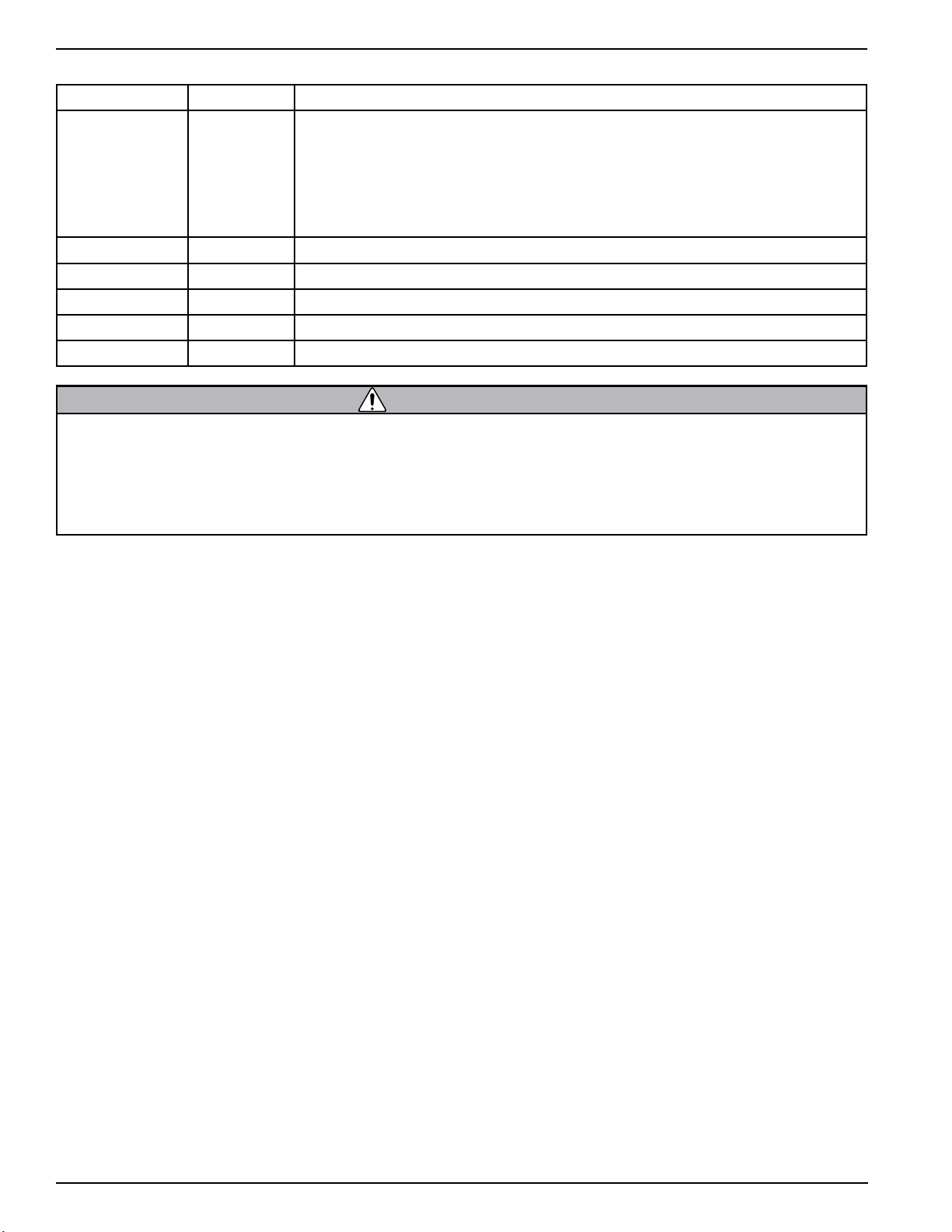

Location # Part # Description

52 540-095 Washer

53 520-024 Packing

54 550-091 Packing Nut

55 520-525 Knob, Control

56 535-802 Spring

57 550-019 Locknut

58 505-070 Emergency Valve Assembly

59 510-483 O-ring

60 Body

61 Spring

62 Poppet

63 O-ring

64 O-ring

65 Wiper

66 Seat

67 555-117 Adapter, Brass, ¼" NPT/02

68 555-195 One-Way Valve

69 505-060 One-Way Valve Assem.

70a 505-022 “A” Side Block Assem. Complete

70b 505-024 “B” Side Block Assem. Complete

71 515-005 Earphone Right

72 515-006 Earphone Left

510-542 Earphone Cover set

515-008 Speaker

520-015 Speaker Protector

73 515-009 Microphone

74 515-030 Communications Set

75 560-023 Starboard Weight

75a 520-054 Visor

76 530-070 Screw

77 530-540 Washer

78 545-027 Snap Tab

79 530-078 Screw

80 510-446 O-ring

81 510-211 O-ring

82 550-038 Nut, Regulator Mount

83 510-747 Mask, Oral/Nasal (silicone)

84 510-550 Valve, Oral/Nasal Intake

85 520-020 Body, Oral/Nasal Intake Valve

86 545-015 Nose Block device

510-575 Nose Block Pad

87 530-090 Alignment Screw

88 550-339 Alignment Sleeve

89 560-005 Rear Weight

90 530-070 Screw

91 530-540 Washer

92 520-065 Helmet, Fiberglass

93 560-014 Handle

94 530-040 Screw

95 560-019 Port Weight

96 530-535 Washer

97 530-415 Washer

98 530-317 Nut

Order

Complete

see

Loc. # 68

© Copyright 2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #100310007

For

Replacement

Parts

Order

Kit

#525-330

Location # Part # Description

99 545-016 Air Train

99a 510-762 Air Train Gasket

100 530-535 Washer

101 530-317 Nut

102 530-050 Screw

103 530-052 Screw, Port Plug Screw

104 530-035 Screw

105 510-010 O-ring

106 510-008 O-ring

107 555-180 Packing Nut

108 550-062 Knob, Nose Block

109 550-061 Spacer

110 540-015 Plate

111 530-045 Screw

112 545-022 Regulator Body

113 550-060 Piston

114 535-807 Spring Set

115 550-059 Spacer

116 550-057 Shaft

117 520-032 Washer

118 510-011 O-ring

119 550-055 Packing Nut

120 550-053 Knob, Adjustment

121 530-601 Retaining Pin

122 510-553 Diaphragm

123 545-018 Cover Assembly

123a 535-905 Retaining Clip

123b 540-055 Cover

123c 535-810 Spring, Purge Button

123d 520-017 Purge Button

123e 520-078 Purge Button Sticker

124 530-030 Screw

125 545-020 Clamp

126 530-303 Nut

127 550-052 Spacer

128 545-038 Roller Lever

129 530-506 Washer

130a 550-046 Inlet Nipple “A”

131b 550-050 Jam Nut “B”

132b 550-048 Inlet Nipple “B”

133 510-014 O-ring

134 545-026 Inlet Valve

134a 510-580 Valve Seat

134b 530-505 Washer

135 535-804 Spring

136 510-552 Exhaust Valve

137 505-026 Demand Reg. Assem. “A”

138a 505-027 Demand Reg. Assem. “B”

138b 505-028 Reg. Adjustment Knob Assem.

