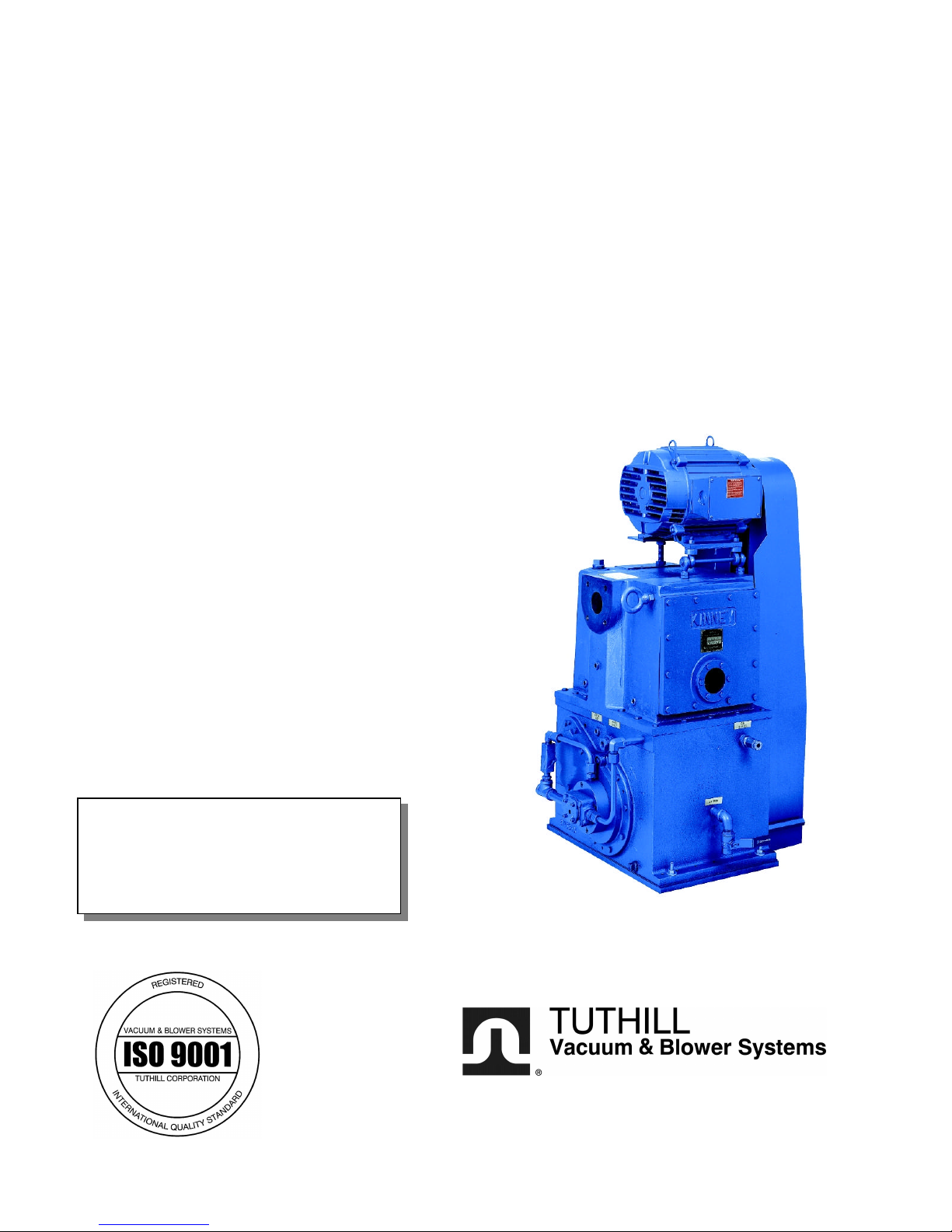

KINNEY KT SERIES, KT-300, T-150, KT-500, KT-850 Installation Operation Maintenance Repair Manual

Manual 1843-1

KINNEY® KT™ SERIES

Single Stage, Triplex Rotary Piston Pumps

Models

KT-150 KT-300 KT-500 KT-850

INSTALLATION

OPERATION

MAINTENANCE

REPAIR

MANUAL

WARNING

DO NOT OPERATE BEFORE

READING MANUAL.

06/2003

ADVANCING THE STANDARDS IN VACUUM TECHNOLOGY

4840 West Kearney Street

Springfield, Missouri USA 65803-8702

Tel 417 865-8715 800 825-6937 Fax 417 865-0307

E-mail: kinney@tuthill.com

http://vacuum.tuthill.com

! WARNING

DO NOT OPERATE

WITHOUT BELT

GUARD

809762-A000

The above safety instruction tags were permanently affixed to

your pump prior to shipment. Do not remove, paint over or

obscure in any manner.

