1

Ⅰ.SAFE DRIVE

Rules for Safe Drive

Check must be conducted,bef ore starting the engine,to prevent mishaps and damage to components.

Only the qualified person who has passed the drive examination with a drive license is permitted to drive the

vehicle but not anybody else without a drive license.

Full preoccupation is required during drive, paying attention to the following points to avoid any possible

hurt to you by other motorized vehicles:

Do not drive too close to other vehicles;

Never contend for lane.

Strictly observe the local traffic rules.

As driving at overspeed is the cause of many accidents. Do not drive at a speed that the actual situation does

not permit.

Particular care should be exercised at the level crossing of roads, entrance and exit of parking lot or on the

autonobile lane.

During drive, grasp the left handlebar by the left hand and the throttle twist grip by the right hand,with feet

on the footrests.

2

Protective wear

1.Protective wear such as helmet with protective mask, dustproof glasses and gloves should be worn during

drive for the sake of personal safety.

2.Loose clothes are not suitable for motorcycle drive or ride as they may get caught on the operating lever

,kick ,footrest or wheel, resulting in danger.

Modification of the vehicle

Caution:

Any unauthorized modif ication of the vehicle or replacement of the original parts can not ensure driving

safety and is illicit. The user must observe the regulation s of the traffic conrtol authorities, We are no t responsible

for any vehic le with unauthorized modification.

3

Ⅱ.MAIN DATA

Item 50 type Item 50 type

Overall length 1910mm Cylinder bore x stroke

39×41.4

Overall width 760mm Compression ratio

8.8:1

Overall height 1140mm Output,max

2.0kw/7000r/min

Wheelbase 1260 mm Torque,max

2.2N.m/62500r/min

Dead weight 92kg Idling speed

1500r/min±100r/min

Payload 150kg Displacement of cylinder

49ml

Front wheel 3.25-18 Spark plug

A7TC

Rear wheel 3.00-16 Spark plug gap

0.6~0.8mm

Speed,max 45km/h

Gap of air valve

Inlake valve:0.05mm

Braking distance ≤7m(30km/h)

