Kinze Grain Carts User Manual

MODEL 900/1100/1300/1500

GRAIN CARTS

OPERATOR MANUAL

M0238-01 Rev. 7/14

Record model number and serial number of your grain cart along with date purchased:

Model Number __________________________________

Serial Number ___________________________________

Date Purchased __________________________________

SERIAL NUMBER

Record your serial number and purchase date above for quick reference.

The serial number provides important information about your planter and is required to obtain correct replacement

parts. Always provide planter model and serial number to your Kinze Dealer when ordering parts or anytime

correspondence is made with Kinze Manufacturing, Inc.

Serial number plate location

Kinze® and the Kinze® logo are registered trademarks of Kinze Manufacturing, Inc.

Shur-Co®, LLC is a registered trademark of Shur-Co.

Microsoft® Excel®, and Internet Explorer® are registered trademarks of Microsoft Coroporation.

Grain Tracker™ is a trademark of Digi-Star LLC

All other tradmarks are the property of their respective owners.

Page intentionally blank.

®

Predelivery/Delivery Checklist

Grain CartM0238-01

900-1100-1300-1500 Grain Cart

PREDELIVERY/DELIVERY CHECKLIST

TO THE DEALER

Predelivery service includes assembly, lubrication, adjustment and test. This service ensures cart is delivered to retail

customer/end user ready for field use.

PREDELIVERY CHECKLIST

Use this checklist to inspect cart after it is completely assembled. Check off each item as it is found satisfactory or after

proper adjustment is made.

Wheel nuts torqued to 350 ft-lb (474 N-m).

Tires inflated to specified air pressure. (If Applicable)

All grease fittings lubricated and gearbox oil level checked.

All safety decals and SMV sign are correctly located and legible. Replace if damaged.

SMV decal is in place and shipping cover removed.

Safety/warning lights working properly.

Test run augers. Do not operate tractor PTO above 750 PTO RPM with augers empty.

Check driveline. See “Driveline Inspection” in Operation section.

V-belts aligned and properly tensioned.

Check track alignment. See “Track Alignment” in Maintenance section. (If Applicable)

Safety screens over horizontal auger are in place and properly secured.

Auxiliary safety chains are properly installed and hardware torqued to specification.

Paint all parts scratched in shipment.

This wagon has been thoroughly checked and to the best of my knowledge is ready for delivery to the customer.

(Signature Of Set-Up Person/Dealer Name/Date)

OWNER REGISTER

Name Delivery Date

Street Address Model No. Serial No.

City, State/Province Dealer Name

ZIP/Postal Code Dealer No.

5/12 1

®

Predelivery/Delivery Checklist

M0238-01Grain Cart

DELIVERY CHECKLIST

Check off each item as it is fully explained to retail customer/end user when grain cart is delivered.

Durability and longevity is dependent on regular maintenance as directed in Operator Manual.

Tell retail customer/end user about all safety precautions that must be observed while using this cart.

Advise retail customer/end user of specified tractor requirement for use with this cart.

Along with retail customer/end user check reflective decals and SMV sign are clearly visible with cart attached to

tractor. Check safety/warning lights are in working condition. Tell retail customer/end user to check and follow federal,

state/provincial, and local regulations before towing on a road or highway.

Along retail customer/end user check hitch height when attached to tractor is sufficient to prevent severe bends in PTO

U-joint angles. Check PTO is correct length for making turns and operating on uneven terrain.

Give Operator and Parts Manuals to retail customer/end user and explain all operating adjustments.

Complete Warranty And Delivery Report form.

To the best of my knowledge this machine has been delivered ready for field use and customer has been fully

informed as to proper care and operation.

(Signature Of Delivery Person/Dealer Name/Date)

AFTER DELIVERY CHECKLIST

Suggested items to check during first season of use:

Check cart performance with retail customer/end user.

Review with retail customer/end user importance of proper maintenance and adherence with all safety precautions.

Check for parts that may need to be adjusted or replaced.

Retorque all wheel nuts to 350 ft-lb (474 N-m).

Safety shields and screens are in place.

Safety and reflective decals, and SMV sign are correctly located and decals are legible. Replace if damaged or missing.

Check safety/warning lights are properly installed and working properly.

Check recommended lubrication procedures are being followed.

(Signature Of Follow-Up Person/Dealer Name/Date)

All registrations must be submitted online at “business.kinze.com” within 5 business days of delivery.

Retain a copy of this form for auditing purposes.

Tear Along Perforation

Rev. 7/14

2

Table of Contents

Grain CartM0238-01

OVERVIEW

To the Owner ....................................1-1

Warranty ........................................1-2

General Information ...............................1-2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Specifications ....................................1-3

General Safety Rules ..............................1-7

Safety Precautions ................................1-7

Safety Signs And Decals ...........................1-8

Safety Instructions, Signs, and Decals. . . . . . . . . . . . . . . . .1-8

OPERATION

Machine Preparation ..............................2-1

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Tractor Preparation and Hookup. . . . . . . . . . . . . . . . . . . . . .2-1

Joystick Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Cart Operation ...................................2-4

PTO Torque Limiting/Overrunning Clutch Protection ......2-6

Belt Engagement Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Hydraulic Flow Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Auger Inspection Cover ............................2-7

Grain Tank Clean Out Sweep ........................2-8

Vertical Auger Work Light . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Cameras ........................................2-9

Manual and Electric Roll Tarp .......................2-10

Roll Tarp Remote Control Troubleshooting . . . . . . . . . . . . .2-13

Electronic Scale - GT 400. . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Electronic Scale - GT 460. . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Electronic Scale - GT 460 AutoLog ..................2-16

Electronic Scale Printing Options . . . . . . . . . . . . . . . . . . . .2-17

Electronic Scale Troubleshooting ....................2-20

Electronic Scale Troubleshooting ....................2-21

Data Downloader Troubleshooting ...................2-22

LUBRICATION AND MAINTENANCE

Drive Belts and Pulleys. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Driveline Inspection ..............................3-18

Electronic Scale .................................3-33

Gearbox .......................................3-21

Gearbox Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Grease Fittings ..................................3-3

Horizontal Auger Bearings ..........................3-1

Horizontal Auger Replacement. . . . . . . . . . . . . . . . . . . . . .3-21

Hydraulic Control Schematic - Manual . . . . . . . . . . . . . . . .3-30

Hydraulic Control Schematic - Remote ...............3-31

Joystick Electrical Schematic .......................3-32

Lower Vertical Auger Replacement ..................3-20

Mounting Bolts and Hardware .......................3-9

Preparation for Storage ...........................3-29

PTO Shaft Coupling ...............................3-2

Row Crop Inside Tire Repair or Removal .............3-24

Splines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Tire Servicing ...................................3-11

Torque Values Chart - Plated Hardware ................3-9

Track Alignment .................................3-23

Track Endwheel and Midwheel Bearings ...............3-1

Track Endwheel/Midwheel Bearing Replacement .......3-26

Track Tension ...................................3-22

Upper Vertical Auger Replacement ..................3-19

V-Belt Replacement ..............................3-16

V-Belt Tension Adjustment and Alignment . . . . . . . . . . . . . 3-12

Vertical Auger Counter Balance Valves ...............3-10

Wheel Bearing Replacement .......................3-28

Wheel Bearings ..................................3-1

Wheel Nuts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

Rev. 4/13 i

TM

This page intentionally blank.

To the Owner

Grain CartM0238-01

Kinze Manufacturing, Inc. thanks you for your patronage. We appreciate your confidence in Kinze farm machinery. Your

Kinze grain cart has been carefully designed to provide dependable operation in return for your investment.

This manual has been prepared to aid you in the operation and maintenance of the grain cart. It should be

considered a permanent part of the machine and remain with the machine when you sell it.

It is the responsibility of the user to read and understand the Operator Manual in regards to safety, operation,

lubrication and maintenance before operation of this equipment. It is the user’s responsibility to inspect and service

the machine routinely as directed in the Operator Manual. We have attempted to cover all areas of safety, operation,

lubrication and maintenance; however, there may be times when special care must be taken to fit your conditions.

Throughout this manual the symbol and the words DANGER, WARNING, and CAUTION are used to call

attention to safety information that if not followed, will or could result in death or injury. NOTICE and NOTE are used to

call your attention to important information. The definition of each of these terms follows:

DANGER Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

NOTE: Special point of information or machine adjustment instructions.

WARNING

Improperly operating or working on this equipment could result in

death or serious injury. Read and follow all instructions in Operator

Manual before operating or working on this equipment.

