Kirby Morgan EXO Maintenance Manual

O

M

I

R

B

Y

R

G

A

N

K

D

I

V

E

S

Y

S

T

E

M

S

Operations & Maintenance Manual

for the EXO Original

,

I

.

c

n

and EXO Balanced Regulator Full Face Mask

Part #: 100-030

Kirby Morgan Dive Systems, Inc.

1430 Jason Way

Santa Maria, CA 93455, USA

Telephone (805) 928-7772

FAX (805) 928-0342

E-Mail: Info@KirbyMorgan.com

Web Site: www.KirbyMorgan.com

Publication Date of this Document: January 15, 2008

SuperLite-17, SuperLite-27, SuperLite-17C, SuperLite-17K, SuperFlow 350, Band Mask, Kirby Morgan, DCS-2A,

EXO-26 and KMB are all registered trademarks of Kirby Morgan Dive Systems, Inc. Use of these terms to describe

products that are not manufactured by KMDSI is not permitted.

© Copyright 1987-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. This manual is made available for the

express use of owner of this Kirby Morgan product. No part of this manual may be reproduced, stored in any retrieval

system, or transmitted, or used in any form or by any means, whether graphic, electronic, mechanical, photocopy, or

otherwise by technology known or unknown, without the prior written permission of Kirby Morgan Dive Systems, Inc.

Document # 080115002

®®

1a

1 305-057 Inlet Valve Assembly,

D

i

v

i

n

g

S

y

s

t

e

m

s

I

n

t

e

r

n

a

t

i

o

n

a

l

S

a

n

t

a

B

a

r

b

a

r

a

C

A

U

S

A

1

2

4

3

5

6

7

8

9

10

14

15

16

13

12

11

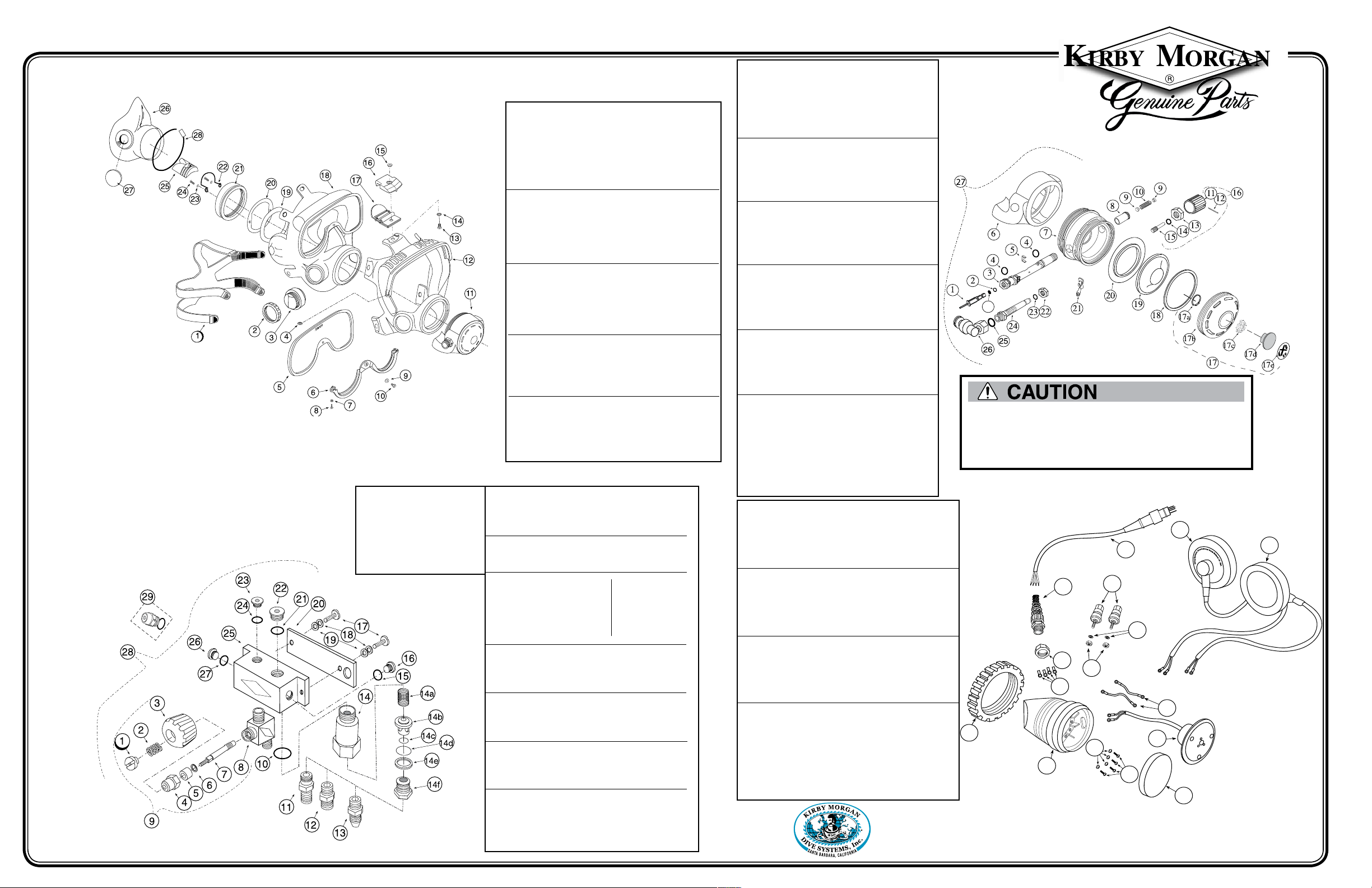

Kirby Morgan EXO BR Balanced Regulator Full Face Mask

EXO-BR, Rex

1a 310-070 Seat

1 310-025 Spider

2 320-026 Comm Mount Nut

3 305-020 Comm Plug, w/ screws & Washers

4 330-105 Nut

5 365-002 Lens

6 320-028 Clamp, yellow

7 330-205 Washer

8 330-005 Screw

9 330-506 Washer

10 330-010 Screw

11 305-040 Regulator Assembly

12 320-016 Frame EXOskeleton, yellow

13 330-020 Screw

14 330-210 Washer

15 350-040 Nut

16 320-019 Buckle Cap, yellow

17 345-010 Buckle

18 310-001 Mask Seal

19 320-040 Reg. Mount Washer

20 340-015 Mount Ring

21 350-047 Mount Nut

22 330-900 Wire Retainer

23 330-515 Washer

24 330-040 Screw

25 310-357 Equalizer

26 310-055 Oral Nasal

Following publication of this booklet, certain changes in standard equipment, options, prices and the like may have occurred which would not be included in these pages. Your Authorized KMDSI dealer is your best source for up-to-date

information on any of these products. © Kirby Morgan Dive Systems, Inc. reserves the right to change product

specifications at any time without incurring obligations.

1 550-019 Locknut

2 535-802 Spring

Optional Manifold Block Assembly

3 520-525 Knob

4 550-091 Packing Nut

5 520-024 Packing

6 540-095 Washer

7 550-138 Stem

Product Changes

Order P/N 325-055 Oral Nasal Mask w/ Tie Wraps

27 320-001 Plug

28 320-048 Tie Wrap

8 550-140 Emergency Valve Body

9 505-070 Emergency Valve Assembly

10 510-483 O-Ring

11 355-205 Scuba Adapter

12 555-117 Adapter, Brass O

13 355-225 Adapter, Brass #6 JIC

2

14 555-195 One Way Valve High Flow

14a Spring

14b Poppet

14c O-Ring

14d O-Ring

14e Wiper

14f Seat

Order

Complete

see

Loc. # 14

For

Replacement

Parts

Order

Kit

#525-330

15 310-003 O-Ring

16 550-095 Plug, small w/O-ring

17 530-070 Screw

18 330-405 Lock washer

19 530-527 Washer

20 340-011 Backing Plate

21 510-013 O-Ring

22 350-060 Plug, Large w/O-ring

23 550-095 Plug, Small w/O-ring

24 310-003 O-Ring

25 350-050 Manifold Block

26 550-095 Plug, Small w/O-ring

27 310-003 O-Ring

28 300-150 Manifold Assem. complete (O2)

300-155 Manifold Assem. complete (#6 JIC)

300-145 Manifold Assem. complete (scuba)

29 200-017 Over Pressure Relief Valve

© Copyright 2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #100310007

2 310-006 O-Ring

3 350-032 Main Tube

4 310-013 O-Ring

5 340-004 Horseshoe

6 310-020 Exhaust Whisker

7 320-041 Regulator Body

8 350-035 Sleeve

9 350-065 Spacer

10 535-910 Spring

11 320-035 Knob, Adjustment

12 530-601 Roll Pin

13 350-025 Packing Nut

14 510-011 O-Ring

15 350-052 Shaft, Adjustment

16 305-045 Reg Adjustment Assem.

17 305-060 Cover Assembly

17a 535-905 Retaining Clip

17b 350-075 Cover

17c 535-810 Spring, Purge Button

17d 520-017 Purge Button

17e 320-080 Purge Button Sticker

18 320-030 Washer

19 510-553 Diaphragm

20 310-065 Exhaust Valve

21 545-038 Roller Lever

22 350-020 Nut, Adjustment Lock

23 310-007 O-Ring

24 350-042 Nipple Tube

25 510-010 O-Ring

26 305-017 Hi Flow air inlet swivel.

(w/25)

27 305-040 Regulator Assembly

1 320-026 Comm Mount Nut

2 305-020 Comm Module w/3 & 4

320-023 Comm Module, drilled for posts

320-024 Comm Module, drilled for W.P.C.

3 330-035 Washer

4 330-030 Screw

5 510-630 Rubber Cover

6 515-020 Shure Mic. Assembly

7 515-055 Wiring Harness

8 315-016 Earphone Assembly Left

9 315-015 Earphone Assembly Right

10 515-045 Male W.P. Connector

11 315-005 Pigtail

12 350-070 Mount Nut, Pigtail

13 515-049 Terminal

14 315-020 Comm Posts, EXO

15 530-525 Washer

16 530-308 Hex Nut

17 315-210 Comm Module complete assembly

w/comms & posts

315-215 Comm Module complete Assem..

w/comms & Male W.P.Connector

Kirby Morgan Dive Systems, Inc.® 1430 Jason Way, Santa Maria, CA 93455

Balanced Regulator Assembly

Use only Kirby Morgan original replacement parts. The use

of other manufacturer's parts will interfere with the performance

characteristics of your life support equipment and may jeopardize your

safety. Additionally, any substitutions will void any warranties offered

by KMDSI. When ordering spares, always insist on Kirby Morgan

original parts.

