User Guide

®

KINOVA

Gen3

Ultra lightweight

robot

Contents

Introduction............................................................................................................................................................... 6

Welcome.......................................................................................................................................................................6

About this document............................................................................................................................................... 6

Normal use definition..............................................................................................................................................6

Risk assessment........................................................................................................................................................7

EU Declaration of Incorporation.......................................................................................................................... 7

FCC Declaration of Comformity........................................................................................................................... 8

Safety directives and warnings......................................................................................................................... 10

Warranty.....................................................................................................................................................................12

Disclaimer.................................................................................................................................................................. 12

Acronyms and abbreviations.............................................................................................................................. 13

Robot components................................................................................................................................................. 16

Overview.....................................................................................................................................................................16

Base..............................................................................................................................................................................16

Controller quick connect system............................................................................................................. 17

Controller connector panel.......................................................................................................................20

Actuators...................................................................................................................................................................20

Interface module..................................................................................................................................................... 21

Vision module.......................................................................................................................................................... 23

Robot communications and network interfaces.........................................................................................24

Getting started........................................................................................................................................................27

Overview.................................................................................................................................................................... 27

What's in the case?................................................................................................................................................27

Manipulating the robot joints when the robot is powered off...............................................................28

Robot mounting options......................................................................................................................................28

Mounting the robot on a tabletop......................................................................................................... 28

Mounting the robot on a horizontal surface without the table clamp...................................... 30

Mounting the robot on a wall or ceiling...............................................................................................32

Robot power adapter and E-stop.....................................................................................................................34

Powering on the robot..........................................................................................................................................35

Power-up, booting, and initialization sequence.......................................................................................... 35

Resetting the robot to factory settings......................................................................................................... 36

Operating the robot...............................................................................................................................................36

Supported gamepad controllers............................................................................................................. 36

Home and retract positions...................................................................................................................... 41

Putting the robot into admittance using the interface buttons....................................................41

Connecting a computer to the robot...............................................................................................................42

Connecting a computer to the robot via Ethernet (for the first time)........................................42

KINOVA® KORTEX™ Web App...................................................................................................................44

Changing the robot wired connection IP address and connecting the robot to a LAN..........46

Connecting a computer to the robot via Wi-Fi.................................................................................. 46

Dimensions, specifications, and capabilities................................................................................................ 48

Schematic and dimensions - 7 DoF spherical wrist...................................................................................48

Technical Specifications.......................................................................................................................................49

Sensors.......................................................................................................................................................................52

Base readings available............................................................................................................................. 53

Tool readings available...............................................................................................................................53

Actuators readings available................................................................................................................... 54

Interface readings available..................................................................................................................... 54

Gripper readings available........................................................................................................................ 54

Effective workspace.............................................................................................................................................. 55

Maximum payload vs. workspace.................................................................................................................... 56

Interface, expansion, and vision........................................................................................................................57

Interface module expansion - tips for installing tools............................................................................. 57

End effector reference design................................................................................................................. 58

Removing end cap from Interface module...........................................................................................61

Robotiq Adaptive Grippers installation (optional).............................................................................61

Robotiq 2F-85 Gripper tool configuration........................................................................................... 63

Interface module bolting pattern...........................................................................................................64

Interface module user expansion connector pinout........................................................................64

Using interface module expansion to control devices via API......................................................66

Spring-loaded connector pinout............................................................................................................. 66

Accessing Vision module color and depth streams................................................................................... 67

Concepts and terminology..................................................................................................................................69

Robot key concepts............................................................................................................................................... 69

Terminology reference...........................................................................................................................................71

General mathematics and robotics.........................................................................................................71

Features, components and functionalities.......................................................................................... 73

Control and Operation Modes..................................................................................................................74

Robot control...........................................................................................................................................................75

High-level and low-level robot control.......................................................................................................... 75

High-level and low-level robot control methods overview.................................................................... 75

Control features...................................................................................................................................................... 77

Singularity avoidance.................................................................................................................................. 77

Protection zones........................................................................................................................................... 77

Angular limits.................................................................................................................................................78

Cartesian limits.............................................................................................................................................80

Control modes overview..................................................................................................................................... 80

Trajectory control modes........................................................................................................................... 81

Joystick control modes...............................................................................................................................82

Admittance modes.......................................................................................................................................82

Configurations and safeties...............................................................................................................................84

Configurable parameters.................................................................................................................................... 84

Control library configuration................................................................................................................... 84

Base configuration.......................................................................................................................................85

Actuators configuration.............................................................................................................................86

Interface configuration...............................................................................................................................86

Device configuration....................................................................................................................................87

Vision configuration.....................................................................................................................................87

Safety items.............................................................................................................................................................88

Base (controller) safeties..........................................................................................................................88

Actuators safeties........................................................................................................................................89

Interface module safeties..........................................................................................................................91

KINOVA® KORTEX™ Web App User Guide........................................................................................................93

Introduction.............................................................................................................................................................. 93

Purpose...................................................................................................................................................................... 93

Device availability of Web App..........................................................................................................................93

Platform and browser support..........................................................................................................................95

User login.................................................................................................................................................................. 95

Web App layout and navigation........................................................................................................................96

Robot control panel..............................................................................................................................................101

Pose virtual joystick control....................................................................................................................101

Angular virtual joystick control.............................................................................................................102

Virtual joystick keyboard shortcuts.....................................................................................................103

Admittance modes panel.........................................................................................................................105

Actions panel................................................................................................................................................105

Camera panel............................................................................................................................................... 106

Snapshot tool...............................................................................................................................................106

Main pages..............................................................................................................................................................106

Configurations page group......................................................................................................................106

Safeties........................................................................................................................................................... 110

Operations page group..............................................................................................................................110

Systems page group...................................................................................................................................121

Users................................................................................................................................................................125

KINOVA® KORTEX™ Developer Guide............................................................................................................. 128

Introduction............................................................................................................................................................ 128

Devices and services...........................................................................................................................................128

Available services.................................................................................................................................................129

Users, connections and sessions....................................................................................................................129

Services, methods, and messages................................................................................................................. 130

KINOVA® KORTEX™ API and Google Protocol Buffer................................................................................130

Service client-server model..............................................................................................................................130

Notifications............................................................................................................................................................ 131

Blocking and non-blocking calls...................................................................................................................... 131

Robot servoing modes.........................................................................................................................................131

High-level servoing....................................................................................................................................132

Low-level servoing.....................................................................................................................................132

Device routing........................................................................................................................................................ 133

Error management............................................................................................................................................... 133

KINOVA® KORTEX™ GitHub repository...........................................................................................................133

KINOVA® KORTEX™ ROS packages and GitHub repository overview..................................................134

KINOVA® KORTEX™ MATLAB® API and GitHub repository overview................................................... 134

Working with camera streams using GStreamer...................................................................................... 134

Windows command examples............................................................................................................... 135

Linux command examples.......................................................................................................................135

KINOVA® KORTEX™ ROS vision module package and Github overview..............................................136

Guidance for advanced users........................................................................................................................... 137

Overview...................................................................................................................................................................137

Reference frames and transformations....................................................................................................... 137

Standard Cartesian reference frames................................................................................................. 137

Homogeneous transforms.......................................................................................................................137

Homogeneous transform matrices - 7 DoF spherical wrist........................................................ 138

Vision module sensors reference frames..........................................................................................140

Denavit-Hartenberg (DH) parameters - 7 DoF spherical wrist................................................... 141

7 DoF singular configurations..........................................................................................................................143

Inertial parameters definition..........................................................................................................................145

Inertial parameters of the 7 DoF robot........................................................................................................ 145

Maintenance and troubleshooting................................................................................................................. 149

Maintenance...........................................................................................................................................................149

Troubleshooting..................................................................................................................................................... 151

Base controller LEDs................................................................................................................................. 152

How to respond to safety warnings and errors.............................................................................. 152

Contacting Kinova support...................................................................................................................... 154

KINOVA® Gen3 Ultra lightweight robot User Guide 6

Introduction

Welcome

Welcome to the KINOVA® Gen3 Ultra lightweight robot.

Thank you for choosing our robot as a tool for your pathbreaking research needs.

This document is meant to provide you with all the information you need to get up and running with your

new robot and get the most out of it.

We are here to help you in your journey. If you need any help or have any questions about how to get to

where you're going with the robot, please feel free to contact our support team:

www.kinovarobotics.com/support

About this document

User Guide contents and warnings.

Read all instructions before using this product and any third-party options.

Read all warnings on the product and in this guide.

This document contains information regarding product setup and operation. It is intended for Kinova

product end users.

All third-party product names, logos, and brands appearing herein are the property of their respective

owners and are for identification purposes only. Their use in this document is not meant to imply

endorsement by Kinova.

Kinova has made every effort to ensure that this document is accurate, accessible and complete. As

part of our commitment to continuous improvement, we welcome any comments or suggestions at

www.kinovarobotics.com/support.

From time to time, Kinova will make udpates to this document. To download the most up to date version

of this document, visit the product technical resources page at www.kinovarobotics.com/knowledge-hub/

gen3-ultra-lightweight-robot.

For general inquiries please contact us at +1 (514) 277-3777

Normal use definition

This section describes the normal use of the robot.

The definition of normal use includes lifting, pushing, pulling, or manipulating (without a gripper or other

end effector attached) a maximum load of:

• mid-range, continuous: 4 kg

• full-reach, temporary: 4.5 kg

• full-reach, continuous 1.1 kg

The robot is designed to hold, move, and manipulate objects in the user environment. However, for some

loads in certain positions (near maximum load and reach), holding an object for an extended period of time

may result in heating. To protect the robot hardware from excessive heat, safety thresholds shut down the

robot if the temperature rises above a certain threshold. Before this is reached, an API notification will be

rendered as a user alert on the KINOVA® KORTEX™ Web App.

The robot includes a number of temperature-related safeties:

• base - CPU core and ambient temperatures

• actuators - CPU core and motor temperatures

• interface module - CPU core and gripper motor temperatures

If you receive any temperature warnings, put down any object as soon as is practical and place the robot

into a stable rest position to allow it to cool down.

KINOVA® Gen3 Ultra lightweight robot User Guide 7

During normal operation, the robot joints are subject to heating. The joints are normally covered in plastic

rings to protect the user from the metal surfaces which may become hot.

Risk assessment

Before proceeding it is imperative that a risk assessment be performed (note that this is required by law

in many countries). As it is a machine, the safety of the robot depends on how well it is integrated with its

environment and with other machines.

The recommended international standards for conducting a risk assessment are as follows:

• ISO 12100

• ISO 10218-2

The risk assessment should take into consideration all activities carried out in the context of the robot

application, including (but not limited to):

• teaching the robot (during set-up)

• development of the robot installation

• robot troubleshooting

• robot maintenance

• everyday robot operation

The risk assessment must be completed before integration of the robot in an application and should address

configuration settings as well as the need for any additional emergency stop buttons.

EU Declaration of Incorporation

The Declaration of Conformity is a self-declared assessment produced and signed by a manufacturer of a

product to assert that the product meets all of the requirements of the applicable directives.

In the case of KINOVA® Gen3 Ultra lightweight robot KR L53 0007, the applicable directives that are eligible

for CE declaration are the following:

• Machinery Directive 2006/42/EC

• Electromagnetic Compatibility (EMC) Directive 2014/30/EU

The Machinery Directive 2006/42/EC Article 2 (g) states that:

‘Partly completed machinery’ means an assembly which is almost machinery but which cannot in

itself perform a specific application. A drive system is partly completed machinery. Partly completed

machinery is only intended to be incorporated into or assembled with other machinery or other

partly completed machinery or equipment, thereby forming machinery to which this Directive

applies; is not eligible to CE marking by its own because it is an “incomplete machine.”