Exhaust valve:0.08mm

Climbability ≥18° Ground clearance

200mm

Capacity of gasoline

5.5L Ignition means

CDI

Transmission ratio

1 st gear 3.273 2nd gear 1.937 3rd gear 1.611

4th gear

1.350

5th gear

Final reduction 3.286

4

III.PARTS & SUBAS SEMBLIES

5

6

7

IV.OPERATION

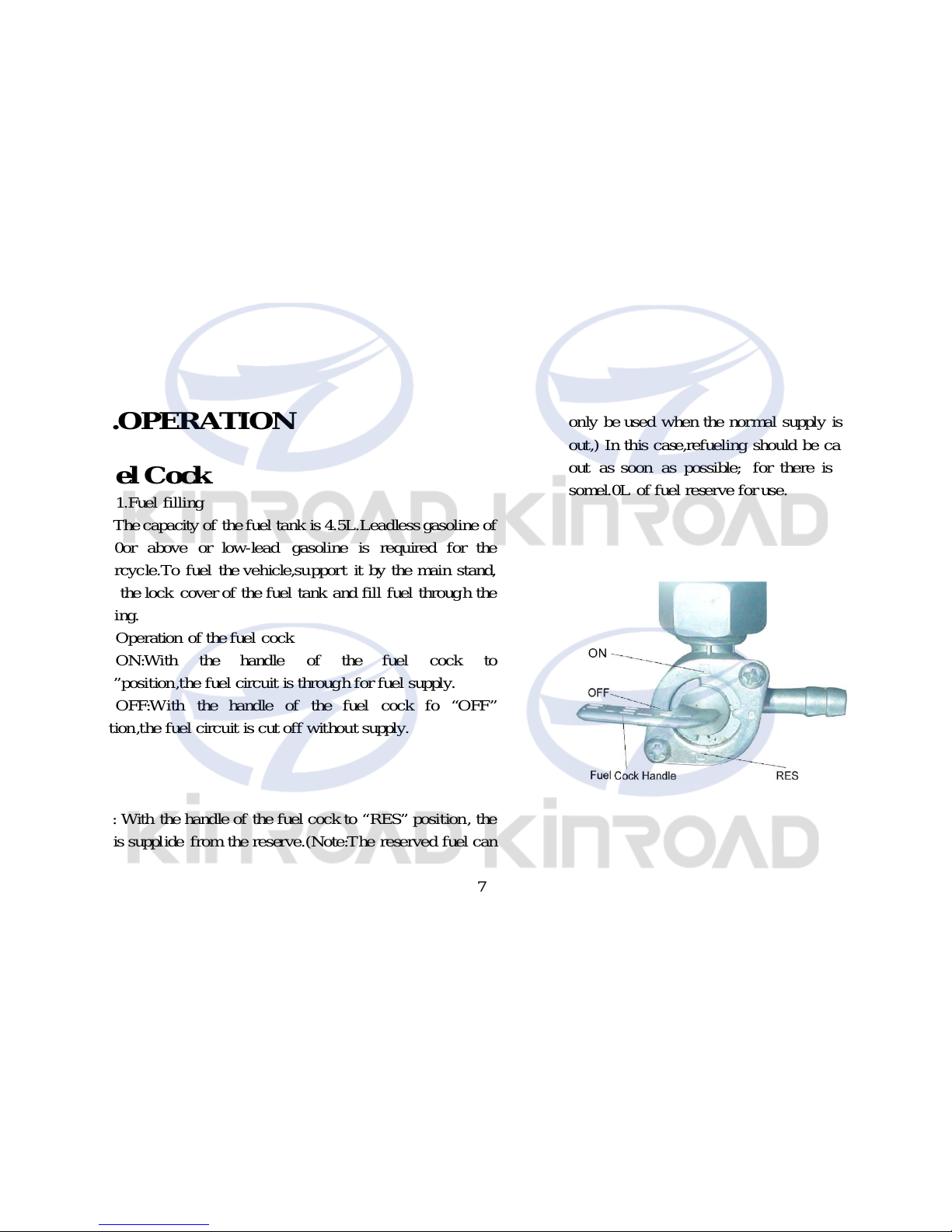

Fuel Cock

1.Fuel filling

The capacity of thefuel tank is 4.5L.Leadless gasoline of

No.90or above or low-lead gasoline is required for the

motorcycle.To fuel the vehicle,support it by the main stand,

open the lock cover of the fuel tank and fill fuel through the

opening.

Operation of thefuel cock

ON:With the handle of the fuel cock to

“ON”position,the fuel circuit is through for fuel supply.

OFF:With the handle of the fuel cock fo “OFF”

position,the fuel circuit is cut off without supply.

RES: With the handle of the fuel cock to “RES” position, the

fuel is supplide from the reserve.(Note:The reserved fuel can

only be used when the normal supply is run

out,) In this case,refueling should be carried

out as soon as possible; for there is only

somel.0L of fuel reserve for use.

8

Engine Startin

g

Warning:Never startthe engine in a closed

p

lace orwarehouse orwarehouse asthe

exhausted

gas

from the vehicle contains toxic

carbon monoxide.

1.Se

t

the keyofthe ignition switch to

“ON”

p

osition.

2.Ascertain the neutral

p

osition,where it

should

b

edisplayed.

3.Ascertain the amount o

f

fuel in the tank,

4.Se

t

the fuel cockhandle to “ON”position.

★T

o

startacoldengine;

1.Pull u

p

the chokebarofthe carburetor(to

close the choke

)

.

2.Rotate the throttle twist

grip

by

1/8to

1/4turn.

3.Start the en

g

inebythe electric orthe kick

startin

g

system.

4.Sli

g

htlyturn the throttle twistgripto

increase the s

peedof

the engine so asto

war

m

upthe engine.

5.Turn the carbureto

r

chokebardownward

to full

yop

en the choke whenthe engine is

sufficientl

y

warmedup.

★Caution:

The engine can only be started after the

neutral position is ascertained.Otherwise

accident will happen.

Unnecessary idle running(especially at a

high speed) is harmful to the engine.

★ Procedures for stopping the engine:

1.Release the throttle twist grip to slow

down the engine.

2.Turn to the neutral position.

3.Se

t

the ignition switch keyto

“OFF”

p

osition.

4.Set the fuel cockhandle to “OFF”

position.

Switches on Right Handle bar

9

Electric start button

The electric start button is located below the right handlebar.When the

ignition switch is set in “ON” position and the engine is in the neutral

position, push the button to start the engine

Light switch

The front light switch has three positions,

And“●”(a white point).

When the switch i s in this position,the front head

li ght button ,tail and meter lights are all lit up.

When the switch is in this position,the tail, betraying and m eter

Iights are lit up.

“● ”When it is in this position. The front illumin ator, tail, betraying and

meter lights are all off.

10

Switches on LeftHandle bar

1. Headli ghts dimmer button

Positi on,Headligh is in hig h beam.

Positi on, Headligt is in low beam.

2. turning light switch

position,Left

position,Right

3.Horn button

press this button for horn

11

Gear Shifting

A non-c

y

clingmode o

f

gear

shift ingis employed ofthis motorcycle

● The throttle must

b

e c losse

d

b

eforthegearshift ingeverytime,

Shifin

g

thegea

r

b

efore closingthe condition o

f

b

ackingit forfou

r

times.

● The s

peed

shift in

g

p

edalmustbeoperatedsuitably.

● Ste

pping

on thegearshift in

g

p

edal is forbided whendrivingto

p

revent damagingthe clutch whenchangingthegearabruptly.

N

OTE

(N)

N

eutralgea

r

(1)

1

th

gear

(2)

2

nd

gear

(3)

3

rd

gear

(4)

4

th

gear

(5)

5

th

gear

Points for AttentionduringDrive

1.Avoid unnecessar

y

idlingofthe engine andit is not allowed. I

n

p

articu lar.to have it id lingatahighspeed.