Failure to heed these warnings could result in serious bodily

injury to the personnel operating and maintaining this

OPERATING PUMP. ENSURE ADEQUATE

REFER TO MANUAL SAFETY INSTRUCTIONS.

NOTICE

! CAUTION

DO NOT VALVE OR RESTRICT PUMP

DISCHARGE OPENING.

USE OIL MIST ELIMINATOR WHEN

VENTILATION WHEN DISCHARGING

INDOORS.

SAFETY PRECAUTIONS FOR ROTARY PISTON PUMPS

Please read the following safety information on this page before operating your vacuum pump.

• Do not operate the pump without the belt guard properly attached. Disconnect the pump motor from the electrical

supply at the main disconnect before removing the belt guard. Replace the belt guard before reconnecting the

power supply to the pump motor. Operating the pump without the belt guard properly installed exposes personnel

in the vicinity of the pump to risk from rotating drive components.

• Do not operate the pump with oxygen-enriched gas (greater than 20% by volume) in the suction line, unless the

pump has been prepared with an inert fluid suitable for the application.

Pumping oxygen-enriched gases with mineral oil or other non-inert fluids can cause fire or explosion in the

pump, resulting in damage or serious bodily injury.

• Take precautions to avoid prolonged or excessive exposure to oil mist or process materials emanating from the

discharge of the pump.

• Do not allow the pump to discharge into a closed, or inadequately ventilated room. Always use a discharge oil mist

eliminator unless the pump discharge is discharged to outside atmosphere. Laws and ordinances may pertain to

your local area regarding discharge of oil mist or vapor to atmosphere. Check local laws and ordinances prior to

operation of the pump with discharge to outside atmosphere. Venting of the discharge of an oil mist eliminator to

outside atmosphere is highly recommended.

• Do not restrict the pump discharge in any way, or place valves in the discharge line. The vacuum pump is a

compressor and will generate high pressures without stalling the motor when operated at low suction pressures.

Excessive pressure could cause damage or serious bodily injury.

• Disconnect the pump motor from the electrical supply at the main disconnect before disassembling or servicing

the pump. Make sure pump is completely reassembled, the belt guard is properly installed, and that all fill and

drain valves are installed and closed before reconnecting the power supply. Accidental starting or operation of

the pump while maintenance is in progress could cause damage or serious bodily injury.

• Lift pump only by the lifting lugs supplied with the pump. DO NOT lift equipment attached to pump by the pump

lifting lugs.

• Do not touch hot surfaces on the pump. In normal operation at low pressures, surface temperatures will not

normally exceed 180° F (82° C). Prolonged operation at 200 Torr (267 mbar a) may cause surface temperatures as

high as 220° F (104° C)

2

SECTION

TABLE OF CONTENTS

SAFETY PRECAUTIONS AND WARNINGS 2

INTRODUCTION 4

DESCRIPTION

Specifications 5

Description 6

INSTALLATION

Installing the Vibramounts 7

Suction Manifolding 8

Proper Venting 9

Discharge Manifolding 9

Cooling Water 9

Filling the Pump with Oil 11

Vacuum Gauges 12

Electrical Connections 12

OPERATION

General 12

Prestart Checks 12

Starting The Pump 13

Stopping The Pump 13

Handling Large Quantities of Water 13

Gas Ballast 14

MAINTENANCE

General 14

Periodic Maintenance 14

Oil Contamination 14

Changing the Oil 15

Lubricating the Pump 15

Stalling 16

Pump Leaks 16

Checking Pump Performance 16

Checking Process Equipment 16

Discharging Valves 17

Shaft-Seal Assembly 19

V-Belt Drive 19

DISASSEMBLY 20

ASSEMBLY 20-21

Replacement Parts 22

Recommended Oil 22

Troubleshooting Chart 23

Parts List & Exploded Views 24-29

WARRANTY STATEMENT 30

3

INTRODUCTION

CONGRATULATIONS on your purchase of a new KINNEY

Pump from Tuthill Vacuum & Blower Systems. Please examine the pump for shipping damage, and if any damage is

found, report it immediately to the carrier. If the pump is to be installed at a later date make sure it is stored in a

clean, dry location and rotated regularly. Make sure covers are kept on all openings. If pump is stored outdoors be

sure to protect it from weather and corrosion.