WARNING

Some photos in this manual may show safety covers, shields, or

lockup devices removed for visual clarity. NEVER OPERATE OR

WORK ON machine without all safety covers, shields, and lockup

devices in place as required.

NOTE: Photos in this manual may be of prototype machines. Production machines may vary in

appearance.

NOTE: Some photos and illustrations in this manual show optional attachments installed. Contact

your Kinze Dealer for purchase of optional attachments.

5/12 1-1

TM

Introduction

M0238-01Grain Cart

Warranty

The Kinze Limited Warranty for your new machine is stated on the retail purchaser’s copy of the Warranty And Delivery

Receipt form. Additional copies of the Limited Warranty can be obtained through your Kinze Dealer.

Warranty, within the warranty period, is provided as part of Kinze’s support program for registered Kinze products

which have been operated and maintained as described in this manual. Evidence of equipment abuse or modification

beyond original factory specifications will void the warranty. Normal maintenance, service and repair is not covered by

Kinze warranty.

To register your Kinze product for warranty, a Warranty And Delivery Receipt form must be completed by the Kinze

Dealer and signed by the retail purchaser, with copies to the Dealer, and to the retail purchaser. Registration must be

completed and submitted to Kinze Manufacturing, Inc. within 5 business days of delivery of the Kinze product to the

retail purchaser. Kinze Manufacturing, Inc. reserves the right to refuse warranty on serial numbered products which

have not been properly registered.

If service or replacement of failed parts which are covered by the Limited Warranty are required, it is the user’s

responsibility to deliver the machine along with the retail purchaser’s copy of the Warranty And Delivery Receipt to

the Kinze Dealer for service. Kinze warranty does not include cost of travel time, mileage, hauling or labor. Any prior

arrangement made between the Dealer and the retail purchaser in which the Dealer agrees to absorb all or part of this

expense should be considered a courtesy to the retail purchaser.

Kinze warranty does not include cost of travel time, mileage, hauling, or labor.

General Information

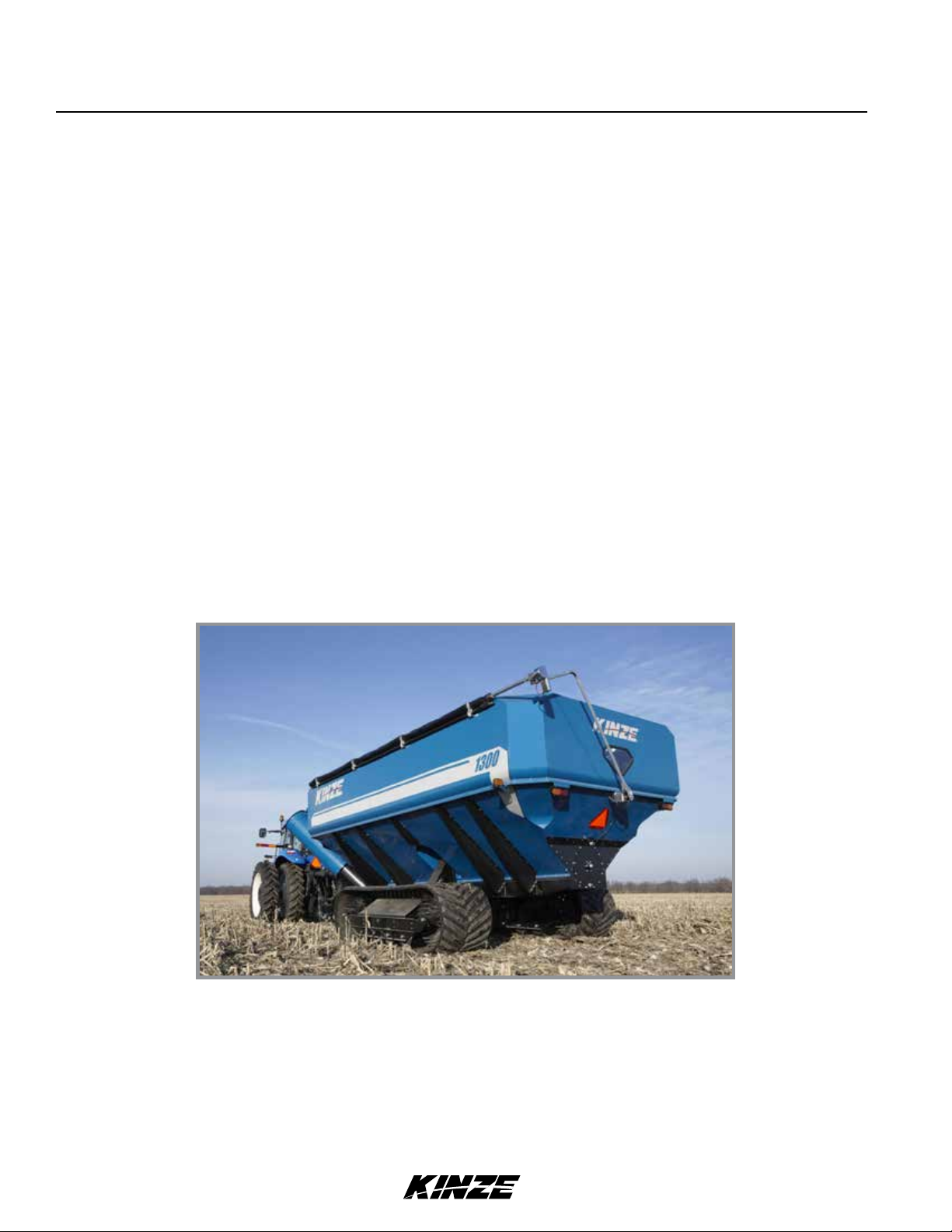

Model 1300 Tracked Corner Auger Grain Cart w/optional electric roll tarp and cameras

Information used in these instructions was current at time of printing. However, due to Kinze’s ongoing product

improvement, production changes may cause your machine to appear slightly different in detail. Kinze Manufacturing,

Inc. reserves the right to change specifications or design without notice and without incurring obligation to install the

same on machines previously manufactured.

Right hand (R.H.) and left hand (L.H.), as used throughout this manual, are determined by facing direction machine

travels in use unless otherwise stated.

