Page 1

Installation Instructions

Model Number VFI30 Gas Fired Direct Vent Room

Heater Inserts

Model VFI30 Listed Certified for USA, and Canada

Minimum Fireplace Opening Required: 29”W x 20 3/4”H x 16 1/2”D

Certified to: ANZI Z21.88-2009, CSA2.33-2009

Read this complete manual before beginning installation.

These instructions must be kept with the unit for future reference.

FOR YOUR SAFETY

WARNING: If the information in these instructions is not

followed exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

WARNING: The VFI30

Fireplace Insert was designed for

installation in a solid fuel fireplace

that has been installed in

accordance with national,

provincial/state and local building

codes and is constructed of

noncombustible materials. Do not

remove any refractory materials

from any masonry solid fuel

fireplace.

The VFI30 Fireplace Insert was

designed for installation in a zero

clearance type listed solid fuel

burning factory built fireplace. It may

be necessary to remove the damper

plate, refractory liners, log grates,

glass door, and screen rails/mesh.

Removal of the smoke baffle is

necessary in most cases.

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, personal

injury or loss of life. Refer to this manual. Installation and service

must be performed by a qualified installer, service agency or the

gas supplier.

Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

What to Do If You Smell Gas

Do not try to light any appliance.

Extinguish any open flame.

Do not touch any electrical switch.

Do not use any phone in your building.

Immediately call your gas supplier from a neighbour’s phone.

If you can not reach your gas supplier, call the fire department.

A Division of R-Co. Inc.

2340 Logan Avenue

Winnipeg, Manitoba, Canada R2R 2V3

Ph: (204) 632-1962

Printed in Canada October 19, 2009 30 VFI-MAN

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

This appliance may be installed in an aftermarket permanently located, manufactured home (USA only) or mobile

home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible

for use with other gases, unless a certified kit is used.

Page 2

2

Why does my fireplace or stove give off odour?

It is normal for your fireplace to give off some odour. This is due to the curing of the paint, adhesives, silicones

and any undetected oil from the manufacturing process as well as the finishing materials used with the installations (e.g. marble, tile and the adhesives used to adhere this product to the walls can react with heat and cause

odours).

It is recommended that you burn your gas fireplace or stove for a minimum of four hours at a time with the fan off

after the curing of the paint has been completed. These odours can last upward to 40 hours of burn time, keep

burning at a minimum of four hours per use until odours dissipate.

About curing of the paint

Your stove or fireplace has been painted with the highest quality silicone stove paint. This paint dries quickly in

15-20 minutes when first applied at the factory. However, due to the high temperature silicone components, the

paint will cure when heat is applied to the appliance as it is first used.

The following information applies to the curing process to get the paint fully hard and durable.

Fire the appliance four successive times for 10 minutes each firing and a 5 minute cool down between each. Be

aware during log and firebox paint curing that a white deposit may be developing on the inside of the glass

doors. It is important to remove this white deposit from the glass doors with an appropriate cleaner to prevent

build-up (such as Windex or a commercial fireplace glass cleaner).

• Babies, small children, pregnant women and pets should leave the area during the cure phase.

• Ventilate well, open doors and windows.

• Do not touch during curing.

Noise coming from the fireplace?

• Noise caused by metal expanding and contracting as it heats up and cools down, similar to the sound pro-

duced by a furnace or heating duct. This noise does not affect the operation or longevity of your fireplace.

• Different types and thicknesses of steel will expand and contract at different rates resulting in “cracking”

and “ticking” sounds throughout the heating and cooling periods.

• You should also be aware that as temperatures change within the unit these sounds will likely re-occur.

Again this is normal for steel fireboxes, and is not a defect.

Cleaning the Glass

During the first few fires, a white film may develop on the glass front, as part of the curing process. The glass

should be cleaned after the unit has cooled down or the film can bake on and become very difficult to remove.

Use a non-abrasive cleaner and do not attempt to clean the glass while it is hot.

PRE-INSTALLATION QUESTIONS and ANSWERS

Page 3

3

1. Pre-Installation Questions and Answers . . . . . . . . . . . . . . . .2

2. Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. Mobile Home /Manufactured Housing Installations . . . . . . . .4

4. Warnings, Installations and Operations . . . . . . . . . . . . . . . . .5

5. Operations and Maintenance Instructions . . . . . . . . . . . . . . .6

6. Installation Requirements for the

Commonwealth of Massachusetts . . . . . . . . . . . . . . . . . . . . .6

7. Unit Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

8. Heat Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

9. Unpacking the Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

10. Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

11. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

12. Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

13. Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

14. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Log Placement C5 or F5 . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Log Placement C6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

15. Field Conversion for ZDV6000-VFI25-VFI30 . . . . . . . . . . . .13

16. Combustion Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

17. Unit Operation & Checkout . . . . . . . . . . . . . . . . . . . . . . . . . .14

18. Check-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

19. Unit Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

20. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

21. Bay Window Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

22. Surround and Brass Trim Assembly Instructions . . . . . . . . .19

and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

23. Wiring Diagram - SIT Valve System . . . . . . . . . . . . . . . . . . .21

24. Wiring Diagram - Robertshaw Valve System . . . . . . . . . . . .22

25. Accessory List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-24

26. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-26

27. Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Kingsman Industries Warranty . . . . . . . . . . . . . . . . . . . . . . .28

Table of Contents

Page 4

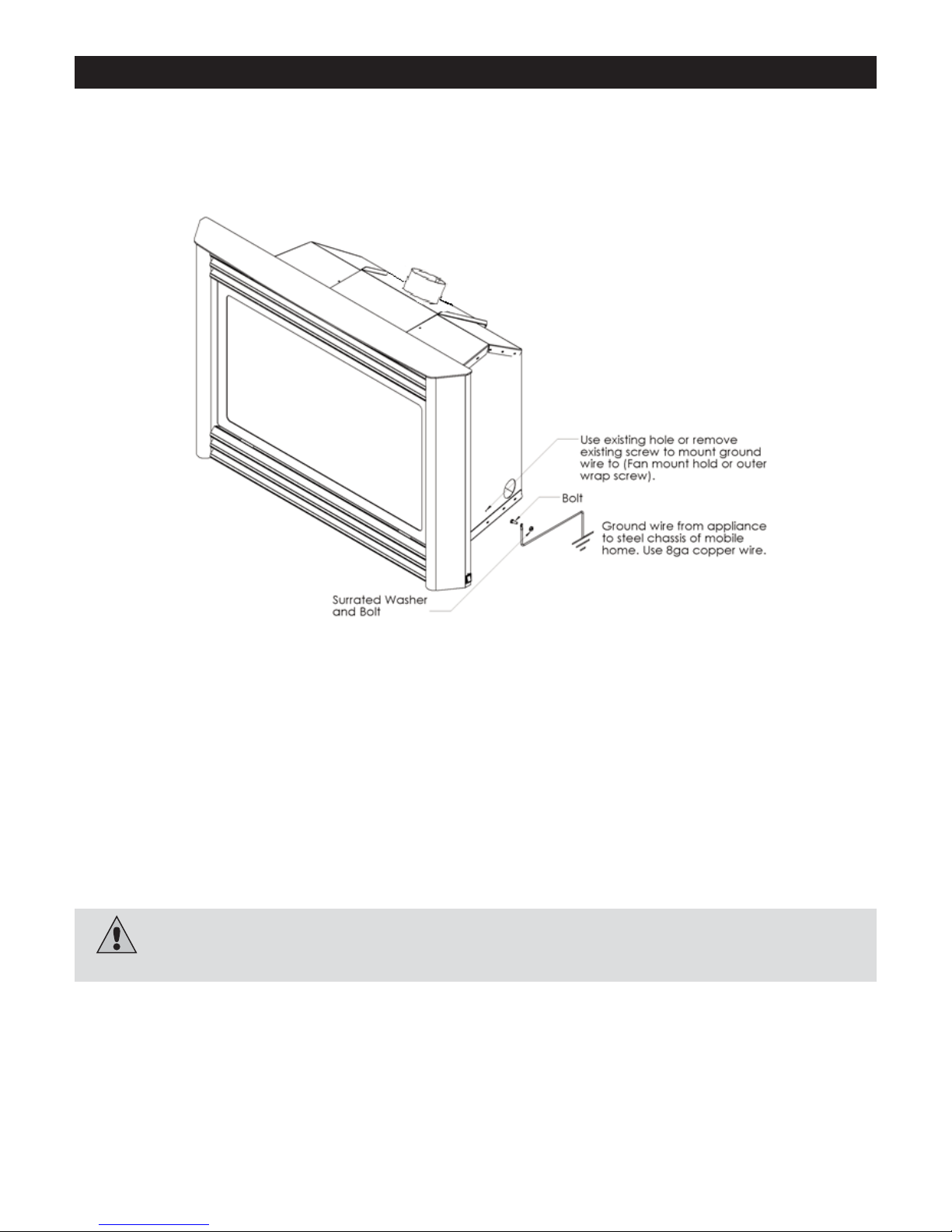

Mobile Home/Manufactured Housing Installation

THIS APPLIANCE MAY BE INSTALLED IN MANUFACTURED (MOBILE) HOMES AFTER FIRST SALE.

