Kinze KPM III User Manual

KPM III ELECTRONIC SEED MONITOR

OPERATOR

MANUAL

M0248 6/13

This manual is applicable to: KPM III Electronic Seed Monitor

Phase 3 Software

Record the serial numbers of your planter control system and the purchase date:

Planter Monitor Serial Number ___________________________________

Date Purchased _______________________________________________

Measured Pulses Per Mile/km

(Radar Distance Sensor) ________________________________________

Measured Pulses Per Mile/km

(Magnetic Distance Sensor) _____________________________________

Kinze® and the Kinze® logo are trademarks owned by Kinze Manufacturing, Inc.

Monitor Operation

KPM III ELECTRONIC SEED MONITOR VER. 3.1

KPM IIIM0248

INTRODUCTION

ESC

KINZE

ACK

NOTE: Refer to IS715 for installation instructions for your KPM III.

The KPM III electronic seed monitor system consists of:

•

A tractor mounted KPM III console powered by tractor 12 VDC battery receives and displays information from planter mounted sensors.

• Seed tube and sensor installed in each planter row unit.

• A magnetic distance sensor installed on planter or a radar distance sensor installed on tractor.

• Shaft rotation sensors (if applicable) installed on planter drill shafts.

• Vacuum, pneumatic down pressure, ASD, and hydraulic level/temperature (If applicable), installed on planter.

• Planter harnesses (junction Y-harness and extension harness where applicable), to which the individual seed tube sensors connect.

The primary harness, which connects the monitor console to the planter harness, is hard-wired into the safety/warning light harness or

control console harness included as standard equipment with the planter.

The KPM III console uses a backlit Liquid Crystal Display (LCD) to show number of monitored rows, relative seed rate for each row (using

bargraph displays), and alarm and warning messages. A continuous audible alarm sounds upon system malfunction or underow conditions

for any monitored row. Alarms must be acknowledged. Various warnings also sound an alarm or ash one or more messages. The LCD

displays row spacing, units (Metric or English), speed (MPH or KM/H), volume, seed population, seed spacing, eld area, and total area.

KPM III software allows simultaneous viewing of seed ow bargraphs for standard and Interplant System rows (up to 36 rows).

The monitor system powers down if there is no new seed ow or operator push key input within one hour.

CONTENTS

Acre Count Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adding Even-Row Package

(Front Rows Previously Programmed) ...........10

Adding Interplant Rows

(Rear Rows Previously Programmed Only) ........9

Area Counters ................................25

Area Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Changing Volume, Contrast, and Backlighting

with AV Key .................................3

Clearing Field Area ............................26

Conguring Planter Monitor. . . . . . . . . . . . . . . . . . . . . . . 3

General Settings (Programming Interplant condition,

row spacing and units) .......................5

Monitor Key Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Programming/Connecting Seed Tubes, Shaft Rotation

