Congratulations, and welcome to the fabulous world of EX35/40/45/50 ownership, where serious work is made

fun again!

This versatile tractor is a culmination of the entire tractor and diesel knowledge gained by the Daedong Industrial Co.,LTD over the years since 1947 and has been designed with the finest materials and under rigid quality

control standards set forth by the KIOTI Engineering Department.

Knowledge of tractor operation is essential for many years of dependable service and reliability. To help new

owner's familiarize themselves with the KIOTI EX35/40/45/50, it is the policy of KIOTI tractor to provide an

owner's manual which includes helpful information about tractor safety, operation and maintenance. If the infor-

mation you seek is not found in this manual, your KIOTI tractor dealer will be happy to help you.

Please feel free to contact DAEDONG IND. CO.,LTD with your questions/concerns.

FOREWORD

This manual includes information titled as WARNING, CAUTION, IMPORTANT

and NOTE. These titles indicate the following:

SAFETY AND VEHICLE DAMAGE WARNING

NOTE

This indicates that interesting or helpful information is being

provided.

CAUTION

!!

!!

!

This indicates that a condition may result in damage to your

vehicle or its equipment if the caution is not heeded. Follow the

advice provided with the caution.

WARNING

This indicates that a condition may result in harm, serious injury

or death to you or other persons if the warning is not heeded.

Follow the advice provided with the warning.

!!

!!

!

This mark indicates emphasis on notable characteristics of working procedures, and information about technology for easier

operation.

IMPORTANT

ABBREVIATION LIST

ABBREVIA TIONS

4WD

API

ASAE

ASTM

fpm

Hi-Mid-Lo

HST

m/s

PTO

RH/LH

ROPS

m

-1

(rpm)

S

-1

(r/s)

SAE

SMV

DEFINITIONS

Four Wheel Drive

American Petroleum Institute

American Society of Agricultural Engineers, USA

American Society of Testing and Materials, USA

Feet Per Minute

High Speed-Middle Speed-Low Speed

Hydrostatic Transmission

Meters Per Second

Power Take Off

Right-hand and Left-hand sides are determined by facing in the direction of forward travel

Roll-Over Protective Structures

Revolutions Per Minute

Revolutions Per Second

Society of Automotive Engineers, USA

Slow Moving Vehicle

Various universal symbols have been used on the instruments and controls of your KIOTI tractor. Below is a list

of the universal symbols and their meanings.

UNIVERSAL SYMBOLS

Fuel-Level

Engine Coolant-Temperature

Parking Brake

Battery Charging Condition

Engine Oil-Pressure

Turn Signal

Power Take-Off Clutch Control-

ON Position

Power Take-Off Clutch Control-

OFF Position

Differential Lock

Position Control-Lowered Position

Hazard Warning Lights

Headlight-Low Beam

Headlight-High Beam

Four-Wheel Drive-ON

Fast

Slow

Creep

High Range

Middle Range

H

L

Low Range

Coolant

Preheat

QT lamp

H:High speed travel light

M:Middle speed travel light

L:Low speed travel light

Neutral Position

Single brake light

M

N

SAFETY PRECAUTIONS .............................................

SERVICING OF TRACTOR .........................................

SPECIFICATIONS.........................................................

DESCRIPTION OF OPERATING SYSTEM ..............

OPERATION...................................................................

THREE-POINT HITCH & DRAWBAR........................

HYDRAULIC UNIT ........................................................

TIRES, TREAD AND BALLAST .................................

MAINTENANCE .............................................................

PERIODIC SERVICE ....................................................

STORAGE.......................................................................

TROUBLESHOOTING ..................................................

OPTIONS ........................................................................

INDEX ..............................................................................

TABLE OF CONTENTS

SECTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

BEFORE OPERATING THE TRACTOR .................... 1-2

OPERATING THE TRACTOR .................................... 1-5

DRIVING THE TRACTOR ........................................... 1-8

PARKING THE TRACTOR ......................................... 1-9

OPERATING THE PTO ............................................. 1-10

USING 3-POINT HITCH ............................................. 1-10

SERVICING THE TRACTOR .................................... 1-11

TRACTOR SAFETY LABELS ................................... 1-14

SAFETY PRECAUTIONS

EX35/40/45/50

1

-2

A careful operator is the best operator.

Most accidents can be avoided by observing certain precautions. To help prevent accidents, use these safety

precautions, and pay attention to the

job at hand. If you can prevent an

accident, your time will have been well

spent.

BEFORE OPERA TING THE

TRACTOR

5. Keep safety decals clean of dirt and

debris.

6. Watch where you are going at all

times so that you are able to avoid

obstacles that can cause injury or

damage to your tractor.

7. When starting the tractor make sure

your path is clear of people to avoid

accidents caused by sudden

movements.

8. Before making reverse movements

with your tractor, you should always

check to see that the path is clear.

1. It is recommended that you read and

understand this entire manual before

operation of your new tractor. Failure to do so could result in accidents

or injury.

2. Only persons who are properly

trained should be allowed to operate

the tractor.

3. Read and follow all warning labels

and decals affixed to the tractor.

4. Replace any missing or damaged

decals as soon as it is practical. A

list of decals is shown on page114~16.

T46O101A T46O102A

1

-3

SAFETY PRECAUTIONS

16. All persons using the tractor should

have knowledge of its proper operation and should read this manual

carefully.

17. Never get off the tractor without setting the parking brake, lowering the

implement to the ground and shutting of the tractor.

18. No alterations should be made to

your KIOTI tractor.

12. Never start the engine while standing on the ground.

13. Only the operator should ride on the

tractor unless a passenger seat is

installed. Keep bystanders away

from the tractor while in operation.

14. When getting on and off the tractor,

handholds and step plates should

always be used. This will help to

prevent accidental slips trips and

falls.

15. Be sure to scrape off mud or soil

from your shoes before mounting

the tractor.

T46O103A T46O104A T46O105A

9. Never operate this tractor or any

other agricultural equipment while

under the influence of alcohol,

drugs or while fatigued.

10. While working in cooperation with

other tractors always communicate

your intentions.

11. Do not start your tractor by shorting across the starter.

EX35/40/45/50

1

-4

21. Extra caution should be taken when

driving tractors with narrow tread

widths. For added stability you

should adjust your rear wheel tread

width, see page 8-4.

19. Before starting your tractor you

should depress the clutch and

make sure that all shift levers are

in the neutral position and parking

brake is applied.

20. For your safety ROPS with a seat

belt is recommended for all

applications.

(1) Tread

T46O106A

T46O107A

A ROPS should never be modified by

welding, grinding or cutting, as this

can weaken the ROPS structure. If any

components of the ROPS unit is

damaged, it must be replaced.

If the ROPS unit is removed or loos-

ened for any reason, the parts should

be fitted back to their original positions

and all bolts should be properly

torqued.

Always use seat belt when the

tractor is equipped with a ROPS.

Never use the seat belt when trac-

tor is not equipped with a ROPS.

NOTE

1

-5

SAFETY PRECAUTIONS

1. Avoid accidental contact with gear

shift levers while the engine is

running. Unexpected tractor movements can result in bodily injury.

2. Do not park your tractor on a steep

incline, and remember to shut off the

engine and PTO before dismounting the tractor.

OPERATING THE TRACTOR

T46O109A

T46O108A T46O110A

3. Do not operate your tractor in an enclosed building without the proper

ventilation. Exhaust fumes contain

carbon monoxide and may cause

series injury or death.

EX35/40/45/50

1

-6

7. Always use the proper ballast weight

on your tractor when using rear

implements.

8. Watch front and rear to avoid obstacles at row ends, near trees and

around other obstructions.

4. Make sure that all pressure lines are

tight before starting the tractor.

5. Pull only from the drawbar. Never

hitch anything to the axle housing or

any other point except the drawbar.

Pulling from any other location only

increase the risk of serious personal

injury or death.

6. If the front of the tractor tends to rise

up when heavy implements are attached to the three point hitch,

weights should be installed on the

tractor. Do not operate the tractor

with a light front end.

(1) Drawbar

T46O111A T46O112A T46O113A

1

-7

SAFETY PRECAUTIONS

9. Do not leave equipment in the

raised position when the vehicle is

stopped or unattended.

10. When using implements or attachments with your tractor you should

first read their respective owner's

manual. You should always keep

their safe operation procedures in

mind.

11. You should be familiar with your

equipment and its limitations.

12. If abused or used incorrectly your

tractor can become dangerous to

you and bystanders. Overloading

your tractor or using unsafe equipment can also be dangerous and

should be avoided. Refer to the

"Specifications of Implement

Limitation", which outlines the

maximum load for safe tractor

operation.

15. When working in groups, always let

the others know what you are going to do before you do it.

16. Never "freewheel". Disengaging the

clutch or shifting into neutral while

descending a slope as this could

lead to a loss of control.

17. Do not operate near ditches, holes,

embankments, or other terrain features which may collapse under the

tractor's weight. The risk of tractor

upset is even higher when the

ground is loose or wet.

13. Driving forward out of a ditch or

steep inclines can cause the tractor to tip over backwards. To avoid

this you should back out of these

positions. Four wheel drive tractors

can give you a false sense of security in the tractors ability to maneuver out of these positions, so

extra caution should be taken.

14. Never try to get on or off a moving

tractor.

