Page 1

Kirby Morgan Air Control System 5

K

I

R

B

Y

M

O

R

G

A

N

D

I

V

E

S

Y

S

T

E

M

S

,

I

n

c

.

Operations and Maintenance Manual

Part # 100-075

KMDSI

United States of America

Telephone (805) 928-7772

Kirby Morgan Air Control System 5, KMACS 5,

Dive Control System-2A, DCS-2A, DCS-3 and DCS-1 are trademarks of KMDSI .

Use of these terms to describe products that are not manufactured by KMDSI is not permitted

Manual prepared by Marine Marketing and Consulting & KMDSI .

1430 Jason Way

Santa Maria, California

Postal Code 93455

Fax (805) 928-0342

© 2003 KMDSI Document # 041112001

Page 2

This page not used

Page 3

Definitions of Signal Words

Used in this Manual

DANGER: This word indicates an imminently hazardous situation, which

if not avoided, will result in death or serious injury.

WARNING: This word indicates a potentially hazardous situation, which

if not avoided, could result in death or serious injury.

CAUTION: This word indicates a potentially hazardous situation, which

if not avoided, may result in minor or moderate injury. It may also be

used to alert against unsafe practices.

Page 4

Warranty Information

KMDSI warrants every new mask, helmet, SCUBA regulator or air control system (KMACS) (each, a Product)

to be free from defects in workmanship for a period of ninety (90) days from the date of purchase from a KMDSI

authorized dealer. This warranty covers all metal, fiberglass, and plastic parts, but does NOT cover rubber parts,

communications components, or head cushions.

Any defect of the product in workmanship or material covered by this warranty discovered within ninety (90)

days from the date of purchase must be promptly communicated in writing to the nearest authorized KMDSI

dealer or (if no such dealer in the buyer’s country) contact KMDSI directly at (805) 928-7772. No Product

returns will be accepted by KMDSI without a returned merchandise authorization (RMA) number from

KMDSI. Upon receipt of the RMA from KMDSI, the buyer should return the defective Product or part, freight

prepaid, to an authorized KMDSI dealer or the KMDSI plant, as directed by the RMA. KMDSI will repair or

replace the Product at no charge, within a reasonable time, as it deems necessary.

This warranty is null and void if:

1) The Product is not registered with KMDSI within ten (10) days of purchase, or

2) The Product has not been properly serviced and/or maintained according to KMDSI factory recommended

procedures described in the manual or Product updates have not been performed as recommended by KMDSI,

or

3) Unauthorized attachments or modifications have been made to the Product, or

4) The Product has been used for purposes other than those for which it was designed, or otherwise has been

abused, misused, or subjected to unusual conditions, or the Productís intended service has been exceeded.

EXCEPT AS SPECIFICALLY PROVIDED HEREIN, THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES FOR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE PRODUCT COVERED

BY THIS WARRANTY IS MARKETED AND SOLD BY KMDSI SOLELY FOR COMMERCIAL OR

INDUSTRIAL USE AND IS NOT A CONSUMER PRODUCT INTENDED FOR PERSONAL, FAMILY,

OR HOUSEHOLD USE.

In purchasing any Product subject to this warranty, the buyer agrees that its sole and exclusive remedy and

KMDSI’s entire obligation in contract, tort, or otherwise under this contract will be repair or replacement at

KMDSI’s option of the Product or any parts which KMDSI determines during the applicable warranty period are

defective in workmanship or material covered by this warranty. All exchanged parts are the property of KMDSI.

The buyer’s exclusive remedy and the KMDSI’s entire liability in contract, tort, or otherwise is the payment by

KMDSI of the buyer’s actual damages up to but not to exceed the amount paid by the buyer for the Product.

In no event shall KMDSI be liable to the buyer for indirect, special, incidental or consequential damages

(including, but not limited to, damages for lost profits, lost sales, loss of business opportunity, or for injury to

persons or property arising out of the use of the Products). Any claim or action for breach of warranty must be

commenced within one year following delivery of the Product to the buyer.

Buyer acknowledges that this warranty is the sole and exclusive warranty of the Product and that it supersedes

any and all oral or written representations and undertakings between KMDSI, its dealers, and the buyer relating

to the Products. This warranty allocates the risks of product failure between KMDSI and the buyer, which

allocation is recognized by both parties and is reflected in the price of the goods. The buyer acknowledges that

it has read this agreement, understands it, and is bound by its terms.

Page 5

Table of Contents

Section Title Page #

1.0 General Information 1

1.1 Definitions 1

1.2 Design Purpose 2

1.3 Specifications 3

1.4 General Description 3

1.4.1 Breathing Air Sub System 4

1.4.2 Principle Operating Features 4

1. Dive Control Panel 4

2. Red Diver Depth Gauge 4

3. Umbilical Pressure Gauge 4

4. White Diver Depth Gauge 4

5. Blue Air Supply Flow Indicator Line 4

6. Orange Air Supply Flow Indicator Line 5

7. Low Pressure Inlet Fitting 5

8. Blue Breathing Air Supply Gauge 6

9. Orange Breathing Air Supply Gauge 6

Section Title Page #

2.3 Connecting the Air Supply 8

2.4 Connecting Diver’s Hoses 9

2.5 Pre-Dive Checklist 10

2.5.1 Testing the L.P. Supply 10

2.5.2 Testing Communications 11

2.5.3 Testing the Pneumo 12

2.6 Preparing the Diver 12

2.7 Dive Supervisor and KMACS Operator 12

2.8 Descent 13

2.9 Diver at Depth 14

2.10 Changing out High Pressure Cylinders 14

2.11 Procedures During the Diver’s Ascent 14

2.12 Decompression 15

2.13 Completion of Diving Operations 15

3.0 Maintenance 16

3.1 Recommended Maintenance 16

10. High Pressure Cylinder Yokes 6

11. Bottom of Case 6

12. Air Supply Selector Valve Handle 6

13. Regulator Adjustment Knob 6

14. Outlet Manifold 7

15. Pneumo Valve Handle, White Diver 7

16. Pneumo Valve Handle, Red Diver 7

17. O-Ring Seal 7

18. Communicator Panel 7

19. Communicator 7

2.0 Operating Instructions 8

2.1 Unpacking the KMACS 5 8

2.2 First Use of KMACS 5 8

3.2 Replacing the Battery 16

4.0 Troubleshooting

17

4.1 General 17

4.2 No Communications 17

4.3 No Pneumo Reading 18

4.4 No Air to the Diver 18

5.0 Appendix 19

5.1 Emergency Procedures 19

5.2 Diver Line Pull Signals 19

5.3 Communications Wiring Schematics 20

5.4 Exploded Views & Parts Listz 20

5.5 Dive Log Master Sheet 24

Page 6

Kirby Morgan Air Control System 5

with no communications.

Kirby Morgan Air Control System 5 with communications.

Page 7

Section 1.0

GENERAL INFORMATION

1.1 DEFINITIONS

The following terms may be unfamiliar to the reader.

They are defined as they relate to this manual and

diving. All parts locations are referenced by LETTER

on the diagram, Figure 5, Page 8.

KMACS 5 : Kirby Morgan Air Control System

5. The Trademark name of the device this manual

describes. The KMACS 5 contains all of the

components necessary to properly control and monitor

surface supplied air dives. Included in the KMACS 5

is a two-way voice communicator for talking between

the KMACS 5 operator and the diver(s), or diver-todiver. The communicator operates in both the two

wire and four wire mode. The KMACS 5 will supply

plenty of air for two surface supplied divers.

KMACS 5 MANUAL

High Pressure (H.P.) Hose: A flexible hose de-

signed to carry a working pressure of gas (or air) of

more than 300 pounds (20.7 bars) per square inch.

The rated working pressure is usually indicated on

the hose and must not be exceeded. The working

pressure of the high pressure hose on the KMACS

5 is 5000 psi (345 bars).

Whip: A hose complete with fittings at each end for

use in hooking up two pieces of deck equipment for

gas (or air) flow. For instances, the hoses and fittings

used to connect the KMACS 5 to the high pressure

tanks are called “high pressure whips.”

H.P.: High pressure. Usually any pressure over 300

psi. (20.7 bars).

Scuba: Self contained underwater breathing apparatus.

SSAir Diving: Surface Supplied Air Diving. Diving

operation where the diver is supplied breathing air by

way of a hose which is part of the diver’s umbilical

from the surface. Usually the source of the breathing

air is a compressor, but compressed air tanks on the

surface can also be used.

Diver’s Umbilical: Several components run together

from the KMACS 5, (Dive Control System 2A) to the

diver. These components are joined together, usually

by tape, forming the umbilical. The most common

components used in the diver’s umbilical are: (A)

a hose through which the breathing air flows to the

diver; (B) a multiconductor wire for communications

transmission; (C) another (smaller) hose which is used

to show the diver’s depth on the pneumofathometer

(see below); (4) a strong line used as a strength member to prevent strain on the other components of the

umbilical. The umbilical should be taped every 10 feet

with colored tape to indicate the length of the hose.

