Kipor KM2V80 User Manual

Thank you for purchasing Kipor KM2V80 series diesel engine. In order to ensure proper

operation, reliable running and good economic benefit of your machine, it is especially important

for you to operate correctly and maintain carefully. This manual will tell you how to operate and

maintain the machine correctly, it will also give you detail instruction about the main technical

specification, configuration and troubleshooting.

Content

Instruction of products……………………………………………………………………………..1

1. Brief instruction of products……………………………………………………………....1

2. Composition of model and its meaning………………….………………………………1

3. External installation drawings and names of parts……………………………………. 2

4. Specification………………………………………………………………………………. 6

5. Main adjusting parameter………………………………………………………………… 7

6. Tighten torque values of main bolts and nuts……………………………………………7

7. Fit clearance and interference table………………………………………………………8

Technical maintenance………………………………………………………………………………9

1. Daily check and periodic check …………………………………………………….9

2. Procedure of periodic maintenance………………………………………………………..9

Disassembly and reassembly…………………………………………………………………….. 13

1. Basic procedure of disassembly…………………………………………………………..13

2. Basic procedure of reassembly……………………………………………………………18

Check and maintenance……………………………………………………………………………22

1. Cylinder cover…………………………………………………………………………….. 22

2. Camshaft...............................………………………………………………………………23

3. Piston and piston pin……………………………………………………………………… 24

4. Crankshaft………………………………………………………………………………… 25

5. Cylinder block and cylinder cover................................................................................

6. Lubrication system……………………………………………………………………….. 27

7. Cooling system…………………………………………………………………………… 27

8. Fuel system……………………………………………………………………………… 28

The electrical system…………………………………………………………………………… 29

1. Starter motor……………………………………………………………………………… 29

2. Heater plug............…………………………………………………………………… .31

Troubleshooting and remedy of engine………………………………………………………...35

Preliminary run...........................................................................................................….........39

Instruction of products

1. Brief instruction of products

This model is double cylinder, V-type, four strokes, water cooled, and swirl type diesel engines.

This model will be exploited into multi-purpose engine with vertical or horizontal shaft.

This model is simple in structure, convenient in disassembly or reassembly, and have smart

size, short axial length, light weight, good performance, reliable quality, long running time. They

will meet various demands for each customer, and are ideal complementary power for

generating sets, construction machinery, ship, combined harvester, agricultural machine etc.

Welcome you to purchase.

2. Composition of model and its meaning

KM 2 V 80

Cylinder bore (mm)

V-type

Cylinder No.