KINNEY KT vacuum pumps are built to exacting standards and if properly installed and maintained will provide

many years of reliable service. We urge you to take time to read and follow every step of these instructions when

installing and maintaining your pump. We have tried to make these instructions as straightforward as possible. We

realize getting any new piece of equipment up and running in as little time as possible is imperative to production.

WARNING: Serious injury can result from operating or repairing this machine without first reading the service

manual and taking adequate safety precautions.

IMPORTANT: Record the pump model and serial numbers in the OPERATING DATA form below. You will save

time and expense by including this reference identification on any replacement part orders, or if you require service

or application assistance.

®

KT™ Single-Stage, Tri-plex Rotary Piston Vacuum

OPERATING DATA

It is to the user’s advantage to have the requested data filled in below and available in the event a problem

should develop in the blower or the system. This information is also helpful when ordering spare parts.

Model No. __________________________________ V-Belt Size ______________ Length _____________

Serial No. __________________________________ Type of Lubrication:

(Recorded from nameplate on unit) _____________________________

Startup Date ________________________________ ________________________

Pump RPM ________________________________ Operating Vacuum ____________________________

Pump Sheave Diameter ______________________ Any other special accessories supplied or in use:

Motor Sheave Diameter _______________________

Motor RPM _______________ HP ______________ ___________________________________________

NOTES:

4

KINNEY® KT™ SERIES MANUAL 1843-1

© 2003, Tuthill Corporation

INTRODUCTION

This manual applies to Kinney Vacuum models KT-150, KT-300, KT-500 and KT-850. You should be thoroughly

familiar with these instructions before attempting to install, operate or repair this unit. Consult Tuthill Vacuum &

Blower Systems when problems arise that cannot be resolved after reading this manual. Always include pump

nameplate information when ordering parts or components.

SPECIFICATIONS

KT-150 KT-300 KT-500 KT-850

Free Air

Displacement

Pump Speed (rpm) RPM 1055 870 721 581

Motor speed at 50

Hz

Motor speed at 60

Hz

Motor Power HP 7.5 15 30 40

Oil Capacity (total/

refill)

Cooling water at

60° F (16° C)

Cooling Water Inlet Inch

Suction, 150 lb.

ANSI Flanged

Discharge, 150 lb.

ANSI Flanged

CFM

m³/h

RPM 1,500 1,500 1,500 1,500

RPM 1,800 1,800 1,800 1,800

US gal.

Liters

Gpm

L/min

NPT

3 4 6 8

2 3 4 5

150

255

6/5

23/19

1/4 1.5/6 2.5/9 3.5/13

1/4” 3/8” 3/8” 3/8”

300

510

10/8.5

38/32

490

840

15/12.5

57/47

780

1325

28/25

106/95

Height w/o oil mist

eliminator

Floor Space Inches

Weight Lbs

Ultimate

Pressure

Noise Level

(Typical at 10 Torr)

Inches

mm

mm

Kg

Microns 10 10 10 10

dBA 71 72 73 75

43

1092

24x26

609x660

800

363

51

1295

27x34

686x864

1,525

692

63

1600

34x38

864x965

2,625

1,191

71

1803

38x49

965x1245

4,175

1,894

5

Description

The KT-Series pumps covered herein have an oil circulating pump to provide adequate lubrication at all pressures

including atmosphere. The vacuum pump has three cams and pistons pumping in parallel, driven by a common

shaft. The cams are positioned on the shaft so as to dynamically balance moving parts. This balancing technique

applied to the Rotary Piston Principle was developed by Tuthill Vacuum & Blower Systems and virtually eliminated

vibration.