Please follow the current ANSI/NFPA 70 National Electrical Code in the USA and CAN/CSA C22.1 Canadian

National Electrical Code in Canada.

An appliance must be grounded to the steel chassis of the home with 8ga. copper wire using a serrated or star washer to penetrate paint or protective coating to insure grounding.

Use carriage bolt at the attachment point (see diagram above) to secure the appliance to the floor.

Bedroom approved.

Warning: Do not compromise the structural integrity of the manufactured home wall, floor or ceiling,

during installation of appliance or venting.

For required venting components see venting installation in appropriate section of this manual.

This Vent System Appliance must be installed in accordance with the manufacturer’s installation instructions and the

Manufactured Home Construction and Safety Standard Title 24 CFR, Part 3280, or the current Standard for Fire

Safety Criteria for Manufactured Home Installation, Sites, and Communities ANSI/NFPA 501A, and with CAN/CSA

Z240 MH Mobile Home Standard in Canada.

4

Page 5

Warnings, Installations, and Operations

Warning

• Gas fired appliances may be used only for supplemental heat and/or decorative purposes and under no circumstances

shall they provide a primary heat source.

FOR SAFE INSTALLATION AND OPERATION OF YOUR GAS FIREPLACE PLEASE NOTE THE FOLLOWING:

1. Do not clean when the glass is hot.

2. Do not use abrasive cleaners.

3. Using a substitute glass will void all product warranties.

4. For safe operation, glass doors must be closed.

5. When purging the gas line, the glass front must be

removed.

6. Do not strike or abuse glass. Take care to avoid breakage.

7. Do not alter gas orifice.

8. No substitute materials may be used other than factory

supplied components.

9. This appliance gives off high temperatures and should be located out of heavy traffic areas and away from furniture and

draperies.

10. Children and adults should be alerted to the hazards of the high surface temperatures of this appliance and should stay

away to avoid burns or ignition of clothing.

11. Young children should be carefully supervised when they are in the same room as the appliance. Toddlers, young children

and others may be susceptible to accidental contact burns. A physical barrier is recommended if there are at risk individuals in the house. To restrict access to a fireplace or stove, install an adjustable safety gate to keep toddlers, young children

and other at risk individuals out of the room and away from hot surfaces.

12. Under no circumstances should any solid fuels (wood, paper) be used in this appliance.

13. Under no circumstances should this appliance be modified. Any parts that have to be removed for servicing should be

replaced prior to operating this appliance.

14. Installation and repair should be done by a qualified service person. The appliance should be inspected before use and at

least annually by a professional service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding material, et cetera. It is imperative that control compartments, burners and circulating air passageways of the

appliance be kept clean. Make sure that the gas valve and pilot light are turned off before you attempt to clean this unit.

15. Clothing or other flammable material should not be placed on or near the appliance. This appliance should not be used as

a drying rack for clothing nor should Christmas stockings or decorations be hung from it.

16. Do not use this heater if any part has been under water. Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system and any gas control which has been under water.

17. Do not operate appliance unless completely installed as per installation instructions.

18. Failure to position the parts in accordance with these diagrams or failure to use only parts specifically approved with this

appliance may result in property damage or personal injury.

19. Do not operate appliance with the glass front removed, cracked or broken. Replacement of the glass should be done by a

licensed or qualified service person.

20. The front of the fireplace gives off high temperatures that could ignite combustible material which is kept close to the front

of the unit.

21. Ensure that power to the Fireplace is turned off before servicing.

22. Do not operate this Fireplace without the glass front or with a broken glass.

23. Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to the

owner’s information manual provided with this appliance. For assistance or additional information consult a qualified

installer, service agency, or the gas supplier.

24. Operation of this appliance when not connected to a properly installed and maintained venting system or tampering with

the blocked vent shutoff system can result in carbon monoxide (CO) poisoning and possible death.

Installation Regulations

This gas appliance must be installed by a qualified installer in accordance with local building codes, or in the absence of local

codes, with the current CAN/CGA-B149.1 Installation Code (in Canada) or the current National Fuel Gas Code Z223.1 when

installed in the United States.

This appliance, when installed, must be electrically connected and grounded in accordance with local codes, or in the absence of

local codes, with the current CSA C22.1 Canadian Electrical Code or with the national Electrical Code; ANSI/NFPA 70-1987 when

installed in the United States.

5

Page 6

6

• If the factory-built fireplace has no gas access hole(s) provided, an access hole of 1.5in [37.5mm] or less may be drilled

through the lower sides or bottom of the firebox in a proper workmanship like manner. This access hole must be plugged with

non-combustible insulation after the gas supply line has been installed.

• Cutting any sheet-metal parts of the fireplace, in which the gas fireplace insert is to be installed, is prohibited.

• This appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance.

• Installer must mechanically attach the supplied label to the inside of the fireplace into which the gas fireplace insert is installed.

NOTE: It is recommended that a Carbon Monoxide (CO) Detector be installed in or near bedrooms and on all levels of your

home. Place a detector about 15ft [4.5m] outside the room that houses your gas appliance.

Certified for installation in a bedroom or bed/sitting room. In Canada must be installed with listed millivolt thermostat. In USA see local codes.

For safe installation and operation note the following:

• The Burner/Log Assembly has been engineered and permanently adjusted for proper flame control.

• Periodically remove the logs from the grate assembly and vacuum any loose particles from the grate and burner areas. See

Log Placement page to remove logs. Vacuum burner parts and replace logs.

• Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

In the Commonwealth of Massachusetts, the installer or service agent shall be a plumber or gas fitter licensed by the

Commonwealth.

When installed in the Commonwealth of Massachusetts or where applicable codes; the unit shall be installed with a CO

detector per the requirements listed below.

1. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment, where the bottom of the

vent terminal and the air intake is installed below four feet above grade the following requirements must be satisfied:

A. If there is not one already present, on each floor level where there are bedroom(s), a carbon monoxide detector and

alarm shall be placed in the living area outside the bedroom(s). The carbon monoxide detector shall comply with NFPA

720 (2005 Edition).

B. A carbon monoxide detector shall be located in the room that houses the appliance or equipment and shall:

• Be powered by the same electrical circuit as the appliance or equipment such that only one service switch services

both the appliance and the carbon monoxide detector;

• Have battery back-up power;

• Meet ANSI./UL 2034 Standards and comply with NFPA 720 (2005 Edition); and

• Have been approved and listed by a Nationally Recognized Testing Laboratory as recognized under 527 CMR.

C. A Product-approved vent terminal must be used, and if applicable, a Product-approved air intake must be used.

Installation shall be in strict compliance with the manufacturer’s instructions. A copy of the installation instructions shall

remain with the appliance or equipment at the completion of the installation.

D. A metal or plastic identification plate shall be mounted at the exterior of the building, four feet directly above the loca

tion of vent terminal. The plate shall be of sufficient size to be easily read from a distance of eight feet away, and read

“Gas Vent Directly Below”.

2. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment where the bottom of the

vent terminal and the air intake is installed above four feet above grade the following requirements must be satisfied:

A . If there is not one already present, on each floor level where there are bedroom(s), a carbon monoxide detector and

alarm shall be placed in the living area outside the bedroom(s). The carbon monoxide detector shall comply with NFPA

720 (2005 Edition).

