Page 1

Installation Instructions

Listed Certified for USA. and Canada

Certified to: ANSI Z21.44a-1992, Can1-2.19-M81, CGA I.R.#41, CGA I.R.#55, CAN/CGA 2.17-1991

Model Number ZDV1001

Stock #’s: ZDV 360, 960, 1160, 1560, 1960, 2560

“Zero Clearance”

Direct Vent Gas Fireplace

Read this complete manual before beginning installation.

These instructions must be kept with the unit for future reference.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

What T

o Do If You Smell Gas

Do not try to light any appliance.

Extinguish any open flame.

Do not touch any electrical switch.

Do not use any phone in your building.

Immediately call your gas supplier from a neighbour’s phone.

If you can not reach your gas supplier, call the fire department.

KINGSMAN INDUSTRIES

A Division of R-Co. Inc.

3 Winfield Way

Winnipeg, Manitoba, Canada R2R 1V8

Phone (204)-632-1962

Warning: Improper installation, alteration, service or maintenance can cause property damage, personal

injury or losses of life. Refer to this manual. Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Printed in Canada 05/96 Part # 1000-P920CP Revision 2

Page 2

2

Installation and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Locating your appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Framing your gas fireplace . . . . . . . . . . . . . . . . . . . . . . . . .4,5

Gas line installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operating and maintenance instructions . . . . . . . . . . . . . . . . .6

General glass information . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Log assembly and fan kit . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Fan kit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Millivolt system, lighting, & burner control . . . . . . . . . . . . . .8

Vent termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9,10

Venting graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

General vent installation information . . . . . . . . . . . . . . . . . .11

Installation of top flue side wall venting . . . . . . . . . . . . .11,12

Installation of back vents . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Repair parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Valve System Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Kingsman Fireplace part numbers &

specifications Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Kingsman Fireplace accessories . . . . . . . . . . . . . . . . . . . . . .14

Kingsman Fireplace options . . . . . . . . . . . . . . . . . . . . . . . . .14

Kingsman Fireplace venting . . . . . . . . . . . . . . . . . . . . . . . . .14

Trouble shooting the gas control system . . . . . . . . . . . . . . . .15

Kingsman Industries Gas Fireplace – Limited Warranty . . .16

Table of Contents

Page 3

3

Installation and Operation

Installation Regulations

This gas appliance must be installed by a qualified installer in accordance with local building codes, or in the absence of local codes, with

the current CAN/CGA-B149.1 or .2 Installation Code (in Canada) or

the current National Fuel Gas Code Z223.1 when installed in the

United States.

This appliance, when installed, must be electrically connected and

grounded in accordance with local codes, or in the absence of local

codes, with the current CSA C22.1 Canadian Electrical Code or with

the national Electrical Code; ANSI/NFPA 70-1987 when installed in the

United States.

FOR SAFE INSTALLATION AND OPERATION OF

YOUR GAS FIREPLACE PLEASE NOTE THE FOLLOWING:

1. This appliance gives off high temperatures and should be located

out of heavy traffic areas and away from furniture and draperies.

2. Children and adults should be alerted to the hazards of the high surface temperatures of this appliance and should stay away to avoid

burns or ignition of clothing.

3. Children should be carefully supervised when they are in the same

room as your fireplace appliance.

4. Under no circumstances should this appliance be modified. Any

parts that have to be removed for servicing should be replaced prior

to operating this appliance.

5. Installation and any repairs to this appliance should be done by a

qualified service person. A professional service person should be

called to inspect this appliance annually. Make it a practice to have

all your gas appliances checked annually.

6. Control compartments, burners and air passages in this appliance

should be kept clean and free of dust and lint. Make sure that the

gas valve and pilot light are turned off before you attempt to clean

this unit.

7. The venting system (chimney) of this appliance should be inspected

at least once a year and if needed, your venting system should be

cleaned.

8. Keep the area around your appliance clear of combustible materials,

gasoline and other flammable vapors and liquids. This appliance

should not be used as a drying rack for clothing nor should

Christmas stockings or decorations be hung from it.

9. Under no circumstances should any solid fuels wood, paper) be

used in this appliance.

10. For safe operation, glass doors must be closed.

11. Do not use this heater if any part has been under water. Immediately

call a qualified service technician to inspect the heater and to

replace any part of the control system and any gas control which

has been under water.