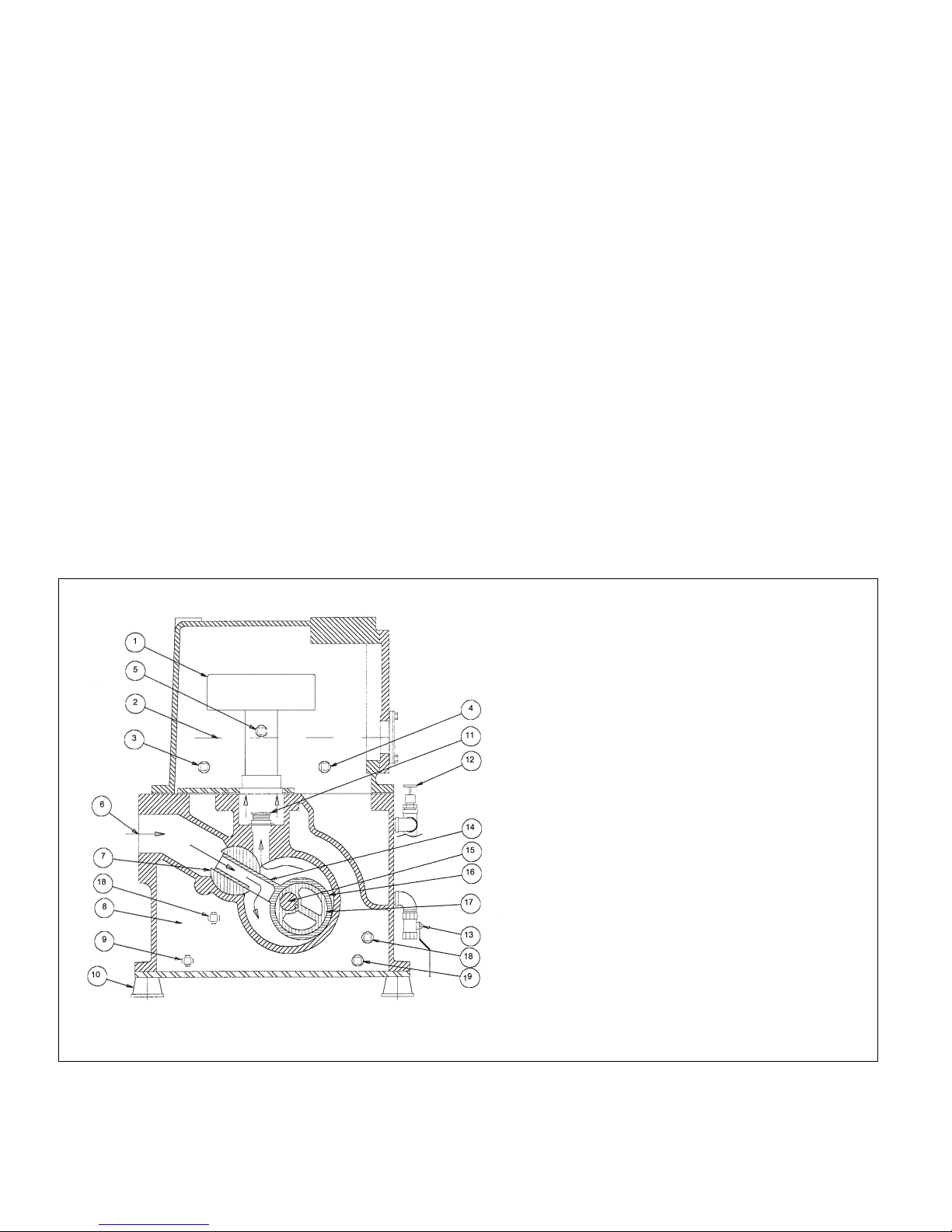

Figure 1. shows a cross section of the pump with the pistons being driven by the cams and revolving within the

cylinder.

Gas is drawn into the pump through a common inlet, channeled to the three piston slides and into the space behind

the pistons as they rotate. The gas ahead of the pistons is compressed and forced out the discharge valves. As the

gas is forced through the pump, sealing oil is mixed with the discharged gas and the discharged mixture is

channeled into the separator, which is located in the reservoir, and there the gas is separated from the oil. Sealing

and lubricating oil is provided by the oil pump which is mounted on the non-drive ahead and driven by direct

coupling to the vacuum pump drive shaft. The oil pump provides forced feed oil circulation at all operating pressures

including atmosphere.

All models have a channeled drive shaft with an opening at each cam to distribute oil through the pump.

Oil is taken from the reservoir at a point some distance above the reservoir bottom. This provides an area for

impurities to collect for draining.

Figure 1. Cross Section of KT Series Vacuum Pump

Key to Figure 1.

1. Air/Oil Separator

2. Oil Level

3. Connection for optional

temperature switch

4. Connection for optional temperature gauge

5. Connection for “scum” take-off

6. Pump Inlet

7. Slide Pin

8. Water cooling jacket

9. (Far Side) Cooling Jacket drain 1 of 2

10. Mounting Pads

11. Discharge Valve

12. Gas Ballast Valve

13. Oil Drain

14. Piston Slide

15. Shaft

16. Piston

17. Cam

18. Connection for optional heater

19. Cooling jacket drain 2 of 2

6

INSTALLATION

General

Installing the Vibramounts

KT pumps are supplied with vibramounts (vibrasprings on the KT-850) which enable them to run quietly and

vibration free. The pump can be operated on any floor which will support its weight. The pump must be installed on

the vibramounts and flexible connectors fitted in suction, discharge, water and electrical connections. It is not

necessary to bolt the pump to the floor.