Othe

r

wise it will damagecomponen ts seriously.

2.Shif

t

to the low spee

d

gear

whenfeeliingthatthepoweris not strongenoush on climbing.

3.I

t

is forbidden to usethe frontbrake onlyortocoas

t

by

the n eutralgearespeciallywhendescendingordrivin

g

athighspeed.

4.On braking. Narrow the throttle. and then apply the brake

12

V.Checki

ng,

Adj

ustm

-

entan

d

Mai

ntenance

Machi

ne

Oil

Checki

ng

★The vehicle should be checked for

machine oil before drive by sup-porting

i t with the

Main stand on a flat ground.The oil

livel should be between the upper and

lower

Lines of the oil gauge. Which is not

screwed into the filling orifice.

★ High quality 4-stroke machine

oil. Class SE or SD in API classif i-

cation.of SAE15W-40 in viscosity will

help maintain a long service life or the

engine.In case those are not available,a

substitute suitable for the ambient

temperature of application should be

selected according to the table on the

right side.

R

enewalo

f

Machi

ne

Oil

Machine oil plays a very important

role in the normal operation of the

engine and for this reason,it is necessary

to check the motorcycle for machine oil

periodically and renew the oil once

every800-1,000k m of driving by the

follow ing procedures.

Remove the screw plug from the

bottom of the hot engine to drain off all

old oil.

Wash the oil filter screen clean and

remount it really to positi on.Then fill in

0.8L fresh machine oil and start the

engine for idle running2-3 minutes.

Let the engine stop for 1-2

minutes and check to see whether the

oil level is in between the upper and

l ower lines of the oil gauge.

Do not use any machine oil of a

different grade than the specif ied one

toavoid machinery failure.

13

Cl

eaning ofmachine o

il

tank

Check-up ofSpark Plug.

1.Drain off all the run –in machine oil from

the o il tank.

2.Dismount the related parts.

3.Wash clean all the related parts.

4.Fill in the required oil.

* This job should not be done by untrained

persons but shall be done at an authorized service

center. 1.Remove the cap of spark plug and screw off

the spark plug by the plug wrench.

2.Clean the spark plug all aroud or replace it

if i t is corroded or there is too much deposit on it.

3.Regulate the gap of the spark plug to 0.6-

0.7mm.

4.The spark plug of the designated type should

be used. The applicable type of spark plug: NHSP

LD D8TC made i n China.

14

Check-up & Cleaning ofAir Filter

Take out the air filter and check if it is

contaminated.

Dismounting:

Remove the right side cover,take out the screw

and disassemble the air filter.

Cleaning:

Wash the filter i n cl ean washing oil and wipe it

dry with dry cloth.

Soak it in clean machine oil,squeeze it dry and fit

it back to position.

Recommended oil:15W/40QE

Caution:

The air filter element for use must be intact or the

enine will suck in dust and dirt, resulting in a shorter

service life of the engine.

Water should be prevented from entering into the

filter in washing the vehicle.

The filter shall neve

r

b

e cleanedwithgasoline oran

y

otheragentofalowignitionpoint.

15

AdjustmentofThrottle Cable

Make sure that the adjusting nut of the throttle

cable and l ocking nut work normally.

Check to see if the throttle twist grip is with the

required free operating movement.

Therequired free operating movement:2-6mm.

If the grip can not be so moved freely.turn the

adjust ing nut to ensure it.

After adjustment, start the engine and check for

the free operating movenent again,Repeat the

adjustment if necessary until it is as required.