12. Do not operate appliance unless completely installed as per installation instructions.

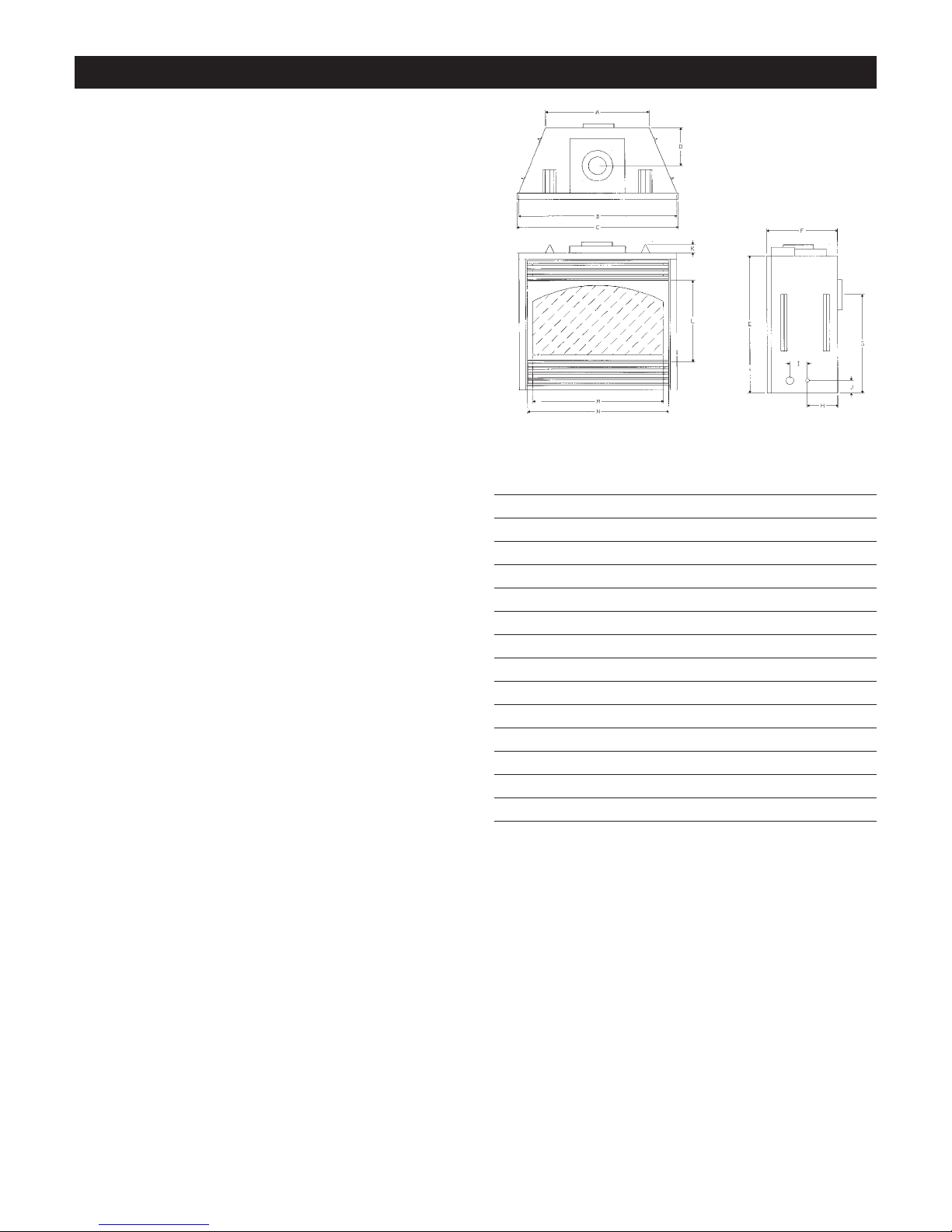

Dimension Top Vent Back Vent

A 23 1/2” 23 1/2”

B 36” 36”

C 36 3/4” 36 3/4”

D 7 1/4” Top Vent only

E 31 3/4” 31 3/4”

F 15” 15 1/4”

G Back Vent Only 22 7/8”

H 5 7/8” 5 7/8”

I 5 1/8” 5 1/8”

J 2 7/8” 2 7/8”

K 2” 1/2”

L 19 1/8” 19 1/8”

M 29 3/4” 29 3/4”

N 32 1/4” 32 1/4”

Note: Pipe diameters for both the back vent and top vent are 4” for

the inner pipe 7” for the outer pipe.

Page 4

4

Locating your Appliance

(above or below grade)

Installing with Top Vent Option

Island installation with a top vent is possible as long as the horizontal portion of the vent system does not exceed 10 feet (305cm). When you install

your fireplace as in position ‘B’, ‘D’ or ‘E’, a minimum of 6 inches

(153mm) clearance must be maintained from the perpendicular wall and

the front of the appliance.

(above grade)

Installing with Back Vent Option

A - Flat on a wall D - As a room divider

B - Across the corner E - Flat on wall corner

C - As an island F - Exterior wall

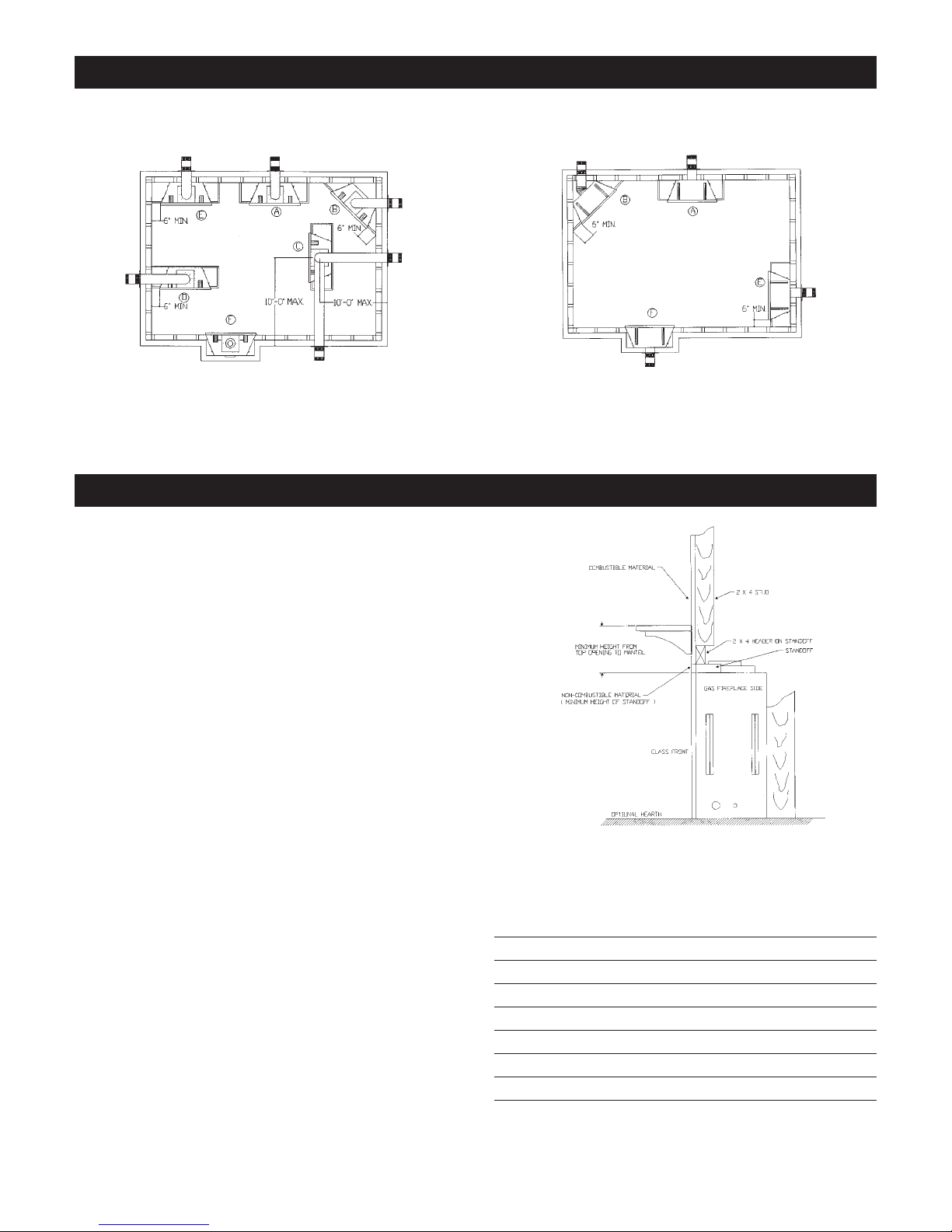

Framing for your Gas Fireplace

Framing Specifications

1. Choose fireplace location and frame in accordance with the fireplace dimensions specified on page one of this manual. When using

a wide 3.5 in. surround the fireplace must be 1/2” (13mm) ahead of

the wall. Also allowances must be made for drywall tile or any other

facing used around the unit. When using Slim Line Brass surround

or no surround fireplace face maybe built out from the framing

specification using non combustible materials such as brick or

stone, giving a reset appearance.

2. Place fireplace into position and secure to floor with 1 1/2” screws

or nails. Nailing tab located left and right lower side of fireplace.

3. Cold climate installation recommendation: when installing this fireplace against non-insulated exterior wall or chase, it is recommended that the outer walls be insulated to conform to applicable insulation codes. Drywall should be installed around the unit to prevent

insulation from contacting the body.