Optional

Communications Assemblies

Phone: 805/928-7772 Fax: 805/928-0342

www.KirbyMorgan.com e-mail: kmdsi@KirbyMorgan.com

®

1a

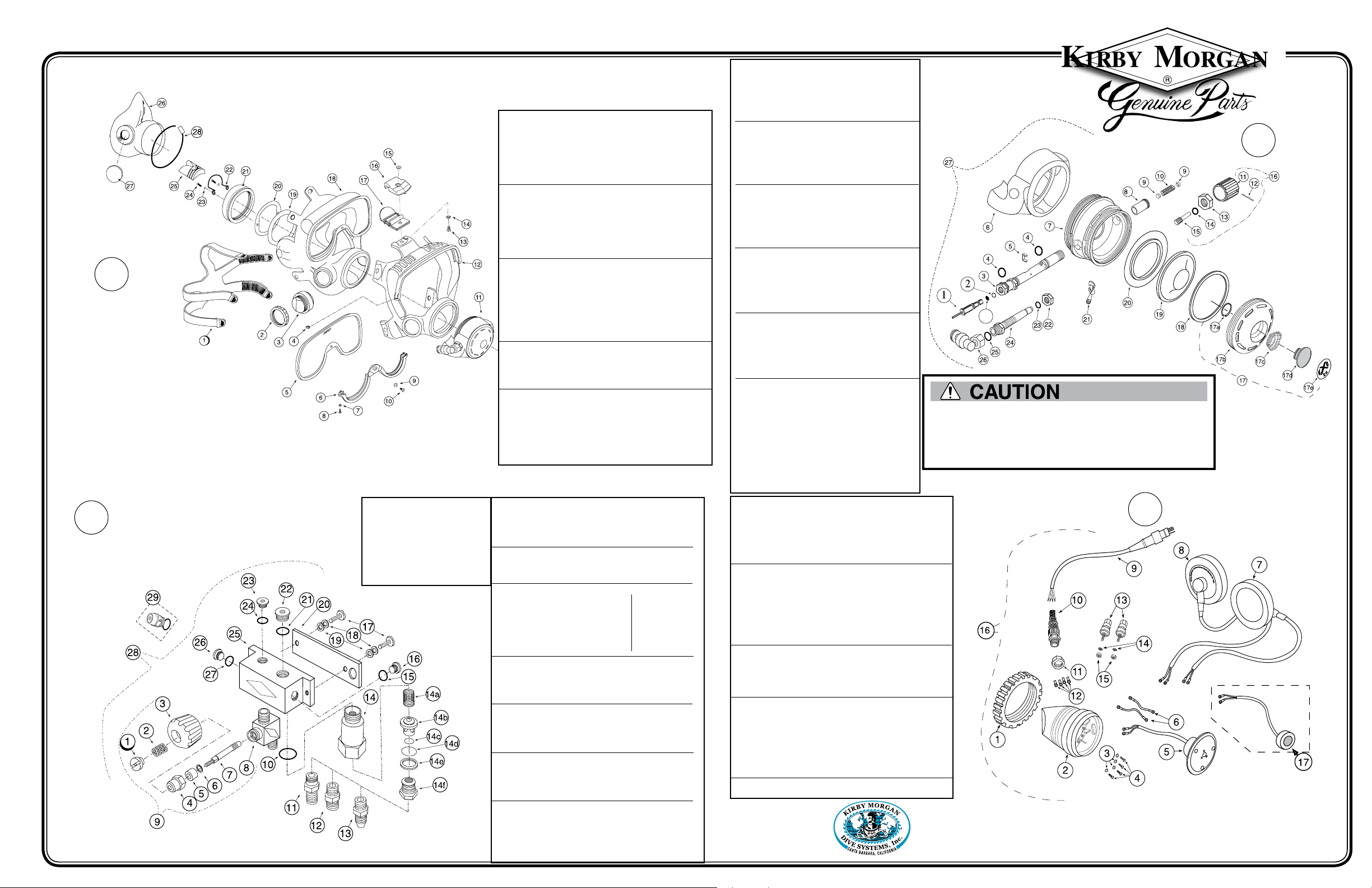

Kirby Morgan EXO BR MS Balanced Regulator Full Face Mask

A

Following publication of this booklet, certain changes in standard equipment, options, prices and the like may have occurred which would not be included in these pages. Your Authorized KMDSI dealer is your best source for up-to-date

information on any of these products. © Kirby Morgan Dive Systems, Inc. reserves the right to change product

specifications at any time without incurring obligations.

D

Optional Manifold Block Assembly

Product Changes

1 550-019 Locknut

2 535-802 Spring

3 520-525 Knob

4 550-091 Packing Nut

5 520-024 Packing

6 540-095 Washer

7 550-138 Stem

1 305-057 Inlet Valve Assembly,

EXO-BR, Rex

1a 310-070 Seat

2 310-006 O-Ring

1 310-025 Spider

2 320-026 Comm Mount Nut

3 305-020 Comm Plug, w/ screws & Washers

4 330-105 Nut

5 365-002 Lens

6 320-028 Clamp, yellow

7 330-205 Washer

8 330-005 Screw

9 330-506 Washer

10 330-010 Screw

11 305-040 Regulator Assem.

12 320-016 Frame EXOskeleton, yellow

13 330-020 Screw

14 330-210 Washer

15 350-040 Nut

16 320-021 Buckle Cap, yellow

17 345-010 Buckle

18 310-001 Mask Seal

19 320-040 Reg. Mount Washer

20 340-015 Mount Ring

21 350-047 Mount Nut

22 330-900 Wire Retainer

23 330-515 Washer

24 330-040 Screw

25 310-357 Equalizer

26 310-055 Oral Nasal

Order P/N 325-055 Oral Nasal Mask w/ Tie Wraps

27 320-001 Plug

28 320-048 Tie Wrap

8 550-140 Emergency Valve Body

9 505-070 Emergency Valve Assembly

10 510-483 O-Ring

11 355-205 Scuba Adapter

12 555-117 Adapter, Brass O

13 355-225 Adapter, Brass #6 JIC

14 555-195 One Way Valve High Flow

14a Spring

14b Poppet

14c O-Ring

14d O-Ring

14e Wiper

14f Seat

15 310-003 O-Ring

16 550-095 Plug, small w/O-ring

17 530-070 Screw

18 330-405 Lock washer

19 530-527 Washer

20 340-011 Backing Plate

21 510-013 O-Ring

22 350-060 Plug, Large w/O-ring

23 550-095 Plug, Small w/O-ring

24 310-003 O-Ring

25 350-050 Manifold Block

26 550-095 Plug, Small w/O-ring

27 310-003 O-Ring

28 300-150 Manifold Assem. complete (O2)

300-155 Manifold Assem. complete

300-145 Manifold Assem. complete

29 200-017 Over Pressure Relief Valve

© Copyright 2010 Kirby Morgan Dive Systems, Inc. All rights reserved. Document #100310007

Order

Complete

Loc. # 14

see

2

For

Replacement

Parts

Order

Kit

#525-330

(#6 JIC)

(scuba)

3 350-032 Main Tube

4 310-013 O-Ring

5 340-004 Horseshoe

6 310-020 Exhaust Whisker

7 320-041 Regulator Body

8 350-035 Sleeve

9 350-065 Spacer

10 535-910 Spring

11 320-035 Knob, Adjustment

12 530-601 Roll Pin

13 350-025 Packing Nut

14 510-011 O-Ring

15 350-052 Shaft, Adjustment

16 305-045 Reg Adjustment Assem.

17 305-060 Cover Assembly

17a 535-905 Retaining Clip

17b 350-075 Cover

17c 535-810 Spring, Purge Button

17d 520-017 Purge Button

17e 320-080 Purge Button Sticker

18 320-030 Washer

19 510-553 Diaphragm

20 310-065 Exhaust Valve

21 545-038 Roller Lever

22 350-020 Nut, Adjustment Lock

23 310-007 O-Ring

24 350-042 Nipple Tube

25 510-010 O-Ring

26 305-017 Hi Flow air inlet swivel.

27 305-040 Regulator Assembly

1 320-026 Comm Mount Nut

2 305-020 Comm Module w/3 & 4

320-023 Comm Module, drilled for posts

320-024 Comm Module, drilled for W.P.C.

3 330-035 Washer

4 330-030 Screw

5 515-020 Shure Mic. Assembly

6 515-055 Wiring Harness

7 315-016 Earphone Assembly Left

8 315-015 Earphone Assembly Right

9 515-045 Male W.P. Connector

10 315-005 Pigtail

11 350-070 Mount Nut, Pigtail

12 515-049 Terminal

13 315-020 Comm Posts, EXO

14 530-525 Washer

15 530-308 Hex Nut

16 315-210 Comm Module complete assembly

w/comms & posts

315-215 Comm Module complete Assem..

w/comms & Male W.P.Connector

17 315-026 Optional Preamplified Microphone

(w/ 25)

Balanced Regulator Assembly

Use only Kirby Morgan original replacement parts. The use

of other manufacturer's parts will interfere with the performance

characteristics of your life support equipment and may jeopardize your

safety. Additionally, any substitutions will void any warranties offered

by KMDSI. When ordering spares, always insist on Kirby Morgan

original parts.

B

Optional

C

Communications Assemblies

Kirby Morgan Dive Systems, Inc.® 1430 Jason Way, Santa Maria, CA 93455

Phone: 805/928-7772 Fax: 805/928-0342

www.KirbyMorgan.com e-mail: kmdsi@KirbyMorgan.com

EXO Full-Face Mask Manual

CAUTION

KMDSI must have your current address to ensure that you receive all safety notices and

other important information concerning the mask. Please notify KMDSI of any change of

address.

II © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

EXO Full-Face Mask Manual

RECORD OF CHANGES

It is the responsibility of the owner of this product to register their ownership with Kirby Morgan Dive

Systems, Inc., by sending the warranty card provided. This card is to establish registration for any necessary

warranty work and as a means of communication that allows KMDSI to contact the user regarding this product.

The user must notify KMDSI of any change of address by the user or sale of the product.

All changes or revisions to this manual must be recorded in this document to ensure that the manual

is up to date.

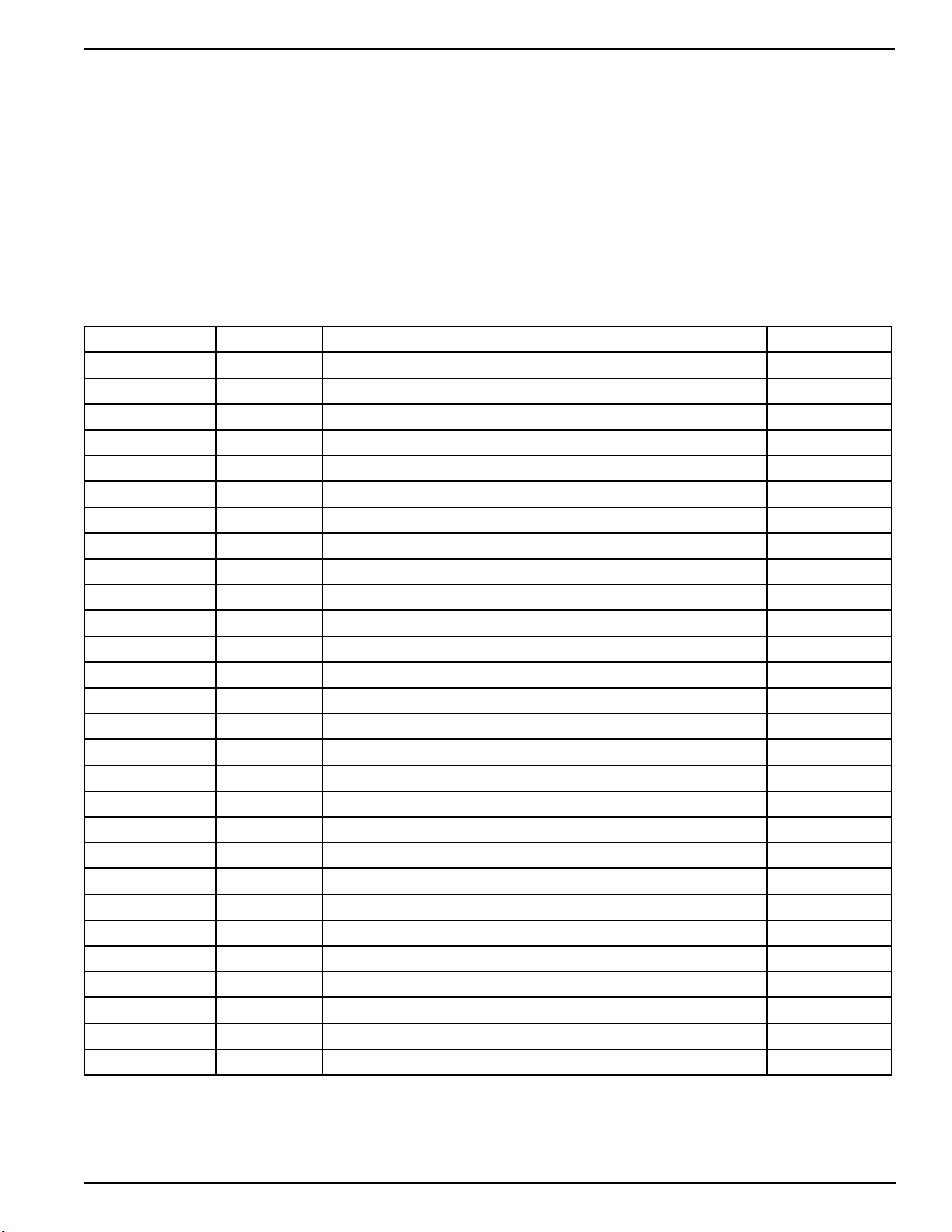

Change Number Date Description of Change Page Number

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 III

EXO Full-Face Mask Manual

Table Of Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VII

Definitions of Signal Words Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VII

