NO.9CCF

MULTIFUNCTIONAL IGBT INVERTER

MULTIFUNCTIONAL IGBT INVERTER

SPOT WELDING MACHINE

SPOT WELDING MACHINE

Read this manual and follow all the safety rules and

operating instructions before using this product.

http://www.kingtony.com

Enjoy your work

Contents

1. Safety Precautions Symbols

2. Symbols and Definitions

3. Accessories and Spare Parts List

4. Installation

1. Specifications

2. Duty Cycle and Overheating

3. Machine Installation

4. Selecting a Location

5. Connecting Input Power

5.

Operation

1. Controls

2. Welding Gun and Adaptors

3. Various Operations

a. Spot Welding

b. Washer Welding

c. Triangle Washer Welding

1

2

3

4

4

5

5

6

7

8

9

10

11

d. Carbon Rod Heating

e. Wriggle Form Wire Welding

f. Cupules

6. Maintenance

1. Troubleshooting

12

13

14

15

Safety Precautions Symbols

Protect yourself and others from injury,read and

follow these precautions before installation and operation

Read instructions

1.Read owners Manual before using or servicing unit

2.Use only manufacturer’s supplied replacement

Exploding parts can injureAlways wear a face shield

and long sleeves

Static can damage PC boards

1.Put on grounded wrist strap before handing boards or parts

2.Use proper static-proof bags and boxes to storemoveor

ship PC boards

1.Wear approved face shield or safety goggles with side shields

2.Wear proper body protection to protect skin

Flying metal can injure eyes

1.Wear safety glasses with side shields or face shield

1.Magnetic fields can affect pacemakers Pacemaker

wearers keep away

2.Wearers should consult their doctor before going near

plasma arc cutting operations

Electric shock can kill

1.Do not touch live electrical parts

2.Wear dry,hole-free insulating gloves and body protection

3.Do not wrap electrical cable aroundyour body

4.Ground the workpiece with a good electr- ical ground

Fumes and gases can be hazardous welding produces fumes and gases

Breathing these fumes and gases can be hazardous to your health

If inside,ventilate the area

Do not weld in a confined space only if it is well ventilated

Eye protection for welding

Current level in amperage Minimum shade number

30-150A---------------------------#8

150-300A-------------------------#10

300-500A-------------------------#12

Moving parts can cause injury

Keep away from moving parts such as fans

The heat from the workpiece can cause serious burns

.

.

Overuse can cause overheating

Allow cooling period ,follow rated duty cycle before startingto

weld again.

Cylinders can explode if damaged

Gas cylinders contain gas under high pressure

If damaged,a cylinder can explode Be sure to treat them carefully

Do not weld in the height !

