Kingsman ZV3600N, ZV3600NE, ZV3600LP, ZV3600LPE, ZV4200N Installation Instructions Manual

...

Installation Instructions Installation Instructions

Model Numbers: ZV3600N, ZV3600NE, ZV3600LP, ZV3600LPE, Model Numbers: ZV3600N, ZV3600NE, ZV3600LP, ZV3600LPE,

ZV4200N, ZV4200NE, ZV4200LP, ZV4200LPE are ZV4200N, ZV4200NE, ZV4200LP, ZV4200LPE are

Certified to: ANSI Z21.50b-2009, CSA 2.22b-2009, CGA 2.17-M91 Certified to: ANSI Z21.50b-2009, CSA 2.22b-2009, CGA 2.17-M91

ZERO CLEARANCE VENTED GAS FIREPLACE ZERO CLEARANCE VENTED GAS FIREPLACE

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Read this complete manual before beginning installation.

These instructions must be kept with the unit for future reference.

FOR YOUR SAFETY

WARNING: If the information in these instructions is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

Warning: Improper installation, adjustment, alteration, service or maintenance can cause property

damage, personal injury or loss of life. Refer to this manual. Installation and service must be performed by

a qualified installer, service agency or the gas supplier.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

What To Do If You Smell Gas

Do not try to light any appliance.

Extinguish any open flame.

Do not touch any electrical switch.

Do not use any phone in your building.

Immediately call your gas supplier from a neighbour's phone.

If you can not reach your gas supplier, call the fire department.

A Division of R-Co. Inc.

2340 Logan Avenue

Winnipeg, Manitoba, Canada R2R 2V3

Ph: (204) 632-1962

Printed in Canada Febru

y 21, 2013 Part # 36ZV-MAN

ar

2

Pre-installation Questions and Answers

About curing of the paint

Your stove or fireplace has been painted with the highest quality silicone stove paint. This paint dries quickly in 15-20

minutes when first applied at the factory. However, due to the high temperature silicone components, the paint will cure

when heat is applied to the appliance as it is first used. The following information applies to the curing process to get the

paint fully hard and durable.

Fire the appliance four successive times for 10 minutes each firing and a 5 minute cool down between each. Be aware

during log and firebox paint curing that a white deposit may be developing on the inside of the glass doors. It is important

to remove this white deposit from the glass doors using a commercial fireplace glass cleaner.

• Babies, small children, pregnant women and pets should leave the area during the cure phase.

• Ventilate well, open doors and windows.

• Do not touch during curing.

Why does my fireplace or stove give off odour?

It is normal for your fireplace to give off some odour. This is due to the curing of the paint, adhesives, silicones and any

undetected oil from the manufacturing process as well as the finishing materials used with the installations (e.g. marble,

tile and the adhesives used to adhere this product to the walls can react with heat and cause odours).

It is recommended that you burn your gas fireplace or stove for a minimum of four hours at a time with the fan off (if a fan

is present) after the curing of the paint has been completed. These odours can last upward to 40 hours of burn time; keep

burning at a minimum of four hours per use until odours dissipate.

Noise coming from the fireplace?

Noise is caused by the expansion and contraction of metal as the appliance heats up and cools down. This is normal and

is similar to the sounds produced by a furnace or heating duct. This noise does not affect the operation or longevity of

your fireplace.

Operating Instructions

1. Be sure to read and understand all the instructions in this manual before operation of appliance.

2. Ensure all wiring is correct and properly enclosed to prevent possible shock.

3. Check for gas leaks.

4. Make sure the glass door is properly installed before operation. Never operate the appliance with the glass door

removed.

5. Make sure venting and termination cap are installed and unobstructed.

6. If brick or porcelain liners are used, ensure they are installed.

7. Verify that the pilot can be seen when lighting the appliance. If not, the log or rock placement is incorrect.

8. If the unit is turned off, you must wait a minimum of 60 seconds before re-lighting it.

3

Table of Contents

Pre-installation Questions and Answers………………………………….............. 2

Operating Instructions………………………………………………………............. 2

Table of Contents……………………………………………………………............. 3

Warnings, Installations, and Operations………………………………….............. 4-5

Installation Requirements for the Commonwealth of Massachusetts…............. 5

Installation and Operation & Maintenance.......................................................... 6

Locating your Appliance..................................................................................... 7

Framing for your Gas Fireplace.......................................................................... 7-8

Clearance to Combustibles / Mantels................................................................. 9

Fan Installation.................................................................................................... 10

Installing Brick Panels......................................................................................... 11

General Glass Information.................................................................................. 12

Confirming Proper Venting of Appliance............................................................. 12

Log Assembly for Models ZV3600 and ZV4200................................................. 13

Log C42 Placement Guidelines.......................................................................... 14-15

Log C43 Placement Guidelines.......................................................................... 16-17

Log C44 Placement Guidelines.......................................................................... 18-20

Gas Line Installation........................................................................................... 21

Millivolt System, Lighting, and Burner Control.................................................... 22

Burner System Maintenance.............................................................................. 23

Conversion Kit Instructions – PART A................................................................ 23-24

Gas Conversion for Top Convertible Pilot (Series 019065X) – PART B............. 25

Gas Conversion for Modulator – PART C........................................................... 26

Spill Safety Switch.............................................................................................. 27

IPI Electronic Ignition System......................................................................... 28

Remote Control Operation.................................................................................. 29

IPI Electronic Ignition Parts List – Standard System.......................................... 30

IPI Configuration #1: Basic................................................................................. 31

IPI Configuration #2: Remote On / Off................................................................ 32

EGTM / GTM System -No Batteries.................................................................... 33

Configuration #3: Remote ON/OFF, Variable HI/LO, and Fan............................ 34

Electronic Ignition Lighting Instructions............................................................... 35

Vent Instructions................................................................................................. 36

Parts Lists........................................................................................................... 37-38

Trouble Shooting The Gas Control System........................................................ 39

-Glass Safety- All Units....................................................................................... 40

Limited Lifetime Warranty................................................................................... 41

Warnings, Installations and Operations

4

Installation Regulations

This gas appliance must be installed by a qualified installer in accordance with local building codes, or in the absence of local codes, with the current

CAN/CSA-B149.1 or .2 Installation Code (in Canada) or the current National Fuel Gas Code Z223.1-

This appliance, when installed, must be electrically connected and grounded in accordance with local codes, or in the absence of local codes, with the

current CSA C22.1 Canadian Electrical Code or with the National Electrical Code; ANSI/NFPA 70 when installed in the United States.

In the U.S.A

. Thermostats are not permitted for Vented Gas Fireplaces (ANSI Z21.50b-Decorative).

WARNING

FOR SAFE INSTALLATION AND OPERATION OF YOUR GAS FIREPLACE PLEASE NOTE THE FOLLOWING:

1. Do not clean when the glass is hot.

2. Do not use abrasive cleaners.

3. Using a substitute glass will void all product

warranties.

4. For safe operation, glass doors must be

closed.

5. When purging the gas line, the glass front

must be removed.