Kirby Morgan Dive Systems, Inc.® 1430 Jason Way, Santa Maria, CA 93455

Location # Part # Description

139 510-554 Whisker™, Rubber (Pre 2004)

140 525-759 Quad-Valve™ Exhaust

140a 510-786 Starboard Whisker™

140b 510-787 Port Whisker™

140c 510-760 Quad Valve Exhaust Main Body

140d 520-200 Whisker™ Exhaust Valve Insert

140e 510-776 Exhaust Valve

140f 520-042 Tie Wrap

140g 520-118 Tri/Quad Valve Whisker Clamp

140h 530-008 Brass Screw

140i 530-009 Brass Nut

141 550-116 Nose Block Guide

142 560-070 Port Ret. Assembly

143 520-004 Face Port

520-128 Face Port, pre 1979

144 510-260 O-ring

145 550-040 Nut

146 530-308 Nut

147 530-525 Washer

148 540-054 Earphone Retainer

149 530-032 Screw

150 550-063 Exhaust Body

151 510-561 Exhaust Valve

152 530-021 Screw

152a 530-019 Screw, Quad Exhaust

152b 510-007 O-ring, Quad Exhaust Screw

153a 560-530 Exhaust Cover, Quad Exhaust

153b 520-042 Tie Wrap, Quad Exhaust

153c 510-033 O-ring, Quad Exhaust

154 515-061 Terminal Block

155 515-035 Communications Post

156 510-481 O-ring

157 550-043 Plug

158 515-049 Terminal

159 515-045 Waterproof Conn, Male

160 510-481 O-ring

161 555-175 Packing Gland

162 520-113 Ferrule Set

163 555-178 Packing Nut

164 505-047 W.P. Connector Assembly

165 505-130 Chin Strap

166 505-134 Strap Guide

167 505-138 Yoke Strap

525-620 Tool Kit (not shown)

Phone: 805/928-7772 Fax: 805/928-0342

www.KirbyMorgan.com e-mail: kmdsi@KirbyMorgan.com

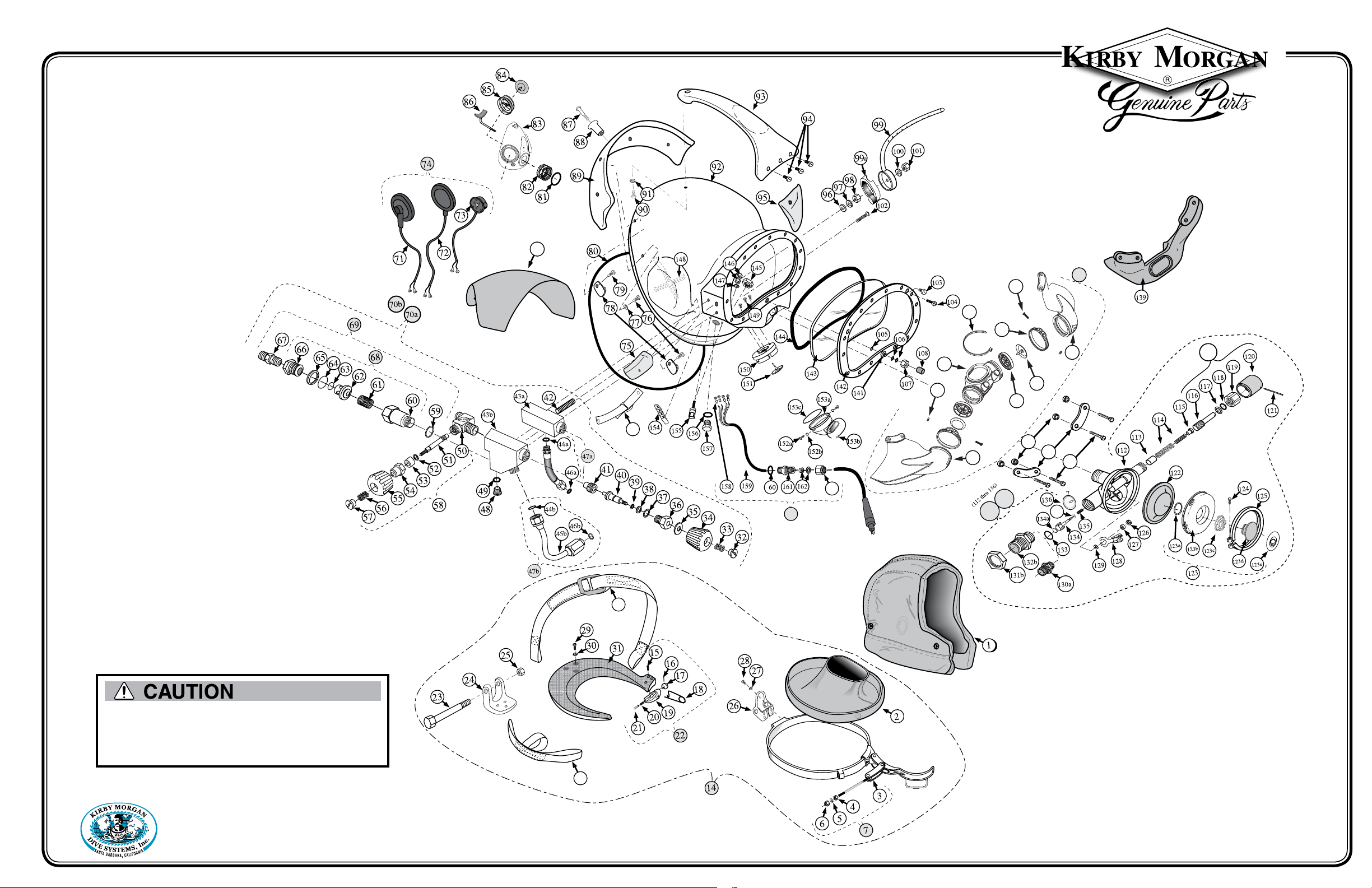

Page 4

®

75a

134b

165

167

166

164

163

137

138a

138b

109

110

111

140f

140b

140d

140e

140g

140h

140i

140c

140a

140

SuperLite® 17 A/B Helmet

Use only Kirby Morgan original replacement parts. The use

of other manufacturer's parts will interfere with the performance

characteristics of your life support equipment and may jeopardize your

safety. Additionally, any substitutions will void any warranties offered

by KMDSI. When ordering spares, always insist on Kirby Morgan

original parts.

Kirby Morgan Dive Systems, Inc.® 1430 Jason Way, Santa Maria, CA 93455

Phone: 805/928-7772 Fax: 805/928-0342

www.KirbyMorgan.com e-mail: kmdsi@KirbyMorgan.com

Following publication of this booklet, certain changes in standard equip-

Product Changes

ment, options, prices and the like may have occurred which would not

be included in these pages. Your Authorized KMDSI dealer is your best

source for up-to-date information on any of these products.

© Kirby Morgan Dive Systems, Inc. reserves the right to

change product specifications at any time without incurring obligations.

© Copyright 2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #100310007

Page 5

SuperLite® 17B

Record Of Changes

It is the responsibility of the owner of this product to register their ownership with Kirby Morgan Dive

Systems, Inc., by sending the warranty card provided. This card is to establish registration for any necessary

warranty work and as a means of communication that allows KMDSI to contact the user regarding this product.

The user must notify KMDSI of any change of address by the user or sale of the product.

All changes or revisions to this manual must be recorded in this document to ensure that the manual is

up to date. Quantities marked in parenthesis.

Change Number Date Description of Change

1 05/28/2008 Reworded: 2.1 Product Specifications, 2.4 Operational Specifications & Limitations,

Warnings Corrected, 7.12.1 to the correct 7.16.1 and Table of Contents Updated.

Added: Appendix A2, 3 and 4

®

Moved: 2.4 Operational Specifications & Limitations, The SuperFlow

Regulator Image Rotated and Scaled to fit.

Removed: Table 1 and Table 2 from chapter 2.

2 08/20/2008 Page III Removed page number column.

Page 16 First paragraph Part number added to Hard Shell.

Page 17 Second paragraph 77 added to list of helmets.

Chapter 1 rearranged and CE text added to KM-77 description.

Pg 63 and 64 Chapter 5 made to two columns format and font changed to lower

case instead of all caps.

Page 65 Added Whisker Clamp Replacement Kit: Part # 525-032.

Page 66 Corrected text to read “SL 17” instead of “KM 37 and 57” in 6.2, last

sentence and photo caption.

Page 102 step 17 corrected, "sssembly" to read "assembly."

Page 173 Torque Specification corrections.

Page 174 Added note about thread locking compound.

3 03/13/2009 Page 75: Space added between 6.5.1 Quad.

