Page 1

VI-MMXII Page 1

TRUCK

MOUNTED

OPERATION AND MAINTENANCE

MANUAL

TRUCK AND

TRAILER

MOUNTED

V

E

R

T

I

C

A

L

FEED

MIXER

Kirby Manufacturing

P.O. Box 989

Merced, California; 95341-0989

(209)-723-0778 Kirby Mfg.

TRAILER

MOUNTED

Page 2

VI-MMXII Page 2

TABLE OF CONTENTS

SECTION

i. WARRANTY

ii. CHECKLIST / SIGN-OFF SHEET

1.0 SAFETY PROCEDURES

2.0 MIXER STRUCTURE AND TRAILER

3.0 MAIN AUGERS, SHAFTS, AND BEARINGS

4.0 SPROCKETS AND CHAINS

5.0 GEARBOXES

6.0 DRIVELINES AND POWER TAKEOFFS

7.0 MAIN HYDRAULIC SYSTEM

8.0 LUBRICATION AND MAINTENANCE

9.0 ELECTRONIC SCALES AND LOADCELLS

10.0 EQUIPMENT OPERATIONS

11.0 SPARE PARTS

12.0 APPENDIX

Copyright: rev.: 8/22/2017

Page 3

VI-MMXII Page 3

KIRBY MANUFACTURING, INC.

NON-TRANSFERRABLE LIMITED WARRANTY

GENERAL TERMS AND CONDITIONS:

KIRBY MANUFACTURING, INC. (henceforth referred to as KMI), hereby warrants to the

original purchaser of a newly manufactured KMI product, that all new KMI products are guaranteed

against defects in materials or manufacture under normal use for a period of one year (1) or duty

cycle of 3000 hours (whichever comes first) from the original in-service date.

Improper Activity will void this limited warranty. “Improper Activity” includes any, and all, of the

following: Installation by anyone other than KMI or its authorized agent, improper installation,

use/operation/maintenance other than in accordance with KMI’s instructions, tampering, neglect or

damage by the application of force, acts of vandalism, accidents, misuse, abuse, repair/alteration or

adjustment by anyone other than KMI or its authorized agent.

FOR THE WARRANTY TO BE IN EFFECT: The warranty registration form must be signed,

dated and submitted to KMI within 15 days of the delivery date by the end user. If not returned, the

warranty period begins from the date the equipment was invoiced to the dealer.

This warranty is subject to any existing conditions of supply which may directly affect our ability to

obtain materials or manufacture replacement parts. This warranty shall in no way make KMI liable

for personal injuries or damages, loss of time or expense of any kind either direct or indirect resulting

from part failure or defect.

KIRBY MANUFACTURING, INC. DISCLAIMS ALL OTHER WARRANTIES, INCLUDING,

WITHOUT LIMITATION, ANY WARRANTIES, EITHER EXPRESSED OR IMPLIED, OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NO AGENT OR

EMPLOYEE OF KIRBY MANUFACTURING, INC IS AUTHORIZED TO EXTEND ANY

OTHER WARRANTY OR OBLIGATION. THERE ARE NO WARRANTIES THAT EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF.

WARRANTY PROVISIONS: During the warranty period (12 months or 3,000 hours), KMI will

repair or replace parts of the product that prove defective because of improper material or

workmanship, under normal use and maintenance. This warranty is subject to the following

provisions:

1. Labor is covered for a period of 90 days from the original in-service date, except defects in

workmanship, which is covered for the entirety of the warranty (12 months or 3,000 hours).

2. Labor will be paid at the dealer’s standard hourly rate.

3. KMI will pay for standard ground shipping of parts within 90 days of the original in-service

date.

a. The shipping carrier will be at the discretion of KMI.

b. All priority shipping is the responsibility of the dealer or customer.

4. All warranty work requires a KMI warranty claims form to be filled out and returned with

all required documentation.

5. Warranty forms must be requested within 48 hours of the first business day after the repair.

6. All warranty claims must be submitted within 30 days of the warranty claim form date.

Page 4

VI-MMXII Page 4

7. Replacement parts will have a 90-day warranty or the remainder of the KMI warranty period,

whichever is longer. Parts must be installed by an authorized dealer or agent of KMI.

8. Any removed parts must be marked with serial number of the unit, date of repair and warranty

number.

9. Parts must be held by the dealer upon request of KMI for 30 days.

10. Parts may be requested by KMI to be returned to KMI or a supporting vendor.

a. Supporting vendor - A return goods authorization (RGA) and warranty claim number

will be issued.

b. KMI - Warranty claim number will be issued.

11. If deemed defective by KMI, parts with an RGA/Warranty claim number will be reimbursed,

replaced or credited back to the dealer at the net dealer cost.

12. Parts invoice for warranty goods received will be requested with warranty. If a part is

purchased outside of KMI proof of purchase will be required for reimbursement.

13. The following are not covered under this warranty:

c. Overtime, freight and travel.

d. Rental fees for loaner equipment to the end customer.

e. Other out of pocket expenses incurred during downtime.

f. Overnight/priority shipping.

g. Damages or repairs to tractors used with KMI equipment.

h. Truck and all truck parts/components (truck mounted models).

i. Normal wear and tear for normal replacement parts, cutting knives, exterior finish,

chains, hydraulic oil & filters, belts, sprockets, u-joints etc.

j. Scale Systems have their own warranty and are not included in Kirby's limited warranty

coverage. The warranty stated by the scale manufacturer will be honored by KMI. This

does not include any freight, service calls or loaner unit for the specified repair. Scale

warranty is outlined in the Scale System’s owner's manual.

k. All parts requiring periodical maintenance, that have not been (but not limited to):

➢ Greased (bearings, PTO & driveline u-joints).

➢ Nuts and bolts tightened.

➢ Chains adjusted.

➢ Oil changed.

➢ Filter changed.

➢ Hydraulic hoses tightened.

14. Tires, wheels and batteries have a limited warranty of 3 months from the date of original sale

and warranty acceptance form. This includes oil seals for the axle hub. This does not include

any flats or damage caused by negligent use or foreign objects.

15. Electrical switches and controls installed by KMI are covered against defect in workmanship

for a period of one year under normal use. Part component switches are covered for 30 days.

PRODUCT IMPROVEMENTS: KMI reserves the right to make improvements and changes in

material and / or design of its products with no obligation to incorporate such improvement into

previously manufactured equipment.

Page 5

VI-MMXII Page 5

DEALERS RESPONSIBILITIES

1. Instruct the customer in the safe operation and servicing of the unit.

2. Review the owner's manual with the customer and ensure the customer understands the

complete operation, service, safety procedures and warranty of the unit.

3. Ensure customer signs and sends warranty registration to KMI within 15 days of delivery of

unit.

4. Customer should be advised to have failed parts repaired or replaced immediately upon

failure and that continued use could result in additional damage and excessive wear, voiding

the warranty.

5. Follow correct warranty procedures including but not limited to notifying warranty

department at KMI (209-723-0778) & submitting completed warranty claim form to KMI

within the specified time as set forth under the “Warranty Provisions” section.

6. Perform warranty and service repairs.

7. ALL DEALERS MUST WARRANTY THEIR TECHNICIAN'S WORK TO THE

PURCHASER AND MUST INDEMNIFY KMI FROM SUCH CLAIMS.

DELAYED WARRANTY REPAIRS

Warranty repairs should be scheduled and performed as soon as possible after notification of the

dealer to KMI. There may be extenuating circumstances that require the availability of repair parts

necessary to complete the repairs. In those cases, the dealer must notify KMI, in writing of the

extenuating circumstance and advise that the continued use of the product will not add to the

warranty claim. These claims, pre-approved by KMI, will then be processed as if the product is still

within the warranty period.

DENIED CLAIMS

Dealers will be notified of a denied claim in writing that will state the reason for the denial. The

dealer has the right to appeal this claim and must do so within 30 days of notification of denial. If

there has been no appeal within the 30-day period the claim will be considered closed.

Questions or comments? Contact Us:

Kirby Manufacturing, Inc.

P.O. Box 989

Merced, CA – 95341-0989

PH: (209) 723-0778

Fax: (209) 723 -3941

Email: rwallace@kirbymfg.com

Page 6

VI-MMXII Page 6

OPTIONAL EXTENDED WARRANTY

As a onetime offer, KMI offers the owner of a newly manufactured Kirby feed mixer the option to

purchase an extended warranty policy. This extended warranty policy offers a total of 3 years of

coverage (one-year standard warranty plus two years beyond the standard warranty). This extended

warranty policy must be purchased at the time of equipment sale and will go into effect upon initial

equipment start-up. A completed extended warranty acceptance documentation is required for the

extended warranty to be in effect.

This extended warrant policy covers the replacement parts itemized below:

1. Hydrostatic hydraulic pumps

2. Hydraulic motors for planetary

3. Planetary gearboxes

The following items are NOT covered under this extended warranty:

1. Hydraulic auxiliary pump (pump for door ram and crossfeed motor)

2. Hydraulic Oil

3. Hydraulic Cooling systems including hydraulic fan motors.

The general terms and conditions of the standard warranty also apply to the extended warranty in

addition to the special terms and conditions as listed below. This policy requires the equipment

owner to take and send in oil samples at predetermined time intervals or have an authorized Kirby

Service agent maintain and record all service schedules according to owner's manual.

These time intervals are as follows:

1. Gearbox oil samples every 6 months or 1,000 hours whichever comes first. (plus initial

sample taken 50 hours after start-up)

2. Hydraulic system oil samples every 3 months or 500 hours, whichever comes first.

These samples are to be sent in by the equipment owner to "WEARCHECK" laboratories for

analysis. "WEARCHECK" laboratories will analyze the samples and send a complete report to the

equipment owner stating the condition of the oil, as well as make recommendations about any

concerns they may see regarding the condition of the oil. It is the equipment owner's responsibility

to maintain the best oil condition in accordance with "WEARCHECK" laboratories

recommendations.

(Note: sample bottles are pre-addressed to "WEARCHECK" laboratories. It is the equipment

owner's responsibility to pay all mail charges to send samples to "WEARCHECK" laboratories)

Page 7

VI-MMXII Page 7

Proration with limitations of the planetary gearbox with extended warranty

Shaft seals and O-rings of the planetary gearbox are warranted for only one year and not subject to

the proration of the planetary. Prices based on suggested list price of planetary.

1. 1 to 12 months or 3,000 hours of usage, KMI at its sole discretion will replace or repair (parts

and labor) defective gearbox. Included are shaft seals and O-rings (100% replacement with

labor cost)

2. 13 to 24 months or 6,000 hours of usage, KMI at its sole discretion will replace or repair

(parts and labor) (75% of cost replacement and 75% of labor cost).

3. 25 to 36 months or 9,000 hours of usage, KMI at its sole discretion will replace or repair

(parts and labor) (50% of cost replacement and 50% of labor cost).

Equipment owner's responsibilities to maintain warranty

1. Purchase all sample bottles when purchasing equipment

Mechanically driven unit: 18 sample kits (6-2 speed, 12-planetary)

Hydraulically driven unit; 24 sample kits; (12-hydraulic system, 12-planetary)

4. Perform regular maintenance as specified in the Operation and Maintenance Manual

5. Take and send oil samples into WEARCHECK per time intervals stated above

6. Review oil reports and take corrective actions per WEARCHECK recommendations

7. All warranty claims must be accompanied with hard copies of the WEARCHECK reports

Any replacement provided under this warranty will be warranted for the remainder of the warranty

period applicable to the product in which it is installed or which it replaces.