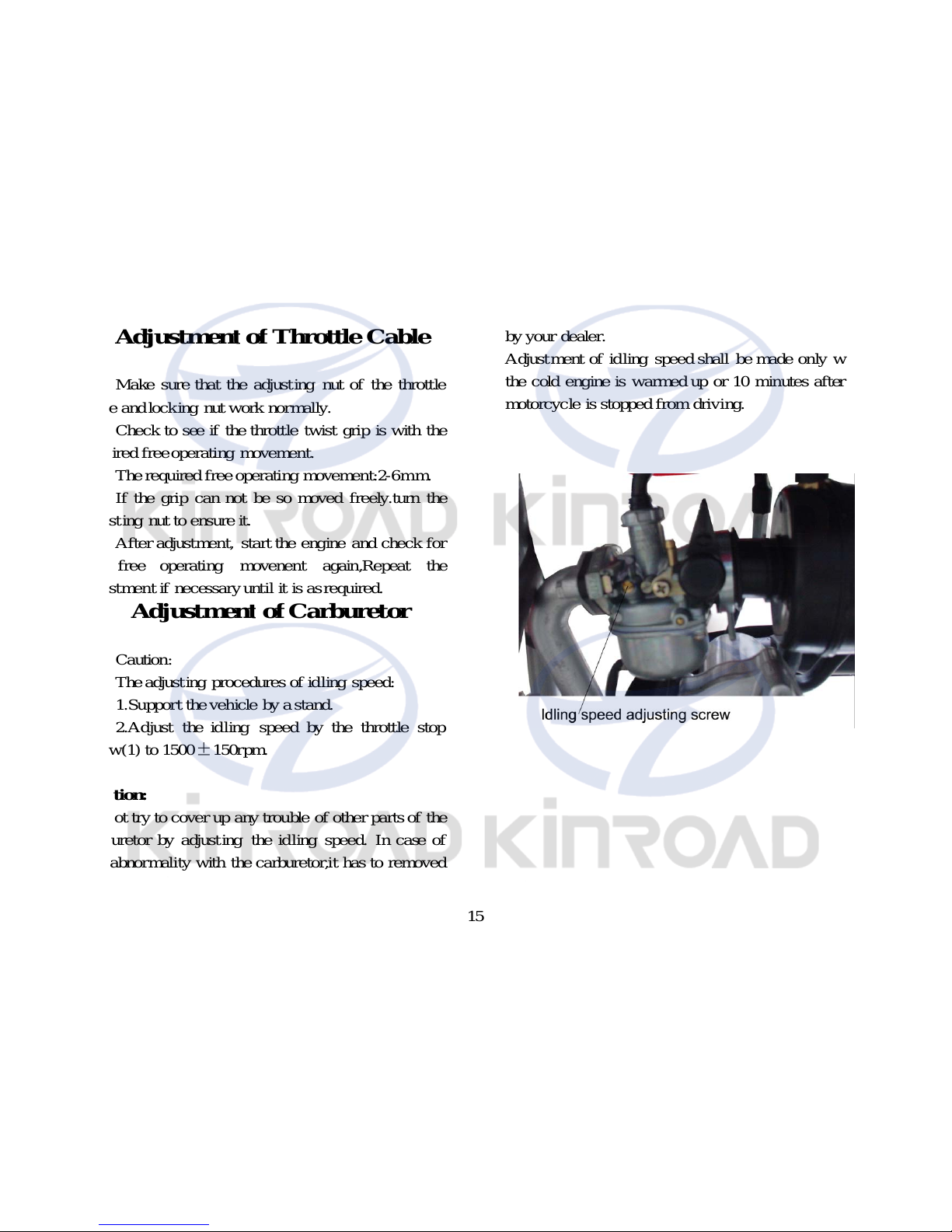

AdjustmentofCarburetor

Caution:

The adjusting procedures of idling speed:

1.Support the vehicle by a stand.

2.Adjust the idling speed by the throttle stop

screw(1) to 1500±150rpm.

Caution:

Do not try to cover up any trouble of other parts of the

carburetor by adjust ing the idling speed. In case of

any abnormality wi th the carburetor,it has to removed

by your dealer.

Adjust ment of idling speed shall be made only when

the cold engine is warmed up or 10 minutes after the

motorcycle is stopped from driving.

16

Check-up & AdjustmentofAir ValveGap

Noise will stem from too big gap of the air valve. However if there is too small gap or even no gap at all,

closing of the valve will be hindered, which will cause burn of the valve and output drop. Therefore, the air valve gap

must be checkedperiod ically.

The gap of the air valve should be inspected and adjusted with a cold engine by the following procedures:

1.Remove the capsof the central hole and the top hole (the ignition timing observation hole)in the left crankcase

cover.

2.Remove the capsof the two air valves on the cylinder head.

3.Insert the “T” key into the central hole of the crankcase cover, jam it against the nut of the flying wheel and

then turm the flying wheel clockwise nutilthe engraved “T” mark on the flying wheelalin\gns with the engravedline

on the top of the crankcase cover.Swing the rocking arm slightly.A l oose rocking arm(which indicates the existence

of clearance) shows that the pi ston is i n the upper stop position of the compressing t\stroke, where the valve can be

adjusted. A tight rocking arm means thar the piston is in the lower stop position of the compressing stroke, In this

case, continuously turn the “T” key clock wise for 360 degrees until the alignment of those engravd marks, where the

valve canbe adjustd,Af terwards, check the valve gap by inserting a feeler in betweenthe valve adjusting screw and

the end of the valve.

The specified air valve gap :0.05mm for the intake and exhaust valves respecively.

Brake Checking

(1) pull up the front andrearbrakes respectively and check for wearof the brake shoes. If the mark“△”onthe

brake drum cover aligns with that “△ ” on the brake cam, it means that the brake shoes are already worn to the limit

andhave to be replaced.

(2) Replacement should be carriedout at a designated service center and it is recommended that the parts made

byour company areusedtherein.

17

AdjustmentofFrontBrake

(1) The front brake has a free operating

movement of 10-20mm as shown in the figure on the

right side.