6. Do not strike or abuse glass. Take care to

avoid breakage.

7. Do not alter gas orifice.

8. No substitute materials may be used other

than factory supplied components.

9. This appliance gives off high temperatures and should be located out of heavy traffic areas and away from furniture and

draperies.

10. Children and adults should be alerted to the hazards of the high surface temperatures of this appliance and should stay

away to avoid burns or ignition of clothing.

11. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children

and others may be susceptible to accidental contact burns. A physical barrier is recommended if there are at risk individuals

in the house. To restrict access to a fireplace or stove, install an adjustable safety gate to keep toddlers, young children and

other at risk individuals out of the room and away from hot surfaces.

12. Under no circumstances should any solid fuels (wood, paper) be used in this appliance.

13. Under no circumstances should this appliance be modified. Any parts that have to be removed for servicing should be

replaced prior to operating this appliance.

14. Any safety screen or guard removed for servicing an appliance must be replaced prior to operating the appliance.

15. Installation and repair should be done by a qualified service person. The appliance should be inspected before use and at

least annually by a professional service person. More frequent cleaning may be required due to excessive lint from

carpeting, bedding material, et cetera. It is imperative that control compartments, burners and circulating air passageways of

the appliance be kept clean. Make sure that the gas valve and pilot light are turned off before you attempt to clean this unit.

16. Clothing or other flammable material should not be placed on or near the appliance. This appliance should not be used as a

drying rack for clothing nor should Christmas stockings or decorations be hung from it.

17. Do not use this heater if any part has been under water. Immediately call a qualified service technician to inspect the heater

and to replace any part of the control system and any gas control which has been under water.

18. Do not operate appliance unless completely installed as per installation instructions.

19. Failure to position the parts in accordance with these diagrams or failure to use only parts specifically approved with this

appliance may result in property damage or personal injury.

20. Do not operate appliance with the glass front removed, cracked or broken. Replacement of the glass should be done by a

licensed or qualified service person.

21. The front of the fireplace gives off high temperatures that could ignite combustible material which is kept close to the front of

the unit.

22. Ensure that power to the Fireplace is turned off before servicing.

23. Do not operate this Fireplace without the glass front or with a broken glass.

24. Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to the

owner’s information manual provided with this appliance. For assistance or additional information consult a qualified

installer, service agency, or the gas supplier.

25. Operation of this appliance when not connected to a properly installed and maintained venting system or tampering with the

blocked vent shutoff system can result in carbon monoxide (CO) poisoning and possible death.

26. This appliance is equipped with a three-prong (grounding) plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle. Do not cut or remove the grounding prong from this plug.

WARNING

NFPA 54 when installed in the United States.

HOT GLASS WILL

CAUSE BURNS

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

• Gas fired appliances may be used only for supplemental heat and/or decorative purposes and under no circumstances shall they

5

provide a primary heat source.

• This appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance.

NOTE: It is recommended that a Carbon Monoxide (CO) Detector be installed in or near bedrooms and on all levels of your home.

Place a detector about 15ft [4.5m] outside the room that houses your gas appliance.

Certified for installation in a bedroom or bed/sitting room. In Canada must be installed with listed millivolt thermostat.

In the U.S.A. Thermostats are not permitted for Vented Gas Fireplaces (ANSI Z21.50b-Decorative).

In USA see local codes.

Operations and Maintenance Instructions

For safe installation and operation note the following:

• Venting systems should be periodically examined by a qualified agency.

• The flow of combustion and ventilation air must not be obstructed.

• The Burner/Log Assembly has been engineered and permanently adjusted for proper flame control.

• Periodically remove the logs from the grate assembly and vacuum any loose particles from the grate and burner areas. See Log

Placement page to remove logs. Vacuum burner parts and replace logs.

• Never use your gas fireplace as a cooking device.

• Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify

proper operation after servicing.

Installation Requirements for the Commonwealth of

Massachusetts

In the Commonwealth of Massachusetts, the installer or service agent shall be a plumber or gas fitter licensed by the Commonwealth.

When installed in the Commonwealth of Massachusetts or where applicable codes; the unit shall be installed with a CO detector per the

requirements listed below.

1. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment, where the bottom of the vent

terminal and the air intake is installed below four feet above grade the following requirements must be satisfied:

A. If there is not one already present, on each floor level where there are bedroom(s), a carbon monoxide detector and alarm

shall be placed in the living area outside the bedroom(s). The carbon monoxide detector shall comply with NFPA 720.

B. A carbon monoxide detector shall be located in the room that houses the appliance or equipment and shall:

• Be powered by the same electrical circuit as the appliance or equipment such that only one service switch services

both the appliance and the carbon monoxide detector;

• Have battery back-up power;

• Meet ANSI./UL 2034 Standards and comply with NFPA 720; and

• Have been approved and listed by a Nationally Recognized Testing Laboratory as recognized under 527 CMR.

C. A Product-approved vent terminal must be used, and if applicable, a Product-approved air intake must be used.

Installation shall be in strict compliance with the manufacturer’s instructions. A copy of the installation instructions shall

remain with the appliance or equipment at the completion of the installation.

D. A metal or plastic identification plate shall be mounted at the exterior of the building, four feet directly above the location of

vent terminal. The plate shall be of sufficient size to be easily read from a distance of eight feet away, and read “Gas Vent

Directly Below”.

2. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment where the bottom of the vent

terminal and the air intake is installed above four feet above grade the following requirements must be satisfied:

A. If there is not one already present, on each floor level where there are bedroom(s), a carbon monoxide detector and alarm

shall be placed in the living area outside the bedroom(s). The carbon monoxide detector shall comply with NFPA 720.

B. A carbon monoxide detector shall:

• Be located in the room that houses the appliance or equipment;

• Be either hard-wired or battery powered or both; and

• Shall comply with NFPA 720.

A Product-approved vent terminal must be used, and if applicable, a Product-approved air intake must be used. Installation shall be in

strict compliance with the manufacturer instructions. A copy of the installation instructions shall remain with the appliance or equipment

at the completion of the installation.

For the state of Massachusetts a T-handle gas shut-off valve must be used on a gas appliance. This T-handle gas shut-off valve must be listed and

approved by the state of Massachusetts. This is in reference to the state of Massachusetts state code CMR238.

Installation and Operation & Maintenance

Installation Regulations

This gas appliance must be installed by a qualified installer in

accordance with local building codes, or in the absence of local

codes, with the current CAN/CGA-B149.1 or .2 Installation Code

(in Canada) or the current National Fuel Gas Code Z223.1 when

installed in the United States.

This appliance, when installed, must be electrically connected and

grounded in accordance with local codes, or in the absence of local

codes, with the current CSA C22.1 Canadian Electrical Code or

with the national Electrical Code; ANSI/NFPA 70-1987 when

installed in the United States.

The ZV3600 and ZV4200 model series is suitable for installation in

a bedroom or a bed/sitting room, when installed with a listed wall

thermostat.