1-2 5/12

TM

Specifications

Grain CartM0238-01

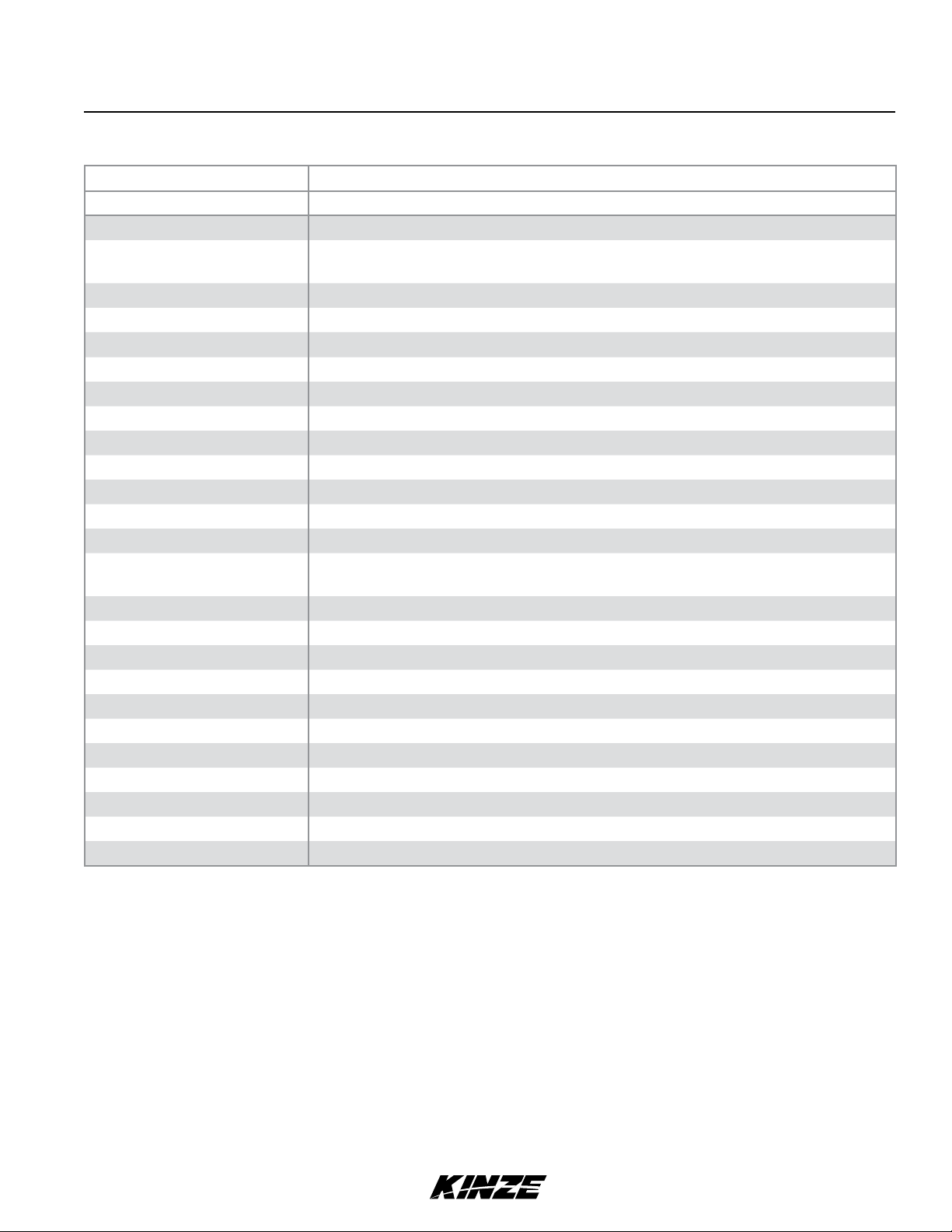

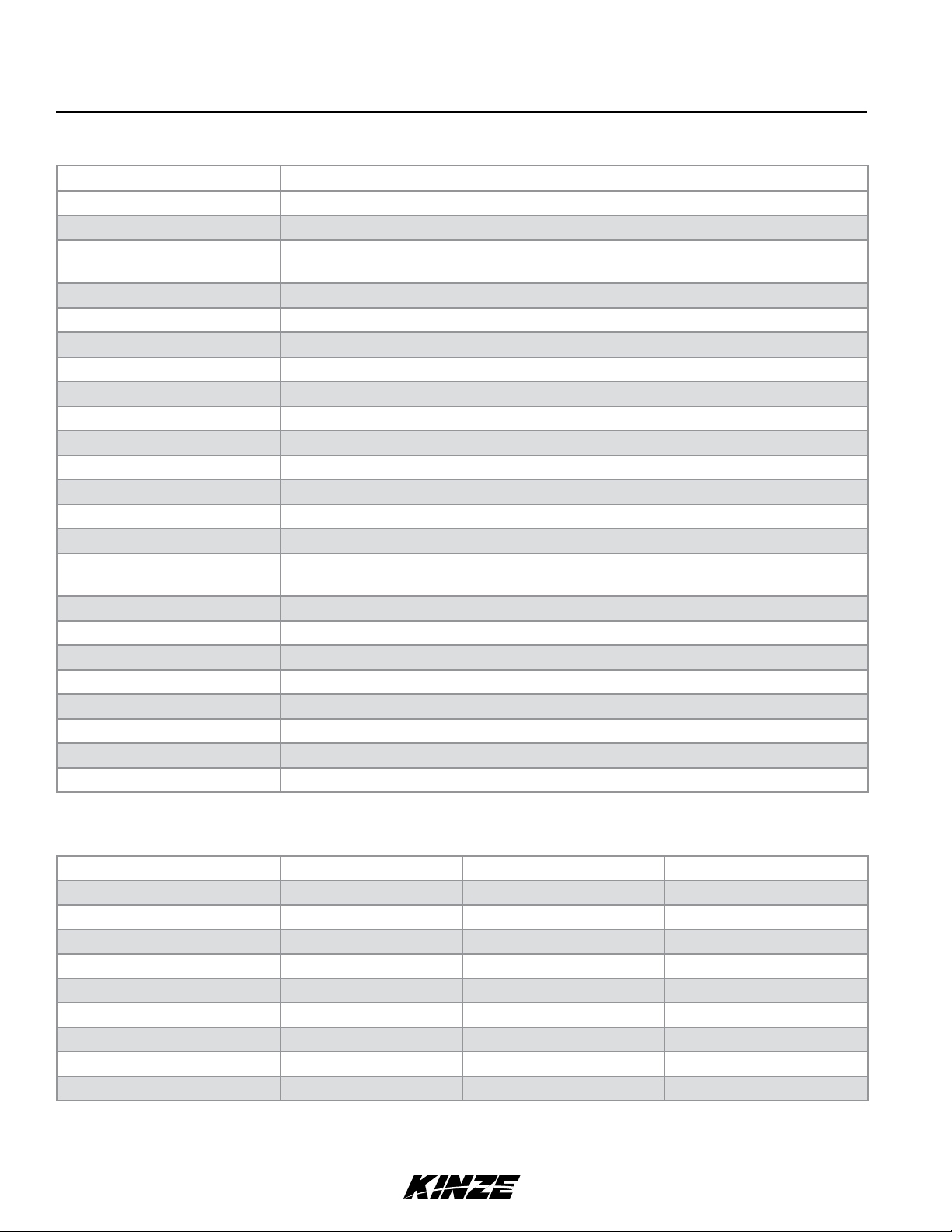

900 Grain Cart

Feature Specification

Total Capacity* 900 Bushels

Bushels/Minute - Average* 500 Bushels/minute

Vertical Auger 20" Dia flighting in 23½" Dia. tube; ¼" T edge; " T root flighting. 10° auger position

control. Lower portion of lower vertical auger hard faced flighting.

Bearings - Vertical Auger 2"

Horizontal Auger 20" LH ¼"T edge; " T Root flighting.

Bearings - Horizontal Auger 6-bolt (rear) cast iron hubs with tapered roller bearings, (front) 2" ball bearing.

Gearbox Bevel & spur gear with 2:1 ratio.

Drive Belts Two 4-band, multi-strand V-belts.

Drive Sheaves Eight groove - 7½" drive/15" driven.

PTO - 1000 RPM PTO auger drive with overrunning and torque limiting clutch.

PTO Yoke 1"-21 spline or 1¾"-20 spline.

Spindle Two 4 ½" high alloy.

Hub 20 bolt 13.189 bolt center (2) cast ductile iron.

Safety Chains Two ½" 40,500 lbs rated, grade 70, certified to ASAE S338.5.

Adjustable Discharge Spout Remotely adjustable spout with +/- 14° of up/down motion and fitted with flexible

discharge nozzle.

Tire Size/Pressure 66/43.00-25 (20 Ply) R-1 35 PSI (241 kPa) Min. 40 PSI (275 kPa) Max.

Hydraulic Requirements 5 SCVs (manual) or 2 SCV's (remote) with standard 2320 minimum system psi.

Weight - Empty 21,776 lbs.

Hitch Weight - Empty 3,400 lbs.

Hitch Weight - Loaded 5,000 lbs.

Transport Width 13'-0"

Width - Grain Tank 12'-0"

Length - Grain Tank 18'-6"

Height - Grain Tank 10'-11"

Length - Overall 27'-11

Height - Grain Discharge 13'-2"

* Approximate with 15% moisture corn. Capacity and bushels/minute will vary with moisture content of grain and/or

PTO RPM.