B. A carbon monoxide detector shall:

• Be located in the room that houses the appliance or equipment;

• Be either hard-wired or battery powered or both; and

• Shall comply with NFPA 720 (2005 Edition).

A Product-approved vent terminal must be used, and if applicable, a Product-approved air intake must be used. Installation shall

be in strict compliance with the manufacturer instructions. A copy of the installation instructions shall remain with the appliance or

equipment at the completion of the installation.

For the state of Massachusetts a T-handle gas shut-off valve

must be used on a gas appliance. This T-handle gas shut-off

valve must be listed and approved by the state of Massachusetts. This is in reference to the state of Massachusetts state code

CMR238.

Operations and Maintenance Instructions

Installation Requirements for the Commonwealth of Massachusetts

Warning: This fireplace has been converted for use with a gas fireplace insert only and cannot be used

for burning wood or solid fuels unless all original parts have been replaced, and the fireplace re-approved by

the authority having jurisdiction.

Page 7

With each insert the following must be purchased:

(1) Log Set (4 pce) Cast or Fibre

(1) Standard Surround Kit

(1) Grill Kit

For a list of options please see page 23-24 and contact your local

dealer.

4. CLEARANCES

This fireplace was designed for installation in a solid fuel

fireplace that has been installed in

accordance with National, Provincial/State and Local

building codes and is constructed of non-combustible

materials. DO NOT remove any refractory materials from

any masonry solid fuel fireplace. For installation in zero

clearance type listed solid fuel burning factory built fireplaces, it may be necessary to remove the damper plate

and refractory liners. Removal of the smoke baffle is

necessary in most cases.

Clearance from the front of the unit to a

combustible floor is 0.15 metres( 6 inches).

Clearance from adjacent side wall is 7 inches from

side of unit.

• Minimum clearances from the top of the grill to a mantel and maximum mantel width are:

MANTEL HEIGHT ABOVE

WIDTH GRILL OPENING

A 7”(17.8cm) 13”(33.0cm)

B 6”(15.3cm) 12”(30.5cm)

C 5”( 12.7cm) 11”(27.9cm)

5. ELECTRICAL CONNECTIONS

The blower for the fireplace insert comes

pre-wired from the factory all that is needed is to plug in

to 120 volt supply.

Fan Temperature Sensor

The wiring harness has two wire ends that must be

attached to the Temperature Sensor. The Temperature

Sensor is mounted underneath the burner, attached by

two screws securing the

thermodisc to the bottom of the burner.

(See page 19 for drawing assembly of SIT Wiring

Diagram).

NOTE: MAKE SURE THE WIRE HARNESS IS

ROUTED AGAINST THE SURROUND,

NOT THE SIDE OF THE FIREPLACE.

7

1. UNIT IDENTIFICATION

Vented Fireplace Insert (VFI30N or VFI30LP). This unit

is offered with variable speed fan and variable gas input.

VFI30N (NATURAL GAS)

(0- 4500ft) Output BTU/HR

Input BTU/HR Fan “OFF” Fan “ON HI”

Max 30,000 22,200 23,400

Min 20,000 14,800 15,600

Air Shutter .156 Orifice #36

MINIMUM FIREPLACE OPENING

WIDTH 29” (73.7 cm)

HEIGHT 203⁄4

” (52.7 cm)

DEPTH 161⁄ 2

” (41.9 cm)

2. HEAT OUTPUT

It must be remembered that both the units in this manual produce significant amounts of heat within a varying

input range.

3. UNPACKING THE INSERT

The unit has been packaged to ensure that the

fireplace remains undamaged during regular

handling.

It is important to inspect the packaging for signs of damage that may have affected the unit.

Included with the fireplace is the following:

(1) fireplace insert

(1) ceramic glass panel (fragile)

(1) draft hood

(1) installation instructions

VFI30LP (PROPANE/LP)

(0- 4500ft) Output BTU/HR

Input BTU/HR

Fan “OFF” Fan “ON HI”

Max 30,000 22,800 24,300

Min 22,000 16,720 17,820

Air Shutter .500 Orifice #52

Page 8

8

Thermostat Connection and On/Off Switch Millivolt

Thermostat ( optional but recommended). All controls

are connected directly to the gas valve and the circuit is

made between:

• Robertshaw Valve

TH and TP- PG

• SIT Valve TH and TP-TH

See Section 18 SIT Wiring Diagram

6. GAS PIPING

All gas piping must be done in accordance with all

applicable codes CAN./CGA-BI49.1 or installation codes

or ANSI -Z223.1 as well as local codes.

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

The gas line to the fireplace insert should be of

adequate size to minimize the pressure drop and should

never be smaller than that supplied with the valve. A

ground joint union should be used as close to the valve

as possible to facilitate removal of the gas valve and

burner base pan.

Check that the gas piping is not supported by the gas

valve. A manual shut-off valve should be installed in the

gas line, inside the fireplace. All piping joints must be

tight and an approved non-hardening sealing compound

shall be used (one which is suitable for future service).

For the state of Massachusetts a T-handle gas shut-off

valve must be used on a gas appliance. This T-handle

gas shut-off valve must be listed and approved by the

state of Massachusetts. This is in reference to the state

of Massachusetts state code CMR238.

CAUTION: Never use a flame to check for

leaks - use an approved leak test solution.

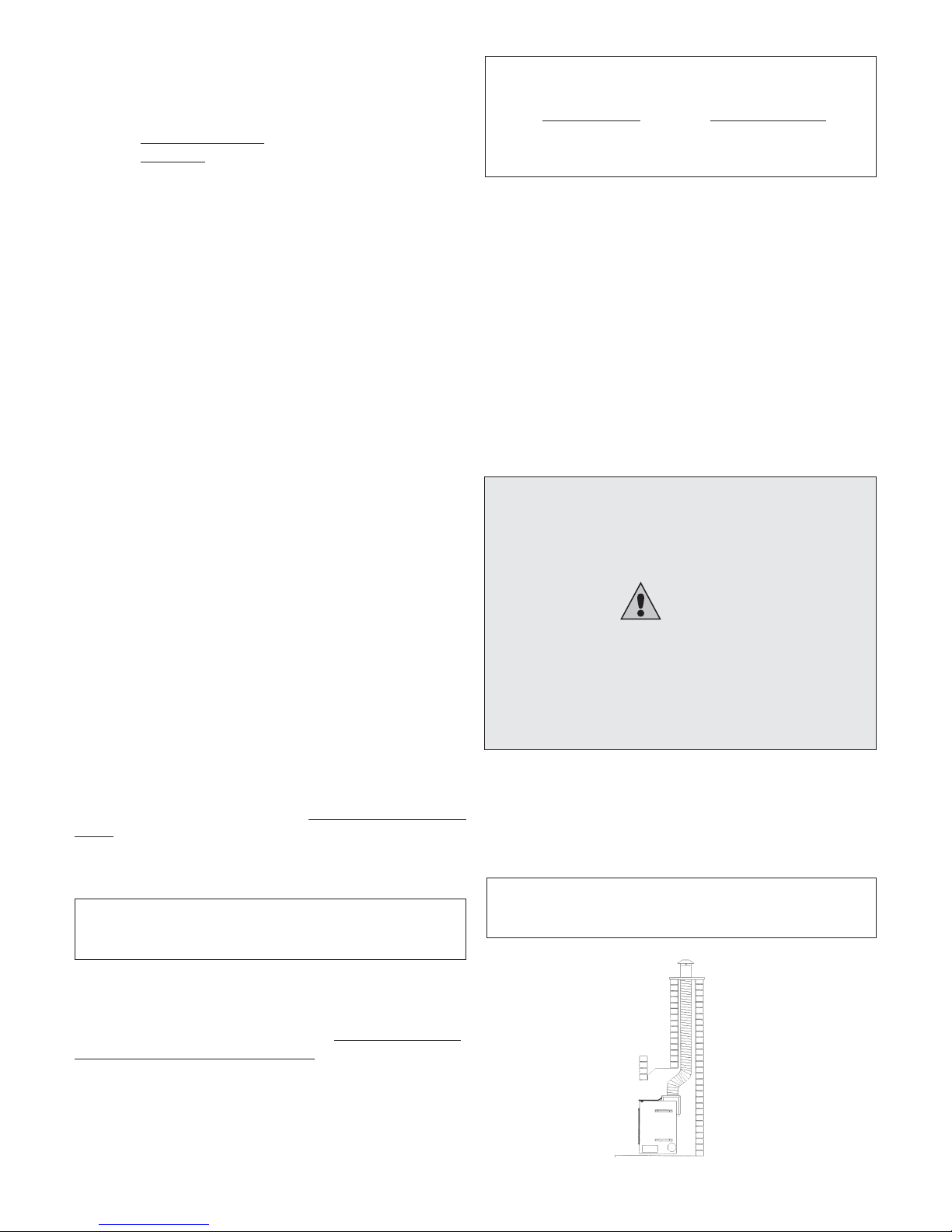

7. VENTING

Before any vent liner is run through a masonry chimney

or other approved venting system the chimney must be

inspected. cleaned and repaired if necessary . A

chimney which was used for a solid fuel fireplace must

be professionally cleaned in order to reduce corrosion of

the vent and other possible safety hazards.