Sensors, or Radar/Magnetic Distance Sensors ....13

Programming Row Unit Alarm Levels ...............7

Replacing Faulty Sensor(s) . . . . . . . . . . . . . . . . . . . . . . 26

Reprogramming Speed Sensor. . . . . . . . . . . . . . . . . . . 11

Seed Meter Settings ............................6

Speed Sensor Calibration/Programming ............14

Test Mode ...................................17

Warnings and Alarms ..........................21

Data Logging Mode .............................8

Enabling/Disabling Interplant Rows ................17

Field Operation ...............................23

6/13 1

TM

Monitor Operation

M0248 KPM III

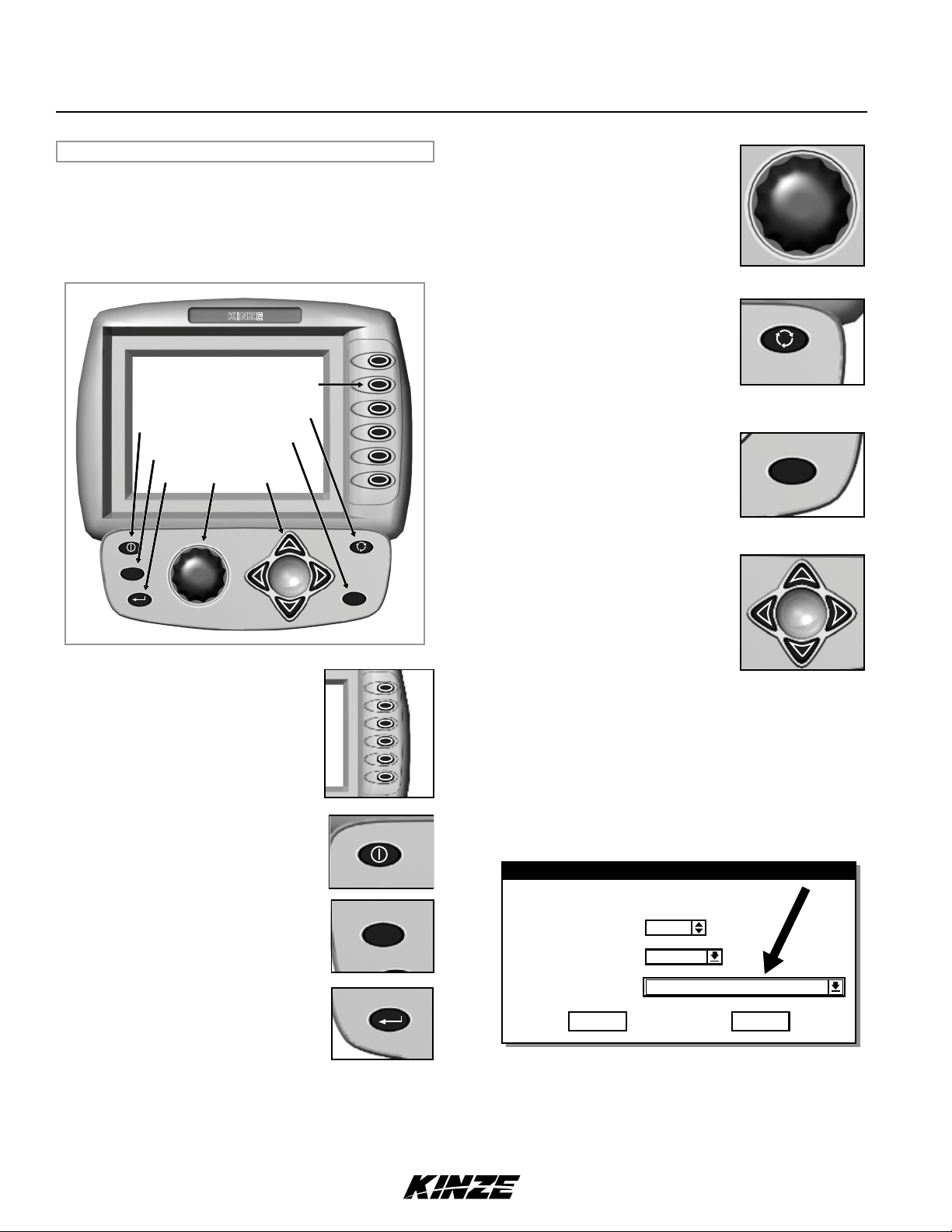

MONITOR KEY FUNCTIONS

Push keys select or change operating mode, active displays,

or the current conguration. Depending on operating mode

or current display selected, some keys may not be active.

Each valid key press is acknowledged by a short beep and an

action is taken. If a key press has no action associated, it is

considered invalid, and there is no feedback.

KINZE

Physical Keys (F1-F6)

Audio/Video Key

On/Off

Escape

Enter

ESC

Rotary

Encoder

Knob

Acknowledge

Arrow Keys

ACK

ROTARY ENCODER KNOB

• Turn knob clockwise to increase or

counterclockwise to decrease value of

item.

• Turn knob clockwise to scroll up or

counterclockwise to scroll down.

• Press knob to enter selection.

AV (AUDIO/VIDEO) KEY

• Set alarm volume.

• Adjust the contrast.

• Adjust backlighting of the LCD display.

Can be used at any time.

ACK (ACKNOWLEDGE) KEY

• Used to silence (acknowledge) the

warning alarm when various error

conditions occur.

NOTE: Alarms can be viewed by

pressing the STATUS key.

ARROW KEYS

• UP arrow key is used to move up.

• DOWN arrow key is used to move

down.

• LEFT arrow key is used to move to the

left.

• RIGHT arrow key is used to move to

the right.

ACK

PHYSICAL KEYS

• Located on R.H. side of console and

referred to as F1, F2, F3, F4, F5 and

F6

• Keys are referenced in descending

order with F1 at the top and F6 at the

bottom.

ON/OFF KEY

• Powers the unit on and off.

ESC KEY

• Used as the CANCEL (escape) key.

ENTER KEY

• Conrms or accepts the highlighted

selection.

ESC

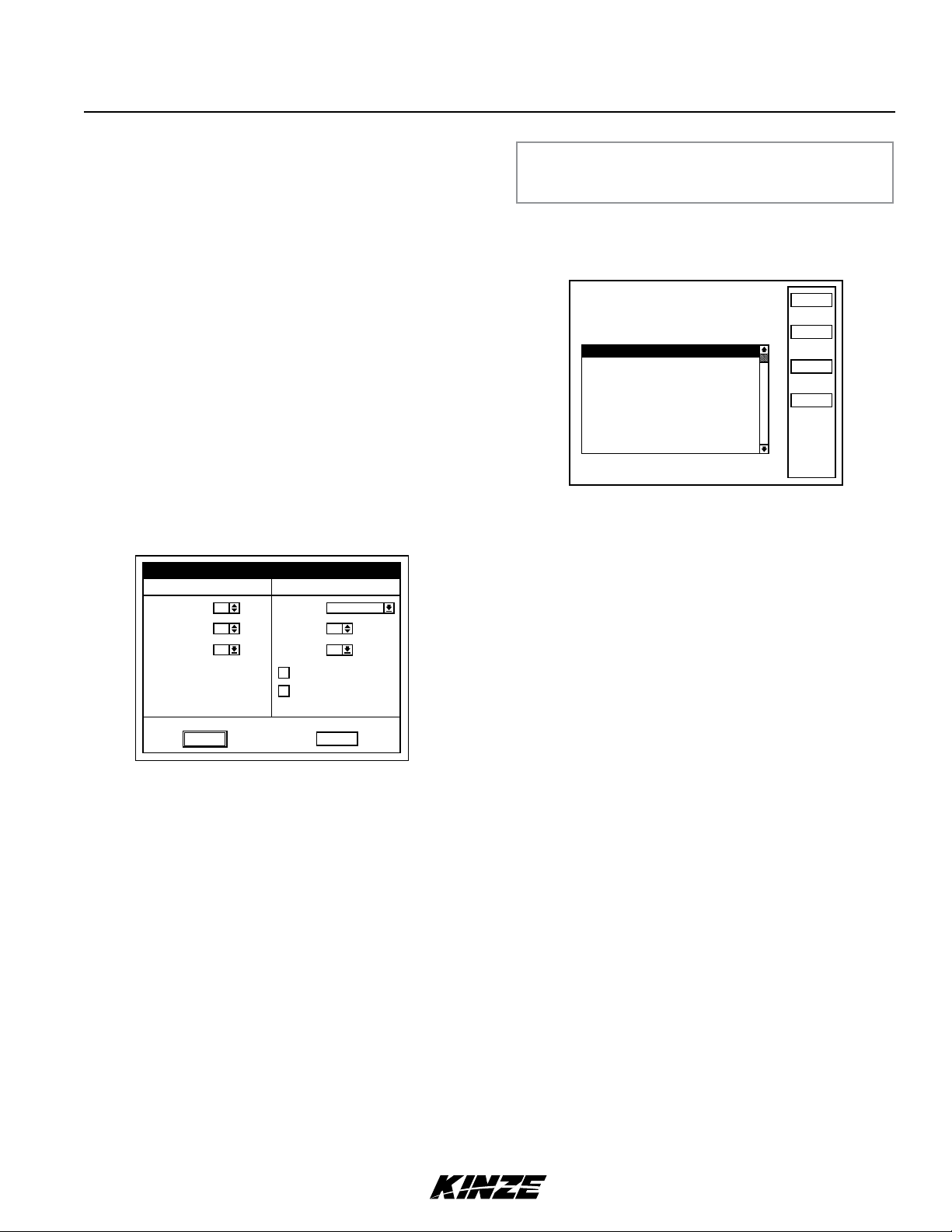

NOTE: Within the LCD, the black box around the smaller

box as shown below indicates which field is selected/

highlighted. Turning the rotary encoder knob or pressing

the UP or DOWN arrow keys moves the black box. When

the black box is positioned on a programmable item, such

as Shaft Sensors, Speed Sensor, Front Row Units or Rear

Row Units, pressing the knob or ENTER key will highlight

the programmable item. A programmable item may only be

changed when it is highlighted.

