Kingsman OB36MAP, OB24MAP, OB36MAN, OB24MVN, OB36MVN User Manual

...

OUTDOOR LINEAR FIRE PIT MANUAL

⚠ DANGER

If you smell gas:

1. Shut off gas to the

appliance.

2. Extinguish any open flame.

3. If odor continues, keep

away from the appliance

and immediately call your

gas supplier or fire

department.

⚠ WARNING

Do not store or use gasoline

or other flammable vapors and

liquids in the vicinity of this or

any other appliance.

An LP-cylinder not connected

for use shall not be stored in

the vicinity of this or any other

appliance.

⚠ WARNING

For Outdoor Use Only.

⚠ WARNING

Improper installation,

adjustment, alteration, service

or maintenance can cause

injury or property damage.

Read the installation,

operating and maintenance

instructions thoroughly before

installing or servicing this

equipment.

⚠ DANGER

CARBON MONOXIDE HAZARD

This appliance can produce carbon

monoxide which has no odor.

Using it in an enclosed space can

kill you.

Never use this appliance in an

enclosed space such as a camper,

tent, car or home.

Kingsman Fireplaces 2340 Logan Ave., W innipeg, Mb Canada Ph: 204-632-1962 Printed in Canada P/N 24LFP-MAN April 4, 2017

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

This appliance is designed as an “attended appliance”. Adults

must be present when the unit is operating. DO NOT leave this

unit burning when unattended. If this product is left burning

unattended it may cause damage or serious injury.

OLTN / OLTW

OUTDOOR FIRE TABLE

OFP S1 / S2

OUTDOOR FIREPLACE

OB

OUTDOOR BURNER

OFS

OUTDOOR FIRE STAND

VALVE

OUTDOOR BURNERS: OB24MAN, OB24MAP, OB24MVN, OB24MVP,

OB36MAN, OB36MAP, OB36MVN, OB36MVP,

OB48MAN, OB48MAP, OB48MVN, OB48MVP,

OB72MVN, OB72MVP, OB96MVN, OB96MVP

-CERTIFIED FOR USA & CANADA- ANSI Z21.97-2014 • CSA 2.41-2014 OUTDOOR DECORATIVE GAS APPLIANCES

NOTE: LP MANUAL (MAP) VALVE SYSTEMS ARE SHIPPED WITH AN ACCOMPANYING ORIFICE FOR NG CONVERSION.

ALL MILLIVOLT VALVE SYSTEMS ARE SHIPPED AS NG SYSTEMS (MVN) AND REQUIRE A CONVERSION KIT FOR LP CONVERSION.

OUTDOOR FIRE STANDS (c/w Burner): OFS24MAN, OFS24MAP, OFS36MAN, OFS36MAP, OFS48MAN, OFS48MAP

OUTDOOR FIRE TABLES (Burner Required): OLTN24, OLTW24, OLTN36, OLTW36, OLTN48, OLTW48

OUTDOOR FIREPLACES (Burner Required): OFP4336S1, OFP4336S2, OFP5548S1, OFP5548S2, OFP7972S1, OFP7972S2

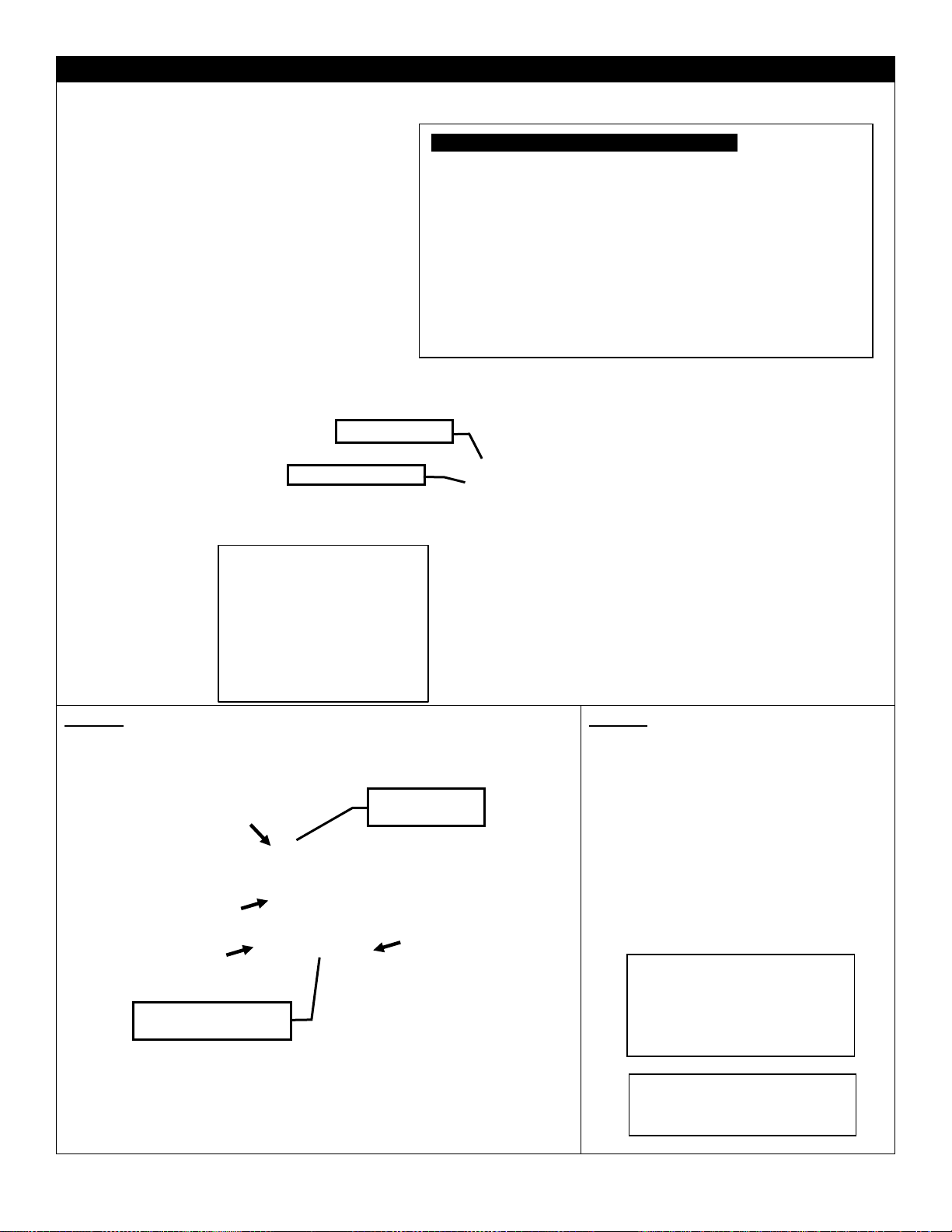

Warnings, Installations and Operations

WARNING

FOR SAFE INSTALLATION AND OPERATION OF YOUR GAS FIREPLACE PLEASE NOTE THE FOLLOWING:

1. when an appliance is for connection to a fixed piping system, the installation must conform with local codes or,

in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 • NFPA 54; National Fuel Gas

Code; Natural Gas and Propane Installation Code, CSA B149.1; or Propane Storage and Handling Code, CSA

B149.2, as applicable.

2. This appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70; or the Canadian Electrical Code, CSA C22.1,

if applicable.

3. THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

4. Always keep the appliance clear and free from combustible materials, gasoline, and other flammable vapors

and liquids.

5. Inspect the fuel supply connection (including the hose for LP models) before each use of the appliance. See

Lighting Instructions for removal of Access Panel.

6. If it is evident there is excessive abrasion or wear, or the hose is damaged, it must be replaced prior to the

appliance being put into operation. Locate the hose out of pathways where people may trip over it or in areas

where the hose may be subject to accidental damage

7. Locate the hose out of pathways where people may trip over it or in areas where the hose may be subject to

accidental damage.

8. Children and adults should be alerted to the hazards of the high surface temperatures of this appliance and

should stay away to avoid burns or ignition of clothing.

9. Young children should be carefully supervised when they are in the area of the appliance.

10. Clothing or other flammable material should not be placed on or near the appliance. This appliance should not

be used as a drying rack for clothing.

11. Any safety screen or guard removed for servicing an appliance must be replaced prior to operating the

appliance.

12. Installation and repair should be done by a qualified service person. The appliance should be inspected before

use and at least annually by a professional service person. More frequent cleaning may be required due to

excessive lint from carpeting, et cetera. It is imperative that control compartments, burners and circulating air

passageways of the appliance be kept clean.

13. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the unit and to replace any part of the control system and any gas control which has been underwater.

2

This gas appliance must be installed by a qualified installer in accordance with local building codes, or in the absence of

local codes, with the current CAN/CSA-B149.1 or .2 Installation Code (in Canada) or the current National Fuel Gas Code

Z223.1- NFPA 54 when installed in the United States.

This appliance, when installed, must be electrically connected and grounded in accordance with local codes, or in the

absence of local codes, with the current CSA C22.1 Canadian Electrical Code or with the National Electrical Code;

ANSI/NFPA 70 when installed in the United States.

In the Commonwealth of Massachusetts, the installer or service

agent shall be a plumber or gas fitter licensed by the

Commonwealth of Massachusetts.

For the State of Massachusetts, flexible connectors shall not

exceed 36 inches in length.

For the state of Massachusetts a T-handle gas shut-off valve

must be used on a gas appliance.

Table of Contents

INTRODUCTION

Warnings, Installations and Operations……….........

2

Table of Contents………………………………..........

3

Pre-installation Questions and Answers……...........

4

Important Information About Outdoor

Fireplaces………………………………………...........

4

Locating Your Appliance / Outdoor Spaces…..........

5

Clearance Specifications……………………….........

6

Outdoor Burners Basic Models and

Applications………………………………………........

7

24 / 36 / 48 / 72 / 96 OUTDOOR BURNERS

Burner Systems for Custom Applications, OB /

OFS / OLTN / LTW / OFP Models……....................

8

Clearance to Combustibles for Outdoor Burners,

Outdoor Fire Stands, Outdoor Fire

Tables......................................................................

8

Dimensions - OB24 / OB36 / OB48 / OB72 / OB96

Outdoor Burners.......................................................

9

OB Burners – Unpacking and Setup – Manual

Valve Systems.........................................................

10

OB Burners – Unpacking and Setup – Millivolt

Valve Systems.........................................................

11

CUSTOM ENCLOSURES

Custom Enclosures-OB24 / 36 / 48 / 72 / 96............

12

Custom Enclosures – Optional LED Lighting...........

13

Enclosures for LP (Propane) Gas Supply

Systems...................................................................