OPTIONAL EXTENDED WARRANTY

Business Name: Date:

Model Type: Serial No:

Page 8

VI-MMXII Page 8

1.0 SAFETY PROCEDURES

When inspecting the machine all power must be shut off and secured.

Do not attempt to work on machine when machine is running.

Caution must be used when checking rotating parts under power. It is advisable to have two (2)

persons present when checking for safety. The second person should be positioned by a stop

switch so the machine can be stopped immediately in case of an emergency.

Do not leave machine unattended while in operation.

Be sure all guards and safety devices are in place.

Scale service requires special cautions-See section 9

Caution: The tractor power take-off (PTO) drive line should be removed from the tractor and the

key removed prior to servicing or working on the mixer unit.

Caution: The truck engine should be shut off and keys removed and P.T.O. disengaged when

servicing or working on the mixer unit.

SAFE OPERATIONS:

Operation of this mixer/feeder shall be limited to competent and experienced persons. In

addition, anyone who will operate or work around a mixer/feeder must use good common sense. In

order to be qualified, he or she must also know and meet all other qualifications, such as:

1. Some regulations specify that no one under the age of sixteen (16) may operate power

machinery. It is your responsibility to know what these regulations are in your area and/

or situation.

2. Current OSHA regulations state in part: At the time of initial assignment and at least

annually thereafter, the employer shall instruct EVERY employee in the safe operation

and servicing of all equipment with which the employee is, or will be involved.

3. Unqualified persons are to STAY OUT OF THE WORK AREA.

4. A person who is qualified to operate the machinery should be trained in and/or have read &

understood all operating and safety procedures.

FAILURE TO READ THIS MIXER/FEEDER MANUAL AND ITS SAFETY

INSTRUCTIONS ARE A MISUSE OF THE EQUIPMENT.

Page 9

VI-MMXII Page 9

SAFETY

IMPORTANT SAFETY PRECAUTIONS

These operating and maintenance instructions contain safety information to:

• make you aware of the hazards associated with the machine

• inform you of the risk of injury associated with those hazards

• tell you how to avoid or reduce the risk of injury.

TAKE NOTE: THE BELOW SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING

YOUR PERSONAL SAFETY AND THE SAFETY OF OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS:

-ATTENTION

-BECOME ALERT

-YOUR SAFETY IS INVOLVED

SIGNAL WORDS: Note the use of the signal words DANGER, WARNING, and CAUTION with

the safety messages. The appropriate signal word for each has been selected using the following

guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in serious

injury or death. This signal word is to be limited to the most extreme situations typically for machine

components which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, will result in serious

injury or death, and includes hazards that are exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

If you have questions not answered in this manual or require additional copies or the manual is

damaged, please contact your dealer or Kirby Manufacturing, P.O. Box 989, Merced, California;

Phone number (209)-723-0778.

Page 10

VI-MMXII Page 10

OPERATING PRECAUTIONS & INSTRUCTIONS

A. Check to see that no obstructions are present in the mixer prior to start up.

B. Before loading, run the mixer empty and check all operations.

C. Do not overload the mixer.

Maximum load is 16,000LB for 800 cu.ft. single axle mixer.

Maximum load is 30,000LB for 1000+ cu.ft. tandem axle mixer.

Maximum load is determined by weight, not volume.

D. Be sure all shields are in place before operation.

E. Use common sense when operating equipment.

ALWAYS REMEMBER SAFETY FIRST: The careful operator is the best operator. Most

accidents are caused by human error.

Certain precautions must be observed to prevent the possibility of injury or death.

DO NOT ALLOW PERSONNEL OTHER THAN THE TRAINED AND QUALIFIED

OPERATOR NEAR THE MACHINE.

NEVER START MACHINE UNTIL ALL GUARDS AND SAFETY SHIELDS ARE

IN PLACE.

DO NOT CLEAN, ADJUST OR LUBRICATE THE MACHINE WHILE IT IS IN

MOTION, ( ALWAYS turn off and remove keys prior to performing maintenance on

the machine)

BEFORE STARTING TRACTOR ENGINE, BE SURE PTO SHIELDS TURN

FREELY.

LOOSE CLOTHING SHOULD NOT BE WORN BY ANYONE NEAR THE

MACHINE

Page 11

VI-MMXII Page 11

EQUIPMENT SAFETY GUIDELINES

Safety is a key concern when designing and developing a new piece of equipment. Designers and

manufactures build in as many safety features as possible. However, every year many accidents

occur which could have been avoided by a few seconds of thought and a more careful approach to

handling equipment. You, the operator, can avoid many accidents by observing the following

precautions in this section. To avoid personal injury, study the following precautions and insist those

working with you, or for you, follow them. Perform regular safety audits to ensure adherence.

To provide a better view, certain photographs or illustrations in this manual may show an assembly

with a safety shield removed. However, equipment should never be operated in this condition. Keep

all shields in place. If shield removal becomes necessary for repairs, replace the shield prior to use.

Replace any CAUTION, WARNING, DANGER or instruction safety decal that is not readable

or is missing.

Do not attempt to operate this equipment under the influence of drugs or alcohol.

Review the safety instructions with ALL users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator

should be a responsible adult familiar with farm machinery, and trained in this equipment’s

operations. Do not allow persons to operate or assemble this unit until they have read this manual

and have developed a thorough understanding of the safety precautions and of how it works.

To prevent injury or death, use a tractor equipped with a Roll Over Protective System (ROPS). Do

not paint over, remove or deface any safety signs or warning decals on your equipment. Observe all

safety signs and practice the instructions on them.

Never exceed the limitations of a piece of machinery, in its ability to do a job, or to do so Safely! If

in question - DON’T TRY IT!

LIGHTING AND MARKING

It is the responsibility of the customer to know the lighting and marking requirements of the local

highway authorities and to install and maintain the equipment to provide compliance with the

regulations. Add extra lights when transporting at night or during periods of limited visibility.

Page 12

VI-MMXII Page 12

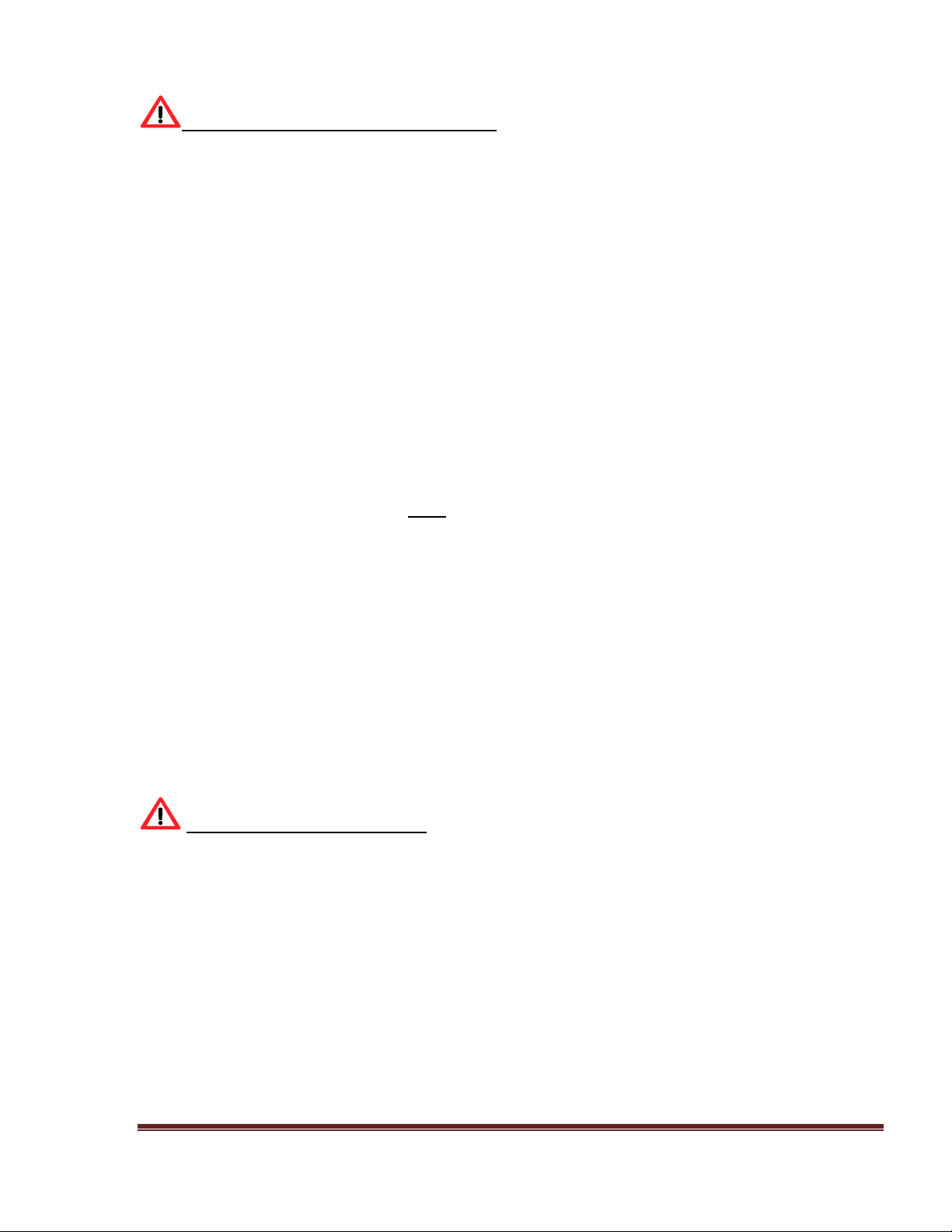

KEEP ALL SHIELDS IN PLACE

Do not operate mixer/feeder without safety shields in place.

Rotating parts can crush or dismember causing personal injury or

death.

Disconnect PTO driveline before removing shields for adjustment

or service.

OPERATE MIXER/FEEDER SAFELY

Rotating parts can entangle or strike people, resulting in personal

injury or death.

Never enter a mixer/feeder while in operation.

Operate the mixer/feeder from the operator’s seat only.

Do not exceed load capacity of the mixer/feeder. (See loading

instructions).

Reduce speed when turning or traveling on rough terrain.

Avoid traveling over or near loose fill, rocks, ditches or holes.

Keep transmissions in gear when traveling downhill.

KEEP RIDERS OFF MIXER/FEEDER

Keep riders off.

Riders are subject to injury such as being struck by foreign

objects, falling into the mixer and by being thrown off. Riders

also obstruct the operator’s view, resulting in the machine

being operated in an unsafe manner.