T46O114A T46O115A

EX35/40/45/50

1

-8

1. Lock the brake pedals together when

traveling at road speeds. Brake both

wheels simultaneously when making an emergency stop. Uneven

braking at road speeds could cause

the tractor to tip over.

DRIVING THE TRACTOR

(1) Interlock (2) Brake Pedal (L)

(3) Brake Pedal (R)

(1) Interlock (2) Brake Pedal (L)

(3) Brake Pedal (R)

MANUAL type

T46O118AT46O117AT46O116A

HST type

2. Always slow the tractor before

turning. Turning at high speed may

tip the tractor over or cause an operator to lose control of the tractor.

1

-9

SAFETY PRECAUTIONS

3. Make sure that the Slow Moving Vehicle (SMV) sign is clean and visible.

Use hazard lights as required.

1. Disengage the PTO, lower all

implements, place all control levers

in the neutral position, set the parking brake, stop the engine and remove the key.

PARKING THE TRACTOR

(1) SMV Emblem

T46O119A T46O120A

4. Observe all local traffic and safety

regulations.

5. Turn the headlights on. Dim them

when meeting another vehicle.

6. Drive at speeds that allow you to

maintain control at all times.

7. Do not apply the differential lock

while traveling at road speeds. As

the tractor may lose the ability to

steer.

8. Avoid sudden movements of the

steering wheel as this can cause a

loss of control of the tractor. This

risk is especially great when traveling at road speeds.

9. Do not operate an implement while

the tractor is on the road. Lock the

three point hitch in the raised

position.

10. When towing other equipment, use

a safety chain and place an SMV

emblem on it as well.

EX35/40/45/50

1

-10

(1) 3-point hitch lowering speed knob

(A) “FAST” (C) “LOCK”

(B) “SLOW”

USING 3-POINT HITCH

1. Use the 3-point hitch only with equipment designed for 3-point hitch

usage.

2. When using a 3-point hitch mounted

implement, be sure to install the

proper counterbalance weight on the

front of the tractor.

3. When transporting on the road, set

the implement lowering control in the

"LOCK" position to hold the implement in the raised position.

(1) PTO Shield

(2) PTO Shaft Cap

OPERATING THE PTO

T46O122AT46O121A T46O123A

1. Make sure the tractor is completely

stopped, gears are in neutral and all

moving components have completely stopped before connecting,

disconnecting, adjusting, cleaning or

servicing any PTO driven equipment.

2. Keep the PTO shield in place at all

times. Replace the PTO shaft cap

when the shaft is not in use.

3. Before installing or using PTO driven

equipment, read the manufacturer's

manual and review the safety labels

attached to the equipment.

4. When operating stationary PTO driven

equipment, always apply the tractor

parking brake and place chocks behind and in front of the rear wheels.

Stay clear of all rotating parts.

5. Do not attach a PTO driven implement

if the implement’s safety shields are

damaged or not in place. Rotating

shafts are an entanglement hazard.

1

-11

SAFETY PRECAUTIONS

2. Allow the tractor time to cool off before servicing any part that may have

become hot while the tractor was

running.

3. You must always stop the engine before refueling the tractor. Avoid overfilling the tractor or spilling the fuel.

4. Before jump starting a dead battery,

read and follow all of the instructions.

5. It is recommended to keep a first aid

kit and fire extinguisher handy at all

times.

In order to service your tractor you must

park it on a flat level surface, set the

parking brake, place the gear shift lever in neutral and stop the engine.

1. Do not smoke while working around

the battery or when refueling your

tractor. Keep all sparks and flames

away from the battery and fuel tank.

The battery presents an explosive

hazard because it gives off hydrogen and oxygen… especially when

recharging.

SERVICING THE TRACTOR

6. Do not remove the radiator cap while

the coolant is hot. When cool, slowly

rotate the cap to the first stop and

allow sufficient time for excess pressure to escape. After all the pressure is released remove the cap

completely. If your tractor is

equipped with a coolant recovery

tank, add coolant there rather than

to the radiator.

T46O124A T46O125A T46O126A

EX35/40/45/50

1

-12

(1) Cardboard (3) Magnifying Glass

(2) Hydraulic Line

12. Make sure that wheel bolts have

been tightened to the specified

torque.

13. Escaping hydraulic fluid under pres-

sure has sufficient force to penetrate skin, causing serious personal injury. Be sure to release all

residual pressure. Before disconnecting hydraulic lines.

Before adding pressure to the hydraulic system, make sure that all

connections are tight and that all

line, pipes and hoses are free of

damage.

7. When working with your tractors

electrical components you must first

disconnect the battery cables.

8. To ensure that there are no accidents

from sparks you must first disconnect the negative battery cable.

T46O129AT46O128AT46O127A

9. Tire mounting should be done by

qualified professionals, with the

proper equipment.

10. Maintaining correct tire pressure is

important for the life of your tires.

Do not inflate the tires above the

recommended pressure specified

in the owner’s manual or on the

tractor tire.

11. Securely support the tractor when

changing wheels or the wheel tread

width.

1

-13

SAFETY PRECAUTIONS

14. Fluid escaping from pinholes may

be invisible. Do not use hands to

search for suspected leaks;

Use a piece of cardboard or wood,

instead. Use of safety goggles or

other eye protection is also highly

recommended. If injured by escaping fluid, see a medical doctor at

once. This fluid can produce gangrene and/or severe allergic

reaction.

T46O130A T46O131A

15. Keep environmental pollution in

mind. When replacing coolant or

oil, dispose of it the right way.

Be sure to observe all relevant

regulations when you dispose of

engine oil, transmission oil, fuel,

coolant, filters and battery.

EX35/40/45/50

1

-14

T46O132A

TRACTOR SAFETY LABELS

1

-15

SAFETY PRECAUTIONS

(2) Part No. : T2625-55111 (4) Part No. : T4625-52361

(3) Part No. : T4625-52351 (5) Part No. : T2615-54112

(6) Part No. : T2350-54141

(1) Part No. : T2615-53561

EX35/40/45/50

1

-16

(7) Part No. : T2325-50512 (9) Part No. : T2181-54121

(10) Part No. : T2325-50743(8) Part No. : T2445-50724

2

SERVICING ..................................................................2-2

SERVICING OF TRACTOR

2

-2 EX35/40/45/50

SERVICING

T46O201A

Your dealer is interested in your new

tractor and has the desire to help you

get the most value from it. After reading this manual thoroughly, you will find

that you can do some of the regular

maintenance yourself.

However, when in need of parts, warranty or major service, be sure to see

your KIOTI dealer. For service, contact the KIOTI dealership from which

you purchased your tractor or your lo-

cal authorized KIOTI dealer.

When in need of parts, be prepared to

give your dealer both the tractor and

engine serial numbers.

The tractor serial number is located on

the front axle support on the left side

of the tractor. The engine serial number is located on the upper side of the

engine head cover. The transmission

number is located on the rearward of

the tractor and the transmission case

in the upward of the PTO cover. Locate the serial numbers now and record

them in the space provided.

S/N Identification No.

Engine Serial No.

T ransmission Serial No.

To be filled in by purchaser

Date of Purchase

(1) S/N Identification Plate (2) Transmission Serial Number (3 ) Engine Serial Number

Before using NON-KIOTI approved

implements or attachments, contact

your nearest dealer regarding safety

and application.

3

SPECIFICATIONS........................................................ 3-2

TRAVELING SPEED .................................................... 3-4

IMPLEMENT LIMITATIONS ........................................ 3-7

SPECIFICATIONS

3

-2 EX35/40/45/50

SPECIFICATIONS

Model

Engine

Capacities

Model

Type

Displacement cc (cu.in.)

Gross Engine Power HP (kW)

PTO HP (kW)

Rated speed rpm

Fuel Tank

(U.S. gals.)

T/M Case

(U.S. gals.)

F/A Case

(U.S. gals.)

Clutch

Transmission

Speed

KPH (MPH)

4-Wheel drive

Steering

Brake

Traveling

4 Cyl., In-line Vertical, Water-cooled 4-cycle

diesel engine

1,999 (121.98)

41 (30.5)

2,600

45 (11.9)

7.5 (2.0)

Dry type single stage

Button Switch FWD

Hydrostatic Power steering

Wet disk

3 Cyl., In-line Vertical, Water-cooled 4-cycle

diesel engine

1,826 (111.43)

38 (28.3)

2,600

45 (11.9)

7.5 (2.0)

Dry type single stage

Button Switch FWD

Hydrostatic Power steering

Wet disk

3B183LXM

28.5 (21.2)

52 (13.7)

F12/R12

[Option:F24/R24]

Synchro Shuttle

1.4~23.4 (0.8~14.5)

[Option:0.16~23.4

(0.1~14.5)]

4A200LXM

34.0 (25.3)

52 (13.7)

F12/R12

[Option:F24/R24]

Synchro Shuttle

1.4~24.5 (0.9~15.2)

[Option:0.17~24.5

(0.11~15.2)]

3B183LXH

27.0 (20.1)

42 (11.1)

3 Range HST Hydraulic

servo mechanism

Twin pedal

0~25.8 (0~16.0)

4A200LXH

32.5 (24.2)

42 (11.1)

3 Range HST Hydraulic

servo mechanism

Twin pedal

0~27.0 (0~16.7)

[MODEL: EX35/40/45/50]

EX40

Manual HST

EX35

Manual HST

3

-3

SPECIFICATIONS

Model

Engine

Capacities

Model

Type

Displacement cc (cu.in.)