FOR SAFE INSTALLATION AND OPERATION OF

YOUR GAS FIREPLACE PLEASE NOTE THE

FOLLOWING:

1. This appliance gives off high temperatures and should be

located out of heavy traffic areas and away from furniture

and draperies.

2. Children and adults should be alerted to the hazards of the

high surface temperatures of this appliance and should stay

away to avoid burns or ignition of clothing.

3. Children should be carefully supervised when they are in

the same room as your fireplace appliance.

4. Under no circumstances should this appliance be modified.

Any parts that have to be removed for servicing should be

replaced prior to operating this appliance.

5. Installation and repair should be done by a qualified service

person. The appliance should be inspected before use and

at least annually by a professional service person. More

frequent cleaning may be required due to excessive lint

from carpeting, bedding material, etcetera. It is imperative

that control compartments, burners and circulating air

passageways of the appliance be kept clean.

6. Control compartments, burners and air passages in this

appliance should be kept clean and free of dust and lint.

Make sure that the gas valve and pilot light are turned off

before you attempt to clean this unit.

7. The venting system (chimney) of this appliance should be

inspected at least once a year and if needed, your venting

system should be cleaned.

8. Keep the area around your appliance clear of combustible

materials, gasoline and other flammable vapors and liquids.

This appliance should not be used as a drying rack for

clothing nor should Christmas stockings or decorations be

hung from it.

9. Under no circumstances should any solid fuels (wood,

paper) be used in this appliance.

10. For safe operation, glass doors must be closed.

11. Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system and any

gas control which has been under water.

12. WARNING: Do not operate appliance with the glass front

removed, cracked or broken. Replacement of glass should

be done by a licensed or qualified service person.

13. Do not operate appliance unless completely installed as per

installation instructions.

14.

Gas fired appliances may be used only for supplemental heat

and/or decorative purposes and under no circumstances shall

they provide a primary heat source.