5/12 1-3

TM

Specifications

M0238-01Grain Cart

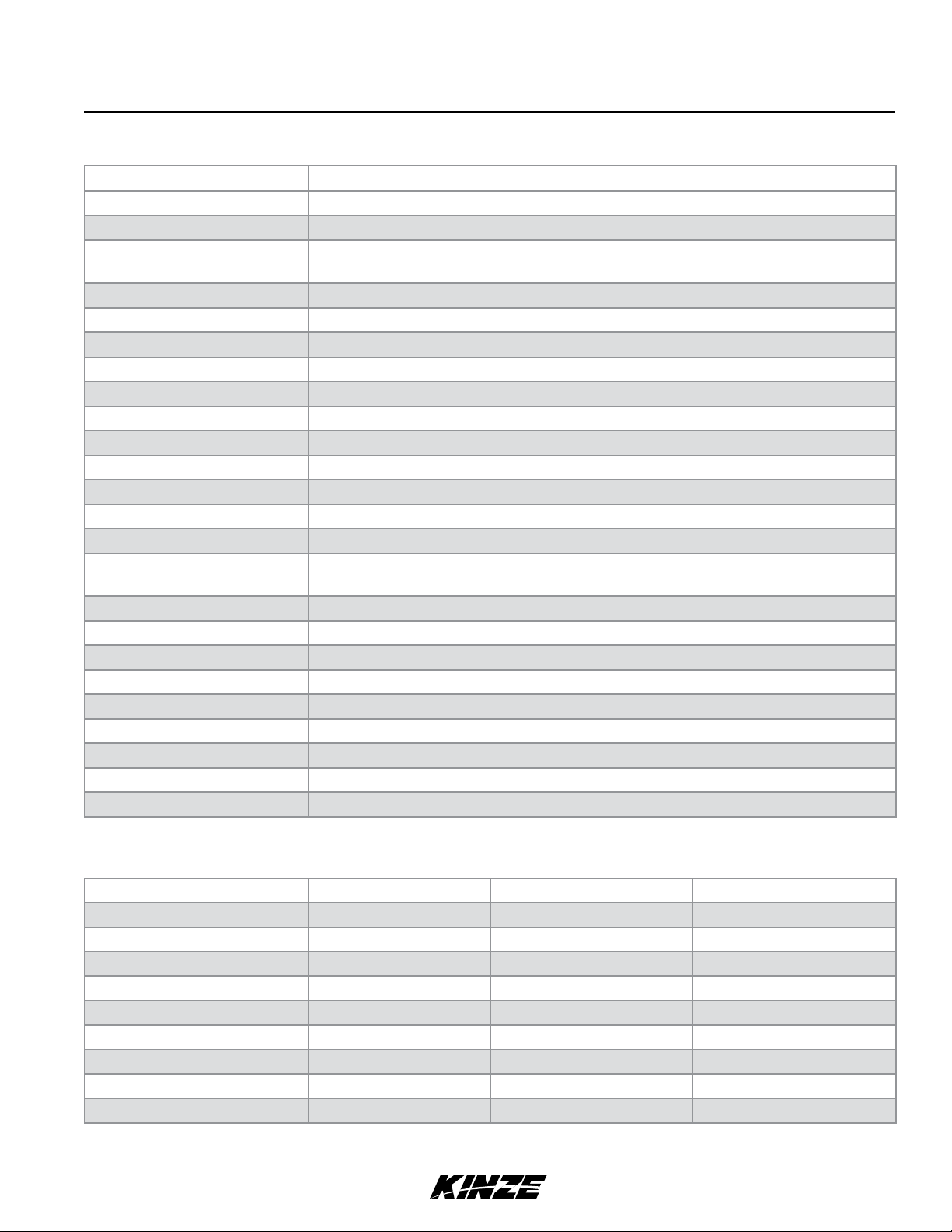

1100 Grain Cart

Feature Specification

Total Capacity* 1100 Bushels

Bushels/Minute - Average* 750 Bushels/minute

Vertical Auger 22" Dia flighting in 23½" Dia. tube; ¼"T edge; ⁄" T root flighting. 10° auger position

control. Lower portion of lower vertical auger hard faced flighting.

Bearings - Vertical Auger 2"

Horizontal Auger 20" LH ¼"T edge; "T Root flighting.

Bearings - Horizontal Auger 6-bolt (rear) cast iron hubs with tapered roller bearings, (front) 2" ball bearing.

Gearbox Bevel & spur gear with 2:1 ratio.

Drive Belts Two 4-band, multi-strand V-belts.

Drive Sheaves 8 groove - 9¼" drive/18.7" driven.

PTO - 1000 RPM PTO auger drive with overrunning and torque limiting clutch.

PTO Yoke 1¾"-20 spline.

Spindle Four 4½ or two 4½" high alloy.

Hub two 20 bolt or four 10 bolt 13.189 bolt center cast ductile iron.

Safety Chains Two ½" 40,500 lbs rated, grade 70, certified to ASAE S338.5.

Adjustable Discharge Spout Remotely adjustable spout with +/- 14° of up/down motion and fitted with flexible

discharge nozzle.

Hydraulic Requirements 5 SCVs (manual) or 2 SCV's (remote) with standard 2320 minimum system psi.

Flotation Tire Size 1100/45 R46 189 A8 51 PSI (352 kPa) Min. 56 PSI (386 kPa) Max.

Row Crop Tire Size 520/85 R42 165 A8/B 42 PSI (290 kPa) Min. 47 PSI (324 kPa) Max.

Row Crop Tire Adjustment 30" - 40" rows.

Track Width 36"

Track Length 153"

Track End Wheels (Per Track) Two cast iron segmented 36½" diameter.

Track Mid Wheels (Per Track) Eight 16" steel.

* Approximate with 15% moisture corn. Capacity and bushels/minute will vary with moisture content of grain and/or

PTO RPM.

Flotation Tire Row Crop Tracked

Weight - Empty 22,678 lbs. 23,478 lbs. 28,898 lbs.

Hitch Weight - Empty 3,750 lbs. 3,750 lbs. 3,750 lbs.

Hitch Weight - Loaded 6,100 lbs. 6,100 lbs. 6,100 lbs.

Transport Width 13'-0" 12'-7" (30") 15'5" (40") 13'-0"

Width - Grain Tank 12'-0" 12'-0" 12'-0"

Length - Grain Tank 21'-9" 21'-9" 21'-9"

Height - Grain Tank 11'-5" 11'-4" 11'-4"

Length - Overall 31'-7" 31'-7" 31'-7"

Height - Grain Discharge 14'-1" 14'-1" 14'-1"

1-4 5/12

TM

Specifications

Grain CartM0238-01

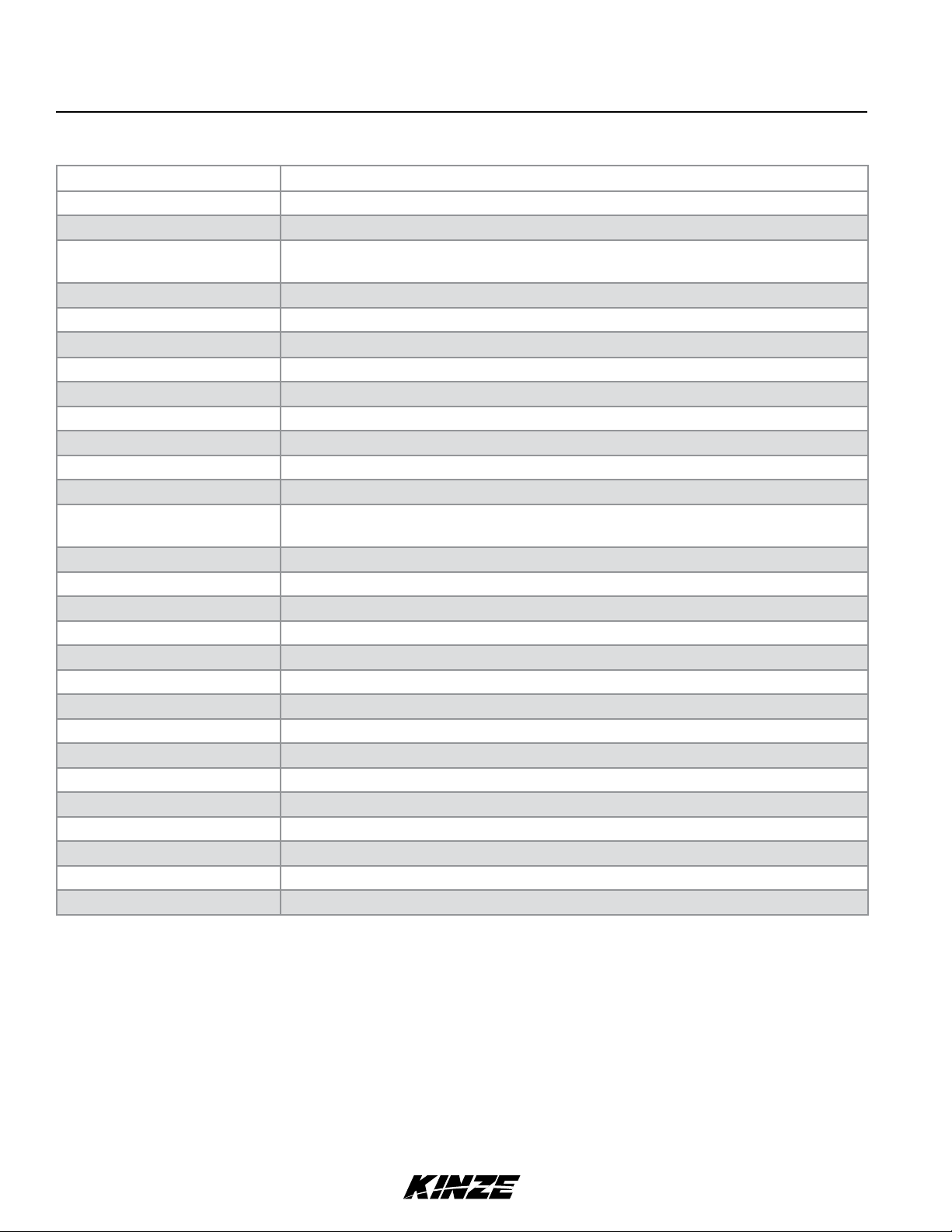

1300 Grain Cart

Feature Specification

Total Capacity* 1300 Bushels

Bushels/Minute - Average* 750 Bushels/minute

Vertical Auger 22" Dia flighting in 23½" Dia. tube; ¼"T edge; ⁄" T root flighting. 10° auger position

control. Lower portion of lower vertical auger hard faced flighting.