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

Chapter 1.0 General Information Regarding Kmdsi Products . . . . . . . . . . . . . . . . . . . . . . . 12

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 The Kirby Morgan Diving Helmets, Masks & Air Control System . . . . . . . . . . . . . . . . . . . 13

Chapter 2 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 First Use and Pre-Dive Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Pre Dress-in Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Clean Face Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6 Adjusting the Equalizer EXO Standard or BR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7 Checking Regulator Functions & Preparing the EXO for Use In SCUBA Mode. . . . . . . . 20

2.8 Test the Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.9 Wireless Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.10 Using the EXO in the Surface-Supplied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.11 Testing the Manifold Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.11.1 Testing the One-Way Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.11.2 Testing the Emergency Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.12 Diver’s Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.13 Installing the Manifold Block on the Diver’s Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.14 Bail-Out Bottle (Emergency Air Supply) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.15 First Stage Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.16 Over-Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.17 Configuring Your Emergency Gas System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.18 Connecting the Hoses to the Manifold Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.19 Use of Quick-Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.20 Connecting the Umbilical to the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.21 Opening the Breathing Gas Supply to the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.22 Fogging Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.23 Proper Hood Fit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.24 Recommendations for Donning and Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.25 Donning the EXO Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.26 Removal of the EXO Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 3 Diving With The EXO Full-Face Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2 Water Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.3 Regulator Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.4 Spider Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5 Purging the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.6 Procedures to Follow for Loss of Breathing Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 4 Post Dive Procedures And General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2 Required tools, Sealing, Cleaning Agents, Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

IV © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

EXO Full-Face Mask Manual

4.3 Component and Parts Cleaning

4.3.1 Component and Parts Lubrication

4.4 Disconnecting the Mask from the Diving System

4.5 Daily Maintenance

4.6 Inspection Procedures

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7 General Cleaning Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.7.1 Mild Soap Solution for General Cleaning and Leak Detector Use

4.7.2 Acidic Cleaning Solution and Procedures

4.7.3 Germicidal Cleaning Solutions and Procedure

4.8 Communications Inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . 45

4.9 Reassembling the Mask After Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 5 EXO Regulator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1 General Information

5.1.1 Special Regulator Tools

5.2 Original and Standard EXO Regulator Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3 Original and Standard EXO Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.4 EXO Balanced Regulator Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.5 EXO-BR Regulator Reassembly

5.6 Regulator Assembly Removal and Installation

5.6.1 Regulator Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.6.2 Regulator Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.7 EXO Regulator Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.8 Manifold Block Maintenance

5.8.1 Daily Maintenance

5.8.2 Post Dive Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.8.3 Annual Overhaul of the Manifold Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.8.3.1 Disassembly Of Manifold Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.8.3.2 Disassembly and Cleaning of the One Way Valve.

5.8.3.3 Reassembly of the One Way Valve

5.8.3.4 Disassembly of the Emergency Gas Supply Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.8.3.5 Cleaning and Lubricating the Emergency Gas Supply Valve . . . . . . . . . . . . . . . . . 68

5.8.3.6 Reassembly of Emergency Gas Supply Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.9 Overpressure Relief / Bleed Valve Overhaul Procedures

5.9.1 Overpressure Relief Valve General

5.9.2 Overpressure Relief Valve Disassembly and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.9.3 Overpressure Relief Valve Reassembly

5.9.4 Overpressure Relief Valve Lift Check/Setting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 6 Frame And Lens Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2 Lens Replacement

6.2.1 Lens Removal

6.2.2 Lens Installation

6.3 Buckle Replacement

6.3.1 Buckle Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.3.2 Buckle Installation

6.4 Replacing the Face Seal or Frame

6.4.1 Face Seal Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 V

EXO Full-Face Mask Manual

6.4.2 Face Seal Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Chapter 7 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.1 Bare Wire Binding Posts

7.2 Waterproof Connector (WPC)

7.3 Wireless Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.4 Removing the Communications Module

7.5 Installing the Communications Module

7.6 Earphone and/or Microphone Removal

7.7 Earphone and/or Microphone Installation

7.8 Removing the Waterproof Connector (WPC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.9 Installing the Waterproof Connector (WPC)

7.10 Removing the Binding Posts

7.11 Installing the Binding Posts

7.12 Waterproof Connector (WPC) Assembly Rebuild

7.13 Waterproof Connector (WPC) Pin Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.14 Post Dive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix Breathing Gas Requirements EXO Balance Regulator Full-Face

Mask

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2 Regulator Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.1 EXO-BR® Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.2 Minimum Operating Temperature

8.3 Cage Code

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.4 CR Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.5 CE Approved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.6 Operational Specifications & Limitations for Surface-Supplied Diving . . . . . . . . . . . . . . . . . 93

8.6.1 Using the EXO-BR Regulator with a Low Pressure Compressor Supply

. . . . . . . . 93

8.6.2 Using the EXO-BR Regulator Low-Pressure Compressor Supply Pressure

Requirements Table

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

8.6.3 Using a High-Pressure Breathing Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table of Equivalents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

KMDSI Document Changes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

VI © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

EXO Full-Face Mask Manual

WARNING

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

About this Manual

The information in this manual is intended to aid the user in optimizing the performance of this mask. This

manual gives reference to using EXO- 26 masks in open circuit scuba mode as well as in surface supplied diving mode. The use of some of this information will often depend on the use of associated support equipment

and operational scenarios. It is not the intention of this manual to teach diving techniques, but rather to give

the user the required technical information to allow Kirby Morgan helmets and masks to be integrated with the

complete diving system.

Definitions of Signal Words Used in this Manual

For your protection, pay particular attention to items identified by signal words in this manual. These terms are

identified as, CAUTION, WARNING AND DANGER. It is especially important for you to read and understand

these sections.

CAUTION

This word indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

This word indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

This word indicates an imminently hazardous situation, which if not avoided, will result

in death or serious injury.

If English is not your native language and you have any difficulty understanding the language of any warnings

as they appear in the manual, please have them translated.

Este é um aviso importante. Queira mandá-lo traduzir.

Este es un aviso importante. Sirvase mandario traducir.

Quest è un avviso importante. Tradurlo.

Ceci est important. Veuillez traduire.

Diese Mitteilung ist wichtig. Bitte übersetzen lassen.

If you have any questions regarding the information in this manual, or the operation of your mask, call KMDSI

at (805) 928-7772

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 VII

EXO Full-Face Mask Manual

WARNING

WARNING

WARNING

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

This EXO Full Face Mask is intended for use by trained divers who have successfully completed a recognized training

course in the use of a full face mask, and if used in the surface supplied mode, an approved surface supplied diving

course.

Read this manual before using or maintaining the mask, even if you have experience with other full-face masks. If you

Follow all the instructions in this manual carefully and heed all safety precautions. Improper

use of this diving mask could result in serious injury or death.

Kirby Morgan Dive Systems, Inc. (KMDSI) warns all divers who use the EXO Full Face Mask

to use only KMDSI original spare parts from a KMDSI authorized dealer. Although other

parts, O-rings and fittings may not to be manufactured to the same standards maintained

by KMDSI. The use of any spares other than KMDSI original parts may lead to equipment

failure and accidents.

Diving in an environment that is chemically, biologically, or radiologically contaminated is

extremely hazardous. Although the EXO Full Face Mask may be adapted for use in some

contaminated environments, special training, equipment, and procedures are necessary.

Do not dive in a contaminated environment unless you have been thoroughly trained and

equipped for this type of diving.

Diving is a life threatening occupation. Even if you do everything right you can still be killed

or injured. None of the models of full-face masks can prevent accidents, injuries or death

due to improper training, lack of health, improper supervision, improper job requirements,

improper maintenance or acts of God.

DO NOT dive this mask in water containing high concentrations of petroleum based chemicals. DO NOT use any chemical locking liquids anywhere on the mask. DO NOT use any

type of aerosol sprays on the mask. These chemicals can attack, damage, and compromise

the structural integrity of the plastic parts on the mask . Clean the mask using only mild

soap and water.

have purchased the mask new from a dealer, be sure to send in the warranty registration card so we may keep you informed regarding any safety notices that affect this product. If you resell or loan this mask to another diver, be sure this

manual accompanies the mask and that the person reads and understands the manual.

This manual is supplied to the original purchaser of this mask. If you have any questions about the use of the mask or

you need another copy of this manual, Part Number 100-030, contact KMDSI. If you have any questions regarding the

use, maintenance, or operation of this mask, contact KMDSI at (805) 928-7772

VIII © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

EXO Full-Face Mask Manual

WARNING

WARNING

WARNING

WARNING

WARNING

This mask was completely checked and should be ready to dive as it was shipped from

the factory. However, it is always the diver's responsibility to check all the components of

the mask prior to diving.

The EXO comes from the factory lubricated for oxygen service. If the exo

is to be used for enriched air or oxygen use it must be carefully maintained

and cleaned in accordance with this manual. components requiring Lubrication must be only be lubricated with an oxygen compatible lubricant such

as Christo Lube or Krytox. Any breathing mixture containing an oxygen

content greater than 23% oxygen is considered enriched gas.

All Kirby Morgan helmets, masks, and low pressure demand regulators must not be used with oxygen mixtures in excess

of 50% oxygen by volume without first ensuring all low pressure (less than 225 psig, 15.5 bar) gas transporting components have been cleaned for oxygen service. Only oxygen compatible lubricants such as Krytox™ and ChristoLube™

should be used on components requiring lubrication and lubricants should be used sparingly. Never mix different types

of oxygen compatible lubricants. Helmets or masks used primarily for air diving and occasionally for enriched gas use

should be cleaned at more frequent intervals than helmets used for mixed gas diving only.

KMDSI regards the use of any breathing gas mixture greater than 50% oxygen

to be treated as oxygen. This belief is in keeping with the recommendations

set forth by the National Fire Protection Association (NFPA), Compressed

Gas Association (CGA), and the American Society for Testing and Materials

(ASTM).

Kirby Morgan “High Pressure Components” (greater than 225 p.s.i.g., 15.5 bar)

must not to be used with pure oxygen, Nitrox, or any breathing gas mixtures

with oxygen content greater than 23.5 % by volume. Using oxygen mixtures

in excess of 23.5 % by volume may lead to a fire or explosion, which could

result in serious injury or death.