Fire or explosion hazard

Do not locate unit on,over,or near combustibe surfaces

Do not install unit near flammables

Protect yourself

Warn others

Keep away from the torch tip

Remove all flammables of the welding area

Falling unit can cause injury

Never cut on pressurized cylinder

Factory safety

Maintenance regularly

1

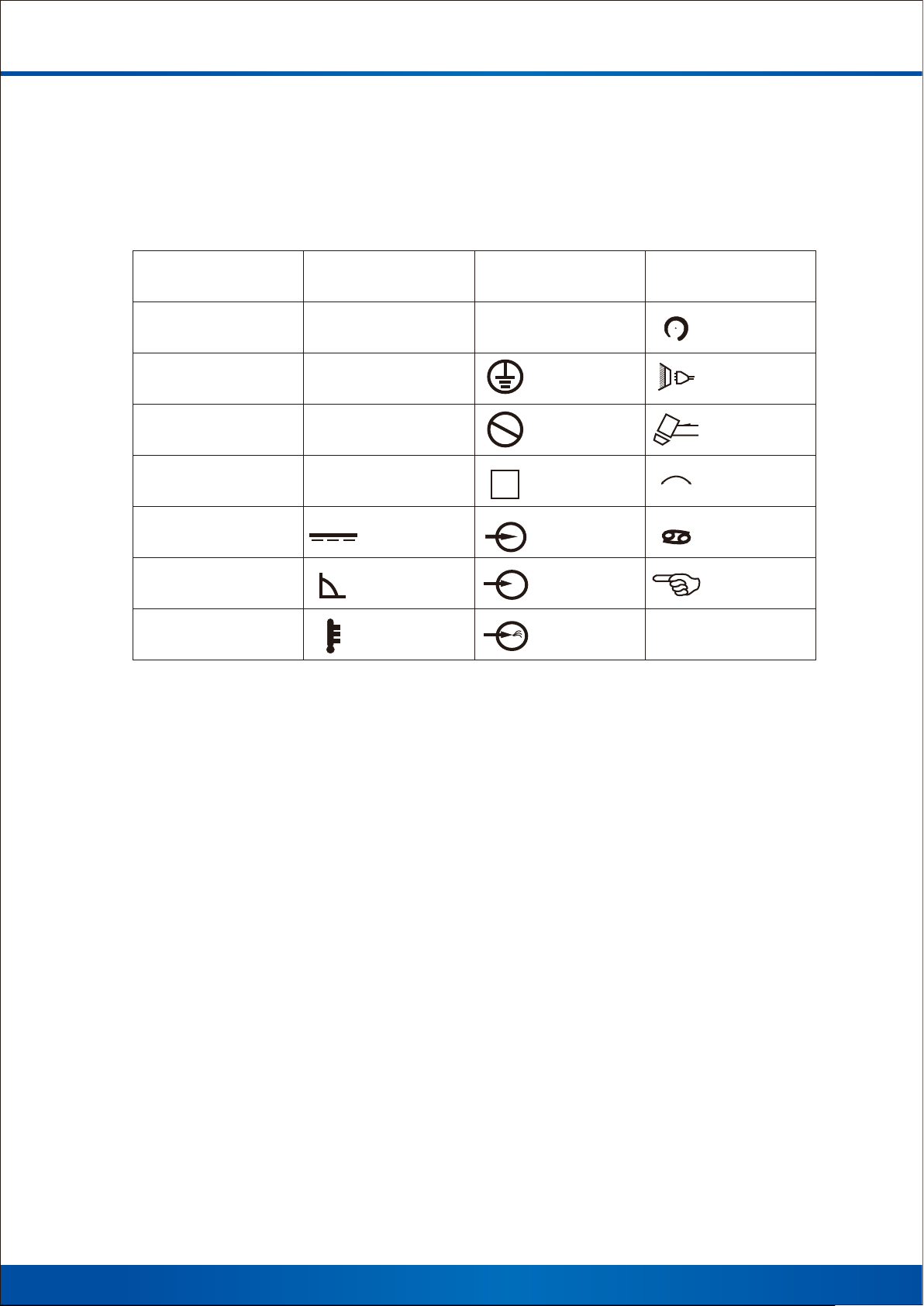

Symbols and Definitions

A

V

I

2

S

1

HZ

U

1

U

0

U

2

Amperes

Volts

Ra te d we ld in g

cu rr en t

Power rating,

productof voltage

and current(KVA)

Hertz

Pr im ar y vo lt ag e

Rated no load

voltage(Aaverage)

Conventional

load voltage

I

1m a x

I

1eff

IP

1

~

X

Rated maximum

supply current

Maximum effective

supply current

Degree of protection

Si ng le p ha se

Du ty c yc le

Direct current

Constant crrent

Temperature

I

O

S

V

On

Of f

Protective earth

(Ground)