14

OUTDOOR FIRE STANDS

Outdoor Fire Stands (OFS) Dimensions - OFS24 /

OFS36 / OFS48.......................................................

15

Outdoor Fire Stands (OFS) Unpacking and Setup...

16

OUTDOOR FIRE TABLES

Outdoor Fire Tables (OLTN / OLTW) Dimensions –

OLTN24 / OLTW24..................................................

17

Outdoor Fire Tables (OLTN / OLTW) Dimensions –

OLTN36 / OLTW36..................................................

18

Outdoor Fire Tables (OLTN / OLTW) Dimensions –

OLTN48 / OLTW48..................................................

19

Outdoor Fire Tables – Assembly..............................

20

Outdoor Fire Tables– Burner Installation.................

21

Outdoor Fire Tables – Optional LED Lighting..........

22

Outdoor Fire Tables – 20lb Cylinder Installation......

23

OUTDOOR FIREPLACES

Outdoor Fireplaces (OFP) OFP4336S1 &

OFP4336S2 Dimensions..........................................

24

Outdoor Fireplaces (OFP) OFP5548S1 &

OFP5548S2 Dimensions..........................................

25

Outdoor Fireplaces (OFP) OFP7972S1 &

OFP7972S2 Dimensions..........................................

26

Outdoor Fireplaces (OFP) – Handling Unit..............

27

Adjustable Support Guide -Hearth Flush With

Fireplace Opening....................................................

28

Outdoor Fireplace (OFP) Optional Framing (S1 &

S2)............................................................................

29

Outdoor Fireplace (OFP) Clearances and Mantels..

30

Surround Installation OFP43SS / OFP55SS /

OFP79SS.................................................................

31

Weather Cover Installation OFP43WC / OFP55WC

/ OFP79WC..............................................................

32

Outdoor Fireplace (OFP) Wind Guard Glass...........

33

About Stainless Steel Parts And Accessories..........

33

Outdoor Fireplace (OFP) Optional LED Lighting......

34

Outdoor Fireplace (OFP) Burner Removal &

Installation................................................................

35

ACCESSORIES AND OPTIONS

Glass Media for Outdoor Burners............................

36

Optional Media Accessories.....................................

36-37

Optional Wind Guards..............................................

38

MAINTENANCE

Burner System Maintenance....................................

39

General Maintenance Instructions...........................

40

BURNER LIGHTING / GAS INSTALLATION

Manual Lighting Instructions....................................

41

Millivolt Lighting Instructions....................................

42

Gas Line Installation.................................................

43

LP Cylinder Requirements / LP Conversion Kits......

44

Gas Conversion - Manual Systems..........................

45

Gas Conversion Part A – Millivolt Systems..............

46

Gas Conversion Part B – Top Convertible Pilot.......

47

Gas Conversion Part C – Valve Modulator..............

48

Optional Electronic Spark Assist..............................

49

Troubleshooting the Gas Control System................

50

PARTS LISTS

Plumbing Parts.........................................................

51

Outdoor Burners- Parts List......................................

52-53

Limited Warranty......................................................

54

3

Pre-installation Questions and Answers

Important Information About Outdoor Fireplaces

-Operating Instructions-

1. Be sure to read and understand all the

instructions in this manual before

operation of appliance.

2. Ensure all wiring is correct and properly

enclosed to prevent possible shock.

3. Check for gas leaks.

4. If brick or porcelain liners are used,

ensure they are installed.

5. Verify that the pilot can be seen when

lighting the appliance. If not, the log or

rock placement is incorrect.

6. If the unit is turned off, you must wait a

minimum of 60 seconds before relighting it.

4

About curing of the paint

Your stove or fireplace has been painted with the highest quality silicone

stove paint. This paint dries quickly in 15-20 minutes when first applied at

the factory. However, due to the high temperature silicone components,

the paint will cure when heat is applied to the appliance as it is first used.

The following information applies to the curing process to get the paint

fully hard and durable.

Fire the appliance four successive times for 10 minutes each firing and a

5 minute cool down between each. Be aware during log and firebox paint

curing that a white deposit may be developing on the inside of the glass

doors. It is important to remove this white deposit from the glass doors

using a fireplace glass cleaner.

Babies, small children, pregnant women and pets should leave

the area during the cure phase.

Ventilate well, open doors and windows.

Do not touch during curing.

Why does my fireplace or stove give off odour?

It is normal for your fireplace to give off some odor at first. This is due to the curing of the paint, adhesives, silicones and

any undetected oil from the manufacturing process as well as the finishing materials used with the installations (e.g.

marble, tile and the adhesives used to adhere this product to the walls can react with heat and cause odours).

It is recommended that you burn your gas fireplace or stove for a minimum of four hours at a time with the fan off (if a fan

is present) after the curing of the paint has been completed. These odours can last upward to 40 hours of burn time; keep

burning at a minimum of four hours per use until odours dissipate.

Noise coming from the fireplace?

Noise is caused by the expansion and contraction of metal as the appliance heats up and cools down. This is normal and

is similar to the sounds produced by a furnace or heating duct. This noise does not affect the operation or longevity of

your fireplace.

Note to the Installer:

Be sure appliance is working properly and its operation (including remote control operation, if included) is fully explained

to and understood by the customer.

Before you build in this appliance:

Do not insulate around the appliance. Heat buildup could lead to component failure.

Pay attention to all clearances to combustibles and specifications stated in this manual.

Drainage- If this appliance is installed in a location where it will be exposed to water and moisture, drainage is an

important consideration.

Inadequate drainage will cause rust, which is not covered by the warranty.

Information about outdoor fireplaces

Outdoor fire burning appliances may not function properly at all times regardless of the circumstances.

Wind can greatly affect flame performance. If used in windy conditions a wind guard is recommended.

Outdoor units require adequate ventilation in order to burn properly.

Restricted access to air is not only dangerous for persons near the appliance, but the appliance also will not

function correctly.

This appliance consumes air, burns fuel, and emits heat and exhaust gases.

Only approved media and accessories listed in this manual should be used with this appliance.

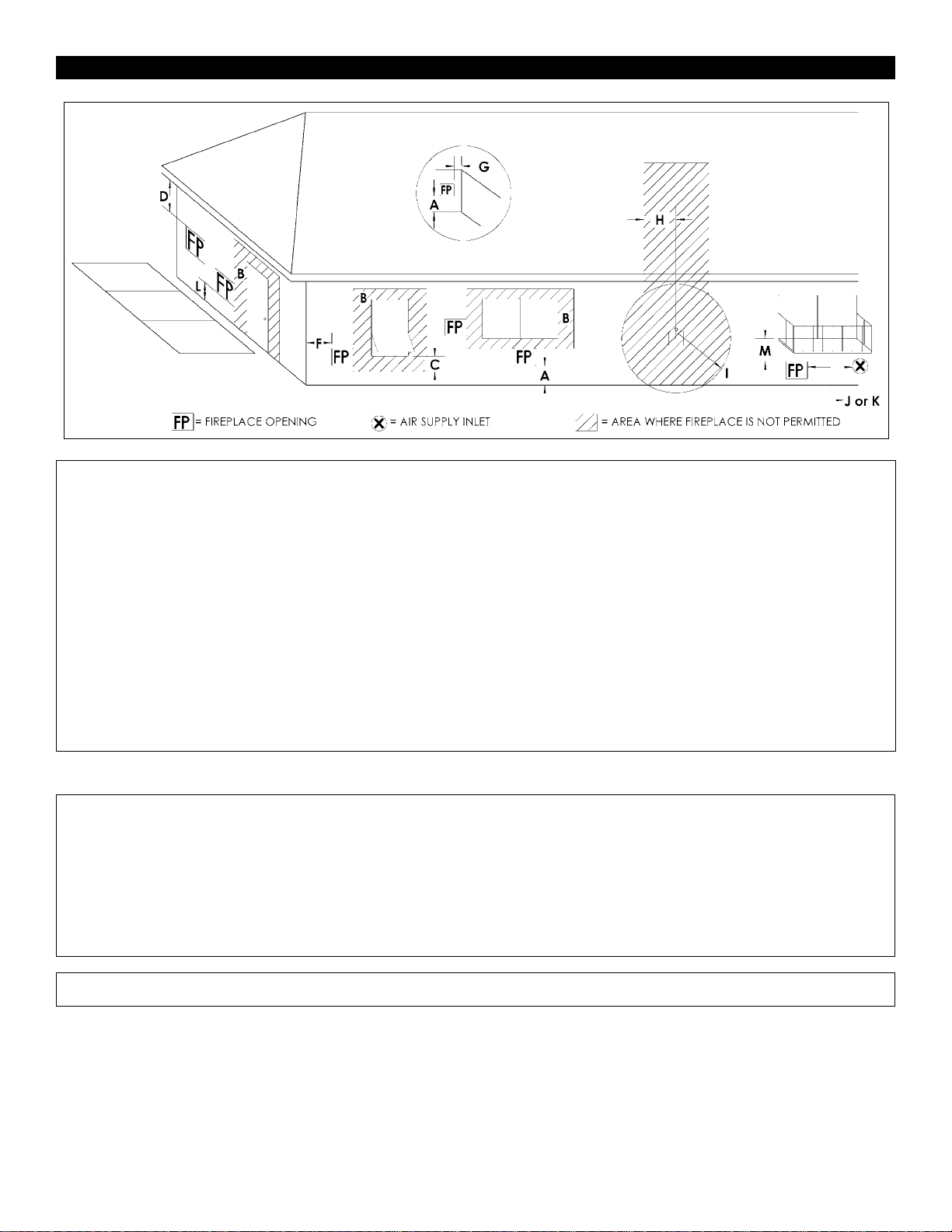

Locating Your Appliance

Note: Ventilation and air flow comes from openings in the walls and ceiling. Open floor space around the appliance

must not be considered ventilation and air flow space.

This unit requires combustion air and will produce exhaust gases. Install in an open-air situation with natural

ventilation and without stagnant areas.

Avoid installing in tight spaces and corners.

Be aware of combustibles (i.e. furniture) near appliance. Clearance is Minimum 36”.

