Page 1

MODEL 3110

RIGID MOUNTED PLANTER

OPERATOR’S MANUAL

M0255-01 Rev. 6/19

This manual is applicable to: Model 3110 Mounted Planter

2015 Production Year and on

Record the model number and serial number of your planter along with date purchased:

Model Number ____________ 3110 _________________

Serial Number ___________________________________

Date Purchased __________________________________

Monitor Serial Number _______________________________________________

Measured Pulses Per Mile/Km (Radar Distance Sensor) ____________________

Measured Pulses Per Mile/ Km (Magnetic Distance Sensor) _________________

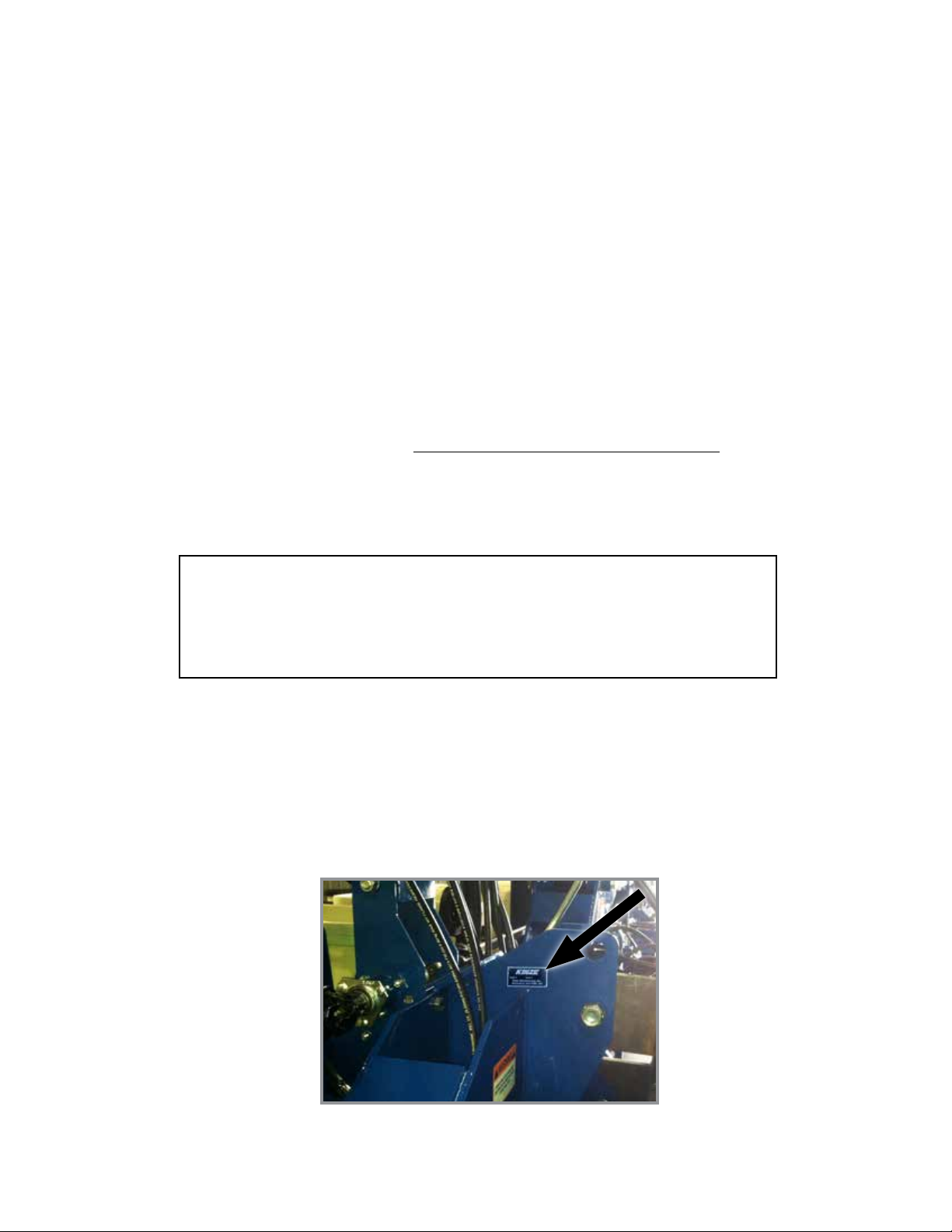

SERIAL NUMBER

The serial number plate is located on the planter frame to be readily available. It is suggested that your serial number

and purchase date also be recorded above.

The serial number provides important information about your planter and may be required to obtain the correct

replacement part. Always provide the model number and serial number to your Kinze Dealer when ordering parts or

anytime correspondence is made with Kinze Manufacturing, Inc.

Serial number plate location - R.H. side of 3-point mount

Kinze® and the Kinze® logo are registered trademarks of Kinze Manufacturing, Inc.

Page 2

This page left blank intentionally.

Page 3

Predelivery/Delivery Checklist

Model 3110M0255-01

TO THE DEALER

Predelivery service includes assembly, lubrication, adjustment, and test. This service makes sure planter is delivered to

the retail customer/end user ready for field use.

PREDELIVERY CHECKLIST

Use the following checklist and inspect planter after it is completely assembled. Check off each item found satisfactory

or after proper adjustment is made.

Row units properly spaced and optional attachments correctly assembled.

Vacuum components properly installed (as applicable).

All grease fittings in place and lubricated.

All working parts move freely, bolts are tight, and cotter pins are spread.

Check all drive chains for proper tension and alignment.

Check for oil leaks and proper hydraulic operation.

Hydraulic hoses correctly routed to prevent damage.

Inflate tires to specified air pressure and torque wheel lug bolts and lug nuts as specified in the manual.

All safety decals correctly located and legible. Replace if damaged.

All reflective decals and SMV sign correctly located and visible when the planter is in transport position.

Safety/warning lights correctly installed and working properly.

Paint all parts scratched in shipment or assembly.

All safety lockup devices on the planter and correctly located.

Auxiliary safety chain properly installed and hardware torqued to specification.

This planter has been thoroughly checked and to the best of my knowledge is ready for delivery to the retail

customer/end user.

(Signature Of Set-Up Person/Dealer Name/Date)

RETAIL CUSTOMER/END USER

Name Delivery Date

Street Address Model No. 3110 Serial No.

City, State/Province Dealer Name

ZIP/Postal Code Dealer No.

Rev. 9/17 1

TM

Page 4

Predelivery/Delivery Checklist

M0255-01Model 3110

DELIVERY CHECKLIST

Use the following checklist at time planter is delivered as a reminder of very important information which should be

conveyed to retail customer/end user. Check off each item as it is fully explained.

Check for proper operation of vacuum fan (If applicable) with tractor to be used with planter.

Life expectancy of this or any other machine is dependent on regular lubrication as directed in the Operator Manual.

All applicable safety precautions.

Along with retail customer/end user, check reflective decals and SMV sign are clearly visible with planter in transport

position and attached to tractor. Check safety/warning lights are in working condition. Tell retail customer/end user

to check federal, state/provincial, and local regulations before towing or transporting on a road or highway.

Give Operator Manual, Parts Manual, and all Instruction Sheets to retail customer/end user and explain all operating

adjustments.

Read warranty to retail customer/end user.

Complete Warranty and Delivery Report form.

To the best of my knowledge this machine has been delivered ready for field use and customer has been fully

informed as to proper care and operation.

(Signature Of Delivery Person/Dealer Name/Date)

AFTER DELIVERY CHECKLIST

The following is a list of items we suggest to check during the first season of use of the equipment.

Check planter performance with retail customer/end user.

Check performance of vacuum or mechanical seed metering system with retail customer/end user.

Review importance of proper maintenance and adherence to all safety precautions with retail customer/end user.

Check for parts that may need to be adjusted or replaced.

Check all safety decals, reflective decals, and SMV sign are correctly located as shown in the Parts Manual and that

decals are legible. Replace if damaged or missing.

Check safety/warning lights are working properly.

(Signature Of Follow-Up Person/Dealer Name/Date)

All registrations must be submitted online at “business.kinze.com” within 5 business days of delivery.

Retain a copy of this form for auditing purposes.

Tear Along Perforation

2 Rev. 1/18

TM

Page 5

Table of Contents

Model 3110M0255-01

MACHINE OPERATION

Row Marker Lockups

(Conventional Row Markers Only). . . . . . . . . . . . . . . . . 2-1

Initial Preparation ................................2-2

Tractor Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Tractor Preparation and Hookup ....................2-4

Cylinder Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Hydraulic Hose Information ........................2-8

Leveling the Planter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Toolbar Height Adjustment. . . . . . . . . . . . . . . . . . . . . . . . 2-10

Parking Stand Adjustment . . . . . . . . . . . . . . . . . . . . . . . .2-11

Seed Rate Transmission Adjustment . . . . . . . . . . . . . . . . 2-12

Contact Wheel Drive Sprockets . . . . . . . . . . . . . . . . . . . . 2-12

Contact Wheel Spring Adjustment. . . . . . . . . . . . . . . . . . 2-13

Shear Protection ...............................2-13

Wrap Spring Wrench ............................2-13

Vacuum System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Digital Vacuum Readout. . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Analog Vacuum Gauge ..........................2-14

Vacuum Fan Motor Valve Block Assembly. . . . . . . . . . . . 2-14

Row Marker Operation ...........................2-15

Row Marker Speed Adjustment . . . . . . . . . . . . . . . . . . . . 2-16

Row Marker Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Point Row Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Front Mounted Drive Wheel Option .................2-19

Planting Speed ................................2-19

Field Test .....................................2-19

Check Seed Population ..........................2-20

Determining Pounds Per Acre (Brush-Type Meter) .....2-21

Determining Bushels Per Acre. . . . . . . . . . . . . . . . . . . . . 2-21

Field Check Granular Chemical Application ..........2-22

ROW UNIT OPERATION

Planting Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

“V” Closing Wheel Adjustment (Rubber or Cast Iron) ....3-1

Closing Wheel Shield

(Rubber or Cast Iron “V” Closing Wheels) . . . . . . . . . . .3-2

Drag Closing Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Covering Discs/Single Press Wheel Adjustment ........3-3

Brush-Type Seed Meter . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Brush-Type Seed Meter 2.0 ........................3-5

Finger Pickup Seed Meter . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Vacuum Settings ................................3-7

Seed Meter Cleanout. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Additives .....................................3-12

Bayer Fluency Agent ............................3-13

Seed Hoppers .................................3-14

Seed Meter Drive Release. . . . . . . . . . . . . . . . . . . . . . . . 3-14

Rev. 6/19 1-1

Row Unit Extension Brackets. . . . . . . . . . . . . . . . . . . . . . 3-14

Row Unit Chain Routing. . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Quick Adjustable Down Force Springs Option ........3-16

Frame Mounted Coulter (Pull Row Only). . . . . . . . . . . . . 3-17

Residue Wheels (for Frame Mounted Coulter). . . . . . . . . 3-17

Row Unit Mounted Disc Furrower (Pull Row Only) .....3-18

Row Unit Mounted Bed Leveler (Pull Row Only) .......3-18

Row Unit Mounted Residue Wheel .................3-19

Row Unit Mounted No Till Coulter ..................3-20

Coulter Mounted Residue Wheels . . . . . . . . . . . . . . . . . . 3-20

Dual Gauge Wheels ............................3-21

Spiked Closing Wheel ...........................3-21

Granular Chemical Hopper and Drive ...............3-22

Spring Tooth Incorporator ........................3-22

Granular Chemical Banding Options . . . . . . . . . . . . . . . .3-23

Granular Chemical Bander Shield . . . . . . . . . . . . . . . . . .3-23

RATE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

LUBRICATION AND MAINTENANCE

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Sealed Bearings ................................5-1

Drive Chains ...................................5-2

Bushings ......................................5-4

Wrap Spring Wrench Assembly. . . . . . . . . . . . . . . . . . . . . 5-5

Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Grease Fittings .................................5-6

Mounting Bolts and Hardware ......................5-8

Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Model 3110 Operating Tire Pressure. . . . . . . . . . . . . . . . 5-10

Chain Tension Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Finger Pickup Seed Meter Inspection/Adjustment. . . . . . 5-12

Cleaning Finger Pickup Seed Meter For Storage ......5-13

Brush-Type Seed Meter Maintenance ...............5-14

Cleaning Brush-Type Seed Meter For Storage ........5-15

Vacuum Manifold Maintenance ....................5-15

Vacuum Seed Meter Maintenance. . . . . . . . . . . . . . . . . . 5-16

Seed Meter Cleanout. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Drag Closing Attachment ........................5-17

Gauge Wheel Adjustment ........................5-17

Gauge Wheel Arm Bushing/Seal Replacement. . . . . . . . 5-18

Gauge Wheel Arm Pivot Spindle Replacement . . . . . . . . 5-18

15" Seed Opener Disc Blade/Bearing Assembly .......5-19

Seed Tube Guard/Inner Scraper ...................5-21

Frame Mounted Coulter .........................5-21

Residue Wheels

(For Use With Frame Mounted Coulter) ...........5-21

TM

Page 6

Table of Contents

Row Unit Mounted Disc Furrower ..................5-22

Row Unit Mounted Bed Leveler . . . . . . . . . . . . . . . . . . . . 5-22

Row Unit Mounted No Till Coulter ..................5-22

Coulter Mounted Residue Wheels . . . . . . . . . . . . . . . . . . 5-23

Row Unit Mounted Residue Wheel .................5-23

Granular Chemical Attachment ....................5-23

Spring Tooth Incorporator ........................5-24

Spiked Closing Wheel ...........................5-24

Single Point Row Clutch Maintenance ...............5-25

Row Marker Sequencing/Flow Control Valve Inspection

Row Marker Bearing Lubrication or Replacement . . . . . . 5-27

Wheel Bearing Repack or Replacement .............5-28

Vacuum Check Valve Inspection ...................5-29

Vacuum Relief Valve Cartridge Inspection ...........5-29

Preparing Planter for Storage .....................5-29

Electrical Wiring Diagram for Light Package ..........5-30

Electrical Wiring Diagrams for Point Row Clutches .....5-31

Hydraulic Hose Life .............................5-32

Hydraulic Diagram - Vacuum Fan Motor System .......5-33

. . . . 5-26

M0255-01Model 3110

TROUBLESHOOTING

Brush-Type Seed Meter . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Closing Wheel ..................................6-1

Vacuum Seed Meter .............................6-2

Finger Pickup Seed Meter . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Point Row Clutch ................................6-5

Row Marker Operation ............................6-6

1-2 Rev. 6/19

TM

Page 7

To the Owner

Model 3110M0255-01

Kinze Manufacturing, Inc. would like to thank you for your patronage. We appreciate your confidence in Kinze farm

machinery. Your Kinze planter has been carefully designed to provide dependable operation in return for your investment.