(2) inspect the reseivoir capacity and refill if

necessary in order to maintain proper level in the

reservior.This should be the major project of your

regular inspection

(3) check the front brake lining for its worm

depth.if its worn depth is up to the limited mark,

replace the brake lining.if the lining doesn’t have

limited mark but a concave slot as the figure,replace

the lining while its worn depth up to the bottom of

concave slot.replacement of a pair of linings shall be

conducted sumultaneously despite only one of them

is worn.

18

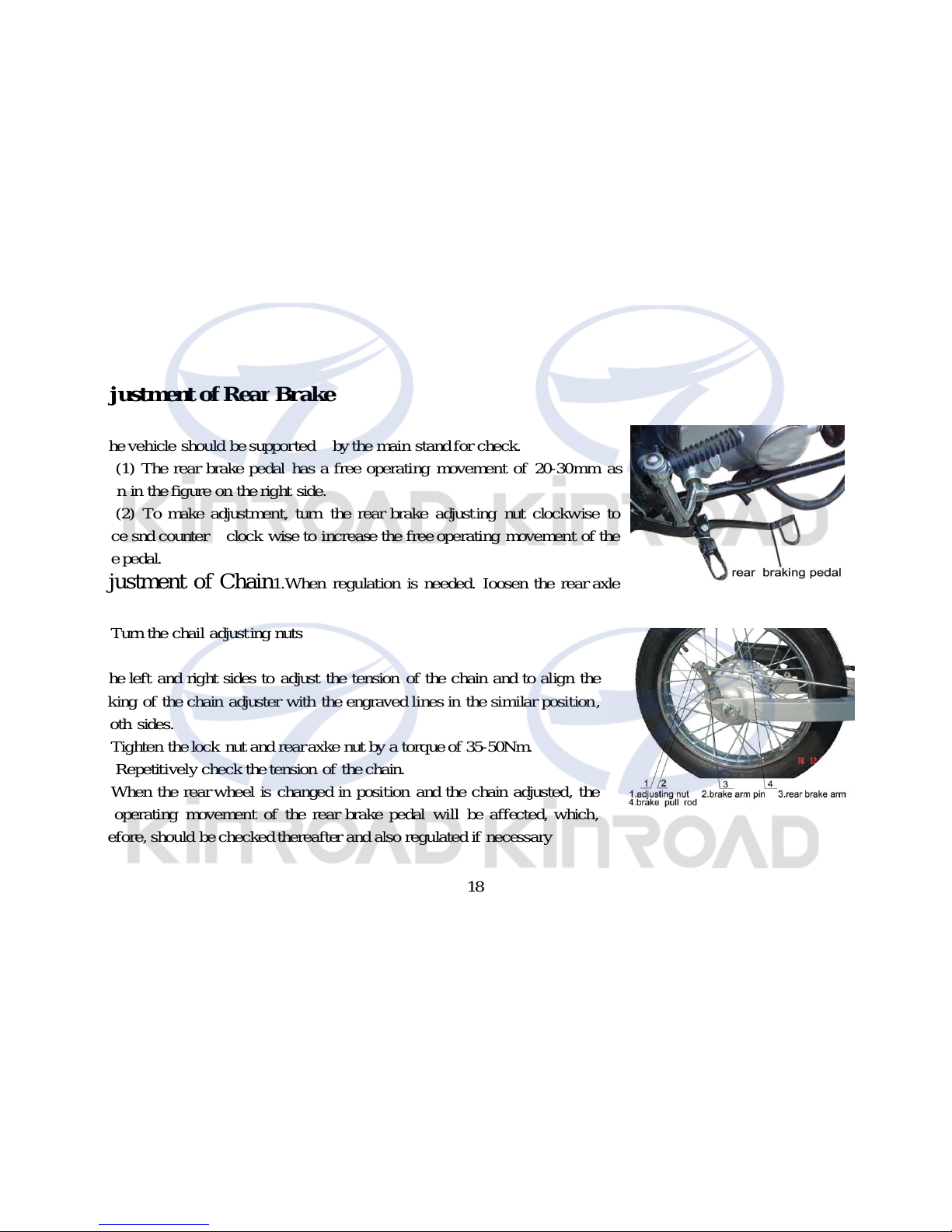

Adjustment ofRearBrake

★The vehicle should be supported by the main stand for check.

(1) The rear brake pedal has a free operating movement of 20-30mm as

shown in the figure on the right side.

(2) To make adjustment, turn the rear brake adjusting nut clockwise to

reduce snd counter clock wise to increase the free operating movement of the

brakepedal.

Adjustment of Chain

1.When regulation is needed. Ioosen the rear axle

nut

2.Turn the chail adjusting nuts

on the left and right sides to adjust the tension of the chain and to align the

marking of the chain adjuster with the engraved lines in the similar position,

on both sides.

3.Tighten the lock nut and rear axke nut by a torque of 35-50Nm.

4. Repetitively check the tension of the chain.

5.When the rearwheel is changed in position and the chain adjusted, the

free operating movement of the rear brake pedal will be affected, which,

therefore, should be checkedthereafter and alsoregulated if necessary

19

[Greasing procedures tothe driving chain]

1.Shut off the engine.