Based on this definition, our product Gen3 Ultra lightweight robot KR L53 0007 is considered partly

completed machinery because it has no specific application. The robot application is determined when it is

incorporated in a system, given an end-effector and expected workpieces. Once the product is incorporated

into a complete system and the system complies to all applicable directives, then the integrator is permitted

to issue a Declaration of Conformity and affix a CE marking to the completed machine. For incomplete

machinery, a Declaration of Incorporation (DoI) is required from the manufacturer. The Declaration of

Incorporation for the robot is inserted below.

KINOVA® Gen3 Ultra lightweight robot User Guide 8

EU DECLARATION OF INCORPORATION (In accordance with ISO/IEC 17050-1:2004)

Manufacturer:

Kinova Robotics

4333 Boulevard de la Grande-Allée,

Boisbriand, QC J7H 1M7, Canada

Telephone: +1 514-277-3777

Manufacturer’s authorized EU representative :

Kinova Europe GmbH

Grosskitzighofer. Str. 7a,

86853 Langerringen

Telephone: +49 8248 8887-928

Description and identification of the partially completed machine(s):

Product and function : Robot (Multi-axis manipulator)

Models :

KINOVA® Gen3 Ultra lightweight robot L53 0007

KINOVA® Gen3 Ultra lightweight robot L53 0006

KINOVA® Gen3 Ultra lightweight robot shall only be put into service upon being integrated into a

final complete machine (robot system, cell or application), which conforms with the provisions of the

Machinery Directive and other applicable Directives.

When this incomplete machine is integrated and becomes a complete machine, the integrator is

responsible for determining that the completed machine fulfils all applicable directives and updating the

relevant harmonized standards, other standards and documents.

It is declared that the above products, for what is supplied, fulfil the following directives as detailed

below:

• Machinery Directive 2006/42/EC The following essential health and safety requirements are

applied and fulfilled :

1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.4.3, 1.2.6, 1.3.4, 1.3.8.1, 1.5.1,

1.5.2, 1.5.6, 1.5.10, 1.6.3, 1.7.2, 1.7.4

• Electromagnetic Compatibility

(EMC) Directive 2014/30/EU

The partly completed machinery is also compliant with the following relevant standards:

• IEC 62368-1:2014/AC:2015 Audio/video, information and communication technology

equipment - Part 1: Safety requirements

• ISO 12100:2010 Safety of machinery - General principles for design - Risk

assessment and risk reduction

• IEC 61000-6-1:2016 Electromagnetic compatibility (EMC) - Part 6-1: Generic

standards - Immunity for residential, commercial and lightindustrial environments

• IEC 61000-6-3:2016 Electromagnetic compatibility (EMC) - Part 6-3: Generic

standards - Emission standard for residential, commercial and

light-industrial environments

The manufacturer or its authorised representative will undertake to transmit, in response to a reasoned

request by the national authorities, relevant information on the partly completed machinery.

The Technical Construction File is kept and maintained at the corporate headquarters of Kinova

Robotics located at 4333 Boulevard de la Grande-Allée, Boisbriand, QC J7H 1M7, Canada.

Louis-Joseph Caron L'Écuyer

Chief Operaon Officer & Co-Founder

Boisbriand Canada, 08 August 2019

KINOVA® Gen3 Ultra lightweight robot User Guide 9

FCC Declaration of Comformity

FCC Regulatory Disclosures: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected

• Consult the dealer or an experienced radio/TV technician for help

The Declaration of Conformity for the robot is inserted below.

FCC SUPPLIER'S DECLARATION OF CONFORMITY

Manufacturer:

Kinova Robotics

4333 Boulevard de la Grande-Allée,

Boisbriand, QC J7H 1M7, Canada

Telephone: +1 514-277-3777

Description and identification of the devices:

Product and function : Robot (Multi-axis manipulator)

Models :

KINOVA® Gen3 Ultra lightweight robot L53 0007

KINOVA® Gen3 Ultra lightweight robot L53 0006

These devices contains the following certified modular transmitter : FCC ID A3LSIP007AFS00

These devices comply with Part 15 of the FCC Rules and Regulations for Information Technology

Equipment :

• FCC 47 CFR Part 15, Subpart B – Verification

Operation is subject to the following two conditions:

(1) these devices may not cause harmful interference, and

(2) these devices must accept any interference received, including interference that may cause undesired

operation.

We, the responsible party Kinova Robotics, declare that the products Gen3 Ultra lightweight robot KR

L53 0007 and Gen3 Ultra lightweight robot KR L53 0006 are to conform to the applicable FCC rules and

regulations. The method of testing was in accordance with the appropriate measurement standards, and

all necessary steps have been taken to ensure that all production units of these devices will continue to

comply with the Federal Communications Commission's requirements.

Boisbriand Canada, 11 October 2019

Louis-Joseph Caron L'Écuyer

Chief Operaon Officer & Co-Founder

KINOVA® Gen3 Ultra lightweight robot User Guide 10

Safety directives and warnings

Directives, warnings and safety considerations for the KINOVA®Gen3 Ultra lightweight

robot.

IMPORTANT

Before operating the robot for the first time, ensure that you have read, completely understood and

complied with all of the following directives, warnings and cautionary notes. Failure to do so may result in

serious injury or death to the user, damage to the robot, or a reduction in its useful life.

Table 1: Safety

There is no mechanical brake on the robot. If the power supply is cut or an unrecoverable error

occurs, be aware that the robot will fall. However, mechanisms are in place within the actuators will

slow the descent in the absence of external power.

For your personal

safety, and that of others, it is

strongly recommended that

the following be carried out:

For your personal

safety, and that of others,

never:

- risk assessment, before integration of the robot into a given application.

- hazard analysis, before integration into an environment which includes

atomized flammable dust / particles or explosive / flammable gases, etc.

- use the robot near a flame or source of heat.

- use the robot to submerge objects in water.

- exceed the maximum specified payload.

- attempt to stop the robot or prevent its movement by holding it (except

in admittance mode).

- install the robot base within 20 cm of your body (base contains a Wi-Fi

transmitter).

- power up and boot, reboot, or update the firmware of the robot unless

the robot is in a stable position.

- the robot does not encounter any obstacles (persons or objects).

Although inherently safe in its default configuration, disabling the robot

safeties requires that the user be responsible for ensuring a secure

working space.

- the end effector never collides with a hard surface.

For your personal

safety, and that of others,

always ensure that:

- the grasping of objects by gripper fingers is stable, to prevent the risk of

dropped or thrown objects (if using a gripper).

- the wrist is supported before turning the power off (otherwise it may fall

and cause damage).

- eye protection is worn when manipulating fragile objects with the robot.

- the working area is safe when containers of hot (or extremely cold)

liquids are to be manipulated with the robot.

- the robot working area is safe if sharp objects are to be handled by the

robot

- the robot has its base securely fixed to the work surface when in

operation.

- before using the robot, it is confirmed that there are no warnings.

- the robot is protected adequately before being used near any messy

process (e.g. welding or painting).

KINOVA® Gen3 Ultra lightweight robot User Guide 11

When using a tool and payload with the robot, ensure that the robot is configured with the

parameters of the tool and payload using the Web App or robot Kinova.Api.ControlConfig API.

For more details, see the API documentation on GitHub and the "Interface, expansion, and vision"

section of the robot User Guide. The robot may behave in an unexpected manner if the tool and payload

parameters are not properly configured.

When mounting the robot in a wall or ceiling mount, ensure that special considerations and

configurations set out in the user guide are followed, including analysis of the mounting surface, use of

the base locking screw, orientation of the base connector panel, and configuration of the gravity vector.

High-level force control is supported as an experimental feature. Users should exercise caution.

Low-level torque control is for advanced users only and should only be used by users who

know what they are doing. It is very important to carefully monitor the torque commands sent to the

actuators to ensure that excessive values are not sent. Incorrect use can lead to rapid movements that

can be dangerous for people and equipment. Make sure that the area around the robot is clear before

experimenting with torque control.

Do not power on the product if any external damage to the vision module is apparent.

Do not attempt to open the vision module.

To avoid eyesight injury from wide angle infrared laser light, do not view the front-facing surface of

the vision module through magnifying optical elements.

The robot should not be used without the provided emergency stop connected.

Do not operate the robot when the relative humidity exceeds the maximum specified limit. In

such a case, put down any object in the gripper, bring the robot to a resting position and wait until the

humidity decreases to an allowable value.

The robot is not certified for use in applications in sterile environments (e.g. food production,

pharmaceuticals, medical, surgical).

Table 2: General

Do not connect the USB ports on the base to one another.

It is recommended that surge protection be used to protect the robot against external surges on

the main AC line which might be caused by lightning or other abnormal conditions.

The base must be mounted as specified in the installation section, with particular attention to the

bolt pattern, strength requirements and any table or tripod-specific mounting.

Any end effector must be mounted as specified in the installation section (including bolt pattern,

power requirements, etc.).

Table 3: Maintenance

Do not use the robot in heavy rain. If this happens, contact Kinova support to schedule

maintenance by an authorized Kinova technician.

KINOVA® Gen3 Ultra lightweight robot User Guide 12

Immediately following exposure to saline air conditions, contact Kinova support to schedule

maintenance by authorized Kinova technician.

The controller mating interface must be kept free of dust and moisture to protect the electrical

contacts. Wipe down the surface with a soft dry cloth to keep the surface of the interface clean.

Warranty

This section describes the Kinova warranty terms.

Subject to the terms of this clause, Kinova warrants to End User that the Products are free of defects in

materials and workmanship that materially affect their performance for a period of two (2) years from the

date Kinova ships the Products to the End User ("Delivery Date").

Kinova agrees to repair or replace (at Kinova's option) all Products which fail to conform to the relevant

warranty provided that:

1. notification of the defect is received by Kinova within the warranty period specified above;

2. allegedly defective Products are returned to Kinova, (at the End User’s expense, with Kinova's prior

authorization) within thirty (30) days of the defect becoming apparent;

3. the Products have not been altered, modified or subject to misuse, incorrect installation, maintenance,

neglect, accident or damage caused by excessive current or used with incompatible parts;

4. the End User is not in default under any of its obligations under this Agreement;

5. replacement Products must have the benefit of the applicable warranty for the remainder of the

applicable warranty period.

If Kinova diligently repairs or replaces the Products in accordance with this section, it will be deemed to

have no further liability for a breach of the relevant warranty.

Allegedly defective Products returned to Kinova in accordance with this contract will, if found by Kinova

on examination not to be defective, be returned to the End User. Kinova may charge a fee for examination

and testing.

The warranty cannot be assigned or transferred and is to the sole benefit of the End User.

Where the Products have been manufactured and supplied to Kinova by a third party, any warranty granted

to Kinova in respect of the Products may be passed on to the End User.

Kinova is entitled in its absolute discretion to refund the price of the defective Products in the event that

such price has already been paid.

Disclaimer

KINOVA® and the Kinova logo are registered trademarks of Kinova inc., herein referred to as Kinova.

KORTEX™ is a trademark of Kinova inc.

All other brand and product names are trademarks or registered trademarks of their respective owners.

The mention of a product name does not necessarily imply an endorsement by Kinova. This manual is

furnished under a lease agreement and may only be copied or used in accordance with the terms of

such lease agreement. Except as permitted by the lease agreement, no part of this publication may be

reproduced, stored in any retrieval system, or transmitted, modified in any form or by any means, electronic,

mechanical, recording, or otherwise, without prior written consent of Kinova.

The content of this manual is furnished for informational use only and is subject to change without notice.

It should not be construed as a commitment by Kinova. Kinova assumes no responsibility or liability for any

errors or inaccuracies that may appear in this document.

Changes are periodically made to the information herein and will be incorporated into new editions of this

publication. Kinova may make improvements and/or changes to the products and/or software programs

described in this publication at any time.

Any questions or comments concerning this document, the information it contains or the product it

describes may be addressed through the support page on the Kinova website:

KINOVA® Gen3 Ultra lightweight robot User Guide 13

www.kinovarobotics.com/support

Kinova would like to thank you for your contribution, while retaining the right to use or distribute whatever

information you supply in any way it believes appropriate (without incurring any obligations to you).