This fireplace insert is approved for use with a 4” inch

diameter pipe.

VENT LENGTH (4” Diameter Vent)

Vertical (rise)

Horizontal (run)

Min l0 ft - 3.1m 0 ft - 0.0 m

Max 50 ft - 16.2 m 2 ft - 0.6 m

All venting lining products must be approved and

installed according to the vent manufactures installation

instructions. All vent liners must terminate in a rain cap

to prevent debris and rain from entering the vent and

possibly damaging the appliance or creating an unsafe

condition. The area between the existing chimney and

liner must be capped off for the same reasons as above

and to reduce the chances of venting problems and corrosion of the vent.

It is strongly recommended that the area between the

damper and the liner be blocked to prevent the possibility

of flue products entering the area between the chimney

and the vent liner.

This heater must be properly connected to a

venting system. This heater is equipped with

a vent safety spill switch shutoff system.

WARNING

Operation of this heater when not connected to a

properly installed and maintained venting

system or tampering with the vent safety spill switch

shutoff system can result in carbon monoxide (CO)

poisoning and possible death.

If this fireplace insert is to be used to replace an existing

fireplace insert the existing vent liner must be of the

proper size and if so it must be inspected for

obstructions, damage and/or corrosion. Replacement

must be done as necessary .

NOTE: Follow vent manufacturerʼs

installation instructions.

Page 9

9

When installing the venting please take note of the

following:

1. A masonry chimney or other approved

venting system must be clean and inspected

for any damage which might make it unsafe.

Chimney must be constructed of noncombustible material.

2. Any chimney clean-outs must be tight fitting

as to minimize air leaks into the chimney.

3. Any flue damper must be blocked open or

removed to provide a minimum opening of

13 square inches and must not distort the

liner.

4. The liner is to be inserted from the top of the

chimney and through the damper opening.

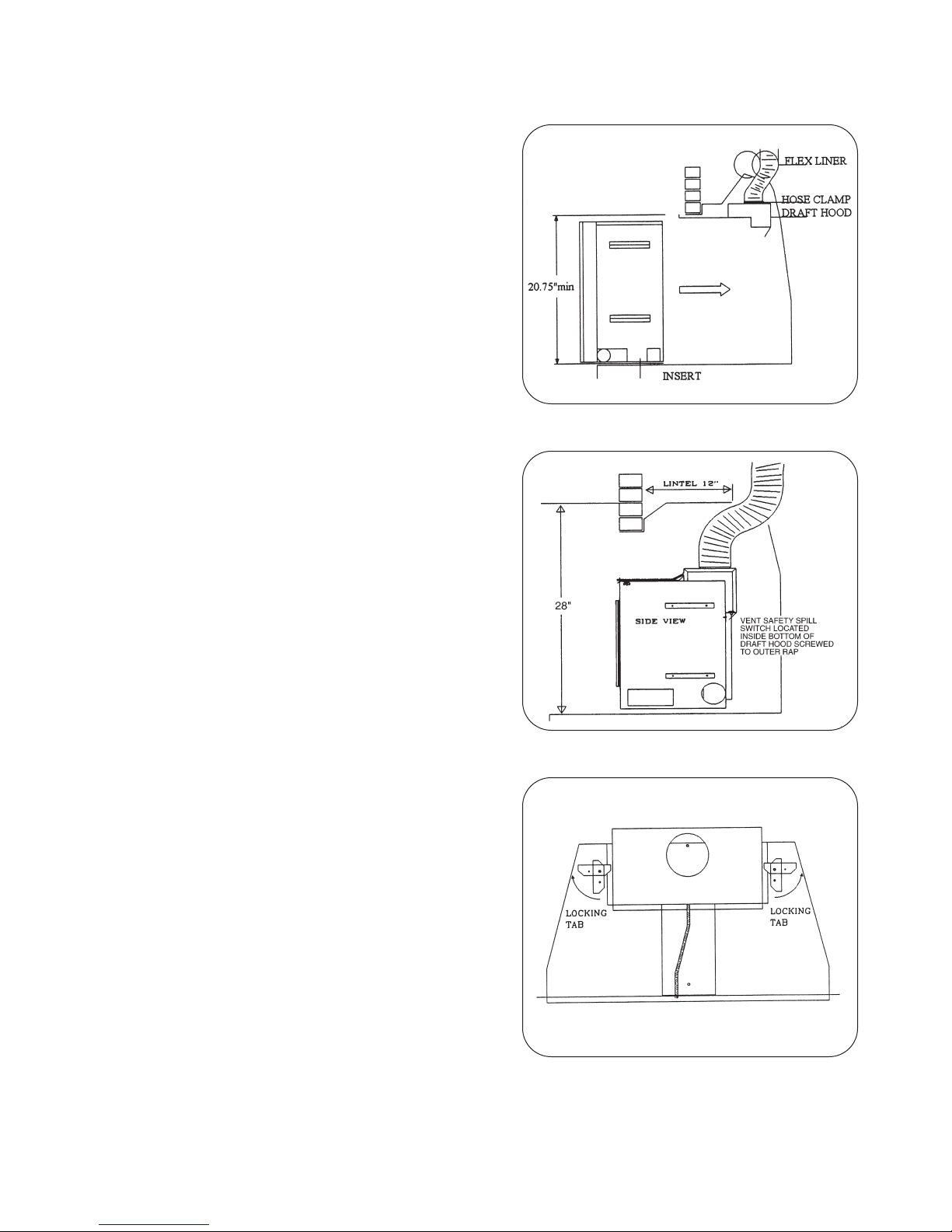

5. The draft hood is to be removed from the

fireplace insert and attached to the liner using

(

3) sheet metal screws and a clamp

(See Figure 1). It may not be necessary to

remove the draft hood if there is sufficient

space in the solid fuel fireplace to attach the

liner with the draft hood in place 24”

is required.

6. If the lintel is wider than 12” (305mm) then

the height of the solid fuel fireplace must be

at least 28” (711mm) to allow for an offset

elbow. (See Figure 2). If providing an

offset, do not collapse the flex pipe. This

will restrict the vent and cause a red flame

which will produce soot on glass.

7. If however the draft hood must be removed

then it must first be attached to the liner using

four (4) sheet metal screws and a clamp. The

fireplace insert can then be slid into place and

the draft hood should be located so that the

screw on the locating bracket mates with the

hole on the top centre front of the insert. The

locating bracket should be pulled as far

forward as it will go and be bolted into place

(a flashlight should be used to confirm that

the draft hood is flat on the top of the unit).

Once the draft hood is in place a long screw

driver or piece of rod must be used to rotate

the locking brackets so that the lock over top

the flanges on the side of the draft hood.