Kipor

Introduction of products

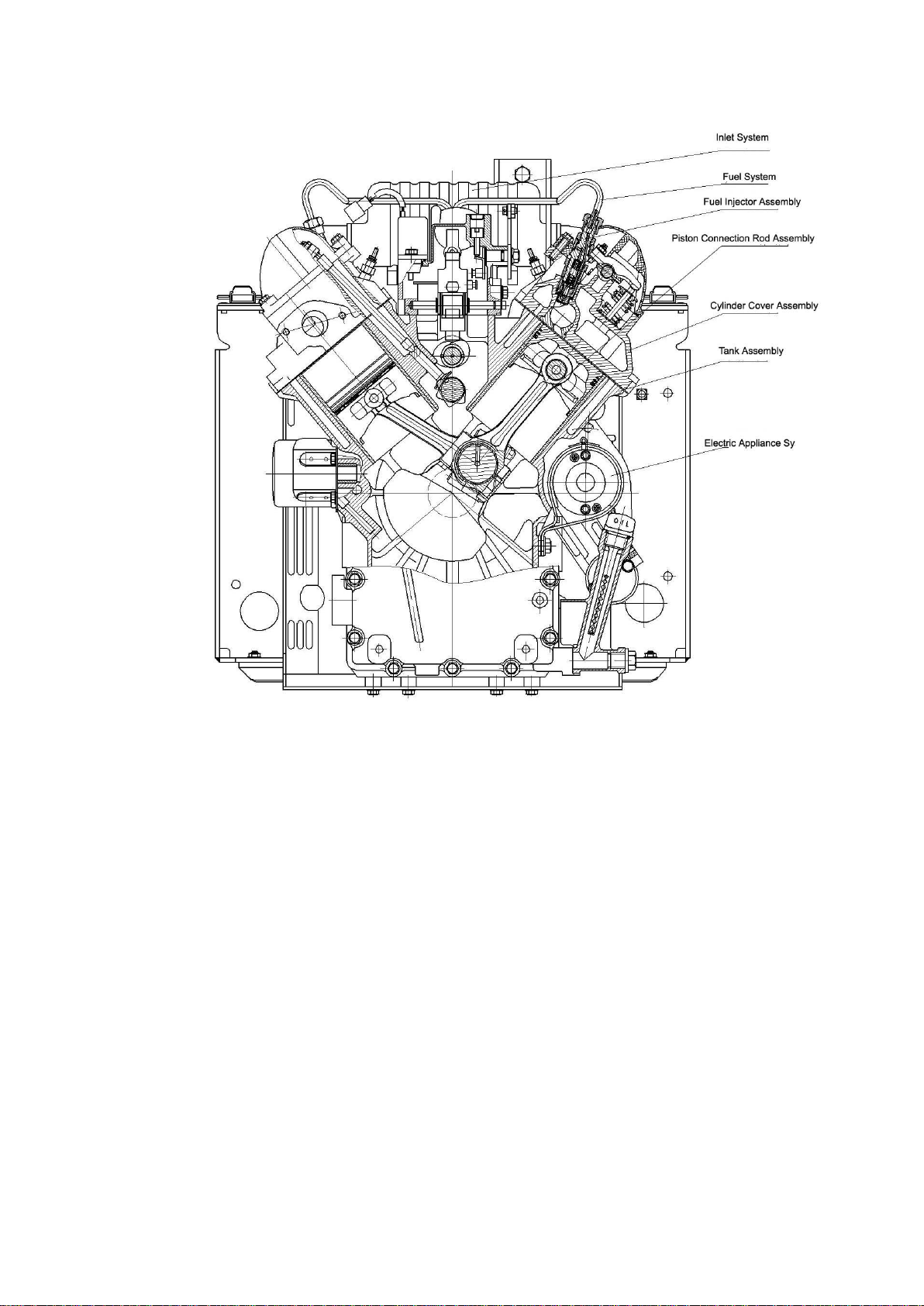

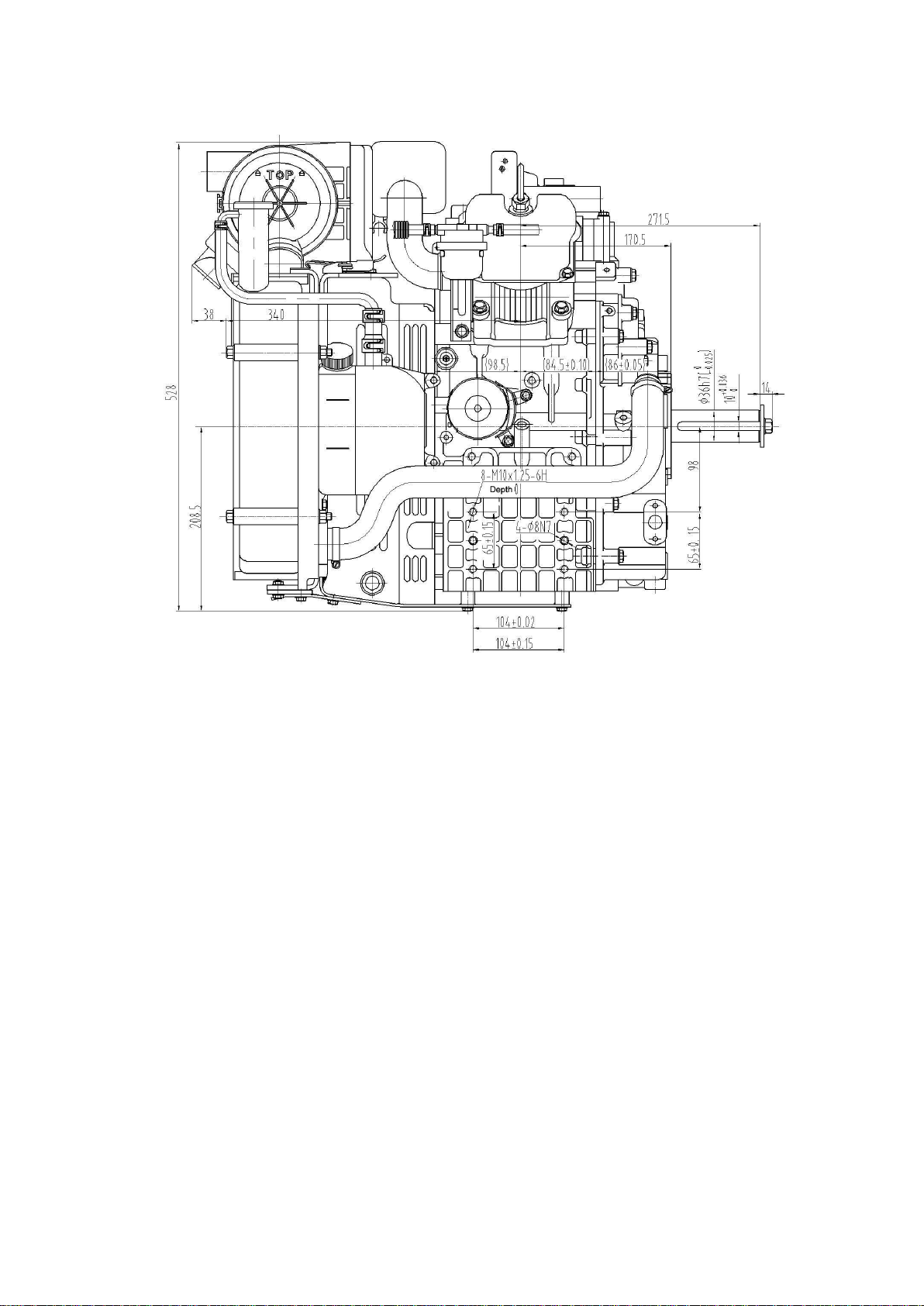

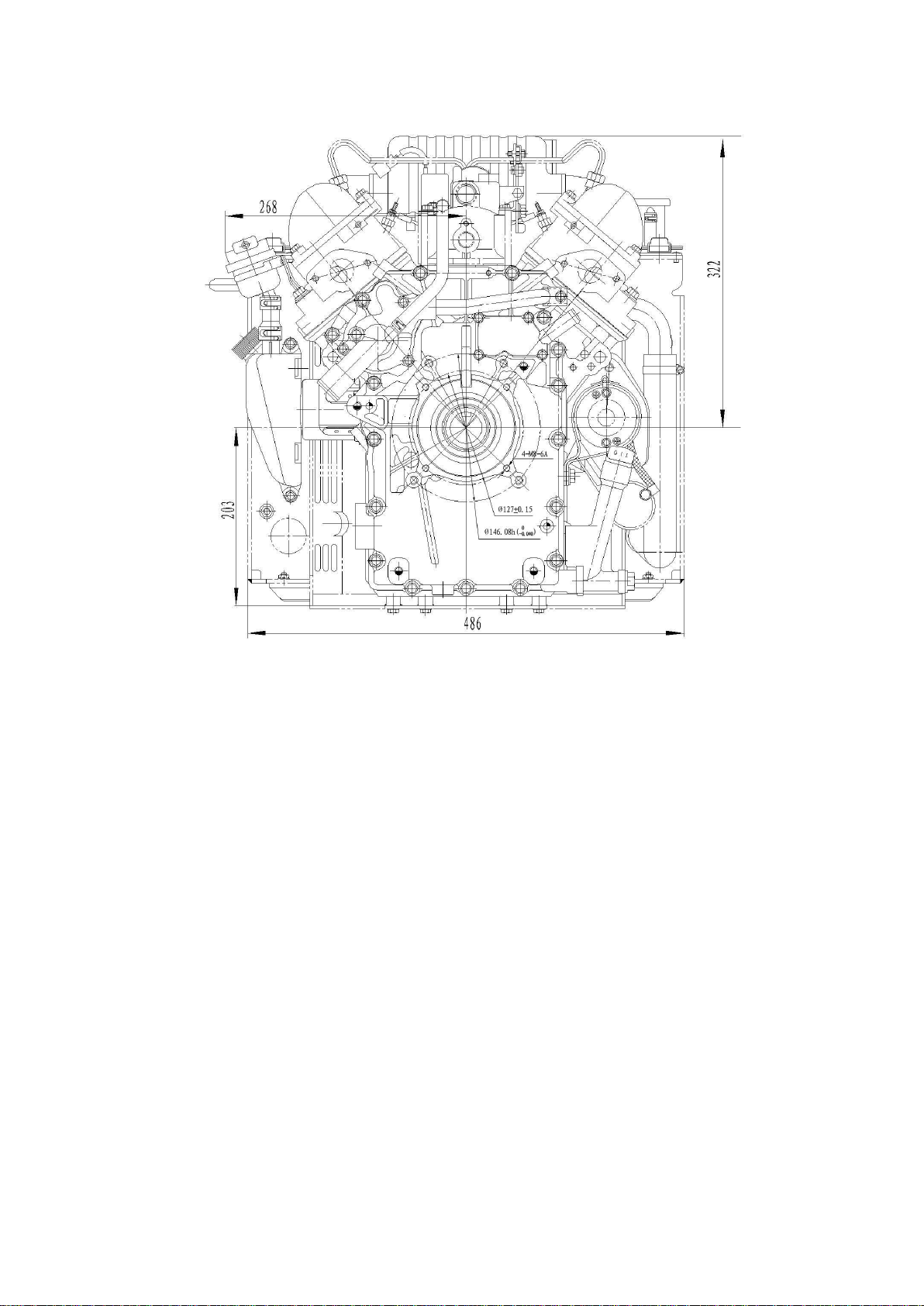

3. External installation drawings and name of parts

Please refer to picture 1, picture 2, picture 3 and picture 4 for details.