L.P.: Low pressure. Usually any pressure under

300 psi. (20.7 bars).

Pneumofathometer: (pronounced “new-mo-fathometer”) This device measures the diver’s depth.

A small hose, which is part of the diver’s umbilical

runs from the KMACS 5 to the diver. The hose is

open at the diver’s end and attaches with a fitting to

a gauge at the KMACS 5. The gauge is calibrated

in feet and meters of sea water. A valve is attached

between the hose and the gauge so the operator can

use a small amount of breathing air to purge water

from the small hose. When the valve is shut off,

excess air bubbles out of the hose at the diver’s end,

and the air left in the hose will be at a pressure equal

to the pressure of the water column. This is the exact

depth of the diver.

Pneumo: Short for pneumofathometer. Used such

as “pneumo-gauge,” “pneumo -valve”, “pneumohose”, to describe the parts that make up the pneumofathometer subsystem.

Dressed-in: A commercial diver’s suit was originally called a “dress.” Although the name changed

© 2003 KMDSI Document # 041112001

1

Page 8

KMACS 5 MANUAL

to “suit” the term “dressed-in” has remained to

describe putting the suit on. A diver who is “dressedin” has a suit on. The term is also used to describe

a diver who, in addition to his suit, has more, or all

of his/her equipment on.

Bailout Bottle: This is the emergency tank of

breathing gas. “Bailout” which is the familiar term

for parachuting from an airplane, also applies to the

shallow water diver who ditches part of his diving

gear and swims to the surface. The “bailout” bottle

term came from this use.

The bailout bottle is an independent air source connected directly to the diver’s mask or helmet via a

first stage scuba regulator and hose. The first stage

regulator must be equipped with an overpressure

relief valve (Part #200-015). The overpressure

relief valve will vent pressure in the event of a first

stage leak and prevent the low pressure hose from

rupturing, causing a complete loss of the diver’s

bailout supply.

The bailout bottle is worn on the diver’s back,

mounted to a harness. The diver’s umbilical should

be attached to this harness to prevent a direct pull

on the diver’s mask or helmet.

The size/volume of the bailout bottle should be

determined by the diver’s depth, or the distance

required for a direct ascent to the surface. For

deeper dives, or penetration dives inside wrecks

or pipelines, a larger capacity bailout bottle should

be used.

1.2 DESIGN PURPOSE

The Kirby Morgan Dive Control System 5 (KMACS

5) is designed to provide a central control center

for the operator/dive supervisor during a surfacesupplied air dive. Provisions for the control of the

breathing air supply, diver depth monitoring, and

voice communications are all located on a simple

panel. The KMACS 5 is a full service control system

for all Surface Supplied Air diving operations.

The KMACS 5 is fitted with shut off valves on the

diver’s air supply. The shut off valves are designed

to allow air to be shut off on either or both of the

diver’s umbilicals. When the handles of the valves

are vertical the valves are open and air is flowing to

the divers. When the valve handles are horizontal the

valves are shut and the air to the divers umbilicals

is off.

By having total control located at one panel, the

KMACS 5 operator can rapidly respond to the

diver’s needs without leaving the control station.

In a standard commercial SSAir diving operation

the KMACS 5 provides a backup air supply system

which the operator can activate in the event of the

main air supply failure (such as compressor malfunction). This can be accomplished without leaving the

control panel, which allows the operator to inform

the diver and continuously monitor umbilical supply

pressure and depth at the same time.

The compact size of the KMACS 5 usually makes

it possible to locate it at the water entry site, allowing the operator to tend the diver’s umbilical while

maintaining control of the KMACS 5.

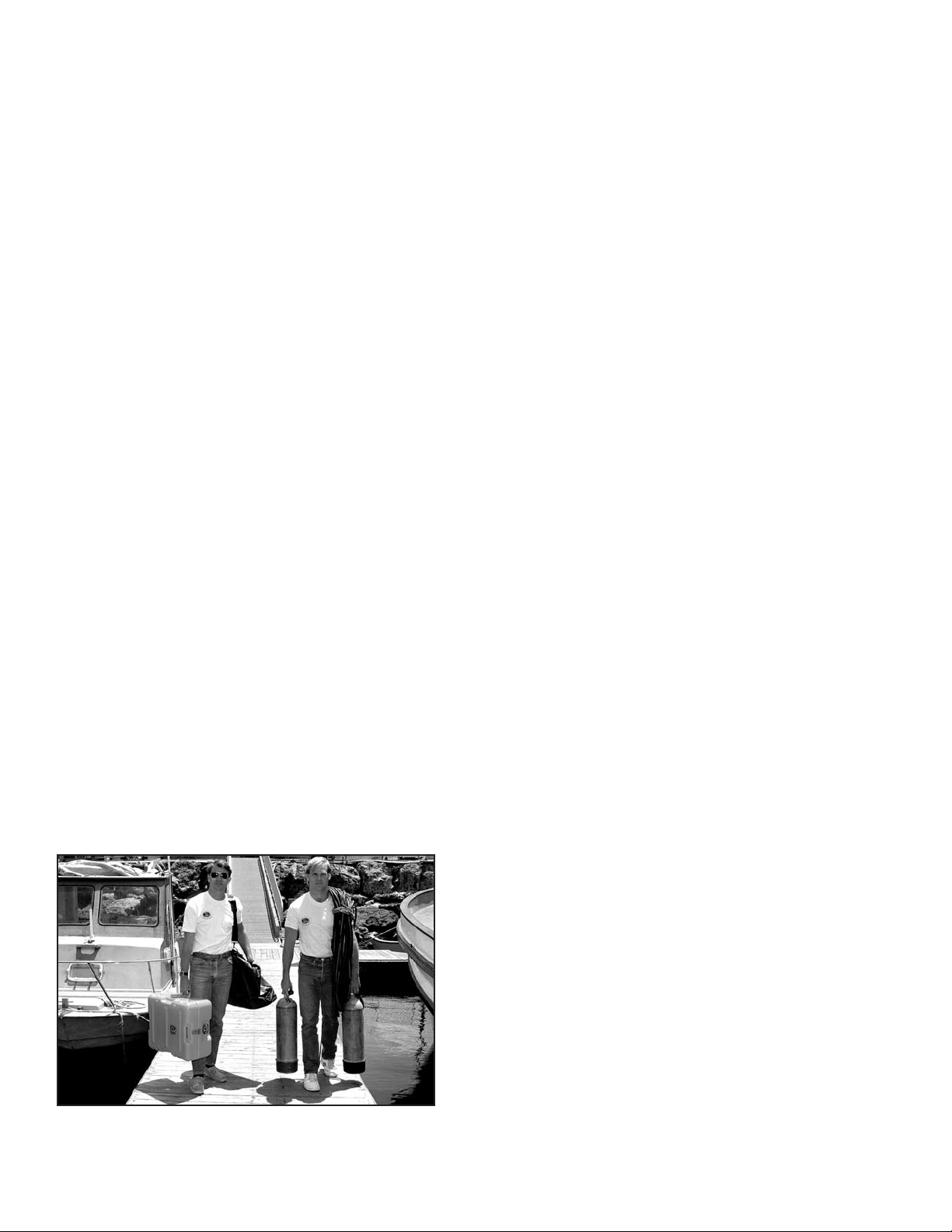

Fig. 1 Divers with all of the gear they need to dive.

2

In addition to its compact size, the ability of the

KMACS 5 to use high pressure air allows SSAir

diving from small boats or remote locations where

transportation and setup of a compressor would be

impractical. Two or more standard scuba bottles can

be used as the breathing air supply.

For example, when commercial divers are working

on an offshore rig, a common SSAir diving job is

the inspection and cleaning of a propeller on a crew

boat. This job can be performed easily and simply

with the KMACS 5, a couple of scuba bottles, a full

face mask or helmet, and an umbilical. Transporta-

© 2003 KMDSI Document # 041112001

Page 9

tion to the job site is simple and a large surface

support vessel is not needed. At the dive site, full

communications, backup breathing supply, pressure

readouts, and depth monitoring are provided by the

KMACS 5.

This is one of many situations where the KMACS 5

can be used to provide the safe and efficient operation of SSAir diving.

KMACS 5 MANUAL

CAUTION: Although the high pressure

gauges on the KMACS 5 are rated to 5000

psi (345 bars), this is a safety precaution

only. The regulator on the KMACS 5 is not

designed to operate at pressures greater

than 4500 psi (300 bars).

Umbilical Pressure Range: 115-225 pounds per

square inch. (8-15.5 bars)

1.3 SPECIFICATIONS

Use: For SSAir diving only. Pure oxygen MUST

NOT be used. Compressed air from high pressure

tanks (scuba or other types of compressed air tanks),

or from a compressor should be the only supply to

the KMACS 5

CAUTION: Pure oxygen is a potential fire

hazard, its use can lead to explosion of

the KMACS 5. Pure oxygen also presents a

physiological hazard to the diver.