MOVING PARTS KEEP

ALL SHIELDS IN PLACE

BEWARE OF

KM 01

ROTATING AUGER

HAVE SPOUT IN UP

POSITION WHEN MIXING

KEEP HANDS AWAY

FAILURE TO HEED

WILL RESUL IN

PERSONAL INJURY

OR DEATH

KM 03

Page 13

VI-MMXII Page 13

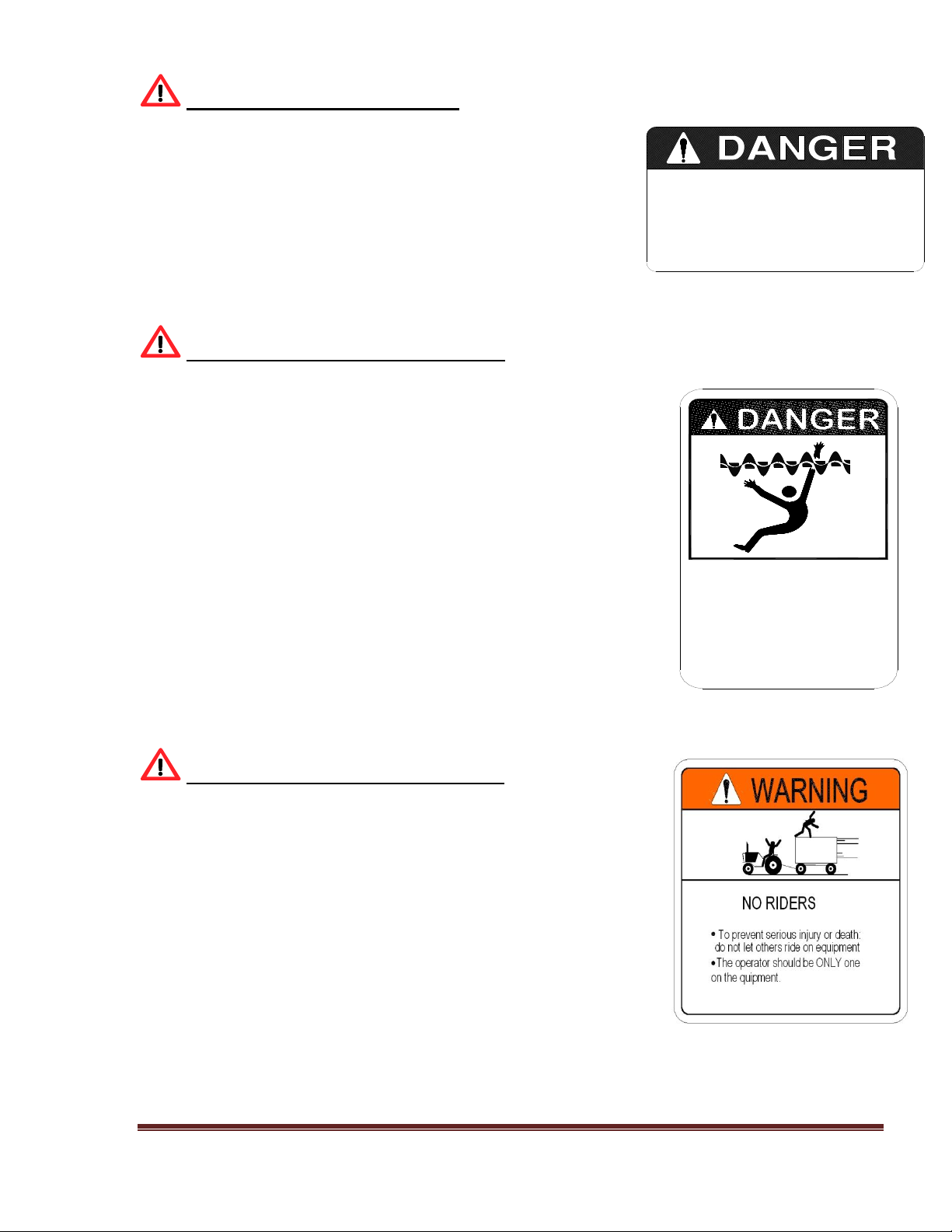

STAY CLEAR OF ROTATING DRIVELINES

Entanglement in rotating driveline can cause serious injury or

death.

Keep tractor master shield and driveline shields in place at all

times. Make sure rotating shields turn freely.

Wear close fitting clothing. Stop the engine and be sure PTO

driveline is stopped before making adjustments, connections, or

cleaning out PTO driven equipment.

AVOID HIGH-PRESSURE FLUIDS

Escaping fluid under pressure can penetrate the skin causing serious

injury or death.

Avoid the hazard by relieving pressure before disconnecting hydraulic

or other lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and

body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected

into the skin must be surgically removed within a few hours

or gangrene may result. Doctors unfamiliar with this type of injury

should reference a knowledgeable medical source.

SERVICE AND ADJUSTMENT

OF HYDRAULIC SYSTEM

SHOULD ONLY BE PERFORMED

BY QUALIFIED PERSONNEL.

IMPROPER ADJUSTMENT COULD

CAUSE SERIOUS INJURY,

DAMAGE TO SYSTEM,

AND VOID WARRANTY.

DO NOT WORK ON

WITHOUT DISCONNECTING

POWER SOURCE

KM 07

Page 14

VI-MMXII Page 14

PREPARING TRACTOR FOR TRAILER MIXER

IMPORTANT: Drive components can be damaged from excessive speed. Do not operate tractor at

speeds in excess of recommended PT0 rpm.

This feed mixer may be equipped with either a 1000 RPM or a 540 RPM driveline.

Match tractor PTO with the feed mixer driveline.

IMPORTANT: To prevent driveline damage, adjust tractor drawbar to recommended setting.

Disengage power to tractor PTO before turning tractor.

Remove clevis if equipped. Turn offset drawbar down.

Adjust drawbar length.

ADJUST TRAILER HITCH CLEVIS

Mixer should be approximately level when attached to tractor.

SAFETY DECAL CARE

Keep safety decals and signs clean and legible at all times.

Replace safety decals and signs that are missing or have become illegible.

Replaced parts that displayed a safety sign should also display the current sign.

Safety decals or signs are available from your dealer or Kirby Manufacturing.

Page 15

VI-MMXII Page 15

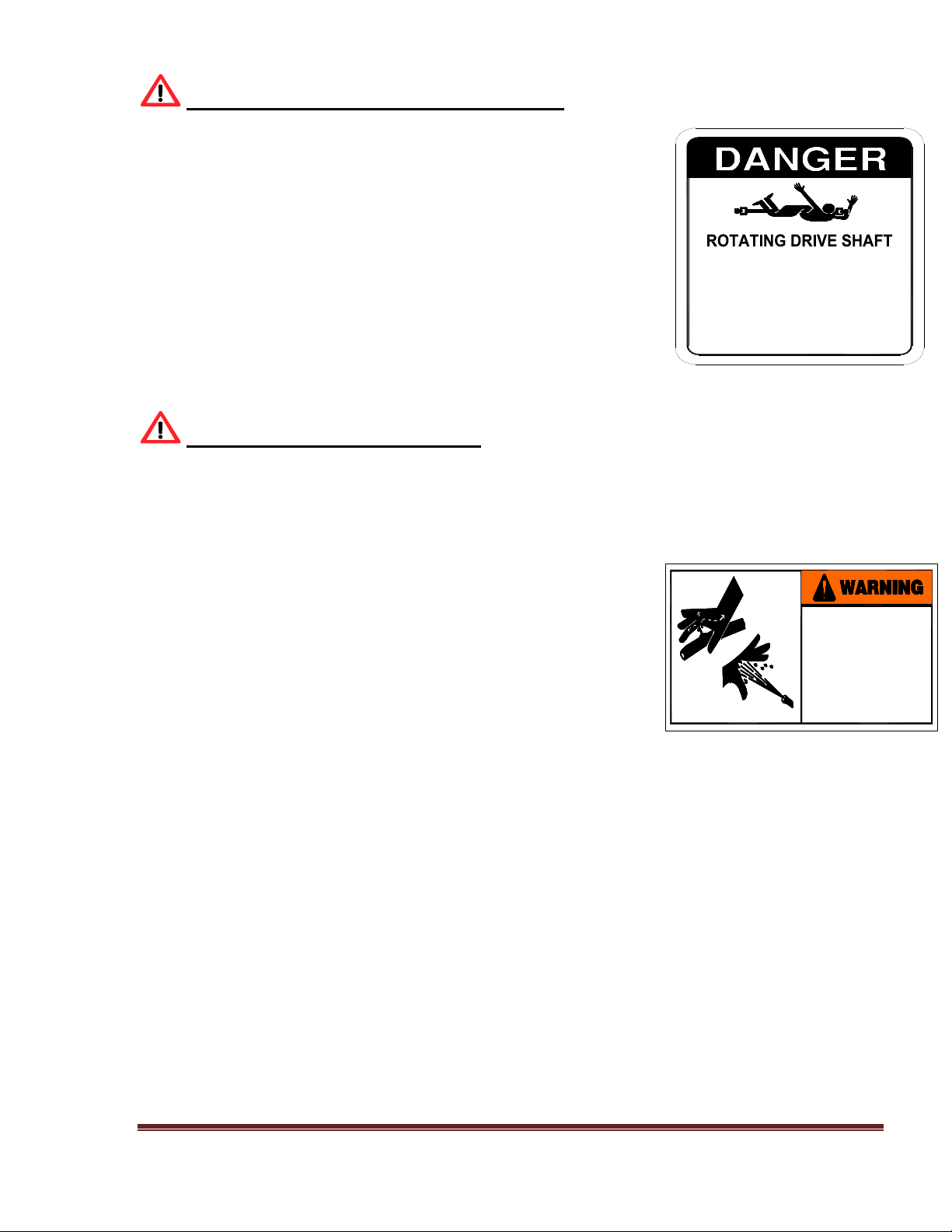

REPLACEMENT SAFETY DECALS

Immediately replace all and any worn or damaged Safety Decals. When ordering replacement

decals please provide the unit’s serial and model number.