2.Add some machine oil or chain grease to the driving chain.

Attention:

When the rear wheel axil has moved to the back adjust ing limit , if excess loose be cause of wearing to the

driving chain, please change with a new one.

20

VehicleWashing

Cleaning the vehicle reularly can slow down the color fading of its body and make it easier to check if there is

anydamage and oil leakage with if.

Caution:

Washing the motorcycle with over-pressurized water may cause damage to some of its components. Therefore,

do not jet over-pressurized water directly on to the following parts:

——Wheel hub

—— Exhaust pipe

——Fuel tank and lower portion of cushion

——Carburetor

——Head lock andignition switch

——Meters

(1) After pre-wiping ,the vehicle should be washed with clean water to remove dirty residues so as to prevent

corrosion. Plastic subassemblies should be cleaned by wiping with cloth or foam soaked i n neutral detergent solution,

followed by washing with cleanwater.

(2) Afterthe cleanedvehicle is air dried, greasethe chain andrun the engine atidling speedfor a fewminutes.

(3) Prior to driving, carefully check the braking systemrepeatedly and repair or adjust it if necessary.

21

Instructions forStorage

Forthe motorcycle not tobeusedforalon

g

p

eriod

o

f

time, forexampl e,in wintertime,some stepsshould

b

etakentoperventmalfunction ofanddamagetoits

com

p

onen ts which migh

t

b

e cause

d

by

longstorage,

Besides,

b

efore the longstorage,proper maintenanc

ehastob

e carride out forfearthatit migh

t

b

eforgotte

n

whenthe vehicle isputbak into u seafterstorage.

1.Chan

g

eengine oil andoil filter.

2. Drain of

f

fuel from the fuel tank andcarburetor,

s

pray

atomized anti-r ustoil noto the inside wall ofthe

tank an

d

then close the tank.

Attention:

I

f

the storage will lastformore than one month,

feul in the carbureto

r

mustbefullydratinedoff,which is

ver

yimp

ortantbecausei t will helpensurethatthe

Carbureto

r

maintai ns its normalperformance afterthe

stora

g

e.

Warnin

g

:

Gasoline is inflammable an

dmay

causefire an

d

evenexplosion under certain conditions. Therefore, do

not smoke, make fire o

r

have anyfire lef

t

b

ehind on

drainin

g

offfuel.

3.Takeout the spar

k

plug,p

our about 15-20ml o

f

cleanengi ne oil into the cylinder, stepdown the kick

leve

rrep

ectit ivelyforseveral, stepdown the kick leve

rrep

etit ivelyforseveraltimes so asto have machine oil

distribute

d

all overthe engine andfinallyfit the spar

k

plug

back

on.

Attention:

The i

g

nition switch mustbesetto “ ¤ ”(off

)

p

lsitionbefore steppingdown the kick lever. T

o

p

rotec

t

the ignition system from damage, the spar

k

plug

should

b

einsertedin its capandearthed.

4.Was

h

the vehicle clean, wipeitdryandapplya

n

evencoatofwaxto thepaintedsurfaceandacoato

f

antir ustoil the chrome-pla ted surface.

5.Inflate the t

y

re asrequiredan

d

pad

the vehicle u

p

by

woodenblocks with the two wheels clearofthe

g

round.

6.Pu

t

the vehicle in a shadyandcoolplace fre

e

from humidityanddirectsunshine andcoverit

prop

erll

y

(

but not withplastic orothe

r

p

ainte

d

materials).Ifthereisgarage, store it therein.

Resumption ofServise afterstorage

22

1.Remoe the coverin

g

andcleanthe vehicle. Change the lubricatingoil ifthe vehicle ha

s

beenoff

serv ice fo

r

over4months.

2.Drain offthe remainingatomized antirustoil from the fuel tank, followedbyfillingit with fres

h

g

asoline

therein.

3.Prior to driving, all the requiredcheck-upsmustbe made. Itisbetterto drive it atalowspeedin aplace o

f

traffic safetyto testitsperformancebefore normal drive.