Outer Dimensions: Length = 21 inches

Width = 10 1/2 inches

Height= 17 1/2 inches

Weight: 54 pounds. (24.5 kilos)

Shipping Weight: 60 pounds. (27 kilos)

Regulator Output: 40 SCFM at 2500 psi (172 bars)

supply pressure with 150 psi (10.3 bars) delivery

pressure.

Relief Valve: Set at 300 psi (20.7 bars).

Pneumofathometer Range: 0-250 FSW (feet of

sea water) (0-76 meters).

Communicator: 4 wire system. Can also be used

in 2 wire mode.

Battery Type: Rechargeable, 12 volt system.

Battery Performance: 20 hours of continuous use

between charges in 4 wire mode.

Charger: Will accept external 12 volt source.

Communicator Power Output: 8 watts.

Communicator Frequency Response: 600 to

12,000 HZ.

Recommended Maximum Dive Support Depth:

130 fsw (feet of sea water) (40 meters).

CAUTION: Decompression and other human

limits must be observed. Decompression

diving should not be conducted with the

KMACS 5 unless a properly equipped

recompressi on chamber facilit y with

oxygen is immediately available at the

dive site. In-water decompression is not

recommended.

High Pressure Supply Pressure Maximum: 4500

pounds per square inch. (300 bars)

Low Pressure Supply Pressure Maximum: 225

pounds per square inch. (15.5 bars)

Remote Operation Capability: Yes, with optional

unit.

Direct Recording Capability: Yes.

1.4 GENERAL

DESCRIPTION

Only equipment certified and tested according to EN

250/E DIN 58 642 may be used with the KMACS

5 when conducting diving operations in European

EC compliant countries.

The KMACS 5 components are housed in a durable

polyethylene case. However, caution should be used

in transporting the KMACS 5. Rough handling will

rarely cause damage to the case, but it is possible

to damage the calibrated pneumo gauges and/or

© 2003 KMDSI Document # 041112001

3

Page 10

KMACS 5 MANUAL

the electronic components. The KMACS 5 should

be treated as you would any expensive life support

equipment.

1.4.1 BREATHING AIR

SUBSYSTEM

The diver’s breathing air subsystem starts with the

supply tank yokes (K) and connects to the diver’s

supply manifold. The high pressure hoses with the

yokes are stored for transit by connecting them to

the posts on the panel inside the lid of the KMACS

5. The knurled knobs on the yokes should be tightened until just snug. Excessive force should not be

applied.

1.4.2 PRINCIPLE

OPERATING FEATURES

l. DIVE CONTROL PANEL (A)

The panel is the main frame to which the functional

components are mounted. In addition, the component names and some instructions are on the panel.

The blue and orange lines (K, Q) on the panel

represent the flow paths of supply air from the two

high pressure hoses/yokes (S).

2. RED DIVER DEPTH GAUGE (C)

(PNEUMOFATHOMETER)

4. WHITE DIVER DEPTH GAUGE (P)

(PNEUMOFATHOMETER)

This gauge indicates the “white” diver depth. The

white diver pneumo valve knob (O), is turned to

supply a small volume of air to the small pneumohose that is part of the diver’s umbilical. The gauge

reads the pressure of the air in the pneumo-hose. This

pressure, measured in feet (or meters) of sea water,

equals the water pressure at the diver’s depth.

5. BLUE AIR SUPPLY FLOW INDICATOR

LINE

The “BLUE” air supply flow indicator line (Q) indicates the flow path of breathing air from entry into

the KMACS 5 to exit to the diver’s umbilical(s) at

the fittings on the manifold (G). There are two high

pressure whips which are color coded BLUE and

ORANGE.

Starting from the high pressure air tank, the BLUE

air supply flows through the whip into the KMACS 5.

Following the BLUE flow indicator line (Q) it shows

the flow to the BLUE Breathing Air Supply Pressure

Gauge (M), then to the Breathing Air Supply Selector Valve which is controlled by the Breathing Air

Selector Valve Handle (I). The Selector Handle (I)

must be turned all the way “UP” until it stops for the

BLUE supply. This places the selector valve handle

in line with the flow path indicating the “BLUE” air

supply (Q). The ORANGE supply is off when the

Selector Handle is in the up position.

This gauge indicates the “red” diver depth. The red

diver pneumo valve knob (D), is turned to supply a

small volume of air to the small pneumo hose that

is part of the diver’s umbilical. The gauge reads

the pressure of the air in the pneumo hose. This

pressure, measured in feet (or meters) of sea water,

equals the water pressure at the diver’s depth.

3. UMBILICAL PRESSURE GAUGE (B)

This gauge (B) is connected to the low pressure air

supply system that supplies both umbilical fittings.

It indicates the breathing air pressure that is in both

the “red” and “white” diver umbilicals. When the air

supply is from high pressure tanks (such as scuba

tanks) the umbilical hose pressure can be varied by

turning the regulator adjustment knob (H)

4

CAUTION: When using H.P. air, the selector

handle must be turned up until it stops for

BLUE supply or down until it stops for Orange

supply. Never allow the selector handle to

stay in the marked “H.P. OFF ZONE”. Both

high pressure air supplies are off in the

yellow striped H.P. OFF ZONE”.

After flowing through the Selector Valve the BLUE

air supply enters the Breathing Air Supply Regulator

(H) which reduces the high pressure breathing air

to an adjustable range between 115-225 pounds per

square inch (psi) (8-15.5 bars). The BLUE air supply then goes to both diver’s umbilicals through the

fittings on the manifold (G).

© 2003 KMDSI Document # 041112001

Page 11

6. ORANGE AIR SUPPLY FLOW

INDICATOR LINES

The “ORANGE” air supply flow indicator line

indicates the flow path of breathing air from entry

into the KMACS 5 to exit to the diver’s umbilical(s)

at the fittings on the manifold (G). The second high

pressure whip is color coded ORANGE.

KMACS 5 MANUAL

After flowing through the Selector Valve the ORANGE air supply enters the Breathing Air Supply

Regulator (H) which reduces the high pressure

breathing air to an adjustable range between l15-225

psi (8-15.5 bars). Then the ORANGE air supply goes

to both diver’s umbilicals through the fittings on the

manifold (G).

Starting from the high pressure air tank, the OR-

7. LOW PRESSURE INLET FITTING (N)

ANGE air supply flows through the whip into the

KMACS 5. Following the ORANGE flow indicator line (K) it shows the flow to the ORANGE

Breathing Air Supply Pressure Gauge (L), then

to the Breathing Air Supply Selector Valve which

is controlled by the Breathing Air Selector Valve

Handle (H). The Selector Handle must be all the

way “DOWN” until it stops for the ORANGE

supply. The BLUE supply is off when the Selector

Handle is in the down position.

The low pressure inlet fitting is positioned between

the connections for the two H.P. supply hoses. It

is marked by the arrow containing the words “L.P.

Supply”. Low pressure supply breathing air, usually

from a compressor (with volume tank) is supplied

through a whip (low pressure hose and fittings) that

attaches here. When the low pressure supply is the

only air source, the supply pressure will be indicated

on the umbilical pressure gauge (B). In the low pressure supply mode, the selector/valve handle will he

positioned in the H.P. OFF ZONE.

CAUTION: When using H.P. air, the selector handle must be turned up until it stops for BLUE supply

or down until it stops for ORANGE supply. Never allow the selector handle to stay in the marked “H.P.

OFF ZONE”. Both high pressure air supplies are off in the yellow striped H.P. OFF ZONE”.

A Dive Control panel

G

B

H

V

U

T

A

S

R

Q

P

O

N

I

J

K

L

M

B Umbilical Pressure

C Red Diver Depth Gauge

D Pneumo Valve Handle, Red

E Divers Umbilical Breathing Hose Attachment Fittings

F Pneumofathometer Hose Attachment Fittings

G Outlet Manifold

H Regulator Adjustment Knob

I Breathing Air Supply Selector Valve Handle

J Case

K Orange Air Supply Flow Line

L Orange Breathing Air Supply Gauge

M Blue Breathing Air Supply Gauge

N Low Pressure Inlet Fitting

O Pneumo Valve Handle, White

P White Diver Depth Gauge

Q Blue Air Supply Flow Line

R Communicator

S Yokes w/DIN Fittings for H.P. Cylinder Attachment

T Access door for storage compartment.

U O-Ring Seal

V Communicator Panel

Fig. 2

D

C

E

F

© 2003 KMDSI Document # 041112001

5

Page 12

KMACS 5 MANUAL

Blue Air Supply

Flow Path Indicator Line

Blue Air Supply Whip

Orange Air Supply Whip

Orange Air Supply

Flow Path Indicator Line

Fig. 3 Air flow paths from the H.P. cylinders.

8. BLUE BREATHING AIR SUPPLY

PRESSURE GAUGE (M)

The Blue pressure gauge (M) indicates the pressure remaining in the “BLUE” high pressure tank.

(NOTE: If two divers are supplied by the KMACS 5

both divers will be breathing from the same selected

high pressure supply).

half of the case (J). The top half of the case contains

the communicator panel with the yoke blocks and

the communicator if there are communications. If

there are no communications there are only the yoke

blocks. ( see picture in front of manual). The top is

not designed to be removed.