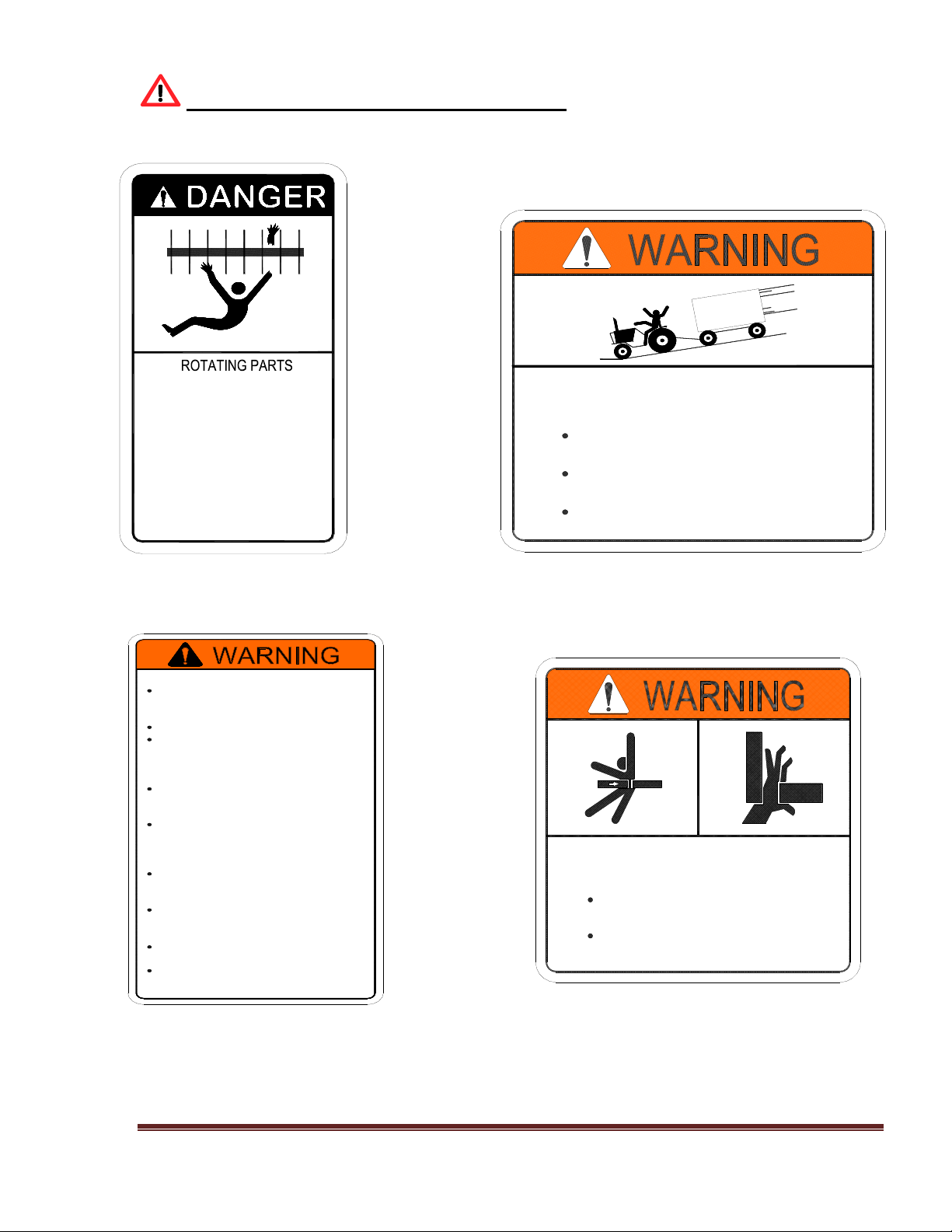

Figure A Figure B

DANGER, Rotating Parts WARNING, Run-Away Hazard

Part No. KM-09 Part No. W-300

Figure C Figure D

WARNING To prevent Serious Injury WARNING, Crushing Hazard

Part No. W-100 Part No. W-200

Disengage PTO before

servicing, cleaning, or

clearing a clogged machine.

Stay off machine when it's

running.

Machine can be hazardous

in the hands of an

UNFAMILIAR, UNTRAINED, or

COMPLACENT operator.

Don't risk INJURY or DEATH.

KM 09

down steep grades.

RUN-AWAY HAZARD

To prevent serious injury or death:

Shift to lower gear before going

Keep towing vehicle in gear at

Never exceed a safe travel speed.

all times.

W-300

To prevent serious injury or death:

Read and understand owner's

manual before using. Review safety

precautions annually.

No riders allowed when transporting.

Securely attach to towing unit. Use

a high strength appropriately sized

hitch pin with a mechanical retainer

and attach safety chain.

Do not exceed 20 mph (33kph).

Slow down for corners and rough

terrain.

Do not drink and drive.

Before moving running gear, be sure

required lights and reflectors are

installed and working.

Before maintenance or repair, stop

vehicle, set parking brake, and

remove ignition key.

Place safety stands under frame and

chock wheels before working on

tires or running gear.

Maintain wheel bolts at torque as

recommend in the manual.

If equipped with brakes, maintain

proper adjustment.

W-100

CRUSHING HAZARD

To prevent serious injury or death:

Keep hands and body out of hitch

area when attaching towing vehicle.

Keep body clear of crush point

between towing vehicle and load.

W-200

Page 16

VI-MMXII Page 16

REPLACEMENT SAFETY DECALS; (cont.)

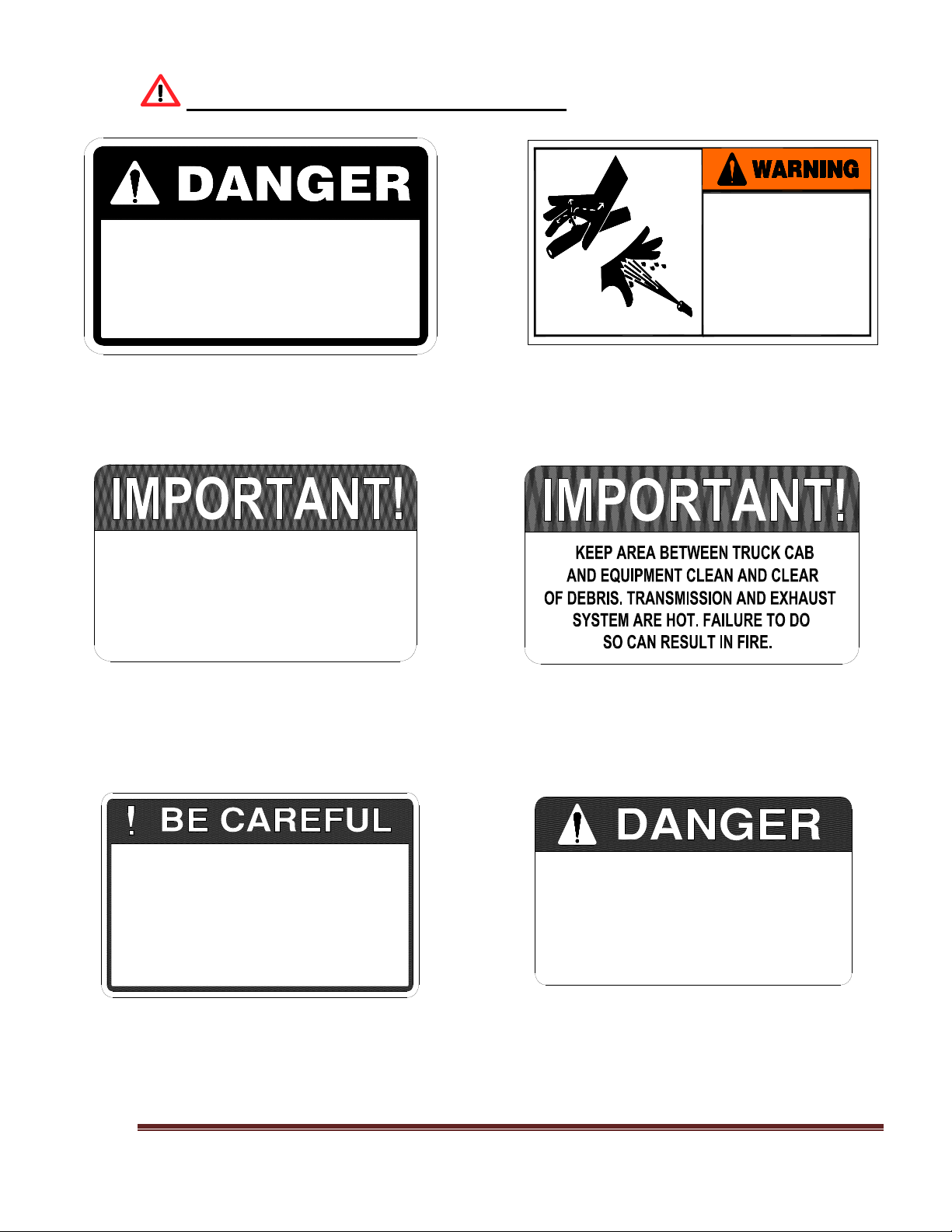

Figure E Figure F

DANGER; use only authorized WARNING; service and adjust

Part No. KM-02 Part No. W-100

Figure G Figure H

IMPORTANT; auger bolts must be kept IMPORTANT; keep area between

Part No. N/A Part No. N/A

Figure I Figure J

BE CAREFUL; keep all shield in place Danger; beware of moving parts

Part No. KM-10 Part No. KM-01

USE ONLY AUTHORIZED

KIRBY SHEAR PINS

KM-02

SERVICE AND ADJUSTMENT

OF HYDRAULIC SYSTEM

SHOULD ONLY BE PERFORMED

BY QUALIFIED PERSONNEL.

IMPROPER ADJUSTMENT COULD

CAUSE SERIOUS INJURY,

DAMAGE TO SYSTEM,

AND VOID WARRANTY.

OR MISSING BOLTS.

REPLACEMENT.

CHECK MONTHLY FOR LOOSE, DAMAGED

AUGER BOLTS MUST BE KEPT TIGHT!

USE ONLY KIRBY AUGER BOLTS FOR

8. MAKE CERTAIN EVERYONE IS CLEAR OF MACHINE BEFORE STARTING ENGINE

LUBRICATE, CLEAN OR UNCLOG MACHINES, UNLESS OTHERWISE SPECIFICALLY

7. USE FLASHING WARNING LIGHTS WHEN OPERATING ON HIGHWAYS EXCEPT

1. KEEP ALL SHIELDS IN PLACE.

WHEN PROHIBITED BY LAW.

OBSERVATION IS PROVIDED.

5. KEEP OFF EQUIPMENT UNLESS SEAT OR PLATFORM FOR OPERATION AND

4. KEEP HANDS, FEET AND CLOTHING AWAY FROM POWER DRIVEN PARTS.

3. WAIT FOR ALL MOVEMENT TO STOP BEFORE SERVICING THE MACHINE.

RECOMMENDED IN THE "OPERATORS MANUAL".

2. STOP ENGINE BEFORE LEAVING OPERATOR'S POSITION TO ADJUST,

6. KEEP ALL OTHERS OFF.

OR OPERATION.

KM 10

MOVING PARTS KEEP

ALL SHIELDS IN PLACE

BEWARE OF

KM 01

Page 17

VI-MMXII Page 17

REPLACEMENT SAFETY DECALS; (cont.)