(See Figure 3)

(Figure 1)

(Figure 2)

(Figure 3)

Page 10

10

8. INSTALLATION

NOTE: INSTALLATION AND REPAIR SHOULD BE

PERFORMED BY A QUALIFIED SERVICE

PERSON. THE APPLIANCE SHOULD BE

INSPECTED BEFORE USE AND AT LEAST

ANNUALLY BY A PROFESSIONAL SERVICE

PERSON. MORE FREQUENT CLEANING MA Y BE

REQUIRED DUE TO EXCESSIVE LINT FROM

CARPETING, ETC. IT IS IMPERATIVE THAT THE

CONTROL COMPARTMENT, BURNING AND

CIRCULATING AIR PASSAGEWAYS OF THE

APPLIANCE BE KEPT CLEAN.

Install the fireplace insert in the following order:

1. Clean and inspect chimney.

2. Plan layout of gas line.

3. Plan layout of electrical.

4. Install the chimney liner as instructed in

SECTION

9.

5. Clean out and vacuum the solid fuel fireplace.

Make sure that the fireplace is completely

cool and has not been used for a few days.

6. Make sure that the solid fuel fireplace base is

level and if not make any necessary adjustments.

7. Slide unit into place attaching draft hood and or

chimney liner as required.

8. Hook up gas line.

9. Hook up electrical.

10. Remove glass by removing two screws behind

upper grill and lifting door off bottom door retainer

(glass is very fragile).

11. Log Installation:

- Remove logs from carton (4) and

inspect.

- Install as per Log Placement Guidelines

and set ups.

- Purge lines and test pilot operation.

12. Ember Kit Instructions:

Spread supplied rock evenly on the bottom of the

fireplace (DO NOT PLACE ROCK ON BURNERS), next tear ember wool into small thin pieces

and place evenly over front burner .

13. Re-install the glass door.

14. Check for correct operation

(See SECTION

10)

15. Install Surround and Grills as per

instructions.

16. Gas fired appliances may be used only for sup-

plemental heat and/or decorative purposes and

under no circumstances shall they provide a primary heat source.

(Figure 4)

NOTE: DO NOT BLOCK THE SIDES OR

TOP OF THE APPLIANCE AS THIS WILL AFFECT

THE PROPER AND SAFE

OPERATION OF THE UNIT.

C5 Log

Page 11

11

C5 or F5 Parts

Burner

Step 1: Break ember wool into thumbnail

size pieces. Place glowing embers evenly on

to the front burner tube as shown.

Step 2: Place Log #1 on burner as shown

and pull forward to the grate bars. Place log

#2 on rear log holder and center it.

Step 3: Place Log #3 onto the notched areas

as shown. Place Log #4 onto the notched

areas as shown. (Refer to step 2 for notched

area locations).

Step 4: Place lava rock around the sides and

the front of the burner as shown. Sprinkle vermiculite over top of the lava rock as shown.

(Do not place lava rock or vermiculite on the

burner tube areas).

LOGC5 OR LOGF5 PLACEMENT GUIDE

Page 12

12

Log C6 Parts List

Burner

Step 1: Place Log #1 on rear log holder, center it, and push back. Place Log #2 against

the left burner mount and back against the

ember plate log stop as shown. (Log must not

impinge on main flame pattern).

Step 3: Place Log #5 on the notched locations of Log #4. (Refer to step 2 for Log #5

notch locations). Fill the exposed areas of the

ember plates and front burner tube with

ember rocks. (Do not place ember rocks on

rear burner tube).

Step 4: Place lava rock around the sides and

front of the burner. Sprinkle the vermiculite

over top of the lava rock. (Do not place lava

rock and vermiculite on burner or ember

plates).

Step 2: Place Log #3 onto the left notch of

Log #1 and against the left grate bar as

shown. Place Log #4 onto the right notch of

Log #1 and against the right grate bar as

shown.

LOGC6 PLACEMENT GUIDELINES

Page 13

13

Field Conversion for ZDV6000 - VFI25 - VFI30

C6GEK: ZDV6000 Conversion C30GEK: VFI25 & VFI30 Conversion

2 - Ember Plates 2 - Ember Plates

1 - Ember Plate Bridge 1 - Ember Plate Bridge

1 - Grate Assembly with 5/8” Bars 1 - Grate Assembly with 1/2” Bars

4 - 1/2” x 8-18 DT Screws 2 - 1/2” x 8-18 DT Screws

Tools Required: Drill, 1/8” Drill Bit, 1/4” Nut Driver Bit

Step 1: Remove existing grate bar by bending bar slightly forward and drill out rivets.

Step 2: Seal rivet holes with two supplied screws. (ZDV6000 ONLY)

Step 3: Center legs of Grate Bar on either side of burner support and fasten with supplied self drilling Screws. (Ref: 1)

Step 4: Place Ember Plates between burner tubes right and left of Burner.

NOTE: Raised flange of Ember Plates must be to back of Burner.

Step 5: Slide Ember Plate Bridge between Ember Plates. (Ref: 2)

Warning: Failure to position the parts in accordance with these diagrams or failure to use only parts

specifically approved with this appliance may result in property damage or personal injury.

Page 14

14

9. COMBUSTION AIR

Indoor combustion air must conform to the requirements

of the applicable code:

Canada Installation Code CAN/CGA-B149.1 or (USA.)

National Fuel Gas Code ANSI-Z223.1

In homes of normal construction, sufficient combustion air

can usually be obtained by air infiltration. The fireplace

insert must be installed in area that is free of excessive

dust and dirt and where ventilation is sufficient to provide

proper combustion of gas, proper venting and the

maintenance of safe operating temperatures. When

infiltration does not provide adequate air for combustion,

outside air shall be introduced as specified in the

installation codes.

The draft hood must be installed so as to be in the same

atmospheric pressure zone as the combustion air inlet to

the appliance.

To check if there is adequate air for combustion perform

the following procedure: (See Figure 5)

I. Close all windows and doors.

2. Turn all exhaust fans on high.

3. Turn on fireplace insert.

4. To check for proper draft action a draft meter

with a minimum graduation of 0.01 inches of

water column is required. The meter is to be

attached to the 1/4 inch aluminum tube

originating in the draft hood using high

temperature silicone (tubing should not be

allowed to contact glass and unit should be

allowed to run for a minimum of 10 minutes;

area of sensing tube will become quite hot).

A minimum draft pressure of .02 inches of

water column is required to ensure that there

is no spillage at the draft diverter. This

number was arrived at through testing under

various severe conditions, actual vent

pressures under normal conditions will be

much higher. A draft pressure under .02 will

indicate either a blocked vent, down draft,

adverse house de-pressurization or improper

venting.

If there is not the proper draft then provide outside air as

instructed by the applicable code.

(Figure 5)

NOTE: DO NOT OBSTRUCT FLOW TO THE FRONT OF

THE FIREPLACE AS THIS COULD AFFECT

COMBUSTION AND BE A FIRE HAZARD. FAILURE TO

DO SO COULD RESULT IN PROPERTY DAMAGE,

INJURY AND/OR LOSS OF LIFE.

10. UNIT OPERATION & CHECK-OUT

Before trying to light the unit for the first time it is advisable

to purge the gas. Once the gas line is purged it is best to

wait a few minutes with a few open windows before trying

to light the fireplace. For detailed lighting instructions see

page 27.

Start-up Instructions:

1. Turn wall switch ( or thermostat) to the off

position.

2. Turn gas valve to “PILOT” and depress.

3. Press the red spark button repeatedly until a

steady pilot flame is present.

4. Keep the “PILOT” position on the gas valve

depressed for approximately 45 seconds.

5. Turn gas valve to the on position.

Page 15

15

Sequence of operation:

1. Turn On/Off switch (or thermostat) to the

on (call for heat) position.

2 Main burner lights.

3. If blower variable speed switch is in the

“On” position then the blower will turn on

automatically once the unit is hot enough.

4. Once the On/Off switch is turned off (or

thermostat is satisfied) then the flame will

extinguish.

5. Blower will keep on running until the fire

place has cooled down.

Shut Down Instructions:

1. Turn On/Off switch (or thermostat) to the

off position.

2. Depress gas valve and turn to “OFF”

position.

11. CHECK-OUT

Once installed, the unit should be operated at least

three (3) times to ensure that all is in working order.

NOTE: MANUFACTURING OILS AND PAINT WILL

SMOKE DURING INITIAL FIRING OF APPLIANCE.

OPEN WINDOWS FOR VENTILATION.

