Kinze 3000 User Manual

OPERATOR MANUAL

M0246

KINZE ISOBUS ELECTRONICS PACKAGE

FOR 3000 SERIES PLANTERS

Rev. 5/14

KINZE ISOBUS ELECTRONICS PACKAGE

FOR 3000 SERIES PLANTERS

OPERATOR

MANUAL

M0246 Rev. 5/14

This manual is applicable to: Kinze ISOBUS Planter Monitoring/Control System

Firmware Version: 2.0

Record the serial numbers of your planter control system and the purchase date:

Planter Monitor Module Serial Number _____________________________

Planter Control Module Serial Number _____________________________

Date Purchased _______________________________________________

Measured Pulses Per Mile

(Planter Seed Sensor) __________________________________________

Kinze®, the Kinze® logo, Twin-Line®, Interplant®, and EdgeVac®

are trademarks owned by Kinze Manufacturing, Inc.

John Deere® is a trademark of Deere and Co.

This page left blank intentionally.

Table of Contents

ISOBUSM0246

OVERVIEW

To The Owner ........................1

Warranty ............................2

Introduction ..........................3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . .4

SYSTEM OVERVIEW

ISOBUS System ......................5

CAN-Bus Technology ...................5

9-Pin Connector .......................5

ISOBUS Diagram. . . . . . . . . . . . . . . . . . . . . .6

Home Screen. . . . . . . . . . . . . . . . . . . . . . . . .7

PLANTER CONFIGURATION

Configuration Wizard ...................9

Sensor Programming ..................11

PLANTING SETUP

Custom Crop ........................13

Crop Selection Screen. . . . . . . . . . . . . . . . .13

Set Population Screens . . . . . . . . . . . . . . . .14

Edit Presets . . . . . . . . . . . . . . . . . . . . . . . . .14

Basic Population .....................15

Halves Population ....................15

Prescription Population ................16

Software Update .....................17

Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page Layout Screen. . . . . . . . . . . . . . . . . . .19

Plant Screens .......................20

SETTINGS

Advanced Settings. . . . . . . . . . . . . . . . . . . .36

Bulk Fill Pressure. . . . . . . . . . . . . . . . . . . . .33

Bulk Fill Scale .......................34

Diagnostics .........................37

MUXBUS ...........................35

Pneumatic Down Force (PDP). . . . . . . . . . .31

Population Monitoring .................32

Section Control Diagnostics. . . . . . . . . . . . .38

Seed Count Diagnostics ...............38

Seed Sensor Sensitivity (Seed Counter) . . .34

Settings Screen ......................29

Speed Input . . . . . . . . . . . . . . . . . . . . . . . . .29

Vacuum ............................33

OFFSETS AND LOOK AHEADS ....... 23

Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Look-Aheads ........................24

ALARMS .......................... 27

Rev. 5/14 i

TM

This page left blank intentionally.

To The Owner

ISOBUSM0246

Kinze Manufacturing, Inc. thanks you for your patronage. We appreciate your confidence in Kinze farm machinery. Your

Kinze planter has been carefully designed to provide dependable operation in return for your investment.

This manual has been prepared to aid you in the operation and maintenance of the ISOBUS display. It should

be considered a permanent part of the machine and remain with the machine when you sell it.

It is the responsibility of the user to read and understand the Operator Manual in regards to safety, operation,

lubrication and maintenance before operation of this equipment. It is the user’s responsibility to inspect and service

the machine routinely as directed in the Operator Manual. We have attempted to cover all areas of safety, operation,

lubrication and maintenance; however, there may be times when special care must be taken to fit your conditions.

Throughout this manual the symbol and the words DANGER, WARNING, and CAUTION are used to call

attention to safety information that if not followed, will or could result in death or injury. NOTICE and NOTE are used to

call your attention to important information. The definition of each of these terms follows:

DANGER Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

NOTE: Special point of information or machine adjustment instructions.

WARNING

Improperly operating or working on this equipment could result in

death or serious injury. Read and follow all instructions in Operator

Manual before operating or working on this equipment.