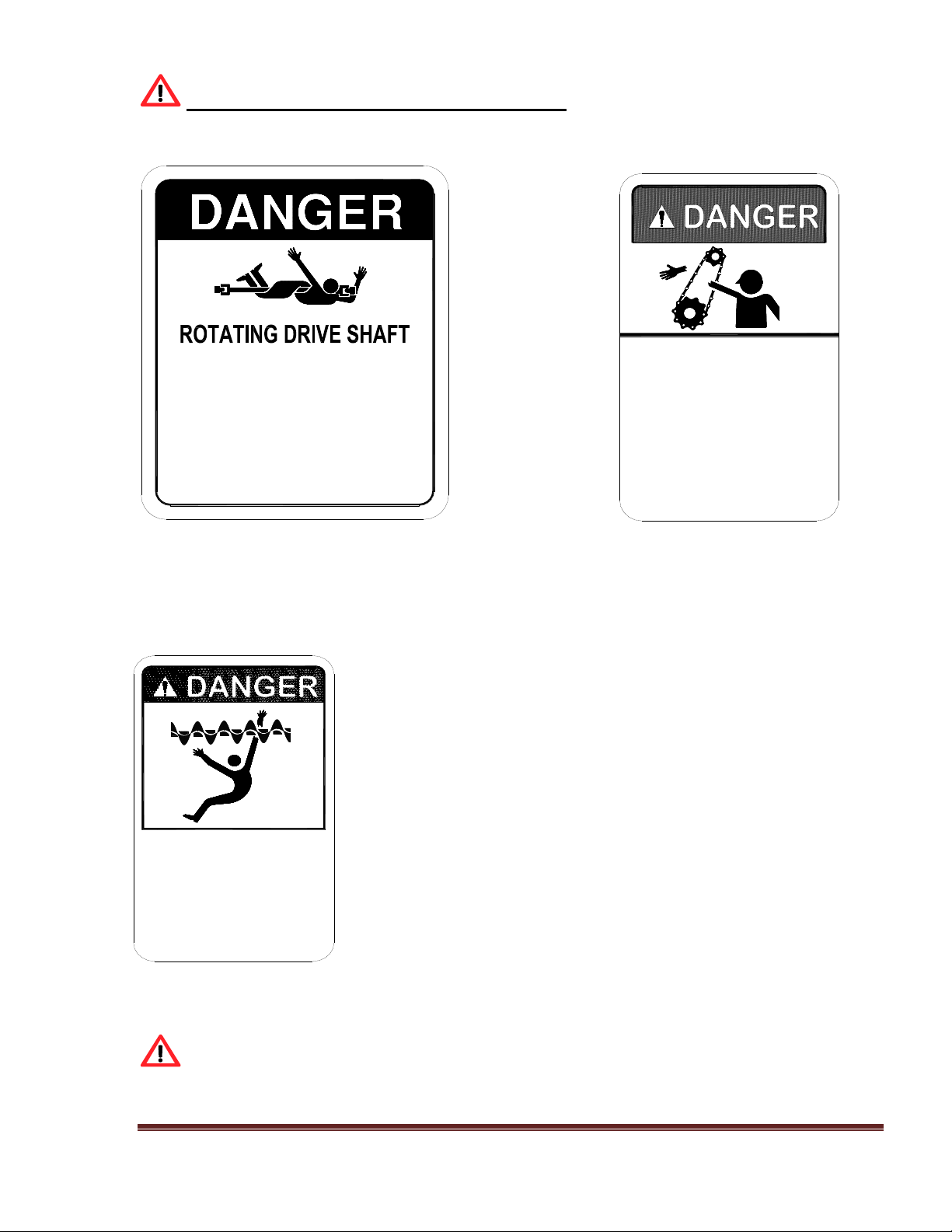

Figure K Figure L

DANGER; drive shaft DANGER; if you can read this

Part No. KM-07 Part No. KM-05

Figure K

DANGER; rotating auger

Part No. KM-03

Your best assurance against accidents is a careful and responsible operator. If there is

any portion of this manual or function you do not understand, contact your dealer or Kirby

Manufacturing.

DO NOT WORK ON

WITHOUT DISCONNECTING

POWER SOURCE

KM 07

IF YOU CAN READ

THIS, THE SHIELD

IS NOT IN PLACE

SHUT MACHINE OFF

REPLACE SHIELD

MOVING PARTS-

FAILURE TO HEED

CAN RESULT IN

DEATH

KM-05

ROTATING AUGER

HAVE SPOUT IN UP

POSITION WHEN MIXING

KEEP HANDS AWAY

FAILURE TO HEED

WILL RESUL IN

PERSONAL INJURY

OR DEATH

KM 03

Page 18

VI-MMXII Page 18

BEFORE OPERATION

Carefully study and understand this manual. Note: it is the responsibility of the owner to train all

current, new and future operators of the equipment. If assistance is needed, please contact Kirby

Manufacturing.

Do not wear loose-fitting clothing which may catch in moving parts.

Always wear protective clothing and substantial shoes.

Keep wheel lug nuts or bolts tightened to specified torque.

Assure that agricultural implement tires are inflated to the proper pressure.

Prior to operating the equipment, give the equipment a visual inspection for any loose bolts, worn

parts or cracked welds, and make necessary repairs. Follow the maintenance safety instructions

included in this manual.

Be sure that there are no tools lying on or in the mixer/feeder.

Do not use the unit until you are sure that the area is clear, especially of children and animals.

Always check inside of mixer prior to starting it up.

Because it is possible that this mixer/feeder may be used in dry areas or the presence of combustibles,

special precautions should be taken to prevent fires and firefighting equipment should be readily

available.

Don’t hurry the learning process or take the unit for granted. Ease into it and become familiar with

your new mixer/feeder.

Practice operation of your mixer/feeder and its attachments. Completely familiarize yourself and

other operators with its operation before using.

Securely attach to towing unit. Use a high strength, appropriately sized hitch pin with a mechanical

retainer.

Do not allow anyone to stand between the tongue or hitch and the towing vehicle when backing up

to the mixer/feeder.

Page 19

VI-MMXII Page 19

DURING OPERATION

Beware of bystanders, particularly children! Always look around to make sure that it is safe to

start the engine of the towing vehicle or move the unit. This is particularly important with higher

noise levels and quiet cabs, as you may not hear people shouting. NO PASSENGERS ALLOWED

- Do not carry passengers anywhere on, or in, the tractor or equipment, except as required for

operation.

Keep hands and clothing clear of moving parts. Do not clean, lubricate or adjust your mixer/feeder

while it is running.

Be especially observant of the operating area and terrain - watch for holes, rocks or other hidden

hazards. Always inspect the area prior to operation.

Do not operate on steep slopes as overturn may result. Operate up and down (not across)

intermediate slopes. Avoid sudden starts and stops. Pick the most level possible route when

transporting across fields. Avoid the edges of ditches or gullies and steep hillsides. Be extra careful

when working on inclines.

Periodically clear the equipment of hay, feed, twine or other materials to prevent buildup of dry

combustible materials.

Maneuver the tractor or towing vehicle at safe speeds. Avoid overhead wires or other obstacles.

Contact with overhead lines could cause serious injury or death. Allow for unit length when making

turns.

Do not walk or work under raised components or attachments unless securely positioned and

blocked.

Keep all bystanders, pets and livestock clear of the work area.

Operate the towing vehicle from the operator’s seat only. Never stand alongside of the unit with

engine running. Never attempt to start engine and/or operate machine while standing alongside of

unit.

Never leave a running mixer/feeder unattended.

As a precaution, always check the hardware on mixer/feeder prior to operating the equipment.

Correct all problems. Follow the maintenance safety procedures.

FOLLOWING OPERATION

Following operation, or when unhitching, stop the tractor or towing vehicle, set the brakes, disengage

the PTO and all power drives, shut off the engine and remove the ignition keys.

Store the unit in an area away from high traffic areas.

Page 20

VI-MMXII Page 20

To prevent damage to the equipment and injury to livestock, do not park equipment where it will

be exposed to livestock for long periods of time.

Do not permit children to play on or around the stored unit.

Make sure parked machine is on a hard, level surface and engage all safety devices.

Wheel chocks should be used to prevent unit from rolling.

HIGHWAY AND TRANSPORT OPERATIONS

Keep the brake pedals latched together at all times. Never use independent braking with machine in

tow as loss of control and/or upset of unit can result.

Always drive at a safe speed relative to local conditions and ensure that your speed is low enough

for an emergency stop to be safe and secure. Keep speed to a minimum.

Reduce speed prior to turns to avoid the risk of overturning.

Avoid sudden uphill turns on steep slopes.

Always keep the tractor or towing vehicle in gear to provide engine braking when going downhill.

Do not coast.

Comply with state and local laws governing highway safety and movement of farm machinery on

public roads.

Use approved accessory lighting, flags and necessary warning devices to protect operators of other

vehicles on the highway during daylight and nighttime transport. The use of flashing amber lights is

acceptable in most localities. However, some localities prohibit their use. Local laws should be

checked for all highway lighting and marking requirements.

When driving the tractor and mixer/feeder on the road or highway under 20 MPH (40 KPH) at night

or during the day, use flashing amber warning lights and a slow-moving vehicle (SMV)

identification emblem.

Plan your route to avoid heavy traffic. Be a safe courteous driver. Always yield to oncoming traffic

in all situations, including narrow bridges, intersections, etc.

Be observant of bridge loading ratings. Do not cross bridges rated lower than the gross weight at

which you are operating. Watch for obstructions overhead and to the side while transporting.

Always operate mixer/feeder in a position to provide maximum visibility at all times.

Make allowances for increased length and weight of the mixer/feeder when making turns, stopping

the unit, etc.

Page 21

VI-MMXII Page 21

PERFORMING MAINTENANCE

Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

Make sure there is plenty of ventilation. Never operate the engine of the towing vehicle in a closed

building. The exhaust fumes may cause asphyxiation.

Before working on the mixer/feeder, stop the towing vehicle, set the brakes, and disengage the PTO

and all power drives, shut off the engine and remove the ignition keys.

Be certain all moving parts on attachments have come to a complete stop before attempting to

perform maintenance.

Always use a safety support and block the wheels. Never use a jack to support the machine.

Always use the proper tools or equipment for the job at hand.

Use extreme caution when making adjustments.

Never use your hands to locate hydraulic leaks on attachments. Use a small piece of cardboard or

wood. Hydraulic fluid escaping under pressure can penetrate the skin.

When disconnecting hydraulic lines, shut off hydraulic supply and relieve all hydraulic pressure.

Openings in the skin and minor cuts are susceptible to infection from hydraulic fluid. If injured by

escaping hydraulic fluid, see a doctor at once. Gangrene can result. Without immediate treatment,

serious infection and reactions can occur.

Replace all shields and guards after servicing and before moving. After servicing, be sure all tools,

parts and service equipment are removed.

Do not allow grease or oil to build up on any step or platform.

Never replace hex bolts with less than grade five (5) bolts unless otherwise specified.

Where replacement parts are necessary for periodic maintenance and servicing, genuine factory

replacement parts must be used to restore your equipment to original specifications.

Kirby Manufacturing will not be responsible for damages caused using unapproved parts and/or

accessories. This will void your warranty.

If equipment has been altered in any way from original design, Kirby Manufacturing does not accept

any liability for injury or warranty.

A fire extinguisher and first aid kit should be kept readily accessible while performing maintenance

on this mixer/feeder.

Page 22

VI-MMXII Page 22

2.0 MIXER STRUCTURE AND TRAILER

2.1 Observe for cracks in metal and welds in mixer chamber, trailer frame, and axle assembly and

around discharge door and chute. Re-weld as necessary.

2.2 Observe trailer hitch for

(I) Cracked welds. Re-weld as necessary.

(II) Bent or worn. Replace or repair as necessary.

2.3 Observe that all bolts are in place and that all sets crews are properly seated. Replace or

tighten as required.

2.4 Observe for hydraulic oil leaks. Repair any leaks.

2.5 Trailer mount only. Observe trailer tires:

(I) For cuts or punctures in tires.

(II) Check for proper inflation using pressure gauge.

(fill to the maximum pressure rating shown on side of tire)

2.6 Observe wheel hubs and bearings.

(I) Check for oil seal leaks. Replace if seal leaks.

(II) Check wheel hubs for proper bearing tightness. Tighten as required.

(III) Observe oil level in cap, oil must be level with bottom of filler hole. Fill with proper

lubricant to over flow.

3.0 MAIN AUGERS, SHAFTS, AND BEARINGS

CAUTION! THE MIXER SHALL NOT BE IN OPERATION FOR THE FOLLOWING:

3.1 Observe auger flighting, in mixing chamber

(I) Bent, deformed, or worn to less than 25% of new thickness.

(II) Replace flighting as necessary.

(III) Check blades on mixer replace when worn

3.1 Observe mixing chamber, sides and ends.

(I) Walls and ends should be straight, not bulging in appearance. This condition can result

from over loading or foreign objects present in ration.

(II) Look for signs of excessive wear

3.2 Observe tractor drive line and mixer drive line for bent shafts.

(I) Ensure all shields are in place and operational (sliding without restrictions)

Page 23

VI-MMXII Page 23

4.0 SPROCKET AND CHAINS, (CROSSFEED)

4.1 Observe chain for properly seating on sprocket. Use caution while observing mixer while in

operation. Look for chain jerking motion, when chain wraps around sprocket. Jerking motion

may indicate:

(I) Misalignment of chain and sprocket. Realign

(II) Worn or loose chain. Replace worn chain.

(III) Loose chain idlers. Reposition and tighten idler.