Gross Engine Power HP (kW)

PTO HP (kW)

Rated speed rpm

Fuel Tank

(U.S. gals.)

T/M Case

(U.S. gals.)

F/A Case

(U.S. gals.)

Clutch

Transmission

Speed

KPH (MPH)

4-Wheel drive

Steering

Brake

Traveling

4 Cyl., In-line Vertical, Water-cooled 4-cycle

diesel engine

2,197 (134.06)

45 (33.5)

2,600

45 (11.9)

7.5 (2.0)

Dry type single stage

Button Switch FWD

Hydrostatic Power steering

Wet disk

4A220LXM

38.0 (28.3)

52 (13.7)

F12/R12

[Option:F24/R24]

Synchro Shuttle

1.5~25.8 (0.9~16.0)

[Option: 0.18~25.8

(0.1~16.0)]

4A220LXH

36.0 (26.8)

42 (11.1)

3 Range HST Hydraulic

servo mechanism

Twin pedal

0~28.5 (0~17.7)

4 Cyl., In-line Vertical, Water-

cooled 4-cycle diesel engine

2,435 (148.6)

50 (37.2)

2,600

45 (11.9)

7.5 (2.0)

Dry type single stage

Button Switch FWD

Hydrostatic Power steering

Wet disk

4B243LXM

39.5 (29.5)

52 (13.7)

F12/R12

[Option:F24/R24]

Synchro Shuttle

1.5~25.8 (0.9~16.0)

[Option: 0.18~25.8

(0.1~16.0)]

4B243LXH

37.5 (27.9)

42 (11.1)

3 Range HST Hydraulic

servo mechanism

Twin pedal

0~28.5 (0~17.7)

[MODEL: EX35/40/45/50]

EX50

Manual HST

EX45

Manual HST

3

-4 EX35/40/45/50

Model

Hydraulic

PTODimensions

1,667 (3,375)

1,664 (3,338)

8-16 / 6PR

27-8.5-15 / 4PR

10-16.5 / 6PR

13.6-24 / 6PR

41-14.0-20 / 4PR

14.9-24 / 6PR

Position,draft and mixed control

63.9 (16.8)

SAE Category I

1,131 (2,493)

1,334 (2,940)

Hydrostatic,Independent

SAE 1-3/8, 6 Splines

540

16/32 Involute spline

2,000

3,505 (138.0)

1,635 (64.4)

2,415 (95.1)

1,880 (74.0)

1,245 (49.0)

1,290~1,490 (50.8~58.7)

340 (13.4)

2.91 (9.5)

1,780 (3,924)

1,745 (3,847)

7-16 / 6PR

27-8.5-15 / 4PR

27-10.5-15 / 6PR

12.4-24 / 6PR

41-14.0-20 / 4PR

43-16-20 / 4PR

Position,draft and mixed control

57.8 (15.2)

SAE Category I

1,081 (2,383)

1,172 (2,583)

Hydrostatic, Independent

SAE 1-3/8, 6 Splines

540

16/32 Involute spline

2,000

3,422 (134.7)

1,552 (61.1)

2,395 (94.3)

1,767 (69.6)

1,248 (49.1)

1,221~1,348 (48.1~53.1)

320 (12.6)

2.85 (9.3)

Weight(With ROPS)

kg (lbs.)

Front

Rear

Hydraulic control

Pump capacity

/min (U.S.gpm)

Three point hitch

Lift capacity

Rear

Mid

(Option)

Overall length

(includes 3P)

mm(in.)

Overall width

(minimum tread)

mm(in.)

Overall height(from Top of ROPS)

mm(in.)

Wheel base mm(in.)

Wheel tread

Min.ground clearance

mm(in.)

Min. turning radius

(with brake)

m(feet)

24” aft. of hitch

Lift Link Ends

Type

Shaft size

Speed rpm

Front

mm(in.)

Rear mm(in.)

AG

Turf

Industrial

AG

Turf

Industrial

Standard Tire size

kg (lbs.)

[MODEL: EX35/40/45/50]

EX40

Manual

HST

EX35

Manual

HST

3

-5

SPECIFICATIONS

Model

Hydraulic

PTODimensions

1,800 (3,968)

1,785 (3,935)

Weight(With ROPS)

kg (lbs.)

Front

Rear

Hydraulic control

Pump capacity

/min (U.S.gpm)

Three point hitch

Lift capacity

Rear

Mid

(Option)

Overall length

(includes 3P)

mm(in.)

Overall width

(minimum tread)

mm(in.)

Overall height(from Top of ROPS)

mm(in.)

Wheel base mm(in.)

Wheel tread

Min.ground clearance

mm(in.)

Min. turning radius

(with brake)

m(feet)

24” aft. of hitch

Lift Link Ends

Type

Shaft size

Speed rpm

Front

mm(in.)

Rear mm(in.)

AG

Turf

Industrial

AG

Turf

Industrial

Standard Tire size

kg (lbs.)

[MODEL: EX35/40/45/50]

9.5-16 / 6PR

29-12.5-15 / 4PR

12-16.5 / 6PR

13.6-26 / 6PR

21.5L-16.1 / 4PR

17.5L-24 / 8PR

Position,draft and mixed control

63.9 (16.8)

SAE Category I

1,131 (2,493)

1,334 (2,940)

Hydrostatic, Independent

SAE 1-3/8, 6 Splines

540

16/32 Involute spline

2,000

3,505 (138.0)

1,646 (64.8)

2,445 (96.3)

1,880 (74.0)

1,365 (53.7)

1,305~1,480 (51.4~58.3)

370 (14.6)

3.13 (10.2)

EX45

Manual

HST

9.5-16 / 6PR

29-12.5-15 / 4PR

12-16.5 / 6PR

13.6-26 / 6PR

21.5L-16.1 / 4PR

17.5L-24 / 8PR

Position,draft and mixed control

63.9 (16.8)

SAE Category I

1,131 (2,493)

1,334 (2,940)

Hydrostatic, Independent

SAE 1-3/8, 6 Splines

540

16/32 Involute spline

2,000

3,505 (138.0)

1,646 (64.8)

2,445 (96.3)

1,880 (74.0)

1,365 (53.7)

1,305~1,480 (51.4~58.3)

370 (14.6)

3.13 (10.2)

1,792 (3,950)

1,780 (3,924)

EX50

Manual

HST

3

-6 EX35/40/45/50

TRAVELING SPEED

Km/h(m/h)

Hi-Low Main

Forward

Low

Mid

High

1

2

3

4

1

2

3

4

1

2

3

4

EX35 EX40 EX45/50 EX35 EX40 EX45/50

Shuttle Reverse

1.36(0.85)

1.90(1.18)

2.44(1.52)

3.32(2.06)

3.48(2.16)

4.86(3.02)

6.24(3.88)

8.48(5.27)

9.61(5.97)

13.43(8.35)

17.25(10.72)

23.42(14.55)

1.42(0.88)

1.99(1.24)

2.56(1.59)

3.47(2.16)

3.64(2.26)

5.08(3.16)

6.53(4.06)

8.86(5.51)

10.05(6.25)

14.04(8.72)

18.04(11.21)

24.48(15.21)

1.50(0.93)

2.10(1.31)

2.69(1.67)

3.65(2.27)

3.83(2.38)

5.36(3.33)

6.88(4.28)

9.34(5.80)

10.59(6.58)

14.80(9.20)

19.00(11.81)

25.80(16.03)

1.21(0.75)

1.69(1.05)

2.17(1.35)

2.95(1.83)

3.09(1.92)

4.32(2.68)

5.55(3.45)

7.53(4.68)

8.54(5.31)

11.93(7.41)

15.33(9.53)

20.81(12.94)

1.27(0.79)

1.77(1.10)

2.27(1.41)

3.08(1.91)

3.23(2.01)

4.52(2.81)

5.80(3.60)

7.88(4.90)

8.93(5.55)

12.48(7.76)

16.03(9.96)

21.76(12.94)

1.33(0.83)

1.86(1.16)

2.39(1.49)

3.25(2.02)

3.41(2.12)

4.76(2.96)

6.11(3.80)

8.3(5.16)

9.41(5.85)

13.15(8.17)

16.89(10.50)

22.92(14.24)

[MANUAL TRANSMISSION TYPE 12X12]

Forward

EX35 EX40 EX45/50

EX35 EX40 EX45/50

RANGE

Reverse

Km/h(m/h)

Low

Mid

High

6.08(3.78)

10.49(6.52)

25.85(16.06)

6.36(3.95)

10.97(6.82)

27.03(16.80)

6.70(4.16)

11.56(7.18)

28.47(17.69)

[HST TYPE]

6.08(3.78)

10.49(6.52)

25.85(16.06)

6.36(3.95)

10.97(6.82)

27.03(16.80)

6.70(4.16)

11.56(7.18)

28.47(17.69)

3

-7

SPECIFICATIONS

[MANUAL TRANSMISSION TYPE 24X24 : OPTIONAL]

Km/h(m/h)

Hi-Low Main

Forward

Low

Mid

Low

1

2

3

4

1

2

3

4

1

2

3

4

EX35 EX40 EX45/50 EX35 EX40 EX45/50

Shuttle Reverse

0.16(0.10)

0.23(0.14)

0.29(0.18)