This manual has been prepared to aid you in planter operation and maintenance. It should be considered a

permanent part of the machine and remain with the machine when you sell it.

It is the responsibility of the user to read and understand this Operator Manual before operating this equipment. It

is the user’s responsibility to inspect and service the machine routinely as directed in this Operator Manual. We have

attempted to cover all areas of safety, operation, lubrication and maintenance; however, there may be times when special

care must be taken to fit your conditions.

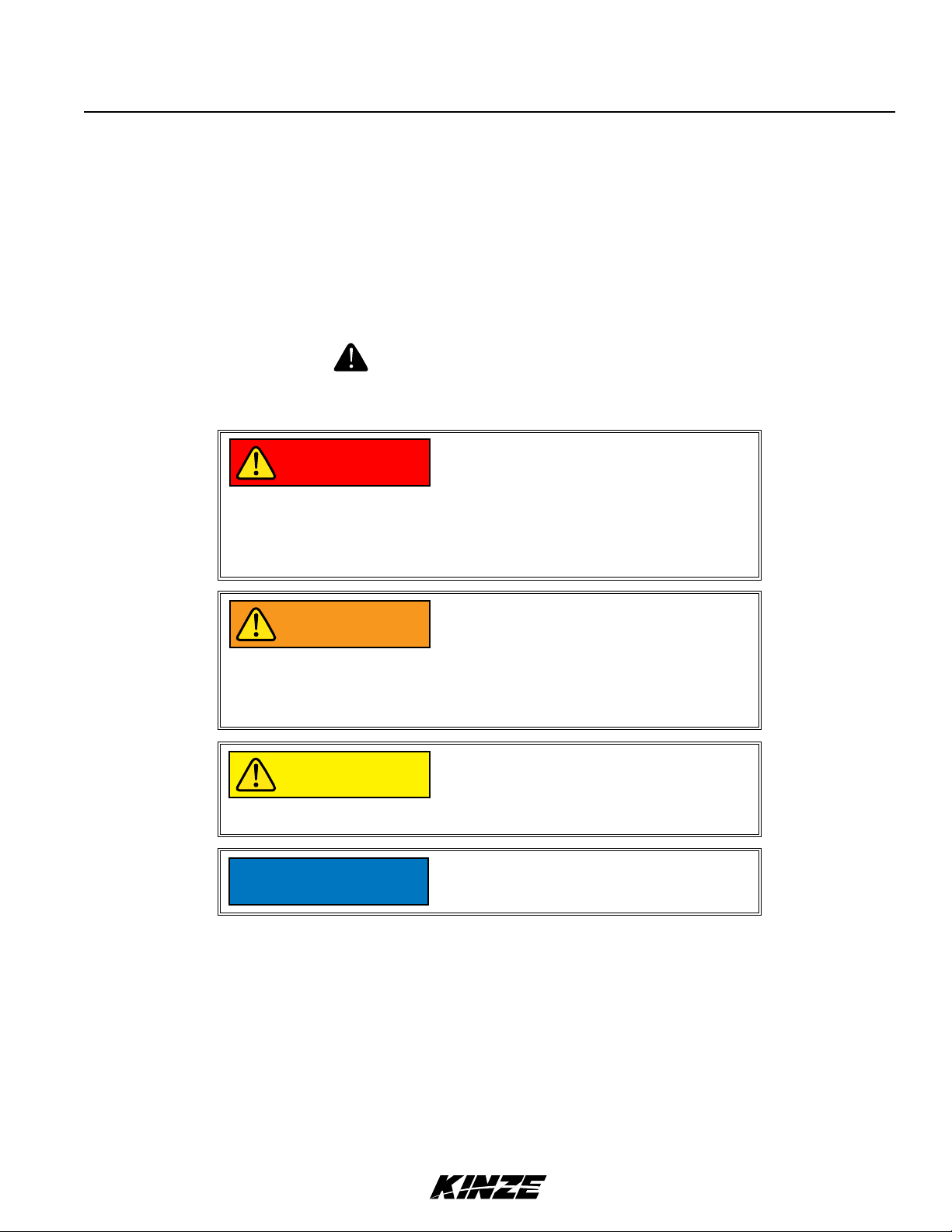

Throughout this manual the symbol and the words DANGER, WARNING, and CAUTION are used to call attention

to safety information that if not followed, will or could result in death or injury. NOTICE and NOTE are used to call your

attention to important information. The definition of each of these terms follows:

Indicates an imminently hazardous

DANGER

situation that, if not avoided, will

result in death or serious injury. This

signal word is to be limited to the most

extreme situations, typically for machine

components which, for functional

purposes, cannot be guarded.

Indicates a potentially hazardous

WARNING

CAUTION

NOTICE

NOTE: Special point of information or machine adjustment instructions.

situation that, if not avoided, could result

in death or serious injury, and includes

hazards that are exposed when guards

are removed. It may also be used to alert

against unsafe practices.

Indicates a potentially hazardous

situation that, if not avoided, may result

in minor or moderate injury. It may also

be used to alert against unsafe practices.

Used to address safety practices not

related to personal injury.

Rev. 1/18 1-3

TM

Page 8

M0255-01Model 3110

Improperly operating or working on

WARNING

WARNING

NOTE: Some photos in this manual may have been taken of prototype machines. Production

machines may vary in appearance.

NOTE: Some photos and illustrations in this manual show optional attachments installed. Contact

your Kinze Dealer for purchase of optional attachments.

this equipment could result in death

or serious injury. Read and follow all

instructions in Operator Manual before

operating or working on this equipment.

Some photos in this manual may show

safety covers, shields, or lockup devices

removed for visual clarity. NEVER

OPERATOR OR WORK ON machine

without all safety covers, shields, and

lockup device in place as required.

1-4 Rev. 1/18

TM

Page 9

Warranty

Model 3110M0255-01

The Kinze Limited Warranty for your new machine is stated on the retail purchaser’s copy of the Warranty And Delivery

Receipt form. Additional copies of the Limited Warranty can be obtained through your Kinze Dealer.

Warranty, within the warranty period, is provided as part of Kinze’s support program for registered Kinze products which

have been operated and maintained as described in this manual. Evidence of equipment abuse or modification beyond

original factory specifications will void the warranty. Normal maintenance, service and repair is not covered by Kinze

warranty.

To register your Kinze product for warranty, a Warranty And Delivery Receipt form must be completed by the Kinze

Dealer and signed by the retail purchaser, with copies to the Dealer, and to the retail purchaser. Registration must be

completed and submitted to Kinze Manufacturing, Inc. within 5 business days of delivery of the Kinze product to the retail

purchaser. Kinze Manufacturing, Inc. reserves the right to refuse warranty on serial numbered products which have not

been properly registered.

If service or replacement of failed parts which are covered by the Limited Warranty are required, it is the user’s responsibility

to deliver the machine along with the retail purchaser’s copy of the Warranty And Delivery Receipt to the Kinze Dealer

for service. Kinze warranty does not include cost of travel time, mileage, hauling or labor. Any prior arrangement made

between the Dealer and the retail purchaser in which the Dealer agrees to absorb all or part of this expense should be

considered a courtesy to the retail purchaser.

Kinze warranty does not include cost of travel time, mileage, hauling or labor.

Rev. 1/18 1-5

TM

Page 10

Specifications

M0255-01Model 3110

GENERAL INFORMATION

The Model 3110 Mounted Planter is available with vacuum or mechanical meters, conventional hoppers, and various

other options. Contact your Kinze dealer for additional options which may be available for your specific model year planter.

Information in this manual was current at time of printing. However, due to Kinze’s ongoing product improvement, production

changes may cause your machine to appear slightly different in detail. Kinze Manufacturing, Inc. reserves the right to

change specifications or design without notice and without incurring obligation to install the same on machines previously

manufactured. To obtain the most recent version of your publication, please contact your Kinze dealer.

Right hand (R.H.) and left hand (L.H.), as used throughout this manual, are determined by facing in the direction the

machine will travel when in use, unless otherwise stated.

TOOLS REQUIRED

Hardware Size / Tool Required

/" = /" /" = /"

(nut for /" hardware uses /" tool)

/" = /" /" = /" /" = 1/" 1/" = 2/"

/" = /" /" = /" 1" = 1/"

/" = 1/" 1/" = 1/"

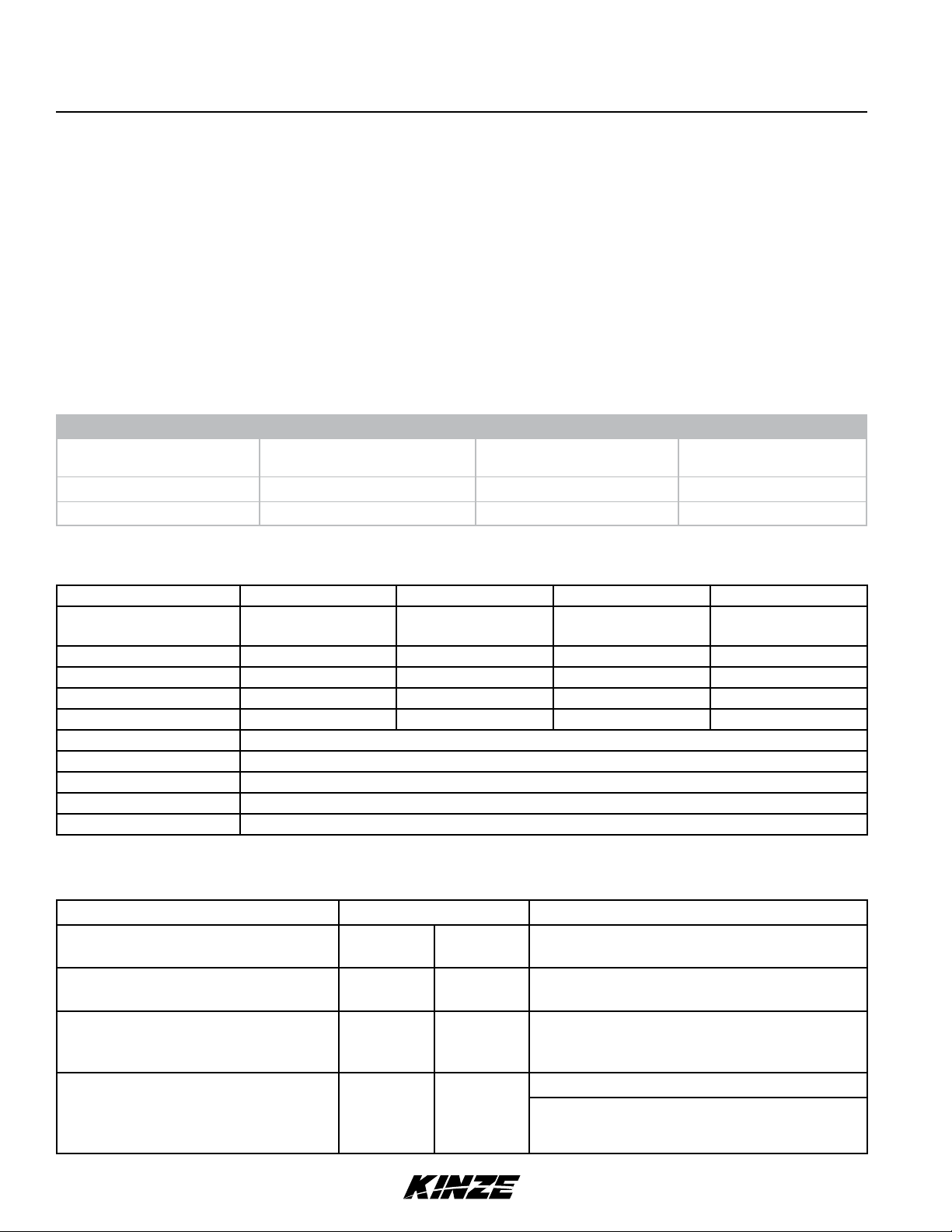

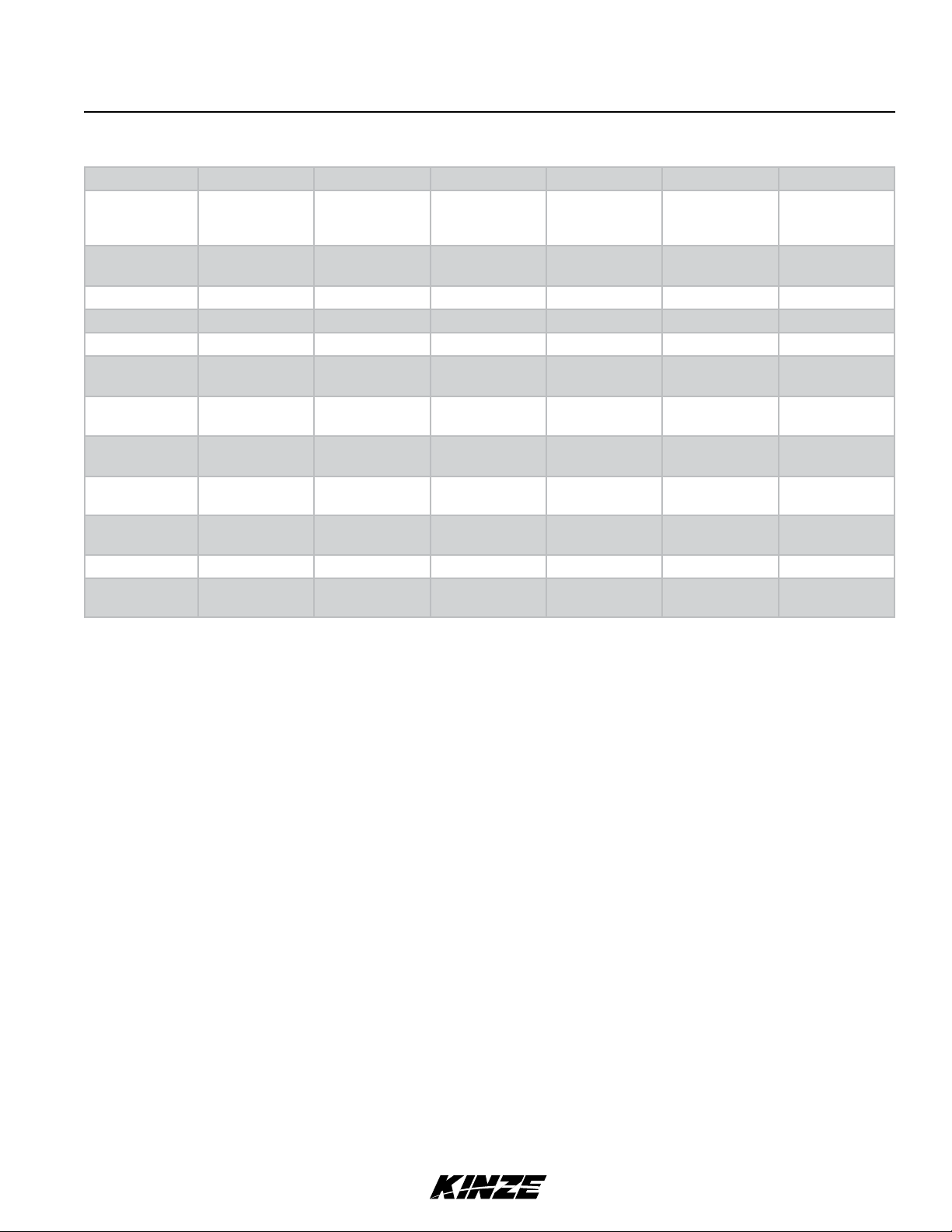

SPECIFICATIONS

Planter Size 6 Row 30" 6 Row 36"/40" 8 Row 30" 8 Row 36"/40"