General Settings

For row spacing enter the smallest spacing between row units

Row Spacing

Units of Measure

Area Counters

15 in

English

Confirm each enable/disable

CancelOK

2 6/13

TM

Status

RowPop

Area

Other

Spacing

90

80

70

60

90

80

70

60

Status

RowPop

Area

Other

Spacing

MPHAvg

Status

RowPop

Area

Spacing

Monitor Operation

KPM IIIM0248

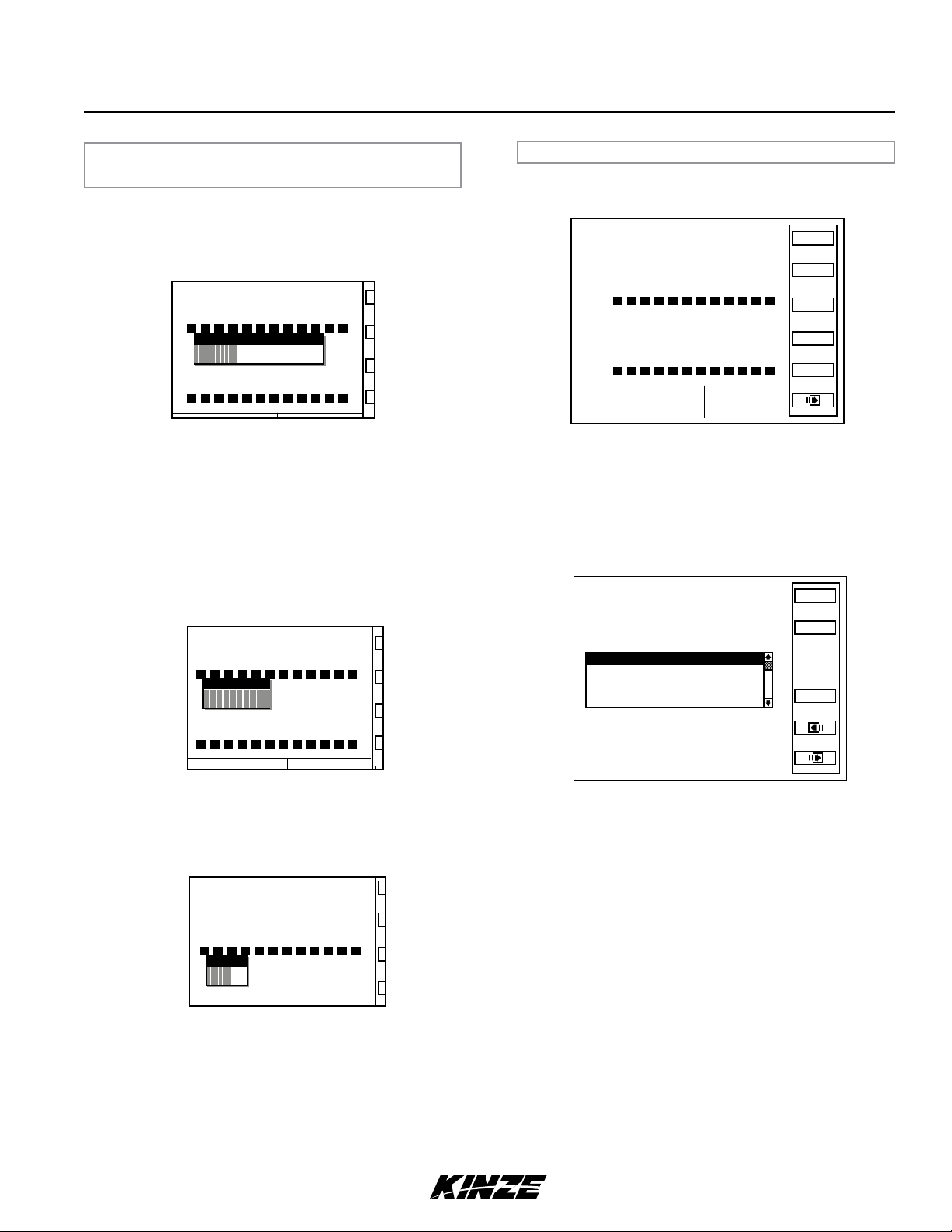

CHANGING VOLUME, CONTRAST, AND BACKLIGHTING

WITH AV KEY

Alarm, volume, LCD screen contrast, and backlighting may be

adjusted at any time, regardless of what is displayed on screen.

STEP 1 Press AV key. Contrast adjustment dialog box

appears in center of display.

%

1 2 3 4 5 6 7 8 9 10 11 12

%

1 2 3 4 5 6 7 8 9 10 11 12

Contrast

STEP 2 Use arrow keys or turn rotary encoder knob to adjust

contrast. Adjustment will be visible on the screen.

STEP 3 To adjust speaker or backlight, go to STEP 4. If

nished press Enter key to save and exit.

STEP 4 Press AV button a second time. The Backlight

adjustment dialog box will appear in center of the

display.

STEP 5 Use arrow keys or turn knob to adjust backlighting.

The effect of the adjustment will be visible on display.

CONFIGURING PLANTER MONITOR

When the KPM III is powered on for the rst time it will go directly

into the Planter Conguration screen (STEP 4).