Bearings - Vertical Auger 2"

Horizontal Auger 20" LH ¼"T edge; "T Root flighting.

Bearings - Horizontal Auger 6-bolt (rear) cast iron hubs with tapered roller bearings, (front) 2" ball bearing.

Gearbox Bevel & spur gear with 2:1 ratio.

Drive Belts Two 4-band, multi-strand V-belts.

Drive Sheaves 8 groove - 9¼" drive/18.7" driven.

PTO - 1000 RPM PTO auger drive with overrunning and torque limiting clutch.

PTO Yoke 1¾"-20 spline.

Spindle Four 4½ or two 6" high alloy.

Hub four 10 bolt 13.189 bolt center or two 20 bolt 20" bolt center cast ductile iron.

Safety Chains Two ½" 40,500 lbs rated, grade 70, certified to ASAE S338.5.

Adjustable Discharge Spout Remotely adjustable spout with +/- 14° of up/down motion and fitted with flexible

discharge nozzle.

Hydraulic Requirements 5 SCVs (manual) or 2 SCV's (remote) with standard 2320 minimum system psi.

Flotation Tire Size 1100/45 R46 189 A8 51 PSI (352 kPa) Min. 56 PSI (386 kPa) Max.

Row Crop Tire Size 520/85 R42 165 A8/B 42 PSI (290 kPa) Min. 47 PSI (324 kPa) Max.

Row Crop Tire Adjustment 30" - 40" rows.

Track Width 36"

Track Length Overall 153"

Track Length Contact 108"

Track End Wheels (Per Track) Two cast iron segmented 36½" diameter.

Track Mid Wheels (Per Track) Eight 16" steel.

* Approximate with 15% moisture corn. Capacity and bushels/minute will vary with moisture content of grain and/or

PTO RPM.

Flotation Tire Row Crop Tracked

Weight - Empty 23,580 lbs. 24,380 lbs. 29,800 lbs.

Hitch Weight - Empty 4,200 lbs. 4,200 lbs. 4,200 lbs.

Hitch Weight - Loaded 6,525 lbs. 6,525 lbs. 6,525 lbs.

Transport Width 13'-0" 12'-7" (30") 15'5" (40") 13'-0"

Width - Grain Tank 12'-0" 12'-0" 12'-0"

Length - Grain Tank 25'-1" 25'-1" 25'-1"

Height - Grain Tank 11'-5" 11'-4" 11'-4"

Length - Overall 34'-11" 34'-11" 34'-11"

Height - Grain Discharge 14'-1" 14'-1" 14'-1"

5/12 1-5

TM

Specifications

M0238-01Grain Cart

1500 Grain Cart

Feature Specification

Total Capacity* 1500 Bushels

Bushels/Minute - Average* 750 Bushels/minute

Vertical Auger 22" Dia flighting in 23½" Dia. tube; ¼"T edge; ⁄" T root flighting. 10° auger position

control. Lower portion of lower vertical auger hard faced flighting.

Bearings - Vertical Auger 2"

Horizontal Auger 20" LH ¼"T edge; "T Root flighting.

Bearings - Horizontal Auger 6-bolt (rear) cast iron hubs with tapered roller bearings, (front) 2" ball bearing.

Gearbox Bevel & spur gear with 2:1 ratio.

Drive Belts Two 4-band, multi-strand V-belts.

Drive Sheaves 8 groove - 9¼" drive/18.7" driven.

PTO - 1000 RPM PTO auger drive with overrunning and torque limiting clutch.

PTO Yoke 1¾"-20 spline.

Safety Chains Two ½" 40,500 lbs rated, grade 70, certified to ASAE S338.5.

Adjustable Discharge Spout Remotely adjustable spout with +/- 14° of up/down motion and fitted with flexible

discharge nozzle.

Hydraulic Requirements 5 SCVs (manual) or 2 SCV's (remote) with standard 2320 minimum system psi.

Track Width 36"

Track Length 153"

Track Length Contact 108"

Track End Wheels (Per Track) Two cast iron segmented 36½" diameter.

Track Mid Wheels (Per Track) Eight 16" steel.

Weight - Empty 30,861 lbs.

Hitch Weight - Empty 5,050 lbs.

Hitch Weight - Loaded 7,200 lbs.

Transport Width 13'-0"

Width - Grain Tank 12'-0"

Length - Grain Tank 29'-0"

Height - Grain Tank 11'-4"

Length - Overall 38'-10"

Height - Grain Discharge 14'-1"

* Approximate with 15% moisture corn. Capacity and bushels/minute will vary with moisture content of grain and/or

PTO RPM.

1-6 5/12

TM

General Safety Rules

Safety Precautions

Grain CartM0238-01

1. Read and understand instructions provided in this

manual and warning labels. Review these instructions

frequently!

2. This machine is designed and built with your safety

in mind. Do not make any alterations or changes to this

machine. Any alteration to design or construction may

create safety hazards.

3. A large portion of farm accidents happen from fatigue

or carelessness. Safe and careful operation of tractor and

grain cart will help prevent accidents.

4.

Never allow cart to be operated by anyone unfamiliar

with operation of all functions of the unit. Operators must

read and thoroughly understand all instructions given in

this manual before operating or working on equipment.

5. Be aware of bystanders, particularly children! Always

look around to make sure it is safe to start tow vehicle

engine or move grain cart. This is particularly important

with higher noise levels and quiet cabs, as you may not

hear people shouting.

6. Make sure cart weight does not exceed towing capacity

of tractor, or bridge and road limits. This is critical to

maintain safe control and prevent death or injury, or

property and equipment damage.

7. Never ride or allow others to ride on cart

8. Store cart in an area away from human activity. DO

NOT permit children to play on or around stored unit.

9. Keep hands, feet, and clothing away from moving parts.

Do not wear loose-fitting clothing which may catch in

moving parts.

16. Make sure parked machine is on a hard, level

surface. Wheel chocks may be needed to prevent unit

from rolling.

17. Follow all federal, state/provincial and local

regulations when towing farm equipment on a public

highway. Use safety chain (not an elastic or nylon/

plastic tow strap) to retain connection between towing

and towed machines in the event of primary attaching

system separation.

18. Make sure all safety/warning lights, SMV sign, and

reflective decals are in place and working properly

before transporting machine on public roads.

19. Tow only with farm tractor of a minimum 90 HP. Allow

for unit length when making turns.

20. Track carts should be limited to road use only when

empty and speed to less than 15 MPH.

21. Maintain field drive speeds that are appropriate to

the load condition and field condition.

22. Reduce speed prior to turns to avoid the risk of

overturning. Avoid sudden uphill turns on steep

slopes. Always drive at a safe speed relative to local

conditions and ensure your speed is slow enough for a

safe emergency stop.

23. Always keep the tractor in gear to provide engine

braking when going downhill. Do not coast.

24. Always disengage PTO, shutoff tractor engine and

remove the ignition key before leaving tractor seat,

lubricating or working on grain cart, or when cleaning

out debris.

10. Always wear protective clothing, shoes, gloves, and

hearing and eye protection applicable for the situation.

11. Do not allow anyone to stand between tongue or hitch

and towing vehicle when backing up to cart.

25. Always make sure U-joint yokes are securely locked

on tractor and implement shaft before operating cart.

26. Be especially observant of the operating area and

terrain. Watch for holes, rocks or other hidden hazards.

Always inspect area before operation. DO NOT operate

13. Prevent electrocution, other injuries, or property and

equipment damage. Watch for obstructions such as wires,

tree limbs, etc. when operating machine. Be aware of

clearances during turns and when folding/unfolding grain

near edge of drop-offs or banks, or on steep slopes as

overturn may result. Operate up and down (not across)

intermediate slopes. Avoid sudden starts and stops. Be

extra careful when working on inclines.

chute.