Width - Transport

(Includes Markers)

Width - Planting 17'-8" (5.4M) 21'-0" (6.4M) 21'-10" (6.7M) 27'-8" (8.4M)

Weight (Mechanical) 2483 lb. (1105.86 kg) 2560 lb. (1161.2 kg) 3092 lb. (1402.5 kg) 3494 lb. (1584.85 kg)

Weight (Vacuum) 2763 lb. (1253.28 kg) 2854 lb. (1294.55 kg) 3407 lb. (1545.4 kg) 3830 lb. (1737.26 kg)

Toolbar 7" x 7" x ¼" wall 7" x 7" x ¼" wall 7" x 7" x ¼" wall 7" x 7" x ¼" wall

Seed Capacity 1.75 bu. (62 liters) (Vacuum/Hopper); 1.90 bu. (67 liters) (Mechanical/Hopper)

Tires

Drive System

Seed Transmission

Drive/Drill Shafts

17'-8" (5.4M) 21'-0" (6.4M) 21'-10" (6.7M) 27'-8" (8.4M)

Two 7.60" x 15" 8 ply - adjustable height

Two 4.10" x 6" spring-loaded contact drive tires with no. 40 chain

Two wheel module-mounted, quick-adjust with machined sprockets and no. 40 chain

' hex drive/drill shafts

TRACTOR HYDRAULIC REQUIREMENTS

Configuration Requirements Description

Base machine with mechanical meters

Base machine with mechanical meters

and optional row marker package

Base machine with vacuum meters

(external case drain required for

vacuum hydraulic circuit)

Base machine with vacuum meters

and optional row marker option

(external case drain required for

vacuum hydralulic circuit)

0 SCV

1 SCV

1 SCV

2 SCV

0 gpm

(0 L/min)

10 gpm

(38 L/min)

15 gpm

(57 L/min)

25 gpm

(95 L/min)

No hydraulic requirements

#1 SCV: row markers with sequencing/flow

control valve

#1 SCV: Vacuum metering

#1 SCV: Vacuum metering

#2 SCV: row markers with sequencing/flow

control valve

1-6 Rev. 1/18

TM

Page 11

General Safety Rules

Model 3110M0255-01

1. Read and understand instructions provided in this

manual and warning labels. Review these instructions

frequently!

2. This machine is designed and built with your safety

in mind. Do not make any alterations or changes to this

machine. Any alteration to design or construction may

create safety hazards.

3. A large portion of farm accidents happen from fatigue

or carelessness. Safe and careful operation of tractor and

planter will help prevent accidents.

4. Never allow planter to be operated by anyone

unfamiliar with operation of all functions of the unit.

Operators must read and thoroughly understand all

instructions given in this manual before operating or

working on equipment.

5. Be aware of bystanders, particularly children! Always

look around to make sure it is safe to start tow vehicle

engine or move planter. This is particularly important with

higher noise levels and quiet cabs, as you may not hear

people shouting.

6. Make sure planter weight does not exceed towing

capacity of tractor, or bridge and road limits. This is critical

to maintain safe control and prevent death or injury, or

property and equipment damage.

7. Never ride or allow others to ride on planter.

8. Store planter in an area away from human activity. DO

NOT permit children to play on or around the stored unit.

highway. Use safety chain (not an elastic or nylon/plastic

tow strap) to retain connection between towing and

towed machines in the event of primary attaching system

separation.

17. Make sure all safety/warning lights, SMV sign, and

reflective decals are in place and working properly before

transporting the machine on public roads.

18. Limit towing speed to 15 MPH. Tow only with farm

tractor of a minimum 90 HP. Allow for unit length when

making turns.

19. Reduce speed prior to turns to avoid the risk of

overturning. Always drive at a safe speed relative to local

conditions and ensure your speed is slow enough for a

safe emergency stop.

20. Chemical application is often an integral part of

planting. Follow label instructions for proper chemical

mixing, handling and container disposal methods.

21. Be familiar with safety procedures for immediate first

aid should you accidentally contact chemical substances.

22. Use the proper protective clothing and safety

equipment when handling chemicals.

23. Chemicals are supplied with Material Safety Data

Sheets (MSDS) that provide full information about the

chemical, its effects on exposure, and first aid needs

in the event of an emergency. Keep your MSDS file

up-to-date and available for first responders in case of

emergency.

9. Keep hands, feet, and clothing away from moving parts.

Do not wear loose-fitting clothing which may catch in

moving parts.

10. Always wear protective clothing, shoes, gloves,

hearing, and eye protection applicable for the situation.

11. Do not allow anyone to stand between tongue or hitch

and towing vehicle when backing up to planter.

13. Prevent electrocution, other injuries, or property

and equipment damage. Watch for obstructions such as

wires, tree limbs, etc. when operating machine. Be aware

of clearances during turns and when folding/unfolding

planter.

14. Reinstall all guards removed for maintenance

activities. Never leave guards off during operation.

15. Use of aftermarket hydraulic, electric, or PTO drives

may create serious safety hazards to you and people

nearby. If you install such drives, follow all appropriate

safety standards and practices to protect you and others

near this planter from injury.

16. Follow all federal, state/provincial, and local

regulations when towing farm equipment on a public

24. When servicing ground engaging components such

as opening disks and firming points, use special care to

avoid points and edges worn sharp during use.

25. Use professional help if you are unfamiliar with

working on hydraulic systems. Pressurized hydraulic fluid

can penetrate body tissue and result in death, serious

infection, or other injuries.

26. Disposing of waste improperly can threaten the

enviroment. To dispose of your equipment properly

contact your local environmental or recyling center.

Never pour waste onto the ground, down a drain, or into

any water source.

When disposing of waste such as oil, use leakproof

containers. Be sure to use containers that do not

resemble food or beverage which may mislead someone

into consuming them. Dispose of oil per your local,

regional requirements.

When disposing of any fertilizer chemicals used, contact

the supplier of the chemicals.

Model 3110 planter consists of 85% recyclable metals,

10% recyclable plastic and rubber, and 5% waste.

Rev. 1/18 1-7

TM

Page 12

Safety Instructions, Signs, and Decals

M0255-01Model 3110

Following are some common hazard warnings associated with this equipment. Pay close attention to all safety,

operating, and maintenance information in this manual and decals applied to your equipment.

Contacting or coming close to power

DANGER

WARNING

lines or other high energy sources will

cause death or serious injury.

Keep away from power lines or high

energy sources at all times.

Improperly operating or working on

this equipment could result in death

or serious injury. Read and follow all

instructions in Operator Manual before

operating or working on this equipment.

WARNING

WARNING

Falling equipment can cause death or

serious injury. Install all lockup devices

or lower planter to ground before

working on equipment.

Explosive separation of rim and tire

parts can cause death or serious injury.

Overinflation, rim and tire servicing,

improper use of rims and tires, or worn

or improperly maintained tires could

result in a tire explosion.

1-8 Rev. 1/18

TM

Page 13

Model 3110M0255-01

SAFETY SIGNS AND DECALS

All safety/warning lights, reflective

WARNING

Safety signs and decals are placed on the machine to warn of hazards and provide important operating and maintenance

instructions. Information on these signs are for your personal safety and the safety of those around you. FOLLOW ALL

SAFETY INSTRUCTIONS!

• Keep signs clean so they can be easily seen. Wash with soap and water or cleaning solution as required.

• Replace safety signs if damaged, painted over, or missing.

decals, and SMV sign must be in place

and visible before transporting machine

on public roads or death, serious injury,

and damage to property and equipment

may result. Check federal, state/

provincial, and local regulations before

transporting equipment on public roads.

• Check reflective decals and SMV sign periodically. Replace if they show any loss of of reflective properties.

• When replacing decals, clean machine surface thoroughly with soap and water or cleaning solution to

remove all dirt and grease.

NOTE: Safety sign and decal locations are shown in the Parts Manual for this machine.

NOTE: Style and locations of SMV sign, reflective decals, and safety/warning lights conform to

ANSI/ASABE S279.14 JUL 2008 and ANSI/ASABE S276.6 JAN 2005.

Rev. 1/18 1-9

TM

Page 14

This page left blank intentionally.

Page 15

Machine Operation

Model 3110M0255-01

The following information is general in nature and was written to aid the operator in preparation of the tractor and

planter for use, and to provide general operating procedures. The operator’s experience, familiarity with the machine

and the following information should combine for efficient planter operation and good working habits.

Always raise planter out of ground when

NOTICE

making sharp turns or backing up or

tractor and equipment may be damaged.

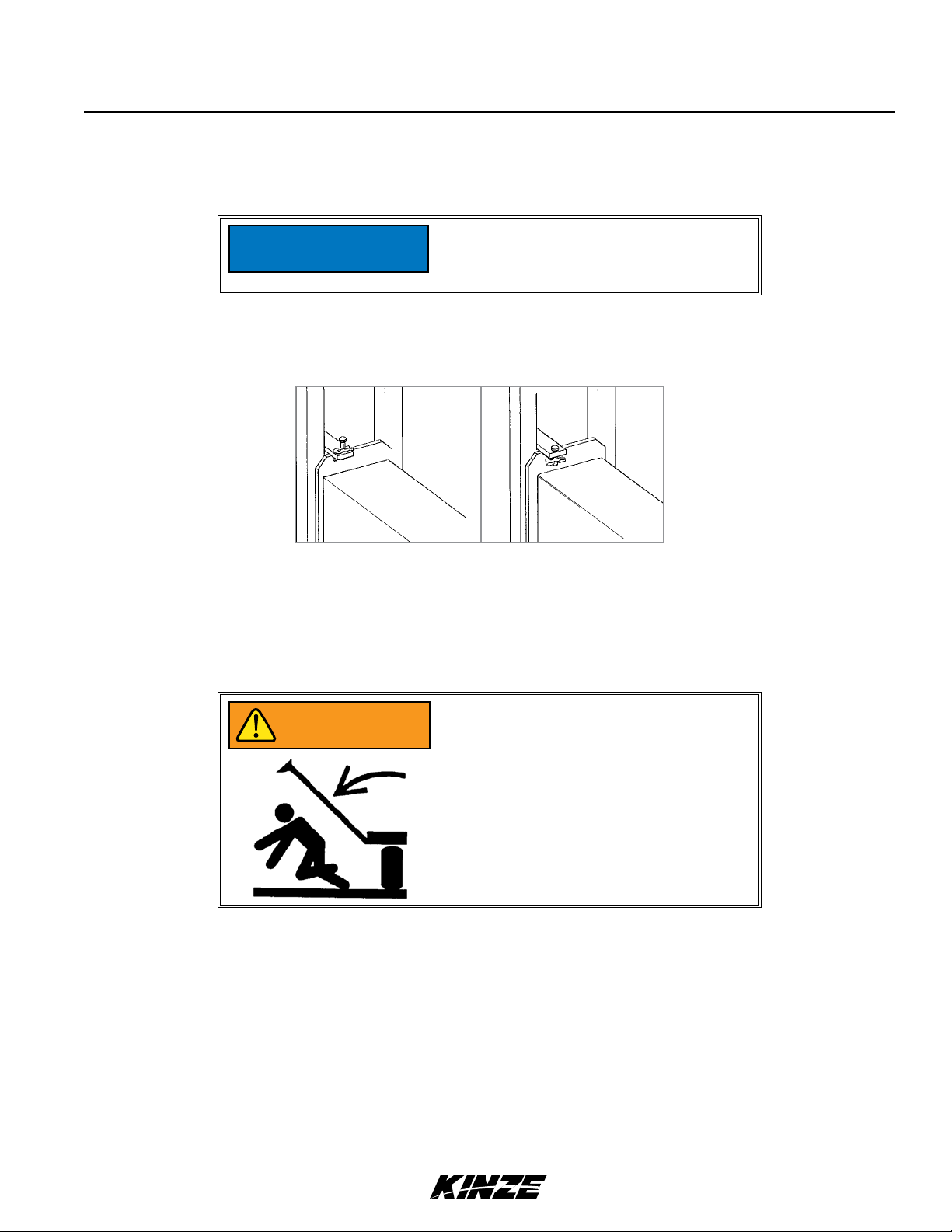

ROW MARKER LOCKUPS (CONVENTIONAL ROW MARKERS ONLY)

When lockups are not in use, store lockup pin in raised position with hair pin clip on upper side of tab. Install marker

lockups when transporting the planter or working around the planter.

Pin Stored In Raised

Position For Marker

Operation

WARNING

Row Marker Locked

Up For Transport Or

Working Around The

Machine

Row marker can lower at any time and

could cause death or serious injury. Stay

away from row markers! Install safety

lockup device when not in use.

Rev. 1/18 2-1

TM

Page 16

Machine Operation

M0255-01Model 3110

INITIAL PREPARATION

Following information is general in nature to aid in preparation of tractor and planter for use, and to provide general

operating procedures. Operator experience, familiarity with the machine, and the following information should combine

for efficient planter operation and good working habits.

Lubricate the planter and row units per the lubrication information in this manual. Make sure all tires have been properly

inflated. See “Tire Pressure”. Check all drive chains for proper tension, alignment and lubrication.

Improperly operating or working on

WARNING

WARNING

this equipment could result in death

or serious injury. Read and follow all

instructions in Operator Manual before

operating or working on this equipment.

Loose transport wheel lug bolts can

result in wheel separation from planter

and cause death, serious injury, and

damage to property and equipment.

Torque transport wheel "- 18 lug bolts

to 90 ft-lb (122 N-m) before operating

planter for the first time and periodically

after.