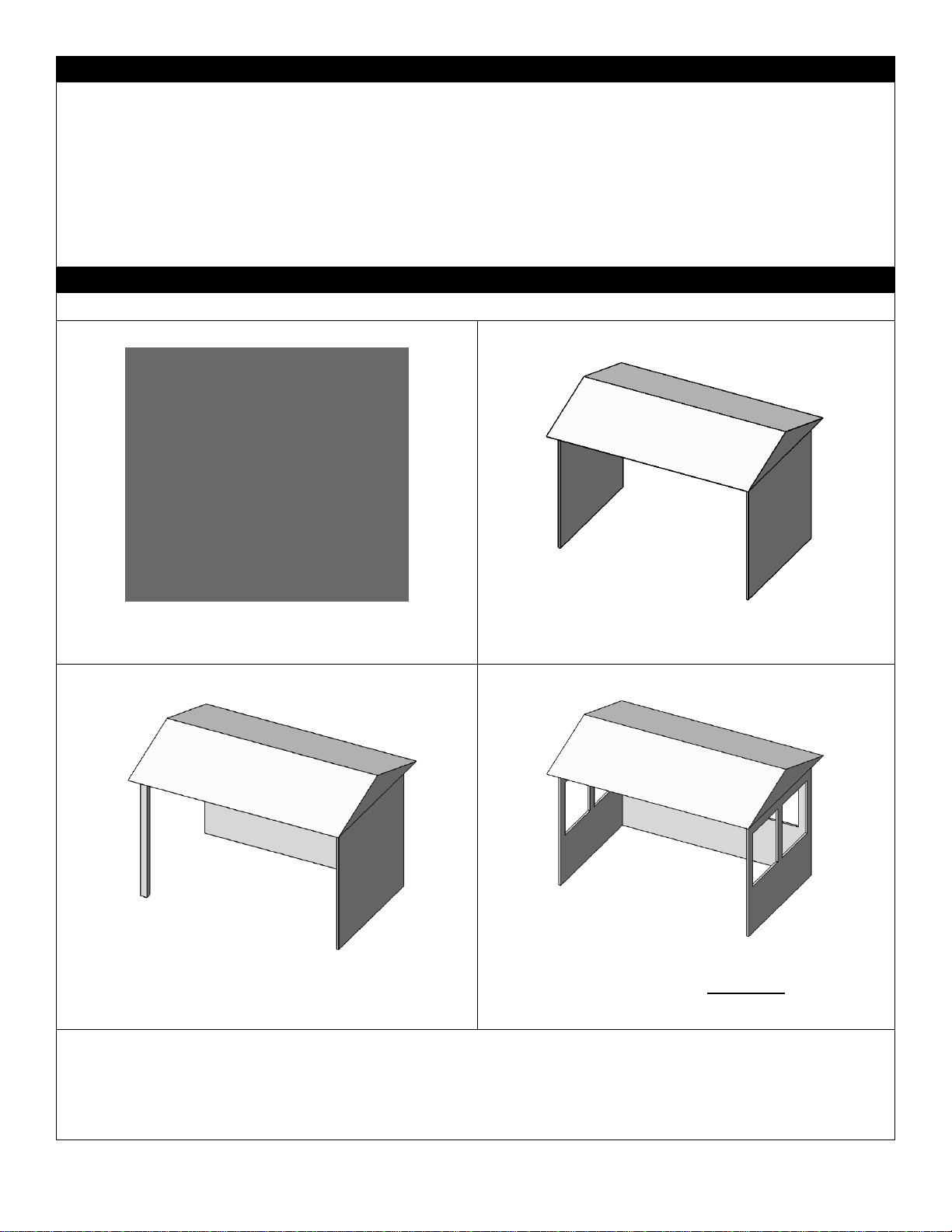

By definition, an outdoor space is not enclosed. Any area in which these appliances are used shall comply with

the structures shown below.

Locating Your Appliance – Outdoor Spaces

This appliance may be installed within the following structures:

1.

Walls on all sides (Minimum area of 96 square feet), but

with no overhead cover and at least one permanent

opening (doorway) at ground level.

2.

Within a partial enclosure that includes an overhead cover

and no more than two side walls.

3.

These side walls may be parallel, as in a breezeway, or at

right angles to each other.

4.

Within a partial enclosure that includes an overhead cover

and three side walls, as long as 30 percent or more of the

horizontal periphery of the enclosure is permanently open.

All models can be installed safely in a screened porch area within the following guidelines:

Minimum porch area is 96sq. feet with one side fully open.

A minimum of two (2) walls can be screened, but must be open to outside ventilation, with a minimum screen area of 64

sq. feet, and a minimum side wall height of 78” inches.

5

Clearance Specifications

A =

2in………….

Clearances above grade, veranda, porch,

deck or balcony.

I =

3ft (USA)……..

6ft (Canada)

Clearance to service regulator

vent outlet and electric service.

B =

12in…………

36in…………

Clearances to window or door that may be

opened, or to permanently closed window.

Vinyl windows or siding.

J =

9in (USA)…….

12in (Canada)

Clearance to non-mechanical air

Supply inlet to building or the

combustion air inlet to any other

appliance.

C =

12in…………

Clearance below an operable window.

K =

3ft (USA)…….

6ft (Canada)

Clearance to a mechanical air

supply inlet

D =

47in…………

60in…………

Vertical clearance to unventilated soffit or

to or to ventilated soffit located above the

fireplace.

Vinyl clad soffits.

L*=

54in………......

(See note 1)

Clearance above paved sidewalk

or a paved driveway located on

public property.

G =

3-1/2in…….

48in………..

Clearance to inside corner.

Vinyl windows or siding.

M**=

47in…………..

Clearance under veranda, porch,

deck, balcony or overhang.

H =

3ft. (Canada)

Not to be installed above a gas

meter/regulator assembly within 3ft

horizontally from the center line of the

regulator.

Not allowed….

Vinyl.

* A fireplace shall not open directly above a sidewalk or paved

driveway which is located between two single family

dwellings and services both swellings.

**Only permitted if veranda, porch, deck or balcony is fully

open on a minimum of 2 sides beneath the floor, or if the

screened porch guidelines are followed.

Note 1: Local codes or regulations may require different

clearances.

This appliance can be installed safely in a screened porch area

within the following guidelines:

Minimum porch area is 96sq. feet with one side fully open.

A minimum of two (2) walls can be screened, but must be open to

outside ventilation, with a minimum screen area of 64 sq. feet,

and a minimum side wall height of 78” inches.

Note: There may be some odor and small amounts of soot associated with burning the fireplace in a screened porch. Ensuring good

cross draft ventilation and routine maintenance of the fireplace will maximize comfort and cleanliness.

6

NOTE: Diagrams & Illustrations not to scale.