27. Never step across any driveline. Do not attach

14. Pick levelest possible route when transporting across

fields.

drivelines with bolts or pins longer than recommended.

Never operate cart with damaged PTO driveline guards.

15. Never operate grain cart without PTO driveline guards,

tractor master shield and implement shields in place.

Make certain PTO driveline guards turn freely and are

properly attached.

Rev. 4/14 1-7

TM

Safety Instructions, Signs, and Decals

M0238-01Grain Cart

Following are some common hazard warnings associated with this equipment. Pay close attention to all safety,

operating, and maintenance information in this manual and decals applied to your equipment.

DANGER!

Contacting or coming close to power lines or other high energy

sources will cause death or serious injury. Keep away from power

lines or high energy sources at all times.

WARNING

Improperly operating or working on this equipment could result in

death or serious injury. Read and follow all instructions in Operator

Manual before operating or working on this equipment.

WARNING

Contact with rotating PTO shafts can cause death or serious injury.

Stay away from PTO shafts at all times unless clearly disconnected

from power source.

WARNING

Explosive separation of rim and tire parts can cause death or serious

injury.Overination.rimandtireservicing,improperuseofrimsandtires,

or worn or improperly maintained tires could result in a tire explosion.

Safety Signs And Decals

WARNING

Allsafety/warninglights,reectivedecals,andSMVsignmustbe

in place and visible before transporting machine on public roads or

death, serious injury, and damage to property and equipment may

result. Check federal, state/provincial, and local regulations before

transporting equipment on public roads.

Safety signs and decals are placed on the machine to warn of hazards and provide important operating and maintenance

instructions. Information on these signs are for your personal safety and the safety of those around you. FOLLOW ALL

SAFETY INSTRUCTIONS!

• Keepsignscleansotheycanbeeasilyseen.Washwithsoapandwaterorcleaningsolutionasrequired.

• Replacesafetysignsifdamaged,paintedover,ormissing.

• CheckreectivedecalsandSMVsignperiodically.Replaceiftheyshowanylossofofreectiveproperties.

• Whenreplacingdecals,cleanmachinesurfacethoroughlywithsoapandwaterorcleaningsolutionto

remove all dirt and grease.

NOTE: Safety sign and decal locations are shown in the Parts Manual for this machine.

NOTE:StyleandlocationsofSMVsign,reectivedecals,andsafety/warninglightsconformto

ANSI/ASABE S279.14 JUL 2008 and ANSI/ASABE S276.6 JAN 2005.

1-8 5/12

TM

Operation

Grain CartM0238-01

MACHINE PREPARATION

Lubricate grain cart per lubrication information in this manual prior to initial operation and at prescribed intervals. Make

sure all tires are properly inflated or track tension is properly adjusted before each use. Check drive V-belts for proper

tension and alignment. Torque all wheel lug nuts to specified torque.

TRACTOR REQUIREMENTS

Consult your dealer for information on horsepower requirements and tractor compatibility. Two remote SCV’s are

required for remote joystick operation and five SCV’s are required for standard cab operation . A 12 volt DC electrical

system is required on all sizes to operate safety/warning lights, auger-mounted work light, optional electronic scale

system, or electronic roll tarp.

TRACTOR PREPARATION AND HOOKUP

1. Slide tractor drawbar in as far as possible and still allow PTO shaft to have sufficient clearance to prevent damage

to driveline components when making sharp turns and operating over uneven ground.

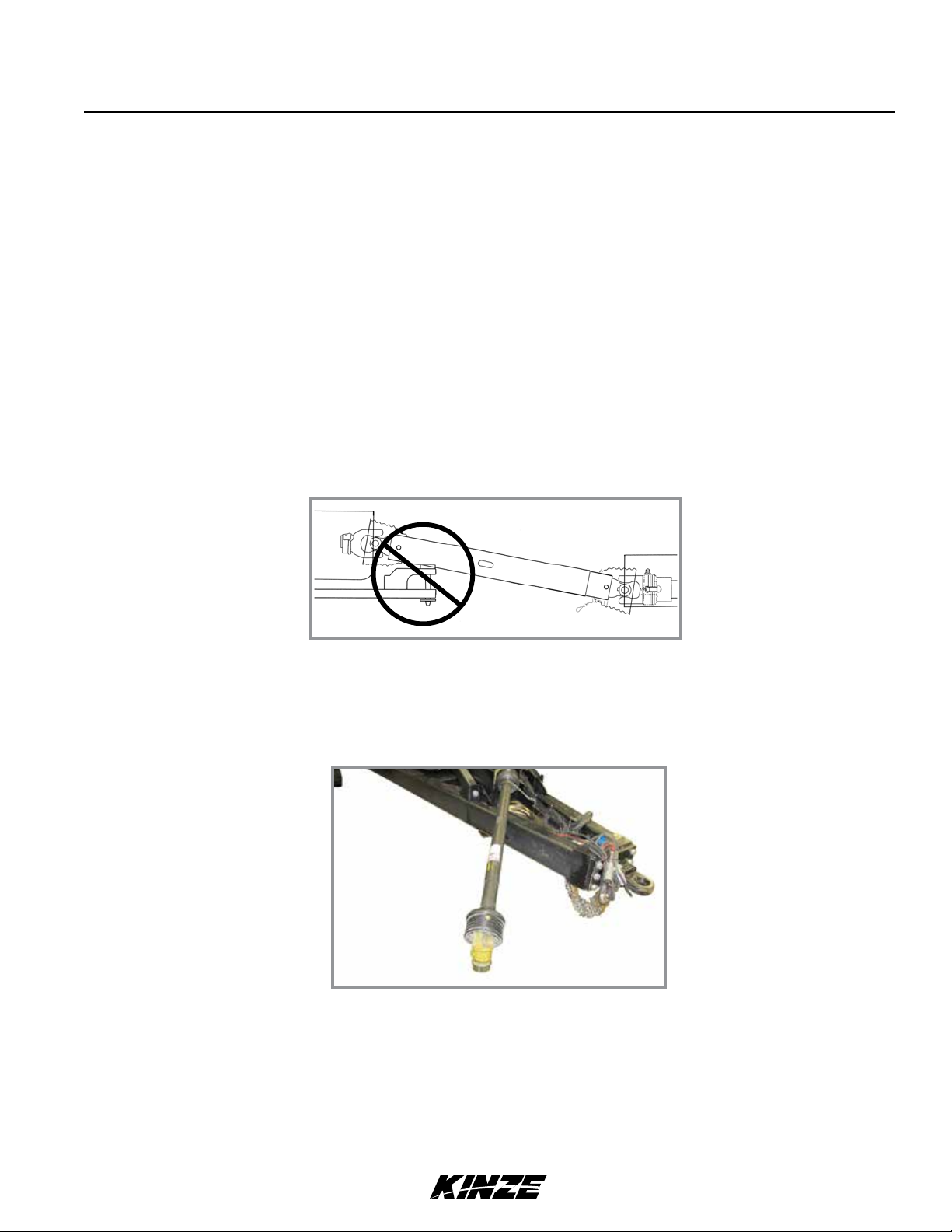

Avoid clevis hitch interference

NOTICE

Clevis hitch (hammer strap style) drawbars may need to be

removed to prevent damage to PTO assembly.

PTO shaft positioned for tractor hookup

NOTICE

Adjust tractor drawbar to prevent severe bends in PTO U-joint

angles and to allow sufficient clearance between tractor drawbar/

hitch pin and PTO shaft.

2. Position PTO as far right of hitch as possible until parking jack is raised.

5/12 2-1

TM

Operation

Jack handle stowed Jack handle installed

3. Remove hairpin clip and jack handle from storage location.

4. Install jack handle on jack shaft and raise cart.

NOTICE

Clean and grease PTO shaft coupling each time PTO is installed.

Apply coating of high-speed industrial coupling grease, such

as Chevron® Coupling Grease, that meets AGMA CG-1 and CG-2

standards to extend shaft spline life.

M0238-01Grain Cart

5. Connect cart to tractor hitch. Use a high quality hitch pin of sufficient length and strength and secure pin with a

locking device.

6. Raise jack. Return jack handle to storage location and install hairpin clip.

Safety chains

7. Attach cart PTO connecting yoke to tractor PTO shaft. Spring loaded yoke pin must engage groove in tractor PTO

shaft. Slip tube grease fitting must be visible through hole of outer tube.

8. Transport safety chain must be used to ensure connection is retained between cart and tractor in the event of a

hitch pin/drawbar failure. Torque attaching hardware to 840 ft-lb (1138 N-m).