WARNING

Explosive separation of rim and tire

parts can cause death or serious injury.

Overinflation, rim and tire servicing,

improper use of rims and tires, or worn

or improperly maintained tires could

result in a tire explosion.

2-2 Rev. 1/18

TM

Page 17

Machine Operation

Model 3110M0255-01

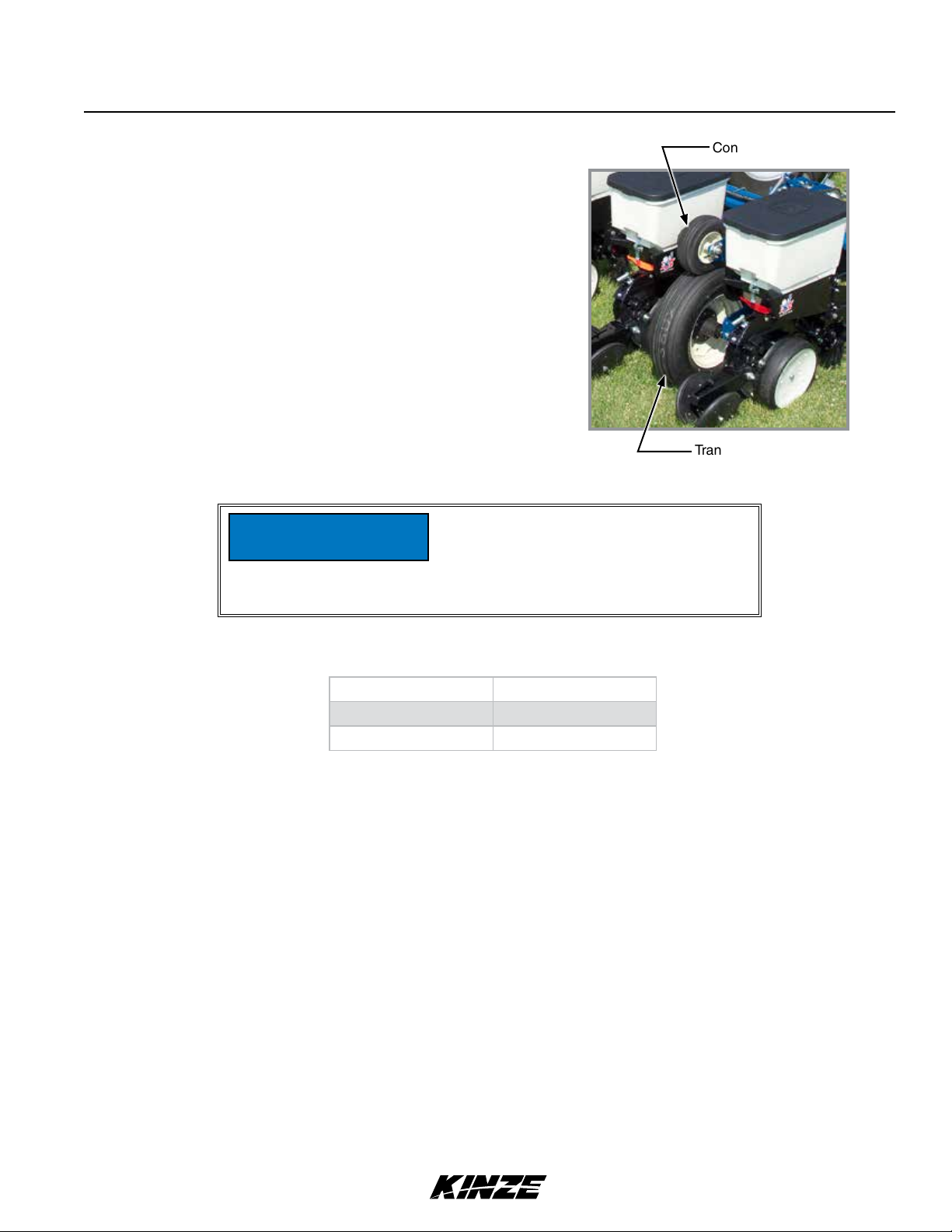

1. Torque transport wheel "- 18 lug bolts to 90 ft-lb (122 N-m).

2. Inflate transport/ground drive tires to 40 psi (275.7 kPa).

3. Inflate contact drive tires to 50 psi (344.7 kPa).

TRACTOR REQUIREMENTS

All Hydraulic Requirements: Minimum

NOTICE

Pressure 2350 PSI (16202.6 kPa); Maximum

Pressure 3000 PSI (20684.2 kPa). Check

tractor hydraulics to ensure that maximum

pressure cannot be exceeded.

Contact drive

Transport/ground drive

Approximate required minimum tractor horsepower (HP) required for field work is listed below:

Row Sizes Horsepower

6 Row 55 - 85 HP

8 Row 75 - 110 HP

NOTE: The tractor must have adequate 3 point hitch lift capacity to lift the weight of the machine, attachments,

seed and dry chemicals. Shipping weights do not include seed, dry chemicals or additional optional attachments.

Tractor front end stability is necessary for safe efficient operation. Therefore, it may be necessary to add front ballast to

your tractor for satisfactory field operation, as well as adequate transport stability. Refer to your tractor operator’s manual

for front ballast recommendations.

A quick-attaching coupler (quick hitch) is recommended for safe and easy attaching and detaching.

A 12 volt DC electrical system is required for operate planter safety/warning lights, digital vacuum gauge.

One SCV remote hydraulic outlet is required to operate optional row markers and one SCV plus a zero pressure case

drain is required to operate the seed metering system vacuum fan.

Maximum hydraulic flow rate of 13 GPM (49 L/min) @ 2000 PSI (13789.5 kPa) is required to operate the vacuum fan motor.

IMPORTANT: Connect hydraulic motor case drain to a case drain return line with zero PSI (kPa) on the tractor.

Failure to connect to a return with zero PSI (kPa) will cause damage to the hydraulic motor shaft seal. Warranty

will not apply on damaged motors resulting from improper hydraulic line connection. DO NOT connect hydraulic

motor case drain to a SCV outlet or motor return circuit connection. Contact tractor manufacturer for specific

details on “zero pressure return”.

Rev. 1/18 2-3

TM

Page 18

Machine Operation

M0255-01Model 3110

TRACTOR PREPARATION AND HOOKUP

1. Set tractor rear wheel spacing at double the planter row spacing. For example: On a planter set for 36" rows, set

the tractor wheel spacing at 72" (183 cm) center-to-center. On wide front end tractors set front wheel spacing equal

to rear wheel spacing. Check tractor operator’s manual for correct front and rear tire pressure.

2. Adjust lift links on tractor so planter will lift level from side to side and raise high enough for planter transport

clearance. Set the sway blocks on the tractor in position to prevent side sway. Be sure the individual lift link arms

are in the float position.

3. Back tractor up to planter. Position lower hitch pins and

bushings as shown in the following diagrams for your type

of tractor hitch. Line up holes and insert hitch pins and lock

in place with pins provided. It may be necessary to change

the length of the tractor upper link with the adjusting

handle.

NOTE: When using a quick-attaching coupler (customer supplied),

match pin location to pin spacing in quick-attaching coupler.

Lower Hitch Pins

32" - Category 2 & 3N

38" - Category 3

Category 2 Bushing Position

Category 2 Requires Pin Only

Category 3 And 3N Requires Pin And Bushing

Upper Hitch Pin

The upper hitch point has two sets of holes. The hitch pin

must be positioned in lower set of holes for use with tractors

equipped with Category 2 quick-attaching coupler. The hitch pin

must be positioned in upper set of holes for use with tractors

equipped with Category 3N and 3 quick-attaching coupler.

NOTE: Always use top hole when not using quickattaching coupler.

Bushing

Category 3 And 3N

Bushing Position

Category 3N & 3

Category 2

Connect ASAE Standards 7 terminal connector for safety/warning lights on planter to ASAE Standards receptacle on

4.

tractor. If your tractor is not equipped with an ASAE Standards receptacle, check with your tractor manufacturer for

availability. Check to be sure safety/warning lights on planter are working in conjunction with safety/warning lights on

tractor.

Connect harness on planter to digital vacuum gauge console on tractor. Connect power lead to power source. A

power lead adapter may be required.

2-4 Rev. 1/18

TM

Page 19

Machine Operation

Model 3110M0255-01

5. Connect hydraulic hoses to tractor ports in a sequence familiar and comfortable to the operator.

hoses, move tractor control levers back and forth to relieve any pressure in the tractor hydraulic system.

Pressurized hydraulic fluid can penetrate

WARNING

NOTICE

body tissue and result in death, serious

infection, or other injuries. Fluid injected

under skin must be IMMEDIATELY

removed by a surgeon familiar with this

type of injury. Make sure connections

are tight and hoses and fittings are

not damaged before applying system

pressure. Leaks can be invisible. Keep

away from suspected leaks. Relieve

pressure before searching for leaks or

performing any system maintenance.

Wipe hose ends to remove any dirt

before connecting couplers to tractor

ports or contamination may cause

equipment failure.

Before attaching

Rev. 1/18 2-5

TM

Page 20

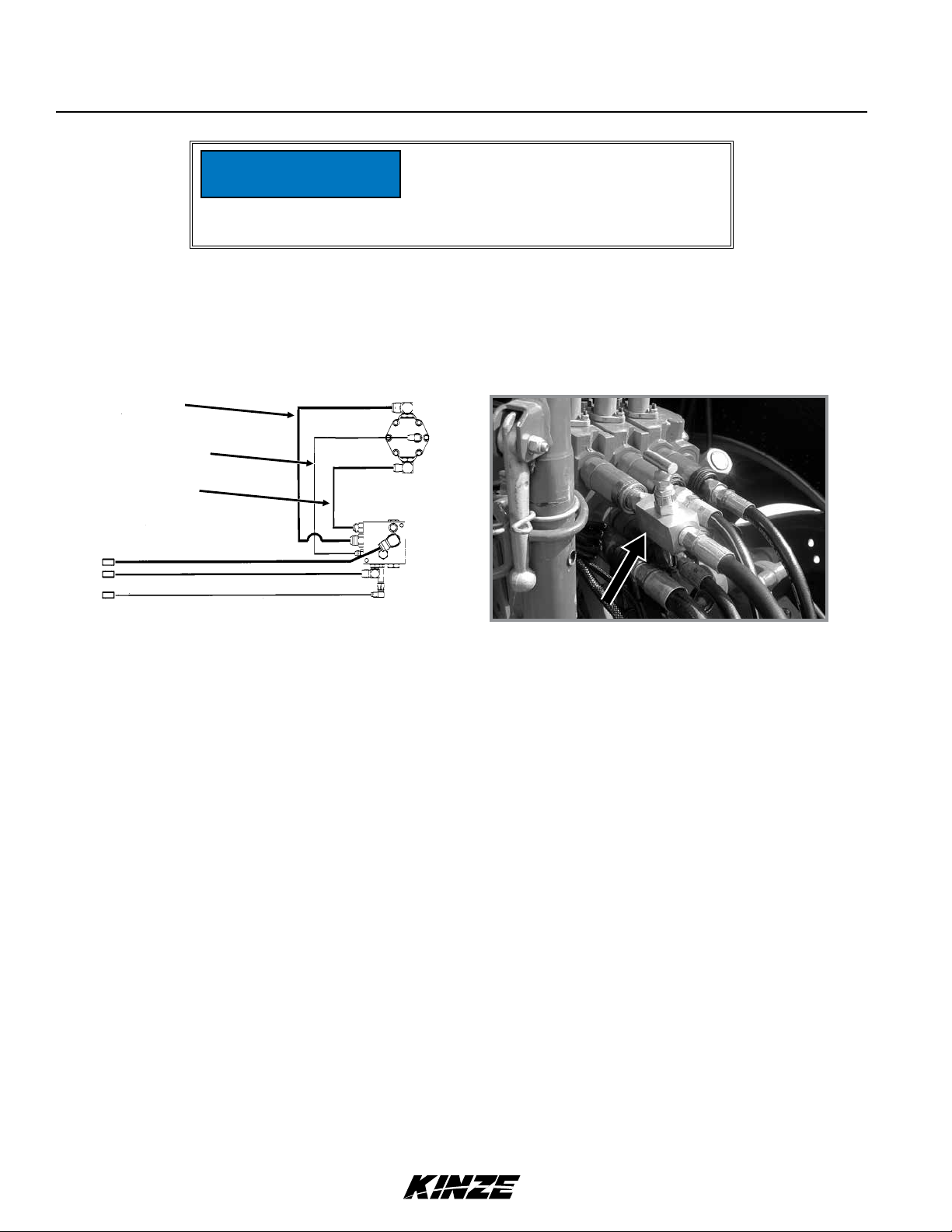

Machine Operation

Vacuum fan motor hydraulic hoses and

NOTICE

The vacuum fan motor operation hydraulic hoses are as follows:

" hose from motor - Case Drain (CD - Orange or CD - Green)

¾" hose from motor - Return

½" hose to motor - Pressure

Return

Case Drain

Pressure

case drain must be installed correctly.

Motor can be damaged or equipment will

not operate properly.

M0255-01Model 3110

G1K426 Needle Valve Kit

NOTE: A Flow Control Needle Valve Kit, to provide a flow control option for tractors that are not

equipped with a method for fine adjustment of hydraulic flow, is available from Kinze Repair Parts

through your Kinze Dealer.

6. Raise planter slowly and watch for any interference. Remove pin from each parking stand and raise each to the

transport position. Secure stands in raised position with pin in lowest hole.

7. For proper operation of the planter and row units, it is important that the planter frame and row unit parallel arms be

level side-to-side and front-to-rear. The toolbar should operate at a 20"-22" (51-56 cm) height from planting surface.

Tire pressure must be maintained at pressures specified and toolbar height must be adjusted equally. Check to be

sure planter toolbar is level and at correct operating height. See “Leveling The Planter”.

NOTE: As a general safety practice and to avoid damage to the tractor hydraulic system, always lower the

planter when not in use.