Page 77: Removed grammatical error beneath image.

Page 81: Corrected 40 inch pounds to 35 inch pounds in step 3. Lacquer thinner

changed to acetone.

Page 82: Corrected 40 inch pounds to 15 inch pounds in step 6. Lacquer thinner

changed to acetone.

Page 95: Corrected amount omitted inch pounds to 40 inch pounds in step 6.

Page 105: Corrected 75 inch pounds to 100 inch pounds twice in step 18. Corrected

30 inch pounds to 40 inch pounds in step 22.

Page 120: Corrected 75 inch pounds to 100 inch pounds in step 4.

Page 122: Corrected 75 inch pounds to 100 inch pounds in step 8. Corrected 35 inch

pounds to 40 inch pounds in step 9.

Page 124: Removed step 11 and merged SPECIAL CARE text with step 10. Corrected 75 inch pounds to 100 inch pounds in step 16.

Page 136: Corrected 35 inch pounds to 20 inch pounds in step 4.

Page 140: Corrected 30 inch pounds to 20 inch pounds in step 3.

Page 143: Corrected 35 inch pounds to 35-50 inch pounds in step 1.

Page 152: Corrected 15 inch pounds to 20 inch pounds in step 5.

Demand

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003 III

Page 6

SuperLite® 17B

WARNING

Change Number Date Description of Change

3 (Continued) 03/13/2009 Page 154: Corrected 35 inch pounds to 25 inch pounds in step 5. Grammatical error,

"resuse" corrected to reuse in step 7. Corrected 35 inch pounds to 20 inch pounds

in step 1 of section 8.10.1.2. Corrected 35 inch pounds to 20 inch pounds in step 3

of section 8.10.1.2.

Page 175: Location #94's part number corrected from 530-045 to 530-040. Added

location #'s 6, 107 and 152a.

4 07/23/2009 CE material added

5 10/05/2009 Changed location # 82's part number from 550-372 to 550-038 in the torque specs.

6 11/06/2009 Chapter 2: addition of CE conforming criteria.

7 04/19/2010 Updated images and diagrams with new whiskers.

8 07/20/2010 Added wiring diagram to chapter 8.

Diving with compressed breathing gas is a hazardous activity. Even if you do everything

right there is always the potential for serious injury or death. No one piece of diving

equipment can prevent the possibility that you may be injured or killed any time you

enter the water. We do not herein make any effort to teach the principles of diving. The

information in this manual is intended for users of Kirby Morgan helmets and persons

that maintain or service Kirby Morgan helmets.

IV © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

Page 7

SuperLite® 17B

Table Of Contents

Warranty Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � II

Record Of Changes

Denition of Signal Words Used in this Manual

Chapter 1 General Information KMDSI Products � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1

1.1 Introduction

1.2 Full-Face Masks and Manifolds

1.3 Kirby Morgan Diving Helmets

Chapter 2 Description & Operational Specications - SuperLite®-17B � � 9

2.1 CR Marking

2.2 CE Certication

2�2�1� CE Marking � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

2�2�2� Notied Body � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

2.3 Product Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

2.4 Regulator Performance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

2.5 Cage Code � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

2.6 Operational Specications & Limitations

2.7 Helmet Features

2.8 General Description � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

2�8�1 Helmet Shell � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

2�8�2 Gas Flow Systems � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

2�8�3 Emergency Gas Supply System (EGS) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

2�8�4 Helmet Attachment to the Diver � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

2�8�5 Sealing Arrangement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

2�8�6 Reducing Carbon Dioxide � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

2�8�7 Communications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

2�8�8 Equalizing the Middle Ear � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

2�8�9 Face Port or Viewing Lens � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

2�8�10 Latch Catch Assembly, Pull Pin � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

2.9 Accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

2�9�1 Eye Protection for Welding � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

2�9�2 Hot Water Shroud � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

2�9�3 Special Regulator Tools � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

2.10 Helmet Transport And Storage � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

2�10�1 Helmet Carrying Bag � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

2.11 Use of Kirby Morgan Original Replacement Parts

Chapter 3 Operating Instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

3.1 Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

3.2 Design Purpose

3.3 First Use of Your Kirby Morgan Diving Helmet

3.4 Initial Adjustments to Your Helmet

3�4�1 Head Cushion � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

3�4�2 Adjusting the Neck Dam � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 28

3.5 Pre Dress-In Procedure

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � III

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � XI

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 1

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 29

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003 V

Page 8

SuperLite® 17B

3�5�1 Pre-Dive Visual Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 29

3.6 Preparing the Helmet for Diving� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

3�6�1 Clean Face Port � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

3�6�2 Check Moving Parts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

3�6�3 Check Communications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

3�6�4 One-Way Valve Check � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

3) You can also test the one-way valve by opening the steady-ow valve and attempting to

suck air back through the one-way valve. This is also a good way to test. � � � � � � � � � � � � � � � � � � 30

3.7 Emergency Gas System (EGS) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31

3.8 Setting Up to Dive

3�8�1 Flushing Out the Umbilical � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 35

3�8�2 Connecting the Umbilical to the Helmet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 35

3�8�3 Opening the Breathing Gas Supply to the Helmet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

3�8�4 Fogging Prevention � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 36

3�8�5 Donning The SuperLite®-17B � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 37

3�8�6 Testing the Breathing System � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

3�8�7 Sealing Integrity Check � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 42

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 35

3.9 Diving Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�9�1 Standing By to Dive � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�9�2 Attaching the Umbilical to the Harness � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�9�3 Diver Dons Helmet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�9�4 Diver Check Gas Flow Systems � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�9�5 Communications Check � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�9�6 Diver Ready � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 43

3�9�7 Water Entry and Descent � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

3.10 Emergency Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

3�10�1 Flooding � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

3�10�2 Inhalation Resistance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

3�10�3 Gas Flow Stops � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 44

3�10�4 Demand Regulator Free Flow � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

3.11 Post Dive Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

3�11�1 Removing the Equipment � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

3�11�2 Removing the Helmet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 45

3�11�3 Storage of the Helmet Between Dives � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 46

Chapter 4 Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

4.1 General � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

4.2 Communication Malfunction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

4.3 One Way Valve Malfunction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 47

4.4 Side Valve Malfunction

4.5 Water Leakage Into Helmet

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 48

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 48

4.6 Demand Regulator Malfunction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 49

4.7 Emergency Gas Supply Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 49

Chapter 5 Inspection and Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

5.1 Routine Maintenance

5�1�1 Daily Pre-Dive Maintenance A2�3 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

5�1�2 Daily Post Dive Maintenance A2�6 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

5�1�3 Supervisors Equipment Checks A2�4 and A2�5 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

VI © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

Page 9

SuperLite® 17B

5.2 Monthly Maintenance

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

5.3 Yearly Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

5�3�1 Overhaul/Inspection Checklist A2�1 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

Chapter 6 General Preventative Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 53

6.1 Introduction

6.2 Required tools, Cleaning Agents, Lubrication � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 53

6�2�1 Component and Parts Cleaning � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 54

6�2�2 Component and Parts Lubrication � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 54

6�2�3 Teon® Tape � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

6�2�4 RTV Sealant � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

6�2�5 Thread Locker � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

6.3 General Cleaning & Inspection Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 55

6�3�1 O-Ring Removal/Inspection/Cleaning and Lubrication � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

6�3�2 General Cleaning Guidelines � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 56

6�3�2�1 Mild Soap Solution for � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

General Cleaning and Leak Detector Use � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

6.3.2.2 Acidic Cleaning Solution and Procedures � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

6.3.2.3 Germicidal Cleaning Solutions and Procedure � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 57

6.4 Daily Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 59

6.5 Monthly Inspections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 61

6�5�1 Quad-Valve™ Exhaust System � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 61

6�5�2 Emergency Valve Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 62

6�5�3 Steady Flow/Defogger Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 62

6�5�4 Bias Device Adjustable Section of Demand Regulator � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 62

6�5�5 Neck Clamp and Yoke Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 62