4. Drywall can extend flush with the appliance on the bottom and sides

of the fireplace. A non-combustible material must be used to extend

flush with the top of the fireplace and must have a vertical length

equivalent to the height of the standoffs.

5. If you are installing the top vent unit with a 90˚ bend, the minimum

clearance to combustibles directly above the 90˚ bend is 4”

(102mm).

6. Non-combustible materials such as brick and tile can be extended

across the face of the fireplace. If wide 3.5” brass trim kit is going

to be installed, brick and tile will have to be installed flush with the

front of this appliance. If slim line brass trim kit is used, brick or

tile may extend past the front of unit.

Hearth

A hearth is not mandatory but is recommended for aesthetic purposes.

We recommend a non-combustible hearth projecting out 12” (305mm)

or more in front of the fireplace.

Clearance to Combustibles

Back (from Standoffs) 0 inches/0 mm

Side (from standoffs) 0 inches/0 mm

Floor 0 inches/0 mm

Top (from standoffs) 0 inches/0 mm

Top (from front of unit) 2.5 inches/64 mm

Top of 90 Bend 4 inches/102 mm

Top of Horizontal Pipe 2.5 inches/64 mm

Note: See Mantel Chart

Page 5

5

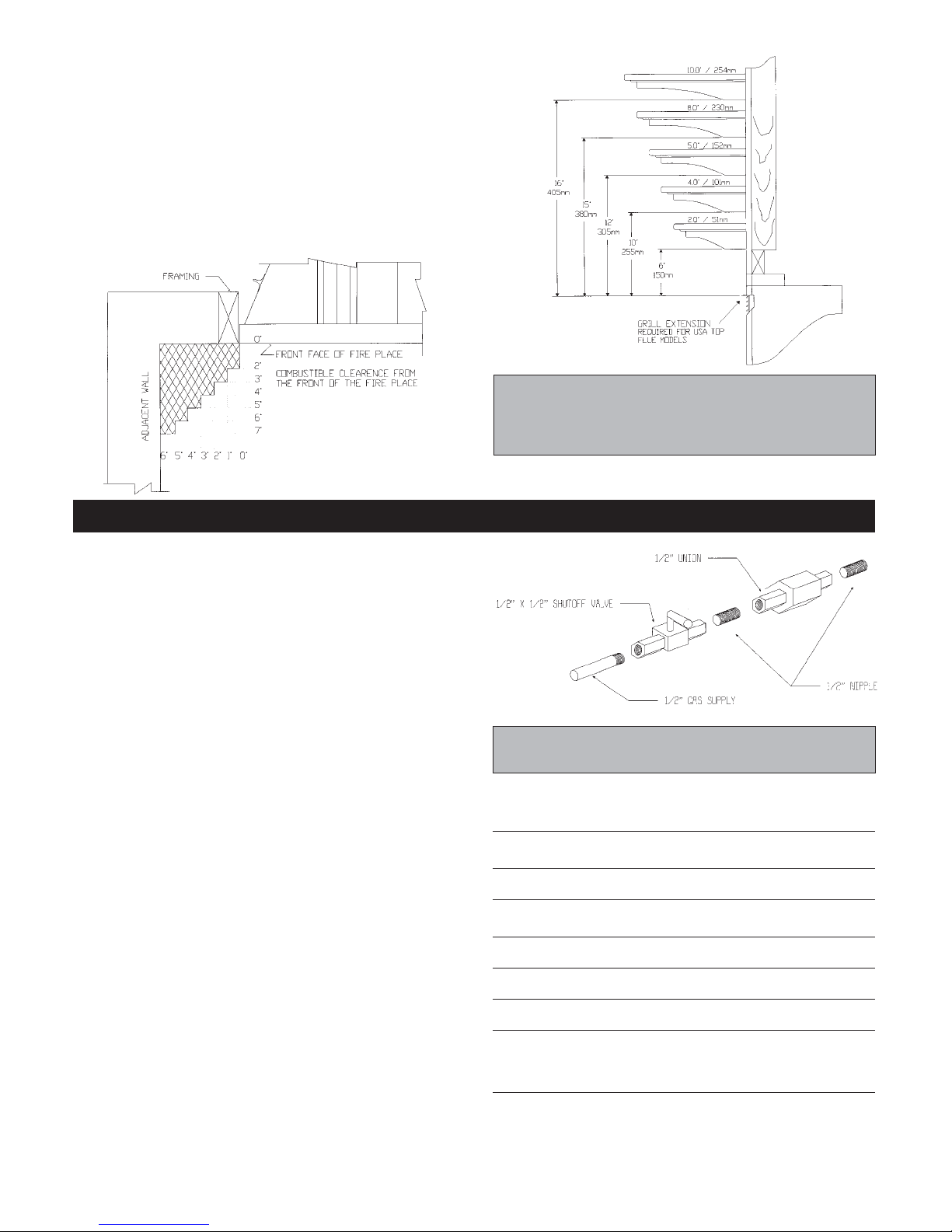

Gas Line Installation

This gas appliance should be installed by a qualified installer in accordance with

local building codes and with current CAN/CGA - B149.1 or .2 installation codes for

Gas Burning appliances and equipment in Canada and the National Fuel Gas Code

ANSI Z223 in the U.S.A.

1. The gas pipeline can be brought in through either the right or the left side of the

appliance. A knockout is provided at either location to allow for the gas pipe

installation and testing of any gas connection.

2. The gas control inlet is 1/2” NPT. Typical installation layout for rigid pipe is

shown at right.

3. When using copper or flex connector, use only approved fittings. Always provide a union so that gas line can be easily disconnected for burner or fan servicing. See gas specification for pressure details and ratings.

4. When a vertical section of gas pipe is required for the installation, a condensation trap is needed. See CAN/CGA-B149.1 or .2 for code details.

5. For natural gas, a minimum of 3/8” iron pipe with gas minimum pressure of 4.5

w.c. must be used for supply from the gas meter. Consult with the local gas utility if any questions arise concerning pipe sizes.

6. A 1/8” NPT plugged tappings are accessible for test gauge connection both on

the inlet and outlet of the gas valve.

7. Turn the gas supply ON and check for leaks. DO NOT USE OPEN FLAME

FOR THIS PURPOSE. Use an approved leak testing solution.

8. The appliance and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 PSIG (3.5 KPa).

9. The appliance must be isolated from the gas supply piping system by closing its

individual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 PSIG (3.5 KPa).

Note: The gas line connection may be made of 1/2” rigid pipe, 1/2” copper pipe

or an approved flex connector. Since some municipalities have additional local

codes, it is always best to consult your local authorities and the current

CAN/CGA - B149.1 or .2 installation code in Canada or the National Fuel Gas

code ANSI Z223.1 in the U.S.A.