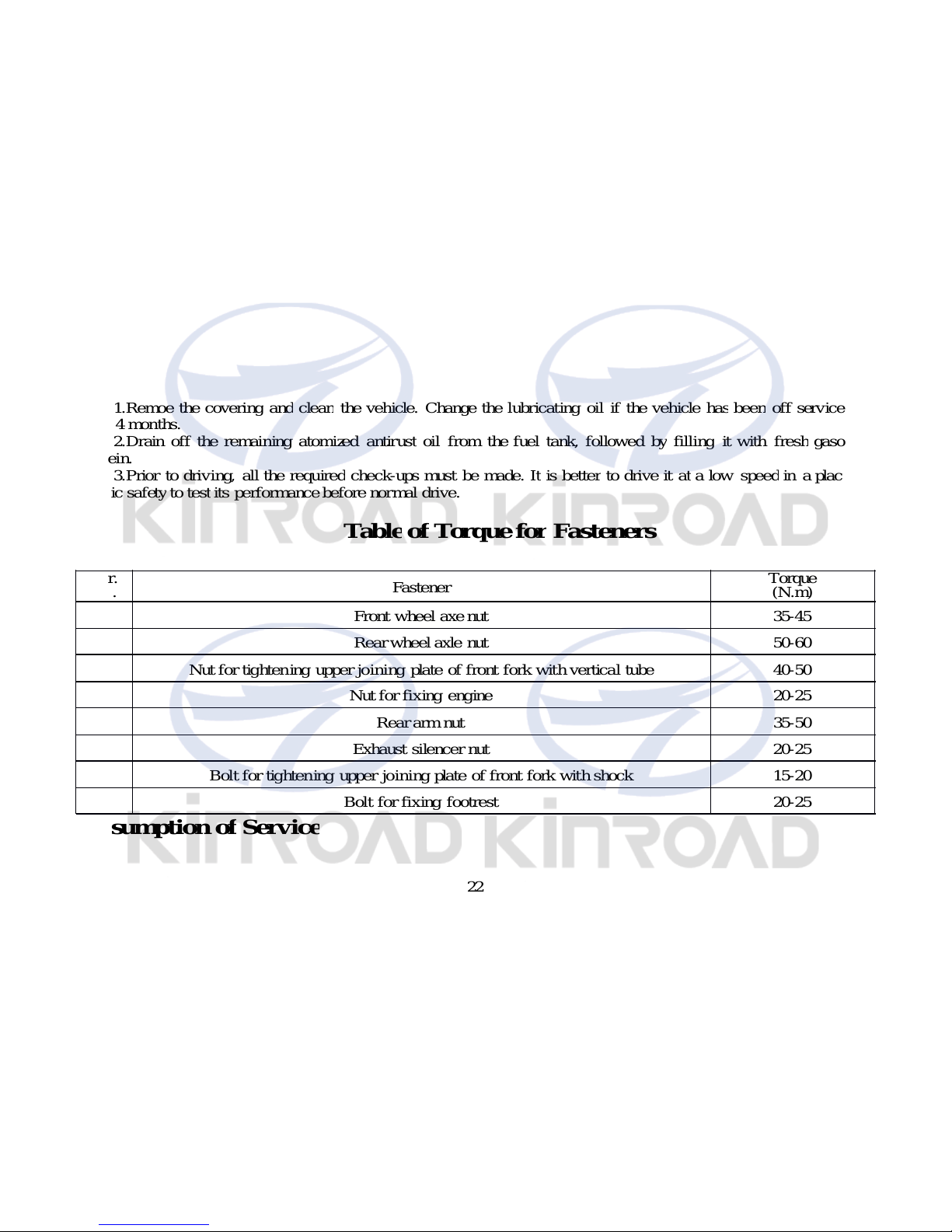

TableofTo rque forFasteners

Resumption o

f

Servic

e

S

er.

N

o.

Fastener

Tor

q

ue

(

N.m

)

1 Front wheel axe nut 35-45

2 Rear wheelaxle nut 50-60

3 Nut for tightening upper joining plate of front fork with vertical tube 40-50

4 Nut for fixing engine 20-25

5 Rear arm nut 35-50

6 Exhaust silencer nut 20-25

7 Bolt for tightening upper joining pl ate of front fork with shock 15-20

8 Bolt for fixing footrest 20-25

23

1.Remove the coverin

g

andcleanthe vehicle. Change the lubricatingoil ifthe vehicle ha

s

beenoff

serv ice fo

r

over4months.

2.Char

g

ethebatteryandremountit.

3.Drain of

f

the antirustsolution from the fuel tank, followedbyfillingfuel therein to therequiredlevel.

4.Prior to drivin

g

,testthe vehicle atlow speedin a saf

e

p

lace.

Maintenance Routine Dia

g

ram

The vehicle should

b

e undergood maintenance asspecifiedin the follow ingtable, where:

“I”means:Check, cleanin

g

,adjustment, lubrication and/orreplacement areneeded.

“C”means:Cleanin

g

is needed.

“

R

”means:Replacementis needed.

“A”menas”Ad

j

ust mentis needed.

“L”means::Lubrication is needed.

“*”means:This item o

f

maintenance shouldbe carriedout ata service centre. Itma

y

b

e also donebythe use

r

himself with referenceto this manualprovided he hasspecial tools, spar

e

p

artsandis capable ofthisjob.

“** ”means:This item ca

n

onl

y

b

e carriedoutbythe serviceman a

t

p

rof essional service centerin orderto

ensure safet

y

.

N

otes:1.Ma intenanceshouldbe conductedmore frequentlywhenthe motorcycod drevesin dustyareas.

2.When the read-ou

t

ofthe odometer exceeds the maximum figures specifiedin the table, maintenance should

b

estill cycledaccordingto the intreval ofmileage statedherein.