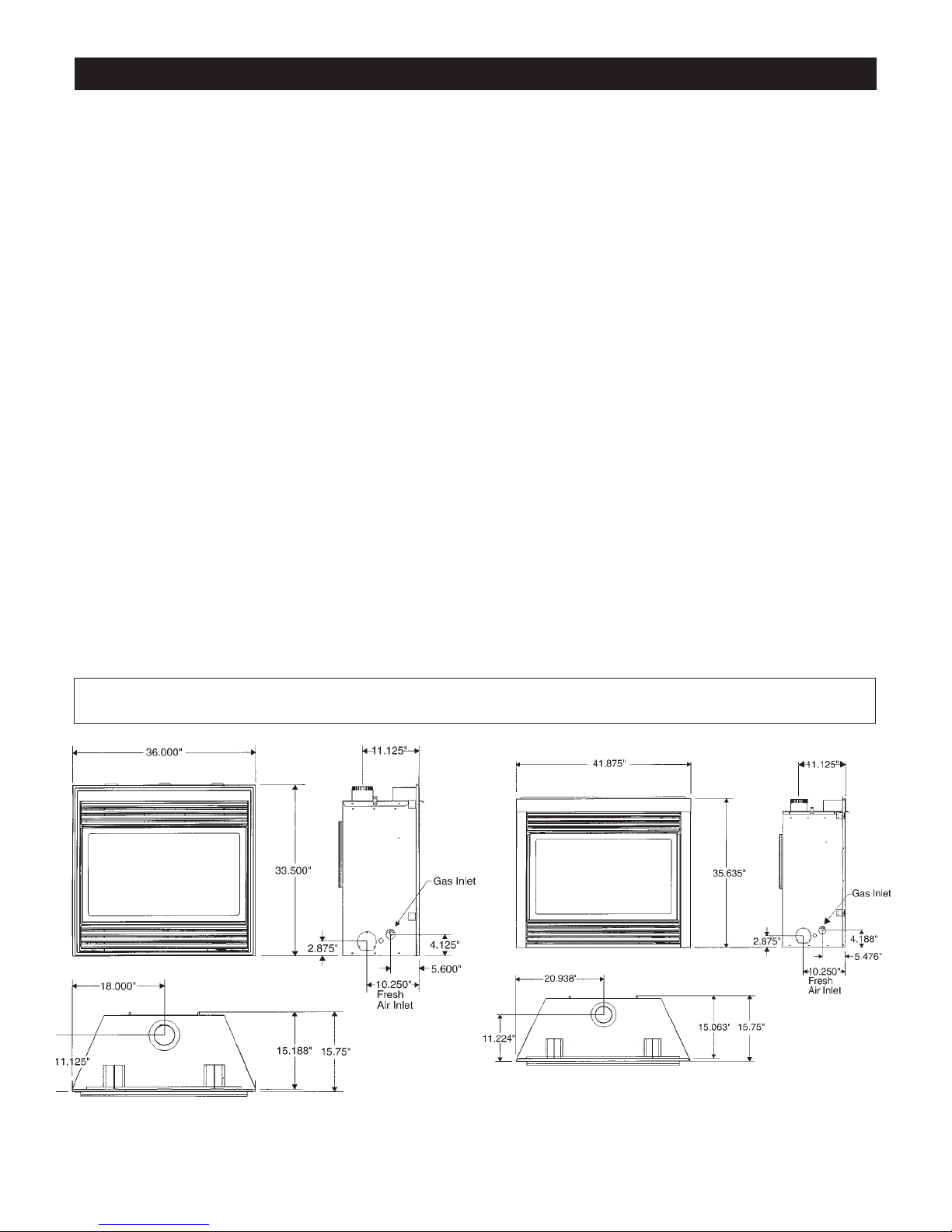

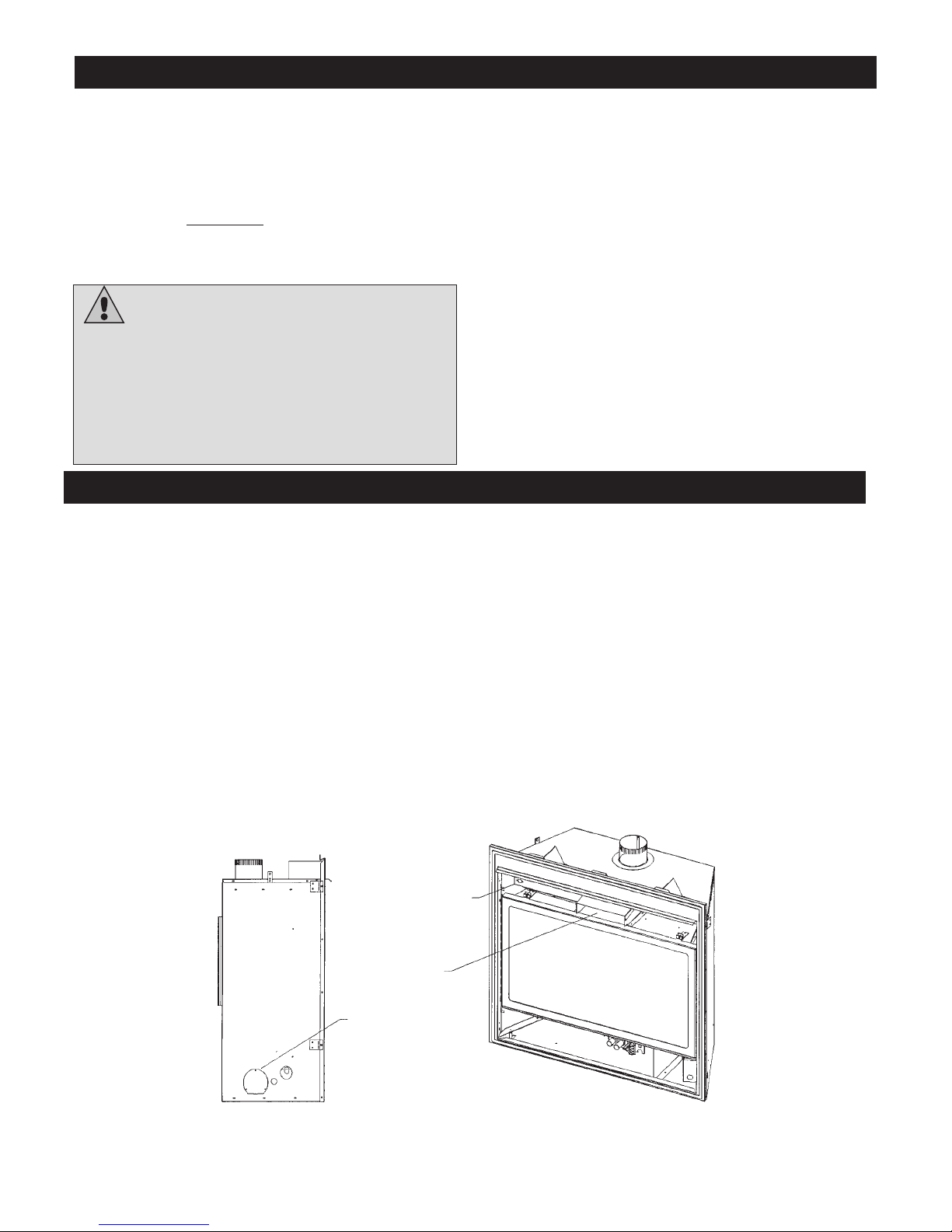

Dimensions for ZV3600

Dimensions for ZV4200

NOTE: It is recommended that a Carbon Monoxide (CO) Detector be installed in or near bedrooms and on all levels of your home. Place a

detector about 15 feet (4.5 meters) outside the room that houses your gas appliance.

6

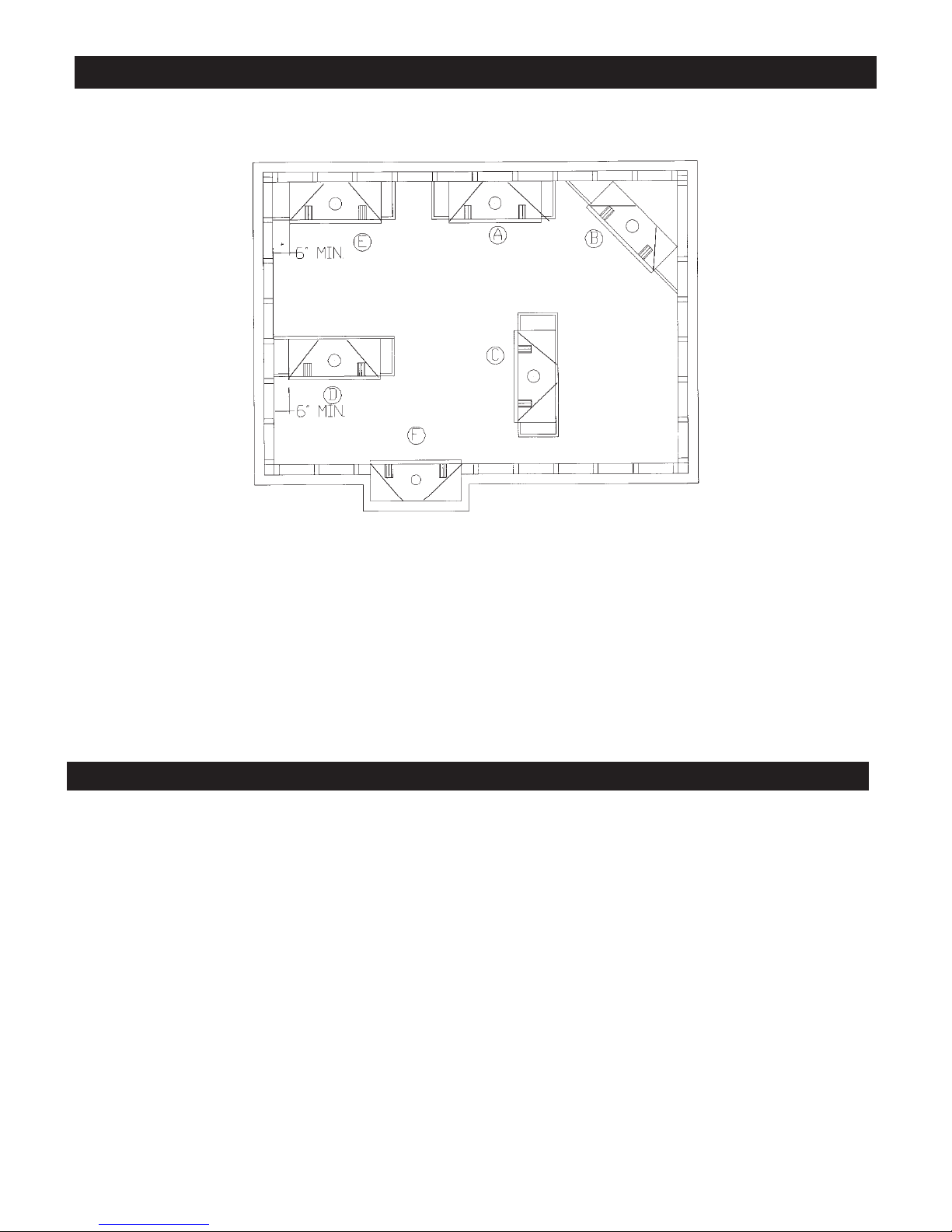

Locating your Appliance

(above or below grade)

Installing with Top Vent

When you install your fireplace as in position ‘B’, ‘D’ or ‘E’, a minimum

of 6 inches (153mm) clearance must be maintained from the perpendicular wall and the front of the appliance.