12. BREATHING AIR SUPPLY SELECTOR

VALVE HANDLE (I)

This handle (I) controls the two position Breathing

Air Supply Selector Valve and allows uninterrupted

diving operations while full air supply tanks replace

expended tanks. The selector valve controls ONLY

the high pressure air supply. It is NOT possible

to shut off any low pressure supply connected to

the low pressure inlet fitting (N), at the KMACS 5

itself.

CAUTION: When using H.P. air, the selector

handle must be turned up until it stops

for BLUE supply or down until it stops for

ORANGE supply. Never allow the selector

handle to stay in the marked “H.P. OFF

ZONE”. Both high pressure air supplies are

off in the yellow striped H.P. OFF ZONE”.

9. ORANGE BREATHING AIR SUPPLY

PRESSURE GAUGE (L)

The Orange pressure gauge (L) indicates the pressure remaining in the “ORANGE” high pressure

tank. (NOTE: If two divers are supplied by the

KMACS 5, both divers will be breathing from the

same selected high pressure supply).

10. YOKES FOR HIGH PRESSURE

CYLINDER ATTACHMENT (S)

The yoke fittings (S) provided have standard U.S.

scuba cylinder attachments as well as Din Fittings.

Each yoke has a bleeder valve to vent the remainder of the pressure in the whip when changing out

scuba bottles. The yokes attach to posts mounted

on the panel in the lid of the KMACS 5 for storage

and transport.

11. CASE (J)

When changing out the H.P. air supply cylinders,

always observe the diver’s umbilical pressure gauge

(B) for any sudden fall in pressure. Should this occur,

it indicates that the cylinder in use has mistakenly

been turned off. If so, immediately turn the cylinder

back on and move the selector valve handle to select

the full cylinder and change out bottles.

Due to the construction of the selector valve, it is

impossible for gas to back-flow from one cylinder

to the other.

The Dive Control panel (A) is attached to the bottom

6

© 2003 KMDSI Document # 041112001

Page 13

KMACS 5 MANUAL

13. REGULATOR ADJUSTMENT KNOB

FOR UMBILICAL PRESSURE (H)

The regulator Adjustment Knob (H) allows the

operator to adjust the umbilical pressure within a

range of 115 psi to 225 psi (8-15.5 bars). Incoming

high pressure air from the ‘ORANGE” or “BLUE”

supply is reduced by the internal regulator. The

Adjustment Knob controls the regulator. Turning the

Knob clockwise decreases the umbilical pressure;

counterclockwise increases it.

14. OUTLET MANIFOLD INCLUDING

DIVER’S UMBILICAL FITTINGS (G)

The “WHITE DIVER” and “RED DIVER” air

supply hoses are connected to the KMACS 5 at the

manifold (G). The fittings coming out of the KMACS

5 are male #6 JIC (3/8”, 37°) flared fittings. The

diver’s air supply hoses must have matching female

#6 JIC flared fittings with swivel nuts.

The “WHITE DIVER” and “RED DIVER” pneumofathometer hoses are also connected to the KMACS

5 at the manifold (G). The fittings coming out of

the KMACS 5 are male #4 JIC ( 1/4”, 37°) flared

fittings. The diver’s pneumofathometer hoses must

have matching female #4 JIC (1/4”, 37°) flared fittings with swivel nuts.

15. PNEUMO VALVE KNOB, WHITE DIVER

(O)

The Pneumo Valve Knob, White Diver turns on and

off the air supply to the “WHITE” pneumofathometer

system.

17. O-RING SEAL (U)

The O-ring seal helps keep dust and moisture out of

the KMACS 5 when the case is closed. The O-ring

seal is not pressure proof, however, and the KMACS

5 case will flood if the box is submerged.

18. COMMUNICATOR PANEL (V)

The diver’s electronic communicator (R) is attached

to the communicator panel. The battery for the communicator is located behind this panel.

19. COMMUNICATOR (R)

The MK3-KMDSI communicator is a standard open

circuit/round robin diver’s communicator, which

functions like a telephone. It can also be used as

a 2 wire, “push-to-talk” system. It is connected to

the diver’s umbilicals by “banana plug” fittings on

the communicator. The communicator is mounted

on the communicator panel. You should read and

understand the accompanying radio operations

manual supplied with the unit before using the

unit. Improper use or connections could damage

the radio.

CAUTION: Never connect the charger during

a dive or when anyone is in contact with

connected equipment. Although electrical

shock danger is remote, connection of the

recharging cord should only be done when

the KMACS 5 is not in use.

16. PNEUMO VALVE KNOB, RED DIVER

(D)

The Pneumo Valve Knob, Red Diver turns on and

off the air supply to the “RED” pneumofathometer

system.

© 2003 KMDSI Document # 041112001

7

Page 14

KMACS 5 MANUAL

OPERATING INSTRUCTIONS

Section 2.0

2.1 UNPACKING THE KMACS 5

When you first receive your KMACS 5, carefully

unpack it and examine it for any damage that may

have occurred during shipment. Be sure to complete

the enclosed warranty card and return it to KMDSI

immediately. No warranty claims will be honored

without a satisfactorily completed warranty card on

file at KMDSI.

Visually check the KMACS 5 to ensure that it has

not been damaged in transport.

2.2 FIRST USE OF THE KMACS 5

Place the Dive Control System on a firm surface.

The KMDSI logo should be right side up. Release

the latches and lift up the lid to expose the panels.

When using the KMACS 5 aboard a vessel subject to

waves or swell be sure to tie the KMACS 5 securely

in position so that it doesn’t fall. Thread a piece of

line through the handles and fasten the ends to fittings on the boat. Tie back the lid of the KMACS 5

as well to prevent damage or injury.

2.3 CONNECTING THE AIR SUPPLY

Loosen the knurled knobs which connect the yokes

to their storage posts in the KMACS 5 and remove

the yokes (S) from the blocks. Attach each yoke

to a high pressure cylinder as you would connect

a scuba regulator to a tank. The knobs on the yoke

should be screwed down finger tight. Do not apply

Fig. 5 Note the line which passes through the handle of the

KMACS 5 and is secured to the rail to prevent the KMACS 5

from moving about.

8

Fig. 6 Connecting a scuba air supply to the KMACS 5.

© 2003 KMDSI Document # 041112001

Page 15

KMACS 5 MANUAL

excessive force to the knobs; air pressure from the

tanks will create a good seal. Be sure the bleed valve

on each yoke is in the closed position. Do not turn

the cylinders on at this time.

Prior to connecting the low pressure hose to the

KMACS 5, the deck whip should be flushed with air

to make sure no foreign matter is in the hose. Connect the deck whip to the low pressure compressor

and while firmly holding the end of the hose start

the compressor and flow air through the deck whip

for at least one minute. Attach the low pressure hose

to the low pressure inlet fitting (N) and screw the

fitting down finger tight. While using one wrench

to hold the low pressure inlet fitting tighten the hose

fitting with a second wrench. Do not use excessive

force as this will only damage the fitting and cause

it to leak.

2.4 CONNECTING DIVER’S HOSES

TO THE KMACS 5

Each diver’s umbilical should be color coded with

plastic tape to identify each individual hose. This

action will not only serve to make it easier to connect

the hoses, but will also serve to differentiate between

hoses for purposes of inspection or repair.

Fig. 7 Always use the right size wrench to connect the hoses

to the KMACS 5.

Check the function of the selector handle to ensure

correct operation.

If available, a low pressure compressor should be

used as the primary air supply and scuba cylinders

should be used as a backup, or reserve air source.

CAUTION: Low pressure compressors used

for breathing air should be specifically

designed for diving. Paint compressors

or similar equipment are unacceptable for

diving applications. (Contact KMDSI for a

list of equipment manufacturers who supply

compressors with breathing quality air).

DANGER: If a low pressure compressor

is used, the intake must be at a sufficient

distance from and upwind of the exhaust.

If exhaust gas is sucked into the intake,

the diver will suffer from carbon monoxide

poisoning. This can be fatal.

© 2003 KMDSI Document # 041112001

A standby diver should always be equipped and

ready to go to the diver’s aid whenever a surface

supplied diver is working in the water. Generally,

it is not necessary for more than one diver to be in

the water at a given time when using surface supplied gear. However, a standby diver is considered

essential for safe, surface supplied operations. The

standby diver can be either a scuba diver or another

hose supplied diver since the KMACS 5 provides

enough air for two hose supplied divers. In contaminated water diving operations, however, both divers

must be equally equipped with a vulcanized rubber

dry suit, dry gloves, and Kirby Morgan dive helmet

equipped with either a double exhaust system or the

new TriValve™ exhaust system.

CAUTION: Contaminated water diving

operations are very hazardous. They should

not be attempted without specialized

training, procedures, and equipment.

Remove the protective caps from the outlets of the

manifold (G) on the console. Connect the diver’s

umbilical hose fittings (air supply hose and pneumo)

to the KMACS 5. Remove the end caps from the

hoses themselves and while firmly holding the end

of the hose, blow out the lines before connecting the

9

Page 16

KMACS 5 MANUAL

hoses to the mask or helmet, (refer to the manual

for the mask or helmet for the proper connection

procedures for your life support equipment). This

action will prevent any foreign matter from entering

the helmet or mask breathing system. Once the hose

is blown out, immediately connect the fitting on the

hose to the fitting on the mask or helmet.