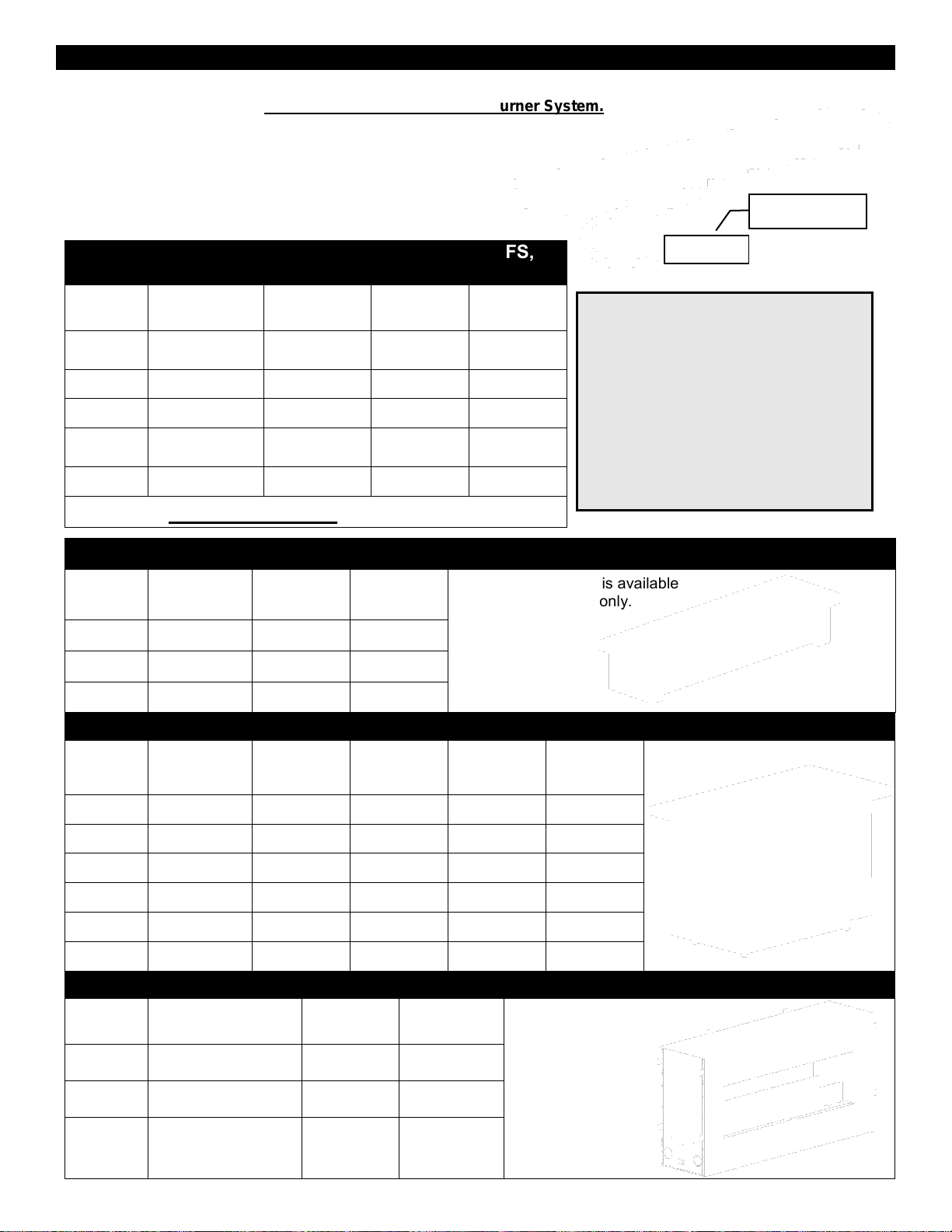

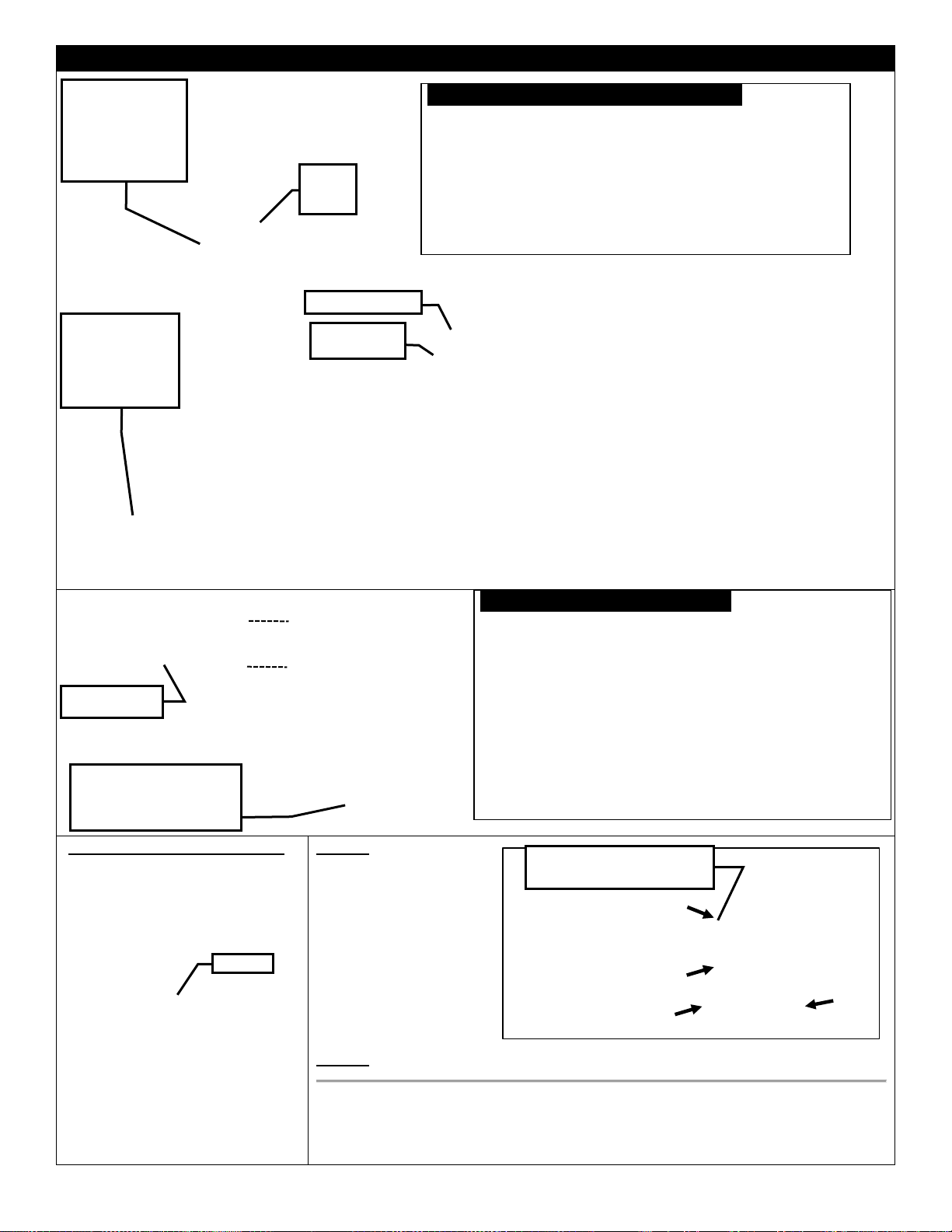

Outdoor Burners Basic Models and Applications

The Outdoor Burners (OB24, OB36, OB48, OB72, and OB96) are the basic component of the Barbara Jean

Series. These burners are a Complete Certified and Listed Burner System.

They consist of: -Burner

-Valve Control (Manual or Millivolt)

-Label

These burners can be placed into Custom Enclosures

which meet the specifications stated in the manual.

Burners for Custom Applications and Optional OFS,

OFT, and OFP Installations

LISTED

BURNER

MAP

Manual-LP

MAN

Manual-NG

MVP

Millivolt-LP

MVN

Millivolt-NG

OB24-

✔ c/w NG Orifice

✔

Conversion Kit

Required

✔

OB36-

✔ c/w NG Orifice

✔

Conversion Kit

Required

✔

OB48-

✔ c/w NG Orifice

✔

Conversion Kit

Required

✔

OB72-

N/A

N/A

Conversion Kit

Required

✔

OB96-

N/A

N/A

Conversion Kit

Required

✔

The following Approved Accessories can also be ordered:

Outdoor Fire Stand (OFS) Approved Accessory (Burner is Included)

LISTED

BURNER

OFS

Fire Stand

MAP

Manual-LP

MAN

Manual-NG

Outdoor Fire Stand is available

with a Manual Valve only.

OB24-

OFS24-

✔

✔

OB36-

OFS36-

✔

✔

OB48-

OFS48-

✔

✔

Outdoor Fire Tables (OLTN / OLTW) Approved Accessory (Burner is ordered separately)

LISTED

BURNER

OFT

Outdoor

Fire Table

MAP

Manual-LP

MAN

Manual-NG

MVP

Millivolt-LP

MVN

Millivolt-NG

Outdoor Fire Table

OB24-

OLTN24

✔

✔

Conversion Kit

Required

✔

OB24-

OLTW24

✔

✔

Conversion Kit

Required

✔

OB36-

OLTN36

✔

✔

Conversion Kit

Required

✔

OB36-

OLTW36

✔

✔

Conversion Kit

Required

✔

OB48-

OLTN48

✔

✔

Conversion Kit

Required

✔

OB48-

OLTW48

✔

✔

Conversion Kit

Required

✔

Outdoor Fireplace (OFP) Approved Accessory (Burner is included)

LISTED

BURNER

OFP

Outdoor Fireplace

MVP

Millivolt-LP

MVN

Millivolt-NG

Outdoor Fireplace

OB36-

OFP4336

S1 or S2

Conversion

Kit Required

✔

OB48-

OFP5548

S1 or S2

Conversion

Kit Required

✔

OB72-

OFP7972

S1 or S2

Conversion

Kit Required

✔

Label is attached

to Valve

VALVE

Burner systems may be connected

together in series (i.e. OB36MAP &

OB48MAP). See Custom Enclosures

section.

ALL LP MANUAL (MAP) VALVE SYSTEMS

ARE SHIPPED WITH AN ACCOMPANYING

ORIFICE FOR NG CONVERSION.

ALL MILLIVOLT VALVE SYSTEMS ARE

SHIPPED AS NG SYSTEMS (MVN) AND

REQUIRE A CONVERSION KIT FOR LP

CONVERSION.

7

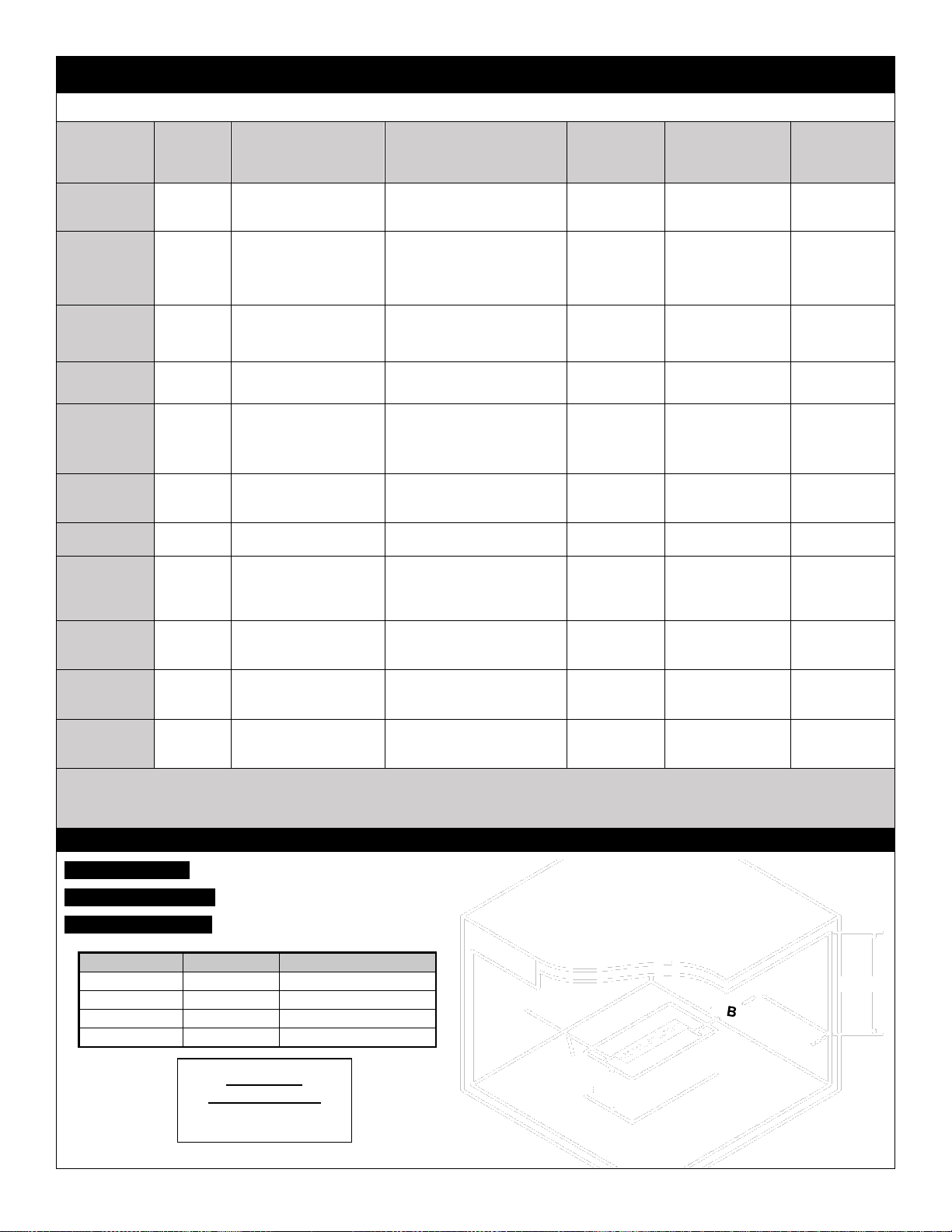

-Burners-

Burner Systems for Custom Applications, OB / OFS / OLTN / OLTW / OFP Models

Burner

System c/w

Valve

Valve

System

Stocked Burner

Conversion Kit shown

Burner (OB) Dimensions

for Custom Applications

(Add 1/8” per side for

tolerance)

Outdoor

Fire Stand

(OFS)

Outdoor Fire

Table

(OLTN or OLTW )

Outdoor

Fireplace

(OFP)

OB24MAP

Dante

Manual

LP Burner

(c/w NG Orifice)