(IV) Bent shafts. Replace with new shafts.

4.2 Observe sprocket tooth wear pattern.

(I) Tooth worn on sides indicates misalignment. Realign sprocket.

(II) Tooth worn to a sharp point indicates loose or worn chain. Adjust sprockets

(III) Tooth worn to cup at base indicates excessive load on chain. Adjust sprockets

4.3 Observe sprockets for the following.

(I) Main key sheared or shearing. Replace key.

(II) Main set screws loose or missing. Tighten or replace.

(III) Movement or signs of movement of sprockets on shaft. Tighten or replace.

(IV) Alignment - Using a straight bar, insure that both sprocket faces are in full contact with

the edge of the bar.

5.0 GEAR BOXES

5.1 Main planetary drive.

(I) Observe oil level of gearbox reservoirs, use clear view tube on oil reservoir.

(II) Observe for any over-fill oil coming out of the gearbox oil reservoir tank.

5.2 Two speed gearboxes

(I) Observe shaft seals for leaks. Replace seals.

(II) Check for loose bolts that secure gearbox to mounting bracket.

(III) Check for misalignment to other components: U-joints. Shear hub

(IV) Check input shaft, movement indicates worn bearings. Replace.

(V) Check out put shaft for movement, realign and tighten set screws.

(VI) Check to see that the oil is level with the filler plug located on the side of this gearbox.

Fill to overflow.

(VII) Check tightness of gearbox mounting bolts.

Check shifting lever and cables. Adjust cable for optimum engagement in both high and low speed

selections on gearbox.

5.3 For regular service, refer to the “Preventive Maintenance and Lubrication Schedule” located

in Section 8 of the manual.

Page 24

VI-MMXII Page 24

6.0 DRIVELINES AND POWER TAKEOFFS

6.1 Tractor PTO driveline

(I) Shields must be secured by locking devices

(II) Shields must slide freely.

(III) Observe shields for damage.

(IV) Driveline shafts must slide freely, binding may cause false readings on the scale

system. Lubricate all shaft splines.

(V) U-joints cross & yoke must fit tight in the bearing cups and have zerk fittings for

lubrication.

6.2 Truck mounted mixer PTO’s

(I) Observe for oil leaking around PTO shaft seal. Replace seal.

(II) Check PTO for loose bolts holding PTO to transmission or engine crank shaft. Tighten

bolts.

(III) Check U-joints, bearings, yokes, and set bolts. Replace worn parts and tighten all

bolts.

(IV) Lubricate driveline “U” joints as per the “Preventive Maintenance and Lubrication

Schedule”

6.3 Mixer drive line.

(I) Check for loose or missing set screws or lock collars in pillow block bearings and

driveline yokes. Tighten or replace lock collars set screws.

(II) Check for loose or missing bolts in pillow block bearings. Tighten or replace.

(III) Observe driveline under operation. CAUTION STAY CLEAR OF ALL MOVING

PARTS, DO NOT WEAR LOOSE CLOTHING!!

(IV) Check for vibration, worn bearings, bad U-joint bearings, or bent shaft. Replace worn

or damaged parts.

(V) Observe for linear movement through bearings, this is indicated by unpainted surface of

shaft exposed on each side of bearing locking collar. Realign and tighten loose locking

bolts.

(VI) Observe for loose set screws or PTO shaft not slipping in sleeve, causing end thrust load

on the bearings.

(VII) Check for bent shaft. Replace and grease as per lubrication schedule.

Page 25

VI-MMXII Page 25

7.0 MAIN HYDRAULIC SYSTEM

STATIONARY AND TRUCK MOUNTED VERTICAL MIXERS

QUICK REFERENCE INFORMATION

Thank you for your investment in a Kirby hydraulic driven mixer. With proper care and service you

can extend the life of the hydraulic system.

Your system is equipped with two (2) Sauer-Sundstrand Series 90 axial piston pumps, two (2)

Parker/VOAC variable displacement hydraulic motors Series V14 and two (2) Fairfield planetary

gearboxes.

In order to ensure hydraulic system efficiency only fresh, clean oil should be added to the hydraulic

tank. ALL hydraulic oil that is added to the system must be filtered through a 10-micron filter to

ensure oil cleanliness. If any lines are damaged, unfastened or replaced, extreme care must be

taken to prevent dirt from entering the hydraulic system. All open lines should be capped. Filter

indicator should be checked regularly and the filters should be replaced if indicated, or as hours of

use require. When replacing the filters always replace O-ring on canister.

Kirby Manufacturing recommends that only authorized Kirby filters be used for replacement. The

filters used must be at least a 10-micron filter. Oil specifications are Pennzoil AW68.

It is critical that proper maintenance and filter changes be made on a regular basis. Warranty is based

on the regular maintenance of your system. Not changing your oil and filters properly and within the

time frame given WILL VOID YOUR WARRANTY. All filters should be kept clean and free of

foreign contaminants when replacing to avoid oil contamination.

All hydraulic filters and all planetary gearbox oil should be changed after the first initial 50 hours

of use. Thereafter, all hydraulic filters should be changed every 500 hours. Use the reservoir filter

gauges, located on the top of the hydraulic fluid reservoir, to help determine when the next filter

change is necessary.

The first oil change on the planetary gearboxes should occur after 50 hours of use. Thereafter, oil

changes should occur every 1,000 hours.

Page 26

VI-MMXII Page 26

Procedure for changing the oil in the planetary gearbox:

1. First, run unit to warm oil in gear boxes

2. To drain the planetary gearbox oil, place a bucket under the planetary gearbox to catch the

used oil, detach the bottom hose (the other end of this hose goes to the bottom of gear oil

supply reservoir) from the bottom of the gearbox. Let the oil from the gearbox and the bottom

hose drain into the bucket.

3. Take the plug out of the end of the gearbox’s top hose. This is the other hose that hangs down

from the side of the planetary gearbox. Place an air hose to the end of the top hose. Using

compressed air (no more than 20 psi.) gently force the oil out the bottom of the gearbox.

Note: Excessive air pressure could damage the top output seal of the gearbox.

4. To fill the gearbox, re-attach the bottom hose to the bottom of the gearbox.

5. Add (warm) oil through the reservoir fill cap, located on the reservoir, until oil comes out of

the end of the top hose.

6. Re-place plug in top hose and (if needed) add oil until oil reaches fill line on sight glass and

check periodically to ensure that the level is correct.

Recommended oil for this gearbox is PENNZOIL MULTI-PURPOSE GEARLUBE 4140,

GRADE SAE-85W-140 with “EP” (Extreme Pressure) additive (for other oil choices see the

additional specification listed below)

If you have opted for the “Extended Warranty”, you will be provided with oil sampling kits. You

should use these kits when pulling oil samples on your equipment. It is crucial that oil samples be

pulled in accordance to the provided schedule. YOUR WARRANTY WILL BE VOID IF ONE

OIL SAMPLING TEST IS MISSED.

Once your oil sample is sent in and analyzed, the information will then be sent back to you. This

information will provide you with valuable information on the condition and maintenance of your

hydraulic system. It is your (the customer’s) responsibility to maintain the oil cleanliness to the

specifications provided. OIL SAMPLING SHOULD BE DONE WITH EVERY OIL FILTER

CHANGE, INCLUDING THE FIRST 50 HOURS.

After you receive your fluid analysis report, you should check it to ensure that it meets or exceeds

the specifications stated. For hydraulic oil the “cleanliness code” specifications are as follow: Your

hydraulic oil should be in the 18/16/13 range. Any sampling that is lower than this is good; any

sampling that is higher is an indication that your oil is not clean and thus will reduce the life

expectancy of your system. You must immediately change your hydraulic filters and oil. Then run

the unit for 50 hours and take another sample.

ISO CODE MEANING

18/16/13 = # of particles

Particles > 2 microns Particles > 15microns

Particles > 5 microns

Page 27

VI-MMXII Page 27

If you have opted for the “Extended Warranty”, you will receive all the necessary oil sampling

kits when you receive your equipment. It is the customer’s responsibility to pull the oil samples

and send them in for analysis. All mail charges will be paid by the customer.

At this time, we suggest you buy your next set of change of filters. It will require two (2) intank element part # 7954, two (2) charge pump filters # 7956, and two (2) small breather filters

part # 7953 B (located on the side of the filler cap near the top of the hydraulic oil reservoir).

We recommend that you NEVER use paper element filters. Kirby offers a high efficiency, and

high capacity Microglass III type.

Oil temperature, cooling system and low fluid volume shut-down

Your unit is equipped with a hydraulic oil temperature readout (optional read-out) and hydraulic oil

cooling system.

Normal operating temperature range of your system depends on ambient temperature and duty cycle.

The range should vary between 150 and 180 degrees Fahrenheit.

An automatic hydraulic shut-off for the system is set at 190 degrees Fahrenheit. If the hydraulic oil

reaches the 190-degrees mark, the hydraulic system will automatically shut down.

You will still be able to drive your truck (truck mounted models), but the system will not come back

on until the oil cools down. If this failure occurs and you are unable to find the cause, call Kirby

Mfg. Inc 209-723-0778 for further assistance.

Your system has a hydraulic oil cooling system equipped with fan(s), which automatically will turn

on when the oil temperature reaches 120 degrees. The radiator for this system should be cleaned on

a daily basis. NOTE: be careful not to damage cooling fins on radiator when using compressed air

to blow out radiator. You should periodically physically check the fans to ensure they are working

when the hydraulic fluid temperature is above 120 degrees. DO NOT use water for cleaning the

hydraulic cooler.

Your unit is also equipped with a low volume hydraulic sensor in the hydraulic fluid reservoir. If for

any reason there is a loss of hydraulic fluid in the system the unit will automatically shut down. For

truck mounted units with front mounted pumps, the truck engine must not be started. SEVERE

DAMAGE will occur to the hydraulic system if you run the truck engine after the hydraulic

system has automatically shut down.

A check of the system should be made to determine the cause of the low volume shut-down. If for

whatever reason, your unit is not equipped with the “automatic shut-down” feature and you have a

major loss of hydraulic fluid in the system, you must shut down the truck engine immediately or

the hydraulic system will be severely damaged.

Page 28

VI-MMXII Page 28

GENERAL CHECK LIST

7.1 Observe all fittings, pipes, tubes, and hoses for leakage. Tighten as needed.

7.2 Observe oil level in main tank. On truck mount or stationary units the dipstick capacity allowed

is 95 liters. (25 gallons)

7.3 On tractors, the maximum pump capacity required to operate the mixer is 53 liters per minute

(14 gpm) @ 2200 P.S.I.. The minimum pump capacity required to operate the mixer is 46 liters

per minute (12 gpm) @ 2200 P.S.I..

7.4 Manifold block specification is 53 liters per minute (14 gpm) @ 3000 P.S.I. Caution: do not

exceed these limits.

7.5 Manifold relief valve is factory set @ 2200 P.S.I. for maximum safety to the system.

7.6 Manifold needle valve controls the speed at which the door opens. It may be adjusted as needed.

7.7 Discharge conveyor motor specification, maximum 57 liters per minute (15 gpm) @ 1700 P.S.I.

7.8 Discharge conveyor motor under normal operation requires a minimum of 46 liters per minute

(12 gpm) to a maximum of 53 liters per minute (14 gpm) to provide adequate unload speed. The

speed is controlled through the crossfeed flow control valve located on the mixer.