120

110

100

90

80

70

60

%

1 2 3 4 5 6 7 8 9 10 11 12

120

110

100

90

80

70

60

%

1 2 3 4 5 6 7 8 9 10 11 12

Pop

0 0.0

MPHAvg

RowPop

Spacing

Accuracy

Area

Other

NOTE: Planter Configuration screen displays planter rows

as programmed into KPM III software. The above screen

shows 12 front (Interplant) rows and 12 rear rows. If the KPM

III were programmed for 8 front (Interplant) rows and 8 rear

rows the screen would display 8 front and 8 rear rows.

STEP 1 Press the F6 key until Mode Selection screen

appears.

Kinze Planter Monitor III

Lifetime Area:

0.00

Status

Plant

1. Setup Mode

2. Acre Count Mode

1 2 3 4 5 6 7 8 9 10 11 12

Backlight

1 2 3 4 5 6 7 8 9 10 11 12

3. Disable Interplant (Enabled now)

4. Data logging disabled

5. Test Mode

Please select the operating mode for the

planter monitor or the action to perform.

Effective row spacing: 15.0

About

STEP 6 To adjust speaker go to STEP 7. If nished press

Enter key to save and exit.

NOTE: There are 5 choices on the Mode Selection screen;

1. Setup mode

STEP 7 Press AV button a third time. Speaker adjustment

dialog box will appear in center of display.

2. Acre count mode

3. Disable Interplant (Enabled now) mode

4. Data logging mode

5. Test mode

STEP 2 Select ‘‘1. Setup Mode’’ by turning the rotary encoder

knob or using the arrow keys. Press the knob or

1 2 3 4 5 6 7 8 9 10 11 12

Speaker

Enter key to display the highlighted item.

NOTE: There are 10 choices on the Setup Mode screen;

1. General Settings

2. Seed Meter Settings

STEP 8 Use arrow keys or turn knob to adjust speaker

volume. Volume of sound emitted from speaker

changes as adjustment is made.

STEP 9 Press knob, Enter key or press AV button a fourth

time to save volume, contrast, and backlight settings.

3. Row Unit Alarm Levels

4. Setup Data Logging

5. Configure Planter Monitor

6. Add New Muxbus Sensors

7. Add Single Interplant

®

Row

8. Select Speed Sensor

9. Sensor Setup

10. Calibrate Speed Sensor

6/13 3

TM

Monitor Operation

M0248 KPM III

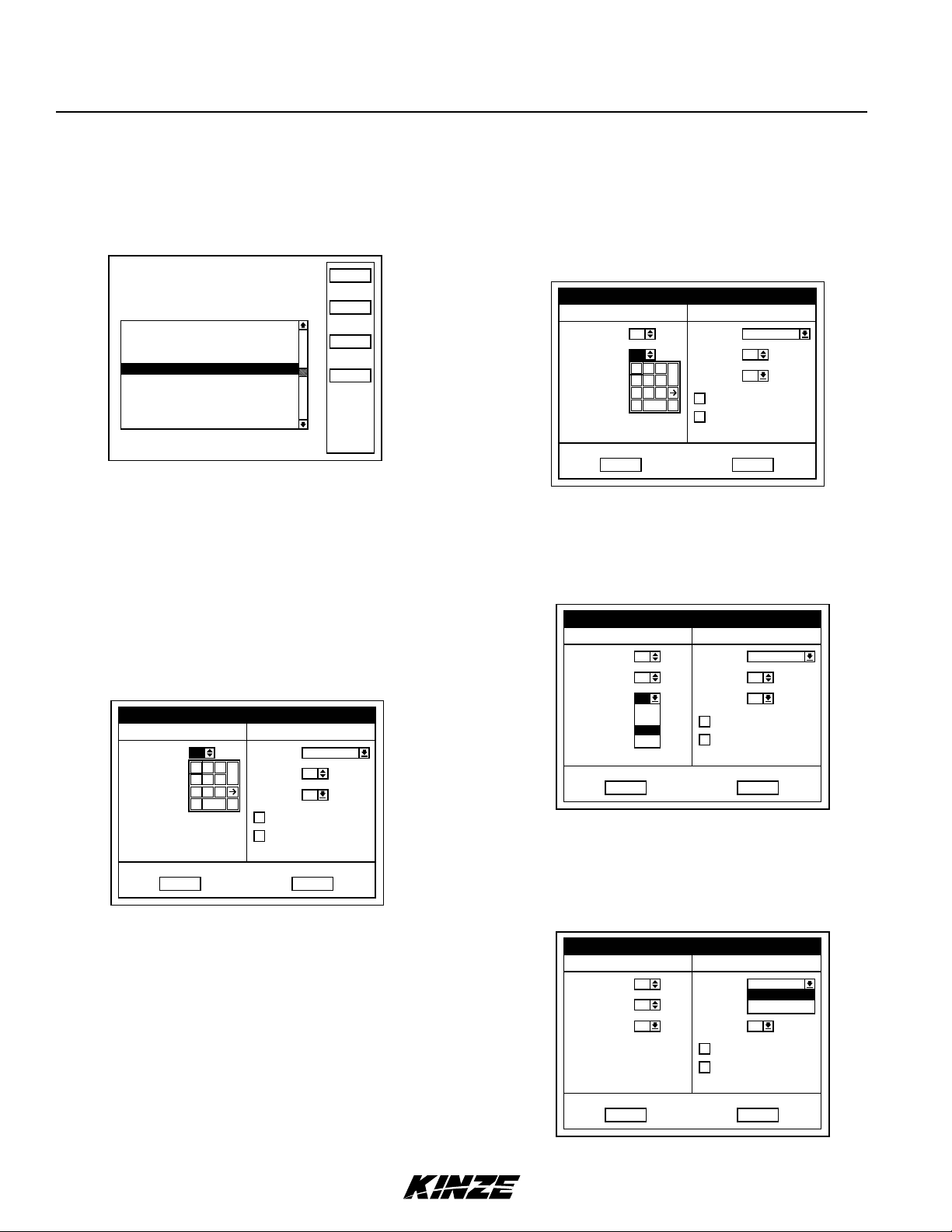

STEP 3 Select ‘‘5. Congure Planter Monitor’’ by turning the

knob or using the arrow keys. Press the knob or the

Enter key to display the highlighted item.

NOTE: Press F2 key next to Plant any time Plant option is

available to return to Planter Configuration screen.