2-6 Rev. 1/18

TM

Page 21

Intended Use

Piston

Gland

Tube

Rod

End Mounts

Tube Seal

Rod Seal

Rod Wiper

Piston Seal

Product

Category

Maximum

Stroke

Working

Pressure

Bore Size

Shaft

Diameter

Cylinder

Configuration

Cylinder

Action

Material

Mounting

Method

Mount

Location

Cylinder

Style

Machine Operation

Model 3110M0255-01

CYLINDER INFORMATION

Row Marker Cylinder,

6 Row 30" (A21167)

Double Acting Applications Double Acting Applications

Ductile Iron Ductile Iron

Ductile Iron Ductile Iron

ST 52 DOM Tubing ST 52 DOM Tubing

1045 Nitro Rod 1045 Nitro Rod

U-Brackets Sleeve End Mount

Buna O-Ring with Polytemp Back-up Buna O-Ring with Polytemp Back-up

Polyester Alloy U-cup Polyester Alloy U-cup

Polyester Alloy Snap In Polyester Alloy Snap In

T-Seal HNBR T-seal HNBR

6 Row 36"/38"/40" and 8 Row 36"/38"/40" (A21158)

Specifications

Hydraulic Cylinder Hydraulic Cylinder

8" (20.32 cm) 20.062" (50.96 cm)

2350-3000 PSI

(16202.68-20684.27 KPa)

2" (5.08 cm) 2" (5.08 cm)

1" (2.54 cm) 1" (2.54 cm)

Simple Simple

Double Double

Steel, Ductile Iron Steel, Ductile Iron

U-Bracket Sleeve

End Cap End Cap

Welded Welded

Row Marker Cylinder,

2350-3000 PSI

(16202.68-20684.27 KPa)

Rev. 1/18 2-7

TM

Page 22

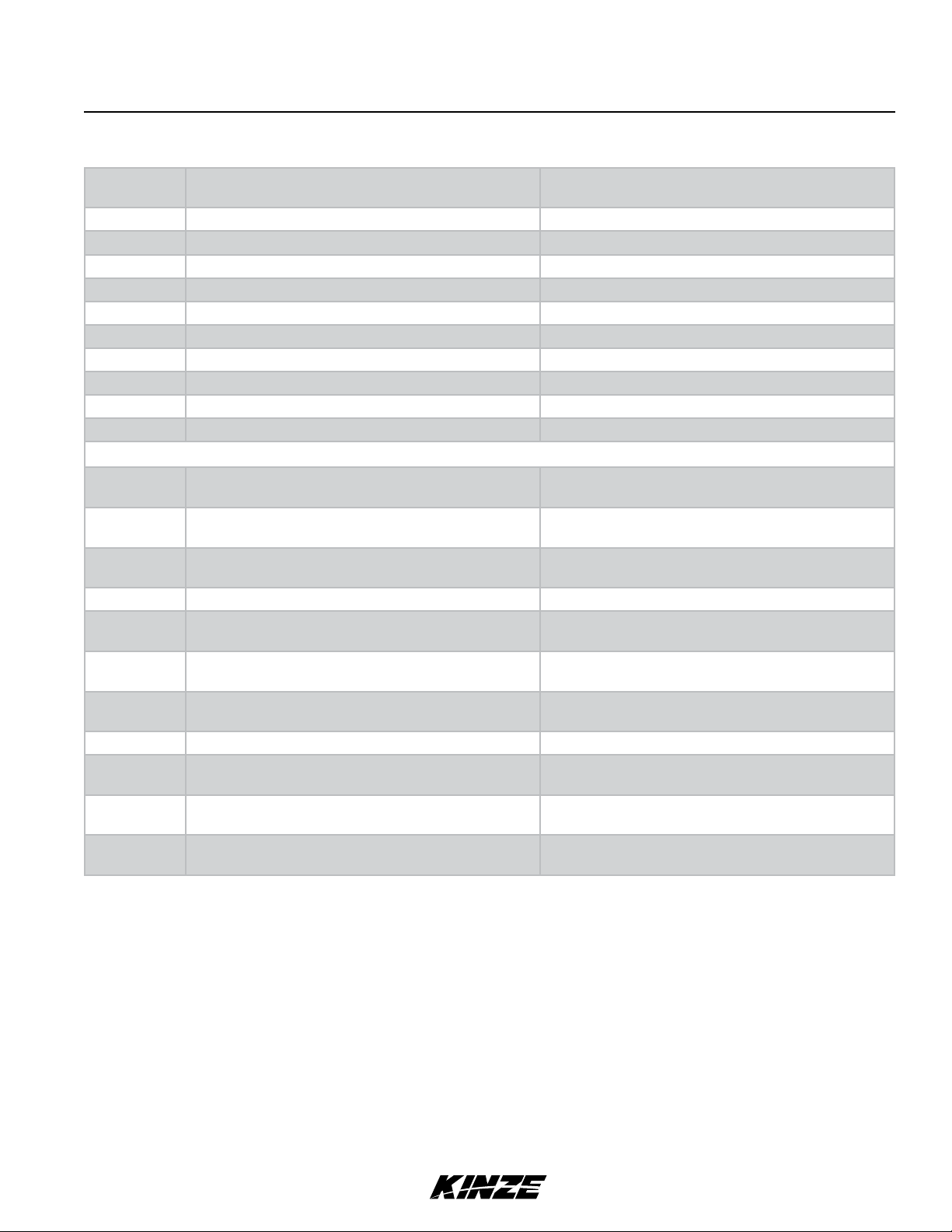

Part Number

Description

Product

Category

Product Form

I.D.

O.D.

Minimum Bend

Radius

Working

Pressure

Temperature

Range

Material

Specialized

Construction

Media

Application

Machine Operation

M0255-01Model 3110

HYDRAULIC HOSE INFORMATION

A3337 A8247 A3266 A3367 A3292 A8273

Hose Assembly,

/" x 60"

(8M-12F)

Hydraulic Hose Hydraulic Hose Hydraulic Hose Hydraulic Hose Hydraulic Hose Hydraulic Hose

Hose; Assembly Hose; Assembly Hose; Assembly Hose; Assembly Hose; Assembly Hose; Assembly

.750" (19 mm) .500" (12.7 mm) .375" (9.5 mm) .750" (19 mm) .375" (9.5 mm) .500" (12.7 mm)

1.110" (28 mm) .800" (20.3 mm) .630" (16 mm) 1.110" (28 mm) .630" (16 mm) .800" (20.3 mm)

3.8"

(9.65 cm)

3500 PSI

(24131.65 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid

Agricultural;

Construction

Hose Assembly,

½" x 60"

(8M-10F)

2.8"

(7.1 cm)

3250 PSI

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

/" x 60"

(8M-6F)

2"

(5.08 cm)

3250 PSI

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

/" x 21"

(12F-12F)

3.8"

(9.65 cm)

3500 PSI

(24131.65 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

" X 22"

(6F-6F)

2"

(5.08 cm)

3250 PSI

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

½" x 21"

(10F-10F)

2.8"

(7.1 cm)

3250 PSI

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Part Number

Description

Product

Category

Product Form

I.D.

O.D.

Minimum Bend

Radius

Working

Pressure

Temperature

Range

Material

Specialized

Construction

Media

Application

A1106 A3114 A1049 A3154 A1168 A3115

Hose Assembly,

¼" X 130"

(6F-6F)

Hydraulic Hose Hydraulic Hose Hydraulic Hose Hydraulic Hose Hydraulic Hose Hydraulic Hose

Hose; Assembly Hose; Assembly Hose; Assembly Hose; Assembly Hose; Assembly Hose; Assembly

.250" (6.3 mm) .375" (9.5 mm) .375" (9.5 mm) .375" (9.5 mm) .250" (6.3 mm) .375" (9.5 mm)

.530" (13.5 mm) .630" (16 mm) .630" (16 mm) .630" (16 mm) .530" (13.5 mm) .630" (16 mm)

4"

(10.1 cm)

3275 psi

(22580.33 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid

Agricultural;

Construction

Hose Assembly,

" x 156"

(8F-8F)

2"

(5.08 cm)

3250 psi

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

" x 160"

(8F-8F)

2"

(5.08 cm)

3250 psi

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

" x 196"

(8F-8F)

2"

(5.08 cm)

3250 psi

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

¼" x 120"

(6F-6F)

4"

(10.1 cm)

3275 psi

(22580.33 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

" x 146"

(8F-8F)

2"

(5.08 cm)

3250 psi

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

2-8 Rev. 1/18

TM

Page 23

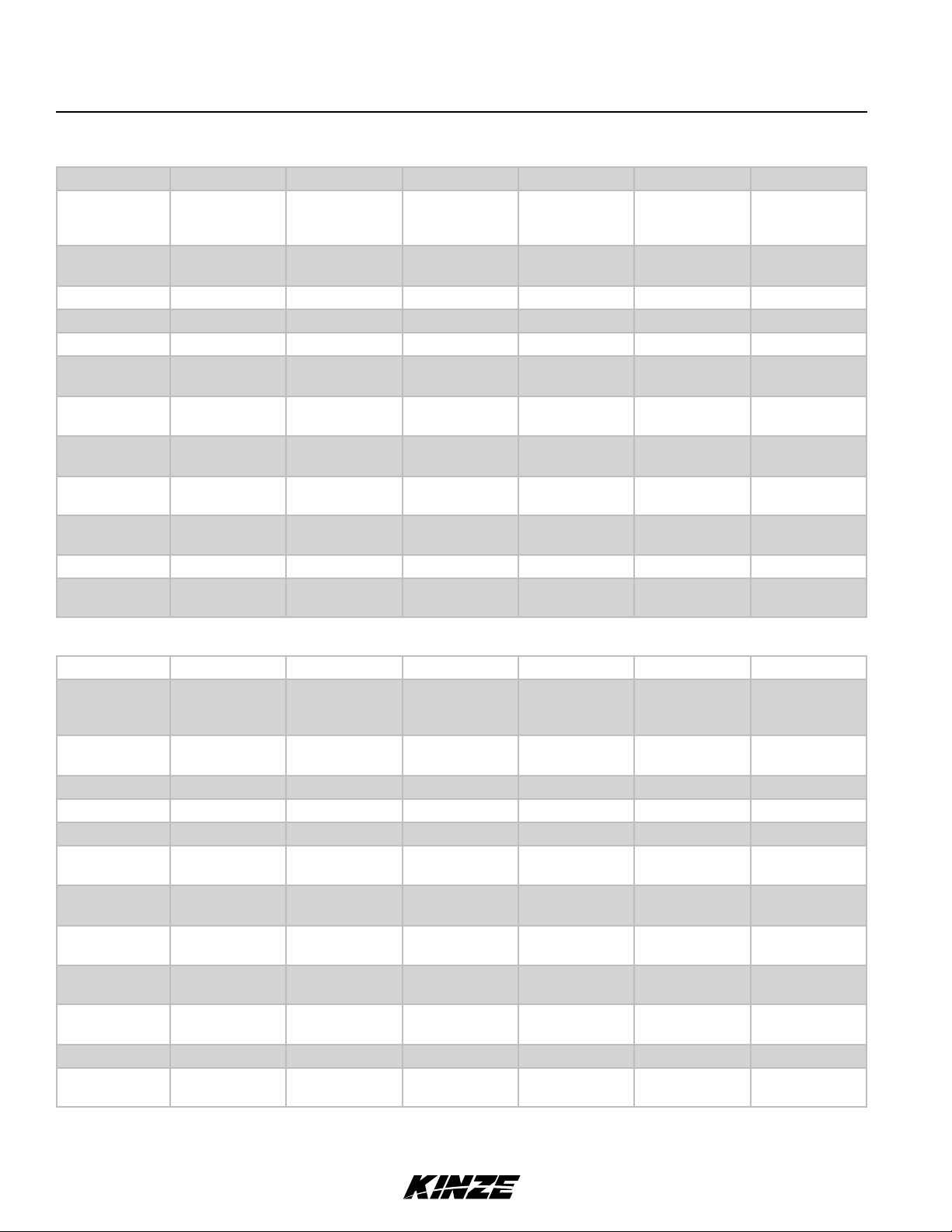

Part Number

Description

Product

Category

Product Form

I.D.

O.D.

Minimum Bend

Radius

Working

Pressure

Temperature

Range

Material

Specialized

Construction

Media

Application

Machine Operation

Model 3110M0255-01

HYDRAULIC HOSE INFORMATION

A1013 A1028 A3186 --- --- ---

Hose Assembly,

" x 150"

(8F-8F)

Hydraulic Hose Hydraulic Hose Hydraulic Hose --- --- ---

Hose; Assembly Hose; Assembly Hose; Assembly --- --- ---

.375" .375" .375" --- --- ---

.630" (16 mm) .630" (16 mm) .630" (16 mm) --- --- ---

2"

(5.08 cm)

3250 psi

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Hydraulic Fluid Hydraulic Fluid Hydraulic Fluid --- --- ---

Agricultural;

Construction

Hose Assembly,

" x 186"

(8F-8F)

2"

(5.08 cm)

3250 psi

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

Hose Assembly,

" x 56"

(8M-6F)

2"

(5.08 cm)

3250 psi

(22407.96 kPa)

-40°F - +212°F

(-40°C - +100°C)

Modified Nitrile

Type C2

High tensile

steel wire

Agricultural;

Construction

--- --- ---

--- --- ---

--- --- ---

--- --- ---

--- --- ---

--- --- ---

--- --- ---

Rev. 1/18 2-9

TM

Page 24

LEVELING THE PLANTER

1. Drive the tractor and planter on level ground.

2. Lower the planter to the ground.

Machine Operation

M0255-01Model 3110

3. Check to be sure toolbar height is 20"-22" (51-56 cm).

See “Toolbar Height Adjustment”.

4. Check to be sure planter is level front-to-rear and row

unit parallel arms are level. Adjust upper link on tractor

accordingly.