Do not do this

Suitable for some

hazardous locations

In pu t

Vo lt ag e in pu t

Low air pressure

light

%

+ -

Pe rc en t

In cr ea se

Li ne c on ne ct io n

Lo os e sh ie ld c up

Adjust air/gas

pressure

Au to ma ti c

Ma nu al

2

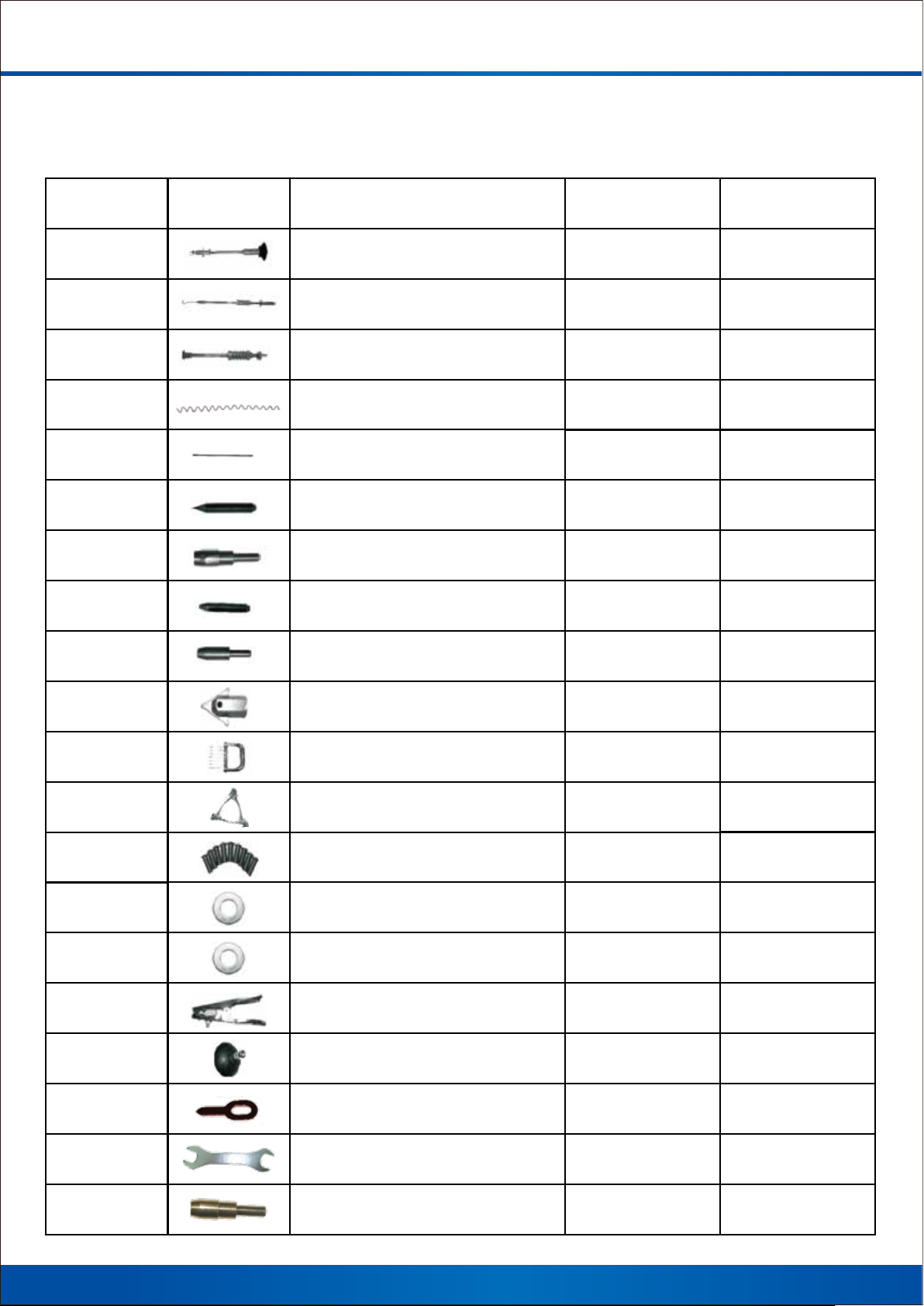

Accessories and Spare Parts List

KT NO. Product Descripon 9CCF31-1AA-B 9CCF41AA-B

KT001 Pneumac vacuum cupule

KT002 Pull hammer

KT003 Dent pulling spot hammer

KT006 Wavy wire

KT007 Carbon rod

KT008 Spot welding electrode p

KT009 Carbon and connector

KT010 Wavy wire electrode p

KT011

Washer connect

X

1 Set

1 Set

15 PCS

3 PCS 3 PCS

1 PCS

1 PCS

1 PCS

1 PCS

X

1 Set

X

X

X

1 PCS

X

1 PCS

KT013 Triangle washer connect

KT014 Claw

KT015 Triangle washer

KT016 Stud

KT017 Ø12mm washer

KT017-1 Ø10mm washer