Setup Mode

Configuration:

1. General Settings

2. Seed Meter Settings

3. Row Unit Alarm Levels

4. Setup Data Logging

5. Configure Planter Monitor

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

9. Sensor Setup

10.Calibrate Speed Sensor

Effective row spacing: 15.0

Front / Rear

Status

Plant

Logdata

About

NOTE: Planter monitor cannot be reconfigured while planting.

STEP 4

If there are front rows (Interplant) on planter, press

knob or Enter key to highlight “Front Rows” eld. A

drop down number pad appears. Turn knob or use

arrow keys to highlight correct value then press tknob

to select number. For numbers containing more than

one digit select one digit at a time. When desired

quantity is displayed above number pad press Enter

key to return to “Kinze Planter Conguration” screen.

If planter has no front rows turn knob or press arrow

keys to advance to “Rear Rows”.

Kinze Planter Configuration

Planter Type Sensors Installed

Front Rows 0

Rear Rows 12

Shafts 2

There should be one sensor

for each Row and each Shaft.

OK

1 2 3

4 5 6

7 8 9

. 0

0

Speed Radar

C

Vacuum 0

SDS

-

SDS = Seed Delivery System

0

Hydraulic Level/Temp

Downpressure Level

Cancel

STEP 5 Press knob or Enter key to select “Rear Rows” eld.

A drop down number pad appears. Turn knob or use

arrow keys to highlight correct value then press knob

to select number. For numbers containing more than

one digit select one digit at a time. When desired

quantity is displayed above number pad, press

Enter key to return to “Kinze Planter Conguration”

screen.

Kinze Planter Configuration

Planter Type Sensors Installed

Front Rows

Rear Rows

Shafts 2

There should be one sensor

for each Row and each Shaft.

OK

11

0

1 2 3

4 5 6

0

7 8 9

. 0

Speed Radar

Vacuum 0

C

SDS

-

SDS = Seed Delivery System

0

Hydraulic Level/Temp

Downpressure Level

Cancel

STEP 6 Rotate knob or use arrow keys to advance to “Shafts”

eld. Press knob or Enter key to select “Shaft” eld.

A drop down menu appears. Turn knob or use arrow

keys to highlight number of “Shafts”. When correct

value is displayed, press knob or Enter key to return

to “Kinze Planter Conguration” screen.

Kinze Planter Configuration

Planter Type Sensors Installed

Front Rows 11

Rear Rows 12

Shafts 2

There should be one sensor

for each Row and each Shaft.

OK

0

1

2

4

Speed Radar

Vacuum 0

SDS

Hydraulic Level/Temp

Downpressure Level

SDS = Seed Delivery System

0

Cancel

STEP 7 Turn knob or use arrow keys to move to “Speed”

eld. Press knob or Enter key and a drop down

menu displays. Select ‘‘Radar’’ or ‘‘Coil Pick-Up’’

(MDS) by turning knob or using arrow keys. When

desired selection is highlighted press knob or Enter

key.

Kinze Planter Configuration

Planter Type Sensors Installed

Front Rows 11

Rear Rows 12

Shafts 2

There should be one sensor

for each Row and each Shaft.

4 6/13

TM

2

OK

Speed

Vacuum 0

SDS

SDS = Seed Delivery System

Radar

Radar

Coil Pick-Up

0

Hydraulic Level/Temp

Downpressure Level

Cancel

Monitor Operation

KPM IIIM0248

STEP 8 If applicable, turn knob or use arrow keys to advance

to “Vacuum”. Press knob or Enter key and a drop

down menu will appear. Select correct number of

vacuum sensors by turning knob or using arrow

keys. Conrm selection by pressing knob or Enter

key.

STEP 9 If applicable, turn knob or use arrow keys to

advance to “SDS” (Seed Delivery System), Press

knob or Enter key. A drop down menu will appear.

Select correct number of SDS Sensors by turning

knob or using arrow keys. Press knob or Enter key

to conrm selection.

STEP 10 If applicable, turn knob or use arrow keys to advance

to “Hydraulic Level/Temp”. Press knob or Enter key

to select or deselect. When selected, a check mark

will appear in the box.

STEP 11 If applicable, turn knob or use arrow keys to advance

to “Downpressure Level”. Press knob or Enter key to

select or deselect. When selected, a check mark will

appear in the box.

STEP 12 Advance to “OK” by using knob or arrow keys. Press

knob or the Enter key to save information.

Kinze Planter Configuration

Planter Type Sensors Installed

Front Rows 11

Rear Rows 12

Shafts 2

There should be one sensor

for each Row and each Shaft.

OK

Speed Radar

Vacuum 0

SDS

SDS = Seed Delivery System

0

Hydraulic Level/Temp

Downpressure Level

Cancel

(PROGRAMMING INTERPLANT CONDITION, ROW SPACING

GENERAL SETTINGS

AND UNITS) (METRIC OR ENGLISH)

STEP 1 Turn knob or use arrow keys to highlight “1. General

Settings”. Press knob or Enter key to display highlighted

item.