Picture1 Vertical section view for KM2V80 diesel engine

Picture 2 Horizontal section view for KM2V80 diesel engine

Picture 3 Vertical figuration view for KM2V80 diesel engine

Picture 4 Horizontal figuration view for KM2V80 diesel engine

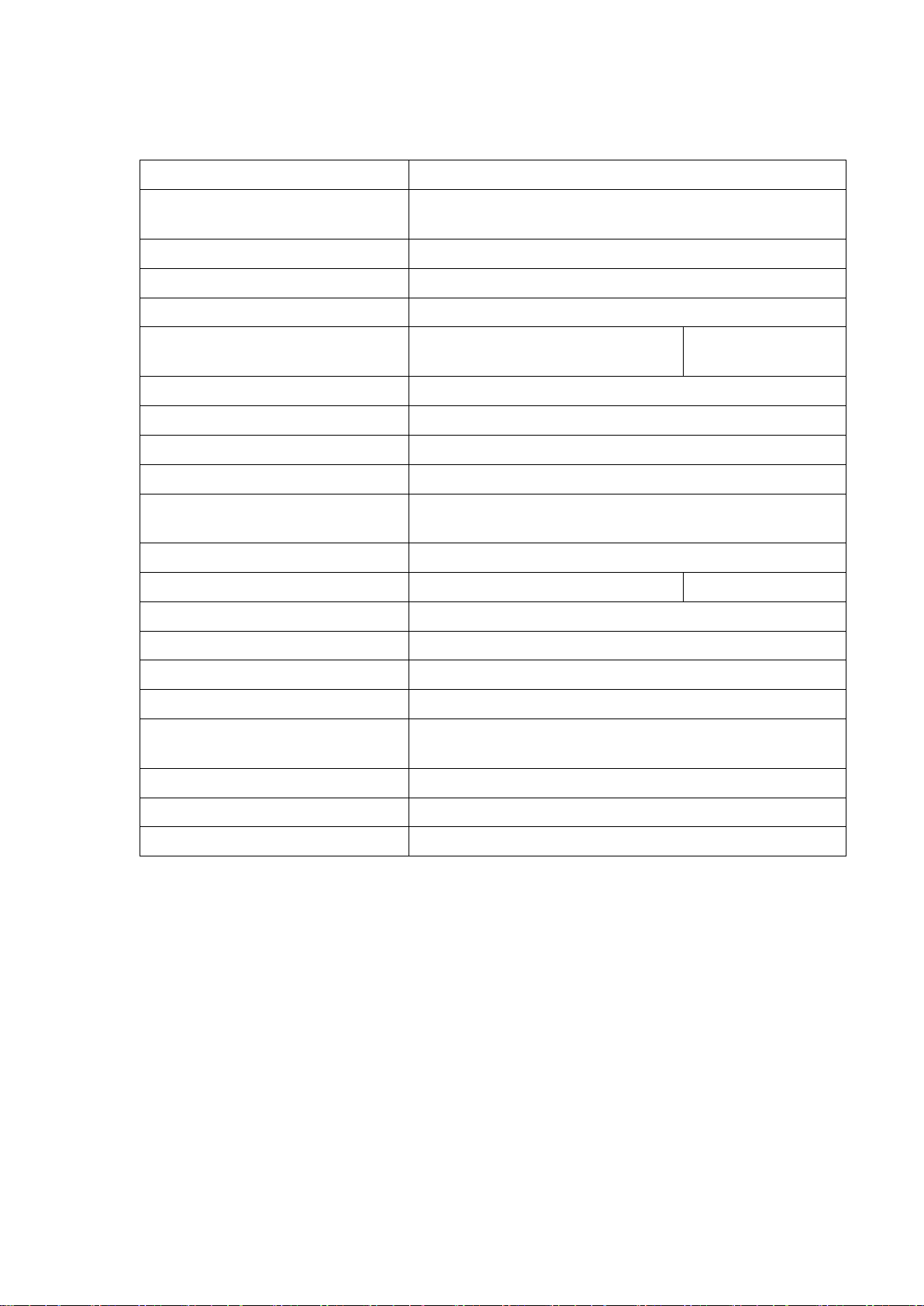

4. Specification

Table 1 Main specification table of KM2V80 diesel engine

Model

KM2V80

Type

Double cylinder, V-type, water-cooled, 4 stroke,

swirl type

Bore×Stroke mm

80×79

Displacement L

0.794

Compression ratio

23

Rated output/Rated speed

kW/r/min

12.5/3000

14.5/3600

Max. torque N·m

49/1600~1800

Min. speed (zero load) r/min

≤900

Lubricating system

Pressure splashed

Starting system

Electric starter

Output terminal direction (face

to the flywheel)

Anticlockwise

Fuel type

0#(summer), -10# or -20#(winter), -35#(chillness)

Fuel consumption ratio g/(kW·h)

285

297

Lube oil type

SAE 10W-30、20W-40 or L-ECD Grade

Lube oil capacity L

2.27

oil consumption ratio g/(kW·h)

≤5

Starting motor capacity V,kW

12V 1.4 kW

Charging generator capacity

(V,A)

12V 20A

Battery capacity (V,AH)

12V 60AH

Overall dimension (L×W×H) mm

616×486×528

Net weight kg

58

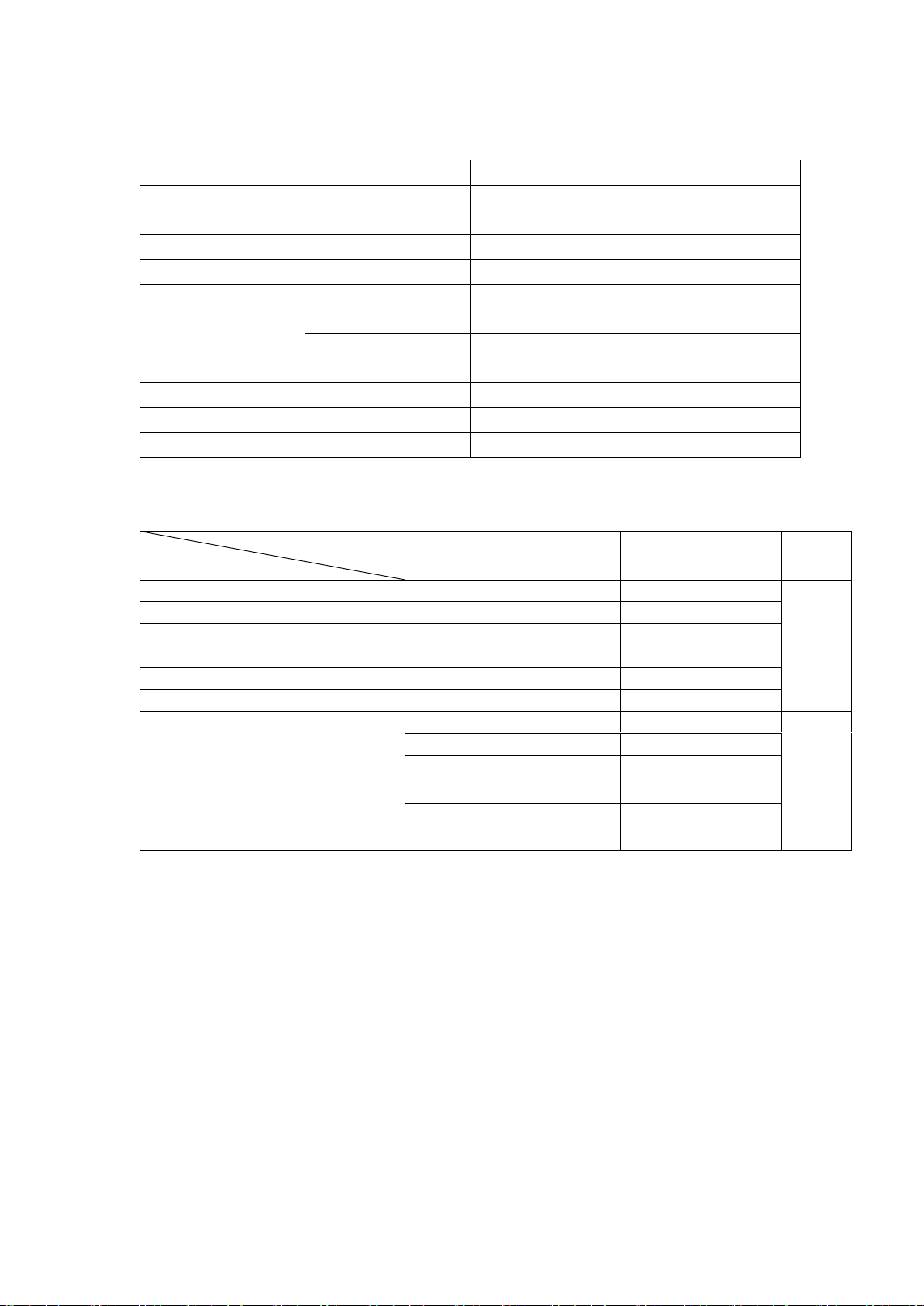

5. Main adjusting specification

Table 2 Main adjusting specification of KM2V80 diesel engine

Item

Standard value

Cylinder compression clearance height

mm

0.88~1.2

Advanced angle of fuel supply

BTDC 18.5°±1°

Fuel spraying pressure Mpa

13°±0.5°

Valve timing

Inlet valve

Open at BTDC 22°

Close at ABDC 56°

Exhaust valve

Open at BTDC 61°

Close at ATDC 26°

Valve clearance mm (cooled state)