Acronyms and abbreviations

API

Application Programming Interface

CIDR

Classless Inter-Domain Routing

CISPR

Comité International Spécial des Perturbations Radioélectriques

EE

End Effector

EMI

Electromagnetic Interference

FOV

Field of View

fps

frames per second

GPIO

General-Purpose Input/Output

HDMI

High-Definition Multimedia Interface

IC

Integrated Circuit

IEEE

Institute of Electrical and Electronics Engineers

I2C

Inter-Integrated Circuit (bus)

I/O

Input / Output

IP

Ingress Protection or Internet Protocol

IT

Information Technology

ISO

International Organization for Standardization

KINOVA® Gen3 Ultra lightweight robot User Guide 14

LED

Light-Emitting Diode

n/c

no connection

NVRAM

Non-Volatile Random-Access Memory

PC

Personal Computer

ROS

Robot Operating System

RPC

Remote Procedure Call

RPM

Revolutions Per Minute

RS

Recommended Standard

Rx

Receiver

SSID

Service Set IDentifier

TCP

Transmission Control Protocol

Tx

Transmitter

UART

Universal Asynchronous Receiver-Transmitter

UDP

User Datagram Protocol

USB

Universal Serial Bus

UL

Underwriters Laboratory

UV

Ultraviolet light

VLAN

Virtual Local Area Network

KINOVA® Gen3 Ultra lightweight robot User Guide 15

WEEE

Waste of Electrical and Electronic Equipment

KINOVA® Gen3 Ultra lightweight robot User Guide 16

Robot components

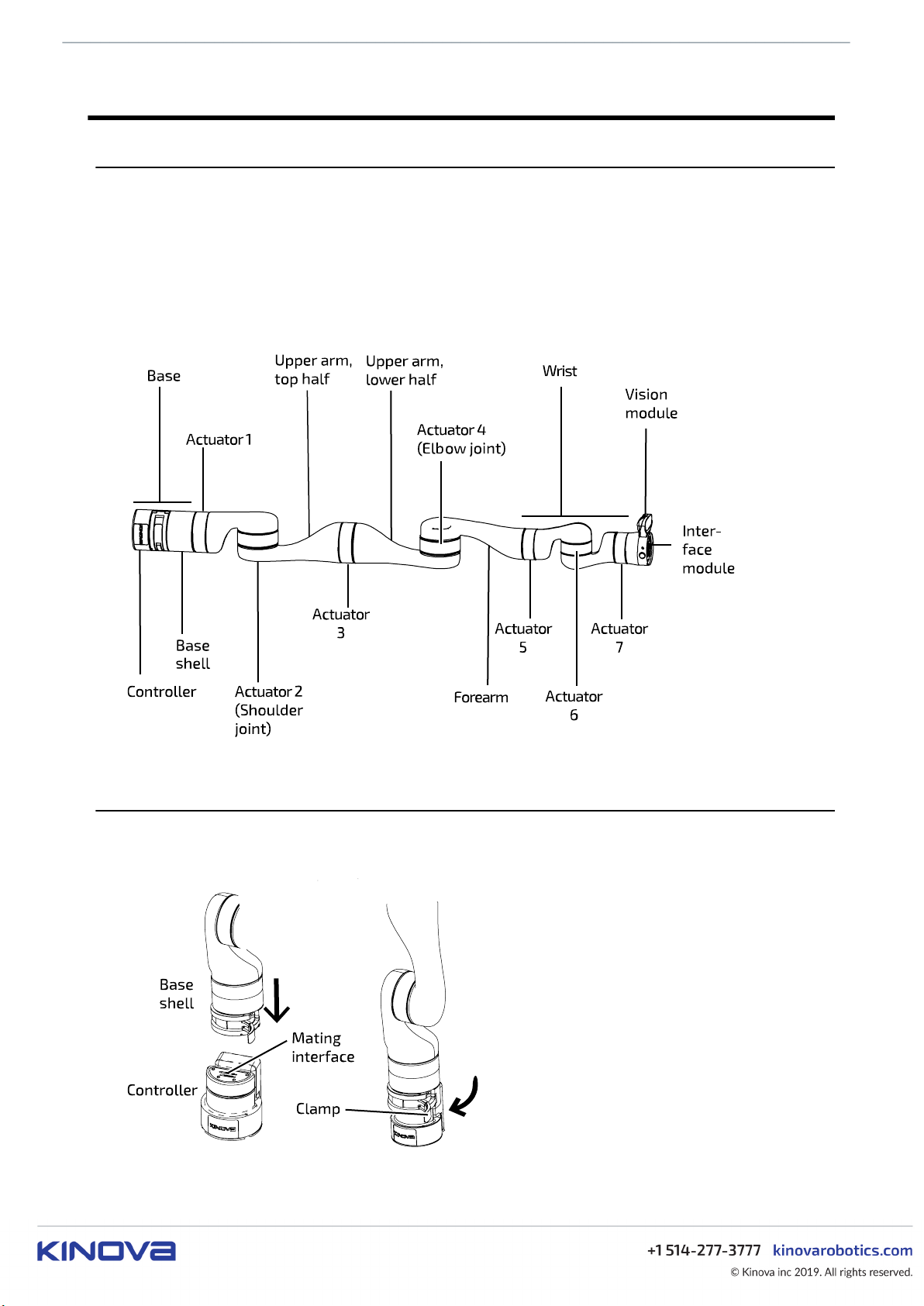

Overview

This section describes the main components of the KINOVA® Gen3 Ultra lightweight robot.

The robot consists of:

• base (base shell and controller)

• actuators

• interface module

• vision module

The following image shows the main components of the robot.

Figure 1: Robot main components (7 DoF model shown)

Base

This section describes the purpose, components, and functionalities of the robot base.

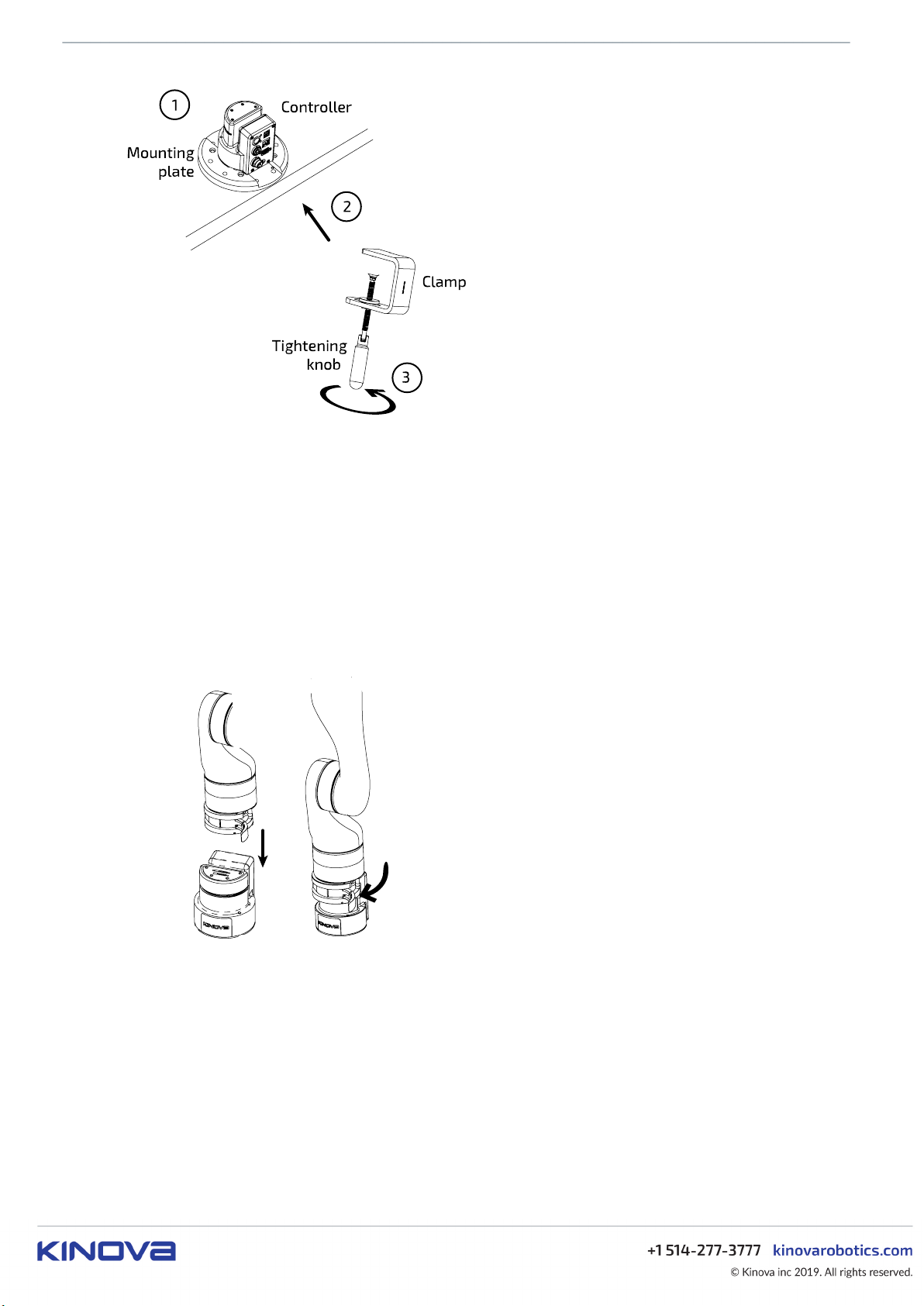

The Gen3 Ultra lightweight robot base features a quick connect base.

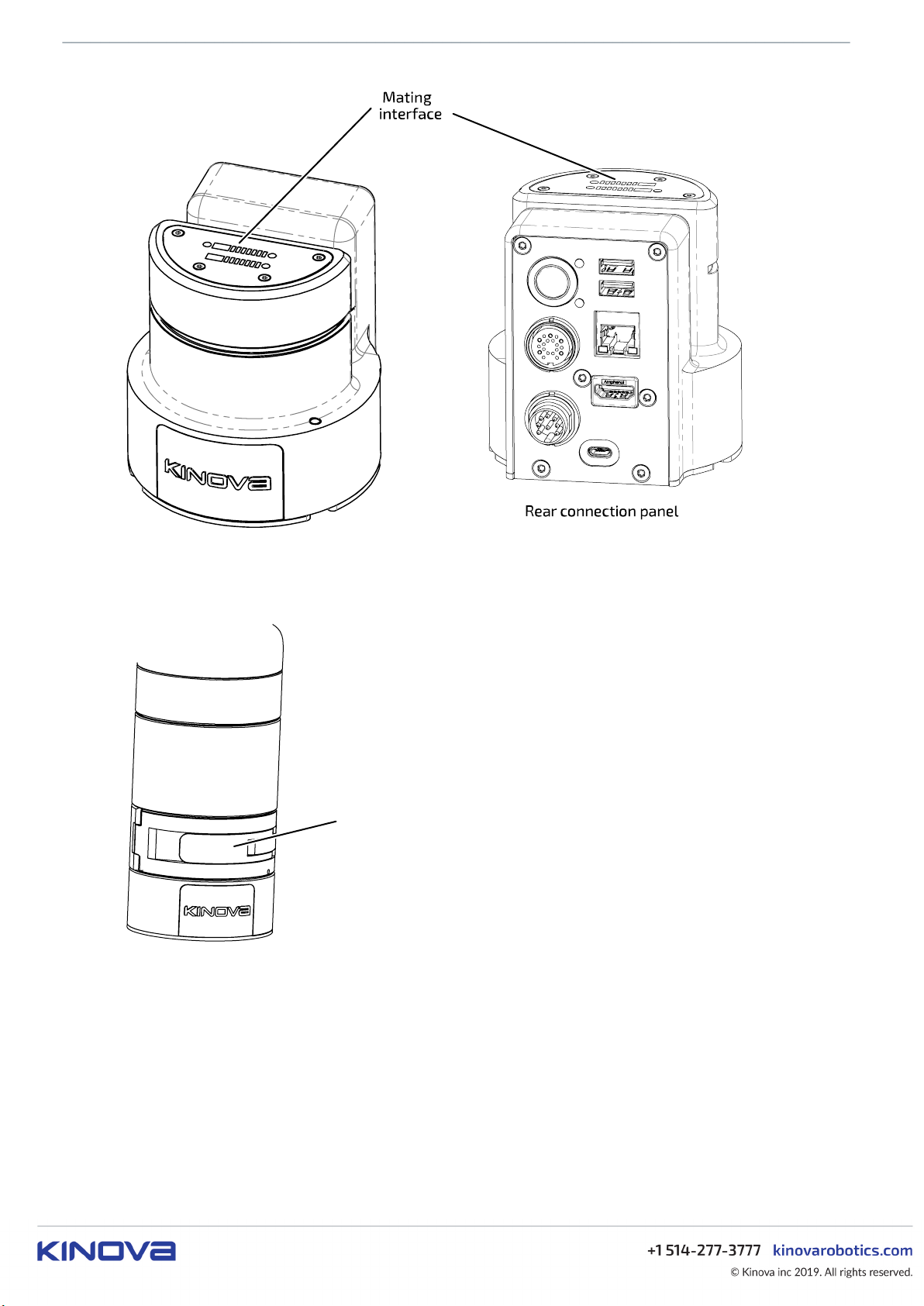

Figure 2: Quick connect base

KINOVA® Gen3 Ultra lightweight robot User Guide 17

The base is a two-part structure securing the robot onto its physical mounting point and connecting the

robot to power and control signals. This consists of:

• controller

• base shell

The controller is the "brains" of the robot. The internal components of the controller include:

• CPU

• Wi-Fi / Bluetooth adapter (Only Wi-Fi is used at present)

• Ethernet switch

• USB hub

• temperature sensor

• accelerometer/gyroscope

A Linux web server runs on the controller and manages connectivity between the controller and the arm

devices, and between the controller and an external computer.

The controller includes a connector panel at the rear for connecting to power and external devices.

The controller has four mounting holes (M6) on its underside. The controller is shipped connected with

screws to a circular mounting plate with through holes for mounting to surfaces and a slot to put a clamp

between the robot and the plate for quick setup and takedown tabletop mounting.

Figure 3: Mounting plate

The mounting plate can also be removed from the controller by removing the screws, giving access to the

four mounting holes and allowing the controller to be mounted directly on the surface.

The base shell, meanwhile, is the bottom part of the robotic arm shell connected to the first actuator. It

mounts onto the controller and is secured in place with an integrated clamp.

A mating interface on the top of the controller provides an electrical connection between the base shell

and the controller.

Note: The controller mating interface needs to be kept free of dust and moisture to protect the electrical

contacts. Wipe down with a soft dry cloth to keep the interface clean.

The clamping mechanism and mating interface allow the robot to be quickly and easily removed from the

controller while leaving the controller mounted in place with cables still connected.

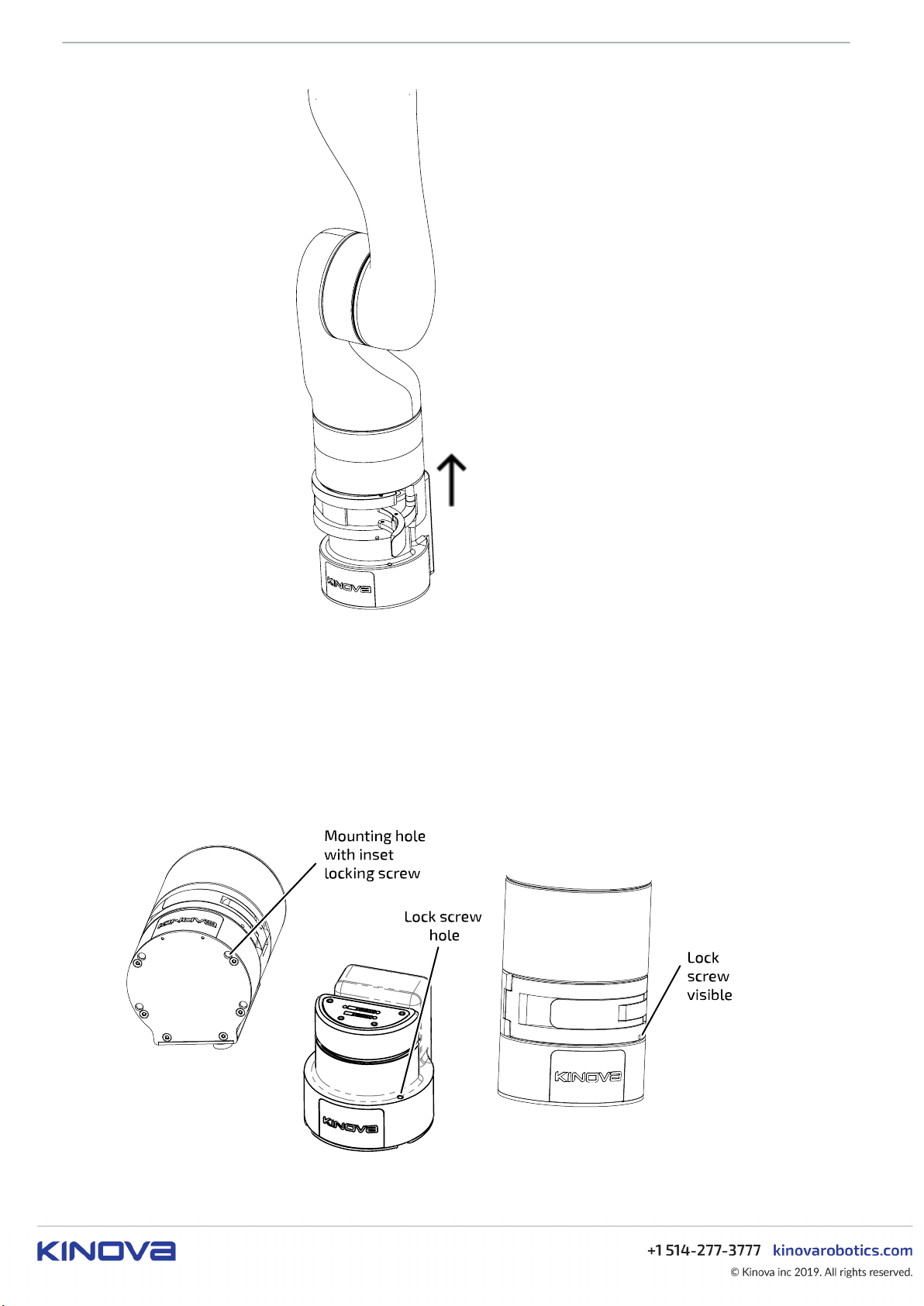

Controller quick connect system

This section describes the controller quick connect system.

The base of the robot is equipped with a quick connect system that allows for simple connect / disconnect

of the base shell and controller. This allows the arm to be quickly detached from the mounting point of the

arm without disconnecting any cables. This can be useful for transport, for removal of the arm for servicing

or for convenient re-siting of the arm between multiple installation sites.

Note: Be careful to avoid damage to the electrical contacts on the mating interface of the controller when

the base shell is disconnected. Make sure to keep the surface dry and free from dust.

KINOVA® Gen3 Ultra lightweight robot User Guide 18

Clamp

Figure 4: Controller quick connect

The base shell slides over and onto the controller, establishing an electrical connection with the arm. The

base shell is secured in place on the controller by closing the front clamp.

Figure 5: Base shell installation

To remove the arm from the controller, flip open the clamp and slide off the base shell.

KINOVA® Gen3 Ultra lightweight robot User Guide 19

Figure 6: Base shell and arm removal

The controller features a locking screw within the mounting hole on the front bottom left (from the

perspective of an observer behind the connector panel). Turning the locking screw with a 3 mm hex key

clockwise will cause the screw to go forward and protrude through a hole above the top surface of the

controller a few mm until it reaches the end of its travel. If the base shell is already clamped onto the

controller when this is done, the set screw will interface with a mechanism on the clamp and prevent the

clamp from opening until the set screw is withdrawn. This serves as a safety mechanism. There is a hole on

the clamp where the end of the lock screw can be seen when it is fully engaged. Confirm visually that the

lock screw is not engaged before trying to open the clamp.

Figure 7: Lock screw mechanism

KINOVA® Gen3 Ultra lightweight robot User Guide 20

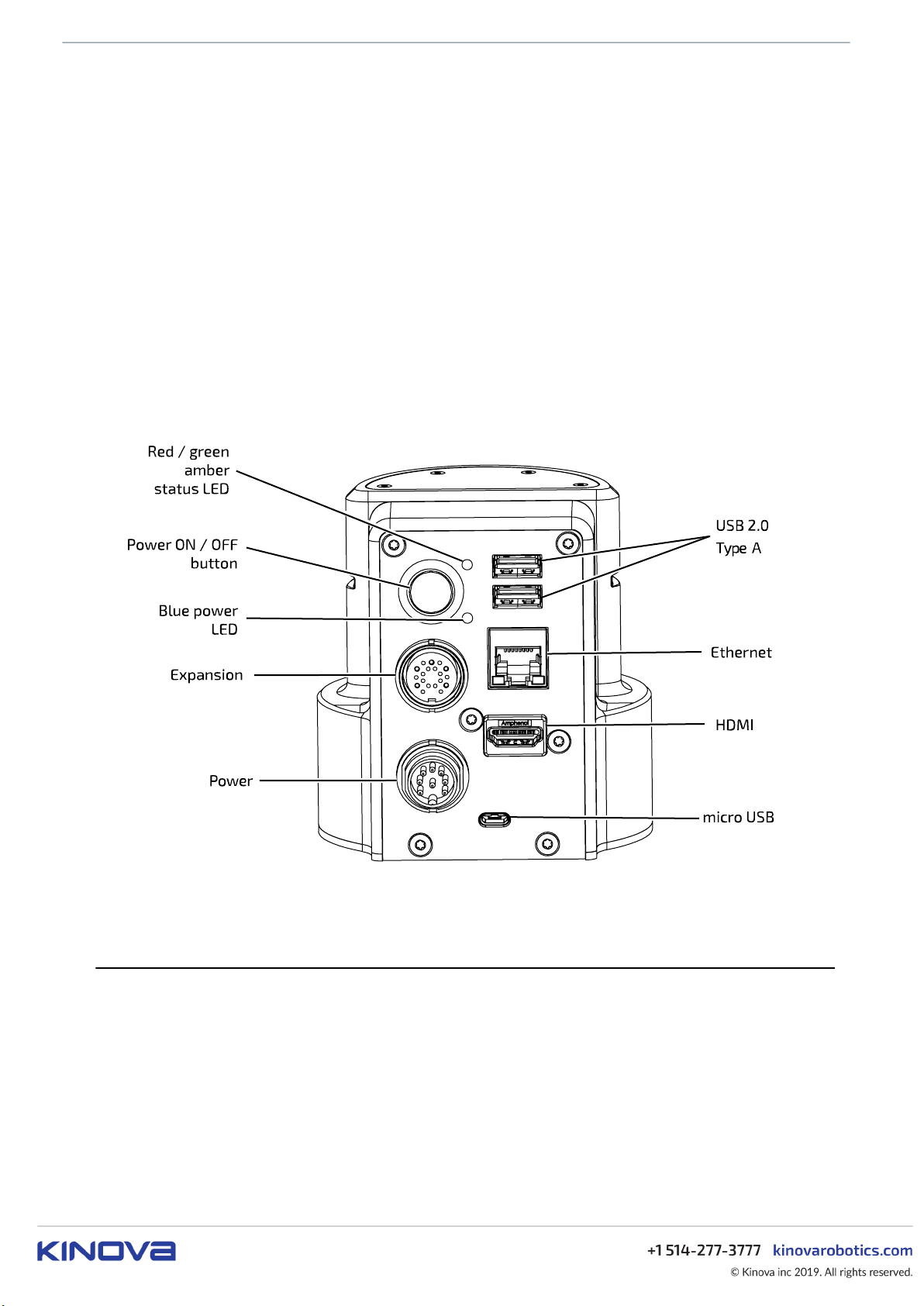

Controller connector panel

This section describes the controller connector panel of the robotic arm.