0.39(0.24)

0.41(0.26)

0.57(0.35)

0.73(0.45)

1.00(0.62)

1.13(0.70)

1.58(0.98)

2.03(1.26)

2.75(1.71)

0.17(0.11)

0.23(0.14)

0.30(0.19)

0.41(0.26)

0.43(0.27)

0.60(0.37)

0.77(0.48)

1.04(0.65)

1.18(0.73)

1.65(1.03)

2.12(1.32)

2.88(1.79)

1.18(0.11)

0.25(0.16)

0.32(0.20)

0.43(0.27)

0.45(0.28)

0.63(0.39)

0.81(0.50)

1.1(0.68)

1.24(0.77)

1.74(1.08)

2.23(1.39)

3.03(1.88)

0.14(0.09)

0.20(0.12)

0.26(0.16)

0.35(0.22)

0.36(0.22)

0.51(0.32)

0.65(0.40)

0.89(0.55)

1.00(0.62)

1.40(0.87)

1.80(1.12)

2.45(1.52)

0.15(0.09)

0.21(0.13)

0.27(0.17)

0.36(0.22)

0.38(0.24)

0.53(0.33)

0.68(0.42)

0.93(0.58)

1.05(0.65)

1.47(0.91)

1.88(1.17)

2.56(1.59)

0.16(0.10)

0.22(0.14)

0.28(0.17)

0.38(0.24)

0.40(0.25)

0.56(0.35)

0.72(0.45)

0.98(0.61)

1.11(0.69)

1.55(0.96)

1.99(1.24)

2.69(1.67)

Creep

High

3

-8 EX35/40/45/50

Km/h(m/h)

Hi-Low Main

Forward

Low

Mid

High

1

2

3

4

1

2

3

4

1

2

3

4

EX35 EX40 EX45/50 EX35 EX40 EX45/50

Shuttle Reverse

1.36(0.85)

1.90(1.18)

2.44(1.52)

3.32(2.06)

3.48(2.16)

4.86(3.02)

6.24(3.88)

8.48(5.27)

9.61(5.97)

13.43(8.35)

17.25(10.72)

23.42(14.55)

1.42(0.88)

1.99(1.24)

2.56(1.59)

3.47(2.16)

3.64(2.26)

5.08(3.16)

6.53(4.06)

8.86(5.51)

10.05(6.25)

14.04(8.72)

18.04(11.21)

24.48(15.21)

1.50(0.93)

2.10(1.31)

2.69(1.67)

3.65(2.27)

3.83(2.38)

5.36(3.33)

6.88(4.28)

9.34(5.80)

10.59(6.58)

14.80(9.20)

19.00(11.81)

25.80(16.03)

1.21(0.75)

1.69(1.05)

2.17(1.35)

2.95(1.83)

3.09(1.92)

4.32(2.68)

5.55(3.45)

7.53(4.68)

8.54(5.31)

11.93(7.41)

15.33(9.53)

20.81(12.94)

1.27(0.79)

1.77(1.10)

2.27(1.41)

3.08(1.91)

3.23(2.01)

4.52(2.81)

5.80(3.60)

7.88(4.90)

8.93(5.55)

12.48(7.76)

16.03(9.96)

21.76(12.94)

1.33(0.83)

1.86(1.16)

2.39(1.49)

3.25(2.02)

3.41(2.12)

4.76(2.96)

6.11(3.80)

8.3(5.16)

9.41(5.85)

13.15(8.17)

16.89(10.50)

22.92(14.24)

Creep

High

3

-9

SPECIFICATIONS

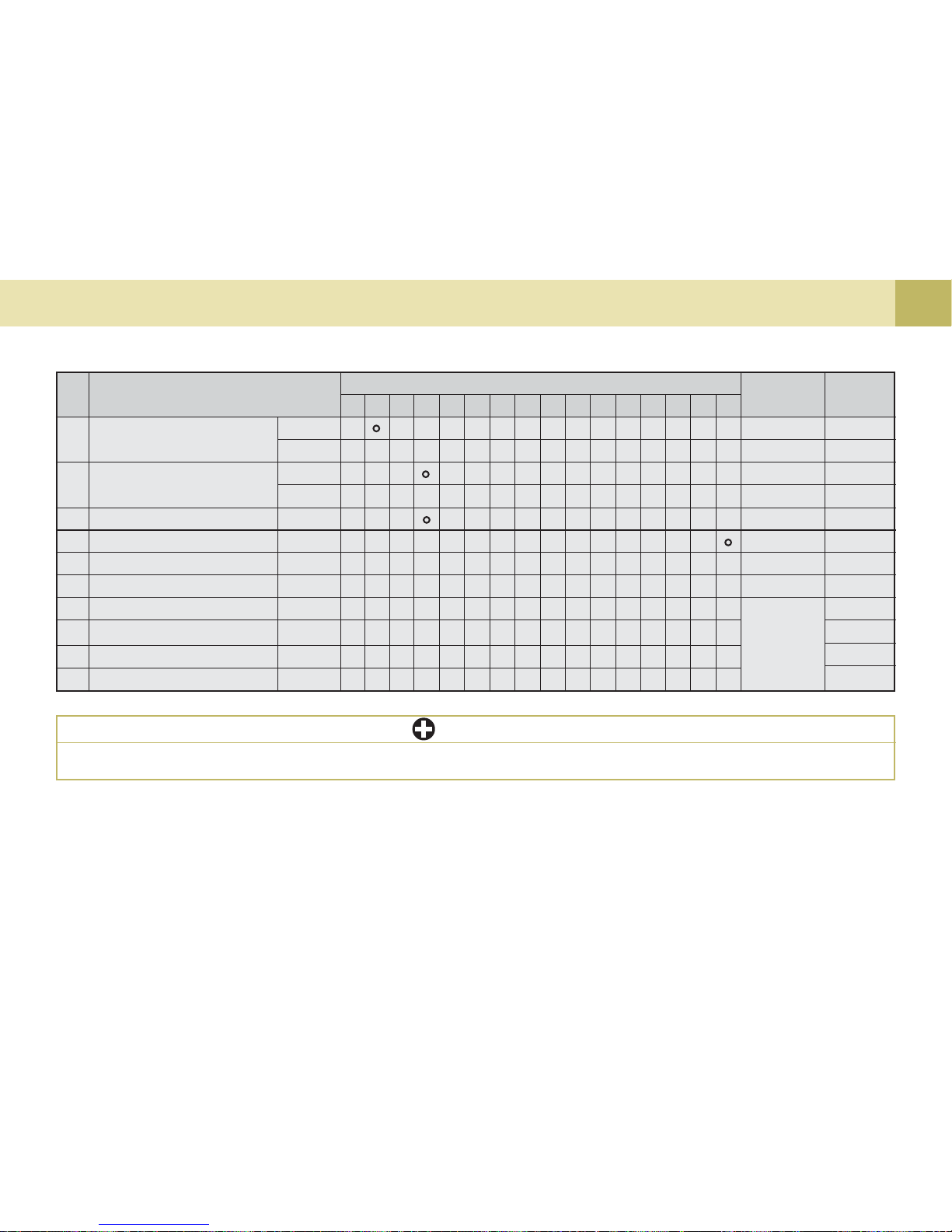

IMPLEMENT LIMIT ATIONS

This KIOTI tractor has been thoroughly tested for proper performance with implements approved by KIOTI. Use with

implements which are approved by KIOTI and which exceed the maximum specifications listed below, or which are otherwise unfit for use with this KIOTI tractor may result in malfunctions or failures of the tractor, damage to other property and

injury to the operator or others. [Any malfunctions or failures of the tractor resulting from use with improper implements are

not covered by the warranty.]

NOTE : Implement size may vary depending on soil types and field conditions.

Front

Tread (max. width)

Rear

Lifting Capacity max. loading weight .......... The max. allowable load which can be put on the 24 in. aft of hitch : W

0

Implement weight ....................................... The implement's weight which can be put on the lower link : W

1

Max. drawbar load ...................................... W

2

Trailer loading weight .................................. The max. loading weight for trailer (without trailer's weight) : W

3

Model

Item

Implement weight W1 and / or size

Actual figures

Max. Drawbar Load W

2

Model

Item

650 kg

(1433.0 lbs.)

1,248 mm (49.1 in)

1,245 mm (49.0 in)

1,365 mm (53.7 in)

1,348 mm (53.1 in)

1,490 mm (58.7 in)

1,515 mm (59.6 in)

As in the following list

(Shown in the next page)

Lifting Capacity max.

loading weight

(24 in. aft of hitch)

T46O301A

Trailer loading weight

W

3

Max. capacity

3,500 Kg

(7716.1 lbs.)

EX35

EX40

EX45/50

EX35

EX40

EX45/50

1,081 Kg (2,383 lbs. )

1,131 Kg (2,493 lbs.)