7-1/2” wide x 26” long

x 2” tall

OFS24MAP

OLTN24

OLTW24

N/A

OB24MAN

Dante

Manual

NG Burner

For LP order

24OB-CKLP5 or

24OB-CKLP10

7-1/2” wide x 26” long

x 2” tall

OFS24MAN

OLTN24

OLTW24

N/A

OB24MVN

SIT

Millivolt

NG Burner

For LP order 24OB-

CKLP

7-1/2” wide x 26” long

x 2” tall

N/A

OLTN24

OLTW24

N/A

OB36MAP

Dante

Manual

LP Burner

(c/w NG Orifice)

7-1/2” wide x 38” long

x 2” tall

OFS36MAP

OLTN36

OLTW36

N/A

OB36MAN

Dante

Manual

NG Burner

For LP order

36-48OB-CKLP5 or

36-48OB-CKLP10

7-1/2” wide x 38” long

x 2” tall

OFS36MAN

OLTN36

OLTW36

N/A

OB36MVN

SIT

Millivolt

NG Burner

For LP order

36OBCKLP

7-1/2” wide x 38” long

x 2” tall

N/A

OLTN36

OLTW36

OFP4336S1

OFP4336S2

OB48MAP

Dante

Manual

LP Burner

(c/w NG Orifice)

7-1/2” wide x 50” long

x 2” tall

OFS48MAP

OLTN48

OLTW48

N/A

OB48MAN

Dante

Manual

NG Burner

For LP order

36-48OB-CKLP5 or

36-48OB-CKLP10

7-1/2” wide x 50” long

x 2” tall

OFS48MAN

OLTN48

OLTW48

N/A

OB48MVN

SIT

Millivolt

NG Burner

For LP order

48OB-CKLP

7-1/2” wide x 50” long

x 2” tall

N/A

OLTN48

OLTW48

OFP5548S1

OFP5548S2

OB72MVN

SIT

Millivolt

NG Burner

For LP order

72OB-CKLP

7-1/2” wide x 74” long

x 2” tall

N/A

N/A

OFP7972S1

OFP7972S2

OB96MVN

SIT

Millivolt

NG Burner

For LP order

96OB-CKLP

7-1/2” wide x 98” long

x 2” tall

N/A

N/A

N/A

Burner systems may be connected together in series (i.e. OB36MAP & OB48MAP). See Custom Enclosures section.

LP MANUAL (MAP) VALVE SYSTEMS ARE SHIPPED WITH ACCOMPANYING ORIFICE FOR NG CONVERSION.

MILLIVOLT SYSTEMS ARE SHIPPED AS NG SYSTEMS (MVN) AND REQUIRE A CONVERSION KIT FOR LP CONVERSION.

Locating Your Appliance –Minimum Clearances to Combustibles

Outdoor Burners (OB24 / 36 / 48 / 72 / 96)

Outdoor Fire Stands (OFS24 / 36 / 48)

Outdoor Fire Tables (OLTN / OLTW24 / 36 / 48)

Clearance

Dimension

Measured From:

A: Side wall

24”

Side of Burner Tray

B: End wall

12”

End of Burner Tray

C: Ceiling

49-1/2”

Top of Burner Tray

D: Floor

8”

Top of Burner Tray

A

C

D

WARNING

-RISK OF FIRE-

All minimum clearances

must be adhered to.

CEILING

8

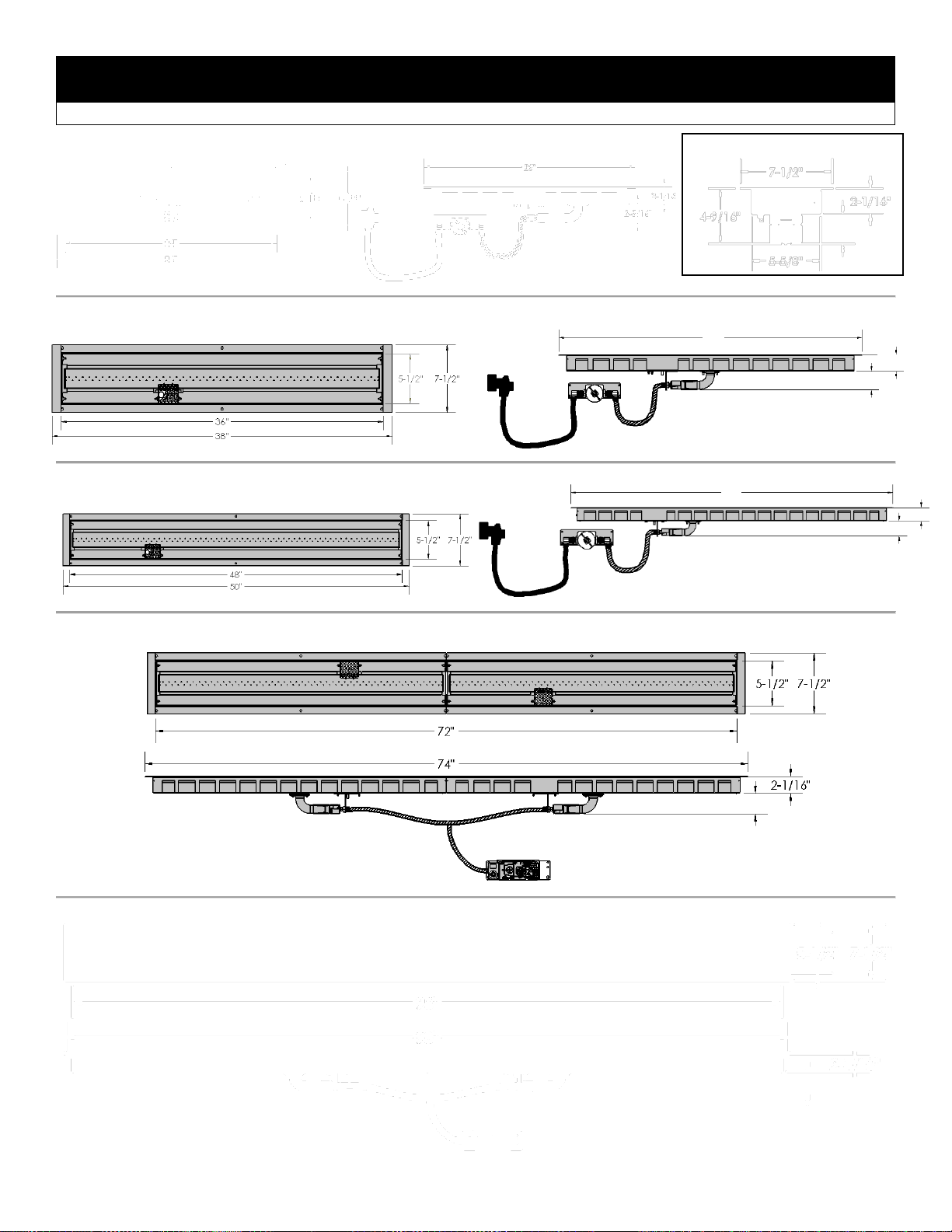

Certified Burners with Label

Dimensions OB24 / OB36 / OB48 / OB72 / OB96 (Outdoor Burners)

END VIEW- ALL BURNERS

2-1/16”

2-5/16”

38”

2-5/16”

2-1/16”

50”

2-5/16”

2-5/16”

2-5/16”

9

OB24 BURNER

OB36 BURNER

OB48 BURNER

OB72 BURNER

OB96 BURNER

OB Burners – Unpacking and Setup – Manual Valve Systems

.

STEP 1: Insert Burner Orifice into mixing sleeve and attach Orifice

Retainer Bracket with [2] 1/2” DT Screws. Then insert Electrode Mount

Plate and Sparker into Burner and install with [2] 1/2” DT Screws.

STEP 2: Install Burner with attached Valve

System into structure.

For Outdoor Fire Tables (OFT) refer to

OFT Burner Installation Instructions.

For Outdoor Fireplaces (OFP) refer to OFP

Burner Installation Instructions.

Refer to Custom Enclosures Section for

Custom Enclosures.

NOTE: Filler Strips must be installed

before media is placed into burner.

Parts List: OB24 / OB36 / OB48 MAP/MAN

[1] Burner, c/w [1] Pilot Shield, [2] Ends, [3] Filler Strips

[1] Manual Valve System (c/w Regulator and 5ft Hose for LP

Systems)

[1] Push Button Igniter c/w wire and Sparker

[1] Valve Key

[1] Key Way Installation Tool

[1] Brass Orifice for NG Conversion (LP Systems)

[1] Tank Retainer (LP Systems)

[1] Hardware Bag: [8] 1/2” DT Screws, [4] #6 Black Screws, [2]

#10 Woodscrews

[3] Filler Strips (See Below)

Orifice Retainer

Bracket

Electrode Mount Plate

and Sparker

24OB – 23-9/16”

36OB – 35-9/16”

48OB – 47-9/16”

24OB – 10-5/8”

36OB – 10-5/8”

48OB – 10-5/8”

24OB – 10-5/8”

36OB – 22-5/8”

48OB – 34-5/8”

FILLER STRIPS:

Long Flange Up

Short Flange Down

Qty [4] 1/2” DT Screws

to attach Valve

NG Conversion Orifices

(Included with MAP Burners)

OB24MAP - #40

OB36MAP - #31

OB48MAP - #30

Air Shutter = 1/16”- NG

Air Shutter = Full Open- LP

10

OB Burners – Unpacking and Setup – Millivolt Valve Systems

STEP 1 (For OB72 & OB96 only):

Connect Burners using [2] 10-24 x

1/2” bolts. Set Cover Clip over joined

burner ends.

STEP 2: Insert Orifice(s)

into mixing sleeve(s) and

install bracket(s) with [4]

1/2” DT Screws. Then

insert Pilot Assembly into

one Burner and attach with

[2] 1/2” DT Screws.

Attach Pilot Opening Cover

in the other Burner with [2]

1/2”DT Screws.

Air Shutter = 1/16”- NG

Air Shutter = Full Open- LP

STEP 3: Install Burner with attached Valve System into structure.

For Outdoor Fire Tables (OFT) refer to OFT Burner Installation Instructions page.

For Outdoor Fireplaces (OFP) refer to OFP Burner Installation Instructions page.

For Custom Enclosures refer to Custom Enclosures Section.

NOTE: Filler Strips must be installed before media is placed into burner.

Parts List: OB72 / OB96MVN

[2] Burners, c/w [2] Pilot Shields, [2] Ends, [6] Filler Strips

[1] Millivolt Valve System (c/w [2] Orifice Assemblies and [1] Pilot

Assembly)

[1] Piezo Button Igniter c/w wire and Sparker

[1] On/Off Rocker Switch (installed on valve)

[1] Pilot Opening Cover

[1] Hardware Bag: [12] 1/2” DT Screws, [8] #6 Black Screws, [2]

10-24 x 1/2” Bolts c/w Star Nuts

[6] Filler Strips

[1] Cover Clip

24OB – 23-9/16”

36OB – 35-9/16” (x 2 for OB72)

48OB – 47-9/16” (x 2 for OB96)

24OB – 10-5/8”

36OB – 10-5/8” (x 2 for OB72)

48OB – 10-5/8” (x 2 for OB96)

24OB – 10-5/8”

36OB – 22-5/8” (x 2 for OB72)

48OB – 34-5/8” (x 2 for OB96)

Connect Electrode

Wire to Piezo.