The controller connector panel is located at the rear of the controller. It features the following elements:

• On / Off power switch

• blue power LED indicator

• red / amber / green status LED indicator

• HDMI Out (camera video*)

• Micro USB (internal use)

• USB 2.0, type A - qty 2 - for wired controller. Top port 1 A for charging. Bottom port 500 mA max, for

peripherals.

• RJ-45 Gigabit Ethernet (LAN)

• Binder-USA 09 0463 90 19 (joystick, discrete I/O, E-Stop, expansion)

• Lumberg 0317 08 (power)

Note: Cables connected to the base controller must be less than 3 m in length. If not, you must perform a

risk analysis. Cables longer than 3 m can potentially have an effect on radio frequency emissions and the

immunity of the product.

Figure 8: Controller connector panel

* to be implemented in future software release

Actuators

This section provides an overview of the robot actuators.

The rotational motion at each of the joints of the robot is powered by rotary actuators. There is one actuator

for each joint. Each actuator allows for potentially unlimited rotation in either direction (There are software

limits however on some joints however to avoid collisions between robot shell segments).

There are two sizes of actuator:

• small

• large

KINOVA® Gen3 Ultra lightweight robot User Guide 21

Each actuator has:

• torque sensing

• current and temperature sensing on each motor phase

Wrist joints use small actuators, while large actuators are used for other joints. All actuators are equipped

with a 100:1 strain wave gear for smooth motion.

The actuators are connected to each other and to the interconnect board using a series of 41-pin flex cables.

These cables convey:

• power

• 2 x full-duplex 100 Mbps Ethernet

º one for 1 kHz control

º one for vision / expansion data traffic

Actuator Specifications:

• actuator speed (maximum, unloaded):

º 25 RPM (small)

º 13 RPM (large)

• actuator torque (small):

º 13 N·m (nominal)

º 34 N·m (peak)

• actuator torque (large):

º 32 N·m (nominal)

º 54 N·m (peak)

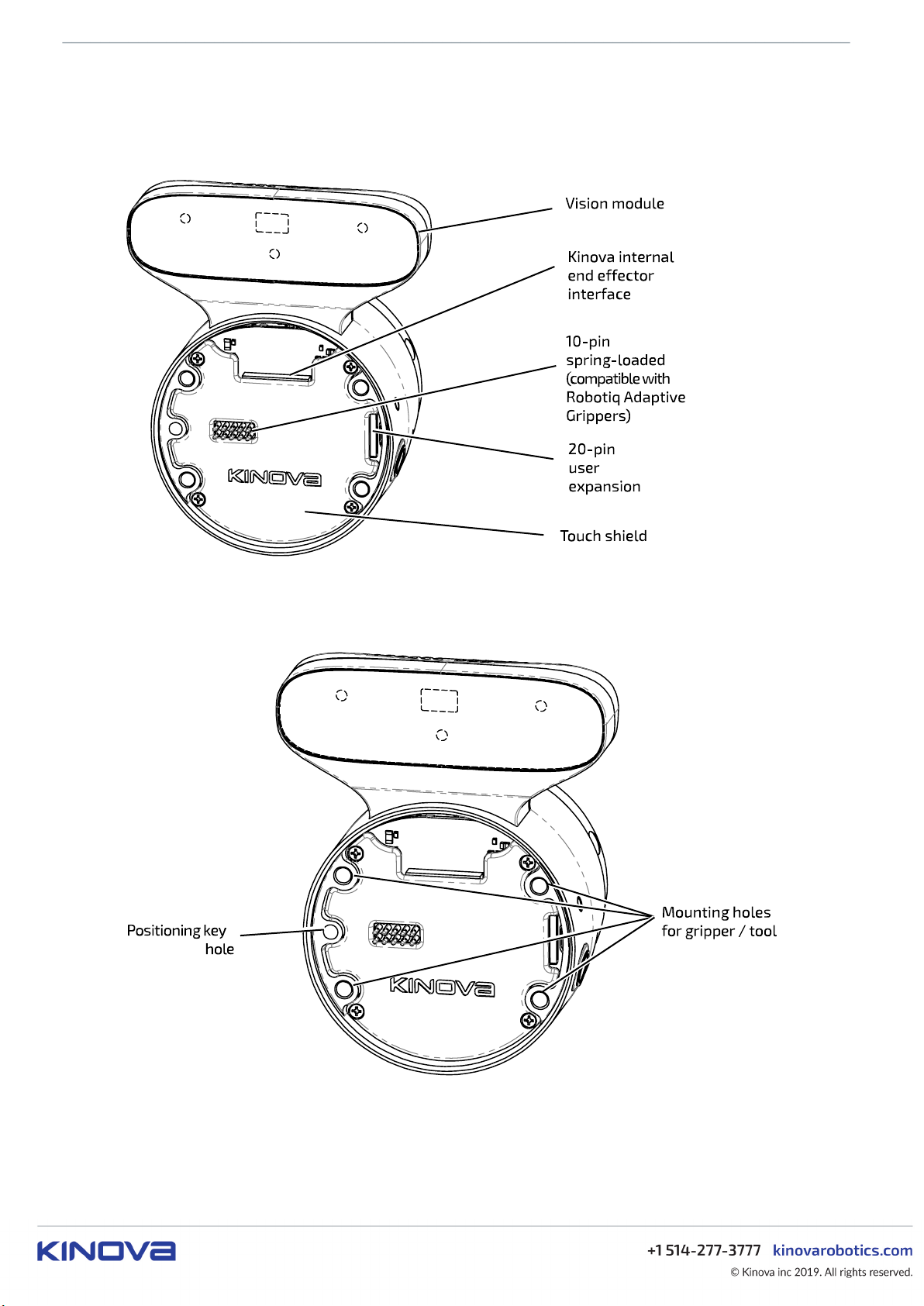

Interface module

This section describes the interface module.

The interface module provides an interface for connecting a gripper or other tools at the end of the arm.

The interface module also provides a mounting point and connection for the vision module.

The interface module has a connection interface at the end of the arm, and is surrounded on the sides by a

bracelet shell. The vision module is mounted on the top of the bracelet.

The bracelet includes two buttons used to activate admittance modes to interact with the robot. By default

the button on the right hand side (viewed from behind) puts the arm into Cartesian admittance while the

button on the left puts the arm into null space admittance. The two buttons can be distinguished easily by

touch without looking; the Cartesian admittance mode button sticks out from the surface in the center,

while the null admittance mode button is slightly indented in in the center and ring-shaped.

Note: Only one of the buttons can be active at any given time. If you press the two buttons together or in

close succession, the button pressed later will take effect.

The bracelet also includes two amber LEDs.

The interface module takes a 41-pin input from the last actuator of the robot.

KINOVA® Gen3 Ultra lightweight robot User Guide 22

The interface exposes connectors that allow different tools to be integrated with the robot. It features:

• Kinova internal end-effector interface

• 10-pin spring-loaded connector with RS-485 (compatible with Robotiq Adaptive Grippers)

• 20-pin user expansion interface

Figure 9: Interface module

The interface also includes four mounting holes for physical mounting of a tool and a position key hole used

for alignment of the tool in the right orientation.

Figure 10: Mounting holes and positioning key hole

The interface module includes a 6-axis accelerometer / gyroscope. The module also includes an Ethernet

switch to route connectivity and control data between the interface module and the vision module and any

connected tool (e.g. gripper).

KINOVA® Gen3 Ultra lightweight robot User Guide 23

Note: The printed circuit board (PCB) of the interface module is partially covered with a touch shield

with holes to expose only the output connectors - 10-pin spring loaded connector, 20-pin user expansion

connector, and Kinova internal end effector interface.

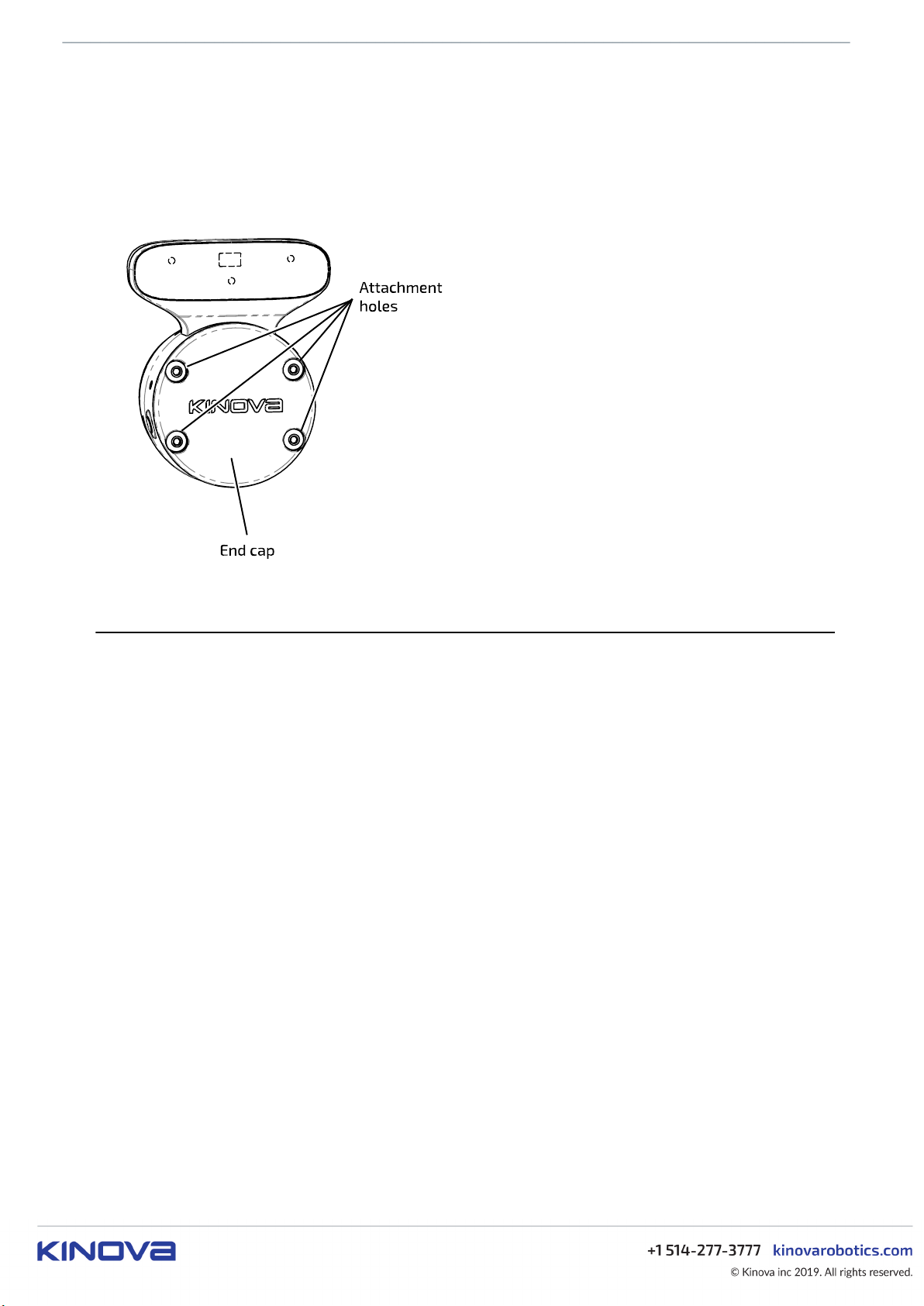

Note: When there is no tool present, an end cap needs to be installed over the face of the interface module

to ensure compliance with EMI/EMC. Kinova provides an end cap with the robot. This end cap is attached

to the interface with screws using the mounting holes on the interface. The end cap needs to be removed

to attach a tool to the robot.