Gas Specifications

Model Fuel Gas Control Maximum Input

ZDV1001 Natural Millivolt

(adjustable) 27500 BTU High

18500 BTU Low

ZDV1001 Propane Millivolt

(adjustable) 27000 BTU High

20000 BTL Low

Gas Inlet White Rodgers 1/2” NPT

Gas Supply Minimum Normal Maximum

Pressure (inches water column)

Natural Gas 4.5 7.0 9.0

Propane Gas 10.8 11.0 12.0

Manifold Natural Gas 3.5 inches water column

Pressure Propane Gas 10.5 inches water column

Orifice Size Natural Gas (0-2000 ft) Front 52, Rear 46

Natural Gas (2000-4500 ft) Front 53, Rear 47

Propane Gas (0-2000 ft) Front 66, Rear 54

Propane Gas (2000-4500 ft) Front 66, Rear 55

Mantles

Depending on the width of the fireplace mantle, it may be installed

higher of lower from the top of the fireplace opening. See drawing and

chart below for proper installation height of your combustible mantelpiece. Non-combustible mantles may be installed at any height above

the fireplace opening.

When installing the top vented unit in the United States, a grill extension must be used. The grill extension should extend 1” (25mm) from

the front face.

Note: When using paint or lacquer to finish the mantle, such paint

or lacquer must be heat resistant (250˚F) to prevent discoloration.

Warning: Combustible objects must not be placed on a non-com-

bustible mantle unless the non-combustible mantle meets the minimum height and width requirements for a combustible mantle.

Important: Always check for gas leaks with a soap and water solution. Do not use

open flame for leak testing.

Page 6

6

Operating and Maintenance Instructions

This gas appliance should be installed by a qualified installer in accordance with local building codes and with current CAN/CGA - B149 (.1

or .2) installation codes for Gas Burning Appliances and Equipment.

For safe installation and operation

note the following:

This appliance gives off high temperatures and should be located out of

heavy traffic areas and away from furniture and draperies.

Children and adults should be alerted to the hazards of high surface

temperatures of this appliance and should stay away to avoid burns or

ignition of clothing.

Under no circumstances should this appliance be modified. Parts that

have to be removed for servicing should be replaced prior to operating

this appliance again.

Installation and any repairs to this appliance should be done by a qualified service person. A professional service person should be called to

inspect this appliance annually. Make it a practice to have all of your

gas appliances checked annually.

Never use your gas fireplace as a cooking device.

The Burner/Log Assembly has been engineered and permanently

adjusted for proper flame control.

Periodically remove the logs from the grate assembly and vacuum any

loose particles from the grate and burner areas.

Control compartments, burners and air passages in this appliance

should be kept clean and free of dust and lint. Make sure that the gas

valve and pilot light are turned off before you attempt to clean this unit.

The venting system (chimney) of this appliance should be inspected at

least once a year and if needed, your venting system should be cleaned.

Keep the area around your appliance clear of combustible materials,

gasoline and other flammable vapors and liquids.

This appliance should not be used as drying rack for clothing, nor

should Christmas stockings or decorations be hung near it.

Under no circumstances should any solid fuels (wood, paper, cardboard, coal) be used in this appliance.

Note: It is normal for your gas fireplace to give off some odor the

first time it is burned. This is due to the curing of the paint and any

undetected oil from the manufacturing process.

Please ensure that your room is well ventilated - open all windows.

It is recommended that you burn your gas fireplace for at least four (4)

hours the first time you use it without the fan on.

Warning: When purging the gas line, the glass front must be

removed.

Do not alter gas orifice.

General Glass Information

Glass Cleaning

It will be necessary to clean the glass periodically. During start-up, condensation, which is normal, forms on the inside of the glass and causes

dust, lint etc. to cling to the glass surface. Also, initial paint curing can

deposit a slight film on the glass. It is therefore recommended that initially the glass be cleaned two or three times with non-abrasive

common household glass cleansers and warm water. After that, the glass

should be cleaned two or three times a season depending on the circumstances.

Cautions and Warnings

• Do not clean when the glass is hot.

• The use of substitute glass will void all product warranties.

• Care must be taken to avoid breakage of the glass.

• Do not operate this fireplace without the glass front or with a broken

glass front.

• Do not strike or abuse glass.

Glass Replacement

REPLACEMENT GLASS FOR BOTH DIRECT VENT UNITS

Only Robax ceramic or coated Neaoceram glass may be used for

replacement. Must be minimum 5mm thick.

Removal of the Glass Door

1. Remove the two screws located behind upper grill.

2. To remove, pull frame forward and lift from bottom door retainer.

3. To replace glass, clean all materials from door frame. Using a high

heat silicone (temperature-resistant to 500˚F (260˚C) apply a bead

of approximately 1/4” to all four sides of frame and insert glass

with new gasket. Frame should be on flat surface, with a small

amount of weight pressing glass into silicone. Let dry approximately 15 to 20 minutes. The door can be re-installed by reversing Steps

1 & 2.

Page 7

7

Log Assembly & Fan Kit

Log Assembly

1. Remove glass door by removing two (2) screws behind upper grills

and lifting door off bottom door retainer.

2. Remove logs from carton (4) and inspect.

3. Rear log should be installed onto rear log holder attached to back of

firebox above and to the rear of the burner pan.

4. Front log should be centered on the log supports between the front

and rear burners. Push log against the back of the supports.

5. Top logs can then be placed across the front and back logs in the

slots provided.

6. Purge lines and test pilot operation.

7. Spread supplied rocks evenly on front burner, being careful not to

get rock in the crossover tube opening below the front log. Next,

tear ember wool into small, thin, irregular pieces and place it evenly

over rocks.

8. Replace glass door. The door must be installed before operating the

fireplace.

Fan Kit Installation

Automatic On/Off Thermostat Controlled

Fan Kit (Part # ZIFK)

1. Open the lower front access cover.

2. Remove the two (2) sensor mounting screws located to the right of

the control valve in the access area on the bottom side of the fire

box. Secure the sensor unit under the fire box being sure to tighten

the screws so the sensor is in contact with the fire box bottom.

3. Insert the two (2) #8x1/2 screws provided with the fan into the

holes in the side of the fireplace opposite the gas line entry. Mount

the fan using the keyhole slots in the fan body.

4. Install a junction box (type to except three prong plug) on the inside

wall of the access area opposite the fan. Large holes are provided to

allow wiring to enter the access area on the left of the unit. Connect

the power, sensor and variable speed wall switch as shown in the

wiring diagram.

Note: If the fan has been installed on the left of the unit it will be

necessary to lengthen the sensor unit leads to reach the sensor.

Install as per diagram.

5. Close lower access cover.

6. Turn the wall switch on (clockwise). Turn the fireplace on. Once the

sensor unit reaches operating temperature in approximately 10 to 15

minutes the fall will turn on. The fan can be switched off, if desired,

by turning the wall switch fully counter-clockwise.

7. To set the minimum fan speed if desired. Remove the variable speed

switch from the wall mount. Turn the variable speed wall controller

to its minimum setting (fully clockwise). Use the set screw on the

side of the variable speed controller to increase or decrease the minimum fan speed. (It may be desirable to lower minimum fan speed

to decrease the sound level created by the fan.) Reinstall switch into

wall mount and cover with face plate.