KT018 Earth clamp

KT019 Manual cupule

KT030 OT washer

X

1 PCS

10 PCS

X

15 PCS

15 PCS

1 PCS

1 PCS

X

1 PCS

1 PCS

10 PCS

X

15 PCS

15 PCS

1 PCS

1 PCS

X

KT033 W

KT034 Stud connect

rench

or

3

1 PCS

X

1 PCS

X

Installation

1. Specifications

Model 9CCF31-1AA-B 9CCF41AA-B

Input voltage

220V / 380V

50/60Hz

Input power 6.5 KVA 6.3 KVA

Input current 42A/14A 40A/12A

Max instant current 2600A 2500A

Output power 1-13V 1-13V

Electronic

Operaon way

mer connuously

Welding me 0-99 s 0-99 s

Dimensions 370 * 230 *280 mm 370 * 230 *280 mm

Weight 9.5 kg 9.0 kg

220V / 380V

50/60Hz

Electronic

mer connuously

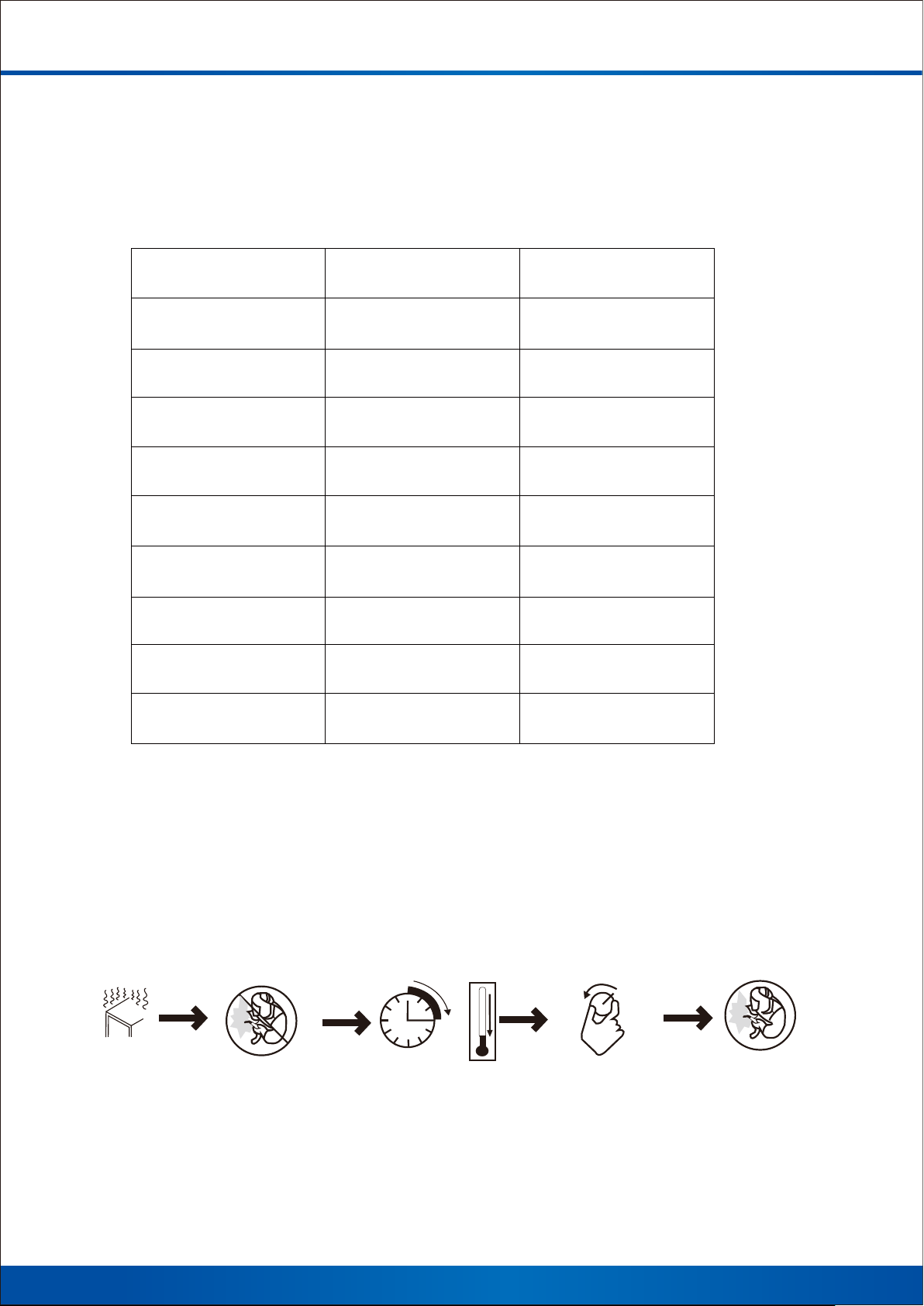

2. Duty Cycle and Overheating

Duty cycle is percentage of 10 minutes that unit can weld at rated load

without overheating.