Any diving helmet, full face mask, regulator, control console or breathing life

support item manufactured or sold by KMDSI must not be used with breathing gas mixtures in excess of 50% oxygen without first ensuring that all gas

transporting components have been cleaned for oxygen service, have oxygen

compatible soft goods lubricated with an approved oxygen compatible lubricant such as Krytox or Christo Lube grease.

The Kirby Morgan SuperFlow 1st stage scuba regulator, as well as all Kirby Morgan dive control consoles and highpressure gas components (greater than 225 p.s.i.g., 15.5 bar) should not be used with pure oxygen, Nitrox, or any breathing

gas containing more than 23.5 % oxygen by volume. The first stage is not intended for use with enriched gas mixtures.

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 IX

EXO Full-Face Mask Manual

Operational specifications and limitations for surface supplied air diving and scuba diving for United States

use, and a separate chart for European Union use are presented on Page 4. The information has been separated

because of the differences imposed or required by certain regulating bodies. Whenever Kirby Morgan diving

equipment is used in countries that have adopted CE Certification, only CE certified components can be used

and all components must be part of the tested certified configuration.

It is important for the user to understand the rules, regulations, and philosophy imposed by the governing or

regulating bodies whenever diving operations are being planned or conducted. Diving operations must only

be conducted within the limits of the operational specifications, and in accordance with the rules and regulations established by the governing authority in the specific country or geographical location where the diving

operations are being conducted. Technical questions regarding this equipment should be directed to Dive Lab

Inc., of 1415 Moylan Road, Panama City Beach Florida. Telephone 850 235-2715, Fax 850-235-0858 e-mail divelab@aol.com

Warranty Information

KMDSI warrants every new mask, helmet, or breathing gas control system to be free from defects in

workmanship for a period of ninety (90) days from the date of purchase. This warranty does not cover

rubber parts or communications components.

Should any part be defective, contact your nearest authorized KMDSI dealer. If there is no dealer in

your area, contact KMDSI directly at (805) 928-7772 or FAX (805) 928-0342. You must have a return

authorization from KMDSI. Upon approval from KMDSI, return the defective part, freight prepaid to

the KMDSI plant. The part will be repaired or replaced at no charge as deemed necessary by KMDSI.

This warranty becomes null and void if:

1) Your completed warranty card is not received by KMDSI within ten (10) days

of purchase date.

2) The Warranty Card is not completely filled our or information on the

warranty card is falsified.

3) The product has not been properly serviced and maintained according to the

appropriate KMDSI manual and the use of Kirby Morgan Genuine replacement parts.

4) Unauthorized modifications have been made to the product.

5) The product has been abused or subjected to conditions which are unusual or

exceed the product's intended service.

X © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

EXO Balanced Regulator Full-Face Mask

Head harness (spider)

Buckle

EXO Full-Face Mask Manual

Mask frame

Earphone

Waterproof connector

Inlet adapter

Lens (viewport)

Regulator

Regulator adjustment knob

Communications module

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 XI

EXO Full-Face Mask Manual

STOP!

BEFORE GOING FURTHER-

This manual will refer to location numbers in specific drawings, or in the exploded view, which is

in the back of this manual. These numbers are called “location” numbers. They may be used to find

the referred to parts in the drawings in this manual only. They are not the part number. Next to the

exploded drawing is a list of the “location” numbers that match the Kirby Morgan part numbers

along with the name of the part. Always check the part number when ordering to make sure it is

correct. When ordering, always specify the helmet model number and serial number as well.

Chapter 1.0

General Information Regarding Kmdsi Products

1.1 Introduction

The Kirby Morgan Corporation was started in 1965.

The copper and brass “heavy gear” or “Standard

Dress” helmets were the first helmets manufactured by

the company. Over the years Kirby Morgan designed,

manufactured and sold many different helmets and

masks for commercial divers.

Staying active in commercial diving has contributed to

the successful design innovations of KMDSI products.

This may be the primary reason for the acceptance of

our designs by professional divers.

Bev Morgan has designed more than Fifty-Seven diving helmets and over 40 diving masks. All employees

of KMDSI participate as part of the Kirby Morgan

design team. It would not be possible for us to supply

the commercial, military, scientific, and public service

diving industries with our equipment, without the team

of people that make up Kirby Morgan Dive Systems,

Inc. (KMDSI)

We feel it is important for the reader to understand

that we at KMDSI consider ourselves as only part

of the process along the path in diving equipment

design. We welcome all input from our customers.

The thinking of many good divers, diving equipment

engineers, diving medical specialists, diving organization administrators and their supporting personnel has

contributed to the current state of the art of diving.

Bev Morgan, Chairman of the Board

Kirby Morgan Dive Systems, Inc.

Each piece of gear we manufacture has in it some of

the thinking of those who have gone before us. To all

those people who give something of themselves to the

men and women who work underwater, we express

a thank you.

We have a strong commitment to providing the best

diving equipment and service possible. This thinking

has been the policy of Kirby Morgan Dive Systems,

Inc. and we will continue to take this approach to our

work.

Our extensive dealer network makes it easy to obtain

genuine Kirby Morgan replacement parts, as well as

technical assistance worldwide.

12 © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

EXO Full-Face Mask Manual

KMDSI has always concentrated on designing and

manufacturing diving equipment that allows most

repairs, inspections, and all routine maintenance to

be performed by the user. Most routine preventative

and corrective maintenance can be accomplished by

the user utilizing this manual, the KMDSI Tool Kit

(P/N 525-620) and common hand tools. Technician

training is available through Dive Lab Inc., information can be obtained on line at www.divelab.com or

by telephone at 850-235-2715.

1.2 The Kirby Morgan Diving Helmets, Masks

& Air Control System

All Kirby Morgan diving helmets and masks are

manufactured by Kirby Morgan Dive Systems, Inc.

(KMDSI). Each step of the manufacturing process is

carefully controlled to assure the customer of a high

quality, durable helmet that will function properly for

many years.

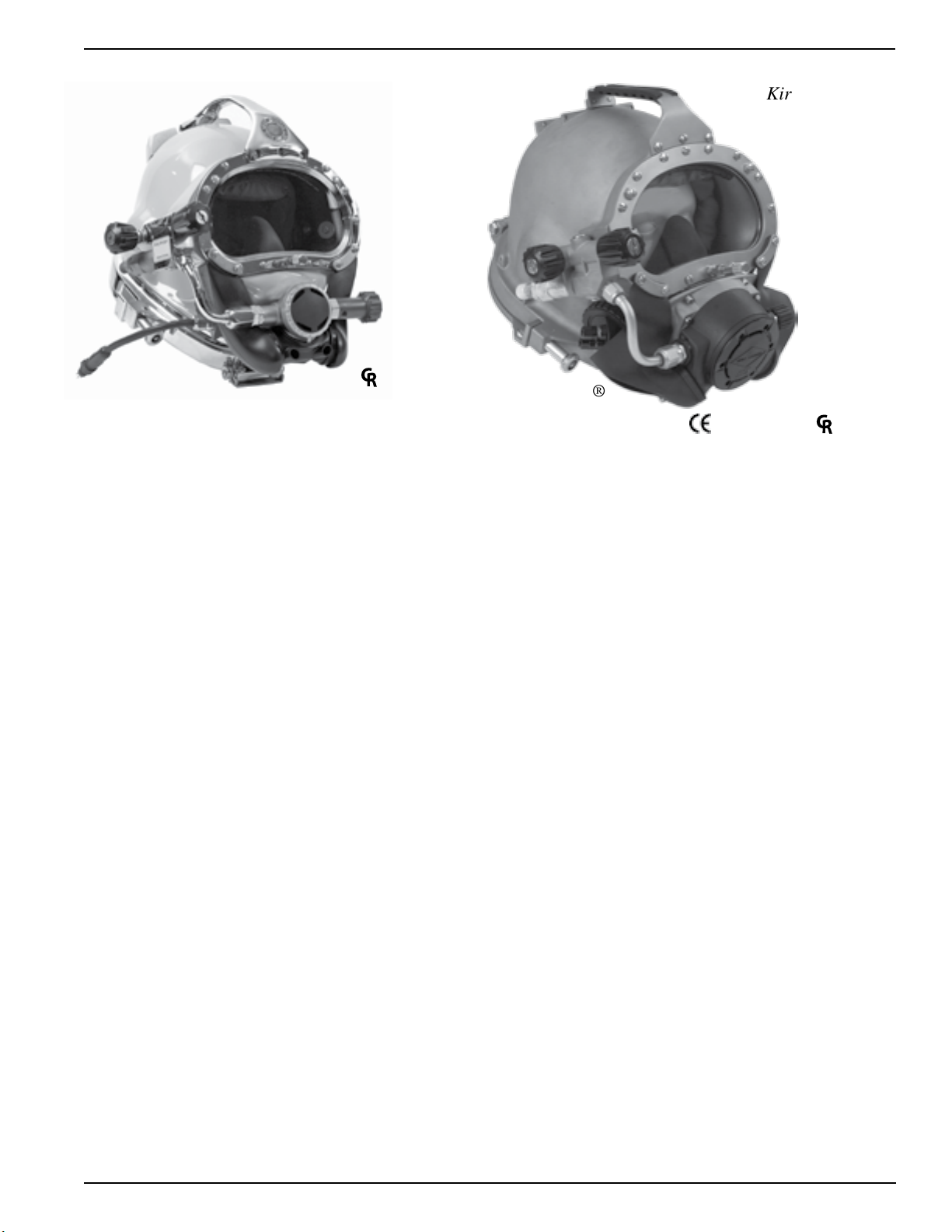

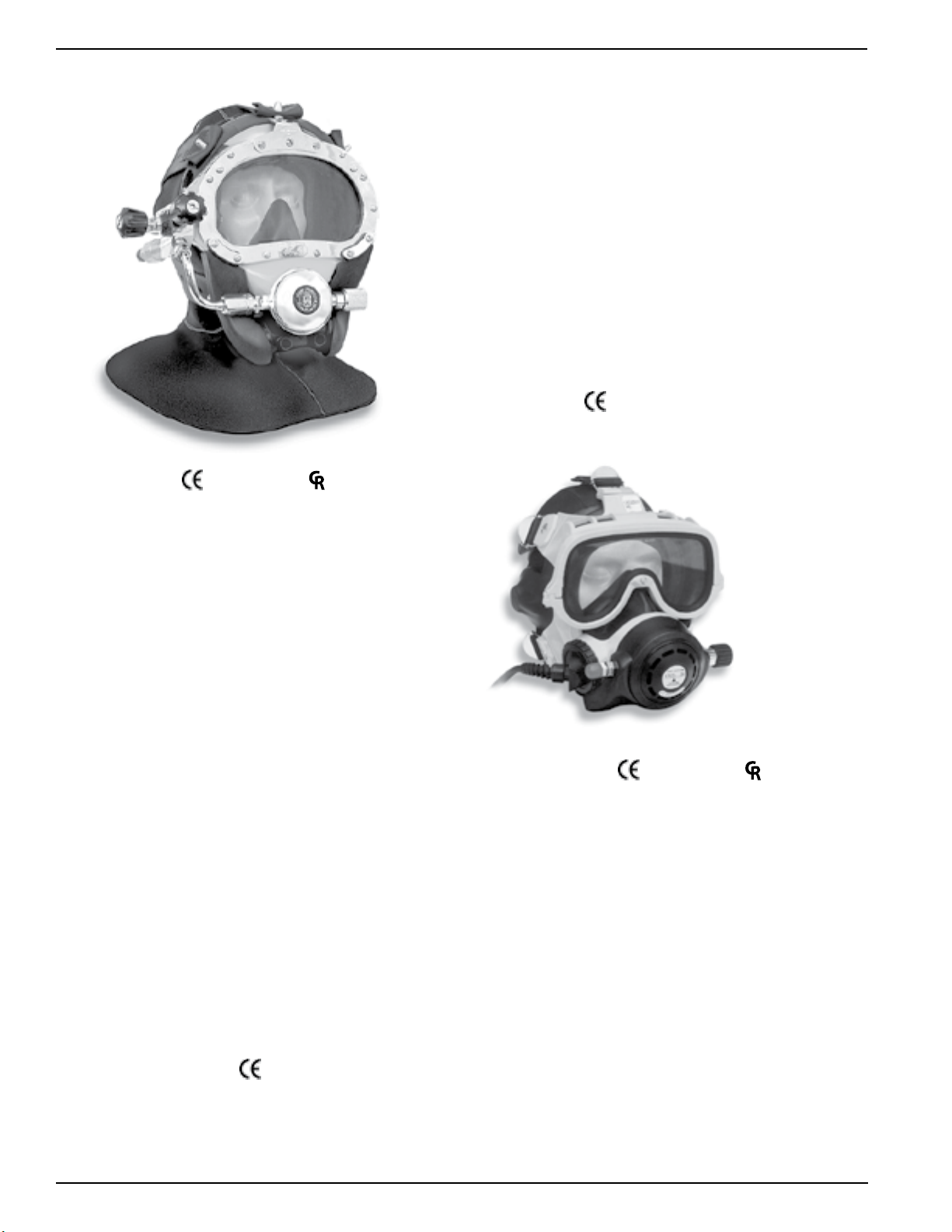

The models of Kirby Morgan diving helmets currently in production are the SuperLite-17B, MK-21