Figure 11: End cap

Vision module

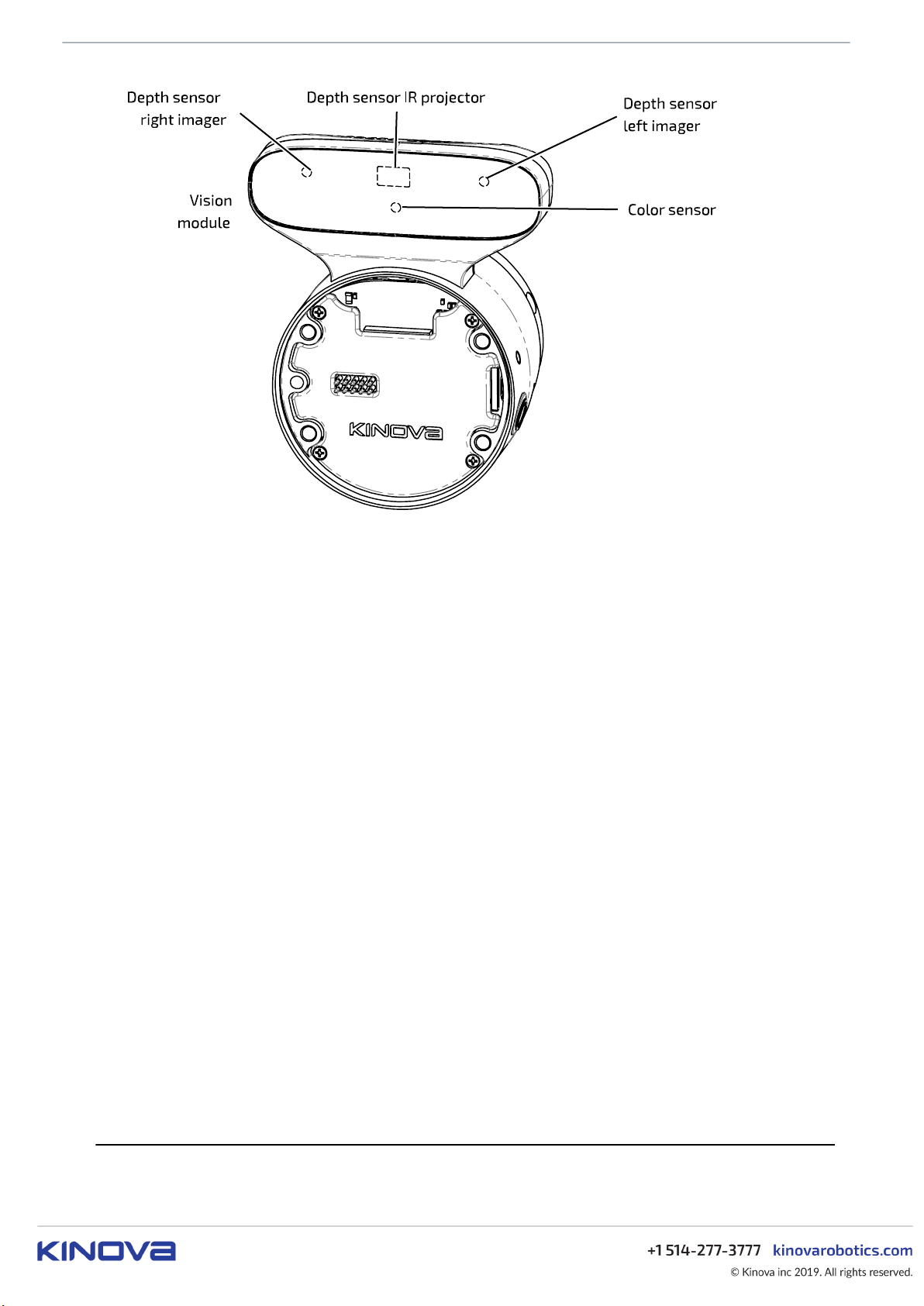

This section describes the Vision module.

The vision module is a module provided by Kinova to enable robotic computer vision applications.

The vision module is included as part of the interface module. A housing containing sensors protrudes from

the top of the Interface module. The sensors are contained on the front face of the housing, facing out

parallel to the axis of the last actuator.

The Vision module is used to capture and stream image data captured looking in the direction the end of

the arm / end effector is pointed. The Vision module includes both a color camera (Omnivision OV5640)

and a stereo depth sensor (Intel® RealSense™ Depth Module D410).

KINOVA® Gen3 Ultra lightweight robot User Guide 24

Figure 12: Vision module sensors

The color sensor captures a 2D array of RGB pixel data representating the field of view from the perspective

of the sensor.

The depth sensor includes an IR projector and two stereo imagers - left and right. Here left and right are

from the perspective of an observer looking out from the sensor toward the imaged region. The depth

sensor captures a 2D array of pixels and the depth for each pixel within the field of view of the sensor.

Together, the two sensors allow the capture of RGBD (color and depth) data. Both camera sensors can be

configured using the KINOVA® KORTEX™ VisionConfig interface.

Note that performance for the Vision module depth sensor may be degraded at temperatures below 0° C.

For more details, please consult the depth sensor data sheet.

The color and depth sensors data streams are made accessible to developers through a computer with a

connection to the robot. For more information on accessing these data streams programatically, see here.

Vision module specifications

Color sensor:

• resolution, frame rates (fps), and fields of view (FOV):

º 1920 x 1080 (16:9) @ 30, 15 fps; FOV 47 ± 3° (diagonal)

º 1280 x 720 (16:9) @ 30, 15 fps; FOV 60 ± 3° (diagonal)

º 640 x 480 (4:3) @ 30, 15 fps; FOV 65 ± 3° (diagonal)

º 320 x 240 (4:3)@ 30, 15 fps; FOV 65 ± 3° (diagonal)

• focusing range - 30 cm to ∞

Depth sensor:

• resolution, frame rates (fps), and fields of view (FOV):

º 480 x 270 (16:9) @ 30, 15, 6 fps; FOV 72 ± 3° (diagonal)

º 424 x 240 (16:9) @ 30, 15, 6 fps; FOV 72 ± 3° (diagonal)

• minimum depth distance (min-Z) - 18 cm

Robot communications and network interfaces

This section describes communications and network interfaces within the robot.

KINOVA® Gen3 Ultra lightweight robot User Guide 25

The devices in the robot, from the base of the arm through the chain of actuators, to the interface

module at the end of the arm, are daisy chained together using 41-pin flex cables which carry power and

communications.

The base, actuators, and interface module each contain an Ethernet switch. The Ethernet port on the

connector panel of the base controller allows an external computer to connect to the Ethernet switch of

the base.

The Kinova vision module and any 3rd party tool that makes use of Ethernet communications user

expansion pins in the interface connect directly to the interface module Ethernet switch. Other tools (for

example any gripper interfacing using the 10-pin spring loaded connector on the interface) will interface

instead with the interface module CPU (which is connected to the Ethernet switch).

Together, this enables dual Ethernet networks between all the devices (base, actuators, interface, Vision

module, and end effector tools) with data carried between the base and interface over the 41-pin flex cables.

This is accessible from a client computer via the 1 Gbps Ethernet port on the base controller connector

panel.

The flex cables carry two distinct 100 Mbps Ethernet communications channels.

• one is for control and monitoring of actuators, interface module, and gripper (if present)

• the other is for data transmission for the vision module and expansion.

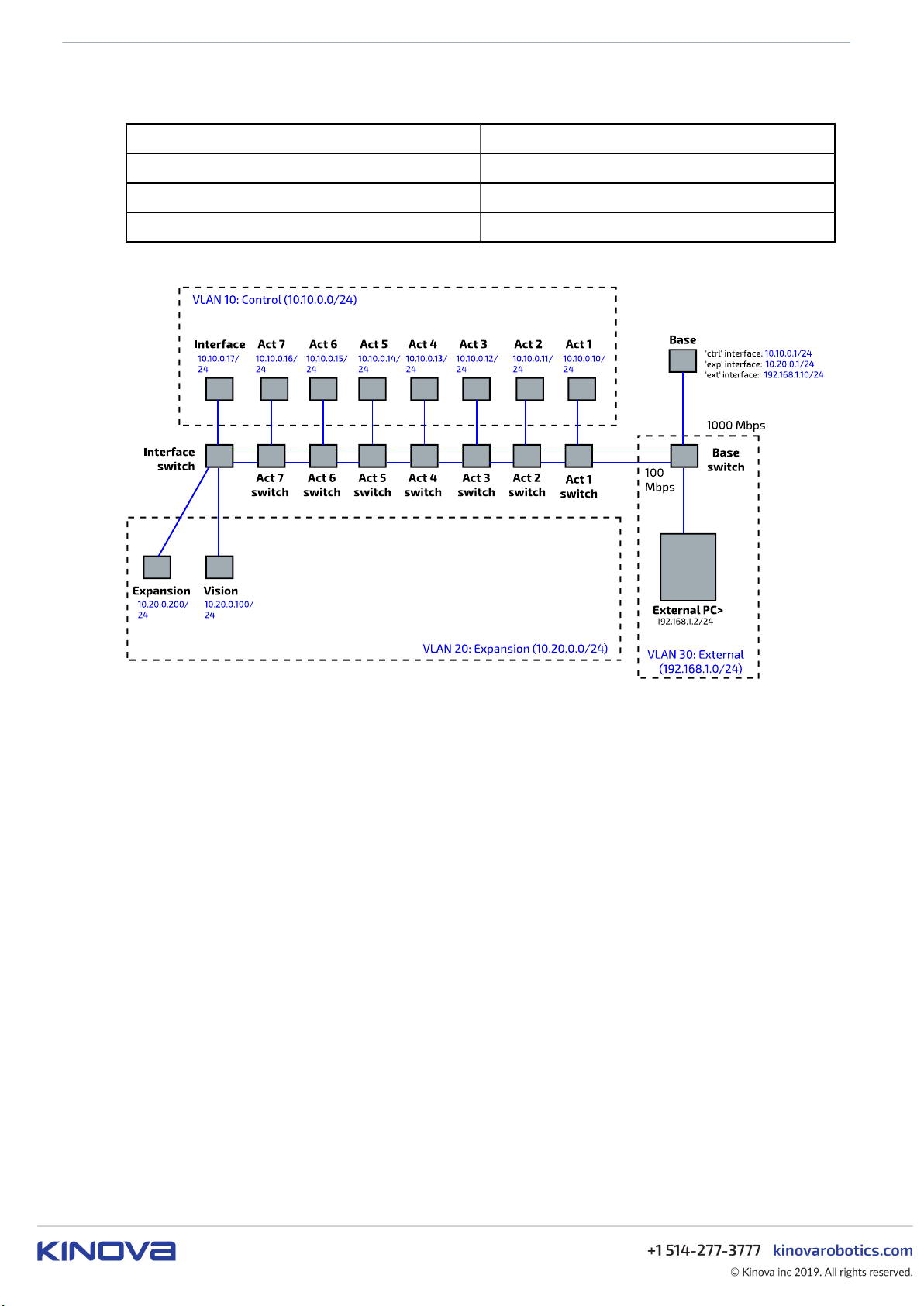

Each device connected to one of the Ethernet switches has an IP address to allow routing of

communications, transmitted using UDP.

The actuators and interface module have the following default IP addresses:

Table 4: Actuator and gripper IP addresses

Device IP address

Actuator 1 10.10.0.10

Actuator 2 10.10.0.11

Actuator 3 10.10.0.12

Actuator 4 10.10.0.13

Actuator 5 10.10.0.14

Actuator 6 10.10.0.15

Actuator 7 10.10.0.16

Interface module 10.10.0.17

The expansion devices (Vision module and expansion tool peripherals) have the following IP addresses:

Table 5: Expansion IP addresses

Expansion Devices IP address

Vision module 10.20.0.100

Expansion device 10.20.0.200/24*

The robot Ethernet network features three VLANs:

• VLAN 10 : control

• VLAN 20 : expansion

• VLAN 30 : external

The base has network interfaces to all three of these VLANs:

KINOVA® Gen3 Ultra lightweight robot User Guide 26

Table 6: Base network interface IP addresses

VLAN IP address

CTRL interface IP address 10.10.0.1/24*

EXP interface IP address 10.20.0.1/24*

EXT interface IP address 192.168.1.10/24*

The graphic below illustrates the topology of the networks.