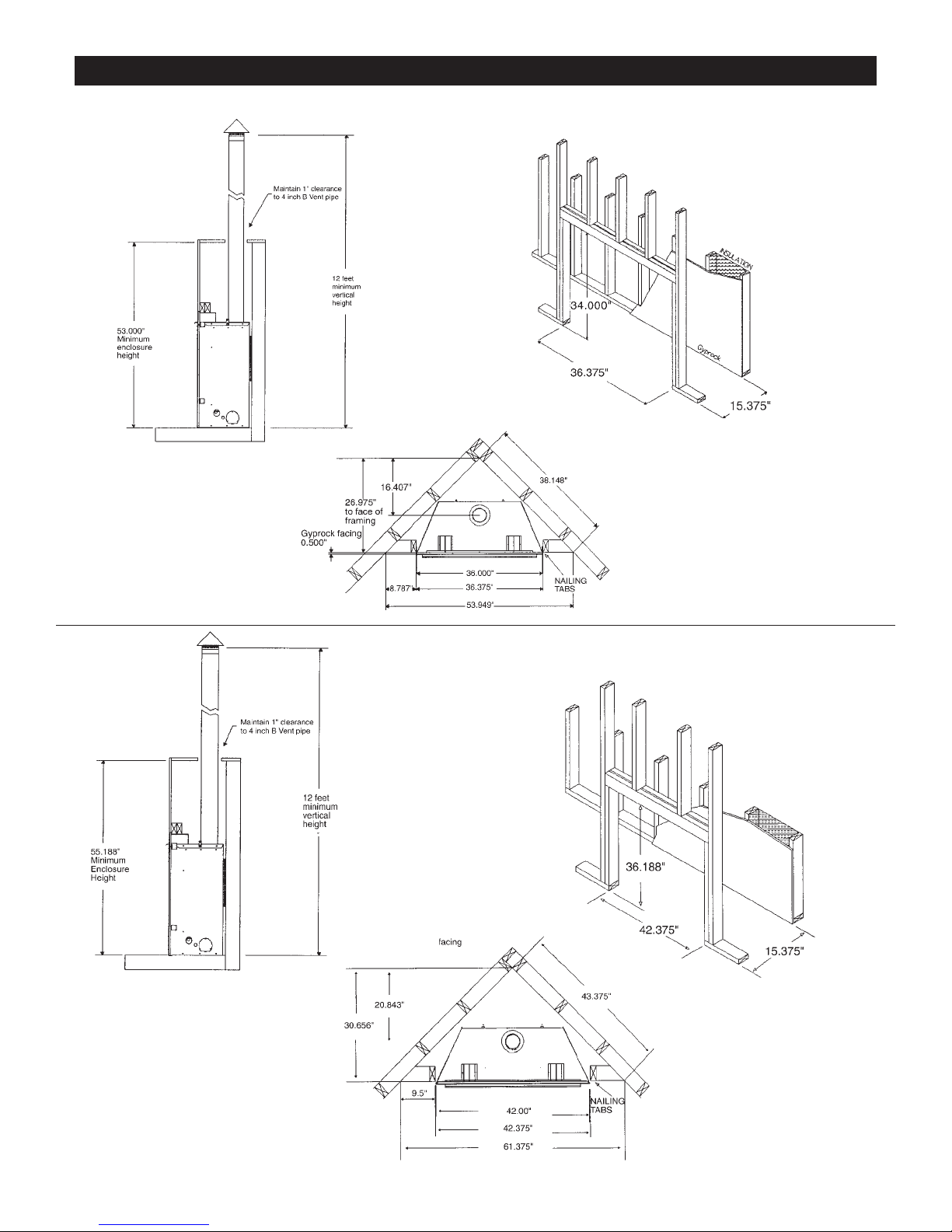

Framing Specifications

1. Cold climate installation recommendation: when installing this fireplace against non-insulated exterior wall or chase, it is recommended that the outer walls be insulated to conform to applicable insulation codes. Drywall should be installed over insulation to prevent

contact of insulation and unit.

2. Choose fireplace location and frame in accordance with the fireplace dimensions specified (See framing diagrams). Bend nailing tabs

forward on left and right of unit and place fireplace into framed enclosure. This allows for 1/2” in front of framing tabs for finishing

materials.

3. Drywall or other material can extend flush with the appliance on the bottom and sides of the fireplace.

4. Non-combustible materials such as brick and tile can be extended across the face of the fireplace. If wide brass trim kit is going to be

installed, brick and tile will have to be installed flush with the front of this appliance. If slim line brass trim kit is used, brick or tile may

extend past the front of unit.

Framing for your Gas Fireplace

A - Flat on a wall D - As a room divider

B - Across the corner E - Flat on wall corner

C - As an island F - Exterior wall

7

Framing for your Gas Fireplace (cont.)

FRAMING FOR ZV3600

FRAMING FOR ZV4200

4” B-Vent

4” B-Vent

8

Warning:

Combustible objects must not be placed on

a non-combustible mantel unless the non-combustible mantel

meets the minimum height and width requirements for a

combustible mantel.