3

-10 EX35/40/45/50

REMARKS

EX35 EX40

IMPLEMENT

Loader

Backhoe with sub frame

Tiller

Box Blade

Rear Blade

Rotary Cutter

Grooming Mower

Aerator

Landscape Rakes

REMARKS

Max. Bucket width mm(in)

Max. Digging depthmm(ft.in)

Max. working widthmm(in)

Max. Cutting width mm(in)

Max. Cutting width mm(in)

Max. Cutting width mm(in)

Max. Cutting width mm(in)

Max. Width mm(in)

Max. Cutting width mm(in)

EX45/50

1,676 (66)

2,280 (7.48)

1,650 (65)

2,133 (84)

2,133 (84)

1,650 (65)

1,828 (72)

1,828 (72)

2,133 (84)

1,828 (72)

2,590 (8.5)

1,854 (73)

2,133 (84)

2,133 (84)

1,854 (73)

1,828 (72)

1,828 (72)

2,483 (96)

1,828 (72)

2,590 (8.5)

1,854 (73)

2,133 (84)

2,133 (84)

1,854 (73)

1,828 (72)

1,828 (72)

2,483 (96)

4

EXTERIOR VIEW ......................................................... 4-2

INSTRUMENT PANEL AND SWITCH ........................4-4

FOOT AND HAND CONTROLS ................................. 4-5

DESCRIPTION OF OPERATING SYSTEM

4

-2 EX35/40/45/50

EXTERIOR VIEW

(1) Seat

(2) Steering Wheel

(3) Fuel Cap Cover

(4) Hood/Bonnet

(5) Head Light

(6) ROPS

(7) Fender

(8) Turn Signal Lamp

T46O401A

4

-3DESCRIPTION OF OPERATING SYSTEM

(1) Turn Signal Lamp

(2) Top Link

(3) Transmission Oil Gauge/Dipstick

(4) PTO Shield

(5) Crank Lifting Rod

(6) Telescopic Sway bar

(7) Draw Bar

(8) Lower Link

T46O402A

4

-4 EX35/40/45/50

(1) Left Turn Indicator

(2) Tachometer

(3) Right Turn Indicator

(4) Fuel Gauge

(5) Coolant Temp. Gauge

(6) Turn Signal Switch

(7) Head Light Switch

(8) Key Switch

(9) Front Wheel Drive Switch

(10) Hazard Lamp Switch

(11) Cruise Control (HST only)

(12) PTO Select Switch (Auto <-> Manual)

(13) PTO Switch

INSTRUMENT PANEL AND SWITCHES

T46O406A

4

-5DESCRIPTION OF OPERATING SYSTEM

FOOT AND HAND CONTROLS

(1) Shuttle Shift Lever

(2) Hand Throttle Lever

(3) Clutch Pedal

(4) Tilt Steering Pedal

(5) Parking Brake Lock Lever

(6) Brake Pedal (L)

(7) Brake Pedal (R)

(8) Main Gear Shift Lever

(9) Creep Gear Shift Lever

(10) Range Gear Shift Lever

(11) 3-Point Hitch Lowering Speed Knob

(12) Mid PTO Shift Lever

(13) Differential Lock Pedal

(14) Joystick Lever

(15) Double Acting Lever(A,B)

(16) Foot Throttle

(17) Double Acting Lever(C,D)

(18) Draft Control Lever

(19) Lift Position Control Lever

Manual Type

T46O407A

4

-6 EX35/40/45/50

(1) Hand Throttle Lever

(2) Brake Pedal (L)

(3) Brake Pedal (R)

(4) Tilt Steering Pedal

(5) Parking Brake Lock Lever

(6) HST Forward Pedal

(7) HST Reverse Pedal

(8) Range Gear Shift Lever

(9) Differential Lock Pedal

(10) 3-Point Hitch Lowering Speed Knob

(11) Mid PTO Shift Lever

(12) Joystick Lever

(13) Double Acting Lever(A,B)

(14) Double Acting Lever(C,D)

(15) Draft Control Lever

(16) Lift Position Control Lever

T46O408A

HST T ype

5

PRE-OPERATION........................................................5-2

OPERATING NEW TRACTOR ...................................5-3

OPERATING THE ENGINE ........................................ 5-4

OPERATING THE TRACTOR .................................. 5-11

OPERATION

5

-2 EX35/40/45/50

- Walk around inspection.

- Check the engine oil level

- Check the transmission oil level

- Check the coolant level

- Clean the grill and radiator screen.

- Check the air cleaner and evacuator valve.

- Check the brake pedals and linkages

- Check all dash gauges and indicators

- Check head lights, tail lights, and all

working lights.

- Check accessible wiring harness for

any damage.

- Check the seat belt and ROPS for

damage.

- Refuel (See "daily check" in the periodic service section)

- Check all danger and warning labels.

PRE-OPERATION

It is a good practice to know the condition of your tractor before you start

it. You should perform a routine check

before each use.

CHECK ITEM

T o avoid personal injury:

Be sure to check and service the

tractor on a level surface with

the engine shut off and the parking brake “ENGAGED”.

Follow the refueling procedures

providing “DAIL Y CHECK” in periodic service section.

Familiarize yourself with all

danger, warning and caution

labels. Maintain all labels in

their proper places in good legible condition.

DAILY CHECK

!!

!!

!

CAUTION

5

-3

OPERATION

OPERATING NEW TRACTOR

CHANGING LUBRICATING OIL

FOR NEW TRACTORS

How a new tractor is handled and maintained determines the life of the tractor.

A new tractor just off the factory production line has of course been, tested,

but the various parts are not accustomed to each other, therefore care

should be taken to operate the tractor

for the first 50 hours at a slower speed

and avoid excessive work or operation

until the various parts become "brokenin." The manner in which the tractor is

handled during the "breaking-in" period

greatly affects the life of your tractor.

Therefore, to obtain the maximum performance and the longest life of the

tractor, it is very important to properly

break-in your tractor.

In handling a new tractor, the following

precautions should be observed.

You should not operate your tractor

at full speed for the first fifty hours

of use.

Avoid sudden starts and stops.

In cold climates, allow your tractor

plenty of time to warm up.

Do not run the engine at speeds

faster than necessary.

Use due caution when operating your

tractor on rough roads or terrain.

The above precautions are not limited

to new tractors only, but are a good

practice for tractors regardless of their

age.

Special attention should be given to

new tractors lubrication oil. New parts

are not accustomed to each other and

are not broken in properly. Small metal

grit can develop in the lubricating system as metal parts begin to "break in"

and continuous use of the contaminated

oil can cause damage and failure.

Therefore you should change the

tractor's oil after the break-in period.

For further details of the oil change and

service schedule, see "maintenance"

section.

5

-4 EX35/40/45/50

T46O552A

(1) To set the parking brake:

1) Interlock the brake pedals

2) Depress the brake pedals

3) Latch the brake pedals with the

parking brake lever.(Check that

the parking brake lamp on the

instrument cluster illuminates.)

(2) To release the parking brake press

the brake pedals again.

STARTING THE ENGINE

(1) Parking Brake Lever

(2) Brake Pedals

(3) Interlock the Brake Pedals

(A) "Depress"

(B) "Push Down"

1. MAKE SURE THE PARKING

BRAKE IS SET

Using starting fluid or ether to start

your tractor will cause damage

and void your tractors warranty.

T o avoid damage to the starter and

battery you should never continuously start your tractor for more

than 10 seconds at a time.

IMPORTANT

Make sure that the parking

brake pedals are fully depressed before pulling the parking brake lever up.

IMPORTANT

OPERATING THE ENGINE

T o avoid personal injury:

You must read and understand

the warning and caution labels

on your tractor.

Proper ventilation is required

when operating your tractor inside a building or enclosed area.

Remember that exhaust fumes

can be deadly.

Never start your tractor’s engine

while standing on the ground.

This can prevent an unexpected

accident from happening.

!!

!!

!

CAUTION

NOTE

When the parking brake is engaged,

the parking brake lamp on the instrument cluster illuminates. When

releasing it, the parking brake lamp

is turned off.

HST T ype

MANUAL T ype

5

-5

OPERATION

T46O554AT46O553A

T46O502A

2. MAKE SURE THE FUEL COCK IS

IN THE OPEN POSITION.

(1) Fuel Cock

(A) Close (B) Open

(C) Air Bleeding

(1) Forward/Reverse Lever

(2) PTO Switch

(3) Range Gear Shift Lever (Hi-Mid-Lo)

3. PLACE THE PTO CLUTCH LEVER

IN "OFF" POSITION.

4. PLACE THE SPEED CONTROL

PEDAL IN "NEUTRAL" POSITION

(HST TYPE).

5. SHIFT THE FORWARD/REVERSE

LEVER TO NEUTRAL POSITION

(MANUAL TYPE).

NOTE

The speed control pedal automati-

cally return to neutral when the

operator's foot is released from the

pedal.

6. PLACE THE RANGE GEAR

SHIFT LEVER (HI-MID-LO) IN

"NEUTRAL" POSITION.

(2) PTO Switch

(3) Range Gear Shift Lever (Hi-Mid-Lo)(HST)

(4) Speed Control Pedal

MANUAL T ype

HST T ype

5

-6 EX35/40/45/50

T46O505A

8. SHIFT THE THROTTLE LEVER TO

“DECRESE” POSITION.

9. INSERT THE KEY INTO THE KEY

SWITCH AND TURN IT “ON”.

MAINTAIN IT UNTIL THE PREHEAT LAMP IS TURNED “OFF”

(APPROX. 8 SEC.).

7. MOVE THE POSITION CONTROL

LEVER.

To lower implement, move the position

control lever forward.