Connect On/Off

Switch to TP and

TH Terminals.

Connect Electrode Wire to

Piezo.

Connect On/Off Switch to

TP and TH Terminals.

Install Pilot Assembly and

Orifice Bracket [4 Dt Screws].

Cover Clip

Pilot Assembly is

installed from

bottom of Burner

Tray – but can be

serviced from the

Top.

Parts List: OB24 / OB36 / OB48MVN

[1] Burner, c/w [1] Pilot Shield, [2] Ends, [3] Filler Strips

[1] Millivolt Valve System (c/w Orifice Assembly and Pilot Assembly)

[1] Piezo Button Igniter c/w wire and Sparker

[1] On/Off Rocker Switch (Installed on valve)

[1] Hardware Bag: [8] 1/2” DT Screws, [4] #6 Black Screws

[3] Filler Strips (See Below)

Orifice

Retainer

Bracket

Pilot Opening

Cover

FILLER STRIPS:

[Qty 4] 1/2”

DT Screws

to attach

valve to

appliance

Long Flange Up

Short Flange

Down

[Qty 2] 1/2”

DT Screws

[Qty 2] 1/2”

DT Screws

11

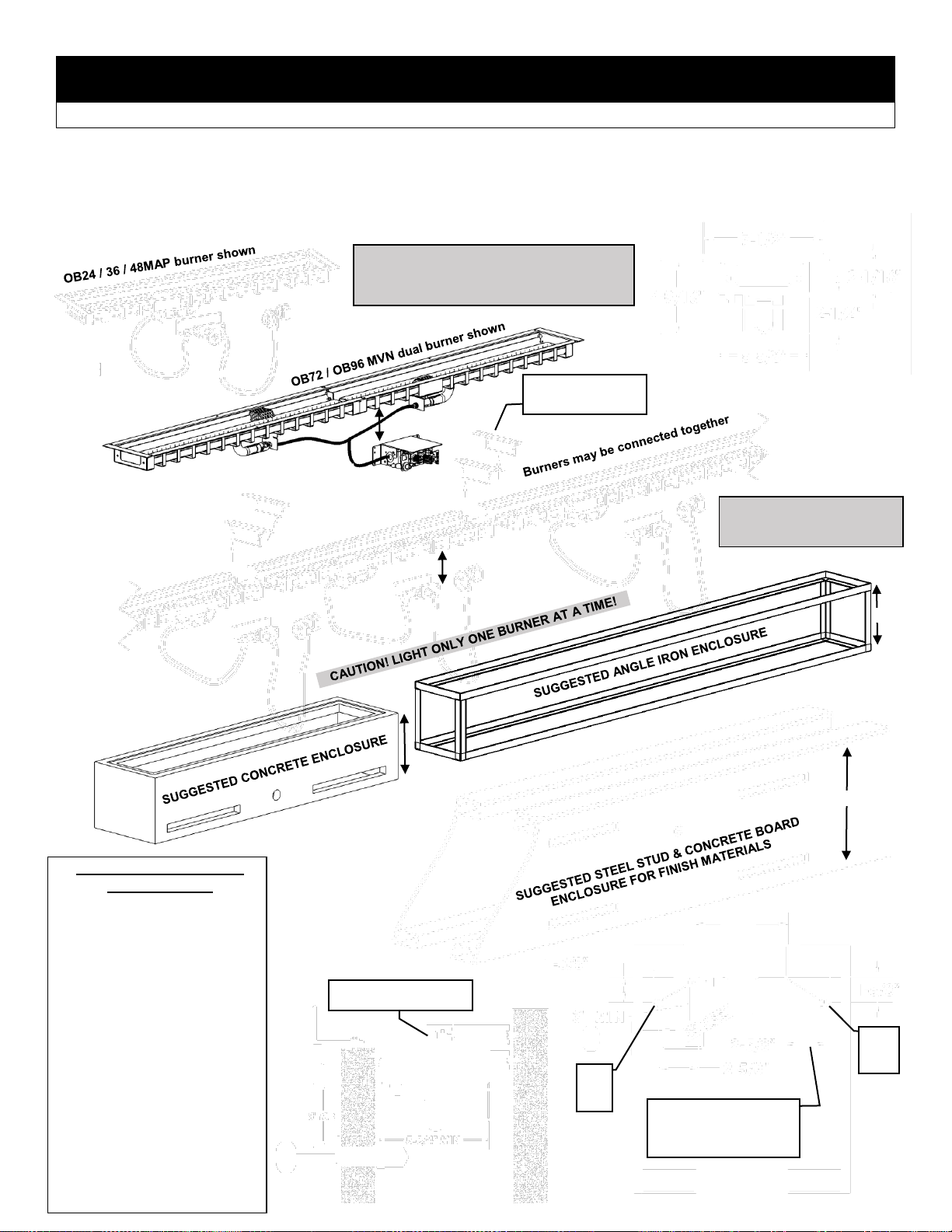

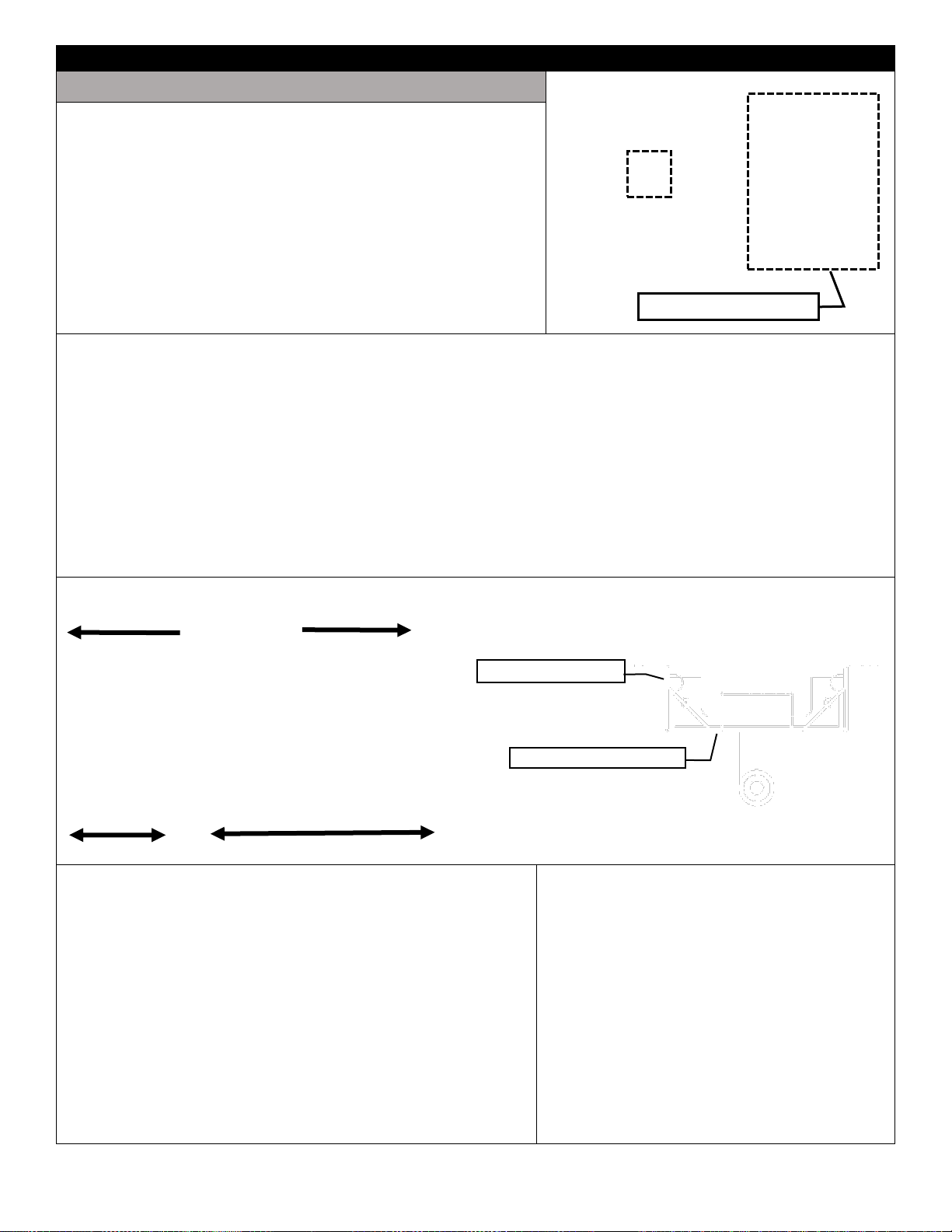

-Custom Enclosures-

OB24 / 36 / 48 / 72 / 96 (Must be non-combustible)

Multiple burners can be connected together in series. ENCLOSURES MUST BE NON-COMBUSTIBLE. Enclosures

3” MIN

3” MIN

5-3/4”

Required Openings for

Stock Burners

OB24 – 5-3/4” x 24-1/2”

OB36 – 5-3/4” x 36-1/2”

OB48 – 5-3/4” x 48-1/2”

OB72 – 5-3/4” x 72-1/2”

OB96 – 5-3/4” x 96-1/2”

Burners may be connected

together in any combination.

When connecting additional

burners, add desired lengths

(24”, 36”, 48”, 72”, 96”) plus

Required Opening for total

opening (e.g. 24” + 72-1/2” +

24” = 120-1/2”).

NOTE: Flame height will be

noticeably higher on OB48

burners. This can be manually

adjusted.

Remove ends when

connecting burners.

END VIEW

ALL BURNERS

Maximum height of

media is 1” above tray.

LED Light Strips must be

at least 1-5/8” below and

2-5/8” away from Burner

Tray.

LED

Light

Strip

LED

Light

Strip

8” MIN

8” MIN

8” MIN

Burner Tray must

be supported.

REFER TO Enclosures for LP

(Propane) Gas Supply

Systems

NOTE: All Gas Controls and

connections must be readily

removable, supported, or accessible.

12

shown are suggestions only. Refer to Clearance to Combustibles section of manual.

NOTE: all manual valve systems are shipped as LP systems (MAP) with accompanying orifice for NG conversion.