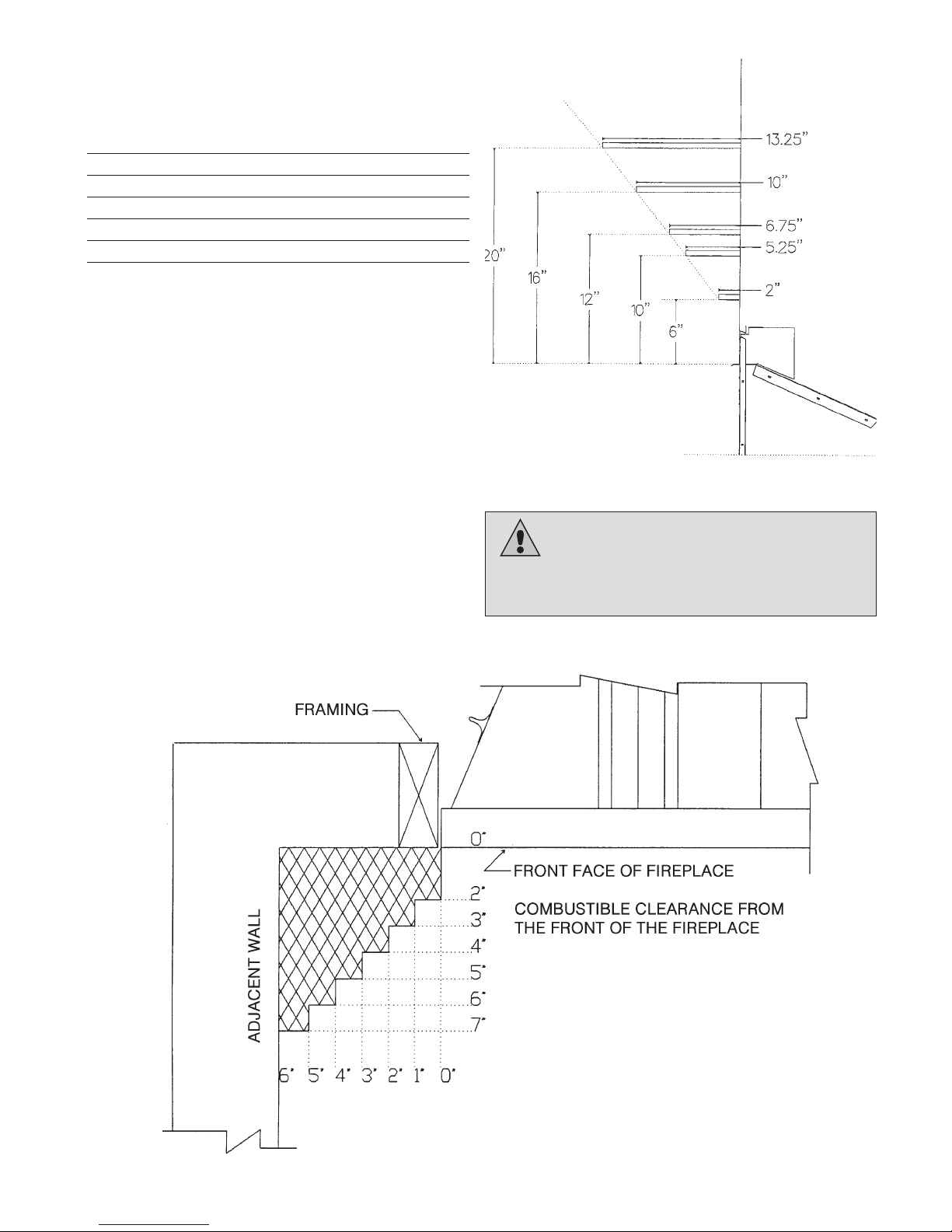

Clearance to Combustibles

Back (from Standoffs) 0 inches/0 mm

Side (from standoffs) 0 inches/0 mm

Floor 0 inches/0 mm

Top (from standoffs) 0 inches/0 mm

Top (from front of unit) 0 inches/0 mm

Note: See Mantel Chart

Hearth

A hearth is not mandatory but is recommended for aesthetic purposes. We recommend a non-combustible hearth projecting out

12” (305mm) or more in front of the fireplace.

9

Mantels

Depending on the width of the fireplace mantel, it may be

installed higher or lower from the top of the fireplace opening.

See drawings for proper installation height of your combustible

mantel. Non-combustible mantels may be installed at any height

above the fireplace opening.

Non combustible materials such as brick, tile, etc. can extend up

to or over the front face of the fireplace (NO PORTION OF

GRILL AREA OR DOOR AREAS CAN BE COVERED).

Combustible material can extend flush to unit up to the top, bottom and sides of fireplace to stand-offs.

If slim line brass surround is used, brick, tiles or other NONCOMBUSTIBLE materials may extend past the front of unit giving a recessed appearance. For COMBUSTIBLE materials

extending in front of fireplace consult “Mantel and Mantel Leg

Drawings”.

If wide brass surround is used finish materials must be flush with

front of unit.

Note: When using paint or lacquer to finish the mantel, such

paint or lacquer must be heat resistant (250˚F) to prevent

discoloration.

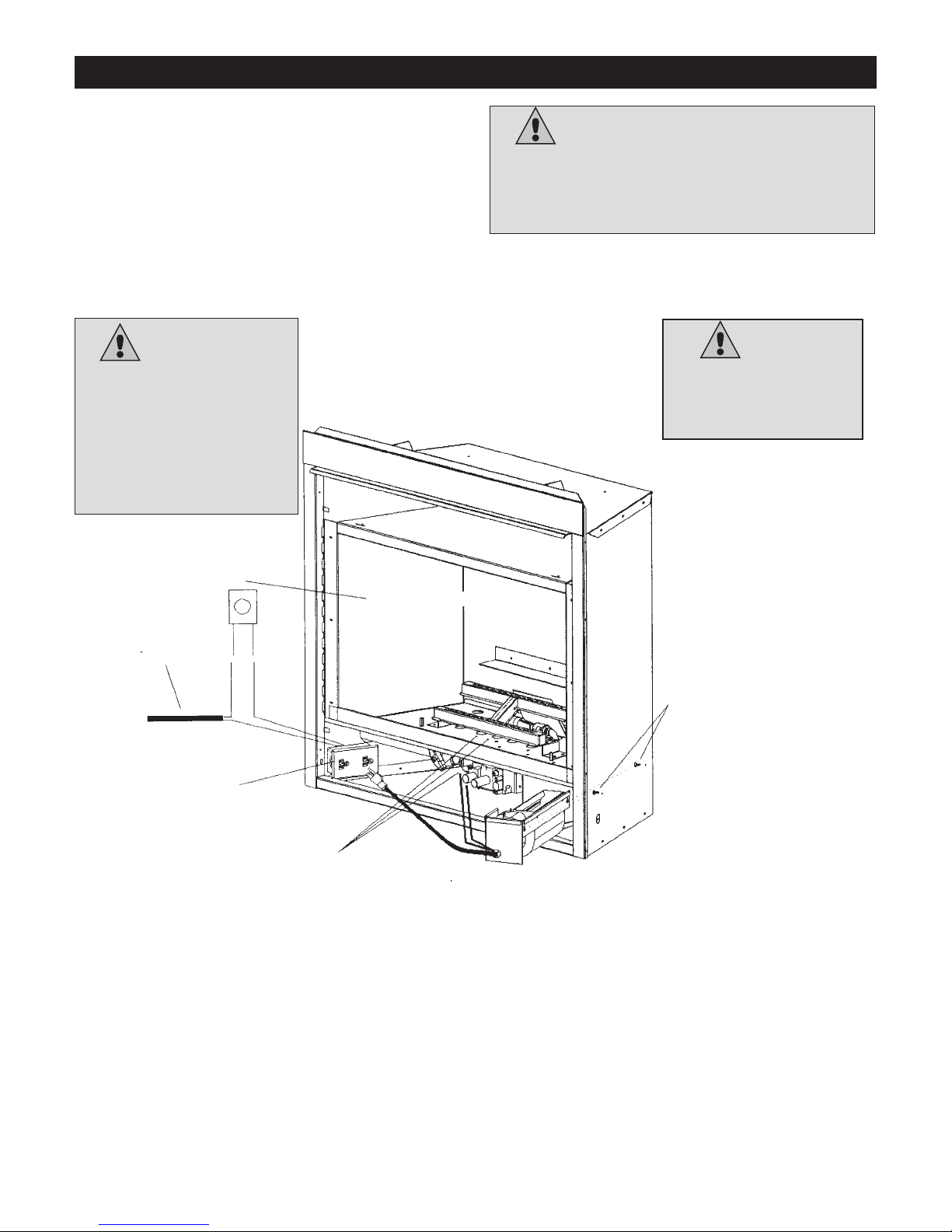

Installation of optional Fan Kit

#8x1/2”

FAN MOUNTING SCREWS

MOUNT FROM INSIDE OUTER RAP.

MOUNTING POSITION OF THERMO DISK

LOCATED LEFT SIDE AND BEHIND VALVE.

VARIABLE SPEED CONTROL

SUGGESTED LOCATION’

FOR 120V JUNCTION BOX

FOR FAN KIT.

120V

Fan Mounting Instructions: Z33FK-FAN ASSEMBLY

1. Attach thermodisk securely to bottom of firebox. Screws are factory installed.

2. Screw #8 x 1/2” screws into outer rap wall from the inside (right side only). Fan housing can

now be positioned by placing teardrop holes over the 2 screws mounted in the outer rap

wall.