WARNING

Some photos in this manual may show safety covers, shields, or

lockup devices removed for visual clarity. NEVER OPERATE OR

WORK ON machine without all safety covers, shields, and lockup

devices in place as required.

NOTE: Photos in this manual may be of prototype machines. Production machines may vary in

appearance.

NOTE: Some photos and illustrations in this manual show optional attachments installed. Contact

your Kinze Dealer for purchase of optional attachments.

Rev. 5/14 1

TM

Warranty

M0246ISOBUS

The Kinze Limited Warranty for your new machine is stated on the retail purchaser’s copy of the Warranty And Delivery

Receipt form. Additional copies of the Limited Warranty can be obtained through your Kinze Dealer.

Warranty, within the warranty period, is provided as part of Kinze’s support program for registered Kinze products

which have been operated and maintained as described in this manual. Evidence of equipment abuse or modification

beyond original factory specifications will void the warranty. Normal maintenance, service and repair is not covered by

Kinze warranty.

To register your Kinze product for warranty, a Warranty And Delivery Receipt form must be completed by the Kinze

Dealer and signed by the retail purchaser, with copies to the Dealer, and to the retail purchaser. Registration must be

completed and submitted to Kinze Manufacturing, Inc. within 5 business days of delivery of the Kinze product to the

retail purchaser. Kinze Manufacturing, Inc. reserves the right to refuse warranty on serial numbered products which

have not been properly registered.

If service or replacement of failed parts which are covered by the Limited Warranty are required, it is the user’s

responsibility to deliver the machine along with the retail purchaser’s copy of the Warranty And Delivery Receipt to

the Kinze Dealer for service. Kinze warranty does not include cost of travel time, mileage, hauling or labor. Any prior

arrangement made between the Dealer and the retail purchaser in which the Dealer agrees to absorb all or part of this

expense should be considered a courtesy to the retail purchaser.

Kinze warranty does not include cost of travel time, mileage, hauling, or labor.

2 Rev. 5/14

TM

Introduction

ISOBUSM0246

ISOBUS is an agricultural industry term used to describe software and hardware that complies with the global

ISO11783 standard. ISO11783 was created by an international standards committee of representatives from different

agricultural companies. The standard was created to allow plug-and-play compatibility between different manufacturers

of tractors, harvesters, sprayers, implements, and more.

There are 14 different parts to the ISO11783 standard. A device does not have to support all 14 parts to be

considered ISO compatible or certified. The parts that are important to the Kinze ISOBUS solution are the Virtual

Terminal (VT) and the Task Controller (TC).