(U.S. Navy version), the SuperLite-27,and the Kirby

Morgan 37, 47, 57 and 77. All are commercially rated

and

marked.

The SuperLite-17B was first developed in 1975 and

quickly set a standard for diving helmet design. Many

large and small commercial diving companies, military organizations, scientific divers, and public safety

divers are successfully using this design around the

world.

The SL-17B helmet system consists primarily of two

major components: the neck dam/yoke assembly, and

the helmet. To don the helmet, the diver first slips the

angled neck dam with the attached yoke over his head.

The helmet is lowered onto the diver’s head with the

help of a tender, then the yoke hinge tab is hooked

onto the alignment screw on the rear weight. The neck

clamp is then slipped onto the helmet and locked.

A

R

T

Y

E

L

D

L

Yoke and Latch Catch

Assembly

SuperLite 17B

approved and ™ marked

A

I

C

R

E

M

M

O

C

D

E

T

S

E

T

B

A

L

E

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

V

E

I

A

D

R

-

™

Kirby Morgan 37

approved and ™ marked

Neck Pad and

Sealed Pull Pins.

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 13

EXO Full-Face Mask Manual

C

O

M

M

E

R

C

I

A

L

L

Y

R

A

T

E

D

-

P

R

O

F

E

S

S

I

O

N

A

L

D

I

V

I

N

G

G

E

A

R

-

D

I

V

E

L

A

B

T

E

S

T

E

D

™

The locking system not only seals the neck dam to the

helmet but also secures the front of the yoke, fastening

the helmet to the diver’s head.

The SuperLite-17A/B shares many common breathing system parts with all Kirby Morgan helmets and

masks. The breathing system has been man-tested to

1600 FSW and approved by the U.S. Navy for surfacesupplied diving to 190 FSW with air and 300 FSW

with mixed gas. It surpasses all requirements of all

governing agencies and it is approved for commercial

diving through out the world.

Other features that are common to all Kirby Morgan

helmets and Band Masks include:

* Face port and retainer ring

* Communications components

* Oral/nasal mask

* Nose block device

* Air train defogger

The Kirby Morgan 37 Commercial Diver’s Helmet

represents what we at Kirby Morgan considered to be

a turning point in modern diving helmet design. The

helmet consists of two major assemblies: the helmet

shell/helmet ring assembly and the neck dam/neck

ring assembly.

diver a comfortable, secure, custom fit.

SuperLite 27

approved and ™ marked

Kirby Morgan 47

The helmet comes with the large tube SuperFlow 350

adjustable demand regulator which provides an easier

breathing gas flow during peak work output. A quick

change communications module is available with

either bare wire posts or a waterproof connector.

®

The helmet ring houses the sealed pull pins and provides protection for the bottom end of the helmet.

The diver is also provided with an externally adjustable chin support. This custom fit and balance seats

the helmet comfortably for long periods of time even

when working in the face down position.

The Kirby Morgan 47 offers the ultimate in a high

performance breathing regulator. This helmet has an

entirely new breathing system, oral nasal mask, and

water ejection system. The Rex

approved and ™ marked

®

Demand Valve (pat-

ents pending), with it’s fully adjustable balanced piston

The SuperLite 27 Commercial Diver’s Helmet has

all the same features of the KM37 on a smaller, low

is a breakthrough design that exceeds the requirements

of all government or other testing agencies.

volume shell design. This helmet is often preferred by

persons with smaller heads.

It has the best work-of-breathing performance when

compared to ANY other commercial diving helmet.

The chrome plated machined brass helmet neck ring

houses the sealed pull pins and provides protection

for the bottom end of the helmet. Like the SL-17K,

37 and 17C, the diver is provided with an externally

The Kirby Morgan 47 Dive Helmet has been tested

and meets or exceeds European CE requirements and

is fully commercially rated. In all other respects, this

helmet is nearly identical to the Kirby Morgan 37.

adjustable chin support. This support, along with the

adjustable neck pad on the locking collar, gives the

14 © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

Kirby Morgan 57

EXO Full-Face Mask Manual

Kirby Morgan 77

®

™

marked

The Kirby Morgan 57 helmet features our revolution-

ary SuperFlow 450 regulator. It's machined from a

stainless steel casting for the ultimate in performance

and reliability. This commercially rated regulator

delivers all the breathing gas you need for the most

demanding work underwater.

The Kirby Morgan 57 also includes our QuadValve™ Exhaust System. It's recommended for diving in biologically contaminated water, when you're

properly trained and equipped, using recommended

procedures. This new exhaust has exceptionally low

exhalation resistance that you must experience to appreciate.

D

®

approved and ™ marked

The Kirby Morgan 77 represents the first in a new

generation of stainless steel diving helmets that provide an alternative for the diver who prefers a metal

helmet. The helmet features a stainless steel version

of our new REX® regulator, which offers the best

performance of any Kirby Morgan system.

It has the best work-of-breathing performance when

compared to ANY other commercial diving helmet.

The Kirby Morgan 77 Dive Helmet has been tested

and meets or exceeds European CE requirements and

is fully commercially rated.

The advantages of this all stainless steel helmet include

the following:

• No renishing required if the surface is scratched

or gouged.

• Faster production of helmets for customer delivery.

• Elimination of threaded inserts for securing the port

retainer to the helmet shell.

• No need to remove the handle to remove the port

retainer.

• One piece sideblock includes both the free-ow valve

and the Emergency Gas System valve.

• The helmet ring is an integral part of the helmet.

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 15

EXO Full-Face Mask Manual

KMB 18 A/B

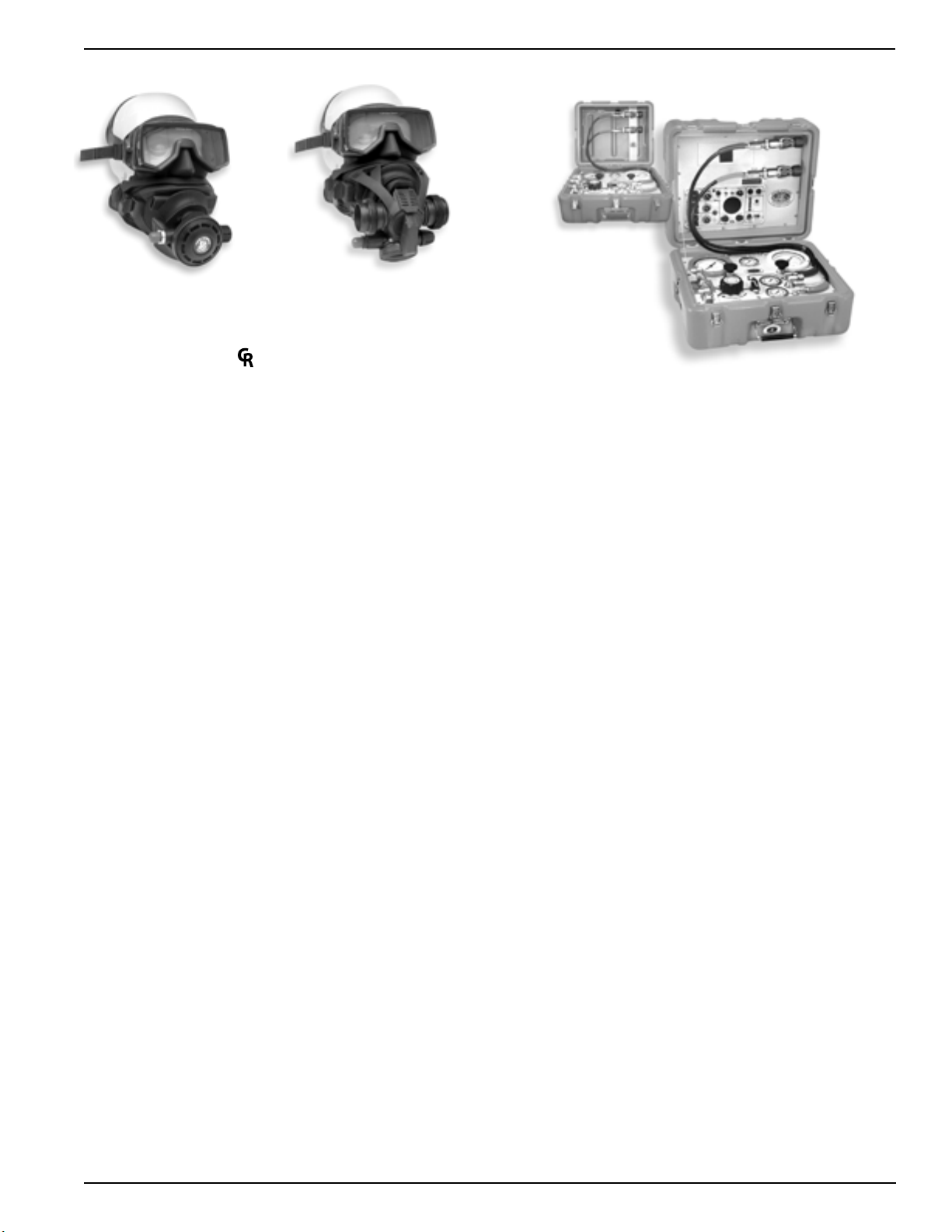

The EXO Full Face Mask is designed for both

surface supplied and scuba diving. By enclosing the

divers eyes, nose and mouth, the EXO permits nearly

normal speech when used in conjunction with most

wireless, and all hardwire underwater communication

systems.

The ORIGINAL EXO (no longer produced) design

came with automatic defogging, no oral nasal mask or

nose block device (optional conversion kits available).

The mask frame was black.