Connect the communications portion of the diver’s

umbilical to the communications fittings on the

communicator and to the mask or helmet. Be sure

the proper connection is made with the right communications line for each diver. The wires in the

diver’s umbilical should be marked so it is easy to

identify which plug connects to the earphone terminals and which plug connects to the microphone

terminals.

2.5 PRE-DIVE CHECK

Prior to EVERY dive, the following should be

checked:

With the free flow and demand regulator on the

mask/helmet(s) shut off, turn on the air supply at

each of the air cylinders. During operation with

scuba bottles as the main supply, the selector valve

handle must be FULLY up or FULLY down. Fully

up turns the “BLUE” supply on and the “ORANGE”

supply off. Fully down turns the “ORANGE” supply on and the “BLUE” supply off.

umbilical pressure is always 150 psi (10.3 bars) over

the pressure at the diver’s depth. Consult the table

below for approximate pressure settings.

TABLE 1

Suggested Regulator settings for the KMACS 5

Depth - fsw Pressure Optimal Minimum

0’ 14.7 psia 150 psig 150 psig

33’ 29.4 psia 165 psig 150 psig

66’ 44.1 psia 180 psig 150 psig

99’ 58.8 psia 195 psig 160 psig

132’ 73.5 psia 210 psig 175 psig

165’ 88.2 psia 225 psig 190 psig

198’ 102.9 psia 225 psig 205 psig

TABLE 1, Metric

Suggested Regulator settings for the KMACS 5

Depth-Meters Pressure Optimal Minimum

0 1 bar 10.3 bars 10.3 bars

10 2 bars 11.4 bars 10.3 bars

20 3 bars 12.4 bars 10.3 bars

30 4 bars 13.4 bars 11.0 bars

40 5 bars 14.5 bars 12.1 bars

50 6 bars 15.5 bars 13.1 bars

60 7 bars 15.5 bars 14.1 bars

Note the air pressure in each cylinder by reading the

gauges (L,M). The low pressure supply should be

switched “OFF” at the source at this time. A check

valve in the low pressure system prevents back flow

to the compressor.

Both cylinders should be full prior to diving. Load

the regulator on the KMACS 5 using the regulator

adjustment knob (H). Observe the umbilical hose

pressure (B) which should be set at 150 psi (10.3

bars) over top side pressure, or 165 psi (11.5 bars)

The regulator used in the KMACS 5 is a non-venting regulator. If the regulator has been left set at a

higher pressure setting than is presently desired,

the operator must turn the regulator adjustment

knob (H) clockwise and vent air from the system

by bleeding either the pneumo system or diver’s

breathing apparatus.

As the diver descends, the KMACS 5 operator

should increase the regulator setting so that the

10

2.5.1 TESTING L.P. SUPPLY

With the air on at the bottles and the communications

switched on, check the regulator function. The diver

should insert his face in the mask/helmet and take

several breaths to test the demand regulator.

To test the low pressure supply, place the selector

valve handle (I) in the “H.P. OFF” zone and the

console will be running off the low pressure supply

only. Observe the umbilical pressure gauge (B). As

the compressor cycles, the gauge will rise and fall as

the compressor’s volume tank fills and empties. The

maximum pressure for the L.P. inlet should be 225

psi. Again, check the mask/helmet function which

will also confirm the low pressure supply routing.

© 2003 KMDSI Document # 041112001

Page 17

2.5.2 TESTING COMMUNICATIONS

Test the communications between the diver and the

KMACS 5. With the communicator (R) switched

on, turn the speaker switch to “on” and adjust the

volume to a comfortable level for both the diver

and the KMACS 5 operator. In the 2 wire mode,

the communicator functions similarly to a citizens

band radio; i.e., the KMACS 5 operator must depress the push to talk switch to speak to the diver.

In the 4 wire mode, the communicator functions

like a telephone conference call; i.e., everyone on

the line can hear and speak to everyone else. In

either mode, for the diver to talk top side, it is only

necessary for him to speak into the oral/nasal microphone in his mask or helmet. If two divers will

be working together, test the cross-talk functions

at this time as well.

To extend the life of the battery, it is recommended

that the communications be used in the 4 wire mode.

Operation as a 2 wire system uses relays inside the

unit which will cause a higher battery drain.

CAUTION: In the 2 wire mode, when the

push-to-talk switch is depressed, the

KMACS 5 operator should keep all of his

communications short (10-15 seconds) at

any one time. This allows the diver to call

for assistance if necessary.

KMACS 5 MANUAL

Unplug the earphone connectors on the diver’s umbilical from the communicator and reinstall them in

the connectors attached to the plugs for the microphone. This will change the communicator to a 2

wire system. Test this system and adjust volumes.

If there are no communications, recheck all of the

connections to ensure they are tight at each junction.

If the KMACS 5 has been operating in a coastal environment, look for corrosion on the top side connectors which may interfere with the communications.

If corrosion is evident, disassemble the connectors,

clean, and retest. If corrosion is heavy, replace the

top side connectors.

Substitute other masks or umbilicals to test for

failures in the microphones or umbilical. Substitute

one piece of new gear at a time to track the fault

down. If the fault is in the mask or helmet, replace

the earphones or microphones as needed.

If the fault is in the umbilical, disconnect the umbilical and carefully inspect its length for damage. Look

for obvious nicks or cuts.

If there is physical damage to the outside of the

communications wire there probably is a break on

the inside, too. Test the continuity of the wire end-to

end with a volt-ohmmeter.

Plug the earphone connectors on the diver’s umbilical into the earphone jacks on the communicator.

Plug the microphone connectors on the umbilical

into the microphone jacks on the communicator.

This will create a 4 wire system/round robin system.

Test the system and adjust all volume controls.

Fig. 8 Preliminary testing of the umbilical with a volt-ohm

meter to check for continuity.

© 2003 KMDSI Document # 041112001

Uncoil the umbilical and lay it out flat with the two

ends close to each other. Set the volt-ohmmeter to

resistance (ohms) and hold one probe to one prong

on an umbilical connector plug and touch the other

probe from the meter to the wires (or connector) at

the opposite end of the diver’s umbilical. Upon locating the other end of the same wire, the meter should

indicate zero resistance, i.e., there is a complete,

uninterrupted circuit. If touching none of the wires

at the other end of the umbilical produces a zero

reading and all readings are infinity (∼), this indicates

a complete break in the wire. If the reading is somewhere between zero and infinity, and changes as the

umbilical is moved, this indicates a partial break, and

communications will be intermittent. In either case,

a waterproof splice must be made in the wire.

11

Page 18

KMACS 5 MANUAL

2.5.3 TESTING THE PNEUMO

The pneumo supply may be tested in either the high

pressure supply mode or the low pressure supply

mode. To test the pneumo, select either mode and

pinch the open end (diver’s end) of the red diver

pneumo hose. With the hose crimped tightly shut,

slowly open the red pneumo valve (D) momentarily,

1/4 turn, and observe the needle’s response on the

red diver depth gauge (C).

2.6 PREPARING THE DIVER

The diver should be dressed in with the appropriate

exposure suit for the local water temperature. The

diver should be equipped with a harness to provide

an attachment point for his umbilical. By attaching the umbilical to the harness, the possibility of

a direct pull on the diver’s helmet or mask will be

eliminated.

A bailout bottle should be mounted on the diver’s

harness. Always dive with a bailout bottle, no matter

how shallow the dive. The danger of entanglement

is always present and a bailout bottle will give the

diver that few extra minutes to free himself in the

event he becomes hung up on fishing line, wire, or

other submerged objects.

The bailout regulator should be equipped with a

quick disconnect whip to make it easier to dress the

diver in and out. In addition, the bailout regulator

should also be equipped with an over pressure relief

valve (Part #200-015). This will permit the regulator

to bleed off and not rupture the low pressure hose

connecting it to the diver’s bailout or emergency

valve, should the first stage develop a leak.

Fig. 9 Carefully test the pneumo prior to every dive.

CAUTION: Do not “peg” the needle on

the pneumofathometer with a maximum

reading. A test of pressure equal to 50 feet

(15 meters) on the gauge is satisfactory to

ensure correct operation.

Close the valve after observing correct operation

and release the end of the pneumo hose. The gauge

needle should return to zero. Repeat the above procedure for the white diver.

With the hose attached to the harness, tuck the

pneumo hose under the harness at the diver’s chest.

This serves two purposes: 1) it provides instant

access in the event the pneumo is to be used as an

alternative air supply; 2) gas absorption and elimination of nitrogen is considered to occur at the diver’s

chest level.

When diving under a potential decompression situation, a depth gauge or dive computer should be worn

by the diver as a backup system. If decompression

is anticipated there must be enough air on hand for

the diver to complete the dive and the decompression obligation.