If the studs are not already installed into the vibramounts, thread the short end into the top of the mount (smaller

diameter) up to the spacer portion of the stud.

The vibramount attachment holes are the four open threaded holes in the flanged edges of the cylinder, in line with

the bottom plate/cylinder bolts, just in from each corner of the pump.

DO NOT USE THE FOUR UNTHREADED HOLES WHICH ARE USED FOR SHIPMENT ONLY.

With the pump lifted off the ground, thread the vibramounts with studs into the vibramount attachment holes until

contact is made between the top of the vibramount and the cylinder bottom plate, and the foot location is parallel to

the pump shaft.

Care must be taken to set the pump down squarely on the mounts when installing the pump in operating position.

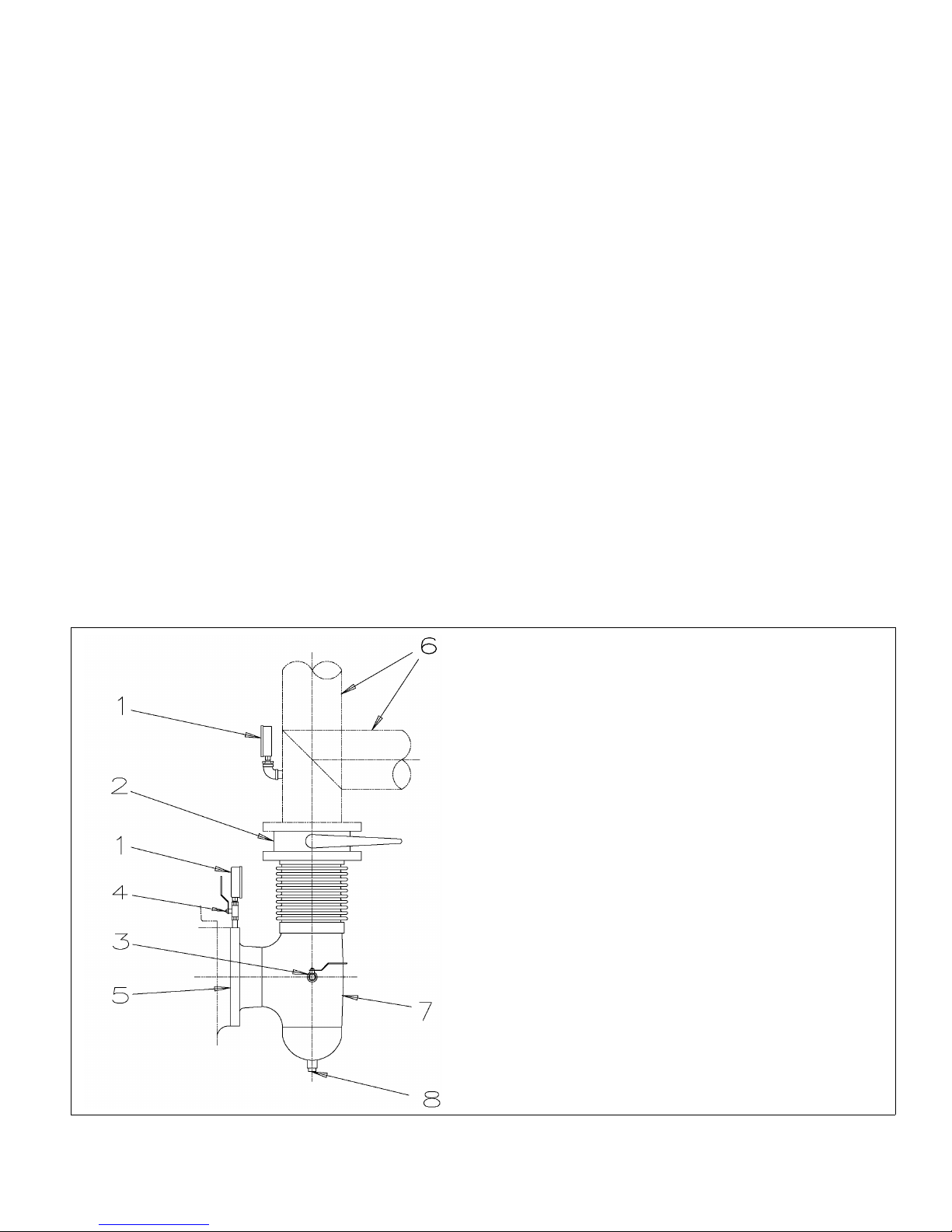

Figure 2. Detailed Manifold Arrangement

Key to Figure 2.