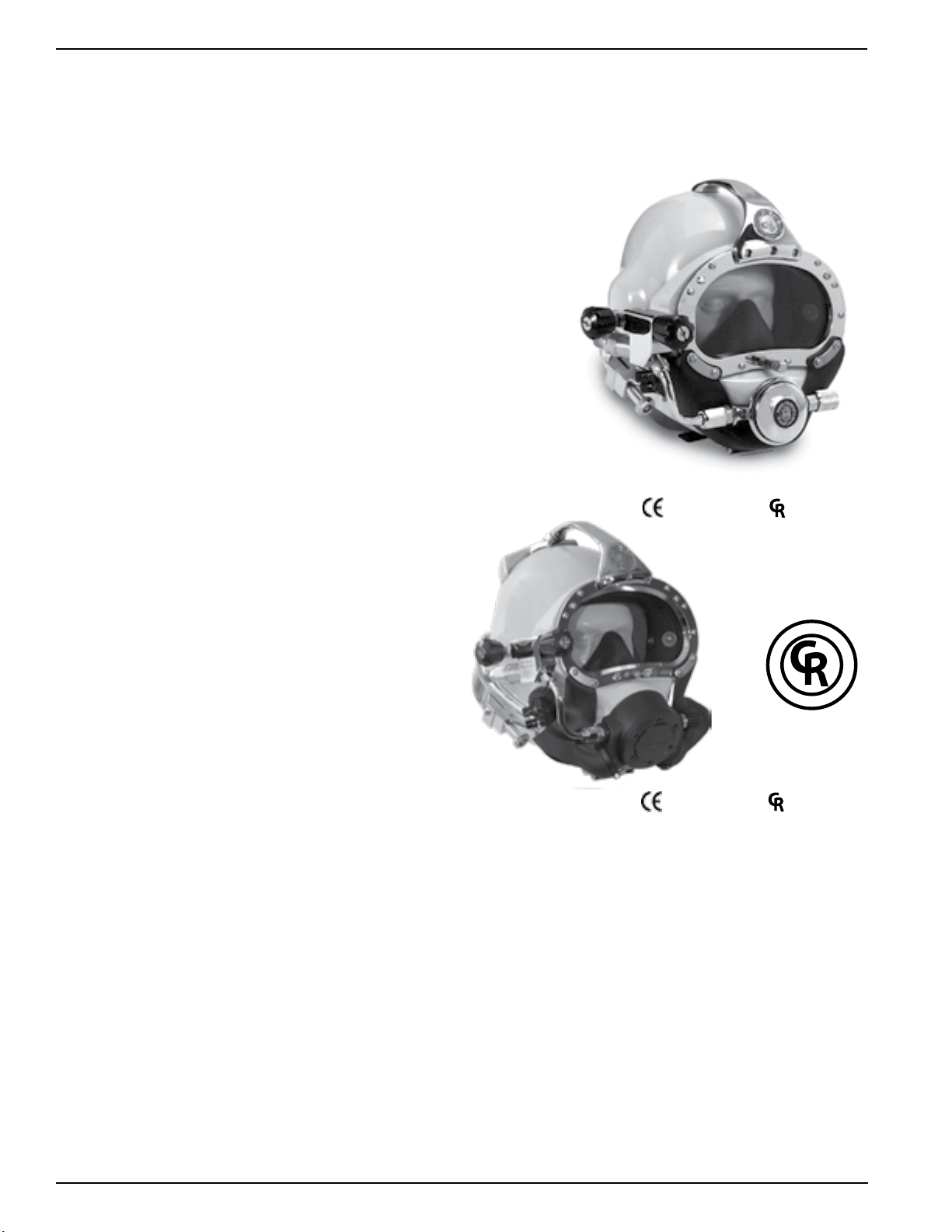

The EXO BR (BALANCED REGULATOR) shown

here is designed to meet or exceed recommended

performance goals in both scuba and surface supplied

modes and is

approved. It meets and surpasses

European standards for regulator performance.

approved and ™ marked

The KMB 18B Band Mask frame is constructed of

hand laid fiberglass. The head harness is a molded,

strong tear resistant neoprene rubber.

The hood, which attaches to the mask frame with

welded stainless steel bands, provides warmth for the

divers head as well as pockets for the earphones. The

communications connections can be either a male

waterproof plug in type or bare wire posts. Both this

mask and the KMB 28B feature the new Tri-Valve™

Exhaust System.

The KMB 28B Band Mask (not shown) is very simi-

lar to the KMB 18, with many parts on the KMB 18B

being interchangeable with the KMB 28B. The major

difference between the 18 and 28 is the material of the

mask frame itself. The KMB 18 has a fiberglass frame

(yellow) while the KMB 28B frame is an extremely

durable injection molded plastic (black).

Other differences include:

1) The main exhaust body of the KMB 28 is part of the

frame itself and uses a #545-041 main exhaust cover

2) no comfort insert is required on the 28

3) the face ports for the 18 and the 28 differ slightly

in size.

EXO BR

approved and ™ marked

The Balanced Regulator helps reduce the work of

breathing for the diver by balancing the intermediate

air pressure against the valve sealing pressure inside

the regulator. This enables the regulator to instantly

adjust to changes in line pressure. The Balanced Regulator is adjustable for a wide range of intermediate

pressures between 100 PSI - 230 PSI.

Both models have a modular communications design that permits rapid and simple maintenance. The

optional Hard Shell provides surfaces for mounting

lights, cameras etc.

Both the 18 and 28 are

approved.

16 © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

KMACS-5

w/ No Comunications

EXO Full-Face Mask Manual

SuperMask M-48

w/ Scuba Pod

™

marked

SuperMask M-48

w/ Rebreather pod

(Military only)

The SuperMask M-48 is an innovative new design

in a full-face mask. It provides the diver with all the

comfort of a full-face mask with the convenience of

changeable second stage regulators as well as the

ability to use a snorkel without having to remove the

mask.

The mask is comprised of two major components,

the mask frame and the interchangeable lower pod.

The removable lower pod is a feature unique to the

SuperMask full-face mask. When diving, the pod is

easily removed and replaced on the mask, providing

the diver the capability to buddy-breathe, snorkel, use

an octopus or perform an “in water” gas switch.

With the pod sealed to the mask, the flexible, silicone

pod cover allows the diver to quickly place the regulator mouthpiece into the mouth or dive with it free of

the mouth for communications. With the mouthpiece

in, the regulator may be used without the pod being

sealed to the mask.

The mask may also be used surface supplied. We are

currently developing several different pod configurations for both open circuit and rebreather use. For

further information, see

our web site at www.Kirby-

Morgan.com.

KMACS-5

w/ Communications

The K irb y Morg an Ai r Con trol Syst em- 5

(KMACS-5) is a lightweight, portable control box

for use in surface supplied air diving operations. The

KMACS-5 controls the diver’s air supply, communications and monitors the diver’s depth. It allows two

divers clear push-to-talk (two wire) or round robin

(four wire) communications. The KMACS-5 is also

available without communications.

The air supply can be either from a low-pressure

compressor or high-pressure cylinders. The adjustable

first stage regulator reduces the high-pressure air and

supplies low pressure through the umbilical to the

diver’s breathing system.

High pressure yokes permit U.S. standard scuba

cylinders to be used. Low-pressure air supply fittings

allow for a compressor to be used as the primary air

source.

A complete pneumo system with dual reading gauges

(both US Standard and Metric) is provided for each

diver’s air, as well as a shut-off/bleed system that uses

two high-pressure feed lines which allows changing

of used cylinders without interruption of the diving

operation. Optional shut off valves allow the isolation

of each diver’s air supply.

The Communication Set is a multipurpose intercommunication system that provides reliable and clear

communications between a topside operator (tender)

and one or more surface-supported divers, recompression chambers, or other submersible systems.

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 17

EXO Full-Face Mask Manual

Chapter 2

Operating Instructions

2.1 Introduction

This section provides the manufacturer’s recommendations on how to use the three EXO Full-face Masks.

The use of these diving masks will vary with the type

of diving and environmental conditions. A proper

training program in the use of full-faced masks must

be undertaken prior to diving the mask.

Practice using the mask in a calm, clear body of water

(pool) before open water diving. There is a video available from Team Visions that goes over many of these

basic procedures. The video, Diving With The EXO-26

Full-face Mask is available from Best Publishing PO

Box 30100 Flagstaff Ariz. 86004

Ph 800 468-1055.

2.2 First Use and Pre-Dive Set-Up

When you first receive your EXO Full-face Mask,

carefully unpack it and examine it for any damage that

may have occurred during shipment. Use the inspection

sheet provided to ensure that no damage has occurred!

Read all warning labels & caution tags.

Be sure to complete the enclosed warranty card and

return to KMDSI as soon as possible. Warranty claims

require that a card be on file at KMDSI 10 days after

purchase. Incomplete warranty cards are considered

invalid.

2.4 Visual Inspection

Visually inspect the entire exterior and interior of the

mask.

- The face seal should be in good condition with no

cracks, tears, or punctures.

- The spider (head harness) should be intact. Stretch

the spider and inspect it carefully for signs of cracking

or tearing.

- Inspect the face port. It should be clean and clear.

Anti fog solutions should be applied prior to use.

-Check the wiring for the communications, if present.

Make sure the communication module mount nut is

screwed down tight.

-In the EXO Original, inspect the air inlet tube and

make sure it is properly seated on the regulator.

-In the EXO Standard or BR, inspect the oral nasal and

equalizer and make sure they are securely mounted.

If the mask does not have communications installed,

be sure to use a microphone hole plug (320-001) in

the oral nasal.

-Check the regulator assembly to ensure that it is secured tightly on the mask frame.

2.3 Pre Dress-in Procedure

Before dressing in for a dive, an inspection of the mask

and all related gear should be made to ensure everything

is in proper working order. This should be done well

in advance of the dive, so any problems or adjustments

can be dealt with. Read and understand this manual

before you dive. Chapter 2 tells you the basic operat-

ing procedures and how to perform the pre-dive mask

inspections and pre-dive regulator function tests.

18 © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

-Check the regulator cover to ensure that it is tight on

the regulator body.

-With no air to the mask, screw the regulator adjustment knob all the way out and back in to ensure that

it turns freely.

2.5 Clean Face Port

Remove any sand or debris from the interior of the mask

and face port which may be inhaled or blown into the

divers face, interfering with the diver's vision.

Under certain conditions, depending upon water temperature, you may find it necessary to prep the mask

lens to keep it from fogging while diving. There are a

number of commercial defoggers available for scuba

diving which work well. Follow the directions on the

label for use.

If no commercial preparation is available it is possible

to use soap. Use a small amount of liquid soap on a

rag and smear a thin film on the inside of the lens.

Do not rinse this film off. Apply the soap just prior to

entering the water.