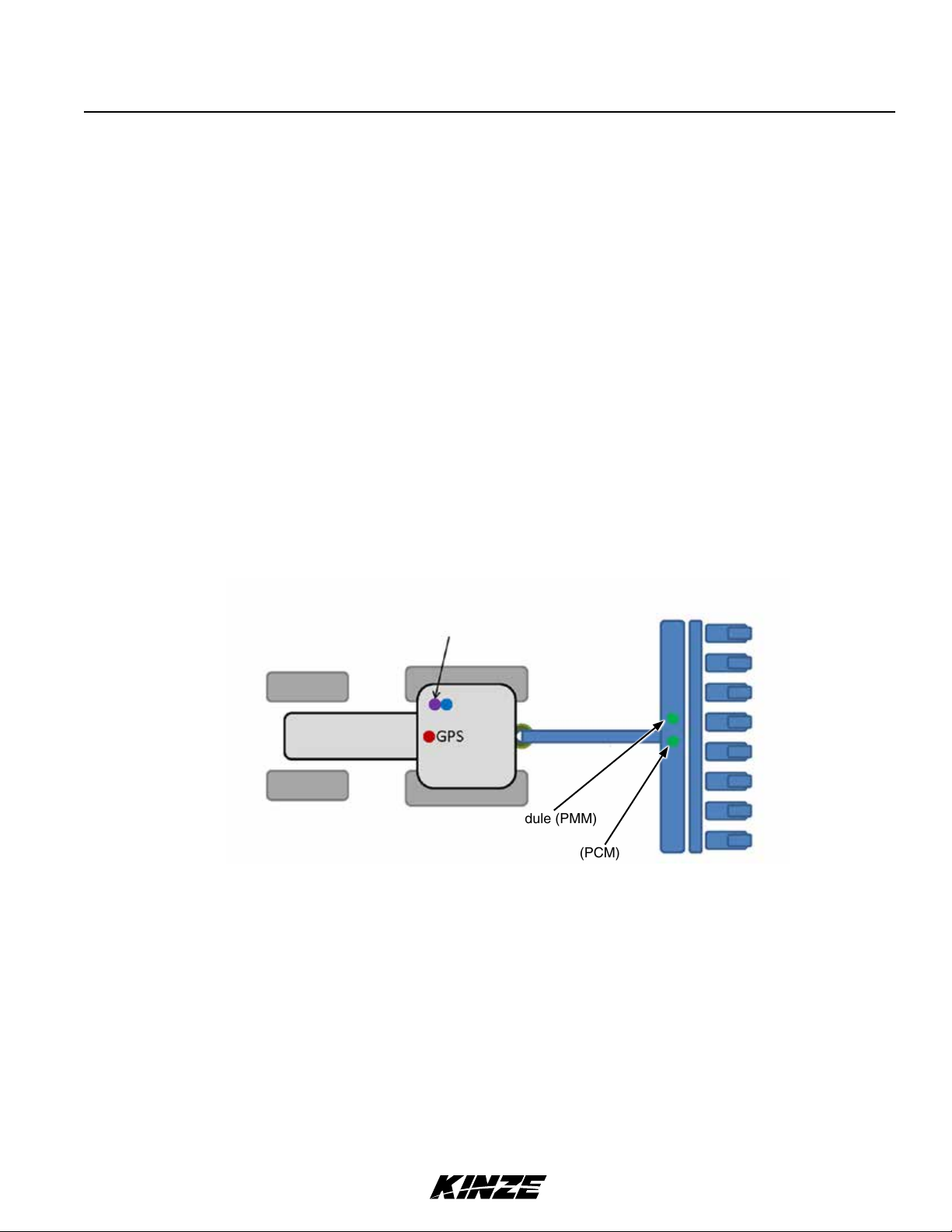

ISOBUS COMPONENTS

• Virtual Terminal (VT) - A display in the cab of the tractor. The operator interacts with the display to monitor

information and change settings.

• Task Controller (TC) - Makes automatic swath control, automatic rate control, and as-applied mapping possible.

The functionality is software based, so does not require a separate box. When present, it is normally built into the

display. Every ISOBUS display is a Virtual Terminal, but not every display has a task controller.

• Planter Monitor Module (PMM) - The brains of the system. This device is found on the planter and relays

information to and takes inputs from the VT. The PMM is part of the Kinze ISOBUS option.

• Planter Control Module (PCM) - Device on the planter that executes the manual and automatic rate control,

clutches and automatic clutch control, plus swath control commands. These functions are available with the Kinze

ISOBUS product control package.

Virtual Terminal Display

with Task Controller

Planter Monitor Module (PMM)

Planter Control Module (PCM)

GENERAL INFORMATION

The information used in this manual was current at the time of printing. However, due to Kinze’s ongoing product

improvement, production changes may cause your planter control system display to appear or operate slightly

different in detail. Kinze Manufacturing, Inc. reserves the right to change specifications or design without notice and

without incurring obligation to install the same on machines previously manufactured.

Right hand (R.H.) and left hand (L.H.), as used throughout this manual, are determined by facing in the direction the

machine will travel when in use, unless otherwise stated.