1. Vacuum Gauge

2. Isolation Valve

3. Air Vent Valve

4. Shut Off Valve

5. Pump Suction Flange

6. To System

7. Right angle flexible connector

8. Trap drain

7

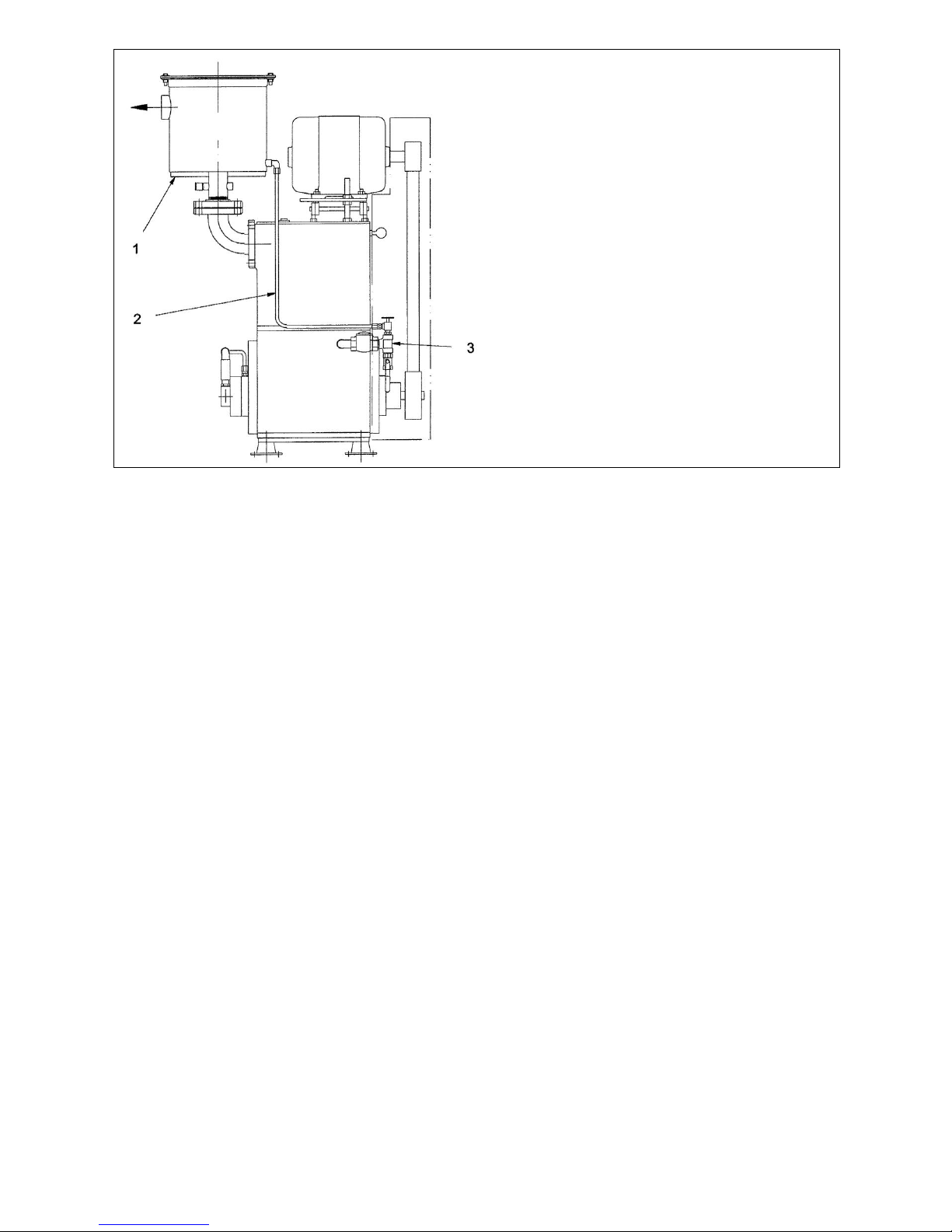

Key to Figure 3.

1. Oil Mist Eliminator

2. Oil Return Line

3. Gas Ballast Assembly

(standard arrangement)

Figure 3. Oil Return to the Gas Ballast Valve

Suction Manifolding

Inlet manifolding should be sized and designed with four objectives in mind:

A. To avoid gas flow restrictions.

B. To prevent pump fluids from entering the process chamber.

C. To protect the pump from the ingestion of particulate matter.

D. To allow proper venting of the pump and suction manifold.

Under the normal conditions, the diameter of the manifolding should not be less than the diameter of the pump

connection and the pipe length should be kept to a minimum.