* CIDR notation

KINOVA® Gen3 Ultra lightweight robot User Guide 27

Getting started

Overview

This section describes how to get started with the arm.

The pages that follow lead you through getting started with the robot. This includes:

• unboxing

• physically mounting the robot securely

• provisioning electrical power

• controlling the robot using an Xbox gamepad

• moving the robot in admittance using physical buttons

• connecting a computer to the robot

•

connecting to the KINOVA® KORTEX™ Web App

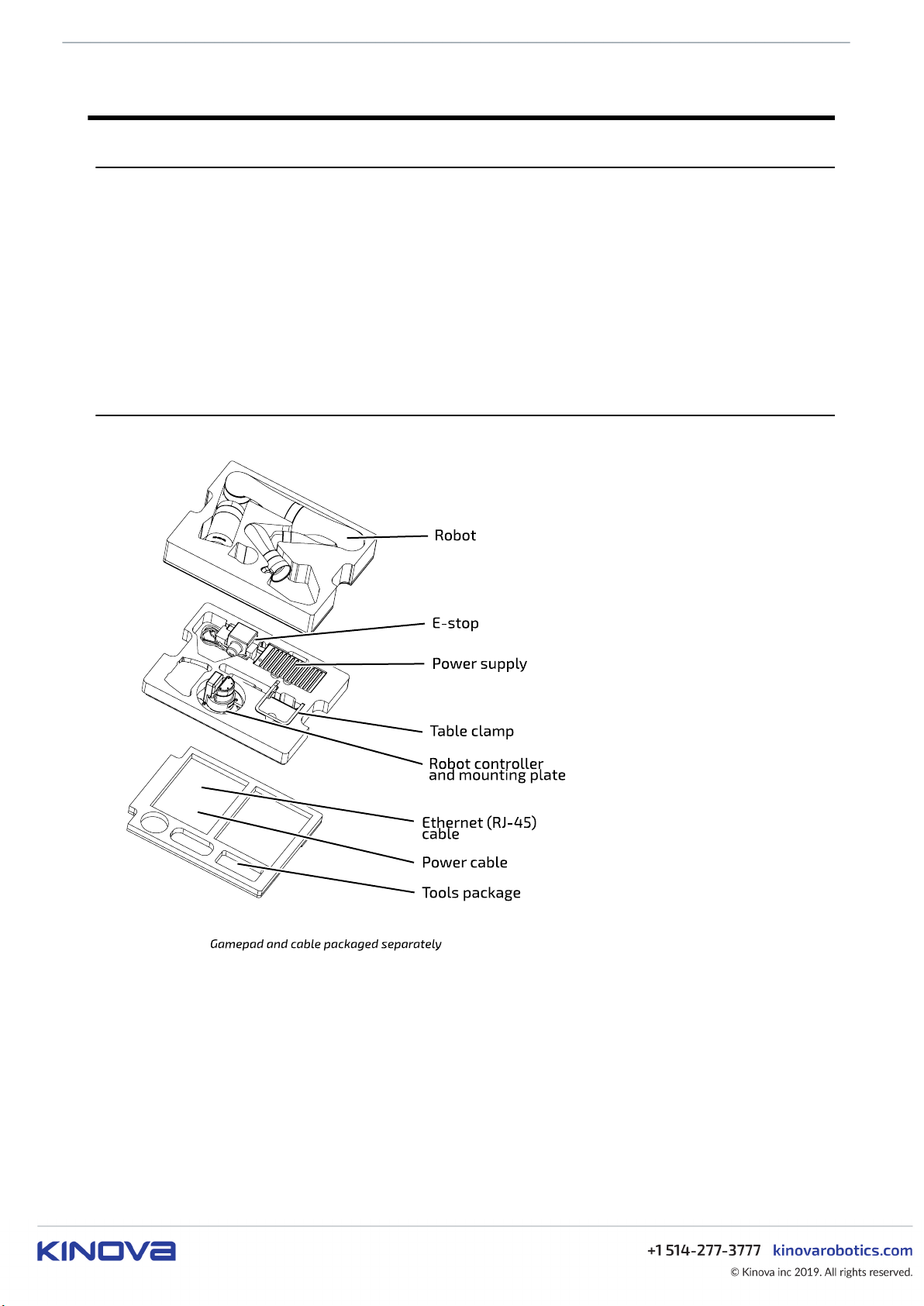

What's in the case?

This section describes the KINOVA® Gen3 Ultra lightweight robot shipping case contents.

Figure 13: Gen3 Ultra lightweight robot shipping case contents

The shipping case contains the following contents.

At the top of the interior of the box, you will find the Quick Start Guide. The Quick Start Guide is a large

printed visual guide.

The Quick Start guide provides a handy reference for first steps, and should have you up and running within

30 minutes. Make sure to keep the Quick Start Guide as a reference for people in your team or organization

getting newly acquainted with your robot. The Quick Start Guide is also available on the Kinova website:

www.kinovarobotics.com/knowledge-hub/gen3-ultra-lightweight-robot

The contents of the box are arranged in three layers from top to bottom. These packing layers can be

removed from the box to unpack the contents.

KINOVA® Gen3 Ultra lightweight robot User Guide 28

In the top layer:

• Robot

In the second layer:

• Power adapter and cable with integrated emergency stop (E-stop) button

• Table clamp

• Mounting plate and robot controller

The bottom area contains:

• Ethernet (RJ-45) cable

• Power cable

• Bag with useful tools and fasteners

º hex keys: 3, 4 and 5 mm

º M5 screws (qty. 4)

An Xbox gamepad and cable are shipped with the robot, but packaged separately.

There is also space for storage of papers and other items.

Note: The shipping case is also useful for transportation and storage of the robot. Make sure to save it and

the packing layers within for future use.

Manipulating the robot joints when the robot is powered off

This describes how to manipulate the robot joints when the robot is powered off.

When the robot is powered on, the actuators will hold their position and prevent the joints from moving

in response to external forces and torques. When the power is on, the arm will not move except when

commanded. The arm joints are stiff and you will not be able to rotate the joints with your hands.

When the robot is powered off, as it is when you first receive the robot, the joints can be moved by hand

slowly.

Note: If you move the joints too quickly, mechanisms within the joints will limit the speed.

This moveability of the joints when the robot is unpowered is useful when taking the robot out of the box

and setting it up to get started. This lets you arrange the joints of the robot into a stable, balanced position

prior to mounting and powering on the robot.

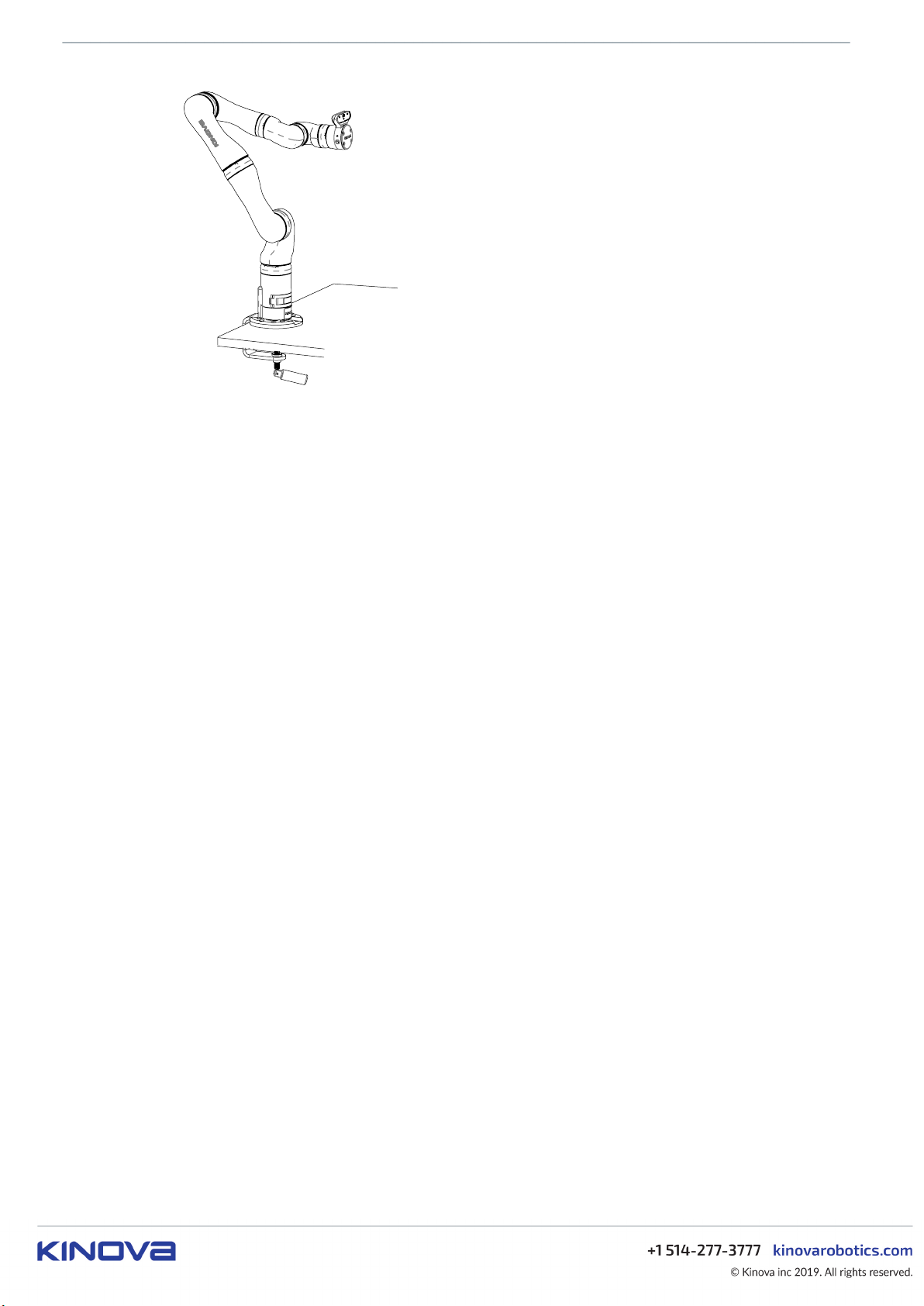

Robot mounting options

This section describes the physical mounting options for the robot.

The first step to getting started with the arm after unboxing is to physically mount the arm in a stable

manner so that the robot can be connected and used.

The most basic mounting option uses the mounting plate and a table clamp to quickly mount the robot on

a tabletop in a "right side up," vertical orientation.

However, if is also possible to mount the robot in different ways, as well as different orientations, depending

on the needs of your particular application. The sections that follow will describe this in more detail.