Electrical Services

All optional fan kits are equipped with a 120V, 60Hz blower.

Note: All electric connections are to be made in accordance with CSA

Standard C22.1 - Canadian Electrical Code part I or with the National

Electrical Code, ANSI/NFPA 70 (latest addition) and/or in accordance

with local codes.

Recommended Maximum Lead Length

(Double Wire) When Using Wall Switch or

Thermostat

Wire Size Max. Length

14 GA. 100 FT.

16 GA. 64 FT.

18 GA. 40 FT.

20 GA. 25 FT.

22 GA. 16 FT.

Caution: Should this fan require servicing, the power supply must be disconnected.

Page 8

8

Millivolt System, Lighting, & Burner Control

Lighting Instructions

1. Open access grill on bottom.

2. Push in gas control knob slightly and turn clockwise to “OFF”.

NOTE: Knob cannot be turned from “PILOT” to “OFF” unless knob is

pushed in slightly. Do not force.

3. Wait five (5) minutes to clear out any gas remaining in burner combustion chamber.

4. Turn knob on gas control counter-blockwise to “PILOT”.

5. Push in control knob all the way and hold in. Immediately light the

pilot with piezo-electric ignitor while continuing to push knob in for

one (1) minute. Release knob. Pilot should remain lit. If it goes out,

repeat steps 2 through 5 until pilot remains lit.

– If knob does not pop up when released, stop and immediately call

your service technician or gas supplier.

– If pilot will not stay lit after several tries, turn the gas control

knob to “OFF” and call your service technician or gas supplier.

6. Turn gas control knob counter-clockwise to “ON”.

7. All models are supplied with a wall switch that

turns the main burner on or off. If main burner does

not light immediately when you turn the gas control

valve to “ON” ensure that the wall switch is in the

“ON” position.

NOTE: The “On/Off” wall switch may be replaced

with a wall thermostat allowing main burner to

light and turn off automatically depending upon

thermostat setting and room temperature.

8. Adjust the gas flow (flame height) with the

HI/LOW gas control knob on valve.

NOTE: Standard gas control valve without

HI/LOW is designed to be either fully on or fully

off. It should never be used to vary flame height or

adjust gas flow.

– LP valve is non-adjustable.

– NG valve is adjustable with HI/LOW control

knob.

9. Close control access grill.

Pilot Burner

Adjustment

1. Remove pilot adjustment cap.

2. Adjust pilot screw to

provide proper sized

flame.

3. Replace pilot adjustment cap.

4. Leak Test.

To Turn Off Gas Appliance

Turn off all electric power to the appliance if service is to be performed. Open control access grill.

Push in gas control knob slightly and turn clockwise to “OFF”. Do not

force. Close control access grill.

Caution: Do Not Wire 120 Volt Power To Millivolt Switches Or Thermostats.

THERMOCOUPLE

OR GENERATOR

Page 9

9

Vent Termination

Vent Terminal

Air Supply

Area Where Terminal Not Permitted.

A - Clearance above grade, veranda, porch, deck, or balcony 12 inches

(30cm) minimum.

1

B - Clearance to window or door that may be opened. 12 inches (30cm)

minimum for appliances 100 000 Btuh (30 kW) and lower.

C - Clearance to permanently closed window minimum 12 inches (30cm)

recommended to prevent condensation on window.

D - Vertical clearance to ventilated soffit located above the terminal within

a horizontal distance of 2 feet (60cm) from the center line of the terminal. 18 inches (46cm) minimum.

E - Clearance to unventilated soffit 12 inches (30cm) minimum.

F - Clearance under veranda, porch, deck or balcony 12 inches

1

(30cm)

minimum.

2

G - Clearance from a perpendicular inside wall to the edge of the vent

terminal is 14” (35.5cm).

H - Not to be installed above a meter/regulator assembly within 3 feet

(90cm) horizontally from the center line of the regulator.

I - Clearance to service regulator vent outlet 6 feet (1.8m) minimum.

1

J - Clearance to non-mechanical air supply inlet to building or the

combustion air inlet to any other appliance 12 inches (30cm) minimum for appliances 10 000 Btuh (30kW) and lower, 36 inches

(90cm) minimum for appliances greater than 100 000 Btuh

(30kW).

K - Clearance to a mechanical air supply inlet 6 feet (1.8m) minimum.

1

L - Clearance above paved sidewalk or a paved driveway located on

public property 7 feet (2.1m) minimum.

3

V

NOTE: Clearances are to the terminal center line. Add 6 inches to

clearances not indicated as measured from center line.

NOTE: Local Codes or Regulations may require different clearances.

Termination

It is imperative that the vent termination be located observing the minimum clearances as shown. There must not be any obstruction such as

bushes, garden sheds, fences, decks or utility buildings within 24” from

the front of the termination.

Do not locate termination where excessive snow or ice build-up may

occur. Be sure to check vent termination area after snow falls and clear

to prevent accidental blockage of venting system. When using snow

blowers, make sure snow is not directed towards vent termination area.

General Venting Information

The gas fireplace is approved to be vented either through the side wall

or vertically through the roof.

ONLY VENTING COMPONENTS SPECIFICALLY APPROVED

AND LABELLED FOR THIS FIREPLACE MAY BE USED.

Minimum clearance between vent pipes and combustible materials is 1

inch (25mm).

NOTE: Clearance between vent pipe and combustibles at the wall

thimble is 2 inches (50mm).

Venting terminal shall not be recessed into a wall or siding.

1 - As specified in CGA B149 installation codes (1991).

2 - Only permitted if veranda, porch, deck, or balcony is fully open on a minimum of two

sides beneath the floor.

1

3 - A vent shall not terminate directly above a sidewalk or paved driveway which is located

between two single family dwellings and serves both dwellings.

Page 10

10

Venting Routes And Components

Since it is very important that the vent system maintain its balance

between the combustion air intake and the flue gas exhaust, certain limitations as to vent configurations apply and must be strictly adhered to.

The table showing the relationship between vertical and horizontal side

wall venting will help to determine the various vent lengths.

The maximum horizontal vent run with the 90 degree bend to the fireplace flue outlet is 3 feet (91cm) Figure 1. The maximum horizontal

vent run is 10 feet (305cm) when the vertical rise is 8 feet (244cm)

Figure 2. Note: 1/4” vertical rise is required for every 12” of horizontal

run.

The maximum number of 90 degree bends per side wall installation is

one (1).

The maximum number of 45 degree bends per side wall installation is

two (2). These bends can be installed in either the horizontal or vertical

run.

Maximum vertical rise is 20 feet (6.09 meters).

Special Note: For each 45 degree bend installed in the horizontal

run, the length of the horizontal run must be reduced by 18”

(45cm). This does not apply if the 45 degree bends are installed on

the vertical part of the vent system.

Example: If according to the table, the length of the horizontal run is

10 feet, and two 45 degree bends are required, the horizontal run length

must be reduced to 7 feet.