6�5�6 Latch Catch Mechanism � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 62

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 53

Chapter 7 Breathing System Maintenance and Repairs � � � � � � � � � � � � � � � � � � � � � � � 63

7.1 Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 63

7.2 One Way Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 63

7�2�1 Disassembly Of The One Way Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 63

7�2�2 Reassembly of the One Way Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 64

7.3 Side Block Assembly� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 65

7�3�1 General � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 65

7�3�2 Side Block Assembly Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 65

7�3�3 Separating the Side Block Assembly from the Helmet Shell � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 66

7�3�4 Side Block Assembly Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 68

7.4 Defogger Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 69

7�4�1 Disassembly of the Defogger Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 69

7�4�2 Cleaning and Lubricating � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 69

7�4�3 Reassembly of the Defogger Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 70

7.5 Emergency Valve Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 71

7�5�1 Disassembly of the Emergency Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 71

7�5�2 Cleaning and Lubricating � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 71

7�5�3 Reassembly of Emergency Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 72

7�5�4 Leak Testing the EGS Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 73

7.6 Bent Tube Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 74

7�6�1 General � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 74

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003 VII

Page 10

SuperLite® 17B

7�6�2 Removal of the Bent Tube Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 74

7�6�3 Inspection of Bent Tube Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 75

7�6�4 Installation of the Bent Tube Assembly� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 75

7.7 Hose Assembly (SL-17A only) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 76

7�7�1 Hose Assembly Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 76

7�7�2 Hose Assembly Inspection “A” style Side Block � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 76

7�7�3 O-Ring Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 76

7�7�4 Hose Assembly Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 76

7�8�2 SuperFlow® Demand Regulator Test for Correct Adjustment, Fully Assembled � � � � � � � � � � � � � 77

®

7.8 SuperFlow

7�8�1 General Regulator Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 77

7�8�3 Inspection of SuperFlow® Regulator Body Interior � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 78

7�8�4 SuperFlow® Demand Regulator Bias Adjustment Servicing, Demand Regulator on the Helmet

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 79

7�8�5 Reassembly of the SuperFlow® Regulator Adjustment System� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 80

7�8�6 SuperFlow® Demand Regulator Removal from Helmet � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 81

7�8�7 Disassembly of the SuperFlow® Demand Regulator� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 82

7�8�8 Inspection of SuperFlow® Demand Regulator Parts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 85

7�8�9 Reassembly of the SuperFlow® 350 Demand Regulator � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 87

7�8�10 Tuning the SuperFlow® Regulator � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 91

7.8.10.1 Important Notes on Regulator Adjustment � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 92

7�8�11 SuperFlow® Regulator Steady Flows When Pressured Up: Special Tools Used � � � � � � � � � � � � 93

7�8�12 Regulator Steady Flows When Pressured Up � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 95

7�8�13 Regulator has Low or No Flow When Pressurized � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 95

7�8�14 Unexplained Demand Regulator Free Flow � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 95

Demand Regulator � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 77

7.9 Oral Nasal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 96

7�9�1 Oral Nasal General Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 96

7�9�2 Oral Nasal Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 96

7�9�3 Inspection of Oral Nasal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 96

7�9�4 Oral Nasal Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 97

7.10 Quad-Valve™ Exhaust Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 98

7�10�1 Quad-Valve™ Assembly Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 98

7�10�2 Quad-Valve™ Exhaust Valve Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 99

7�10�3 SuperFlow® Regulator Exhaust Valve Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 102

7�10�4 Quad-Valve™ Assembly Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 103

7.11 Water Dump Exhaust Body � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 103

7�11�1 Water Dump Valve Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 103

7�11�2 Water Dump Valve Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 103

7�11�3 Water Dump Valve Body Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 103

7�11�4 Water Dump Valve Body Remounting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 103

7.12 Reinstalling the Quad-Valve™ Exhaust Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 105

7�13 Standard Old Style Single Exhaust Whisker PN# 510-554 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 106

7�13�1 Whisker Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 106

7�13�2 Reinstalling the Whisker � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 107

7.14 Double Exhaust Whisker � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 108

7�14�1 Double Exhaust Whisker Cleaning and Overhaul, Whisker PN# 525-102 � � � � � � � � � � � � � � � � 108

7.15 Tri-Valve Exhaust Whisker � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 110

VIII © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

Page 11

SuperLite® 17B

7�15�1 Demand Regulator Assembly Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 110

7�15�2 Replacing the Regulator Exhaust Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 110

7�15�3 Tri-Valve Exhaust Valve Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 111

7�15�4 Installing the Tri-Valve Exhaust System onto the Regulator � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 113

7.16 Overpressure Relief / Bleed Valve Overhaul Procedures

7�12�1 Overpressure Relief Valve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 114

7�16�2 Overpressure Relief Valve Disassembly and Cleaning � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 114

7�16�3 Overpressure Relief Valve Reassembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 115

7�16�4 Overpressure Relief Valve Lift Check/Setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 115

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 114

Chapter 8 Corrective Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 117

8.1 General � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 117

8.2 Yoke/Neck Clamp Assembly and Helmet Shell Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 117

8.3 Nose Block Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 119

8�3�1 Nose Block Assembly Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 119

8�3�2 Nose Block Device Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 120

8.4 Handle and Weights � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 121

8�4�1 Handle Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 121

8�4�2 Handle Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 122

8�4�3 Weight Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 123

8�4�4 Weight Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 123

8.5 Chin Strap and Yoke Strap � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 125

8�5�1 Chin Strap Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 125

8�5�2 Chin Strap Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 125

8�5�3 Removal of the Yoke Strap � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 126

8�5�4 Replacement of the Yoke Strap � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 126

8.6 Alignment Sleeve � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 128

8�6�1 Sleeve Removal and Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 128

8�6�2 Sleeve Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 128

8.7 Port Retainer � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 129

8.8 Face Port � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 129

8�8�1 General � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 129

8�8�2 Face Port and Nose Block Device Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 129

8�8�3 Face Port and Nose Block Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 130

8�8�4 Special Note Regarding Ports � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 132

8.9 Communications System � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 133

8�9�1 General � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 133

8�9�2 Earphone Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 133

8�9�3 Microphone Removal and Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 134

8�9�4 Earphone Removal and Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 135

8�9�5 Waterproof Connector � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 135

8.9.5.1 Connector Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 135

8.9.5.2 Connector Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 136

8�9�6 Communications Posts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 136

8.9.6.1 Communications Post Removal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 136

8.9.6.2 Communications Post Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 138

8.10 Neck Clamp/Yoke Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 138

8�10�1 Yoke � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 139

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003 IX

Page 12

SuperLite® 17B

8.10.1.1 Yoke Removal and Disassembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 139

8.10.1.2 Yoke Replacement and Reassembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 141

8�10�2 Latch Catch Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 141

8.10.2.1 Latch Catch Mechanism Disassembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 141

8.10.2.2 Latch Catch Mechanism Reassembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 142

8�10�3 Neck Clamp Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 142

8.10.3.1 Neck Clamp Assembly Adjustment /Inspection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 142

8�10�4 Neck Dam � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 144

8.10.4.1 Neck Dam Replacement � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 144

Pre-84 and Cold Water Type Neck Dam � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 144

Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 144

8.10.4.2 Four Hole Method of Attaching Neck Dam to Hinge Tab � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 146

8.10.4.3 Patch Method of Attaching Neck Dam to Hinge Tab � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 146

8.10.4.4 Drawstring Type Neck Dam Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 147

8.11 O-Ring Seal Replacement

8.12 Head Cushion Foam Replacement

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 148

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 149

Chapter 9 Accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 151

9.1 Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 151

9.2 Hot Water Shroud General� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 151

9�2�1 Installation of the Hot Water Shroud � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 151

9.3 Low Pressure Inator Hose Installation on the B Sideblock � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 153

9.4 Weld Lens & Weld Shield Assemblies � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 154

9.5 Use of Quick Disconnect � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 156

9.6 Double Exhaust System � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 157

9�6�1 Double Exhaust Kit Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 157

Table of Equivalents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 161

Appendix 1: Torque Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 162

Note on Torque Specications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 163

Checklist, Maintenance, and Pre-Dive Inspections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 163

Appendix A2 Maintenance and Inspection Procedures � � � � � � � � � � � � � � � � � � � � � � 164

Appendix 3 Supply Pressure Requirements & Tables � � � � � � � � � � � � � � � � � � � � � � � � � 166

Appendix 3 Table 1 Work Rate Expressed as Respiratory Minute Volume (RMV)* � � � � � � � � � 167

Appendix 3 Table 2 Compressor Supply Table SuperFlow® and SuperFlow® 350 � � � � � � � � � � 167

Appendix 3 Table 3 SuperFlow® 350 Regulator High Pressure Regulated Source � � � � � � � � � 169

Appendix 4 Standard Kirby Morgan Surface Supply Pressure Formula Old Method � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 169

X © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

Page 13

SuperLite® 17B

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Denition of Signal Words Used in this Manual

For your protection, pay particular attention to items identified by signal words in this manual. These terms are identified

as, CAUTION, WARNING AND DANGER. It is especially important for you to read and understand these sections.