7.9 Stalling of the discharge conveyor motor may be caused by the loss of oil pressure (P.S.I.) to the

motor, due to incorrect adjustment of relief valve, or worn pump/ motor.

7.10 Slow speed of discharge conveyor motor may be caused by the loss of oil flow from the pump

source to the motor, due to worn pump or restricted flow in the tractor hydraulic system/hydraulic

hoses.

7.11 Truck mount and Stationary mixers have 12-volt solenoid valves to operate conveyor motor and

hydraulic door. Solenoids may be shifted manually by inserting 1/8” shaft into the hole at each

end of solenoid. This method will determine if the 12-volt power supply or the switches are

defective. This method can also be used to determine if the solenoid is struck or otherwise

defective resulting in a problem with the operation of the discharge.

7.12 For service see preventive maintenance and lubrication schedule in Section 8.

Page 29

VI-MMXII Page 29

8.0 LUBRICATION AND PREVENTATIVE MAINTENANCE

8.1 Main auger bearings.

(I) Each planetary gearbox (located under the augers) has a top bearing that need lubrication.

Lubricate these bearings from the grease bank zerks located on the sides of the mixer.

Lubricate these bearings every 140 hours!

(II) Check to see that all grease lines and grease zerks are in place and in good working order,

not plugged, loose or kinked.

(III) Pump grease using a standard hand pump one (1) pump for each bearing. Always be sure

the machine is operating and the bearings are rotating to ensure that they take grease.

CAUTION: DO NOT OVER GREASE. THIS SHOULD BE A TWO MAN

OPERATION. ENSURE ALL SAFETY PRECAUTIONS ARE TAKEN.

1.BEWARE OF ALL MOVING PARTS.

2.DO NOT WEAR LOOSE FITTING CLOTHING

3.BEWARE OF THE PTO

8.2 Discharge conveyor bearings.

(I) There are two take-up bearings on the discharge end of the crossfeed conveyor

(II) There are also two flange bearings on the opposite side of the discharge

(III) Both have grease zerk that need greasing once a week

(IV) Check that all grease lines and grease zerks are in place and in good working order, not

plugged, loose or kinked.

(V) Pump grease using a standard hand pump grease gun 3 to 4 times for each bearing.

Always be sure the machine is operating and the bearings are rotating to ensure that they

take grease. Caution: Excessive grease will blow out the bearing seals. DO NOT

OVER GREASE. THIS SHOULD BE A TWO MAN OPERATION. ENSURE ALL

SAFETY PRECAUTIONS ARE TAKEN

1.BEWARE OF ALL MOVING PARTS.

2.DO NOT WEAR LOOSE CLOTHING

3.BEWARE OF THE PTO

8.3 Power takeoff. U-joints and slip sleeves.

(I) Follow safety procedures. DO NOT service while the tractor is running or the PTO is

engaged or in motion.

(II) Key should be removed from tractor or truck before attempting to grease the PTO, U-

Joints & Yokes.

(III) U-joints (crosses and yokes) must be tight in the bearing cups.

(II) Bearings are greased through zerk grease fittings. Pump grease using a standard hand

pump grease gun until you observe grease coming out of ALL FOUR CUPS OF THE

U-JOINT bearings.

8.4 Check all safety shields and ensure that all are in place.

Page 30

VI-MMXII Page 30

LUBRICATION SCHEDULE

(Unless stated differently in this manual use the below chart as a general lubrication

schedule/guideline when performing preventative maintenance on your equipment)

PM

SERVICE

1

st

50

Hours

Every

140

Hours

Every

200

Hours

Every

500

Hours

Every

1000

Hours

Every 3

Months

Every 6

Months

Every

12

Months

Change oil in

All gearboxes

X X

(2)

X

(2)

(1)

Pull gearbox oil

sample for analysis

X X

(2)

X

(2)

Change hyd. Oil &

Send in samples

X

(1)

Pull hydraulic oil

sample for analysis

X

X

(3)

X

(3)

Grease top

Planetary Bearing

X

Change hydraulic

oil filters

X

X

(3)

X

(3)

Grease all

Mixer bearings

X

Grease PTO, Drive

Line & Slip Sleeve

X

Check out

Mixer

X

Repack

Wheel bearings

X

NOTE: For a more detailed Preventative Maintenance (PM) Schedule refer to the

“Maintenance Schedule Checklist” located at the end of this chapter.

(1)

If you have opted for the three (3) year “Extended Warranty Policy” on all major components, it

is required that you sample oils on the frequencies stated in the “Extended Warranty Policy” section

of this manual. This is necessary to not void the “Extended Warranty Policy” (see the “warranty

section” of this manual for more details). Even if you have not chosen the “Extended Warranty

Policy”, it is “best practices” to perform regular oils sampling and analysis for proper maintenance

of the equipment.

(2)

1,000hrs or 6 months whichever comes first.

(3)

500hrs or 3 months whichever comes first.

Page 31

VI-MMXII Page 31

LUBRICANT TYPES:

COMPONENTS

LUBRICATE

NAME

LUBRICATE

TYPE

LUBRICATE

GRADE

PLANETARY

GEARBOX OIL

(IMPORTANT!!)

SEE CHOICES

A: 1,2, or 3

BELOW

SEE CHOICES

A: 1,2, or 3

BELOW

SEE CHOICES

A: 1,2, or 3

BELOW

PLANETARY

GEARBOX TOP

BEARING GREASE

SEE CHOICE

B:

BELOW

SEE CHOICE

B:

BELOW

SEE CHOICE

B:

BELOW

BEARINGS AND

DRIVE LINE YOKES

GREASE

PENNZOIL

AW

NLGI #2

TWO SPEED

SHIFTABLE

GEARBOX OIL

SEE CHOICES

A: 1,2, or 3

BELOW

SEE CHOICES

A: 1,2, or 3

BELOW

SEE CHOICES

A: 1,2, or 3

BELOW

HYDRAULIC

SYSTEM OIL

(TRUCK ONLY)

PENNZOIL

AW

68

HYDRAULIC MOTOR

SPLINES

(TRUCK ONLY)

SEE CHOICE

C:

BELOW

SEE CHOICE

C:

BELOW

SEE CHOICE

C:

BELOW

A. PLANETARY GEARBOX OIL CHOICES:

(ALSO, USE THIS GEAR OIL IN RIGHT ANGLE, TEE AND

TWO SPEED GEARBOXES)

1.) Mobil ........Mobilube SHC 75W-90

2.) Chevron.....Chevron RPM Synthetic Gear Lubricant SAE 75W-90

3.) Texaco......Texaco Syn-Star GL 75W-90

4.) Texaco …Texaco multigear EP SAE 85W-140

* IMPORTANT !!: All gearbox oils MUST have an EP (“Extreme Pressure”) additive.

B. PLANETARY GEARBOX TOP BEARING GREASE:

** Use an NLGI Grade 2 grease with an EP (“Extreme Pressure”) additive.

C. COUPLING GREASE:

Texaco Coupling grease, CPS number 221912

Use when mating male and female splined shafts and coupling to reduce “fretting” of spline

material.

Areas of application:

- between PTO spline connections

- between hydraulic motor splines and planetary input splines

PROCEDURE FOR SAMPLING AND CHANGING OILS:

The following information pertains to changing and sampling the oils in both the gearboxes and the

hydraulic circuit (trucks only) on the mixer.

Page 32

VI-MMXII Page 32

Note: Always make sure to change and sample oil immediately after the equipment has been in

operation. This will ensure that the oils are warm which will allow them to flow more freely when

being drained. Also, this will ensure that any particles that are in the oil will be in suspension while

pulling an oil sample. ALWAYS PARK EQUIPMENT ON A LEVEL SURFACE WHEN

CHANGING OIL AND CHECKING OIL LEVELS.

I. GEARBOXES:

A. Planetary Gearboxes, (truck and trailer):

Draining gearbox:

1. Locate gearbox oil reservoir on outside of unit.

2. Wipe hose end and fitting clean below oil

reservoir.

3. Place drain pan on the ground under oil

reservoir.

4. Remove cap at end of the high-level fill hose

hanging down beside gearbox.

5. Remove hose from bottom of reservoir and

drain, (this hose is used for draining and

filling).

6. While oil is draining out, 30 seconds, then

capture a sample in the cleaning sample bottle.

7. Cap sampling bottle and completely fill out information sheet.

Filling gearbox:

1. Fill gearbox via the reservoir hose. Note: Since

gear oil is thick and doesn’t flow freely, an oil

dispensing pump system is needed when refilling oil. Dispensing pump pressure should

never exceed 10 psi, so seals are not damaged.

2. IMPORTANT: gearbox is full only when oil

starts to flow from the “high level” fill hose, do

not run mixer until oil is seen coming out of

“high level” fill hose.

3. At this point, stop adding oil to the reservoir and

observe “high level” fill hose.

4. When the excess oil has stop flowing from the “high level” fill hose SECURELY replace

cap.

5. Reconnect hose to bottom of reservoir.

6. Check oil level on gearbox reservoir, (the oil level in the reservoir should be located at

approximately the middle of the reservoir, add oil if needed).

7. Run equipment, recheck oil levels and check for leaks.

8. You have now successfully completed the oil changing process.

9. IMPORTANT: Recheck oil levels daily in reservoirs over the next week period to ensure

proper oil levels are maintained.

cap @ end of “high

level” fill hose

Gearbox Reservoir

Reservoir

Fill level

planetary

gearbox

Page 33

VI-MMXII Page 33

B. Two Speed Manual Shift Gearbox, (optional on trailer only):

Draining gearbox:

Step

1. Locate drain plug on bottom of gearbox

2. Wipe area clean around drain plug

3. Place drain pan under gearbox drain plug

4. Remove drain plug from bottom of gearbox.

5. While oil is draining out capture sample in clean

sampling bottle

6. Cap sampling bottle and completely fill-out

information sheet

7. SECURELY replace plug when last of oil has

drained from gearbox

C. Two Speed Manual Shift Gearbox, (optional on trailer only):

Filling gearbox:

Step

1. Remove fill plug on side of gear box, (this plug is in

the middle of the gearbox).

2. Fill gearbox through the fill plug hole, (Note:

warm oil will flow quicker).

3. Continue filling until oil starts to flow from fill

hole.

4. Replace plug and wipe excess oil from area.

5. Run equipment and recheck oil levels and check for

leaks.

Drain plug

Fill plug

Page 34

VI-MMXII Page 34

II. HYDRAULIC SYSTEM, (truck mount only):

BOTTLE SAMPLING PROCEDURE :

1.

A representative oil sample should be

drawn directly after the shut down before

the filter.

2.

Check whether the thread of the pump (1)

is clean, if not please use a lint- free cloth.

3.

The sample can be taken quickly through

the dip-stick opening. Please estimate the

required tube length (use the dip-stick) and

cut the end to an angle of approximately

45°.

4.

Release the aluminum knurled screw (2) on

the pump (1) so that you can insert the tube

through the whole of the knurled screw.

5.

Tighten the knurled screw (2). So the tube

(6) will be fixed to the seal (3). The system

is sealed now.

6.

Screw the open sampling bottle (5) on the

"VAMPIRE" pump (1).

7.

Carefully clean the sample taking tube to

avoid sample contamination.

8.

Insert the end of the sampling tube through

the inlet into the oil. The tube should not

touch the bottom of the oil tank or oil pan.

9.

Always hold the sampling bottle in a

vertical position (see picture).

10.