12. UNIT ADJUSTMENT

BEFORE LEAVING, THE INSTALLER SHOULD

MAKE THE FOLLOWING CHECKS:

(a) BTU/INPUT / GAS PRESSURE

The fireplace input is marked on the Rating Plate. The

gas valve comes factory pre-set to the proper rated

pressure and adjustment should not be necessary. If

there is any question of input then it may be necessary

to check manifold pressure.

Manifold pressure on the S.I.T. Nova valve can be

measured by loosening the slotted pressure taps on

the front bottom left of the valve. (‘E’ Inlet Pressure, and

‘A’ Manifold Pressure) and connecting a manometer .

(b) MAIN BURNER / PILOT

The pilot flame size is factory set. The pilot flame

should be at least 1.5 inches (4 cm) long. The flame

should be impinging on the pilot generator. Pilot size

can be adjusted through the pilot adjust screw. If the

pilot flame is too small and can not be adjusted through

the pilot adjust screw then there is the possibility of dirt

in the pilot orifice in which case the pilot orifice should

be cleaned or replaced.

Pressure ranges are as listed below:

Gas Supply Pressure (inches w.c.)

Min Normal Max

Natural Gas 4.5 7.0 9.0

L.P. (propane) 10.8 11.0 12.0

Manifold Pressure (inches w .c. )

Normal(HI) (LOW)

Natural Gas 3.5 1.6

L.P. (Propane) 10.0 6.3

The unit as shipped is equipped for operation for 0 to

4500 ft.

The main burner should be allowed to operate for 15

to 20 minutes before making any adjustment to the unit.

The air shutter should never be closed all the way. For

Natural Gas and Liquid Propane it is recommended

that the air shutter be set to Factory Specifications.

(See Page 4).

If there is too much primary air then the flame will be

very blue with yellow tips and smaller flame height.

If there is too little primary air then the flame will be

yellow with orange/red tips on the back flames with dark

sooty elongated tips. In this condition the glass and logs

could show signs of soot accumulation within 10 to 20

minutes.

NOTE: With a properly burning flame there

will still be a certain level of sooting. It may be

necessary to clean the glass up to 3 times

during a cold season. The amount of cleaning

required depends on the amount that the fire

place is used.

Page 16

16

13. MAINTENANCE

CAUTION: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

(a) Blower

This motor has been factory oiled and under normal

operating conditions should not require oiling.

Replacement of Blower

Remove glass (two screws behind upper grill), and

remove logs. Blower access panel is visible after rear

log is removed. Remove the screws (five on top, one on

each side) and lift from tabs, blower is then assessable

for servicing. Before re-installing blower access panel,

apply a bead of sealant Millpac to the bottom edge of

panel, (this is to assure blower does not interfere with

combustion), and than secure with screws.

(b) Burner/Pilot

The burner should be periodically cleaned by removing

any ember material and wiping off and vacuuming the

burner pan. At this time it is also recommended to

check the burner for any signs of corrosion which might

impair its operation and replace it if necessary.

The pilot should also be checked for signs of proper

operation and flame.

If replacement of pilot, generator,

thermocouple is necessary replace from top and

bottom of firebox bottom.

(Reference lower diagram Page 27)

(c) Logs

CAUTION: The logs can stay hot for several

hours after the fireplace is shut off. Serious

burns could result. It is recommended that the

fireplace be turned off for several hours before

cleaning is attempted.

DO NOT wash the logs if they have any accumulation

of soot on them. Washing the logs in any sort of

solution will just cause the soot to become imbedded in

the logs surface.

The best way to clean the logs is to blow off the soot

using compressed air at high velocity. It is also effective

to use a clean soft brush in the area of soot

accumulation. Vacuuming the log with a soft brush will

also work but do not forget to carefully wash the brush

before using it on anything else. If at all possible clean

the logs outside the home away from areas you do not

wish the soot to mark.

(d) Firebox and Heat Exchanger

To clean the firebox and heat exchanger use a vacuum.

For the firebox it is recommended to use a soft brush

on the end of the vacm as not to damage any painted

surfaces. The heat exchanger may be more difficult to

clean but can still be cleaned with the combination of a

small brush and the vacuum.

(e) Glass Cleaning

It will be necessary to clean the glass periodically.

During start-up condensation will form, and cause dust

and lint to cling to the surface of the glass.

Furthermore, the initial burn cures the paint but also

leads to the deposit of a filmy residue. It is therfore recommended that the glass be cleaned two or three

times, initially, with non-abrasive common household

glass cleansers and warm water. After that, the glass

can be cleaned two or three times a season depending

on use.

WARNING Electrical Grounding Instructions

This appliance is equipped with a three prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong

receptacle. Do not cut or remove the

grounding prong from this.

Warning: INSURE THAT POWER IS

TURNED OFF TO THE FIREPLACE

BEFORE SERVICING.

Warning and Cautions.

• Do not clean when the glass is hot.

• Do not use abrasive cleaners.

• Using a substitute glass will void all product

warranties.

• Do not strike or abuse glass. Care must be

taken to avoid breakage of the glass.

• Do not operate this fireplace without the glass

front or with a broken glass.

Page 17

17

h) Valve and Burner Replacement

For valve replacement it is recommended that the

burner assembly be removed, this is done by removing

two 1/4” hex screws on the left and right side of the

firebox and lifting the complete burner assembly from

(the unit and replacing defective component and reinstalling. Check for gas leaks after replacing burner

assembly.

WARNING

The appliance area must be kept clear and free from

combustible materials, gasoline and other flammable

vapours and liquids.

14. BAY WINDOW INSTALLATION

Follow all installation instructions and testing of the unit

before installing Bay Window. Turn unit off and let the

unit cool down before installing.

Attach extension knobs (Hi/Lo), (On/Off) to valve. Then

slide variable speed and piezo bracket forward by

loosening screw and secure.

Attach Bay Window Assembly by inserting clips onto

bottom channel and screw into place at top door

channel.

NOTE: The Bay Window assembly replaces the upper

glass retainer provided with the original unit. Insert flat

glass retainer and tighten, making sure glass does not

fall forward.

(See Bay Window figure 6 on page 18)

Warning and Cautions.

• Do not clean when the glass is hot.

• Do not use abrasive cleaners.

• Using a substitute glass will void all product

warranties.

• Do not strike or abuse glass. Care must be

taken to avoid breakage of the glass.

• Do not operate this fireplace without the glass

front or with a broken glass.

Glass Replacement

REPLACEMENT GLASS

Only Robax ceramic or coated NeoCeram glass may

be used for replacement. The glass must be a minimum

of 5mm thick.

Removal of the Glass Door

1. Remove the door by unscrewing the two (2) top

screws of the top channel and loosening the bottom

channel.

2. Once the top of the door is unlatched, pull it out

wards and up to unlatch the bottom.

3. To re-install, place the bottom door ledge into the

lower channel assembly first. Now, swing the door

closed to seal it against the firebox cavity. Re-attach

the upper channel assembly to secure the door to the

appliance. Tighten 4 screws.

4. To replace the class, clean all gasket materials from

the door frame. Using a high heat silicone (resistant to

500º [260ºC]) apply a bead of approximately 1/32’ to

all four sides of the frame and insert the glass with a

new gasket. The door frame should be on a flat surface

with a small amount of weight pressing the glass into

the silicon. Let everythng dry for approximately 15 to 20

minutes. The door can be re-installed by following step

3.

(f) Brass Trim and Surround

All Brass and Painted surfaces should only be wiped

off with a soft non abrasive damp cloth ( a mild dish

soap can be used if necessary ).

DO NOT use brass or other metal polishes,

glass cleaners or any other abrasive cleaners

as this will mark and damage brass or painted

surfaces.

(g) Venting

Venting should be inspected yearly by a qualified

service technician and replaced if necessary . Draft

action should be tested for as outlined in Section

9 to

conform that conditions in the house have not changed

or that the vent has not become blocked or damaged.

Page 18

18

Bay Window Assembly and Parts List:

Ref. No.