This word indicates an imminently hazardous situation, which if not avoided, could result in death or serious injury.

This word indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

CAUTION

This word indicates a potentially hazardous situation, which if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

If English is not your native language and you have any difficulty understanding the language of any warnings as they appear in the manual, please have them translated.

Este é um aviso importante. Queira mandá-lo traduzir.

Este es un aviso importante. Sirvase mandario traducir.

Quest è un avviso importante. Tradurlo.

Ceci est important. Veuillez traduire.

Diese Mitteilung ist wichtig. Bitte übersetzen lassen.

If you have any questions concerning this manual or the operation of your helmet, contact KMDSI (805)

928-7772 or by Email at info@KMDSI.com or Dive Lab Inc. (850) 235-2715 or at Divelab@aol.com

IMPORTANT: A word about this manual. We have tried to make this manual as comprehensive and factual as possible. We reserve the right, however, to make changes at any time, without notice, in prices, colors, materials, equipment, specifications, models and availability. Since some information may have been updated since the time of printing, please contact your local KMDSI dealer if you have any questions. Periodically KMDSI Operations and Maintenance Manuals are reviewed. Any updates/changes will be posted on the KMDSI website and may be downloaded for

insertion/correction.

Important Safety Information:This SuperLite

successfully completed a recognized training course in surface supplied diving

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003 XI

®

17B diving helmet is intended for use by trained divers who have

Page 14

SuperLite® 17B

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Follow all the instructions in this manual carefully and heed all safety precautions. Improper use of this diving helmet could result in serious injury or death.

Kirby Morgan Dive Systems, Inc. (KMDSI) warns all divers who use Kirby Morgan diving helmets or masks to be sure to use only KMDSI original parts from a KMDSI authorized dealer. Although other parts, O-rings and ttings may appear to t your Kirby

Morgan diving helmet or mask, they may not be manufactured to the same standards

maintained by KMDSI. The use of any parts other than KMDSI original parts may lead to

equipment failure and accidents.

Diving in waters that are chemically, biologically, or radiologically contaminated is extremely hazardous. Although Kirby Morgan diving helmets may be adapted for use in

some contaminated environments, special training, equipment, and procedures are

necessary. Do not dive in a contaminated environment unless you have been thoroughly

trained and equipped for this type of diving.

Read this manual before using or maintaining the helmet, even if you have experience with other diving helmets. If

you have purchased the helmet new from a dealer, be sure to send in the warranty registration card so we may

keep you informed of any safety notices that affect this product. If you resell or loan this helmet to another diver,

be sure this manual accompanies the helmet and that the person reads and understands the manual. In addition to the

manual a log book should be used to log all repairs, maintenance and use.

This helmet was completely checked and should be ready to dive as it was shipped

from the factory. However, it is always the diver’s responsibility to check all the components of the helmet prior to diving.

Diving is a life threatening occupation. Even if you do everything right you can still be

killed or injured. None of the models of Kirby Morgan helmets or masks can prevent accidents, injuries or death due to improper training, poor-health, improper supervision,

improper job requirements, improper maintenance or acts of God.

Any and all berglass repairs done to this helmet MUST be done by a KMDSI factory

trained repair facility. Painting is not recommended by KMDSI. Furthermore, many diving companies will not allow painted helmets to be used because painting can mask

previous berglass damage. KMDSI certied technicians are not responsible for certifying helmets free from damage during annual overhauls.

Helmet shells can be re-gel coated by authorized/certied KMDSI trained technicians

that have received berglass training by KMDSI. Helmets that are to be painted for

cosmetic purposes, should be rst, certied free of berglass damage by an authorized

KMDSI technician certied in berglass repair. A log entry should be made in the helmet log that the helmet was free of damage prior to painting. Keep in mind other KMDSI

technicians can refuse to work on helmet shells that have previously been painted or

repaired by non KMDSI certied persons.

XII © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

Page 15

SuperLite® 17B

WARNING

WARNING

WARNING

WARNING

This manual is supplied to the original purchaser of this helmet. If you have any questions about the use of the helmet

or you need another copy of this manual, contact KMDSI or your nearest KMDSI dealer. It may also be downloaded

free from the KMDSI website at www.KirbyMorgan.com.

KMDSI helmets and masks are intended for underwater use only and should only be

used by qualied divers that have received proper training in the use of this type of

equipment. KMDSI helmets and masks should not be used or worn without the appropriate life support systems, such as air or gas supplies and support personnel as described in this manual.

KMDSI helmets and masks should never be used for motor sport racing, aviation /

space craft use, or for chemical warfare use. The helmet must never be used by persons in poor physical condition, by persons with previous head, neck, or back injuries

which could be aggravated by its use. The helmet should not be used by persons under the inuence of drugs or alcohol. Furthermore, infants, children, or persons under

the age of 18 should never wear KMDSI helmets and masks. Failure to pay heed to the

above could result in serious injury or death.

Do not use KMDSI masks or helmets in currents exceeding 3.0 knots Use in currents

greater than 3 knots may allow water to enter the exhaust valve, possibly causing regulator ooding. This could lead to drowning.

Surface-supplied diving can be a strenuous activity. The SuperLite®-17B weighs approximately 30 lbs. KMDSI recommends that persons with a previous neck or back injury

seek professional medical approval prior to engaging in surface supplied diving operations using the SuperLite®-17B. Use of the SuperLite®-17B with a pre-existing physical/

medical condition may result in death or serious injury.

If you have any questions regarding the use, maintenance, or operation of this helmet, contact KMDSI at (805) 9287772, fax: (805) 928-0342, or e-mail: info@kirbymorgan.com.

Components requiring lubrication, should only be lubricated with oxygen compatible lubricants such as ChristoLube®®, Flourolube, or Krytox®. Lubricants must be used sparingly and should not be mixed with other lubricants.

The information contained in this manual is intended to aid the user in optimizing the performance of this helmet. The

application of some of this information will depend on the diving situation and the use of associated equipment. Many

countries have specific laws and rules regarding commercial diving. It is important for the user to understand the rules,

regulations, and philosophy imposed by the governing, regulating bodies whenever using commercial diving equipment.

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003 XIII

Page 16

SuperLite® 17B

WARNING

WARNING

Never use the helmet without rst completing all pre-dive maintenance and set up

procedures. Failure to complete all pre-dive checks could result in helmet failure due to

problems with the incorrect set-up of the equipment. This could lead to serious personal injury or death.

Always read the Material Safety Data Sheet (MSDS) for any chemical - adhesive, cleaning agent, or lubricant - used on your Kirby Morgan helmet. Some of these chemicals

may cause serious bodily injury or death if used improperly or without the proper personal protective equipment.