Start pumping the oil into the bottle. Stop pumping early enough to prevent

contamination of the pump by overflowing the bottle. Leave 1 cm of the

bottle unfilled to allow the oil being shaken.

11.

Loose the knurled screw to release the vacuum and remove the tube from

the pump.

12.

Unscrew the bottle and close it with the cap (4).

Page 35

VI-MMXII Page 35

Maintenance Schedule; (for trailer mounted vertical mixer)

Maintenance Schedule

equipment: vertical mixer (trailer mount)

frequency:

100 hours, (approximately 1 week intervals); (UNLESS STATED OTHERWISE BELOW)

MAJOR AREAS

1. CUSTOMER INFO.

minor areas item description check-off

follow-up

required

(y/n)

general 1 speak with equipment operators

2 speak with maintenance technicians

2. HYDRAULIC SYSTEM

minor areas item description check-off

follow-up

required

(y/n)

general 1 check for leaks; (hoses, fittings, seals, etc)

2 check oil levels, fill if needed (after pulling samples)

3

check pressure bypass settings & record (where applicable)

4 check for worn hoses & loose fittings

5 start mixer and check general operating parameters

6 check operations of hydraulic cylinders & motors

3. MECHANICAL SYSTEM

minor areas item description check-off

follow-up

required

(y/n)

general 1

are all guards in place, (notify customer if not)

2 start mixer and listen for unusual noises

3 look for worn/broken parts

4 lubricate all grease zert fittings and/or points of lubrication

5 check drive line shear pin

planetary gearbox 1

check oil levels (daily), fill if needed; (pull oil sample and

change oil every 1000 hrs, 1st oil change at 50 hrs)

2 pull and identify oil samples, (send out for testing)

3 is oil clear and free of contamination

4 grease top bearing every 140 hours

90 degree &

"Tee" gearbox

1

check oil levels, fill if needed; (pull oil sample and

change oil every 1000 hrs, 1st oil change at 50 hrs)

2 grease bearings; (2 locations per gear box)

augers 1 check backlash & tightness, (rotate auger back & forth)

2 check for damage & wear on flighting

3 check knives for wear & tightness

main tub 1 check wear on inside of tub, (floor & walls)

2 check stainless seams and wear (where applicable)

3 check door operations, adjust if needed & lubricate

Page 36

VI-MMXII Page 36

Maintenance Schedule; (for trailer mounted vertical mixer), con’t

NOTE: It is suggested to make copies of this “Maintenance Schedule” form to assist with

performing routine maintenance inspection of the equipment. This will also serve as a

retention record of all safety and maintenance inspections.

4 check hay brake operations

cross conveyor 1 check for wear on chain assembly

2 check for wear on flooring

3 check drive system

4 check conveyor take-ups and adjust if needed

5 check operations of cross conveyor slide

two speed gear box

1 check yokes for tightness, (check set screws)

2 check oil levels, fill if needed (after pulling sample)

3 check shift pressures & record (where applicable)

4 check shift linkage adjustment & tighten (where applicable)

5 check tightness of gearbox mounting bolts

PTO 1 check and grease shaft, (check set screws & locking collar)

4. WEIGH SYSTEM

minor areas item description check-off

follow-up

required

(y/n)

general 1 check operations of scales

2 check for rotation of load ceils

3 check for damaged wiring

. 4 check and clean load ceil mounting "V" brackets

5 check local support/truck frames for cracks

6 check to see if load cells are loose (i.e. not carrying the load)

5. TEST MIXER'S OPERATIONS

minor areas item description check-off

follow-up

required

(y/n)

general 1 "run-in" mixer for a period of time (15min+) to insure smooth

operations. Walk around equipment and inspect all

components for smooth operations

ADDITIONAL NOTES AND COMMENTS:

AFTER SERVICE IS COMPLETED; WRITE SERVICED DATE WITH YOUR INITIALS ON A STICKER AND

PLACE ON UNIT NEXT TO SERIAL NUMBER ID PLATE.

Page 37

VI-MMXII Page 37

Maintenance Schedule; (for truck mounted vertical mixer)

Maintenance Schedule

equipment: vertical mixer (truck mount)

frequency:

100 hours; approximately 1 week intervals; (UNLESS STATED OTHERWISE BELOW)

Customer ___________________________ Location

__________________

Date service performed Hours on truck

___________________________ Hours on unit

__________________

Equipment ser. no. ___________________________ Service technician

__________________

MAJOR AREAS

1. CUSTOMER INFO.

minor areas item description check-off

follow-up

required

(y/n)

general 1 speak with equipment operators

2 speak with maintenance technicians

2. HYDRAULIC SYSTEM

minor areas item description check-off

follow-up

required

(y/n)

general 1 check for leaks; (hoses, fittings, seals, etc)

2

pull and identify oil samples, (every 500 hrs )

3 check oil levels, fill if needed

4

change all oil filters, (every 500 hrs )

5

change hydraulic oil, (every 4000 hrs.; approx. 1 year)

6

check pressure bypass (relief) settings & record

7 check for worn hoses

8 start mixer and listen for unusual noises

9 start mixer and check general operating parameters

10

check driveline to pumps; (lubricate yokes every 8 hrs)

( a needle lube gun fitting is needed)

11 check operations of hydraulic actuators

12 check and record pressures on pump (w/ load & w/o load)

13 check and record pressures on motor (w/ load & w/o load)

14

clean heat exchanger (radiator) on hydraulic system (daily)

3. MECHANICAL SYSTEM

minor areas item description check-off

follow-up

required

(y/n)

general 1 are all guards in place, (notify customer if not)

2 start mixer and listen for unusual noises

3 look for worn/broken parts

4 lubricate all grease zert fittings and/or points of lubrication

planetary gearbox 1

check oil levels (daily), fill if needed; (pull oil sample and

change oil every 1000 hrs, 1st oil change at 50 hrs)

2 if applicable, identify oil samples; (send out for testing)

3 is oil clear

4 grease top bearing every 140 hours

Page 38

VI-MMXII Page 38

Maintenance Schedule; (for truck mounted vertical mixer), con’t

NOTE: It is suggested to make copies of this “Maintenance Schedule” form to assist with

performing routine maintenance inspection of the equipment. This will also serve as a

retention record of all safety and maintenance inspections.

augers 1 check backlash & tightness, (rotate auger back & forth)

3 check for damage & wear on flighting

4 check knives for wear & tightness

main tub 1 check wear on inside of tub, (floor & walls)

2 check stainless seams and wear

3 check door operations, adjust if needed & lubricate

4 check hay brake operations

cross conveyor 1 check for wear on chain assembly

2 check for wear on flooring

3 check drive system

4 check conveyor take-ups and adjust if needed

5 check operations of cross conveyor slide

4. WEIGH SYSTEM

(mechanical)

minor areas item description check-off

follow-up

required

(y/n)

1 check operations of scales

2 check for rotation of load cells and tighten locking screw

3 check for damaged wiring

. 4 check and clean load cell mounting "V" brackets

5 check local support/truck frames for cracks

6 make sure 7/8" bolt in load mounting bracket is loose

ADDITIONAL NOTES AND COMMENTS:

AFTER SERVICE IS COMPLETED; WRITE SERVICED DATE WITH YOUR INITIALS ON A STICKER

AND PLACE STICKER ON UNIT NEXT TO SERIAL NUMBER ID PLATE.

NOTE: The above maintenance program covers the operation of the mixer and does not include truck maintenance checks

or safety checks, (other than guarding).

Page 39

VI-MMXII Page 39

9.0 ELECTRONIC SCALES AND LOADCELLS

CAUTION: DO NOT WELD ON EQUIPMENT. Scales must be disconnected from power

source and/or battery before welding to prevent damage to micro-processor and strain gauges.

Observe (4) bolts on each load cell stabilizer bracket. They should move freely. Battery or 12 volt

power supply must have a minimum of 12 volt-15volt for satisfactory operation of scale. SEE

SCALE MANUAL FOR PROPER OPERATION.

Battery terminals, connections must be clean and corrosion free and kept tightened.

Loose connection to power or ground will interfere with scale.

Observe J-Box, load cell cables, and power cords for cuts, hanging loose or pulled too tight at the

terminals and for loose connections. Correct these conditions.

CAUTION: DO NOT EXPOSE OPEN WIRES, J-BOX OR SCALE INSTRUMENTS TO

DIRECT FORCE OF WATER. All entry points are water resistant, but must not be subjected to

direct force of water.

Scale instruments are very dependable, but microprocessors are sensitive to electrical interference.

(I) For stationary mixer operated from commercial power, be sure to confirm that the power

source is stable.

(II) Check to eliminate the power supply as the source of a scale problem. To do this connect

the scale directly to a separate charged 12 volt vehicle battery. If the scale problem goes

away, the power source is the problem.

(III) This method may also be used to trace or isolate many other glitches from unknown

sources.

CAUTION: SCALE REPAIRS ARE BEST ACCOMPLISHED BY TRAINED AND

QUALIFIED SCALE REPAIR PERSONNEL.

CAUTION: ELECTRICAL MOTORS, POWER SUPPLIES, AND CONTROL CABINETS

MUST BE REPAIRED BY QUALIFIED SERVICE ELECTRICANS.

** NOTE: SEE APPENDIX FOR ADDITIONAL INFORMATION

Page 40

VI-MMXII Page 40

10.0 EQUIPMENT OPERATIONS

Pre-Startup Check List (Ensure key is out of ignition and unit is not running)

Before operating your Kirby Mixer, make sure the following have been checked: Take appropriate

action to correct any deficiencies.

Truck Mount

• Check that all guards are in place and secure

• Visually inspect all hydraulic lines for wear, fitting tightness and any leaks

• Check hydraulic fluid level in hydraulic tank

• Visually inspect inside of mixer chamber for loose or missing blades, clear of any

foreign objects. If lined with stainless steel liners, check for wear

• Oil levels on planetary gearbox are at the proper levels

• Hydraulic tank filter gauge reads green

• Charge pump filter glass ball at top reads green

• Front discharge door is closed

• Rear door that it is closed

• Check if hay stops are fully out, or at proper insertion

Trailer Mount

• Check that all guards are in place and secure

• PTO lock collar of the mixer is properly locked into place on the output PTO of the

tractor

• PTO guard is installed, PTO is on and shows no signs of damage

• Hydraulic lines are installed to the tractor’s hydraulic remotes

• Visual inspect inside of mixer chamber for loose or missing blades, clear of any

foreign objects. If lined with stainless steel liners, check for wear

• Oil levels on planetary gearbox are at the proper levels

• Visually inspect for any leaks from gearboxes

• Tires have proper inflation (fill to maximum pressure rating shown on side of tire)

• Front discharge door is closed

• Rear door is closed

• Check if hay stops are fully out, or at proper insertion

Loading/Discharging Instructions

IMPORTANT - Idle engine speed down before engaging the Power Take Off (P.T.O) or engaging

hydraulic augers by switch or T lever. Failure to do so could result in damage to the drive system.

Check operation of the following:

• Front door opens and closes

• Rear door (if equipped) opens and closes

• “Discharge Conveyor” chain turns on and off

• “Conveyor Slide” (if so equipped) slides in and out

• Turn on scales and “0” balance or check procedure appropriate for your scale type and

model (scale owner’s manual)

Page 41

VI-MMXII Page 41

• Trailer mount: ensure that the two speed shifts from high to low and ensure you are in low

gear (slowest auger speed) to mix the ration (see section in this manual on two speed

shifting procedure)