Oil may splash from inside the pump through the suction port so the suction line must be designed to prevent oil

from collecting there and draining back to the system or process. See Figure 2 for recommended arrangements as

a guide for fabricating inlet manifolding.

A flexible connection should be installed in the suction manifold to provide freedom for vibramounts. The vacuum

piping must be well aligned with the pump connections so as not to place a strain on the piping.

Provisions for gauge installation and any other drilling in the piping must be made prior to piping installation,

otherwise, drilling particles entering the piping could be entrained into the pump. A vacuum isolation valve should be

installed adjacent to the suction port to be used for leak checking, shutting down the system, or blanking off the

pump.

Before connecting the suction manifolding, distribute 4 quarts of oil over the three slide pins. This will necessitate

reaching through the suction port with a container and pouring oil directly onto the slide pins. Then rotate the pump

by hand a minimum of two revolutions to distribute the oil throughout the pump interior.

During the initial operation and as long thereafter as necessary, a fine mesh screen should be installed across the

inlet connection to prevent abrasive or solid particles left in the line from being sucked into the pump. This screen

can be removed when particles no longer accumulate. If particles continue to accumulate, a filter should be installed

in the line.

8

Proper Venting

The Vacuum pump must be properly vented to ensure all oil is removed from the pumping chamber before the

pump is turned off. Also, the suction line must be properly vented to ensure oil does not migrate into the process

chamber.

Recommended vent valve sizes:

KT-150 .75 inch

KT-300 1.0 inch

KT-500 1.5 inches

KT-850 2.0 inches

The vent valve must be open for at least 10 seconds before the pump is turned off to remove all oil from the pumping

chamber.

Discharge Manifolding

Discharge manifolding should be sized and designed to prevent the following:

A. Return of oil mist condensate to the pump

B. Oil loss

C. Oil mist in the discharged gas.

Under the normal conditions, the diameter of the manifolding should not be less than the diameter of the pump

connection and pipe length should be kept to a minimum.

The installation of a Kinney oil mist eliminator on the discharge is recommended for all applications, (as shown in

Figure 4). Oil which collects in the eliminator should be returned to the pump. The optional oil return kit will drain

allow oil to back into the separator housing when the pump is operating at low pressure or when the pump is

stopped. If the pump is to operate continuously, or normal operating pressure is between 10 torr (13 mbar) and 150

torr (200 mbar), the oil return should be connected to the gas ballast as shown in Figure 3. Over 150 torr (200 mbar)

the oil return should be connected to the pump inlet.

It may be necessary to pipe the pump exhaust fumes away from the pump area, such as outdoors. If this is done,

the piping must be arranged to prevent line condensation from returning to the pump. A flexible connector should be

fitted in the discharge line to provide freedom for the vibramounts.

Cooling Water

The cylinder cooling water jacket is shipped dry, with the drain plugs removed. They are tied to the pump in a small

cloth bag. Replace the plugs in the positions shown in Figure 1 and fill the water jacket before starting the pump.

If an optional water flow modulating valve (Water Miser) is fitted, the cylinder may take 20 minutes or more to fill. The

delay can be avoided by lifting the spring to open the valve. For installation of the valve see Figure 6.

Failure to ensure that the cooling water jacket is filled before starting the pump will result in localized over-heating of

the pump and cause extensive damage.

For installations requiring starting at ambient temperatures lower than 60°F (16°C), electric heaters should be

installed in the water jacket. (See Figure 5.)