TableofMaintenance

24

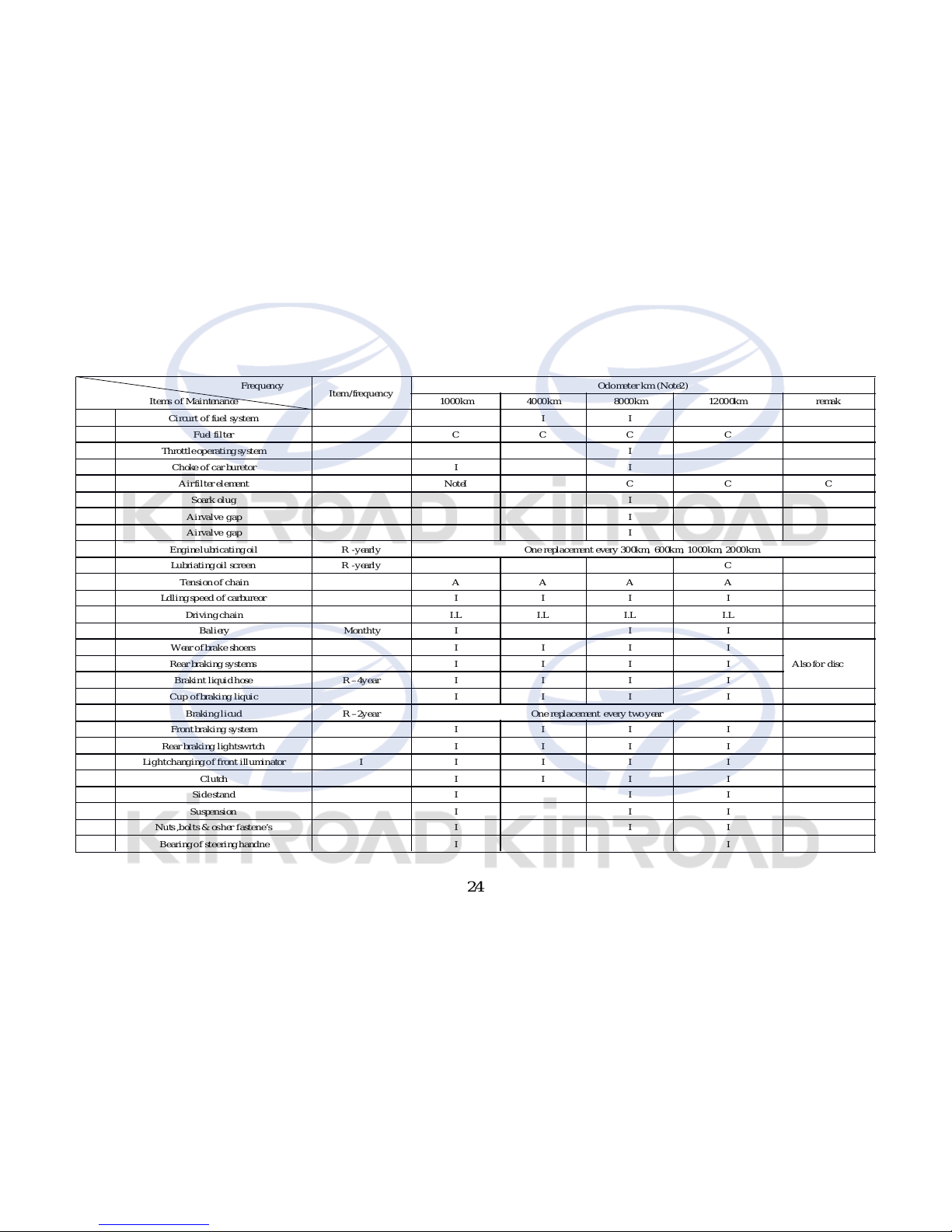

Frequency

Items of Maintenance

Item /frequency

Odometer km (Note2)

1000k m 4000k m 8000k m 12000k m remak

* Circurt offuel system I I

* Fuel filter C C C C

* Throttleoperatingsystem I

* Choke of car bu retor I I

Airfilterelement NoteI C C C

Soark olug I

* Airvalve gap I

Airvalve gap I

Enginelubricatingoil R -yearly One replacement every 300km, 600km, 1000km, 2000km.

Lubriatingoil screen R -yearly C

* Tensionof chain A A A A

* Ldlingspeed of carbureor I I I I

Drivingchain I.L I.L I.L I.L

Baliery Monthty I I I

Wearof brake shoers I I I I

AlsofordiscstyleRear braking systems I I I I

** Brakint l iq uid hose R –4year I I I I

** Cupofbrakingliquic I I I I

** Brakinglicud R–2year One replacement every twoyear

** Front braking system I I I I

* Rear braking lightswrtch I I I I

* Lightchangingof front illuminator I I I I I

Clutch III I

* Sidestand I I I

* Suspension I I I

** Nuts,bolts & osher fastene’s I I I

** Bearingof steeringhandne I I

25

V.ELECTRICAL DIAGRAM

Loading...

Loading...