Rev. 5/14 3

TM

Specifications

KINZE ISOBUS PLANTER CONTROL SYSTEM DISPLAY

Absolute Voltage Range .......................................................... 0 to 60v

Connector ..............................................................(1) 9-Pin Deutsch

Environmental Operating Temperature ............................................14˚ to 149˚F

Full Function Voltage Range .......................................................8 to 18v

Input/Output ...............................................................CAN, Muxbus

Maximum Current Draw ............................................................. 20A

Operating Voltage Range ......................................................... 6 to 19v

Power Loss Protection for Shutdown ....................................................Yes

Reverse Voltage Protection ...........................................................Ye s

Storage Temperature ........................................................ -22˚ to 158˚F

M0246ISOBUS

4 Rev. 5/14

TM

System Overview

ISOBUSM0246

ISOBUS SYSTEM

ISOBUS provides a consistent user interface for planter functionality, regardless of the tractor brand that is pulling the

implement. The ISOBUS control system plugs into a compatible, existing monitor in the cab of the tractor. The existing

monitor becomes a Virtual Terminal (VT) for Kinze controls and monitoring.

CAN-BUS TECHNOLOGY

The ISOBUS system uses Controller Area Network (CAN) technology. CAN systems are comprised of individual

modules, each with their own high speed processor, connected through a high-speed communications cable. CAN

has many benefits, including greater ability to configure and expand the system, compatibility, simpler installs with less

wiring and increased system dependability.

9-PIN CONNECTOR

The 9-Pin round pin connector contains CAN, ECU power, solenoid power, and grounds .

NOTE: The displays used in this manual are from a John Deere virtual terminal. Your

virtual terminal may vary slightly depending on the manufacturer.

Rev. 5/14 5

TM

ISOBUS DIAGRAM

TBC

ISOBUS (Tractor) Connection

Fuse 10 AMP Fuse 20 AMP

PMM

Y-Splitter

System Overview

M0246ISOBUS

ISOBUS Harness

CAN Jumper

Cable

Product Control Module

Cable

PCM

Mux A

(Rear)

Sensor Harnesses (Varies By # of Rows)

NOTE: Sensors for ASD, EdgeVac, PDP, Scale

and Jump Start/Implement can plug into

Mux A or Mux B.

Mux B

(Front)

Clutch Cable

Clutch Adapter Cable

(Polarity Reversal Required)