(1) Position Control Lever

(A) "DOWN"

(1) Hand Throttle Lever

"INCREASE"

"DECREASE"

(1) Key Switch

(

) Off ( ) Manual Pre-Heat

(

) Acc ( ) Start

(

) On(Auto Pre-Heat)

T46O556A T46O557A

5

-7

OPERATION

10. TURN THE KEY TO “ST ART” POSITION AND RELEASE WHEN

THE ENGINE ST ARTS.

1. Be careful not to run the starting

motor longer than 10 seconds due

to its heavy current consumption.

2. If the tractor has not started in 10

seconds stop operating the starter,

wait 30 seconds and then repeat the

starting procedure.

3. Prior to restarting, be sure that the

flywheel is completely stopped.

4. For manual preheating, turn and hold

the key from ON to preheat position.

Only when the brake pedal is en-

gaged with the range shift lever in

neutral position, the motor can be

started(HST).

Only with the shuttle lever in neu-

tral position, the motor can

be started(Manual).

NOTE

11. CHECK TO SEE THAT ALL THE

WARNING LAMPS ON THE INSTRUMENT CLUSTER TURN

“OFF”.

(1) Electrical Charge

(2) Parking Brake

(3) Glow Plug Indicator

(4) Engine Oil Pressure

T46O558A

5

-8 EX35/40/45/50

T46O510A

STOPPING THE ENGINE

1. You must first slow the engine to the

idle position before turning the engine off.

2. Remove the key.

WARMING UP

During warm up of the engine,

be sure that the parking brake

is set.

During warm up of the engine,

make sure that all shift levers

are in the neutral position.

[CHECK EASY CHECKER LAMPS]

1. When the key is turned "ON", lamps

(1), (4) should come on. If trouble

should occur at any location while

the engine is running, the warning

lamp corresponding to that location

comes on.

2. Glow plug indicator (3) also comes

on when the key is turned "ON" to

preheat the engine and goes off automatically when preheat is

completed.

3. The parking brake warning lamp (2)

comes on while parking brake is applied and goes off when it is released.

If any lamp remains on, immediately

stop the engine and determine the

cause.

Daily checks with the Easy

Check only, are not sufficient.

Never fail to conduct daily

checks carefully by referring to

Daily Check. (See “DAILY

CHECK” in Section 10)

IMPORTANT

!!

!!

!

CAUTION

!!

!!

!

CAUTION

If the engine does not stop, con-

sult with your local DAEDONG

dealer.

After starting your tractor's engine allow a five minute warm up period before applying any load to the tractor.

If a load is applied to the tractor before it has time to warm up, serious

damage, can occur like premature

wear, breakage, or seizure.

5

-9

OPERATION

Hydraulic oil serves as transmission

fluid to protect and lubricate moving

parts. This fluid is also circulated

through out the hydraulic circuit to

operate functions like steering, three

point hitch, and remote functions. In

cold weather, the oil will be cold with

increased viscosity. This can cause

delayed oil circulation or abnormally

low hydraulic pressure for some time

after engine start-up. This in turn can

result in trouble to the hydraulic

system. To prevent the above, observe the following instructions:

Warm up the engine at a high idle

according to the table below:

WARM-UP AND TRANSMISSION OIL

IN THE LOW TEMPERA TURE RANGE

Do not operate the tractor un-

der full load condition until it is

sufficiently warmed up.

IMPORTANT

Ambient

temperature

Above 0 ° C

(32 ° F)

0 ~ -10 ° C

(32 ~ 14 ° F)

-10 ~ -20 ° C

(14 ~ -4 ° F)

Below -20 ° C

(-4 ° F)

Warm-up time

requirement

At least 5 minutes

5 ~ 10 minutes

10 ~ 20 minutes

More than 20 minutes

5

-10 EX35/40/45/50

T46O511A

JUMP STARTING

(1) Dead Battery (2) Jumper Cables

(3) Helper Battery

the other vehicle to touch. Start the

vehicle's engine after connecting the

cables and let it run for a few

moments. Turn off all accessories on

both vehicles. Then start the disabled tractor.

7. Disconnect the battery cables in the

exact opposite order as they were

attached.

When jump starting the engine, follow

the instructions below to safely start

the engine.

1. Use a battery of the same voltage

as the disabled tractor battery to

jump start the tractor. Locate the

good battery in a safe place where

the jumper cables will reach.

2. Engage the parking brake of the tractor and shift the transmission gear

to the neutral position.

3. Put on safety goggles and rubber

gloves.

4. Attach the red clamp to the positive

terminal of the dead battery, and attach the other end to the positive terminal of the helper battery.

5. Clamp the black cable to the Engine

hooks or other ground source and attach the other end to the negative

cable of the helper battery.

6. If the helper battery is in another

vehicle, do not allow the tractor and

Keep fire, spark, cigarette, etc.,

from the battery.

If the tractor battery is frozen,

jump starting the engine is

prohibited.

Do not connect the (-) jumper

cable to the negative(-) terminal

of the discharged battery.

!!

!!

!

CAUTION

Use a ground away from the

battery

5

-11

OPERATION

T46O513AT46O512A

TO FOLD THE ROPS

(1) Grip Bolt (2) Set Pin

(3) Clip Pin

(1) ROPS

1. Remove the clip pin and set pin. 2. Loosen the grip bolt and fold the

ROPS.

OPERATING THE TRACTOR

You should always stop the

engine, remove the key and set

the parking brake before raising

or folding the ROPS.

Always perform such tasks from

a safe and stable position at the

rear of the tractor.

Folding the ROPS should only be

done when absolutely necessary,

and should be returned to the upright position as soon as possible.

!!

!!

!

CAUTION

T o avoid personal injury:

Hold the ROPS tightly with both

hands and fold the ROPS slowly

and carefully.

!!

!!

!

CAUTION

T46O514A

3. Align pin holes, insert set pin, and

secure them with the clip pin.

T o avoid personal injury:

Make sure the pins are properly

installed and secured.

(1) Grip Bolt (2) Set Pin

(3) Clip Pin

!!

!!

!

CAUTION

5

-12 EX35/40/45/50

T46O517A

1. ADJUSTING THE OPERATOR’S

POSITION

(1) Position Height Adjuster (4) Weight Adjuster

(2) Height Adjuster Leve (A) “PULL IN”

(3) Seat Reclining Lever

(1) OPERATOR'S SEAT

STARTING

To avoid personal injury:

Make sure that the seat is com-

pletely secured after each

adjustment.

Do not allow any person other

than the driver to ride on the

tractor.

!!

!!

!

CAUTION

T46O515A T46O516A

TO RAISE THE ROPS TO

UPRIGHT POSITION

1. Remove both the grip bolt, clip pin

and set pin.

2. Raise ROPS to the upright position.

3. Align pin holes, insert set pin and

secure them with the clip pin.

4. Fix the ROPS with the grip bolt.

To avoid personal injury:

Make sure that pins are properly

installed and secured.

(1) Grip Bolt (2) Set Pin

(3) Clip Pin

!!

!!

!

CAUTION

T o avoid personal injury:

The ROPS must be raised slowly

and carefully.

!!

!!

!

CAUTION

5

-13

OPERATION

(1) HAZARD LIGHT SWITCH

When hazard light switch is pushed

“on”, the hazard lights flash along

with the indicator on the instrument

panel. Push the switch to “off” to

turn flashers off.

2. SELECTING LIGHT SWITCH POSITIONS

(1) Hazard / Turn Signal Indicator

(2) Turn Signal Light Switch

(3) Hazard Light Switch

T46O559AT46O518A

(2) TRAVEL/HEIGHT ADJUSTMENT

Pull out the position adjust lever and

slide the seat backward or forward, as

required.

(1) Seat Belt

Adjust the seat belt for proper fit and

connect to the buckle. The seat belt is

an auto-locking retractable type.

(3) SEAT BELT

After adjusting the operator’s

seat, be sure to check that the

seat is properly locked.

IMPORTANT

T o avoid personal injury:

Always use your seat belt when

the ROPS is installed.

Do not use the seat belt if your

tractor is not equipped with a

ROPS or when it is removed.

!!

!!

!

CAUTION

(2) TURN SIGNAL LIGHT SWITCH

To indicate a right turn, push forward.

To indicate a left turn, push rearward.

5

-14 EX35/40/45/50

HST T ype

MANUAL T ype

(1) Head Light Switch

(A) “OFF” (B) “ON (LOW)”

(C) “ON (HIGH)”

(3) HEAD LIGHT SWITCH

(A): Head lights OFF.

(B): Head lights - Low Beam ON.

(C): Head lights - High Beam ON.

T46O522A

(1) Brake Pedal (L) ( 2) Brake Pedal (R)

(3) Interlock

(A)Lock (B)Release

(1) Brake Pedal (L) ( 2) Brake Pedal (R)

(3) Interlock

(A) Release (B) Lock

3. CHECKING THE BRAKE PEDAL

1. Before operating the tractor on the

road or before applying the parking

brake, be sure to interlock the right

and left pedals as illustrated.

2. Use individual brakes to assist in

making sharp turns at slow speeds

(Field Operation Only).

Disengage the brake pedal interlock

and depress only one brake pedal.

3. Be sure brake pedals have equal ad-

justment when using locked together.

(1) BRAKE PEDAL (RIGHT AND LEFT)

WARNING

!!

!!

!

To avoid personal injury:

Applying one rear wheel brake at

a time can cause the tractor to

swerve or roll over at high speeds.

T46O561AT46O560A

NOTE

Be sure to return switch to center

position after turning.