How To Use The Vent Table

1. Determine the height of the system and the number of bends

required.

2. Having determined the vertical distance determine the maximum

horizontal section allowed.

3. Vent table has been established for 90˚ horizontal/vertical runs.

With use of flex pipe distance not having 90˚ bends will not fall into

vent table standards. See Fig. B.

Venting Table For Top Vent Models

for venting to a maximum of 20 ft. (6.09meters)

Sidewall or Vertical Venting (See Fig. A & B)

Total Vertical Max Total Horizontal

Feet Meters Feet Meters

4 1.2 3 0.9

5 1.5 4 1.2

6 1.8 6 1.8

7 2.1 8 2.4

8 2.4 10 3.0

9 2.7 11 3.4

10 3.0 12 3.7

11 3.4 13 4.0

12 3.7 14 4.3

13 4.0 15 4.6

14 4.3 16 4.9

15 4.6 15 4.6

16 4.9 14 4.3

17 5.2 13 4.0

18 5.5 12 3.7

19 5.8 11 3.4

20 6.1 10 3.0

Example A:

If the vertical dimension from

the floor of the fireplace is

6.5ft, the horizontal run to the

wall flange of the vent termination must not exceed 7.5ft.

NOTE: The final location of

the fireplace must be such

that the horizontal vent

dimensions fall within those

stated on the graph. The

Maximum Vertical vent run is

20 feet (6.09meters).

Important: Always locate the fireplace in such a way that a minimum of off-

sets and/or horizontal runs are required. 1/4” vertical rise is required for every

12” horizontal run.

Important: Minimum clearance between vent pipes and

combustible materials is 1 inch

(25mm).

7.5

6.5

Page 11

11

General Vent Installation Information

Flex Pipe Venting

Flex pipe is shipped in unexpanded length. When installing pipe

expand the lengths. Pipe can be expanded to twice their lengths e.g. 4ft.

to 8ft.

Do not use more than 2 couplers to extend short pipes. Single sections

are preferred in an installation attaching at the fireplace and termination.

Place the spring spaces provided approximately every two feet to stabilize 4” flex in the center of 7” flex. When forming bends place spring

in bend or before and after. (See Fig. 1).

Horizontal runs require support metal straps every 2 feet. In off set

installation support straps should be used to stabilize pipe.

Expand 4” and 7” flex pipe to the point that the 7” protrudes approximately 2 to 3 inches past outer wall and the 4” flex protrudes approximately 2 to 3 inches past the 7” flex. See Fig. 1. Attach the 4” pipe to

the termination first and secure with sealant and clamp and screw then

attach the 7” flex to the termination with caulking and clamp and

screw. Termination may then be moved back to the other wall and

attached to home screwing into the framing. Silicone around termination to waterproof. If siding shied is going to be used attach at this time

using same attaching hole at tope of terminations after termination has

been caulked for water proofing.

Use Term Hi Temp Sealant

Apply a bead of mill pack high temp caulking to all joints and clamp

with screwtype clamps provided at fireplace, termination and any joint

if joining any sections of pipe.

Installation Of Top Flue Side Wall Venting

Step 1

Locate vent opening on the wall. Cut a hole through the exterior wall

allowing for a 11” x 11” minimum inside framing or an 8 1/2” diameter

hole if venting through a non-combustible wall. Center wall thimble

over 11” x 11” framing to route vent pipes through thimble and wall.

See Fig. 2.

Select the approximate vent length, precise measurement s are not

needed as your flex pipe can expand to twice its shipped length for ease

of installation.

Before joining pipes, apply a bead of high temperature sealant (Mill

Pac) to end of pipe. Attach four inch (4”) flue pipe to fireplace with

sealant and clamp and screws first, then attach the seven inch (7”)

flange ring to fireplace with sealant and clamp and screws, and then

attach the seven inch (7”) pipe by the same method. Join pipes and

secure joints with sealant and clamp.

Step 2

Mount vent termination and seal to wall using caulking around the wall

thimble to weatherproof. After installing the vent termination, double

check to make sure the pipe extends properly through wall thimble and

into vent termination.

NOTE: Clearance to combustibles above an 90˚ bend is 4 inches

(10.2cm)

Step 3

Support horizontal pipes every two (2) feet (61cm) with metal pipe

straps. Re-check fireplace to make sure it is levelled and properly positioned, and nailed or screwed to the floor.

NOTE: It is critical to the proper and safe operation of this fireplace that on all

connections the inner liner and the outer casing are both caulked with liberal

amounts of sealant. Do not use any kind of tape or silicone other than that recommended in this manual. Mill Pac Sealant

FRAMING DIMENSION

Combustible Wall

Cut a 11” hole through exterior wall and frame as shown below.

Non combustible Wall

Cut or drill 8.5” or 216mm diameter hole.

COMBUSTIBLE FRAMING

FOR WALL THIMBLE

FIGURE 1

FIGURE 2

Page 12

12

Using Flex Bends

4. Avoid cutting joists by offsetting the flex pipe. See Fig. 2.

5. Maximum horizontal offset when using 45˚ bends is 6 feet.

6. When using 45˚ bends an bend support is required directly above

the highest bend.

7. Never install a bend in a joist area. Vent sections must pass vertically through framed joist areas.

8. Maximum vertical height of system should not exceed 20 feet.

9. Use roof support and 7” ridge pipe at roof level. Flex not permitted

with in roof support.

10. When penetrating the roof a ridge 7” pipe must be used. Attach the

7” flex to the 7” ridge with high temperature sealant, clamp security

with adjustable clamp, and use two screws/washers either above or

below camp assuring the flex and ridge pipe are secured. 4” flex

pipe must be secured the same way with 2 screws and washers

either above or below the clamp but must penetrate the 4” flex and

4” section of termination. Attach 7” ridge to 7” termination with

sealant and screw with 3 sheet metal screws. (See Fig. 3).

Roof Flashing

Ensure that you have the proper roof flashing by checking your roof

pitch using a level and two rulers, or by using a roof pitch card. See figure below.

Slide a Roof Flashing suitable to your roof slope over the vent. Place

the edge of the flashing plate that will be on the higher part of the roof

slope under the shingles. Both the sides and the lower edge lay on top

of the shingles.

NOTE: At the top edge of the flashing plate, lift the shingles and

nail the plate to the roof deck, then cement the shingles to the plate

with a suitable waterproof mastic.

Ensure that the chimney is plumb. Square up the flashing plate and nail

in place to the roof deck. Use 12 nails with neoprene washers or cover

the heads with a suitable waterproof mastic.

Wrap the storm collar around the vent above the flashing. Secure the

ends together loosely with nut and bolt supplied. Slide the collar down

the vent until it comes in contact with the flashing. Tighten the bolt and

seal the Storm Collar to the vent with a suitable waterproof non-combustible mastic.

The flashing and storm collar should be painted to match the roof shingles. This will extend its life and improve the appearance. Clean, prime

and paint the suitable painting products.