If unit overheat, output stops, and cooling fan runs. Wait 15 minutes for

unit to cool. Reduce amperage or duty cycle before welding.

0

A

15

Overheating

Stop working Wait fifteen minutes

for unit to cool

Reduce amperage

or reduce duty cycle

Weld again

4

3. Machine Installation

Open the package and check the details of supplied accessories than

properly install this equipment as follow diagram.

4. Selecting a Location

a. Select a correct location to place the unit.

b. Determine input power cord length according to its actual operation requirement.

Input power cord must have a minimum inside diameter of 6mm² .

c. Use cart or unit handle to move unit. Do not pull the cords to move or operate unit

where it could tip.

5

5. Connecting Input Power

AC 220V

3

AC 380V

2

L1

L2

3

L3

1. Input power cord. (not less than 6mm² copper cord)

2. Over-current protection.

3. Disconnect device line terminals.

4. Ground wire L1 / L2 input conductors.

■ Installation must meet all national and Local

Codes-have only qualified persons make this installation.

■ Disconnect and lockout/tagout input power before

connecting input conductors from unit.

■ Select type and size of over-current protection.

■ Close and secure door on disconnect device.

Remove lockout / tagout device, and place switch

in the “on” position.

6

Operation

1.Controls

11

12

7

8

5 6

1

2

3

9

4

10

1. Power indicator

2. Error indicator

3. Overheat indicator

4. Gun trigger indicator

5. Spot welding time display

6. Power percentage display

7 / 8. Spot welding time adjustment

9 / 10. Power percentage adjustment

Instruction:

1. Connect input power properly and safely.

2. Turn on the power switch and selection buttons according to required

working mode.

3. Appropriately adjust welding time and power according to actual situation.

4. After setting the parameters, the machine enters into standby mode and

is ready to weld.

5. When the temperature exceeds normal working temperature, the indicator

will light and overload protection will start. Wait few minutes until the light off,

then use the machine again.

6. The error indicator will light when the machine goes wrong, and the machine

enters into automatic protection mode. Cut off the power supply then check,

use the machine again until the problems are solved.

7

2. Welding Gun and Adaptors

2

Single-Sided applications

1

1. Electrode holder

2. Trigger

Connection of negative wire

1. Weld two washers onto the dented

area that needs repairing.

2.Put the ground cable onto

the welded washers.

Carbo Rod Shrinking

OT Washer Welding

Washer Welding

Stud Welding

Single-sided Welding

Wave form Wire Welding

Pulling Spot Hammer

5. Tighten the screw to

securely fix the clamp.

3. Place the earth

clamp over the

welded washers.

8

4. Insert the bolt through

washers and clamp.

3. Operation

a. Spot Welding

Connect negative outside

wire to a clean paint free

location on metal workpiece

as close to welding area as

possible

Set correct time

.

Connect spot welding

electrode tipwith welding

gun and tighten

Select welding function Approximately a 90° angle to

Set correct power

(Position C is recommend)

the workepiece surface

Put on pressureand press trigger

Remark :

1. Setting amperage too high or time too long can cause workpiece surface damage.

2. Setting correct amperage and time according to the workpiece thickness.

3. Continuing another operation is applicable after these procedures finished.

If not, please shut the power off and switch off the unit.

9

b. Washer Welding

Connect negative outside

wire to a clean ,paint free

location on metal workpiece

as close to welding area

as possible.

Set correct time.

Connect washer adaptor with

welding gun and tighten,

Install washer.

Select welding function. Approximately a 90°angle.

Set correct power.

(Position A orB is recommend)

to the dent. Put on pressure

and press trigger.

Remove welding gunHook

the washer with pull hammer

Slide the hammer to opposited

irection to pull out the dent .