3. Junction box should be mounted to opposite side and wired to variable speed control and

120V power.

4. Plug fan into junction box and attach the 2 leads exiting the fan housing into the thermodisk.

Electrical Services

All optional fan kits are equipped with a 120V, 60 Hz

blower.

Note: All electrical connections are to be made in

accordance with CSA Standard C22.1 - Canadian

Electrical Code part I or with the National Electrical

Code, ANSI/NFPA 70 (latest edition) and/or in accordance with local codes.

WARNING:

A

qualified electrician must

connect electrical wiring to

junction outlet for built-in

installation

WARNING:

Electrical Grounding Instructions.

This appliance is equipped with a three-pronged

(grounding) plug for your protection against shock

hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove

the grounding prong from this plug.

WARNING:

Label all

wires prior to disconnection

when servicing controls.

Wiring errors can cause

improper and dangerous

operation.

Verify proper operation after

servicing.

10

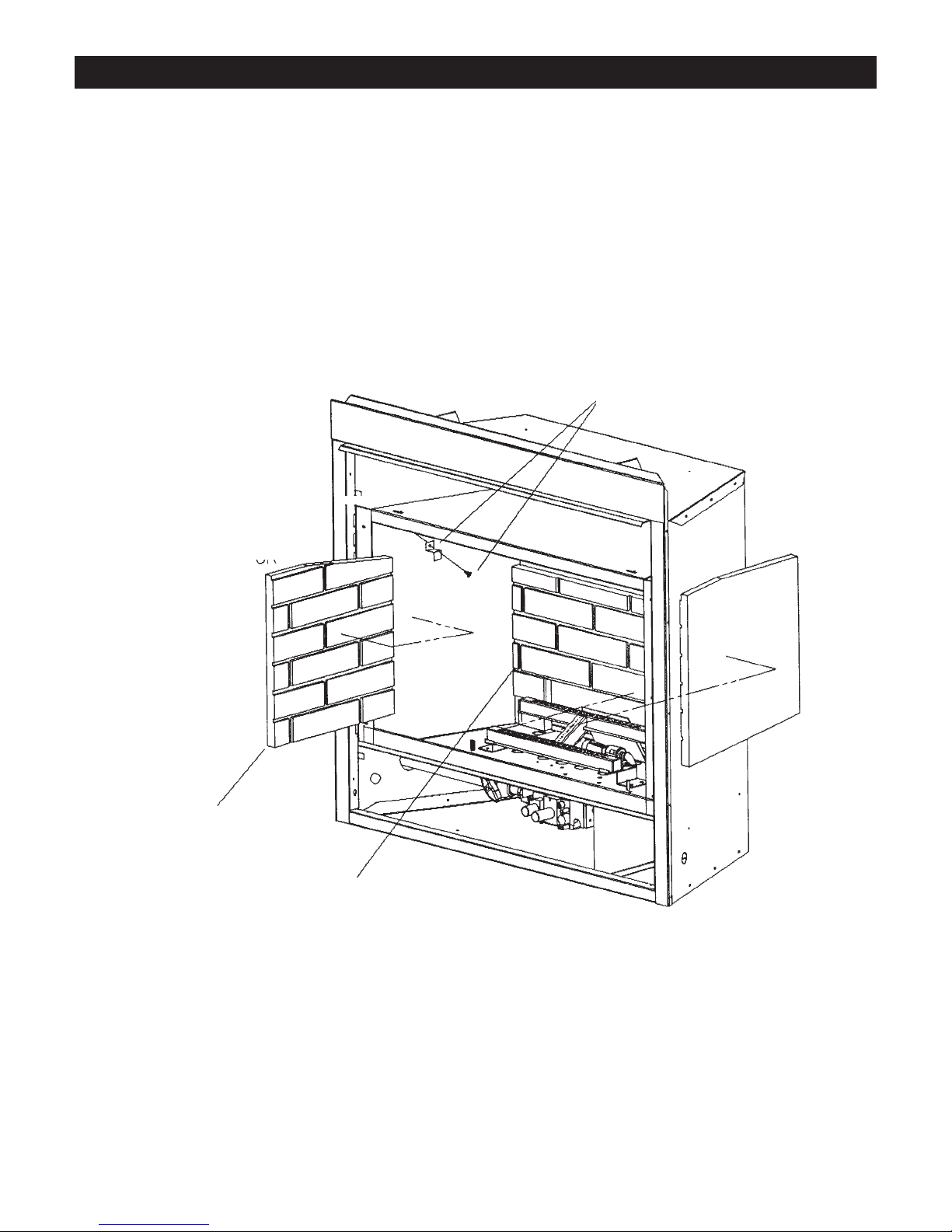

Installing Brick Panels

BRICK CLIP AND SCREW

LEFT AND RIGHT SIDE

REAR BRICK PANEL

LEFT SIDE

BRICK PANEL

1. Place rear brick panel up against the back of the firebox.

2. Loosen screw holding brick clip in position, swing clip up out of the way and place side brick

up to rear

brick and flush against side wall of firebox. Position clip over brick and tighten screw.

3. Repeat same procedure for opposite side brick panel.

11

General Glass Information

Glass Cleaning

It will be necessary to clean the glass periodically. During startup, condensation, which is normal, forms on the inside of the

glass and causes dust, lint etc. to cling to the glass surface.

Also, initial paint curing can deposit a slight film on the glass. It

is therefore recommended that initially the glass be cleaned two

or three times with non-abrasive

common household glass

cleansers and warm water. After that, the glass should be

cleaned two or three times a season depending on the circumstances.

Glass Replacement

REPLACEMENT GLASS FOR BOTH VENTED UNITS

Model Series ZV3600 or ZV4200 can use either tempered glass

or Robax ceramic or coated Neaoceram glass. Must be 5mm

thick.

To replace glass, clean all materials from door frame. Scrape off

old silicone down to metal. Using a high heat silicone (temperature-resistant to 500°F (260°C) apply a continuous bead of

approximately 1/32” to all four sides of frame and insert glass

with new gasket. Frame should be on flat surface, with a small

amount of weight pressing glass into silicone. Let dry approximately 15 to 20 minutes. The door can be re-installed by reversing Steps 1 & 2. Use caution when removing broken glass,

wear gloves.

Removal of the Glass Door

1. Remove the two screws located behind upper grill or unfasten

latches if so equipped.

2. To remove, pull frame forward and lift from bottom door retainer channel.

Confirming Proper Venting of Appliance

To check for proper drafting, use this procedure.

1. Place unit in operation and let run for approx.1 minute to establish up a draft.

2. Open top grill area to expose the draft hood.

3. Using a match or something that will produce smoke, place it up to the opening of the draft

hood and verify that the flame or smoke is being drawn into the draft hood. If the flame or

smoke is blown away from the draft hood opening, you may have to re-check the venting and

verify that there is a minimum of 12 foot of venting or check the house for negative pressure.