2.7 THE DIVE SUPERVISOR

AND THE KMACS 5 OPERATOR

During the diving operation, one person should

always be in charge to avoid confusion. Generally,

this should be the most senior diver, by virtue of his

diving experience.

12

© 2003 KMDSI Document # 041112001

Page 19

The dive supervisor may not always be the KMACS

5 operator. The dive supervisor may want or need

the freedom to direct the entire operation including the tenders and other personnel. As such, he is

responsible for making decisions regarding diving

conditions and safety. However, the KMACS 5

operator must always be an experienced diver who

understands the diver’s needs and has the diver’s

best interests always in mind.

CAUTION: The KMACS 5 operator must not

leave the dive control system unattended

while the diver is in the water. The KMACS

5 operator is directly responsible for the

diver’s safety and well being.

The diver must follow the KMACS 5 operator’s

directions in regards to depth and time. The diver

can NOT run the dive from the bottom. Thus, when

the dive supervisor himself is required to dive he

should relinquish control to the next most senior

diver remaining top side.

KMACS 5 MANUAL

2.8 DESCENT

Upon entering the water, the diver should immediately recheck communications with top side and

ensure that his mask or helmet is working correctly.

When he/she is ready to descend he should notify

the KMACS 5 operator that he is, “Leaving the

surface.”

Both the diver and tender should communicate in a

normal tone of voice. It should not be necessary for

either person to shout to be heard. Although the quality of the communications will usually be excellent,

not all divers speak clearly. The KMACS 5 operator

should listen carefully at all times to what the diver

is saying.

Once the diver has entered the water, monitor his

descent rate using the pneumo valve (D,O) and gauge

(C,P). The diver’s descent rate should not exceed 75

feet (23 meters) per minute.

As the diver descends, the KMACS 5 operator should

adjust the regulator (H) on the KMACS 5 to provide

150 psi (10.3 bars) over the pressure at the diver’s

depth at all times. This provides the best breathing

performance from the diver’s demand regulator.

© 2003 KMDSI Document # 041112001

Fig. 10 KMACS 5 operator taking a reading with the

pneumo knob. The knob should be turned very slowly.

It is essential that the KMACS 5 operator keep pace

with the diver’s descent and not lag behind in his

depth monitoring. If this occurs, it is possible for

the diver to exceed his maximum planned depth

without the KMACS 5 operator being aware this

has occurred.

To operate the pneumo, turn the knob for the appropriate diver, counter clockwise, until the indicator needle on the depth gauge starts moving. When

the depth gauge for the individual diver indicates a

depth that is known to be deeper than the diver, the

knob is turned clockwise until it is off. The indicator

needle on the depth gauge will move shallower as

the air bubbles leave the open end of the pneumo

hose at the diver. When the needle stops, that is the

diver’s actual depth.

Most umbilicals are made up with the diver end of

the pneumo hose having about two feet (.6 meters)

of loose hose. The diver can use this hose as an air

supply for inflating lift bags or for taking an exact

13

Page 20

KMACS 5 MANUAL

reading of the bottom depth. In an emergency, the

pneumo air can be used as a breathing air supply

for a diver. The diver tells the KMACS 5 operator

to “Turn on the pneumo-air...”, then inserts the hose

into the mask or helmet. When using the pneumo in

this mode the air pressure should be regulated by

the KMACS 5 operator to be slightly greater than

the diver’s depth. For example, if the diver is at 100

feet (30 meters), the pneumo should be opened until

the gauge reads a depth of 110 feet (33 meters), so

that a positive pressure exists.

The diver should practice using the pneumo as an

alternative air source under controlled conditions in

shallow water. The pneumo hose should be bubbling

when it is inserted in the diver’s mask, otherwise the

diver will receive a blast of water when the pneumo

is first turned on.

2.9 DIVER AT DEPTH

Once the diver reaches the bottom, or his maximum planned depth, the diver should inform the

KMACS 5 operator that he is, “On the bottom.” At

this time, the KMACS 5 operator should ensure that

he gets an accurate depth reading. The KMACS 5

operator should inform the diver that he is “Taking a

pneumo...”, when he opens the pneumo purge valve.

The diver should observe the end of the pneumo

hose and immediately inform top side that, “He has

bubbles...”. Once the diver has a flow of bubbles at

the end of the hose, the pneumo valve (D,O) should

be closed immediately.

Should the diver move deeper at any time during

his dive he must inform the KMACS 5 operator

and another pneumo should be taken for a new

maximum depth reading. If the KMACS 5 operator

knows that the diver is moving over an uneven bottom he should periodically take additional pneumo

readings to ensure that the diver has not accidentally

gone deeper and neglected to notify top side. Keep

in mind, however, that every pneumo reading does

use some air. If high pressure air is the air source

and the dive is deep, or the diver is working hard,

pneumo readings should be taken as sparingly as

possible.

2.10 CHANGING OUT HIGH PRESSURE

CYLINDERS

The KMACS 5 operator should continuously monitor the diver’s air supply at the two high pressure

gauges (L,M) when diving with high pressure air as

the primary supply. When the initial supply source

pressure drops to between 300 and 500 psi (20.7 and

34.5 bars), depending upon depth, the diver should

be switched over to the second air source using the

selector valve handle (I). While the diver is breathing

off the secondary source a fresh cylinder should be

put on line immediately.

To change out high pressure cylinders, first close

the cylinder valve on the tank which is low. Once

the valve is closed, open the bleeder valve on the

yoke (S) and allow the pressure to bleed from the

line. The high pressure whips are color coded to help

the KMACS 5 operator to ensure he is selecting the

correct one. Always observe the umbilical pressure

gauge (B) carefully during this procedure. If the

KMACS 5 operator is not careful he may accidentally turn off the high pressure cylinder supplying

the diver’s breathing air. If the umbilical pressure

gauge (B) needle starts to “fall”, turn the cylinder

back on immediately and double check to ensure

the correct cylinder is being changed.

When the high pressure whip is empty, unscrew the

knurled knob on the yoke (S) and attach the yoke

to a fresh cylinder. Tighten the yoke knob finger

tight, close the bleeder valve, and slowly open the

cylinder tank valve. Read the new pressure on the

appropriate gauge (L,M).

2.11 PROCEDURES DURING THE

DIVER’S ASCENT

At the end of the dive, the diver should prepare

to leave bottom upon orders from the KMACS 5

operator. The KMACS 5 operator must carefully

note the diver’s depth and time on the dive log. The

KMACS 5 operator is responsible for monitoring the

diver’s ascent rate which should not exceed 60 feet

(18 meters) per minute, or slower if a dive computer

is being used to monitor decompression/no decompression status. The diver should not leave the bottom until he is instructed to do so by the KMACS 5

operator. At the start of the diver’s ascent he should

14

© 2003 KMDSI Document # 041112001

Page 21

KMACS 5 MANUAL

inform top side that he is, “Leaving the bottom.” The

KMACS 5 operator should carefully note the time in

the dive log. The KMACS 5 operator must monitor

the diver’s rate of ascent carefully, observing his

watch and the pneumo gauge (C,P) . There is no need

to pneumo the diver as he ascends because the air in

the pneumo hose will automatically expand and vent

the hose as the diver approaches the surface.

2.12 DECOMPRESSION

If the diver has decompression stop(s) required as a

result of his dive, slow the diver’s ascent as he approaches his first stop. Upon reaching his first stop,

the diver should assume a relaxed and comfortable

position in the water. A weighted line or some other

apparatus should be provided to the diver to assist

him in maintaining a proper depth. Decompression

in mid-water, without a line or other method of fixing

the diver’s depth, is NOT acceptable as it is impos-

sible to maintain an exact depth without something

to hang onto.

An accurate pneumo should be taken at the diver’s

decompression stop. There should be no unnecessary

slack in the diver’s hose, i.e., no part of the umbilical should be lower than the diver, as this will give

a false reading (deeper) of the diver’s depth. Make

sure the end of the pneumo hose is held at the diver’s

chest with the open end pointing down.

2.13 COMPLETION OF DIVING

OPERATIONS

Immediately following the completion of diving

operations the dive station should be disassembled

and the KMACS 5 protected from the weather.

Both high pressure and low pressure air supplies

should be turned off at their source. Bleed the

air from the diver’s umbilical(s) by opening the

free flow valve(s) on the diver’s mask/helmet(s).

Disconnect the mask/helmet(s) from the umbilical

and the umbilical from the KMACS 5. Unplug the

communications connectors and turn off the communicator (R). Plug both ends of the hose and cap

the outlet manifold (G) nipples on the KMACS 5

to prevent foreign matter from entering either.

Open the bleed valves on the HP yokes (S) to allow

any remaining air to vent and replace the yokes on

their storage posts. Disconnect the low pressure

air source if used and cap the low pressure inlet

(N) to prevent foreign substances from entering

the KMACS 5.

If the KMACS 5 has been used on the ocean the

panels should be wiped down with a clean rag

dampened with fresh water. The O-ring seal (U) on

the case may be periodically treated with Armor-All

or other rubber protection.

Fig. 11 All of the outlet fittings on the KMACS 5 must be

capped prior to storage.