Stock No. Description

1 2000-300 Bay Window Assembly

2 2000-310 Upper Brass Window Trim

3 2000-313 Grill (Bottom)

4 1001-P188SI On/Off Pilot Extension Knob

5 1001-P189SI Hi/Lo Extension Knob

6 2000-312 Side Louvers

7 2000-070 Fan/Piezo Bracket

8 5000-P025WS Extension Spring

9 Misc. #8-24 Screw

10 1000-309 Magnet

11 1001-P633SI Valve Nova LP Hi-Lo 0820633

1001-P634SI Valve Nova-NG Hi-Lo 0820634

2000-321 Glass Side - Tempered

2000-322 Glass Front - Tempered

Bay Window (Figure 6)

Page 19

19

Surround Kit Installation:

1. Before attaching surround assembly, check operation of insert and installation of draft hood and

chimney liner .

2. To assemble surround attach panel (1), (2), and (3) with (4) bolts (10/24) and star lock nuts, if

optional brass panel kit was purchased install at this time over the surround kit and than tighten

the (4) bolts to secure all panels.

3. All brass trims (4), (5) and (6) are installed with 5/16 x 6/32 self tapping screws, attach part (4),

(5) and (6) to outer edge of surround. Then place On/Off switch into slot (upper right corner) after

right trim has been attached to surround. Route wires through 3/4” grommet hole, down right side

of surround into right side of insert. A hole is provided in firebox, attach to valve at terminals TP

and TP-TH (for SIT Valve). (Refer to Wiring Diagram on Page

19)

15. Surround and Brass Trim Assembly Instructions

Page 20

20

Replacement Parts List for Surround Kits and Panel Kits

Std. Surround Large Surround

(27-3/4 x 40-1/2”) (30-3/4 x 44”)

Ref. No.

Stock No. Stock No. Description

1 2000-401 2000-421 Top Panel

2 2000-402 2000-422 Left Panel

3 2000-404 2000-423 Right Panel

4 2000-405 2000-424 Brass Top Trim

5 2000-405 2000-425 Brass Left Trim

6 2000-406 2000-426 Brass Right Trim

7 2000-407 2000-427 Brass Top Panel

8 2000-408 2000-428 Brass Left Panel

9 2000-409 2000-429 Brass Right Panel

10 1000-216 1000-216 On/Off Switch

11 1000-243 1000-243 Wire 18-I/C (105 C)

12 Misc. Misc. Screws (10/24)

13 Misc. Misc. Nuts

14 Misc. Misc. Screws Self Tapping (5/16 x 6/32)

15 Misc. Misc. 3/4” Grommet

TYPICAL VENTING DIAGRAM

Page 21

21

16. WIRING DIAGRAM - FOR SIT VALVE SYSTEM

SPILL SAFETY SWITCH - Wiring Diagram

SIT 820-639 and 820-640 True Millivolt Systems

This System does not have a thermocouple

For units with serial number greater than 13930, see 820639 - 820640 systems.

FOR SIT 820633-820634

Wiring diagram SIT 820633820634 thermocouple system

SIT 820633 - 820634 Valves

No

Thermocouple

Page 22

22

17. WIRING DIAGRAM FOR ROBERT SHAW VALVE SYSTEM

Ref. No Stock No.

Description Ref. Letter Wire Description

1 2000-083 *Valve NO Hi/Lo (760 711 454 ) A (2) Female Slip on Insulated End

2000-083P *Valve LP Hi/Lo (760 711 454 )

2 2000-080 Thermostat (F095:105/127:113) B (1) Female Slip on Insulated End

3 1000-P134WR Pilot & Bracket (E39Al) C (1) Female Slip on Insulated End

4 2000-085 Variable Speed Switch D (3) Twist Wire Connectors

5 1000-214 Piezo - Red Button E (2) Universal Bushings

6 2000-081 Blower Motor (QLN65/0024) F (1) Strain Relief Bushing

7 1000-P135WR Thermocouple (H19E924) G (1) Cord 8ft, Three Prong 115 V

8 1000-P136WR Generator (O01A-524)

1000-206 Orifice Pilot NG (F069-2060)

1000-P104WR Orifice Pilot LP (FO69-2462)

1000-216 On/Off Rocker Switch

1000-255 Orifice Burner NG #43 Rear, #49 Front

1000-255 Orifice Burner LP #54 Rear, # 62 Front

(* Valves are factory converted, specify (NG) Natural Gas, or (LP) Liquid Propane)

Page 23

23

18. ACCESSORY LIST

Stock Number Description

Log Set: (Required for each Insert)

LOGF5 Log Set - Four Piece Fibre Split Oak (F5000, ZDV6000, VF130)

LOGC5 Log Set - Four Piece Cast Split Oak (F5000, ZDV6000, VF130)

LOGC6 Log Set - Five Piece Cast Split Oak (6000 VFI30, VFI25) c/w Glowing

Ember Rock Chunks

Surround Kit (Required for each Insert)

V30S2640B Surround Deluxe - Black

V30T2640A Trim Kit - Antique Brass

V30T2640C Trim Kit - Chrome

V30T2640P Trim Kit - Polish Brass

(Size 26 13/16” High x 40 3/4” Wide)

V30S2844B Surround Large Deluxe - Black

V30T2844A Trim Kit - Antique

V30T2844C Trim Kit - Chrome

V30T2844P Trim Kit - Polish Brass

(Size 28 13/16” High x 44 3/4” Wide)

V30S2740B Surround Kit - Black

V30T2740A Trim Kit - Antique Brass

V30T2740C Trim Kit - Chrome

V30T2740P Trim Kit - Polish Brass

(Size 27 3/4” High x 40 1/2” Wide)

V30S3044B Surround Large Kit - Black

V30T3044A Trim Kit - Antique Brass

V30T3044C Trim Kit - Chrome

V30T3044P Trim Kit - Polish Brass

(Size 30 3/4” High x 44” Wide)

V2R2640 Riser for Deluxe Surround (2 1/2”) - For Use on V30S2640B or V25S264 0B

V2R2840 Riser for Deluxe Large Surround (2 1/2”) - For Use on V30S2844B

Grill Kit (Required for each Insert)

Z6GBA Grill Kit - Classic Builder Antique Brass

Z6GBC Grill Kit - Classic Builder Chrome

Z6GBP Grill Kit - Classic Builder Polish Brass

VI30GBL Grill Kit - Black

VI30GAB Grill Kit - Antique Brass

VI30GPB Grill Kit - Polish Brass

Z6GCR Grill Kit - Chrome

Bay Window Kits (Consists of Black Upper Grill and Brass Lower Grill, Three Piece Glass Viewing Area)

VI30BWAB Bay Window (as above) with Antique Brass Louvers

VI30BWCR Bay Window (as above) with Chrome Louvers

VI30BWPB Bay Window (as above) with Polish Brass Louvers

Page 24

24

Accessories - Optional

V30P2740A Panel Kit - Antique Brass (For use on V30S2740B)

V30P2740C Panel Kit - Chrome (For use on V30S2740B)

V30P2740P Panel Kit - Polish Brass (For use on V30S2740B)

V30P3044A Panel Large Kit - Antique Brass (For use on V30S3044A)

V30P3044C Panel Large Kit - Chrome (For use on V30S3044C)

V30P3044P Panel Large Kit - Polish Brass (For use on V30S3044P)

(Note panel Kits are not available for Deluxe Surrounds)

V30ADDX Arch Door Frame - Deluxe Black (352)

V30ADTH Arch Door Frame - Top Half Black (353T)

V30ADDA Arch Door Frame - Double Arch Black (354)

V30ADDD Arch Door Frame - Double Door Arch Black (355)

V30ADBL Arch Door Frame - Black (351)

VI30RL Refractory Brick Liner (3Pce.)