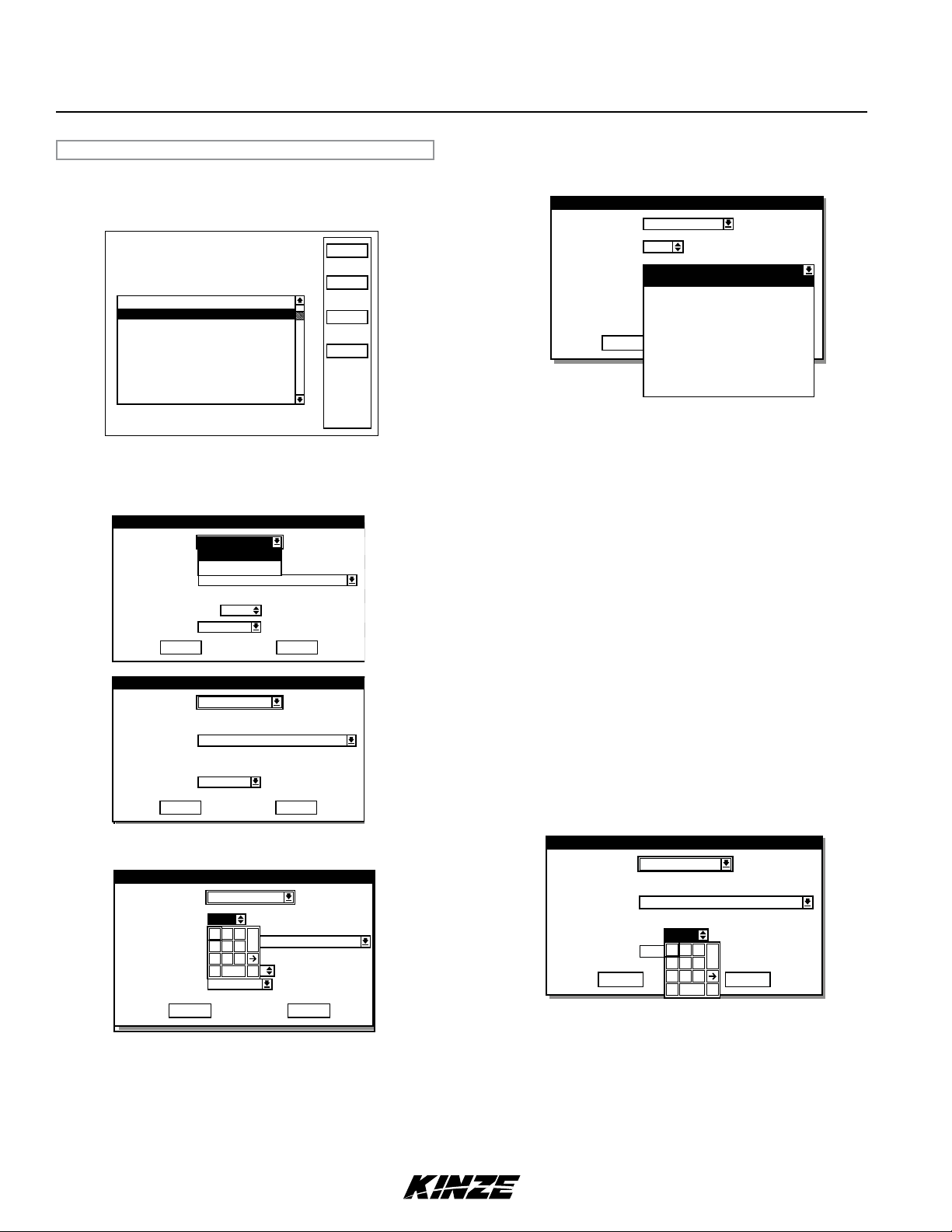

Setup Mode

Configuration:

1. General Settings

2. Seed Meter Settings

3. Row Unit Alarm Levels

4. Setup Data Logging

5. Configure Planter Monitor

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

9. Sensor Setup

10.Calibrate Speed Sensor

Effective row spacing: 15.0

Front / Rear

Status

Plant

Logdata

About

NOTE: When English is selected inches are displayed, if Metric

is selected centimeters are displayed.

STEP 2 Press knob or Enter key to enter correct value for “Row

Spacing”. A drop down number pad will appear. Turn

knob or use arrow keys to highlight rst digit of desired

number and press knob. The number will appear

in “Row Spacing” line. Turn knob or arrow keys to

highlight next digit of number and press knob. Number

will appear in “Row Spacing” line. When correct

number is displayed in “Row Spacing” line, press Enter

key to return to “General Settings” screen.

NOTE: Enter narrowest row spacing planter is equipped to plant

for “Row Spacing”. Example: 12 Row 30 with Interplant, row

spacing would be set to 15.

NOTE: To prevent configuration from being saved select

“Cancel” and press rotary encoder knob or Enter key.

Display will return to “Setup Mode” screen without saving

any changes.

NOTE: When OK is selected monitor automatically advances

to Sensor Setup screen. Sensor Setup can also be selected

from Setup Mode screen. Go to page 6-13 (PROGRAMMING/

CONNECTING SEED TUBES, SHAFT ROTATION SENSORS

AND/OR RADAR/MAGNETIC DISTANCE SENSORS)

STEP 3 Turn knob or use arrow keys to highlight “Units of

Measure” eld. Select “Units of Measure” eld by

pressing knob or Enter key, a drop down menu will

appear. Highlight “English” or “Metric” by turning knob

or using arrow keys. When correct entry is highlighted,

press knob or Enter key to accept unit of measure

entry and return to “General Settings” screen.

STEP 4 Turn knob or use arrow keys to highlight “Area Counters”

eld. Select “Area Counters” eld by pressing knob or

Enter key, a drop down menu will appear. Turn knob

or use arrow keys to highlight “Conrm each enable/

disable”, “Don’t conrm again today”, or “Don’t conrm

enable/disable”. When desired selection is highlighted,

press knob or Enter key to accept selection and return

to “General Settings” screen.

STEP 5 Once correct values are inputed into “General Settings”

screen “OK” button can be selected to save changes,

or “Cancel” button can be selected to discard changes.

Turn knob or use arrow keys to highlight either “OK”

or “Cancel” and press knob or Enter key to return to

“Setup Mode” screen.

6/13 5

TM

Logdata

Seed Meter Settings

Monitor Operation

M0248 KPM III

SEED METER SETTINGS

STEP 1 Scroll to ‘‘2. Seed Meter Settings” by turning rotary

encoder knob or using arrow keys. Press knob or

Enter key to display highlighted item.

Status

Plant

Logdata

About

STEP 2

Setup Mode

Configuration:

1. General Settings

2. Seed Meter Settings

3. Row Unit Alarm Levels

4. Setup Data Logging

5. Configure Planter Monitor

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

9. Sensor Setup

10.Calibrate Speed Sensor

Effective row spacing: 15.0

Front / Rear

Select meter type by highlighting “Meter Type” and

pressing knob or Enter key, then highlight “Mechanical”

or “Vacuum” and press knob or enter key.