All millivolt valve systems are shipped as NG systems (MVN) and require a conversion kit for LP conversion.

NOTE: For propane installations see Enclosures for LP (Propane) Gas Supply Systems.

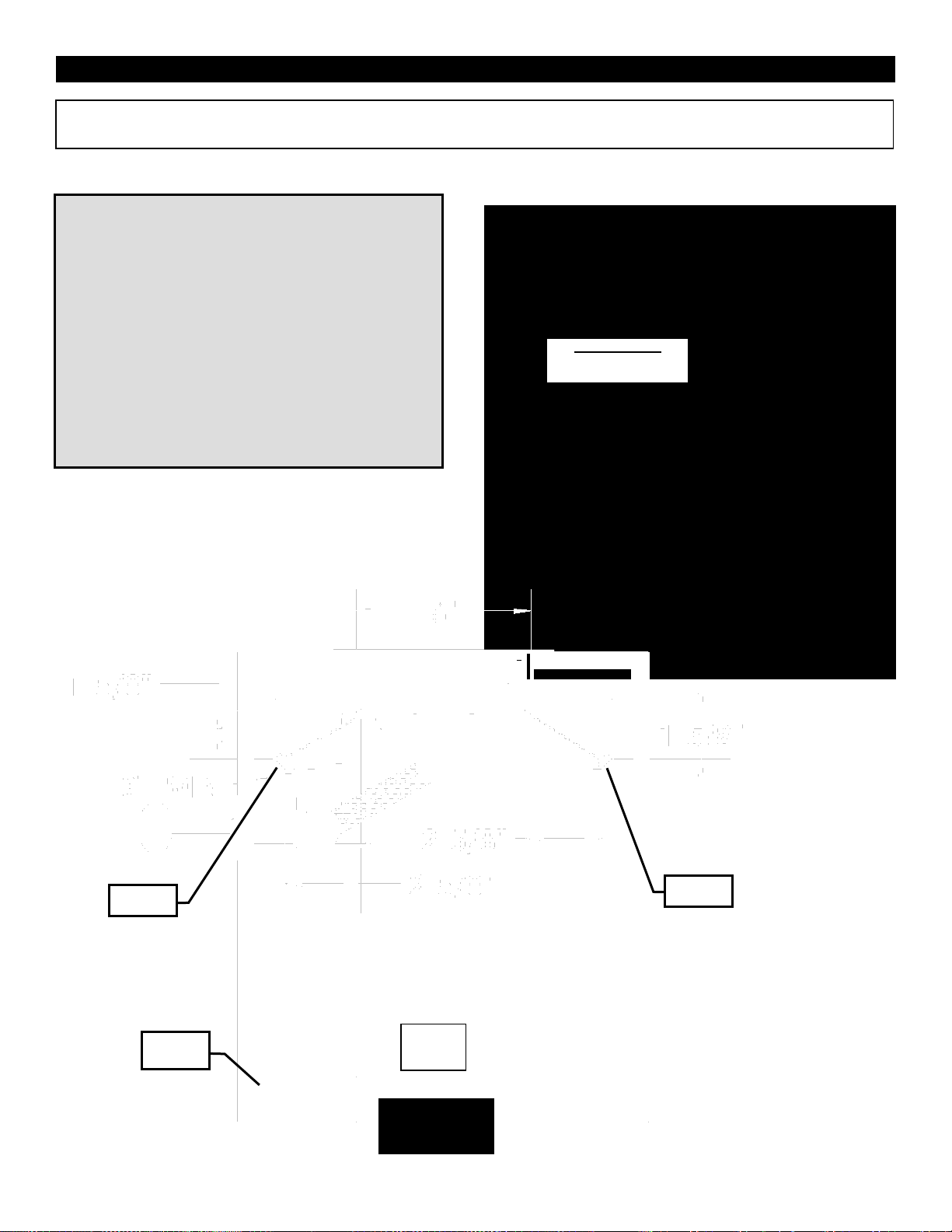

Optional LED Lighting – Custom Enclosures

Please follow the current ANSI/NFPA 70 National Electrical Code in the USA and CAN/CSA C22.1 Canadian

National Electrical Code in Canada.

⚠ WARNING

Electrical Grounding Instructions

This appliance is equipped with a three prong (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

this.

The fireplace receptacle must be connected to an

external GFI protected outlet installed near the fireplace.

Before Servicing

1. Ensure all power supply is shut off.

2. Label all wires prior to disconnecting when servicing

control. Wiring errors can cause improper and

dangerous operation.

SIDE VIEW

CUSTOM

ENCLOSURE

-Junction Box-

Must be connected to

an external GFI outlet

JUNCTION

BOX

LED

CONTROL

BOX

LED LIGHT

STRIP

LED LIGHT

STRIP

13

NOTE: If appliance is directly connected to an electrical supply, it must be anchored using anchor points provided in

bottom of appliance. Use cord and wire restraints provided also.

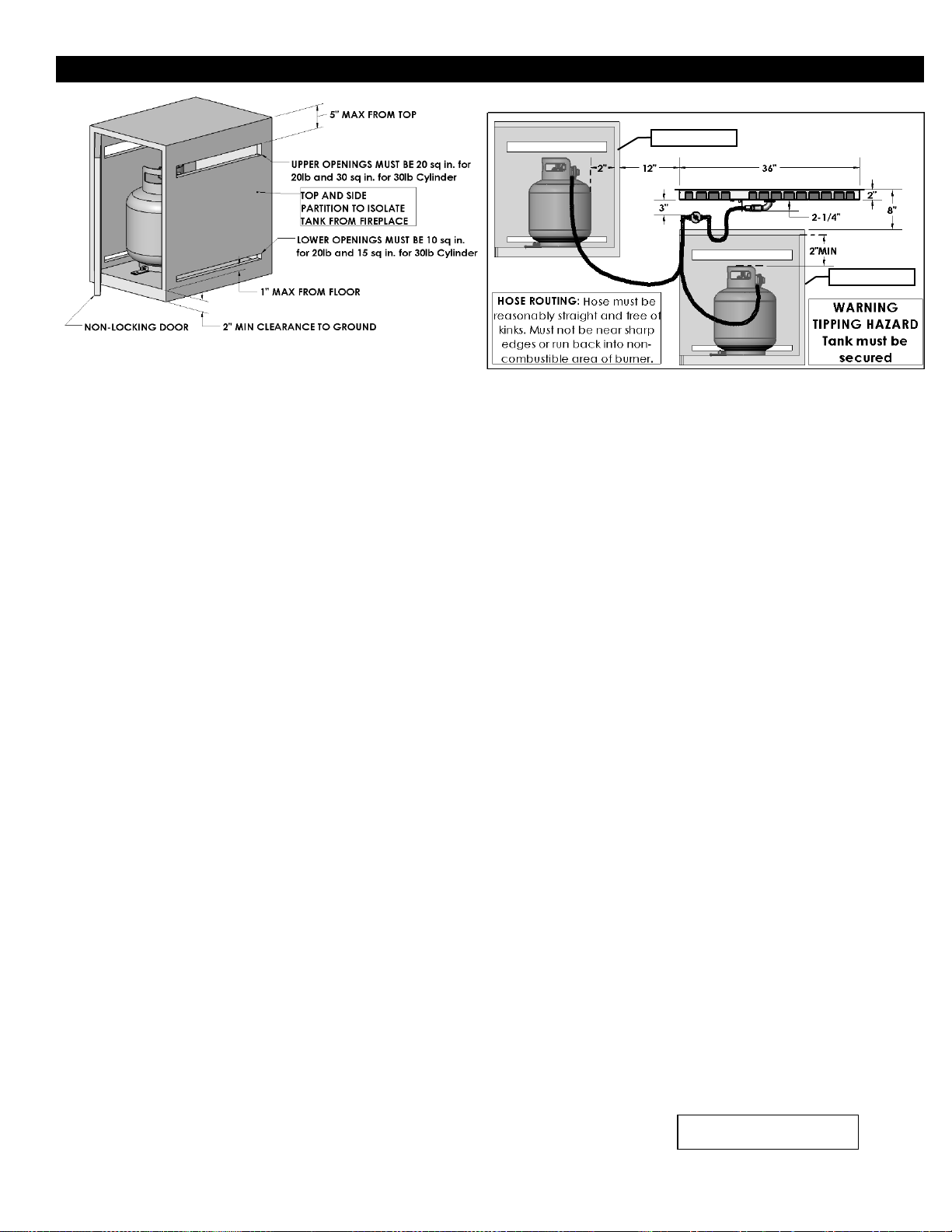

Enclosures for LP (Propane) Gas Supply Systems

LP cylinder with retention

device attached.

Combustible

Combustible

14

If you build an enclosure for an LP gas cylinder you must

follow these specifications. You must also follow local

codes.

An enclosure for an LP-gas cylinder shall be ventilated by

openings at both the upper and lower levels of the

enclosure. This shall be accompanied by one of the

following:

a. One side of the enclosure shall be completely open; or

b. For an enclosure having four sides, a top, and a bottom:

1. At least two ventilation openings shall be provided in the

sidewalls of the enclosure, located within 5 in (217 mm) of

the top of the enclosure, equally sized, spaced at a

minimum of 90 degrees (1.57 rad), and unobstructed. The

opening(s) shall have a total free area of not less than

1square inch per pound (14.2 cm2Ckg) of stored fuel

capacity.

2. Ventilation opening(s) shall be provided at floor level of

the enclosure and shall have a total free area of not less

than 1/2 square inches per pound (7.1 cm2Ckg) of stored

fuel capacity. If ventilation openings at floor level are in a

sidewall, there shall be at least two openings. The bottom

of the openings shall be 1 in (25.4 mm) or less from the

floor level and the upper edge no more than 5 in (127

mm) above the floor level. The openings shall be equally

sized, spaced at a minimum of 90 degrees (1.57 rad),

and unobstructed.

3. Every opening shall have minimum dimensions so as to

permit the entrance of a 1/8 in (3.2 mm) diameter rod.

4. Ventilation openings in sidewalls shall not communicate

directly with other enclosures of the appliance.

The cylinder valve shall be readily accessible for hand

operation. A door on the enclosure to gain access to the

cylinder valves is acceptable, provided it is non-locking and

can be opened without the use of tools. Designs using a

cover to gain access to the cylinder and cylinder valve shall

be provided with handles or equivalent at a minimum of 180

degrees apart to facilitate lifting of the cover.

The enclosure for the LP-gas cylinder shall isolate the

cylinder from the burner compartment to provide:

a. Shielding from radiation;

b. A flame barrier; and

c. Protection from foreign material.