Remark :

1. Setting amperage too high or time too long can cause workpiece surface damage.

2. Setting correct amperage and time according to the workpiece thickness.

3. Continuing another operation is applicable after these procedures finished.

If not, please shut the power off and switch off the unit.

10

c. Triangle Washer Welding

Connect negative outside

wire to a clean paint free

location on metal workpiece

as close to welding area

as possible.

Set correct time.

Connect triangel washer

pull hammer with welding gun.

Select welding function.

Set correct power

(Position A is recommend)

Approximately a 90° angle to the

dent. Put on pressure and

press trigger.

Slide the hammer to opposite

directionto pull the dent.

Remark :

1. Setting amperage too high or time too long can cause workpiece surface damage.

2. Setting correct amperage and time according to the workpiece thickness.

3. Continuing another operation is applicable after these procedures finished.

If not, please shut the power off and switch off the unit.

4. Triangle washer welding can replace washer welding. It can draw out the concavity

directly after welded.

11

d. Carbon Rod Heating

Connect negative outside

wire to a clean paint free

location on metal workpiece

as close to welding area

as possible.

Set correct time.

Connect carbon rod and

carbon rod adaptor with

welding gun.

Select welding function.

Set correct power

(Position A is recommend)

Turn carbon rod clockwise to heat up

the entire convexity surface.

.

Cool the surface with a wet

rag or compressed air.

Remark :

1. Setting amperage too high or time too long can cause workpiece surface damage.

.

2. Setting correct amperage and time according to the workpiece thickness.

3. Continuing another operation is applicable after these procedures finished.

If not, please shut the power off and switch off the unit.

12

e. Wriggle Form Wire Welding

Connect negative outside

wire to a clean paint free

location on metal workpiece

as close to welding area

as possible.

Set correct time.

Connect wave form wire electrode

tip with welding gun.

Select welding function.

Set correct power

(Position A is recommend)

Place a wave form wire horizontally

on the dent Approximatelya 90°angle

to wave form wire Put on pressure

and press trigger.

Connect hook puller with pull hammer

Hook wave form wire and slide

the hammer to pull out the dent.

Remark :

1. Setting amperage too high or time too long can cause workpiece surface damage.

2. Setting correct amperage and time according to the workpiece thickness.

3. Continuing another operation is applicable after these procedures finished.

If not, please shut the power off and switch off the unit.

13

f. Cupules

Manual operating cupule

1. Connect manual operating cupule with pull hammer.

2. Push manual operating cupule in to lock the cupule on the concavity.

3. Slide the hammer to opposite direction to pull the dent out.

Pneumatic vacuum cupule

1. Connect gas/air supply with the adaptor of cupule.

2. Open the valve, sticking cupule to the dent.

3. Slide the hammer to opposite direction to draw the concavity out.

4. Cupule falls off when close the valve.

14

Maintenance

1. Troubleshooting

Problems

No weld output

Trigger not working

Poor weld

Piercing workpiece

Causes Solutions

1. Connected powersupply incorrectly

2. Power switch in off position

1. Trigger damaged

2. Gun control wire broken

3. Control wire plug loosen

4. Mode switch in incorrect position

1. Aamperage too low

2. Weld time too short

3. Input power cord did not meet the

requirement

4. Ground clamp bad contact

1. Output amperage too high

2. Weld time too long

3. Badcontact of electrode tip or

washer with workpiece

1. Connect power supplyaccording to

manufacturer’structions

2. Place power switch in “on”

1. Replace trigger

2. Connect again or replaceif

nec-essary

3. Connect control wire plug again

4. Place Mode switch in correct

pos-ition

1. Increase amperage setting

2. Increase time setting

3. Replace input power cord

4. Change ground clamp location

1. Reduce amperage setting

2. Rrduce weld time

3. Remove coating from material

reduce added pressure

Kriptol working

unstable

Unit stop working

while operation

1. Kriptol did not polish,workpieces

did not polish

2. ncorrect amperage and time setting

1. Trigger plug loosen

2. Gun control wire broken

3. Over heating

1. Polish kriptol and workpieces

2. Set amperage and time according

to workpiece thickness

1.Checkguncontrol wire and

trigger plug

2.Wait for temperature cool down

15

www.kingtony.com

customer service e-mail : service@kingtony.com

899DS11-KT 297x210mm

1

Loading...

Loading...