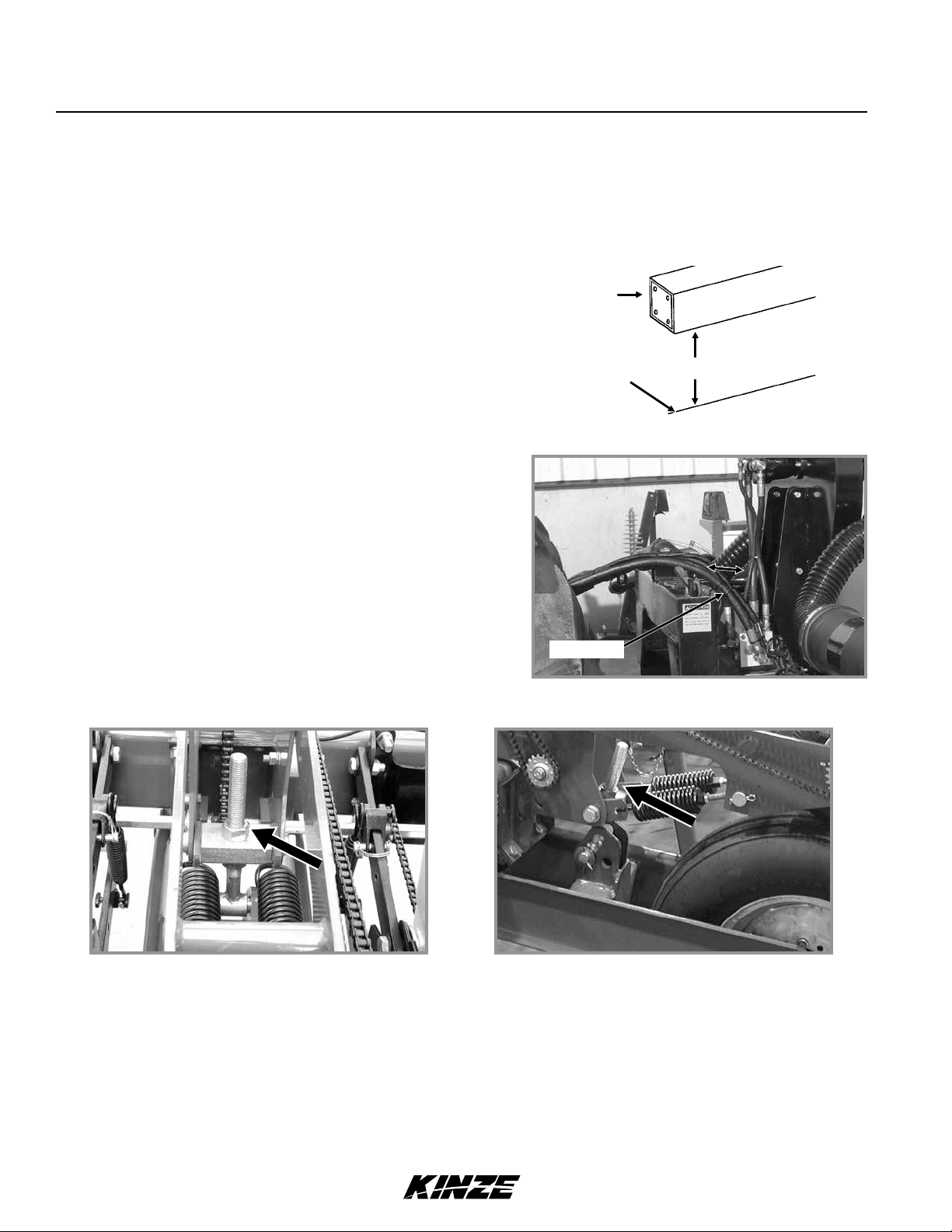

TOOLBAR HEIGHT ADJUSTMENT

Toolbar

Level

Planting

20"-22" (51-56 cm)

Surface

Upper Link

Shown With Customer-Supplied Quick Hitch

Standard Rear Mounted Drive Wheel Optional Front Mounted Drive Wheel

The drive wheel assembly is designed so the wheel can be adjusted to maintain a toolbar height of 20"-22" (51-56 cm)

from the planting surface in all planting situations. This is particularly useful when the planter is used for ridge planting

or planting on beds. The drive wheel assembly has an adjustment range of 7" (18 cm).

To adjust toolbar height:

1. Loosen the jam nut using a 1½" wrench or a 15" adjustable wrench.

2. Turn the adjusting nut using a 1" wrench or 15" adjustable wrench (clockwise to decrease frame height or counter

clockwise to increase frame height).

3. Tighten the jam nut.

2-10 Rev. 1/18

TM

Page 25

PARKING STAND ADJUSTMENT

CAUTION

Machine Operation

Model 3110M0255-01

Improperly lifting could cause muscle

strain or back injury. Use proper lifting

techniques or lifting aids when adjusting

parking stand.

Two parking stands, located on front side of main frame, are standard on all Model 3110 planters. The stands must be

positioned so they are not directly behind tractor tire or they will hit when planter is raised.

Raise to top position and pin when planting. Lower and pin for parking and storage.

On planters equipped with front mounted drive wheels, parking stands are not required.

Each parking stand has six positioning holes. By using these positioning holes, you can set toolbar height from 19" to

25" (48 to 63.5 cm).

Rev. 1/18 2-11

TM

Page 26

Machine Operation

M0255-01Model 3110

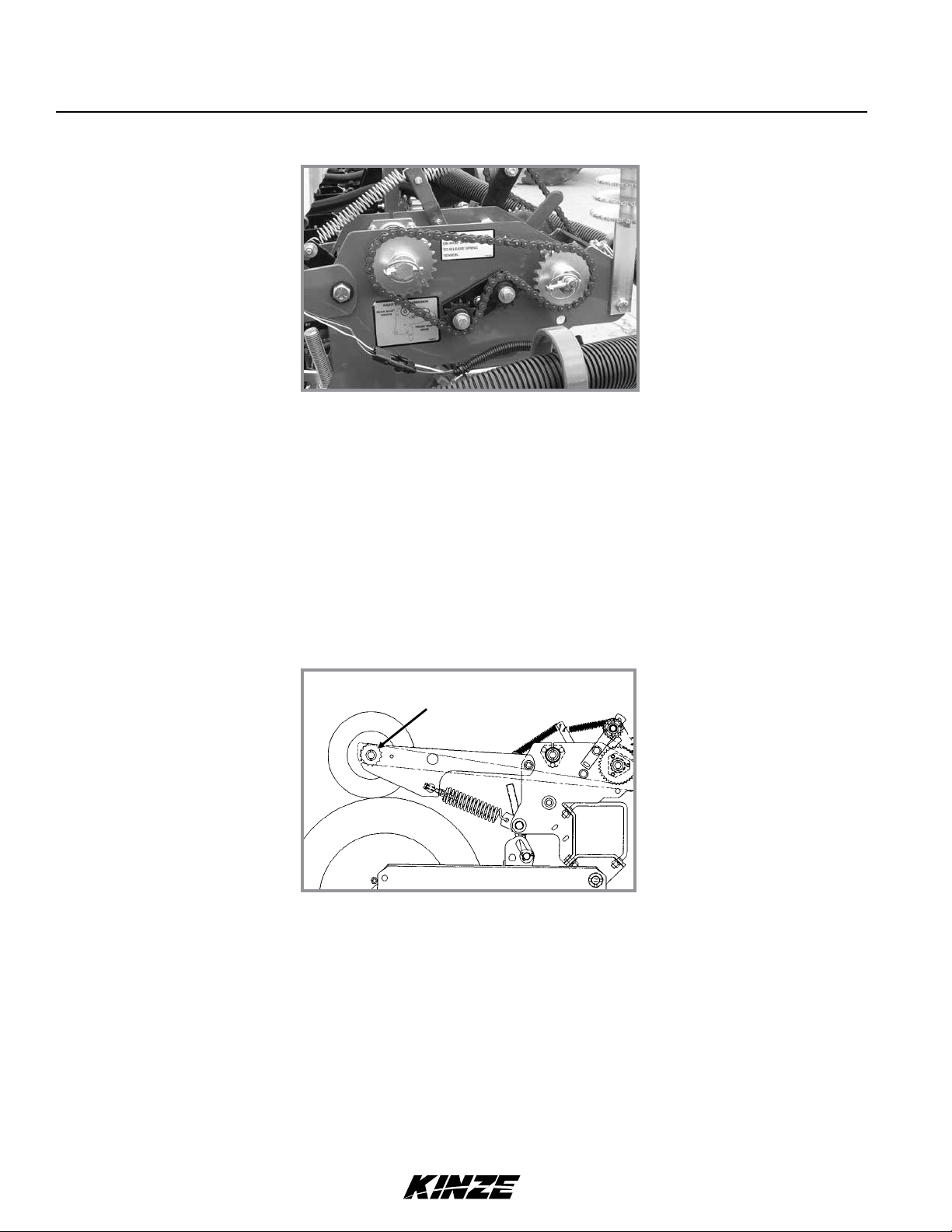

SEED RATE TRANSMISSION ADJUSTMENT

Planting population rate changes are made at the seed rate transmissions. The seed rate transmissions are designed

to allow simple, rapid changes of sprockets to obtain the desired planting population. By removing lynch pins on

hexagon shafts, sprockets can be interchanged with those from the sprocket storage rod bolted to each transmission.

Chain tension is controlled by a spring-loaded, dual-sprocket idler. The idler assembly is adjusted with an easy-release

idler arm. This arm has a release position to remove spring tension for replacing sprockets. The amount of spring

tension on chain is controlled by idler arm. See “Wrap Spring Wrench Operation”.

A decal positioned near each transmission illustrates proper chain routing. The planting rate charts found in the Rate

Charts section will aid you in selecting correct sprocket combinations.

CONTACT WHEEL DRIVE SPROCKETS

Drive Sprocket

NOTE: 15 tooth, 19 tooth or 30 tooth drive sprockets at each contact drive wheel can be interchanged from the

sprocket storage rod bolted to each transmission. The 15 and 19 tooth sprockets require use of a 218 pitch No.

40 chain. The 30 tooth sprocket requires use of a 224 pitch No. 40 chain.

Chain tension is controlled by a spring-loaded sprocket idler. The amount of spring tension on the chain is controlled by

the idler arm.

The planting rate charts found in the Rate Chart section will aid you in selecting the correct sprocket.

NOTE: 15, 19, and 30 tooth drive sprockets are NOT applicable to all rate charts. Check chart titles to ensure

the proper rate chart is selected.

NOTE: After each sprocket combination adjustment, make a field test to be sure you are planting at the desired rate.

2-12 Rev. 1/18

TM

Page 27

Machine Operation

Model 3110M0255-01

CONTACT WHEEL SPRING ADJUSTMENT

There are two down pressure springs on each contact drive

wheel. The spring tension is factory preset and should need

no further adjustment.

The tension is set leaving 1" (2.5 cm) between the spring plug

and the mounting shaft as shown below.

SHEAR PROTECTION

The planter driveline and seed and granular chemical drivelines

are protected from damage by shear pins.

If excessive load should cause a pin to shear, it is important to

determine where binding has occurred before replacing the pin.

Replace shear pins with same size and type.

To prevent future binding or breakage of components, check

driveline alignment and follow prescribed lubrication schedules.

1"

(2.5 cm)

/" Shear Pin

Transmission Shaft

WRAP SPRING WRENCH

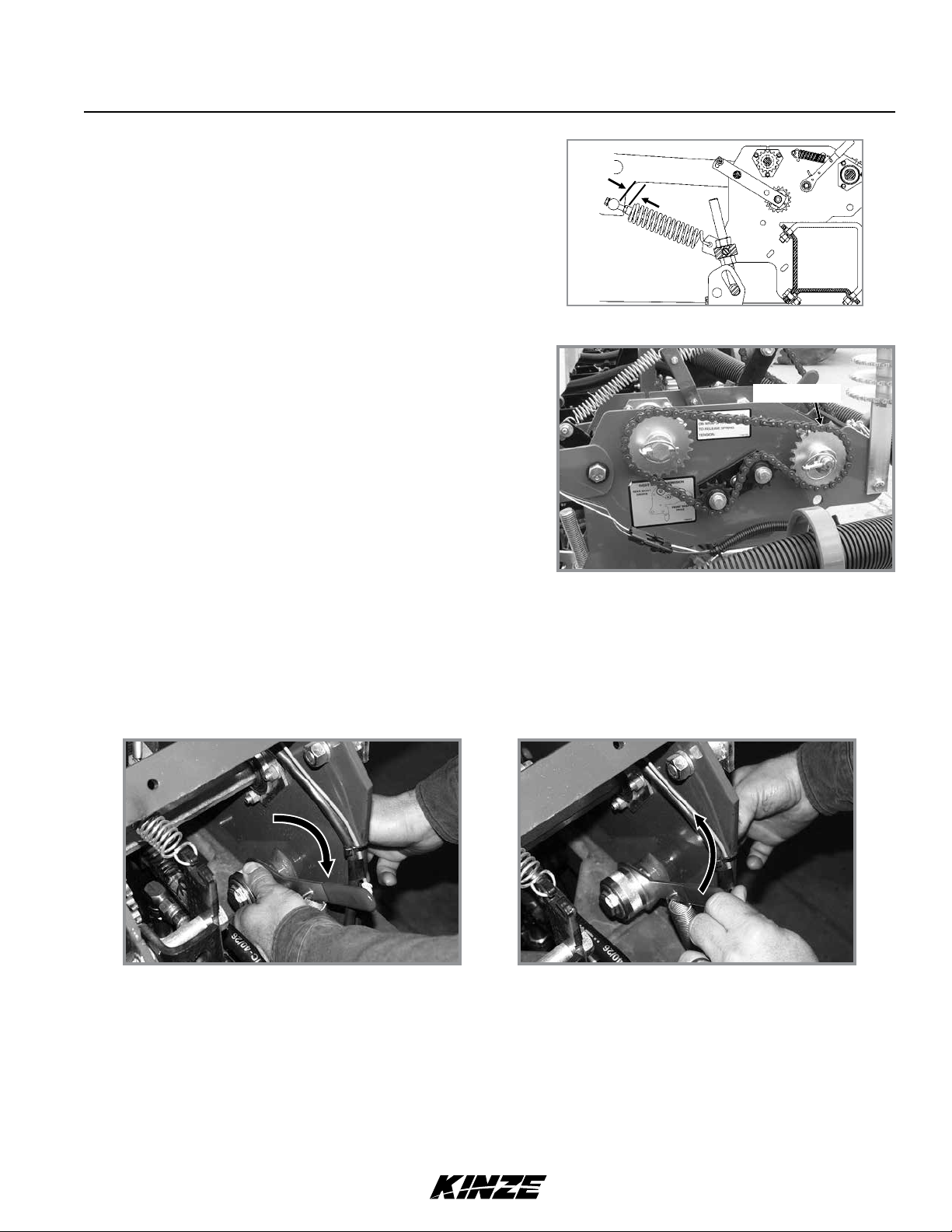

Chain idlers use wrap spring wrenches to release and adjust transmission chain tension.

NOTE: Wrap spring wrenches are L.H. and R.H. specific. L.H. styles have silver metal or grey plastic release

collars. R.H. styles have gold metal or blue plastic release collars.

To add chain tension, rotate the chain idler into

the chain while rotating the handle to tension

idler spring.

Rotate wrap spring wrench knurled collar while rotating chain idler away from chain to release chain tension.

The wrap spring wrenches are made in L.H. and

R.H. configurations, which can be identified by

the silver or gold release collars, respectively.

Rotate chain idler into chain while rotating handle to tension idler spring.

Rev. 1/18 2-13

TM

Page 28

Machine Operation

M0255-01Model 3110

VACUUM SYSTEM

Kinze vacuum seed metering system includes seed meters, seed discs, and an air system consisting of a hydraulic

driven vacuum fan which draws air through manifolds, hoses, and seed meters on each row unit.