0.10~0.15

Valve sunk volume mm

0.5±0.10

Oil pressure Mpa

0.25~0.5

6. Tighten torque of main bolt and nut

Table 3 Tighten torque of main bolts and nuts

Value

Item

Thread

Tighten torque

(N·m )

Remark

Cylinder cover bolt

M9×1.25

60±5

Connection rod bolt

M7×1

28±2

Flywheel bolt

M10×1.25

75~80

Crankcase cover bolt

M8×1.25

22~25

Fuel injector bolt

M20×1.5

50±5

Heater plug

M10×1.25

12±2

General bolt: mechanical performance

is 8.8 grade

M6×1.0

8~12

M8×1.25

17~23

M10×1.5

40~50

M12×1.75

85~100

M14×1.5

130~150

M16×1.5

220~240

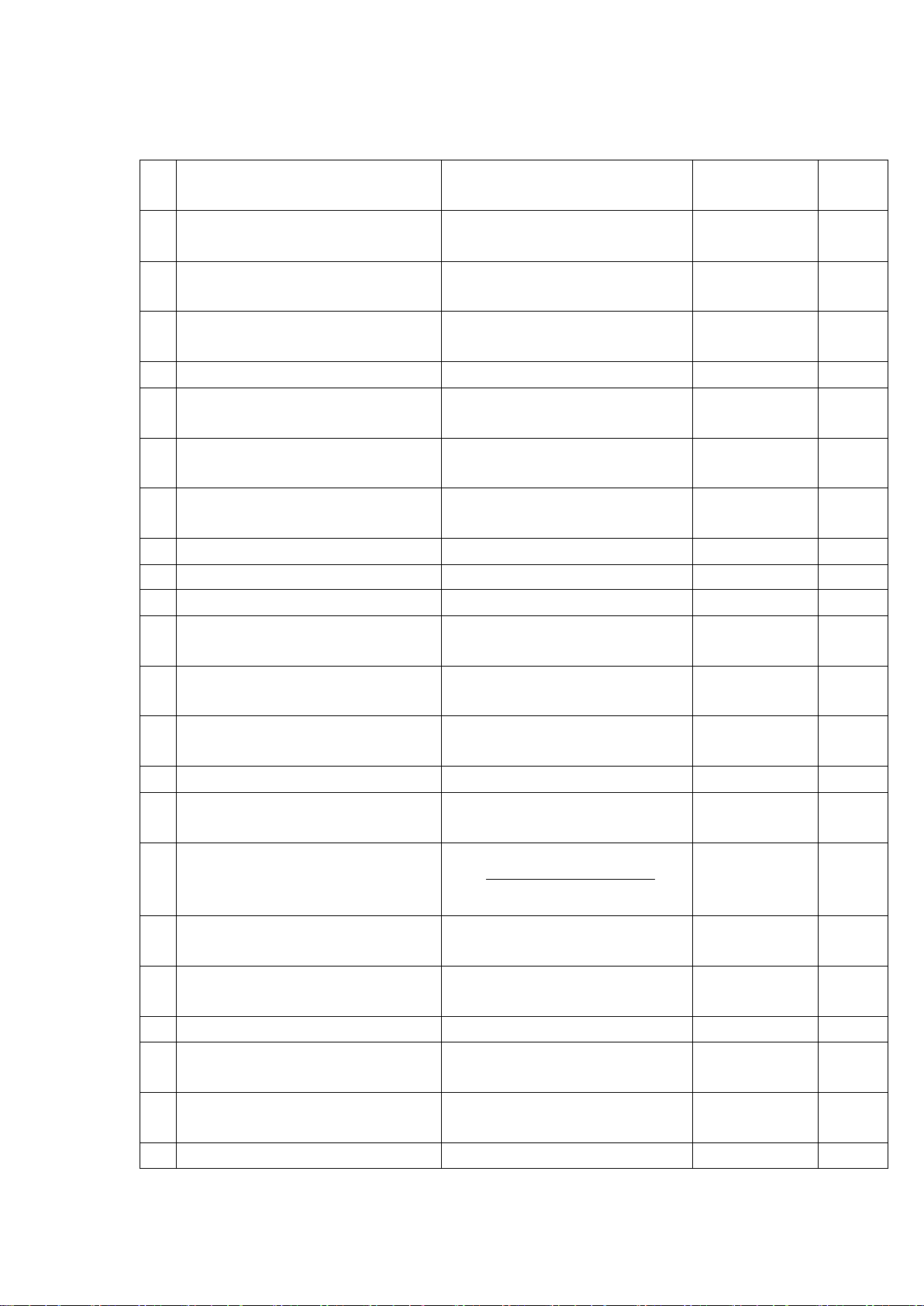

7. Fit clearance and interference table

Table 4 Fit clearance and interference table

No.

Name

Standard dimension(mm)

Fitting clearance

(mm)

Remark

1

Cylinder inner diameter/

Piston top outer diameter

φ80H7(

+0.03

0

)/d-0.515±0.01

0.565~0.635

2

Cylinder inner diameter/

Piston skirt upper part

φ80H7(

+0.03

0

)/d-0.125±0.01

0.175~0.245

3

Cylinder inner diameter/

Piston skirt diameter

φ80H7(

+0.03

0

)/φ80

-0.06

-0.08

0.06~0.110

4.

Piston pin hole/Piston pin

φ20

-0.002

-0.008

/φ20

0 -

0.006

0.004~-0.008

5

The width of ring groove /

The height of 1

st

ring

1.2

+0.060

+0.040

/1.2

-0.01

-0.02

0.05~0.08

6

The width of ring groove /

The height of 2

nd

ring

1.5

+0.040

+0.020

/1.5

-0.01

-0.02

0.03~0.06

7 The width of ring groove /

The height of 3

rd

ring

3.0

+0.030

+0.010

/3

-0.01

-0.02

0.02~0.05

8

Open clearance of 1

st

ring

0.25~0.35

9

Open clearance of 2

nd

ring

0.20~0.35

10

Open clearance of 3

rd

ring

0.15~0.30

11

Connection rod bushing/

Piston pin diameter

φ20

+0.025

+0.015

/φ20

0 -

0.006

0.015~0.031

12

Connection rod bush hole diameter/

Connection rod journal

φ40

+0.032

0

/φ40f5(

-0.025

-0.036

)

0.025~0.062

13

Main bearing bushing hole diameter/

Main journal

φ50

+0.035

+0.015

/φ50f5(

-0.025

-0.036

)

0.040~0.071

14

Crankshaft axial clearance

120.7

+0.10

0

/108.6+12=120.6

0 -

0.10

0.10~0.30

15

Crankshaft axial open split/

The width of connection rod big head

40

+0.25

+0.10

/20

-0.15

-0.20

×2=40

-0.30

-0.40

0.40~0.65

16

(Crankshaft center line to the tank

top)/(piston + connection rod + crank

radius)

13.01.1935.395.1251.28

03.054.193

0.28~0.60

17

Camshaft hole diameter/

Camshaft journal

φ18H7(

+0.018

0

)/φ18e6(

-0.032

-0.043

)