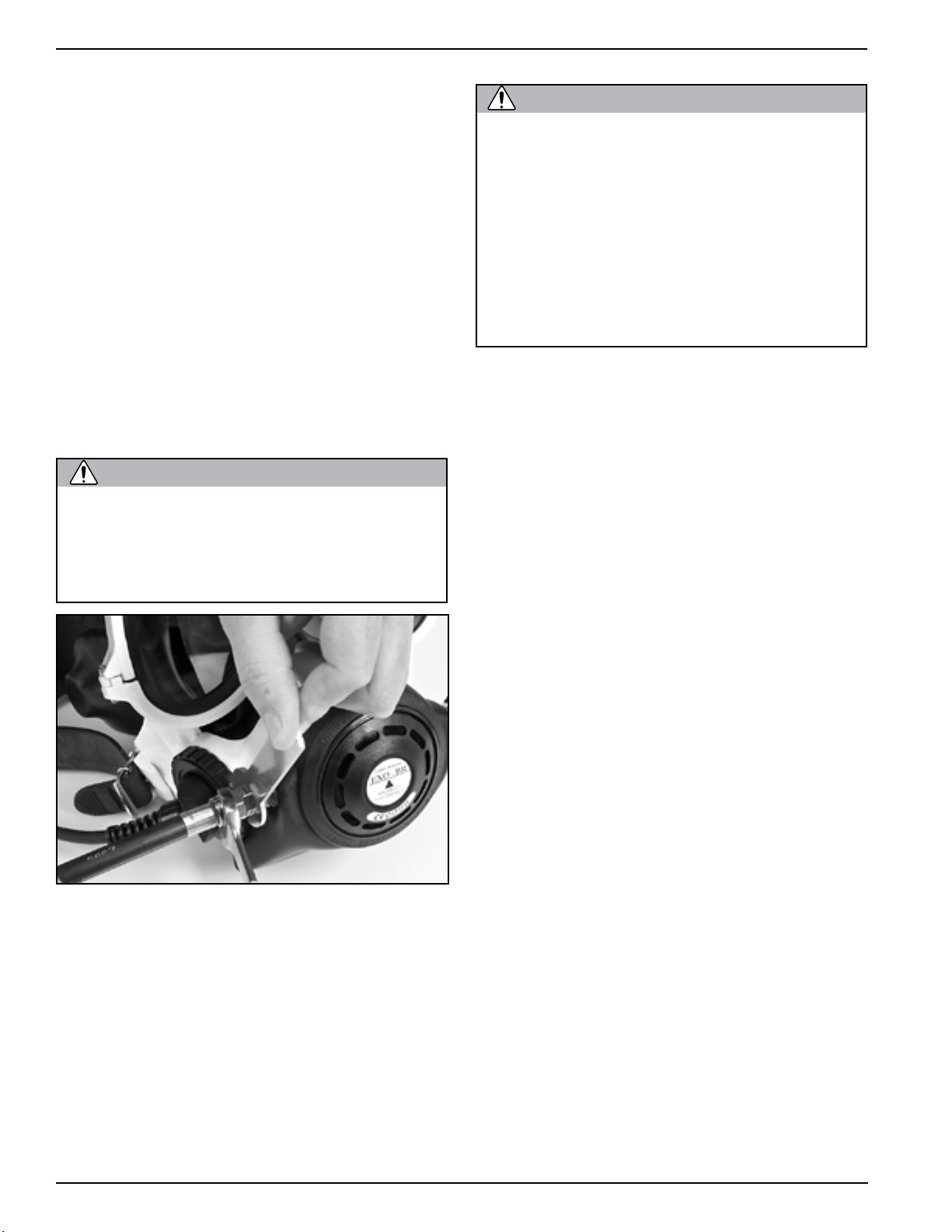

2.6 Adjusting the Equalizer EXO Standard or BR

There are different height positions that the equalizer

can be adjusted to. Carefully peel the equalizer out of

the wire retainer and reposition it in another one of

the molded grooves in the equalizer. The wire retainer

can also be slightly bent in one direction or another,

up or down, to get the angle of the equalizer just right.

Ensure that the corners of the equalizer grooves are

"snapped" into position on the wire retainer so that it

does not come loose.

EXO Full-Face Mask Manual

The equalizing device can be adjusted to the precise

height and position that you need.

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 19

EXO Full-Face Mask Manual

WARNING

CAUTION

2.7 Checking Regulator Functions &

Preparing the EXO for Use In SCUBA

Mode.

Attach the low-pressure hose that is supplied with the

mask to the low-pressure (L.P.) port on your 1st stage

regulator and then to the mask. Never connect the hose

or mask to a high pressure (H.P.) port. When attaching

the hose to the regulator ALWAYS USE A BACK UP

WRENCH ON THE NIPPLE TUBE.

The included angle swivel provides more comfort with

at a variety of head positions. KMDSI recommends

always using this attachment.

Prior to attaching your first stage regulator to your tank

be sure the regulator adjustment knob on the mask is

screwed all the way in. This will prevent the regulator

from free flowing when the air is turned on.

If you are not using the inlet angle fitting,

a backup wrench must be used on the hex

fitting of the regulator when tightening.

Otherwise the regulator may come out of

adjustment!

A submersible pressure gauge is considered essential for full-face mask scuba

diving. The diver must plan his dive to

avoid running out of air while wearing a

full-face mask. There is no way to safely

buddy breathe underwater, use an octopus

rig, or snorkel on the surface while wearing

a the EXO full-face mask. If the submersible pressure gauge should fail during

the course of a dive, the dive should be

terminated immediately.

Your 1st stage regulator should be equipped with a

submersible pressure gauge. Attach the first stage to

your tank and turn the air on while holding the submersible pressure gauge away from you. Once the air

is on, check the pressure gauge to ensure you have a

full tank.

To check the EXO-standard and BR regulators for

proper function and adjustment, first ensure the demand

regulator adjustment knob is in fully clockwise then

bring up a gas supply at between 135-150 psig. Slowly

back out on the adjustment knob counterclockwise until

a slight free flow develops then adjust in until the free

flow just stops.

Always use a back-up wrench when attaching or removing a hose to the regulator. Note the angle swivel

in use.

At this point lightly depress the purge button, the button should only travel between 1/16th to 1/8” before a

flow is started. If the button travels less than 1/16” or

greater than 1/8” before flow starts the regulator will

need to be adjusted (see chapter 6)

Higher first stage regulator pressures may cause free

flow, but turning the regulator adjustment knob in should

stop the flow. In the unlikely event there is still flow,

proceed to the regulator adjustment section in Chapter

6 to reset the regulator.

20 © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

EXO Full-Face Mask Manual

WARNING

2.8 Test the Regulator

Loosen all the straps on the spider and hold the mask

on your face. Take a couple of good breaths, breathing

slow and soft at first then hard and fast. The regulator should be operating with the minimal amount of

breathing resistance and no free flowing.

Any type of an air flow "hiss" should be able to be

adjusted out by using the adjustment knob. If the

adjustment knob is adjusted all the way in and the

regulator still hisses, see the regulator adjustment

section, Chapter 6.

Pressing the purge button should cause a fairly strong

air flow into the mask. If there is no flow when pressing the purge button, or if breathing is difficult, see the

regulator adjustment section in Chapter 6.

Once you enter the water, the regulator can be adjusted

for a variety of diving conditions and positions just by

turning the adjustment knob in or out.

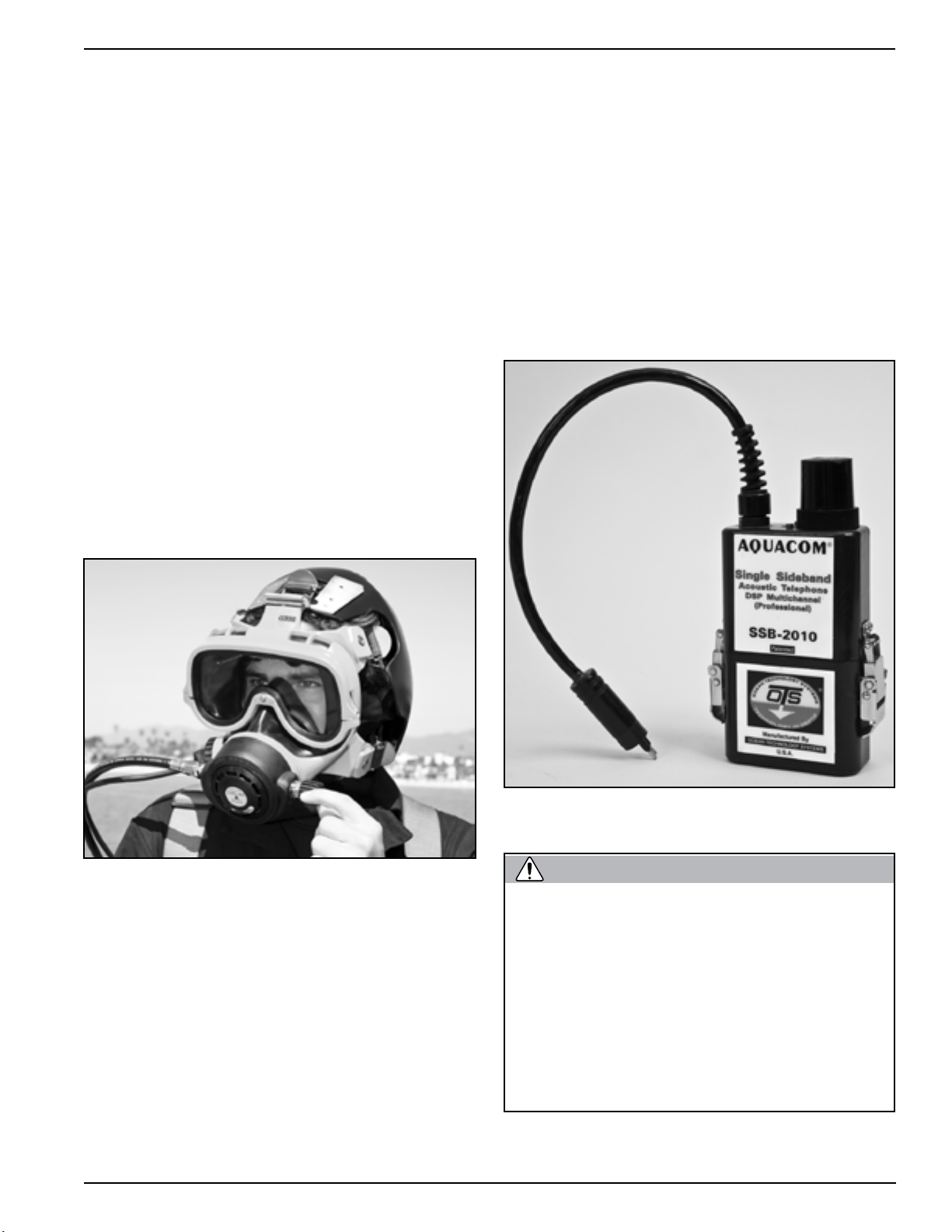

2.9 Wireless Communications

There are several manufacturers that produce a wireless

communications unit that can be used with the EXO

Mask. If you are using wireless communications read

and follow all of the manufacturer’s instructions for

your particular unit.

If you are using wireless communications you should

test the communications by placing the transducers

from both send and receive units in a bucket of water

and speaking into the mask. Communications should

always be tested prior to the diver entering the water.

Your wireless system must not be attached to your

weight belt.

Always test the function of your regulator prior to

entering the water.

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 21

The waterproof case for your wireless communications unit should only be attached

to your scuba backpack, NEVER to your

weight belt. In the event your belt must be

dropped the belt must have a clear drop

path and must not be connected to any

other piece of gear. If this procedure is not

followed the weight belt and wireless electronics case will be attached to the mask

by the connecting wire. This could cause

the mask to flood, leading to drowning.

EXO Full-Face Mask Manual

WARNING

2.10 Using the EXO in the SurfaceSupplied Mode

If you have not been trained in the proper use of surfacesupplied diving equipment we strongly recommend that

you complete a training course in the use of this equipment prior to diving in the surface-supplied mode.

Read and understand the Checking Regulator Function

and Preparing The EXO for use in scuba mode section

of this chapter. The basic connecting instructions of the

mask and regulator function tests are the same.

The one way valve is a very important component. It

prevents the flow of air out of the mask in the event of

a sudden lowering of pressure in the umbilical supply

hose due to an accidental break in the hose or fitting.

Not only would the emergency air be lost if the one

way valve failed (concurrent with a hose or fitting

break) but the diver could be “squeezed”, a very serious accident. Do not dive in the surface-supplied mode

without a one-way valve.