If there is negative pressure, you will have to bring fresh air to the unit.

left side only

safety spill switch

check draft here

Fresh air inlet

A Fresh Air Kit may be required by some building codes, remove cover plate on the bottom side of

unit and insert three inch flex duct into the side of fireplace by screwing it into the hole provided,

attach the other end to the plastic wall vent. When possible place the plastic vent below the bottom of the fireplace

Warning and Cautions.

• Do not clean when the glass is hot.

• Do not use abrasive cleaners.

• Using a substitute glass will void all product

warranties.

• Do not strike or abuse glass. Care must be

taken to avoid breakage of the glass.

• Do not operate this fireplace without the glass

front or with a broken glass.

12

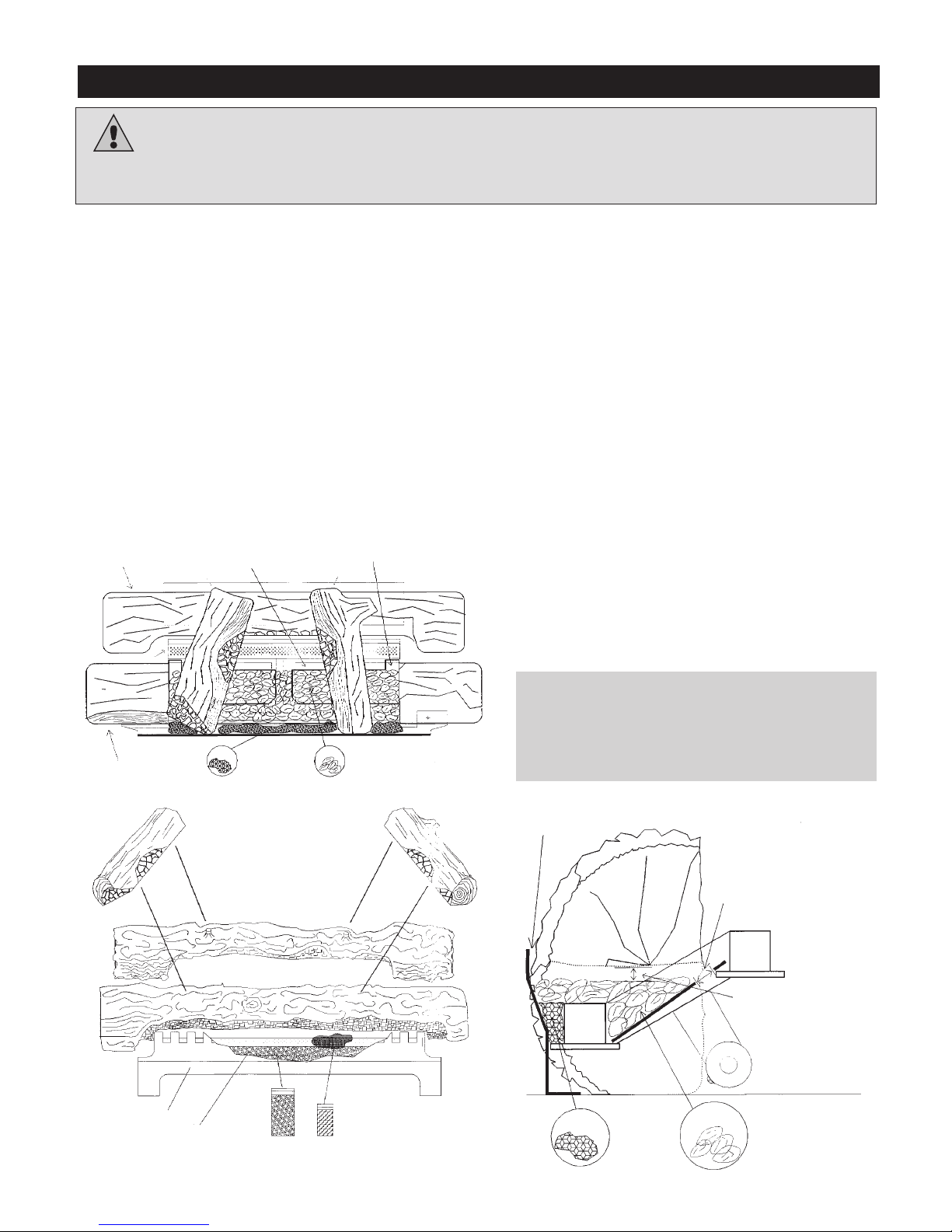

Log Assembly for Models ZV3600 and ZV4200

Log Assembly (LOGC42)

1.Remove glass door by removing two (2) screws behind upper

grills or unfasten latches and lifting door off bottom door

retainer channel.

2.Remove logs from carton (4 pcs) and inspect. (Part

#LOGC42)

3.Verify to see that ember plates (2 pcs) are between front and

back burner, air opening to top (as per diagram). The ember

plates are used to hold the glowing ember, thus simulating a

glowing bed of embers.

4.Place glowing embers (insulation) on surface of front burner

and surface of ember plates.

Height on front burner 1/2” - 3/4”

Height on ember plates 3/4” - 1”

Do not cover back air opening on ember plates.

5.Place rear log on log shelf 1/2” away from back of fireplace.

6.Place front log over front burner, and resting against decorative grate.

7.Place right and left logs across front and back log. Bark

should be to the outside, and right log has a knot.

8.Adjust right and left log so that black charred area sits

between front and rear log.

9.Make sure that a space of at least 3/4” is maintained

between glowing ember and underside of front log ember

bed area.

10.Front log should be centered on the log supports between the

front and rear burners. Pull log against the front of the supports.

11.Top logs can then be placed across the front and back logs in

the slots provided.

12.Place decorative moon rock on bottom of fireplace to simulate

ash and then sprinkle vermiculite over rock.

13.Purge lines and test pilot operation.

14.Replace glass door. The door must be installed before operating the fireplace.

REAR LOG

LEFT LOG

RIGHT LOG

EMBER PLATE

FRONT LOG

LEFT CROSSOVER LOG

Part # 4200-253

REAR LOG

Part # 4200-252

FRONT LOG

Part # 4200-251

FRONT GRATE

FRONT BURNER

ROCK MINERAL WOOL

LOG SET 4200-250

RIGHT CROSSOVER LOG

Part # 4200-254

BURNER

MOON ROCK

GLOWING

EMBERS

! EMBER PLATE AIR OPENING.

! DO NOT COVER UP !

! LOG MUST BE BROUGHT UP TO

FACE OF FENCE !

! EMBER PLATE AIR OPENING.

MUST NOT BE COVERED !

!OPENING BETWEEN

GLOWING EMBERS AND

UNDERSIDE OF LOG. MUST

NOT BE LESS THAN

3/4 INCH !

MOON ROCK

GLOWING

EMBERS

DO NOT PLACE DECORATIVE

ROCK ON BURNERS

WARNING:

Failure to position the parts in accordance with these diagrams or failure to use only parts specifically

approved with this appliance may result in property damage or personal injury.

13

Loading...

Loading...