When the left or right turn signal is

activated, the indicated turning light will

flash and the other will be off.

5

-15

OPERATION

T o help prevent premature clutch

wear.

The clutch pedal must be en-

gaged slowly and disengaged

quickly.

Do not rest your foot on the

clutch pedal.

Select the proper gear and en-

gine speeds according to the

type of job you are doing.

IMPORTANT

4. RAISE THE IMPLEMENT.

The clutch is disengaged when the

clutch pedal is fully pressed down

(Manual type).

5. DEPRESS THE CLUTCH PEDAL

(MANUAL TYPE)

(1) Position Control Lever

(A) UP

(1) Clutch Pedal

T46O523A T46O524A

T o avoid personal injury:

Do not release the clutch suddenly,

it may cause the tractor to lunge

forward unexpectedly.

HST models do not have a

clutch pedal.

!!

!!

!

CAUTION

5

-16 EX35/40/45/50

T46O562A

(1) Forward/Reverse Shift Lever

(2) Main Gear Shift Lever

(3) Creep Gear Shift Lever

(4) Range Gear Shift Lever(Hi-Mid-Lo

)

MANUAL T ype

(1) FORWARD/REVERSE SHIFT LEVER

Push forward or pull backward to select forward or reverse. The direction

of travel can be changed without changing the main shift.

(2)MAIN GEAR SHIFT LEVER

4 level shifts are possible with one

lever. Synchro-mesh type. Just release

the clutch during driving to change the

speed.

The synchronized shuttle shift

lever may be shifted while the

tractor is moving slowly and the

clutch is depressed.

Sudden gear shift changes with-

out clutching may cause transmission damage.

IMPORTANT

6. SELECTING THE TRA VEL SPEED

(MANUAL Type)

N -"NEUTRAL POSITION"

- "HIGH"

-"MIDDLE"

-"LOW"

F -"FORWARD"

R - "REVERSE”

Shifting the shuttle & high

speeds without slowing down

may cause premature synchronizer wear

5

-17

OPERATION

(4)CREEP GEAR SHIFT LEVER

HOW TO USE CREEP GEAR SHIFT

LEVER(OPTION-MANUAL Type)

If you misuse or mishandle the creeping speed, it may cause damage to

the unit, so please note the following.

(3)RANGE GEAR SHIFT LEVER (HI-MID-

LO)

The range gear shift can only be shifted

when tractor is completely stopped and

clutch is depressed. If it is difficult to

shift the range gear, take the following

actions.

1. Be sure the range gear shift lever is

in neutral position.

2. Release clutch pedal(Manual type)

or slightly depress the speed control pedal to rotate the gears inside

of transmission. Release the speed

control pedal to neutral(HST only).

3. Depress clutch pedal(Manual type)

and then shift the range gear shift

lever.

To avoid transmission damage,

depress clutch pedal and stop

tractor before shifting between

ranges.

IMPORTANT

1. Possible times to use:

• A deep tilling application

• When unable to maintain a constant

speed in harsh field conditions

• Transplanting

• When loading and unloading

It may be easy to stall the engine

when operating the tractor in

high range at low engine rpm’s.

!!

!!

!

CAUTION

5

-18 EX35/40/45/50

(1) Range Gear Shift Lever (Hi-Mid-Lo)

H “HIGH SPEED”

N “NEUTRAL POSITION”

M “MIDDLE SPEED”

L “LOW SPEED”

HST T ype

With a creeper transmission, an operator has the option to use 24 F and 24R

gears.

To stop the tractor, be sure to

disengage the clutch first, then

depress the brake pedal. This is

because creep range gives high

torque at low forward speeds

thus making braking ineffective.

To avoid any transmission

damage, do not convert from forward to revere and vice versa

while driving.

!!

!!

!

CAUTION

T46O563A

5

-19

OPERATION

(1) Hand Throttle Lever (2) Foot Throttle

INCREASE DECREASE

7. ACCELERA TE THE ENGINE

(1) HAND THROTTLE LEVER

Pushing the throttle lever forward decreases engine speed, and pulling it

back increases engine speed.

(2) FOOT THROTTLE (MANUAL Type)

Use the foot throttle when traveling

on the road. Press down on it for

higher speed. The foot throttle is interlocked with the hand throttle lever;

when using the foot throttle, keep the

hand throttle lever in low idling

position.

(5) FRONT WHEEL DRIVE SWITCH

4WD is a hydraulically actuated; which

is operated easily with the "ON"/"OFF"

switch.

To connect the 4WD, turn On the 4WD

switch and to release it, turn OFF the

switch.

(1) Front Wheel Drive Switch

“ENGAGED” “DISENGAGED”

T46O528A T46O564A

FRONT WHEEL DRIVE IS EFFECTIVE

FOR THE FOLLOWING JOBS:

1. When greater pulling force is

needed, such as working in a wet

field, when pulling a trailer or when

To avoid personal injury:

You should not engage your front

wheel drive while traveling at road

speeds. This can cause your tractor to stop quickly, and

unexpectedly.

IMPORTANT

Engage the front wheel drive

only when the engine stops and

do not shift if in drive.

Tires will wear quickly if front

wheel drive is engaged on paved

roads.

Damage to the drive train may be

caused due to operation of 4WD

on roads or pave surfaces.

!!

!!

!

CAUTION

working with front-end loader.

2. When working in sandy soil.

3. When working on a hard soil where

a rotary tiller might push the tractor

forward.

5

-20 EX35/40/45/50

9. DEPRESS THE SPEED CONTROL

PEDAL (HST TYPE)

(1) SPEED CONTROL PEDAL

(1) Cruise Control Switch

(2) Forward Pedal

(3) Reverse Pedal

(A)Lock (C)Forward

(B) Release (D)Reverse

T46O531A

WARNING

!!

!!

!

T o avoid personal injury:

If your tractor moves while on

level ground with your foot of

the control pedal, do not operate the tractor.

To prevent serious damage to

the HST do not adjust the stopper bolts.

IMPORTANT

The tractor with a hydrostatic transmission has a forward and reverse pedal

on the right side of the platform and it

is possible to moderate speed and direction continuously.

Forward direction: depress the left

pedal.

Reverse direction: depress the right

pedal.

(1) Brake Pedals

To release the parking brake, simply

depress the brake pedals again. Once

released, the parking brake indicator in

the easy checker will go off.

8. UNLOCK THE PARKING BRAKE

AND SLOWLY RELEASE THE

CLUTCH PEDAL.

T46O530A

HST T ype

MANUAL T ype

5

-21

OPERATION

1. Slow the engine to idle

2. Depress the clutch and brake pedal.

(Manual model)

3. After the tractor has stopped, disengage the PTO, lower the implement,

shift the transmission into neutral,

release the clutch pedal and set the

parking brake.

STOPPING

To avoid personal injury and

maintain optimum control of

tractor, do not use the cruise

control at high speeds or when

driving the tractor on roads.

Speed set device will not oper-

ate in reverse on road.

!!

!!

!

CAUTION

Make sure to keep the cruise con-

trol in the “OFF” position when

starting the tractor.

Return the cruise control to the “OFF”

position when stopping the tractor.

The cruise control can be released

when overloads or any sudden

forces are encountered.

Cruise control disengage if the

brakes are applied

NOTE

T o prevent the damage to cruise

control, do not depress the reverse pedal when the cruise

control is engaged.

IMPORTANT

(2) CRUISE CONTROL

Cruise Control is designed for tractor

operating efficiency and operator

comfort. This device will provide a constant forward operating speed by mechanically holding the speed control

pedal at the selected position.

[To Engage Cruise Control]

1. Accelerate speed to desired level

using Forward Pedal, and pull the

cruise control switch up to the "ON"

position.

2. Release Forward Pedal and desired

speed will be maintained.

[To Disengage Cruise Control]

1. Place the lever to the off position.

Or depress the brake pedal.

5

-22 EX35/40/45/50

CHECK DURING DRIVING

IMMEDIATELY STOP THE ENGINE IF

(1) Battery Charge Warning Lamp

(2) Tachometer

(3) Engine Oil Pressure Warning Lamp

The engine suddenly slows or

accelerates.

Unusual noises are heard.

Exhaust fumes become dark.

(4) Fuel Gauge

(5) Coolant Temperature Gauge

T46O565A

Frequently check all gauges to

verify the tractors operating status.

NOTE

5

-23

OPERATION

If warning lamps come on while operating the engine, immediately stop the

engine and check for the cause.

Never operate the tractor while warning lamps are on.

INSTRUMENT CLUSTER

(1) PTO Operating Indicator

(2) Headlight-High Beam Lamp

(3) Battery Charging Warning Lamp

(4) Parking Brake Lamp

(5) Cruise Operating Indicator

(6) Glow Plug Indicator

(7) Left Turn Indicator

(8) Tachometer

(9) Right Turn Indicator

(10) Neutral Position

(11) Engine Oil Pressure Warning Lamp

(12) Single Brake Lamp

(13) Front Wheel Drive Indicator

(14) Fuel Gauge

(15) Hour-Meter Indicator

(16) Coolant Temperature Gauge

T46O566A

5

-24 EX35/40/45/50

T46O567A T46O568A T46O569A

When the key switch is turned "ON"

this gauge indicates the temperature of

the coolant. "C" is for cold, and "H" is

for hot.