© 2003 KMDSI Document # 041112001

Place the KMACS 5 in a dry area and recharge the

communications.

Refill any high pressure cylinders (scuba) used

during diving operations and store them in a secure

location.

15

Page 22

KMACS 5 MANUAL

Section 3.0

KMACS 5 Maintenance

3.1 RECOMMENDED MAINTENANCE OF THE KMACS 5

The KMACS 5 requires very little user maintenance.

With proper care, the KMACS 5 should last for years

and give excellent service.

On a daily basis, the KMACS 5 operator should inspect the high pressure whips attached to the yokes

(S) for signs of wear.

After each use the case, interior panels and high

pressure hoses should be wiped down with a rag

which has a small amount of Armor-All. Never spray

cleaners directly on the KMACS 5.

Approximately every six months, the high pressure

hoses should be treated with Armor-AIl or similar

protection.

Once a year, the KMACS 5 should be returned to

your authorized dealer, or KMDSI , to service the

regulator, selector valve, and calibrate the diver’s

depth gauges. This is especially important if the

unit is used for deep, decompression, or repetitive

dives.

3.2 REPLACING THE BATTERY

The battery used with the KMACS 5 communicator

is very reliable and will offer many years of service.

However, storing the KMACS 5 with the battery

drained can cause the battery to fail. The battery

should be completely charged before storage. Gel

cell batteries have an excellent shelf life if properly

charged prior to storage.

Fig 12 After each use the case, interior panels and high

pressure hoses should be wiped down with a rag which has

a small amount of Armor-All. Never spray cleaners directly

on the KMACS 5.

To replace the battery, remove the screws which

hold the communicator panel (V) into the top of the

KMACS 5 box. Do not remove the screws which

secure the communicator to the larger panel. Tilt

the panel out but do not remove it from the lid. The

battery is held in place by brackets and “Velcro”

strips on the back of the large panel. Reach behind

the panel and support the battery. Lift the panel and

battery out as a unit.

Replace the old battery with a new unit. Position

the new battery on the back of the large panel using

the “Velcro” strips to hold it in place. Connect the

leads back to the battery and push the communicator panel (V) back into its normal position. Install

the screws which hold the large panel in place and

tighten them in a staggered pattern.

16

© 2003 KMDSI Document # 041112001

Page 23

KMACS 5 MANUAL

Section 4.0

Trouble Shooting the KMACS 5 System

4.1 GENERAL

The KMACS 5 is an extremely simple system which should not malfunction if the instructions in this manual

are followed. Most problems encountered in using the system can be easily remedied. The following information covers the common operating difficulties.

4.2 NO COMMUNICATIONS

Symptoms

1) No sound at either KMACS 5 or

diver’s mask.

2) Battery indicator does not respond.

3) Communications weak or broken

up.

4) Communications will not work

with headset but works otherwise.

5) Communications interrupted

when umbilical is moved.

6) Communications interrupted

when waterproof connector is

moved.

Probable Cause(s)

a)Communication power not on.

b) Communications incorrectly

hooked up.

c) Communications not hooked up.

Battery low or dead.

Terminals covered with corrosion.

Headset not working

Short in internal wiring.

Break in diver’s communication

wire.

Break in splice at waterproof

connector or failure of connector.

Test with VOM.

Remedy

Activate switch and adjust volume.

Switch terminal wires.

Plug into terminals.

Charge or replace battery, or

bypass battery with external power.

Clean Terminals with wire brush to

bright shiny metal.

Replace headset.

Return to factory for repair

Splice wire if damage is minor. Replace wire if damage is major.

Replace splice or connector.

7) Satisfactory communications

through one earphone or microphone only (4 wire mode).

8) No sound at either KMACS 5

or mask.

© 2003 KMDSI Document # 041112001

a) One wire in cable is broken

b) Microphone/earphones dead.

Communicator not functional.

Stack connectors in microphone

terminals. Communications works

in two wire mode.

Replace microphone/earphones.

Return to factory for repair after

verifying no cure by following

above procedures.

17

Page 24

KMACS 5 MANUAL

4.3 NO PNEUMO READING

Symptoms

1) No air to diver’s end of pneumo

2) Gauge reads sustained pressure

at surface.

3) Hose will not hold pressure and

gauge needle will not rise.

4) Needle will not respond properly

to flow.

5) Air can be heard escaping into

console interior.

Probable Cause

Pnuemo hose not connected

Pneumo crimped or plugged.

Pneumo fitting cracked or loose.

a) Hole in pneumo hose.

b) Gauge mechanism damaged.

KMACS 5 internal plumbing may

be cracked or broken.

Remedy

Attach fittings to KMACS 5

Check entire length of hose.

Relieve any restrictions.

Check fittings at console with

soap and water solution. If fittings

bubble, either tighten or replace

as necessary.

Check hose; replace or splice as

necessary.

Replace or repair gauge. Return

to factory.

Return to factory for service.

4.4 NO AIR TO DIVER

Symptoms

1) No hose pressure in diver’s

umbilical

2) No gauge reading on high

pressure gauge.

3) Low hose pressure in diver’s

umbilical.

4) Air can be heard escaping

from hose.

Probable Cause

a) primary air source not connected.

b) Valve closed at low pressure

source

c) Selector valve in “H.P. OFF”

zone.

Val ve clo s e d at hi g h pressu r e

source

Regulator not properly loaded.

Fitting loose on diver’s hose, or

fittings damaged.

Remedy

Connect proper hose to console.

Open valve at low pressure compressor.

Move selector valve handle in

line with flow from either high

pressure source.

Open valve at high pressure

source.

Rotate adjustment wheel in appropriate direction.

Tighten fittings until snug. Do

not over tighten. Replace fittings

if damaged.

5) Umbilical registers pressure

at console gauge, but no flow

at mask.

18

Mask improperly serviced.

Clean and adjust mask.

© 2003 KMDSI Document # 041112001

Page 25

KMACS 5 MANUAL

Symptoms

6) Air can be heard escaping into

console interior.

7) Umbilical hose pressure and

supply pressure drops rapidly.

8) With high pressure air on and

regulator loaded, no umbilical

pressure.

Probable Cause

Leakage in DCS plumbing.

Diver’s Umbilical cut or severed.

Regulator malfunction.

Remedy

Return KMACS 5 to factory

for service.

Replace diver’s hose.

Return DCS- 2A to factory for

service

5.0 APPENDIX

5.1 EMERGENCY PROCEDURES

The following are general recommended emergency procedures. However, it is up to the individual

diver and dive supervisor to make judgements under specific conditions on how to best cope with

particular situations.

Problem

1) Loss of communications

Action

a) Abort dive if operations are not absolutly necessary.

2) Loss of primary air supply.

3) Diver’s umbilical severed.

4) Pneumo will not operate.

5.2 DIVER LINE PULL SIGNALS

# of Pulls

1

2

© 2003 KMDSI Document # 041112001

b) Use line pull signals as per this appendix section.

Switch to emergency backup system and abort dive.

a) Diver switches to bailout bottle and aborts dive.

b) Standby diver enters water and supplies first diver with air

from pneumo.

a) Dive hose should be marked with colored tape every 10 feet.

Take depth readings from this. (will only be approximate)

b) Diver’s personal depth gauge can provide back up.

From Tender to Diver

“Are you all right?”

When diver is descending, one

pull means “Stop!”

“Going down”

During ascent, this means,

“You have come up too far, go

back down until we stop you.”

From Diver to Tender

“I am all right”, or ...

“I am on the bottom”

“Lower me down”, or

“Give me slack”

19

Page 26

KMACS 5 MANUAL

# of Pulls

From Tender to Diver

From Diver to Tender

3

4

“Stand by to come up”

“Come up”

“Take up my slack”

“Haul me up

5.3 COMMUNICATIONS WIRING SCHEMATICS

If your KMACS has communications, refer to the radio manual

5.4 EXPLODED VIEWS & PARTS LISTS

The following parts are not shown on the blow apart drawing and are listed reference only.

Location Part # Description Qty

Not Shown 420-100 Case, KMACS 5 1

Not Shown 405-039 Battery Charger Assembly 1

* The following parts in the interior plumbing require the use of Conical Seals, # 455-135.

the conical seals are provided with the items listed below.

Location Part # Description

29 405-105 Inlet Tube, H.P. (blue)

31 405-105 Inlet Tube, H.P. (orange)

40 405-106 S .S. Tube Assembly, H. P.