Electric Clutches

2-Way Ter minating

Resistor

Jump Start Cable

Connects to

Sensor Harness

Hall Effect Adapter

Section Adapter Cable

Clutch

Control

Ground

Implement

Switch

Encoder

Control

1

Rate

2

Rate Control

Cable

3

Hydraulic

Motor

Jump Start

Sensor

6 Rev. 5/14

Implement Switch Extension Harness

TM

Implement

Switches

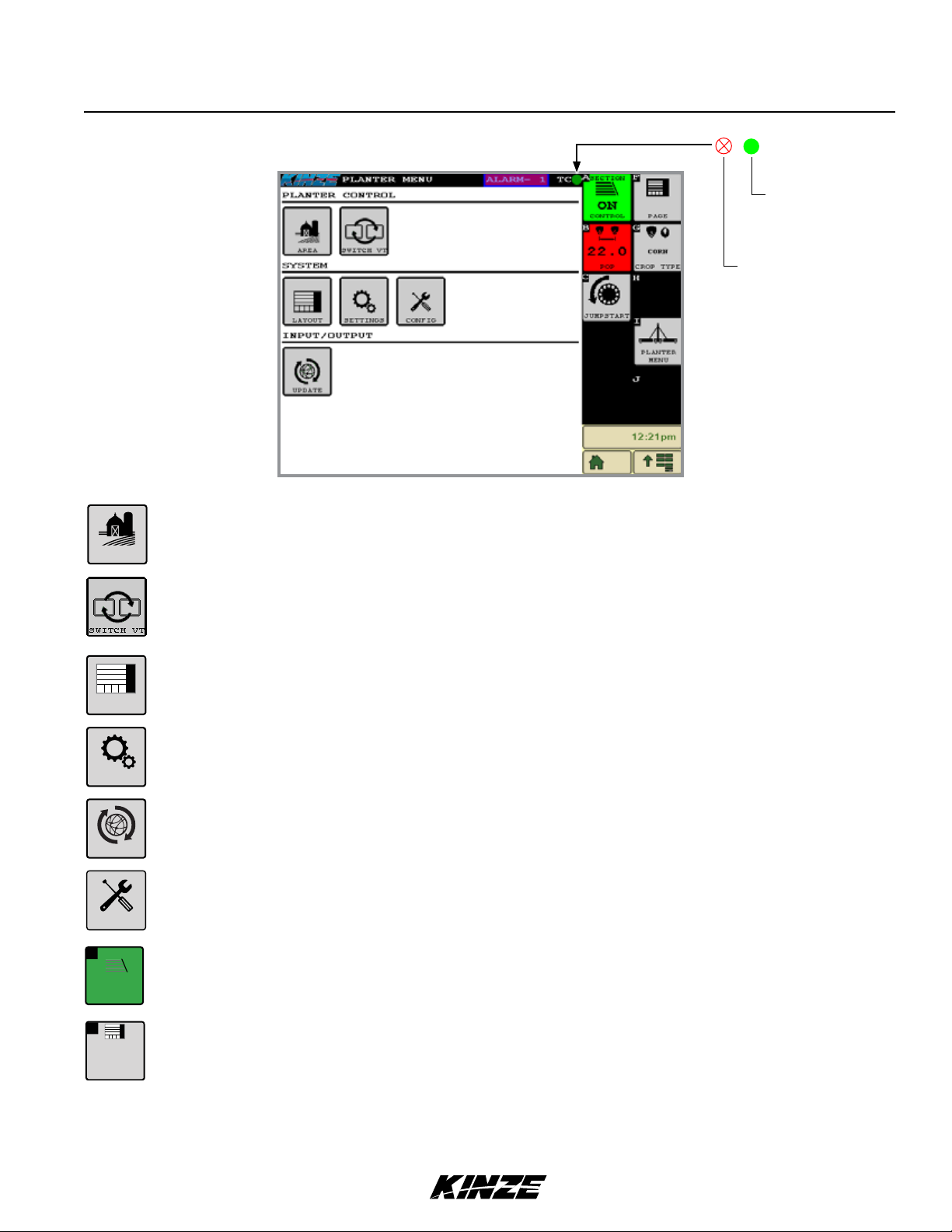

HOME SCREEN

Area opens window that displays multiple acre counters.

System Overview

Task Controller is in

full communication

with planter.

Task Controller is not

present.

ISOBUSM0246

AREA

LAYOUT

SETTING

UPDATE

CONFIG

SECTION

A

ON

CONTROL

Switch VT toggles between displays when more than one display is being used.

Layout button opens window to set the layout and visibility of the plant screens 1-6.

Settings button opens window that display Speed Input, Advance Seed Counter, Muxbus, Pneumatic

Downforce, Seed Sensor Sensitivity, Population Monitoring, Bulk Fill Pressure, Bulk Fill Scale, and

EdgeVac Pressure. For more information, see the Settings Section.

Update button opens window that displays upgrades that are available on a USB Drive.

Configuration button opens a wizard that steps through the configuration of the planter. For more

information, see the Configuration Section.

Section Control button will turn section control on or off from the planter. If turned off, use the manual

section buttons. Refer to page 20 for more information.

F

PAG E

1 OF 4

Rev. 5/14 7

Pages Tapping on the "Pages" button allows you to toggle through the plant screens and menu.

TM

Population button opens window that lets you select a desired planting rate.

B

POPULATION

R 10.0

L 10.0

M0246ISOBUS

G

CORN

JUMP

START

Crop Type button opens window that allows you to select crop type and row spacing.

Jump Start manually turns meters on before desired speed is reached by pushing button and holding.

Planter Menu returns you to the planter menu from any screen.

8 Rev. 5/14

TM

Loading...

Loading...