There shall be a minimum clearance of 2 in (50.8 mm)

between the floor of the non-disposable LP-gas cylinder

enclosure and the ground.

The design of the fireplace shall be such that:

a. A non-disposable LP-gas cylinder can be connected,

disconnected, and the connections inspected and tested

outside the cylinder enclosure; and

b. Those connections which could be disturbed when

installing the cylinder in the enclosure can be leak tested

inside the enclosure.

Be certain to mount or set the LP-gas cylinder on a flat

stable surface and retain it to prevent it from tipping.

Purge the gas supply line of any trapped air prior to the

first firing of the unit.

WARNING: During the initial purging and subsequent

lightings, NEVER allow gas valve to remain in "OPEN"

position without first placing a burning match on the top

of the burner.

Test fire the unit after referring to the SAFETY

INFORMATION and LIGHTING INSTRUCTIONS.

If

LP-Gas outdoor fire

pits

are used

continuously after a

couple

of

hours,

you

could

see the

possibility of the

decreasing

this

happens,

the

control valve

the tank

wait a

valve

couple

flame

in size. If

turn off

and

and

of

hours

before lighting again

or switch

tanks. The

tank is

to the

being taken

propane

propane

freezing

volume

up due

of gas

out of the

tank.

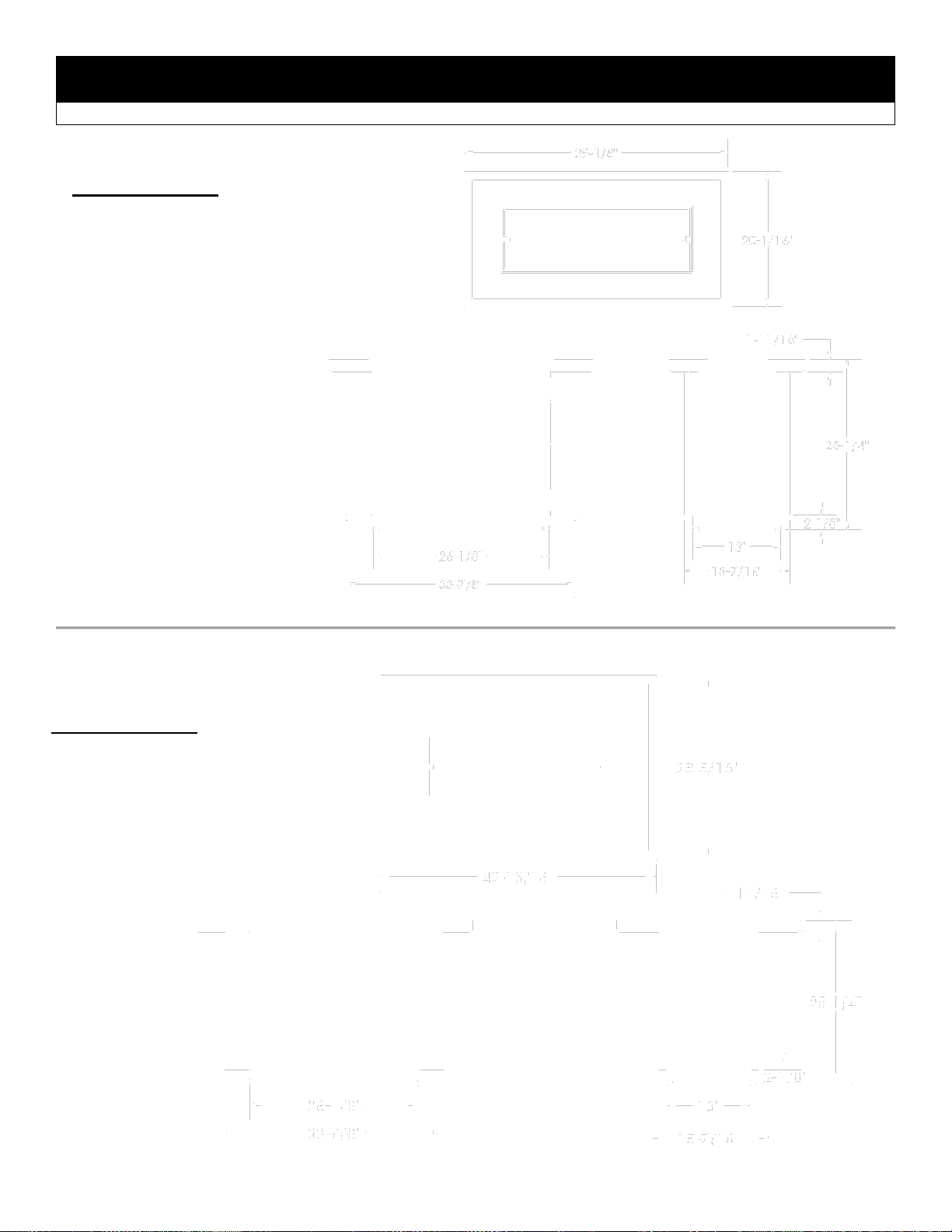

Fire Stands – Approved Accessory

OFS Series Dimensions (Outdoor Fire Stand)

OFS24MAP / OFS24MAN

15

OFS36MAP / OFS36MAN

OFS48MAP / OFS48MAN

OFS Outdoor Fire Stands – Unpacking and Setup

Parts List: OFS24 / OFS36 / OFS48 – MAP/MAN

[1] OFS Outdoor Fire Stand c/w Burner, Valve System and 10ft LP

Hose & Regulator (Installed)

[3ea] Filler Strips

[1] Push Button Igniter (AAA Battery not included) c/w Wire and

Sparker (Installed)

[1] Valve Key

[1] Key Way Installation Tool

[1] Brass Orifice for NG Gas Conversion (LP Systems)

[1] Tank Retainer, [2ea] Wood Screws (LP Systems)

OFS24 Shown – Ready for Media Placement.

See Media Section of Manual for Options.

END VIEW – Outdoor Fire Stand

FILLER STRIPS:

24OB – 23-9/16”

36OB – 35-9/16”

48OB – 47-9/16”

ALL UNITS – 10-5/8”

24OB – 10-5/8”

36OB – 22-5/8”

48OB – 34-5/8”

OFP Bottom View

(MAP System Shown)

INCLUDED WITH MAP (PROPANE)

BURNER SYSTEMS ONLY

Long Flange at Top

Short Flange at Bottom

BURNER END VIEW

Valve Control

Push Button Igniter – Unscrew and insert AAA

Battery here.

16

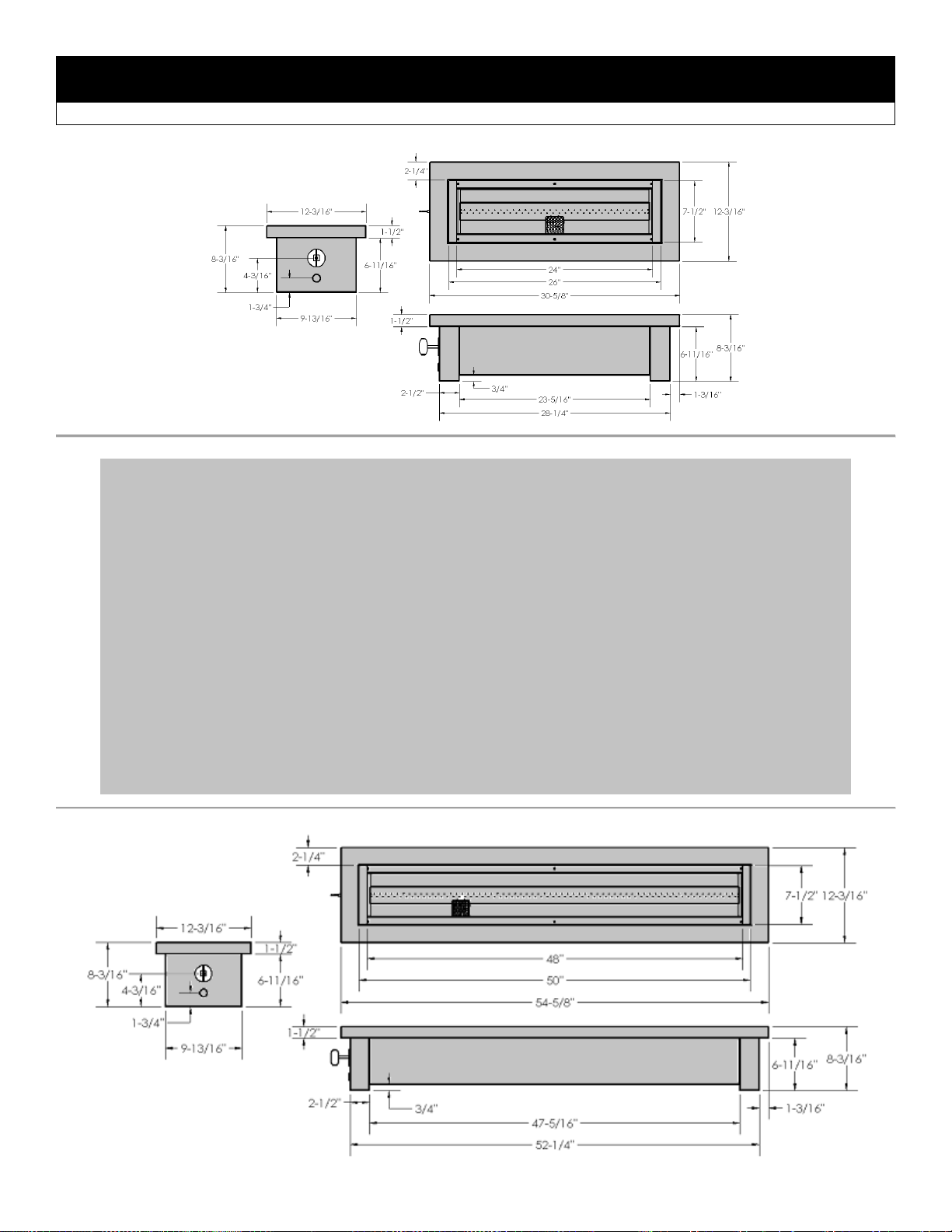

Fire Tables –Approved Accessory

OLTN24 and OLTW24 Dimensions (Outdoor Fire Table)

OLTN24

BURNER OPTIONS:

OB24MAP (c/w #40 Orifice for NG)

OB24MAN (Order 24OB-CKLP5 for LP)

OB24MVN (Order 24OB-CKLP for LP)

OLTW24

BURNER OPTIONS:

OB24MAP (c/w #40 Orifice for NG)

OB24MAN (Order 24OB-CKLP5 for LP)

OB24MVN (Order 24OB-CKLP for LP)

17

Loading...

Loading...