2-2 5/12

TM

Operation

Grain CartM0238-01

WARNING

Pressurizedhydraulicuidcanpenetratebodytissueandresultin

death, serious infection, or other injuries. Fluid injected under skin

must be IMMEDIATELY removed by a surgeon familiar with this

type of injury. Make sure connections are tight and hoses and

fittings are not damaged before applying system pressure. Leaks

can be invisible. Keep away from suspected leaks. Relieve pressure

before searching for leaks or performing any system maintenance.

NOTICE

Wipe hose ends to remove any dirt before connecting couplers to

tractor ports or contamination may cause equipment failure.

9. Connect hydraulic hoses to tractor. Kinze grain carts require 5 SCV’s for manual operation and two SCV’s for

remote (joystick) operation (can only be used on a closed center system).

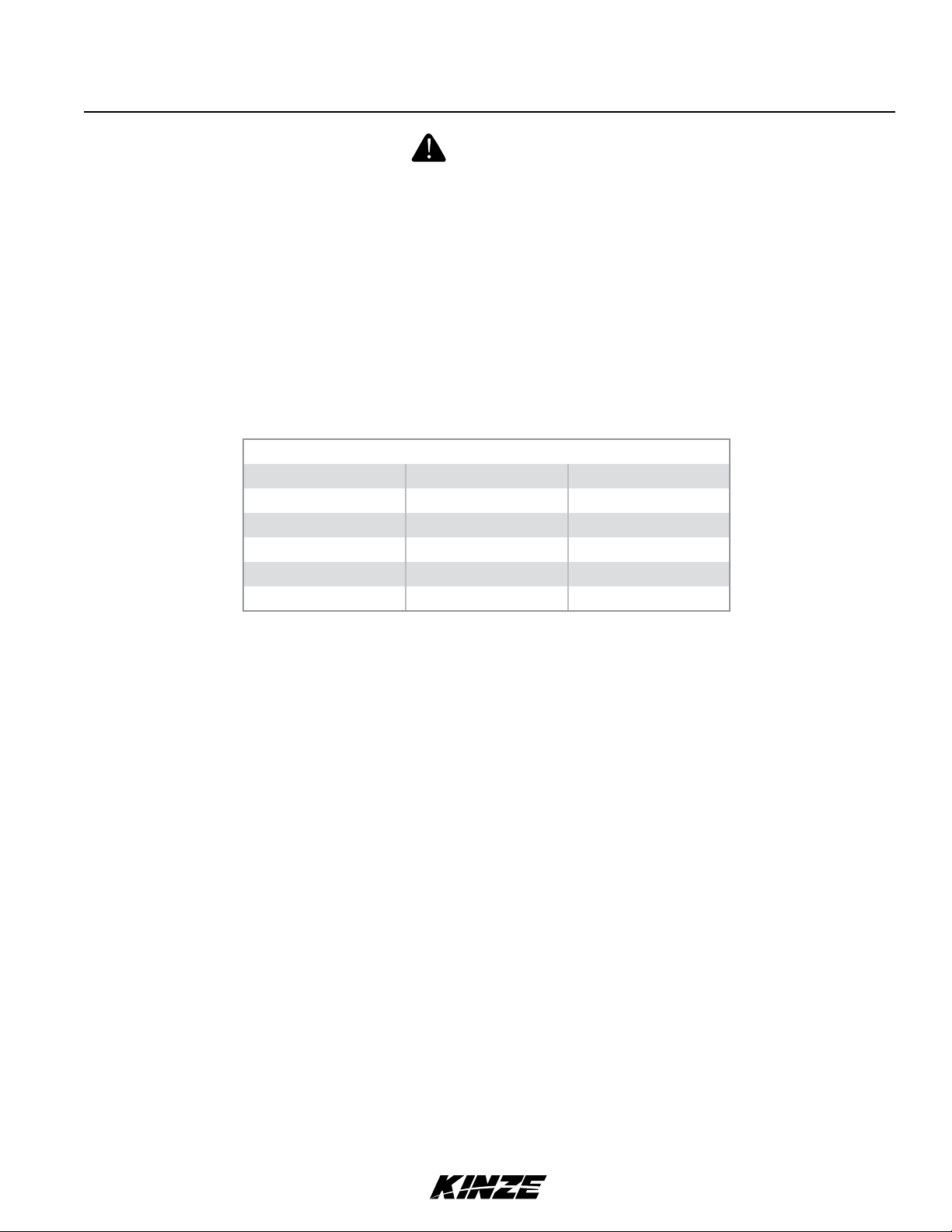

Hydraulic Control Settings

Control Hose color Function

SCV1 Red Auger fold

SCV2 Blue Auger tilt/Remote all

SCV3 Yellow Spout tilt

SCV4 Green Horizontal auger

SCV5 White Flow gate

10. Connect seven terminal breakaway connector for the lighting system on cart to seven pin connector on tractor.

If your tractor is not equipped with SAE Standard 7 terminal connector, obtain through your local tractor supply

dealer. Check clearance lights, signal lights, and auxiliary work light are working properly.

11. Connect optional electric roll tarp and camera harnesses. Check for proper operation.

5/12 2-3

TM

JOYSTICK CONTROLS

Operation

M0238-01Grain Cart

Horizontal auger ON

Auger pivot

Joystick top view

Push Yellow trigger to open flow gate.

Pull Red trigger to close flow gate.

Press AUGER ON button to start the horizontal auger. Press

AUGER OFF button to stop horizontal auger.

PIVOT IN/OUT switch moves vertical auger +/- 10° from cart.

SPOUT IN/OUT adjusts “tippy spout” position.

Horizontal auger OFF

Spout adjust

Front

Flow gate open

Flow gate close

Joystick side view

CART OPERATION

WARNING

Contact with rotating PTO shafts can cause death or serious injury.

Stay away from PTO shafts at all times unless clearly disconnected

from power source.

DANGER!

Because of load capacities on bridges and roads and because machine

is not equipped with brakes, this machine is not intended for hauling

loads on public roadways. It is the operator’s responsibility to be

aware of and follow federal, state/provincial and local regulations in

this regard.

DANGER!

Windows provide a limited view behind cart. Use of a rear-view

mirror or optional cart mounted camera is recommended to aid the

operator in seeing behind the cart. Always check carefully, including

blind spots, before backing or turning cart.

WARNING

Wide loads or loads with a high center of gravity may cause instability

or rollover when operating on hillsides or in rough terrain.

WARNING

Do not transport cart with vertical auger extended this can cause

loss of control and could result in death, serious injury, or damage to

porperty and equipment.

2-4 5/12

TM

Operation

DANGER!

Contacting or coming close to power lines or other high energy

sources will cause death or serious injury. Keep away from power

lines or high energy sources at all times.

Unload Grain Cart

NOTICE

Do not operate tractor PTO above 750 PTO RPM with augers empty

or equipment may be damaged.

NOTICE

Roll tarp must be completely open during unloading operations or

suction will damage equipment.

NOTE: Vertical auger tilt must be in fully retracted position to fold/unfold.