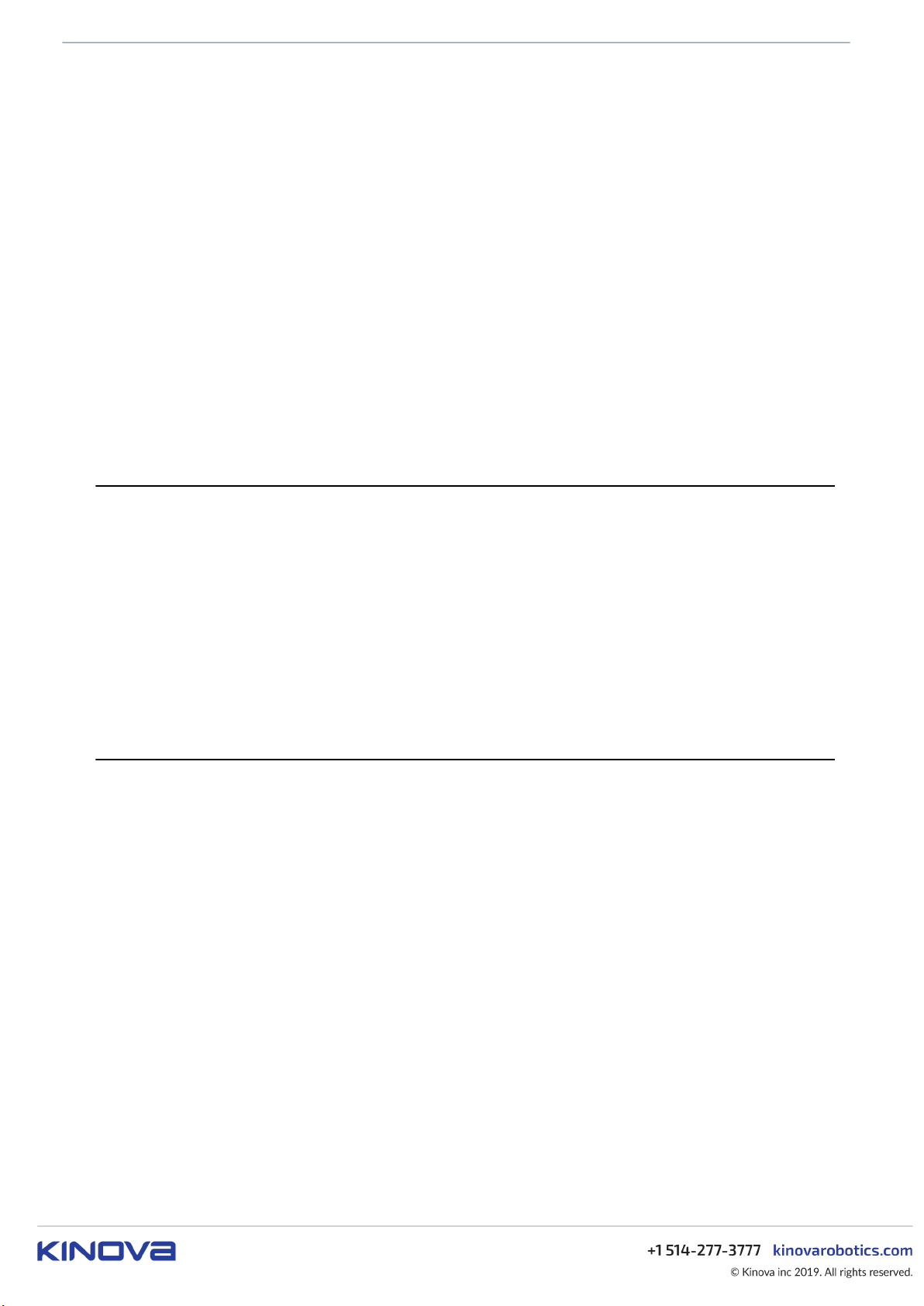

Mounting the robot on a tabletop

This section describes the procedure for mounting the robot oriented vertically on the edge

of a tabletop using the clamp.

Before you begin

The robot should have the joints of the robot unfolded so that it is in a stable, balanced

position ready for mounting.

About this task

The robot is mounted to a tabletop using the base mounting plate and a table clamp.

Note: The table must be large and sturdy to support a tabletop edge mounting. If the table is too small or

too flimsy, the weight of the robot at the table edge combined with the movement vibrations may render

it unstable.

KINOVA® Gen3 Ultra lightweight robot User Guide 29

Procedure

1. Place the base controller and mounting plate on the tabletop, next to the edge.

Note: You can place the controller in one of two orientations. Either with the connector panel facing out

toward the edge of the table, or with the front side of the base controller facing out.

2. Turn the tightening knob on the table clamp to open up the clamp and then slide the clamp into the slot

between the mounting plate and the bottom of the base controller.

3. Turn the tightening knob by hand until the mounting plant is firmly clamped to the table top.

Note: Do not overtorque.

4. Make sure that the clamp at the bottom of the robot base shell is opened. While holding the robot, you can

now lower the base shell of the robot onto and over the base controller.

5. Once the robot is fully lowered onto the base controller, close the clamp to secure the robot in place on

the base controller.

Note: The clamp must be properly closed to ensure stability of the robot. Damage can potentially be done

to the robot if it is operated while unstable.

Results

The robot is now mounted on the tabletop.

KINOVA® Gen3 Ultra lightweight robot User Guide 30

What to do next

You can now proceed to connect the robot to the power supply and E-stop.

Mounting the robot on a horizontal surface without the table clamp

This section describes how to mount the robot on a horizontal surface without the table

clamp..

About this task

Here, we describe mounting the robot in a vertical orientation on a flat, horizontal surface,

affixing the mounting plate or controller base to the surface using screws and sunk holes in

the surface.

Procedure

1. Choose whether to mount the robot base controller directly onto the surface, or whether to use the

mounting plate.

2. Using either the mounting plate bolting pattern or the controller bolting pattern or as a guide, drill holes

into the surface. If the controller is to be mounted directly to the surface, the holes will have to be drilled

all the way through the mounting surface.

3. Use appropriate screws to mount either the base controller or the mounting plate to the surface. If the

base controller is mounted directly, the screws will need to go through the mounting surface from the

other side.

Controller mounting plate bolting pattern

This section describes the bolting pattern of the mounting plate. This is useful when

mounting the robot to a surface using the mounting plate.

Overview

The mounting plate is attached to the bottom of the base controller. The mounting plate has two sets of M8

screw holes (4) and one set of counter-sunk M6 screw holes (4) available for mounting the plate to a surface.

KINOVA® Gen3 Ultra lightweight robot User Guide 31

Mounting details

Figure 14: Mounting plate bolting pattern

Base controller underside bolting pattern

This section describes the bolting pattern on the underside of the base controller. This is

useful when you want to affix the robot base directly to a surface.

Overview

The underside of the controller has four M6 screw holes for mounting purposes. These holes are used for

attaching the mounting plate to the controller. When the mounting plate is removed, these holes can be

used for mounting the controller directly to a surface. In that case, holes must be drilled through the surface

so that screws can go through from the other side and into the controller mounting holes from underneath.

One of the screw holes in the controller base features an inset locking screw. Turning the locking screw

clockwise to the end of its travel (using a 3 mm hex key) while the base shell is clamped to the controller will

lock the two together and prevent the clamp from being opened.

KINOVA® Gen3 Ultra lightweight robot User Guide 32

Mounting details

Figure 15: Base and mounting holes

Figure 16: Base mounting holes pattern

Mounting the robot on a wall or ceiling

This section describes how to mount the robot on a wall or ceiling.

KINOVA® Gen3 Ultra lightweight robot User Guide 33

The procedure for mounting is generally similar to that of mounting onto a horizontal surface:

1. Choose whether to mount the controller directly to the surface, or using the mounting plate.

2. Drill holes in an appropriate pattern in the surface based on the appropriate bolting pattern diagram.

3. Attach the controller or mounting plate to the surface with appropriate screws.

There are however important differences.

It is essential to follow all special considerations for wall and ceiling mounting. This includes the need to:

• perform a careful analysis of the proposed mounting surface

• mount and clamp the robot onto the controller with the locking screw engaged before mounting the

robot on the surface

• configure the gravity vector and compute any needed transformations between the user / lab

reference frame and the robot base frame to account for the new orientation of the robot base

Special considerations and configurations for wall and ceiling mounts

This section describes special considerations that are important for wall and ceiling

mounts.

For safety reasons, there are special preparations and steps that need to be undertaken before mounting

the robot on a wall or ceiling.

Before trying to mount the arm on a wall or ceiling, perform a comprehensive analysis of weight,

torque, and vibrations and ensure the material is stable enough.

The locking screw on the bottom left front of the controller must be screwed in fully with a hex key

while the base shell is clamped on. This will block the clamp from being opened while the arm is mounted

on a wall or ceiling, and provides an added measure of security. The robot therefore needs to be clamped to

the controller and the lock screw adjusted before trying to mount the robot.

For wall mounting, the robot needs to be mounted with the controller connector panel facing

downwards. This is to prevent water ingress at the connector panel.

Note: A robot mounted in a ceiling mount is not certified for ingress protection.

Note: In a wall or ceiling mount, the gravity vector will have a different orientation than usual with respect

to the base reference frame. It will be necessary to set the gravity vector using the Kinova Web App

or Kinova.Api.ControlConfig API. If the gravity vector is not configured appropriately, the robot

control library will not be able to properly compensate for torques due to gravity on the robot and the robot

will behave in unexpected ways.

Note: The Cartesian control of the robot is by default in relation to the base reference frame. This base

reference frame will be rotated relative to the natural reference frame of the perspective of the user /

operator. You will need to apply the appropriate coordinate transformations to control the robot in these

orientations.

Adjusting the controller locking screw to secure base clamp

This section describes how to adjust the controller locking screw to secure the clamp on

the base.

Before you begin

You will need a 3 mm hex key.

About this task

Adjusting the controller locking screw while the base shell is attached and clamped locks

the clamp shut and prevents it from being opened. This improves the safety of the robot

when mounted on a wall or ceiling

KINOVA® Gen3 Ultra lightweight robot User Guide 34

Procedure

1. If the mounting plate is attached to the controller, one of the screws connecting the mounting plate to the

controller from below has to be removed to get at the locking screw. Identify the mounting hole with the

lock screw and remove it using the 3 mm hex key.

2. If the base shell and the robot are not already installed onto the controller, slide the base shell onto the

controller and close the clamp.

3. Using the same hex key, insert the end of the key into the mounting hole until the hex key engages with

the head of the lock screw. Turn the lock screw until it stops at the end of its travel. There is a hole on the

front of the clamp where the end of the lock screw can be seen when the lock screw is engaged with the

clamp mechanism. Confirm that you can see the screw.

4. Test the clamp to ensure that you can not open it.

Robot power adapter and E-stop

This section describes the power adapter and E-stop.

The power adapter allows power to be supplied to the robot using a wall outlet as a source. The cable

from the power adapter connects to the power connector on the base controller using a Lumberg 0322 08

connector.

KINOVA® Gen3 Ultra lightweight robot User Guide 35

The cable from the power adapter to the robot includes an integrated push-button E-stop connected in

series. The E-stop allows users to shut down the robot quickly in case of an emergency.

To engage the E-stop, press down on the red button on top of the E-stop. This will cut the power to the robot,

causing it to shut it down.

When the power is cut, the robot will descend. There are mechanisms within the large actuators to

slow the fall of the arm for safety purposes. However, it is recommended that if possible, users cradle the

robot as it falls.

To disengage the E-stop, rotate the button clockwise until it pops up.

Powering on the robot

This section describes how to connect the robot to an electrical power source.

The robot is powered by a 24V power supply (P/N DTM300PW240D2).

To power up the robot:

1. Connect the captive cable from the power supply to the circular Lumberg connector on the rear connector

panel in the controller of the robot, rotating the outer cylindrical locking shell of the connector until it is

just tight enough to secure the connector.

2. Plug the power supply into a wall outlet.

3. Push the power button and hold in for 3 seconds to power up the robot. This will initiate the power up

sequence.

Note: When the robot is properly powered on, the blue power LED will be illuminated green.

Note: Do NOT hold the power button down for too long. Holding the button for 10 seconds will result

in a factory reset.

Power-up, booting, and initialization sequence

This section describes the LED indications during the power-up sequence.

When the power button is held in to initiate a power-up, the robot will go through a regular boot up and

initialization sequence.

As part of the sequence, the base controller will check the firmware version of the robot devices. If one or

more of the devices are at an earlier version than the base controller, these devices will be updated.

The base LEDs will provide visual feedback as to the progress through the sequence, as follows:

KINOVA® Gen3 Ultra lightweight robot User Guide 36

Table 7: Power-up sequence LEDs indications

Sequence step LEDs indications

System booting