Seed Meter Settings

Setup Mode

Mechanical

Meter Type

Meter Sprocket

Configuration: Front / Rear

Crop Type

1. General Settings

2. Seed Meter Settings

Seeds per rev

3. Row Unit Alarm Levels

Seed Size

4. Setup Data Logging

5. Configure Planter Monitor

Interplant

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

Meter Type

Meter Sprocket

Configuration:

Crop Type

1. General Settings

2. Seed Meter Settings

Seeds per rev

3. Row Unit Alarm Levels

4. Setup Data Logging

Interplant

5. Configure Planter Monitor

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

Vacuum

Mechanical

19 teeth

Soybeans

Vacuum

Corn

12

10

Enabled

OK

Seed Meter Settings

Setup Mode

Mechanical

19 teeth

Front / Rear

Corn

12

Enabled

OK

nominal 10, min 0, max 31

Cancel

Cancel

Status

Plant

Logdata

About

Status

Plant

Logdata

About

NOTE: When Mechanical “Meter Type” is selected “Meter

Sprocket” automatically sets.

Setup Mode

OK

Vacuum

28

1 2 3

C

Corn/Popcorn

4 5 6

7 8 9

39

-

10

. 0

Enabled

Meter Type

Meter Sprocket teeth

Configuration: Front / Rear

1. General Settings

Crop Type

2. Seed Meter Settings

Seeds per rev

3. Row Unit Alarm Levels

Seed Size

4. Setup Data Logging

5. Configure Planter Monitor

Interplant

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

9. Sensor Setup

nominal 10, min 0, max 31

Cancel

Status

Plant

About

NOTE: When Vacuum “Meter Type” is selected “Meter

Sprocket” automatically defaults to 28 teeth. To change

“Meter Sprocket” select “Meter Sprocket” by turning knob

or using arrow keys. Press knob or enter key, a drop down

number pad displays. Turn knob or use arrow keys to

highlight first digit of desired number and press knob. When

correct number is obtain press knob or enter key.

STEP 3 Turn knob or use arrow keys to highlight “Crop Type”.

Press knob or Enter key to display crop drop down

menu.

Seed Meter Settings

Setup Mode

Meter Type

Meter Sprocket teeth

Configuration: Front / Rear

1. General Settings

Crop Type

Seeds per rev

Seed Size

5. Configure Planter Monitor

Interplant

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

9. Sensor Setup

Vacuum

28

Corn/Popcorn

Corn/Popcorn

Low Rate Corn/Popcorn

39

Soybeans

Enabled

High Rate Soybeans

Cotton

Hill Drop Cotton

OK

Milo/Grain Sorghum

Large Dry Edible Beans

Other Large Seed

Other Small Seed

Cancel

Cancel

Status

Plant

Logdata

About

STEP 4 Turn knob or use arrows keys to highlight a crop for

planting then press knob or Enter key. Once crop

type is entered, “Seeds per rev” is automatically set .

A sensitivity threshold (Seed Size) ensures dust and other debris are

ltered out and only actual seeds are counted. Sensitivity threshold is

set to a default for a selected crop which is adequate for most conditions.

Sensitivity can be set between 0 and 31, 0 being most sensitive

(counts smallest particles) and 31 least sensitive (counts large

particles). Adjust threshold one value at a time until desired result

is achieved. Once value is changed it becomes default for that crop.

NOTE: Adjusting threshold too high can cause monitor to

miss seeds and provide inaccurate information. Always

do a ground check to ensure monitor is reading accurately.

STEP 5

Select “Seed Size” and press ENTER key. A

drop down number pad displays.

STEP 6 Turn knob or use arrow keys to highlight rst digit

of desired number. Press knob. When correct

number is obtained, press knob or Enter key.

STEP 7 Turn knob or use arrow keys to highlight “Crop Type”.

Press knob or Enter key to display the crop drop

down menu.

Seed Meter Settings

t

ke

OK

Mechanical

19 teet h

Soybeans

60

v

10

1 2 3

Enabled

4 5 6

7 8 9

39

. 0

nominal 10, min 0, max 31

C

Cancel

-

Meter Type

Meter Sproc

Crop Type

Seeds per re

Seed Size

Interp lant

STEP 8 Turn knob or use arrows keys to highlight a crop

for planting then press knob or Enter key. Once

crop type is entered, the “Seeds per rev” is set

automatically.

6 6/13

TM

Monitor Operation

KPM IIIM0248

STEP 9 (If Applicable) Turn knob or use arrow keys to

highlight “Interplant”. Press knob or Enter key to

display Interplant drop down menu.

Seed Meter Settings

Setup Mode

OK

Vacuum

28

Corn/Popcorn

39

10

Enabled

Enabled

Disabled

Meter Type

Meter Sprocket teeth

Configuration: Front / Rear

1. General Settings

Crop Type

2. Seed Meter Settings

Seeds per rev

3. Row Unit Alarm Levels

Seed Size

4. Setup Data Logging

5. Configure Planter Monitor

Interplant

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

9. Sensor Setup

nominal 10, min 0, max 31

Cancel

Status

Plant

Logdata

About

STEP 10 Turn knob or use arrow keys to highlight “enable” or

“disable” and press the knob or Enter key.

STEP 11 When all changes have been made, highlight “OK”

and press knob or Enter key to return to “Setup

Mode” screen.

PROGRAMMING ROW UNIT ALARM LEVELS

Row Unit Alarm Levels allow thresholds for seed rate alarms to

be set. Default is 50% or Average. If average population drops

below 50% for a given row a seed rate alarm is generated for

that row unit. The alarm threshold can be set to 70%, 50%, 0% or

disabled, or any custom percentage for any row.

NOTE: When alarm threshold is disabled for any row no seed

rate alarm will be generated.