Whenever KMDSI helmets or masks are used in European Countries, which have adopted the C.E. certification programs, they must only be used with C.E. certified components. Diving operations should only be conducted within

the limits of the operational specifications, and in accordance with the rules and regulations established by the governing authority in the specific country or geographical location where the diving operations are being conducted. If

you have any questions concerning this manual or the operation of your helmet, contact KMDSI (805) 928-7772 or at

KMDSI@KirbyMorgan.com or Dive Lab Inc. (850) 235-2715 or at Divelab@aol.com

XIV © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

Page 17

SuperLite® 17B

STOP!

BEFORE GOING FURTHER-

This manual will refer to location numbers in specic drawings, or in the exploded view, which is

in the back of this manual. These numbers are called “location” numbers. They are used to nd

the referred to parts in the drawings in this manual only. They are not the part number. Next to

the exploded drawing is a list of the “location” numbers that match the Kirby Morgan part numbers along with the name of the part. Always check the part number when ordering to make sure

it is correct. When ordering, always specify the helmet model number and serial number as well.

Chapter 1

General Information KMDSI Products

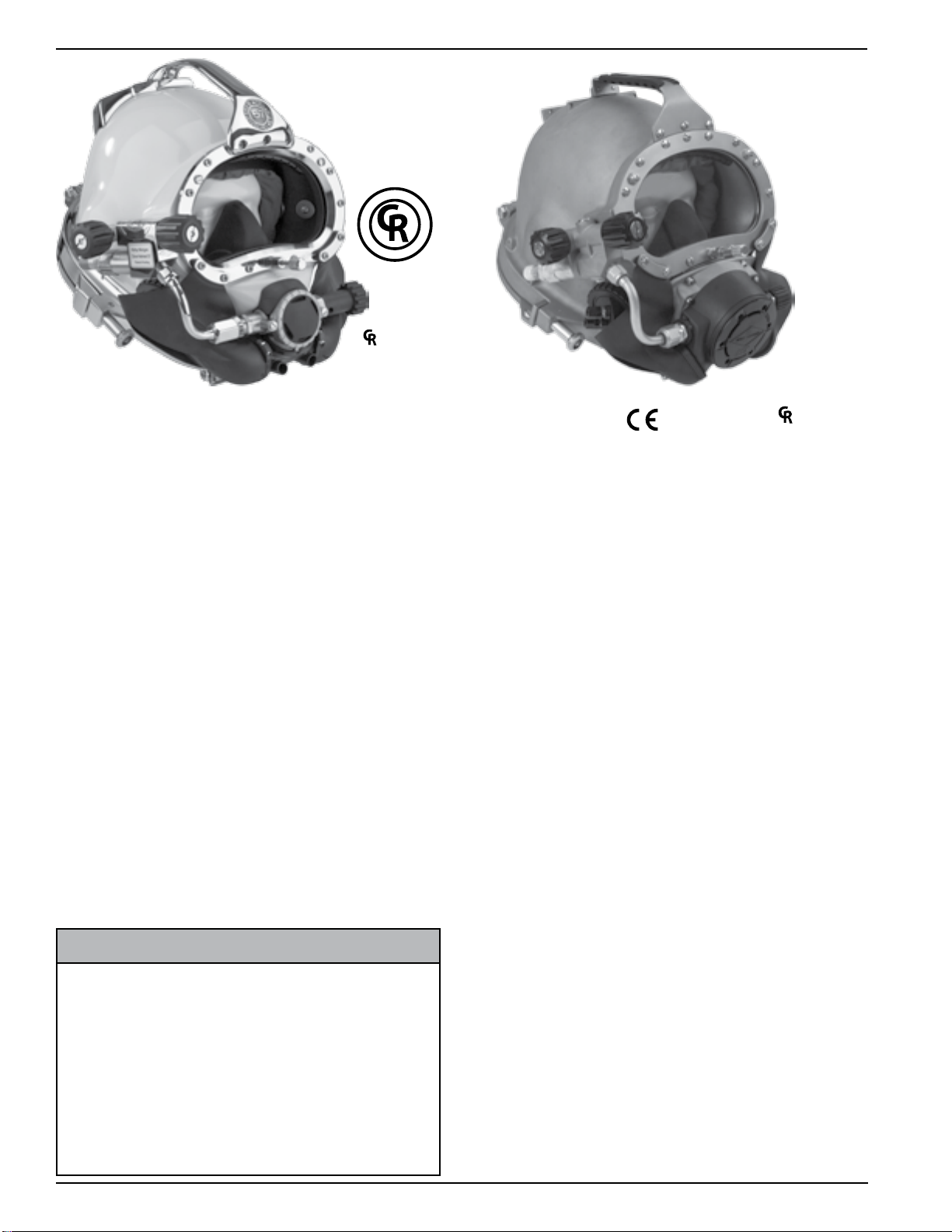

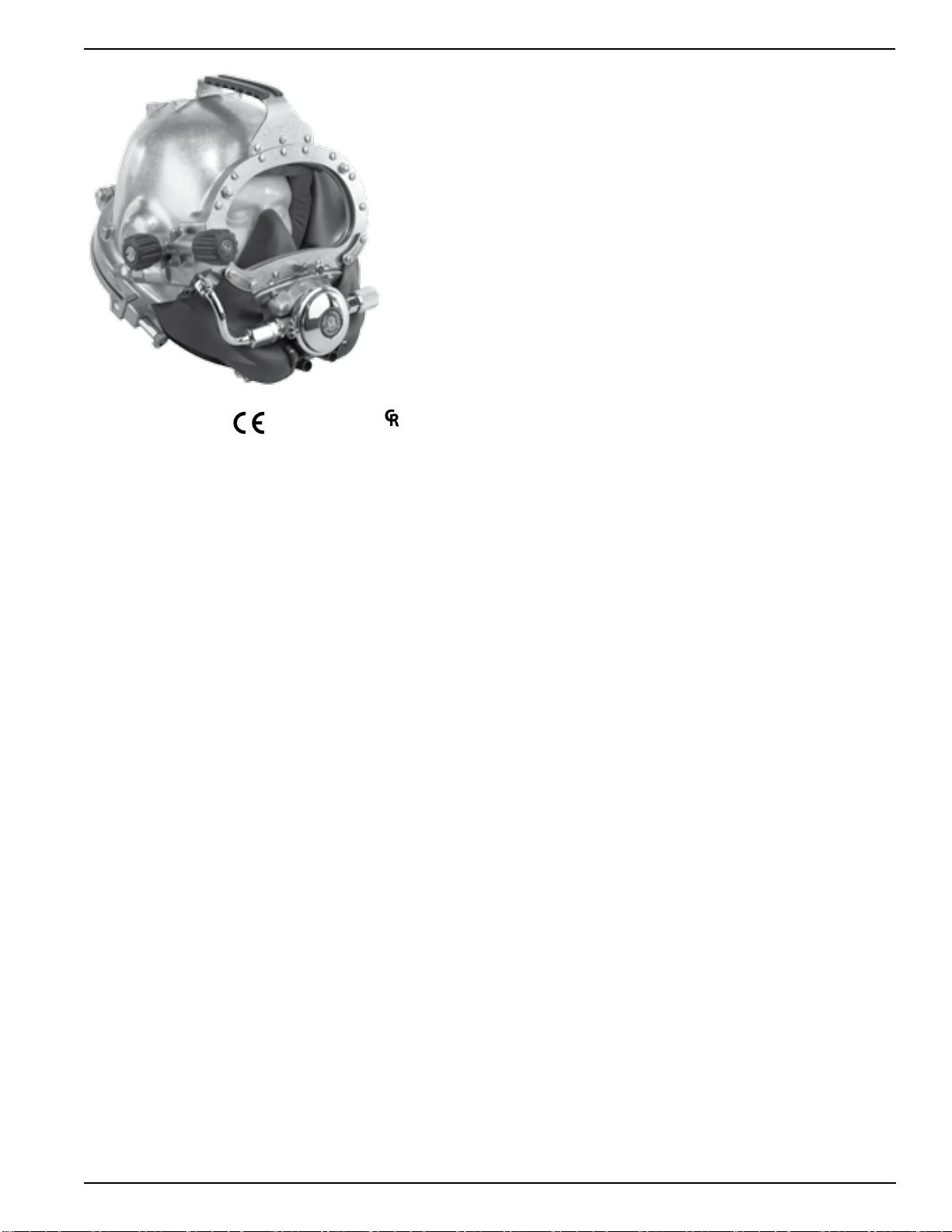

1.1 Introduction

The Kirby Morgan Corporation was started in 1965.