0.032~0.061

18

Side cover camshaft hoe diameter/

Camshaft journal

φ24H7(

+0.021

0

)/φ24f6(

-0.040

-0.053

)

0.040~0.074

19

Camshaft axial clearance

176.5

+0.10

0

/164.1+12.2=176.3±0.05

0.035~0.15

20

Valve tappet hole/

Tappet diameter

φ10H7(

+0.015

0

)/φ10e7(

-0.025

-0.040

)

0.025~0.055

21

Fuel pump tappet hole/

Fuel pump tappet

φ21H7(+0.021 )(

0

)/φ21

-0.047

-0.080

0.047~0.101

22

Valve pipe/ Inlet valve

φ6H7(

+0.012

0

)/φ6

-0.030

-0.045

0.03~0.057

23

Valve pipe/ Exhaust valve

φ6H7(

+0.012

0

)/φ6

-0.035

-0.050

0.035~0.062

24

Cylinder cover pipe hole/

Valve pipe

φ10H7(

+0.015

0

)/φ10

+0.055

+0.045

-0.03~-0.055

25

Cylinder cover housing washer hole/

Inlet valve housing washer

φ33.5H7(

+0.025

0

)/φ33.5

+0.12

+0.09

-0.065~-0.012

26

Cylinder cover housing washer hole/

Exhaust valve housing washer

φ28H7(

+0.021

0

)/φ28

+0.11

+0.09

-0.069~-0.11

27

Cylinder cover insert/

Combustion chamber insert

φ32.5H7(

+0.021

0

)/32.5p6(

+0.042

+0.026

)

-0.005~-0.042

28

Cylinder cover rocker shaft hole/

Rocker shaft diameter

φ12H7(

+0.018

0

)/φ12f6(

-0.016

-0.027

)

0.016~0.045

29

Rocker arm hole/

Rocker shaft diameter

φ12H7(

+0.018

0

)/φ12f6(

-0.016

-0.027

)

0.016~0.045

30

Timing gear hole/

Camshaft journal

φ24H7(

+0.021

0

)/φ25s6(

+0.048

+0.035

)

-0.014~-0.048

31

Crankshaft gear hole/

Crankshaft journal

φ50H6(

+0.016

0

)/φ50p5(

+0.037

+0.026

)

-0.010~-0.037

32

Flywheel gear ring hole/

Flywheel stop ring

φ214H7(

+0.046

0

)/φ214u7(

+0.364

+0.258

)

-0.212~-0.304

33

Connection rod small head hole/

Connection rod bushing outer

diameter

φ22H7(

+0.013

0

)/φ22r6(

+0.041

+0.028

)

-0.015~-0.041

34

Connection rod bolt hole/

Bolt location diameter

φ7.5H7(

+0.015

0

)/φ7.5f6(

-0.013

-0.022

)

0.013~0.037

35

Side cover outer rotor diameter/

Outer rotor diameter

φ41H7(

+0.025

0

)/φ41

-0.075

-0.115

0.075~0.14

36

Side cover oil pump shaft diameter/

Shaft diameter

φ11H7(

+0.018

0

)/φ11f6(

-0.016

-0.027

)

0.016~0.045

37

Inner/outer rotor hole depth/

Inner/outer rotor axial depth

12

+0.08

+0.04

/12

0 -

0.020

0.04~0.10

Technical maintenance

1. Daily check and periodic check

Engine’ performance will be deteriorated if the operation condition becomes worse or time

prolongs, such as: fuel and oil consumption increase, exhaust harmful substance increases, or

vibratory and noise increase. Please strengthen the maintenance service of engine, insist on

daily check and periodic maintenance, which will prove efficiency and prevent fault.

Check can be divided into daily check and periodic check.

Daily check: Do daily check before starting engine, and operate it as a rule.

Periodic check: Suggest you make a running diary, writing down results of everyday operation

and check, accumulating total running time. Start your periodic check and maintenance

according to below table (table 5).

Periodic check can be divided into: 50h、250h、500h、1000h、2000h(h: hours)

Time interval of periodic check can be properly advanced or delayed according to the engine’s

purpose, location condition, fuel or lube oil’s quality and other using conditions.