9

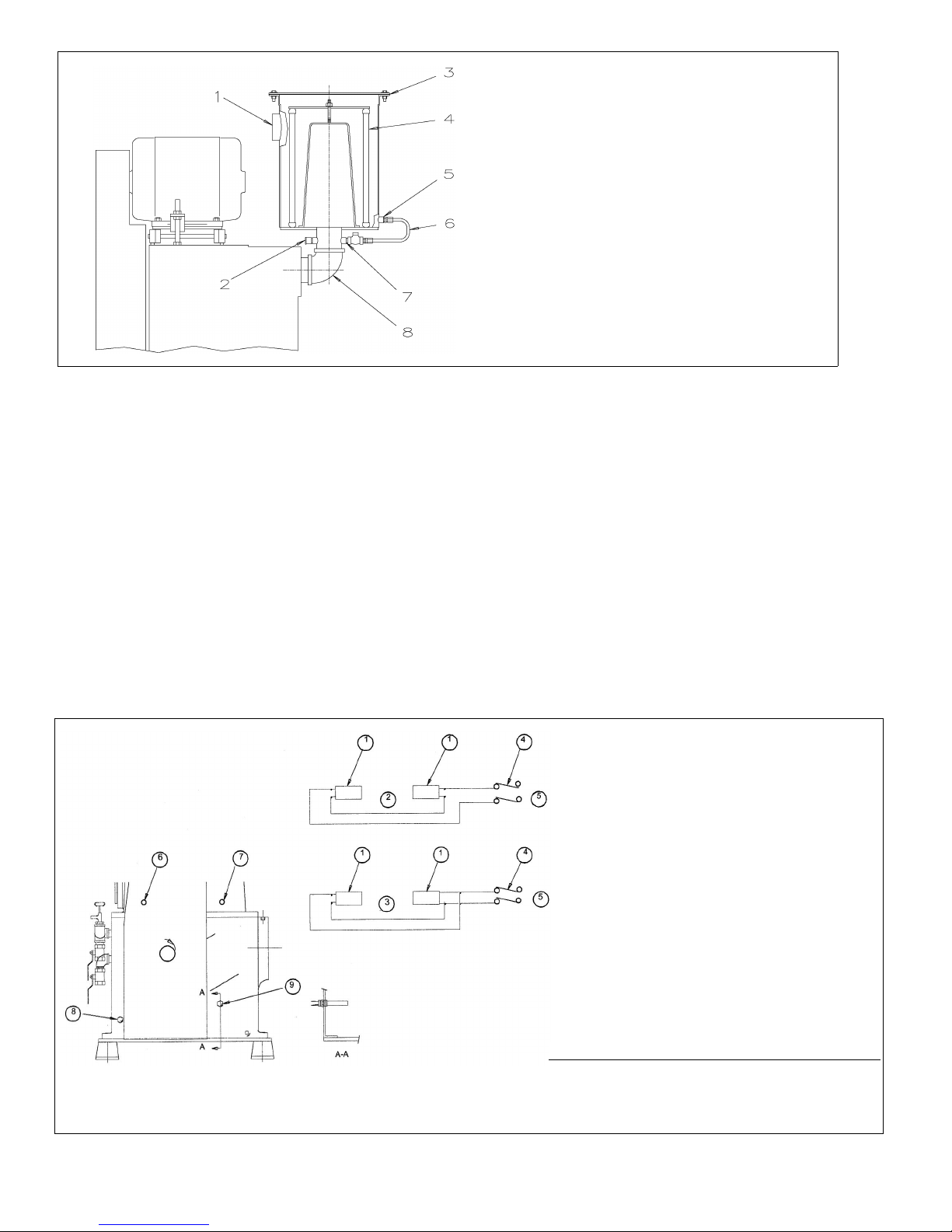

Key to Figure 4.

1. Discharge connection

2. Relief Valve

3. Top cover gasket

4. Element

5. Oil Drain Connection

6. Optional oil drain line

kit

7. Oil Return connection

Figure 4. Oil Mist Eliminator

DO NOT ALLOW THE COOLING WATER TO FREEZE IN THE PUMP.

Freezing of the cooling water jacket usually results in extensive damage to the pump cylinder which cannot be repaired.

Connect a water supply line with “on-off” valve to the water inlet, and an open drain to the water outlet. The inlet

line should have a flow regulating valve. If the water supply unreliable, it is advisable to install a flow switch to stop

the pump or signal when the flow is interrupted. Normally the cooling water will be off when the pump is not running.

A water pressure relief valve is fitted in the water jacket. This relief valve is set to open at 50 PSIG (3.5 bar).

Standard cooling water rates are for up to 80°F (26°C) supply temperature and operation within the design continuous operating pressure range of .1 to 100 Torr (.13-130 mbar a). Sustained operation above 100 torr (130

mbar) and/or long pump downs generally require larger cooling water flow rate and/or external oil heat exchanger.

Larger cooling water rate increases cooling efficiency reduces heat dissipation to room and keeps oil cooler

Key to Figure 5.

1. Heaters

2. For 460 volts

3. For 430 volts

4. Switch

5. Input (fuse protected)

6. Temperature Gauge

7. Optional temperature switch

8. Install (1) heater into ¾ NPT tap far side (½

NPT on KT150, 300)

9. Install (1) heater into ¾ NPT tap this side (½

NPT on KT150, 300)

Before energizing heaters:

1. Be sure water jacket is filled.

2. Turn off cooling water supply.

3. Do not restrict cooling water outlet.

Pump Heaters P/N

KT-150 (2) 300W 074501-0000

KT-300 (2) 500W 074502-0000

KT-500 (2) 750W 074503-0000

KT-850 (2) 1000W 074504-0000

Figure 5. Water Jacket Heater Installation

10

Loading...

Loading...