20

© 2003 KMDSI Document # 041112001

Page 27

KMACS 5 EXPLODED VIEWS & PARTS LISTS

Communications Panel

KMACS 5 MANUAL

Key# Part # Description

1 530-017 Screw

2 415-105 Communicator

3 530-035 Screw

4 430-075 Washer

5 410-003 Gasket, Foam

6 445-105 Panel, Auxiliary

7 450-106 Yoke Retainer

8 420-125 Arrow, Orange

9 420-120 Arrow, Blue

10 445-115 Door, Storage Compartment

11 420-160 Slide Latch

12 330-405 Lock washer

13 530-070 Screw

14 420-105 Box, Plastic

15 410-145 Grommet

16 415-110 Cable, Battery

© 2003 KMDSI Document # 041112001

Key# Part # Description

17 415-056 Battery, Gel Cell 12V

18 430-060 Retainer Ring

19 455-065 Filter

20 510-491 O-Ring

21 455-317 Yoke/Din Assembly (18-21)

22 410-006 Hose Protector, Orange

410-007 Hose Protector, Blue

23 455-054 Hose, H.P. Supply

24 405-175 Hose, Yoke Assem., Blue (18-23)

405-176 Hose, Yoke Assem., Orange (18-23)

25 455-135 Conical Seal

400-046 KMACS 5 with Communicator

400-045 KMACS 5 No Communicator

Bracket for no comm version not shown

440-004 Mount Bracket

530-078 Screw

530-540 Washer

21

Page 28

KMACS 5 MANUAL

Panel Mounted

1 430-111 Screw

2 430-134 Washer

Key# Part # Description

22

Plumbing and Gauges

3 430-134 Washer

4 430-111 Screw

5 430-075 Washer

6 530-035 Screw

7 450-144 Pneumo Block

8 455-032 SS Elbow

9 455-007 Cap, Pneumo

10 455-157 Valve Body

11 455-145 Valve flange

12 455-143 SS Elbow

13 455-006 Cap, Umbilical Outlet

14 430-141 Socket Head Screw

15 430-134 Washer

16 440-210 Handle Stop

17 440-212 Valve Handle

425-110 Kit, Shut Off Valve

18 510-014 O-Ring

19 420-140 Gauge Cover

37 440-155 Gauge, H.P.

38 455-185 H.P. Inlet Elbow

39 455-111 L.P. Inlet Elbow

20 530-070 Screw

21 440-010 Pneumo Gauge, Red

22 440-011 Pneumo Gauge, White

23 440-150 Gauge, L.P.

24 440-115 Hose Holder

25 430-130 Washer

26 455-051 Pneumo Valve Assembly

w/ #18 from interior plumbing drawing.

27 420-135 Decal

28 450-170 Knob, Regulator Adjustment

29 430-110 Set Screw

© 2001 KMDSI Document # 010925001

© 2003 KMDSI Document # 041112001

40 430-116 Washer

41 450-136 Washer

42 455-005 Cap, L.P. Inlet

30 450-125 Mount Nut, Regulator

31 430-126 Washer, Regulator Mount

32 450-120 Stem, Regulator Adjustment

43 430-115 Washer

44 455-152 Nut

45 455-190 Nut, H.P. Inlet Mount

46 445-020 Gauge Bracket

33 420-225 Selector Handle

34 430-140 Set Screw, Selector Handle

35 455-140 Selector Valve Assembly

w/ #37 from interior plumbing drawing.

47 445-100 Main Panel

36 430-205 Washer

Page 29

KMACS 5 MANUAL

CAUTION - WARNING

Use only Kirby Morgan original replacement

parts. The use of other manufacturer’s parts

will interfere with the performance charac-

teristics of your life support equipment and

may jeopardize your safety. Additionally, any

substitutions will void any warranties offered

by KMDSI. When ordering spares, always

Interior Plumbing Arrangement

insist on Kirby Morgan Genuine Parts.

Key# Part # Description

1 455-024 Connector, L.P.

2 455-049 Check Valve, L.P.

3 455-026 Male Elbow

4 405-155 Tube, Regulator Sensor

5 455-120 Elbow

6 455-122 3/8” NPT Nipple

7 455-180 Male Run Tee

8 455-149 Straight Tube Connector

9 350-062 L.P. Plug

10 510-013 O-Ring

11 450-142 Manifold Block

12 455-149 Straight Tube Connector

13 405-150 Tube, Red Pneumo Gauge

14 430-126 Washer, Regulator Mount

15 405-160 Outlet Tube, Red Pneumo

16 455-180 Male Run Tee

17 455-040 Female Elbow

18 455-051 Pneumo Valve

19 455-123 1/4” NPT Nipple

20 455-121 1/4” NPT Street Tee

© 2001 KMDSI , Inc. All Rights Reserved Docu # 000525002-010627001

© 2003 KMDSI Document # 041112001

Key# Part # Description

21 455-051 Pneumo Valve

22 455-040 Female Elbow

23 405-107 Tube, Umbilical Gauge

24 455-180 Male Run Tee

25 455-040 Female Elbow

A 460-110 Regulator Body

B 410-010 Back-up O-Ring

C 510-010 O-Ring

D 450-038 Seat (includes B,C,E,F)

E 410-010 Back-up O-Ring

F 510-010 O-Ring

26 405-161 Outlet Tube, White Pneumo

27 405-102 Tube, White Pneumo Gauge

28 405-105 Inlet Tube, H.P. Blue

29 455-117 Male Branch Tee

G 450-037 Piston Stem

30 405-110 Tube, L.P. Supply

31 405-105 Inlet Tube, H.P. Orange

32 405-104 Tube, H.P. Gauge

33 455-305 Elbow Assembly, Swagelok®34 455-032 Male Elbow

H 510-014 O-Ring

I 450-034 O-Ring Cap, Small

J 510-014 O-Ring

K 510-008 O-Ring

L 410-008 Back-up Ring, Large

M 450-033 O-Ring Cap, Large

N 435-006 Spring

O 450-032 Piston Head

P 410-119 O-Ring

35 455-135 Conical Seal

36 455-196 Male Run Tee, H.P.

37 455-140 Selector Valve

38 430-120 Washer

39 405-106 SS Tube Assy., H.P.

40 455-197 Male Elbow

41 405-120 Regulator Assembly

42 405-145 Tube, Main Pneumo Supply

Q 410-121 Thread Seal

R 430-022 Nylon Locknut

S 450-157 Regulator Cylinder

T 455-026 Regulator Sensor Elbow

43 455-047 Relief Valve

44 455-130 1/2” Check Valve L.P.

23

Page 30

KMACS 5 MANUAL

KMACS 5 DIVE LOG

Diver: Date:

KMACS 5 Operator:

Dive Location:

Weather Conditions:

Purpose of Dive:

Low Pressure Air Source Pressure:

High Pressure Air Source Pressure:

Cylinder # Start Finish

1 _______________________________

2 _______________________________

3 _______________________________

4 _______________________________

5 _______________________________

6 _________________________________

Dive Times:

Diver Left Surface: ________________

Diver Reached Bottom: ____________

Diver Left Bottom: ______________ Maximum Depth:

Diver Reached Surface:______________ Total Bottom Time:

Repetitive Group: ________________ Decompression Required?: Y N

Decompression Schedule:________________________________________________

______________________________________________________________________

Diver’s Signature_____________________ KMACS 5 Operator _________________

24

© 2003 KMDSI Document # 041112001

Page 31

Table of Equivalents

KMACS 5 MANUAL

To convert units appearing in

Column 1 (left column) into

equivalent values in Column

2 (center column), multiply

by factor in Column 3. Example: To convert 7 gallons

into cubic inches, multiply

7 x 231 = 1617. To convert

units appearing in Column

2 (center) into equivalent

values of units in Column

1 (left), divide by factor

in Column 3. Example: To

convert 25 horsepower into

Btu per minute, divide 25 by

0.02356 = 1061

PSI BARS K/Pa

1 0.06895 6.895

15 1.03425 103.425

50 3.4475 344.75

100 6.895 689.5

300 20.685 2068.5

500 34.475 3447.5

1000 68.95 6895.0

2000 137.9 1379.0

3000 206.85 20685.0

4500 10.275 31027.5

5000 44.75 34475.0

TO CONVERT INTO MULTIPLY BY

INTO TO CONVERT DIVIDE BY

33.9

29.92

14.7

778.3

0.2931

0.02356

o

C x 1.8 + 32

0.3937

0.0002642

0.0001

1728

7.48052

0.0005787

0.004329

86.400

0.01745

0.3048

0.0001894

0.0295

0.8826

0.4335

0.01136

0.6818

0.001286

0.0000303

0.001818

0.1337

231

8.3453

42.44

33,000

550

745.7

0.04167

0.005952

2.54

0.03342

1.133

0.4912

0.03613

1000

0.2642

0.00004

5280

88

1.467

0.0625

1.805

0.5

7000

453.59

16

0.06804

2.307

2.036

0.25

144

0.5555

2000

0.001341

Atmospheres

Atmospheres

Atmospheres

BTU

BTU per hour

BTU per minute

Celsius (Centigrade)

Centimeters

Cubic Centimeters

Cubic Centimeters

Cubic Feet

Cubic Feet

Cubic Inches

Cubic Inches

Days

Degrees (Angle)

Feet

Feet

Feet of Water

Feet of Water

Feet of Water

Feet per Minute

Feet per Second

Foot-Pounds

Foot-Pounds per Minute

Foot-Pounds per Second

Gallons (U.S. Liquid)

Gallons (U.S. Liquid)

Gallons of Water

Horsepower

Horsepower

Horsepower

Horsepower

Hours

Hours

Inches