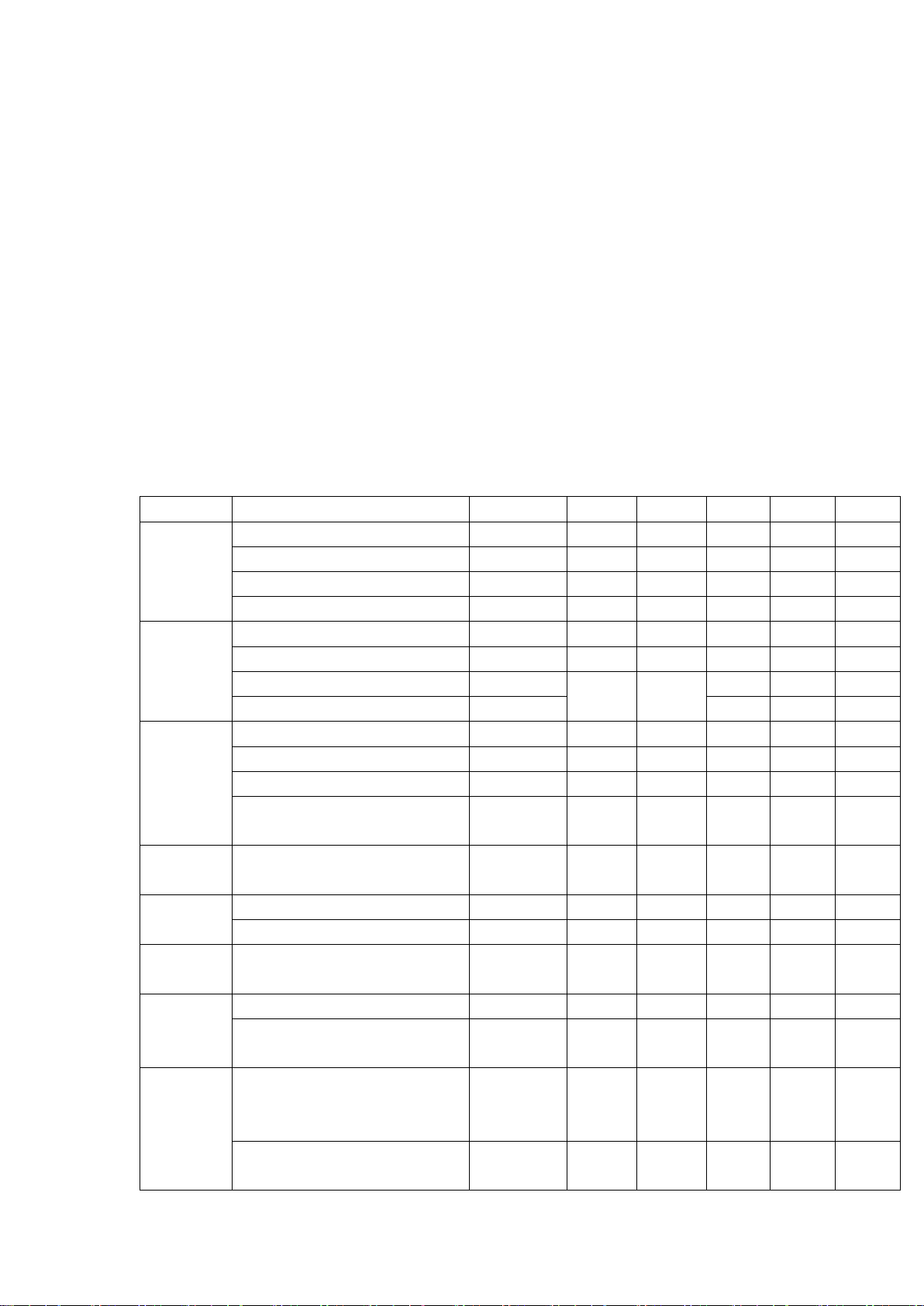

Table 5 Periodic check table of engine

System

Checking item

Everyday

50h

250h

500h

1000h

2000h

Fuel

Check and refill fuel oil

○ Check for oil leakage

○ Drain out fuel oil

○ Replace the oil filter element

◎

Lube oil

Check and refill lube oil

○

Check for oil leakage

○ Replace lube oil

◎first

time

◎seco

nd time

Replace lube filter element

Cooling

water

Check and refill cooling water

○ Clean radiator element

○ Replace cooling water

◎

Wash and maintain cooling

system

●

Robber

pipe

Replace fuel pipe and cooling

water tube

○

◎

Operation

system

Speed regulator operation

○ Idle adjust

●

Inlet

system

Clean and replace air cleaner

element

○clean

◎

Electric

parts

Check alarm

○

Check electrolyte and charge

the battery

○

Cylinder

cover

Adjust clearance of

intake/exhaust valve

○first

time

○seco

nd

time

Wear of intake/exhaust valve

sealing ring belt

●

○:check ◎:replace ●:Contact with Kipor

agent

2. Procedure of periodic check

2.1 First 50h operation check

At the beginning time of operation, the inner parts wear

mutually and the lube oil is polluted soon, so please replace

the lube oil and oil filter element. Oil draining is much easier and quicker when the engine is hot.

Notice: Prevent be scalded when draining out the hot oil, and don’t let the hot oil splash on you.

2.1.1 Drain out lube oil: Prepare an oil basin to store oil before draining, loosen the drain screw

with a spanner, and then begin to drain oil. Make sure you have tightened the drain screw after

draining to prevent be dropped out.

Danger: Indicate that severe damage will result if you haven’t tightened the drain screw.

2.1.2 Replace oil filter element: Revolve down the oil filter element with a filter element spanner

in anticlockwise direction, clean the oil filter seat, smear a thin lube oil on the filter element

sealing gasket before replacing, revolve hard with hand in clockwise direction, then revolve 3/4

circle with filter element spanner.(Tighten torque valve20-23N.m)

2.1.3 Refill fuel, about 6.9L.

Run the engine 5 minutes to preheat the engine, and check for oil leakage. Recheck fuel after

stop running 10 minutes, and refill to the upper limit line.

After the initial maintenance, replace fuel and oil filter element regularly per 250h interval.

2.2 Check per 50h operation

2.2.1 Drain out fuel tank: Prepare an oil basin; revolve down the drain screw, drain out water and

other foreign matter in the fuel tank; install drain screw and tighten up, check for oil leakage.

2.2.2 Check battery: Disconnect battery negative electrode earth wire when checking the electric

appliance system, or fire will result by short circuit; Make sure to be well-ventilated, or hydrogen

caused during charging will burn; Check battery electrolyte and refill to the upper limit location if

it is gong to reach the lower one, otherwise life of battery will be shorten, or even explosion will

be caused. You should always check and refill distilled water since electrolyte lever drops down

quickly in summer. Please recharge the battery if rotation speed of crankshaft is slower than

normal and starting is failure. If you still can’t start the engine after recharging, replace the battery.

2.2.3 Clean air filter: Air filter element will easily be polluted by dust, oil mist or steam, which will

result in increase of intake resistance, decrease of intake volume, and black smoke of engine,

so you should always check and clean the oil filter element, or even replace it; Cleaning should

be more frequent if operating at

Fuel

injector

and fuel

injection

pump

Check and adjust fuel injection

pressure

○

Timing check and adjust of fuel

injection

○

Maintenance of fuel injector

and fuel injection pump

●

Picture 6 Clean air filter places full of dust(such as quarrying plant, coal yard

or road building plant), foreign matter inside the oil filter should be cleaned; Take out filter

element parts from air filter shell, blow dust down with compression air. Please replace filter

element parts if papery filter element is broken. Clean oil sludge inside the air filter; cover the air

inlet port with cloth to prevent some other matter dropping into the air inlet manifold.

2.2.4 Install the air filter, pay attention to the sealing condition between filter element and

connecting pipe to prevent air entering into cylinder not through filter element.

2.3 Check per 250h operation

2.3.1 Replace lube oil and filter element inside the oil filter, replace once per 250h operation from

the second time.

2.3.2 Check and clean radiator element: Dust and dirt adhesion on the radiator element will

reduce radiator’s cooling performance and result in engine’ overheat, you can advance the

cleaning according to special condition, or even clean it everyday; Flow down dust and dirt

around the radiator element with 196kPa(2kgf/cm2)compression air or even the lower air

pressure compression air. If there is still dirt, clean completely with detergent and water; Wear

protecting grasses to prevent dust or floating matter hurting your eyes before using compression

air; don’t try to clean radiator element with high pressure water tap and high pressure air, or try

to clean with brush, which will damage radiator element.

2.3.3 Replace air filter element: Damaged filter element will bring air enter into cylinder without

filtering, and accelerates wear of valve, cylinder, piston and piston ring. Dusty air filter element

will result in hard starting, power decrease and black smoke of engine.

2.4 Check per 500h operation

2.4.1 Replace fuel filter: Regularly replace diesel filter element before it is blocked by oil mist.

(1) Close oil tank switch, disassemble inlet/exhaust pipe, take out diesel filter element, and then

clean the fuel filter seat.

(2) Replace filter element, install the fuel filter.

(3) Install the fuel inlet/exhaust pipe, turn on oil tank switch, and drain out air in fuel line,

otherwise hard starting or stop running after starting will be resulted.

2.4.2 Replace cooling water: Drain out water after the cooling water is cooled down, in order to

prevent be scalded by the splashing hot water.

(1) Cooling water which contains iron rust or incrustation will deduce cooling performance, as

well as refrigerating fluid.

(2) Cooling water should be replaced at least once per year. Fill in soft water only after draining

out the cooling water.

2.4.3 Check and adjust valve clearance

Make sure that the valve is off, because only in that condition there will be valve clearance.

Notice: This single cylinder/double cylinder engine is marked from flywheel terminal to gearing

box terminal, which is different from the normal way. Upper dead point line for each cylinder is

marked on the flywheel; you can see them from the dead point view port hole on flywheel cover

(φ30). Upper dead point line for single cylinder is marked on engine body.

(1) Adjust valve clearance

a) Make sure the 1st cylinder piston is at the compression upper dead point, you can then

adjust the inlet/exhaust air clearance of the 1

st

cylinder 0.1mm;

b) Revolve flywheel 280° in anticlockwise direction after regulation, and adjust the

inlet/exhaust air clearance of 2

nd

cylinder 0.1mm;

Notice: Do remember tighten the adjusting screw cap tightly after regulation, otherwise it will

loosen soon and cause engine fail to work.