Setup Mode

Configuration:

1. General Settings

2. Seed Meter Settings

3. Row Unit Alarm Levels

4. Setup Data Logging

5. Configure Planter Monitor

6. Add New Muxbus Sensors

7. Add Single Interplant Row

8. Select Speed Sensor

9. Sensor Setup

10.Calibrate Speed Sensor

Effective row spacing: 15.0

Front / Rear

Status

Plant

Logdata

About

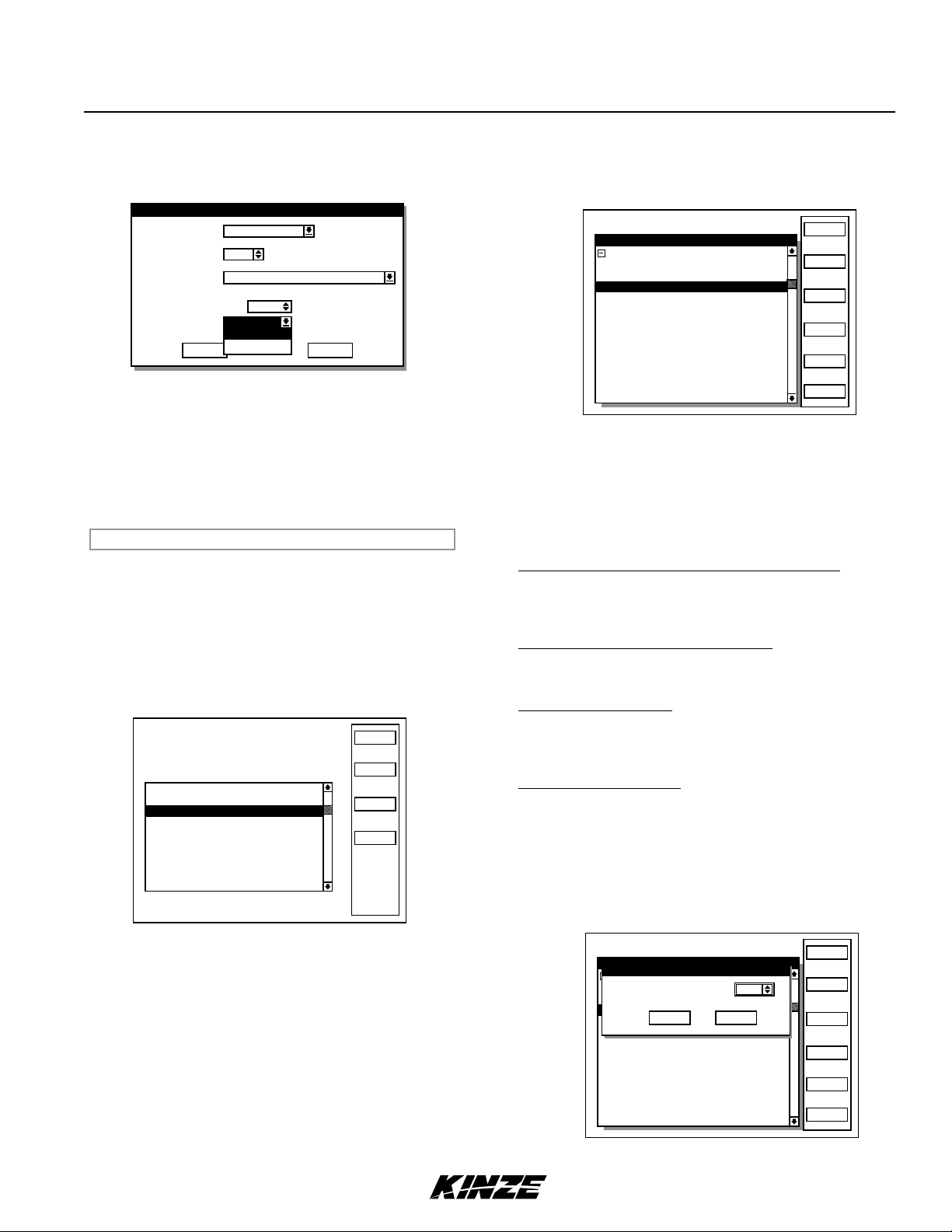

STEP 1 Select ‘‘3. Row Unit Alarm Levels’’ by turning knob or

using arrow keys. Press knob or Enter key to display

highlighted item.

Row Unit Alarm Levels

[Whole Planter]

Rear Row 1 50%

Rear Row 2 50%

Rear Row 3 50%

Rear Row 4 50%

Rear Row 5 50%

Rear Row 6 50%

Rear Row 7 50%

Rear Row 8 50%

Front Row 1 50%

Front Row 2 50%

Front Row 3 50%

Front Row 4 50%

10%

50%

70%

Disable

Other

Done

STEP 2 To set alarm thresholds for whole planter, turn knob

or use arrow keys to highlight “[Whole Planter]” line.

Press key next to desired threshold. When desired

threshold is specied for all row units, press F6 key

next to “Done”.

NOTE: Only configured rows appear on screen.

To set alarm thresholds for all rows in one section, highlight

desired section. Press key next to desired threshold. When

desired threshold is specied for all row units, press F6 key next

to “Done”.

To set alarm thresholds for individual rows, highlight desired row.

Press key next to desired threshold. When desired threshold is

specied for all row units, press F6 key next to “Done”.

To disable row unit alarm, highlight desired section or individual

row. Press F4 key next to “Disable”. When alarm is desired

again highlight disabled section or row. Press key next to desired

threshold.

To enter threshold not listed, highlight desired section or individual

row. Press F5 key next to “Other”. Press knob or Enter key and

a drop down key pad appears. Turn knob or use arrow keys to

highlight rst digit of desired number and press knob. Number

displays in “Enter Alarm Threshold” line. Highlight next digit of

the number and press knob. Number displays in the line. When

correct number is displayed, press Enter key to return to “Set

Alarm Threshold” screen. Turn knob or use arrow keys to advance

to “OK”. Press knob or Enter key to accept threshold levels.

Alarm thresholds can be set for whole planter, any planter section,

or individual rows.

NOTE: A section is a set of rows driven by one or more

shafts, designated to a single shaft sensor.

6/13 7

TM

Row Unit Alarm Levels

[Whole Planter]

Enter Alarm Threshold

Set Alarm Threshold

Rear Row 1 50%

Rear Row 2 50%

Rear Row 3 50%

OK

Rear Row 4 50%

Rear Row 5 50%

Rear Row 6 50%

Rear Row 7 50%

Rear Row 8 50%

Front Row 1 50%

Front Row 2 50%

Front Row 3 50%

Front Row 4 50%

0

Cancel

10%

50%

70%

Disable

Other

Done

Loading...

Loading...