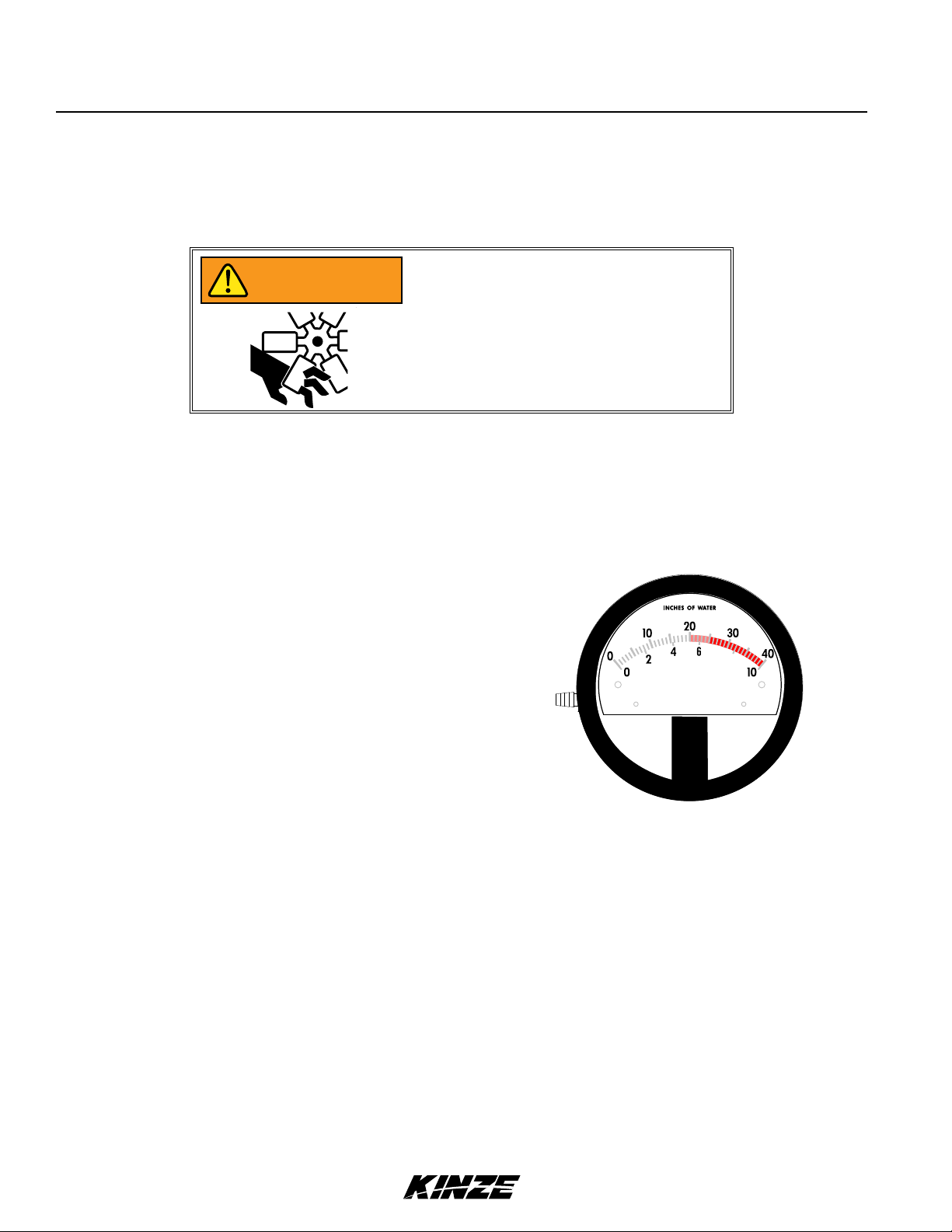

Moving fan blades can cause amputation

WARNING

or severe injury. Never operate vacuum

fan with cover removed.

DIGITAL VACUUM READOUT

Digital vacuum readout is incorporated into in-cab display. Refer to the display operation manual for instructions.

ANALOG VACUUM GAUGE

The analog vacuum gauge connects directly to the manifold or

is teed into the digital sending unit on newer models.

Only gauge adjustment is to “zero” needle with no vacuum

present. If there is a significant difference between this gauge

and a reading taken at meters, a different manifold location

should be found to connect hose to gauge and digital sending

unit.

KILOPASCALS

MAX PRESSURE 15 PSIG (103 KPA)

Analog vacuum gauge

8

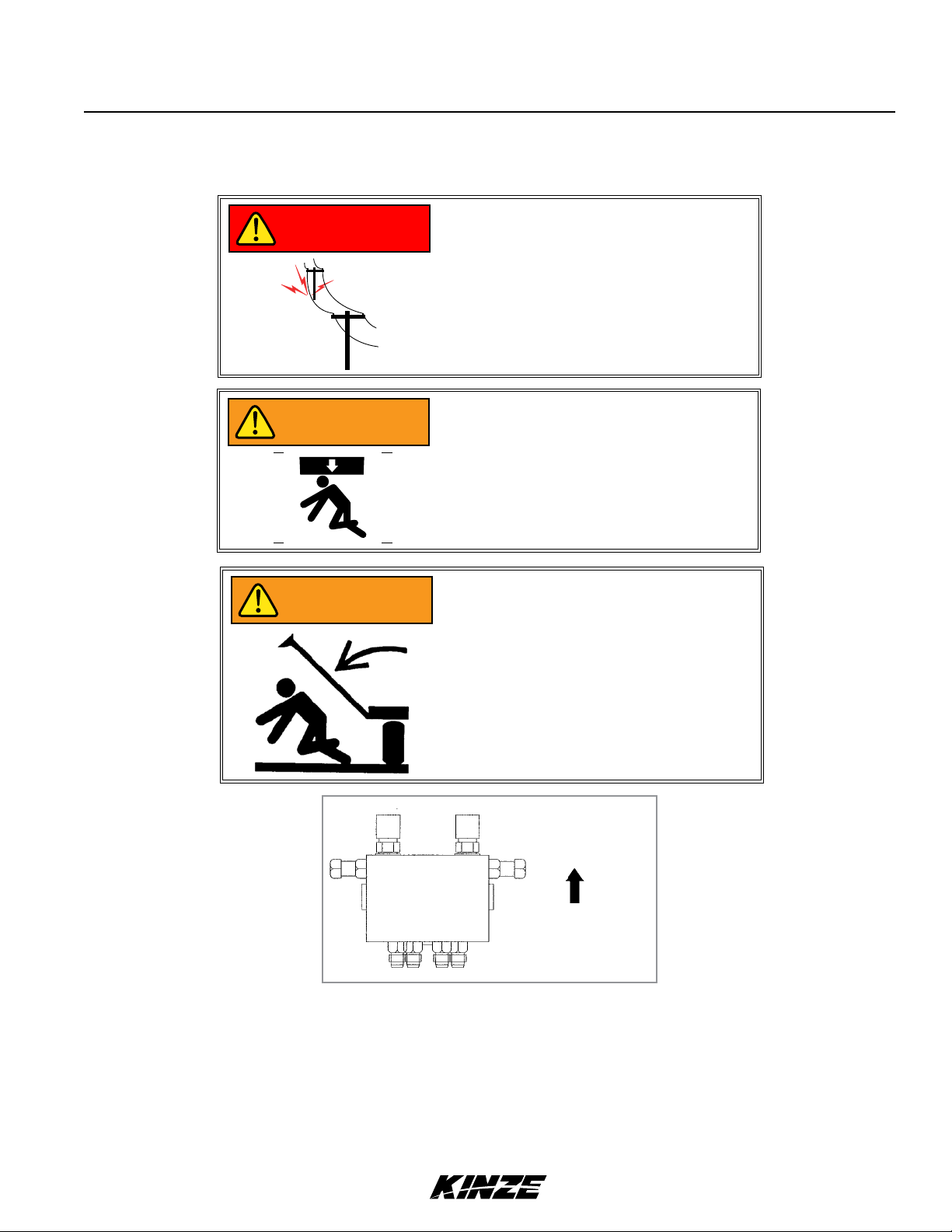

VACUUM FAN MOTOR VALVE BLOCK ASSEMBLY

A pressure relief valve in the hydraulic circuit prevents build up of oil pressure over 35 PSI (241 kPa) in case drain line

when vacuum fan motor is operating. This valve will vent oil outside valve block through a drain hole in the aluminum

valve block. This can occur whenever case drain is improperly connected or pressure in motor circuit builds.

See “Hydraulic Diagram - Vacuum Fan Motor System” in Lubrication and Maintenance section.

Valve block contains a check valve that prevents vacuum fan from operating in wrong direction if pressure is applied to

return side of motor and allows fan to coast to a stop when tractor hydraulic control is returned to neutral position.

NOTE: Fan turns at a reduced speed If reverse pressure is applied.

2-14 Rev. 1/18

TM

Page 29

Machine Operation

ROW MARKER OPERATION

The machine is equipped with a single control valve system for the optional row markers.

Contacting or coming close to power

DANGER

WARNING

lines or other high energy sources will

cause death or serious injury.

Keep away from power lines or high

energy sources at all times.

Uncontrolled movement of equipment

can cause loss of control and could

result in death, serious injury, or damage

to property and equipment. Install

all safety pins before transporting

equipment.

Model 3110M0255-01

Row marker can lower at any time and

WARNING

Sequencing/Flow Control Valve Used With Single

Valve Row Marker Hydraulic System

The single valve marker system uses a sequencing valve which directs hydraulic flow to operate the markers alternately.

could cause death or serious injury. Stay

away from row markers! Install safety

lockup device when not in use.

DIRECTION

OF TRAVEL

With the single valve marker system, both markers can be used at the same time by first lowering one marker and moving

the hydraulic control to the raise position and immediately returning it to the lower position. This will shift the marker

control valve spool and the opposite marker will be lowered.

NOTE: If a marker cylinder has been disconnected or removed for any reason, do not attach the rod end of the

cylinder until the cylinder is cycled several times to remove any air that may be trapped in the system.

Rev. 1/18 2-15

TM

Page 30

Machine Operation

M0255-01Model 3110

ROW MARKER SPEED ADJUSTMENT

Contacting or coming close to power

DANGER

lines or other high energy sources will

cause death or serious injury.

Keep away from power lines or high

energy sources at all times.

The marker hydraulic system includes two flow control valves. One flow control valve sets the lowering speed of both

markers and one sets the raising speed of both markers. To adjust marker speed, loosen the jam nut and turn the

control(s) clockwise or IN to slow the travel speed and counterclockwise or OUT to increase the travel speed. The

flow control(s) determines the amount of oil flow restriction through the valve(s), therefore varying travel speed of the

markers. Tighten jam nut after adjustments are complete.

Flow Control

Marker Raise

Sequencing/Flow Control Valve Used With Single

Valve Row Marker Hydraulic System

Flow Control

Marker Lower

DIRECTION

OF TRAVEL

IMPORTANT: The flow controls should be properly adjusted before the marker assembly is first put into use.

Excessive travel speed of the markers can damage the marker assembly.

NOTE: When oil is cold, hydraulics operate slowly. Make sure all adjustments are made with warm oil.

NOTE: On a tractor where the oil flow can not be controlled, the rate of flow of oil from the tractor may be

greater than the rate at which the marker cylinder can accept the oil. The tractor hydraulic control will have to

be held until the cylinder reaches the end of its stroke. This occurs most often on tractors with open center

hydraulic systems.

On tractors with closed center hydraulic systems, the

tractor's hydraulic flow control should be adjusted to the

full flow position. If oil is restricted, the sequencing valve

may not shift properly.

2-16 Rev. 1/18

TM

Page 31

Machine Operation

ROW MARKER ADJUSTMENTS

1. Multiply number of rows by the average row spacing in inches to determine total planting width.

Model 3110M0255-01

Row Marker Lengths

6 Row 30" 180" (457.2 cm)

6 Row 36" 216" (548.64 cm)

6 Row 40" 240" (609.6 cm)

8 Row 30" 240" (609.6 cm)

8 Row 36" 288" (731.52 cm)

8 Row 40" 320" (812.8 cm)

2. Lower planter and row marker assembly to ground.

3. Measure from planter center line to a point where blade contacts ground.

4. Adjust row marker extension so distance from marker disc blade to center line of planter is equal to total planting

width. Adjust right and left row marker assemblies equally and securely tighten clamping bolts.

Loosen hardware to

Loosen hardware to

adjust marker length.

adjust blade angle.

Depth band

Concave side faces

towards planter.

Row marker disc blade angle adjustment

Setting marker disc blade assembly at a

NOTICE

sharper angle than needed adds stress

to row marker assembly and shortens

bearing and blade life. Set blade angle

only as needed to leave a clear mark.

Marker disc blade is installed with concave side facing inward. Spindle assembly is slotted so hub and blade can be

angled to throw more or less dirt.

5. Loosen hardware and move assembly as required.

6. Tighten bolts to specified torque.

7. Do a field test to ensure markers are properly adjusted.

NOTE: A notched marker blade is available from Kinze through your Kinze Dealer for use in more severe no

till conditions.

Rev. 1/18 2-17

TM

Page 32

Machine Operation

M0255-01Model 3110

POINT ROW CLUTCHES

L.H. Side Of Planter ShownPoint Row Clutch Control Box

Electric-activated clutches disengage drive on either half of planter for finishing up fields or for long point row

situations. Clutch selector switch is located on tractor control box.

Switch must be OFF when planter is not

NOTICE

in use or tractor battery will be drained.

NOTE: Liquid fertilizer piston pump has its own drive wheel and is not affected by point row clutch.

Output hub

Stop collar

Wrap spring

Input hub

Control tang

Clutch consists of a wrap spring riding on an input and output hub. Wrap spring is wrapped tightly over hubs during

operation locking them together. Higher speeds create a tighter grip of spring on hubs.

Input end of spring is bent outward and is called the control tang. Control tang fits into a slot in stop collar located

between input and output hubs over wrap spring. If stop collar is allowed to rotate with input hub, clutch is engaged. If

stop collar is stopped from rotating, control tang connected to it is forced back and spring opens. This allows input hub

to continue rotating without transmitting torque to output hub, stopping planter drive.

Stop collar is controlled by an electric solenoid and an actuator arm. When selector switch on tractor control box is

OFF, solenoid coil is NOT ENERGIZED and actuator arm will not contact stop on stop collar, allowing it to rotate with

hubs and drive planter.

When operational switch is in “DISENGAGE” (right or left) solenoid coil IS ENERGIZED and plunger in solenoid coil

pulls actuator arm against stop on stop collar, disengaging wrap spring and stopping planter drive.

2-18 Rev. 1/18

TM

Page 33

Machine Operation

Model 3110M0255-01

FRONT MOUNTED DRIVE WHEEL OPTION

R.H. Side Of Planter Shown

An optional Front Mounted Drive Wheel Conversion Package is available if front-mounted drive wheels are desired.