The copper and brass “Heavy Gear” or “Standard

Dress” helmets were the first helmets manufactured

by the company. Over the years Kirby Morgan designed, manufactured and sold many different helmets

and masks for commercial divers.

Staying active in commercial diving has contributed

to the successful design innovations of KMDSI products. This may be the primary reason for the acceptance of our designs by professional divers.

Bev Morgan has designed more than fifty-seven diving helmets and over 40 diving masks. All employees

of KMDSI participate as part of the Kirby Morgan

design team. It would not be possible for us to supply the commercial, military, scientific, and public

service diving industries with our equipment, without

the team of people that make up Kirby Morgan Dive

Systems, Inc. (KMDSI)

We feel it is important for the reader to understand

that we at KMDSI consider ourselves as only part

of the process along the path in diving equipment

design. We welcome all input from our customers.

The thinking of many good divers, diving equipment

engineers, diving medical specialists, diving organization administrators and their supporting personnel

has contributed to the current state of the art of diving.

Each piece of gear we manufacture has in it some of

the thinking of those who have gone before us. To

all those people who gave something of themselves

to the men and women who work underwater, we

express a thank you.

We have a strong commitment to providing the best

diving equipment and service possible. This thinking

has been the policy of Kirby Morgan Dive Systems,

Bev Morgan, Chairman of the Board Kirby Morgan

Dive Systems, Inc.

Inc. and we will continue to take this approach to

our work.

Our extensive dealer network makes it easy to obtain

genuine Kirby Morgan replacement parts, as well as

technical assistance worldwide.

KMDSI has always concentrated on designing and

manufacturing diving equipment that allows most

repairs, inspections, and all routine maintenance to

be performed by the user. Most routine preventative

and corrective maintenance can be accomplished by

the user utilizing this manual, the KMDSI Tool Kit

(P/N 525-620) and common hand tools. Technician

training is available through Dive Lab Inc. Information can be obtained on line at www.divelab.com or

by telephone at 850-235-2715.

© Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003 1

Page 18

SuperLite® 17B

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

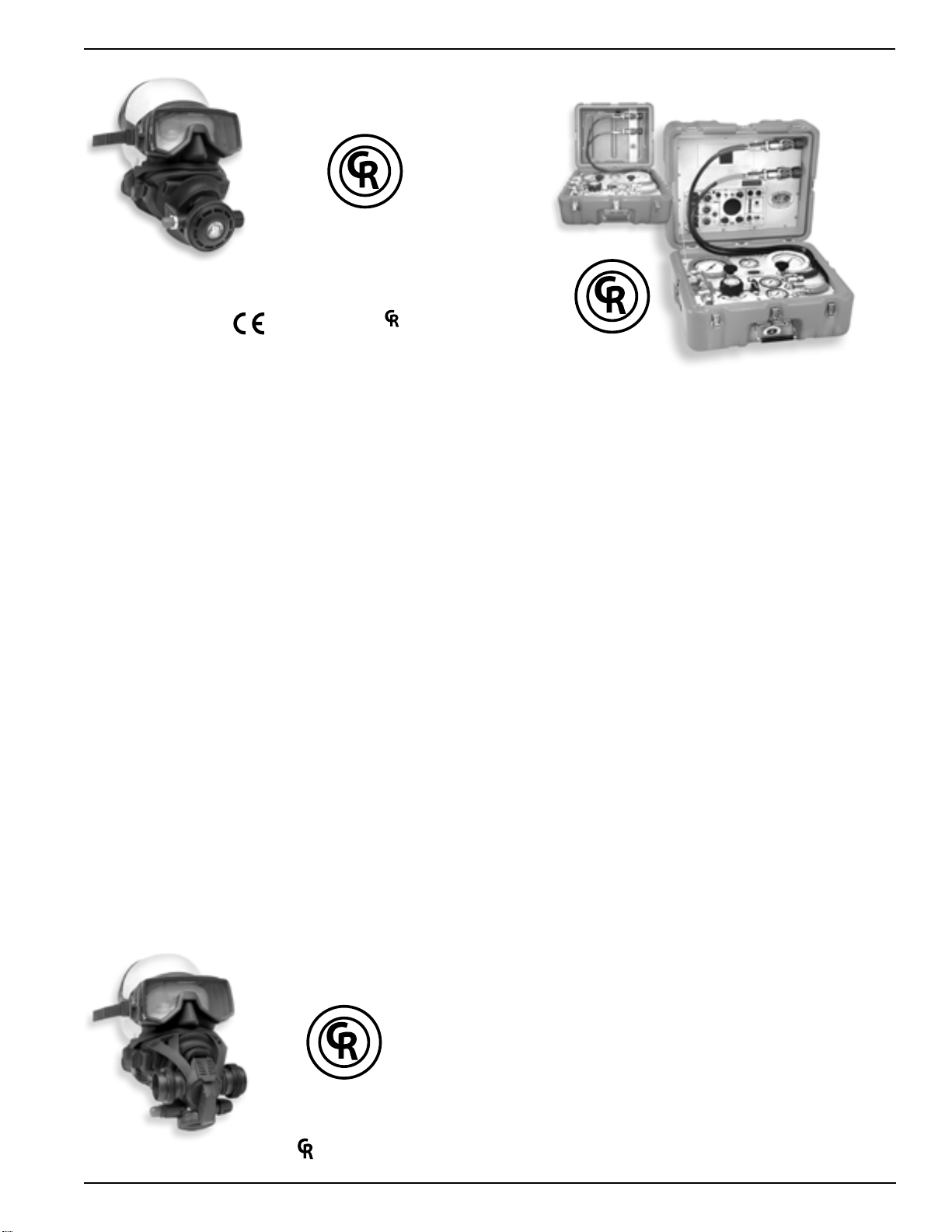

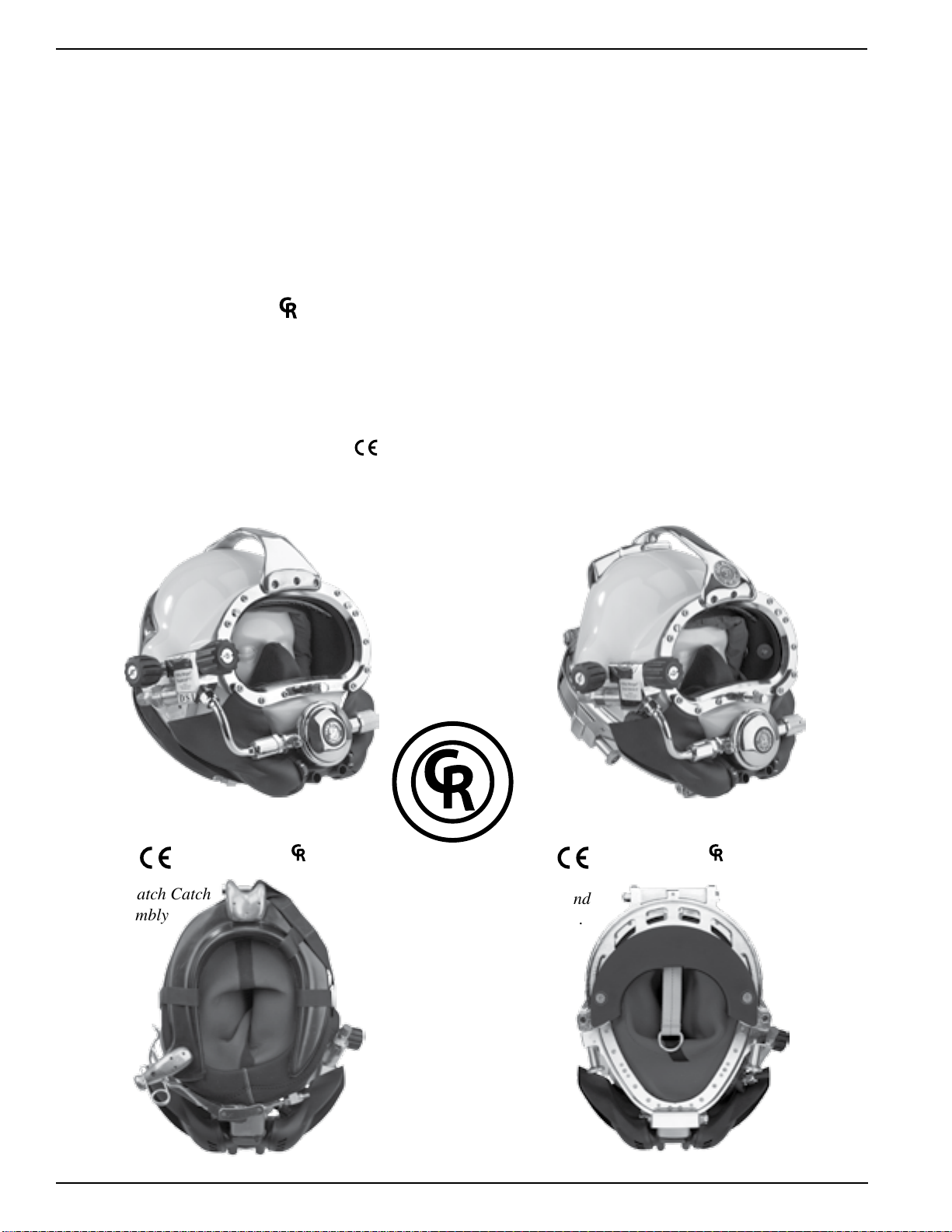

1.2 Full-Face Masks and Manifolds

KMB 18 A/B

approved and ™ marked

The EXO Full Face Mask is designed for both

surface supplied and scuba diving. By enclosing the

divers eyes, nose and mouth, the EXO permits nearly

normal speech when used in conjunction with most

wireless, and all hard wire underwater communication systems.

The EXO BR (BALANCED REGULATOR) shown

here is designed to meet or exceed recommended

performance goals in both scuba and surface supplied

modes and is

approved. It meets and surpasses

European standards for regulator performance.

The KMB 18B Band Mask frame is constructed of

hand laid fiberglass. The head harness is a molded,

strong tear resistant neoprene rubber.

The hood, which attaches to the mask frame with

welded stainless steel bands, provides warmth for

the divers head as well as pockets for the earphones.

The communications connections can be either a male

waterproof plug in type or bare wire posts. Both this

mask and the KMB 28B feature the new Tri-Valve™

Exhaust System.

The KMB 28B Band Mask (not shown) is very simi-

lar to the KMB 18, with many parts on the KMB 18B

being interchangeable with the KMB 28B. The major

difference between the 18 and 28 is the material of the

mask frame itself. The KMB 18 has a fiberglass frame

(yellow) while the KMB 28B frame is an extremely

durable injection molded plastic (black).

Other differences include:

1) The main exhaust body of the KMB 28 is part of

the frame itself and uses a #545-041 main exhaust

cover

2) no comfort insert is required on the 28

3) the face ports for the 18 and the 28 differ slightly

in size.

EXO BR

approved and ™ marked

The Balanced Regulator helps reduce the work of

breathing for the diver by balancing the intermediate

air pressure against the valve sealing pressure inside

the regulator. This enables the regulator to instantly

adjust to changes in line pressure. The balanced

regulator is adjustable for a wide range of intermediate pressures between 90 PSIG – 250 over ambient

pressure (6.2 – 17 bar).

Both models have a modular communications design

that permits rapid and simple maintenance. The

optional Hard Shell provides surfaces for mounting

lights, cameras etc.

Both the KMB 18 and KMB 28 are

2 © Copyright 1970-2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 100720003

approved.

Page 19

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

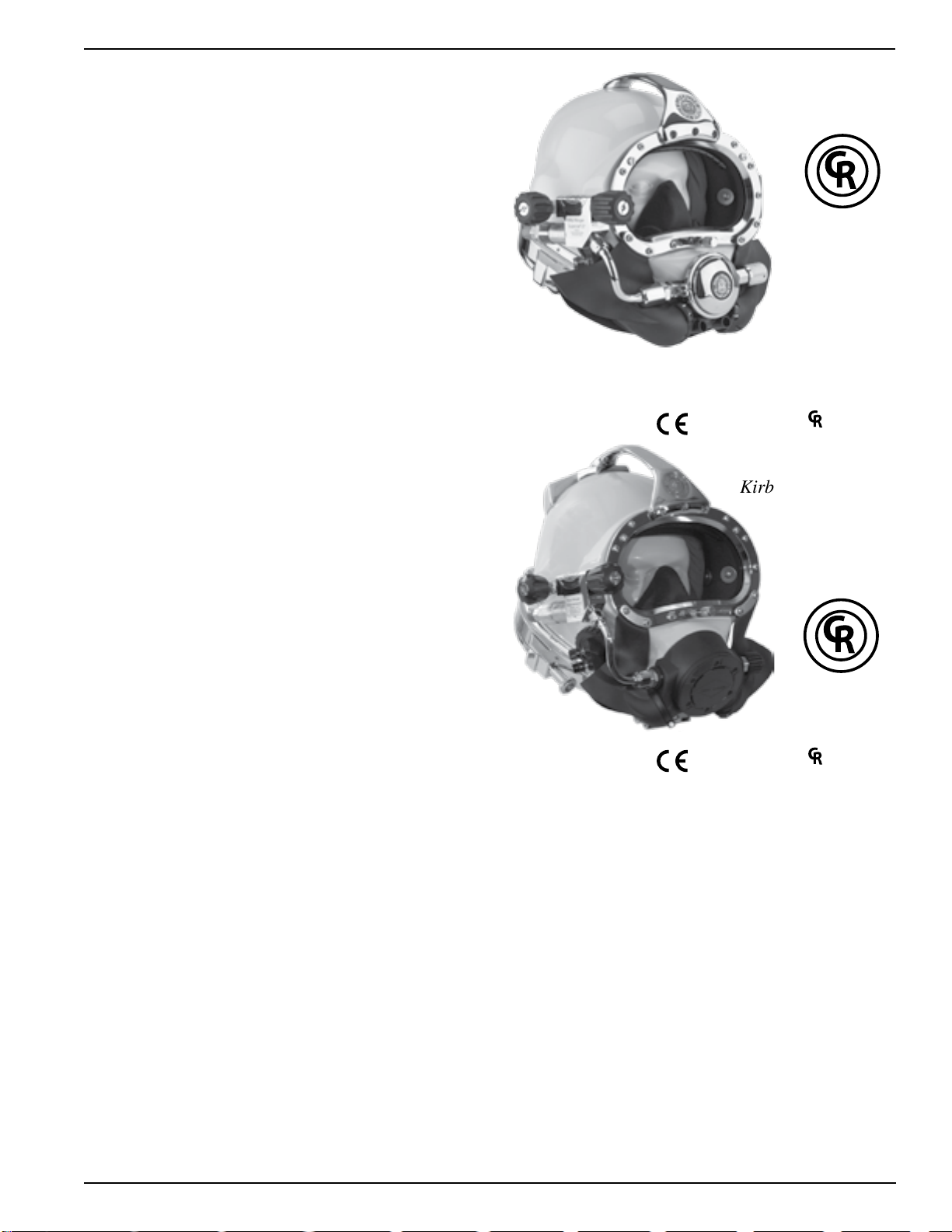

SuperMask M-48

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G