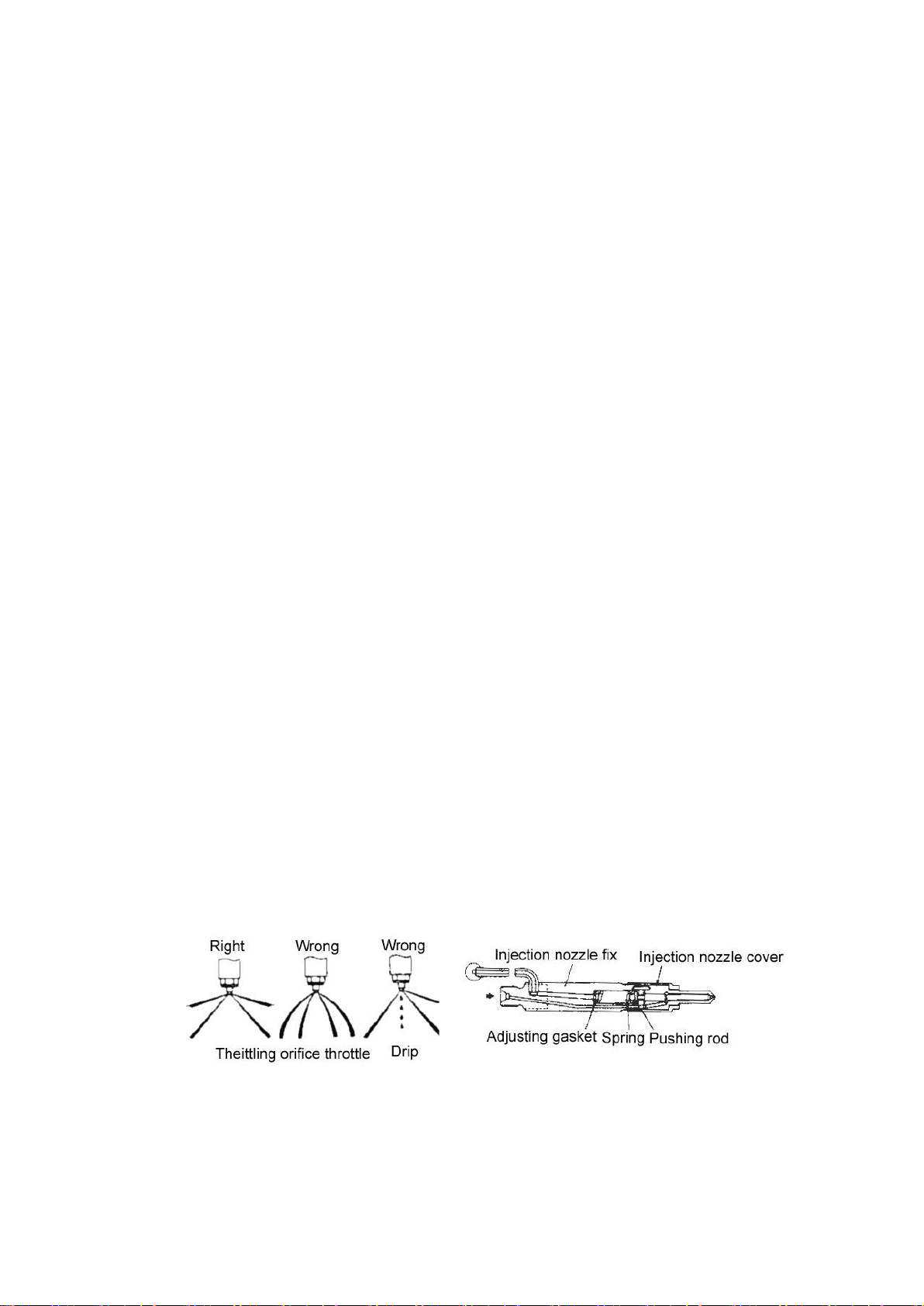

2.4.4 Check and adjust fuel injector: Check and regulation of fuel injecting pressure and injecting

mist quality should be operated on the fuel injecting experiment table.

(1) If the fuel injecting pressure is incorrect, please revolve down the fuel injecting parts fasten

cap, take out adjusting gasket and replace for a new one , so that the fuel injecting pressure

can attach to the correct valve(13±0.5)MPa.

(2)If the fuel injecting pressure is correct while the quality of injecting mist is poor, please clean

the injecting hole or replace the fuel injector parts;

(3)When installing fuel injector into the cylinder cover, please use the original fuel injecting

washer to make sure the fuel injecting head extend 2.2-2.3mm. Too big mistake will affect power,

fuel consumption or exhaust smoke of diesel engine.

2.5 Check per 1000h operation

2.5.1 Check and adjust the injection advance angle (please leave it to specialist, for this task

needs special tools, knowledge and skill).

a. Concrete steps

(1) Refill the fuel injection pump with fuel, and revolve the flywheel in clockwise direction to the

compression upper dead centre. Resolve the flywheel for several times until there is fuel flowing

out.

(2) Install the high pressure oil pipe tie which is used for measuring the oil supplying advance

angle, then resolve the flywheel to drain out the air inside. Stop the flywheel at 30° BTDC.

(3) Resolve the flywheel slowly in clockwise direction and check the oil level, stop the flywheel

immediately when oil begins fluctuating. The oil supplying advance angle is supposed to be 18.5°

±1°, if not, you should disassemble the fuel injection pump assembly, replace the adjust gasket,

check and adjust for another time until the value gets to 18.5°±1°.

(4) Screw on the fuel injection pump fixed bolt after adjusting and install the high pressure oil

pipe parts in turn.

Notice: Drain out the air in the high pressure oil pipe.

The rust and scale in the cooling system will worsen the heat abstraction performance and

increase the cooling water temperature. So please clean the rust and scale in the cooling system

by professional.

2.6 Check per 2000h running

2.6.1 Check and replace fuel、lube oil、cooling water and rubber hose. Check each kind of rubber

hose regularly; replace them if there is damage or aging.

2.6.2 Check and grind sealing ring belt of intake/exhaust valve. Please consult with the specialist

because professional skill is needed. You should check the sinking quantity of air door, width of

sealing ring belt and clearance between valve stem and valve pipe.

2.6.3 Check performance of fuel injection pump, this job needs oil pump experiment table, so

please consult with the specialist to maintain. You should check aiming point oil supply quantity,

starting oil quantity, oil supply uniformity of each cylinder, governor, maximum and minimum

stable rotation limit.

Disassembly and reassembly of diesel engine

1. Basic procedure of disassembly

(1) Prepare necessary room or container to store parts before disassembly, put each kind of bolt

and screw as well as related parts together, in order to prevent possible mistaken.

(2) Make sure what problem there is before disassembling; avoid mistaken disassembly.

1.1 Disassemble muffler weldment

(1) Loosen the four M8 nuts which fix the muffler weldment.

(2) Remove the muffler weldment from the cylinder cover.