PLANTING SPEED

Planters are designed to operate within a speed range of 2 to 8 mph (3.2 - 12.8 kph). See “Rate Charts”. Variations in

ground speed produce variations in rates. Finger pickup seed meter populations tend to be disproportionately higher at

high ground speeds.

NOTE: Seed spacing can be adversely affected at speeds above 5.5 mph (8.8 kph).

FIELD TEST

Perform a field test with any change of field and/or planting conditions, seed size or planter adjustment to ensure

proper seed placement and operation of row units. See “Rate Charts”, “Checking Seed Population” and “Checking

Granular Chemical Application Rate”.

Check planter for front to rear and lateral level operation. See “Level Planter”.

Check all row units to be certain they are running level. Row unit parallel arms should be approximately parallel to

the ground when planting.

Check row markers for proper operation and adjustment. See “Row Marker Adjustment” and “Row Marker Speed

Adjustment”.

Check for proper application rates and placement of granular chemicals on all rows. See “Checking Granular

Chemical Application Field Check”.

Check for desired depth placement and seed population on all rows. See “Check Seed Population”.

Check for proper application rates of fertilizer on all rows. See proper “Fertilizer Application Rate Chart”.

Reinspect machine after field testing.

Hoses And Fittings

Bolts And Nuts

Cotter Pins And Spring Pins

Drive Chain Alignment

Rev. 1/18 2-19

TM

Page 34

Machine Operation

CHECK SEED POPULATION

1. Tie up one or more sets of closing wheels by running a

chain or rubber tarp strap between the hopper support

panel and closing wheels. It may be necessary to decrease

closing wheel arm spring tension.

Planting depth

adjustment handle

2. Plant a short distance and check to see if seed is visible in

the seed trench. Adjust planting depth to a shallower setting

if seed is not visible and recheck.

M0255-01Model 3110

Chain, rubber tarp

strap, or similar.

Deeper Shallower

Planting depth adjustment

3. Measure of an acre. See chart for correct distance for row width being planted. For example, if planting 30"

rows of an acre would be 17' 5".

Acre (Hectare) Seed Population Count Row Width/Distance

Row Width 30" 36" 38" 40"

Distance 17'5" (5.3 m) 14'6" (4.4 m) 13'10" (4.2 m) 13' 1" (3.9 m)

NOTE: Seeds may bounce or roll when planting with closing wheels raised and planting depth set shallow

affecting seed spacing accuracy.

4. Count seeds in measured distance.

5. Multiply number of seeds placed in of an acre by 1000. This gives total population.

Seed count can be affected by drive wheel and seed meter drive ratio, tire pressure, and/or seed meter malfunction.

1. If seed check shows average distance between seeds in inches is significantly different than seed rate chart

indicates, first check drive ratio between drive wheel and seed meter. Check drive wheel air pressure, check for

incorrect sprocket(s) in driveline and check drive and driven sprockets on transmission(s) for proper selection.

EXAMPLE: 30" row spacing 17' 5" equals acre.

26 seeds counted x 1000 = 26,000 seeds per acre

2.

Check for seed meter malfunction. For example, if spacing between kernels of corn at the transmission setting being

used is 8" (20 cm) and a gap of 16" (40.6 cm) is observed, a finger has lost its seed and not functioned properly. If

two seeds are found within a short distance of each other, the finger has metered two seeds instead of one.

3. See “Finger Pickup Seed Meter” and/or “Brush-Type Seed Meter” in the Troubleshooting Section of this manual.

2-20 Rev. 1/18

TM

Page 35

Machine Operation

Model 3110M0255-01

DETERMINING POUNDS PER ACRE (BRUSH-TYPE METER)

Seeds per acre ÷ Seeds per pound (from label) = Pounds per acre

If seeds per pound information is not available use the following averages:

2,600 seeds per pound for medium size soybeans

15,000 seeds per pound for medium size milo/grain sorghum

4,500 seeds per pound for medium size cotton

DETERMINING BUSHELS PER ACRE

Pounds per acre ÷ Seed unit weight = Bushels per acre

Average Unit Weight of:

1 Bushel Soybeans = 60 Pounds

1 Bushel Milo/Grain Sorghum = 56 Pounds

1 Bushel Cotton = 32 Pounds

If seed population check shows planting rate is significantly different than seed rate chart shows or if a particular

meter is not planting accurately, see “Brush-Type Seed Meter Maintenance” and “Brush-Type Seed Meter

Troubleshooting”.

Rev. 1/18 2-21

TM

Page 36

Machine Operation

M0255-01Model 3110

FIELD CHECK GRANULAR CHEMICAL APPLICATION

Temperature, humidity, speed, ground conditions, flowability of different material, or meter obstructions can affect

granular chemical rate of delivery.

Agricultural chemicals can cause death

WARNING

Perform a field check to determine application rates.

or serious injury to persons, animals,

and plants or seriously damage soil,

equipment, or property. Read and

follow all chemical and equipment

manufacturers labels and instructions.

Calibrated vial

Granular chemical field check

1. Fill insecticide and/or herbicide hoppers.

2. Attach a calibrated vial to each granular chemical meter.

NOTE: Disengage clutch to avoid dropping seed during test.

3. Lower planter and drive 1320 feet at planting speed.

4. Weigh chemical in ounces caught in one vial.

5. Multiply that amount by factor shown to determine pounds per acre.

Pounds (Kilograms) Per Acre (Hectare)

Row Width Factor

30" .83

36" .69

38" .65

EXAMPLE: You are planting 30" rows. You have planted for 1320 feet at desired planting speed. You caught 12.0

ounces of chemical in one vial. 12.0 ounces times 0.83 equals 9.96 pounds per acre.

NOTE: Check calibration of all rows.

METERING GATE

Use metering gate setting as a starting point for distributing insecticide or herbicide. Charts are based on 5 mph

(8 kph) planting speed. Use a higher gate setting for speeds faster than 5 mph (8 kph) and a lower setting for speeds

slower than 5 mph (8 kph).

2-22 Rev. 1/18

TM

Page 37

PLANTING DEPTH

Row Unit Operation

Model 3110M0255-01

Planting depth is maintained by adjustable row unit gauge

wheels. Depth adjustment range is approximately ½" to 3½"

(1.27 to 8.89 cm).

1. Raise planter to remove weight from wheels.

2. Push down on depth adjustment handle and reposition it

forward to decrease or rearward to increase planting depth.

Initially adjust all units to the same setting.

3. Lower planter and check operation and planting depth

of all row units. Readjust individual rows as needed for

uniform operation.

Planting depth adjustment

“V” CLOSING WHEEL ADJUSTMENT (RUBBER OR CAST IRON)

Eccentric bushing

Planting depth adjustment handle

Deeper Shallower

Lever

Set closing wheels in

this hole for directly

opposite installation.

Increase Decresase

“V” Closing wheels installed offset

“V” closing wheels should have enough down pressure to close the seed trench and ensure good soil to seed contact.

Move 5-position quick adjustable down force lever on the top of closing wheel arm to the rear to increase closing wheel

spring pressure. Move lever forward to decrease pressure. Adjust all row units to a similar setting. Light soil usually

requires less down force at average depth, approximately 2" (5 cm) while heavy soil requires increased down force.

Eccentric bushings in the wheel arm stop allow for lateral adjustment of the “V” closing wheel assembly. Use a ¾"

wrench to loosen hardware attaching closing wheel arm to wheel arm stop. Use another ¾" wrench to turn eccentric

bushings until closing wheels are aligned with seed trench. Tighten hardware.

Closing wheels can be installed “offset” (to improve residue flow) or “directly” opposite. Use forward installation holes If

set “directly” opposite.

Rev. 1/18 3-1

TM

Page 38

Row Unit Operation

CLOSING WHEEL SHIELD (RUBBER OR CAST IRON “V” CLOSING WHEELS)

Optional closing wheel shield is installed on underside

of closing wheel arm to help prevent root balls and

stalks from clogging closing wheels.

Closing wheel shield

(Shown with closing wheel removed)

M0255-01Model 3110

DRAG CLOSING ATTACHMENT

Eccentric bushing

Adjustment slots

Blade

Drag closing attachment

Drag closing attachment pulls loose soil over the seed trench.

NOTE: Use of a seed firming wheel or other seed firming device is recommended with drag closing attachment.

Front and rear adjustment is made using the slotted holes in the blades. Adjust all rows the same.

Eccentric bushings in the wheel arm stop allow for lateral adjustment of the drag closing attachment. Use a ¾" wrench

to loosen hardware attaching closing wheel arm to wheel arm stop. Use another ¾" wrench to turn eccentric bushings

until drag closing attachment is aligned with seed trench. Tighten hardware.

3-2 Rev. 1/18

TM

Page 39

Row Unit Operation

Model 3110M0255-01

COVERING DISCS/SINGLE PRESS WHEEL ADJUSTMENT

Adjusting bolt

2½"

(6 cm)

Tab

½" Locking nut

Press wheel down force adjustment

Check operation of covering discs/single press wheels after adjusting planting depth. Initial press wheel down force

spring setting is 2½" (6.3 cm) between mounting arm tab and locking nut.

1. Loosen ½" locking nut and turn adjusting bolt in to increase down force or out to decrease down force.

2. Tighten locking nut against spring plug. Adjust all row units to a similar setting.

Locate for staggered or

side-by-side operation

Blade depth

adjustment

Blade angle

adjustment

Eccentric

bushing

Wheel arm stop

Covering disc adjustments

Eccentric bushings in the wheel arm stop allow for lateral adjustment of covering discs/single press wheel assembly.

Use a ¾" wrench to loosen hardware attaching closing wheel arm to wheel arm stop. Use another ¾" wrench to turn

eccentric bushings until covering discs/single press wheel assembly is aligned with seed trench. Tighten hardware.

Two sets of holes in mounting arm locate covering discs for staggered or side-by-side operation.

Five sets of holes in each disc bracket allow ½" (1.27 cm) incremental blade depth adjustment.

Slotted holes in disc mount and bracket allow for 0° - 15° blade angle adjustment.

Adjust covering discs on all row units to similar settings.

Rev. 1/18 3-3

TM

Page 40

BRUSH-TYPE SEED METER

Crop

Soybean Black

Specialty Soybean Dark Blue

Small Milo/Grain Sorghum Red

Row Unit Operation

Upper

Disc Color-Code

(Disc Part No.)

(GA5794)

(GA6184)

(GA5982)

Brush

Retainer Cells

GD11122 60 2200 to 4000

GD11122 48 1400 to 2200

GD8237 30 14,000 to 20,000

M0255-01Model 3110

Seed Size

Range *Lubricant

Graphite

seeds/lb.

(4840 to 8800

seeds/kg)

Graphite

seeds/lb.

(3080 to 4840

seeds/kg)

seeds/lb.

(30800 to 44000

seeds/kg)

Talc

Talc

Talc

Large Milo Grain Sorghum Light Blue

(GA6187)

High-Rate Small Milo/Grain Sorghum

High-Rate Large Milo/Grain Sorghum

Cotton, Acid-Delinted White

Large Cotton, Acid Delinted Ta n

High-Rate Cotton, Acid-Delinted Light Green

Hill-Drop Cotton, Acid-Delinted Brown

Red

(GA5795)

Yellow

(GA6633)

(GA5796)

(GA6168)

(GA6478)

(GA6182)

GD8237 30 10,000 to 16,000

GD8237 60 12,000 to 18,000

GD8237 60 10,000 to 14,000

GD11122 30 4200 to 5200

GD11122 36 3800 to 4400

GD11122 48 4200 to 5200

GD11122

12

(3 to 6

seeds/

cell)

seeds/lb.

(22000 to 35200

seeds/kg)

seeds/lb.

(26400 to 39600

seeds/kg)

seeds/lb.

(22000 to 30800

seeds/kg)

seeds/lb.

(9240 to 11440

seeds/kg)

seeds/lb.

(8360 to 9680

seeds/kg)

seeds/lb.

(9240 to 11440

seeds/kg)

4000 to 5200

seeds/lb.

(8800 to 11440

seeds/kg)

Talc

Talc

Talc

Talc

Talc

Talc

Talc

Small Hill-Drop Cotton, AcidDelinted

*For More information on application rate see Additives section.

Use GD11122 upper brush retainer

when using cotton and soybean discs.

3-4 Rev. 1/18

Dark Green

(GA7255)

GD11122 12

(3 to 6

seeds/

cell)

Use GD8237 upper brush retainer when

using milo/grain sorghum discs.

TM

5000 to 6200

seeds/lb.

(11000 to 13640

seeds/kg)

Talc

Page 41

BRUSH-TYPE SEED METER 2.0

Crop

Soybean Black

Row Unit Operation

Upper

Disc Color-Code

(Disc Part No.)

(GB1123)

Brush

Retainer Cells

GB1084 60 2200 to 4000

Model 3110M0255-01

Seed Size

Range *Lubricant

Graphite

seeds/lb.

Talc

Soybean Dark Gray

(GB1171)

Specialty Soybean Dark Blue

(GB1124)

Small Milo/Grain Sorghum Orange

(GB1130)

Large Milo Grain Sorghum Light Blue

(GB1131)

High-Rate Small Milo/Grain Sorghum

High-Rate Large Milo/Grain Sorghum

Wheat Purple

*For More information on application rate see Additives section.

Use GB1084 upper brush retainer when

using wheat and soybean discs.

Red

(GB1132)

Yellow

(GB1133)

(GB1134)

GB1084 54 2000 to 3000

seeds/lb.

GB1084 48 1400 to 2200

seeds/lb.

GB1107 30 14,000 to

20,000

seeds/lb.

GB1107 30 10,000 to

16,000

seeds/lb.

GB1107 60 12,000 to

18,000

seeds/lb.

GD8237 60 10,000 to

14,000

seeds/lb.

GB1084 54 N/A

Volumetric

Use GB1107 milo insert when using milo/

grain sorghum discs.

Graphite

Talc

Graphite

Talc

Talc

Talc

Talc

Talc

Graphite

Talc

Rev. 6/19 3-5

TM

Page 42

Row Unit Operation

M0255-01Model 3110

Turn seed disc counterclockwise when installing on meter hub while

tightening two wing nuts that retain disc. Seed disc should have slight

resistance when rotated counterclockwise after wing nuts are tight.

Brush-type seed meter attaches to seed hopper same as finger

pickup seed meter. Secure to bottom of seed hopper with two "

thumbscrews. Tighten thumbscrews slightly with pliers. DO NOT

OVER TIGHTEN.

Misalignment between drive coupler and seed meter input shaft may