Continue adding lengths of vent until the proper height is achieved (See

diagram above). Slide raincap into vent.

FIG. 1

FIG. 2

Venting Straight Up Through Roof

1. An Attic Insulation Shield must be installed where the vent passes

from a lower living space into an attic space where the chimney is

not enclosed. It is designed to keep insulation materials away from

the chimney. See Fig. 1.

2. When installing the Attic Insulation Shield where the chimney passes from a living space to an attic space, install the shield from

below and nail in place using 1” spiral nails.

3. A fire stop must be installed on the bottom side of the joists when

passing through a ceiling or floor. If an attic insulation shield is to

be used, a fire stop is not required.

FIG. 3

Page 13

13

Installation of Back Vents

Repair Parts List

General Back Vent Installation and Specification

Straight Back max vent length 36” Vent Kit # ZDVHSK

45˚ Corner Max Number of 45˚ Bends One

Vent Kit #s FDVHT, ZDVWT, ZDVFK4

Max Vent Length after 45˚ Bend 18”

See Fig. 1 & 2 Page 13

NOTE: Minimum clearance between vent pipes and combustible

materials is one inch or 25mm.

Step 1

Locate vent opening on the wall. COMBUSTIBLE WALLS cut a 11” x

11” (280mm x 280mm) minimum hole and frame as shown. NONCOMBUSTIBLE WALL hole opening must be 8.5” (216mm) in diameter. Install wall thimble for vent pipe routing through wall. See Fig. 3.

Step 2

Place fireplace into place and attach vent pipes, four inch (4”) first.

Make sure pipes are pushed on securely. Champs, sealed and screwed.

Step 3

Straight Back Venting. Measure wall thickness. If wall is thinner than

(1Ft.) then1 foot unexpanded length in ZDVHSK must be expanded

add cut. 7” should extend post outer wall approximately 2” to 3” and 4”

flex approximately 2” past the 7” flex then allows enough room to

secure pipe to termination with high heat sealants, clamp and screw, the

press termination back to outer wall and seal. Place spacer spring over

4” flex to stabilize it in the 7” flex if length is over a foot.

Step 4

Cover Back Venting. Only one - 45˚ bend per installation. Install as

per above length. May not exceed Figure 1 page 13 and must be cut to

comply.

Install wall thimble.Place fireplace into place and secure to floor with

nailing tabs.

Step 5

Mount vent termination, make sure 4” and 7” pipes are siliconed. Caulk

around wall thimble to weatherproof.

Corner Installation

Location

NOTE: When the fireplace

is installed cross corner it is

necessary to bend. Use Kit

#FDVHSK, ZDVWT,

ZDVFK4.

Burner Assembly - Complete

1001 - BNGWR NG Burner Assembly (with thermocouple wired

directly to valve)

1001 - BLPWR LP Burner Assembly (with thermocouple wired

directly to valve)

Valve System Parts

Natural Gas Valve System

(with thermocouple wired directly to valve

1000 - P133WR Valve NG Hi/Lo (36D33U-100)

1000 - P134WR Pilot Burner (E39A1)

1000 - P135WR Thermocouple (H19E924)

1000 - P136WR Generator (GO1A-524)

1000 - 206 Pilot Orifice (F069-2060)

LP Gas Valve System

(with thermocouple wired directly to valve

1000 - P101WR Valve LP Hi/Lo (36D33U-101)

1000 - P134WR Pilot Burner (E39A1)

1000 - P135WR Thermocouple (H19E924)

1000 - P136WR Generator (GO1A-524)

1000 - P104WR Pilot Orifice LP (F069-2462)

Miscellaneous Parts

1000 - 134 Gasket for Explosion Disk

1000 - 214 Piezo Electric Spark Ignitor

1000 - 218 On/Off Switch (Wall Mount)

1000 - 227 On/Off Cover Plate

1000 - 255 - 46 Back Burner Orifice NG - (0-2000 ft)

1000 - 255 - 47 Rear Burner Orifice NG - (2000-4500 ft)

1000 - 255 - 52 Front burner Orifice NG - (0-2000 ft)

1000 - 255 - 53 Front Burner Orifice NG - (2000-4500 ft)

1000 - 255 - 54 Rear Burner Orifice Lp - (0-2000 ft)

1000 - 255 - 55 Rear Burner Orifice LP - (2000-4500 ft)

1000 - 255 - 66 Front Burner Orifice LP - (0-4500 ft)

1000 - 301 Straight Door Frame

FIG. 3

FIG. 1

FIG. 2

Page 14

14

1000 - 302 Arch Door Frame

1000 - 305 Glass - Robax or coated Neoceram

1000 - 306 Gasket - Door

1000 - EMBER Ember Kit

1000 - 700 Log Set (4 Pieces)

1000 - 085 Variable Speed Wall Mount Switch

2000 - 080 Sensor for Auto On/Off Fan Kit

Kingsman Fireplace Part Numbers

and Specifications Options

Product Description

Number

ZDV1160 Zero Clearance Fireplace (natural gas) Top Vent,

Arch Door

ZDV2560 Zero Clearance Fireplace PROPANE Top Vent,

Arch Door

ZDV360 Zero Clearance Fireplace (natural gas) Back Vent,

Straight Door

ZDV960 Zero Clearance Fireplace (natural gas) Back Vent,

Arch Door

ZDV1560 Zero Clearance Fireplace (natural gas) Top Vent,

Straight Door

ZDV1960 Zero Clearance Fireplace PROPANE Top Vent,

Straight Door

Kingsman Fireplace Accessories

Catalog

Number Description

ZIFK Fan Kit (Thermostatic On/Off)

ZIRL Refractory Kit

ZIRC Cordless Remote Control

ZIMT Thermostat Wall Mount Millivolt

Kingsman Fireplace Options

Catalog

Number Description

Grills

ZIGBL Grills - Black

ZIGAB Grills - Antique Brass

ZIGPB Grills - Polish Brass

ZIGAL Grills - Almond

ZIGBG Grills - Burgundy

ZIGGR Grills - Green

Surround Kits

ZISAB Surround - Antique Brass

ZISPB Surround - Polish Brass

ZISAL Surround - Almond

ZISBG Surround - Burgundy

ZISGR Surround - Green

ZISSAB Surround (Slim Line) - Antique Brass

ZISSPB Surround (Slim Line) - Polish Brass

Arch Door Frame

ZIADAB Arch Door Frame - Antique Brass

ZIADPB Arch Door Frame - Polish Brass

ZIADAL Arch Door Frame - Almond

ZIADBG Arch Door Frame - Burgundy

ZIADGR Arch Door Frame - Green

Kingsman Fireplace Venting

Catalog

Number Description

ZDVHSK Horizontal Vent Starter Kit - (Back Vent)

Starter Kit Contains:

Horizontal Vent Termination, Wall Thimble, 4”-7”

Dia. x 36” Flex Pipe

Clamps, Silicone.