ZlMT Thermostat Millivolt Wall Mount

Z80PT Thermostat Programmable Digital Millivolt Wall Mount (1F80-40)

ZlRC Remote Control Millivolt (On/Off with LED) (Model I)

ZART Remote Control Thermostat Millivolt (Model K)

RMCBN Remote Control - Basic - Natural Gas (On/Off, Hi/Lo Flame Adjustment)

RMCBP Remote Control - Basic - Liquid Propane (On/Off, Hi/Lo Flame Adjustment)

DCHS Remote Control Heatshield

Venting Accessories

VI4SK25 Chimney Liner Starter Kit - (4” Diameter x 25’)

Kit Includes: Aluminum Liner 25ft, Chimney Flashing, Rain Cap,

Mortar Collar, Screws

ZDV4FP8 Flex Pipe 4” Diameter (4’ Unexpended to 8’ Expanded)

ZDV4FP20 Flex Pipe 4” Diameter (10’ Unexpended to 20’ Expanded)

ZDV4FC Flex Connector 4” Diameter

Page 25

25

19. REPLACEMENT PARTS FOR VFI30 SYSTEM #1 Old SIT System

(If Serial Number is LESS than 13436)

Valve System Parts - S.I. T .

Part Number Description

1000-P136WR Thermopile GOAI-524

1001-P035SI Electrode Sparker 915.035 SIT

1001-P129SI Thermocouple 290.129 SIT unified

1001-P157SI Orifice Pilot LP 977.157 SIT

1001-P159SI Orifice Pilot NG 977.159 SIT

1001-P508SI HT Cable 16

1001-P633SI Valve Nova LP Hi/Lo 0820633

1001-P634SI Valve Nova NG Hi/Lo 0820634

1001-P605SI Pilot Burner LP 190.605 unified SIT

1001-P606SI Pilot Burner NG 190.606 unified SIT

REPLACEMENT PARTS FOR VFI30

New Top convertible SIT System

(If Serial Number is BETWEEN than 13436 - 13930)

Valve System Parts - S.I. T .

Part Number Description

1000-P136WR Thermopile GOAI-524

1001-P069SI Electrode Sparker 915.069 TC SIT

1001-P216SI Thermocouple 290.216 TC SIT

1001-P165SI Orifice Pilot NG 977.165 TC SIT

1001-P167SI Orifice Pilot LP 977.167 TC SIT

1001-P508SI HT Cable 16

1001-P633SI Valve Nova LP Hi/Lo 0820633

1001-P634SI Valve Nova NG Hi/Lo 0820634

1001-P713SI Pilot Burner LP 199.713 TC SIT

1001-P714SI Pilot Burner NG 199.714 TC SIT

REPLACEMENT PARTS FOR VFI30

SYSTEM #3 New SIT TC True Millivolt Vented only

(If Serial Number is equal to or GREATER than 13930)

Valve System Parts - S.I. T .

Part Number Description

1000-P136WR Thermopile GOAI-524

1001-P069SI Electrode Sparker 915.069 TC SIT

1001-P165SI Orifice Pilot NG 977.165 TC SIT

1001-P167SI Orifice Pilot LP 977.167 TC SIT

1001-P639SI Valve Nova LP Hi/Lo 0820639 True MV

1001-P640SI Valve Nova NG Hi/Lo 0820640 True MV

1001-P745SI Pilot Burner LP 199.745 TC TM

1001-P746SI Pilot Burner NG 199.746 TC TM

Page 26

26

Miscellaneous Parts

1000-EMBER Glowing Ember and Slag Kit

1000-255-36 Orifice Burner NG (0 - 4500 ft)

1000-255-52 Orifice Burner LP (0 - 4500 ft)

1000-P5423WS Flat Springs - Bay Window

2000-032F Draft Hood (Assembly)

2000-079 Gasket for Flue

2000-082 Glass - Robax (Neoceram) - (28-1/4 x 13-1/4)

w/ Black edging

2000-092 Manual - VFI30

2000-095 Thermalcord - for Door

2000-BLPSI Burner Assembly (Liquid Propane) c/w Sit Valve

2000-BNGSI Burner Assembly (Natural Gas) c/w Sit Valve

3000-930 Spill Safety Switch (36T21)

C30GEK Grate & Ember Plate Kit for Field Conversion for C6 Log Set

c/w Ember Plate & Grate Bar for VFI25,VFI30

Conversion Kit (SIT Valve only)

30VFI-CKLP LP Conversion Kit

30VFI-CKNG NG Conversion Kit

Page 27

27

20. MILLIVOLT LIGHTING INSTRUCTIONS

Pilot Burner Adjustment

1.Adjust pilot screw to provide

proper sized flame.

Recommended Maximum Lead Length (Double

Wire) When Using Wall Switch or Thermostat

Wire Size Max. Length

14 GA. 100 FT.

16 GA. 64 FT.

18 GA. 40 FT.

20 GA. 25 FT.

22 GA. 16 FT.

CAUTION: DO NOT

WIRE 120 VOLT

POWER TO MILLIVOLT SWITCHES OR

THERMOSTAT.

Page 28

BASIC ONE YEAR WARRANTY

During the first year after installation, we will provide a replacement for any component part of your unit found to be defective in materials

or workmanship, including labour costs. Repair work requires prior approval by Kingsman, labour costs are based on a predetermined rate

schedule and any repair work must be done through an authorized Kingsman dealer.

LIMITED LIFETIME WARRANTY

The heat exchanger, combustion chamber and burner of every Kingsman product excluding the Outdoor Firepit are warranted against

materials or workmanship during the period the product is owned by the original owner. The part to be replaced must be returned to our

distributor in exchange for the replacement part. Any labor, material, freight and/or handling charges associated with any repair

or replacement pursuant to this Limited Lifetime Warranty will not be covered by this warranty.

GENERAL TERMS

In lieu of providing a replacement part, we may, at our option, provide the distributor's component purchase price from us or a credit equal

to the distributors component purchase price from us toward the purchase of any new unit which we distribute. If a credit is given

in lieu of a replacement part, the rating plate from the unit being replaced must be submitted on a warranty claim, and the unit being

replaced must be made available to our distributor for disposition.

In establishing the date of installation for any purpose, including determination of the starting date for the term of this Limited Lifetime

Warranty, reasonable proof of the original installation date must be presented*, otherwise the effective date will be based upon the date of

manufacture plus thirty (30) days.

We will not be responsible for and you, the user, will pay for: (a) damages caused by accident, abuse, negligence, misuse, riot, fire, flood,

or Acts of God (b) damages caused by operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any other

damaging chemicals (other than in a normal residential environment) (c) damages caused by any unauthorized alteration or repair

of the unit affecting its stability or performance (d) damages caused by improper matching or application of the unit or the unit's components

(e) damages caused by failing to provide proper maintenance and service to the unit (f) any expenses incurred for erecting, disconnecting

or dismantling the unit (g) parts or supplies used in connection with service or maintenance (h) damage repairs, inoperation or inefficiency

resulting from faulty installation or application (i) electricity or fuel costs or any increase in electricity or fuel cost whatsoever including

additional or unusual use of supplemental electric heat.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit.

We have not made and do not make any representation or warranty of fitness for a particular use or purpose, and there is no implied condition

of fitness for a particular use or purpose. We make no express warranties except as stated in this Limited Lifetime Warranty. No one is authorized

to change this Limited Lifetime Warranty or to create for us any other obligation or liability in connections with this unit. Any implied

warranties shall last for one year after the original installation. Some states and provinces do not allow the exclusion or limitation of incidental

or consequential damages or do not allow limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions may not apply to you. The provisions of this limited warranty are in additions to and not a modification of or subtraction from any statutory warranties and other rights and remedies provided by law.

Save this certificate. It gives you specific legal rights, and you may also have other rights which may vary from state to state and province to province.

In the event your unit needs servicing, contact your dealer or contractor who installed or serviced your unit. When requesting service,

please have the model and serial number from each unit readily available. If your dealer needs assistance, the distributor is available for support

and we, in turn support the distributor's efforts.

Fill in the installation date and model and serial numbers of the unit in the space provided below and retain this limited warranty for your files.

Model No. Serial No. Date installed

Dealer or Contractor Name :

*

To receive advantage of your warranty, you must retain the original records that can establish the installation date of your unit.

LIMITED LIFETIME WARRANTY

This Limited Lifetime Warranty applies only while the unit remains at the site of the original

installation and only if the unit is installed inside the continental United States, Alaska, Hawaii,

and Canada. The warranty applies only if the unit is installed and operated in accordance

with the printed instructions and in compliance with applicable installation and building codes

and good trade practices.

The Ultimate in Design, Engineering & Quality

Loading...

Loading...