1. Open roll tarp completely.

Grain CartM0238-01

2. Unfold vertical auger.

3. Engage PTO at low tractor RPM.

4. Engage horizontal auger.

5. Start to open flow gate and increase tractor RPM.

6. Set grain flow and tractor RPM to desired level.

7. Adjust auger tilt and/or tip spout.

8. Slow tractor RPM as cart reaches empty

9. Close flow gate.

10. Disengage horizontal auger.

11. Allow vertical auger to clean out and disengage PTO.

12. Ensure auger tilt is in full vertical position.

13. Fold auger to storage position.

5/12 2-5

TM

Operation

M0238-01Grain Cart

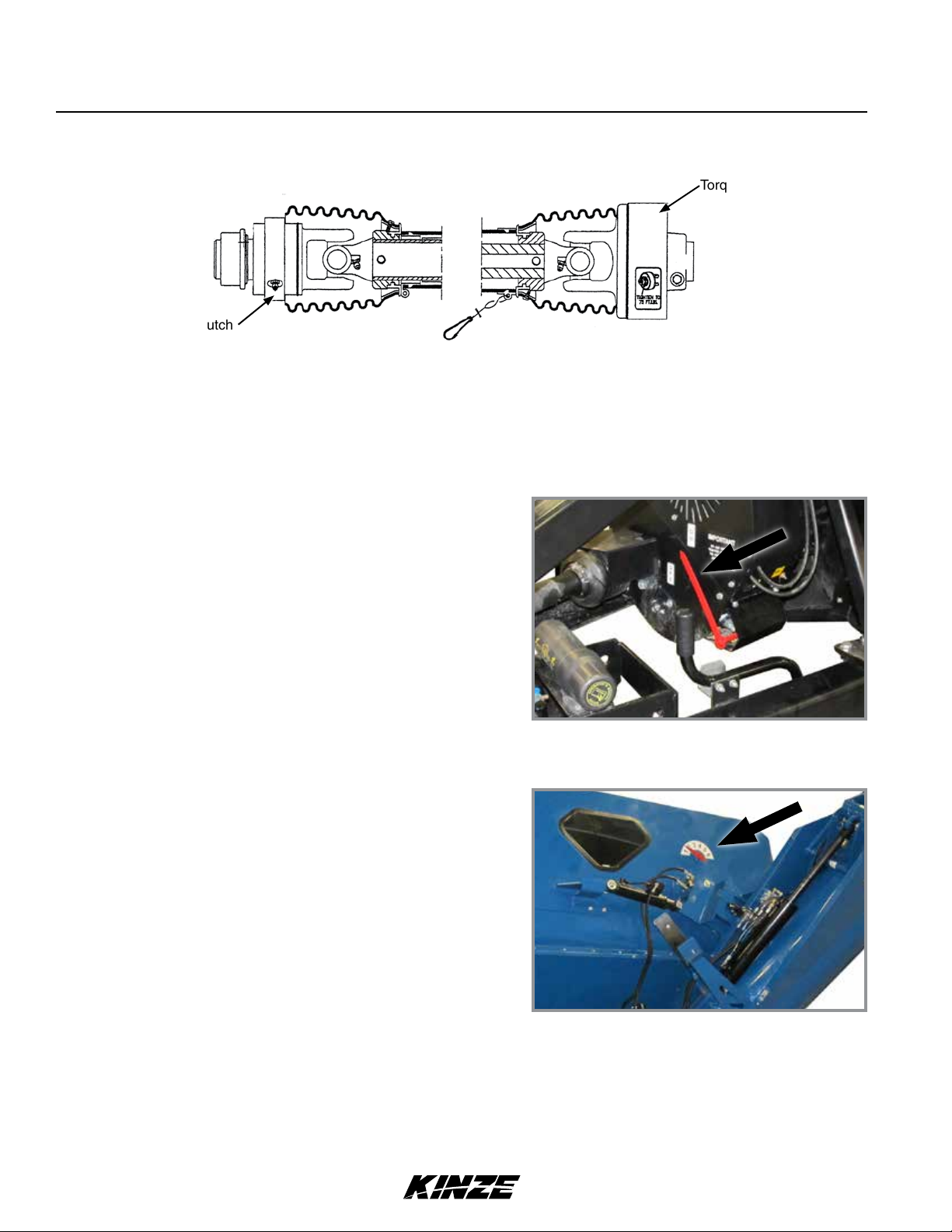

PTO TORQUE LIMITING/OVERRUNNING CLUTCH PROTECTION

Torque limiting clutch

Overrunning clutch

The torque limiting clutch disengages if auger becomes obstructed to prevent driveline and gearbox damage.The torque

limiting clutch resets automatically when PTO RPM is reduced.

The overrunning clutch allows auger system to freewheel and protects tractor and cart from shock damage withPTO

brake-equipped tractors.

BELT ENGAGEMENT INDICATOR

An indicator pointer on front side of belt housing shows if

horizontal auger is engaged (ON) or disengaged (OFF).

indicator should be OFF when PTO is engaged to reduce start up

torque requirements.

As belt tension is disengaged (OFF) you will hear linkage snap

over center and release belt tension.

HYDRAULIC FLOW GATE

Hydraulic flow gate controls volume of grain to horizontal auger.

An indicator on front panel shows position of flow gate.

1. Engage PTO for the vertical auger at low RPM.

2. Engage belt drive clutch to start the horizontal auger.

3. Open gate half way.

4. Adjust flow gate to desired unloading rate.

Belt engagement indicator

Flow gate position indicator

NOTE:Recommendedinitialowgatepositionforriceishalfopen.

2-6 5/12

TM

AUGER INSPECTION COVER

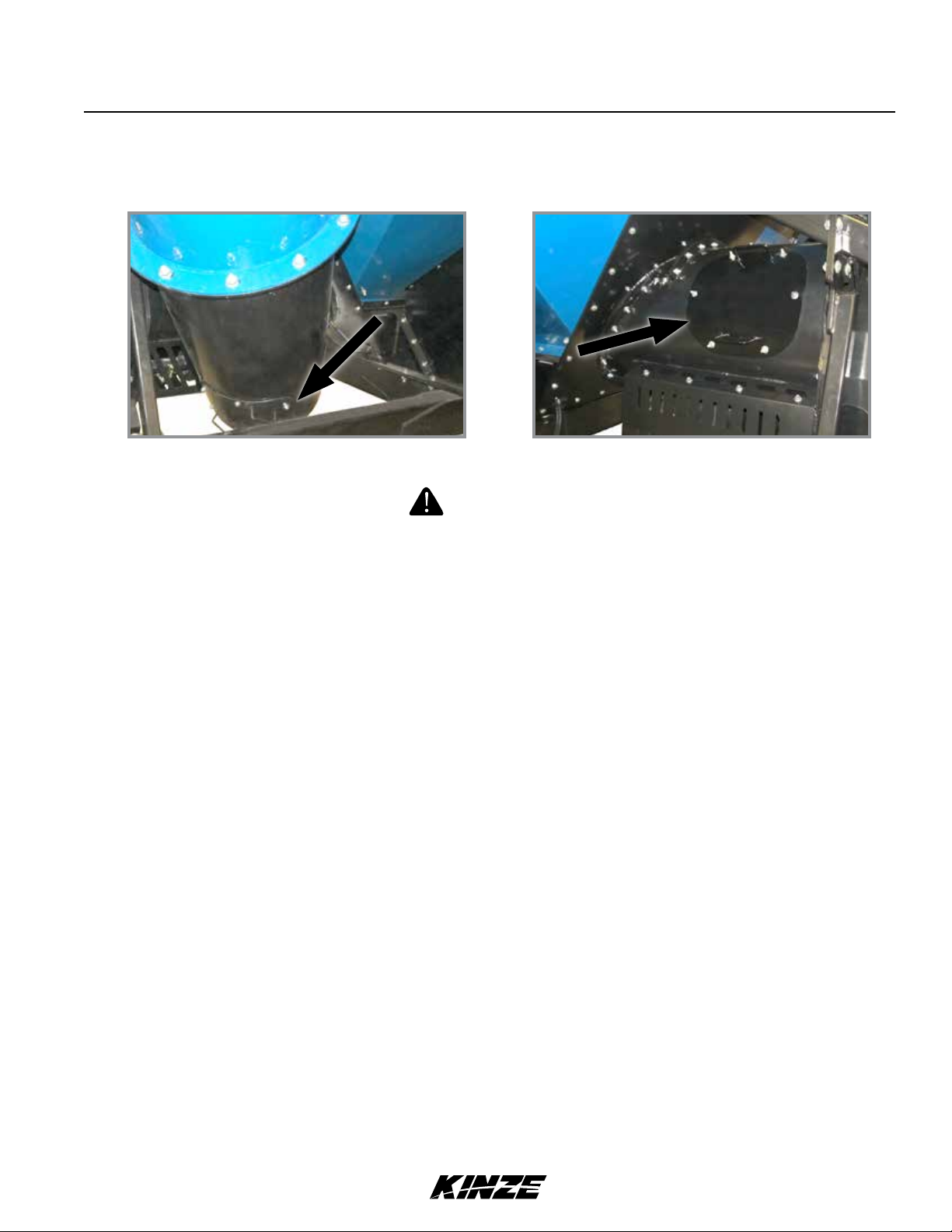

Vertical Auger Cleanout door Horizontal Auger Cleanout door

Never open inspection cover while PTO and/or augers are running.

Operation

Grain CartM0238-01

DANGER!

Grain Carts are equipped with two inspection covers one at the bottom of the vertical auger and one located on the grain

transfer that are used for clean out purposes.

The inspection covers should be removed any time total clean out of the wagon is required, such as when changing

crops, to preserve grain identity, or in preparation for storage.

At the end of each season or after extended use, the inspection covers should be removed and the auger chamber

cleaned of all debris and accumulated grain to prevent rust and mold.

Reinstall covers and tighten hardware evenly after clean out is complete.

5/12 2-7

TM

Loading...

Loading...