At a minimum, if the EXO is to be used for surfacesupplied diving the following systems and components

must be in place and in proper working condition:

1) Air Supply: Either a low-pressure compressor or high

pressure air bottles. (See operating specifications)

2) Dive Control System: An air management box to

control the flow of air delivered to the diver or divers

(like the KMACS-5 - Kirby Morgan Air Control System - offered by KMDSI).

3) Diver's Umbilical: Hose bundle consisting of air

supply hose, pneumofathometer hose (depth sensing),

communications wire and rope as a strength member.

4) Diver's Manifold Block: A metal block that has a

one way valve that the umbilical attaches to, an emergency valve that the bail out system attaches to and

L.P. ports for attaching the mask hose, dry suit inflators

and other accessories.

The EX0-BR works well in the surface-supplied

mode.

Emergency Valve

Accessory Ports

One Way Valve

KMDSI Manifold Block Assembly

The EXO Mask is not equipped with a one

way valve (non-return valve) as supplied

from the factory. For surface-supplied diving, the diver must use a manifold block

equipped with a one way valve. Do not

connect the diver's umbilical directly to the

EXO without a one-way (non-return) valve.

In the event of a rupture of the hose, this

can lead to a squeeze, a potentially fatal

accident.

22 © Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002

WARNING

WARNING

Never dive if the one-way valve is not op-

WARNING

erating properly. If the hose or breathing

gas/air fitting breaks near the surface a

serious injury could result to the diver’s

lungs and/or eyes. In extreme cases this

could be fatal. The one-way valve must be

tested daily prior to the commencement of

diving operations.

The one-way valve must be tested daily,

prior to commencement of diving operations. Failure of the one-way valve could

cause serious injury or death.

If the one-way valve or the adapter is loosened this will allow breathing gas to leak

out of the breathing system. This could

also result in a loss of all pressure to the

mask, leaving the diver with nothing to

breathe.

EXO Full-Face Mask Manual

2.11 Testing the Manifold Block

Prior to assembling a bail-out system, the one way

valve and emergency valve should be tested for proper

function.

Equipment Needed:

-Manifold Block

-Bail-out bottle

-1st Stage regulator w/octopus and scuba reg

hose attached

-KMACS-5 system with an umbilical supply hose

-Bucket of water

2.11.1 Testing the One-Way Valve

1) With all the accessory holes plugged on the manifold

block, attach the SCUBA type regulator hose from a

first stage regulator that also has an octopus attached,

to the emergency valve on the manifold block assembly.

The octopus will be used for depressurization once the

test is concluded.

2) Connect the first stage to the bail-out bottle, open

the emergency valve all the way, and pressurize the

system.

5) Bail-out System: Consisting of a harness, bail out

bottle, first stage regulator with over pressure relief

valve. This system connects to the emergency valve on

the divers manifold block assembly by a hose.

6) Communications System: Provides hard wire

communication between diver and topside.

3) Place the pressurized manifold block in a bucket of

water and check the one way valve for leaks. No air

should leak through the one way valve or from anywhere

else on the manifold block assembly. If there is a leak,

the one way valve MUST be rebuilt or replaced.

4) As a secondary test, close the emergency valve trapping pressure inside the manifold block assembly and

relieve the pressure on the first stage using the octopus.

Disconnect the hose from the emergency valve.

5) Quickly open the emergency valve by turning the

knob. You should hear the trapped air escaping through

the emergency valve.

2.11.2 Testing the Emergency Valve

1) With all the accessory holes plugged on the manifold block, attach the umbilical hose to the one way

valve.

2) Make sure that the emergency valve is closed all

the way and pressurize the umbilical.

3) Place the pressurized manifold block in a bucket of

water and check the emergency valve for leaks. NO

air should leak through the emergency valve or from

© Copyright 1970-2009 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080115002 23

EXO Full-Face Mask Manual

anywhere else on the emergency valve assembly or

manifold block assembly. If there is a leak, the emergency valve MUST be rebuilt or replaced.

4) Turn the umbilical off and open the emergency valve

to depressurize the system and disconnect the hose.

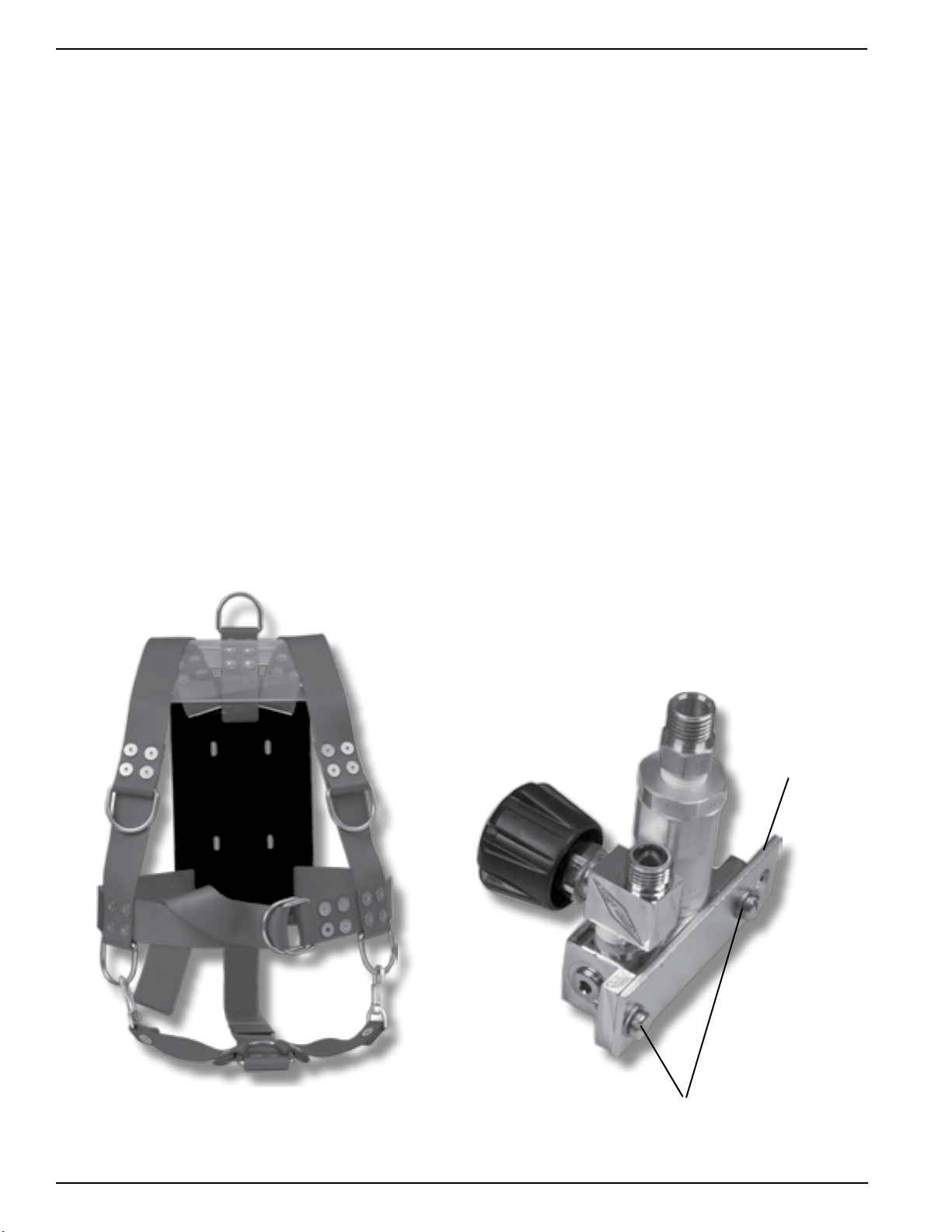

2.12 Diver’s Harness

The harness provides an attachment point for the

manifold block, tools the diver may use while in the

water, and the "D" ring where the umbilical shackle

connects. The umbilical shackle must connect to the

strength member of the umbilical.

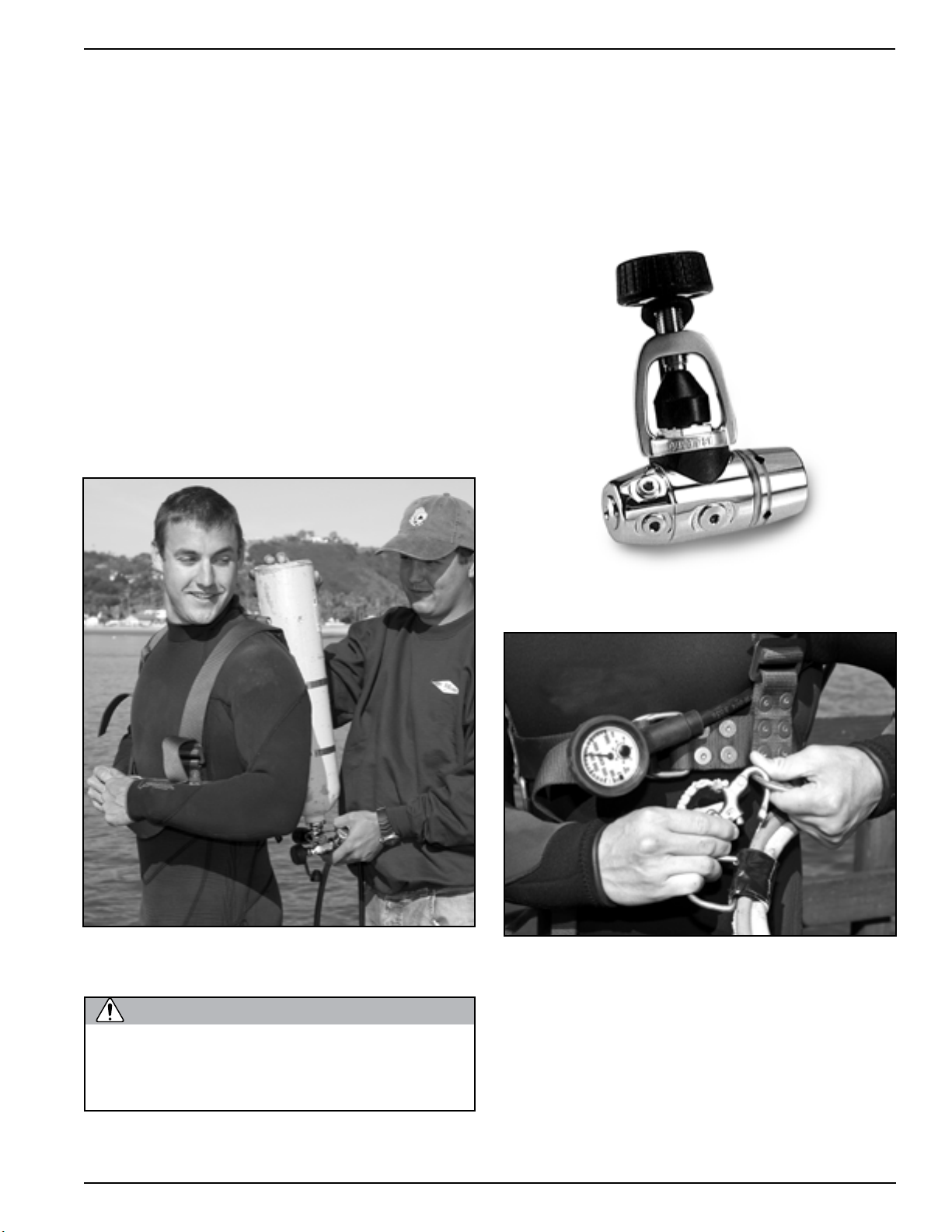

2.13 Installing the Manifold Block on

the Diver’s Harness

The manifold block assembly is designed to be worn

on the diver’s harness. Most divers prefer to attach the

manifold block to the right side of the diver’s harness.