Refer to picture 11

picture 11

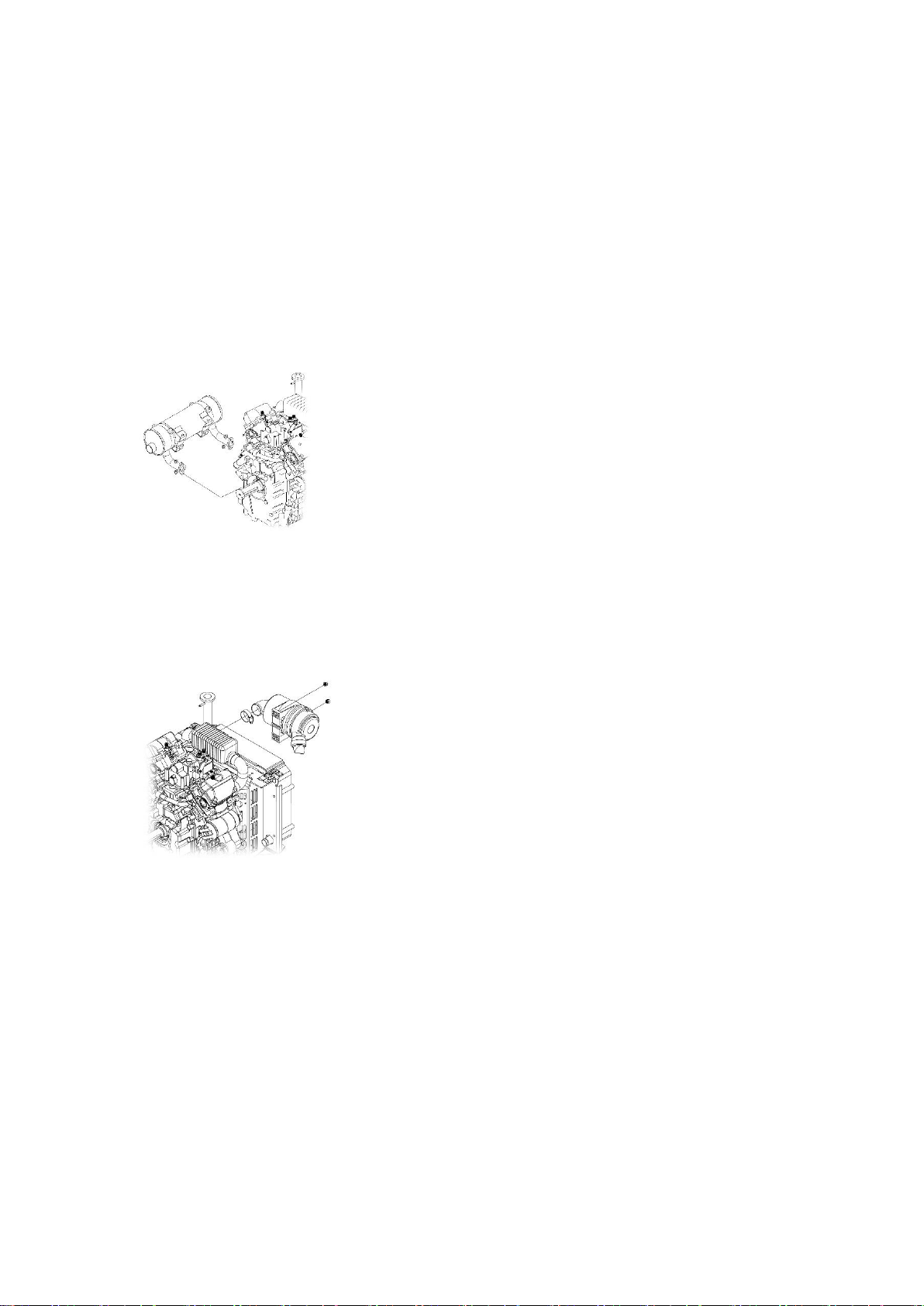

1.2 Disassembly the air filter assembly

(1) Loosen the two M8 nuts which fix the air filter seat.

(2) Loosen the hoop of the connection hose.

(3) Remove the air filter assembly.

Refer to picture 12

picture 12

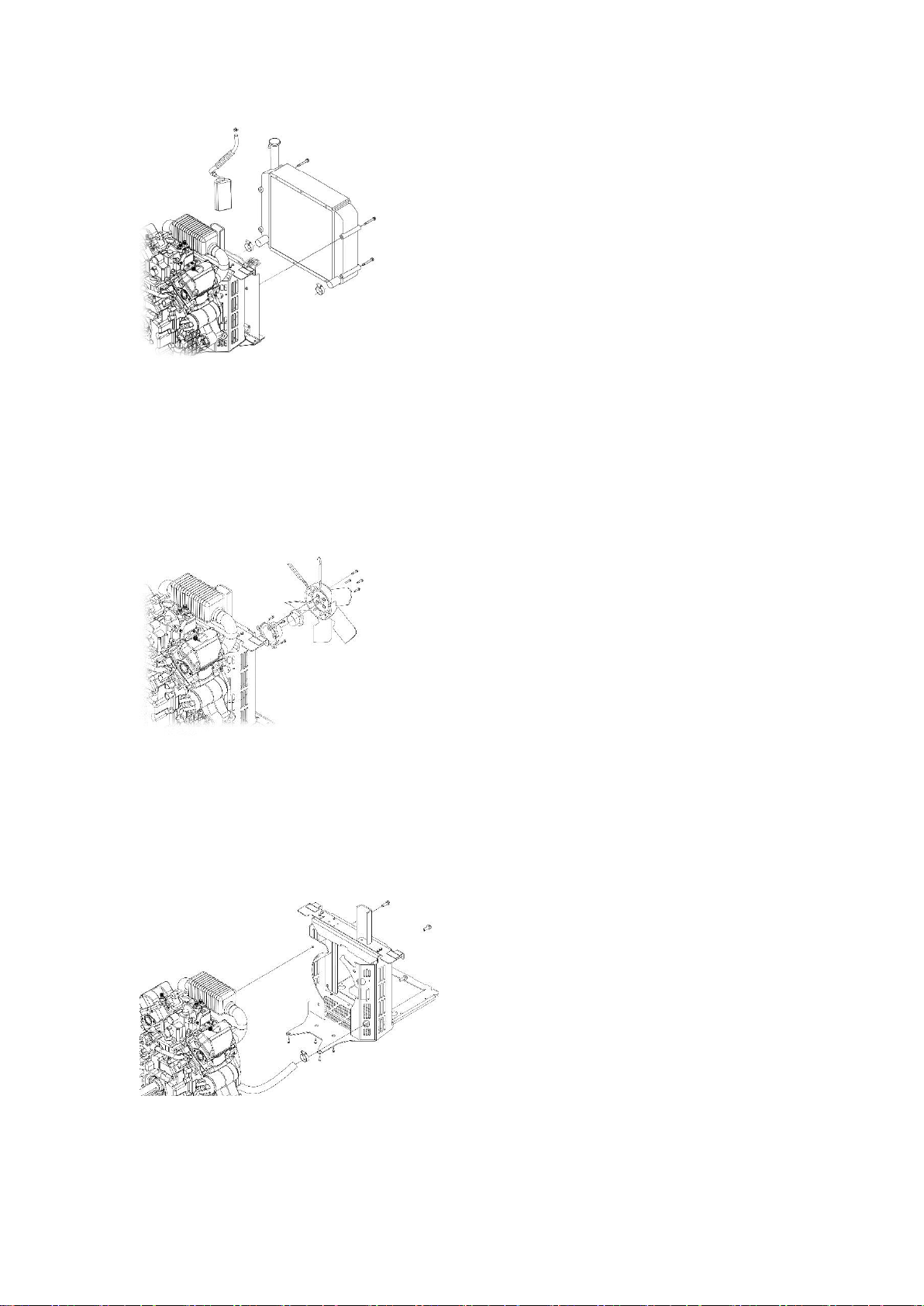

1.3 Disassemble the heat abstraction water tank and overflow tank parts

(1) Loosen the four M8X10 bolts and nuts which fix the heat abstraction water tank parts

(2) Loosen the hoop which fixes the inlet/outlet hose of heat abstraction water tank

(3) Remove the heat abstraction water tank parts

(4) Remove the overflow tank.

Refer to picture 13

picture 13

1.4 Disassemble fan gasket、fan impeller and fan seat

(1) Loosen the four M6×25 bolts, which fix fan impeller and fan gasket and then remove the fan

impeller and fan gasket.

(2) Loosen the three M6×16 bolts which fix fan seat and then remove the fan seat.

Refer to picture 14

picture 14

1.5 Disassembly the air conduct cover parts

(1) Loosen the three M10X20 bolts which fix the air conduct cover parts on the flywheel end.

(2) Loosen the four M6X16 bolts which fix the air conduct cover parts on the engine seat.

(3) Remove the air conduct cover parts

Refer to picture 15

picture 15

1.6 Disassemble the inlet pressurizer tank

(1) Loosen the four M6X18 bolts which fix the inlet pressurizer tank parts on the cylinder cover

Loading...

Loading...