“C”COLD “H”HOT

COOLANT TEMPERATURE

GAUGE

To avoid personal injury:

Do not remove radiator cap un-

til coolant temperature is well

below its boiling point. Then

loosen cap slightly to the stop

to relieve any pressure before

removing cap completely.

!!

!!

!

CAUTION

TACHOMETER

The tachometer indicates the engine

speed and the 540rpm PTO operating

speed.

The hour-meter indicates, in five digits,

the hours that the tractor has been

operated.

When the key switch is on, the fuel

gauge indicates the fuel level.

Be careful not to empty the fuel tank.

Otherwise air may enter the fuel

system.

Should this happen, the system should

be bled (See "Bleeding Fuel System"

in Periodic Service Section).

FUEL GAUGE

“E” EMPTY “F” FULL

5

-25

OPERATION

If the tractor engine oil pressure is below the specified ranges, the warning

lamp will illuminate.

ENGINE OIL PRESSURE

WARNING LAMP

If the battery of the generator is not fully

charged, the warning lamp illuminates

on the instrument cluster. (Illumination

at KEY ON(START OFF) is normal)

BATTERY CHARGING WARNING LAMP

HEAD LIGHT HIGH BEAM

PILOT LAMP

When head lights are turned to high,

an indicator lamp will illuminate on the

dash.

T46O570A T46O571A T46O572A

In the event a warning indicator

lamp illuminates while operating

the tractor, immediately shut the

engine off and consult with your

KIOTI dealer.

NOTE

5

-26 EX35/40/45/50

If the parking lever is engaged, the corresponding indicator will illuminate in

red.

PARKING BRAKE LAMPTURN SIGNAL LAMP GLOW PLUG INDICATOR

If the turn signal lamp switch is turned

left or right, the corresponding indicator will illuminate in green.

When the key switch is turned to the

“on“ position, the glow plug indicator will

illuminate.

T46O573A T46O574A T46O575A

Glow plug operation is controlled

by engine water temperature. The

glow plug indicator will only illuminate if water temperature is below

60 ° C (140 ° F).

NOTE

5

-27

OPERATION

If the range shift is in neutral position,

this lamp turn in green(HST).

If the shuttle lever is in neutral position,

this lamp turns in green(Manual).

If the range shift is at low speed, this

lamp turned in green(HST).

If the range shift is at middle speed,

this lamp turned in green(HST).

T46O576A T46O577A T46O578A

“N” NEUTRAL POSITION

INDICATOR

“L” LOW SPEED TRAVEL

INDICATOR

“M” MIDDLE SPEED TRAVEL

INDICATOR

5

-28 EX35/40/45/50

PARKING BRAKE LEVER

(1) Parking Brake Lever

(2) Brake Pedals (3) Interlock

(A) DEPRESS (B) PUSH “DOWN”

PARKING

To avoid personal injury:

Always set the parking brake

and stop the engine before leaving the tractor seat.

When parking the vehicle on a

hill, position the shift lever in

low forward (1st gear) for uphill

and low reverse (1st gear) for

downhill. Set the parking brake

and chock the wheels.

!!

!!

!

CAUTION

T46O580A

HST TYPE

Leaving transmission in gear

with the engine stopped will not

prevent tractor from rolling.

Park on level ground whenever

possible.

!!

!!

!

CAUTION

HST T ype

MANUAL T ype

If the range shift is at high speed, this

lamp turned in green(HST).

T46O579A

Always lock the parking brake.

“H” HIGH SPEED TRAVEL

INDICATOR

5

-29

OPERATION

If one of the rear wheels should slip,

use the differential lock. This will cause

both wheels to turn together. The differential lock is engaged only when the

pedal is depressed.

OPERATING TECHNIQUES

(1) Differential Lock Pedal

(A) Release to “DISENGAGE”

(B) Press to “ENGAGE”

DIFFERENTIAL LOCK

WARNING

!!

!!

!

To avoid personal injury due to

loss of steering control.

Do not operate the tractor at high

speeds with the differential lock

engaged.

Do not attempt to turn with the

differential lock engaged.

When using the differential lock,

always slow the engine and

press the differential lock down.

If the differential lock cannot be

released in the above manner,

step lightly on the brake pedals

alternately.

IMPORTANT

2. Before getting off the tractor, disengage the PTO, lower all implements,

place all control levers in their neutral

positions, set the parking brake, stop

the engine and remove the key.

To prevent damage to the park-

ing brake lever, make sure that

brake pedals are fully depressed before pulling the parking brake lever up.

IMPORTANT

1. When parking, be sure to set the

parking brake.

To set the parking brake:

1) Interlock the brake pedals.

2) Depress the brake pedals.

3) latch the brake pedals with the

parking brake lever.

T46O545A

5

-30 EX35/40/45/50

(1) SMV Emblem

OPERA TING THE TRACTOR ON A ROAD

T46O546A

Make sure that the warning lamps and

SMV sign are clean and visible at all

times. If you are towing rear mounted

equipment or implements you will need

to install warning lamps and SMV signs

on the equipment.

T o avoid personal injury:

T o help assure straight line stops

when driving at transport

speeds, lock the brake pedals

together. Uneven braking at

road speeds could cause the

tractor to roll-over.

When traveling on road with 3-

point hitch mounted implement

attached, be sure to have sufficient front weight on the tractor

to maintain steering ability.

!!

!!

!

CAUTION

OPERATING ON SLOPES AND

ROUGH TERRAIN

T o avoid personal injury:

Always back up when going up

a steep slope. Driving forward

could cause the tractor to tip

over backward. Stay off hills and

slopes too steep for safe

operation.

Avoid changing gears when

climbing or descending a slope.

If operating on a slope, never

disengage the clutch or shift levers to neutral. Doing so could

cause loss of control.

Do not drive the tractor close to

the edges of ditches or banks

which may collapse under the

weight of the tractor, especially

when the ground is loose or wet.

!!

!!

!

CAUTION

5

-31

OPERATION

DIRECTIONS FOR USE OF POWER

STEERING

1. Power steering is activated only

while the engine is running. Slow

engine speeds make the steering a

little heavier. While the engine is

stopped, the tractor functions in the

same manner as tractors without

power steering.

2. When the steering wheel is turned

all the way to the stop, the relief valve

is activated. Do not hold the steering wheel in this position for a long

period of time.

3. To avoid tire wear and front-end damage only turn steering wheel while

moving.

1. Be sure that the wheels are adjusted

to provide the maximum stability

possible.

2. You should slow down for rough

roads, slope and sharp turns. This

is especially important when you are

transporting heavy equipment on the

rear of the tractor.

3. Use gears according to the decent

of the slope, and try to avoid using

the brake.

5

-32 EX35/40/45/50

1. The tractor has a 540 rpm speed

position.

2. Electric/Hydraulic engagement PTO

shifting needs clutch operation.

Press the clutch pedal down completely to stop the tractor movement

and any PTO driven equipment

movement before shifting the PTO

gear shift lever.

REAR PTO GEAR SHIFT LEVER

(1) Auto-Manual Switch

(2) PTO Switch

PTO OPERATION

T o avoid personal injury:

Disengage PTO, stop engine, and

allow all rotating components to

come to a complete stop before

connecting, disconnecting,

adjusting, or cleaning any PTO

driven equipment.

!!

!!

!

CAUTION

T46O581A

PTO operation is controlled by the auto/

manual switch and the cutoff switch.

1. PTO connected - Auto

If the PTO clutch switch is turned to

AUTO position, when the attachment

is raised to the set position by the

position control lever, PTO is automatically cut off.

2. PTO connected - Manual

If the PTO clutch switch is turned to

Manual position, PTO is operated

regardless of the height of the

attachment.

3. After setting the manual/Auto switch

to the desired setting, turn the PTO

switch “ON” o r “OFF” as required to

operate the PTO.

PTO CLUTCH SWITCH

5

-33

OPERATION

(1) PTO Switch

(2) Mid PTO Lever

MID-PTO LEVER (OPTION)

You should keep the PTO Shield in

place at all times and remember to replace the cap when the PTO shaft is

not in use.

T46O582A

WARNING

!!

!!

!

T o avoid personal injury:

Prior to operation, after selecting

the Mid PTO lever, turn the PTO

switch ON.

Do not operate Rear-PTO driven

implements and Mid-PTO driven

implements at the same time.

The Mid PTO is available to operate KIOTI approved

implements.

(1) PTO Shield (2) PTO Shaft Cap

(A) Normal Position (B) Raised Position

PTO SHIELD AND SHAFT CAP

To avoid shock loads to the PTO,

reduce engine speed when engaging the PTO, then open the

throttle to the recommended

speed:

T o avoid damage to the transmis-

sion before turning the PTO on

fully disengage the clutch.

IMPORTANT

T46O549A

( ):HST Model

There is a PTO-1 (540 rpm) indica-

tor marked on the tachometer.

NOTE

Engine rpm PTO shaftPTOrpmModel

EX35(H)

EX40(H)

EX45(H)

EX50(H)

2520(2500)

6-Spline 540

5

-34 EX35/40/45/50

REAR AND MID-PTO SPEED

The Mid PTO is available for KIOTI ap-

proved implements. Remember to replace the cap after grease the PTO

shaft which is not in use.

To operate the Mid PTO, connect the

Mid PTO lever and turn the PTO switch

ON.

(1) Mid PTO Shaft Cap (2) Bolt

(3) Mid PTO

MID