FDVVT15 Vertical Vent Termination (8’ to 15’)

FDVVT30 Vertical Vent Termination (15’ to 30’)

FDVHT Horizontal Vent Termination

ZDVAIS Attic Insulation Shield

ZDVVOS Offset Support

ZDVFS Firestop Spacer

ZDVRS Roof Support

ZDVSS Siding Shield

ZDVWT Wall Thimble (Horizontal Venting)

ZDVAAF Flashing 0/12 - 6/12

ZDVAF2 Flashing 6/12 - 9/12

ZDVAF3 Flashing 9/12 - 12/12

ZDVFK4 Flex Kit (4” & 7” Dia.) x 2’ (Unexpanded) 4’ Expanded

ZDVFK8 Flex Kit (4” & 7” Dia.) x 4’ (Unexpanded) 8’ Expanded

ZDVFK20 Flex Kit (4” & 7” Dia.) x 10’ (Unexpanded) 20’Expanded

*Kits are complete with spring stand-offs, clamps, silicone.

ZDV4FC Flex Connector 4” Diameter

ZDV7FC Flex Connector 7” Diameter

ZDV4FCL Flex Clamp 4”

ZDV7FCL Flex Clamp 7”

Page 15

15

Trouble Shooting The Gas Control System

WARNING: BEFORE DOING ANY GAS CONTROL SERVICE WORK, REMOVE THE GLASS FRONT.

NOTE: Before troubleshooting the gas control system, be sure external gas shut off is in the “On” position.

Problem Possible Causes Corrective Action

Spark igniter will not light. Defective or misaligned electrode Check for spark at electrode and pilot: if no spark and electrode wire is

at pilot. properly connected, replace igniter.

Defective igniter Using a match, light pilot. If pilot lights, turn off pilot and push the red

(push-button) button again. If pilot will not light - check gap at electrode and pilot

should be 1/8” to 1/4” to have a strong spark.

Pilot will not stay lit after carefully Defective thermocouple Check pilot flame. Must impinge on generator and thermocouple.

following lighting instructions. (flame switch where applicable) Clean and/or adjust pilot for maximum flame impingement on

generator and thermocouple.

Defective valve magnet. Replace valve

Pilot burning, no gas to burner, Wall switch or wires Check wall switch and wires for proper connections. Jumper wire

Valve knob “ON”, Wall defective. across terminals at wall switch. If burner comes on, replace defective

Switch “ON” wall switch. If okay, jumper wires, across wall switch wires at valve.

If burner comes on, wires are faulty or connections are bad.

Generator may not be generating Check generator with millivolt meter. Take reading at generator termisufficient voltage. nals of gas valve. Should read 325 millivolts minimum while holding

valve knob depressed in pilot position and wall switch “off” Replace

faulty generator if reading is below specified minimum.

Plugged burner orifice. Check burner orifice for stoppage and remove.

Defective automatic valve Remove wall switch wires from gas valve. Install jumper wires from

operator. top bottom terminals of gas valve. Turn valve on “ON”. If main burner

does not light, replace valve.

Frequent Pilot outage problem. Pilot flame may be too low or Clean and/or adjust pilot flame for maximum flame impingement

blowing (high) causing the pilot on generator and thermocouple.

safety to drop out.

Flame lifts off burner and goes out Inner 4” liner has come off flue Attach 4” liner to flue or termination using

in less than 30 seconds or termination, flame is starving screws, silicone and clamps as stated in manual

oxygen

Flame lifts off burner on Improper installation of firebrick. Be sure to postion firebrick against firebox walls and

one side while the rest of Firebrick is likely leaning. be sure to use brick clips attached to the inner side

the flame remains lit. of firebox.

Page 16

16

This Limited Lifetime Warranty applies only while the unit remains at the site of the original installation and only if the unit is installed inside the

continental United States, Alaska, Hawaii, and Canada. The warranty applies only if the unit is installed and operated in accordance with the printed

instructions and in compliance with applicable installation and building codes and good trade practices.

Basic One Year Warranty

During the first year after installation, we will provide a replacement for any component part of your unit found to be defective in materials or

workmanship, including all reasonable labour costs.

Limited Lifetime Warranty

The heat exchanger, combustion chamber and burner of every Kingsman product are warranted against materials or workmanship during the period

the product is owned by the original owner.

The part to be replaced must be returned to our distributor in exchange for the replacement part. Any labor, material, freight and/or handling charges

associated with any repair or replacement pursuant to this Limited Lifetime Warranty will not be covered by this warranty.

General Terms

In lieu of providing a replacement part, we may, at our option, provide the distributor’s component purchase price from us or a credit equal to the

distributors component purchase price from

us toward the purchase of any new unit which we distribute. If a credit is given in lieu of a replacement part, the rating plate from the unit being

replaced must be submitted on a warranty claim, and the unit being replaced must be made available to our distributor for disposition.

In establishing the date of installation for any purpose, including determination of the starting date for the term of this Limited Lifetime Warranty,

reasonable proof of the original installation date must be presented*, otherwise the effective date will be based upon the date of manufacture plus

thirty (30) days.

We will not be responsible for and you, the user, will pay for: (a) damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of

God (b) damages caused by operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any other damaging chemicals

(other than in a normal residential environment) (c) damages caused by any unauthorized alteration or repair of the unit affecting its stability or

performance (d) damages caused by improper matching or application of the unit or the unit’s components (e) damages caused by failing to provide

proper maintenance and service to the unit (f) any expenses incurred for erecting, disconnecting

or dismantling the unit (g) parts or supplies used in connection with service or maintenance (h) damage repairs, inoperation or inefficiency resulting

from faulty installation or application (i) electricity or fuel costs or any increase in electricity or fuel cost whatsoever including additional or unusual

use of supplemental electric heat.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit. We have

not made and do not make any representation or warranty of fitness for a particular use or purpose, and there is no implied condition of fitness for a

particular use or purpose. We make no express warranties except as stated in this Limited Lifetime Warranty. No one is authorized to change this

Limited Lifetime Warranty or to create for us any other obligation or liability in connections with this unit. Any implied warranties shall last for one

year after the original installation. Some states and provinces do not allow the exclusion or limitation of incidental or consequential damages or do

not allow limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions may not apply to you. The provisions

of this limited warranty are in additions to and not a modification of or subtraction from any statutory warranties and other rights and remedies

provided by law.

Save this certificate. It gives you specific legal rights, and you may also have other rights which may vary from state to state and province to

province.

In the event your unit needs servicing, contact your dealer or contractor who installed or serviced your unit. When requesting service, please have the

model and serial number from each unit readily available. If your dealer needs assistance, the distributor is available for support and we, in turn

support the distributor’s efforts.

Fill in the installation date and model and serial numbers of the unit in the space provided below and retain this limited warranty for your files.

Model No.

Serial No. Date installed

Dealer or Contractor Name:

*To receive advantage of your warranty, you must retain the original records that can establish the installation date of your unit.

Kingsman Fireplace – Limited Lifetime Warranty

Loading...

Loading...